Patents

Literature

75results about "Multilayer sausage casings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

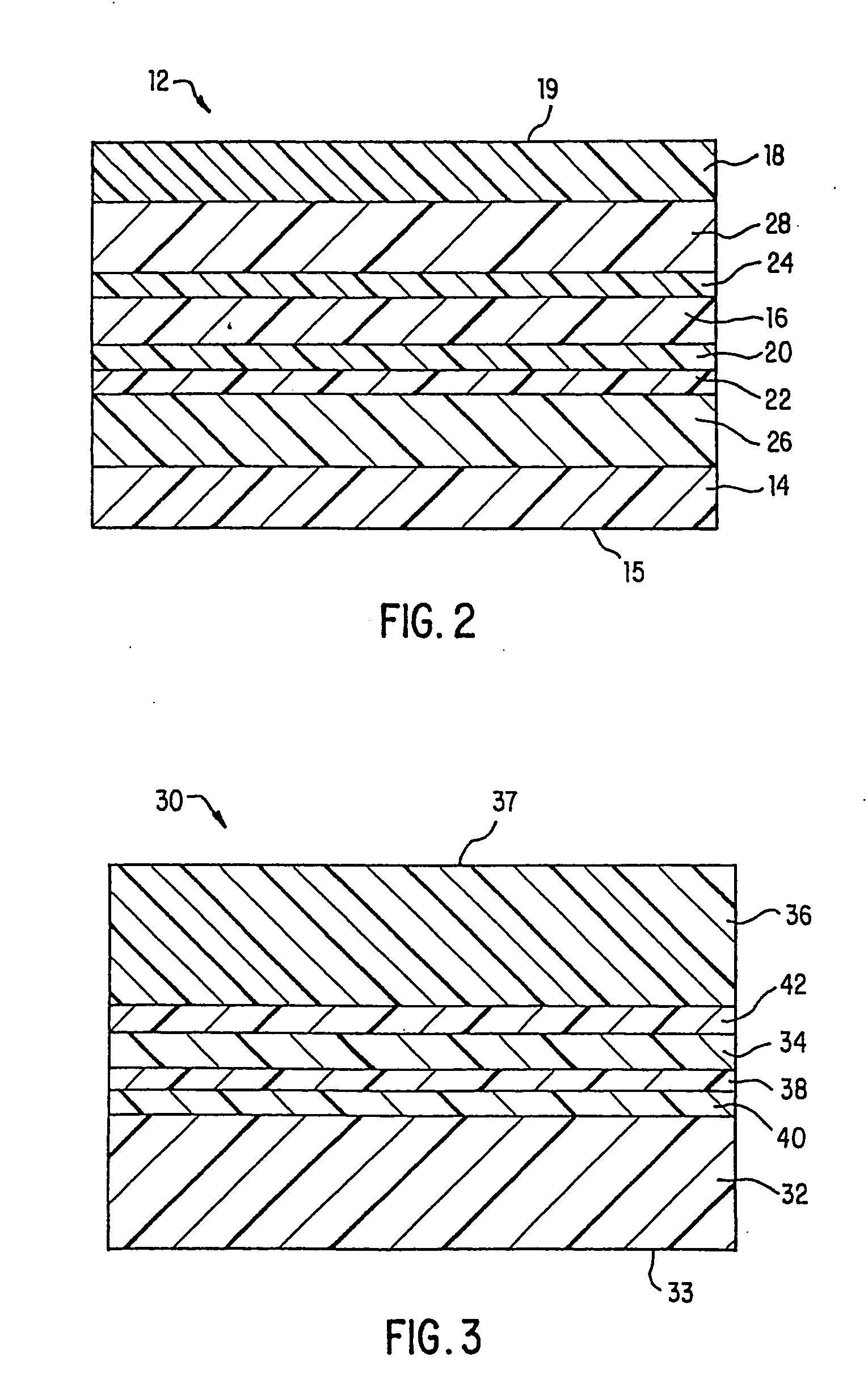

Food casing with barrier action for oxygen and/or water vapor and suitable for absorbing and storing a food additive and releasing it to the food

InactiveUS20090214722A1Avoid weightPrevents aroma lossThermoplastic sausage casingsMultilayer sausage casingsFood additiveWater vapor

The present invention relates to a multilayer seamless tubular film as a food casing with barrier action for oxygen and / or water vapor, which is capable of absorbing and storing a food additive and releasing it to the food. It is used as an envelope of pasty or liquid materials and is particularly suitable as a synthetic sausage casing. The invention further relates to a particular liquid smoke composition which, in combination with such a tubular film, is particularly suitable for transferring the dyes and flavorings present to the food.

Owner:CASETECH

Moisture and gas permeable non-porous ionomeric films

Moisture and gas permeable ionomeric films are described. The films described herein are obtained from blends of ionomers with an organic acid salt in the amount of at least about 5 wt %, and have MVTR greater than films obtained from conventional ionomers. Particularly preferred are the potassium salts of stearic, oleic, isostearic, and isooleic acids. Films comprising a liquid-absorbent ionomer film layer and an impermeable layer are provided. The films are suitable for preparation of tubular casings and shrinkbags, in particular, casings for smoked foodstuffs.

Owner:PERFORMANCE MATERIALS NA INC

Films comprising liquid smoke and flavorants

InactiveUS20090155430A1Thermoplastic sausage casingsMultilayer sausage casingsLiquid smokeEngineering

A process for producing a film having incorporated or applied thereon or therein an additive such as liquid smoke is provided wherein the film comprises a liquid absorbent layer and an impermeable layer. The films can be used for producing a tubular casing or shrinkbag.

Owner:EI DU PONT DE NEMOURS & CO

Smokable polymeric casing

InactiveUS20050163948A1Easy to disassembleImprove performanceMultilayer sausage casingsSmokable sausage casingsPolyvinyl alcoholThin membrane

A novel shrinkable monolayer film that may be produced as a film or a tube, as in a food casing. This newly disclosed film is a blend of a polyamide base, a novel polyvinyl alcohol and optionally, an antiblocking agent.

Owner:VISCASE CORP

Films comprising a liquid-absorbant inner layer and an impermeable outer layer

InactiveUS20040146610A1Multilayer sausage casingsSynthetic resin layered productsEngineeringPolymer science

Owner:PERFORMANCE MATERIALS NA INC

Flavor release casing

InactiveUS20060057258A1Simple preparation processUnique flavorThermoplastic sausage casingsMonolayer sausage casingsFlavouring agentFood flavor

The present invention relates to shirred, nonfibrous casings internally coated with compositions of concentrated oil-based natural flavorants which transfer to foodstuffs, such as sausage meats, encased during cooking, resulting in foodstuffs flavored by the internal casing coating.

Owner:VISCASE CORP

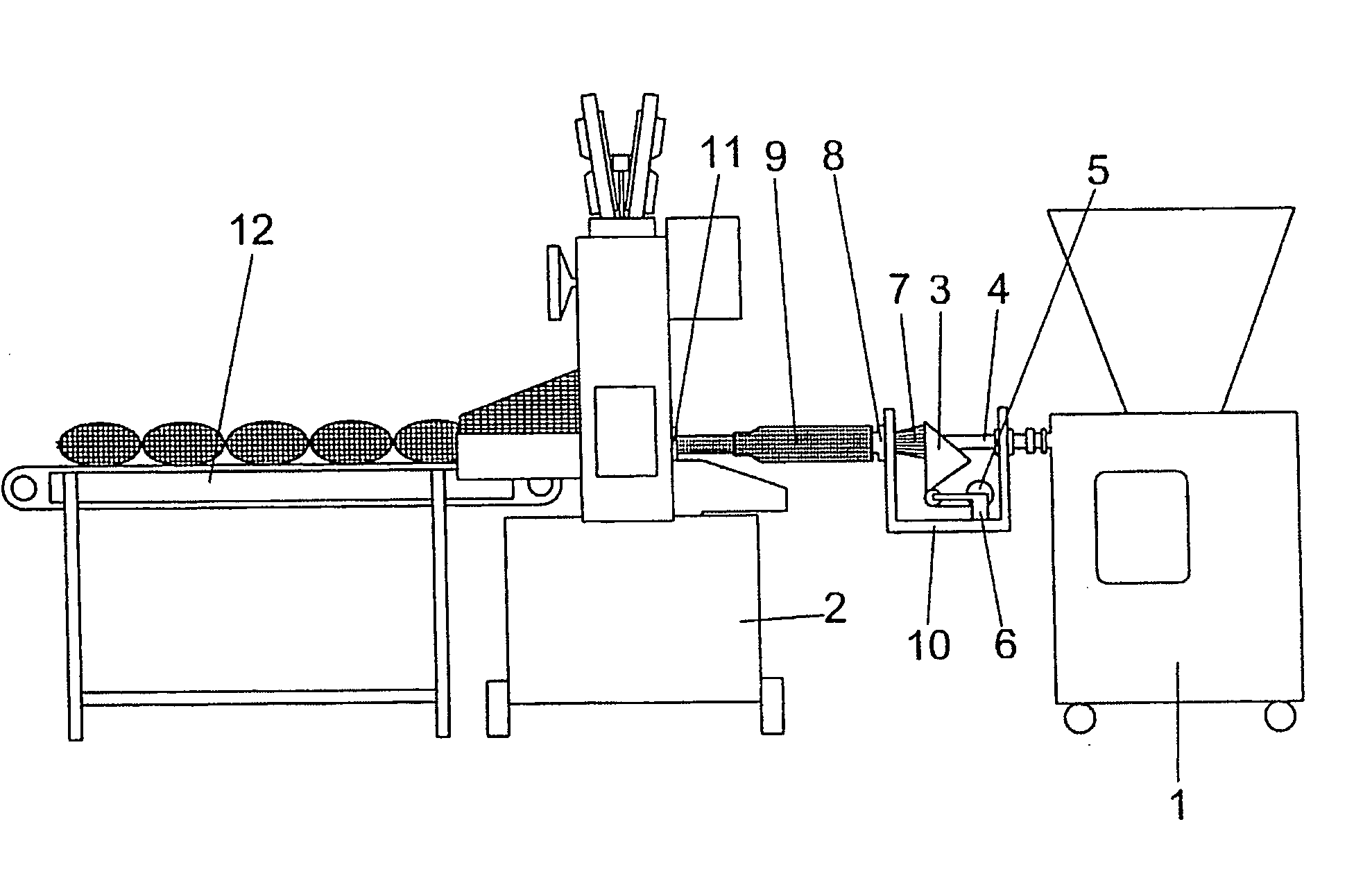

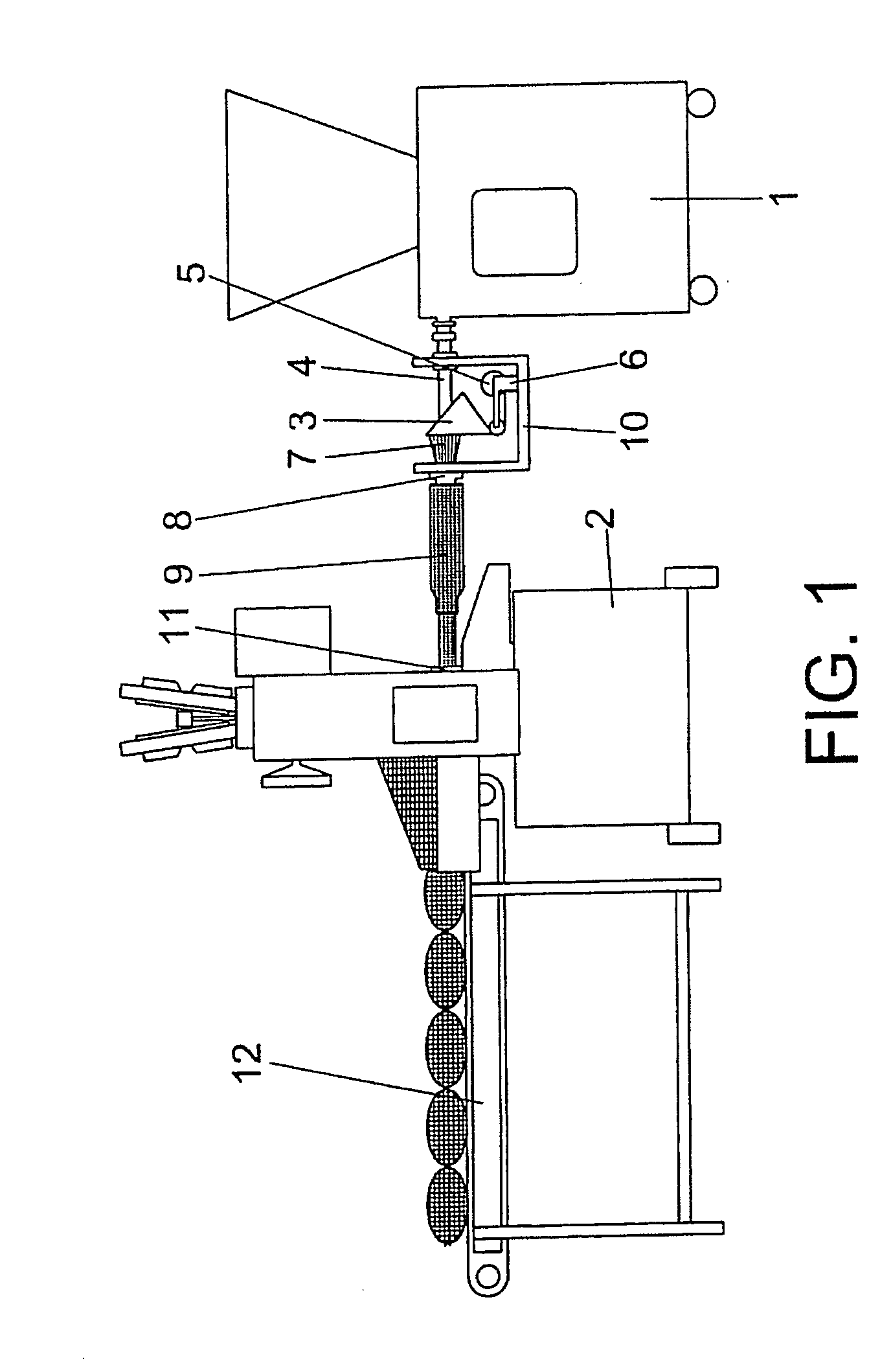

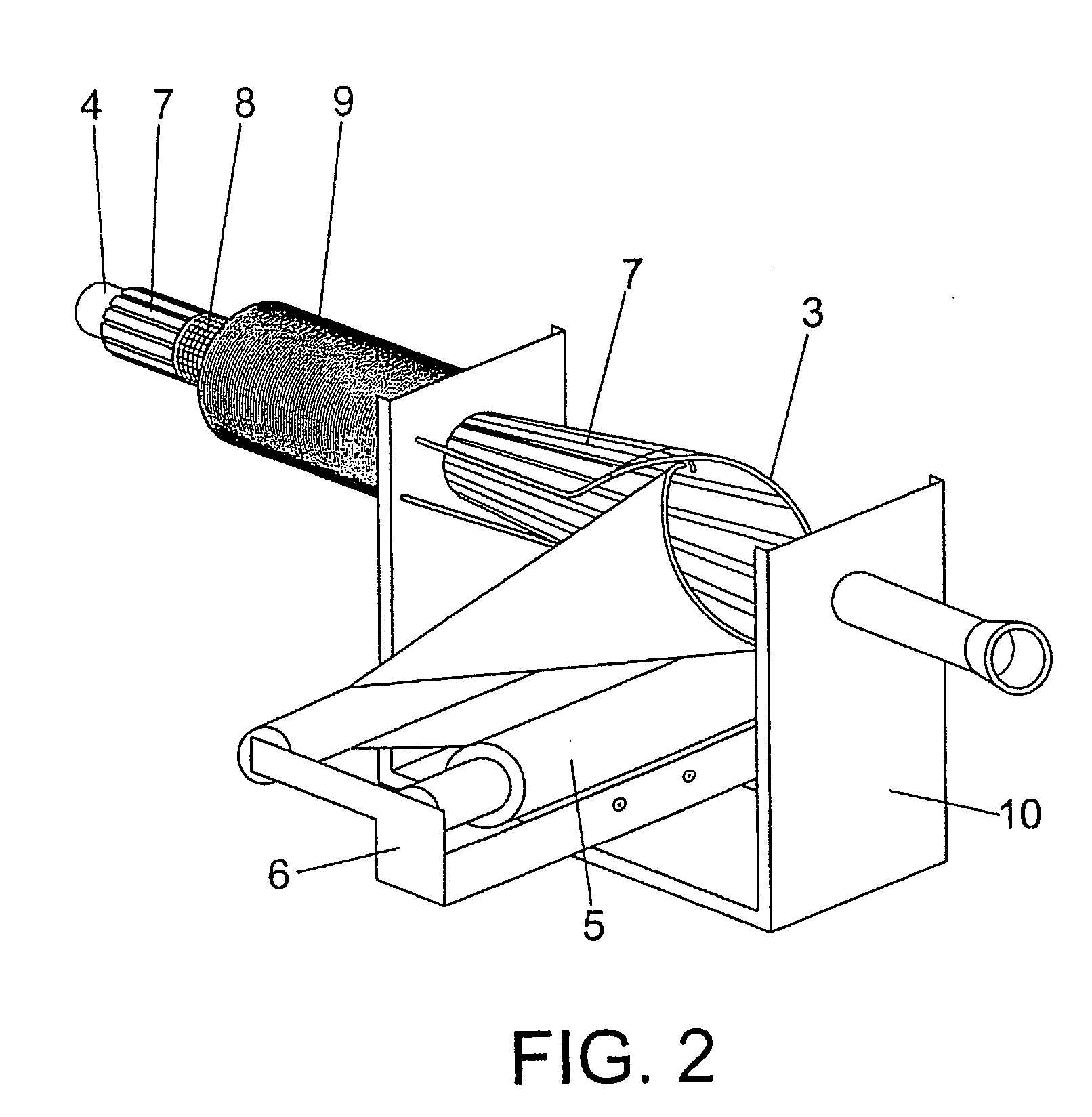

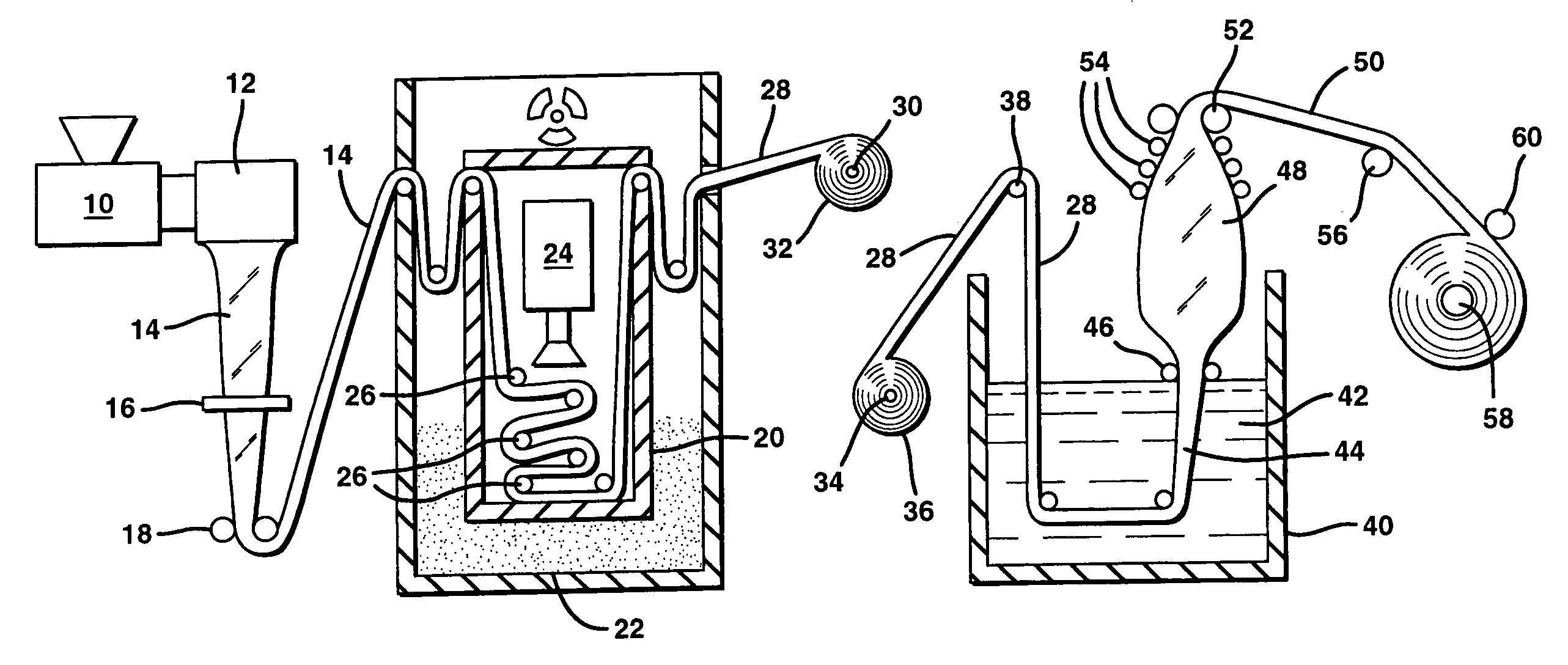

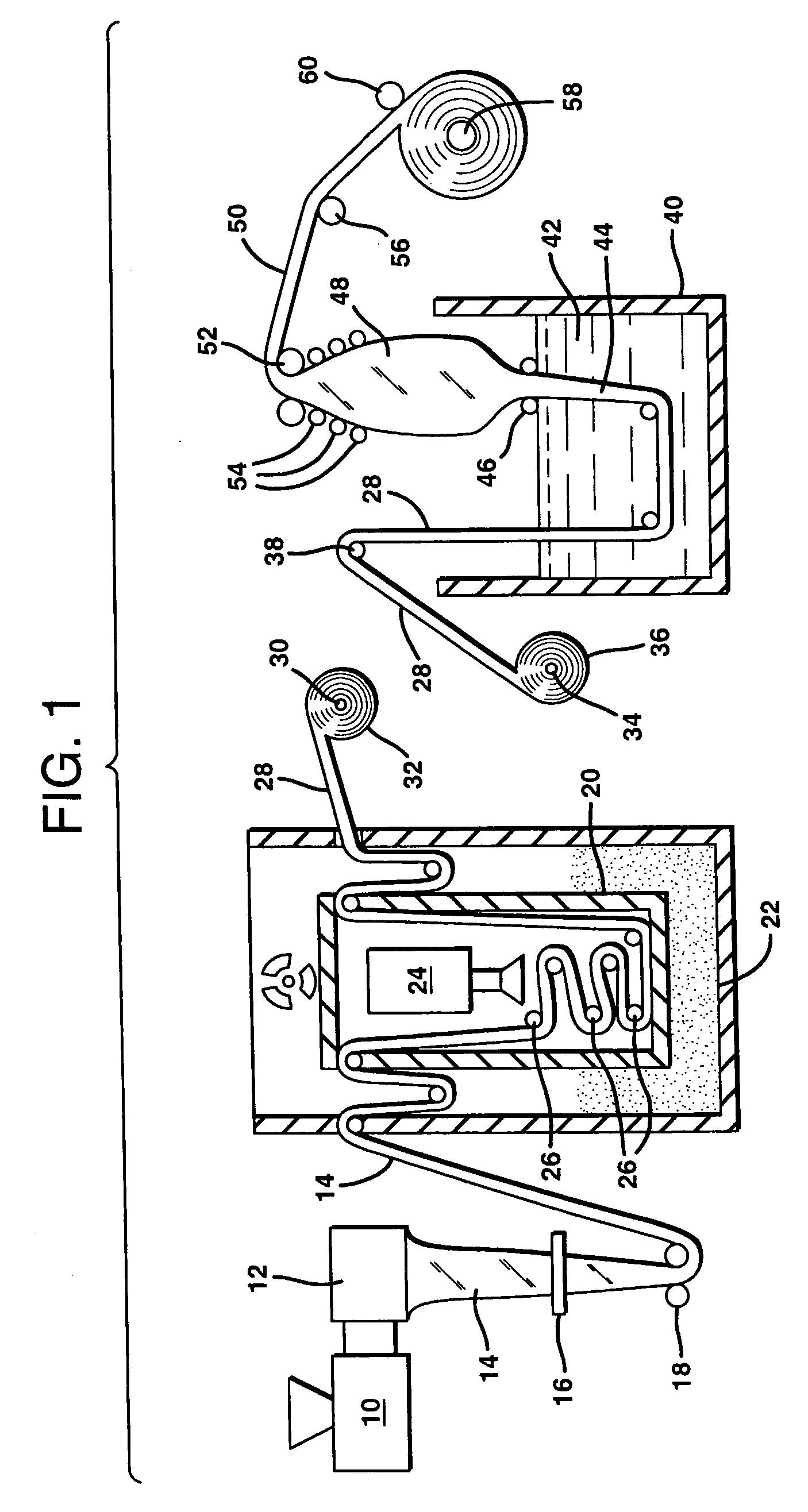

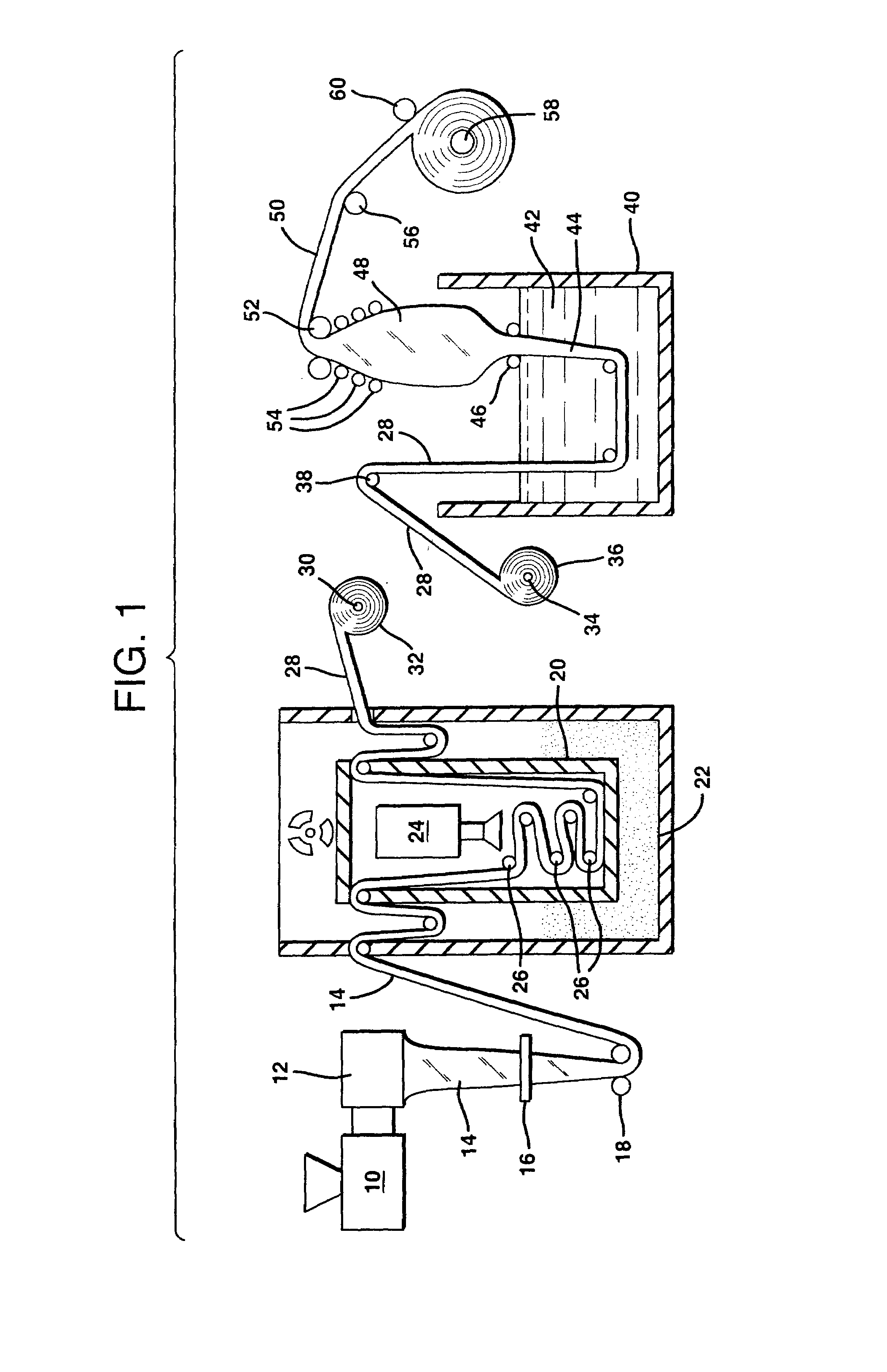

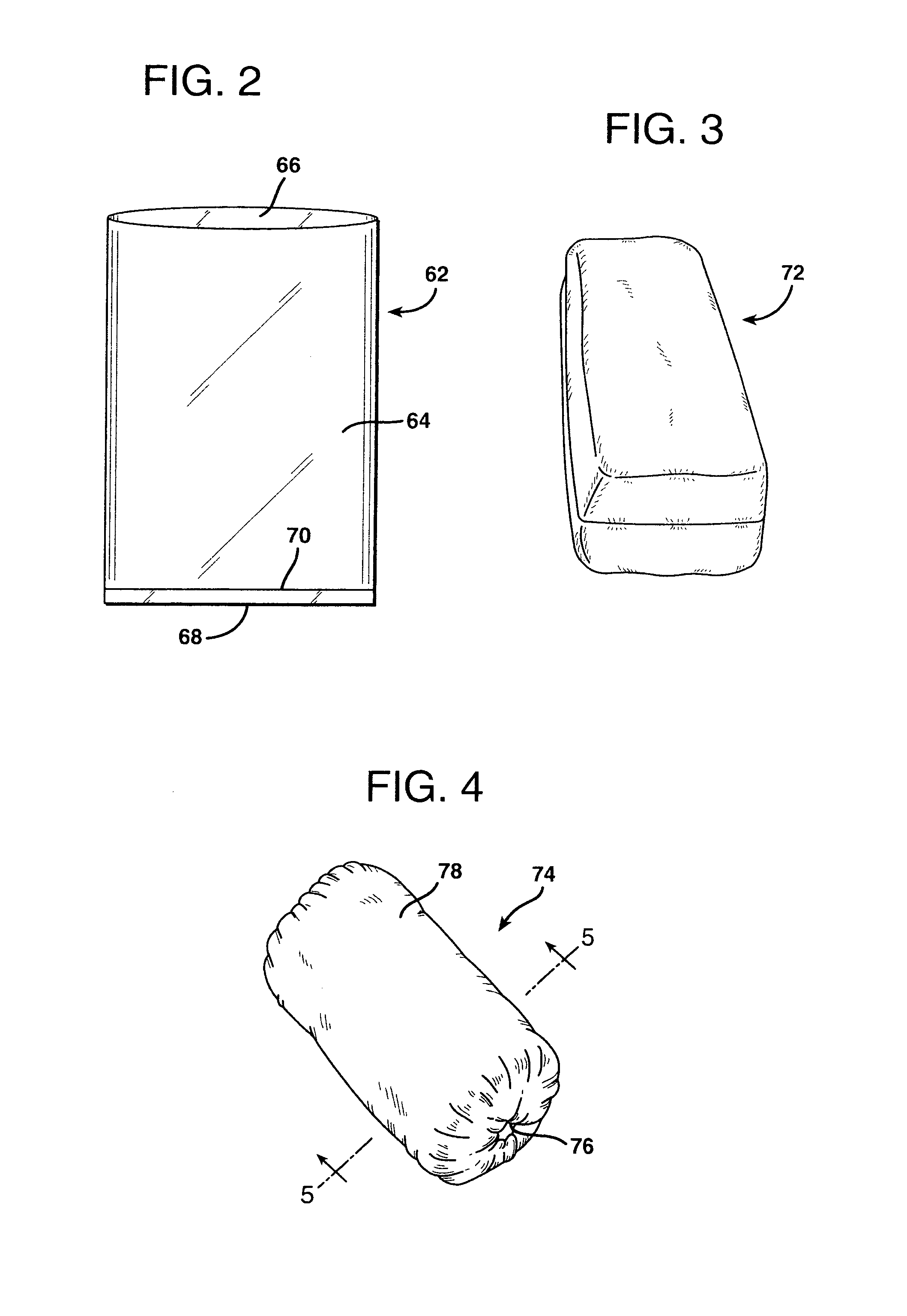

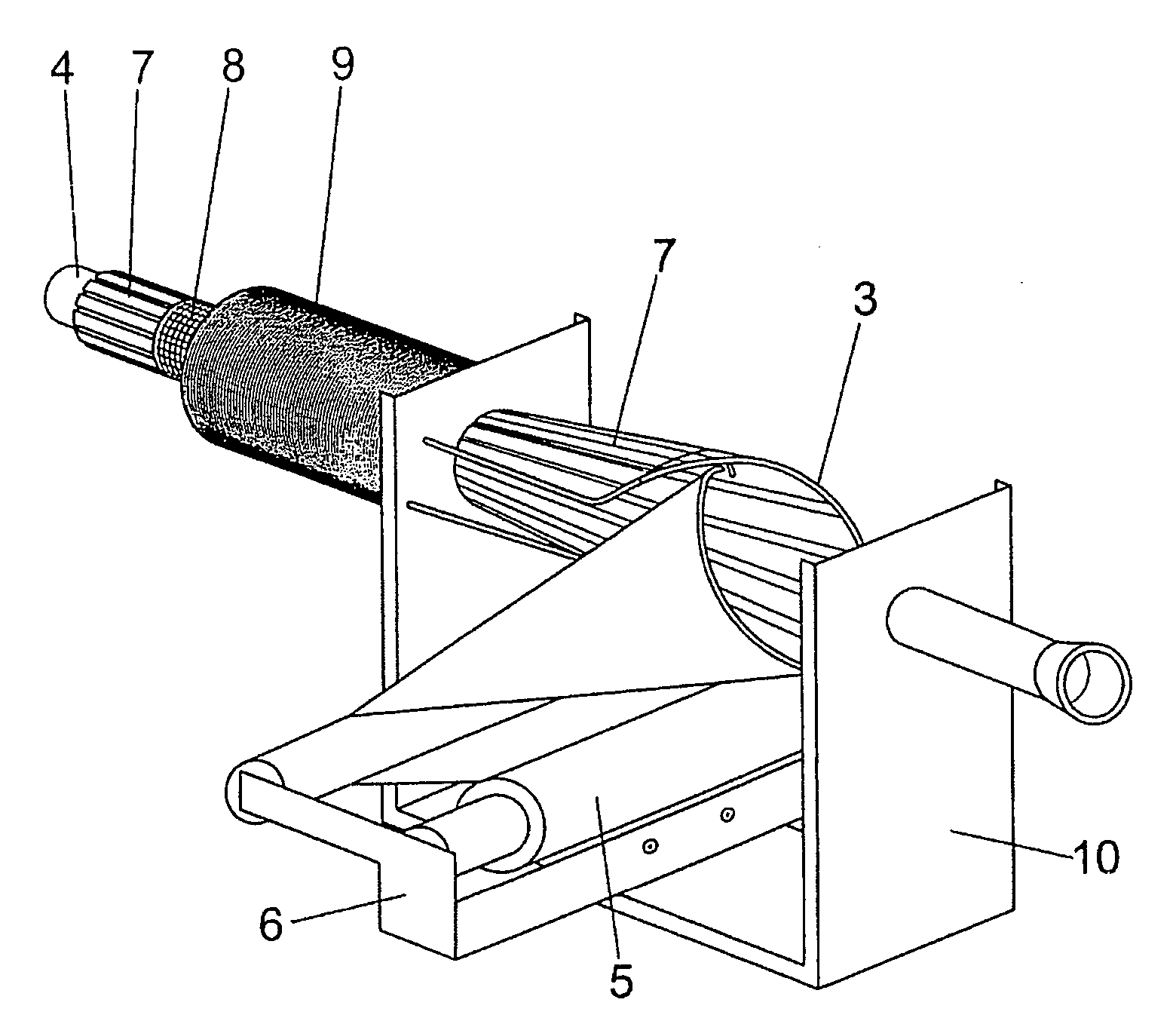

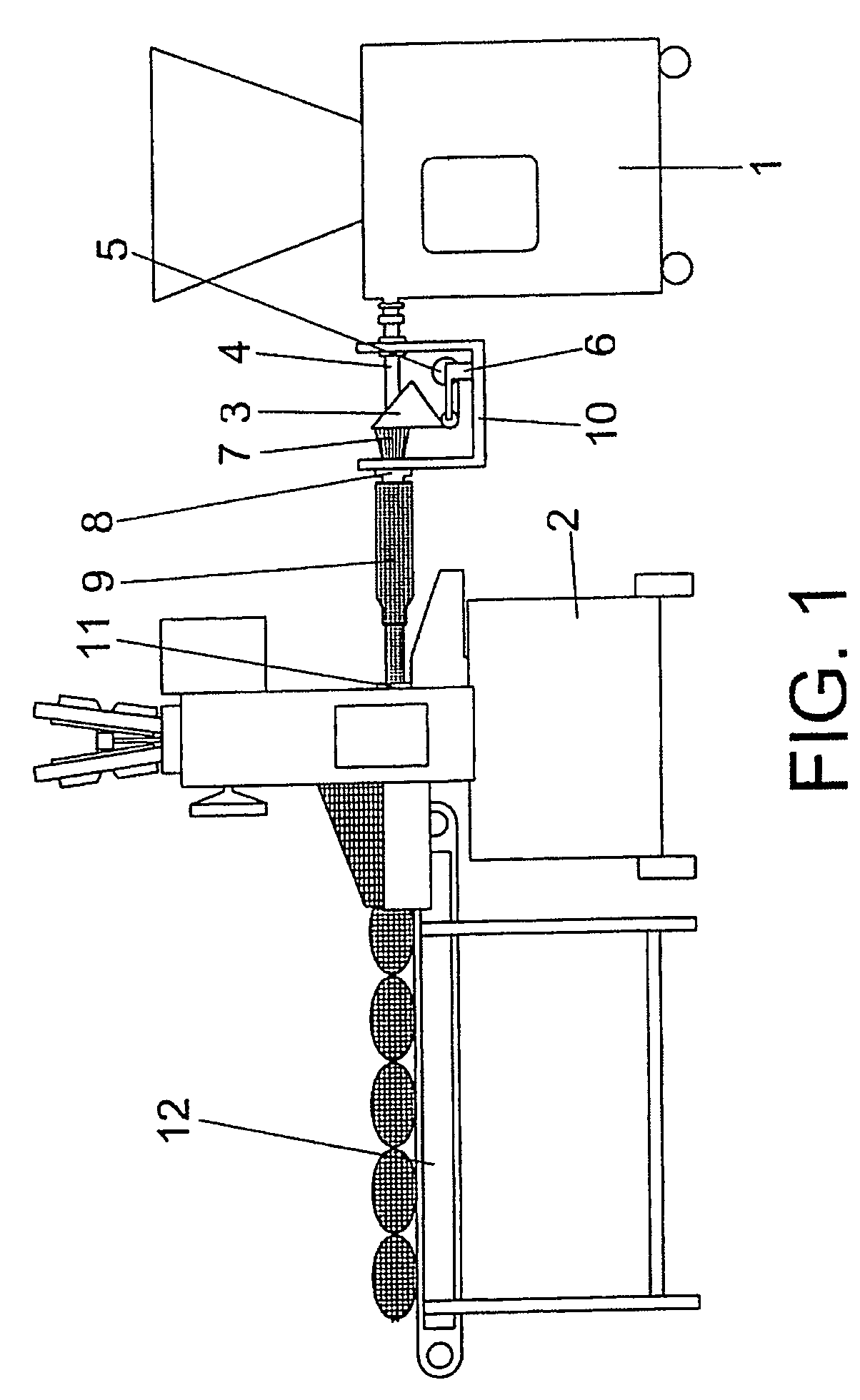

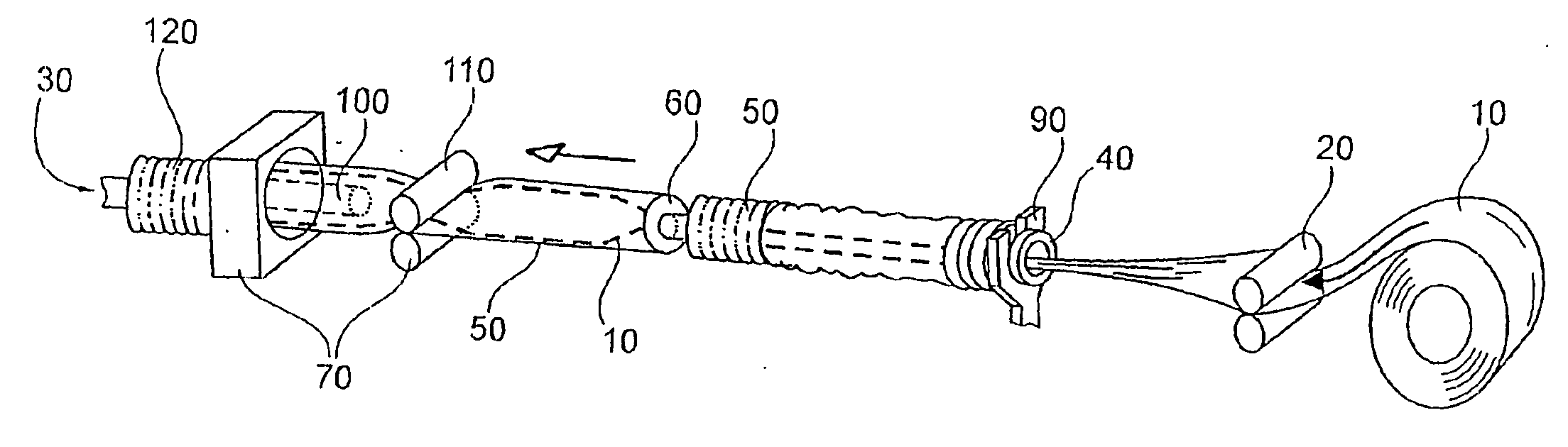

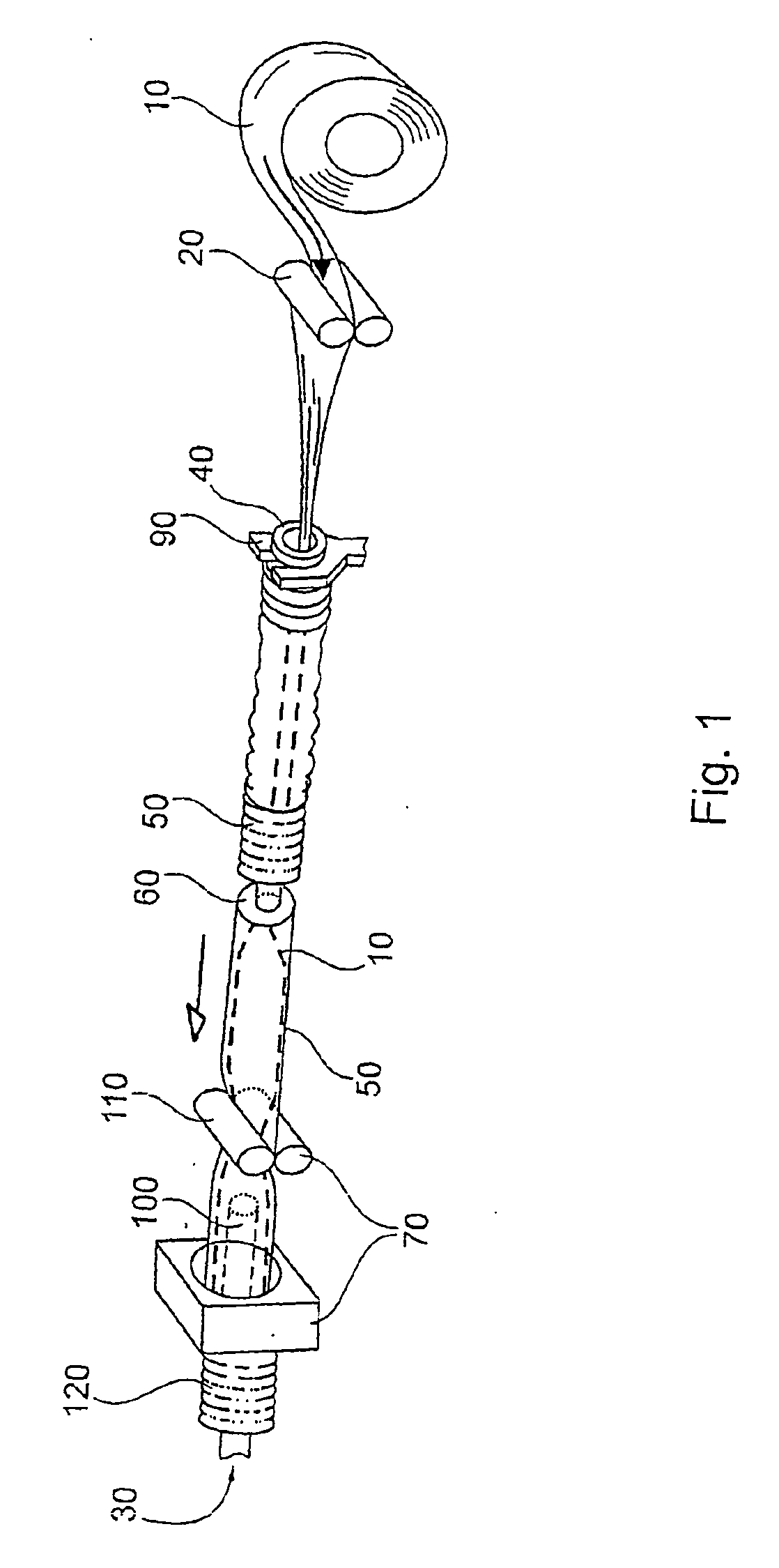

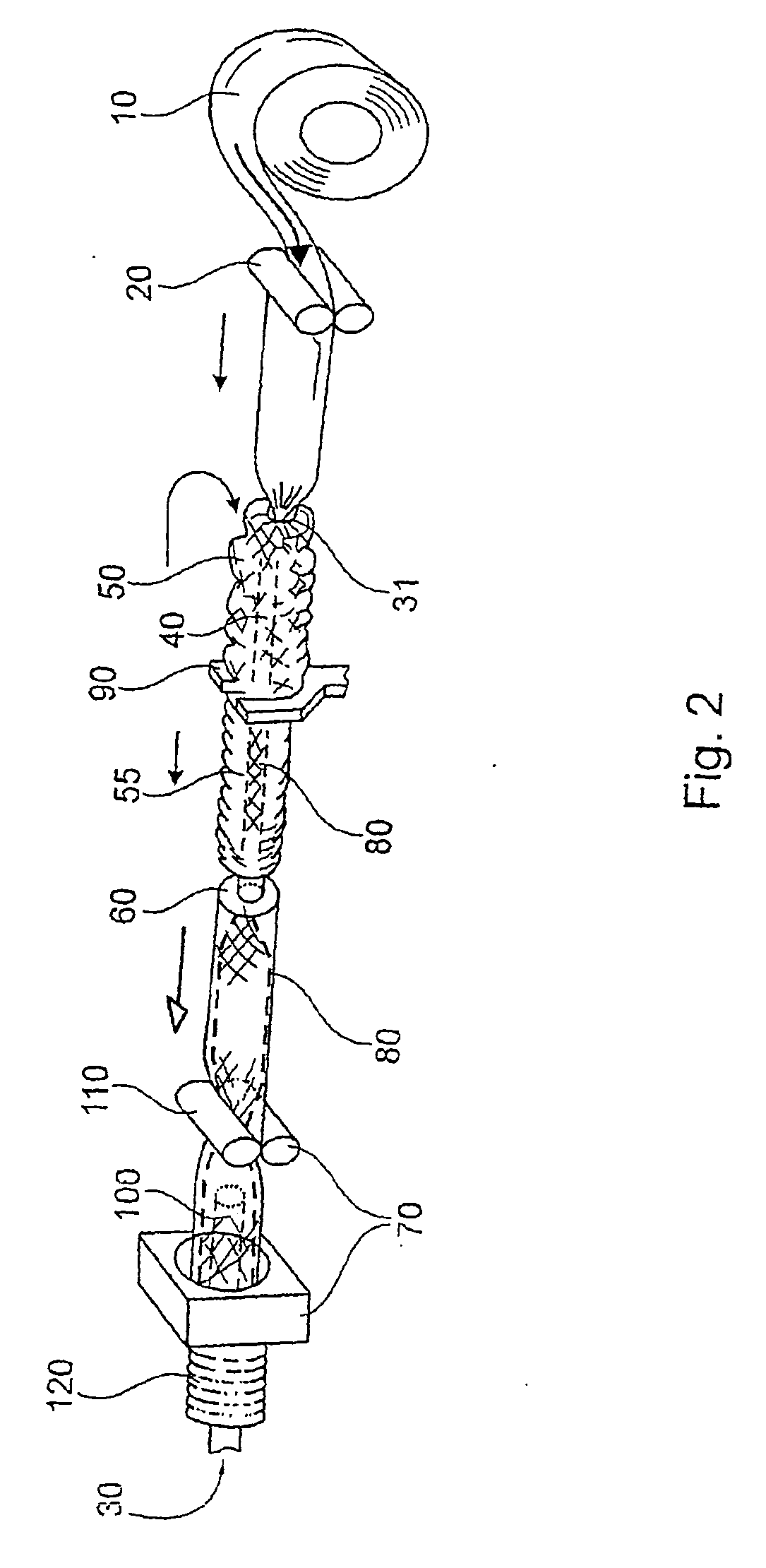

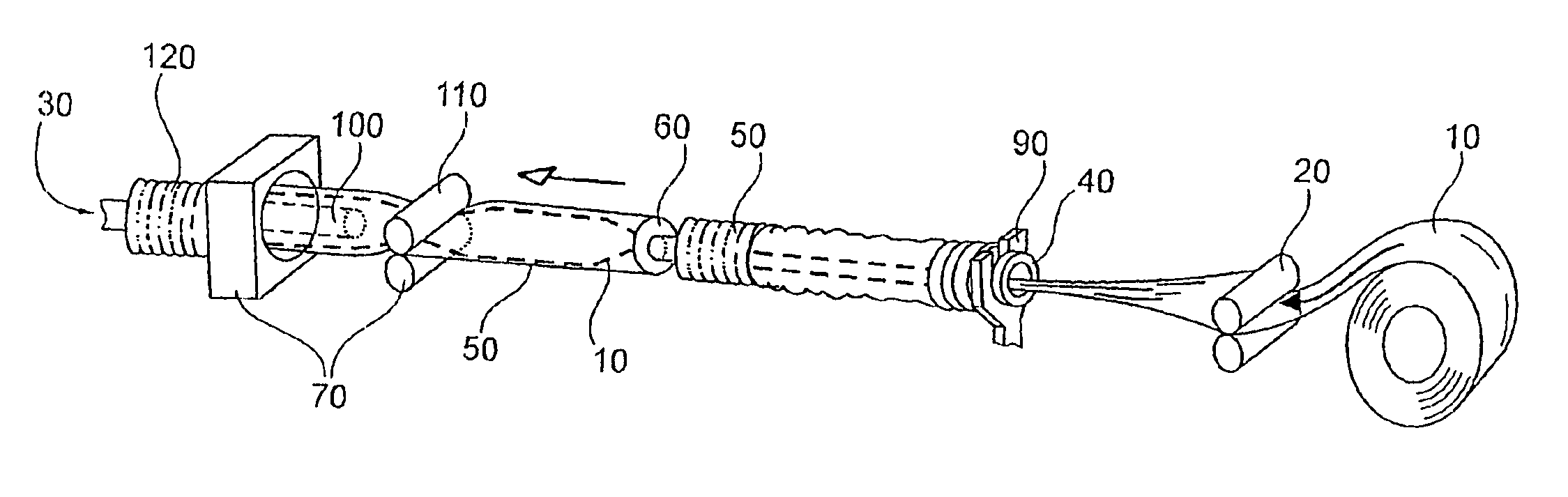

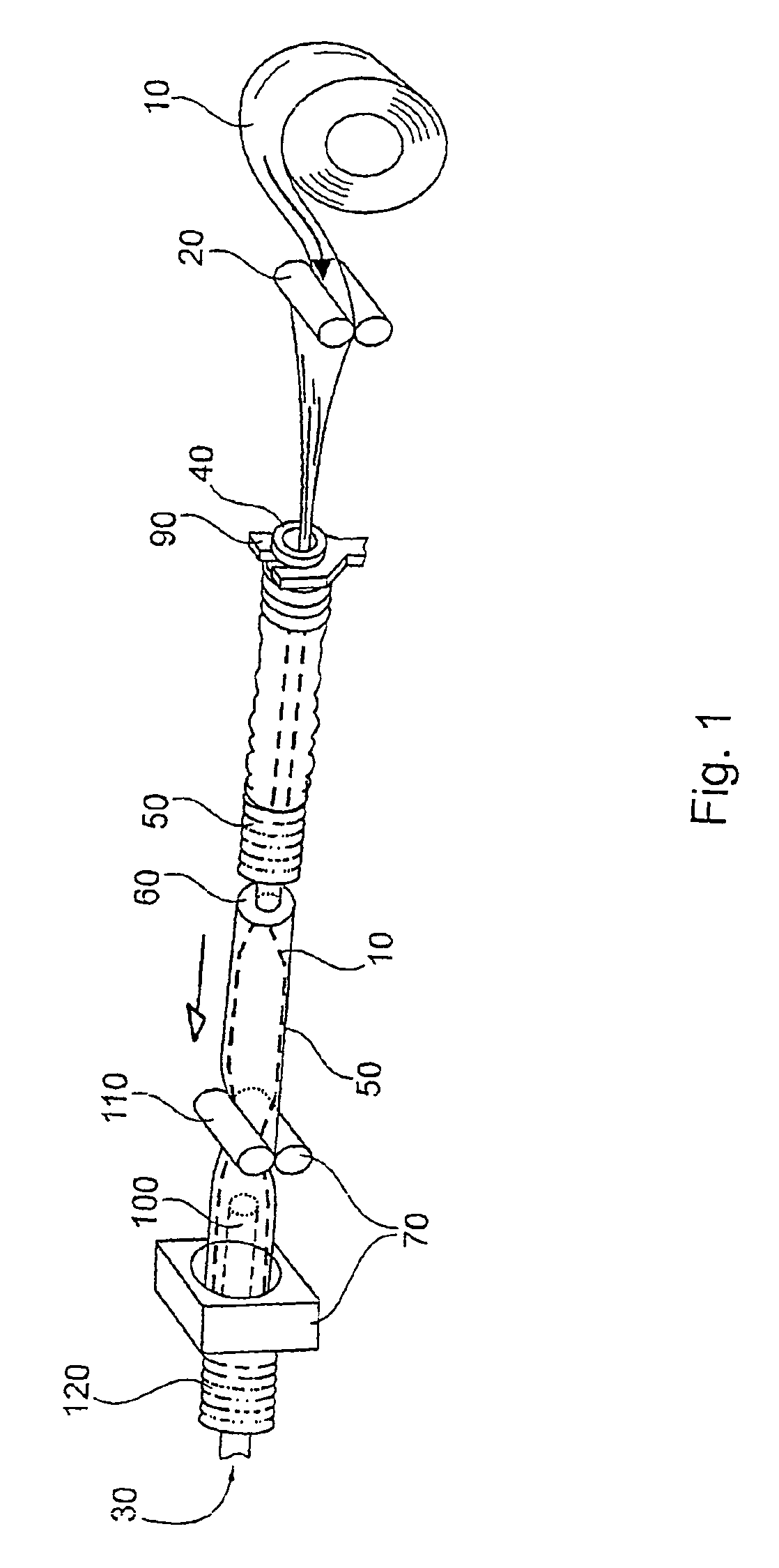

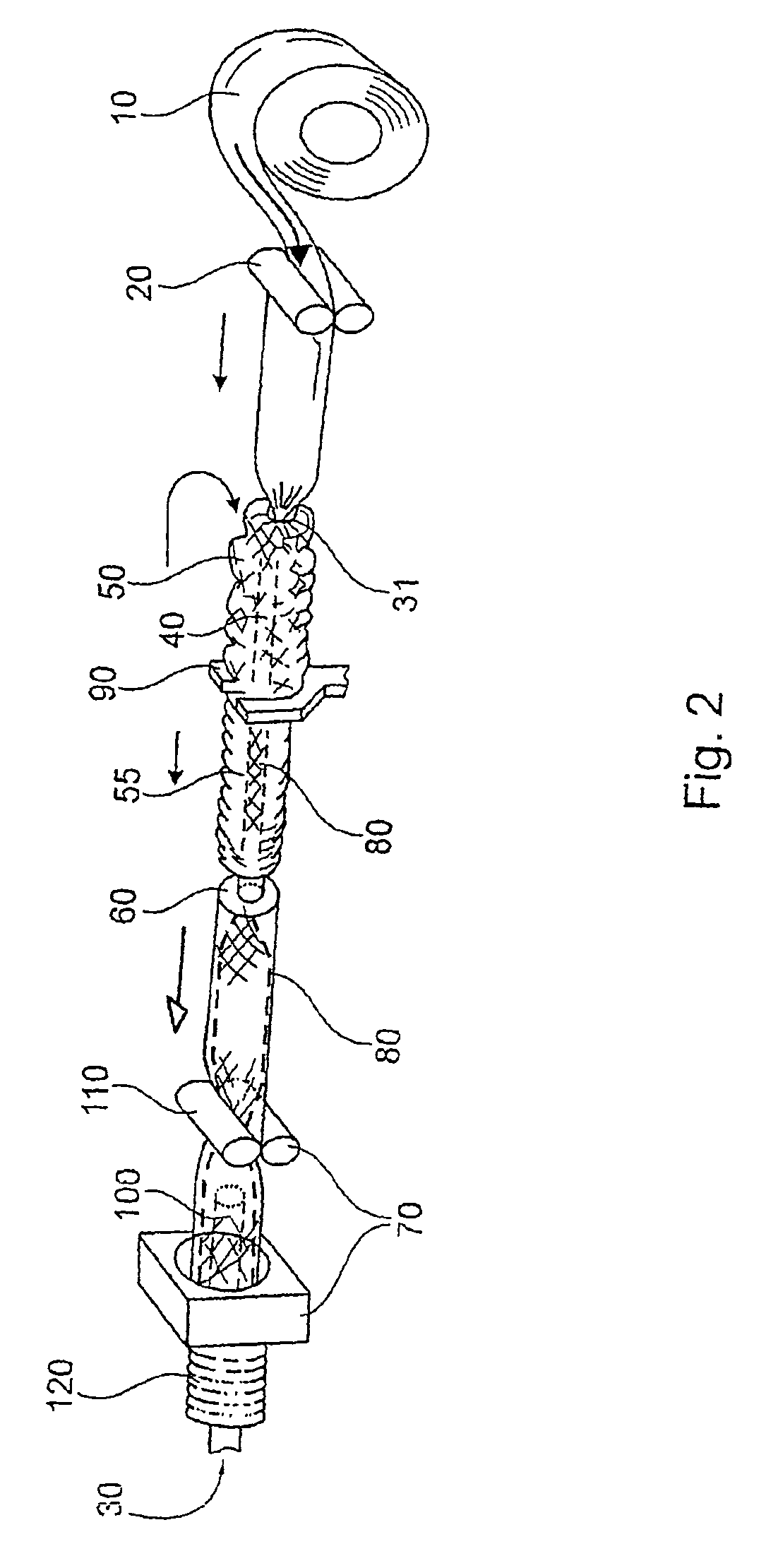

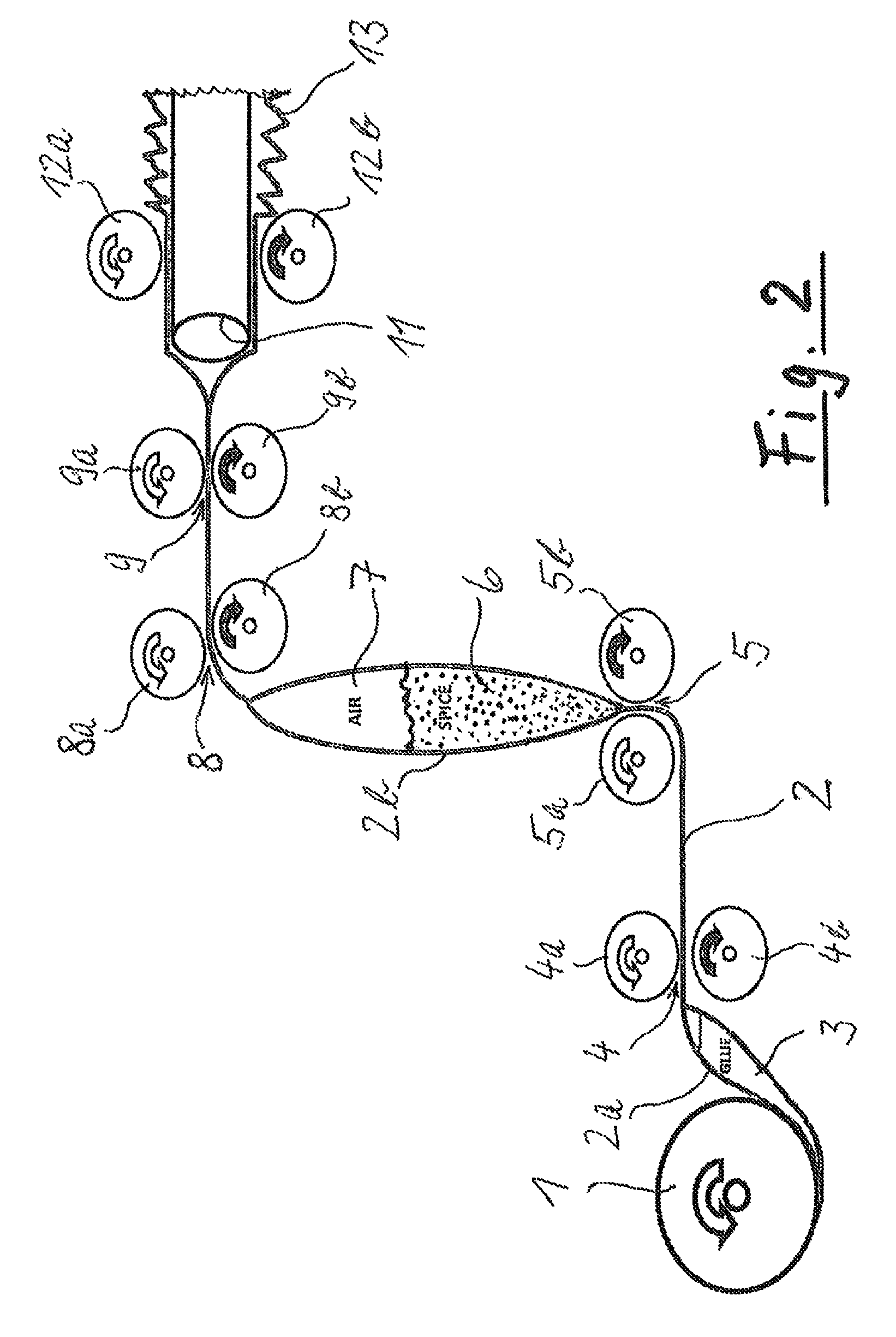

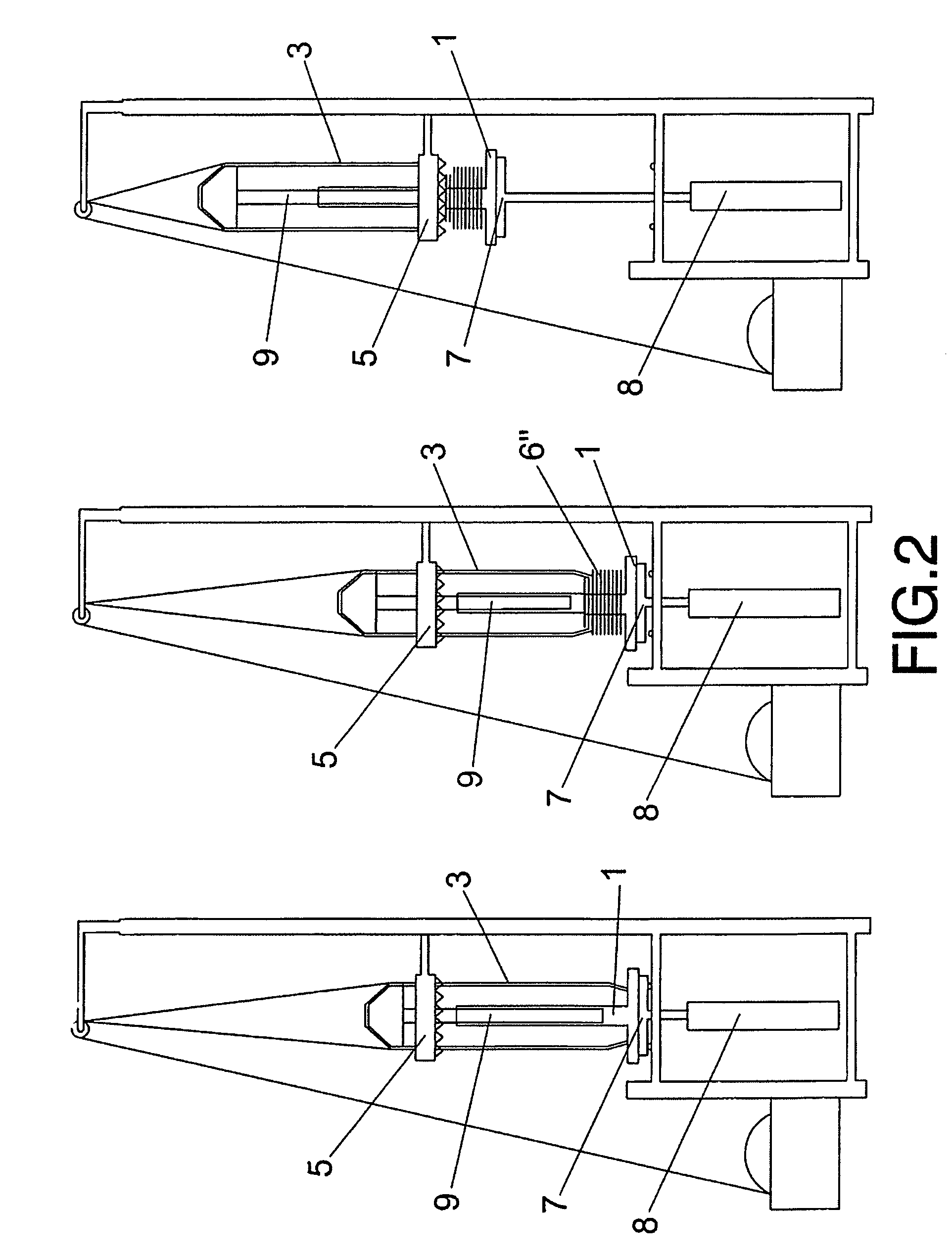

Method and apparatus for the automatic stuffing of meat products into a double casing comprising a sheet and a net

ActiveUS20050126403A1Increase speedImprove load effectMultilayer sausage casingsSkinless sausage makingAutomatic testingFood products

Based on a conventional installation including a stuffing-portioning machine (1) and a fast clipper (2), duly synchronised, between which is established a shaping device (3) that converts the film (5) meant to wrap food products that is supplied in the form of a coil into a tubular element that can be coupled to the stuffing tube (3), on which is coaxially mounted a second tube (8) bearing an external casing (9) based on a tubular net, the invention consists of using tubes (4) and (8) with a small diameter, much smaller than that of the finished product, so that the film (5) is adapted to the tube (4) after the former is profusely folded longitudinally, while the small diameter of the tube (8) allows the multilayer shirring of the tubular net (9), using the pressure provided by the pumping system of the stuffing machine (1) to achieve the radial expansion of the film (5) and the tubular net (9) to obtain the final diameter of the finished product, which will vary according to the speed with which it is separated from the double clipper (2) carried by a conveyor belt (12) with an adjustable speed.

Owner:VISCOFAN

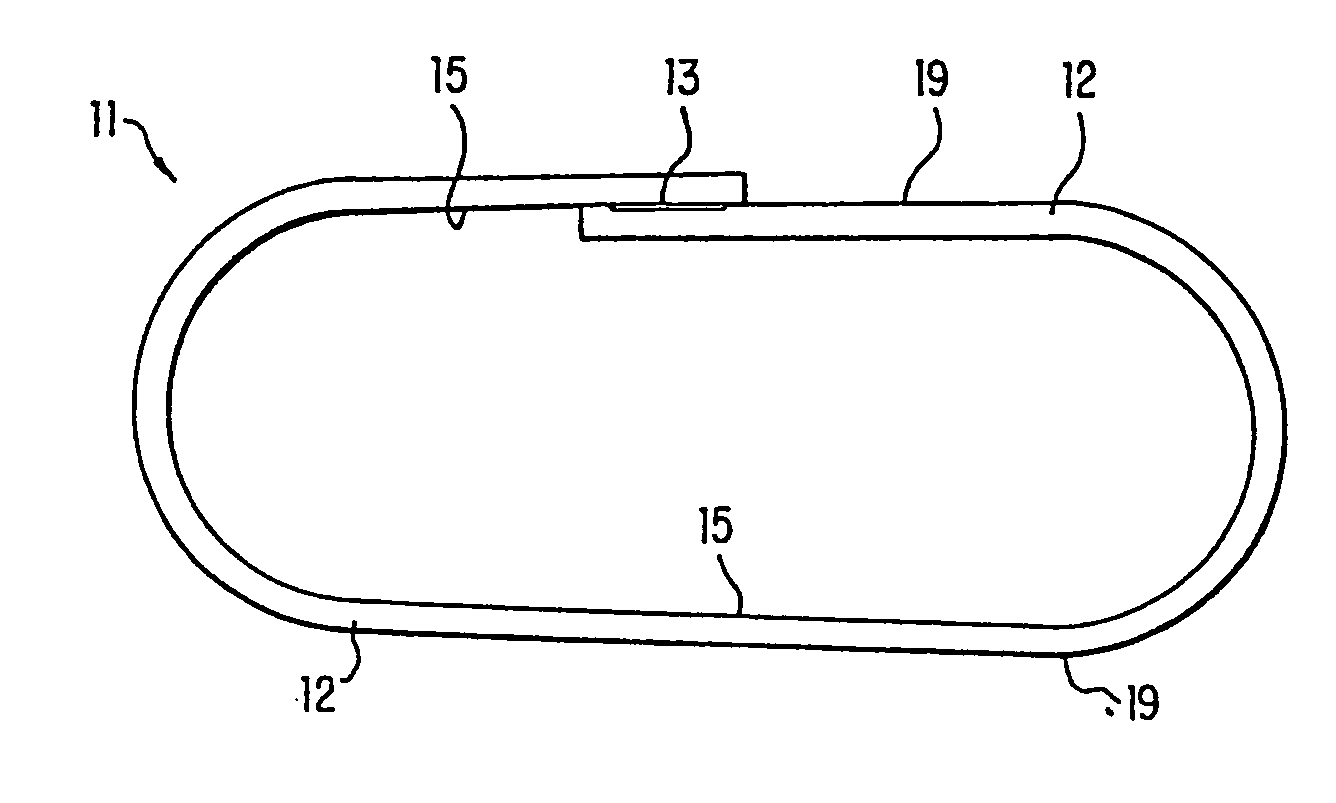

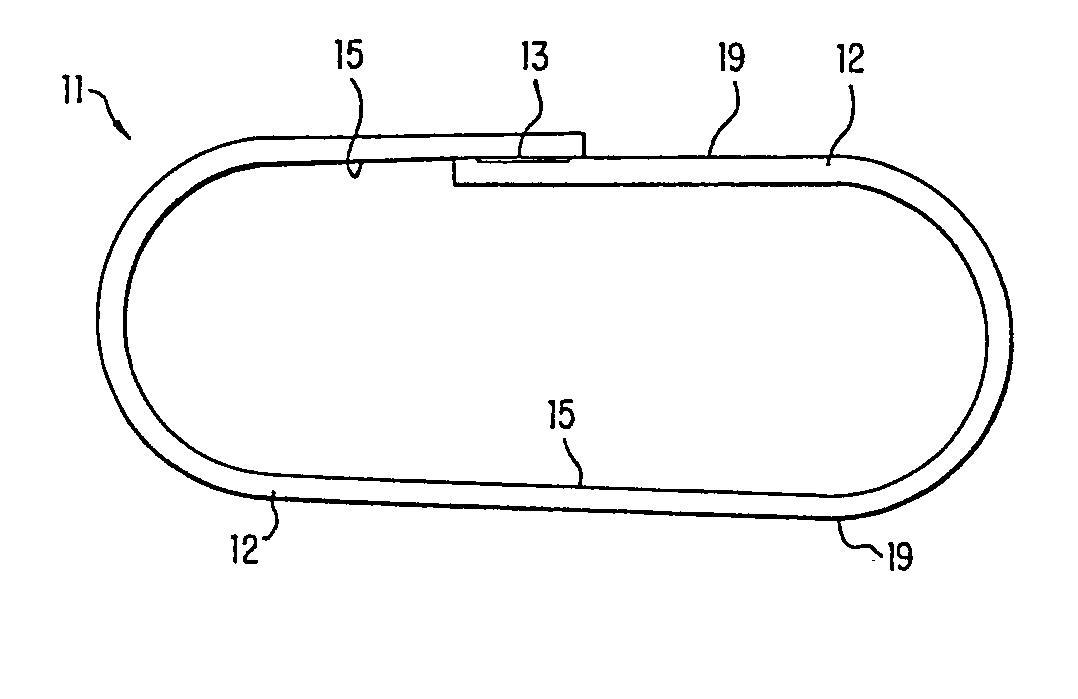

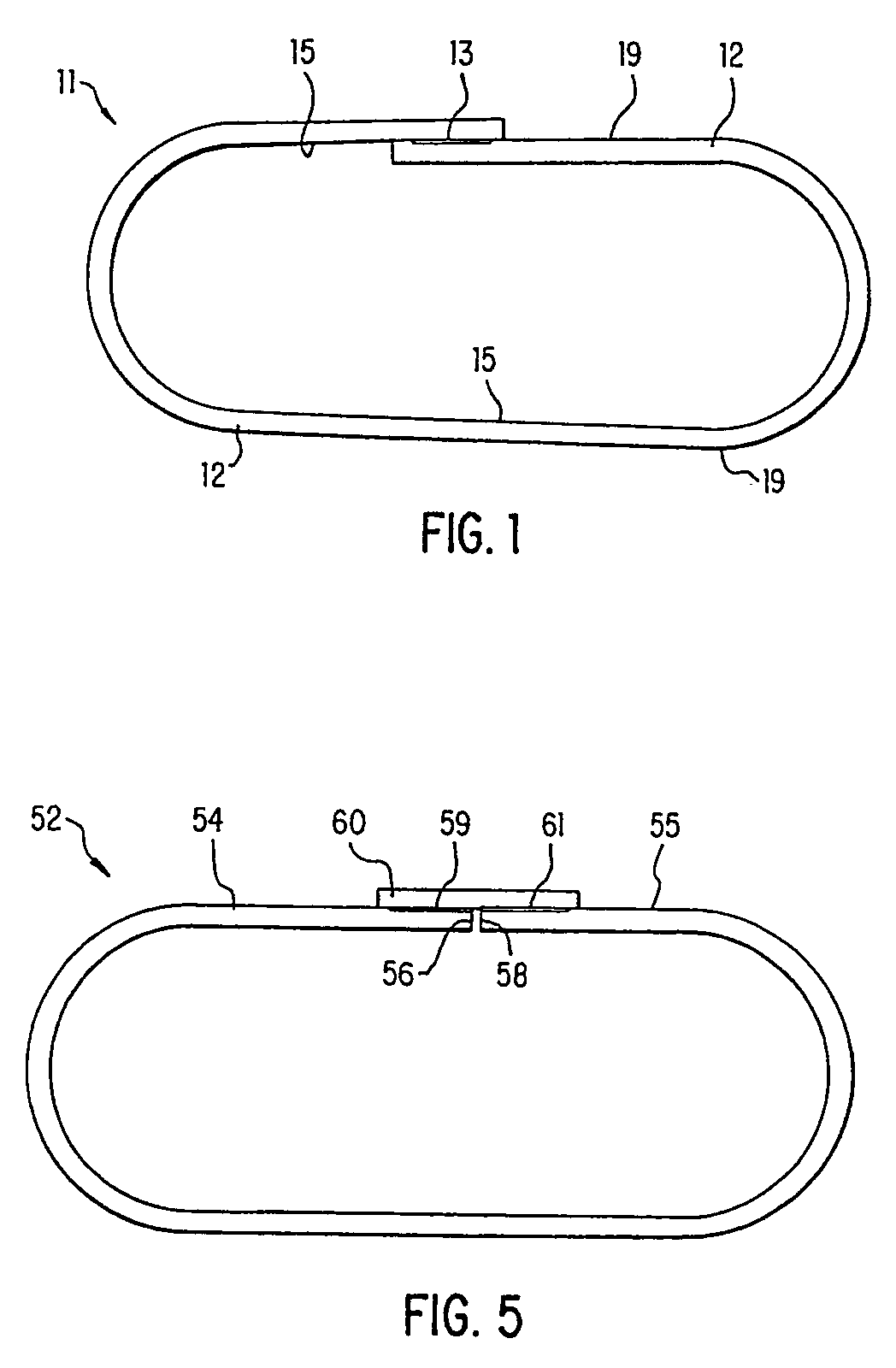

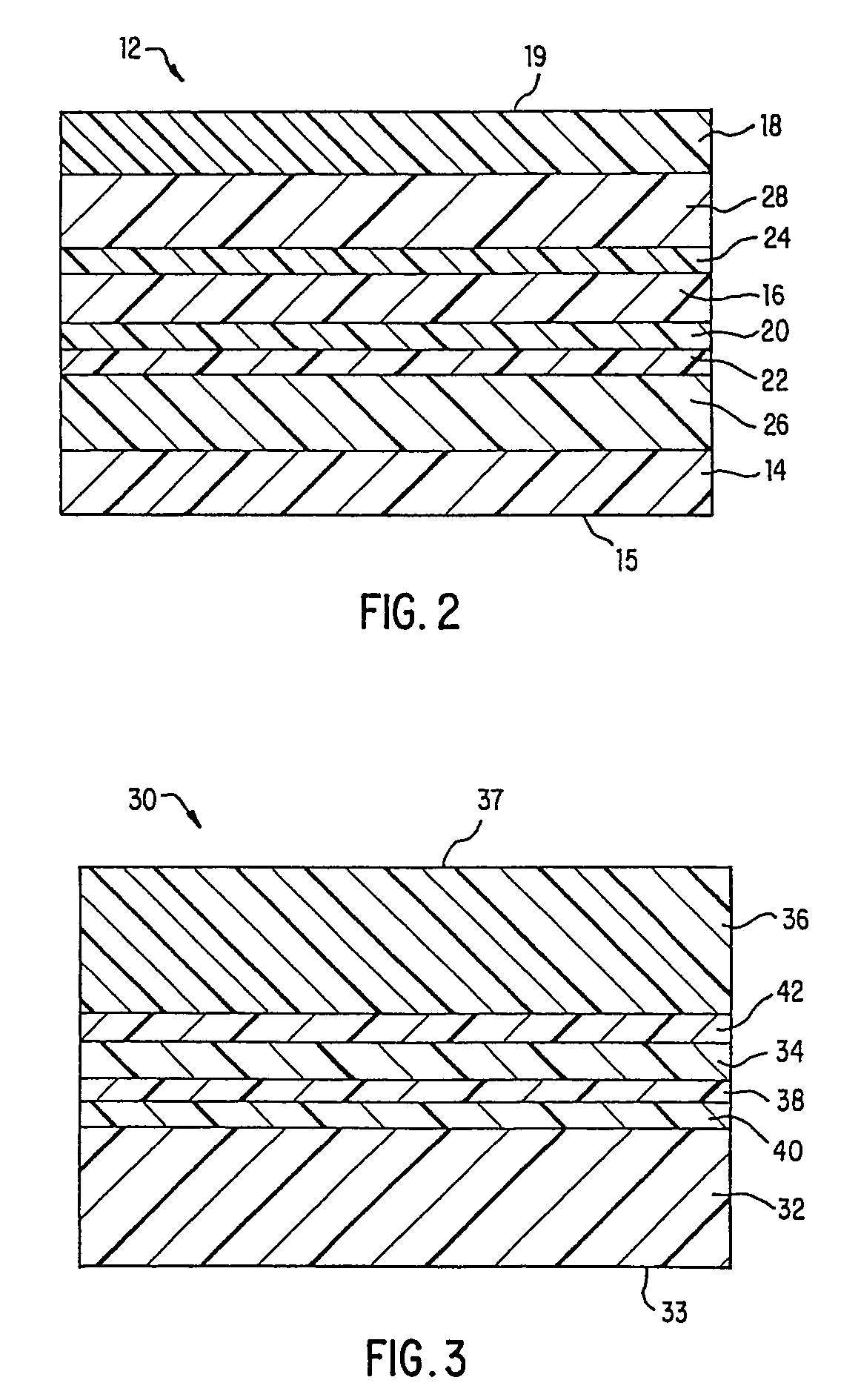

Backseamed casing and packaged product incorporating same

InactiveUS20070014897A1Reduces and destroys corona treatmentAvoid problemsFruit and vegetables preservationMultilayer sausage casingsPolyesterPolyolefin

A heat-shrinkable backseamed casing film comprises a first layer, a second layer, and a third layer, with the first and third layers being outer layers and the second layer being between the first layer and the third layer. The first outer layer serves as an inside casing layer, and comprises polyolefin; the second layer comprises polyester and / or polyamide; the third layer serves as an outside casing layer and comprises polyolefin, polystyrene, and / or polyamide. The second layer has a thickness of at least about 5% of a total thickness of the heat-shrinkable casing film. Alternatively, the first layer comprises polyolefin and has a surface energy level of less than about 34 dynes / cm; the second layer comprises a polyamide having a melting point of at least 300° F.; and the third layer comprises polyolefin, polystyrene and / or polyamide. A package comprises a cooked meat product within the backseamed casing. The second layer of the casing film prevents or reduces necking down on the forming shoe during backseaming. The backseamed casing is especially useful for cook-in applications.

Owner:CRYOVAC INC

Films comprising a liquid-absorbant inner layer and an impermeable outer layer

Owner:PERFORMANCE MATERIALS NA INC

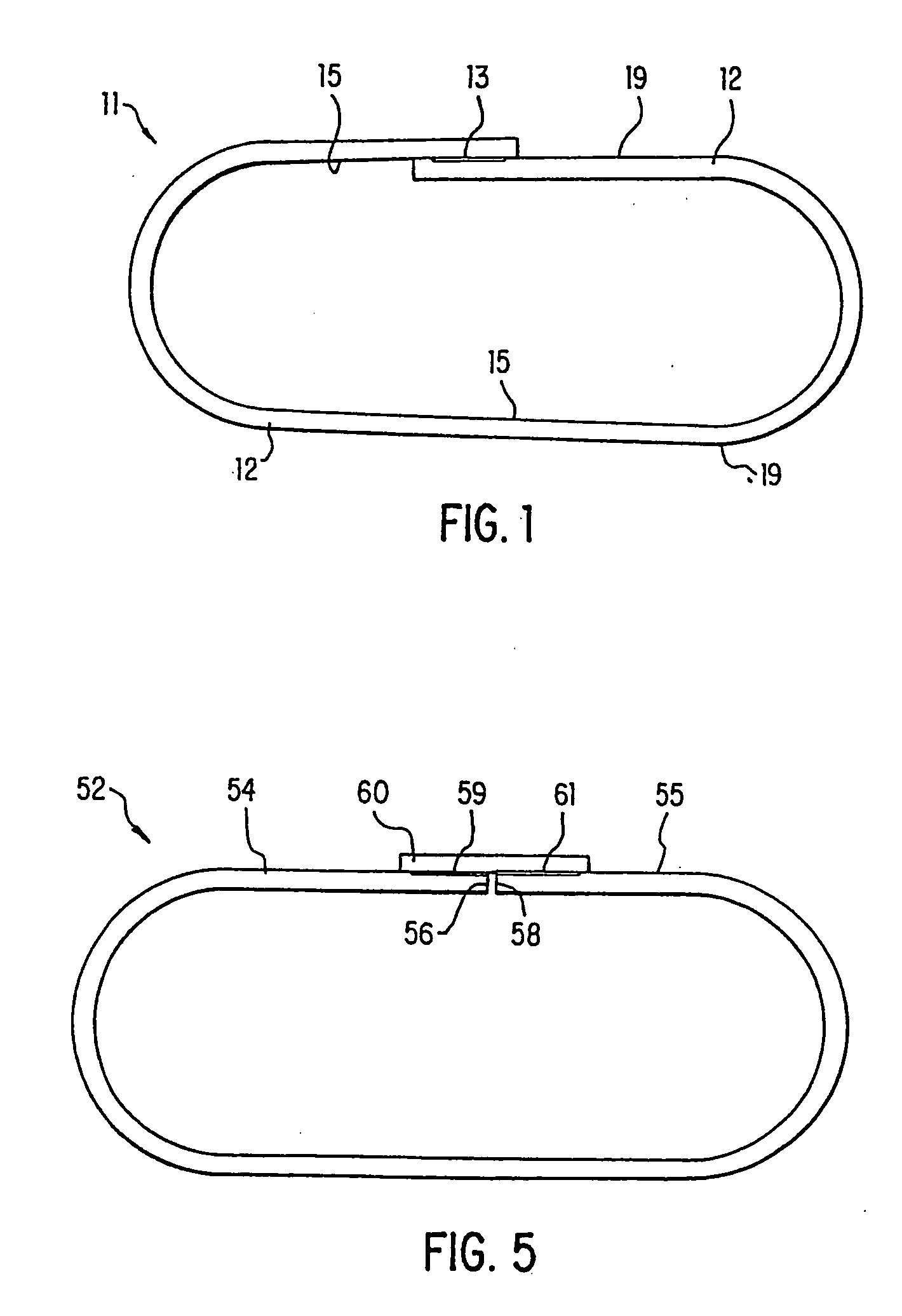

Additive delivery laminate and packaging article comprising same

InactiveUS20060051465A1Ready-for-oven doughsThermoplastic sausage casingsPolymer scienceWater insoluble

An additive delivery laminate is suitable for packaging a food product which is cooked in the package, with an additive transferring from the laminate to the food product. The additive delivery laminate has a substrate and an additive delivery layer. The additive delivery layer contains a water-insoluble thermoplastic polymer, a polymer toughening agent, and additive granules containing a colorant, flavorant, and / or odorant. The polymer toughening agent is present in a blend with the water-insoluble thermoplastic polymer. Polyisobutylene is a preferred water-insoluble thermoplastic polymer, and hydrogenated wood rosin is a preferred polymer toughening agent. The polymer toughening agent decreases the tendency of the water-insoluble thermoplastic polymer to form legs or transfer to the food product upon stripping the laminate from the food product after cooking and transfer to the additive to the food product.

Owner:CRYOVAC ILLC

Additive transfer film suitable for cook-in end use

InactiveUS7183006B2Avoid handlingAvoid wastingThermoplastic sausage casingsWrappersPolyesterPolyolefin

A multilayer film has a first layer and a second layer. The first layer comprises an additive, a binder, and a crosslinking agent. The additive is a flavor, fragrance, colorant, antimicrobial agent, antioxidant, chelating agent, and / or odor absorbent. The binder is a polysaccharide and / or a protein. The crosslinking agent comprises a compound with at least two carbonyl groups. The second layer comprises a non-water-soluble thermoplastic polymer comprising at least one member selected from the group consisting of polyolefin, polyamide, polyester, polyvinylidene chloride, polyvinyl chloride, and polystyrene. Each of the additive, binder, and crosslinking agent are present throughout a thickness of the first layer. Preferably, the first layer is coated onto the second layer, which is preferably a non-water-soluble thermoplastic polymer, e.g., polyolefin, polyamide, and / or polyester. The film is especially useful for cook-in applications, in which a food product (preferably comprising uncooked meat) is packaged in the film with the coated layer against the meat. The meat is then cooked and the additive transfers to the meat, and purge can be very low. The invention also pertains to a process for preparing a cooked food product, process for making a coated film, and articles formed from the film, such as bags and casings.

Owner:CRYOVAC INC

Method and apparatus for the automatic stuffing of meat products into a double casing comprising a sheet and a net

ActiveUS7494405B2Increase speedImprove load effectMultilayer sausage casingsSkinless sausage makingEngineeringAutomatic testing

Owner:VISCOFAN

Process For Producing A Composite Food Casing

InactiveUS20100255230A1Avoid entanglementThermoplastic sausage casingsMultilayer sausage casingsPulp and paper industry

The invention relates to a process for producing a composite casing shirred to a caterpillar, said process comprising steps of pulling an outer casing over the inner casing, and optionally a net between the inner and outer casings, or over the outer casing, and finally shining the composite casing thus obtained to give a compact tube, which is cut to yield caterpillars.

Owner:VISKOTEEPAK BELGIUM NV

Food Casings with Modified Adhesion and Release Properties and Methods of Manufacture

ActiveUS20120052223A1Improve adhesionFacilitated releaseMultilayer sausage casingsPretreated surfacesFiberWet strength

The invention relates to a multilayer fibrous reinforced food casing comprising a fibrous reinforced layer located between an inside layer and an outer layer; the inside layer comprising an adhesion promoter comprising one or more of protein coagulants, proteins, glyoxals, glutaraldehyde, caseins, gelatines, wet strengths resins and any mixtures thereof; and the outer layer comprising a peeling agent comprising one or more of polyalkylene glycols and any mixtures thereof or the inside layer comprising a peeling agent comprising one or more of polyalkylene glycols and any mixtures thereof or the outer layer and the inside layer comprising a peeling agent comprising one or more of polyalkylene glycols and any mixtures thereof.

Owner:VISKOTEEPAK BELGIUM NV

Process for producing a composite food casing

InactiveUS8226457B2Thermoplastic sausage casingsMultilayer sausage casingsPulp and paper industryCaterpillar

The invention relates to a process for producing a composite casing shirred to a caterpillar, said process comprising steps of pulling an outer casing over the inner casing, and optionally a net between the inner and outer casings, or over the outer casing, and finally shirring the composite casing thus obtained to give a compact tube, which is cut to yield caterpillars.

Owner:VISKOTEEPAK BELGIUM NV

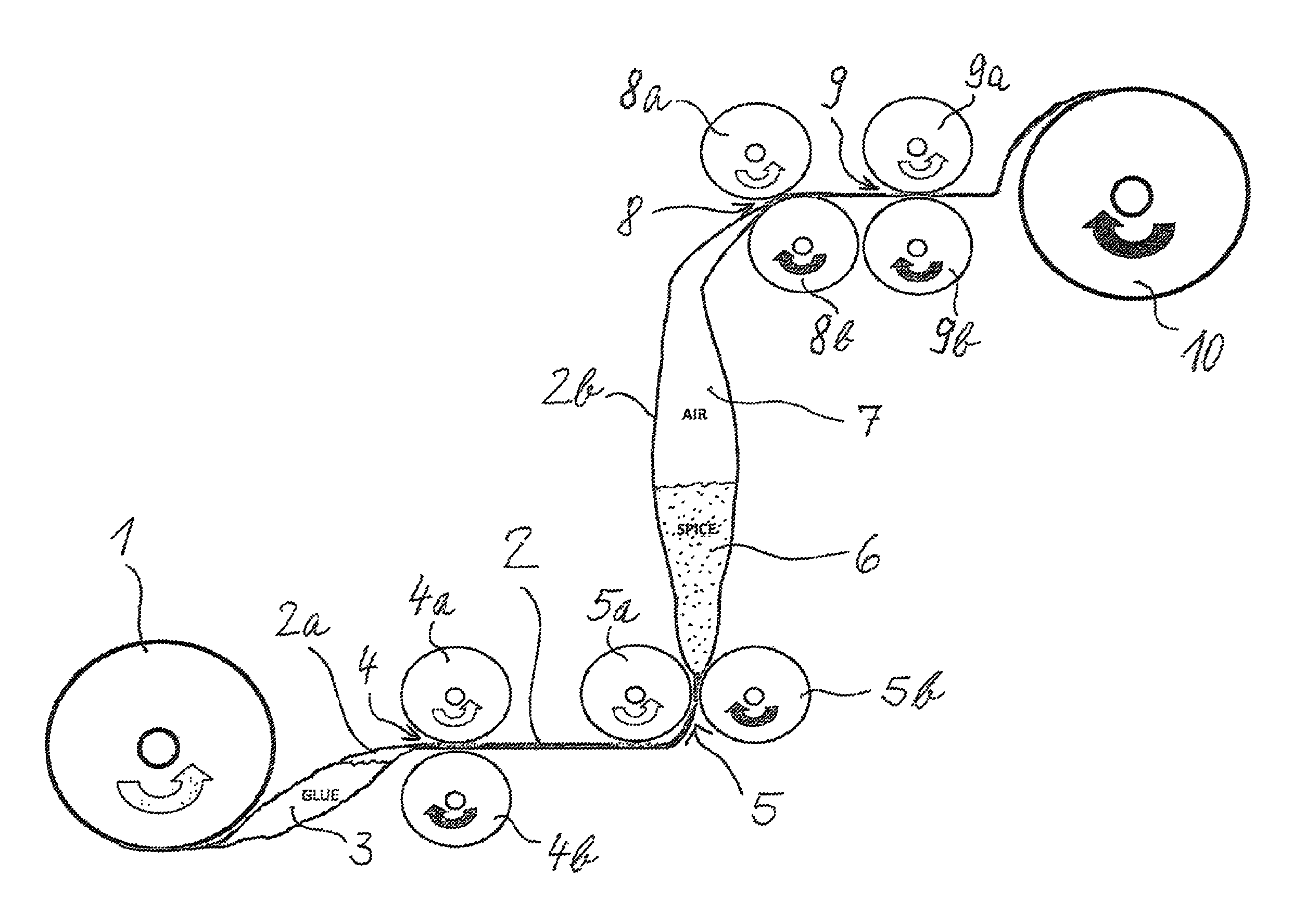

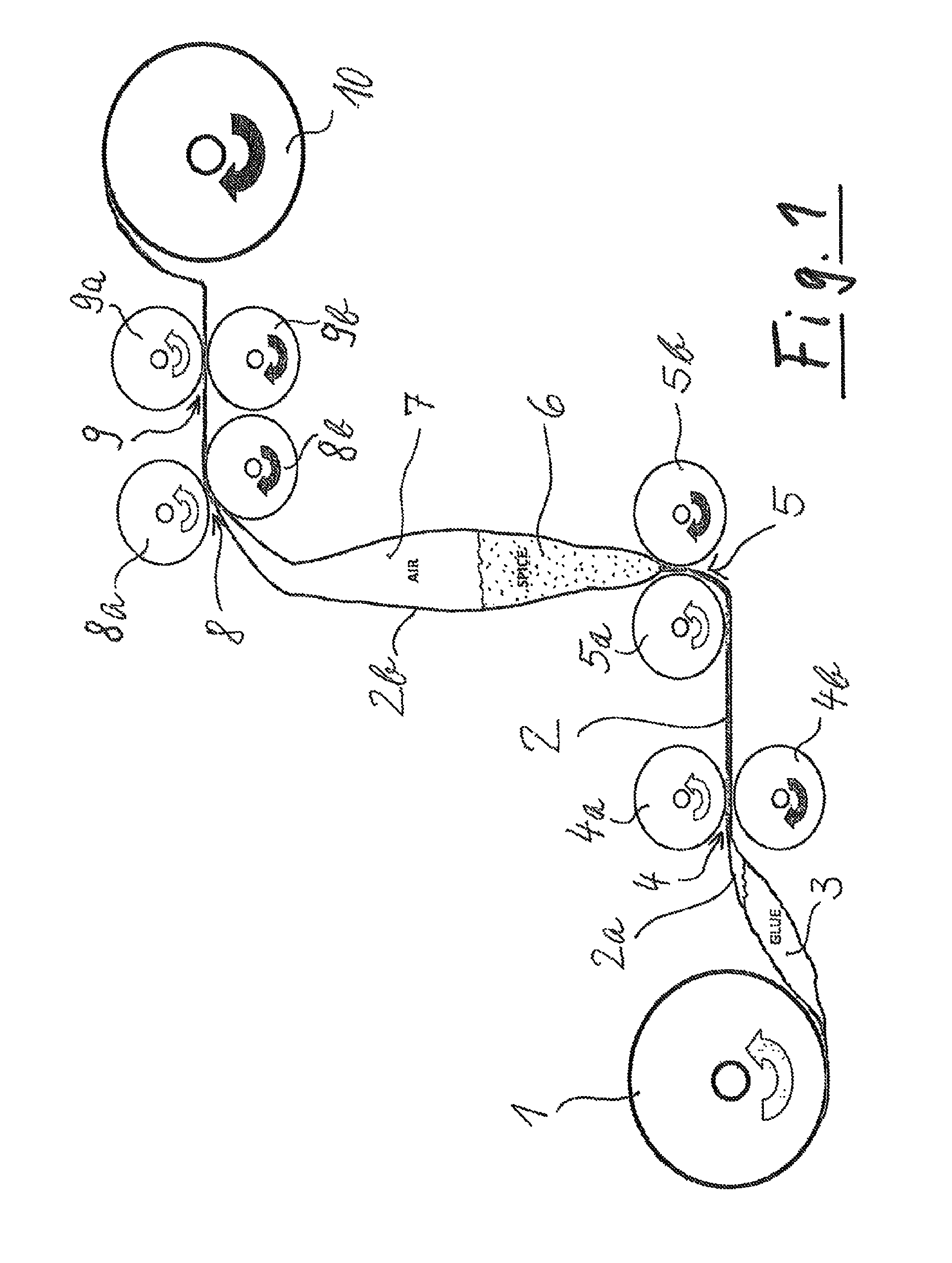

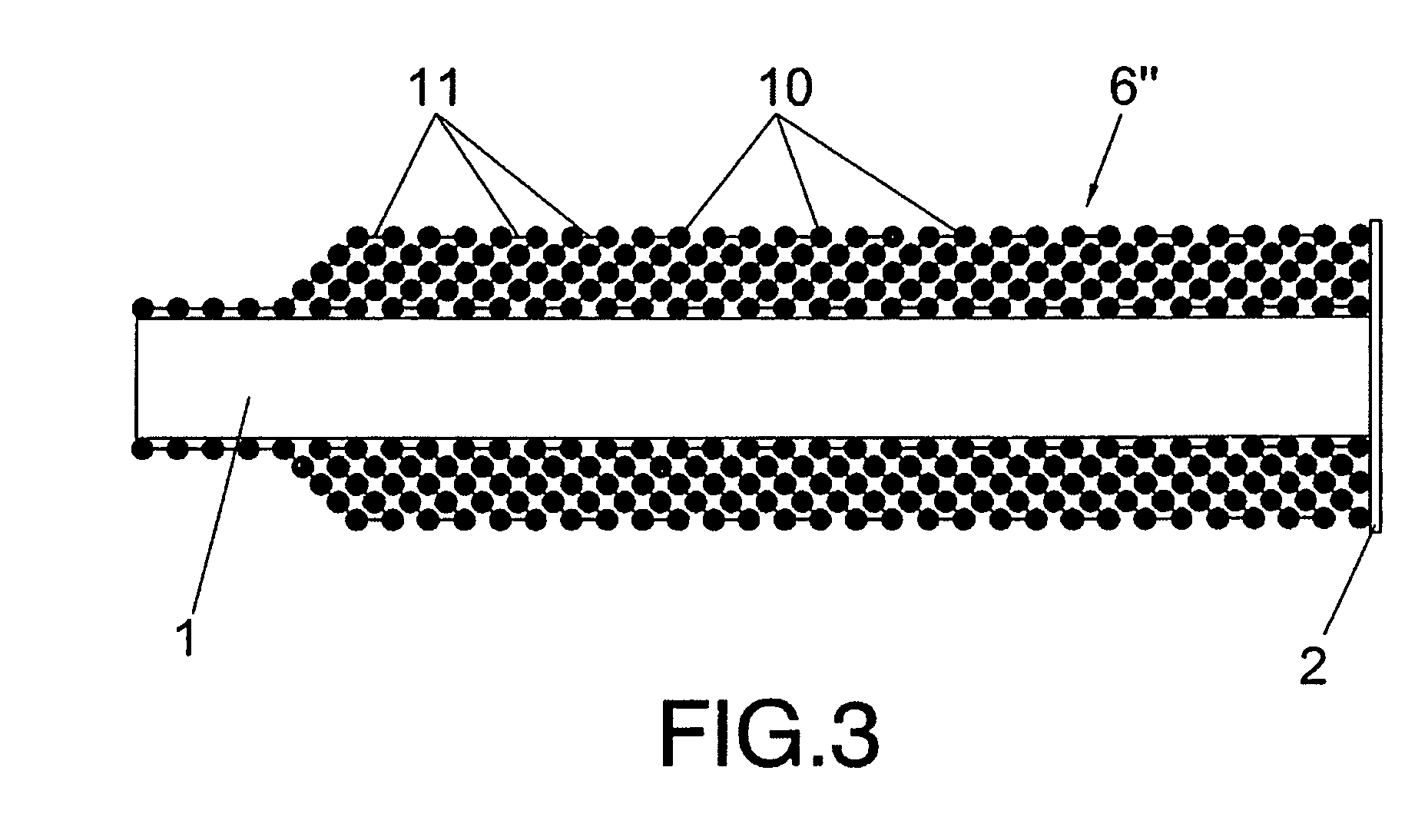

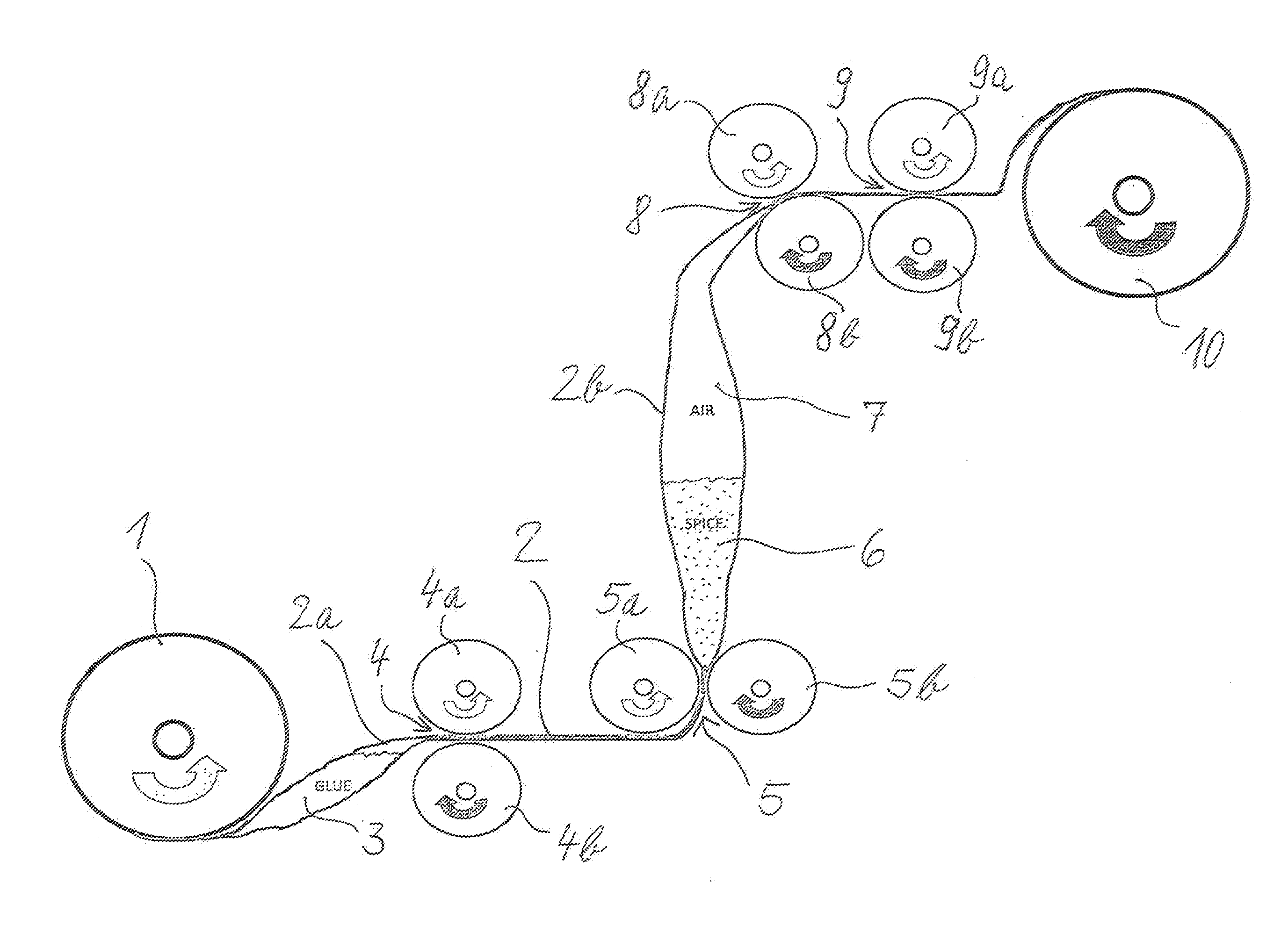

Casing for foodstuff

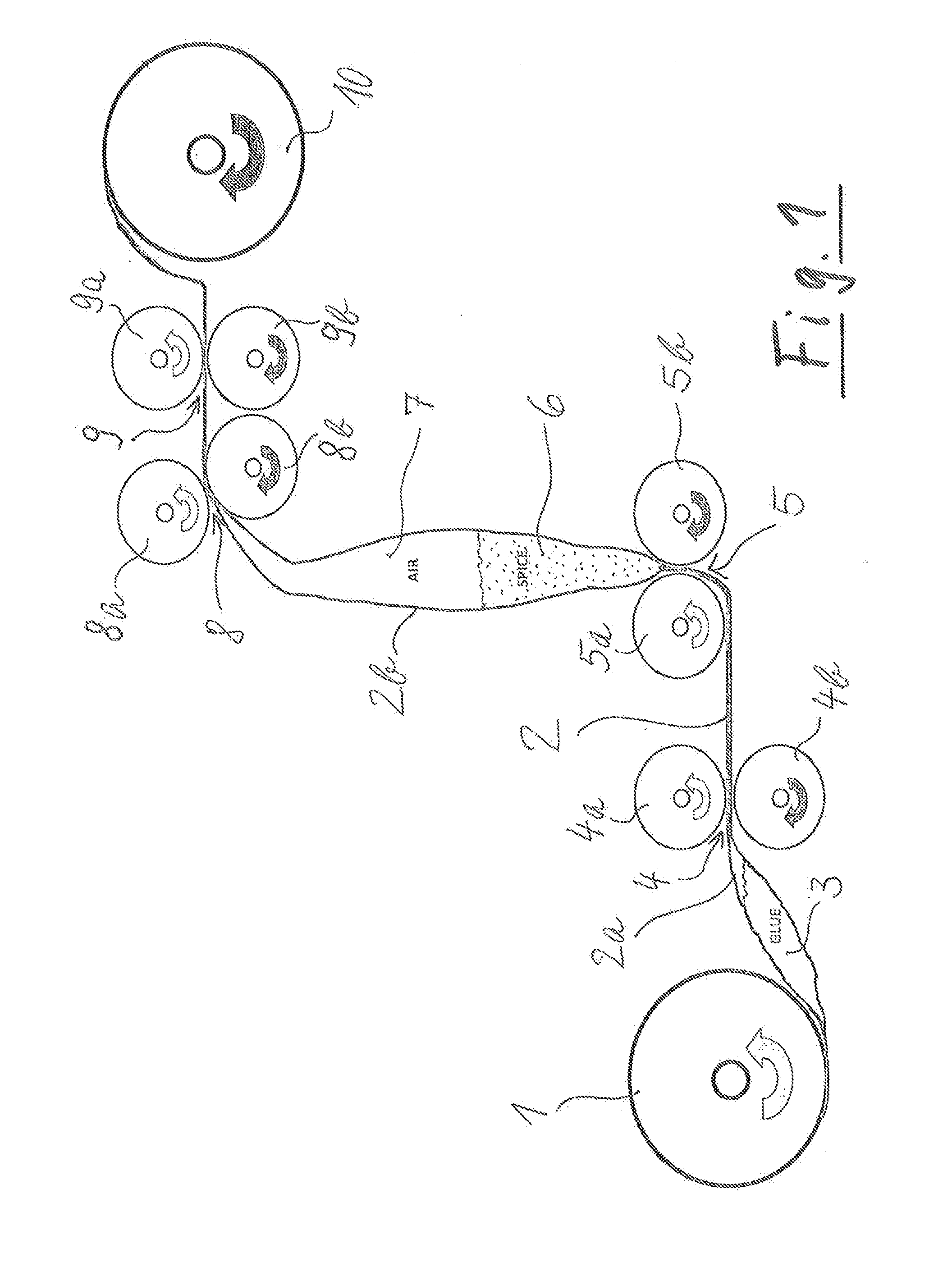

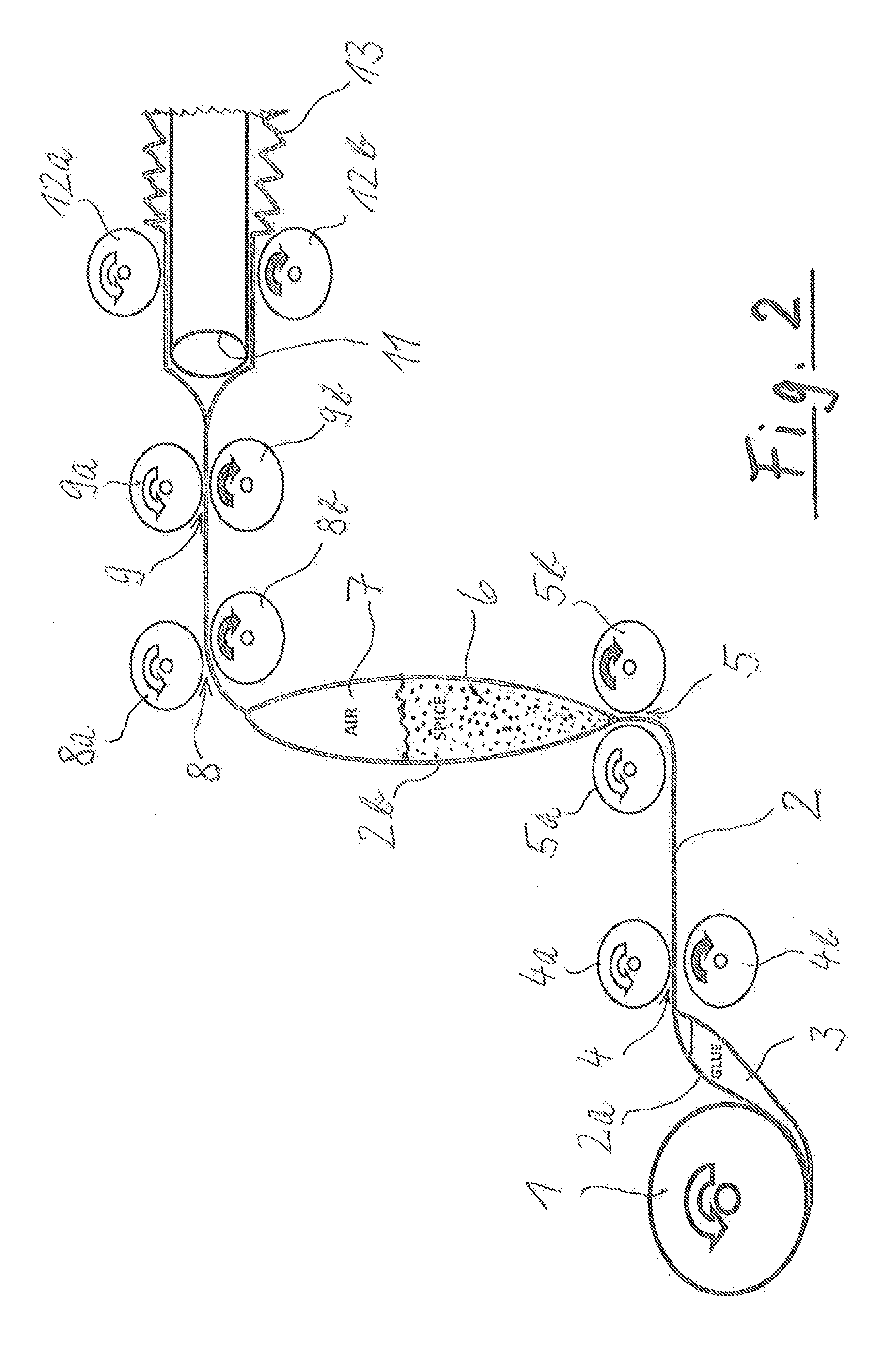

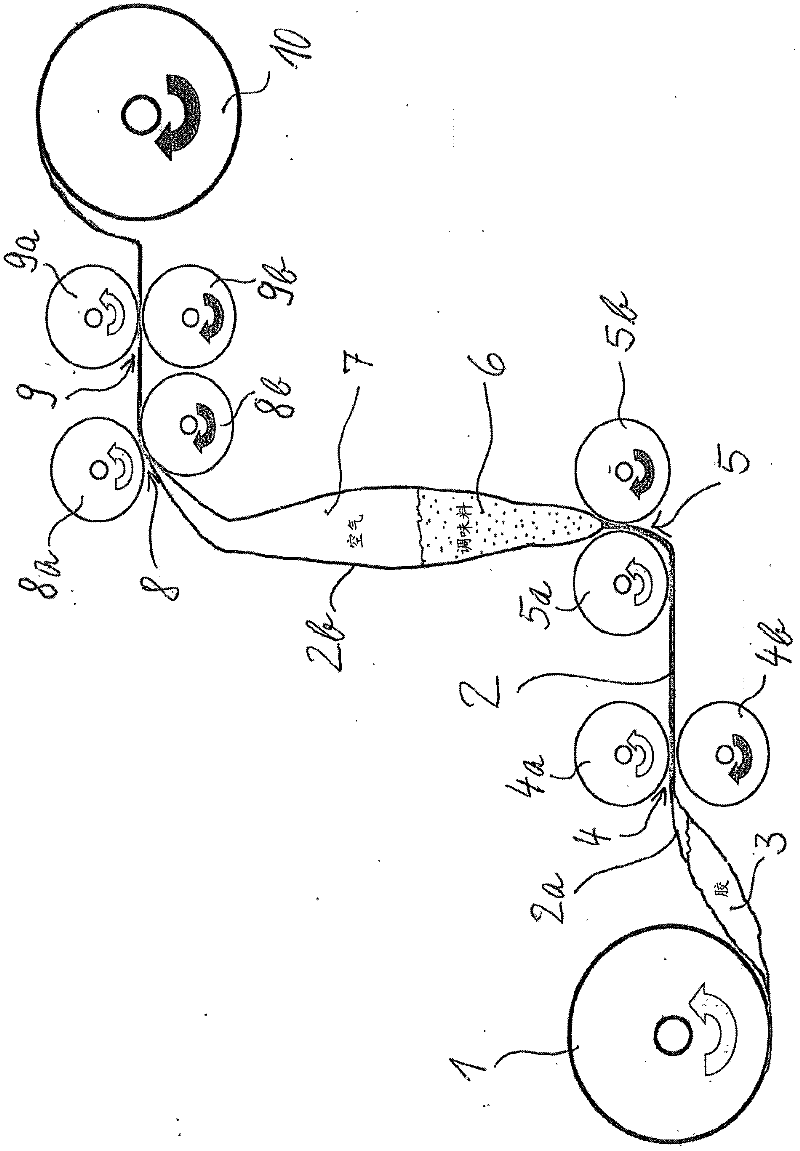

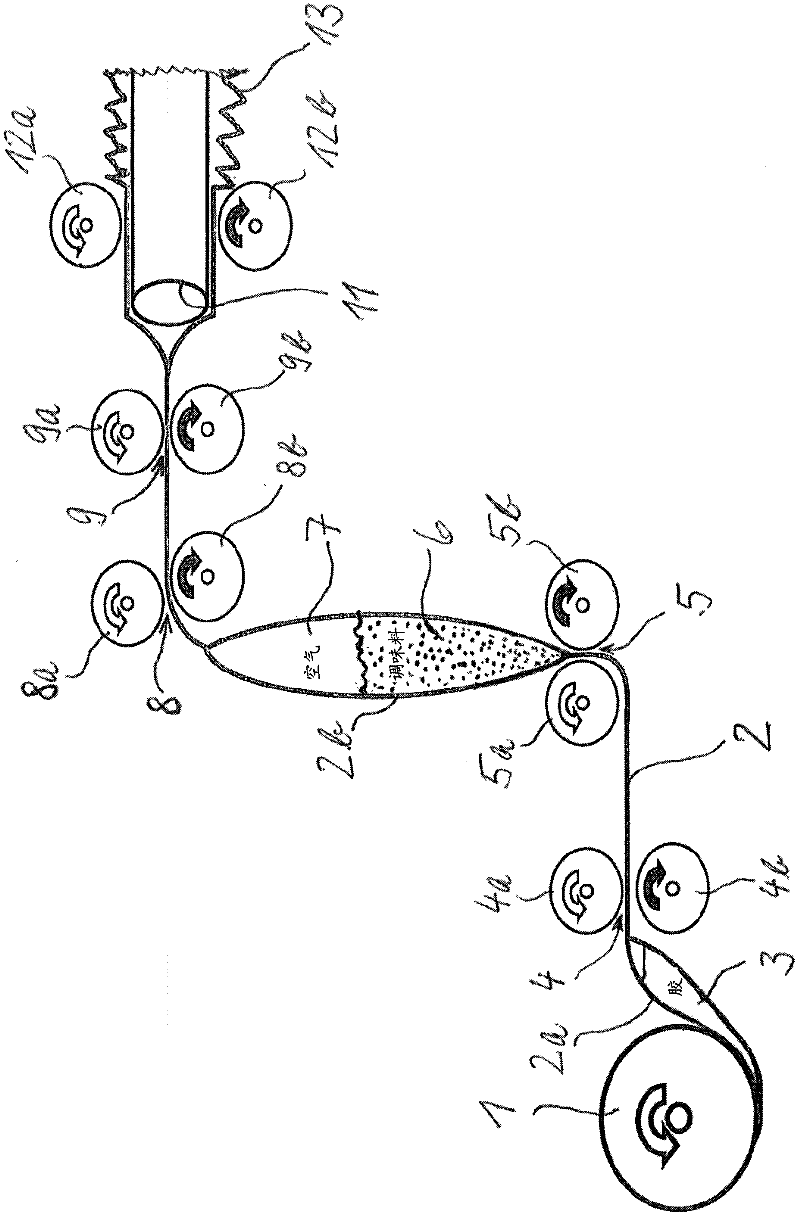

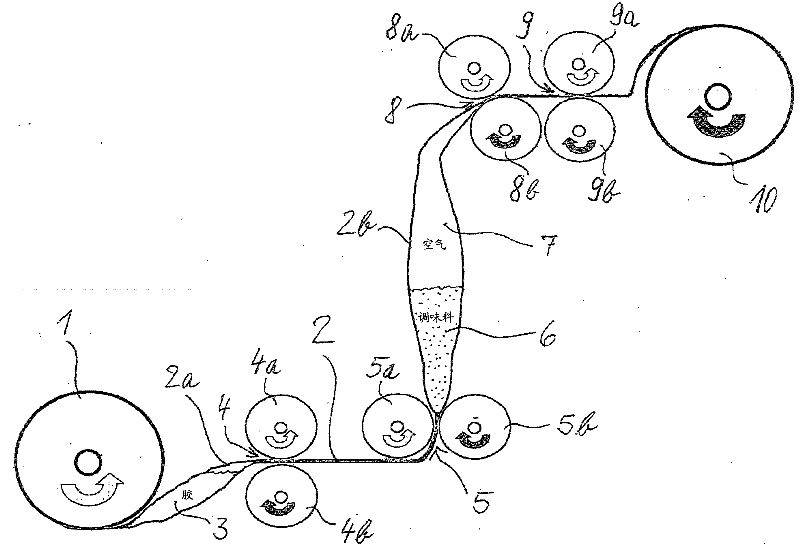

A method for coating tubular food-casings (2), particularly skins with flavoring substances in particle form, includes wetting the casing (2) on the inside with adhesive, and then applying desired flavoring substances (6) onto the formed adhesive layer. The tubular casing (2), coated on the inside with adhesive, is guided through a first squeezing zone (5) and a second squeezing zone (8) in the travel direction, where the respective interior cross-sections of the tubular casing are temporarily closed. The second squeezing zone (8) is positioned higher than the first squeezing zone (5). The tubular casing is brought into the form of an inflated sack (2b) in between the two squeezing zones (5, 8) by a supply of particulate flavoring substances (6) and an air pocket (7) inserted into the interior of the tubular casing. During travel, the casing entrains the flavoring substances (6) from the supply.

Owner:WORLD PAC INT

Backseamed casing and packaged product incorporating same

InactiveUS20040071903A1Precise positioningHigh speedWrappers shrinkageMultilayer sausage casingsPolyesterPolyolefin

A heat-shrinkable backseamed casing film comprises a first layer, a second layer, and a third layer, with the first and third layers being outer layers and the second layer being between the first layer and the third layer. The first outer layer serves as an inside casing layer, and comprises polyolefin; the second layer comprises polyester and / or polyamide; the third layer serves as an outside casing layer and comprises polyolefin, polystyrene, and / or polyamide. The second layer has a thickness of at least about 5% of a total thickness of the heat-shrinkable casing film. Alternatively, the first layer comprises polyolefin and has a surface energy level of less than about 34 dynes / cm; the second layer comprises a polyamide having a melting point of at least 300° F.; and the third layer comprises polyolefin, polystyrene and / or polyamide. A package comprises a cooked meat product within the backseamed casing. The second layer of the casing film prevents or reduces necking down on the forming shoe during backseaming. The backseamed casing is especially useful for cook-in applications.

Owner:RAMESH RAM K +1

Films comprising liquid smoke and flavorants

A process for producing a film having incorporated or applied thereon or therein an additive such as liquid smoke is provided wherein the film comprises a liquid absorbent layer and an impermeable layer. The films can be used for producing a tubular casing or shrinkbag.

Owner:EI DU PONT DE NEMOURS & CO

Nylon food casing having a barrier core layer

ActiveUS7244481B2Good conformationEasy to processWrappers shrinkageSausage casingsThin membraneEngineering

Owner:VISCASE CORP

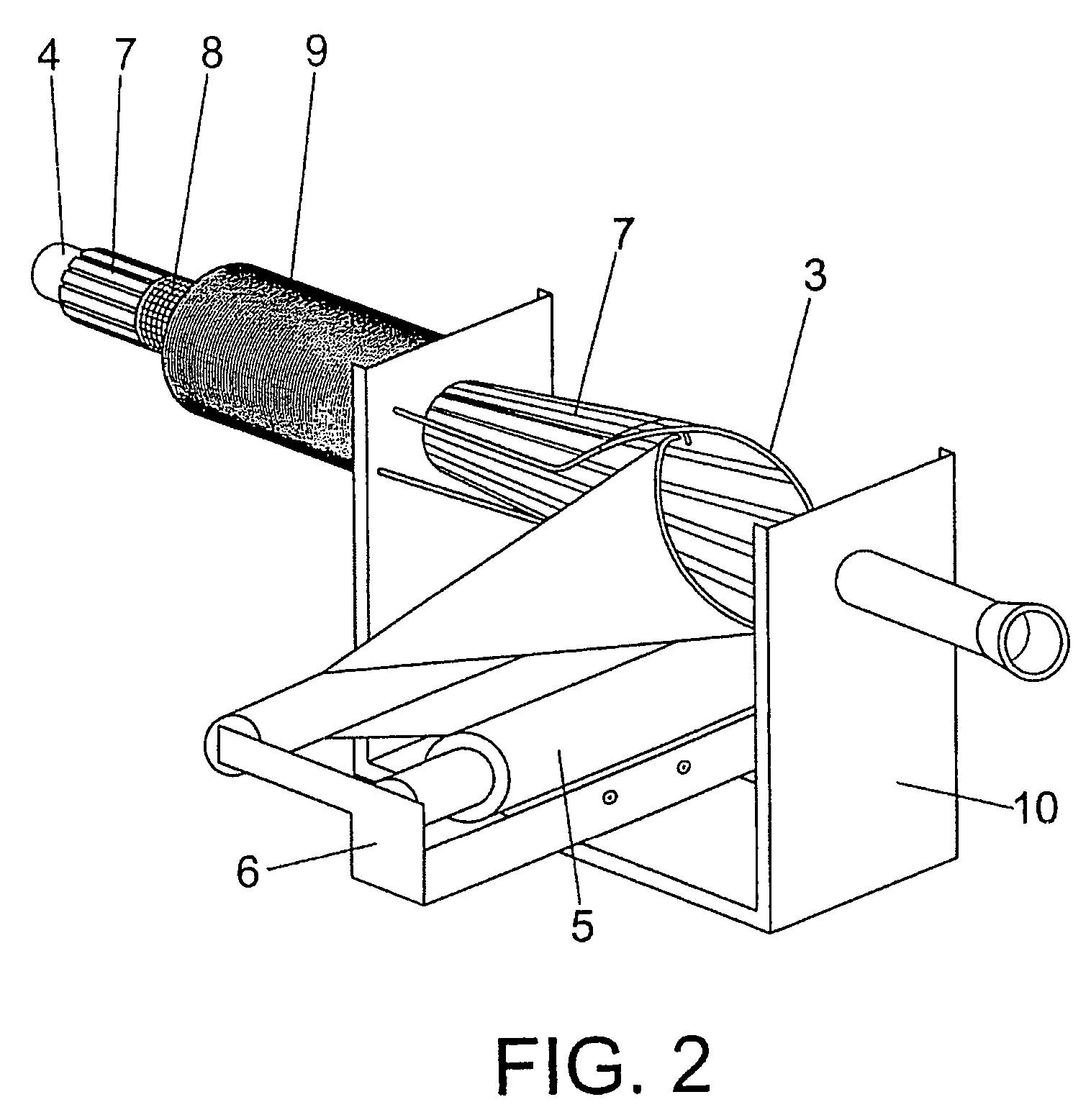

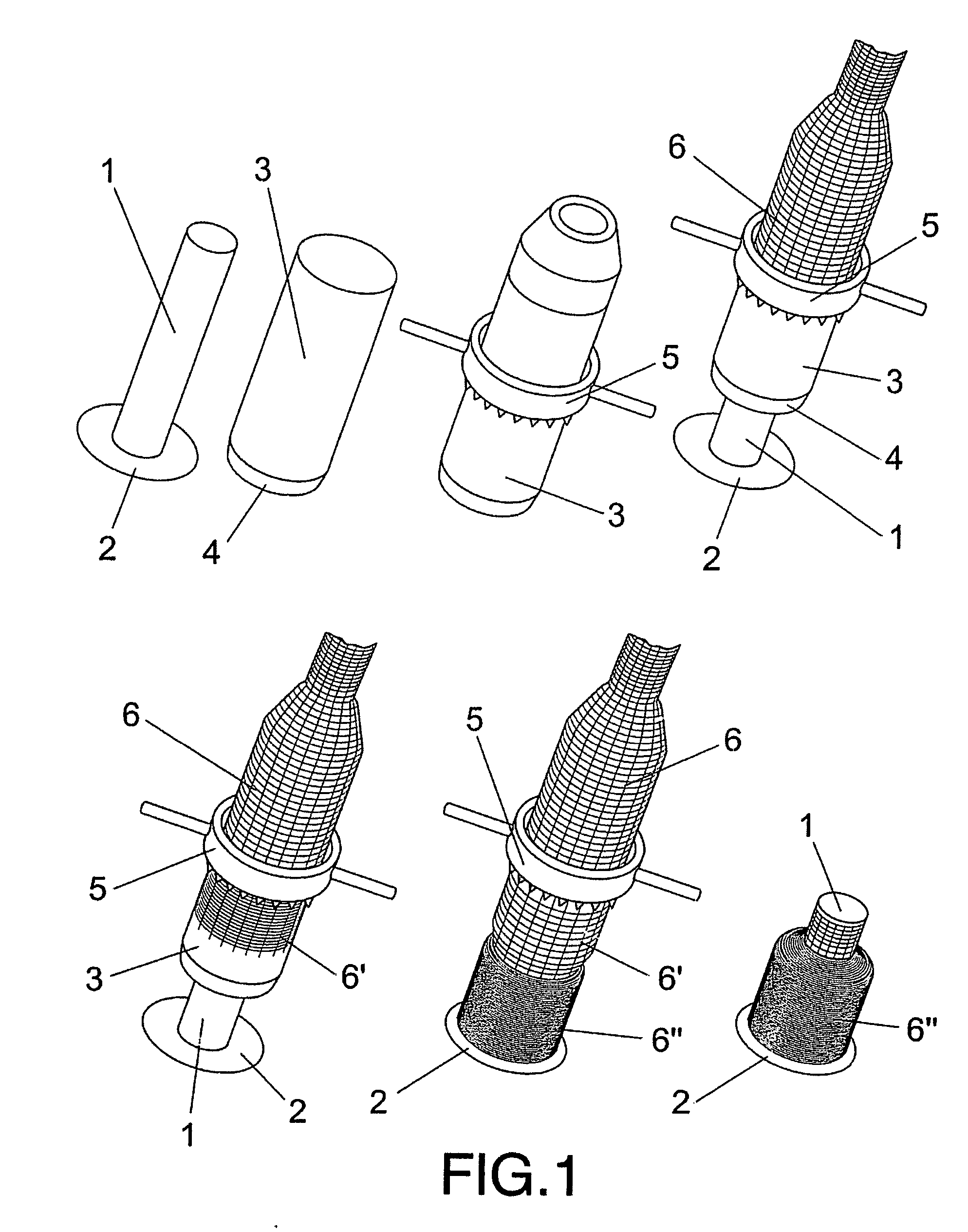

Multi-layer arrangement of a tubular net on a support tube, and device and method for obtaining same

ActiveUS20050281924A1Smoothly unfoldSmooth unloadingContainers for flexible articlesReady-for-oven doughsMaximum diameterEngineering

The invention relates to a method and means which are used to obtain a multi-layer arrangement of a tubular net (6) which is first positioned on a transfer tube (3). According to the invention, a toothed loader (5) is used to slide the net (6) along the outside of the transfer tube (3) to the end thereof, said end comprising a slightly conical end zone (4). When the net (6′) reaches said end zone (4), it falls on to the support tube (1) in an arrangement of concentric layers (6′). In this way, the outer layers of the loaded net (6″) have a maximum diameter equal to that of the transfer tube (3) while the inner diameter of the loaded net (6″), which corresponds to the outer diameter of the support tube (1) is less than the maximum diameter of the stretched net.

Owner:VISCOFAN

Artificial food casing comprising a traceability code, method for manufacturing and method of tracing thereof

The invention relates to an artificial food casing comprising a marking with a traceability code, wherein the marking comprises an ultraviolet-detectable component.

Owner:VISKOTEEPAK BELGIUM NV

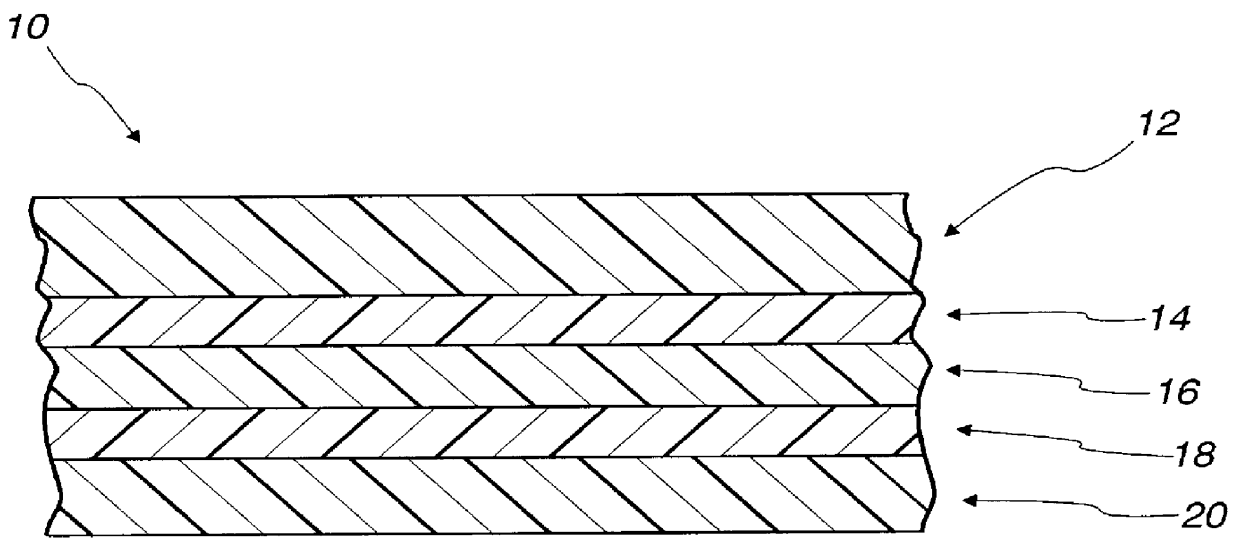

High barrier non-foil laminate composition

InactiveUS6066376ALayered product treatmentMultilayer sausage casingsPolyethylene terephthalateSealant

A high-barrier non-foil laminate composition is disclosed. The laminate composition comprises an outer heat stable layer, a barrier layer, and an inner layer that readily adheres to metal with the application of heat. The outer and inner layers may be bonded to the barrier layer by means of adhesive layers. Preferably, the outer layer comprises a material with a higher melting temperature than the inner layer such as polyethylene terephthalate. The barrier layer may be a high-barrier saran and the sealant layer may be a copolymer of ethylene and acrylic acid.

Owner:BEMIS COMPANY INC +1

Multilayer composite having a polyester layer and a protective layer

Owner:EVONIK OPERATIONS GMBH

Multilayered two-dimensional or tubular food casing or film

ActiveCN101522035AThermoplastic sausage casingsMultilayer sausage casingsEngineeringCompanion animal

The present invention proposes for the first time a two-dimensional or tubular food casing or film with an at least seven-layered laminated structure, which has an EVOH layer as an oxygen barrier and in which the outer layer is formed by a high-temperature-resistant material such as PET, which apart from outstanding appearance-related properties also makes much higher further processing speeds (numbers of cycles) possible than previously known.

Owner:库恩设备制造有限公司

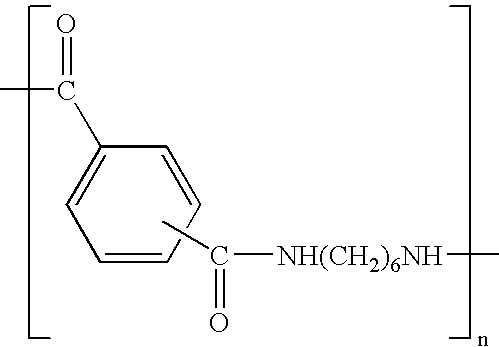

Multilayer Tube for Transfer of Smoke Curing Solution to Food

The present invention provides a multilayer tube for transferring a smoke-curing liquid to food, in which the tube has an innermost layer comprising a polyamide resin and a crosslinked polyvinylpyrrolidone; a packaged food product, in which the food product has been packaged in the multilayer tube for transferring a smoke-curing liquid to food; and a method for producing a smoked food using the multilayer tube for transferring a smoke-curing liquid to food.

Owner:GUNZE LTD +1

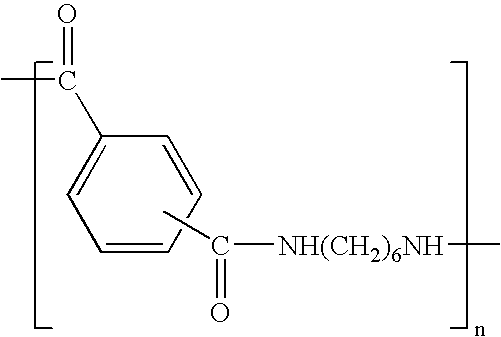

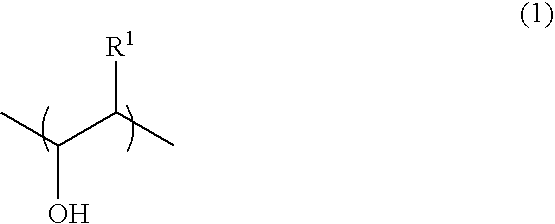

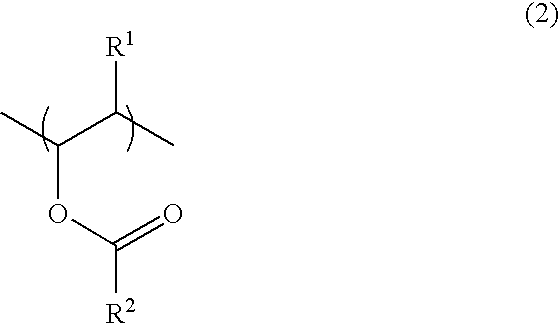

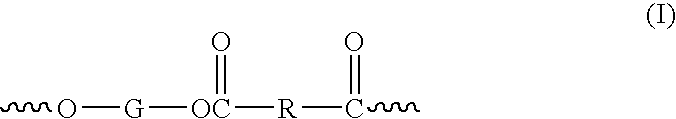

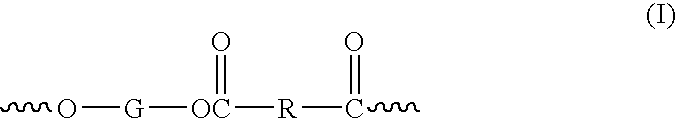

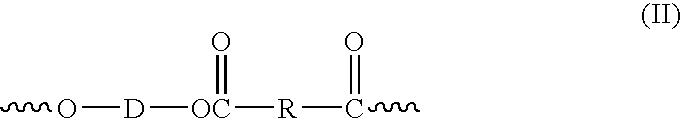

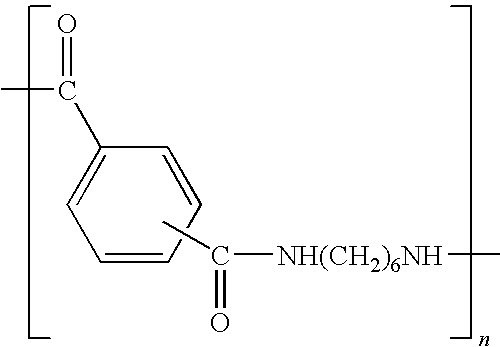

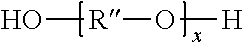

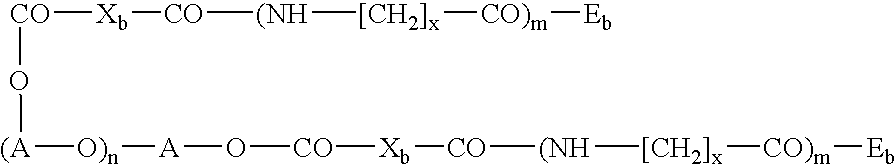

Polyamide-based sausage skin which can be filled manually

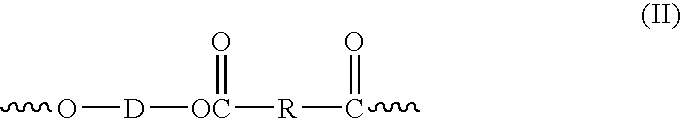

The invention concerns a biaxially stretched and thermoset tubular seamless single- or multi-layered foodstuff skin wherein the layer, or, a multi-layered skin wherein at least one of the layers, contains a block copolymer with “hard” aliphatic polyamide blocks and “soft” aliphatic polyether blocks, the block copolymer corresponding to one of formulae (I) to (III), Ea—(NH—[CH2]x—CO)m—Xa—(A—O)n—A Xa—(CO—[CH2]x—NH)m—Ea (I), (II), —[X—(CO—[CH2]x—NH)o—Y—X—(A—O)p—A]-(III). The invention is particularly suitable as a skin for a sausage which is to be boiled or heated in water, and does not form folds when the filling is introduced manually, with no or only slight pressure.

Owner:KALLE NALO

Low moisture barrier film

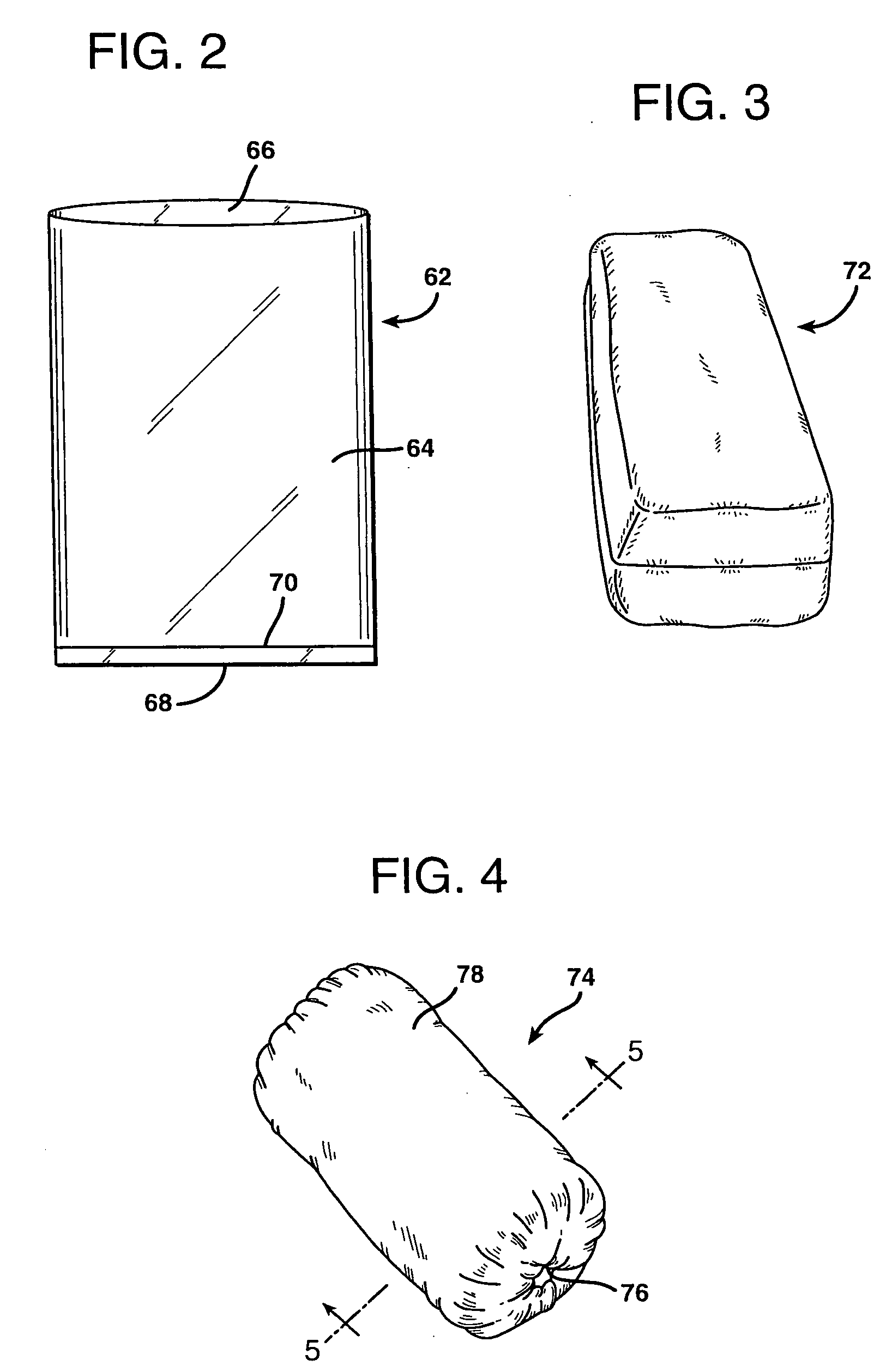

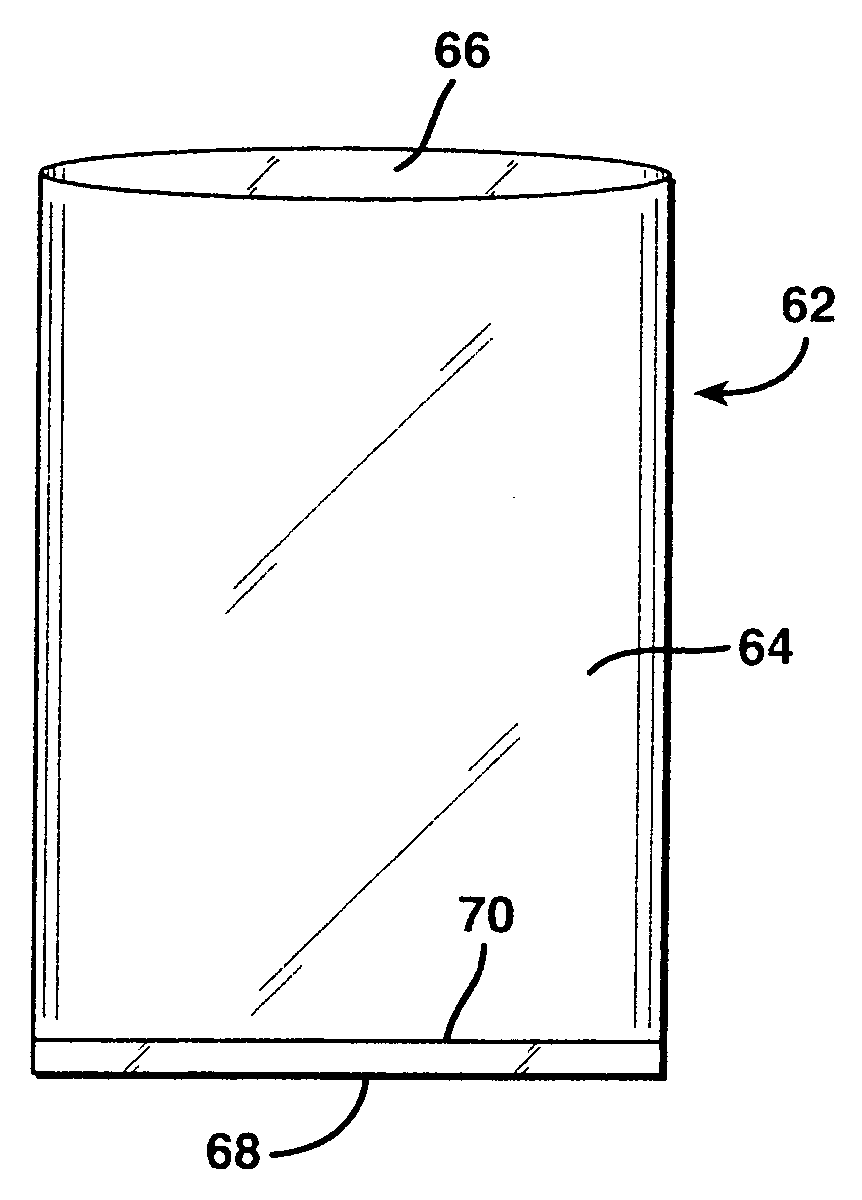

ActiveUS9999233B1Reduce downtimeHigh tensile strengthThermoplastic sausage casingsMultilayer sausage casingsFood contactEngineering

The present invention relates to a flat, multilayered, low moisture, barrier, laminated thermoplastic film with an absorptive food contact layer coated with a flavoring and / or coloring agent, which can be formed on automatic stuffing machinery into a sealed tube in a continuous manner for use as a food casing. This film has an absorptive food contact layer, an oxygen barrier layer, and a polyethylene outer layer. The coloring and / or flavoring agent on the absorptive layer is released onto the surface of encased foodstuff during cooking and processing.

Owner:VISCASE CORP

Flexible tubular food casing coated with meltable, thermoplastic polymers

ActiveUS20110236539A1Reduce expenditureSave energyThermoplastic sausage casingsLayered productsEmulsionThermosetting polymer

A flexible tubular food casing having a flat support material is provided which, on at least one side, has a continuous coating based on a hotmelt polymer, with the coating preferably situated on the outside. The continuous coating has a weight per unit area of 3 to 200 g / m2, preferably 15 to 50 g / m2. The hotmelt polymers have an MVR value in the range of about 25 to 500 cm3 per 10 min, measured at 190° C. with a load of 2.16 kg. The flexible tubular food casing is suitable as a synthetic sausage casing for raw sausage, scalded-emulsion sausage or cooked-meat sausage

Owner:KALLE AG

Casing for Foodstuff

ActiveUS20120082768A1Easy to storeEasy to transportLiquid surface applicatorsWrappersParticulatesAdhesive

A method for coating tubular food-casings (2), particularly skins with flavoring substances in particle form, includes wetting the casing (2) on the inside with adhesive, and then applying desired flavoring substances (6) onto the formed adhesive layer. The tubular casing (2), coated on the inside with adhesive, is guided through a first squeezing zone (5) and a second squeezing zone (8) in the travel direction, where the respective interior cross-sections of the tubular casing are temporarily closed. The second squeezing zone (8) is positioned higher than the first squeezing zone (5). The tubular casing is brought into the form of an inflated sack (2b) in between the two squeezing zones (5, 8) by a supply of particulate flavoring substances (6) and an air pocket (7) inserted into the interior of the tubular casing. During travel, the casing entrains the flavoring substances (6) from the supply.

Owner:WORLD PAC INT

Packaging film for foodstuffs

The present invention provides a method for coating tubular food-casings (2), particularly skins with flavoring substances in particle form, including wetting the casing (2) on the inside with adhesive, and then applying desired flavoring substances (6) onto the formed adhesive layer. The tubular casing (2), coated on the inside with adhesive, is guided through a first squeezing zone (5) and a second squeezing zone (8) in the travel direction, where the respective interior cross-sections of the tubular casing are temporarily closed. The second squeezing zone (8) is positioned higher than the first squeezing zone (5). The tubular casing is brought into the form of an inflated sack (2b) in between the two squeezing zones (5, 8) by a supply of particulate flavoring substances (6) and an air pocket (7) inserted into the interior of the tubular casing. During travel, the casing entrains the flavoring substances (6) from the supply.

Owner:WORLD PAC INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com