Patents

Literature

173results about "Meat/fish preservation using inorganic salts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

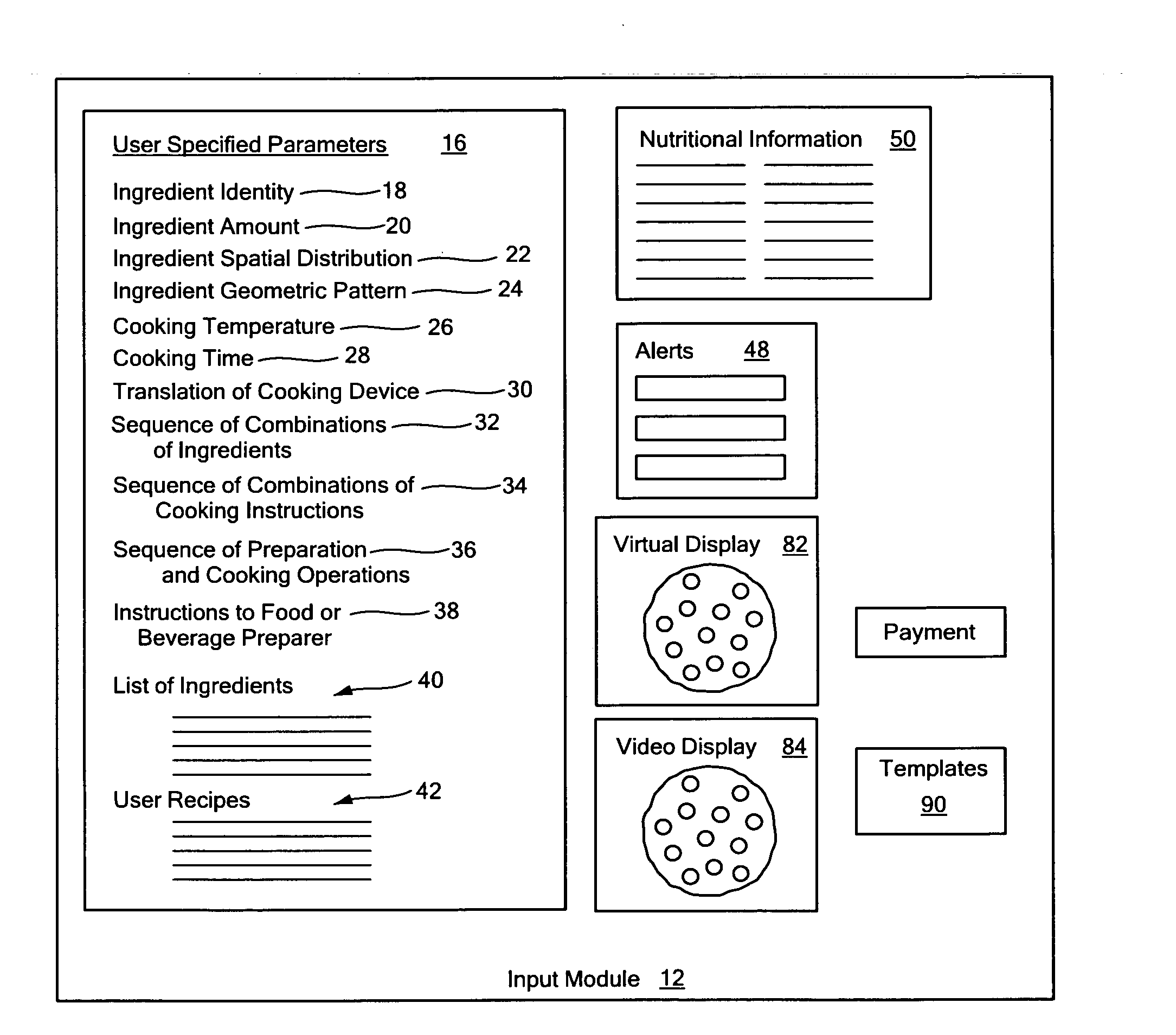

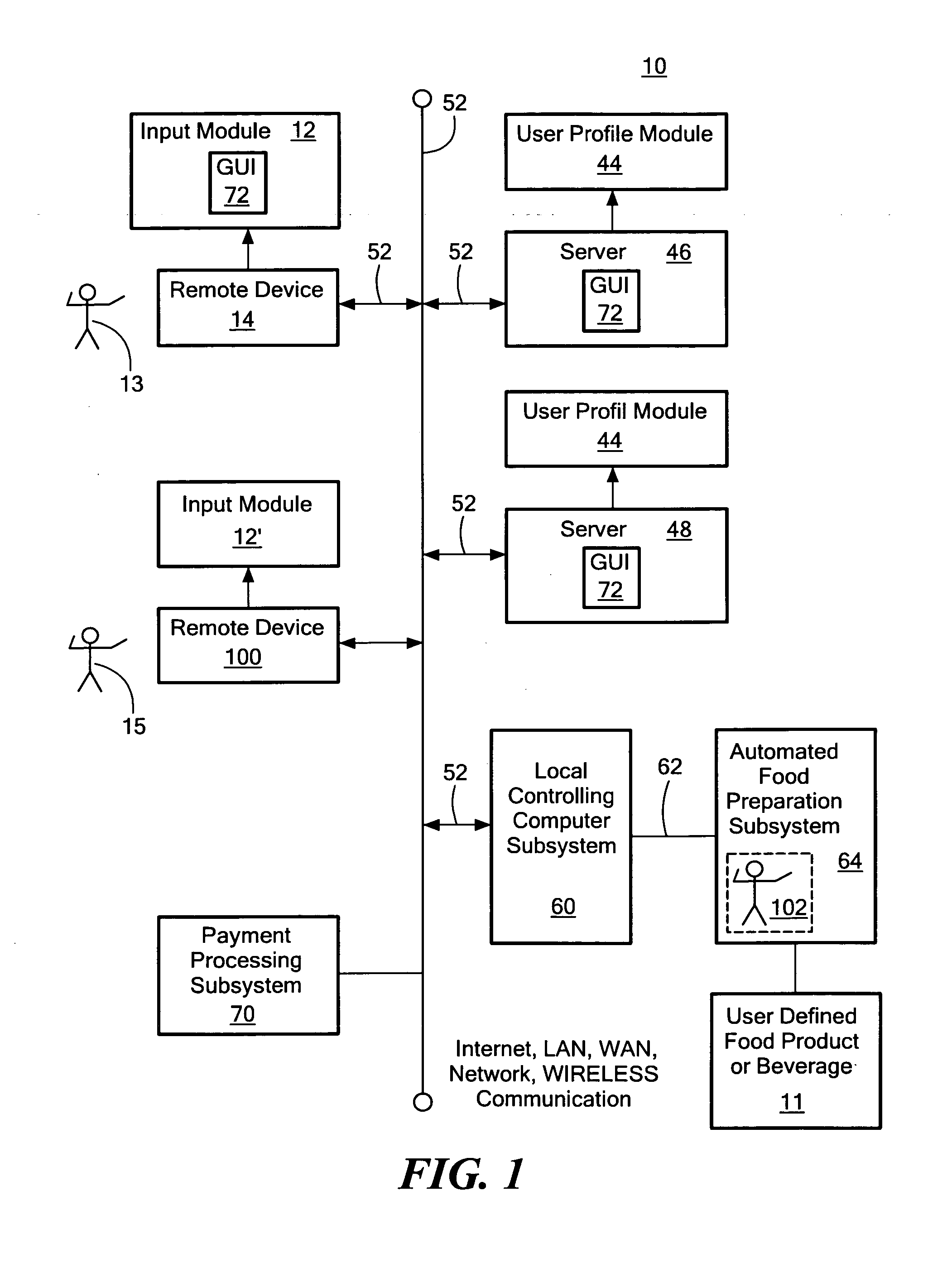

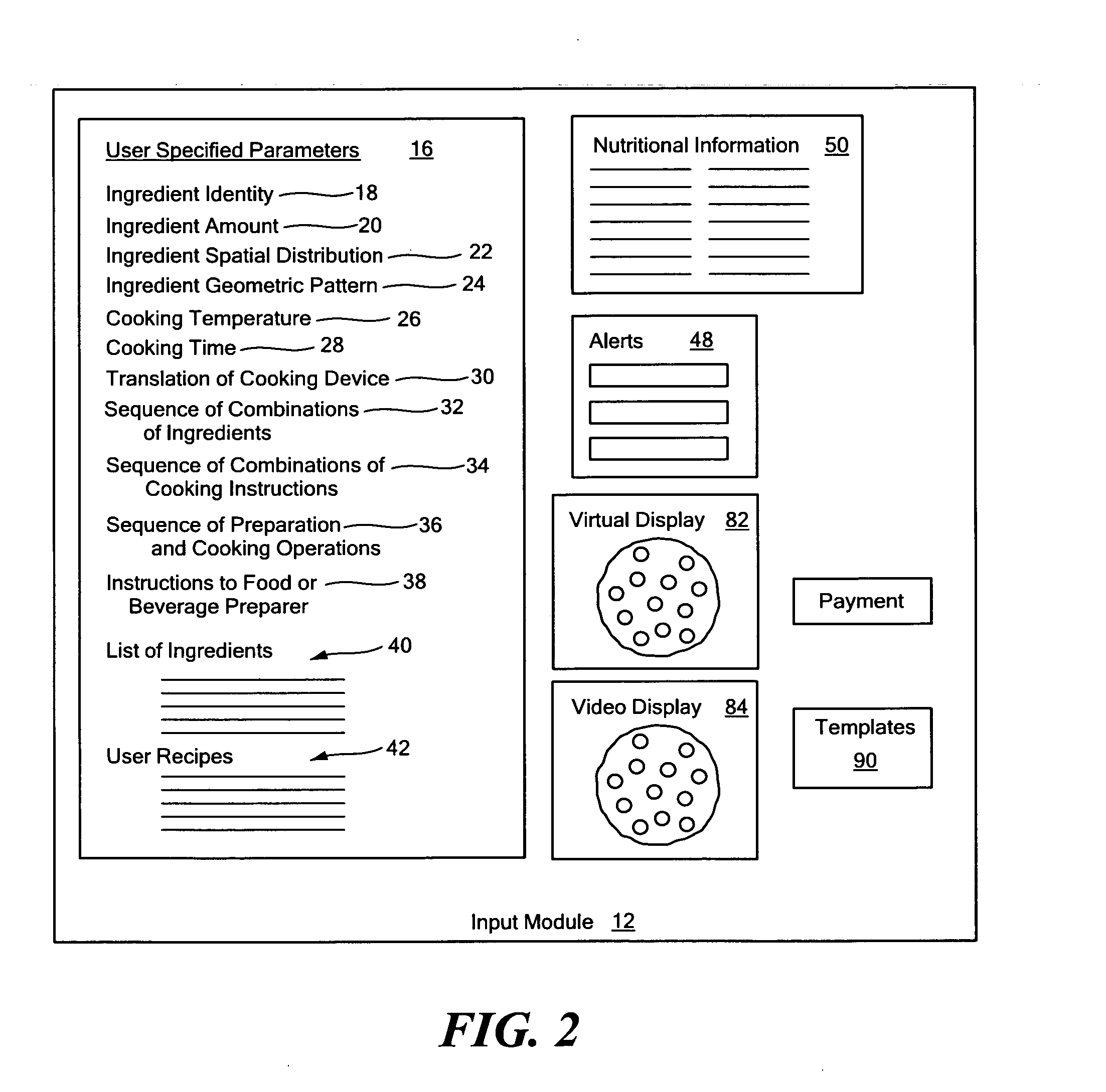

Remotely controlled system and method for the preparation of a user-defined food product or beverage

A remotely controlled system for the preparation of a user-defined food product or beverage including an input module on a remote device configured to input user-specified parameters associated with the preparation of the user-defined food product or beverage. A user profile module on one or more servers is configured to store one or more of the user-specified parameters, predetermined alerts, and nutritional information associated with the user-specified parameters and send one or more of the user-specified parameters, predetermined alerts and nutritional information for display on the input module. A local controlling computer subsystem is responsive to the input module controlling computer subsystem and is configured to prepare the user-defined food product or beverage based on the one or more commands and interactive instructions from the user.

Owner:RADIO ROBOTS

Method, apparatus, and system for coating food items

A method, apparatus, and system for coating food items such as coating empty ice cream cones subsequently containing ice cream. A liquid recovery apparatus is used in the method, apparatus, and system and is fashioned in a tray-like manner to form a slideway that includes a bottom section with openings that have collars along with opposing sidewalls and endwalls that together enable containment of coating liquid such as a chocolate coating. The chocolate coating is recovered and thereby reused as a subsequent topping for the filled ice cream cone.

Owner:NESTEC SA

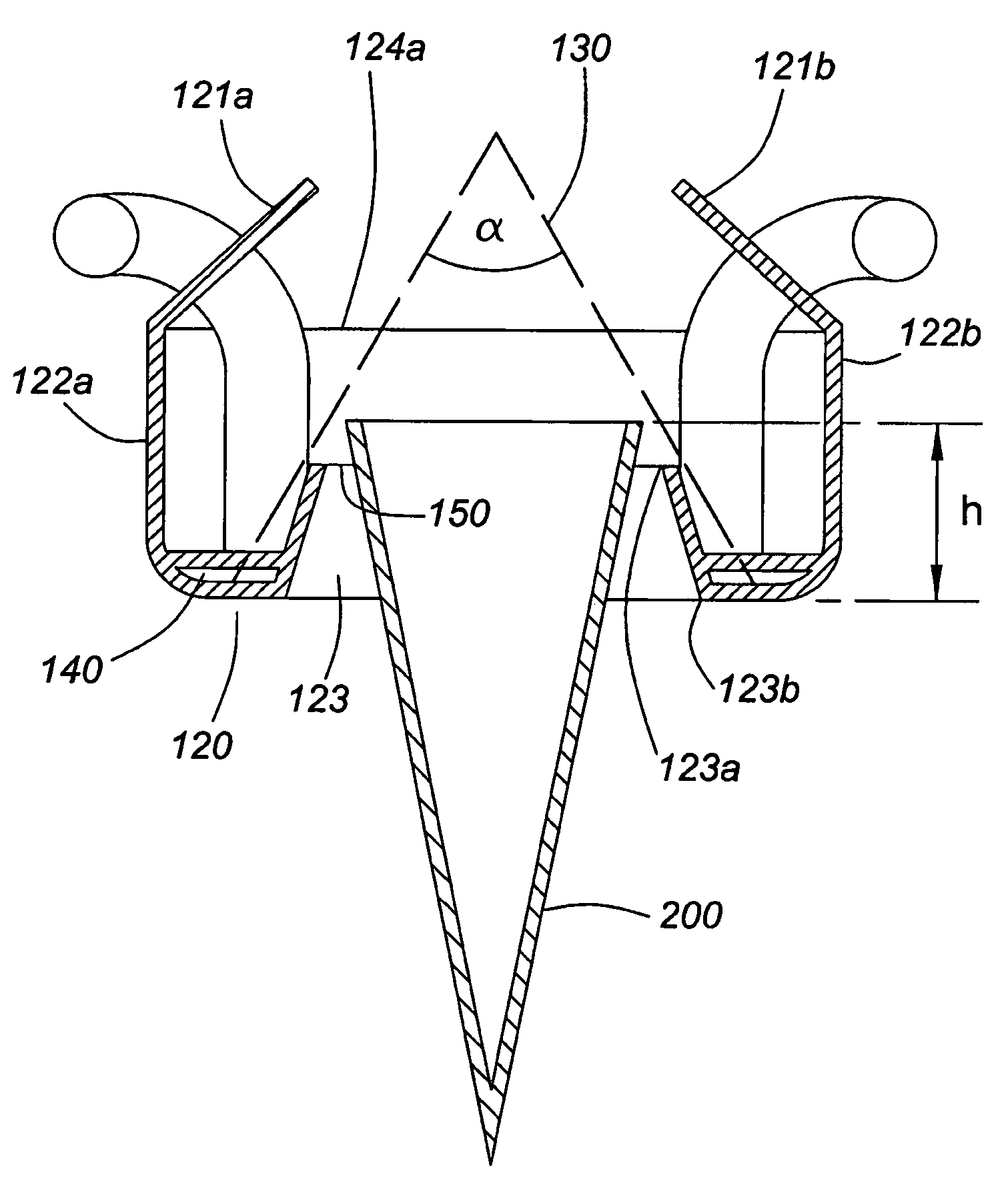

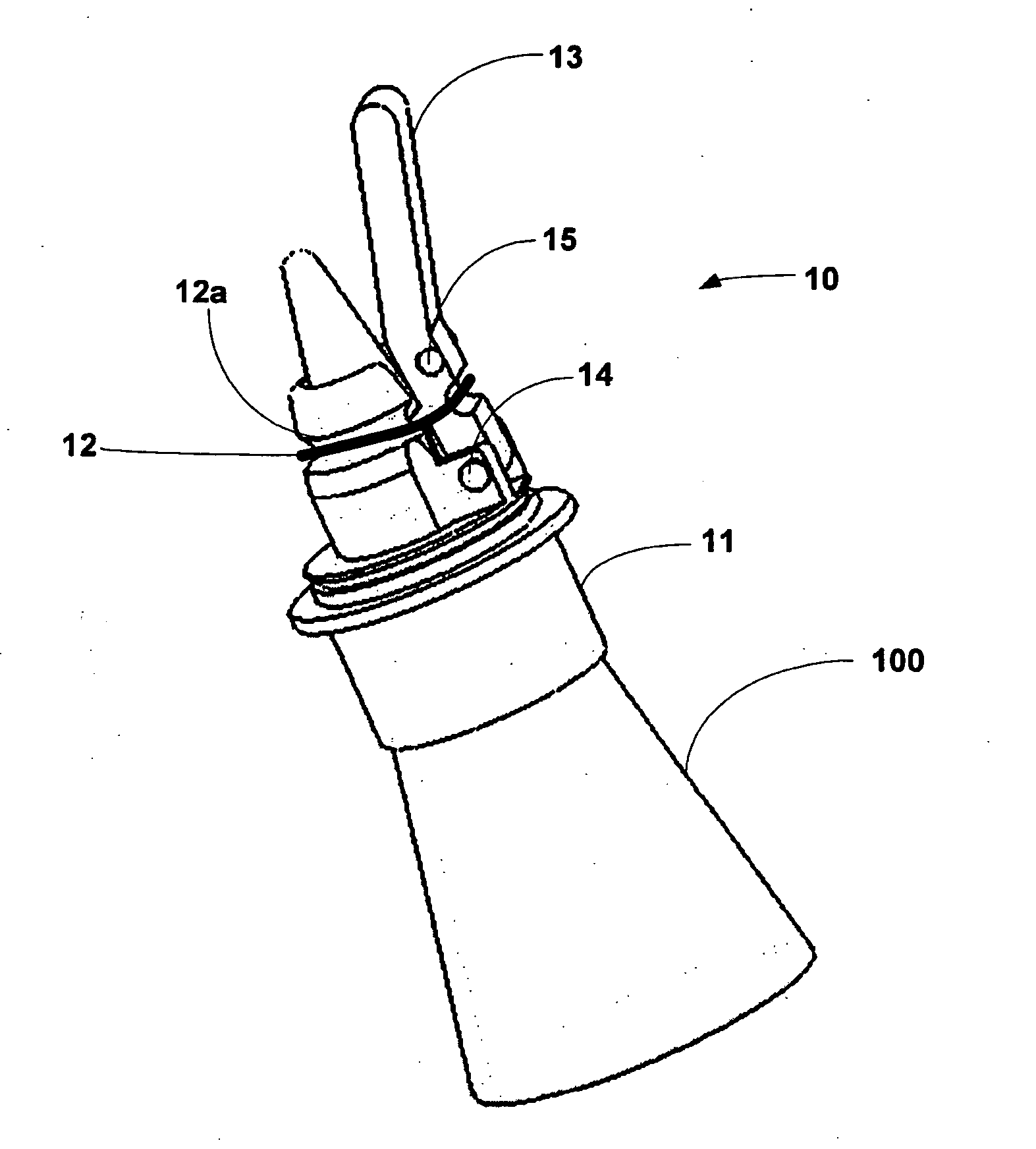

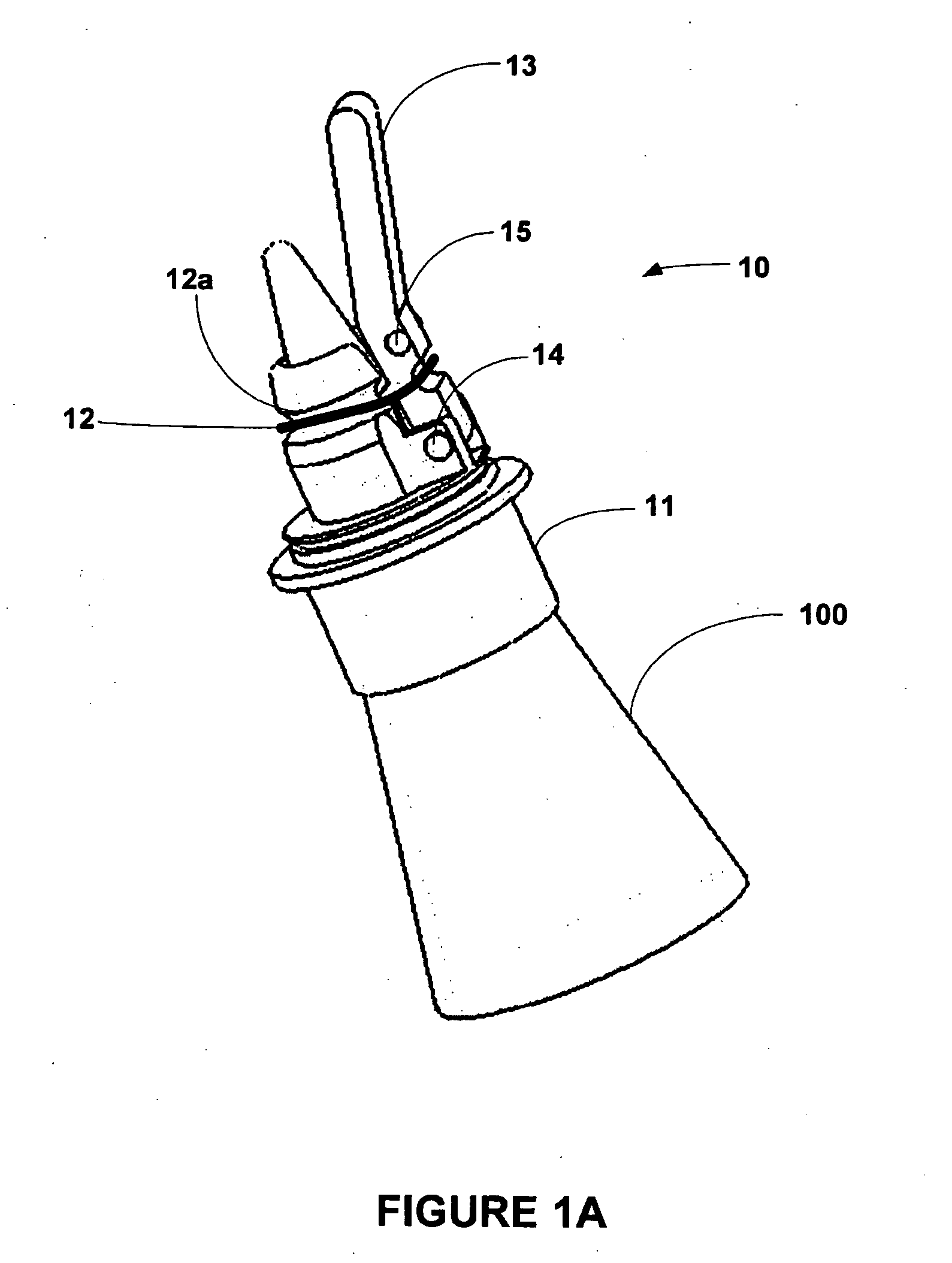

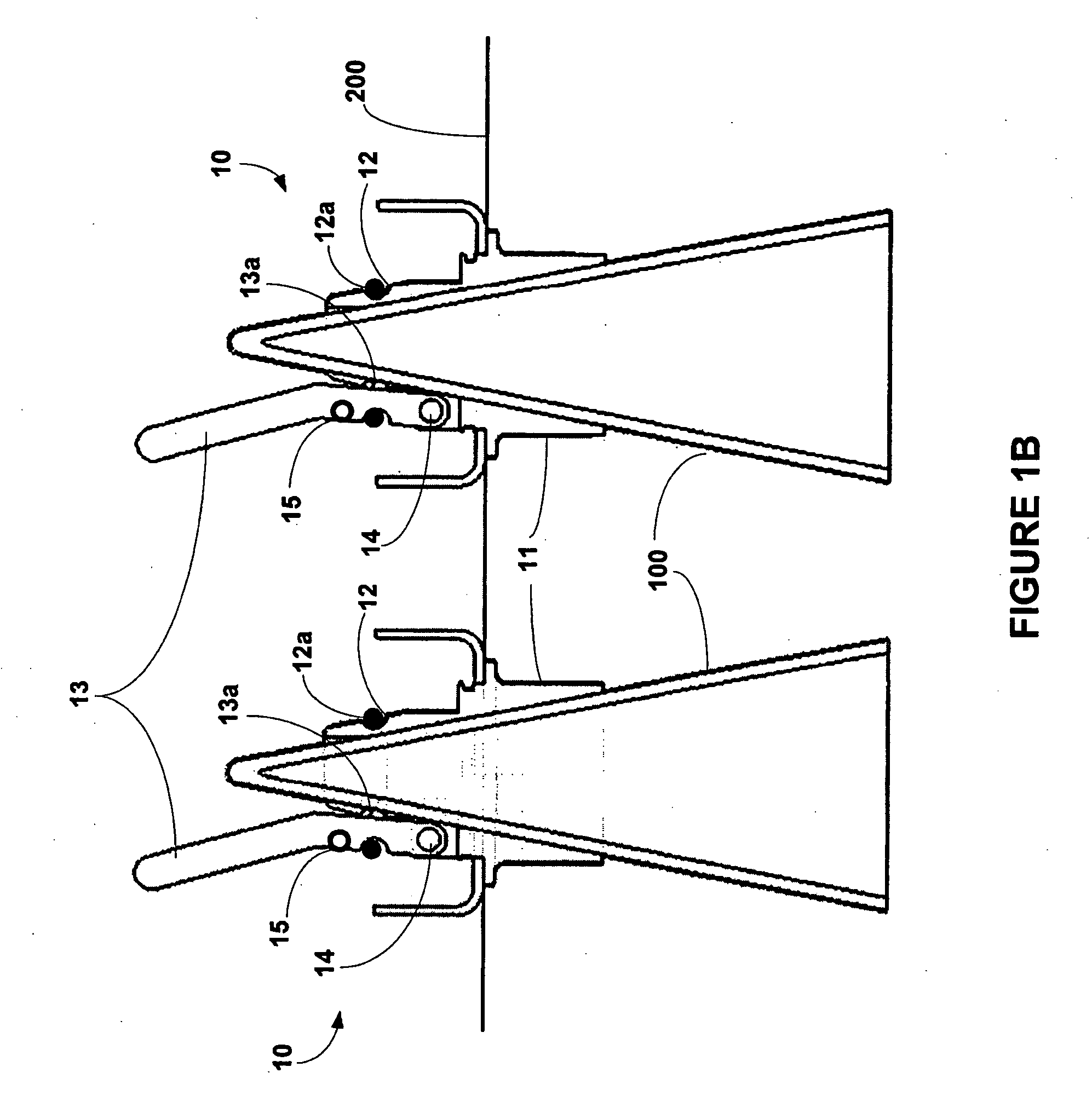

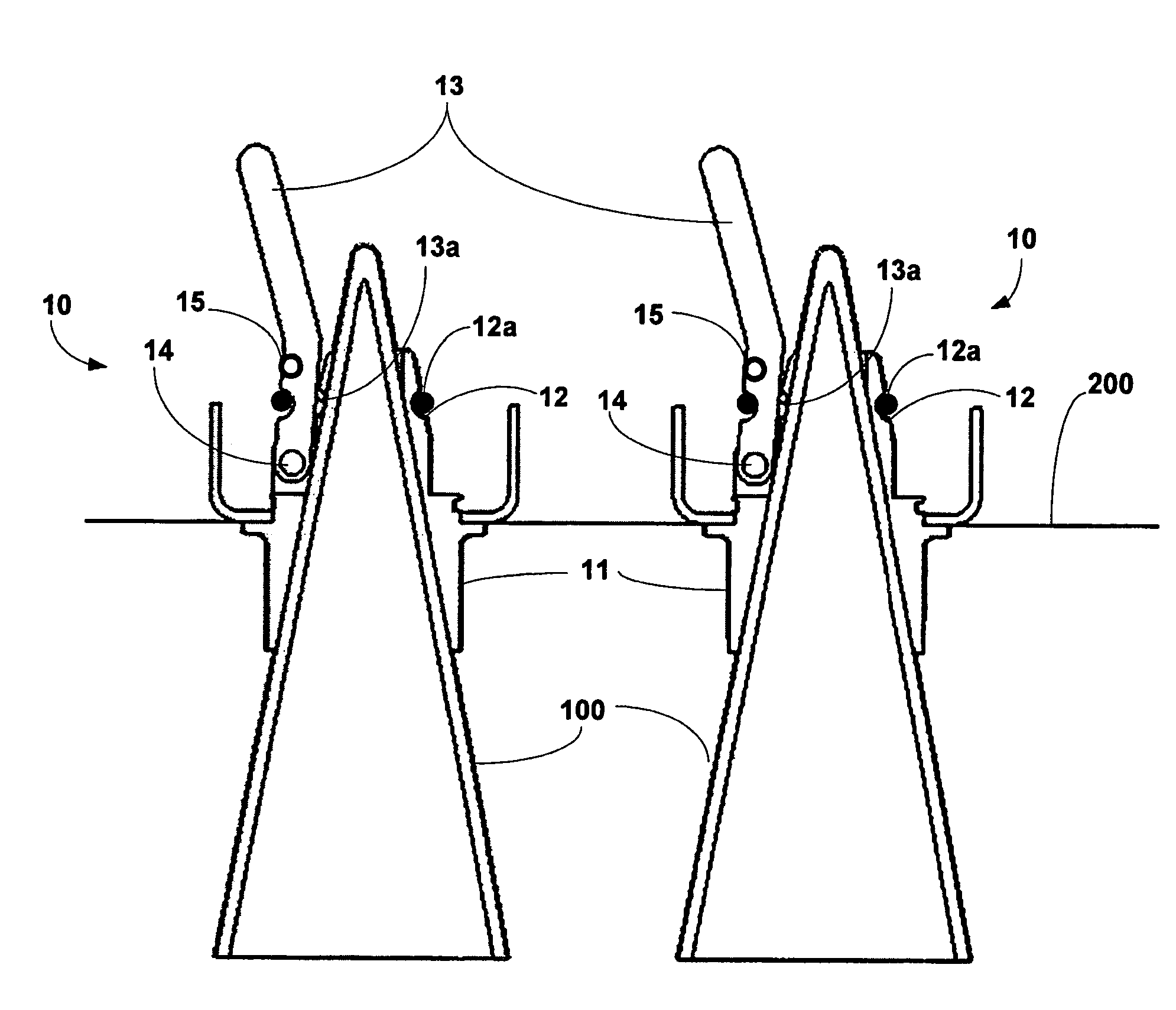

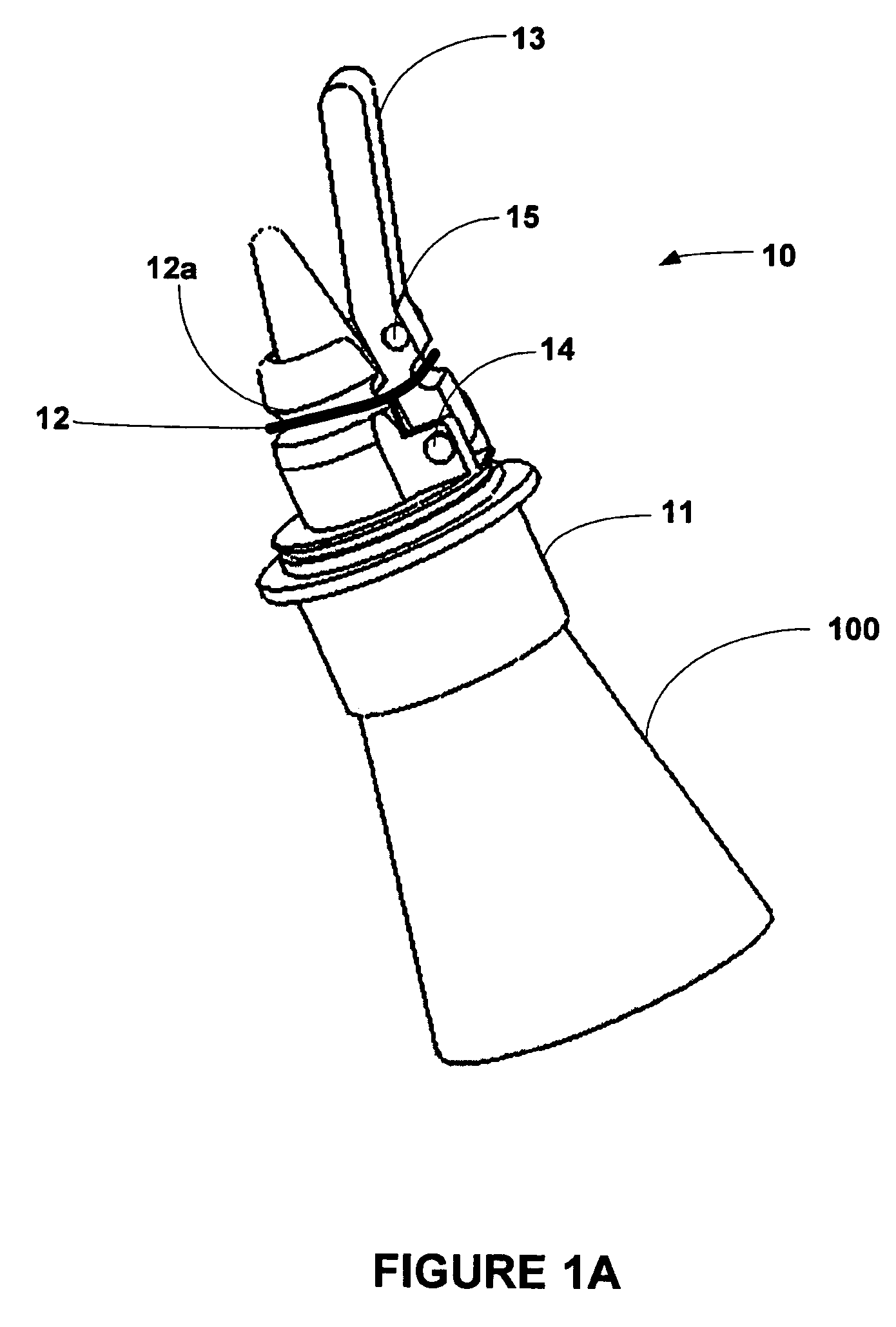

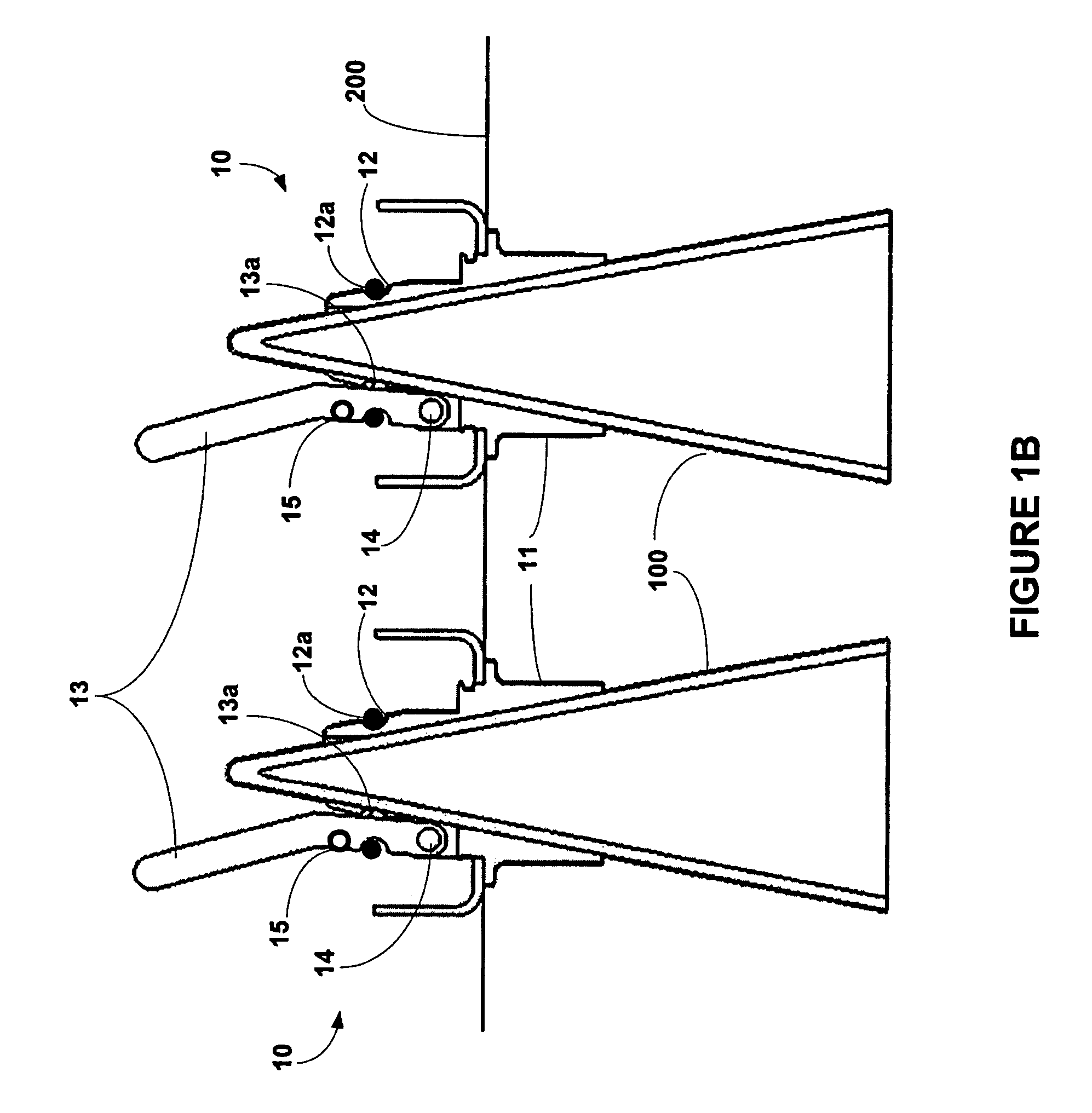

Pin-less socket for frozen confections

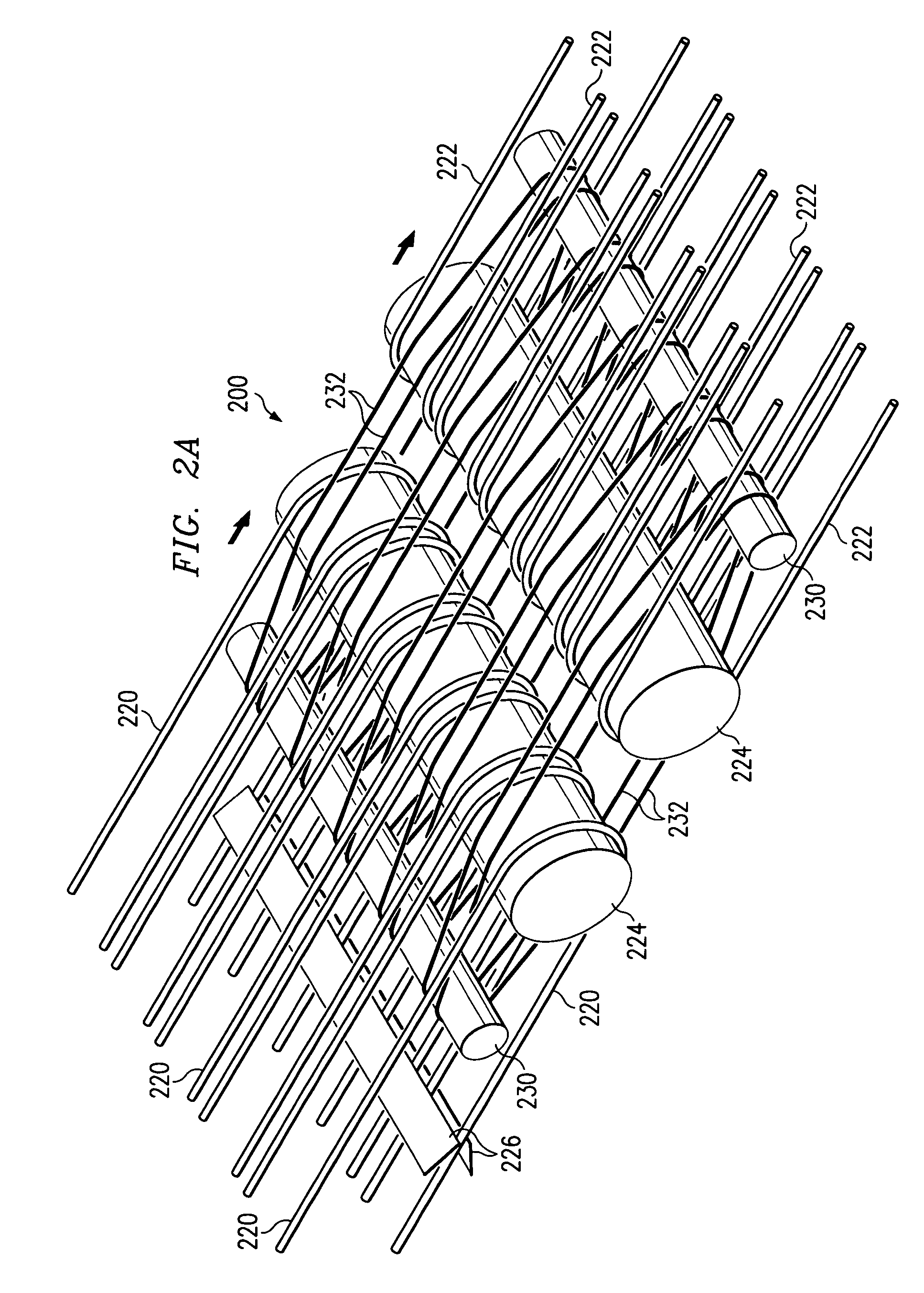

A pin-less socket apparatus and manufacturing system for assembling a frozen confection using such socket apparatus including a socket for accepting a conical food product therein, the socket having a hook with one or more teeth located at an outer periphery of the socket, a hinge located on an outside of the socket, the hook movably attached to the socket via the hinge, a force mechanism for holding the hook in place against the socket. The force mechanism takes the form of either an annular spring or 0-ring located around the socket and hook or a linear spring attached to the hook in a lever-type manner. The manufacturing system includes a coating area for coating a wafer cone with a moisture-resistant layer, a filling area having a filler for inserting a semi-frozen confection into the wafer cone, a cooling area for accepting the wafer cone with the semi-frozen confection and including a hardening tunnel for freezing the wafer cone and the semi-frozen confection, and a dipping area including more than one pin-less socket apparatus for accepting the wafer cone and moving the wafer cone through a dipping bin. Within the system, the coating, filling, cooling, and dipping areas may be on the same or separate assembly loops including the socket apparatus within one or more of such assembly loops.

Owner:NESTEC SA

Pin-less socket for frozen confections

Owner:NESTEC SA

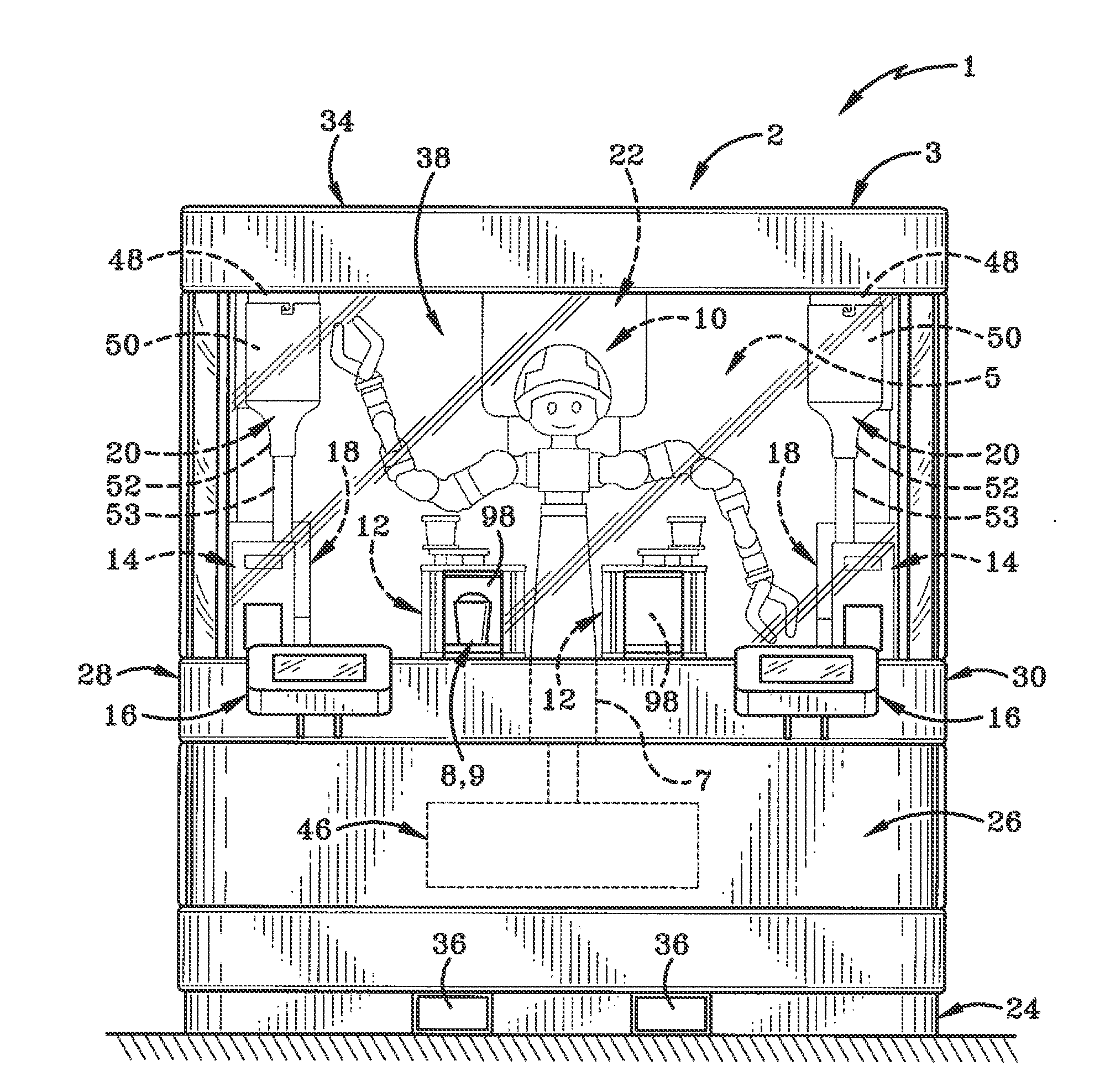

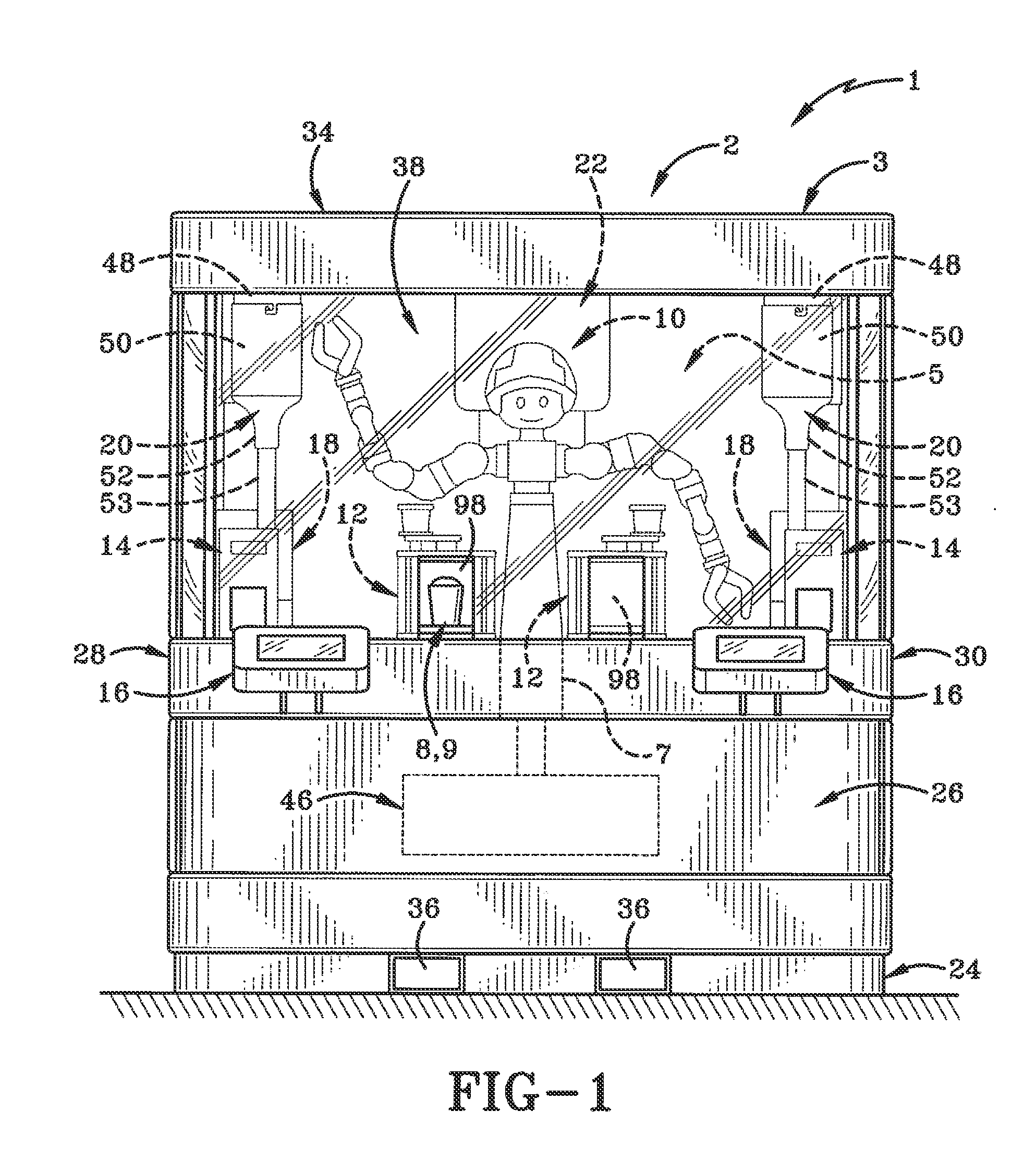

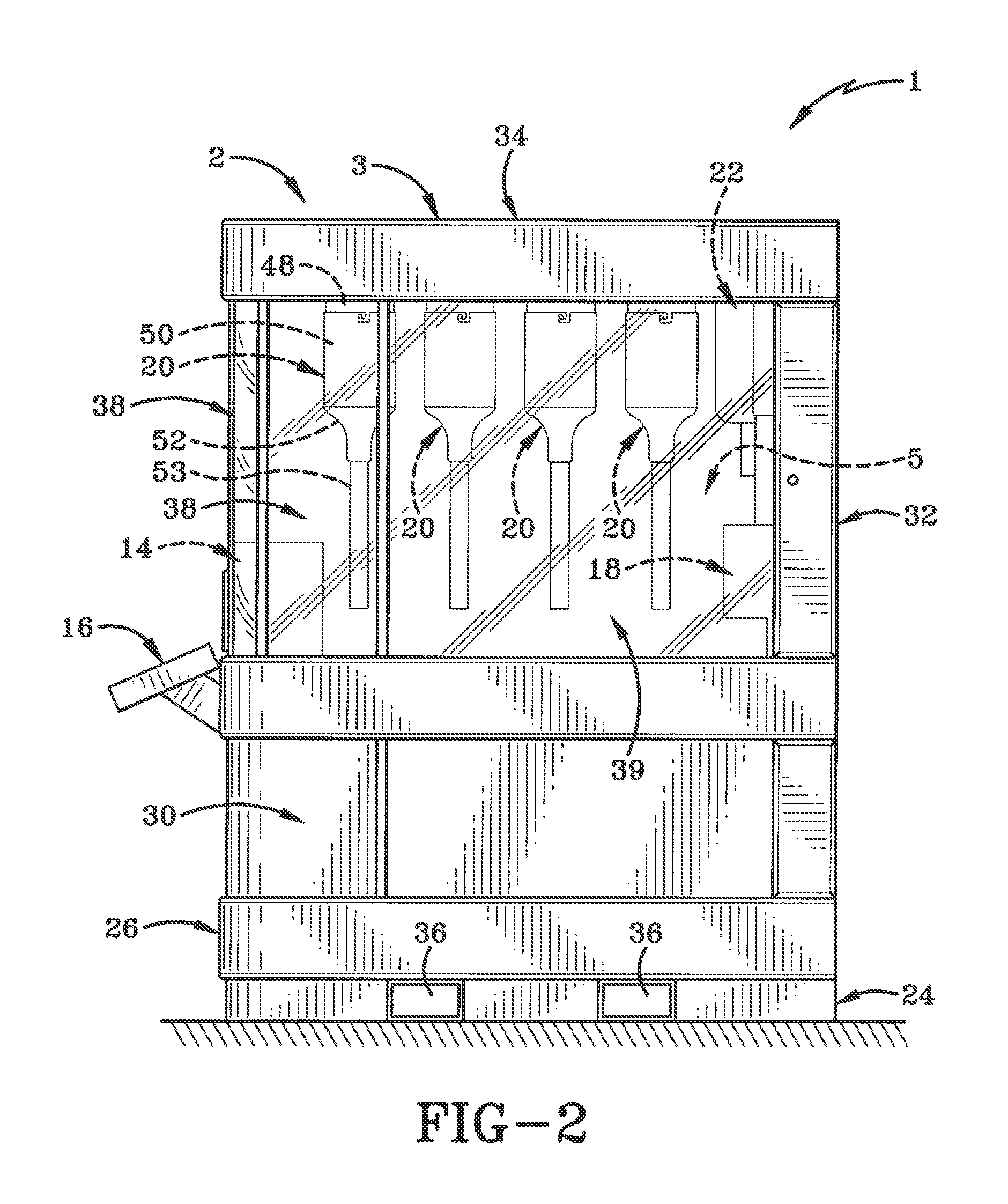

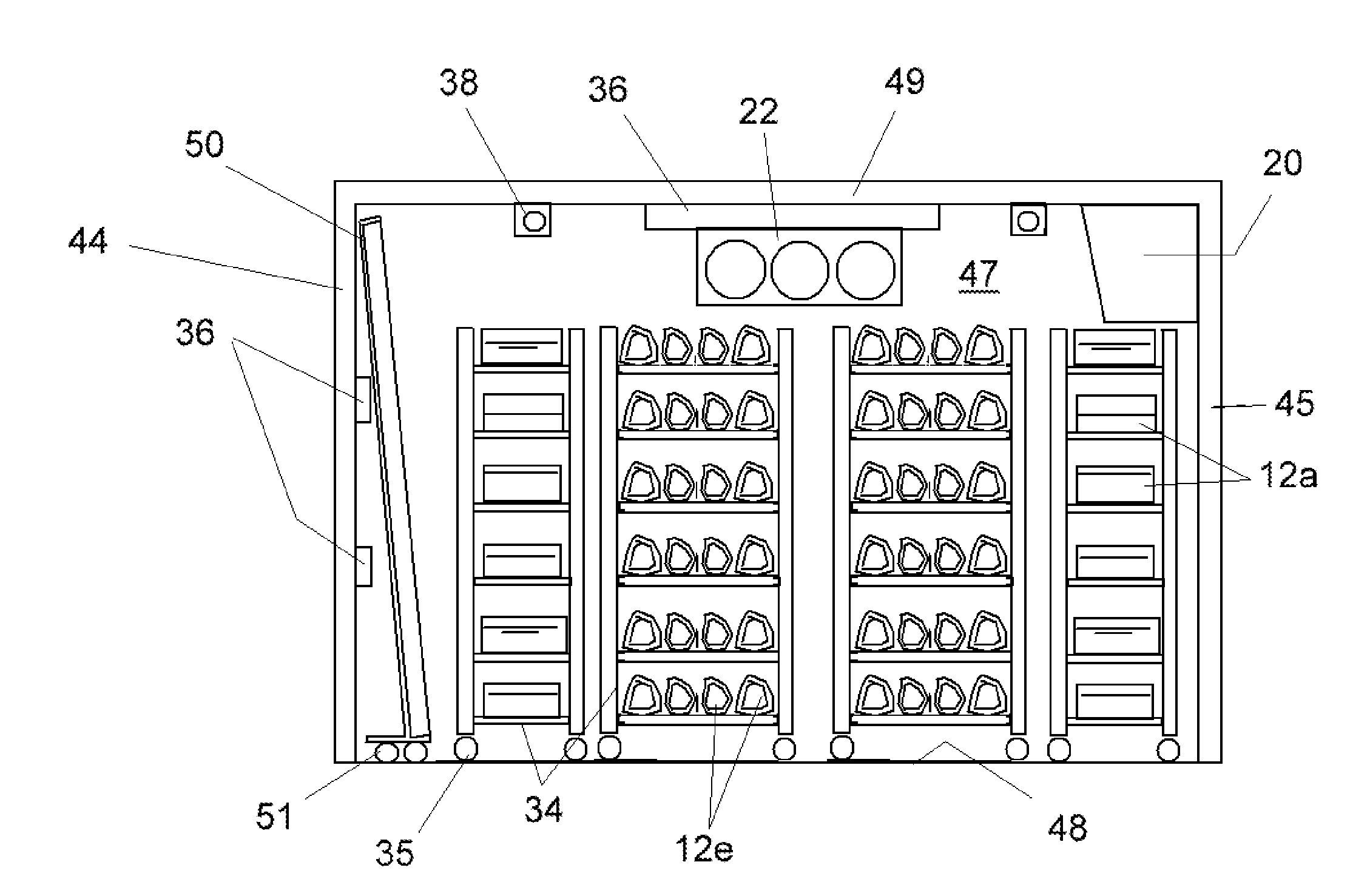

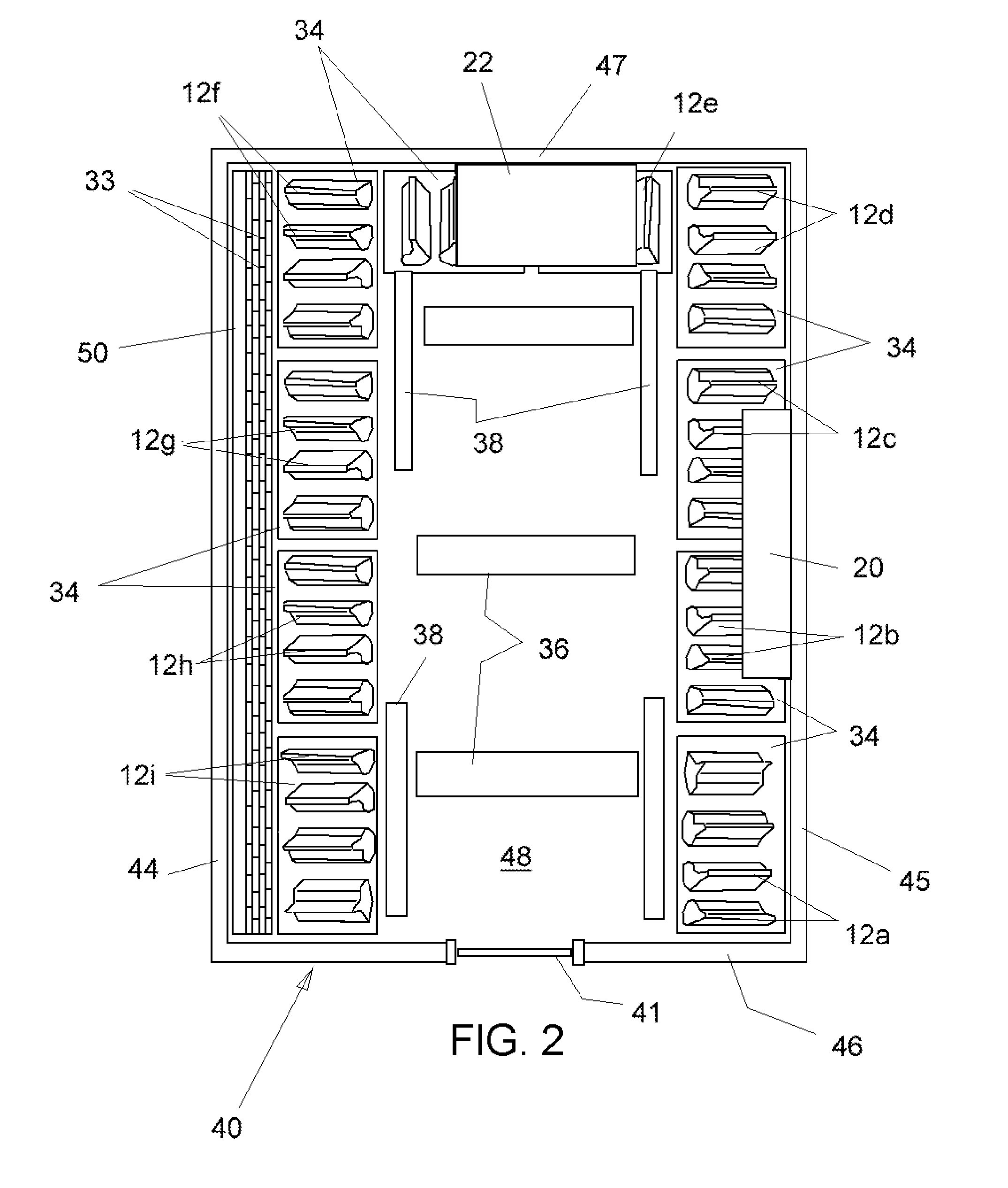

Robotic vending machine

InactiveUS20140120235A1Easy to viewEasy accessFrozen sweetsCoin-freed apparatus detailsSnack foodEngineering

A system and method for preparing treats is presented. A vending machine for building custom ordered treats includes an enclosed housing with windows. A robot is inside the housing and first and second user interfaces are attached to the housing. The first and second user interfaces accept inputs from first and second users respectively. The robot has left and right arms as well as a simulated head to make it appear somewhat human like. The left and right arms work together to assemble a single treat when only one treat has been requested at the vending machine. However, when two different treats have been requested the left arm can work independently, at least sometimes, of the right arm on a custom treat for the first user. Similarly, the right arm can, at least sometimes, work independently of the left arm on a custom treat for the second user.

Owner:ROBOFUSION

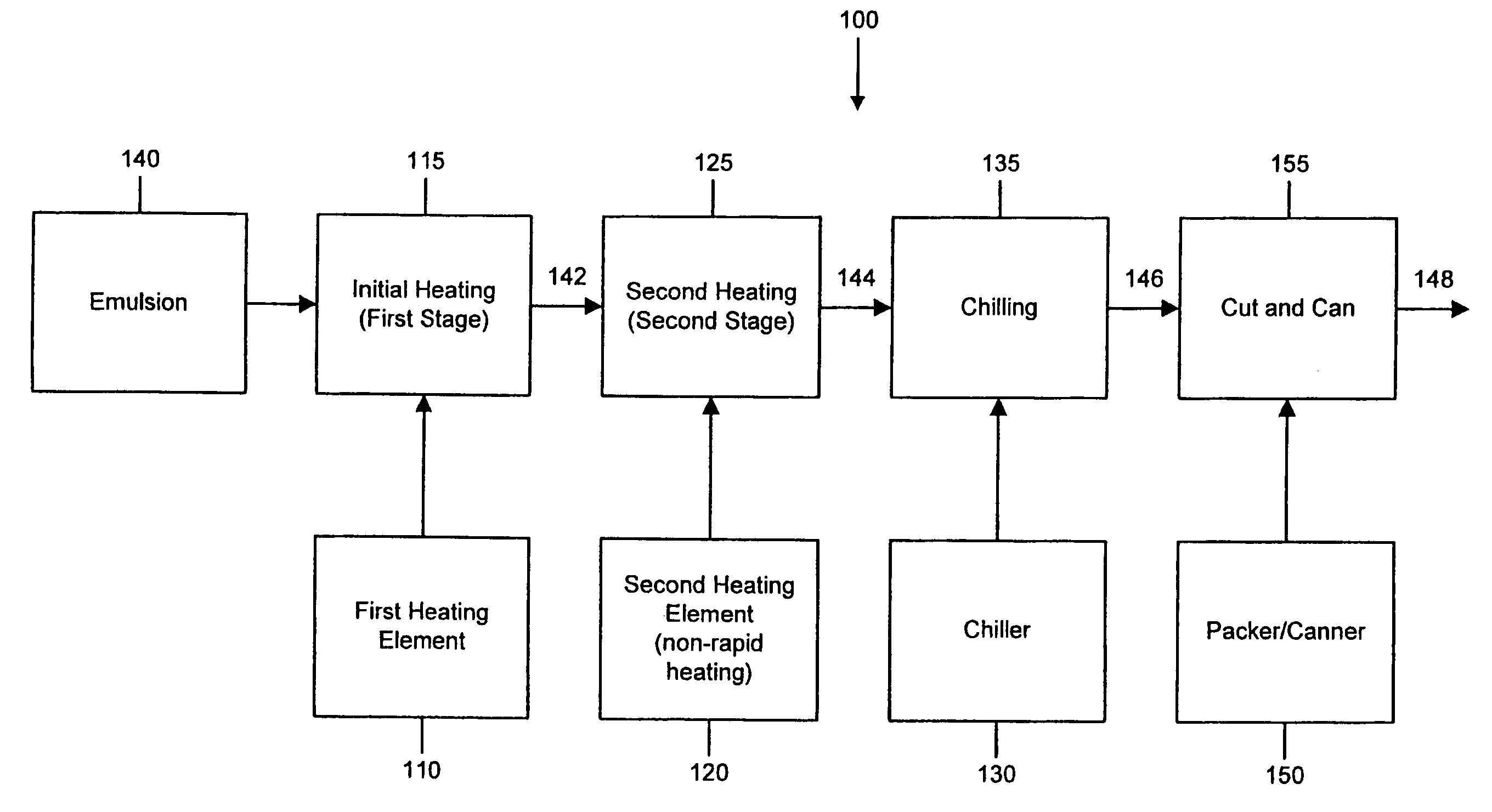

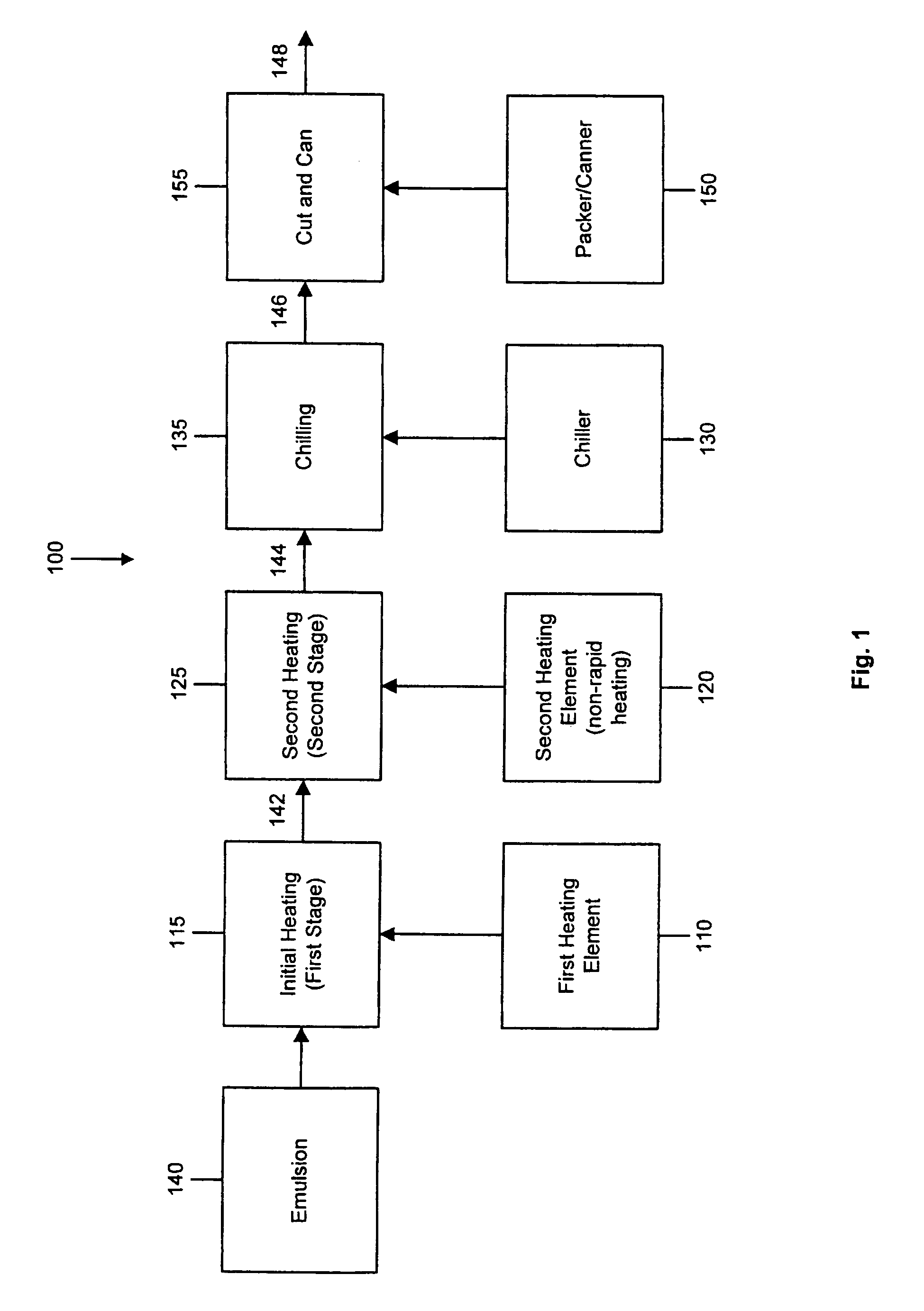

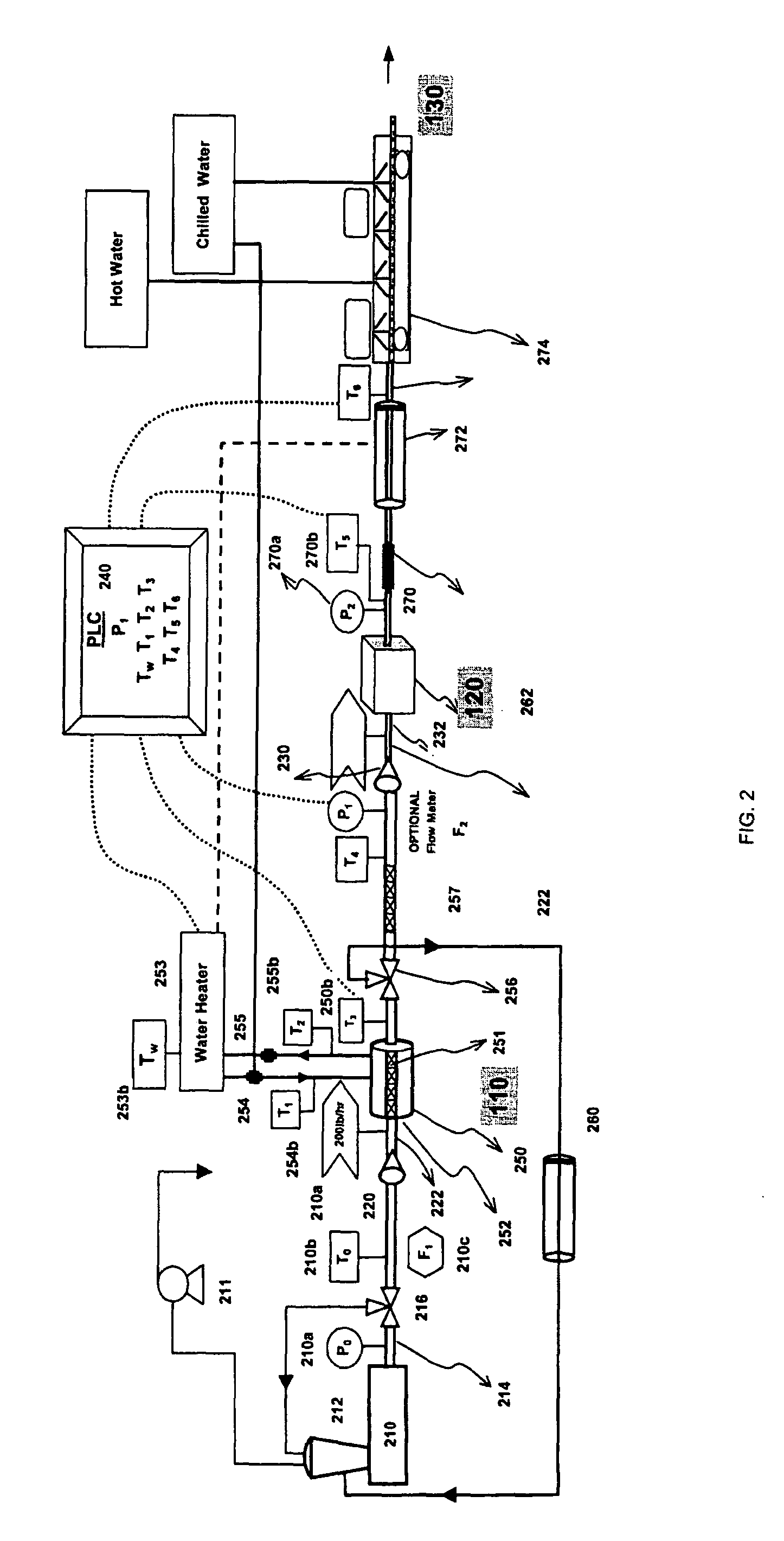

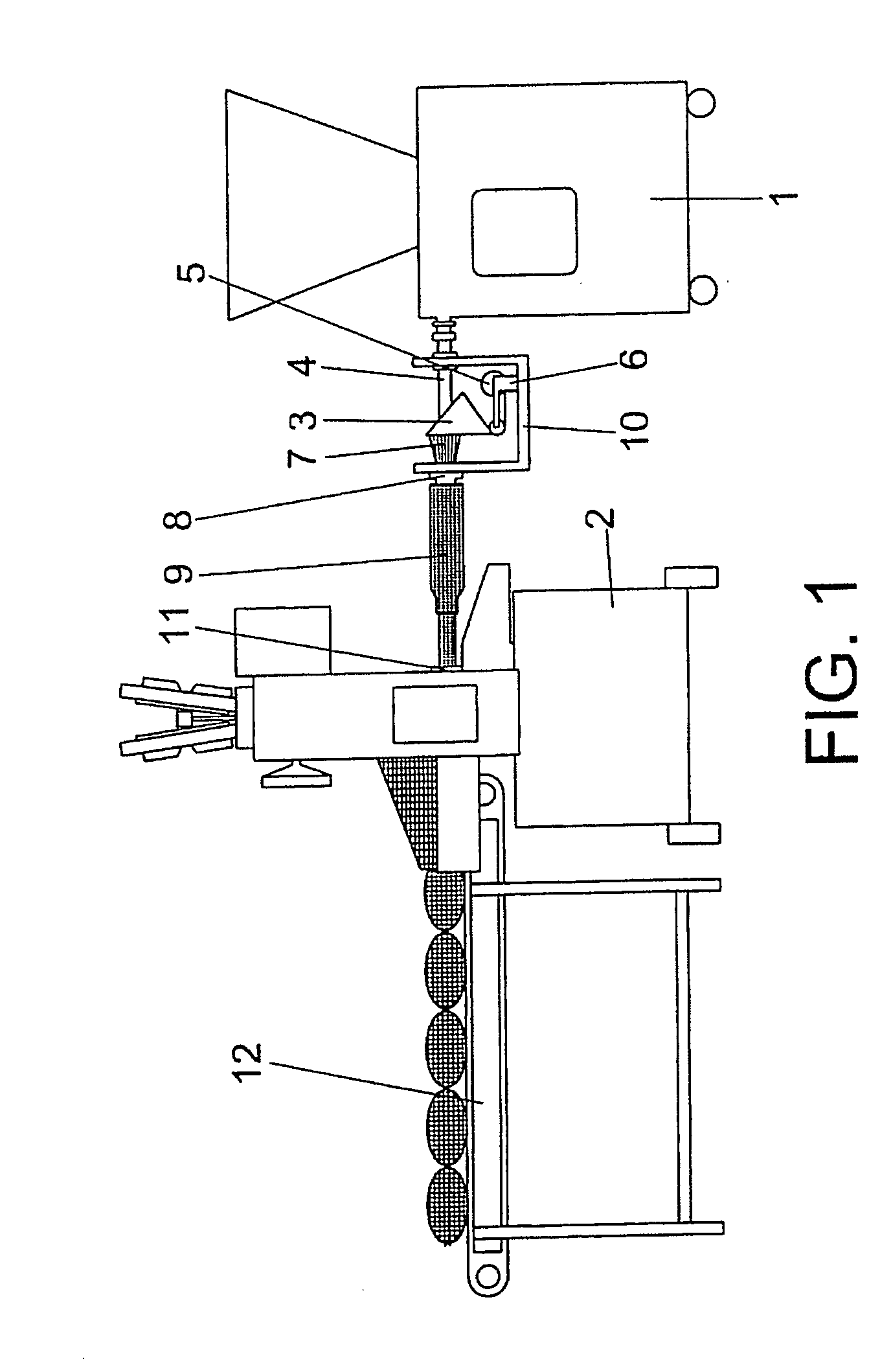

System and method for making casingless sausage

A method and system for producing a casingless sausage product. An emulsion, such as a meat emulsion, is heated by a first heating element, such as conductive element, such as a heat exchanger or a direct heating element, from a first temperature to an initial heating temperature. The initial heating forms a warm emulsion. After the first heating stage, the warmed emulsion is heated again during a second stage with a second heating element from the initial heating temperature to a higher, second heating temperature. Other numbers of heating elements can be utilized as necessary. The second heating element can be a rapid heating element, such as a microwave or radio frequency (RF). The second heating produces a casingless sausage. The casingless sausage is subsequently cooled or chilled to produce the casingless sausage product. The product can be cut to a length and packaged in a container or can.

Owner:CONAGRA FOODS

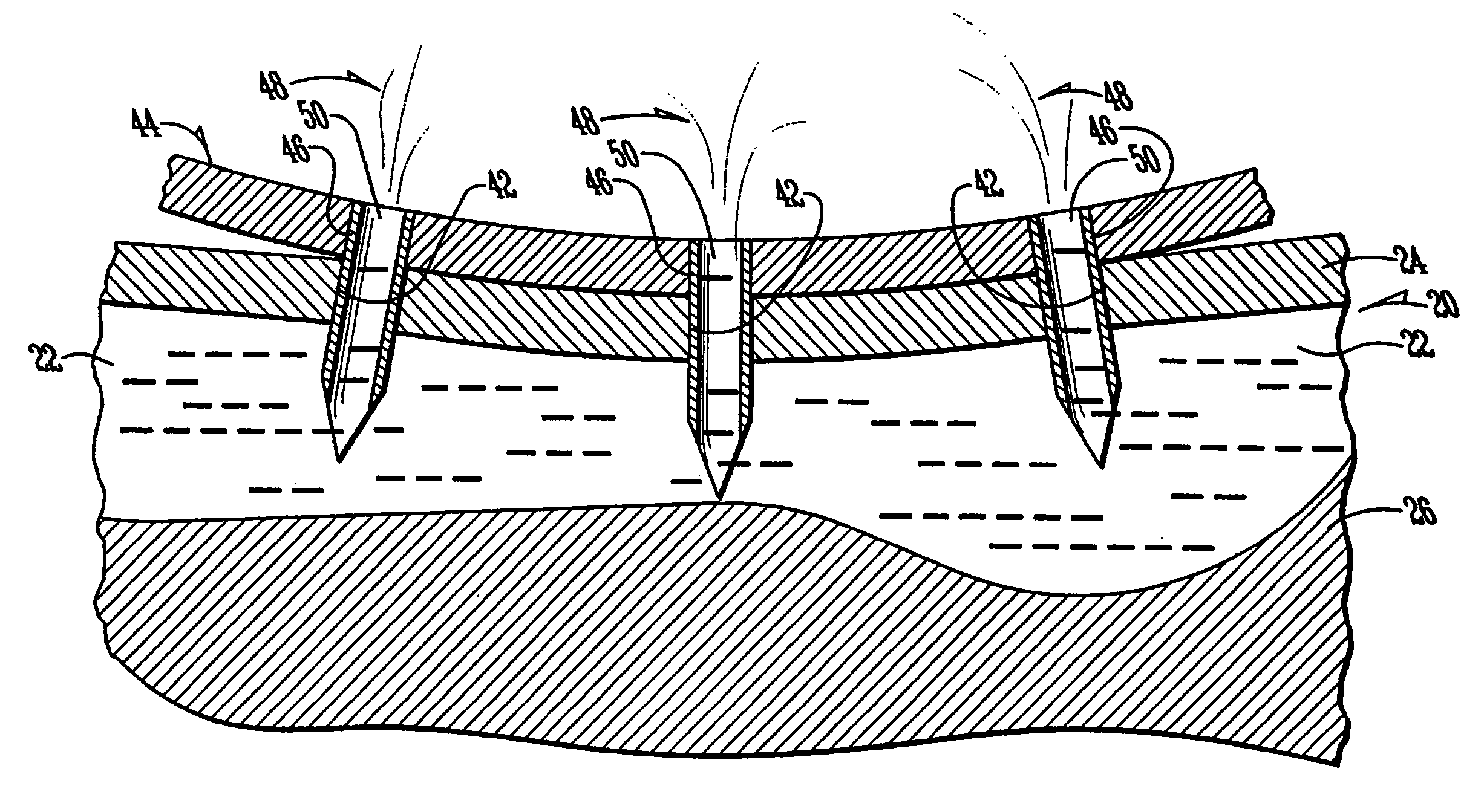

Method and apparatus for evacuating pockets of injected fluid in meat products

Owner:STORK TOWNSEND BV

Food injection device

InactiveUS6840161B2Easy to addEasy to operateBaked article fillingInjection based meat processingReady to useSyringe needle

Owner:LAURUS MASTER FUND +1

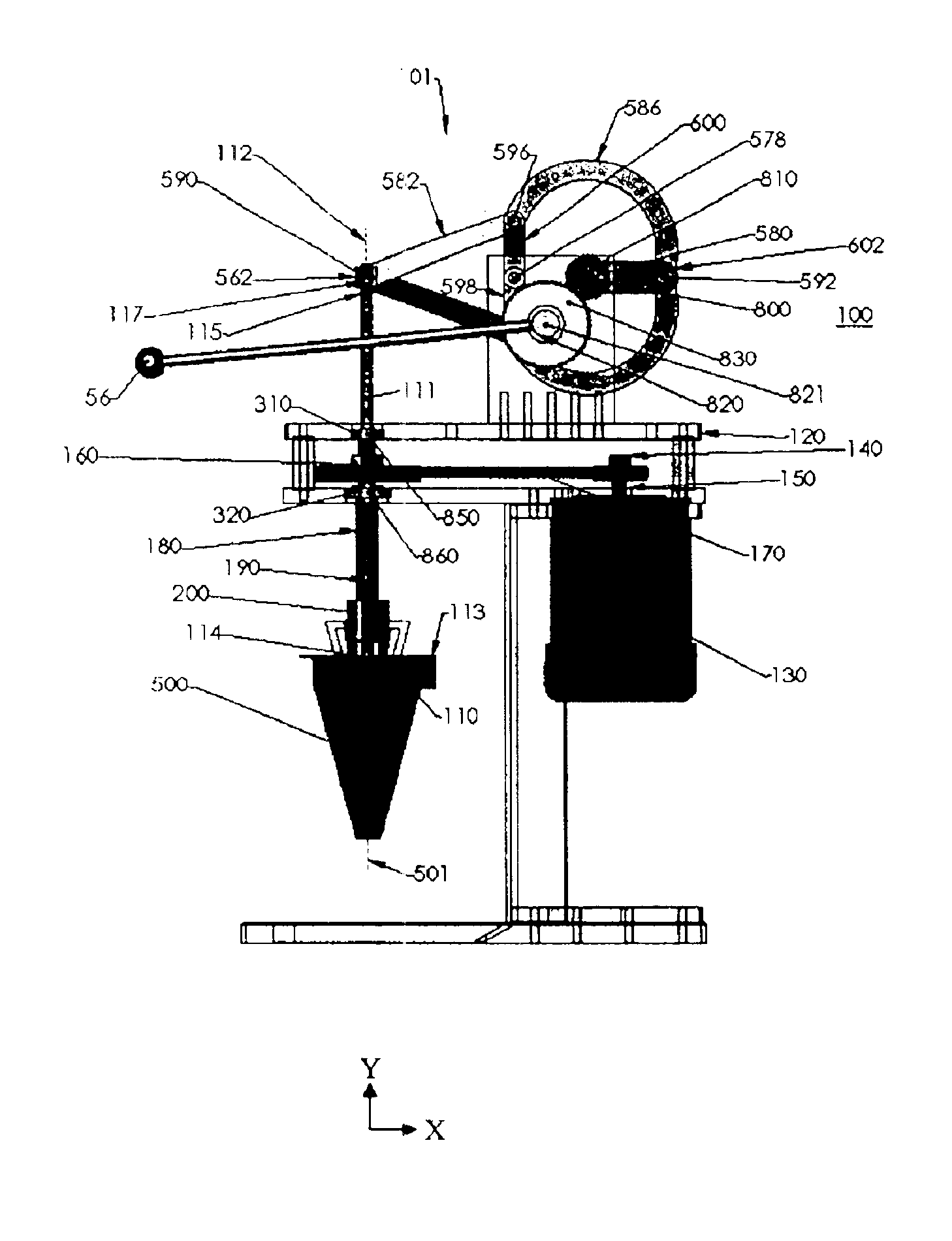

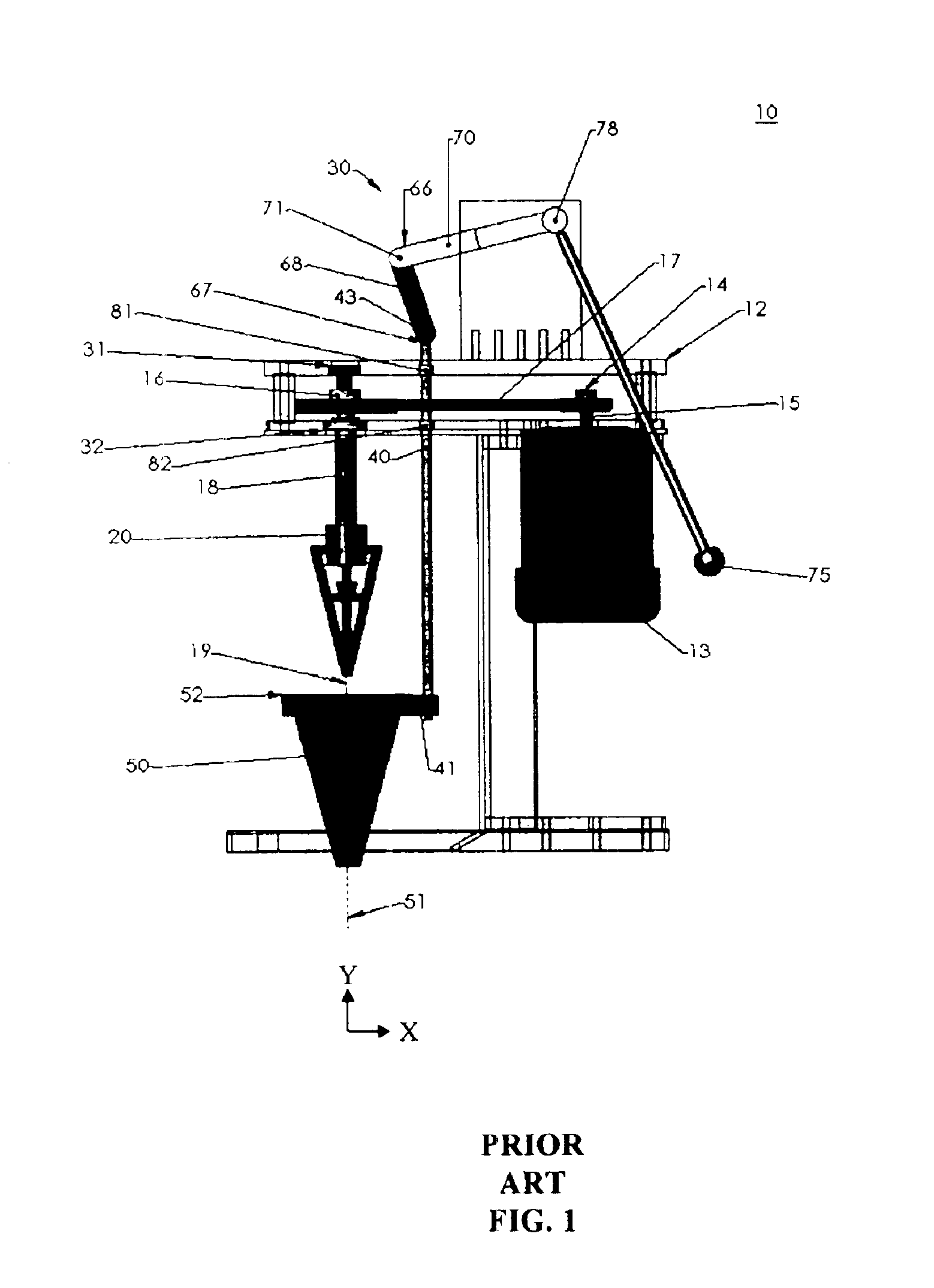

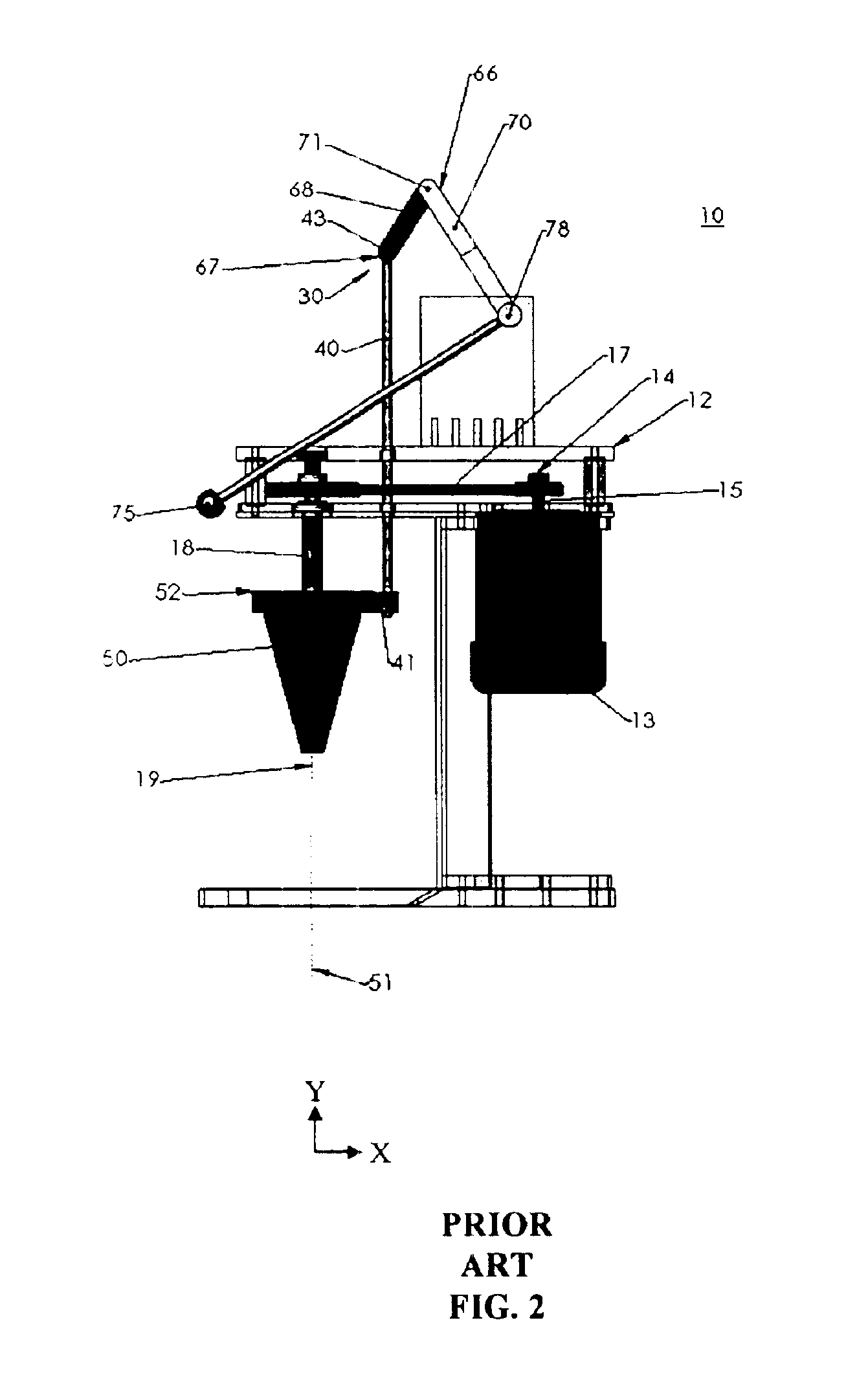

Blending apparatus for ice cream

InactiveUS6848356B1Simple structureQuantity minimizationMilk preservationMilk treatmentSupporting systemLinear motion

An improved ice cream blending apparatus has a hopper support system that incorporates a hopper guidance mechanical linkage that supports the linear motion of the hopper and translates non-linear circular motion of the operating handle into the linear motion of the hopper.

Owner:SWEETREATS +1

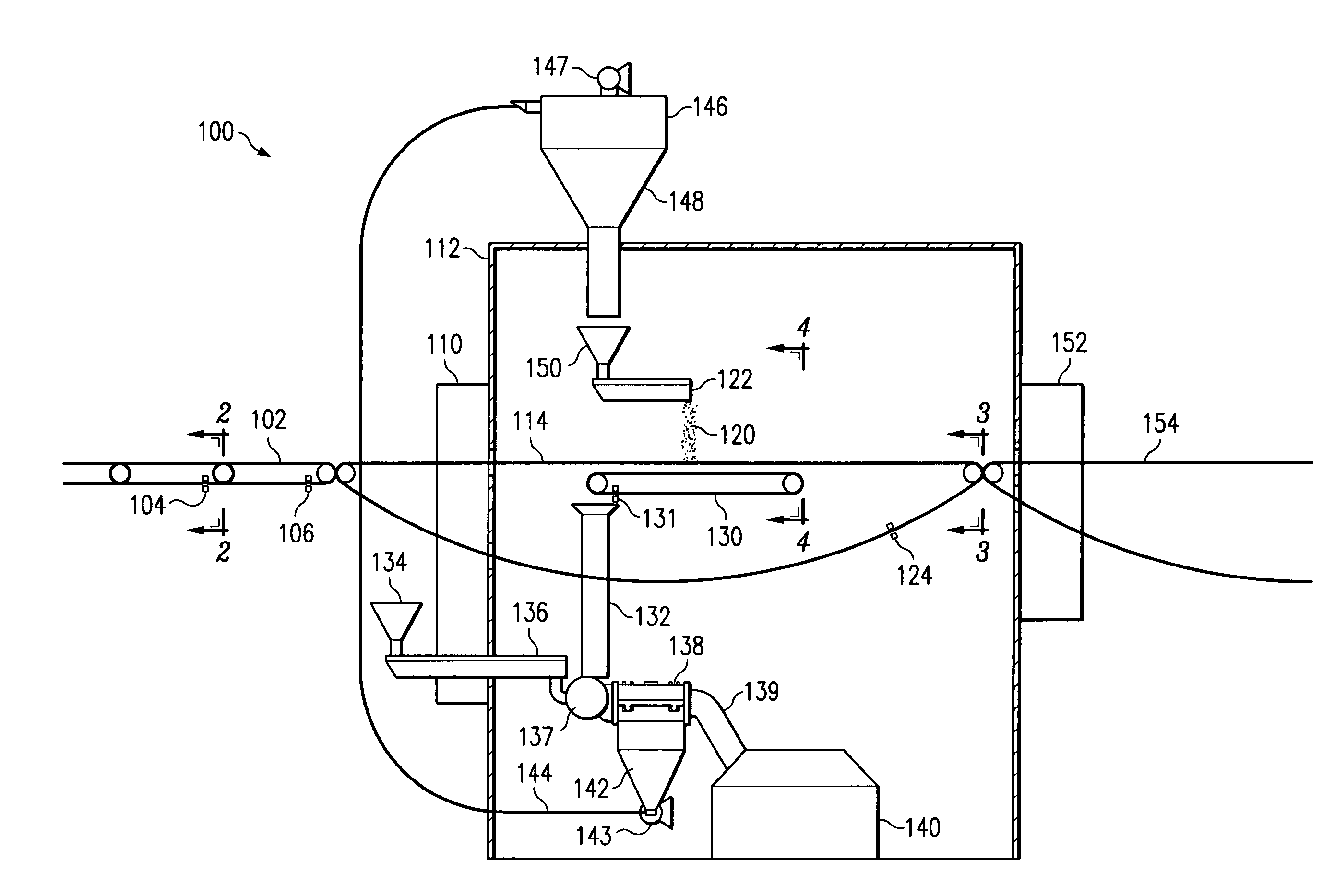

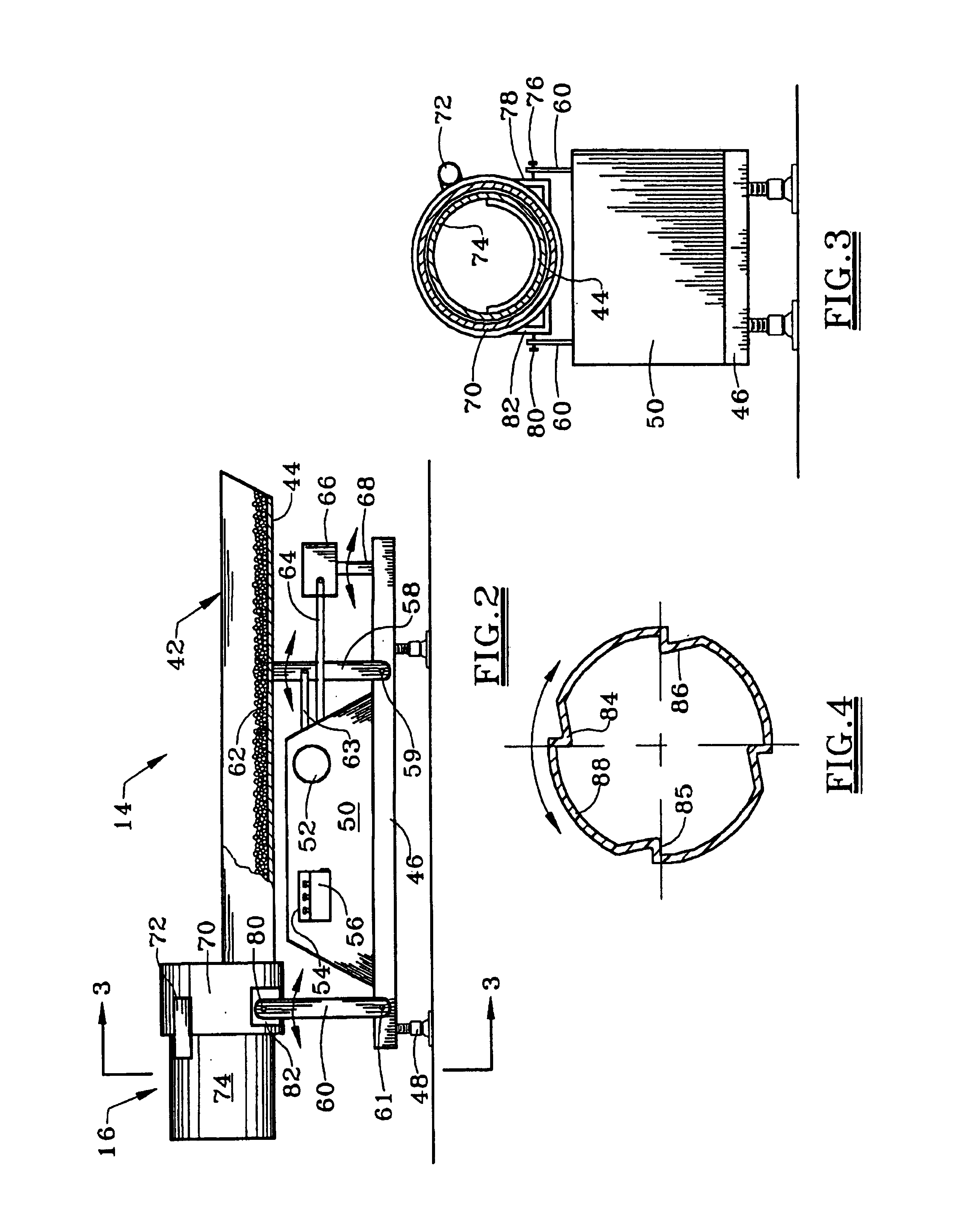

Seasoning recovery and recycle

InactiveUS6962128B2Smooth transferGuaranteed preservation qualityLiquid surface applicatorsConfectioneryProcess engineeringWith snack

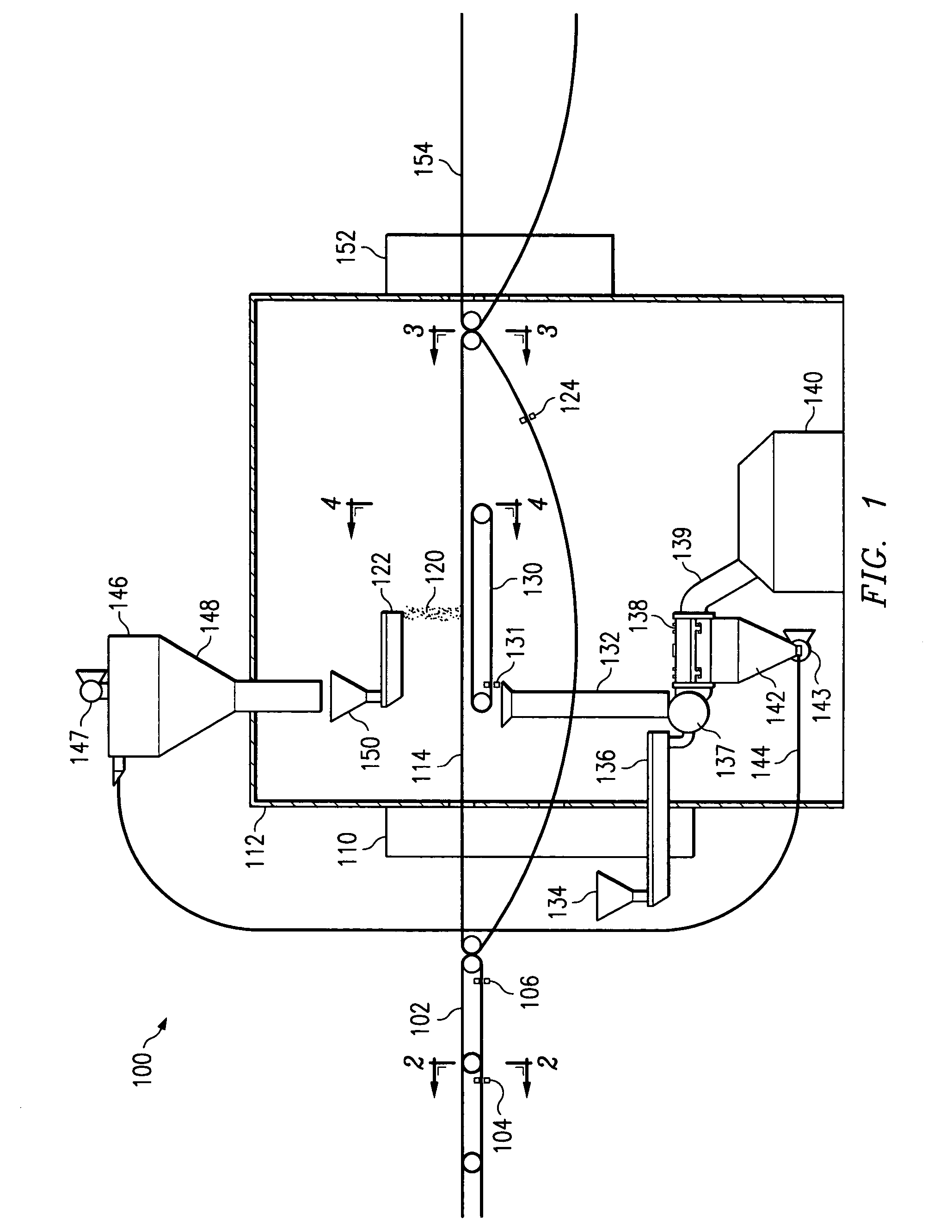

Seasoning for use with snack chips can be recovered and recycled. A seasoning permeable conveyor transports snack chips through a seasoning application. The seasoning applicator deposits seasoning onto the snack chips. The conveyor allows the seasoning not adhered to the moving snack chips to substantially pass through and by toward a seasoning recoverer. The seasoning recoverer, which is positioned beneath the conveyor, collects the seasoning for purification and blending with fresh seasoning. After blending, the seasoning mixture is transported to the seasoning application for use.

Owner:FRITO LAY NORTH AMERICA INC

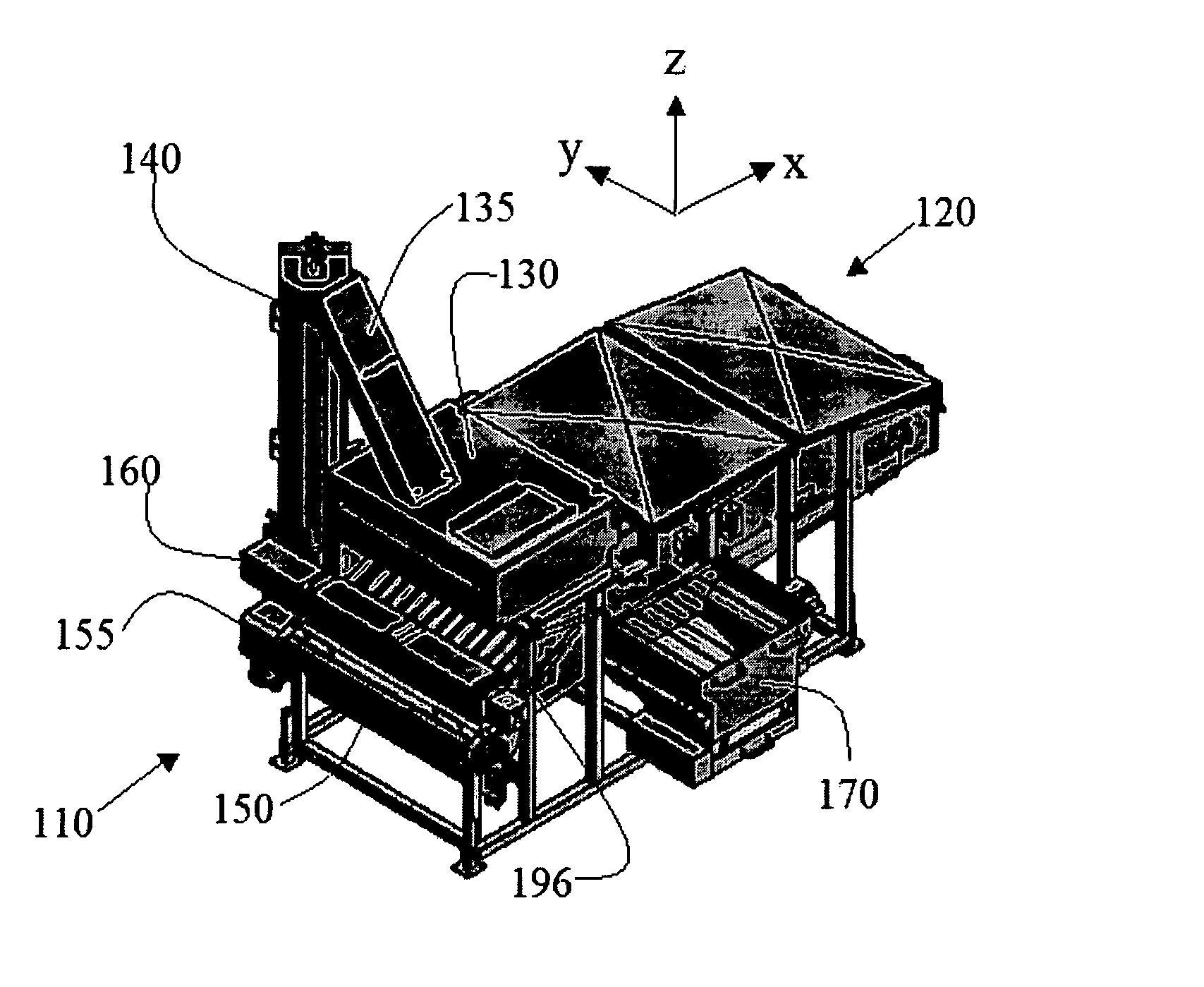

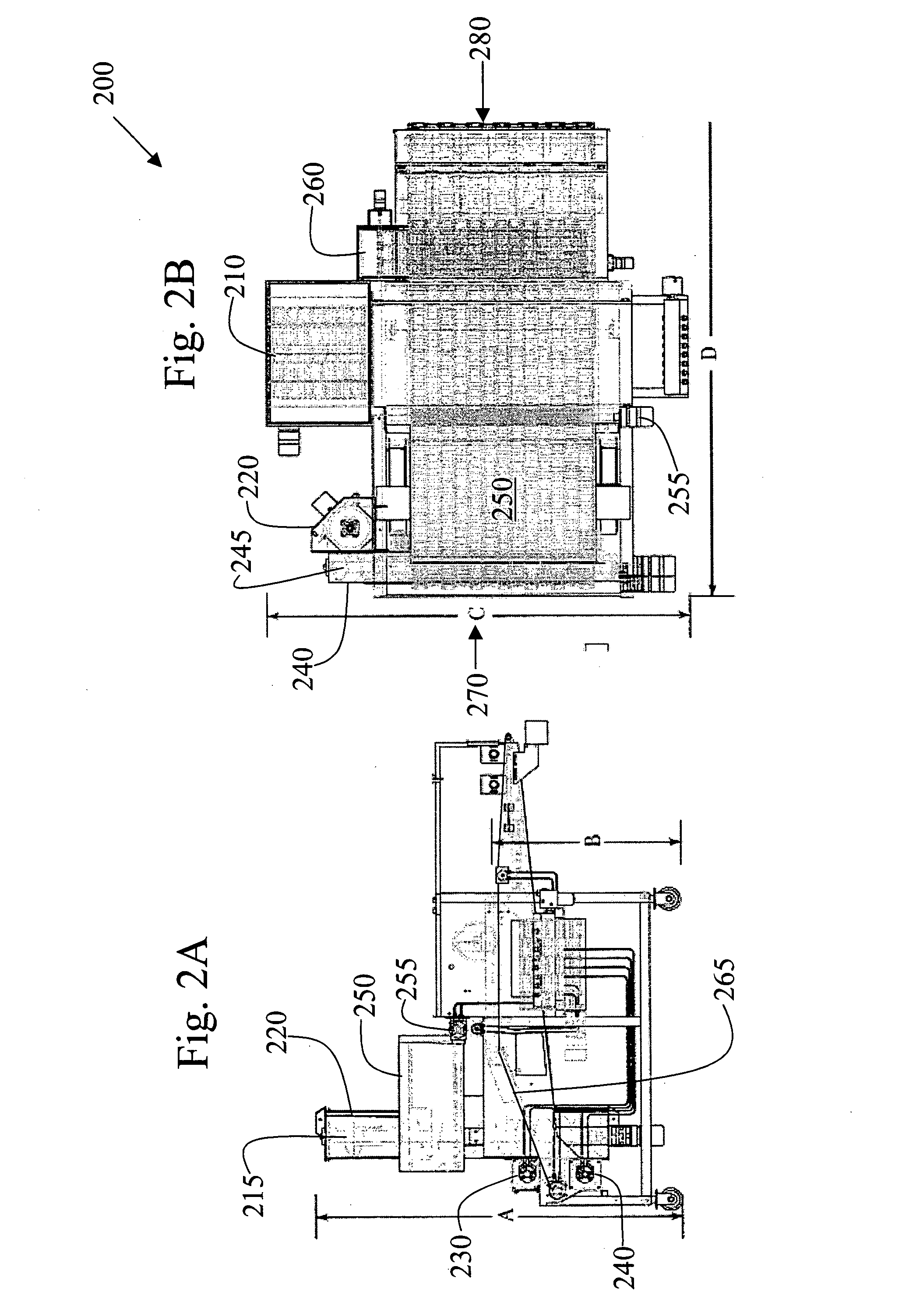

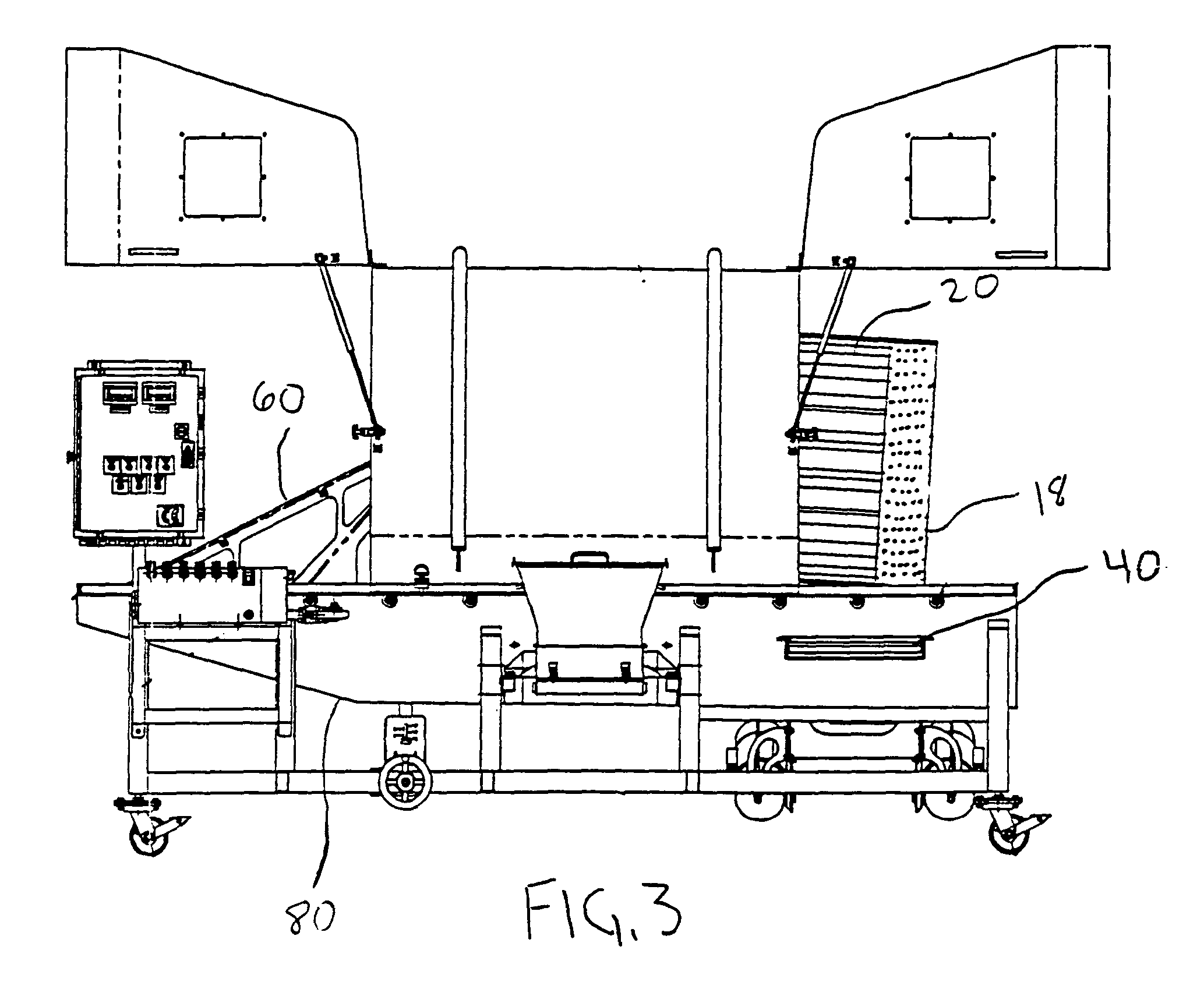

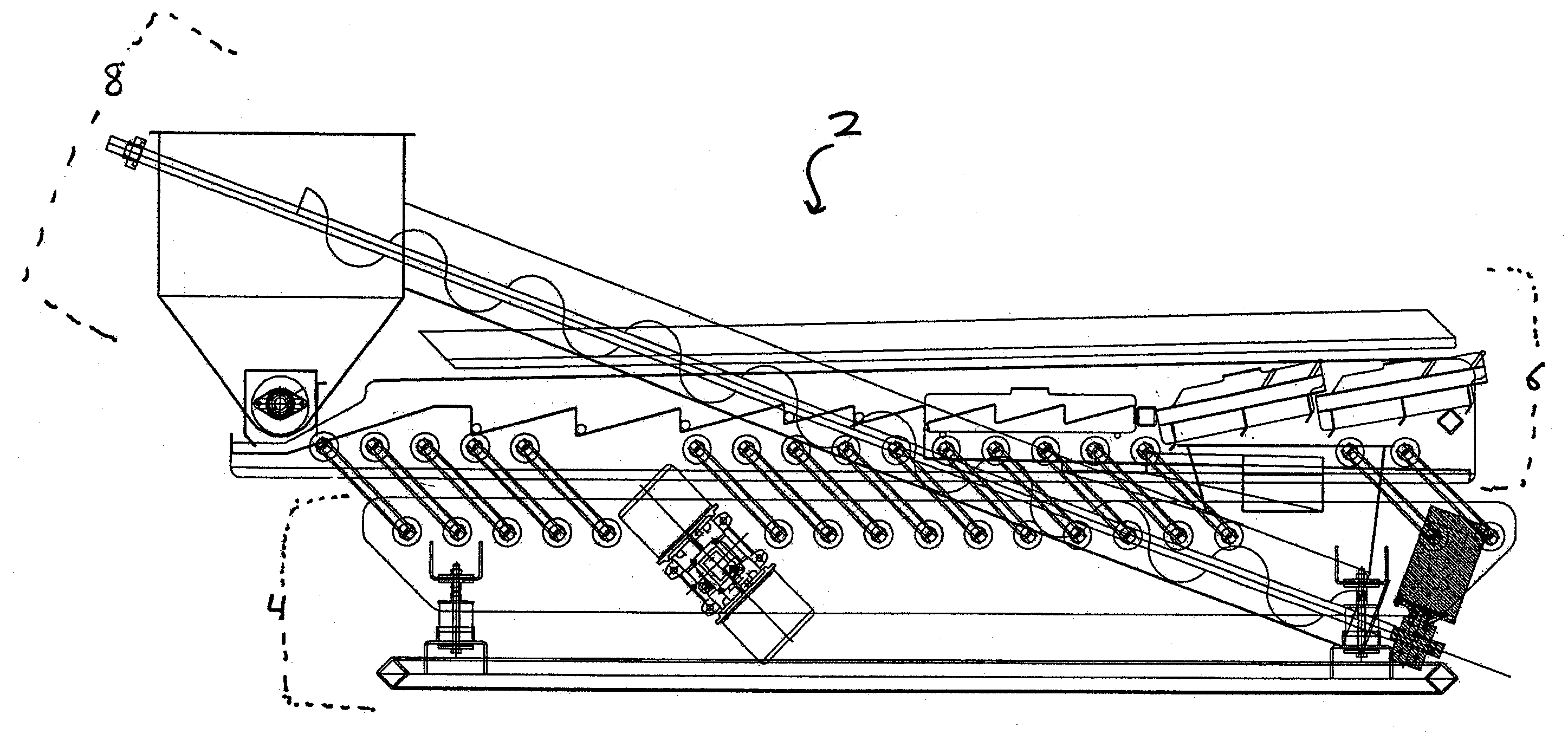

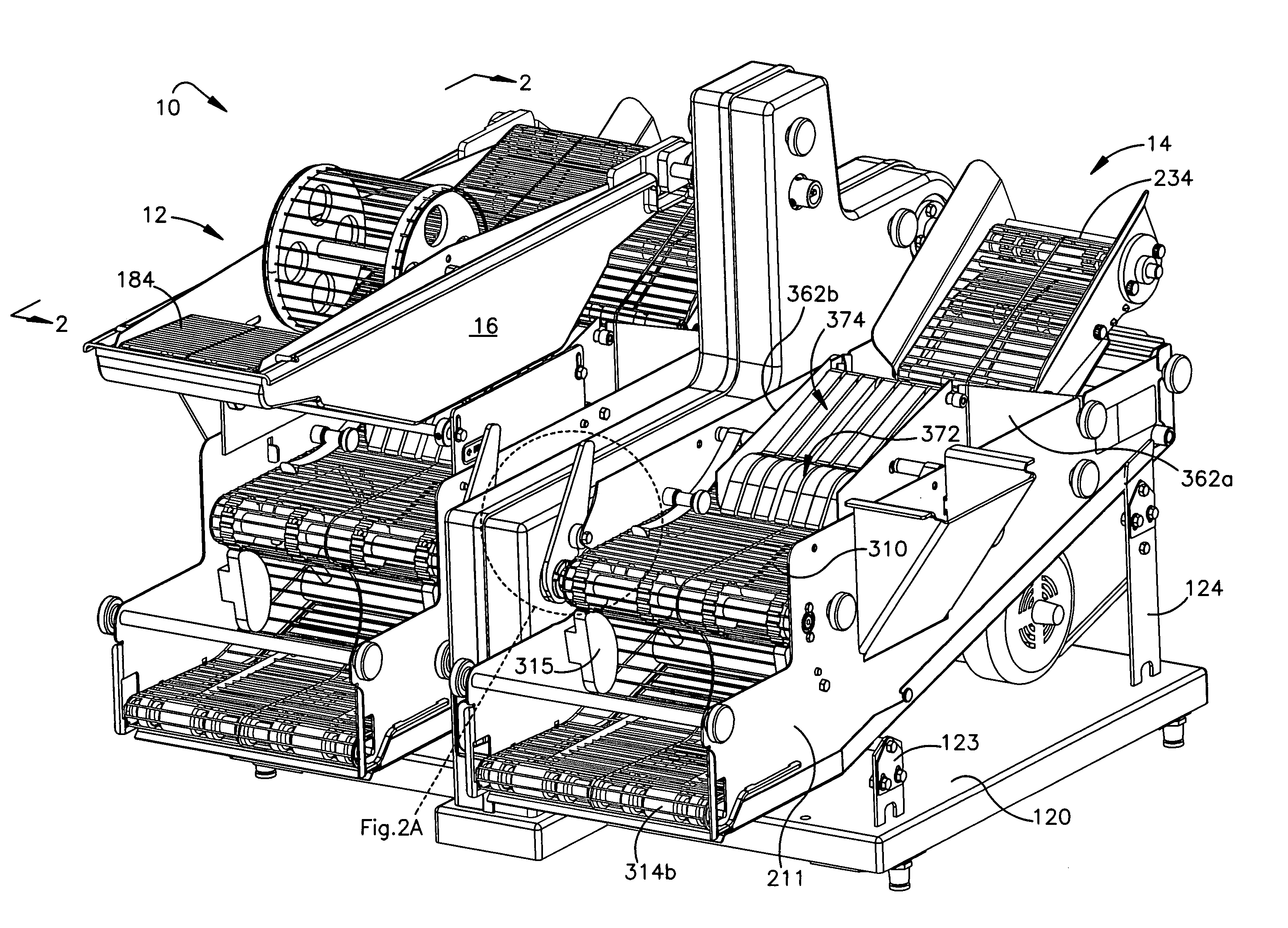

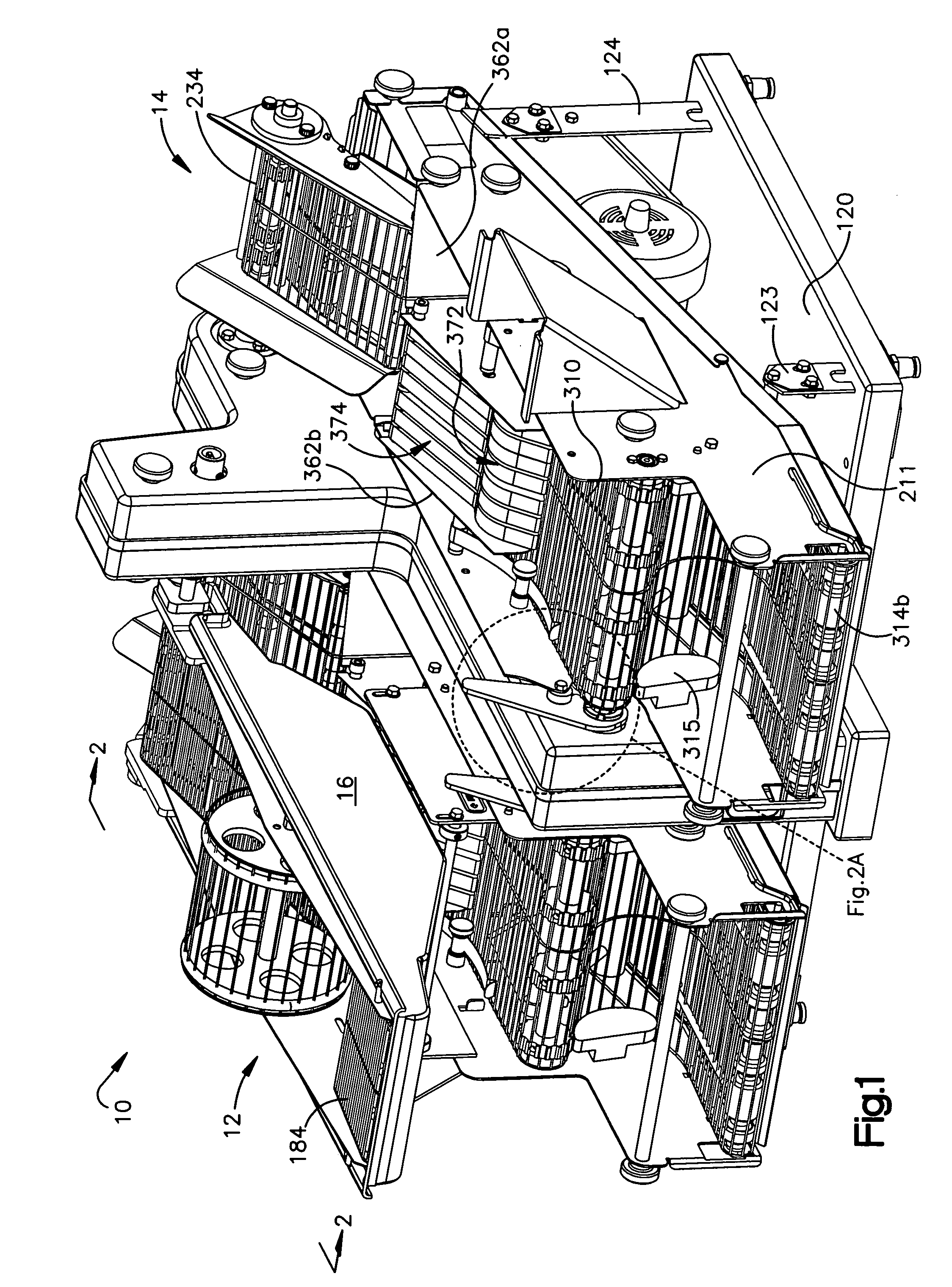

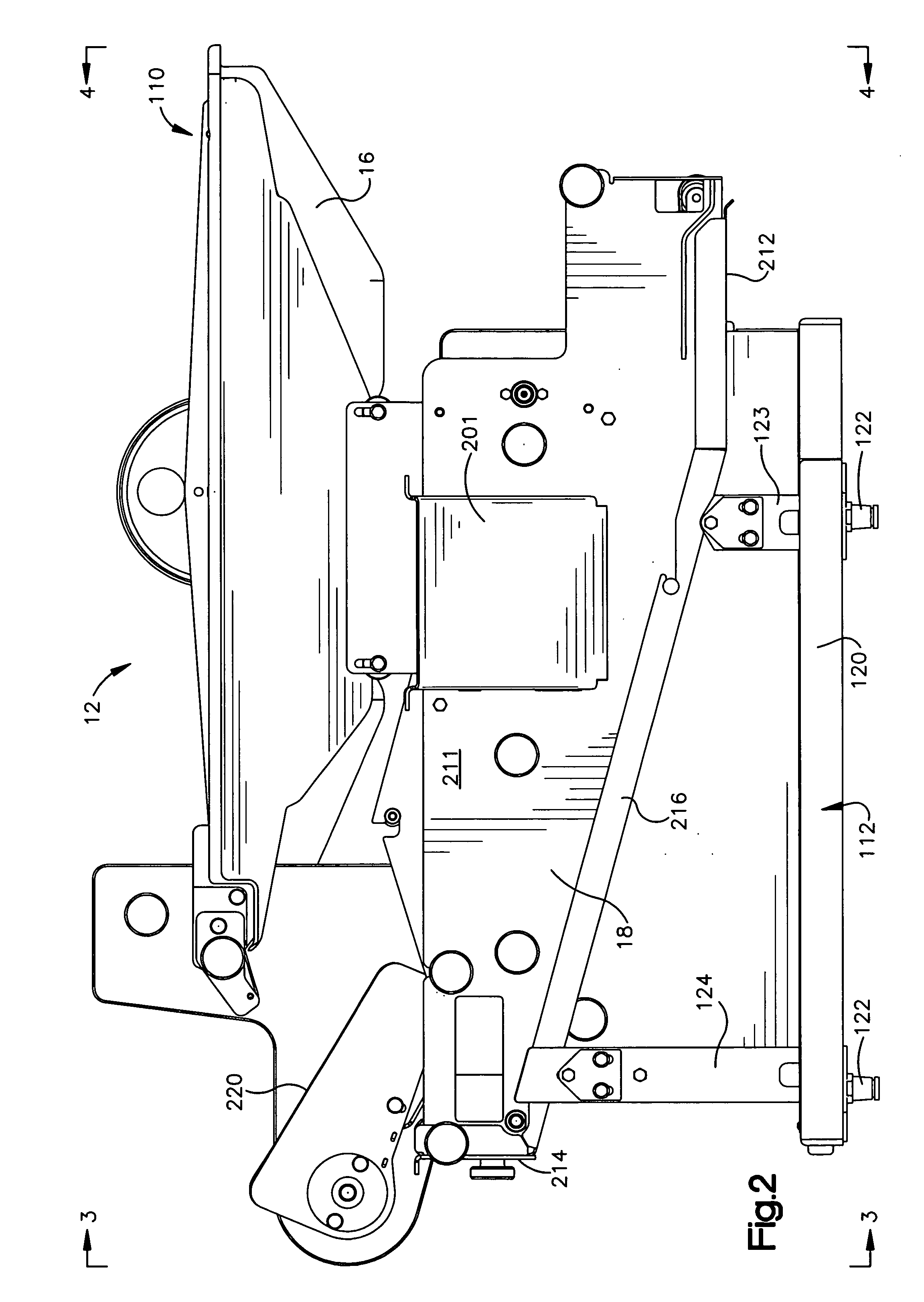

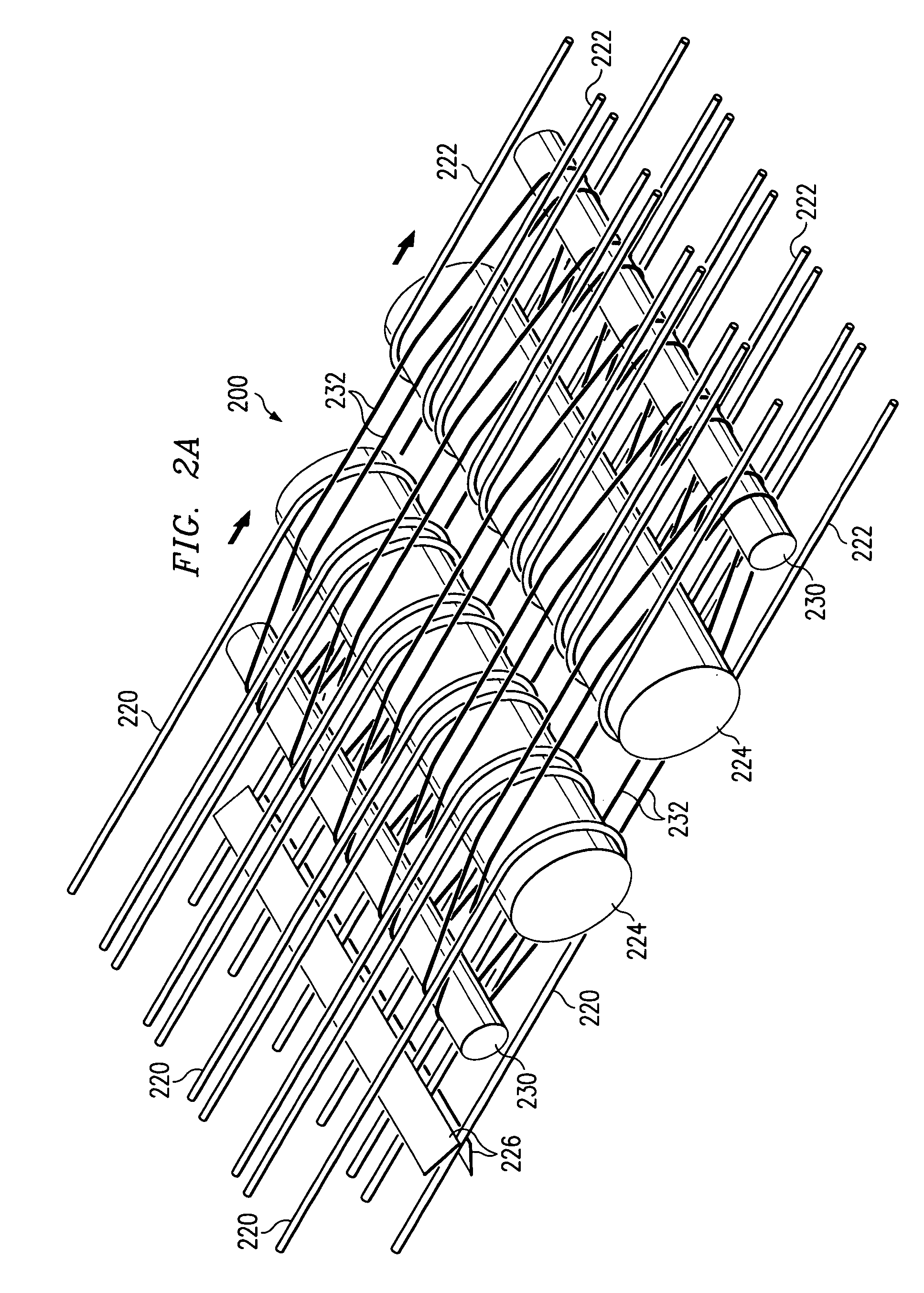

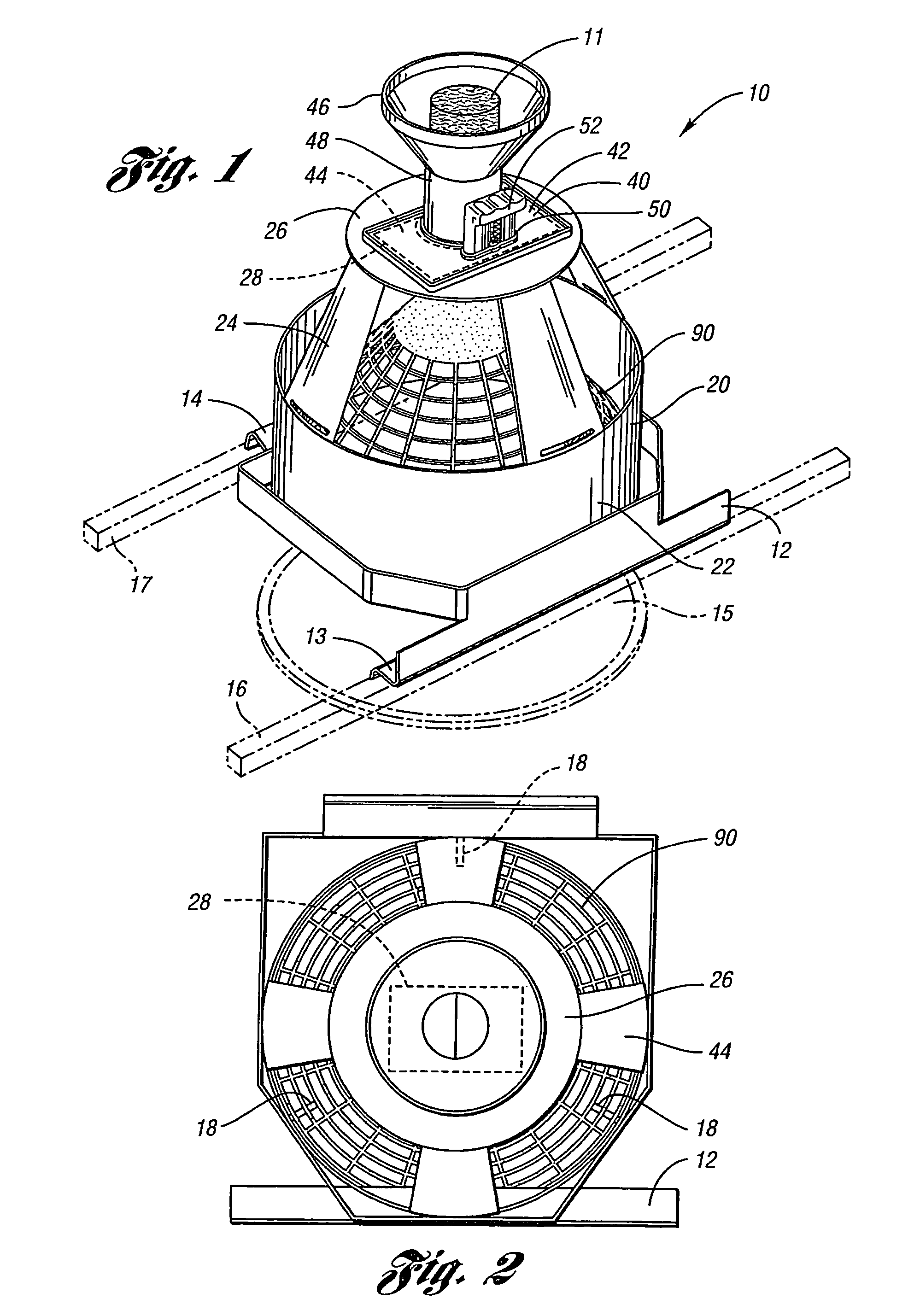

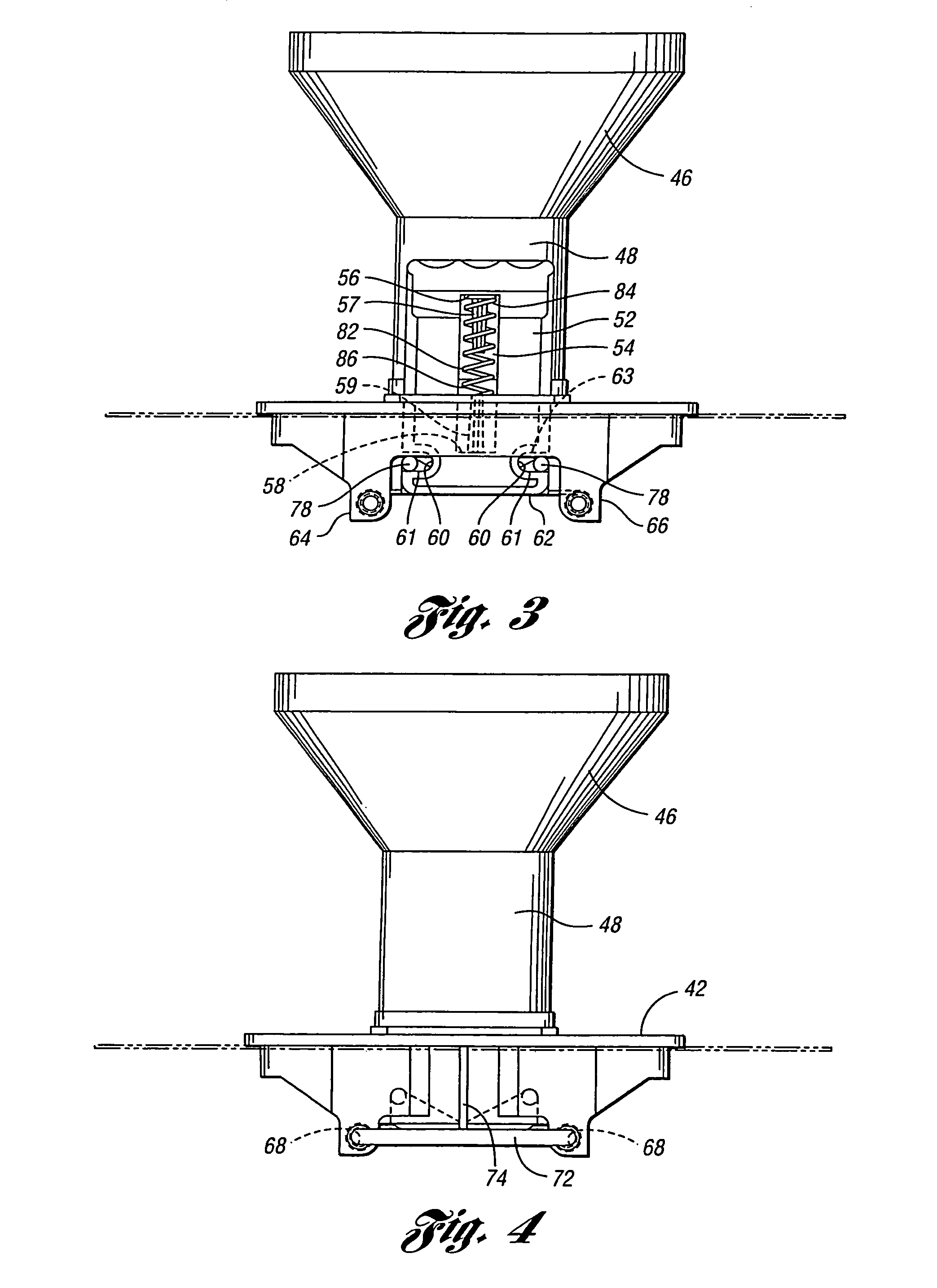

Breading machine and methods of operation

A breading machine, and improvements thereto, for use in high volume food production is disclosed. In accordance with an embodiment of the present invention, an improved breading machine includes a side-mounted feed hopper, a low pressure auger assembly including an auger transfer box with an input port for accepting a cross-feed screw and paddle, and an output port for transferring coating material to a vertical screw. The improved breading machine also includes a substantially cylindrical, rod-based spreader assembly and a transport conveyor belt for feeding the spreader assembly within a top hopper of the breading machine. The improved breading machine further includes a vibrating filter assembly to filter out clumps of coating material while allowing un-clumped material to be re-used within the breading machine.

Owner:MP EQUIP

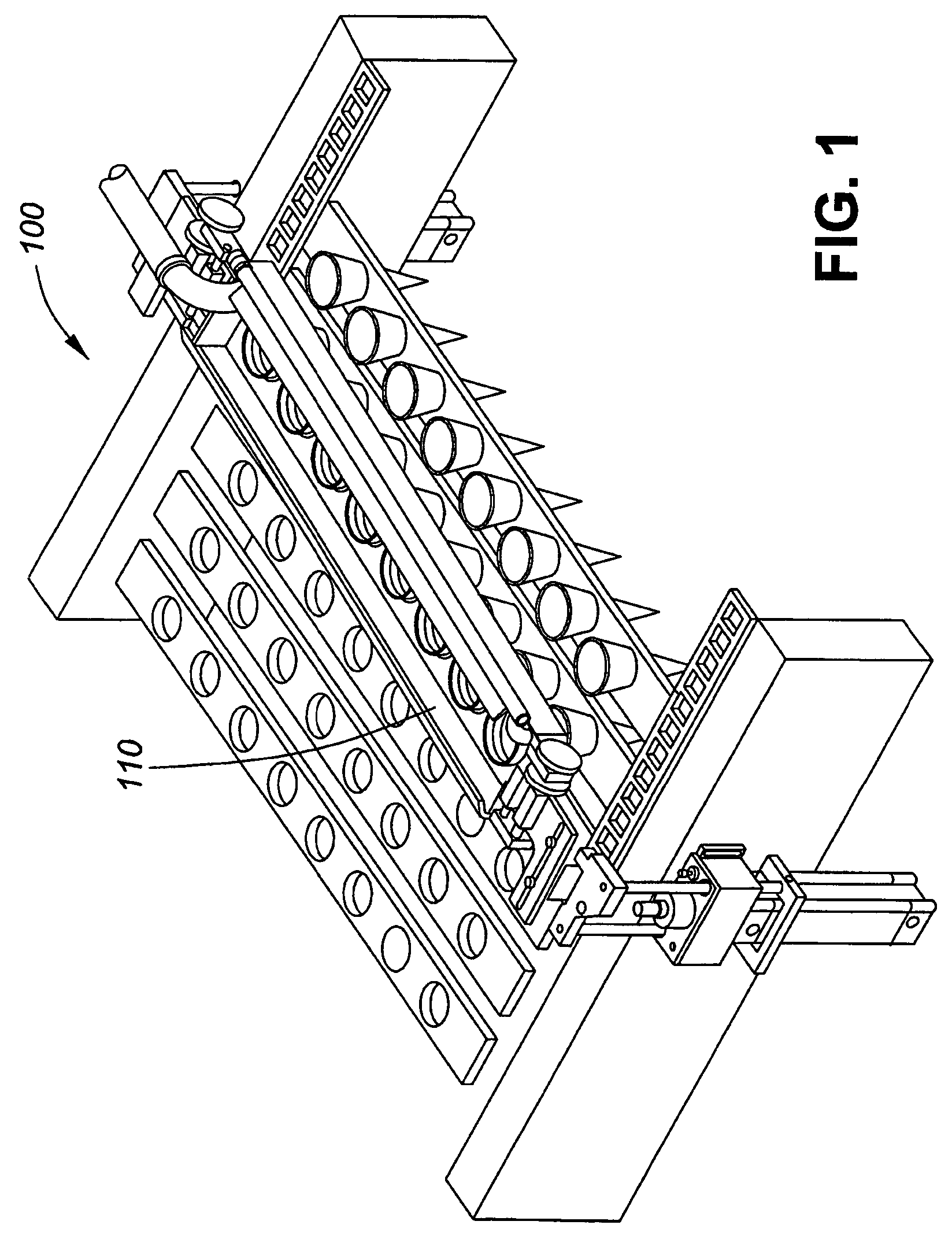

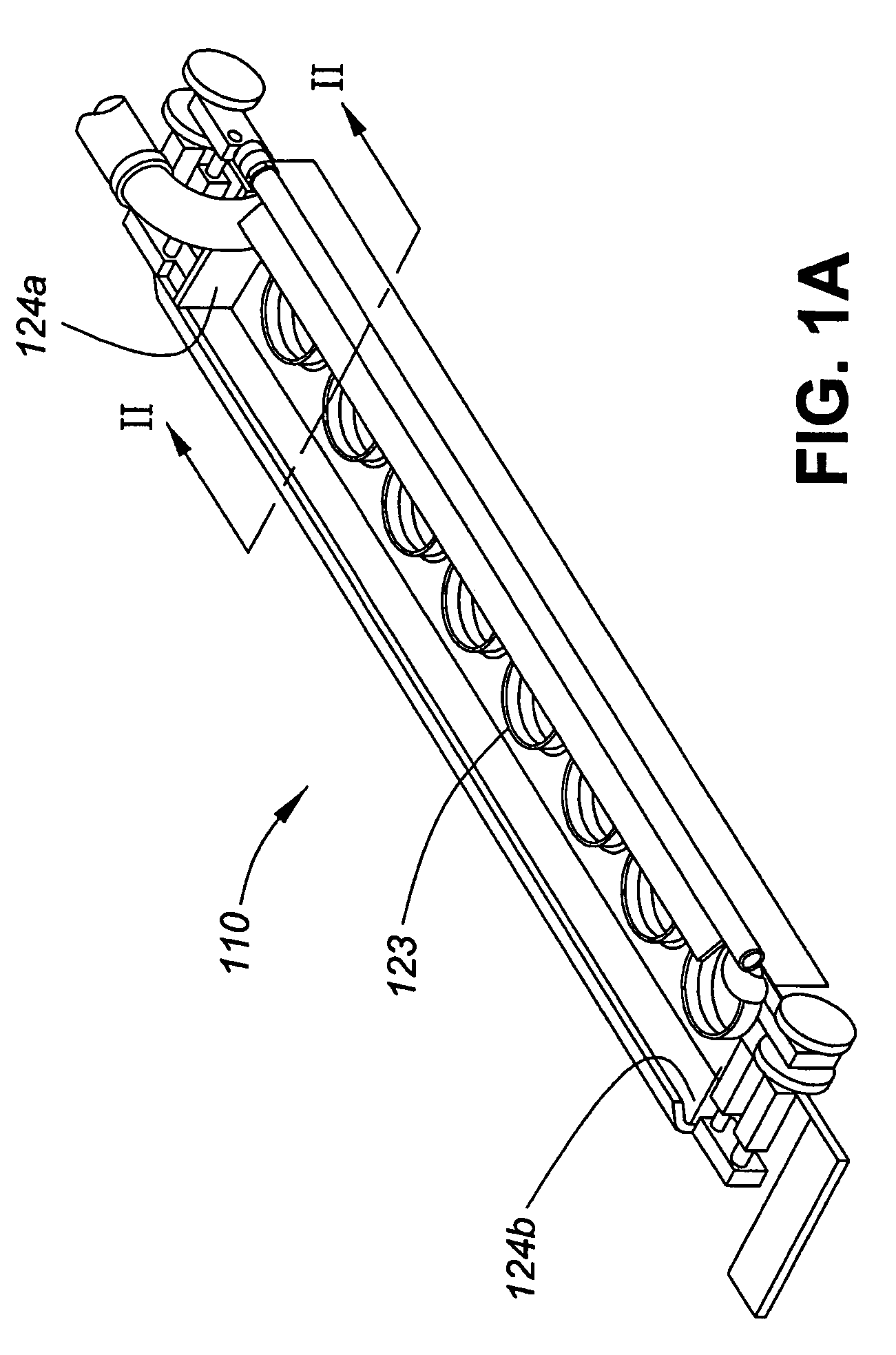

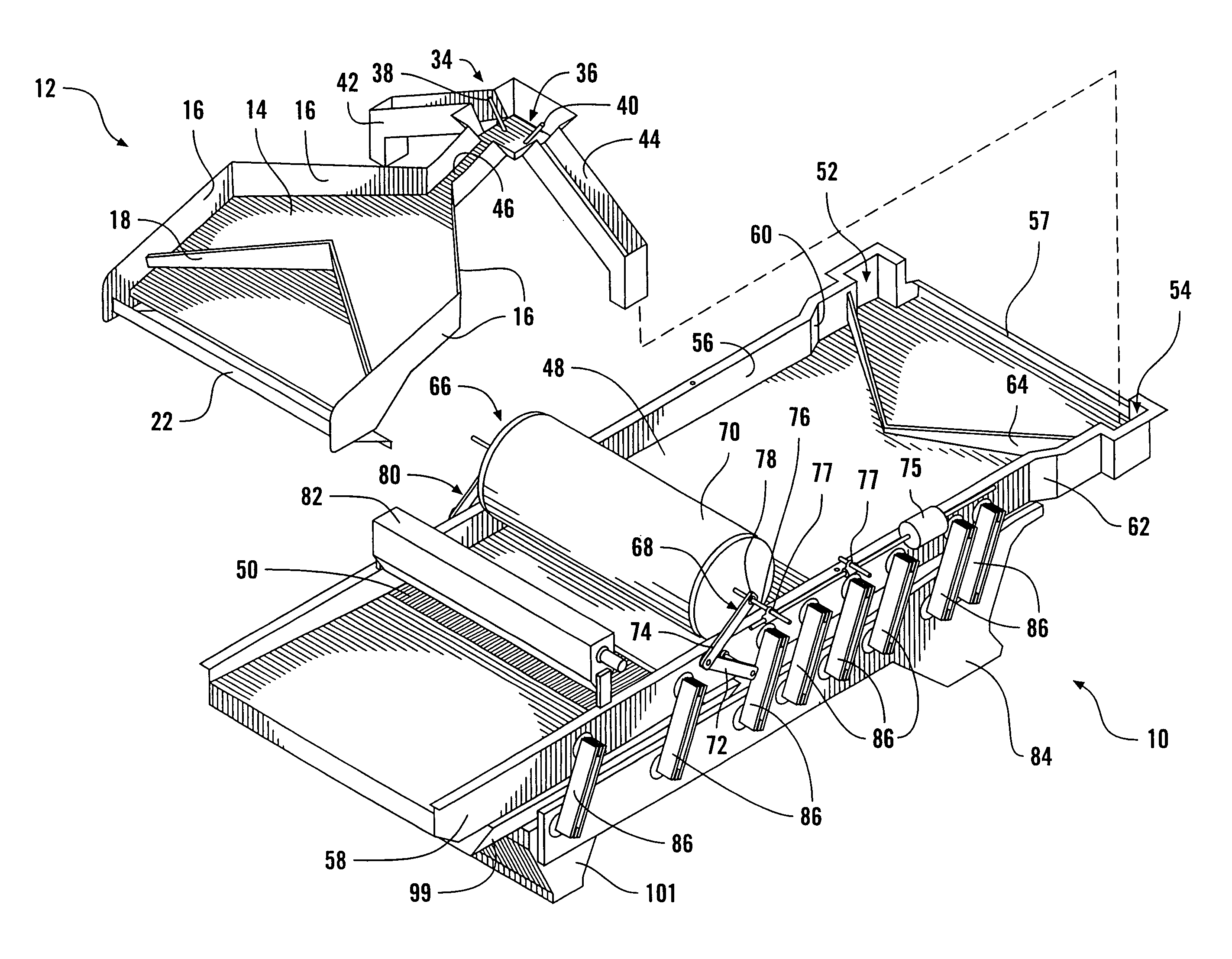

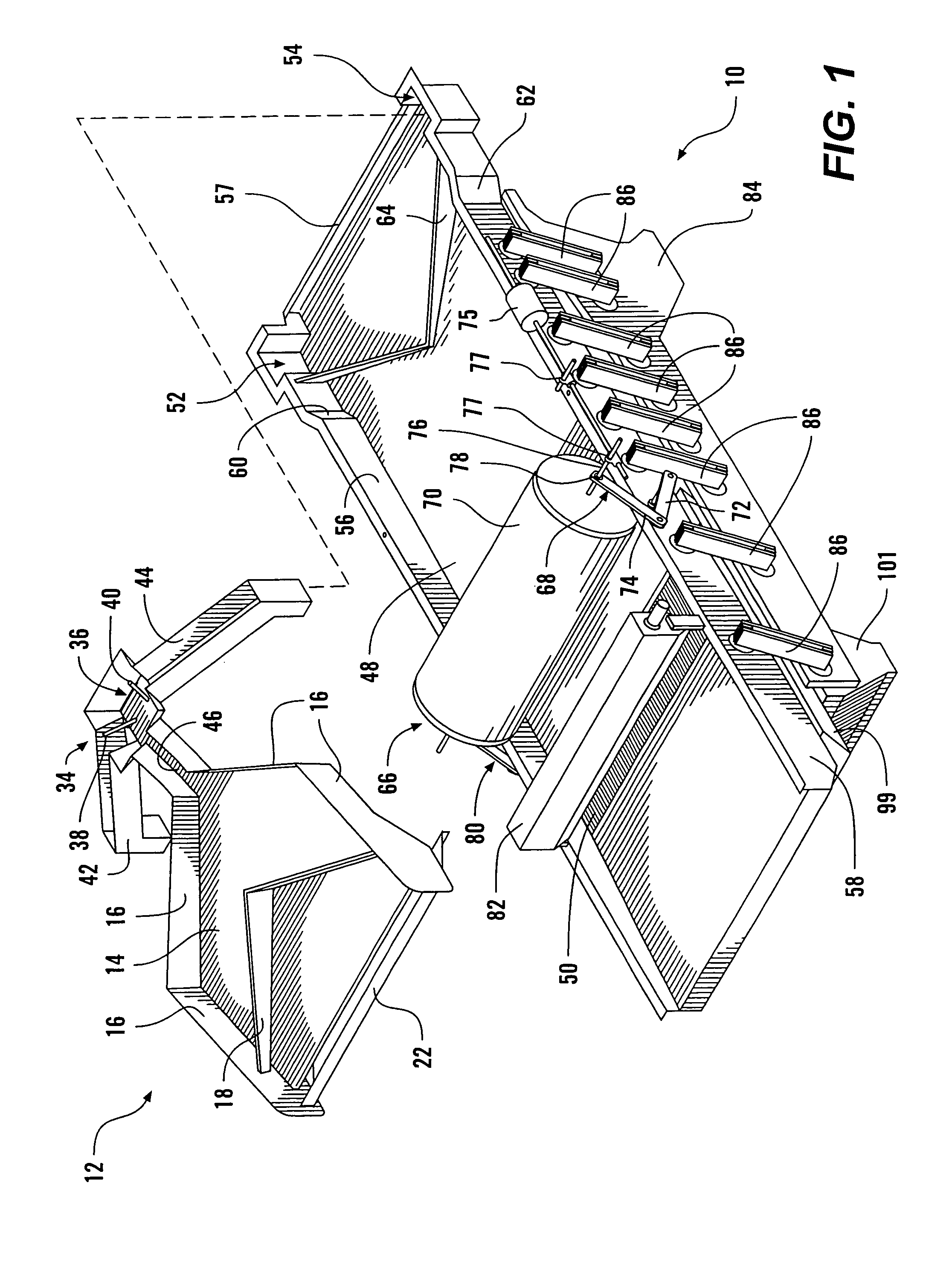

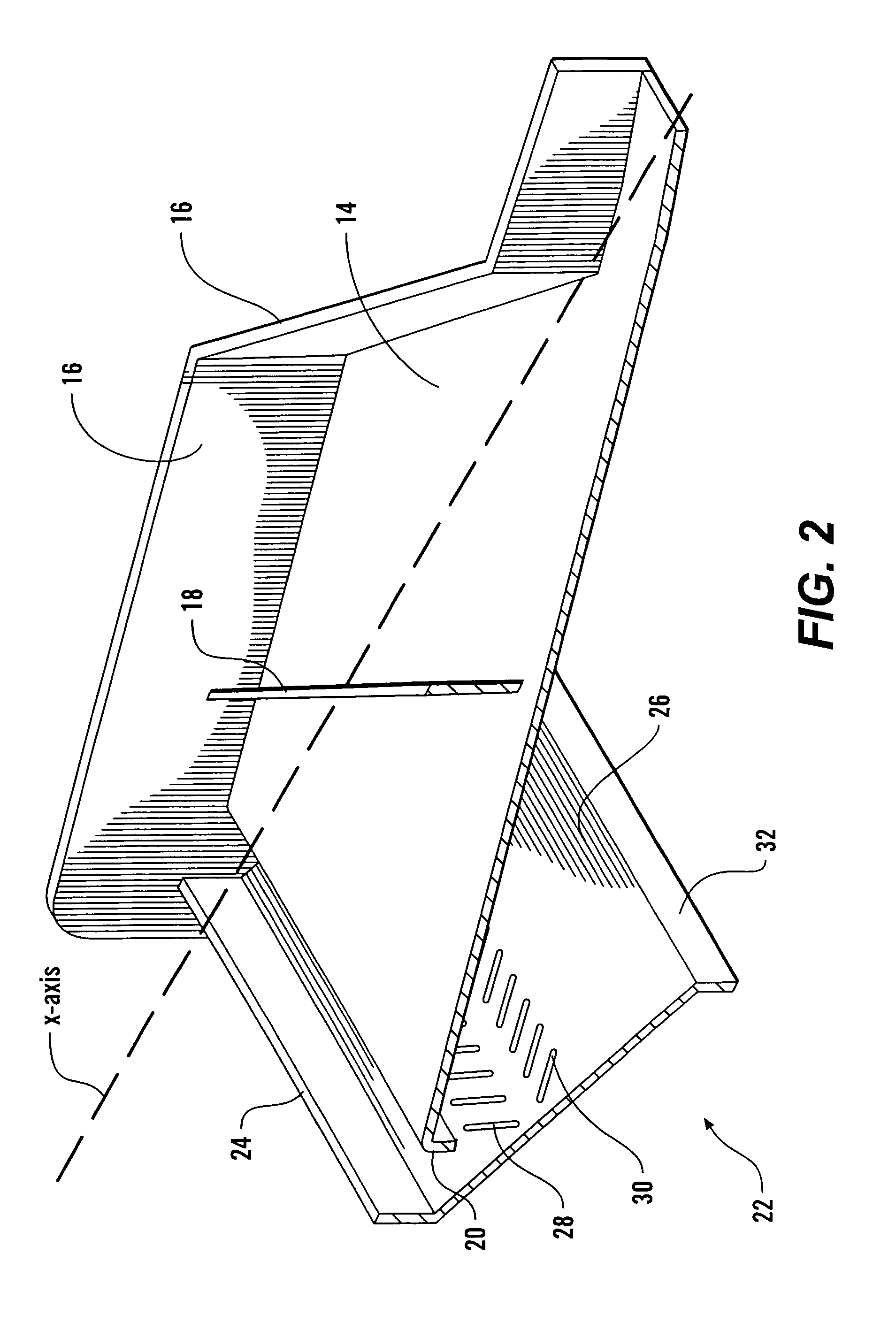

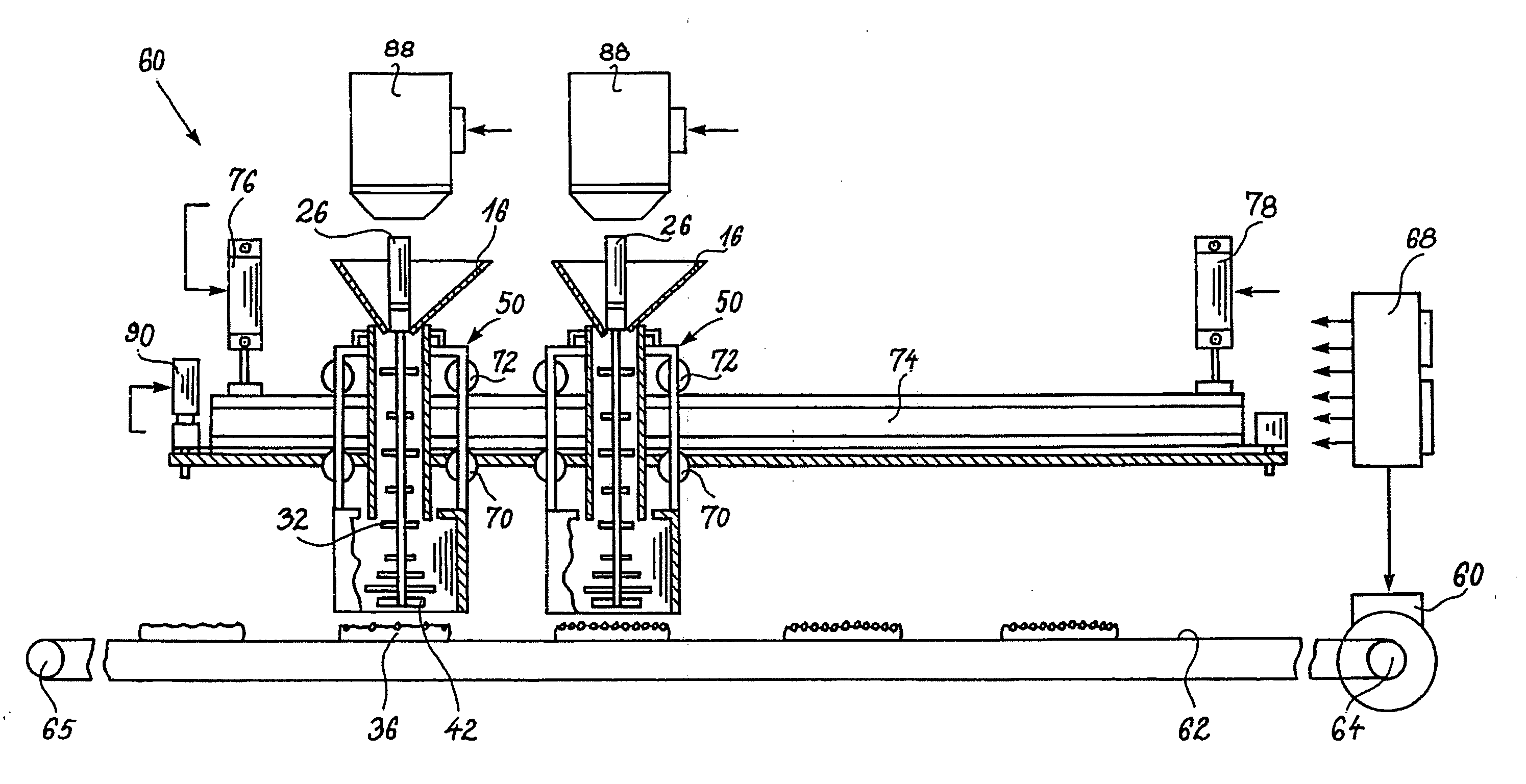

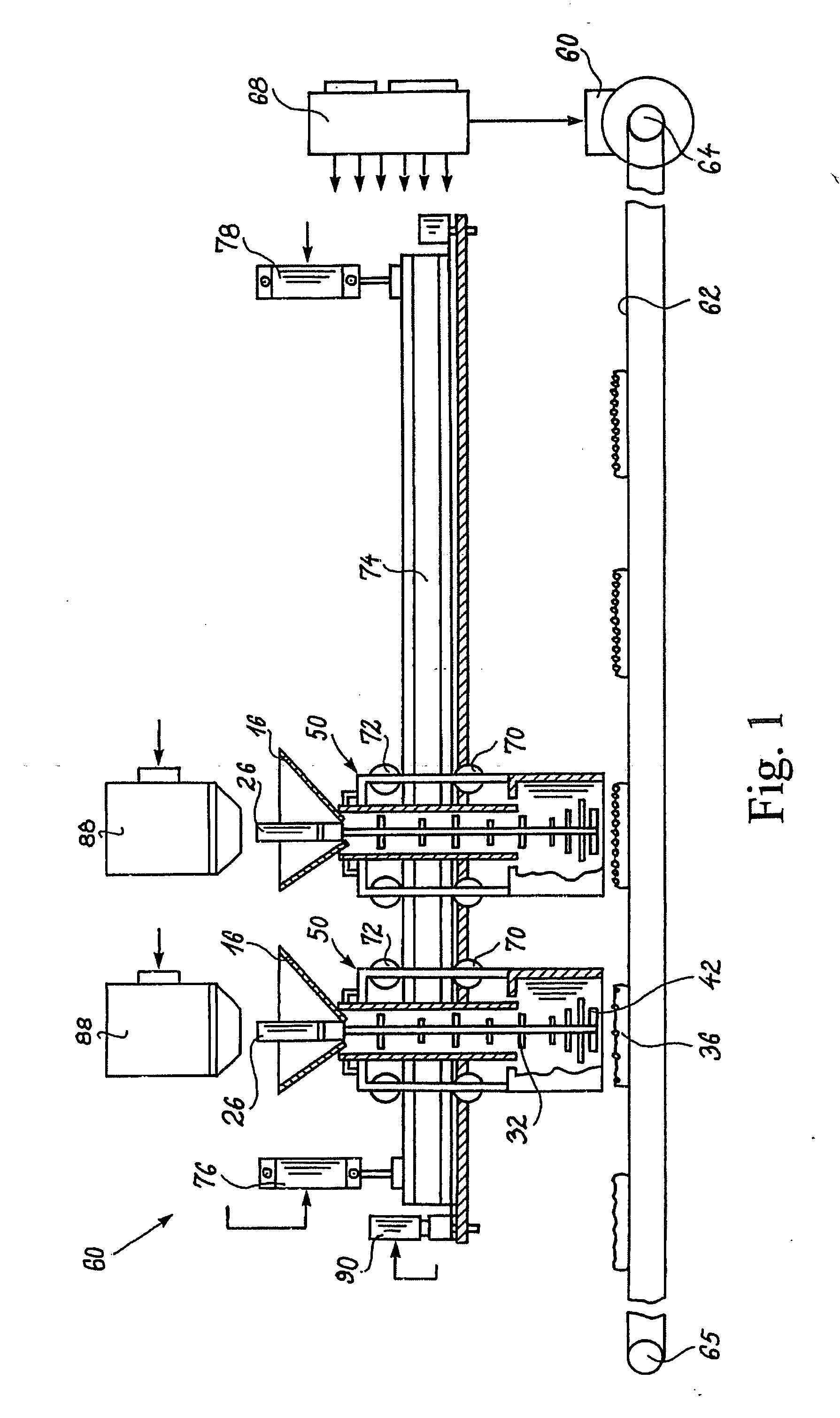

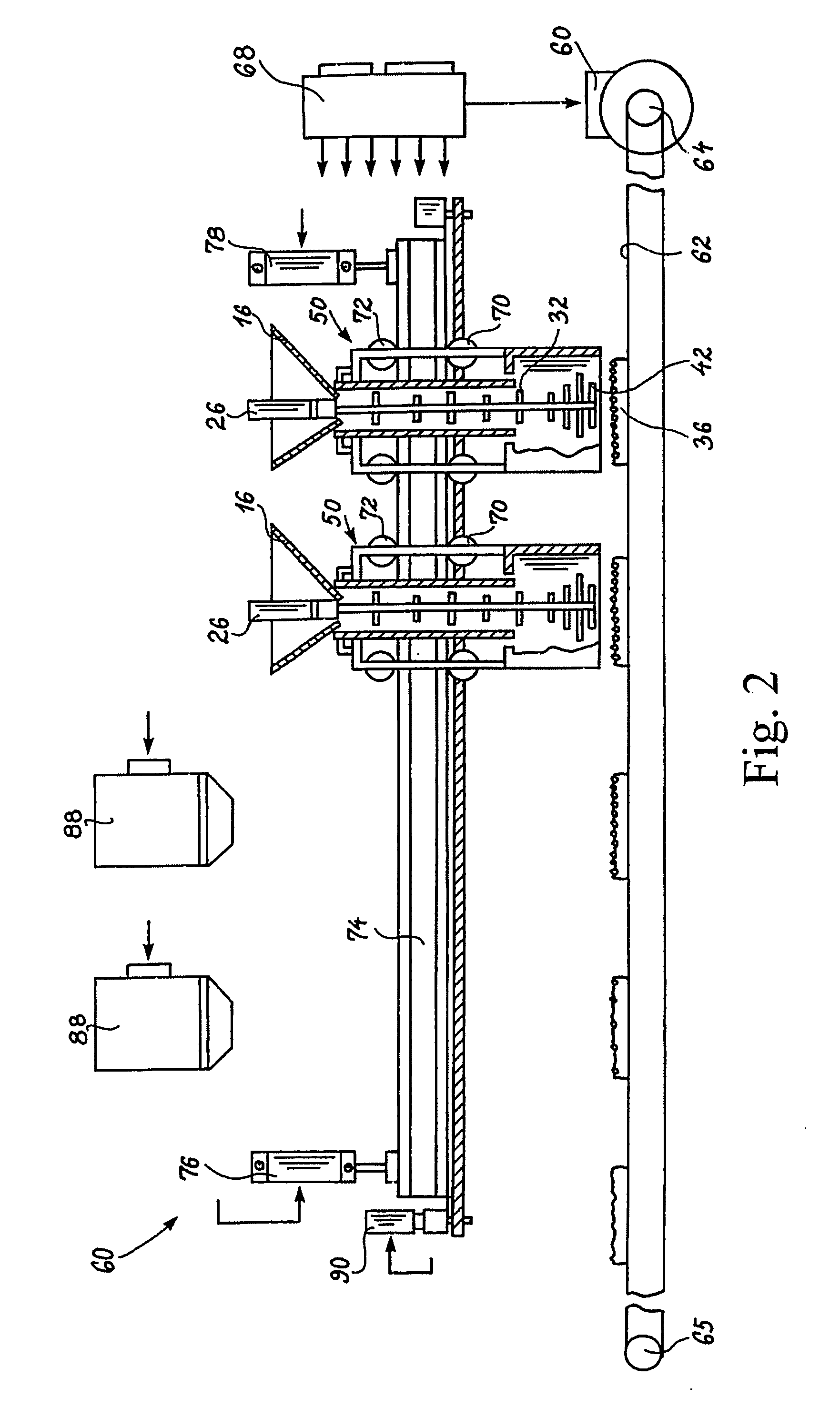

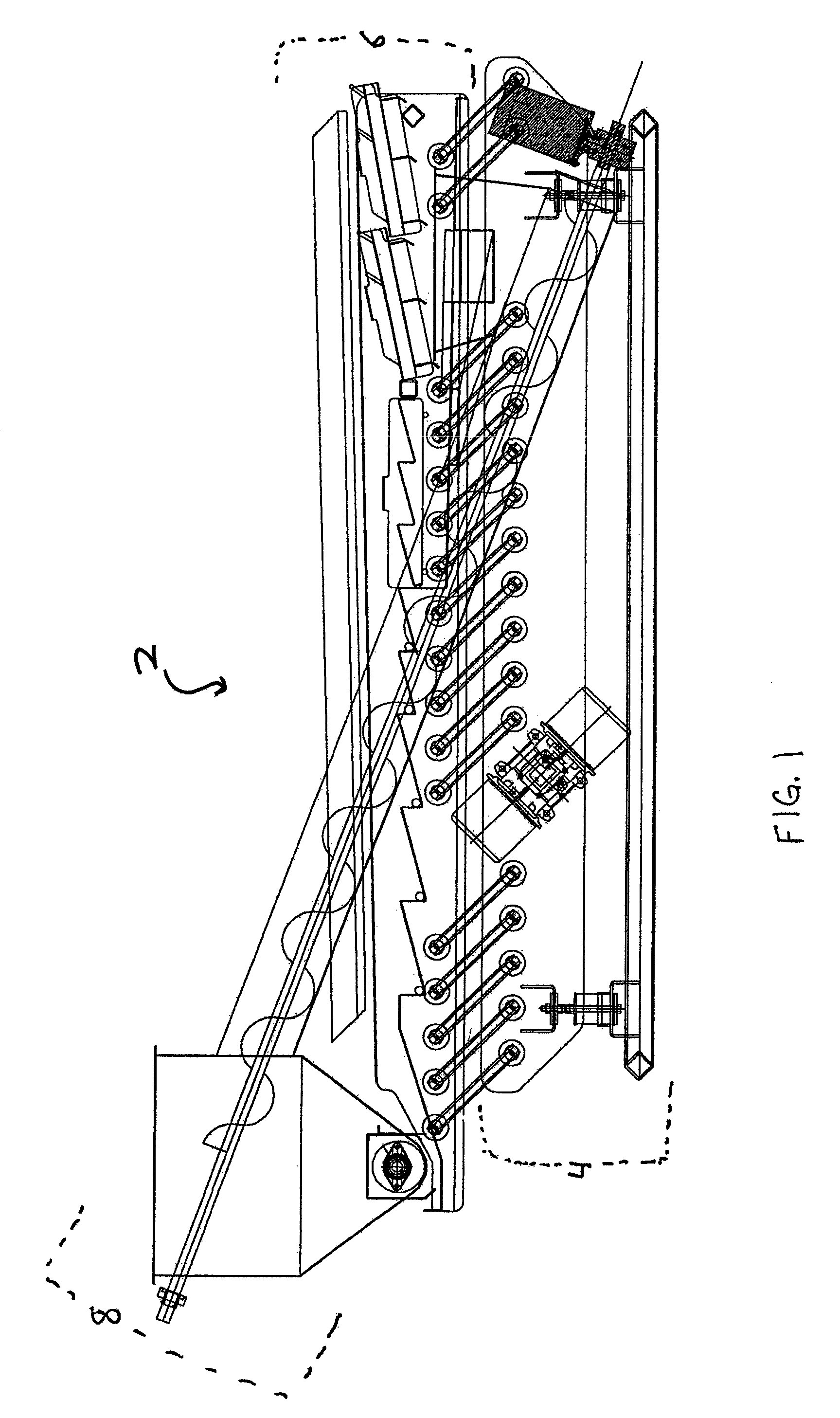

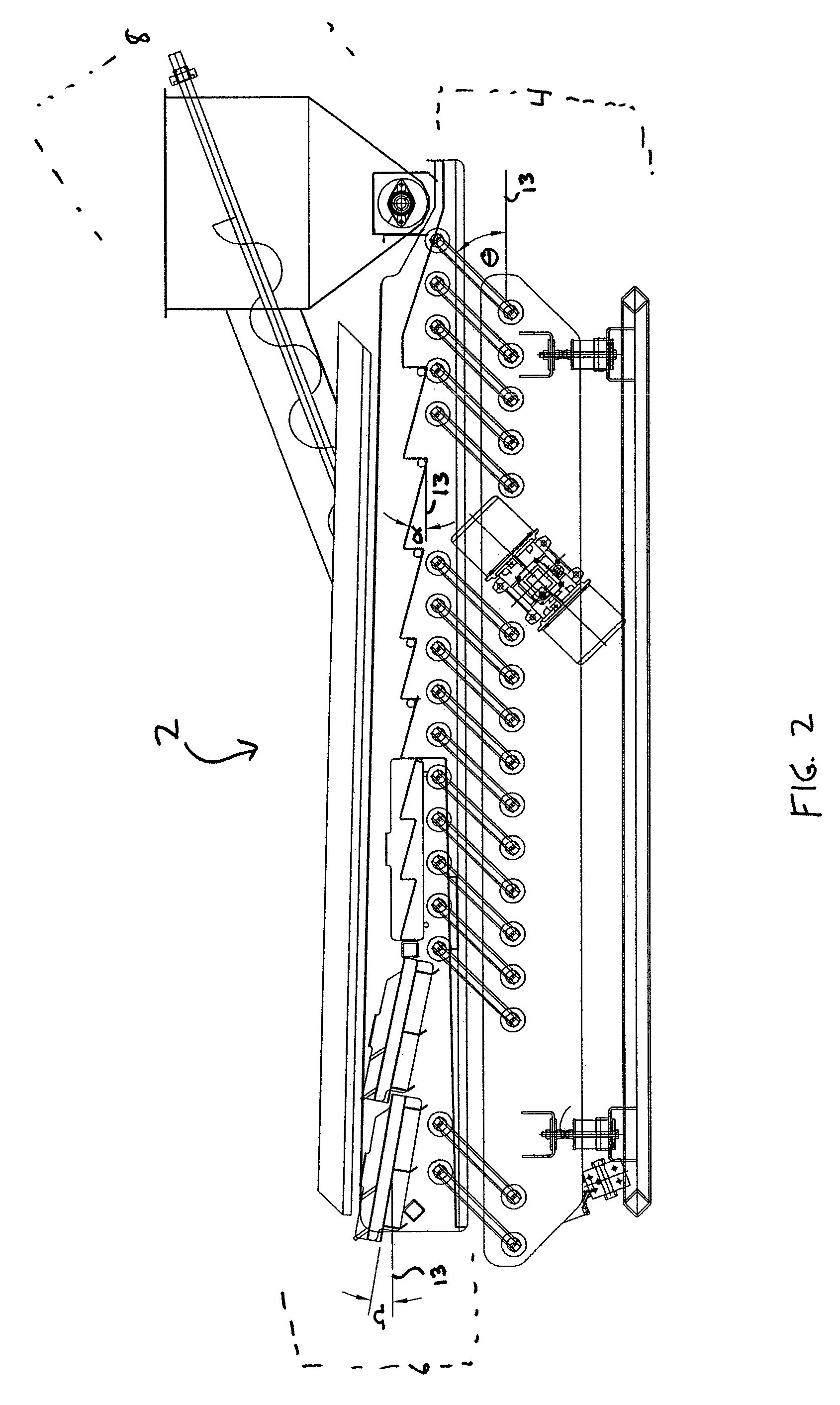

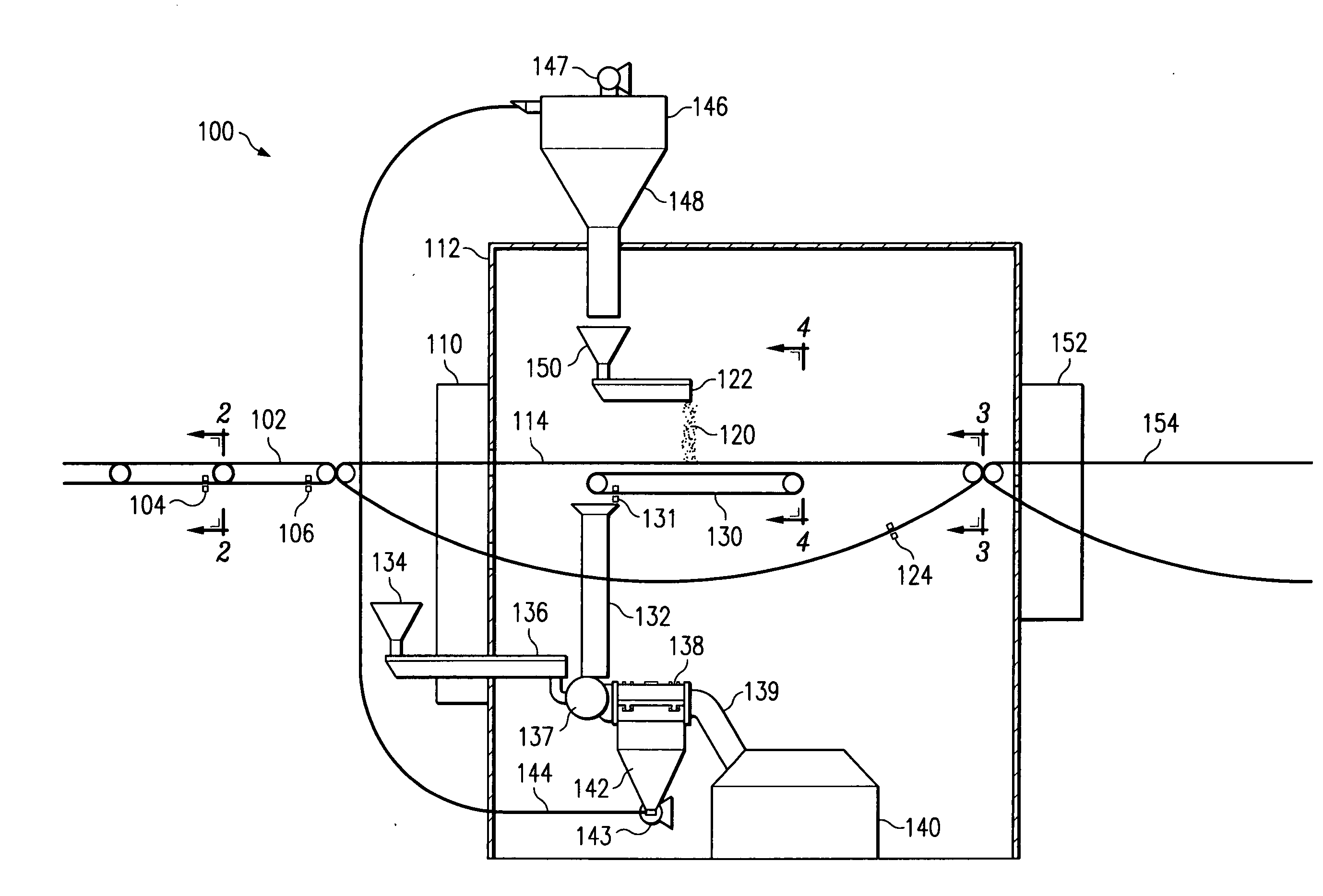

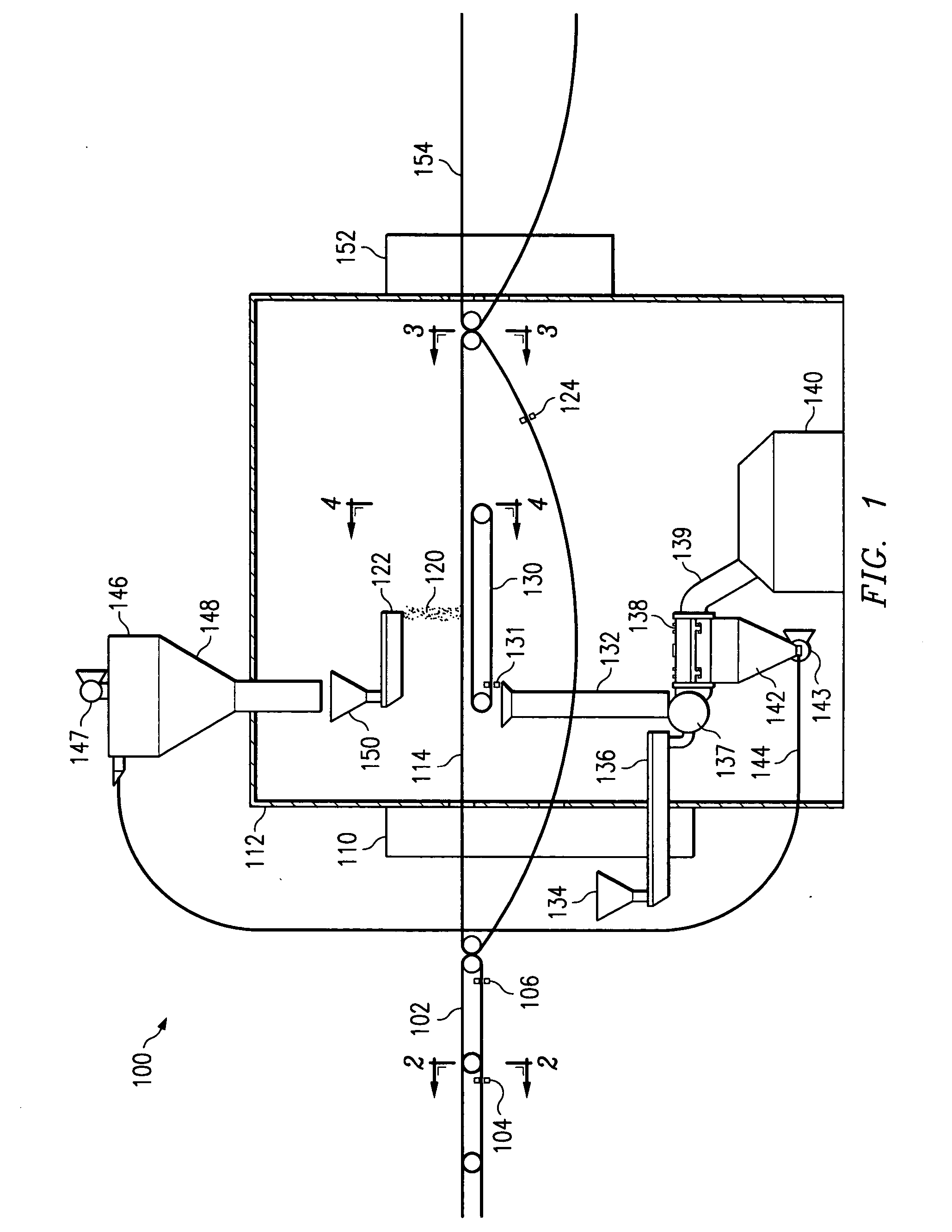

Crumb breading distribution system

A distribution apparatus for a breading machine comprising a hopper having a number of hopper sections includes a downspout for conveying the breading material to the hopper and a spreader plate which is adjustably supported between the downspout and the hopper. By adjusting the position of the spreader plate relative to the hopper, the flow of breading material from the downspout may be distributed as desired between the hopper sections.

Owner:JOHN BEAN TECH CORP

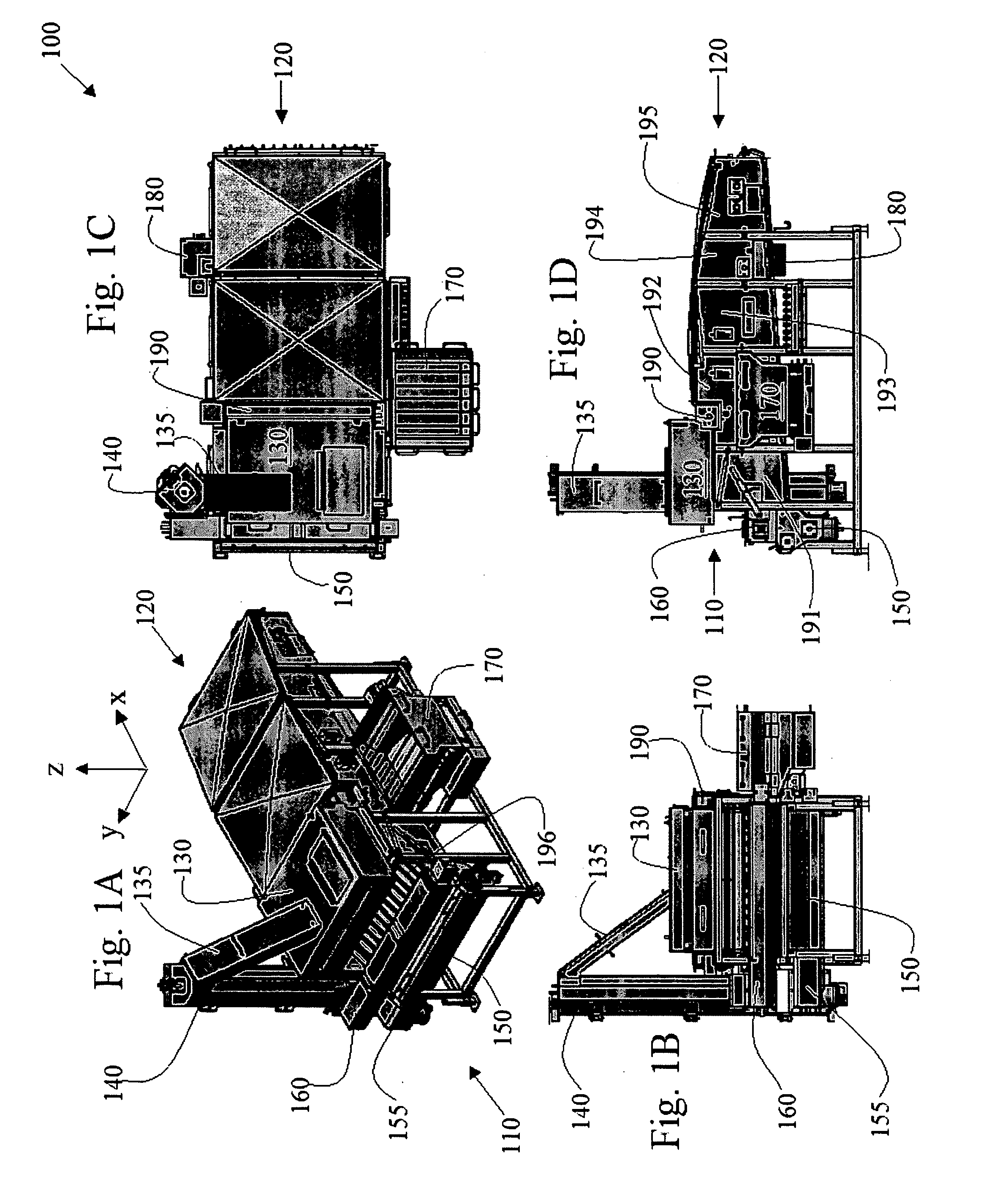

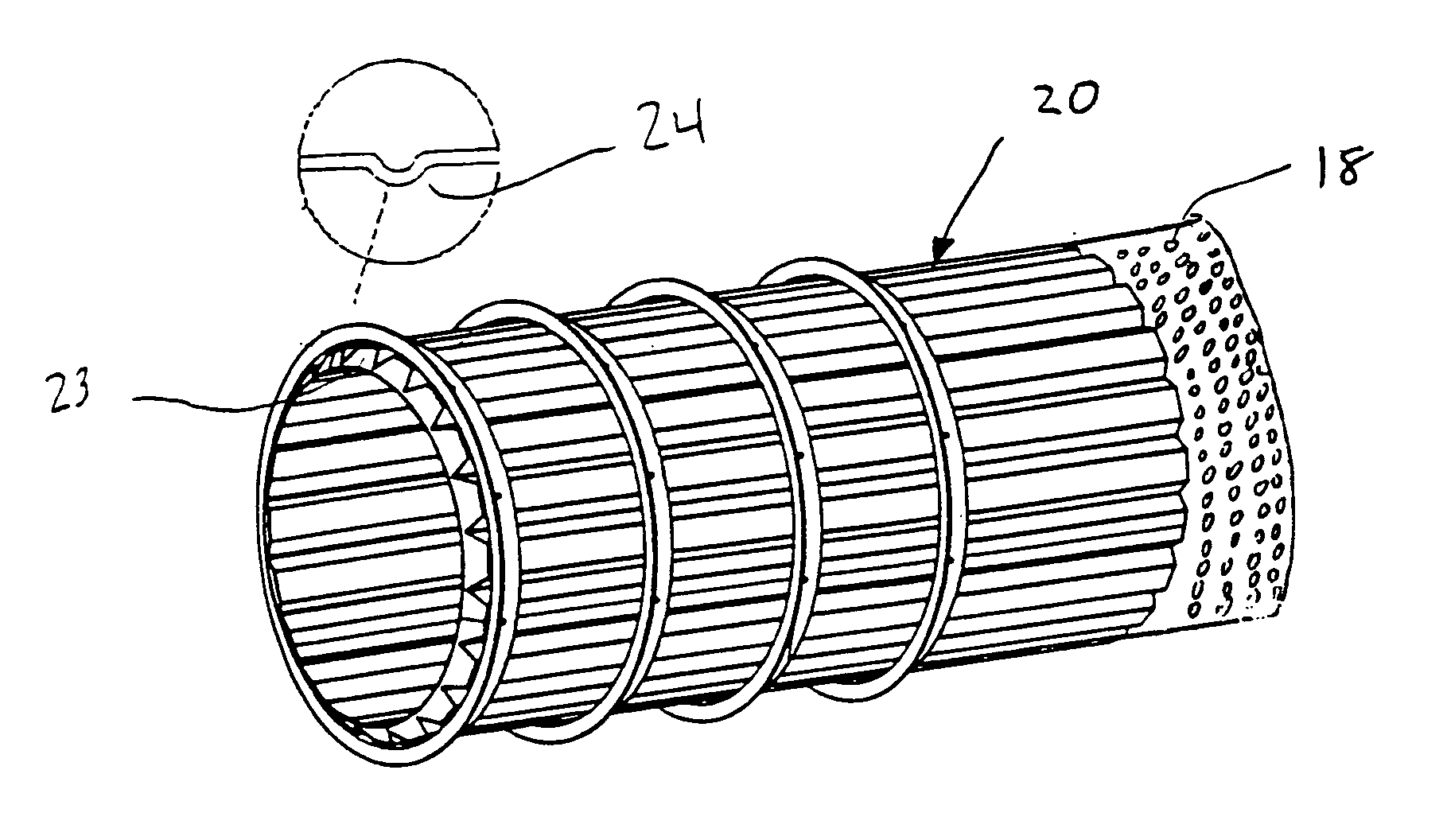

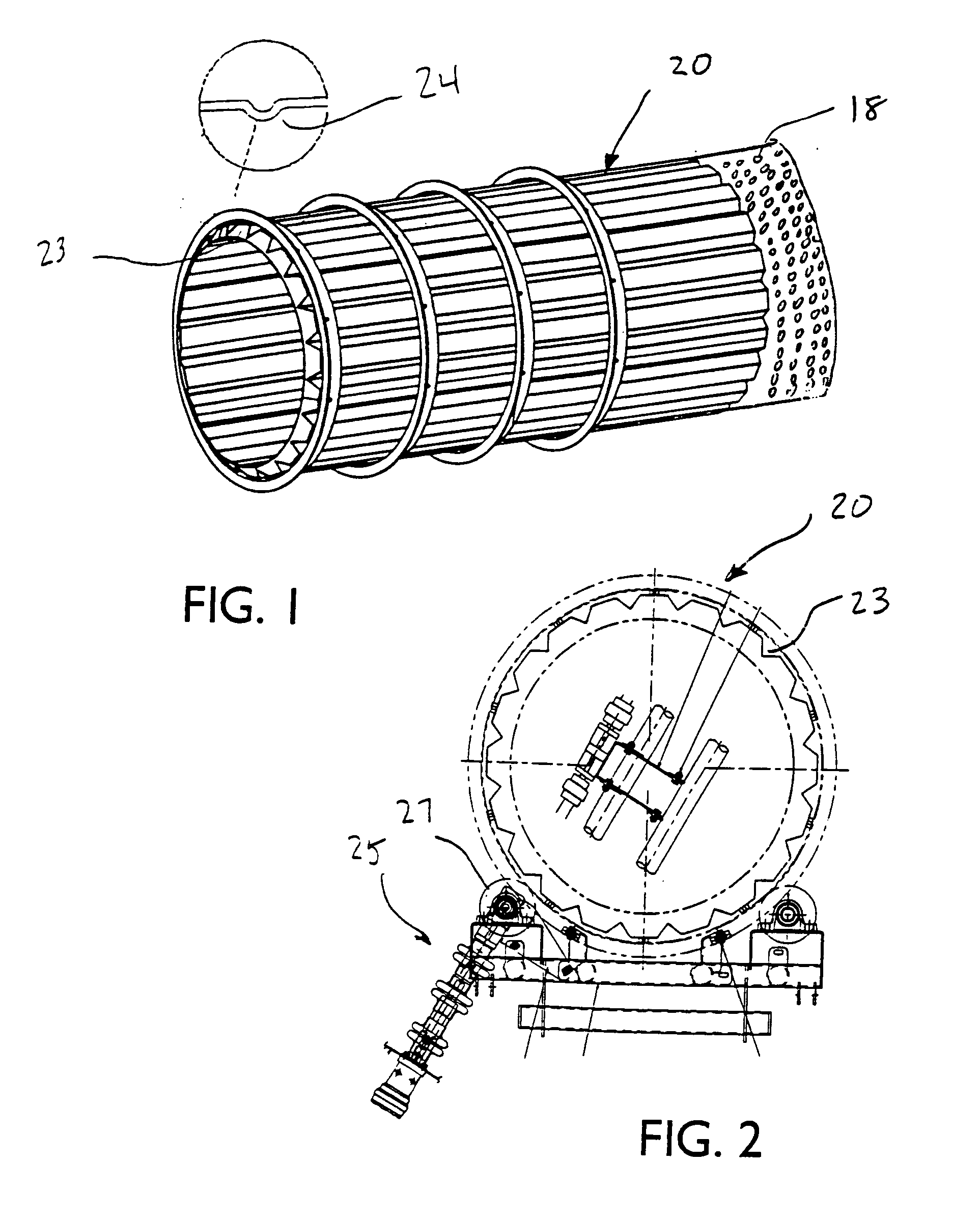

Drum breader and coating redistribution system

A drum breader and coating recirculation system that includes a spreader positioned at an end of the drum, the spreader having a plurality of angled surfaces to distribute coatings evenly; a screening platform positioned downstream of the spreader having a drive device for imparting straight-line angular displacement to the screening platform; and a drum feed conveyor positioned downstream of the screening platform, the drum feed conveyor having a belt extending at least partially along an upward angle.

Owner:JOHN BEAN TECH CORP

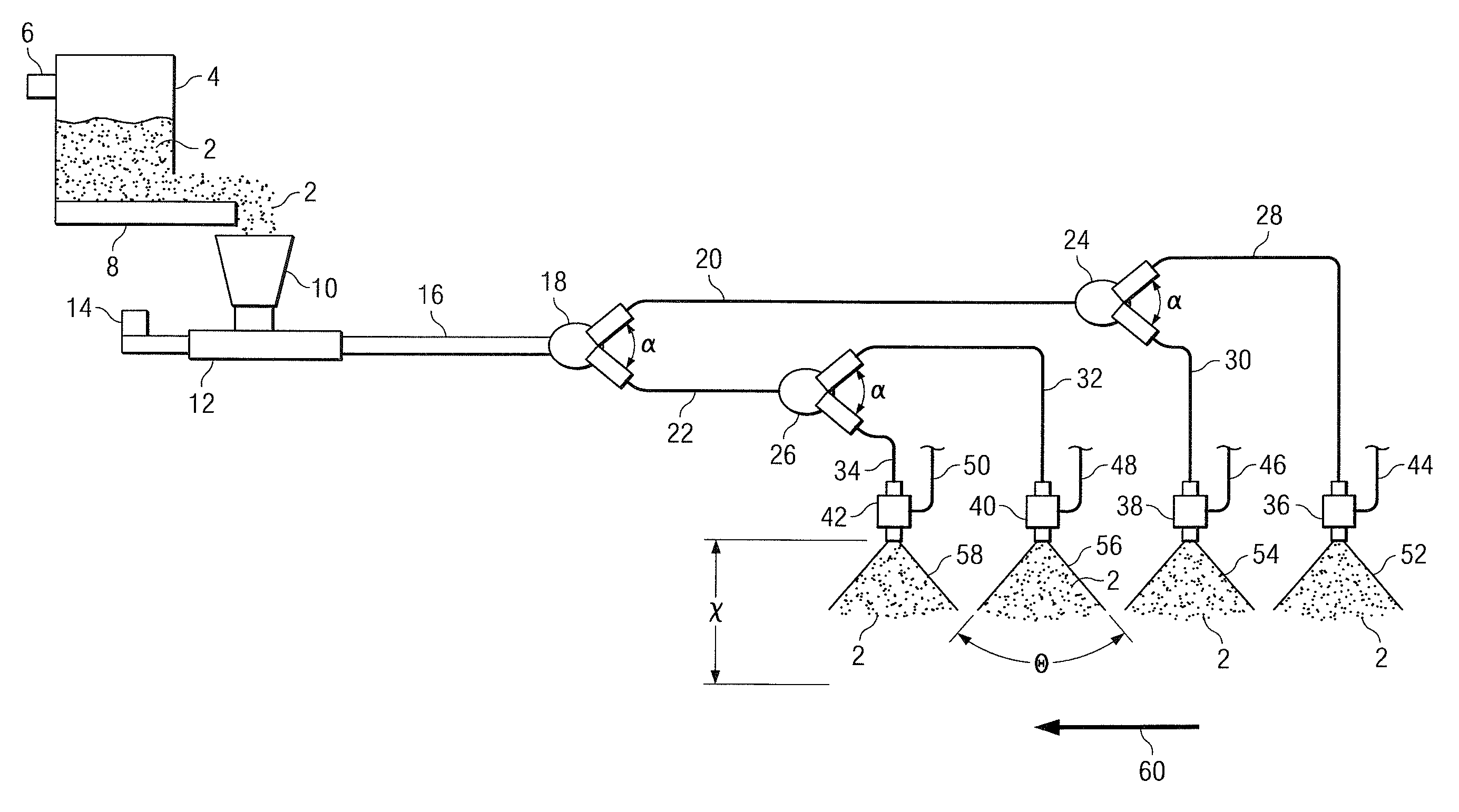

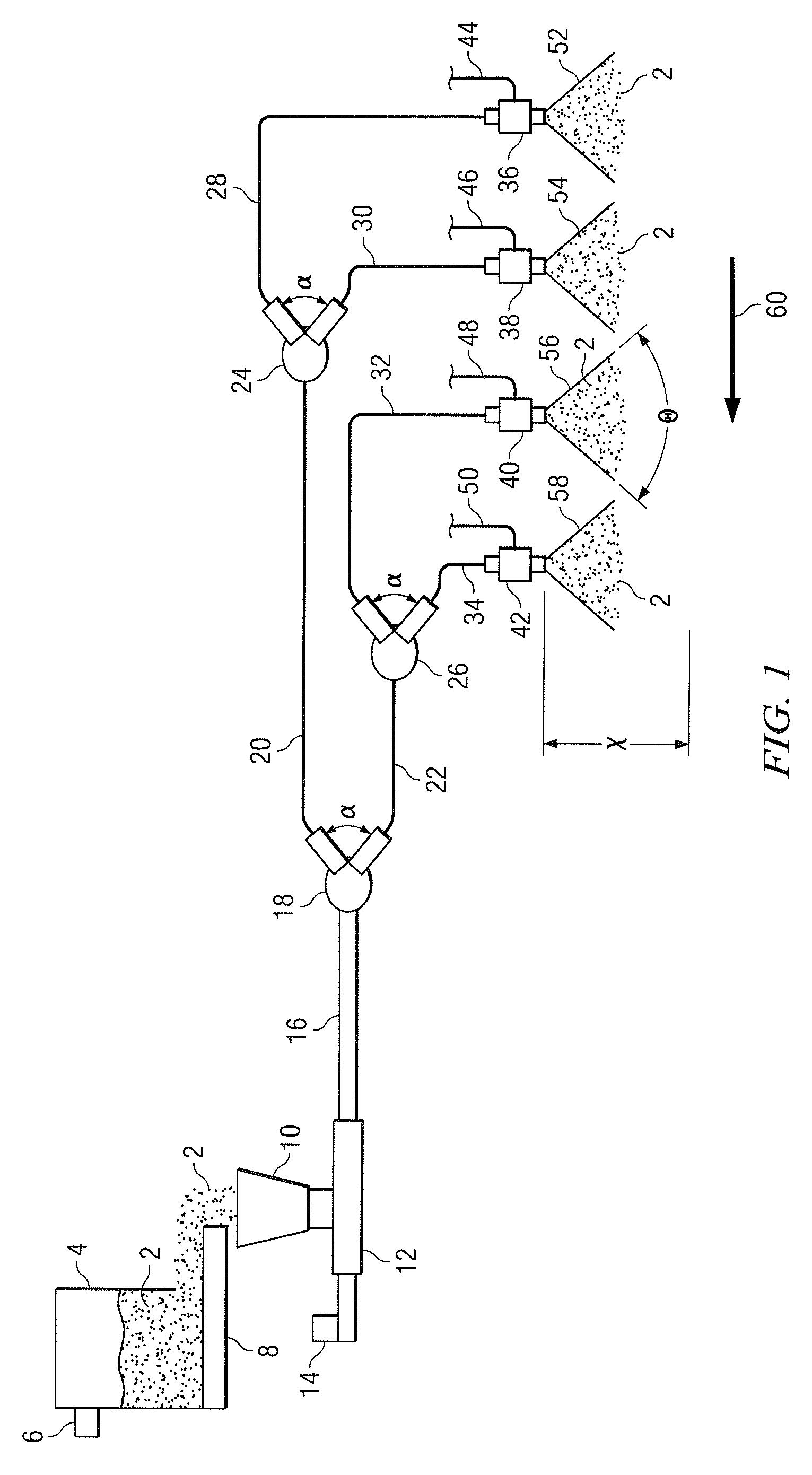

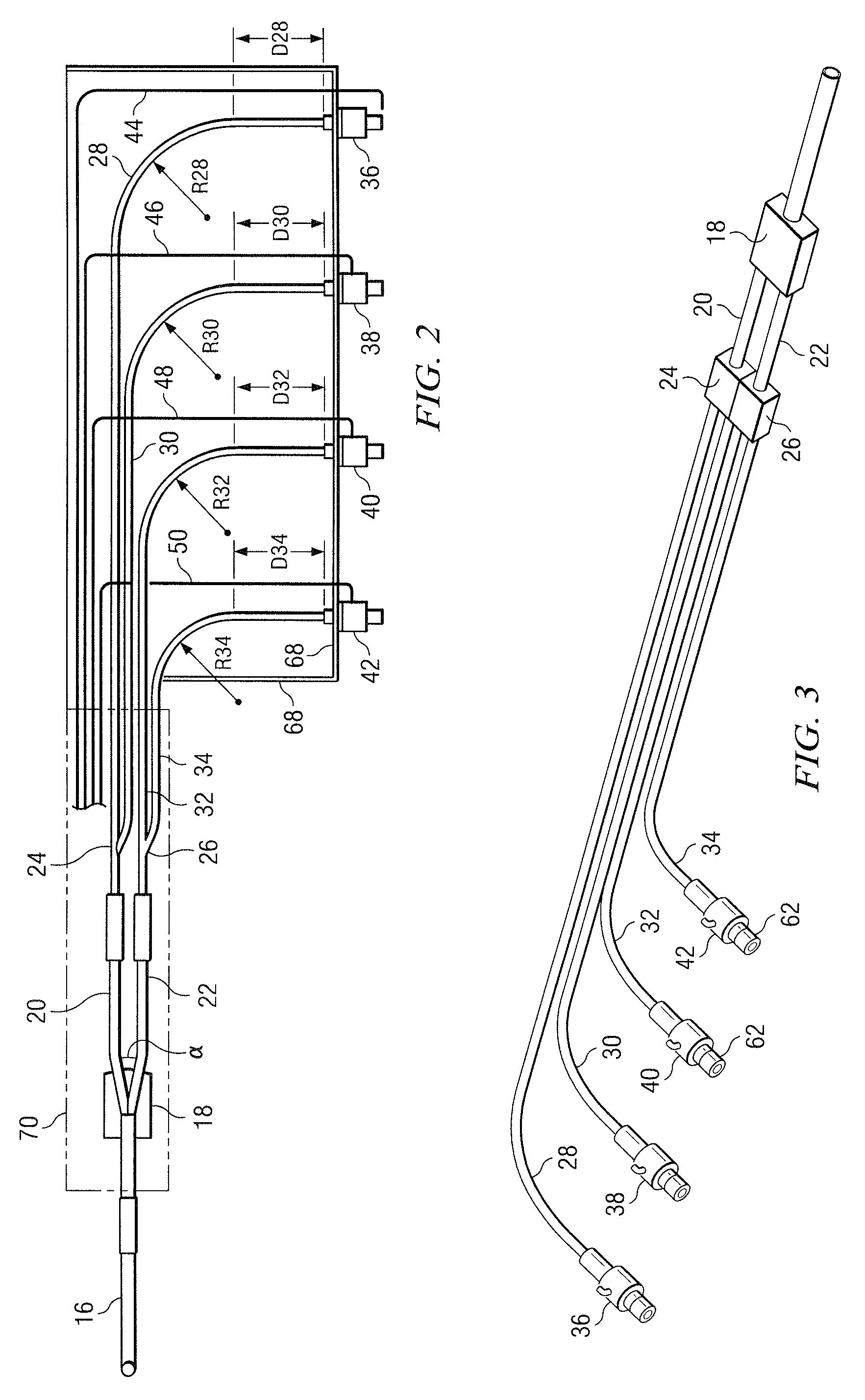

Pneumatic seasoning system

InactiveUS7827929B2Uniform particle distributionPromotes superior adhesion and implantationLiquid surface applicatorsConfectioneryEngineeringRotating drum

A pneumatic seasoning system and method utilizing a rotating drum for seasoning, a funnel-fed pneumatic eductor, line splitters, and a plurality of specially-designed swirl-inducing nozzle spools for inducing a broad and even seasoning plume. In a preferred embodiment, a pneumatic seasoning system transports seasoning from a seasoning hopper to food items within a rotating drum using a combination of an eductor and four in-line vacuum generators, which vacuum generators operate on compressed air. Each vacuum generator comprises a distributing nozzle roughly shaped like a collared spool, wherein compressed air is supplied to the annular region defined between the spool and its collar, and said compressed air exits through swirl ports distributed about the circumference of the spool exit. Each swirl port preferably has a pitch angle of 15° and a yaw angle of 15°.

Owner:FRITO LAY NORTH AMERICA INC

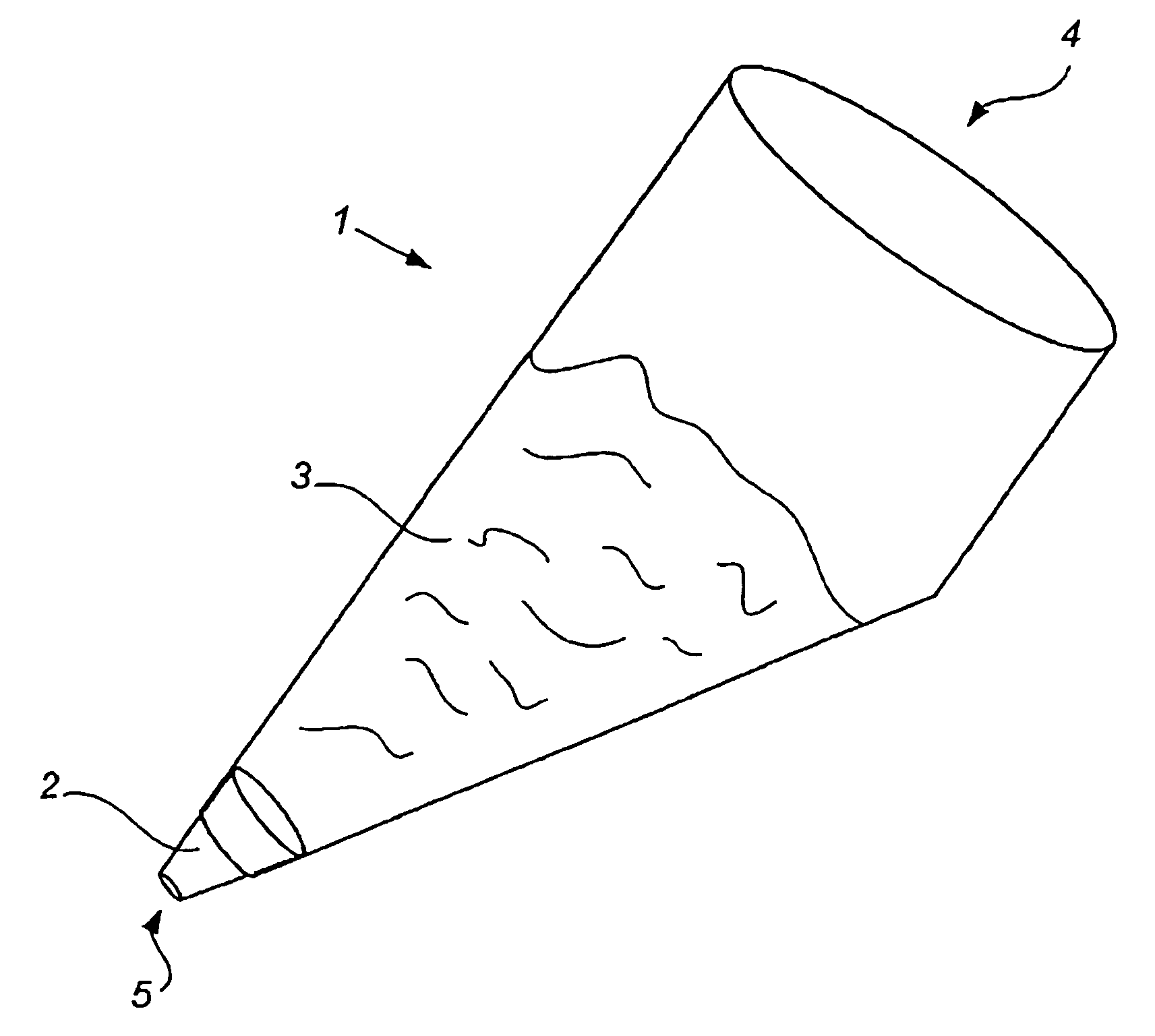

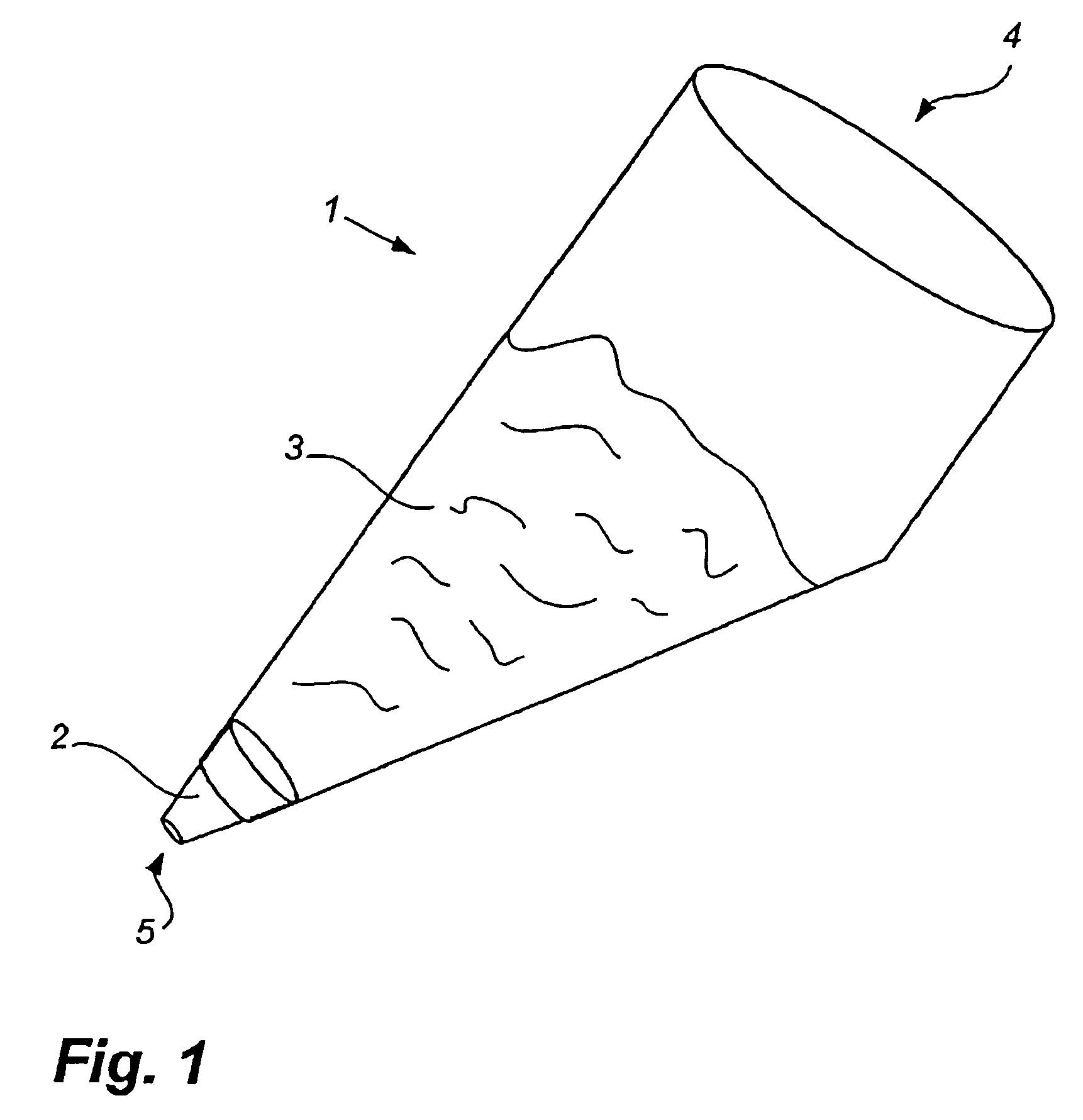

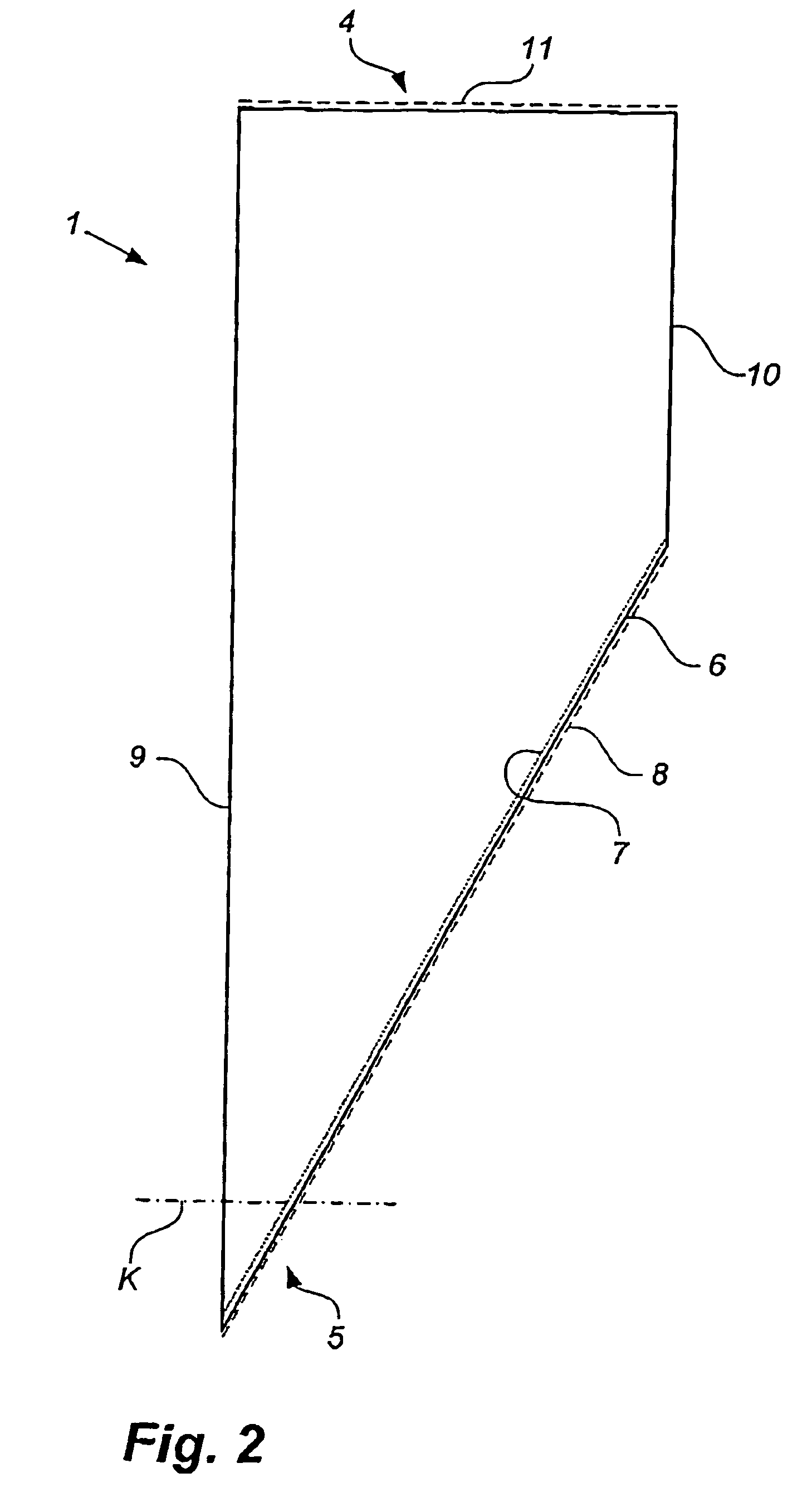

Piping bag, blank for manufacturing a piping bag and method of manufacturing a piping bag

Owner:KEE PLASTICS

Vibrational excited frame food coating apparatus and methods of use thereof

The present invention is directed to an excited apparatus for coating food product with a coating. The apparatus includes an elongate pan having proximal and distal portions; a screen located in the distal portion and adapted to screen coating; an elongate frame; a motorized vibrator adapted to impart energy to the elongate frame at an angle β below horizontal; a plurality of springs mounting the elongate pan to the elongate frame, the springs being mounted at an angle θ above horizontal; another elongate frame; a plurality of dampeners mounting the two elongate frames; another elongate pan having proximal and distal portions, the elongate pan mounted to the other elongate pan and adapted to feed coating to the other elongate pan; a soft roller rotationally actuated by a ratchet assembly, the ratchet assembly engaged by the elongate pan; and, a recycle assembly for transferring screened coating to the elongate pans, wherein the elongate pan's vibrations have longitudinal and vertical vector components at a predetermined amplitude and frequency. The excited apparatus further includes a waterfall distributor member mounted to the elongate pan, the waterfall distributor including one or more transverse rows of a plurality of angular slots.

Owner:VIBRATORY SOLUTIONS

Method and apparatus for applying and distributing particulate material on a substrate

InactiveUS20050178277A1Simple and reliable processImprove distribution efficiencyBaked articles handlingElectrographic processes using charge patternEngineeringParticulate material

A method of distributing a charge of particulate material onto a substrate employs a separator having a first part including a first input, a first output, and a delay line for delaying the transfer of the charge from the first input to the first output; and a second part including a diffuser with a second input that receives the charge from the first output, and a second output through which the charge is spread and delivered to the substrate. The substrate and the separator are moved relative to one another for positioning the substrate below the separator in registration with the second output, and the charge is delivered to the first input. After the charge is distributed onto the substrate, the substrate and the separator are again moved relative to one another to remove the substrate from the position in registration with the second output.

Owner:CARBINPLANT INT AS

Apparatus for applying coating to products and methods of use thereof

An apparatus and method for coating products is disclosed herein. An exemplary apparatus comprises a vibration generating portion and a product coating portion. The product coating portion can include a coating application portion, a sifting portion, and an aligning portion. The exemplary apparatus can include a coating recycle portion as well. The vibration generation portion further comprises a motor vibration assembly secured to a frame wherein the frame is in communication with the product coating portion, such as a pan assembly, by springs that move the pan assembly with a vibratory motion. The product coating portion includes a series of angled steps that guide the coating and vibrating product upwards and forward, while simultaneously allowing the product to be agitated against the coating resting on the step surface. Additionally, the product coating portion can include a moveable wire belt conveyor assembly.

Owner:VIBRATORY SOLUTIONS

Preparation method of liquid-smoked Longsnout catfish soft can

InactiveCN101422259AImprove processing levelClimate change adaptationMeat/fish preservation using chemicalsLiquid smokeEconomic benefits

The invention relates to a preparation method of a liquid smoked longsnout catfish soft can, pertaining to the technical field of aquatic product processing. In the invention, a channel catfish is taken as a raw material, and the finished liquid smoked longsnout catfish soft can is prepared through pretreatment, deboning and skinning, rinsing, draining, fishy smell removing, draining, liquid smoking, rinsing, drying, ripe preparing, vacuum packaging, sterilizing and cooling. The adoption of the channel catfish as the raw material for preparing the liquid smoked longsnout catfish soft can is very beneficial to elevating the processing level of leftovers of agricultural, livestock and aquatic products in China and can produce great economic benefit.

Owner:JIANGNAN UNIV

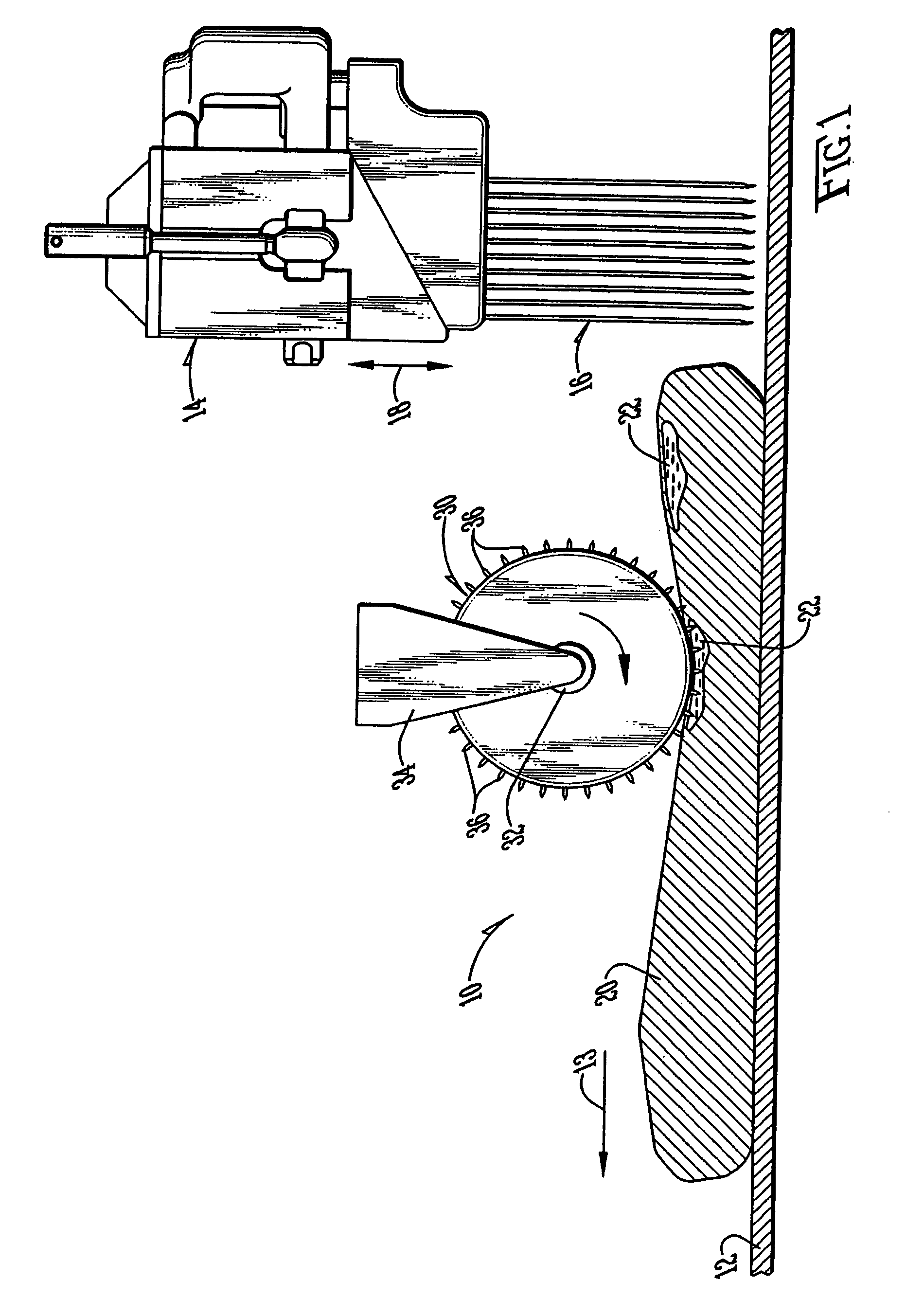

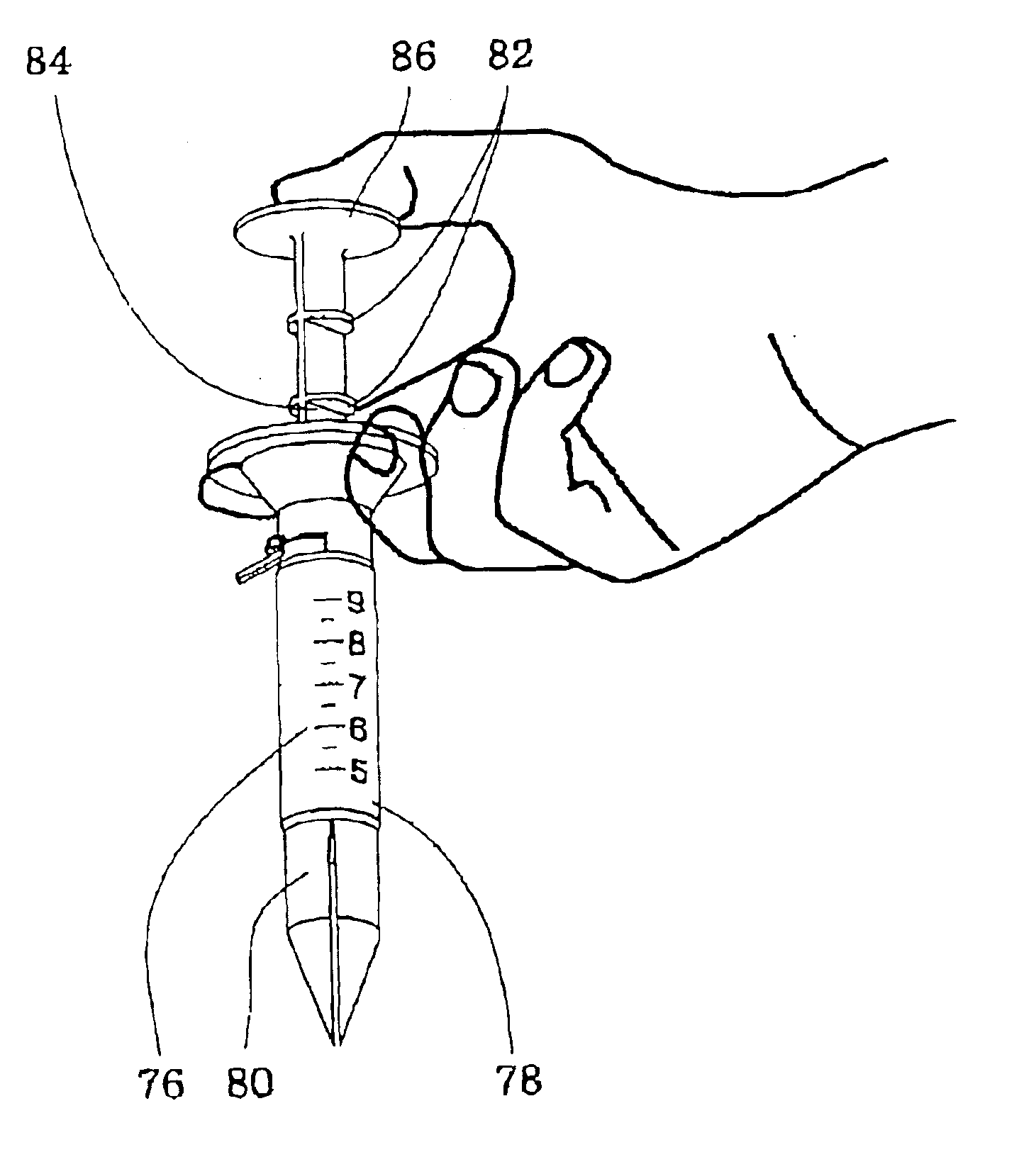

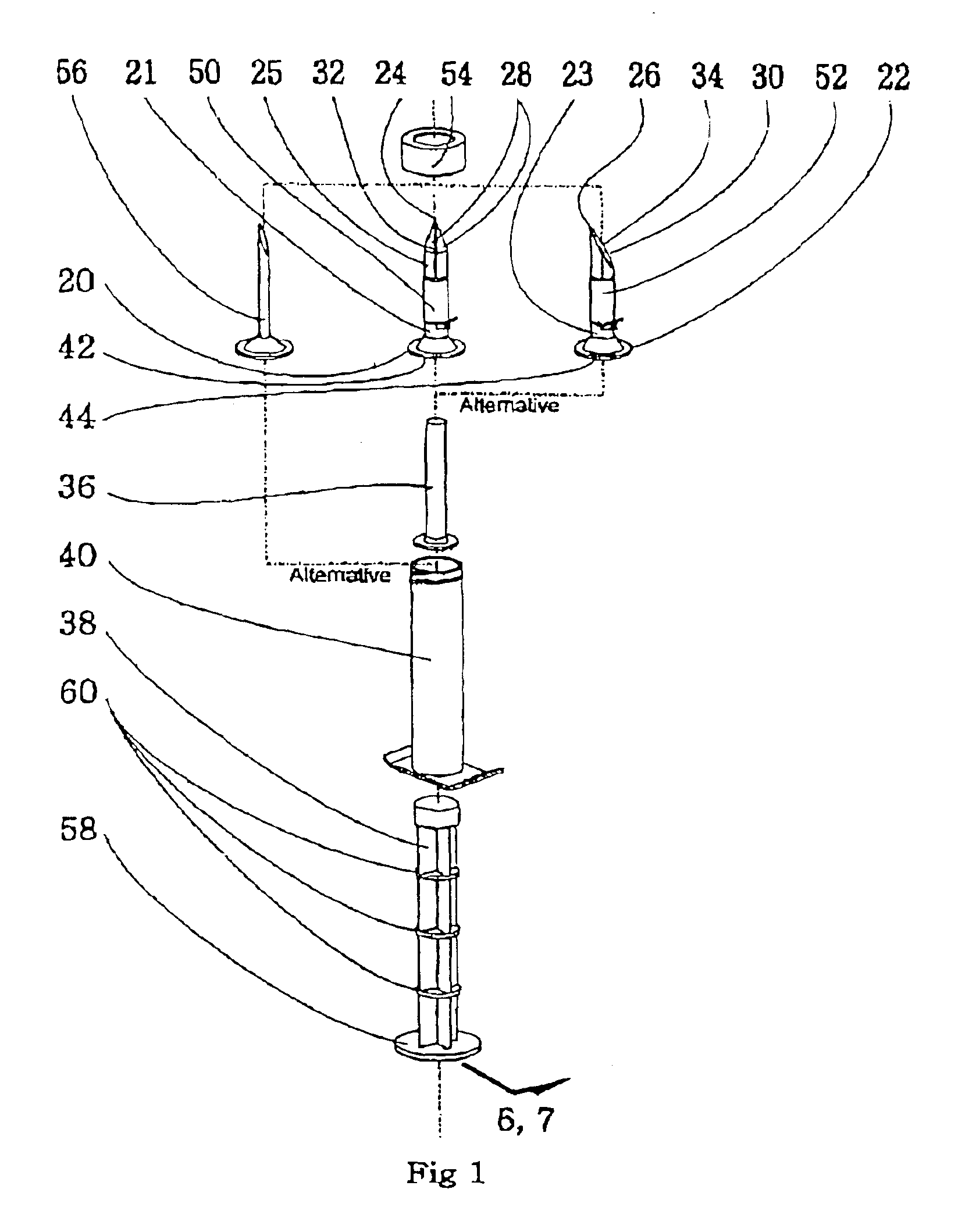

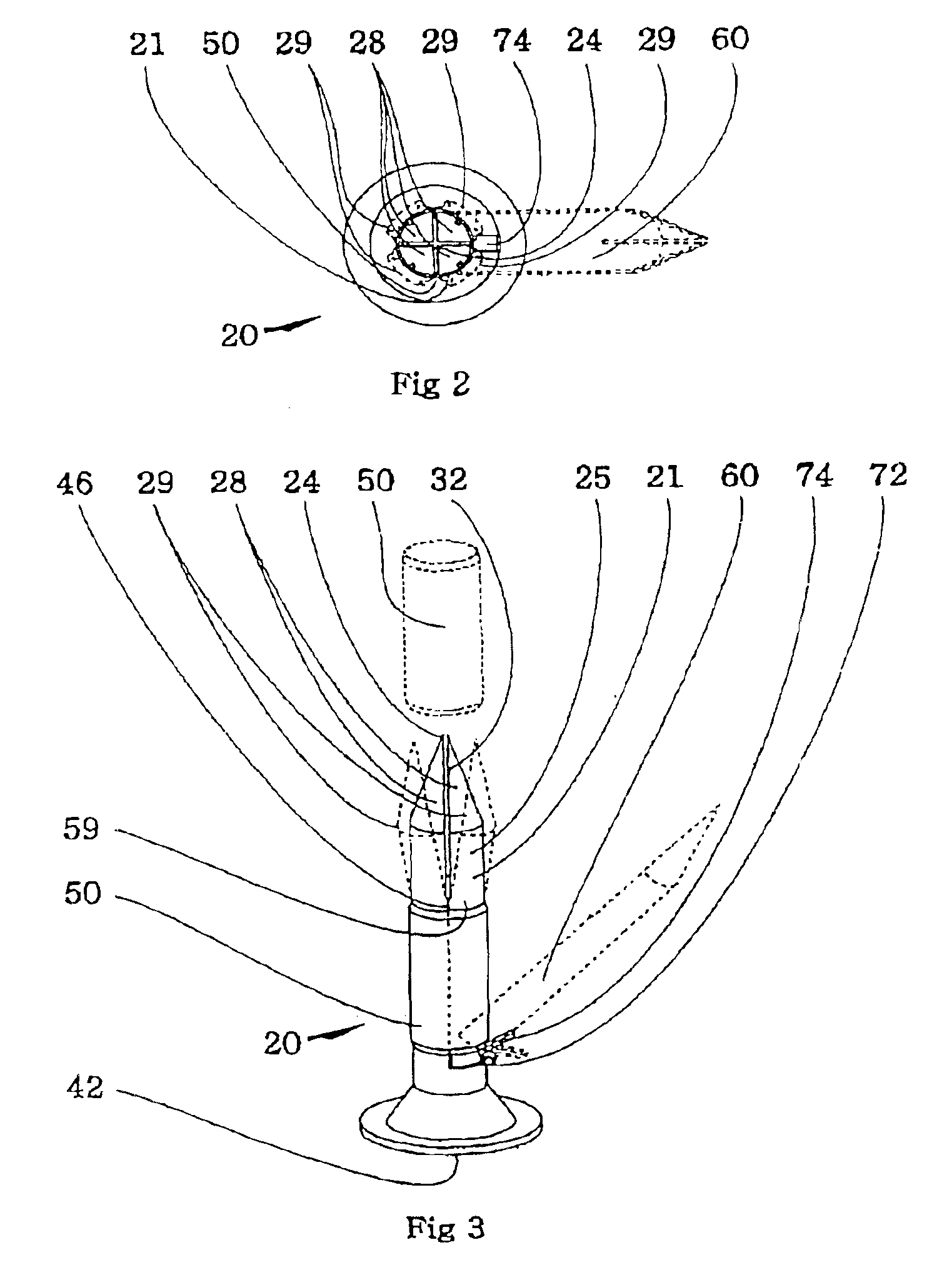

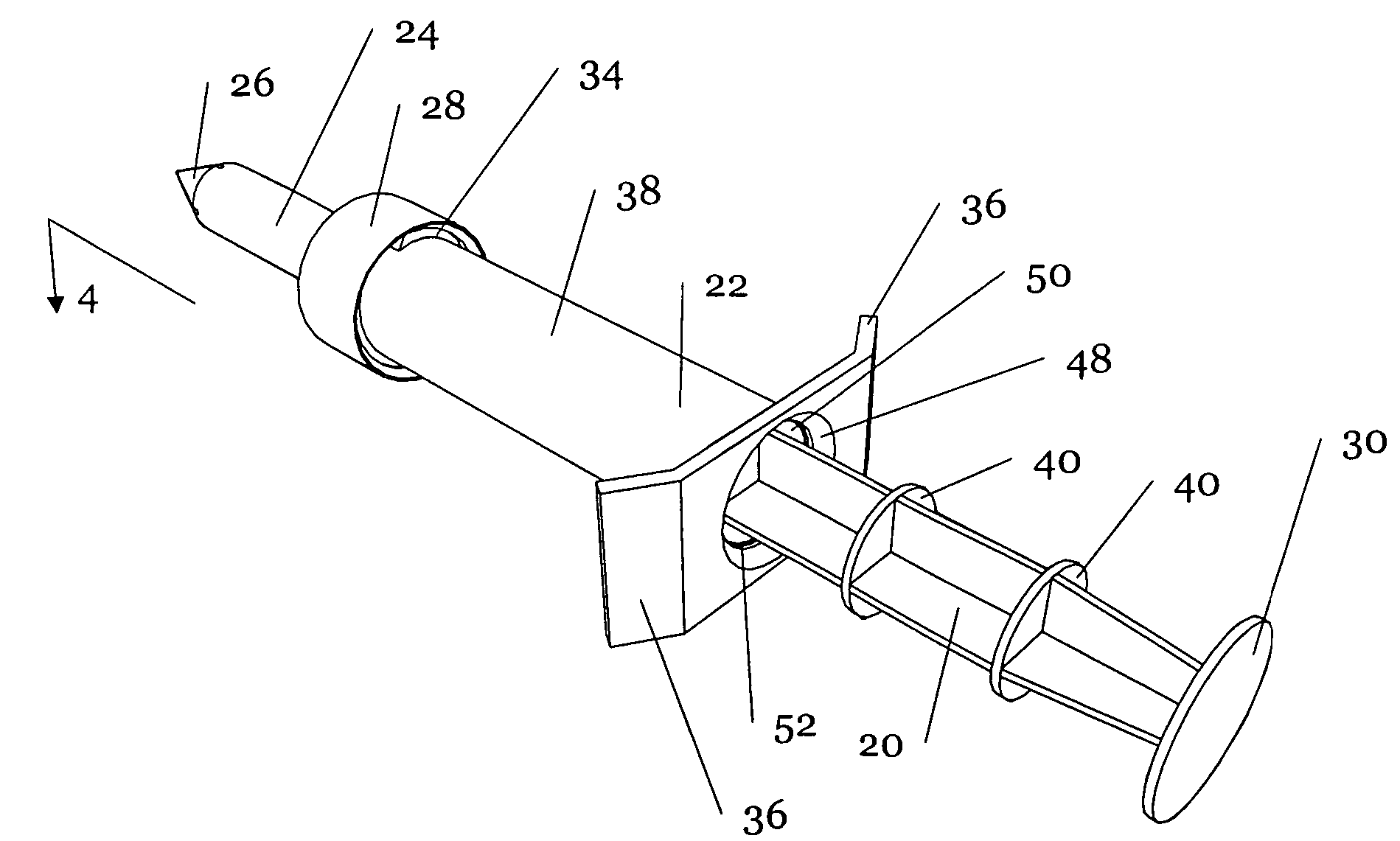

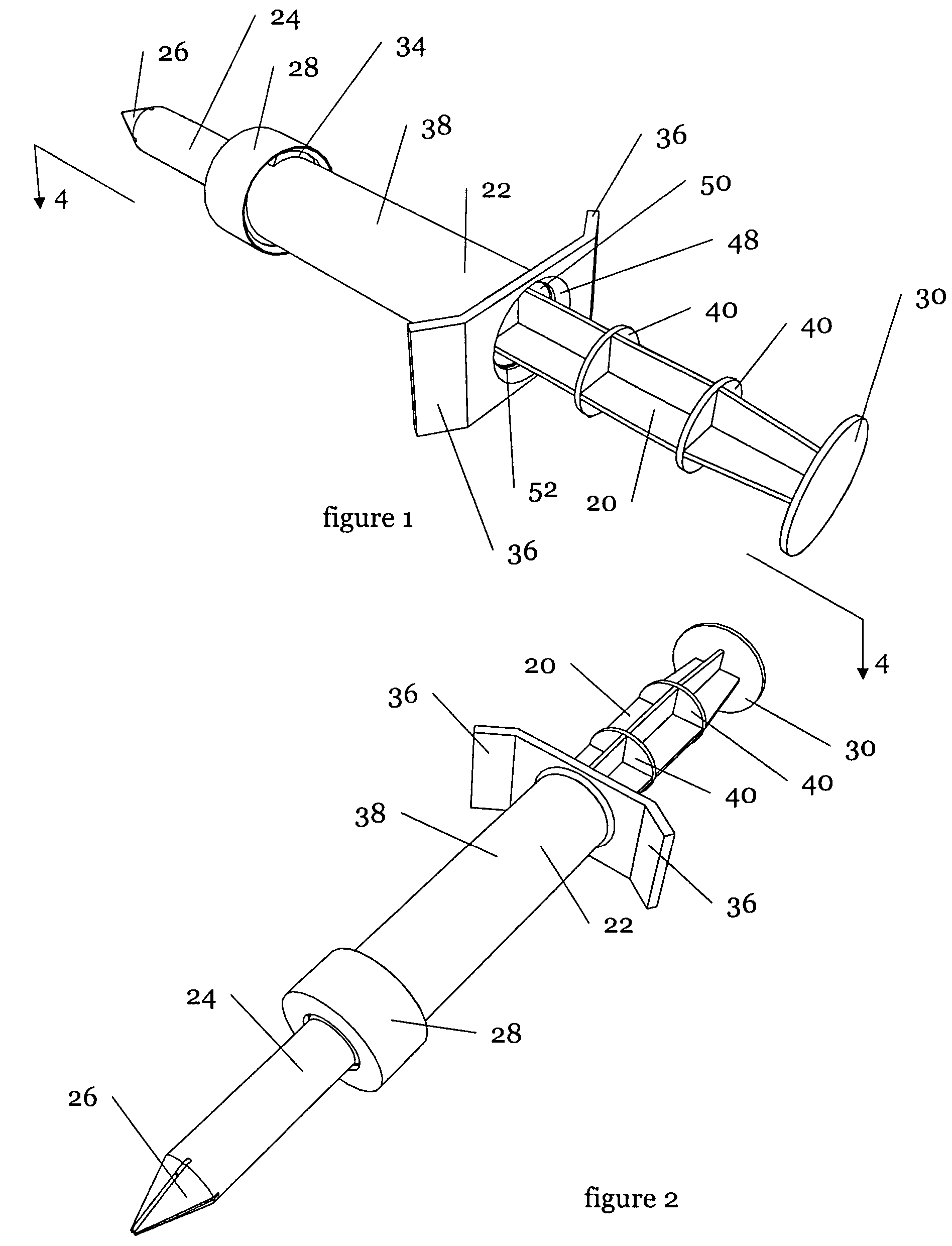

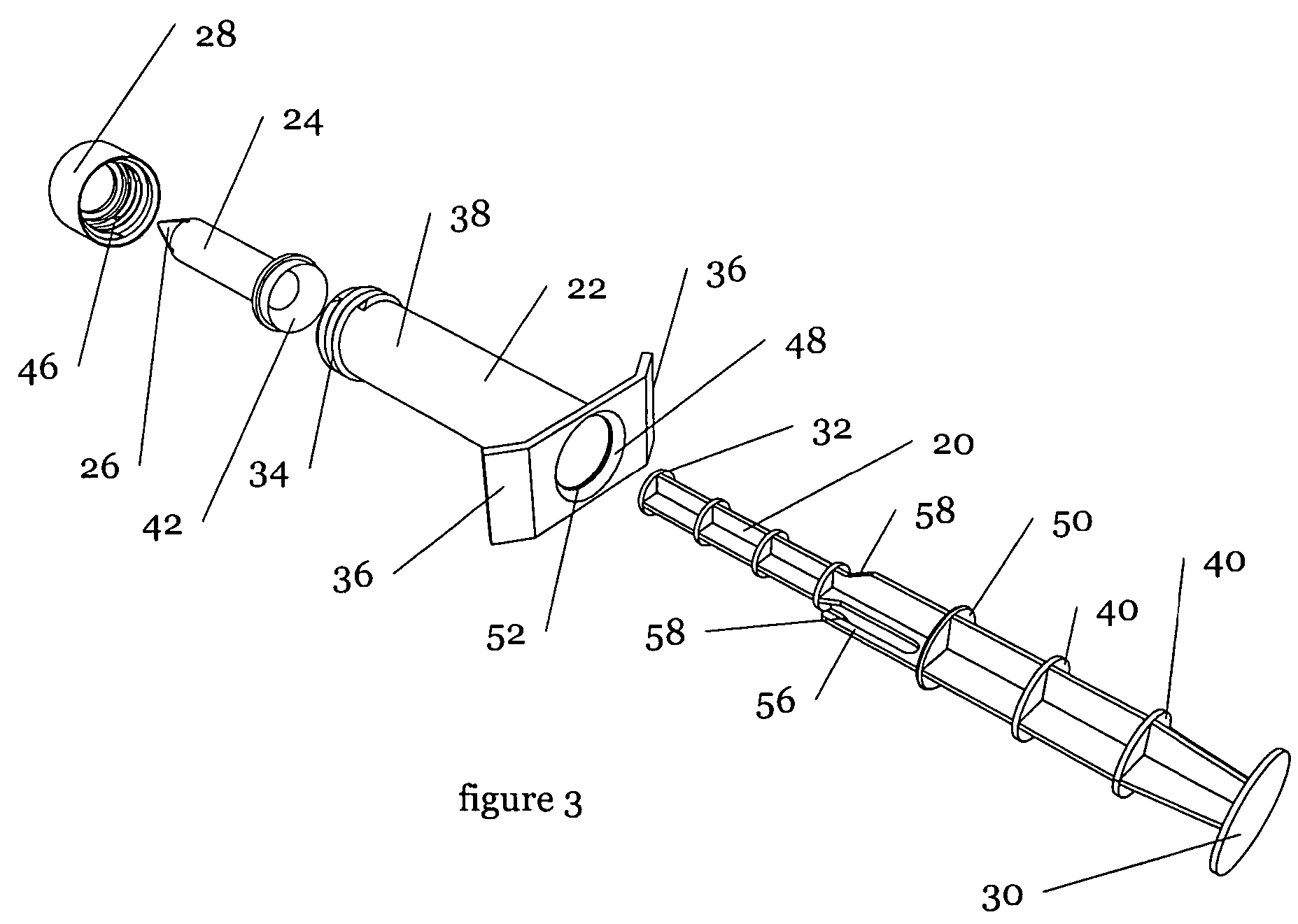

Device to inject foods with solid objects

A device to inject solid materials into foods comprising a piston, a sleeve, and a penetrating tip. Embodiments are described with both segmented and unitary sleeves. Deformation of the tip during storage is minimized by biasing members which withdraw the piston from the tip when an embodiment is not in use. A method is described for flavoring foods with solid objects.

Owner:RONCO HLDG

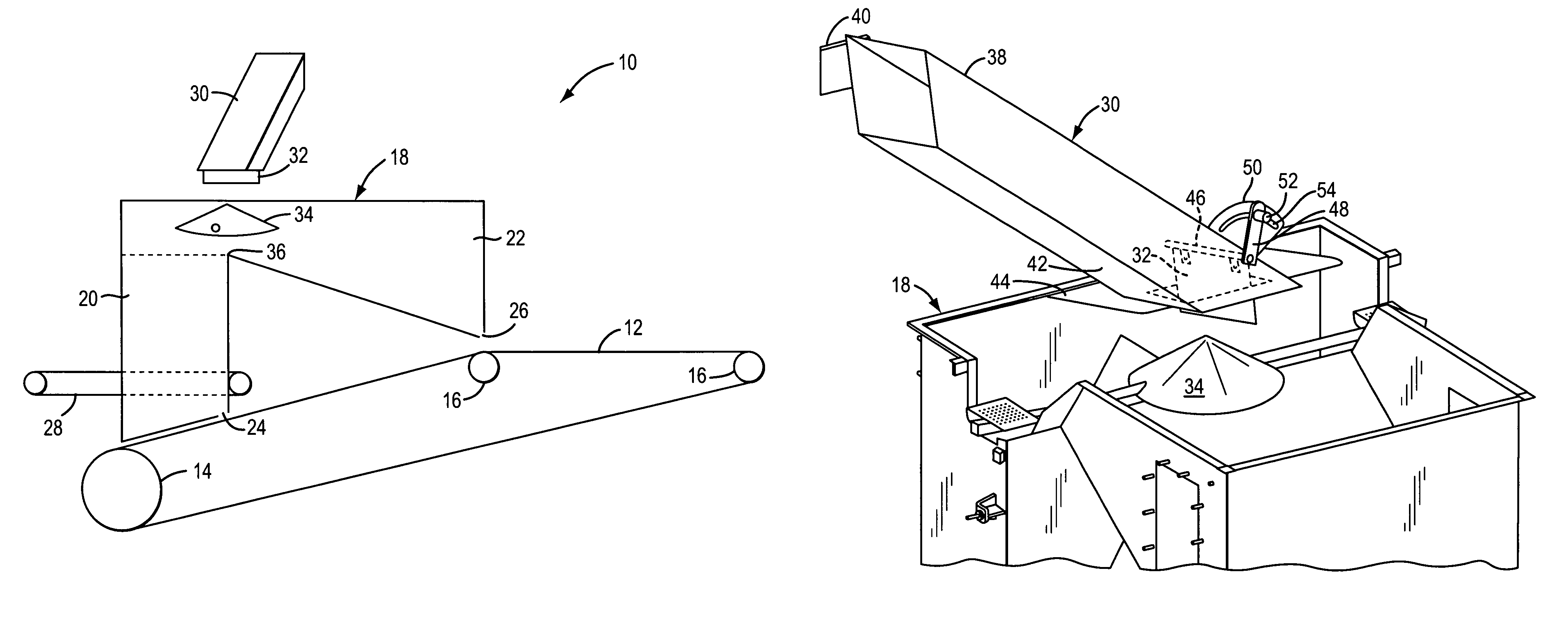

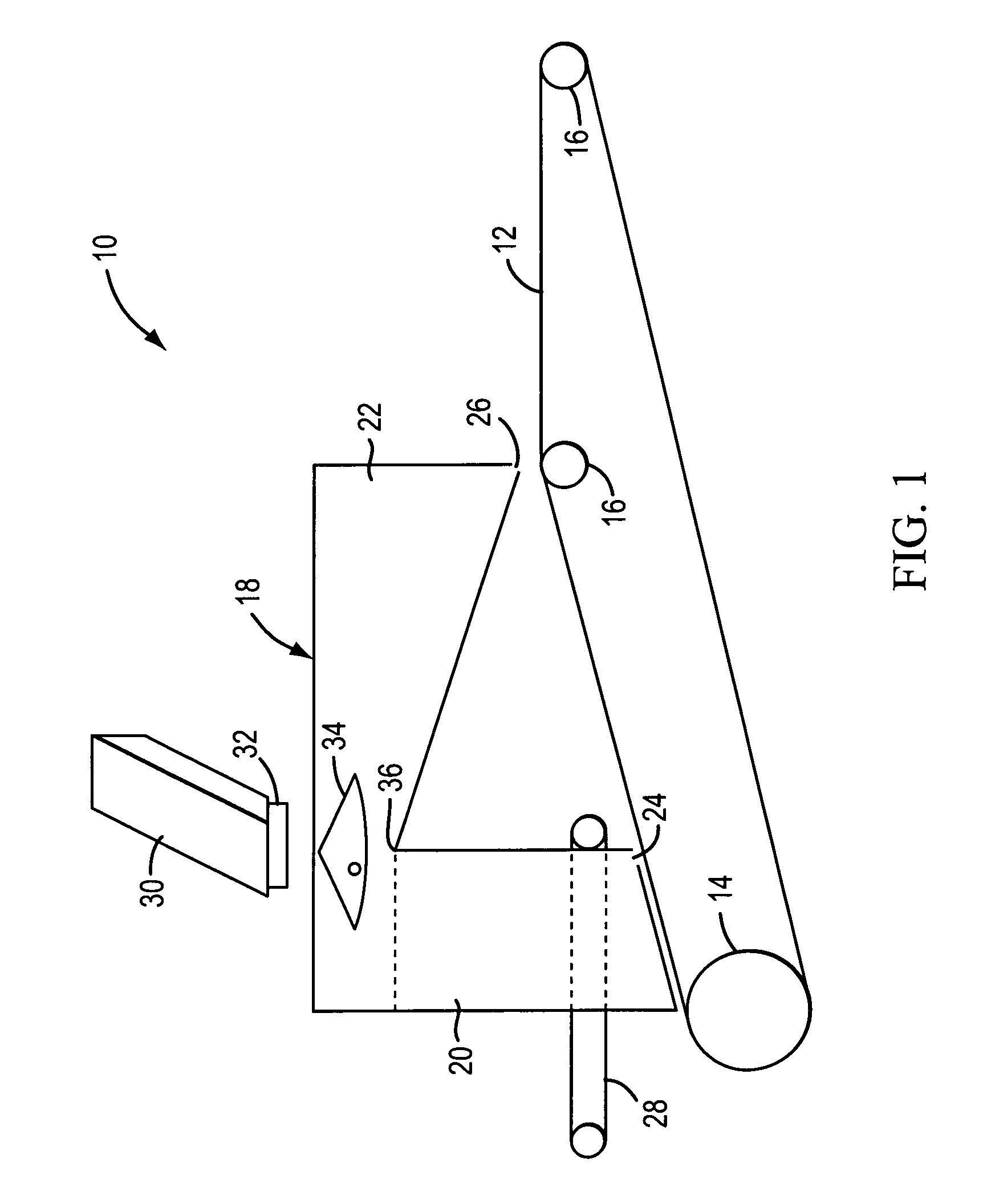

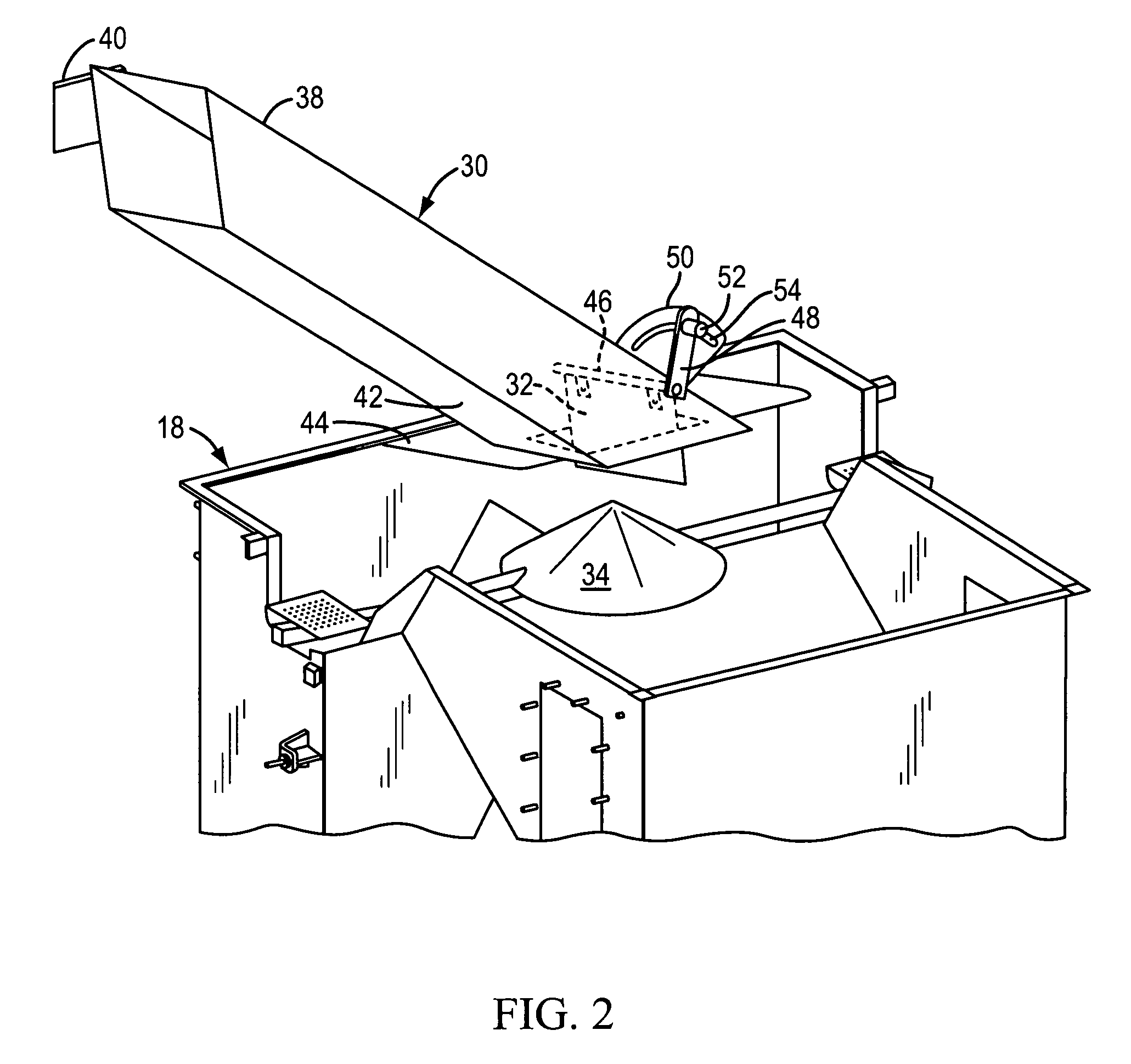

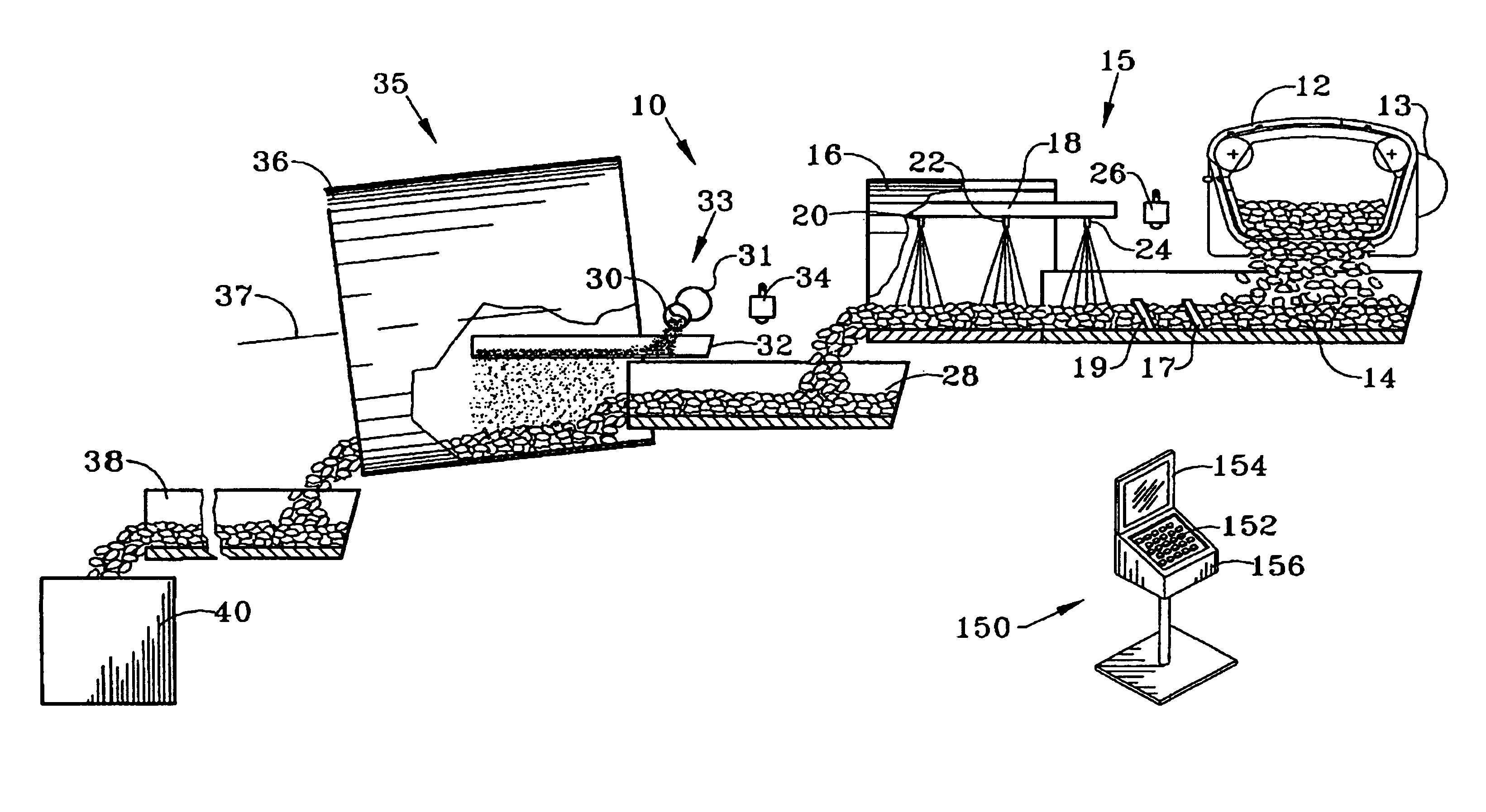

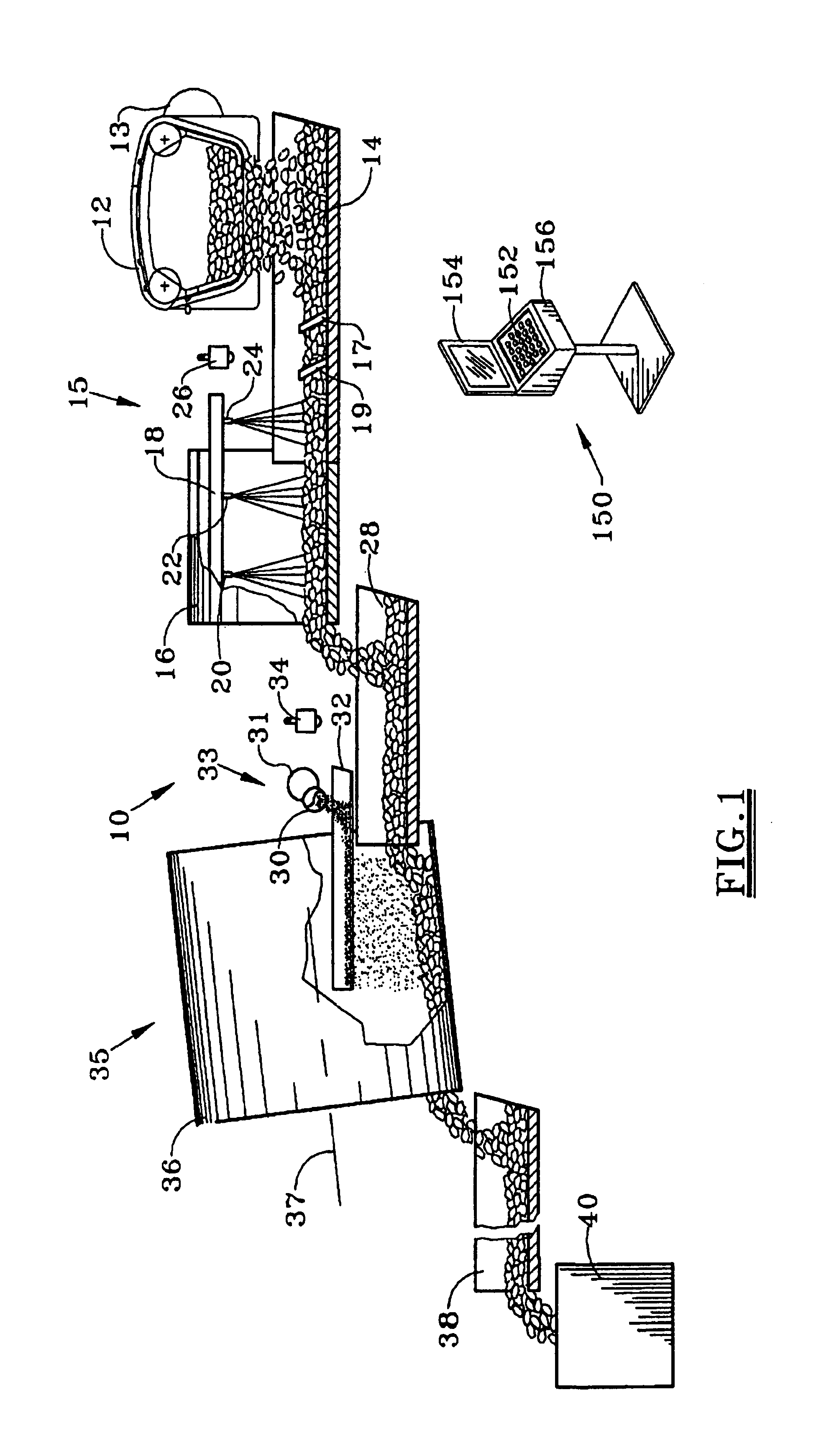

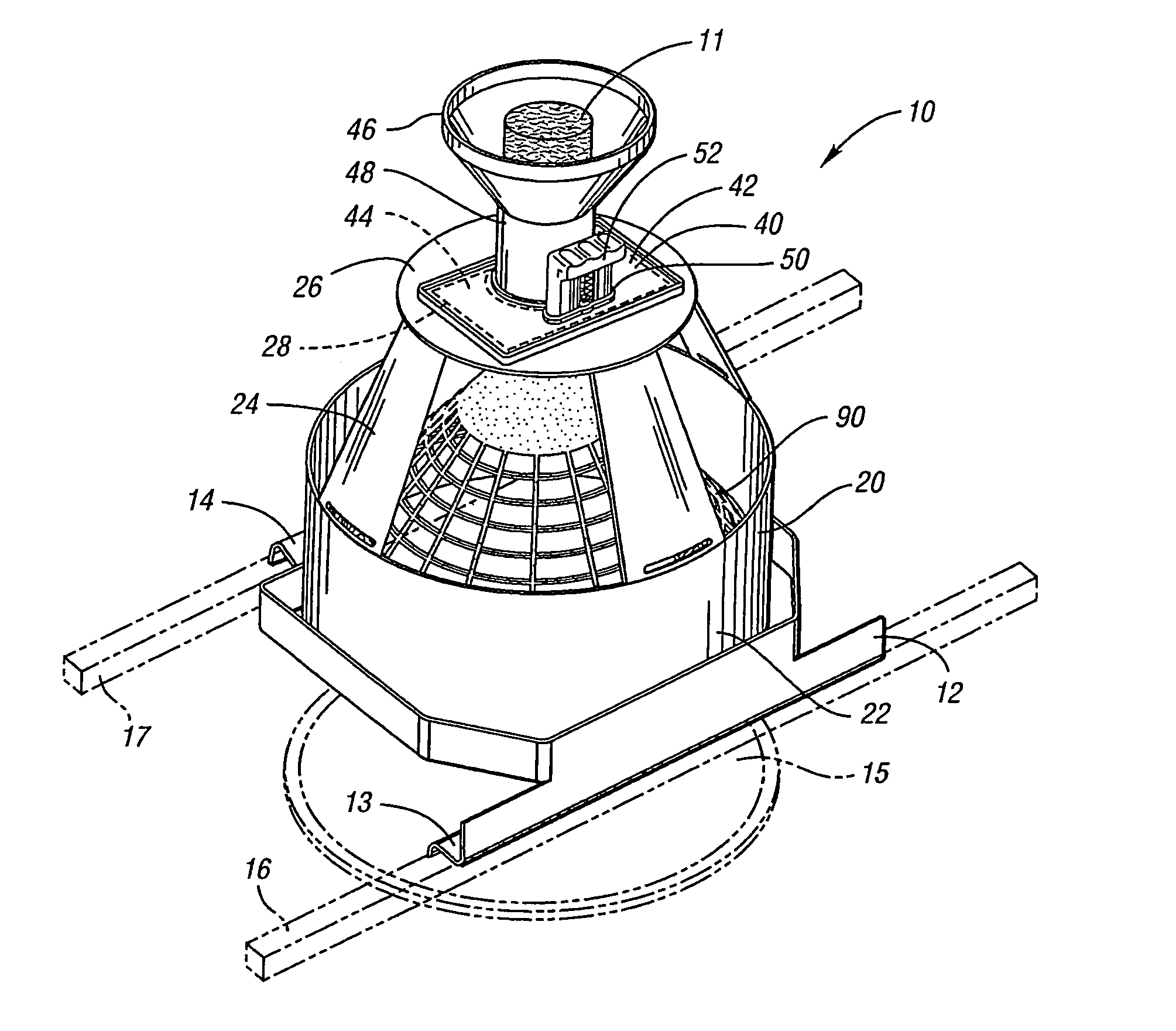

Seasoning system and method

InactiveUS7055455B2Increase coverageGuaranteed uptimeLiquid surface applicatorsConfectioneryMechanical engineeringRotating drum

An improved seasoning system 10, 11, 13 uniformly coats a food product with the desired amount of seasoning, with the seasoning rate preferably being controlled as a function of the product volume signals from the sensors 26, 34, 108 and 110. The seasoning system preferably utilizes linear motion conveyors and either a rotating drum 36 or a deflector 98 and a second seasoning unit 112, 114 between linear conveyors 94, 96. Oil may be sprayed onto food products and tumbled in a drum 16 which both rotates and moves in a reciprocating manner with the conveyor tray 14. An improved seasoning tray 123, 144, 148 has a planar floor 122, 138, 162 with an angled discharge edge 124, 137, 182 for uniformly distributing seasoning on the product. The seasoning system minimizes damage to the food product and uniformly coats the product with a desired amount of seasoning.

Owner:SVEJKOVSKY PAUL A

Breading machine

ActiveUS20060032384A1Small misalignmentLiquid surface applicatorsConfectioneryEngineeringDelivery system

A breading machine has a battering unit for applying a fluent batter to a food product. The battering unit includes a batter reservoir and a battering unit conveyor system for delivering food products from said batter reservoir to a battering unit conveyor discharge section that propels the food product from the battering unit. The combination units also include a breading unit for receiving food product from an associated battering unit. The breading unit includes a breading reservoir and breading unit conveyor system for applying particulate breading to the food product at a breading station by moving breading material from the breading material reservoir and food product coated with the batter to the breading station. A conveyor drive system includes a machine housing and a drive unit rotatably supported by the machine housing that provides motive power to the breading unit conveyor. A breading unit drive is coupled to the breading unit conveyor and is rotated by the drive unit to move said breading unit conveyor.

Owner:BETTCHER INDUSTRIES

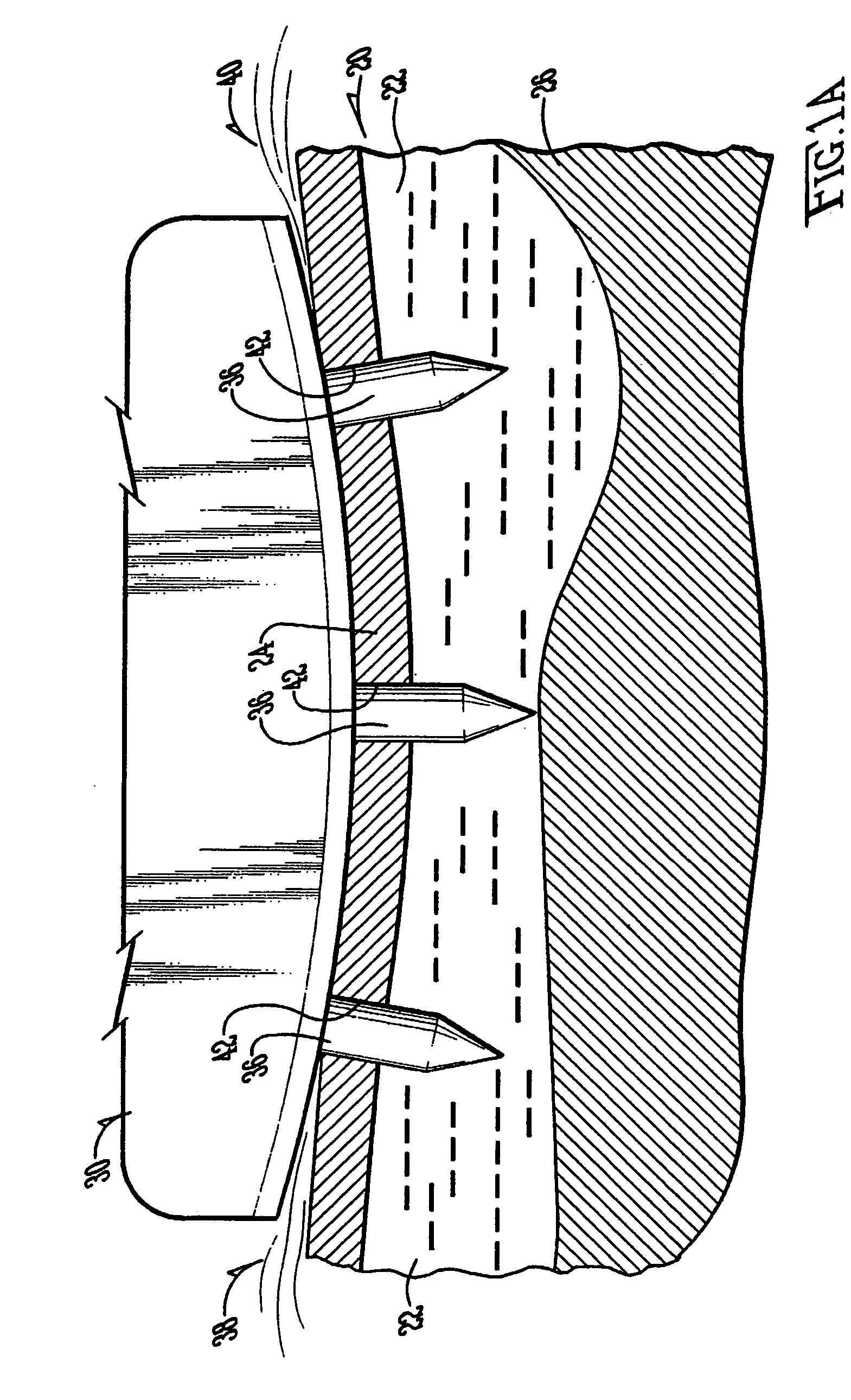

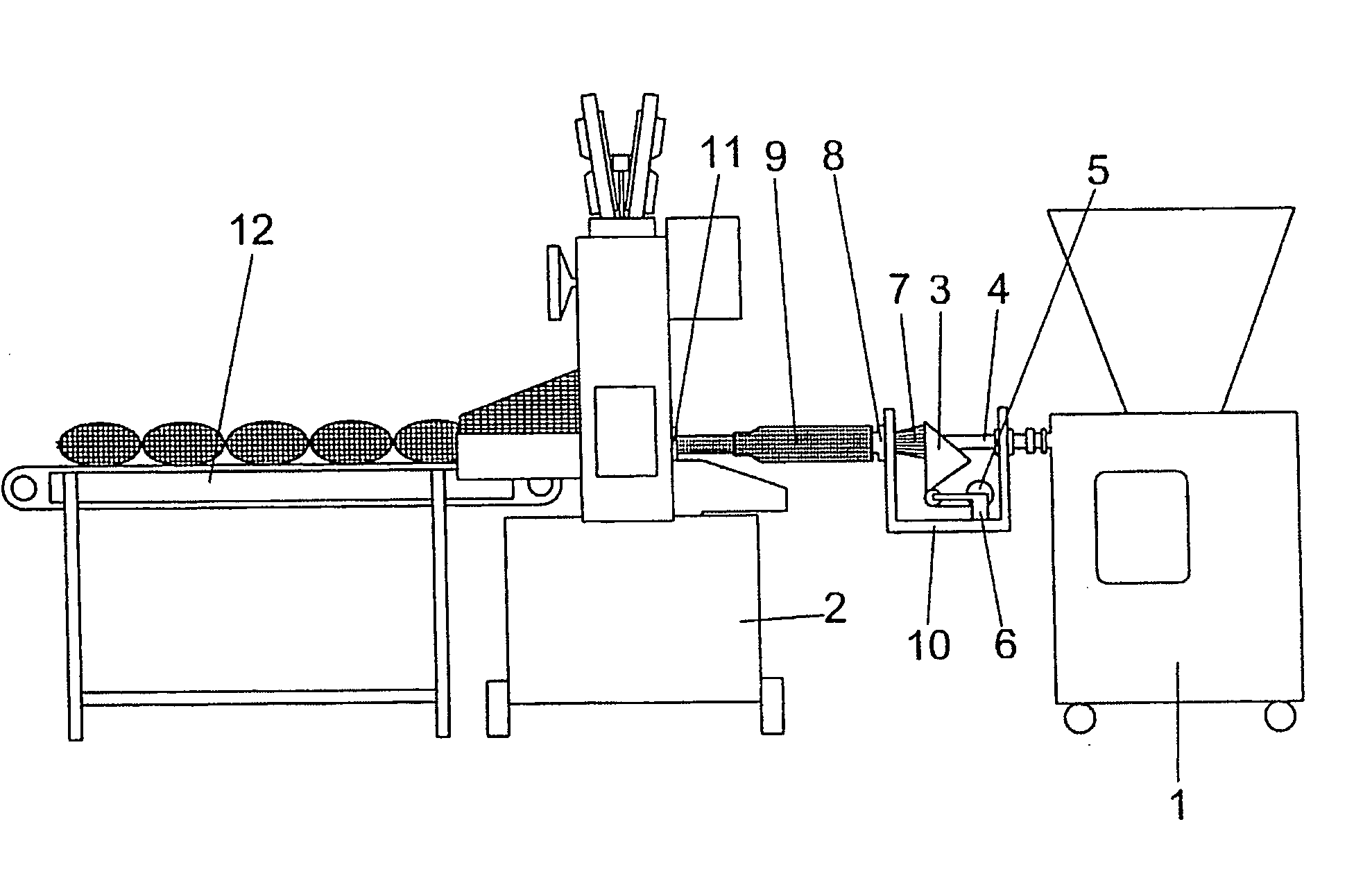

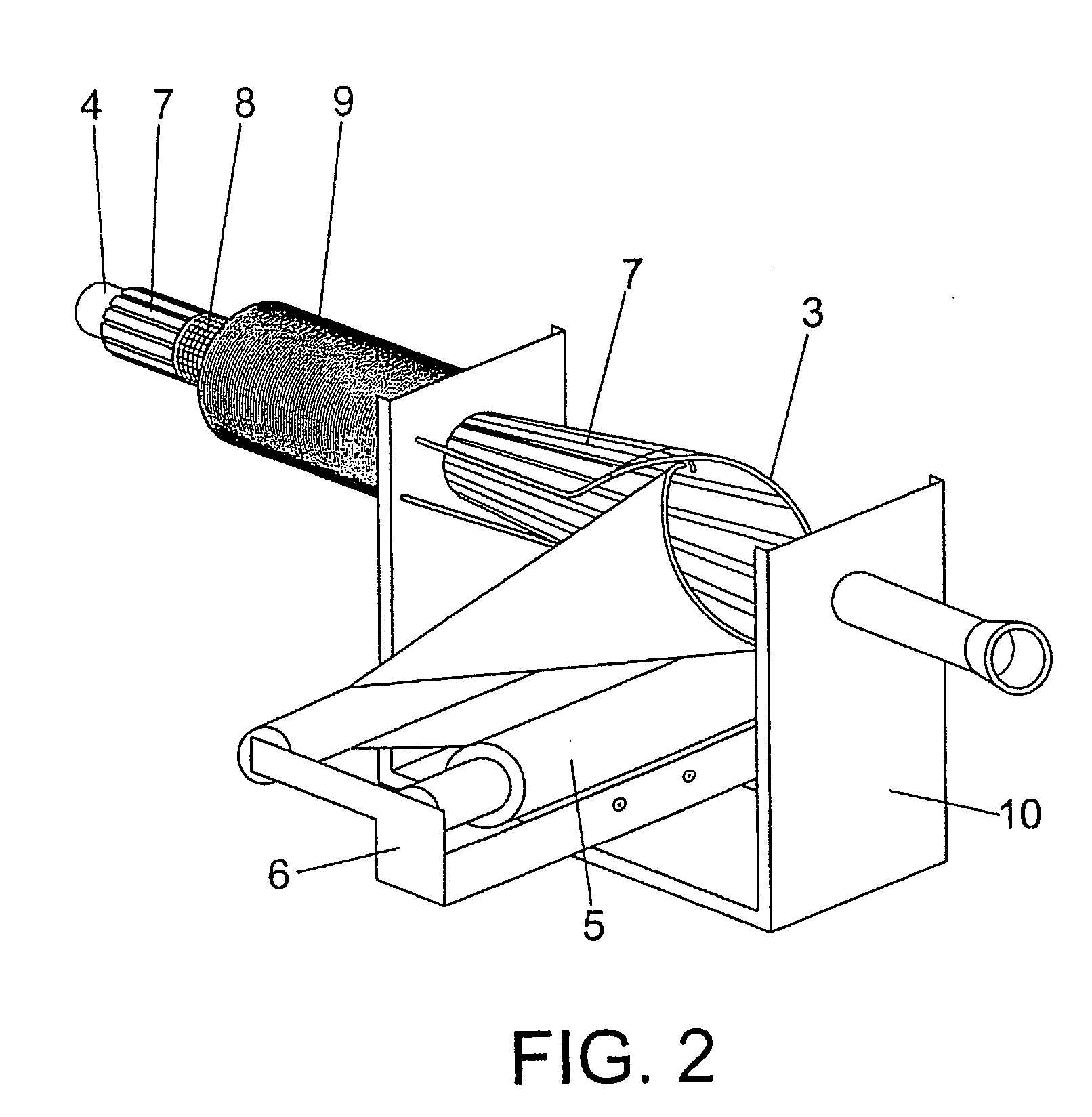

Method and apparatus for the automatic stuffing of meat products into a double casing comprising a sheet and a net

ActiveUS20050126403A1Increase speedImprove load effectMultilayer sausage casingsSkinless sausage makingAutomatic testingFood products

Based on a conventional installation including a stuffing-portioning machine (1) and a fast clipper (2), duly synchronised, between which is established a shaping device (3) that converts the film (5) meant to wrap food products that is supplied in the form of a coil into a tubular element that can be coupled to the stuffing tube (3), on which is coaxially mounted a second tube (8) bearing an external casing (9) based on a tubular net, the invention consists of using tubes (4) and (8) with a small diameter, much smaller than that of the finished product, so that the film (5) is adapted to the tube (4) after the former is profusely folded longitudinally, while the small diameter of the tube (8) allows the multilayer shirring of the tubular net (9), using the pressure provided by the pumping system of the stuffing machine (1) to achieve the radial expansion of the film (5) and the tubular net (9) to obtain the final diameter of the finished product, which will vary according to the speed with which it is separated from the double clipper (2) carried by a conveyor belt (12) with an adjustable speed.

Owner:VISCOFAN

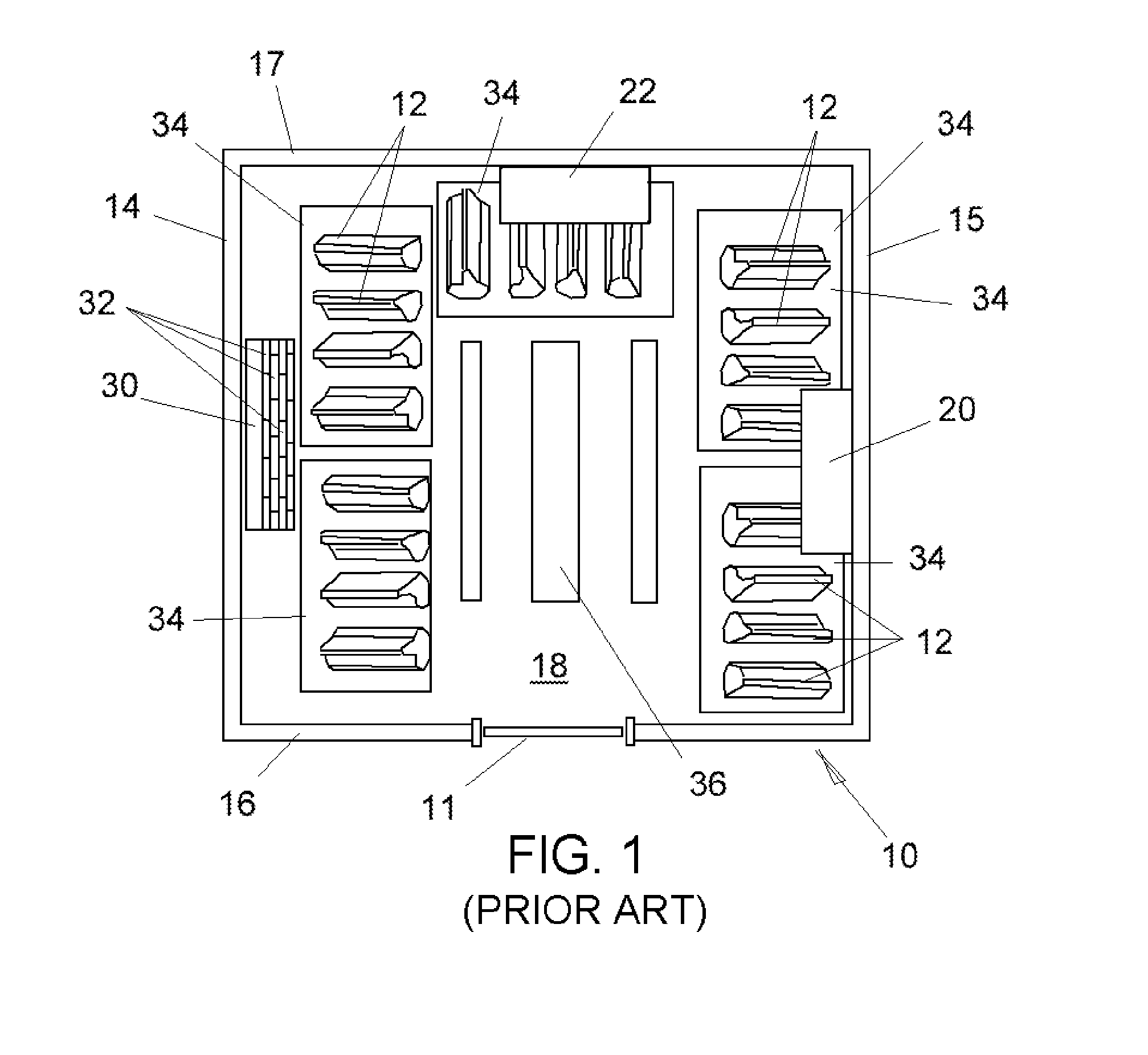

Meat aging process

A process for dry aging meat uses an enclosed, atmosphere controlled room with forced circulation, containing a stainless steel salt rack with a salt brick stack covering one wall. Each brick has a narrow width compared to its length for increased surface area and the salt rack is spaced from the wall for circulation around the bricks. A plurality of unwrapped and uncovered meat piece are loaded onto a meat rack in the room, spaced far from the salt rack and on a timed cycle of days that is a fraction of the total number of days for aging, the meat pieces are moved ever closer to the salt rack until finally, after the expiration of the total selected number of days for the dry aging, they are removed from the aging room for use.

Owner:BURKE DAVID

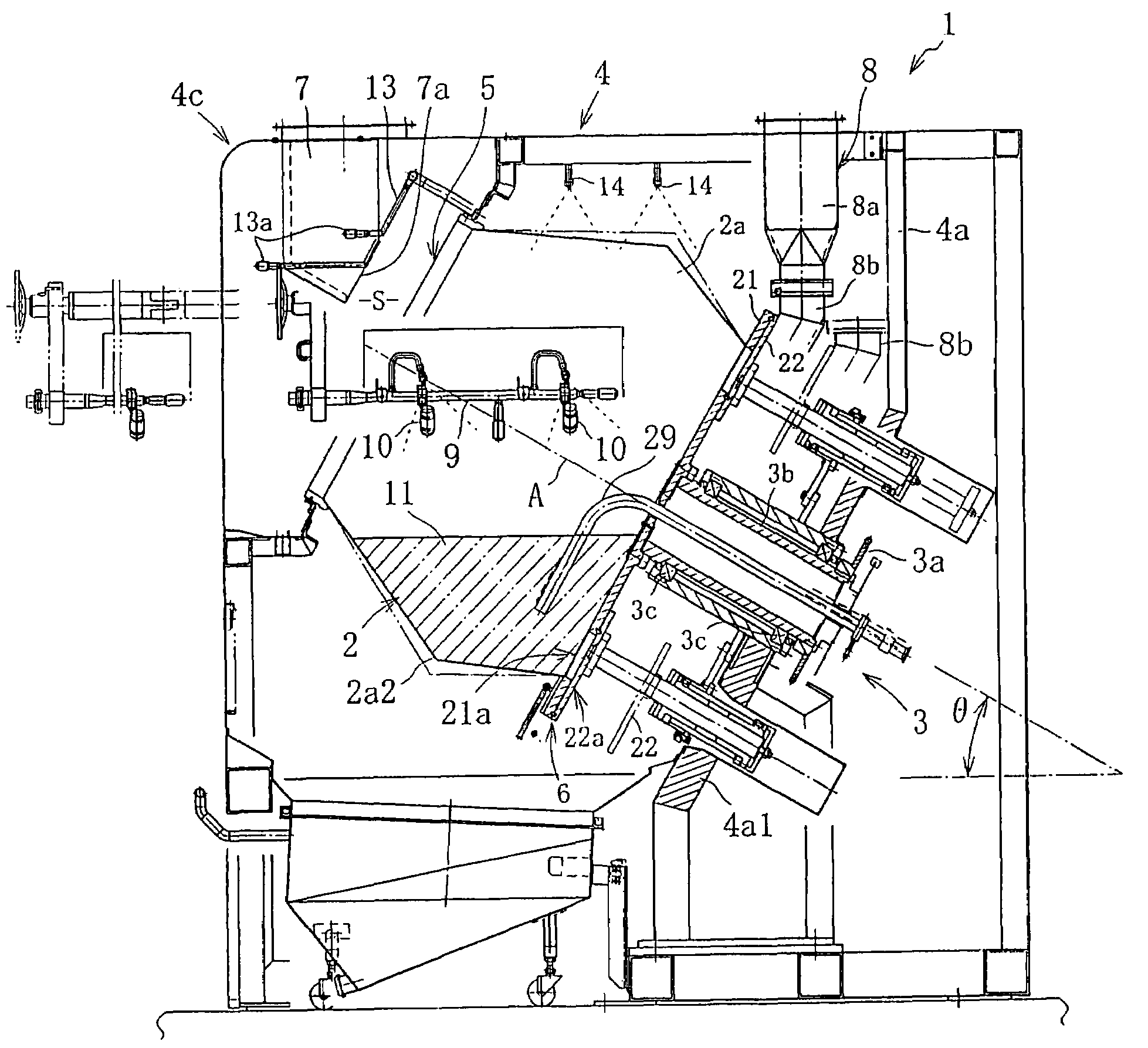

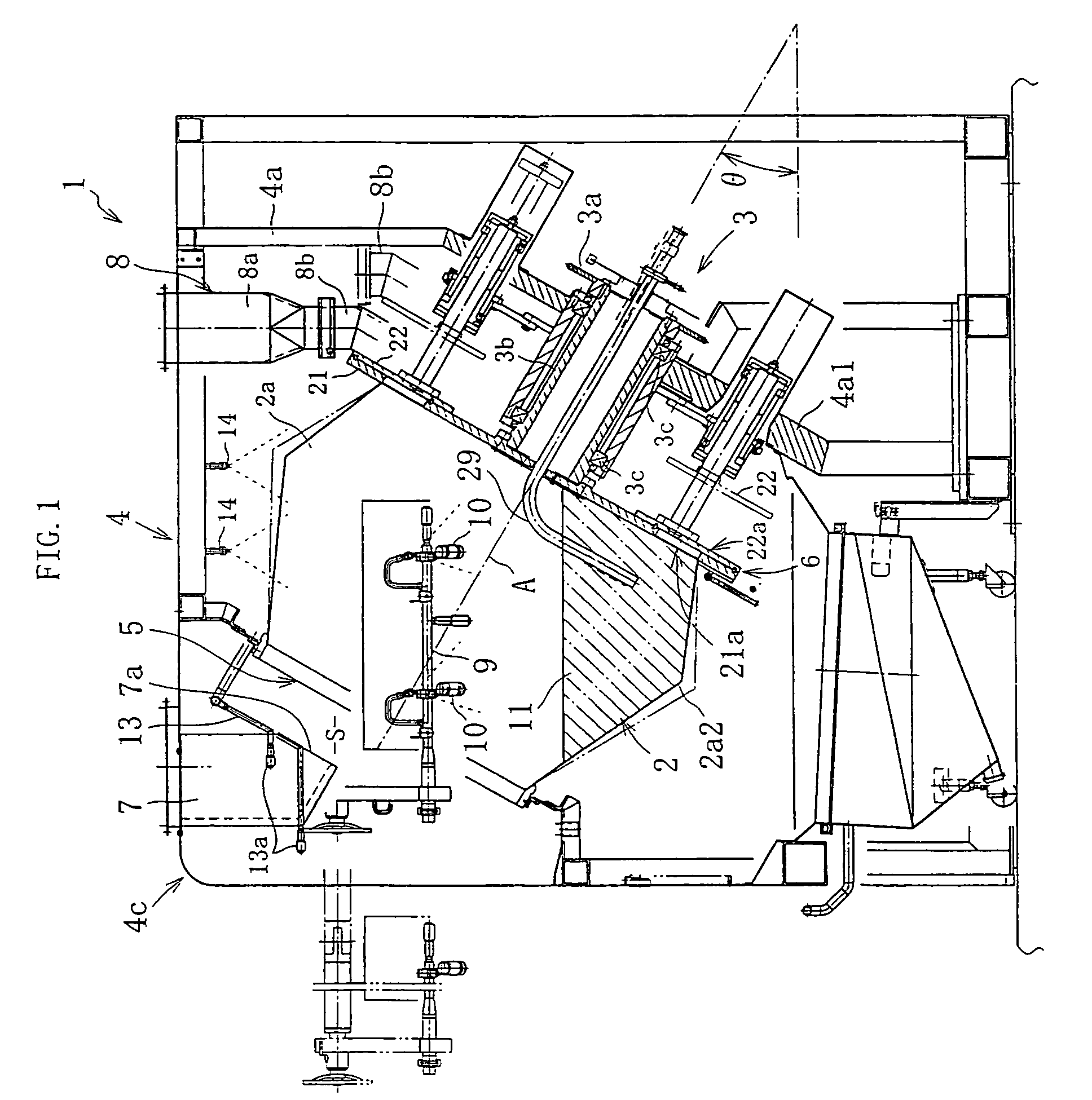

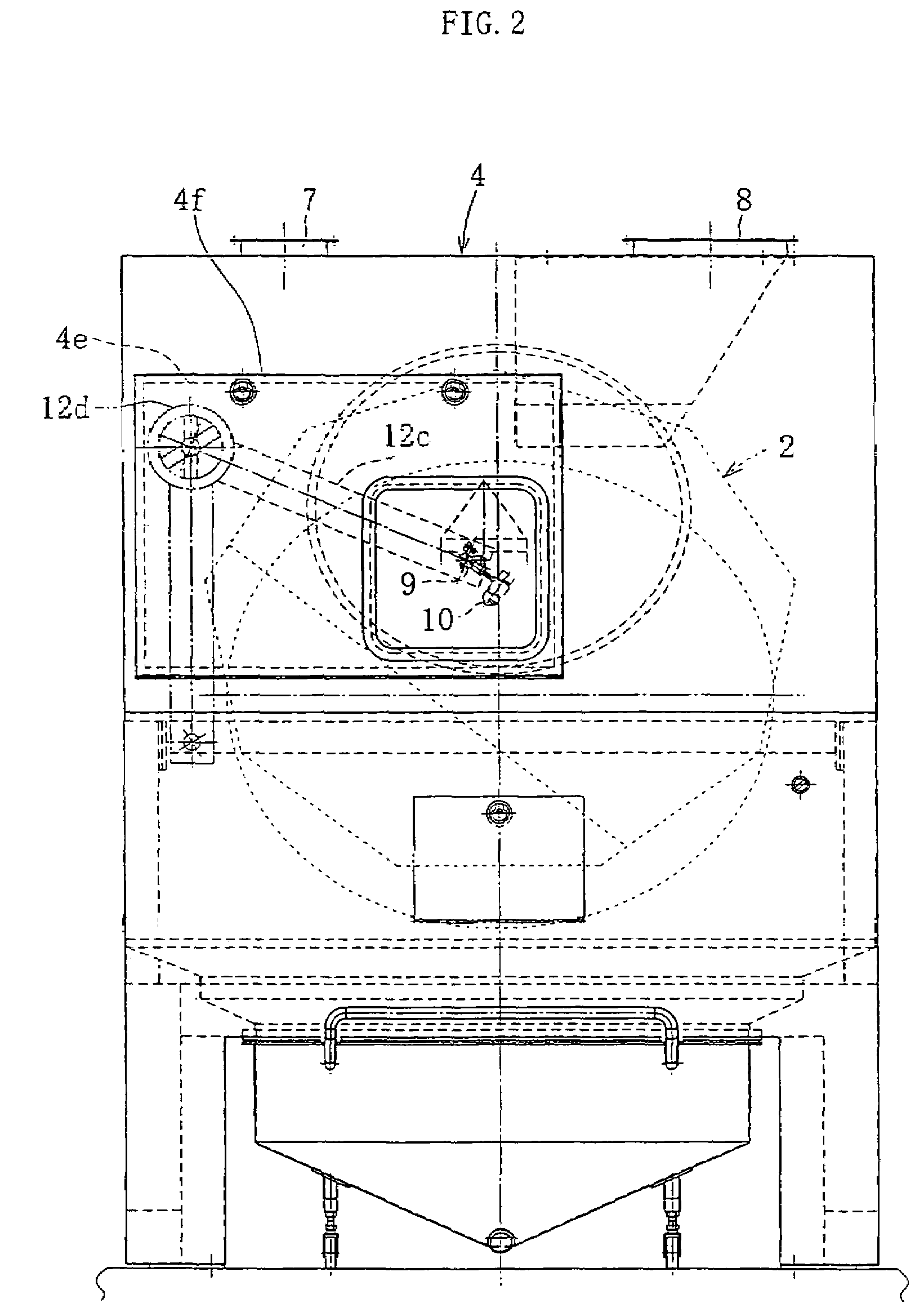

Coating apparatus

InactiveUS7614359B2Easy to cleanQuality improvementLiquid surface applicatorsConfectioneryEngineeringMechanical engineering

The rotating drum 2 rotates around an axial line A that is inclined to the horizontal at a present angle θ. Process gas flows in the rotating a drum 2 from an air vent 7a of an air duct 7 through an air inlet 5 at one end of the rotating drum 2, passes through a layer of granules 11, and flows out into an air outlet duct 8 through an air vent 21a of a first disc plate 21 and a connection hole 22a in a second disc plate 22.

Owner:POWEREX

Seasoning recovery and recycle

InactiveUS20050016447A1Smooth transferGuaranteed preservation qualityLiquid surface applicatorsConfectioneryWith snackFood science

Seasoning for use with snack chips can be recovered and recycled. A seasoning permeable conveyor transports snack chips through a seasoning application. The seasoning applicator deposits seasoning onto the snack chips. The conveyor allows the seasoning not adhered to the moving snack chips to substantially pass through and by toward a seasoning recoverer. The seasoning recoverer, which is positioned beneath the conveyor, collects the seasoning for purification and blending with fresh seasoning. After blending, the seasoning mixture is transported to the seasoning application for use.

Owner:FRITO LAY NORTH AMERICA INC

Dischargeable storage device for distributing food over a surface

A dischargeable storage device instantaneously moveable between a store position and a discharge position. The dischargeable storage device includes a deck having a pair of pivotable trap doors. Each door has a guide post. The dischargeable storage device has a plunger having two guide channels. The plunger is moveable within the aperture. Each guide channel is adapted to cooperate with one of the guide posts such that when the plunger is depressed, the guide posts travel along the guide channels allowing the trap doors to open. An apparatus for for evenly distributing portions of food having a dischargeable storage device is also disclosed.

Owner:DOMINOS IP HOLDER

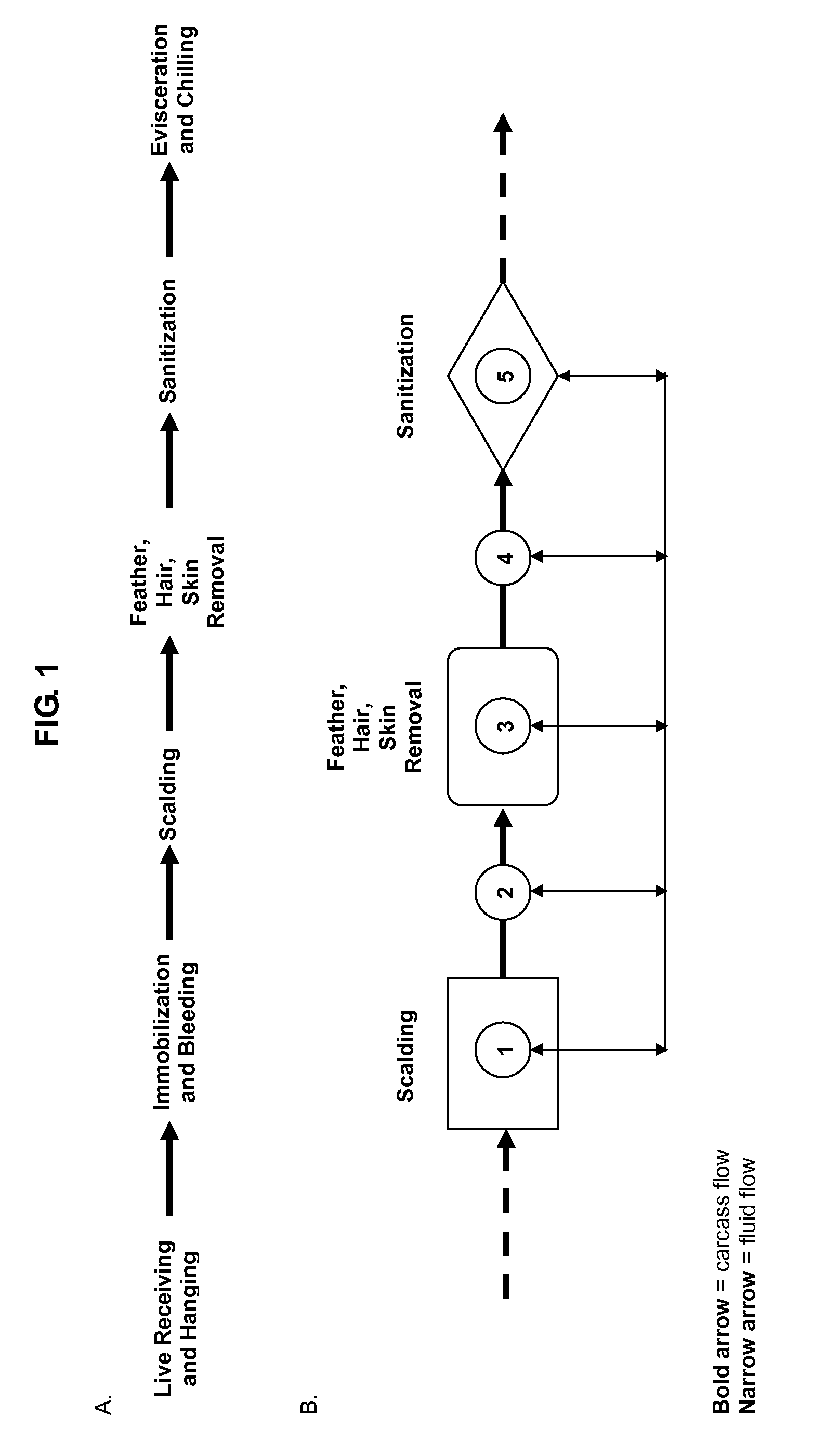

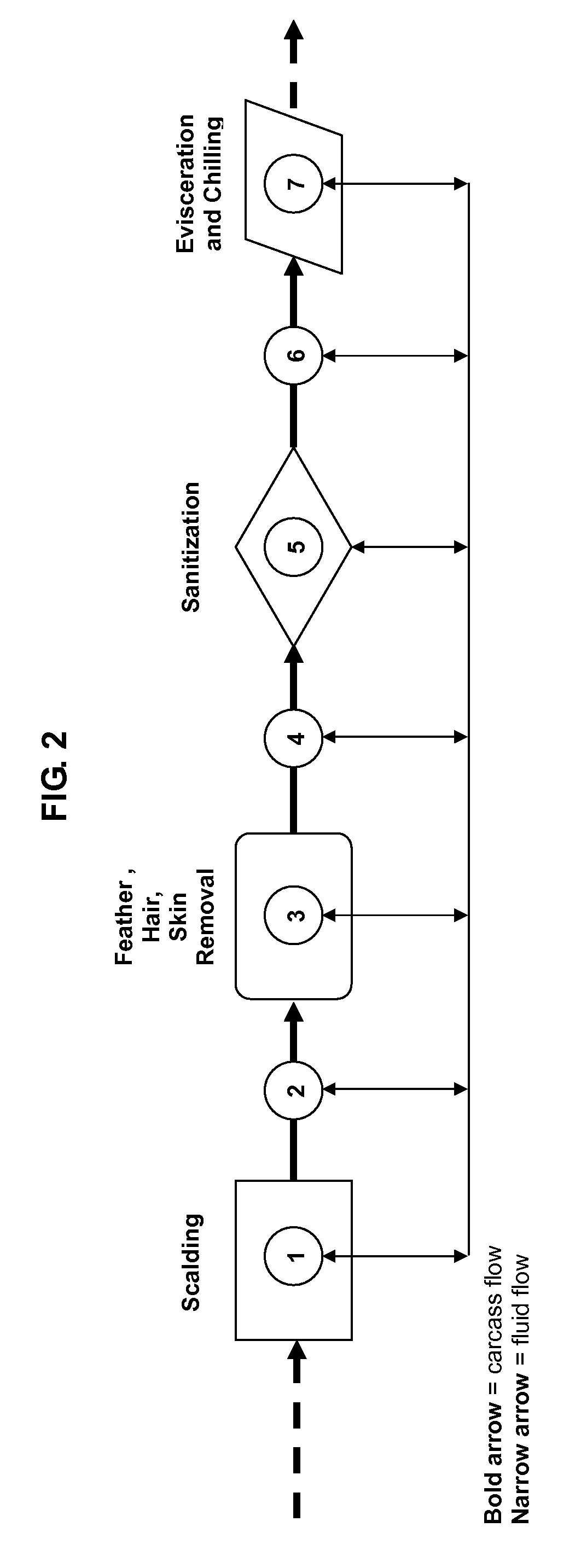

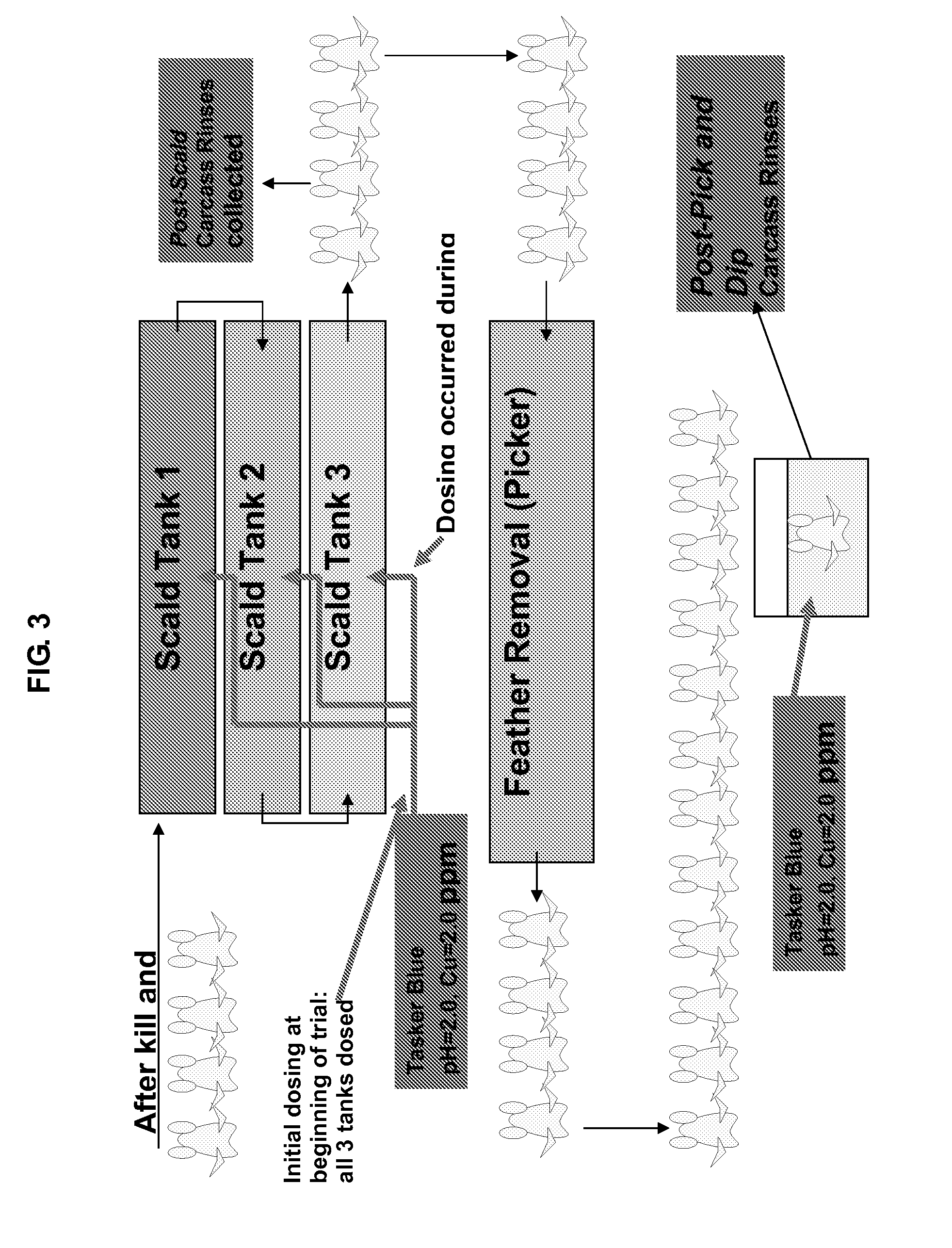

Compositions and methods for reducing microbial contamination in meat processing

InactiveUS20080213444A1Reduce pathogen contaminationHigh organic loadMilk preservationAnimal feeding stuffBiologyMetal

The present invention is directed to compositions, methods, and systems for reducing microbial contamination in meat processing. In accordance with one aspect of the invention, disinfection composition and / or recycled disinfection composition comprising an acid, a buffer, and optionally an antimicrobial metal is applying to a carcass during at least one processing step of sacrificing, scalding, feather / hair / hide removal, eviscerating, and washing. Other aspects of the invention provide a carcass processing system comprising processing stations intermittently fluidly connected via a buffered acidic disinfection composition.

Owner:TASKER PRODS

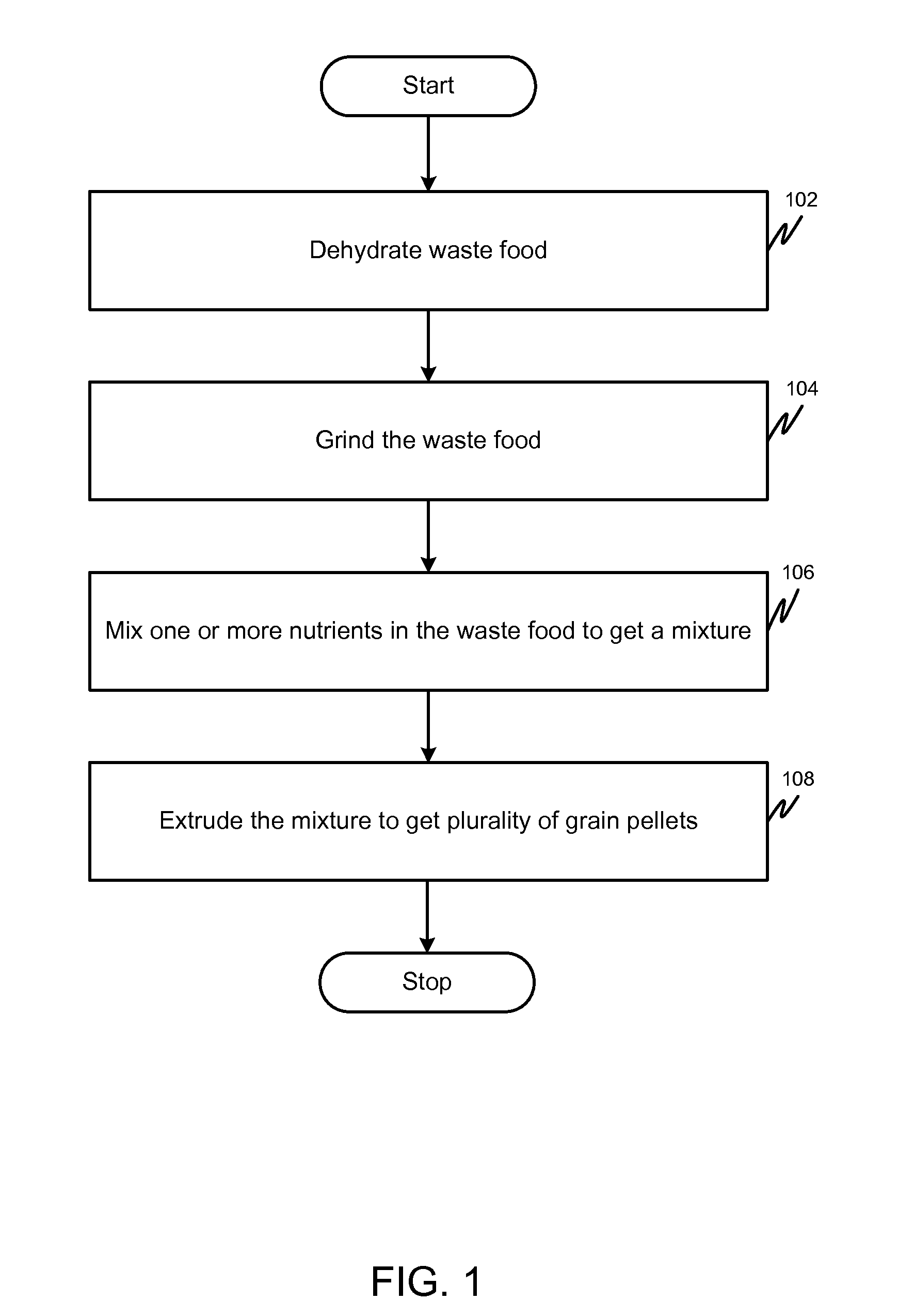

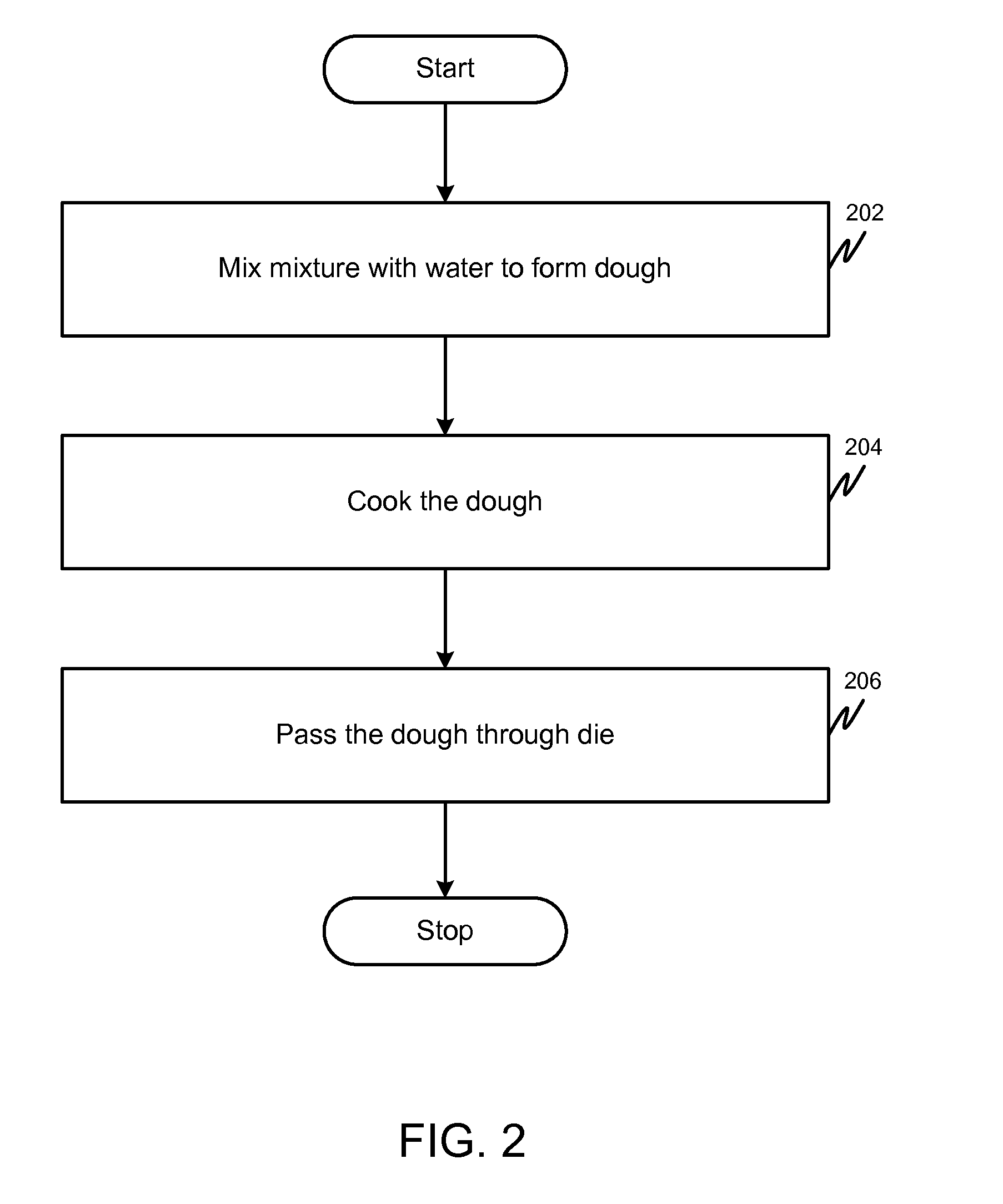

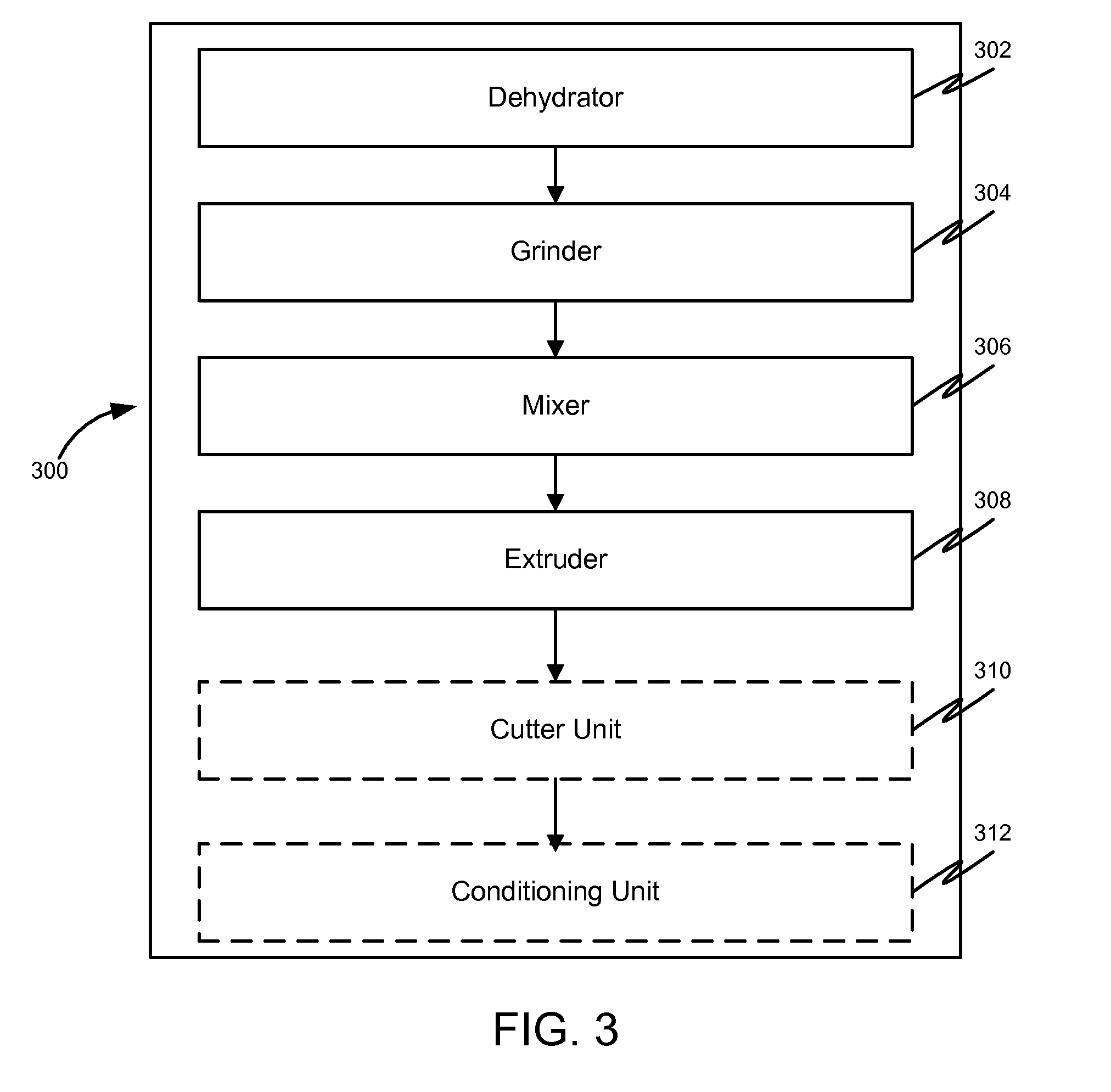

Method and system for deriving animal feed from waste food

A method and system for deriving animal feed from waste food is provided. The method and system involves dehydrating the waste food. The dehydrated waste food is grinded and mixed with one or more nutrients based on requirements of an animal. Thereafter, a mixture of the waste food and the one or more nutrients is extruded to obtain a plurality of grain pellets with a predetermined consistency. The plurality of grain pellets obtained after extrusion are cut to obtain a required shape and size for a grain pellet. Thereafter, the plurality of grain pellets are conditioned by adding one or more of fat, minerals and vitamins to the plurality of grain pellets. The plurality of pellets thus obtained are packaged and supplied as animal feed.

Owner:KING ABDULAZIZ CITY FOR SCIENCE AND TECHNOLOGY

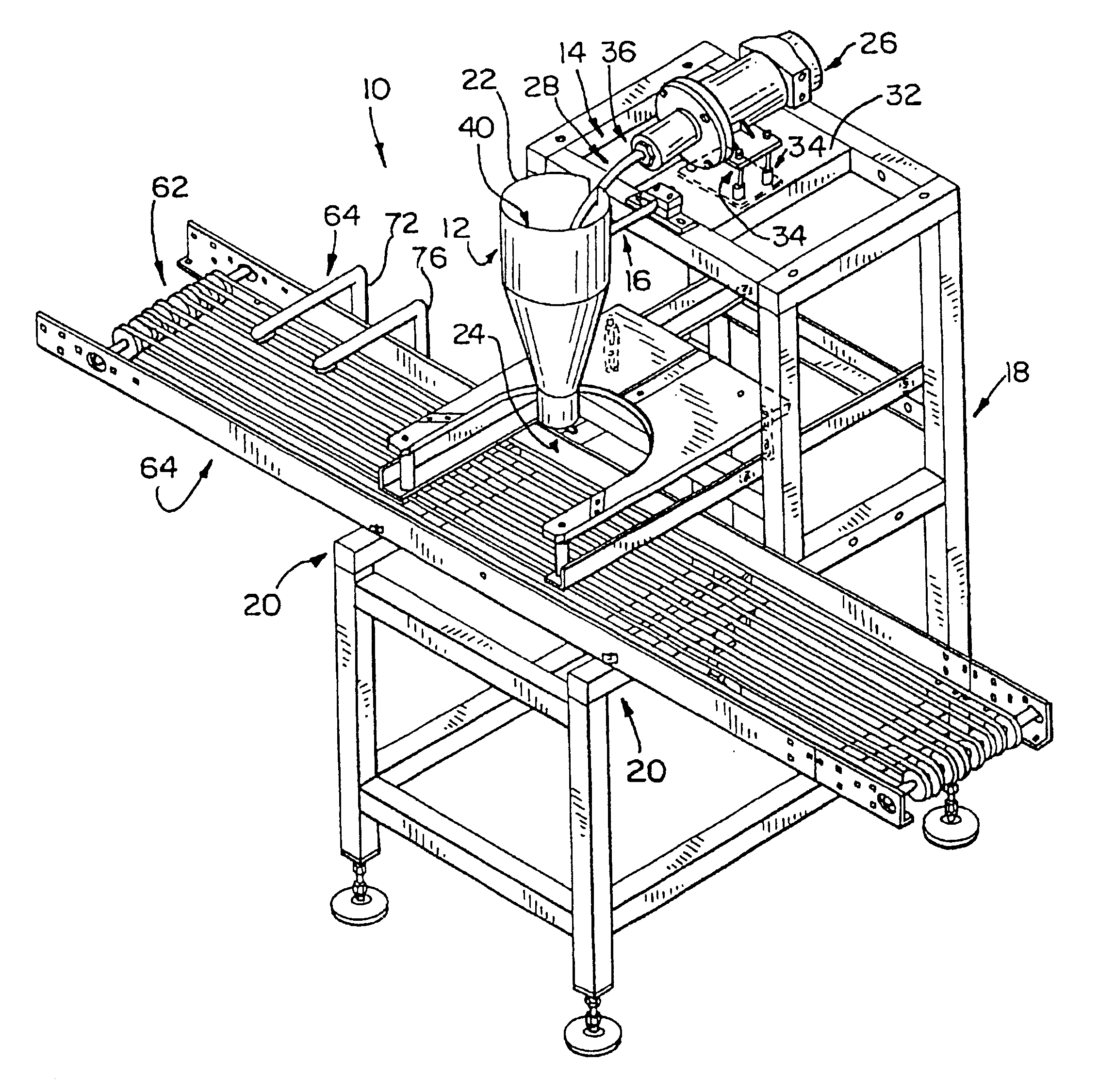

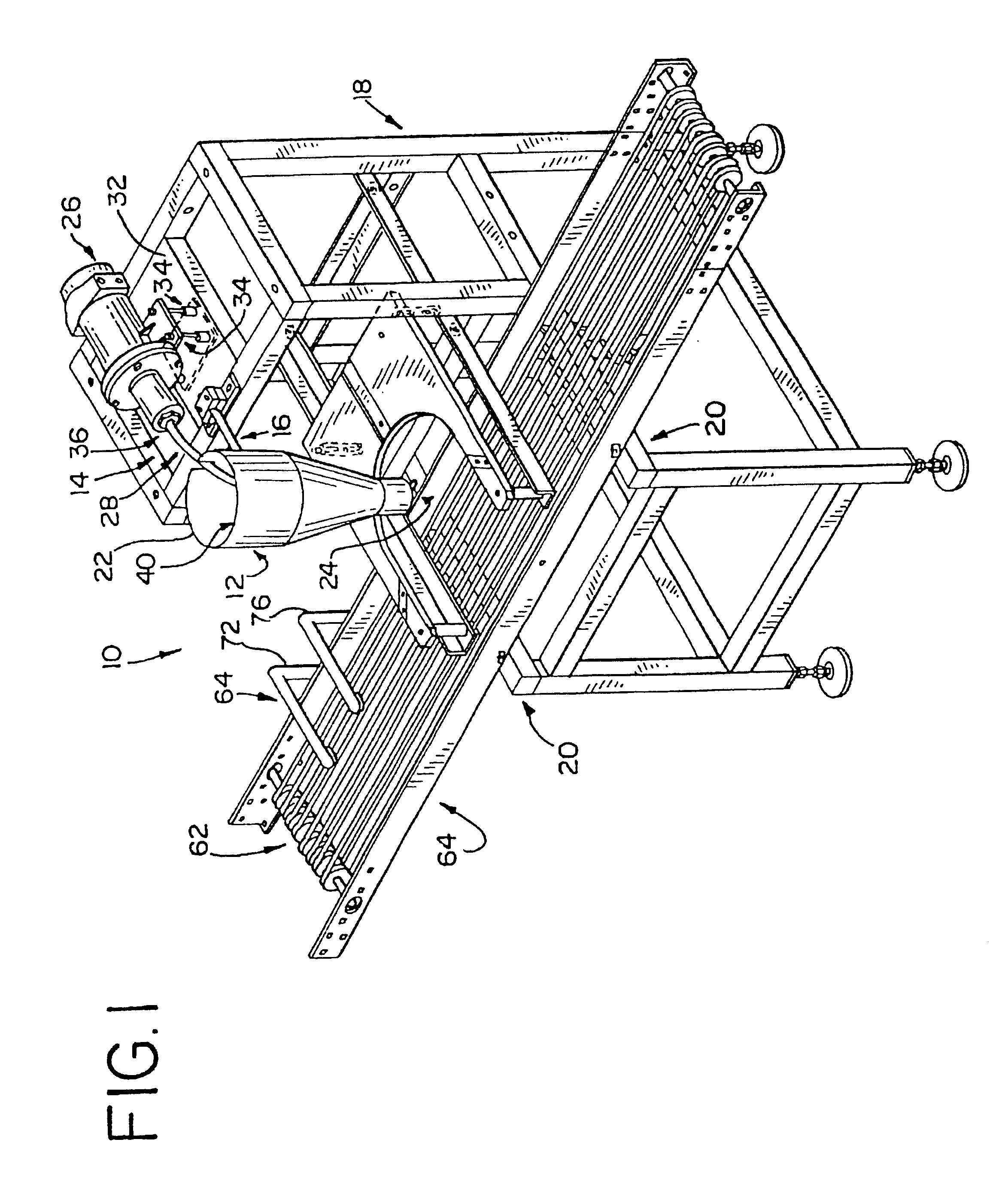

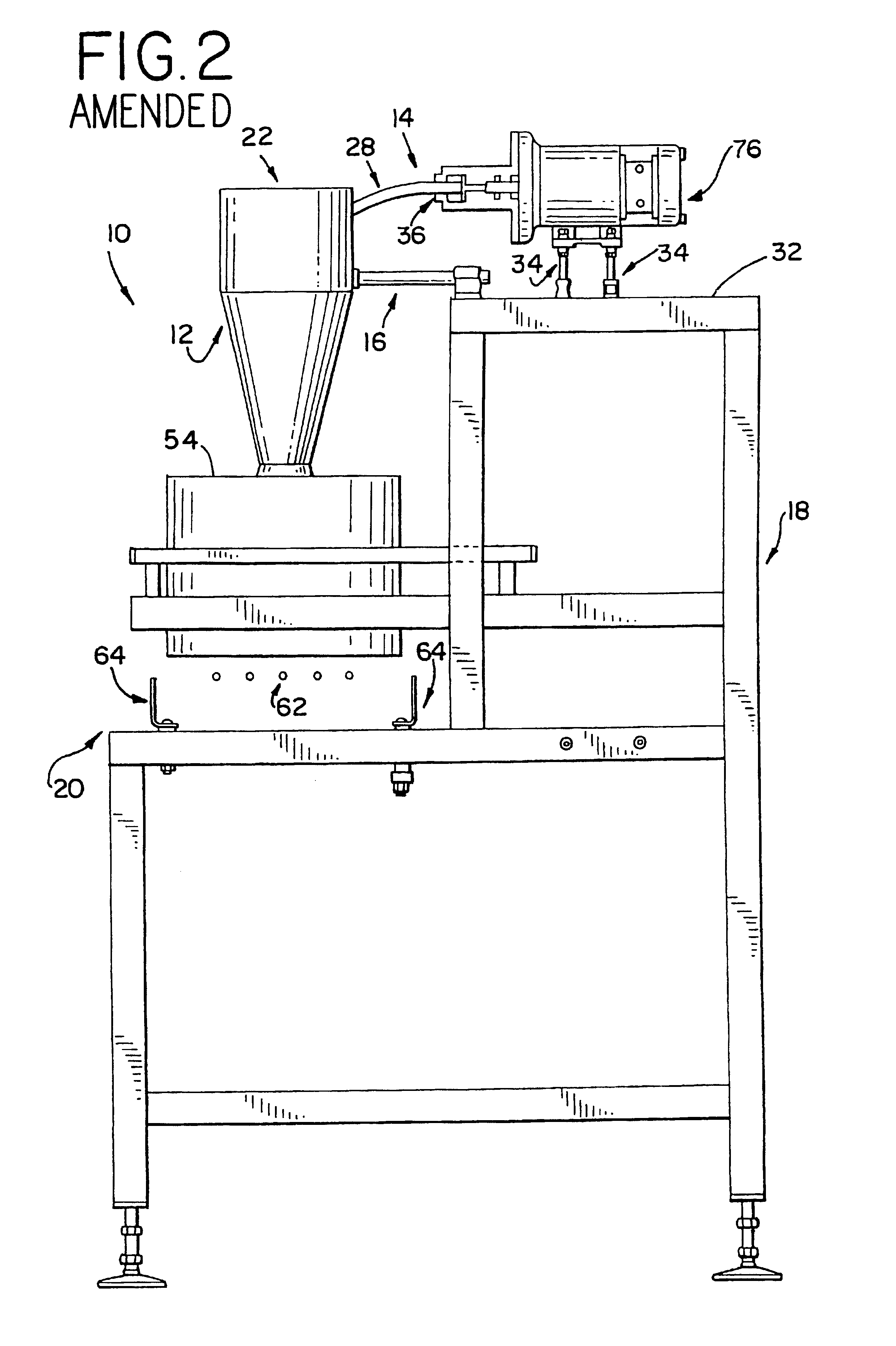

Apparatus for dispensing a quantity of material on a shell

A food material dispensing apparatus for adding a topping to a target food is described. The apparatus comprises a first hopper and a first food distributing system. The first hopper is adapted for receiving the food material at an inlet and delivering the good material through an outlet toward a target location. The first food distributing system is designed for spreading the food material over the target food. The food distributing system includes a motor positioned a horizontal distance from the inlet of the first hopper, a curved conduit, and a flexible, rotary shaft. The curved conduit has a proximal end and a distal end. The proximal end is releaseably connected to the motor, and the distal end is adapted for insertion into the hopper. The flexible, rotary shaft is for stirring and / or mixing the food material. The flexible, rotary shaft .[.passing.]. .Iadd.passes .Iaddend.through the curved conduit and is operatively connected at a first end to the motor .Iadd.and at a second end to a distributing blade. The apparatus can be operated to dispense food material either on sequential target foods that advance on a stop-and-go conveyor belt, or on virtually stationary transfer belts that then advance and deliver food material thereon to sequential target foods that are advancing on a continuously operating conveyor belt.Iaddend..

Owner:J E GROTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com