Preparation method of Taiwan flavor sausage convenient to preserve

A sausage and flavor technology, which is applied in the field of table-style sausage preparation, can solve problems such as insufficient viscosity, easy peeling of casing film, and no clear regulations on meat viscosity, etc., and achieve good fresh-keeping effect, low water vapor transmission rate, and good water retention effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

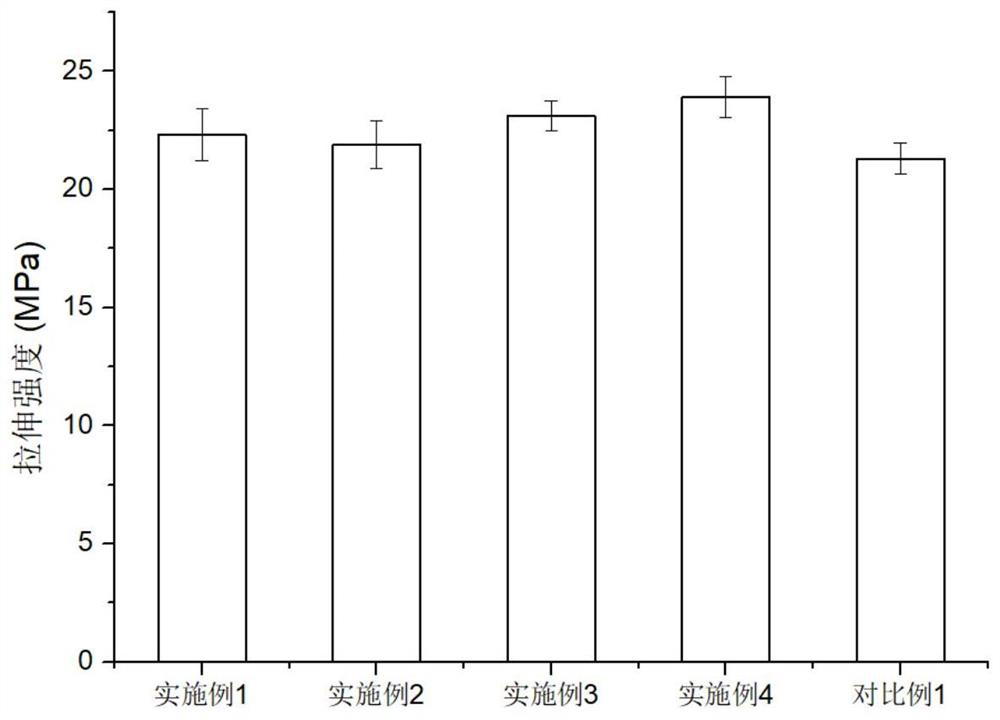

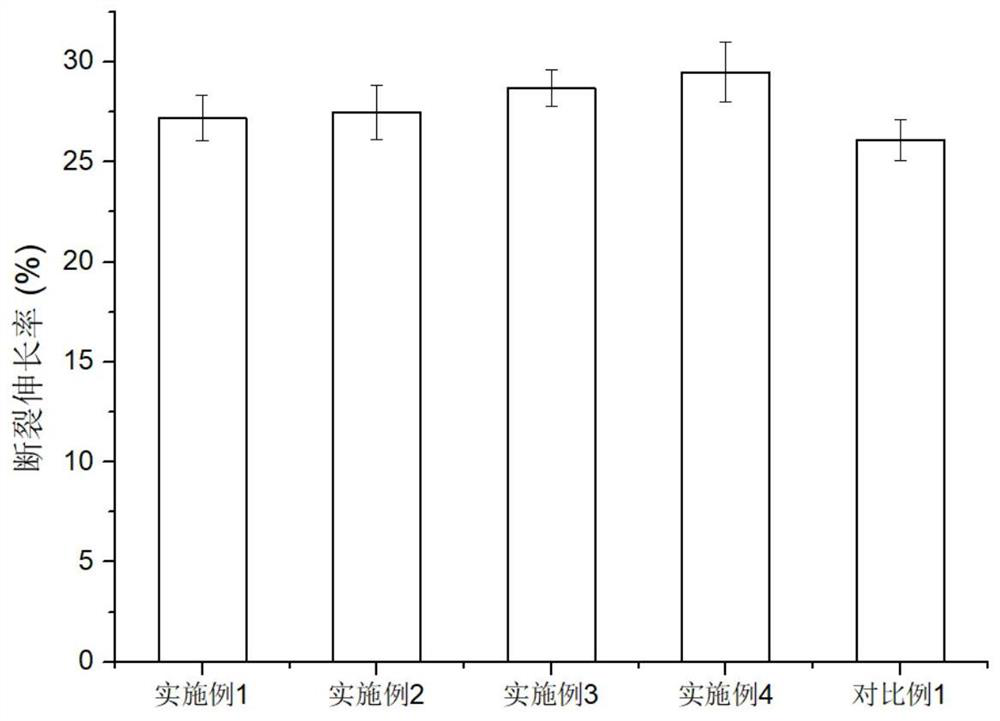

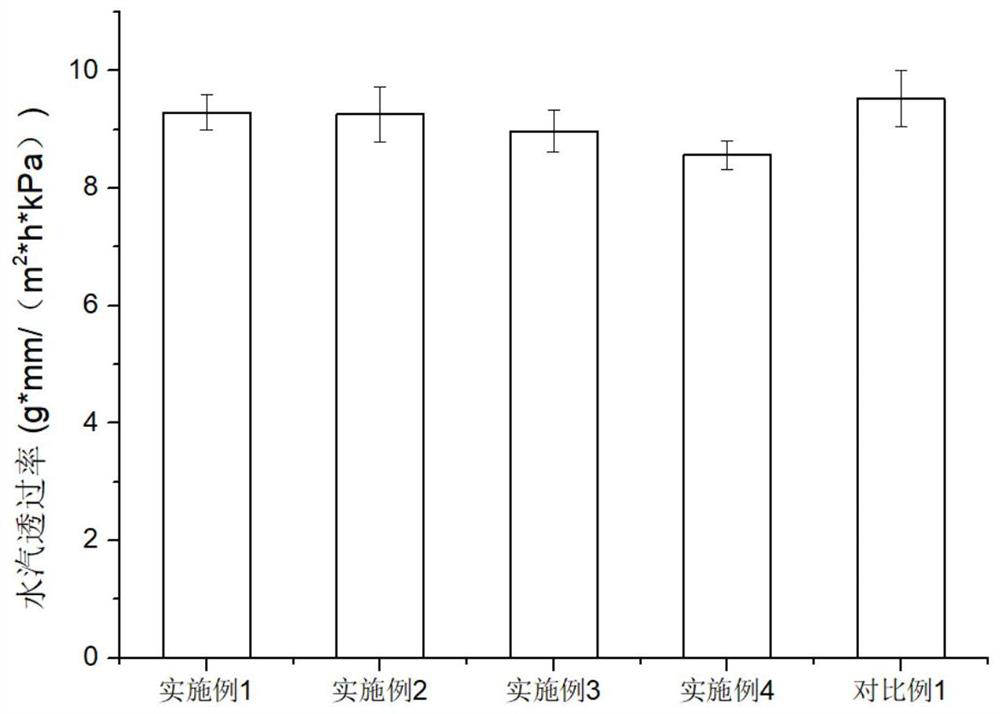

Examples

Embodiment 1

[0042] A kind of preparation method of enteric coating film,

[0043]Enteric coating film preparation: Add collagen, soybean protein, chitosan, glycerin, glutaraldehyde, and isolicorice flavonol to distilled water, adjust the pH to 10, and mix evenly at a temperature of 40°C to obtain a film-forming solution. The solution was uniformly cast on a glass mold, dried in a blast drying oven at a temperature of 50°C for 40 minutes, and finally placed in a constant humidity dryer at a temperature of 25°C and a humidity of 50% for 48 hours to obtain a sausage casing film. The addition of collagen is 9wt% of distilled water; the addition of soybean protein is 5wt% of distilled water; the addition of chitosan is 3wt% of distilled water; the addition of glycerin is 50wt% of distilled water; the addition of glutaraldehyde It is 0.16wt% of distilled water; the addition amount of isoflavonol is 3wt% of distilled water.

Embodiment 2

[0045] A kind of preparation method of enteric coating film,

[0046] Enteric coating film preparation: add collagen, soybean protein, chitosan, glycerin, glutaraldehyde, and glucosyl apigenin to distilled water, adjust the pH to 10, and mix evenly at a temperature of 40°C to obtain a film-forming solution. The solution was uniformly cast on a glass mold, dried in a blast drying oven at a temperature of 50°C for 40 minutes, and finally placed in a constant humidity dryer at a temperature of 25°C and a humidity of 50% for 48 hours to obtain a sausage casing film. The addition of collagen is 9wt% of distilled water; the addition of soybean protein is 5wt% of distilled water; the addition of chitosan is 3wt% of distilled water; the addition of glycerin is 50wt% of distilled water; the addition of glutaraldehyde It is 0.16wt% of distilled water; the added amount of glucosyl apigenin is 3wt% of distilled water.

Embodiment 3

[0048] A kind of preparation method of enteric coating film,

[0049] Enteric coating film preparation: add collagen, soybean protein, chitosan, glycerin, glutaraldehyde, isolicorice flavonol and glucosyl apigenin to distilled water, adjust the pH to 10, and mix evenly at a temperature of 40°C to obtain a film-forming solution , cast the film-forming solution evenly on a glass mold, dry it in a blast drying oven at a temperature of 50°C for 40 minutes, and finally place it in a constant humidity dryer at a temperature of 25°C and a humidity of 50% for 48 hours to obtain sausage casings membrane. The addition of collagen is 9wt% of distilled water; the addition of soybean protein is 5wt% of distilled water; the addition of chitosan is 3wt% of distilled water; the addition of glycerin is 50wt% of distilled water; the addition of glutaraldehyde It is 0.16wt% of distilled water; the added amount of isolicorice flavonol is 1wt% of distilled water; the added amount of glucosyl apig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com