Smoke and water vapor-permeable food casing with optimized bonding properties

A water vapor, casing technology, applied in smoked casings, thermoplastic casings, packaged foods, etc., can solve the problems of impossibility and difficulty in peeling casings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Production of compounds of polyamide and polyvinylpyrrolidone

[0056] PA1 and PVP are metered into a commercial twin-screw extruder with a mass ratio of 85% to 15% (the diameter of the barrel is 25mm, the L / D ratio is 36, 12 barrels, and the feeding point for the pellets is in the barrel 1 Neutralization The feed point for the powder is in the barrel 7 with a twin-hole extrusion die, manufacturer: Coperion GmbH). At a screw speed of 200 rpm and heating in the range of 120-210°C, the polyamide was melted and blended with PVP to form plastic compounds. The clear extrudate exiting the die was cooled by immersion in a water bath and, after solidification, cut with a strip cutter to form pellets. The pellets were dried in a forced air dryer at about 100°C. The pellets are referred to below as Comp.1.

Embodiment 2

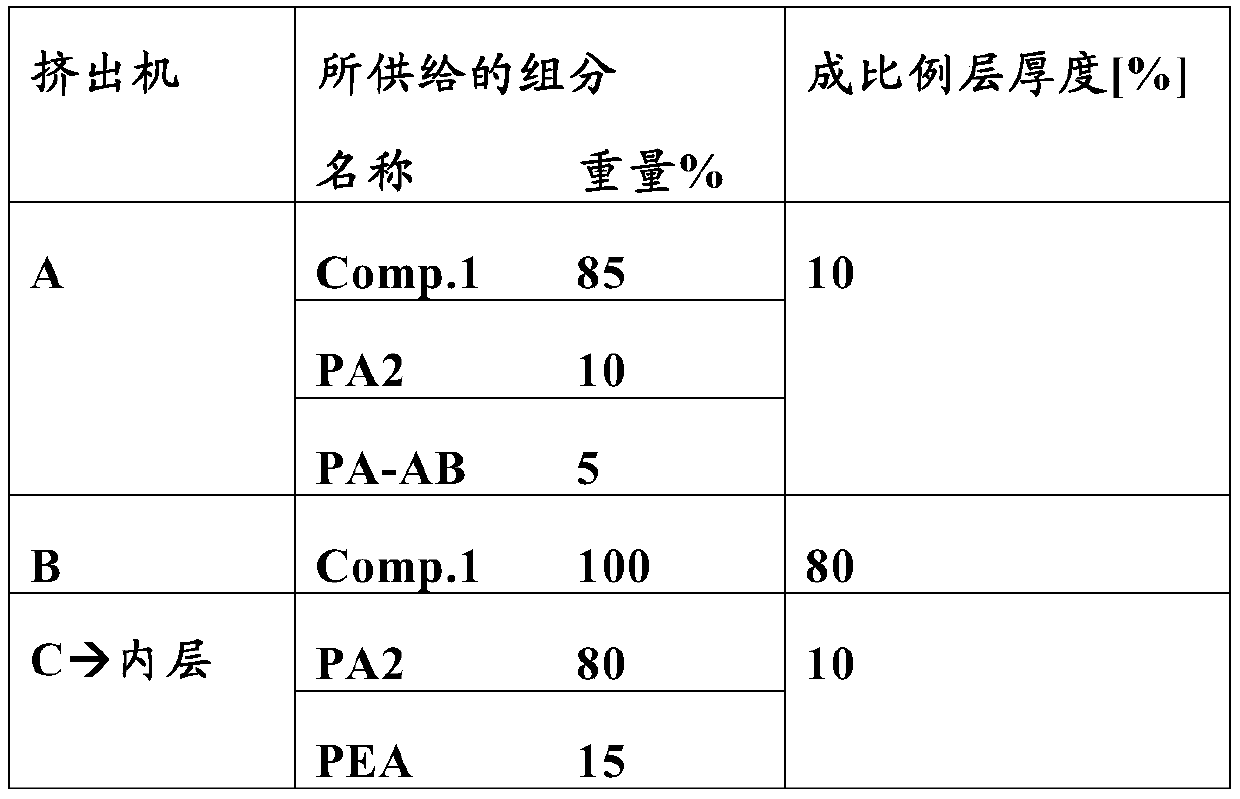

[0058] Production of three-ply, biaxially oriented casings

[0059] The components according to Table 1 below were fed to the three extruders of a commercial coextrusion and tubular film stretching plant (double bubbler unit with three-layer coextrusion annular die). In the extruder, the components are melted, homogenized to form a mixture, and conveyed in the direction of the die. In the die, the melt streams are axially compressed through an annular channel and brought together concentrically. The molten film discharged from the annular gap was formed into a primary tubular film with a diameter of 13 mm by means of a straightener, which was cooled to room temperature. The primary tubular film is then reheated to about 80° C. and stretched in the transverse and longitudinal directions by means of an introduced air cushion. The draw ratio was 3.30 in the transverse direction and 1.95 in the longitudinal direction. After stretching, the tubular film was sent over pinch rolls...

Embodiment 3

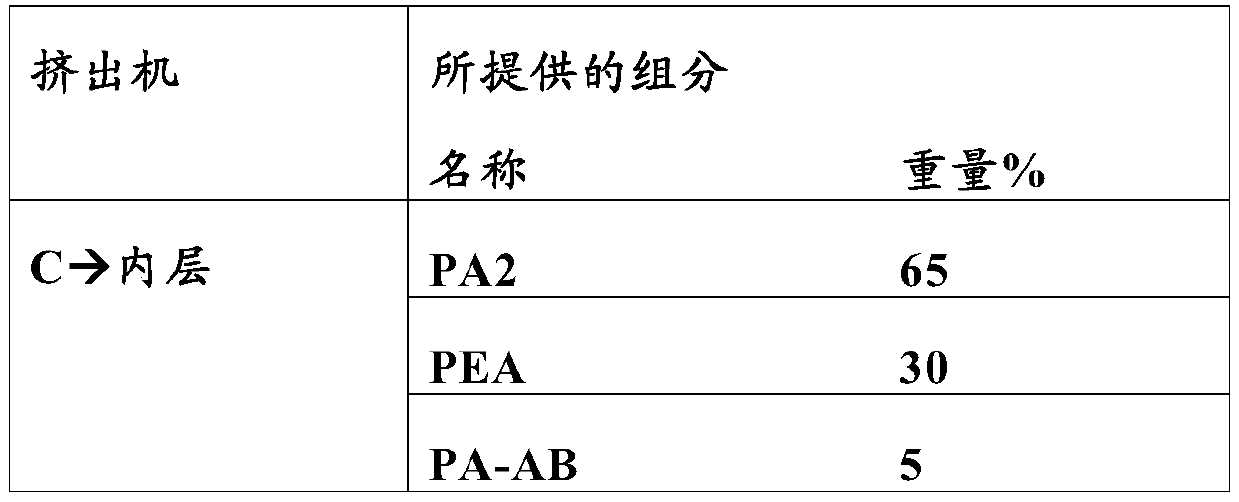

[0064] Inventive Example 2 was repeated except that extruder C was charged with the components according to Table 2 below.

[0065] Table 2

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com