Patents

Literature

49results about "Thermoplastic sausage casings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food casing with barrier action for oxygen and/or water vapor and suitable for absorbing and storing a food additive and releasing it to the food

InactiveUS20090214722A1Avoid weightPrevents aroma lossThermoplastic sausage casingsMultilayer sausage casingsFood additiveWater vapor

The present invention relates to a multilayer seamless tubular film as a food casing with barrier action for oxygen and / or water vapor, which is capable of absorbing and storing a food additive and releasing it to the food. It is used as an envelope of pasty or liquid materials and is particularly suitable as a synthetic sausage casing. The invention further relates to a particular liquid smoke composition which, in combination with such a tubular film, is particularly suitable for transferring the dyes and flavorings present to the food.

Owner:CASETECH

Films comprising liquid smoke and flavorants

InactiveUS20090155430A1Thermoplastic sausage casingsMultilayer sausage casingsLiquid smokeEngineering

A process for producing a film having incorporated or applied thereon or therein an additive such as liquid smoke is provided wherein the film comprises a liquid absorbent layer and an impermeable layer. The films can be used for producing a tubular casing or shrinkbag.

Owner:EI DU PONT DE NEMOURS & CO

Flavor release casing

InactiveUS20060057258A1Simple preparation processUnique flavorThermoplastic sausage casingsMonolayer sausage casingsFlavouring agentFood flavor

The present invention relates to shirred, nonfibrous casings internally coated with compositions of concentrated oil-based natural flavorants which transfer to foodstuffs, such as sausage meats, encased during cooking, resulting in foodstuffs flavored by the internal casing coating.

Owner:VISCASE CORP

Additive delivery laminate and packaging article comprising same

InactiveUS20060051465A1Ready-for-oven doughsThermoplastic sausage casingsPolymer scienceWater insoluble

An additive delivery laminate is suitable for packaging a food product which is cooked in the package, with an additive transferring from the laminate to the food product. The additive delivery laminate has a substrate and an additive delivery layer. The additive delivery layer contains a water-insoluble thermoplastic polymer, a polymer toughening agent, and additive granules containing a colorant, flavorant, and / or odorant. The polymer toughening agent is present in a blend with the water-insoluble thermoplastic polymer. Polyisobutylene is a preferred water-insoluble thermoplastic polymer, and hydrogenated wood rosin is a preferred polymer toughening agent. The polymer toughening agent decreases the tendency of the water-insoluble thermoplastic polymer to form legs or transfer to the food product upon stripping the laminate from the food product after cooking and transfer to the additive to the food product.

Owner:CRYOVAC ILLC

Additive transfer film suitable for cook-in end use

InactiveUS7183006B2Avoid handlingAvoid wastingThermoplastic sausage casingsWrappersPolyesterPolyolefin

A multilayer film has a first layer and a second layer. The first layer comprises an additive, a binder, and a crosslinking agent. The additive is a flavor, fragrance, colorant, antimicrobial agent, antioxidant, chelating agent, and / or odor absorbent. The binder is a polysaccharide and / or a protein. The crosslinking agent comprises a compound with at least two carbonyl groups. The second layer comprises a non-water-soluble thermoplastic polymer comprising at least one member selected from the group consisting of polyolefin, polyamide, polyester, polyvinylidene chloride, polyvinyl chloride, and polystyrene. Each of the additive, binder, and crosslinking agent are present throughout a thickness of the first layer. Preferably, the first layer is coated onto the second layer, which is preferably a non-water-soluble thermoplastic polymer, e.g., polyolefin, polyamide, and / or polyester. The film is especially useful for cook-in applications, in which a food product (preferably comprising uncooked meat) is packaged in the film with the coated layer against the meat. The meat is then cooked and the additive transfers to the meat, and purge can be very low. The invention also pertains to a process for preparing a cooked food product, process for making a coated film, and articles formed from the film, such as bags and casings.

Owner:CRYOVAC INC

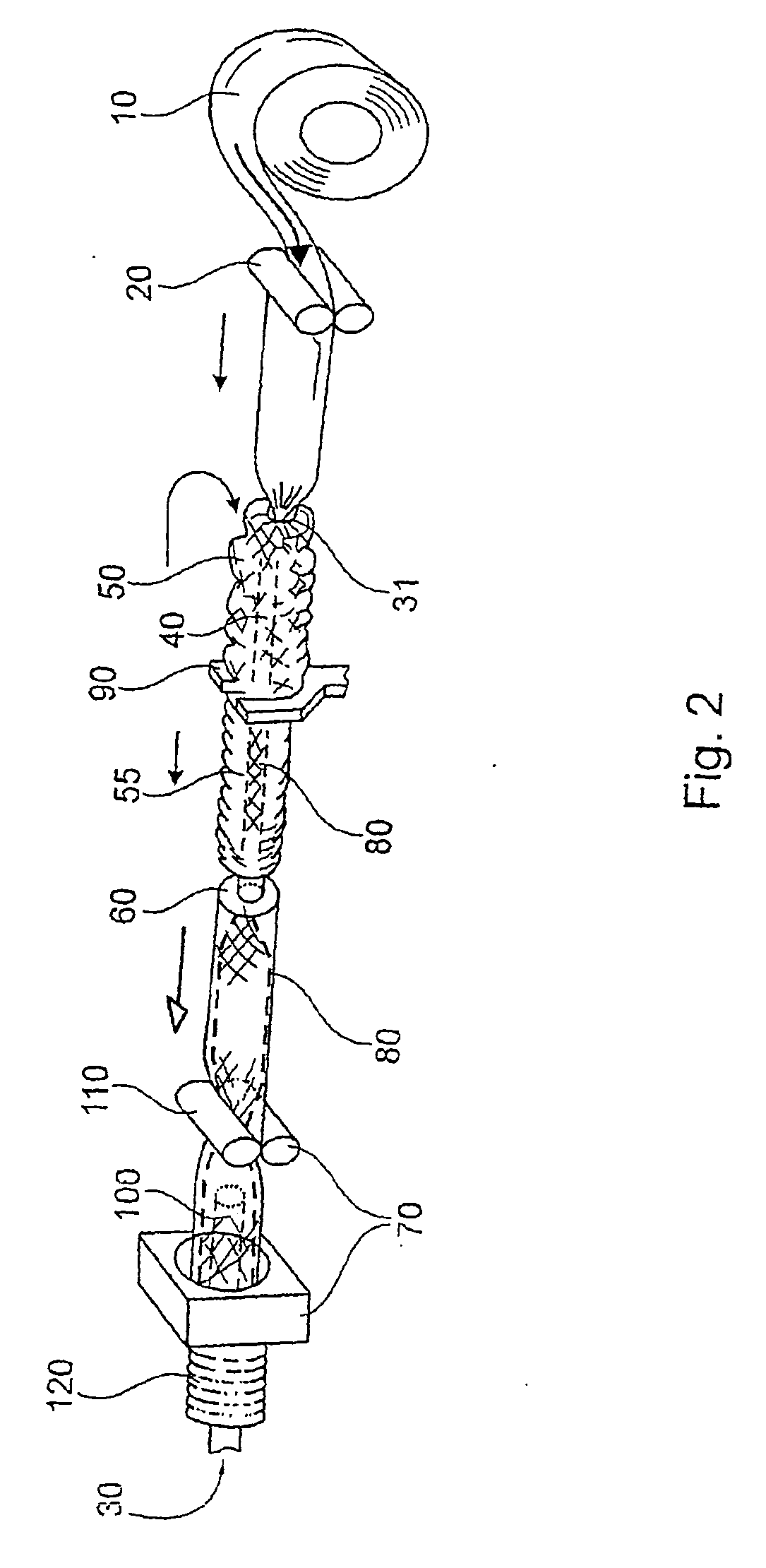

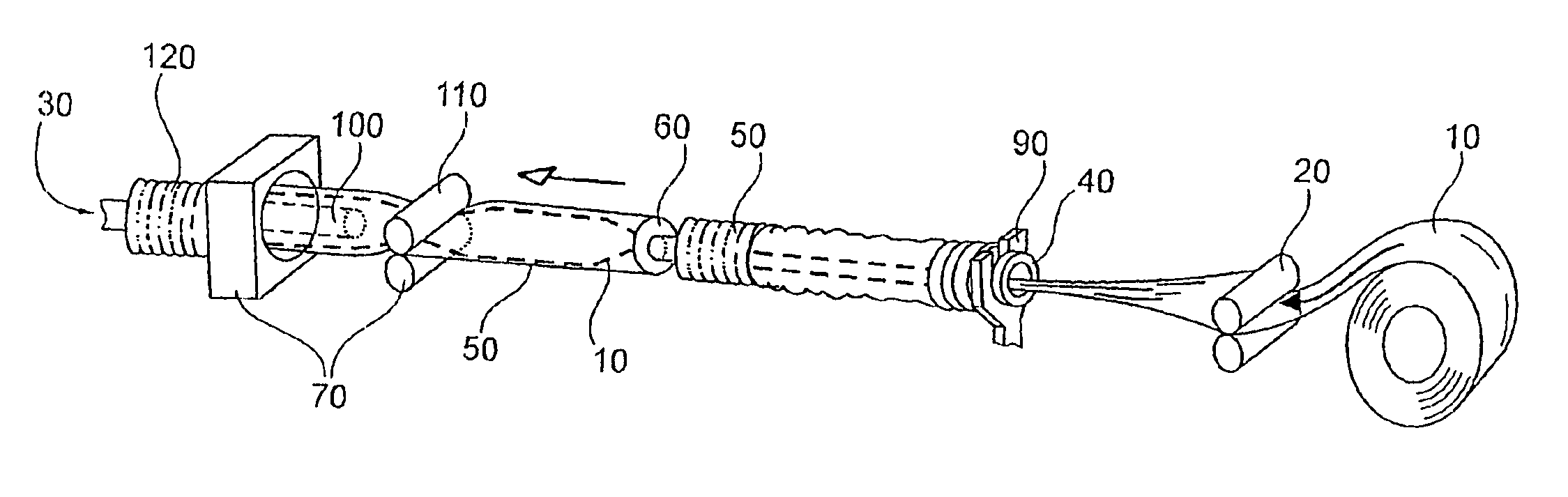

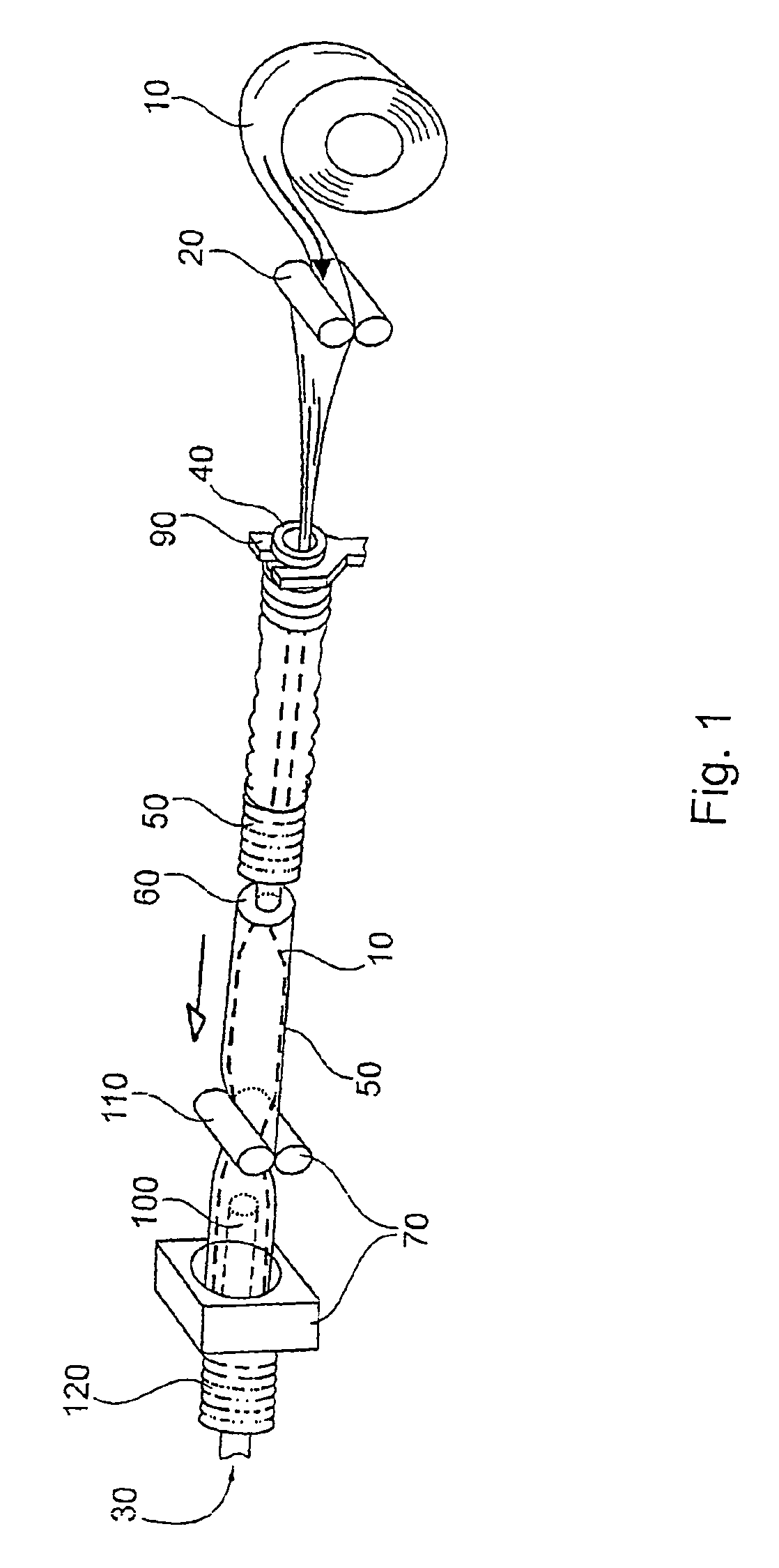

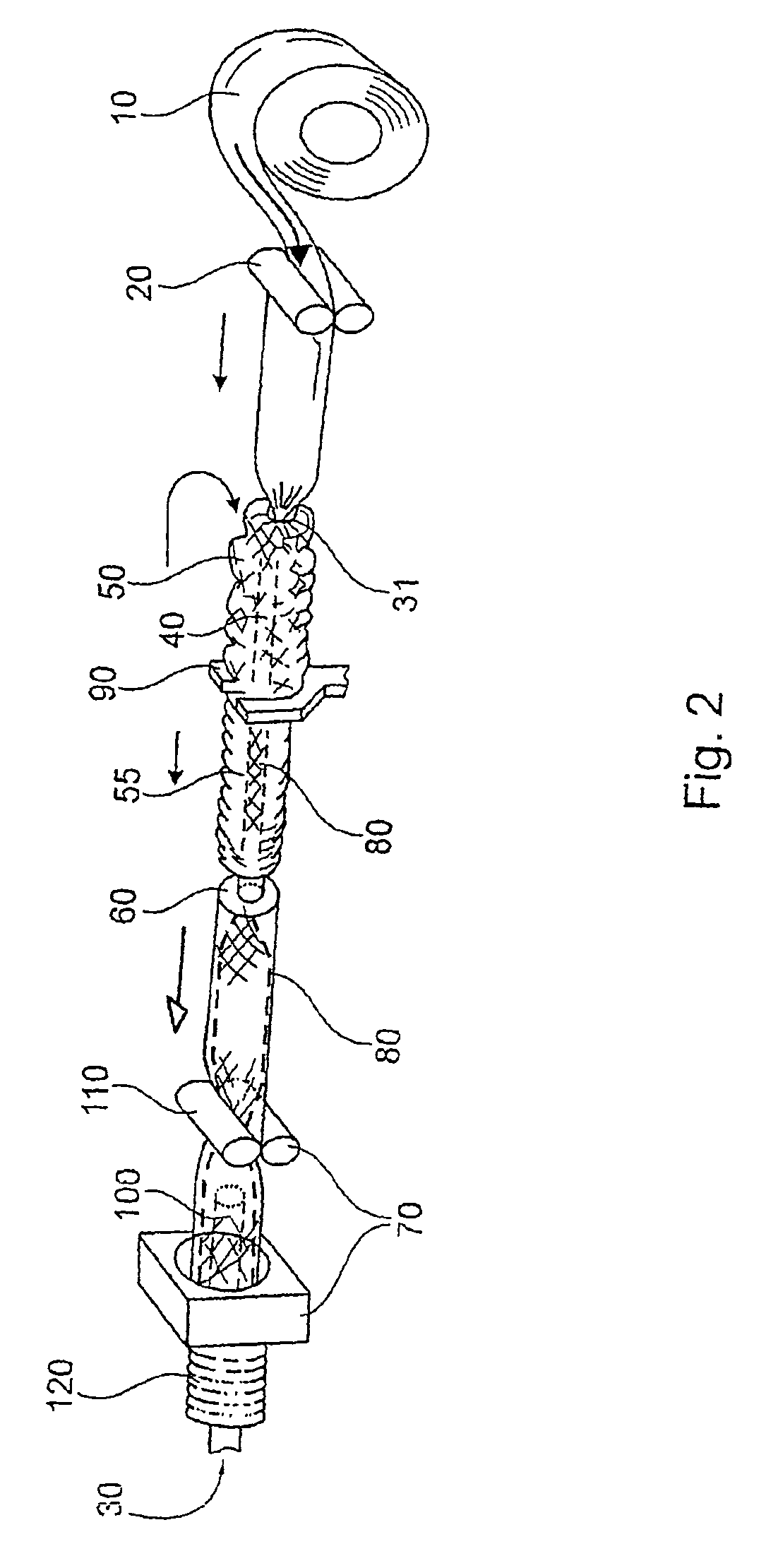

Process For Producing A Composite Food Casing

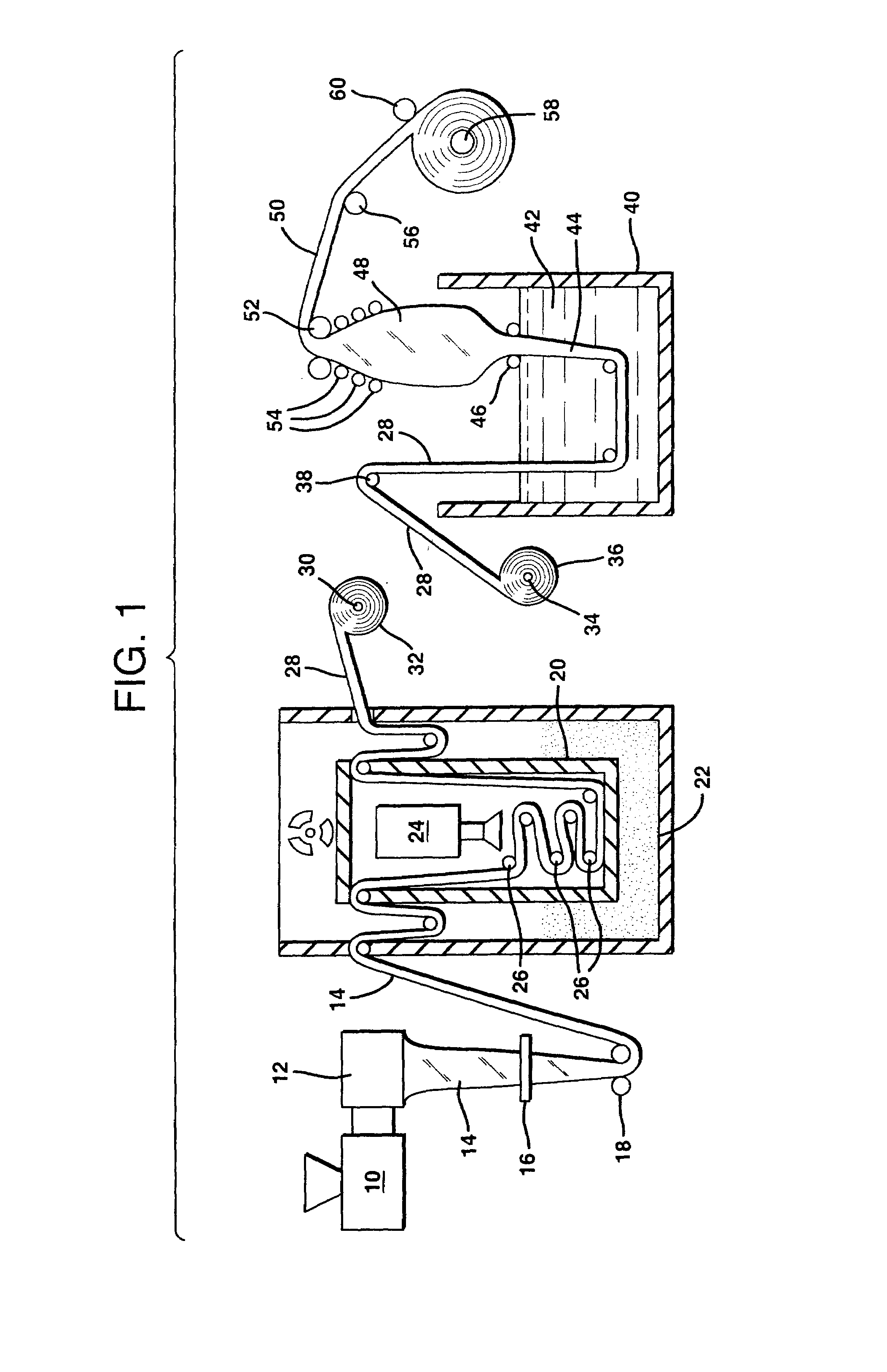

InactiveUS20100255230A1Avoid entanglementThermoplastic sausage casingsMultilayer sausage casingsPulp and paper industry

The invention relates to a process for producing a composite casing shirred to a caterpillar, said process comprising steps of pulling an outer casing over the inner casing, and optionally a net between the inner and outer casings, or over the outer casing, and finally shining the composite casing thus obtained to give a compact tube, which is cut to yield caterpillars.

Owner:VISKOTEEPAK BELGIUM NV

Process for producing a composite food casing

InactiveUS8226457B2Thermoplastic sausage casingsMultilayer sausage casingsPulp and paper industryCaterpillar

The invention relates to a process for producing a composite casing shirred to a caterpillar, said process comprising steps of pulling an outer casing over the inner casing, and optionally a net between the inner and outer casings, or over the outer casing, and finally shirring the composite casing thus obtained to give a compact tube, which is cut to yield caterpillars.

Owner:VISKOTEEPAK BELGIUM NV

Vinylidene chloride polymer compositions and food casings made therefrom

InactiveUS20050255263A1Improve meat adhesionThermoplastic sausage casingsFlexible coversChlorideAlpha-olefin

The present invention is a poly(vinylidene chloride) interpolymer composition comprising (1) a copolymer of an alpha olefin and an alkyl ester of an unsaturated carboxylic acid and (2) an interpolymer of vinylidene chloride and vinyl chloride, the copolymer being present in an amount effective to improve meat adhesion of a food casing made from the interpolymer composition having the copolymer as compared with a composition having the same proportions of components as the interpolymer composition but without the added copolymer (hereinafter effective amount). Preferably, the copolymer comprises ethylene and at least one alkyl ester of an unsaturated carboxylic acid. The invention is also a process for preparing a thermoplastic food casing which comprises adding an effective amount of a copolymer of an alpha olefin and an alkyl ester of an unsaturated carboxylic acid to a an interpolymer of vinylidene chloride and vinyl chloride to improve meat adhesion of the food casing. Additionally, the invention is a film comprising an interpolymer of vinylidene chloride and vinyl chloride and an effective amount of a copolymer of an alpha olefin and an alkyl ester of an unsaturated carboxylic acid. The film is preferably used in applications for contacting meat. Additionally, the invention is a combination of a film comprising an interpolymer of vinylidene chloride and vinyl chloride and an effective amount of a copolymer of an alpha olefin and an alkyl ester of an unsaturated carboxylic acid and, adjacent thereto or in contact therewith, a fatty substance, preferably a meat having a fat content, meat product having fat content, or other food having a fat content. In another aspect, the invention is a package useful for meats or other fatty substances comprising an interpolymer of vinylidene chloride and vinyl chloride and an effective amount of a copolymer of an alpha olefin and an alkyl ester of an unsaturated carboxylic acid wherein the package is designed for contact of interpolymer of vinylidene chloride with the meat or fatty substance. In another aspect, the invention is a sausage casing having a film comprising an interpolymer of vinylidene and chloride vinyl chloride and an effective amount of a copolymer of an alpha olefin and an alkyl ester of an unsaturated carboxylic acid. In yet another aspect, the invention is the use of a vinylidene chloride interpolymer composition comprising and interpolymer of vinylidene chloride and vinyl chloride and an effective amount of at least one copolymer of an alpha olefin and an alkyl ester of an ethylenically unsaturated carboxylic acid in a composition suitable for making a film, the resulting film, a molded article, a package, in each case preferably suitable for contacting or containing a fatty substance or food, preferably in a sausage casing.

Owner:LEE ERIC K C +1

Intrinsically stable shirred plastic food casing

ActiveUS7803437B2Suitably producedSwelling capacityWrappers shrinkageThermoplastic sausage casingsEmulsionPolyamide

Disclosed is a shined tubular food casing based on a thermoplastic blend of at least one polyamide and / or copolyamide and at least one hydrophilic component. The casing is biaxially stretch-oriented and impregnated on the inside and / or outside with a component which allows the pleats which are formed during shining of the casing to adhere to each other. The component preferably comprises at least one polymer. The casing is preferably shirred at a ratio of 80:1 to 500:1. The inventive shined casing is particularly stable from a mechanical perspective and can therefore be used especially for the production of cooked sausages, scalded-emulsion sausages, and small sausages on fully automatic sausage stuffing and clipping apparatuses.

Owner:KALLE AG

Films comprising liquid smoke and flavorants

A process for producing a film having incorporated or applied thereon or therein an additive such as liquid smoke is provided wherein the film comprises a liquid absorbent layer and an impermeable layer. The films can be used for producing a tubular casing or shrinkbag.

Owner:EI DU PONT DE NEMOURS & CO

Nylon food casing having a barrier core layer

ActiveUS7244481B2Good conformationEasy to processWrappers shrinkageSausage casingsThin membraneEngineering

Owner:VISCASE CORP

Food casing having an adhesive system and a transferable functional substance

The invention relates to a single layer or multilayer tubular food casing, in particular for foods which are scalded, cooked or heated in other ways in the casing, preferably for cooked-meat or scalded-emulsion sausages, hams, cured products or processed cheese, wherein the invention only relates to those casings which have an internal layer which consists of a thermoplastic polymer or predominantly comprises one such, having a substantially smooth, non-absorbent, non-porous and non-felt-like and non-woven-fabric-like surface.

Owner:CASETECH

Smoke-and steam-permeable food skin made from a thermoplastic mixture with a natural appearance

ActiveUS7976942B2High smoke permeabilityImprove water vapor permeabilityEnvelopes/bags making machineryThermoplastic sausage casingsWater vapor permeabilityCuticle

The invention relates to a single- or multi-layered food casing, made from a thermoplastic mixture which comprises at least one aliphatic polyamide and / or copolyamide, at least one or more synthetic water-soluble polymers and at least one organic and / or inorganic filler. The skin has a water vapor permeability, as determined according to DIN 53122, in the non-oriented, monoaxially or biaxially oriented state of 50 to 1500 g / m2·d. The food casing is particularly suitable for use as an artificial sausage casing, particularly for raw sausages.

Owner:KALLE AG

Multilayer composite having a polyester layer and a protective layer

Owner:EVONIK OPERATIONS GMBH

Multilayered two-dimensional or tubular food casing or film

ActiveCN101522035AThermoplastic sausage casingsMultilayer sausage casingsEngineeringCompanion animal

The present invention proposes for the first time a two-dimensional or tubular food casing or film with an at least seven-layered laminated structure, which has an EVOH layer as an oxygen barrier and in which the outer layer is formed by a high-temperature-resistant material such as PET, which apart from outstanding appearance-related properties also makes much higher further processing speeds (numbers of cycles) possible than previously known.

Owner:库恩设备制造有限公司

Process for producing raw sausage with shortened ripening time

ActiveUS20100047417A1Short timeMature fastThermoplastic sausage casingsMeat/fish preservationThermoplasticWater vapor permeability

A process accelerating the ripening of raw sausages by incorporating a casing having a water vapor permeability of less than 600 g / m2 d at a relative humidity of less than 60%. Preferably, the process employs casings having a water vapor permeability of 50 to 400 g / m2 d, more preferably 70 to 300 g / m2 d, particularly preferably 80 to 200 g / m2 d. The process concerns, in particular, single-layered or multilayered casings made of thermoplastics, optionally also coated textile fiber skins or cellulose fiber skins.

Owner:KALLE AG

Nonwoven having improved wet fastness and alkali resistance and cellulose hydrate-based food casing from said nonwoven

ActiveUS8268129B2Improve permeabilityBonded firmlyThermoplastic sausage casingsNon-fibrous pulp additionHemp fiberPolypropylene

The invention relates to a wet-fast nonwoven, preferably a fiber paper, which comprises fibers from a cellulose-containing material and fibers from a thermoplastic material welded firmly together at their points of intersection. The fibers from the cellulose-containing material are preferably hemp fibers while the fibers from the thermoplastic material are preferably fibers from polypropylene, polyester or polyamide. The fibers are interlinked under the action of pressure and / or heat, especially using a pair of heated calender rolls. The nonwoven or the fiber paper is especially used to reinforce food casings based on regenerated cellulose, especially in artificial cellulose hydrate-based sausage skins.

Owner:KALLE AG

Low moisture barrier film

ActiveUS9999233B1Reduce downtimeHigh tensile strengthThermoplastic sausage casingsMultilayer sausage casingsFood contactEngineering

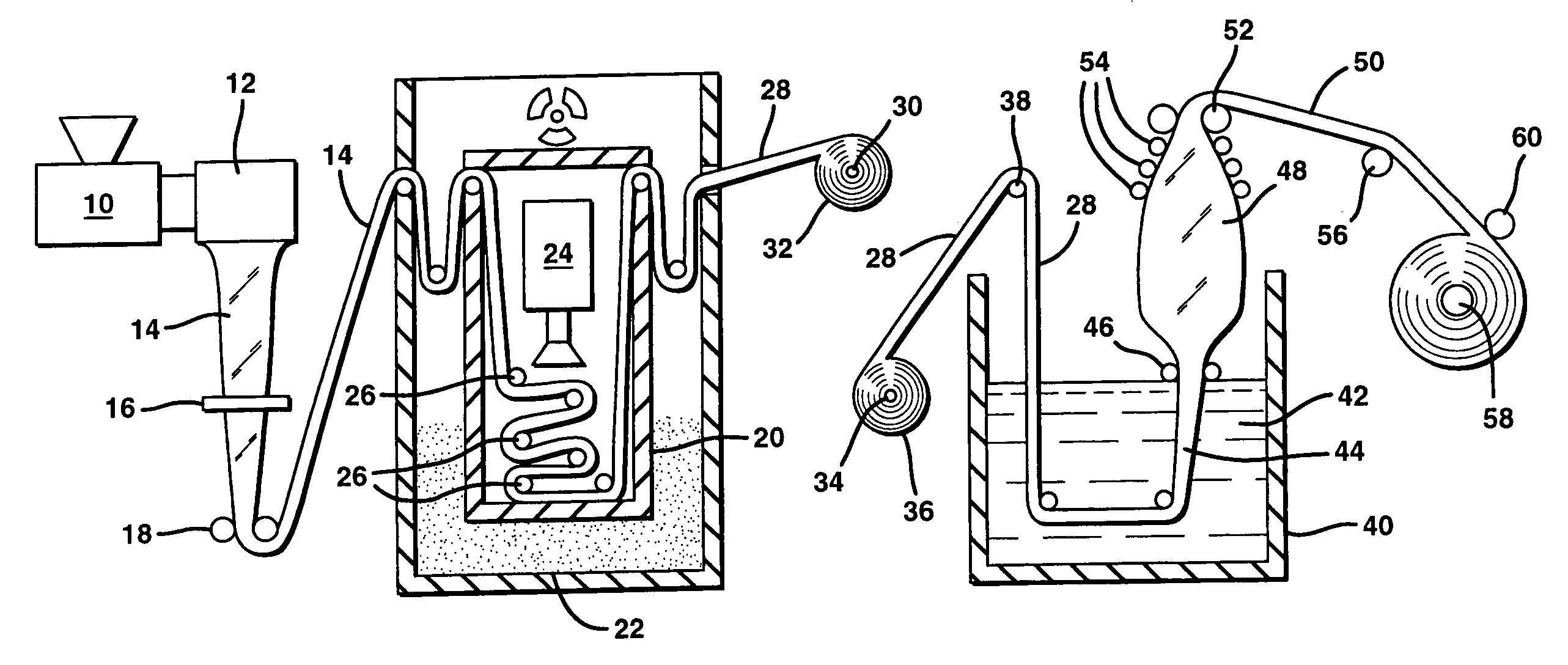

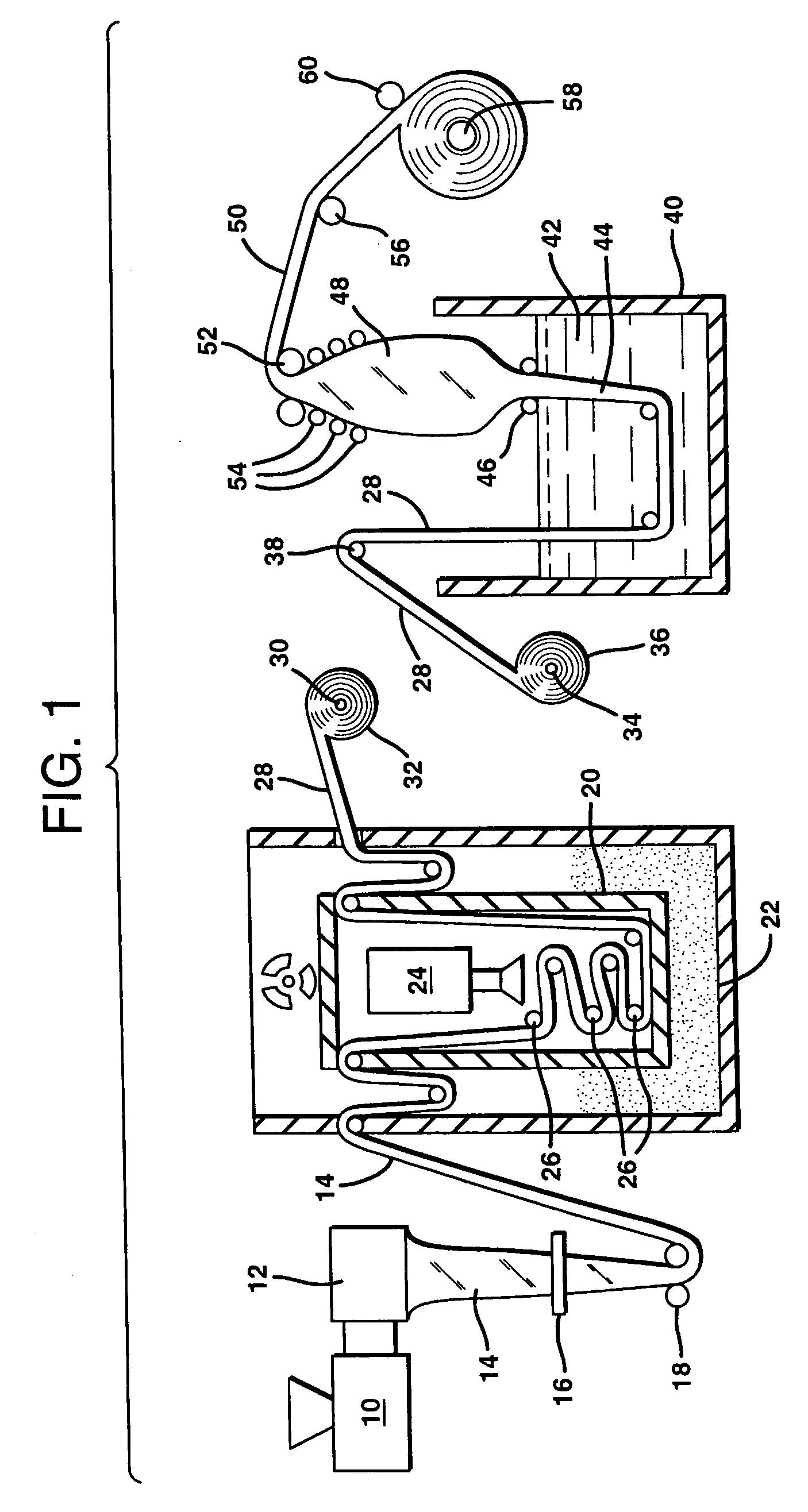

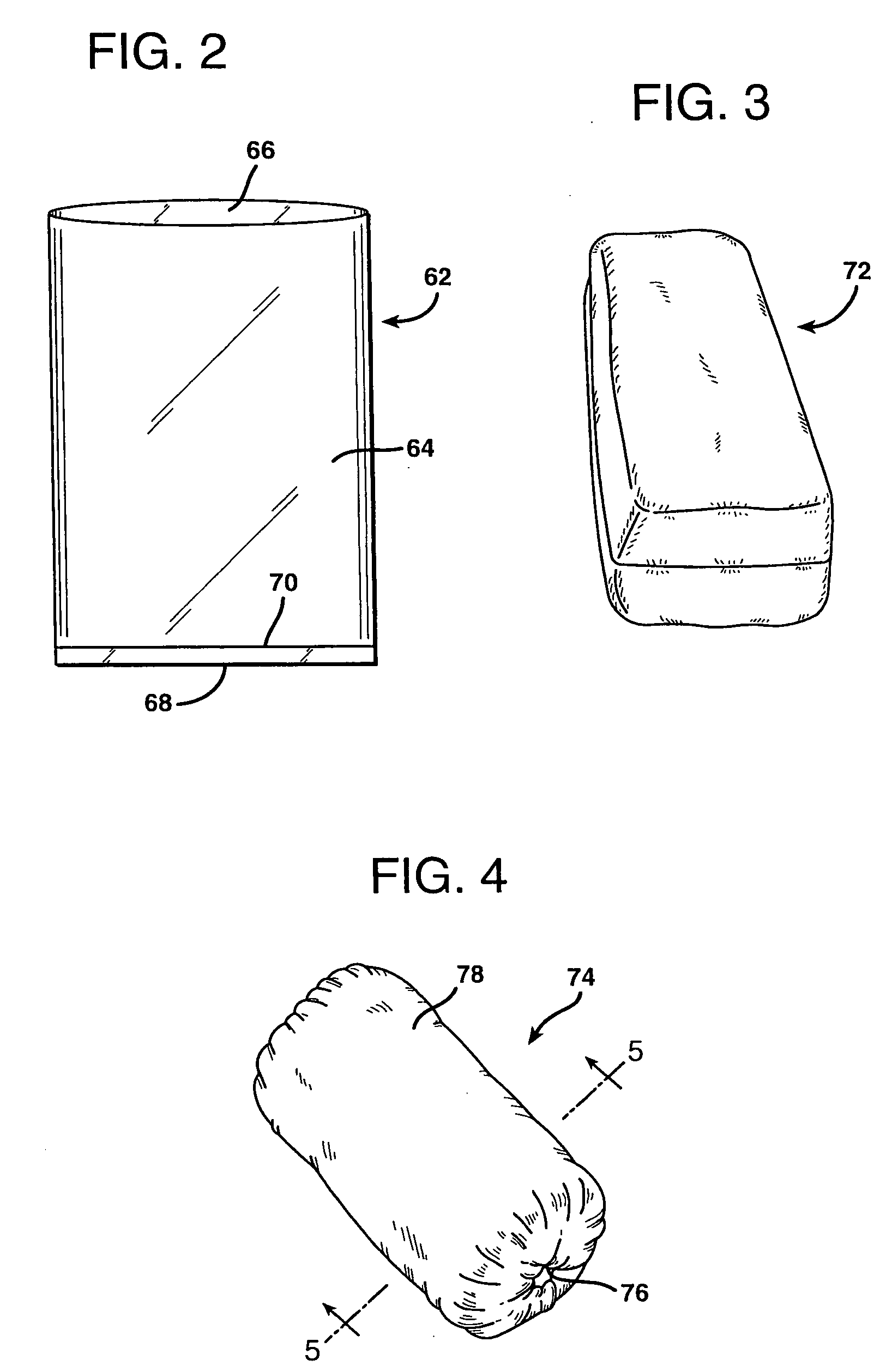

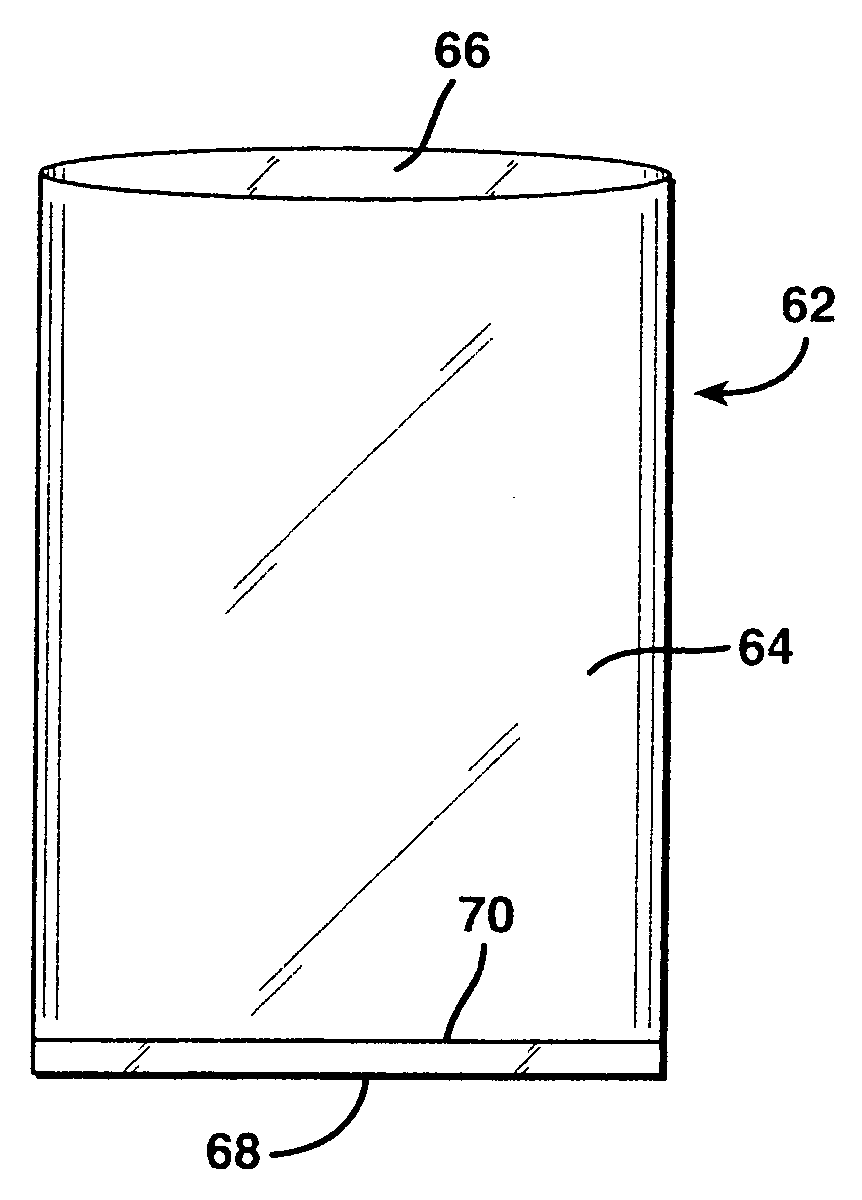

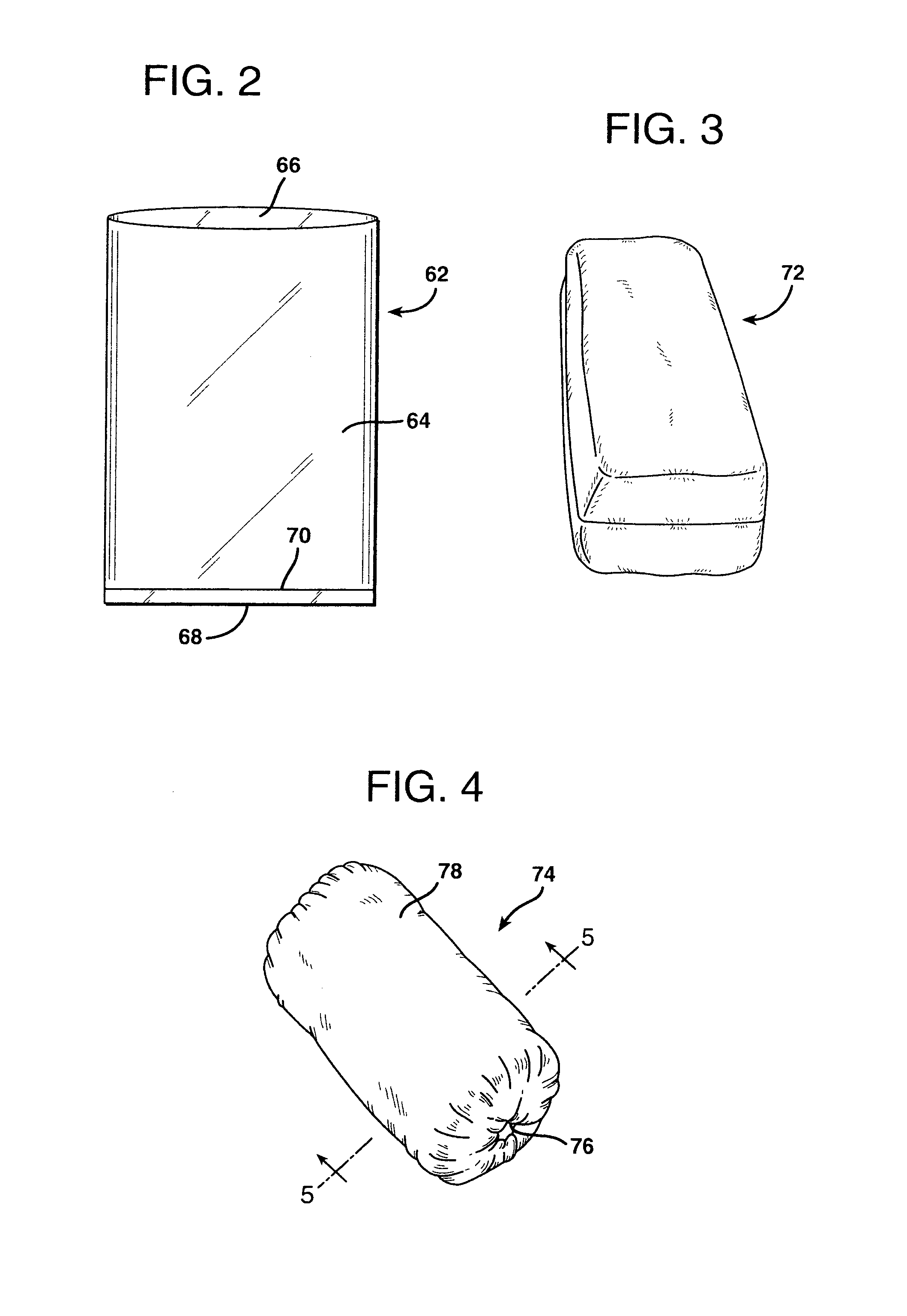

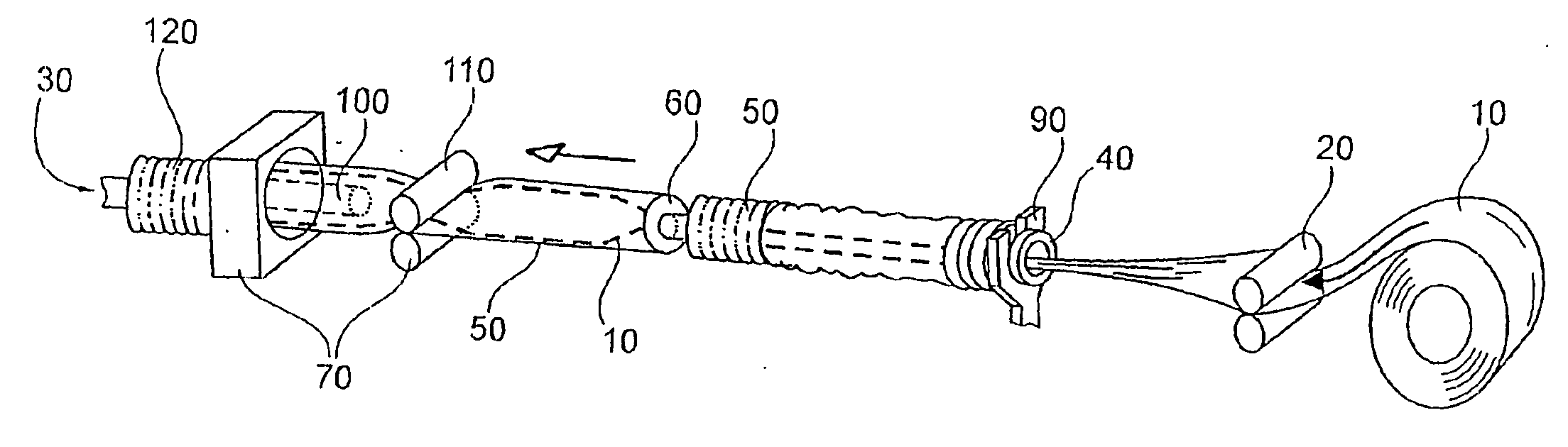

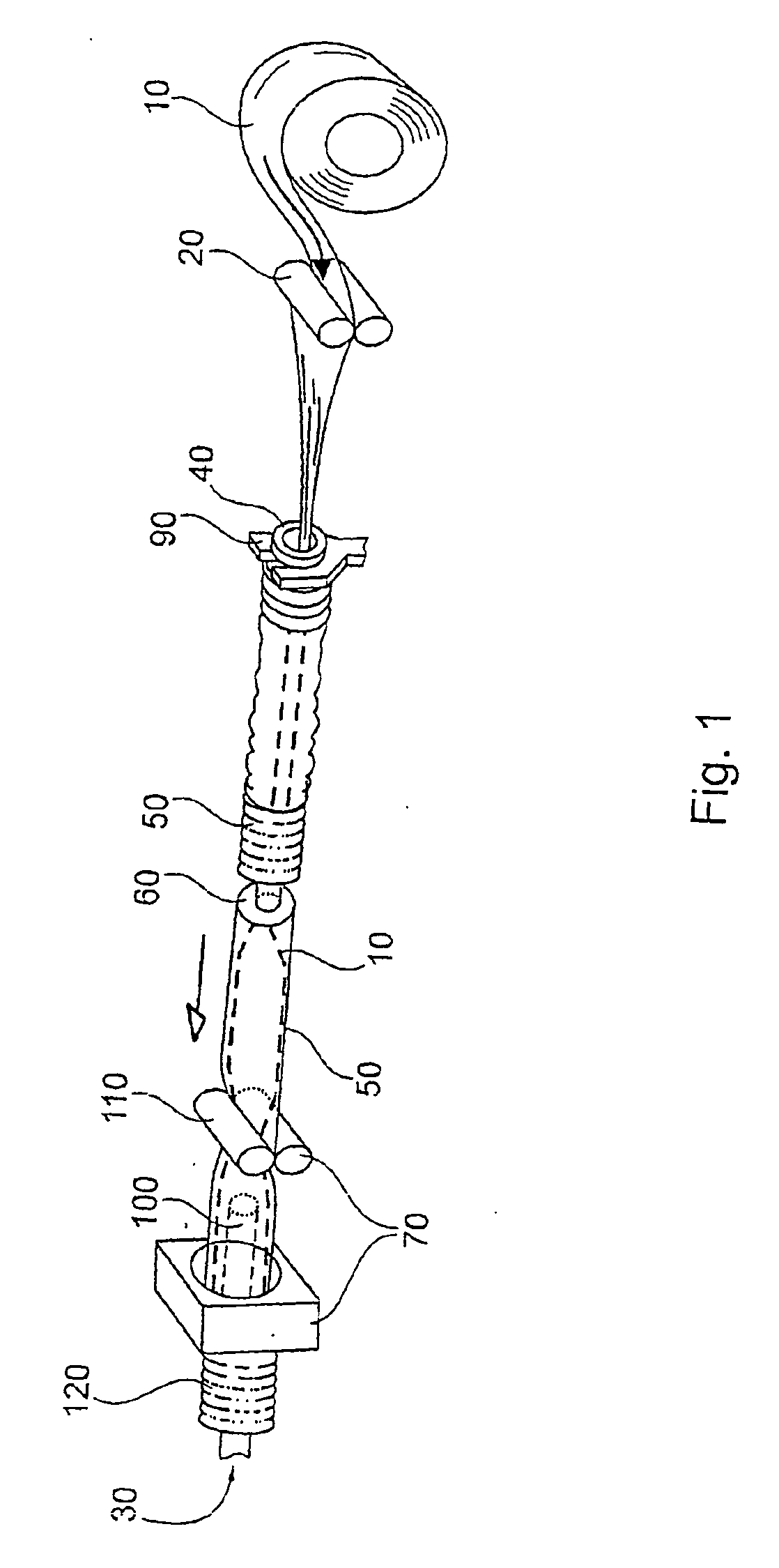

The present invention relates to a flat, multilayered, low moisture, barrier, laminated thermoplastic film with an absorptive food contact layer coated with a flavoring and / or coloring agent, which can be formed on automatic stuffing machinery into a sealed tube in a continuous manner for use as a food casing. This film has an absorptive food contact layer, an oxygen barrier layer, and a polyethylene outer layer. The coloring and / or flavoring agent on the absorptive layer is released onto the surface of encased foodstuff during cooking and processing.

Owner:VISCASE CORP

Flexible tubular food casing coated with meltable, thermoplastic polymers

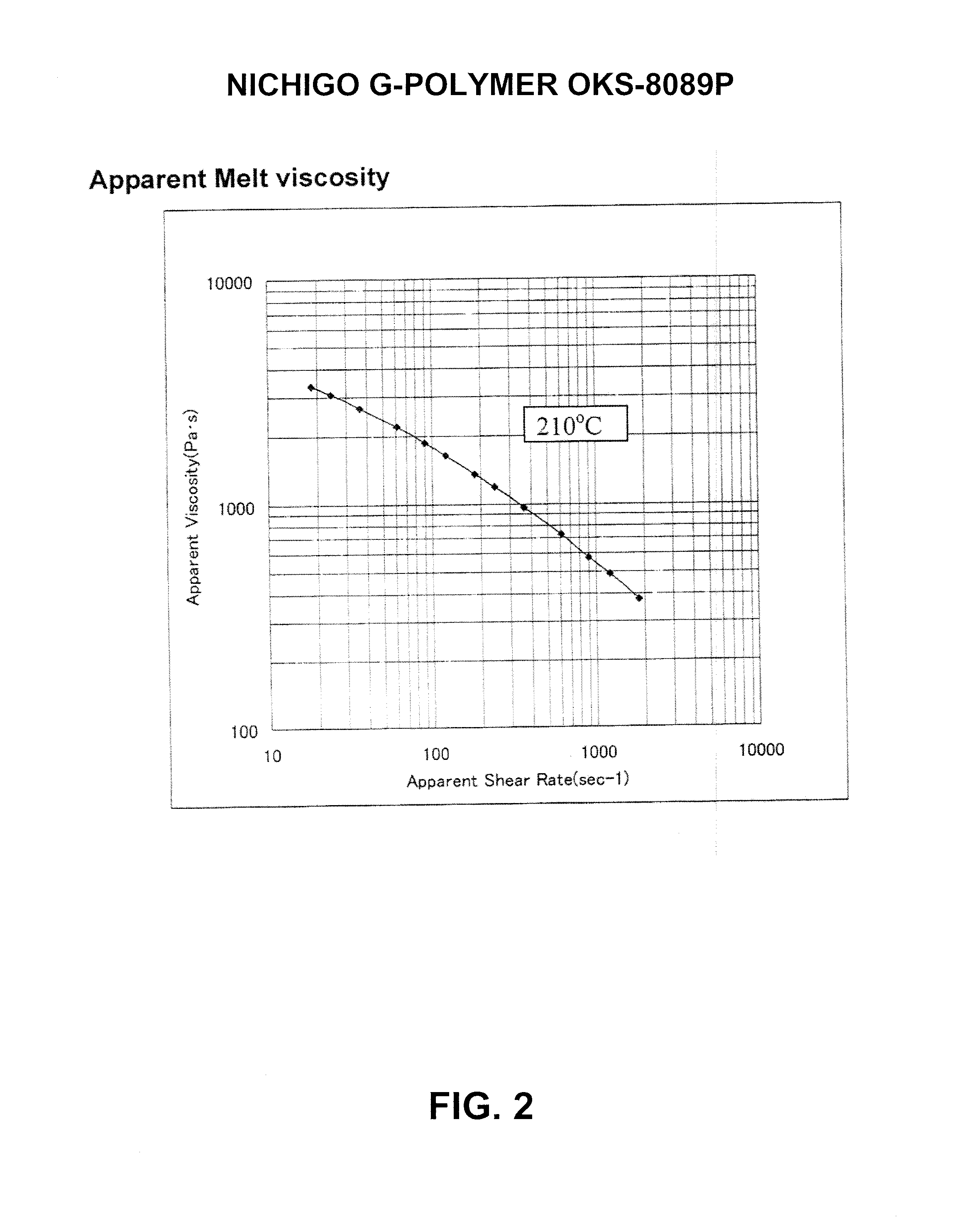

ActiveUS20110236539A1Reduce expenditureSave energyThermoplastic sausage casingsLayered productsEmulsionThermosetting polymer

A flexible tubular food casing having a flat support material is provided which, on at least one side, has a continuous coating based on a hotmelt polymer, with the coating preferably situated on the outside. The continuous coating has a weight per unit area of 3 to 200 g / m2, preferably 15 to 50 g / m2. The hotmelt polymers have an MVR value in the range of about 25 to 500 cm3 per 10 min, measured at 190° C. with a load of 2.16 kg. The flexible tubular food casing is suitable as a synthetic sausage casing for raw sausage, scalded-emulsion sausage or cooked-meat sausage

Owner:KALLE AG

Textured non-porous barrier transfer casing

ActiveUS20200037623A1Sufficient barrier effectPreventing contamination of environmentThermoplastic sausage casingsOrganic chemistryPolymer sciencePolyolefin

The present invention provides a functional additive transferring (co)extruded thermoplastic food casing having a water vapor barrier and / or oxygen barrier effect wherein an inside surface of the thermoplastic food casing has a textured surface which forms a three-dimensional pattern of higher and lower retaining capacity for a functional additive, wherein the thermoplastic food casing having a textured surface in case of a monolayer casing or an inner layer comprising the inside surface having a textured surface in case of a multilayer casing comprises as a main component at least one thermoplastic polymer material selected from the group consisting of (co)polyamides, (co)polyolefins, (co)polyester and vinylidenchloride (co)polymers, wherein the (co)extruded thermoplastic food casing does not comprise a net and / or a material forming a net or any other three dimensional structure on its outside surface, wherein the average thickness of the thermoplastic food casing in the areas having a higher retaining capacity is in a range of from 1 to 100 μm, wherein the average thickness of the thermoplastic food casing in the areas having a lower retaining capacity is in a range of from 191 to 2000 μm, provided that the thickness difference between the average thickness in the areas having higher retaining capacity and the average thickness in the areas having a lower retaining capacity is in a range of from 160 to 1950 μm and that a ratio of the average thickness of the thermoplastic food casing in the areas having a higher retaining capacity and the average thickness of the thermoplastic food casing in the areas having a lower retaining capacity is in a range of from 0.002 to 0.25.

Owner:VISCOFAN

Smokable thermoplastic casing

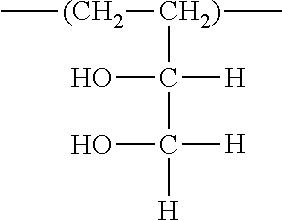

ActiveUS20140322394A1Excellent oxygen barrier propertiesThermoplastic sausage casingsMonolayer sausage casingsThermoplasticLiquid smoke

A novel smokable thermoplastic film, smokable by both liquid smoke and gaseous smoke, that may be produced as a film or a tube, as in a food casing. This newly disclosed film is a blend of a polyamide base, an amorphous polyvinyl alcohol and, optionally, an antiblocking agent.

Owner:VISCASE CORP

Smoke and water vapor-permeable food casing with optimized bonding properties

A tubular, seamless, water vapor permeable, smokable, biaxially draw-oriented and partially or completely heat-set food casing is provided having at least two layers based on thermoplastic polymers. At least one layer A, which does not form the inside layer, comprises a blend of aliphatic (co)polyamide and at least one hydrophilic polymer, while the inside layer I comprises a blend of aliphatic orisocyclic (co)poly amide and a block copolymer selected from polyether-amide, polyether-ester and polyether-urethane. The casing is produced by a tubular-film blowing process or a process with biaxial tubular-film draw-orientation. The casing is envisaged more particularly as synthetic sausage casing, especially for smoked raw sausage, such as salami.

Owner:KALLE AG

Smokable thermoplastic casing

ActiveUS9532578B2Excellent oxygen barrier propertiesThermoplastic sausage casingsMonolayer sausage casingsThermoplasticLiquid smoke

A novel smokable thermoplastic film, smokable by both liquid smoke and gaseous smoke, that may be produced as a film or a tube, as in a food casing. This newly disclosed film is a blend of a polyamide base, an amorphous polyvinyl alcohol and, optionally, an antiblocking agent.

Owner:VISCASE CORP

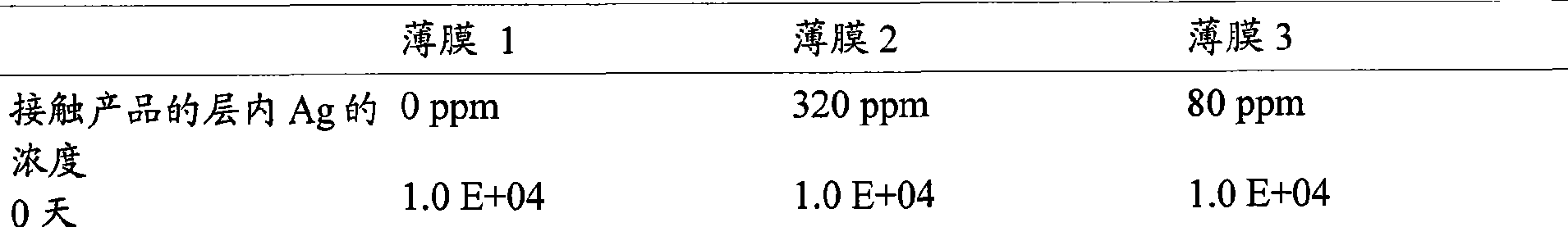

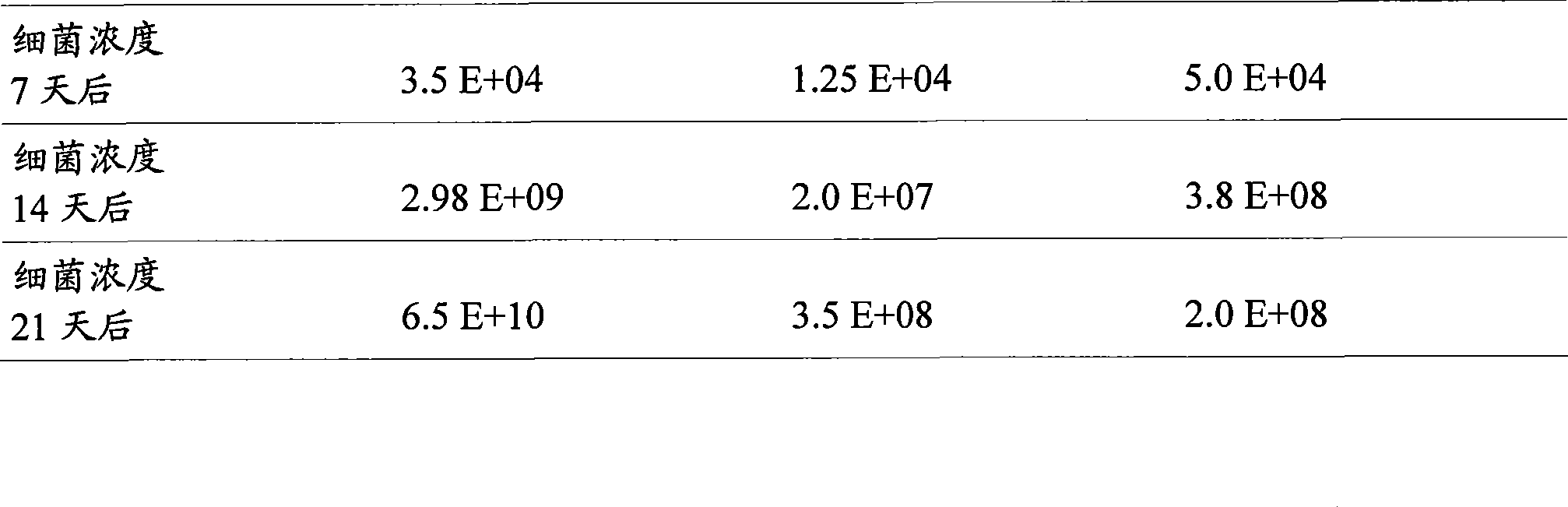

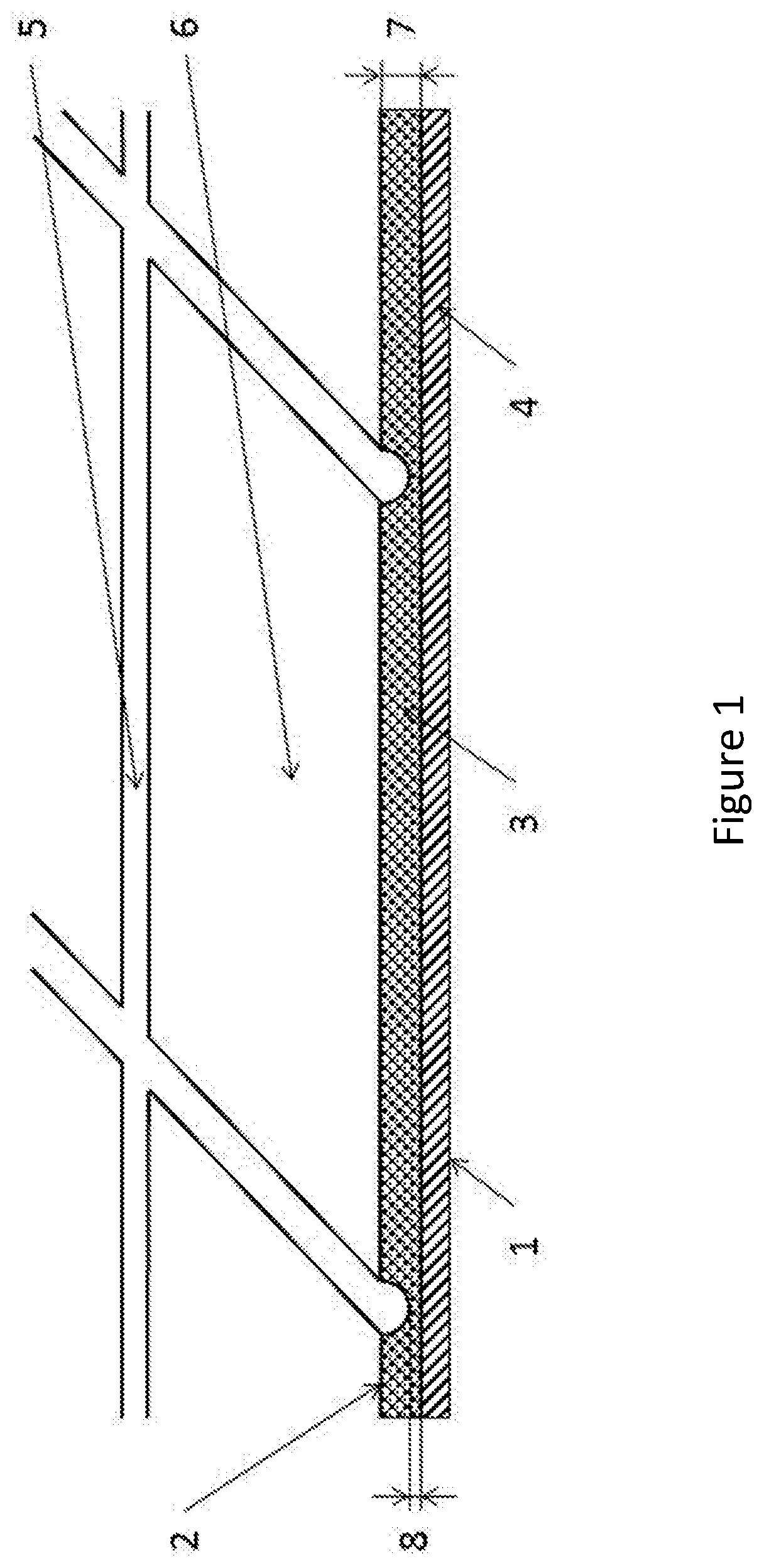

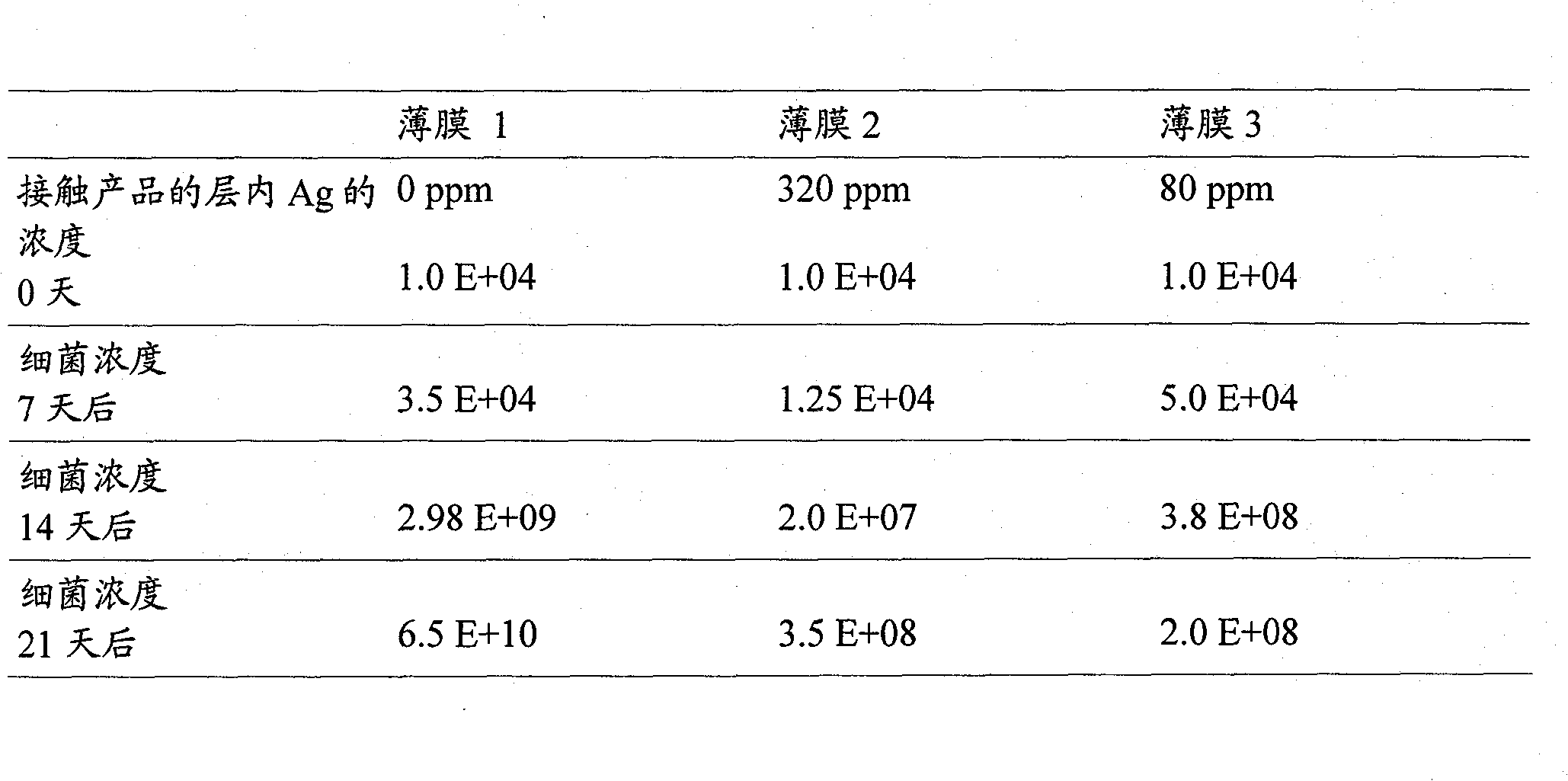

Antimicrobial food packaging

InactiveCN101522036ALoss of strengthLoss of durabilityThermoplastic sausage casingsFlexible coversFood packagingMetal

The invention relates to a single or multi-layered food packaging based on plastic. The layer or at least one of the layers contains at least one antimicrobially active metal. At least one part of the antimicobially active metal has a finely distributed metallic form and the remaining part is in the form of a salt.

Owner:库纳设备制造有限责任公司

Textured porous barrier transfer casing

ActiveUS20200037622A1Sufficient barrier effectAvoid pollutionContainers for flexible articlesThermoplastic sausage casingsPolymer sciencePolyolefin

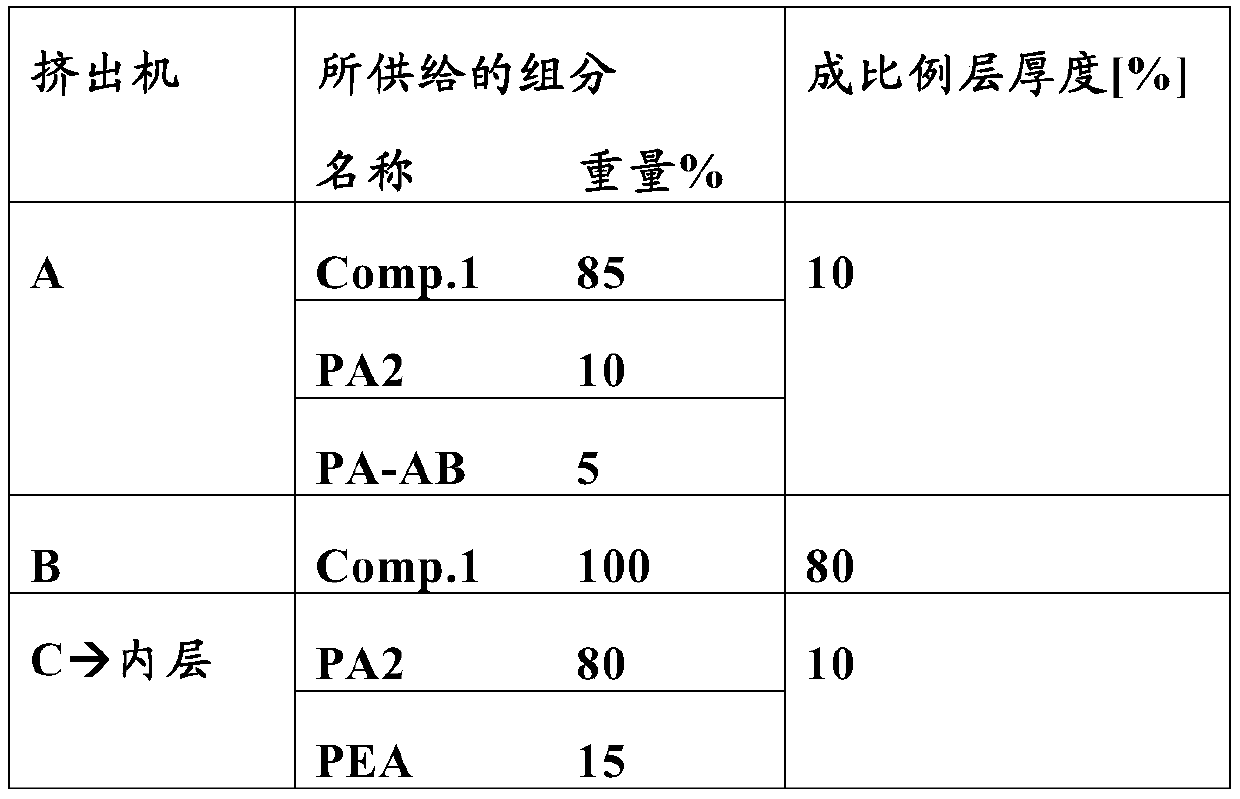

The present invention provides a multi-layered coextruded thermoplastic food casing comprising: at least one thermoplastic porous absorbing layer; and at least one layer having a barrier effect for water vapor and / or oxygen, wherein the at least one layer having a barrier effect for water vapor and / or oxygen has an average layer thickness in a range of from 5 to 60 μm over the entire surface area, wherein the at least one thermoplastic porous absorbing layer comprises as a main component at least one thermoplastic polymer material selected from the group consisting of (co)polyamides and (co)polyolefins, wherein the at least one thermoplastic porous absorbing layer comprises areas having a reduced average layer thickness and areas having a non-reduced average layer thickness, wherein the average layer thickness of the at least one thermoplastic porous absorbing layer in areas having a non-reduced average layer thickness is in a range of from 10 to 200 μm, wherein the average layer thickness in areas having a reduced average layer thickness is lower by 7 to 140 μm and is reduced by a range of from 30 to 85% compared to the areas having a non-reduced average layer thickness of the at least one thermoplastic porous absorbing layer, and wherein both areas having a reduced average layer thickness and a non-reduced average layer thickness comprise pores which are able to absorb a functional additive.

Owner:VISCOFAN

Antimicrobial food packaging

The invention relates to a single or multi-layered food packaging based on plastic. The layer or at least one of the layers contains at least one antimicrobially active metal. At least one part of theThe invention relates to a single or multi-layered food packaging based on plastic. The layer or at least one of the layers contains at least one antimicrobially active metal. At least one part of the antimicobially active metal has a finely distributed metallic form and the remaining part is in the form of a salt.antimicobially active metal has a finely distributed metallic form and the remaining part is in the form of a salt.

Owner:库纳设备制造有限责任公司

Artificial food casing, method for removing and method for manufacturing thereof

ActiveUS9968103B2Easy to detectPrecise positioningThermoplastic sausage casingsPrintable sausage casingsEngineeringArtificial feeding

Owner:VISKOTEEPAK BELGIUM NV

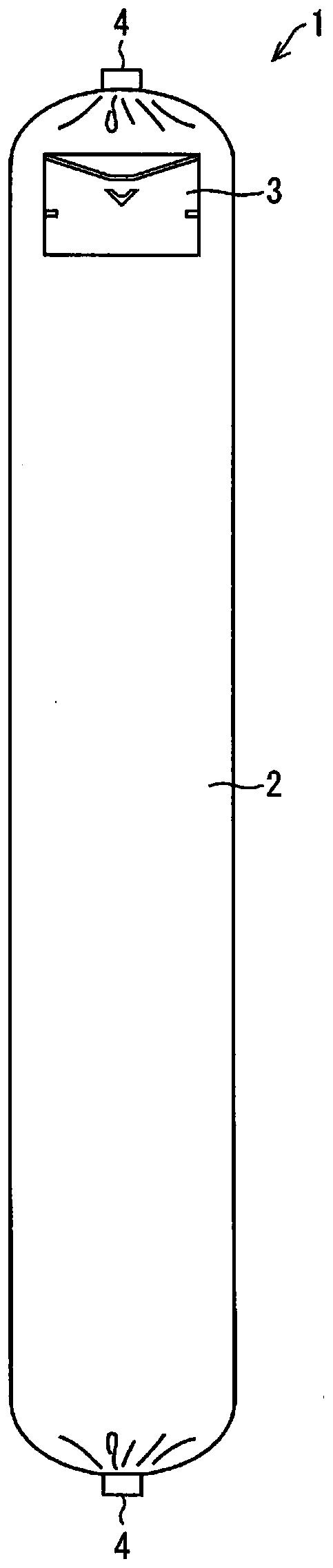

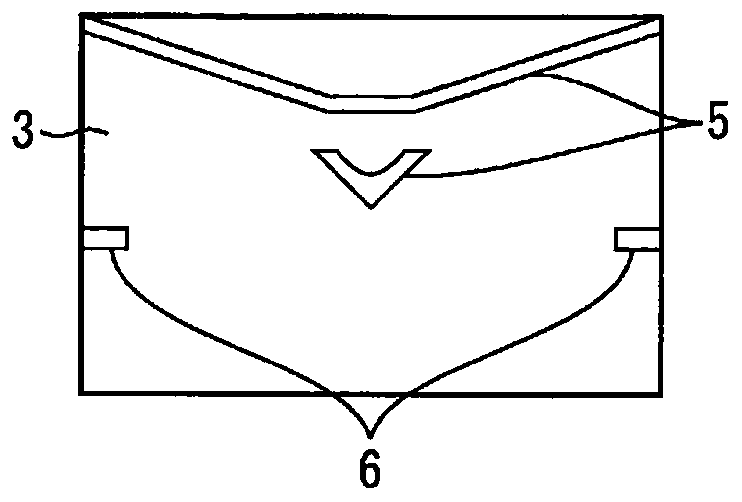

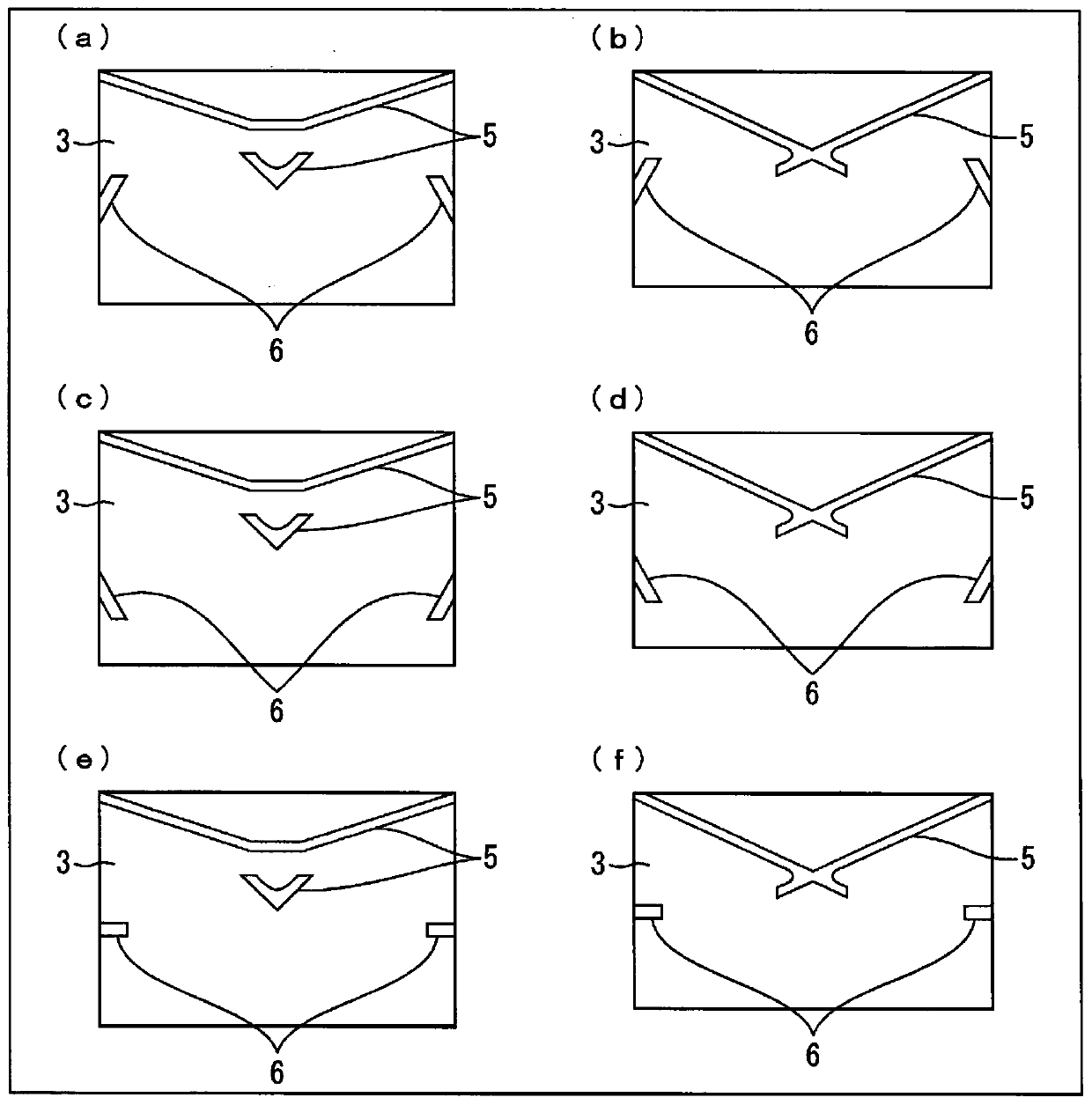

Package with opening piece

ActiveCN110234578AAvoid breakingThermoplastic sausage casingsMultilayer sausage casingsShrinkage rateMechanical engineering

Provided is a package with an opening piece that is configured to enable more secure opening of the package. A package (1) with an opening piece includes: a package (2) that is formed from a first polymeric film, has a tubular body thereof filled with a content, and has both ends thereof closed; and an opening piece (3) that is formed from a second polymeric film and joined to the package in sucha manner that a part of a rim of the opening piece can be pinched, wherein a shrinkage rate of the second polymeric film at 120 DEG C is 15.0% or higher.

Owner:KUREHA KAGAKU KOGYO KK

Artificial food casing, method for removing and method for manufacturing thereof

ActiveUS20160143301A1Easy to detectPrecise positioningThermoplastic sausage casingsPrintable sausage casingsEngineering

Owner:VISKOTEEPAK BELGIUM NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com