Patents

Literature

31results about "Biaxially oriented sausage casings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Films comprising liquid smoke and flavorants

InactiveUS20090155430A1Thermoplastic sausage casingsMultilayer sausage casingsLiquid smokeEngineering

A process for producing a film having incorporated or applied thereon or therein an additive such as liquid smoke is provided wherein the film comprises a liquid absorbent layer and an impermeable layer. The films can be used for producing a tubular casing or shrinkbag.

Owner:EI DU PONT DE NEMOURS & CO

Smokable polymeric casing

InactiveUS20050163948A1Easy to disassembleImprove performanceMultilayer sausage casingsSmokable sausage casingsPolyvinyl alcoholThin membrane

A novel shrinkable monolayer film that may be produced as a film or a tube, as in a food casing. This newly disclosed film is a blend of a polyamide base, a novel polyvinyl alcohol and optionally, an antiblocking agent.

Owner:VISCASE CORP

Polymer based sausage casing

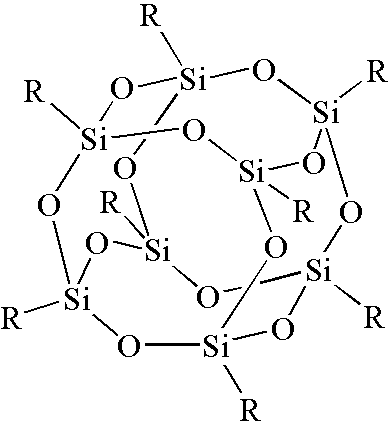

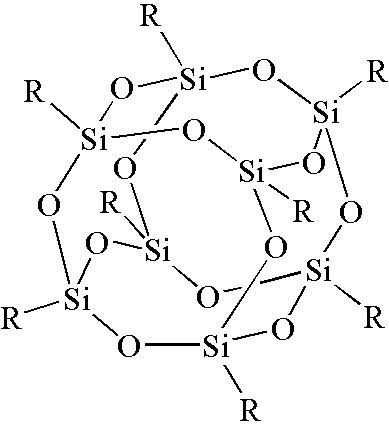

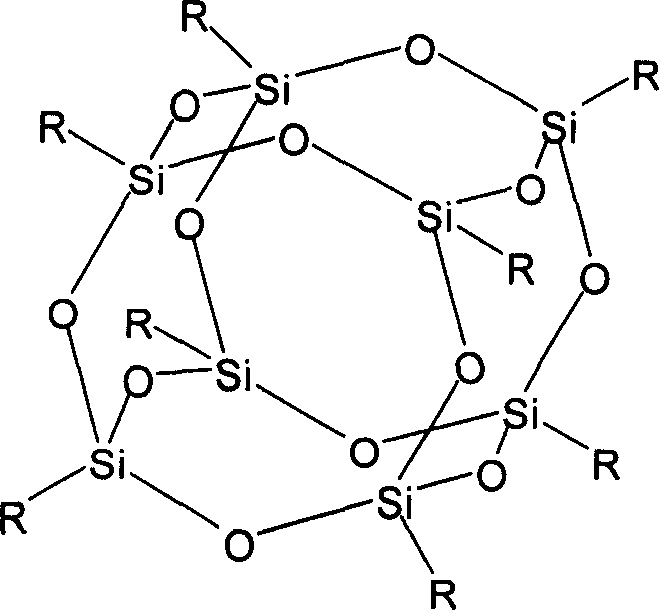

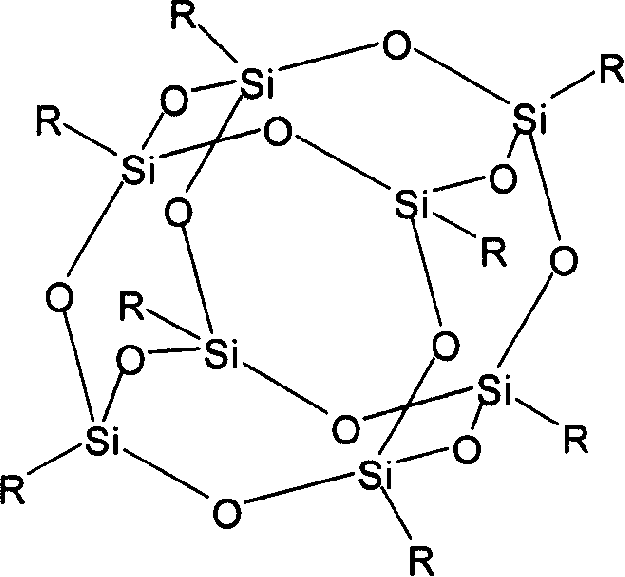

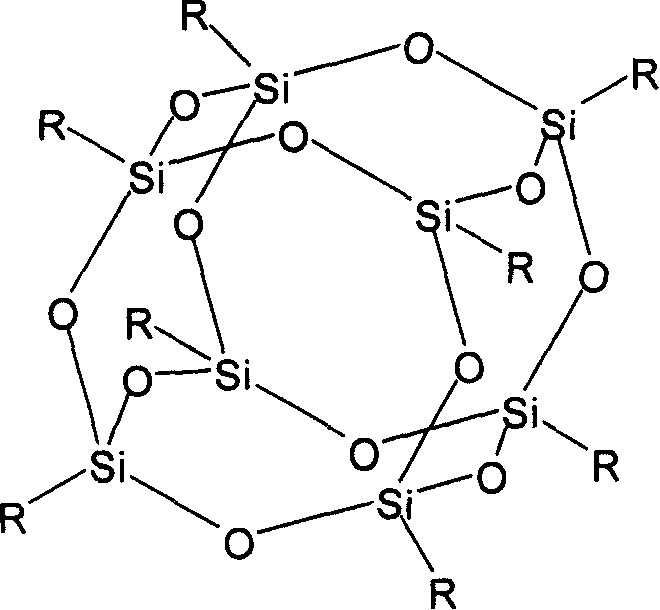

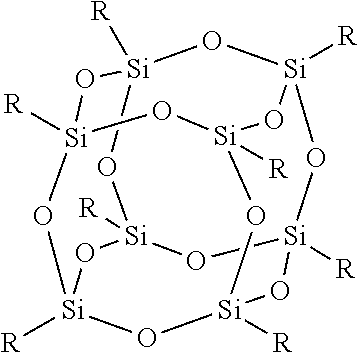

InactiveUS7833594B2Good peeling effectLow viscosityLayered productsBiaxially oriented sausage casingsMoisture barrierMonolayer

A polymer-based sausage casing suitable for use with uncooked meats such as chorizo is disclosed. A polymer resin is blended with a silicon-based barrier control agent, preferably a polyhedral oligomeric silsesquioxane, to increase the permeability of the sausage casing. The resultant blend can be biaxially stretch-oriented to produce a single-layered polymer-based sausage casing suitable for use with uncooked sausage meats such as chorizo, and specifically suitable for the gas and moisture permeability needed during the curing process for uncooked sausage meats. Such polymer-based casings can also be employed for cooked sausages by choosing a silicon-based barrier control agent that increases gas and moisture barrier, thereby increasing shelf-life for unpeeled sausages. A method for improving the peelability of cooked sausage casings by injecting a thin coating of a releasing agent, without the addition of a surfactant, into the sausage casing during the shirring process is also disclosed. The releasing agent is a hydroxypropyl methylcellulose solution that creates a low viscosity releasing agent that effectively improves peelability from any type of sausage casing, but preferably for use with the polymer-based sausage casing of the present invention.

Owner:CASEMATIC S A DE

Polymer-based casing for sausages

InactiveCN1697731AExcellent peelabilityReady-for-oven doughsLayered productsEngineeringSurface-active agents

The invention relates to a polymer-based casing for sausages which is designed to be used with uncooked meats such as chorizo. According to the invention, a polymer resin is mixed with a silicon-based barrier control agent, preferably a polyhedral oligomeric silsesquioxane, in order to increase the permeability of the sausage casing. The resulting mixture can be stretched and oriented biaxially in order to produce a polymer-based sausage casing comprising a single layer, which can be used with uncooked meat in the form of sausages, such as chorizo, and which is specifically designed to enable the gas and moisture permeability which is necessary during the curing of uncooked meats in the form of sausages. The inventive polymer-based casing can also be used for cooked sausages by selecting a silicon-based barrier control agent which increases the gas and moisture barrier, thereby increasing the shelf life of cased sausages. The invention also relates to a method of improving the casing detachment capacity for cooked sausages involving the injection of a thin coating of a release agent into the sausage casing during the gathering process, without the addition of a surface active agent. The aforementioned release agent is a hydroxypropyl methylcellulose solution which creates a low-viscosity release agent which effectively improves the detachment capacity of any type of casing for sausages, but which is preferably used with the inventive polymer-based sausage casing.

Owner:CASEMATIC S A DE

Intrinsically stable shirred plastic food casing

ActiveUS7803437B2Suitably producedSwelling capacityWrappers shrinkageThermoplastic sausage casingsEmulsionPolyamide

Disclosed is a shined tubular food casing based on a thermoplastic blend of at least one polyamide and / or copolyamide and at least one hydrophilic component. The casing is biaxially stretch-oriented and impregnated on the inside and / or outside with a component which allows the pleats which are formed during shining of the casing to adhere to each other. The component preferably comprises at least one polymer. The casing is preferably shirred at a ratio of 80:1 to 500:1. The inventive shined casing is particularly stable from a mechanical perspective and can therefore be used especially for the production of cooked sausages, scalded-emulsion sausages, and small sausages on fully automatic sausage stuffing and clipping apparatuses.

Owner:KALLE AG

Films comprising liquid smoke and flavorants

A process for producing a film having incorporated or applied thereon or therein an additive such as liquid smoke is provided wherein the film comprises a liquid absorbent layer and an impermeable layer. The films can be used for producing a tubular casing or shrinkbag.

Owner:EI DU PONT DE NEMOURS & CO

Nylon food casing having a barrier core layer

ActiveUS7244481B2Good conformationEasy to processWrappers shrinkageSausage casingsThin membraneEngineering

Owner:VISCASE CORP

Multilayered two-dimensional or tubular food casing or film

ActiveCN101522035AThermoplastic sausage casingsMultilayer sausage casingsEngineeringCompanion animal

The present invention proposes for the first time a two-dimensional or tubular food casing or film with an at least seven-layered laminated structure, which has an EVOH layer as an oxygen barrier and in which the outer layer is formed by a high-temperature-resistant material such as PET, which apart from outstanding appearance-related properties also makes much higher further processing speeds (numbers of cycles) possible than previously known.

Owner:库恩设备制造有限公司

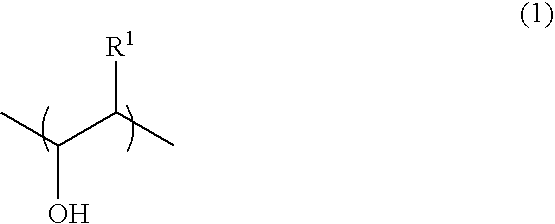

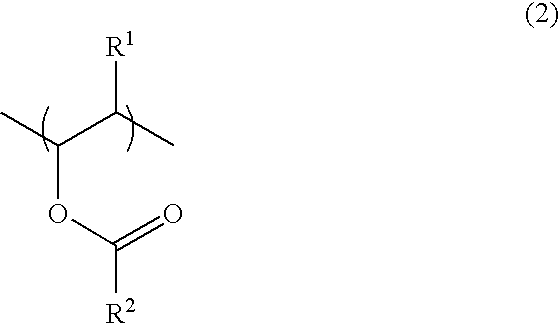

Polyamide-based sausage skin which can be filled manually

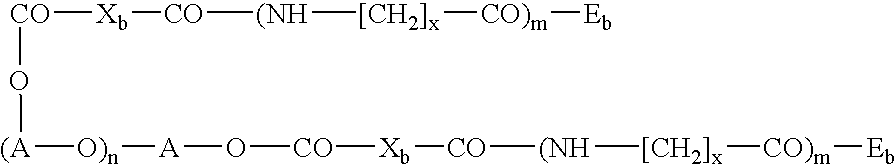

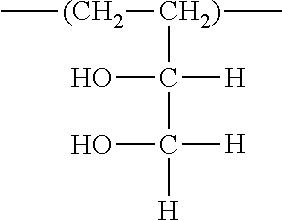

The invention concerns a biaxially stretched and thermoset tubular seamless single- or multi-layered foodstuff skin wherein the layer, or, a multi-layered skin wherein at least one of the layers, contains a block copolymer with “hard” aliphatic polyamide blocks and “soft” aliphatic polyether blocks, the block copolymer corresponding to one of formulae (I) to (III), Ea—(NH—[CH2]x—CO)m—Xa—(A—O)n—A Xa—(CO—[CH2]x—NH)m—Ea (I), (II), —[X—(CO—[CH2]x—NH)o—Y—X—(A—O)p—A]-(III). The invention is particularly suitable as a skin for a sausage which is to be boiled or heated in water, and does not form folds when the filling is introduced manually, with no or only slight pressure.

Owner:KALLE NALO

Single-layer or multi-layer tubular food packaging film capable of being smoked, air-dried, and peelable, especially fully automatic peelable, and manufacturing method thereof

The invention relates to a single-layer or multilayer tubular food packaging film that can be smoked, air-dried, and peeled, especially peeled in a fully automatic manner, particularly a sausage casing for smoked and / or air-dried sausages or meat. Said polymer-based food film is produced from a homogeneous plastic melt in a (co-)extrusion film blow molding plant using extruded plastics that are fed to a nozzle of a blow head and is biaxially stretched in a triple bubble process, the homogeneous plastic melt being produced from a plastic mixture of PS or a mixture of various PS and PVOH and / or PEBA. The invention further relates to a method for producing the food film.

Owner:KUHNE ANLAGENBAU

Five-layered, biaxially-oriented, sealable tubular film for the packaging and wrapping of paste-like foodstuffs meat and meat with bones and use thereof

InactiveUS6998160B2Improve puncture resistanceLow oxygen permeabilityDough treatmentMultilayer sausage casingsHigh resistancePolyolefin

The invention relates to a five-layered, biaxially oriented, shrinkable, sealable tubular film for the packaging and wrapping of paste-like foodstuffs, meat, or meat with bones and to the use thereof. The tubular film of the invention has an inner layer comprised of at least one copolyamide and at least one modified polyolefin, a layer of a modified polyolefin, a middle layer comprised of at least one homopolyamide and / or at lest one copolyamide and / or at least one copolymer of ethylene and vinyl alcohol and / or a modified polyolefin, a layer of at least one ethylene-vinyl alcohol copolymer, and an outer layer comprised of at least one polyolefin and / or at least one modified polyolefin. Such tubular films involve a significant improvement in the seal seam strength, in particular at low sealing temperatures, a high impermeability to oxygen and a comparable to markedly higher resistance to puncturing compared to prior art films.

Owner:NATURIN GMBH & CO

Smokable thermoplastic casing

ActiveUS20140322394A1Excellent oxygen barrier propertiesThermoplastic sausage casingsMonolayer sausage casingsThermoplasticLiquid smoke

A novel smokable thermoplastic film, smokable by both liquid smoke and gaseous smoke, that may be produced as a film or a tube, as in a food casing. This newly disclosed film is a blend of a polyamide base, an amorphous polyvinyl alcohol and, optionally, an antiblocking agent.

Owner:VISCASE CORP

Preparation method of nanofiber membrane and application of nanofiber membrane in cellulose casing

ActiveCN114605683AImprove shrinkageNo wrinklesSmokable sausage casingsBiaxially oriented sausage casingsCellulosePolymer science

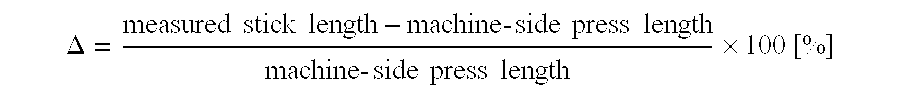

The invention discloses a preparation method of a nanofiber membrane and application of the nanofiber membrane in cellulose casings, and belongs to the field of polysaccharide and derivatives thereof, the preparation method comprises the steps of alkalization and squeezing of pulp, crushing and aging, yellowing, preparation of viscose and membrane preparation. The nanofiber membrane disclosed by the invention is used as the casing, has good contractibility, can contract along with meat stuffing after being smoked, does not have wrinkles, and has the maximum shrinkage rate of 7.4-7.6%; the nanofiber membrane disclosed by the invention is used as a casing, the casing cannot burst in a frozen anhydrous state, and the longitudinal tensile strength is 6.49-6.53 kN / m and the transverse tensile strength is 5.19-5.23 kN / m in a state that the temperature is-20 DEG C and the water content is 0.5%.

Owner:WEIFANG WEISEN FIBER NEW MATERIAL CO LTD

Biaxially drawn tubular film comprising three adjacent polyamide-based layers

ActiveUS9265265B2High inherent stabilityMultilayer sausage casingsSynthetic resin layered productsPolyamideEngineering

Owner:KALLE AG +1

Smoke and water vapor-permeable food casing with optimized bonding properties

A tubular, seamless, water vapor permeable, smokable, biaxially draw-oriented and partially or completely heat-set food casing is provided having at least two layers based on thermoplastic polymers. At least one layer A, which does not form the inside layer, comprises a blend of aliphatic (co)polyamide and at least one hydrophilic polymer, while the inside layer I comprises a blend of aliphatic orisocyclic (co)poly amide and a block copolymer selected from polyether-amide, polyether-ester and polyether-urethane. The casing is produced by a tubular-film blowing process or a process with biaxial tubular-film draw-orientation. The casing is envisaged more particularly as synthetic sausage casing, especially for smoked raw sausage, such as salami.

Owner:KALLE AG

Smokable thermoplastic casing

ActiveUS9532578B2Excellent oxygen barrier propertiesThermoplastic sausage casingsMonolayer sausage casingsThermoplasticLiquid smoke

A novel smokable thermoplastic film, smokable by both liquid smoke and gaseous smoke, that may be produced as a film or a tube, as in a food casing. This newly disclosed film is a blend of a polyamide base, an amorphous polyvinyl alcohol and, optionally, an antiblocking agent.

Owner:VISCASE CORP

Smoke permeable food casing based on polyamide and water soluble polymers

ActiveUS7838094B2Improved oxygen barrierBottlesSynthetic resin layered productsPolymer scienceEmulsion

The invention relates to a smoke-permeable, moisture-resistant, tubular, biaxially oriented, preferably also heat set food casing containing a mixture of at least one aliphatic (co)polyamide and at least one water-soluble synthetic polymer, and having a water vapor transmission rate of between 40 and 200 g / m2·d. The water-soluble polymer is preferably a polyvinyl alcohol. Optionally, the mixture also contains additives which influence the optics, haptics, moisture storage capacity and peeling behavior. The casing is preferably tubular and seamless and is produced by extrusion of a corresponding thermoplastic mixture. The inventive casing is preferably used as an artifical sausage casing, especially for smokeable scalded-emulsion sausages.

Owner:KALLE AG

Food casing with permeability to smoke and water vapour and with improved transparency

The present invention relates to a tubular, seamless, biaxially stretched, smoke-permeable and water vapour-permeable, colouristically neutral and transparent, single-layer food casing formed from a mixture including 50 to 95% by weight of aliphatic (co)polyamide, 3 to 40% by weight of at least one vinyl (co)polymer having units of N-vinyl-2-pyrrolidone and 1.5 to 7.0% by weight of at least one aliphatic diol and / or aliphatic polyol, based in each case on the weight of the mixture. The diol and / or polyol is homogeneously distributed in a matrix formed by the aliphatic (co)polyamide. The food casing is produced by an extrusion method with biaxial tube stretching and subsequent heat-setting. It is particularly suitable as synthetic sausage casing, especially for raw sausage, such as salami or mettwurst.

Owner:KALLE AG

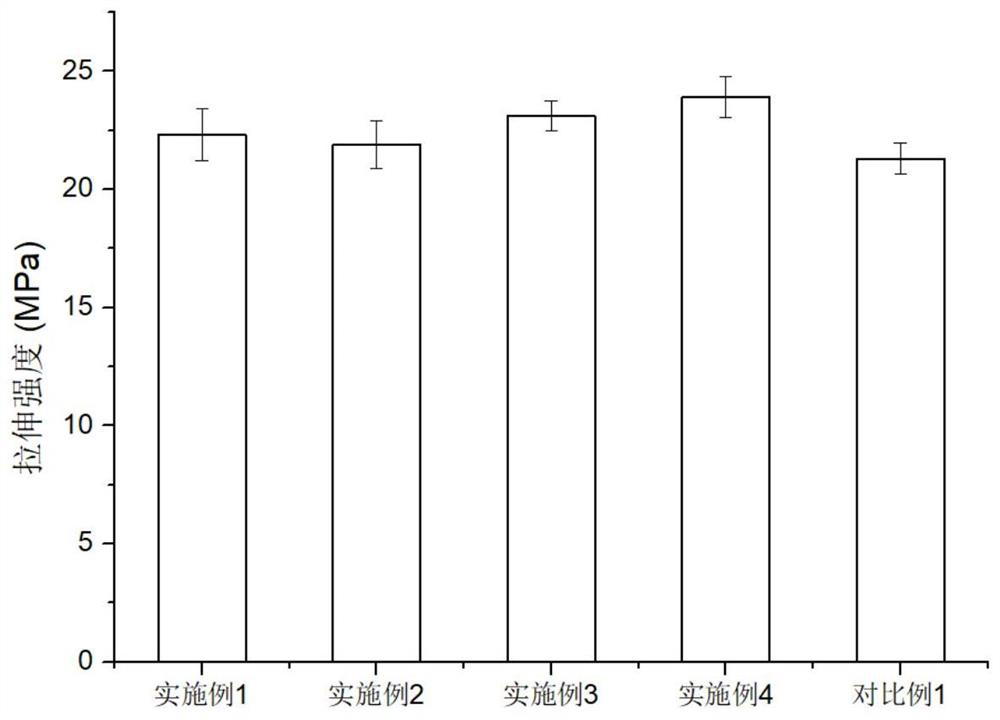

Preparation method of Taiwan flavor sausage convenient to preserve

ActiveCN112450260AReduce transmittanceIncrease stickinessBiaxially oriented sausage casingsMeat/fish preservation using chemicalsGlycerolApigetrin

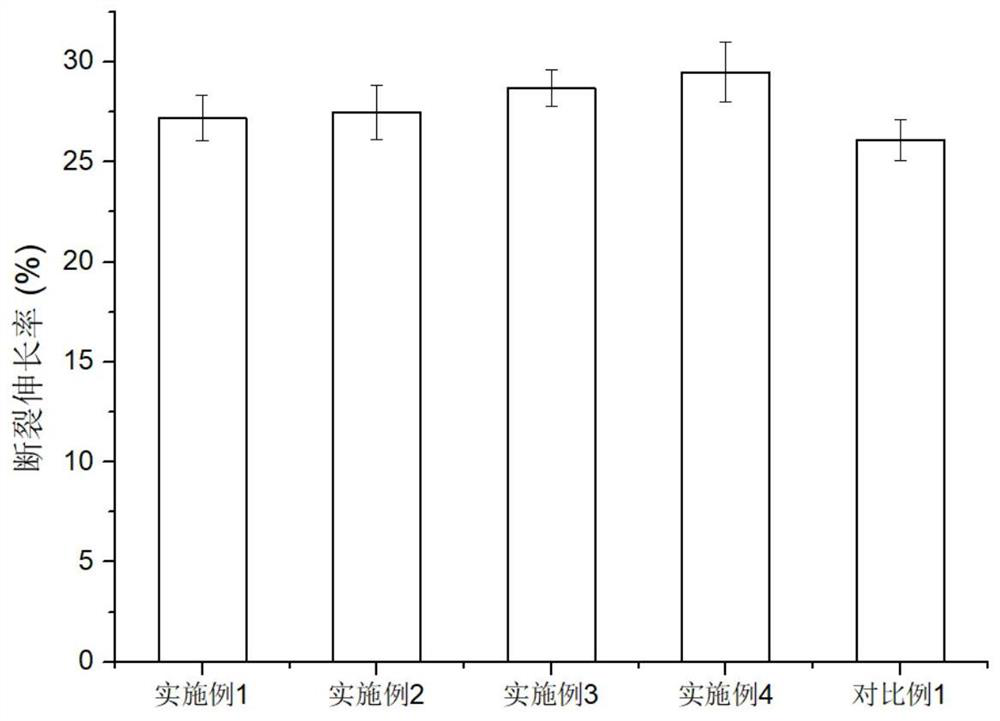

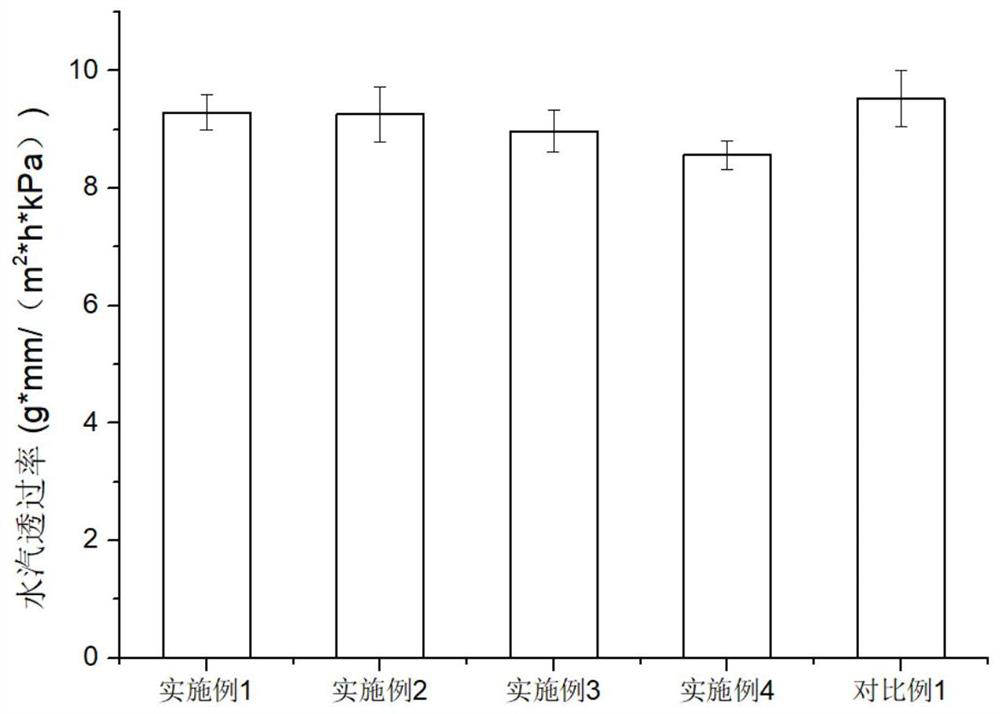

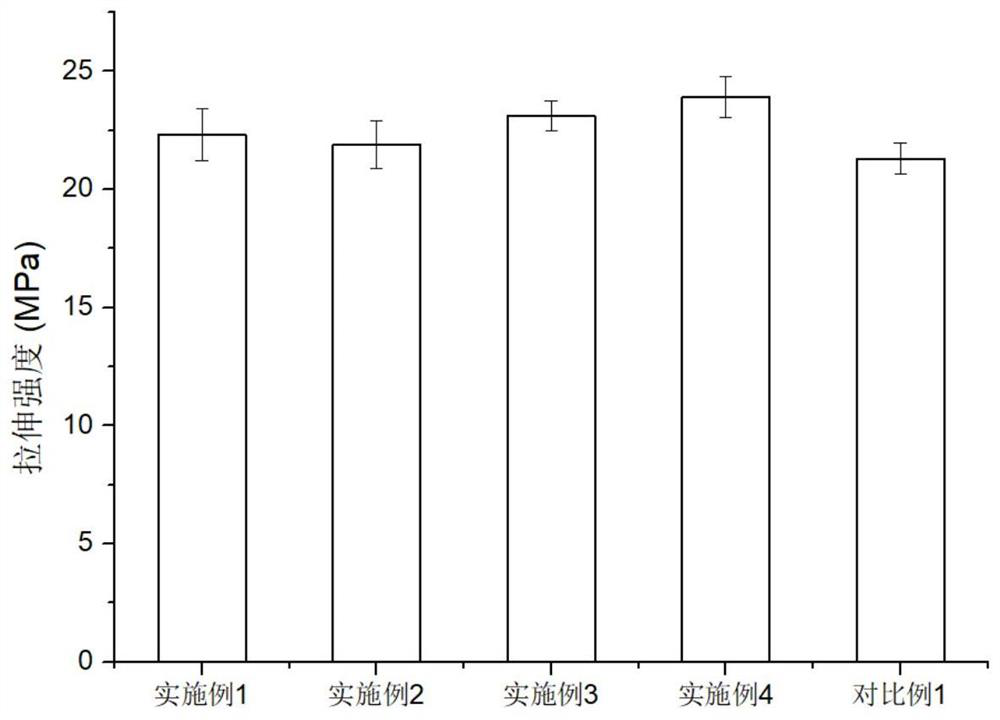

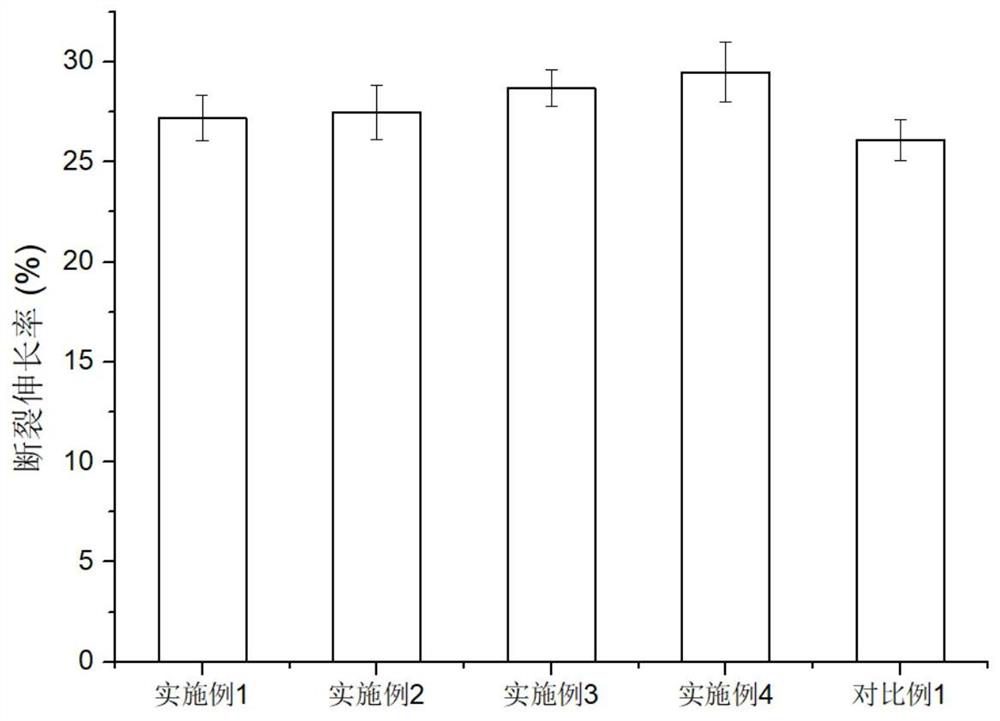

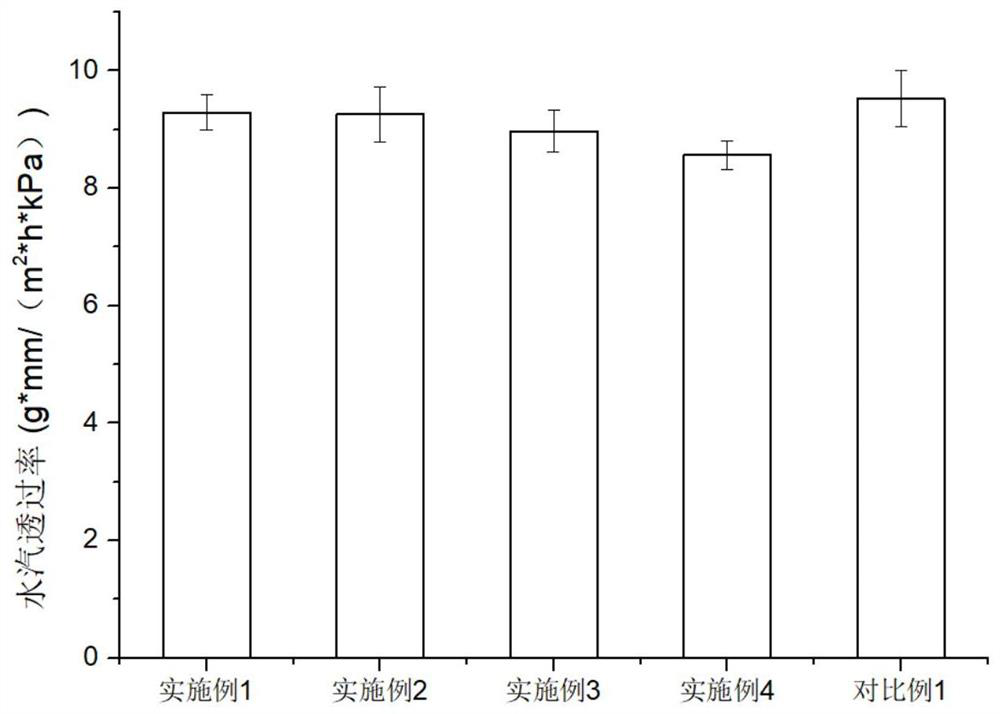

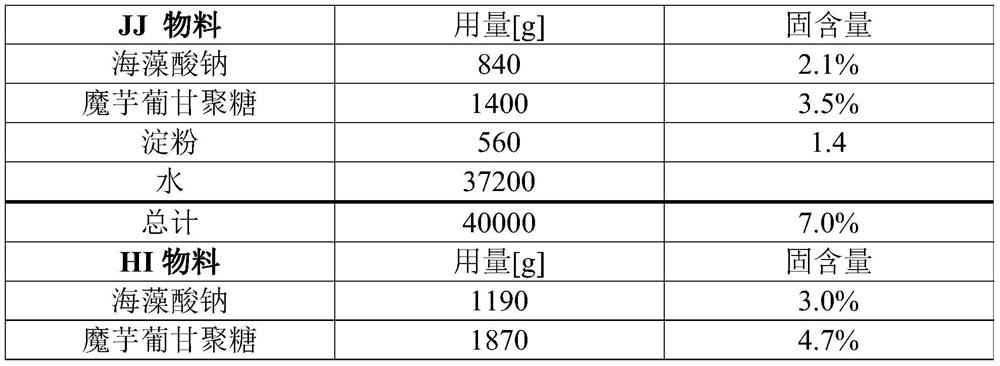

The invention discloses a preparation method of a Taiwan flavor sausage convenient to preserve, belongs to the technical field of sausages. Isolicoflavonol and / or glucosyl apigenin as well as collagen, soybean protein, chitosan, glycerol and glutaraldehyde are adopted to prepare a casing film, and the Taiwan flavor sausage is prepared from the casing film. The obtained casing film is good in mechanical strength, the tensile strength reaches 22 MPa or above, and the elongation at break reaches 27% or above; the water vapor transmission rate is low and reaches 9.40 g.mm / (m<2>. H.kPa) or below; and the viscosity to meat stuffing is good, and the stripping force is 0.25 N or above.

Owner:浙江波拉波拉食品股份有限公司 +1

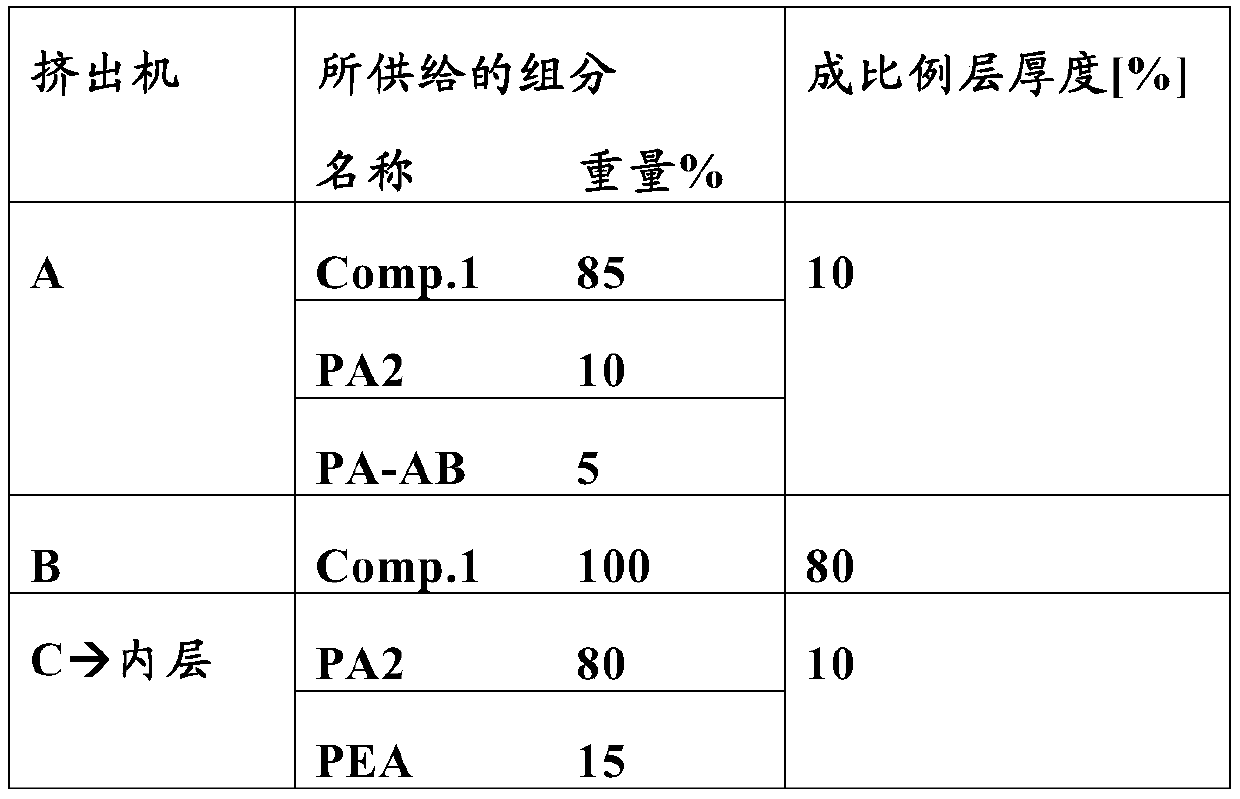

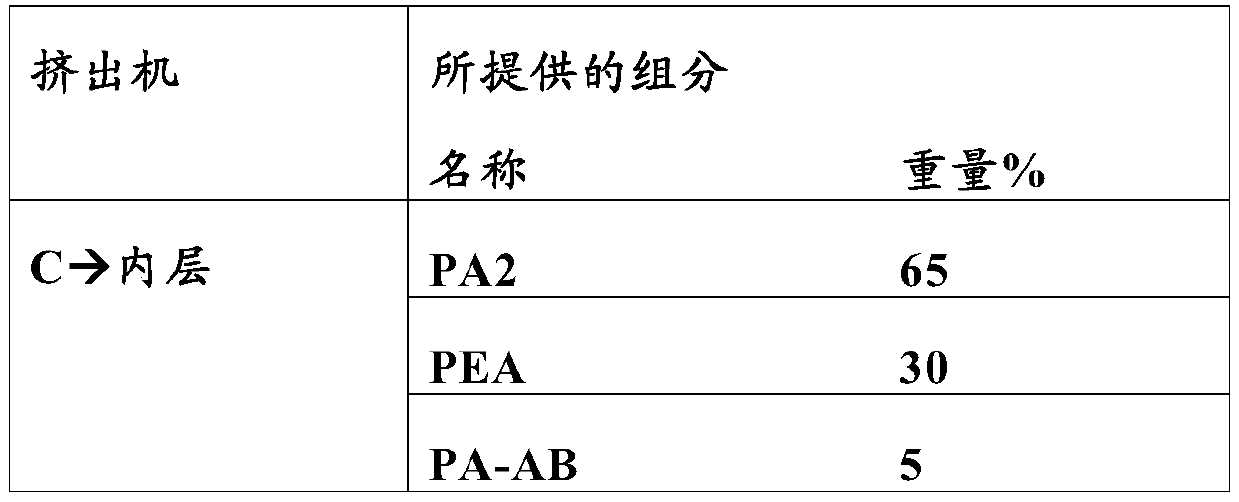

Smoke- and water vapour-permeable food casing with optimized bonding properties

ActiveUS20190230942A1Thermoplastic sausage casingsMultilayer sausage casingsPolymer scienceCarbamate

A tubular, seamless, water vapour permeable, smokable, biaxially draw-oriented and partially or completely heat-set food casing is provided having at least two layers based on thermoplastic polymers. At least one layer A, which does not form the inside layer, comprises a blend of aliphatic (co)polyamide and at least one hydrophilic polymer, while the inside layer I comprises a blend of aliphatic or isocyclic (co)poly amide and a block copolymer selected from polyether-amide, polyether-ester and polyether-urethane. The casing is produced by a tubular-film blowing process or a process with biaxial tubular-film draw-orientation. The casing is envisaged more particularly as synthetic sausage casing, especially for smoked raw sausage, such as salami.

Owner:KALLE AG

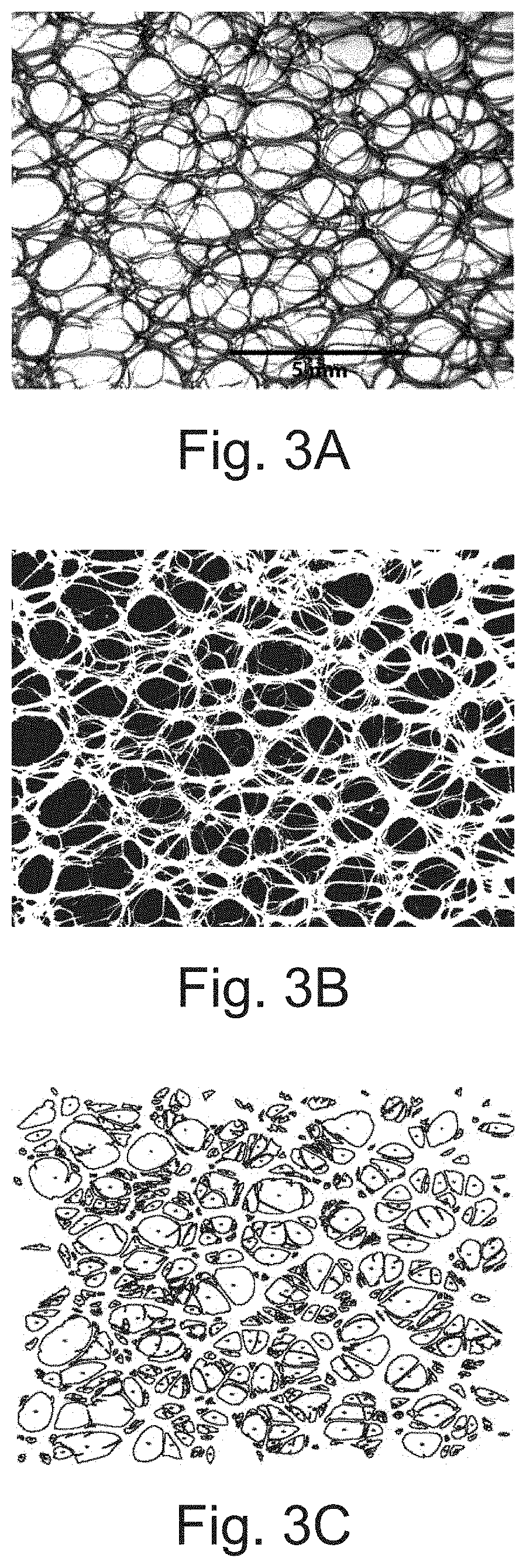

Food packaging film and manufacturing method for making the same

ActiveUS11324227B2Improve efficiencyThermoplastic sausage casingsWrappersFood additiveFlavouring agent

Owner:VISCASE CORP

Food packaging film and manufacturing method for making the same

PendingUS20210289800A1Improve efficiencyThermoplastic sausage casingsMeat/fish preservationFood additiveFlavouring agent

The present invention relates to a multilayer film, especially to a multilayer thermoplastic film, which may be used for food packaging, wherein the multilayer film according to the present invention may be provided, on its inner side, with a food additive, particularly with a flavoring and / or coloring and / or an aroma producing food additive (such as e.g. a liquid smoke), which food additive is then released and transferred onto the surface of a foodstuff encased in the multilayer film during cooking and / or processing of the foodstuff.

Owner:VISCASE CORP

Edible tubular food casings

InactiveCN113163777AImprove performanceMonolayer sausage casingsBiaxially oriented sausage casingsBiotechnologyVegan food

Owner:VISCOFAN TECH SUZHOU

Polymer-Based Sausage Casing

InactiveUS20140050823A1Improve breathabilitySuitable for gas and moisture permeabilityPrintable sausage casingsLayered productsMoisture barrierMonolayer

A polymer-based sausage casing suitable for use with uncooked meats such as chorizo is disclosed. A polymer resin is blended with a silicon-based barrier control agent, preferably a polyhedral oligomeric silsesquioxane, to increase the permeability of the sausage casing. The resultant blend can be biaxially stretch-oriented to produce a single-layered polymer-based sausage casing suitable for use with uncooked sausage meats such as chorizo, and specifically suitable for the gas and moisture permeability needed during the curing process for uncooked sausage meats. Such polymer-based casings can also be employed for cooked sausages by choosing a silicon-based barrier control agent that increases gas and moisture barrier, thereby increasing shelf-life for unpeeled sausages. A method for improving the peelability of cooked sausage casings by injecting a thin coating of a releasing agent, without the addition of a surfactant, into the sausage casing during the shirring process is also disclosed. The releasing agent is a hydroxypropyl methylcellulose solution that creates a low viscosity releasing agent that effectively improves peelability from any type of sausage casing, but preferably for use with the polymer-based sausage casing of the present invention.

Owner:CASEMATIC S A DE

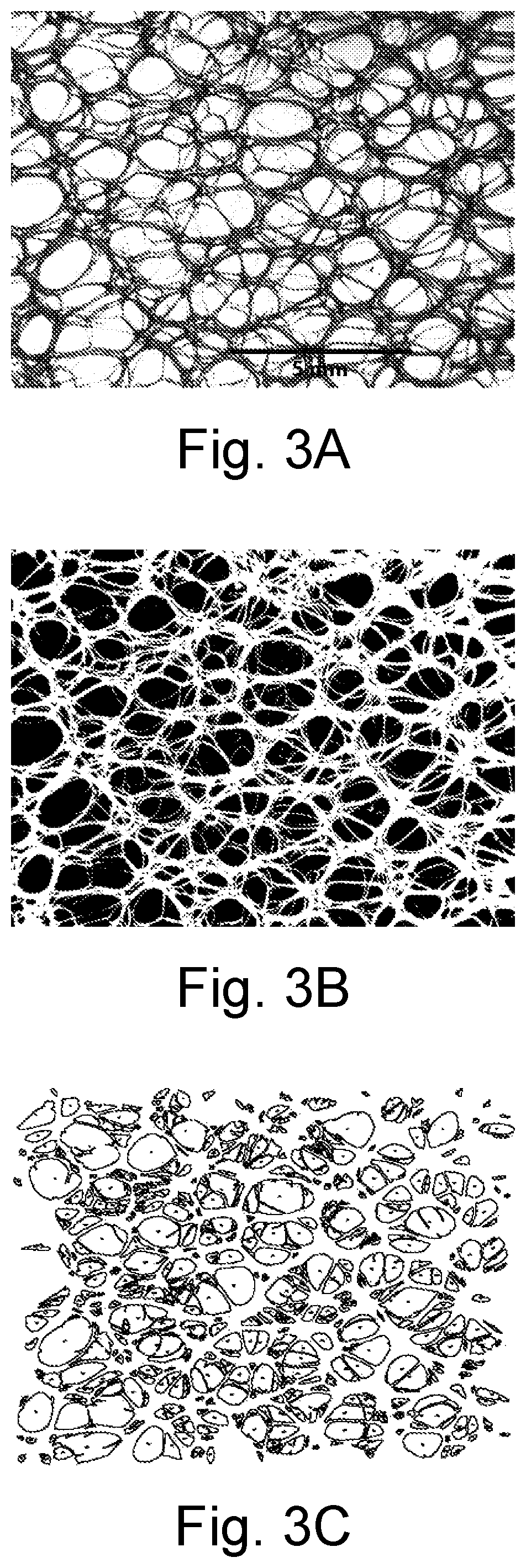

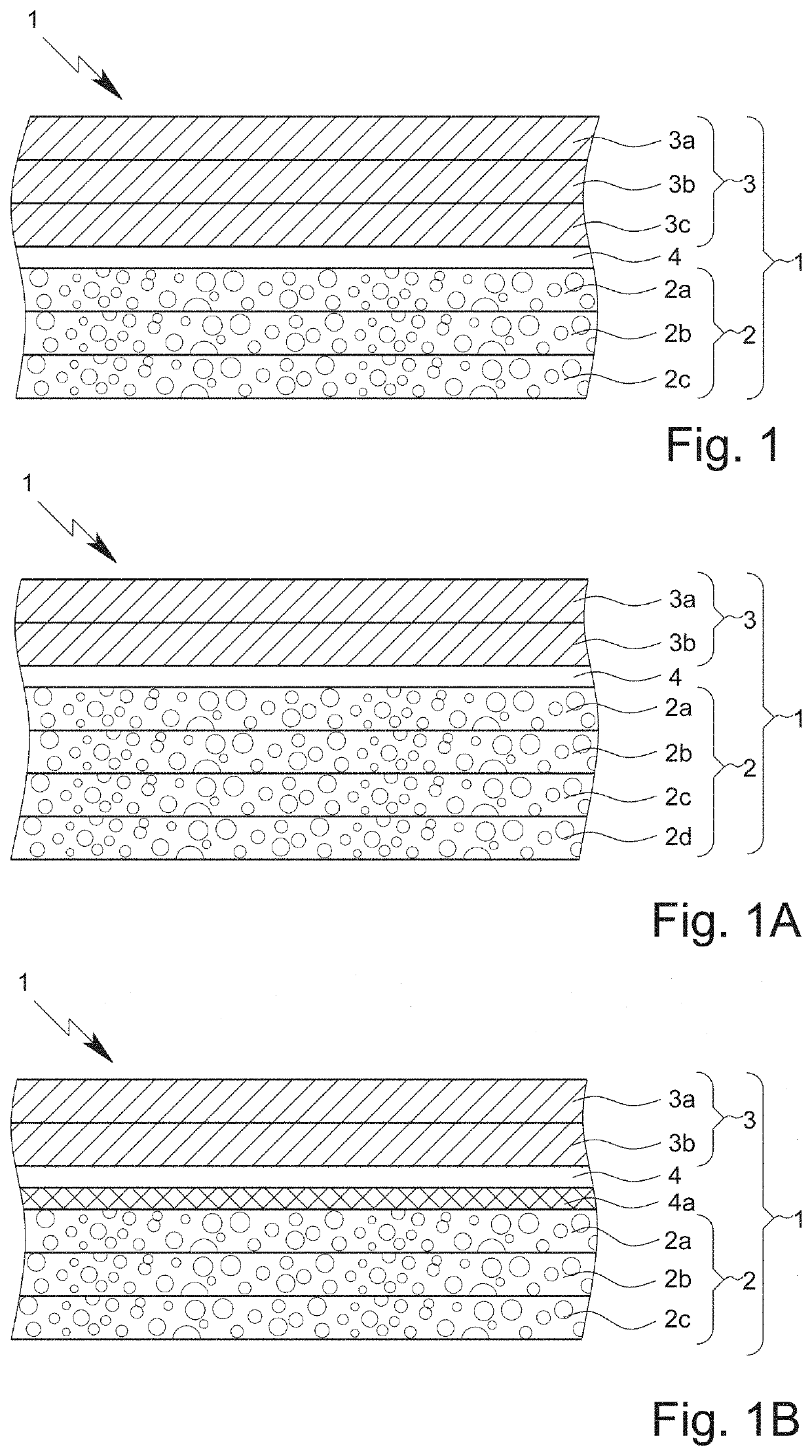

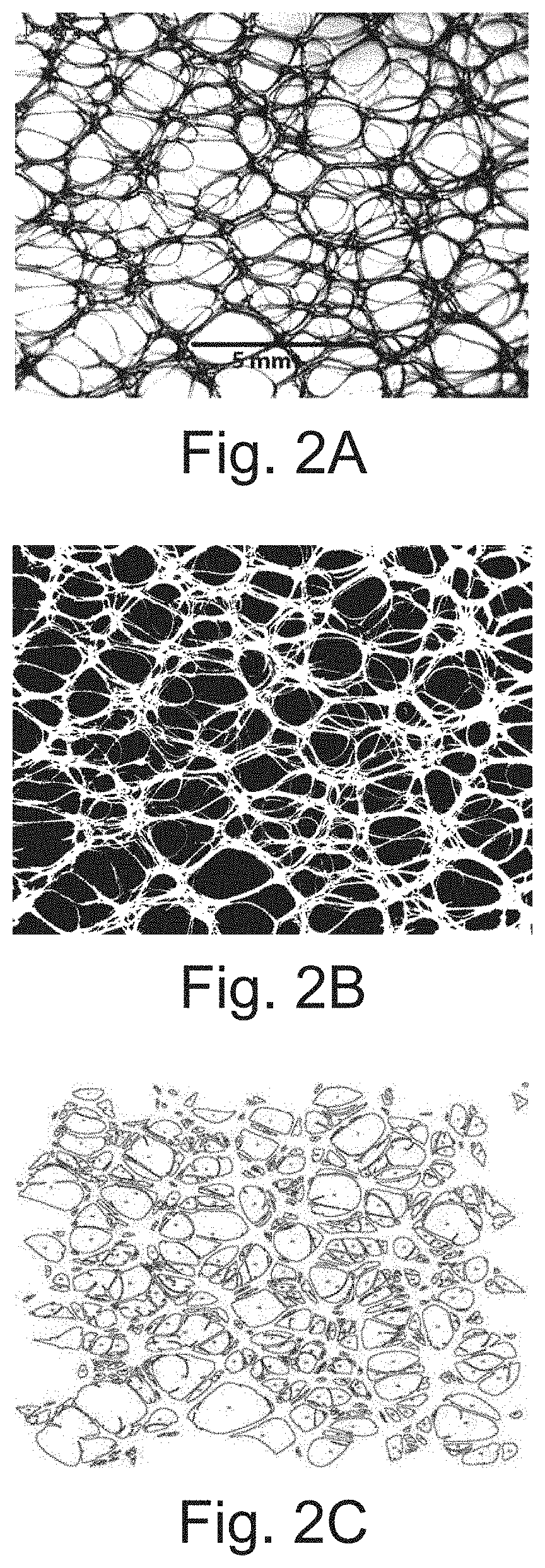

Tubular food casing with transfer function

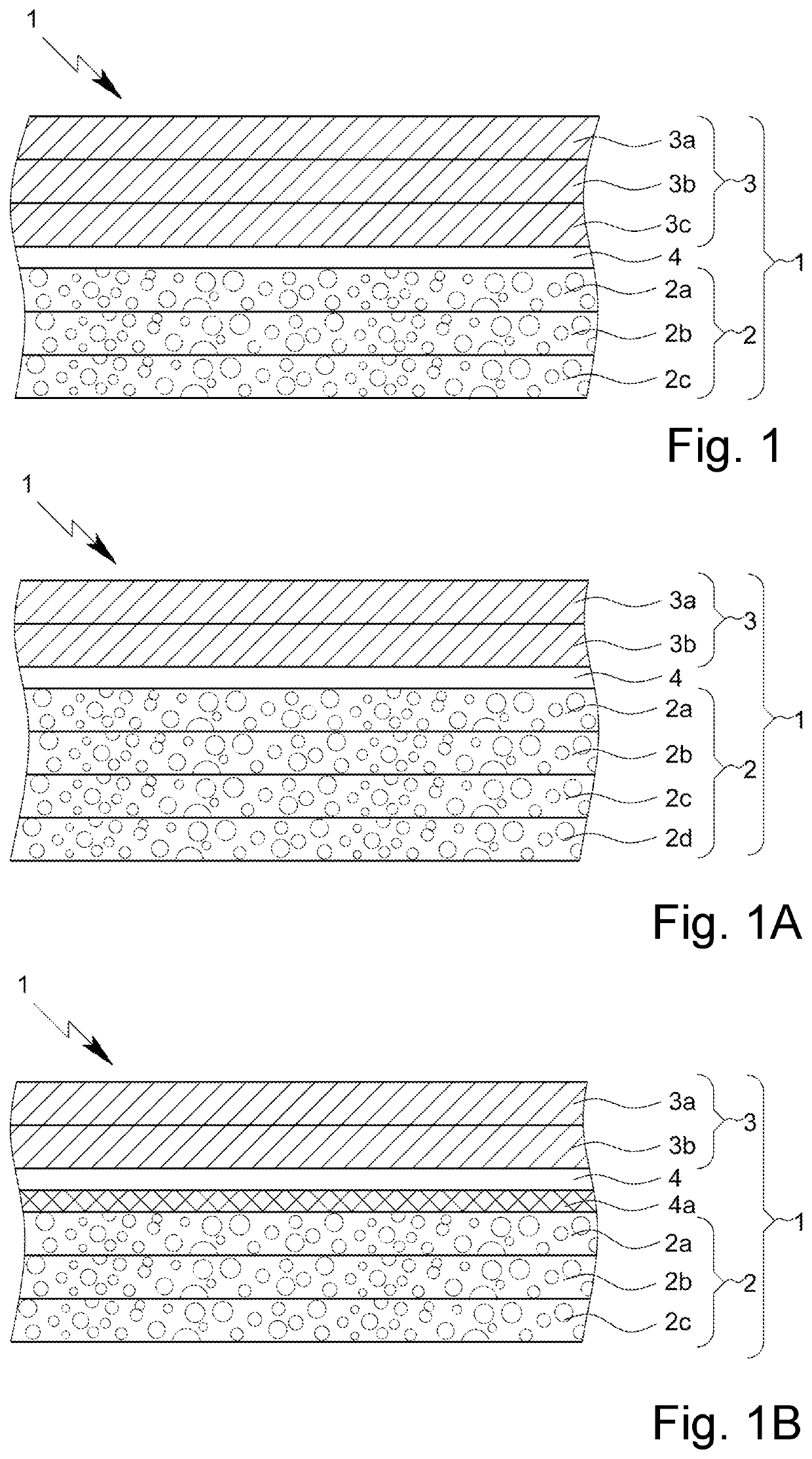

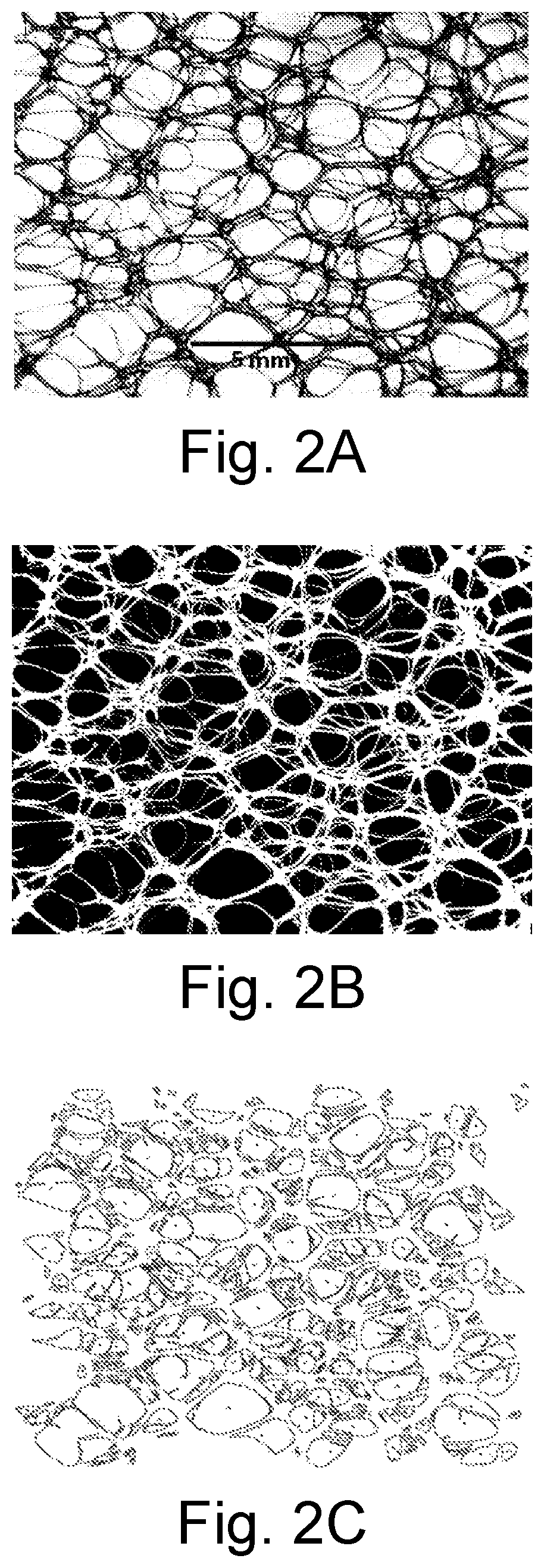

PendingUS20180139991A1Increase elasticityPromote absorptionThermoplastic sausage casingsLayered product treatmentEmulsionAdhesive

A description is given of a tubular food casing having a fiber layer on the inside and having two or more polymer layers. The polymer layers include a first continuous polymer layer (A), with which the inner fiber layer or nonwoven-web layer is coated on the side of the tubular casing facing away from the inside, and completely covers the layer, and at least one polymer layer (B), and a monoaxially or biaxially oriented film based on polyamide and / or copolyamide. At least two of the polymer layers are joined to one another directly by a layer of adhesive. The inner fiber layer may absorb colour, smoke, aroma and / or flavour substance(s), such as liquid smoke or caramel, store these substances and transfer them to a food located within the casino. The casing is suitable as artificial sausage casing, especially for cooked-filling and scalded-emulsion sausage.

Owner:KALLE AG

Smoke- and water vapour-permeable food casing with optimized bonding properties

A tubular, seamless, water vapour permeable, smokable, biaxially draw-oriented and partially or completely heat-set food casing is provided having at least two layers based on thermoplastic polymers. At least one layer A, which does not form the inside layer, comprises a blend of aliphatic (co)polyamide and at least one hydrophilic polymer, while the inside layer I comprises a blend of aliphatic or isocyclic (co)polyamide and a block copolymer selected from polyether-amide, polyether-ester and polyether-urethane. The casing is produced by a tubular-film blowing process or a process with biaxial tubular-film draw-orientation. The casing is envisaged more particularly as synthetic sausage casing, especially for smoked raw sausage, such as salami.

Owner:KALLE AG

Single-layer or multilayer tubular food packaging film that can be smoked, air-dried, and peeled, especially peeled in fully automatic manner, and method for production thereof

The present invention relates to a single-layer or multilayer tubular food packaging film that can be smoked, air-dried and peeled, in particular peeled in a fully automated manner, in particular a sausage casing, for smoked and / or air-dried sausage or meat goods, wherein the polymer-based food film is manufactured of a homogeneous molten plastic material in a (co-)extrusion film blow molding plant by means of (co-)extruded plastics supplied to a nozzle of a blow head and biaxially stretched in the triple-bubble process, the homogeneous molten plastic material being produced of a plastic blend of PS or a blend of various PSs and PVOHs and / or PEBAs. The present invention moreover relates to a method for the manufacture of the food film.

Owner:KUHNE ANLAGENBAU

Multilayered two-dimensional or tubular food casing or film

ActiveCN101522035BThermoplastic sausage casingsMultilayer sausage casingsEngineeringCompanion animal

The present invention proposes for the first time a two-dimensional or tubular food casing or film with an at least seven-layered laminated structure, which has an EVOH layer as an oxygen barrier and The present invention proposes for the first time a two-dimensional or tubular food casing or film with an at least seven-layered laminated structure, which has an EVOH layer as an oxygen barrier andin which the outer layer is formed by a high-temperature-resistant material such as PET, which apart from outstanding appearance-related properties also makes much higher further processing speeds (nuin which the outer layer is formed by a high-temperature-resistant material such as PET, which apart from outstanding appearance-related properties also makes much higher further processing speeds (numbers of cycles) possible than previously known.mbers of cycles) possible than previously known.

Owner:库恩设备制造有限公司

A kind of preparation method of Taiwan flavor sausage convenient for preservation

ActiveCN112450260BReduce transmittanceIncrease stickinessBiaxially oriented sausage casingsMeat/fish preservation using chemicalsGlycerolEngineering

The invention discloses a method for preparing a desktop flavored sausage which is convenient for preservation, and belongs to the technical field of sausages. Aldehydes were used to prepare casing films, and table-style sausages were prepared from the casing films. The mechanical strength of the casing film obtained by the present invention is good, the tensile strength has reached more than 22MPa, and the elongation at break has reached more than 27%; the water vapor transmission rate has reached 9.40g·mm / (m 2 ·h·kPa) or less; good adhesion to meat stuffing, peeling force above 0.25N.

Owner:浙江波拉波拉食品股份有限公司 +1

Edible film

InactiveCN113507837AImprove performanceMonolayer sausage casingsMultilayer sausage casingsBiotechnologyVegan food

The present invention provides edible food casing films, a method for producing said edible food casing films, compositions for forming said edible food casing films and the use of said edible food casing films for example as a sausage casing, which food casings are hot water and sodium salt resistant, stable at high temperatures, can be easily shirred and are ready to be stuffed with foodstuff, especially by meat, cheese or fish products, but also with vegetarian or vegan foodstuff.

Owner:VISCOFAN TECH SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com