Patents

Literature

60results about "Sausage casings by extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food casing with barrier action for oxygen and/or water vapor and suitable for absorbing and storing a food additive and releasing it to the food

InactiveUS20090214722A1Avoid weightPrevents aroma lossThermoplastic sausage casingsMultilayer sausage casingsFood additiveWater vapor

The present invention relates to a multilayer seamless tubular film as a food casing with barrier action for oxygen and / or water vapor, which is capable of absorbing and storing a food additive and releasing it to the food. It is used as an envelope of pasty or liquid materials and is particularly suitable as a synthetic sausage casing. The invention further relates to a particular liquid smoke composition which, in combination with such a tubular film, is particularly suitable for transferring the dyes and flavorings present to the food.

Owner:CASETECH

Moisture and gas permeable non-porous ionomeric films

Moisture and gas permeable ionomeric films are described. The films described herein are obtained from blends of ionomers with an organic acid salt in the amount of at least about 5 wt %, and have MVTR greater than films obtained from conventional ionomers. Particularly preferred are the potassium salts of stearic, oleic, isostearic, and isooleic acids. Films comprising a liquid-absorbent ionomer film layer and an impermeable layer are provided. The films are suitable for preparation of tubular casings and shrinkbags, in particular, casings for smoked foodstuffs.

Owner:PERFORMANCE MATERIALS NA INC

Films comprising liquid smoke and flavorants

InactiveUS20090155430A1Thermoplastic sausage casingsMultilayer sausage casingsLiquid smokeEngineering

A process for producing a film having incorporated or applied thereon or therein an additive such as liquid smoke is provided wherein the film comprises a liquid absorbent layer and an impermeable layer. The films can be used for producing a tubular casing or shrinkbag.

Owner:EI DU PONT DE NEMOURS & CO

Smokable polymeric casing

InactiveUS20050163948A1Easy to disassembleImprove performanceMultilayer sausage casingsSmokable sausage casingsPolyvinyl alcoholThin membrane

A novel shrinkable monolayer film that may be produced as a film or a tube, as in a food casing. This newly disclosed film is a blend of a polyamide base, a novel polyvinyl alcohol and optionally, an antiblocking agent.

Owner:VISCASE CORP

Collagen concentrate, use thereof and also process for production thereof

ActiveUS20090162502A1Rapidly and readily convertibleDisadvantage is compensatedContainers for flexible articlesConnective tissue peptidesCentrifugationSolid fraction

A film-forming collagen concentrate is provided containing at least 18% by weight dry matter. At least 50% by weight of the protein of a homogeneous suspension produced from the concentrate in a 0.15 molar aqueous sodium dihydrogenphosphate buffer having a pH of 7 and a calculated dry matter fraction of 0.5% by weight may be separated as sediment by 15 min centrifugation at 1780 RFC and 15° C. A process is also disclosed for producing a collagen-concentrate-containing food casing that includes (a) producing an aqueous collagen mass; (b) concentrating the aqueous collagen mass until it has a solids fraction of 18% by weight or more; (c) admixing the concentrate with dilute acid to obtain a (co)extrudable or castable collagen mass; (d) coextruding or casting the collagen mass to from a casing; (e) solidifying the casing and, optionally, (f) drying the casing.

Owner:KALLE AG

Films comprising a liquid-absorbant inner layer and an impermeable outer layer

InactiveUS20040146610A1Multilayer sausage casingsSynthetic resin layered productsEngineeringPolymer science

Owner:PERFORMANCE MATERIALS NA INC

Films comprising a liquid-absorbant inner layer and an impermeable outer layer

Owner:PERFORMANCE MATERIALS NA INC

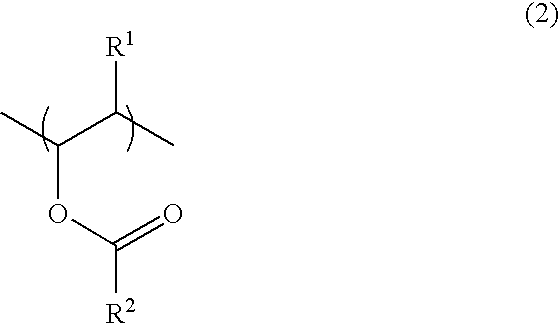

Additive delivery laminate and packaging article comprising same

InactiveUS20060051465A1Ready-for-oven doughsThermoplastic sausage casingsPolymer scienceWater insoluble

An additive delivery laminate is suitable for packaging a food product which is cooked in the package, with an additive transferring from the laminate to the food product. The additive delivery laminate has a substrate and an additive delivery layer. The additive delivery layer contains a water-insoluble thermoplastic polymer, a polymer toughening agent, and additive granules containing a colorant, flavorant, and / or odorant. The polymer toughening agent is present in a blend with the water-insoluble thermoplastic polymer. Polyisobutylene is a preferred water-insoluble thermoplastic polymer, and hydrogenated wood rosin is a preferred polymer toughening agent. The polymer toughening agent decreases the tendency of the water-insoluble thermoplastic polymer to form legs or transfer to the food product upon stripping the laminate from the food product after cooking and transfer to the additive to the food product.

Owner:CRYOVAC ILLC

Additive transfer film suitable for cook-in end use

InactiveUS7183006B2Avoid handlingAvoid wastingThermoplastic sausage casingsWrappersPolyesterPolyolefin

A multilayer film has a first layer and a second layer. The first layer comprises an additive, a binder, and a crosslinking agent. The additive is a flavor, fragrance, colorant, antimicrobial agent, antioxidant, chelating agent, and / or odor absorbent. The binder is a polysaccharide and / or a protein. The crosslinking agent comprises a compound with at least two carbonyl groups. The second layer comprises a non-water-soluble thermoplastic polymer comprising at least one member selected from the group consisting of polyolefin, polyamide, polyester, polyvinylidene chloride, polyvinyl chloride, and polystyrene. Each of the additive, binder, and crosslinking agent are present throughout a thickness of the first layer. Preferably, the first layer is coated onto the second layer, which is preferably a non-water-soluble thermoplastic polymer, e.g., polyolefin, polyamide, and / or polyester. The film is especially useful for cook-in applications, in which a food product (preferably comprising uncooked meat) is packaged in the film with the coated layer against the meat. The meat is then cooked and the additive transfers to the meat, and purge can be very low. The invention also pertains to a process for preparing a cooked food product, process for making a coated film, and articles formed from the film, such as bags and casings.

Owner:CRYOVAC INC

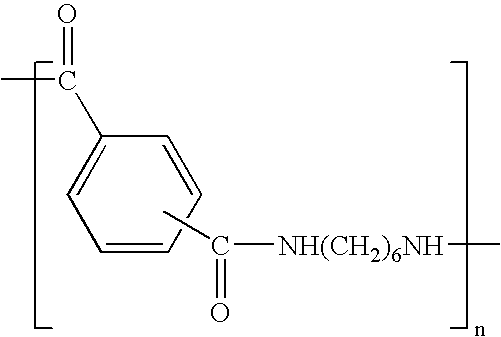

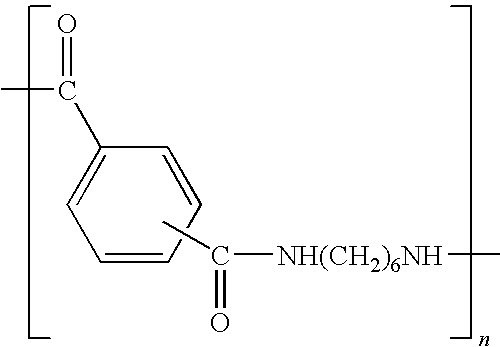

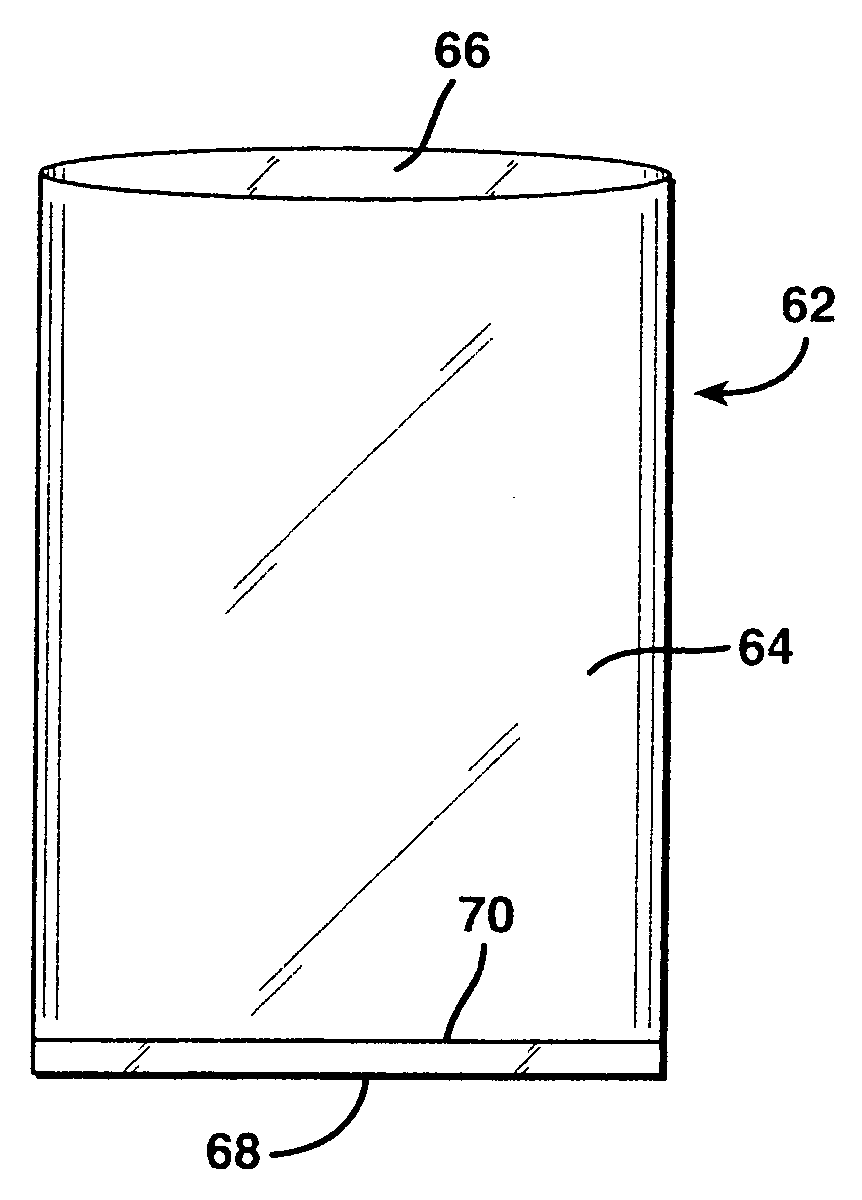

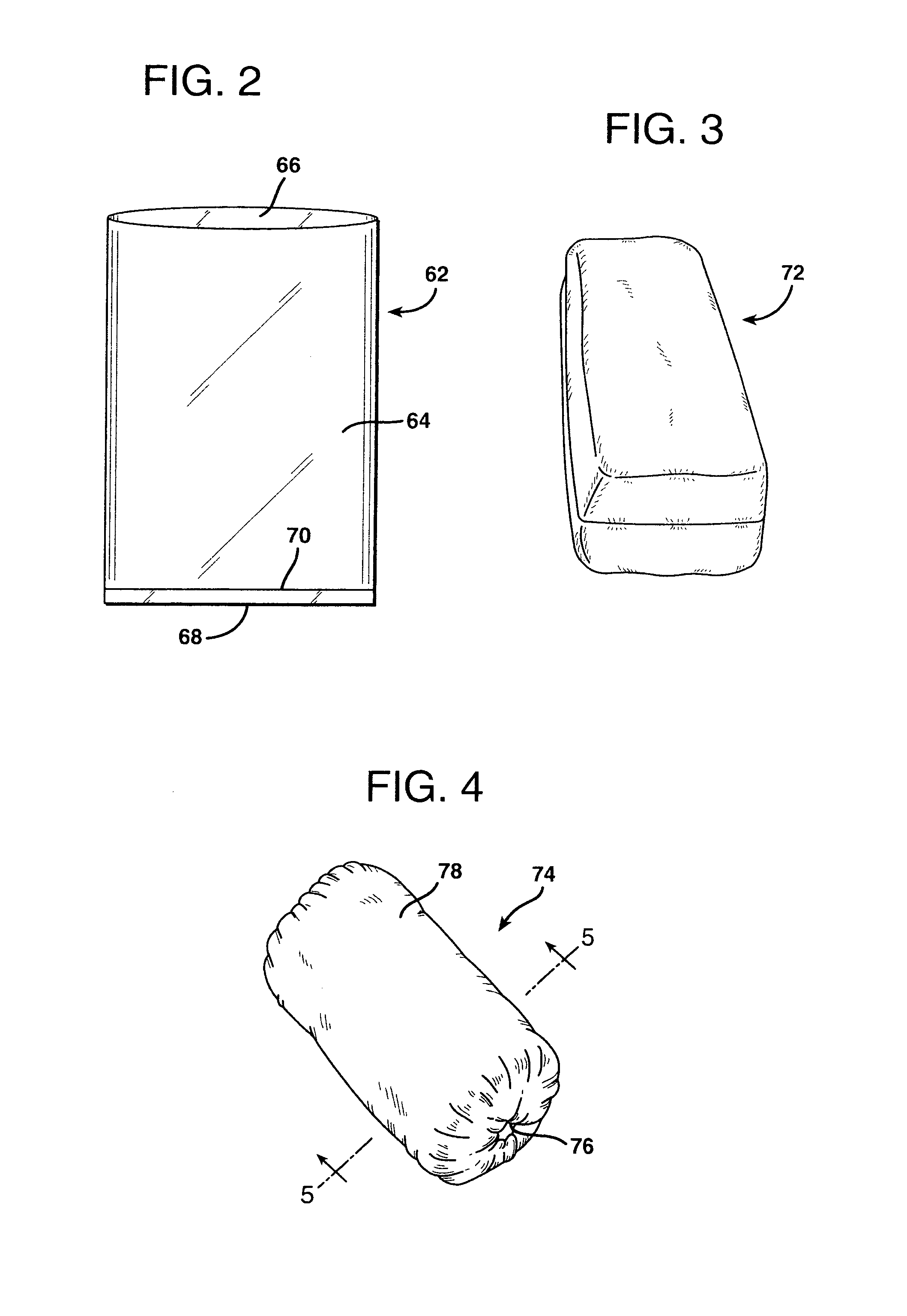

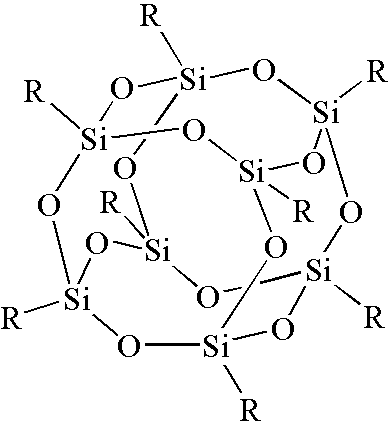

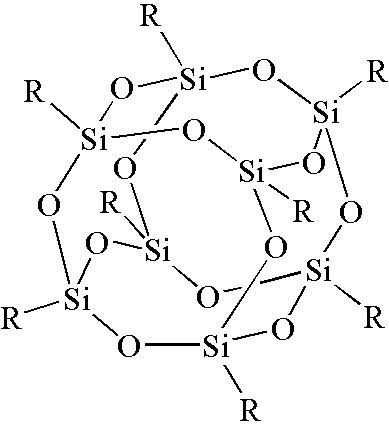

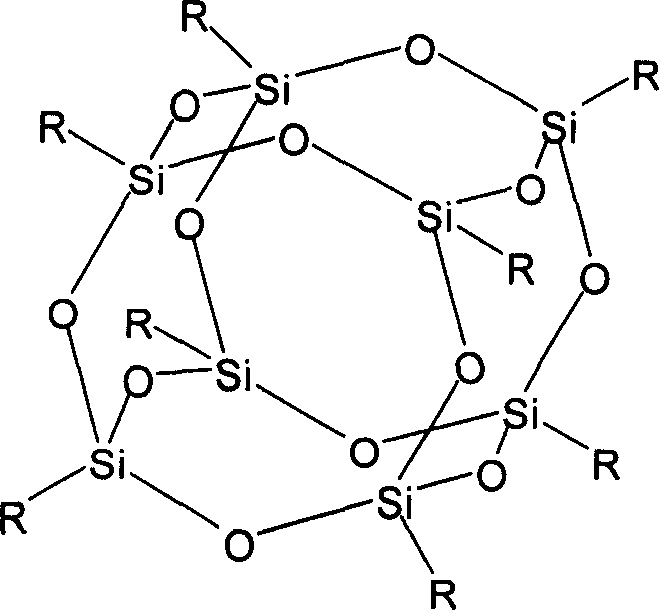

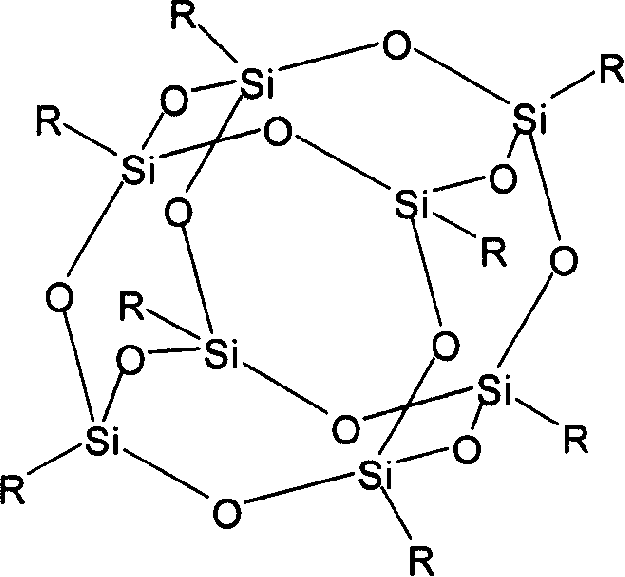

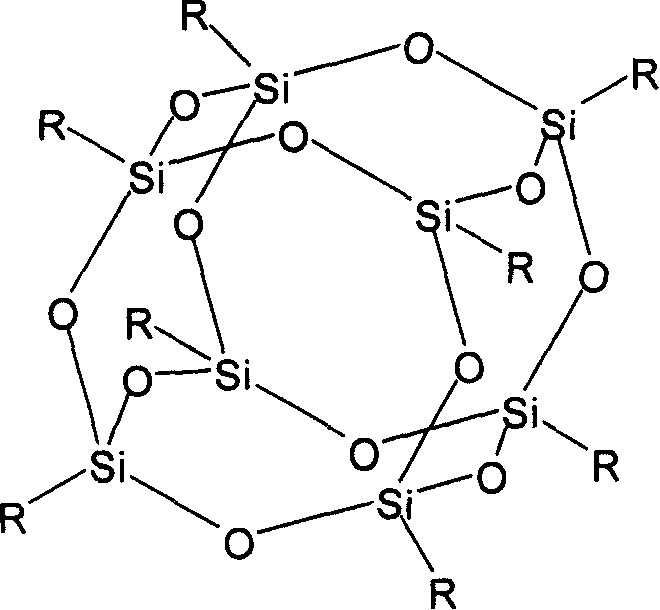

Polymer based sausage casing

InactiveUS7833594B2Good peeling effectLow viscosityLayered productsBiaxially oriented sausage casingsMoisture barrierMonolayer

A polymer-based sausage casing suitable for use with uncooked meats such as chorizo is disclosed. A polymer resin is blended with a silicon-based barrier control agent, preferably a polyhedral oligomeric silsesquioxane, to increase the permeability of the sausage casing. The resultant blend can be biaxially stretch-oriented to produce a single-layered polymer-based sausage casing suitable for use with uncooked sausage meats such as chorizo, and specifically suitable for the gas and moisture permeability needed during the curing process for uncooked sausage meats. Such polymer-based casings can also be employed for cooked sausages by choosing a silicon-based barrier control agent that increases gas and moisture barrier, thereby increasing shelf-life for unpeeled sausages. A method for improving the peelability of cooked sausage casings by injecting a thin coating of a releasing agent, without the addition of a surfactant, into the sausage casing during the shirring process is also disclosed. The releasing agent is a hydroxypropyl methylcellulose solution that creates a low viscosity releasing agent that effectively improves peelability from any type of sausage casing, but preferably for use with the polymer-based sausage casing of the present invention.

Owner:CASEMATIC S A DE

Polymer-based casing for sausages

InactiveCN1697731AExcellent peelabilityReady-for-oven doughsLayered productsEngineeringSurface-active agents

The invention relates to a polymer-based casing for sausages which is designed to be used with uncooked meats such as chorizo. According to the invention, a polymer resin is mixed with a silicon-based barrier control agent, preferably a polyhedral oligomeric silsesquioxane, in order to increase the permeability of the sausage casing. The resulting mixture can be stretched and oriented biaxially in order to produce a polymer-based sausage casing comprising a single layer, which can be used with uncooked meat in the form of sausages, such as chorizo, and which is specifically designed to enable the gas and moisture permeability which is necessary during the curing of uncooked meats in the form of sausages. The inventive polymer-based casing can also be used for cooked sausages by selecting a silicon-based barrier control agent which increases the gas and moisture barrier, thereby increasing the shelf life of cased sausages. The invention also relates to a method of improving the casing detachment capacity for cooked sausages involving the injection of a thin coating of a release agent into the sausage casing during the gathering process, without the addition of a surface active agent. The aforementioned release agent is a hydroxypropyl methylcellulose solution which creates a low-viscosity release agent which effectively improves the detachment capacity of any type of casing for sausages, but which is preferably used with the inventive polymer-based sausage casing.

Owner:CASEMATIC S A DE

Films comprising liquid smoke and flavorants

A process for producing a film having incorporated or applied thereon or therein an additive such as liquid smoke is provided wherein the film comprises a liquid absorbent layer and an impermeable layer. The films can be used for producing a tubular casing or shrinkbag.

Owner:EI DU PONT DE NEMOURS & CO

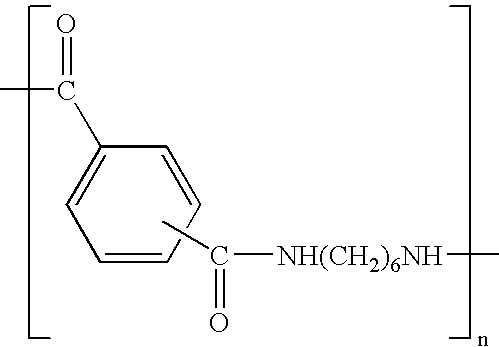

Nylon food casing having a barrier core layer

ActiveUS7244481B2Good conformationEasy to processWrappers shrinkageSausage casingsThin membraneEngineering

Owner:VISCASE CORP

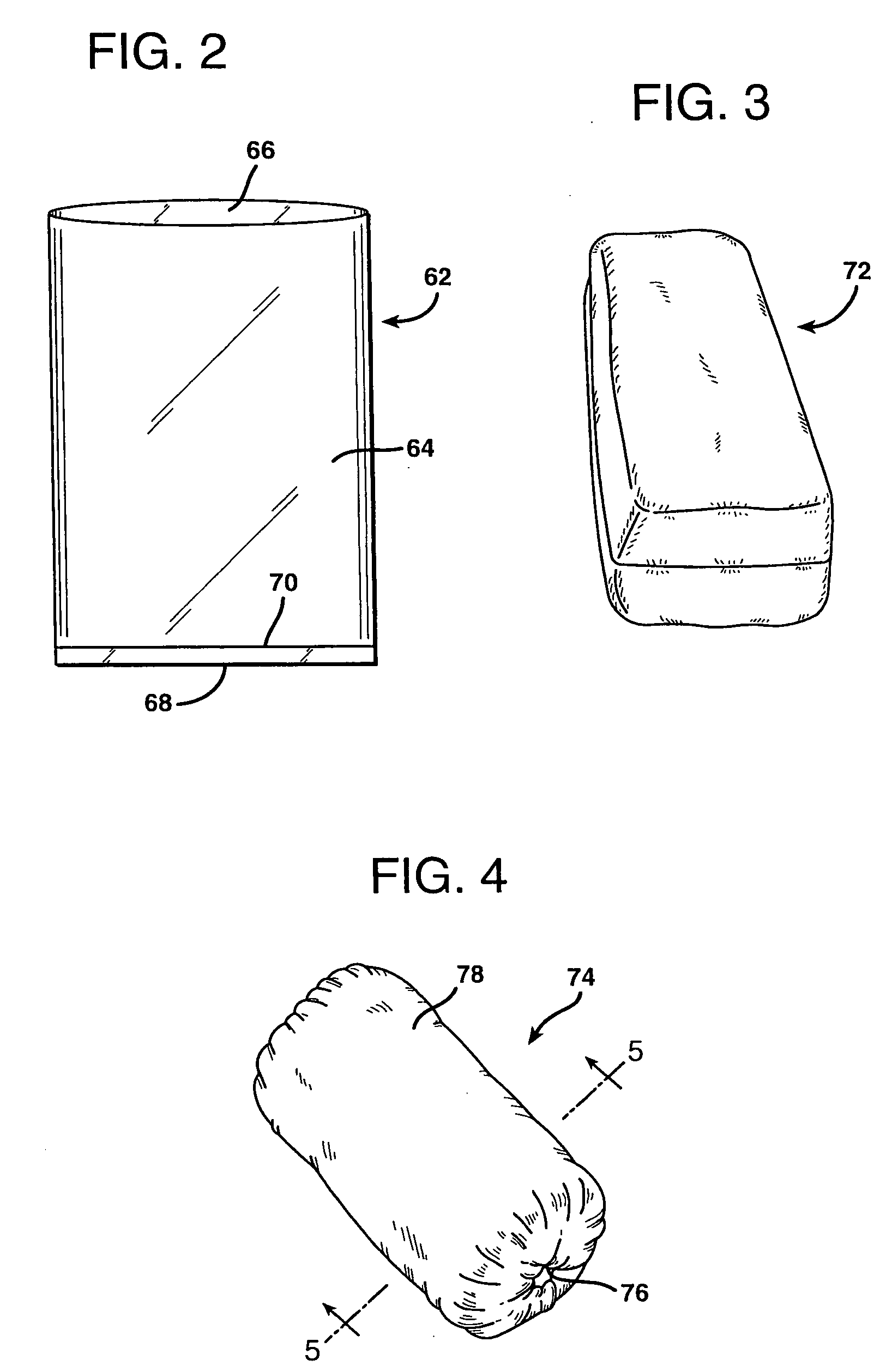

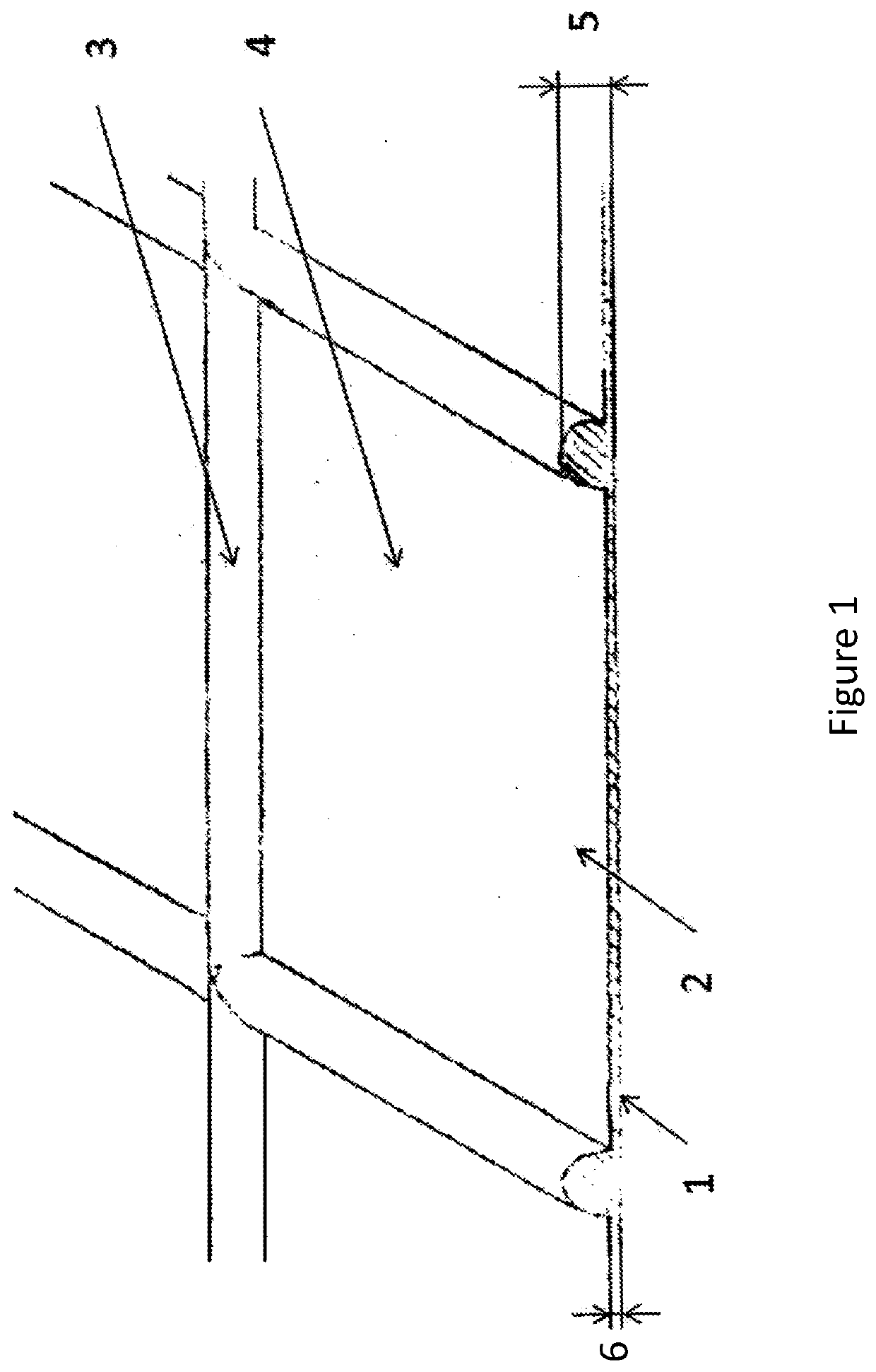

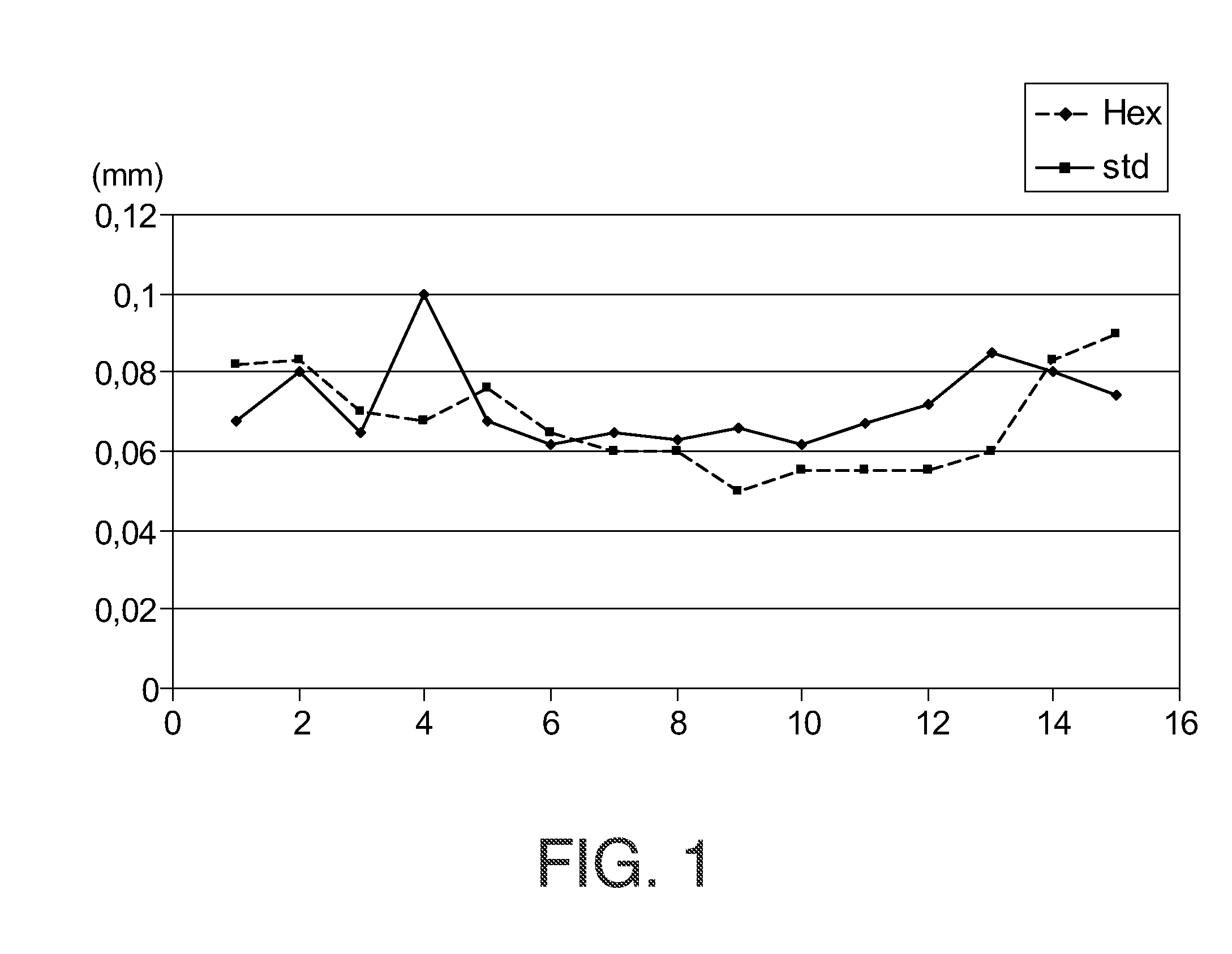

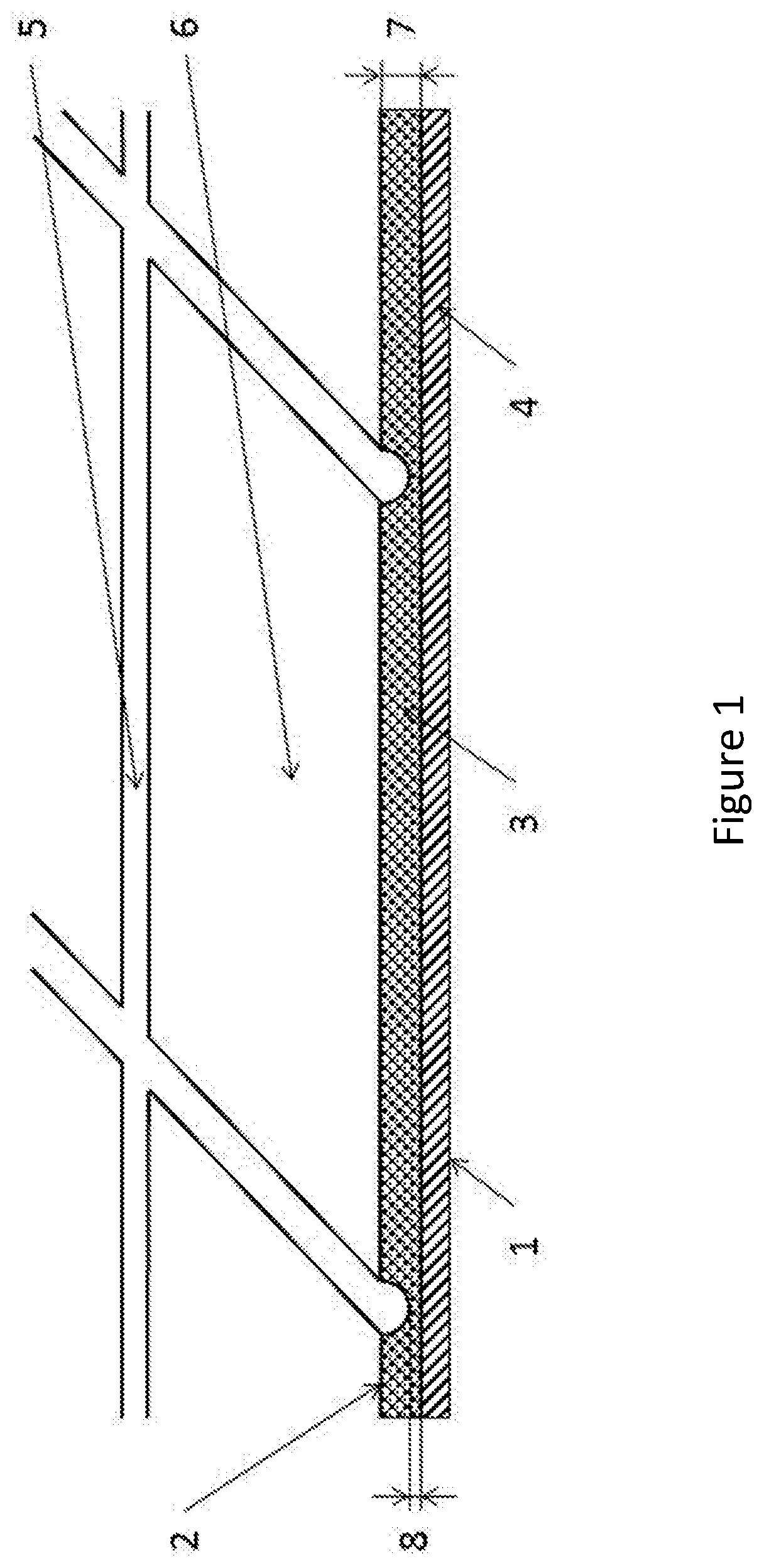

Method for obtaining artificial sausage casing for foodstuffs, artificial casing and resulting products obtained

InactiveCN102740701AChange appearanceBig expansionSausage casing manufactureSausage filling/stuffing machinesEngineeringBiomedical engineering

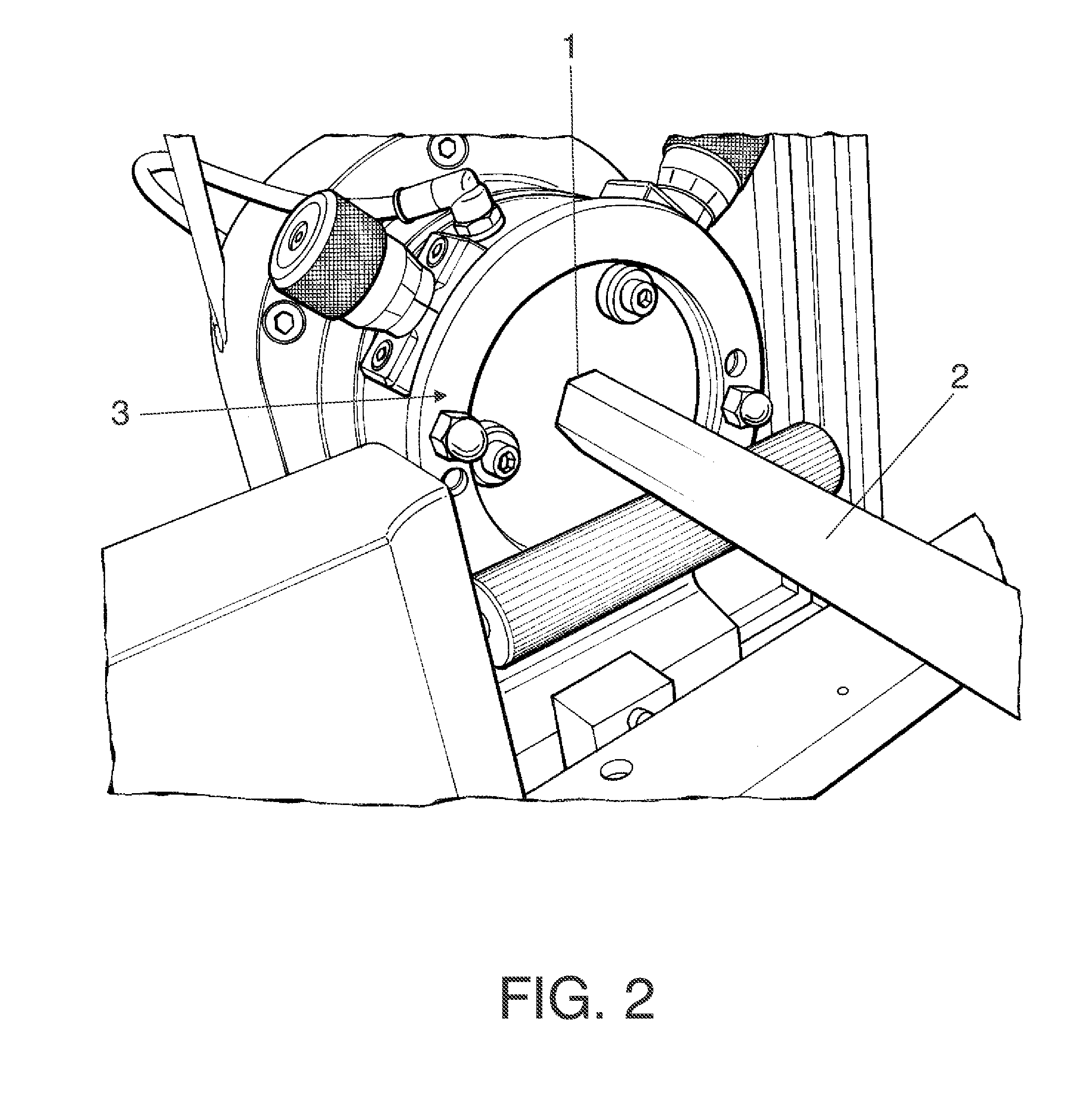

Method for obtaining artificial sausage casing for foodstuffs and artificial casing obtained using said method, which involves extruding gel through an output slot (1) having a closed, polygonal and non-circular geometric configuration, obtaining a tubular film (2) with a circular cross-section through the effect of the pressure exerted by a fluid that is injected inside said hollow tubular film (2) such that the artificial casing obtained has a high dilation capacity in the cross section of the same, while maintaining the same longitudinal traction properties as a casing obtained using a circular slot of the same calibre.

Owner:VISCOFAN

Five-layered, biaxially-oriented, sealable tubular film for the packaging and wrapping of paste-like foodstuffs meat and meat with bones and use thereof

InactiveUS6998160B2Improve puncture resistanceLow oxygen permeabilityDough treatmentMultilayer sausage casingsHigh resistancePolyolefin

The invention relates to a five-layered, biaxially oriented, shrinkable, sealable tubular film for the packaging and wrapping of paste-like foodstuffs, meat, or meat with bones and to the use thereof. The tubular film of the invention has an inner layer comprised of at least one copolyamide and at least one modified polyolefin, a layer of a modified polyolefin, a middle layer comprised of at least one homopolyamide and / or at lest one copolyamide and / or at least one copolymer of ethylene and vinyl alcohol and / or a modified polyolefin, a layer of at least one ethylene-vinyl alcohol copolymer, and an outer layer comprised of at least one polyolefin and / or at least one modified polyolefin. Such tubular films involve a significant improvement in the seal seam strength, in particular at low sealing temperatures, a high impermeability to oxygen and a comparable to markedly higher resistance to puncturing compared to prior art films.

Owner:NATURIN GMBH & CO

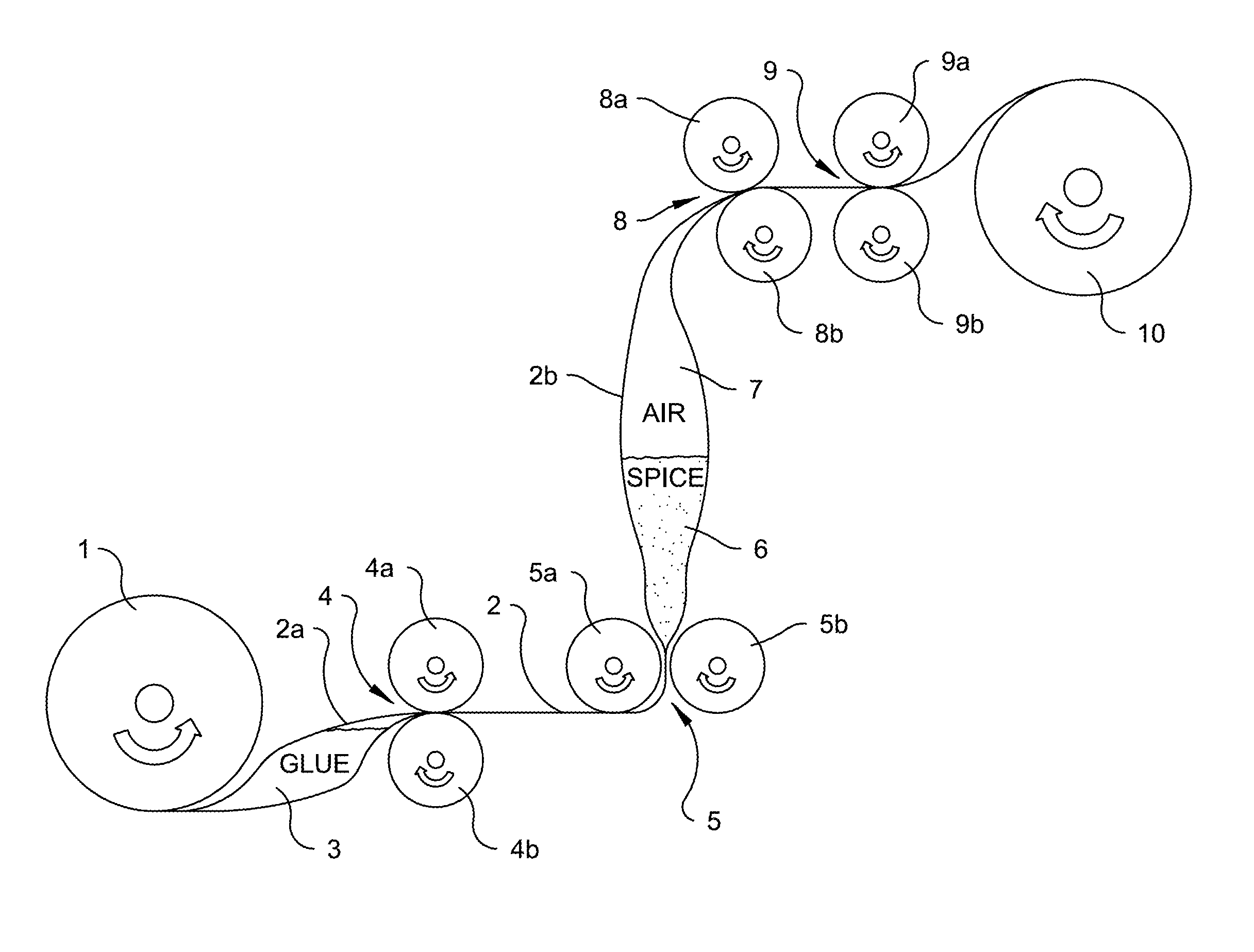

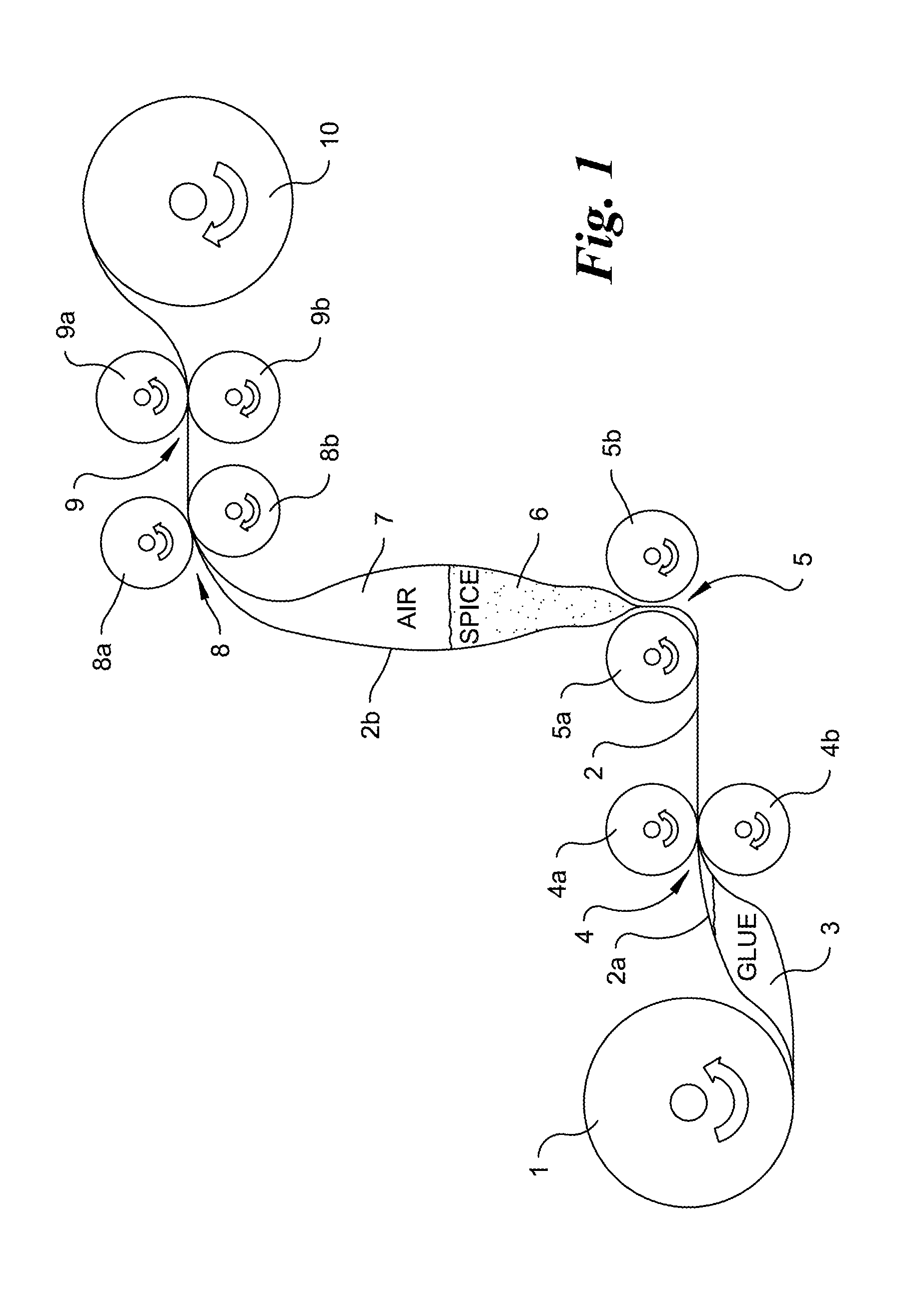

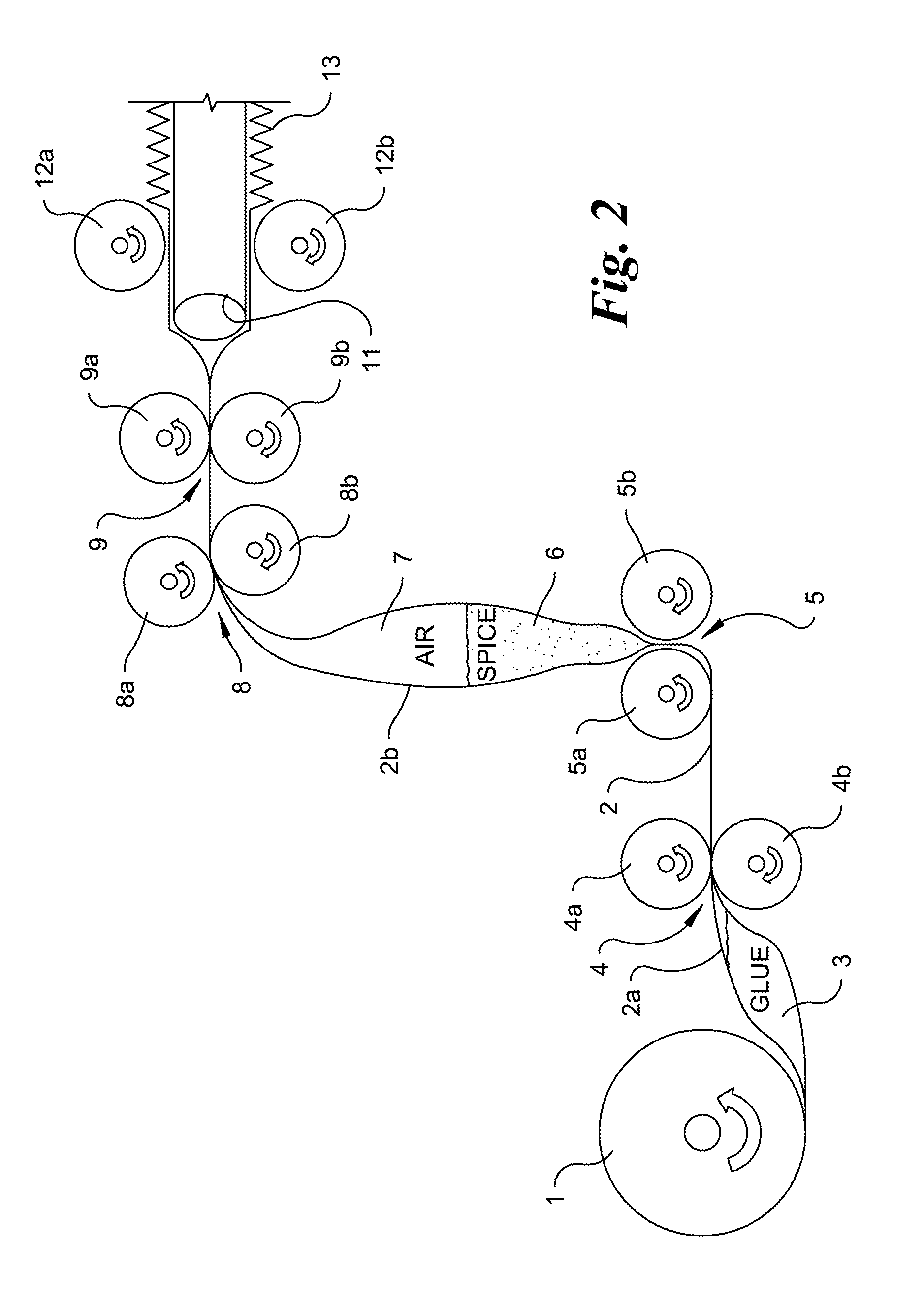

Shirrable spiced casing with inner coating

ActiveUS20130280390A1Easy to storeEasy to transportLiquid surface applicatorsMultilayer sausage casingsAdhesiveEngineering

A method is provided for coating tubular food casings (2), especially intestines, with flavoring substances in particle form, especially spices, wherein the tubular casing (2) is wetted on the inside with adhesive (3) and the desired flavoring substances (6) are deposited on the formed adhesive layer. Here, it is essential that the casing (2), wetted on the inside with adhesive (3), is brought through a particle-shaped flavoring substance supply (6), formed in the interior of the tube, and a gas cushion (7), in particular an air cushion, into a non-flat, open cross-sectional shape. The casing wetted with adhesive on its inner side carries along flavoring substances from the flavoring substance supply (6), when it is pulled through the flavoring substance supply. The casing (2) at least on the inside is made from a hydrophilic plastic.

Owner:WORLD PAC INT

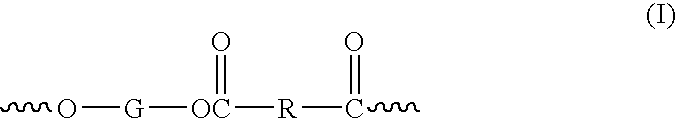

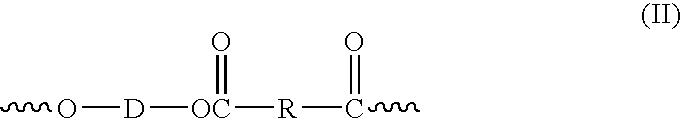

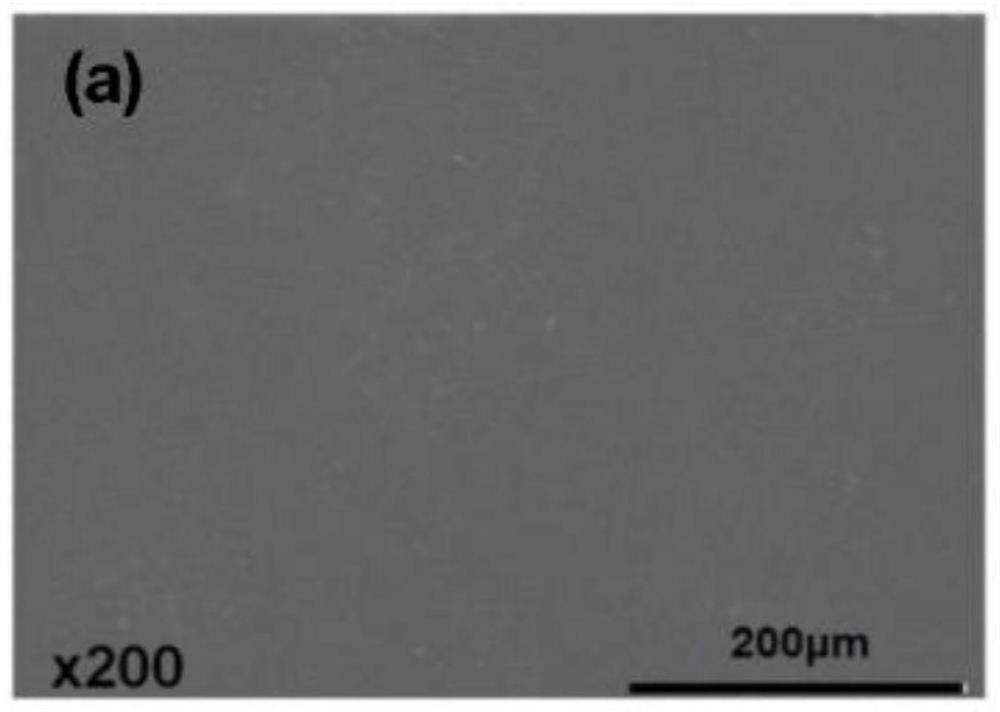

Textured non-porous barrier transfer casing

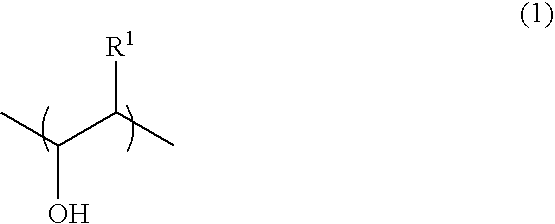

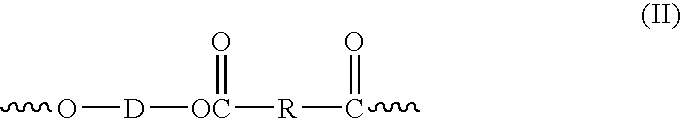

ActiveUS20200037623A1Sufficient barrier effectPreventing contamination of environmentThermoplastic sausage casingsOrganic chemistryPolymer sciencePolyolefin

The present invention provides a functional additive transferring (co)extruded thermoplastic food casing having a water vapor barrier and / or oxygen barrier effect wherein an inside surface of the thermoplastic food casing has a textured surface which forms a three-dimensional pattern of higher and lower retaining capacity for a functional additive, wherein the thermoplastic food casing having a textured surface in case of a monolayer casing or an inner layer comprising the inside surface having a textured surface in case of a multilayer casing comprises as a main component at least one thermoplastic polymer material selected from the group consisting of (co)polyamides, (co)polyolefins, (co)polyester and vinylidenchloride (co)polymers, wherein the (co)extruded thermoplastic food casing does not comprise a net and / or a material forming a net or any other three dimensional structure on its outside surface, wherein the average thickness of the thermoplastic food casing in the areas having a higher retaining capacity is in a range of from 1 to 100 μm, wherein the average thickness of the thermoplastic food casing in the areas having a lower retaining capacity is in a range of from 191 to 2000 μm, provided that the thickness difference between the average thickness in the areas having higher retaining capacity and the average thickness in the areas having a lower retaining capacity is in a range of from 160 to 1950 μm and that a ratio of the average thickness of the thermoplastic food casing in the areas having a higher retaining capacity and the average thickness of the thermoplastic food casing in the areas having a lower retaining capacity is in a range of from 0.002 to 0.25.

Owner:VISCOFAN

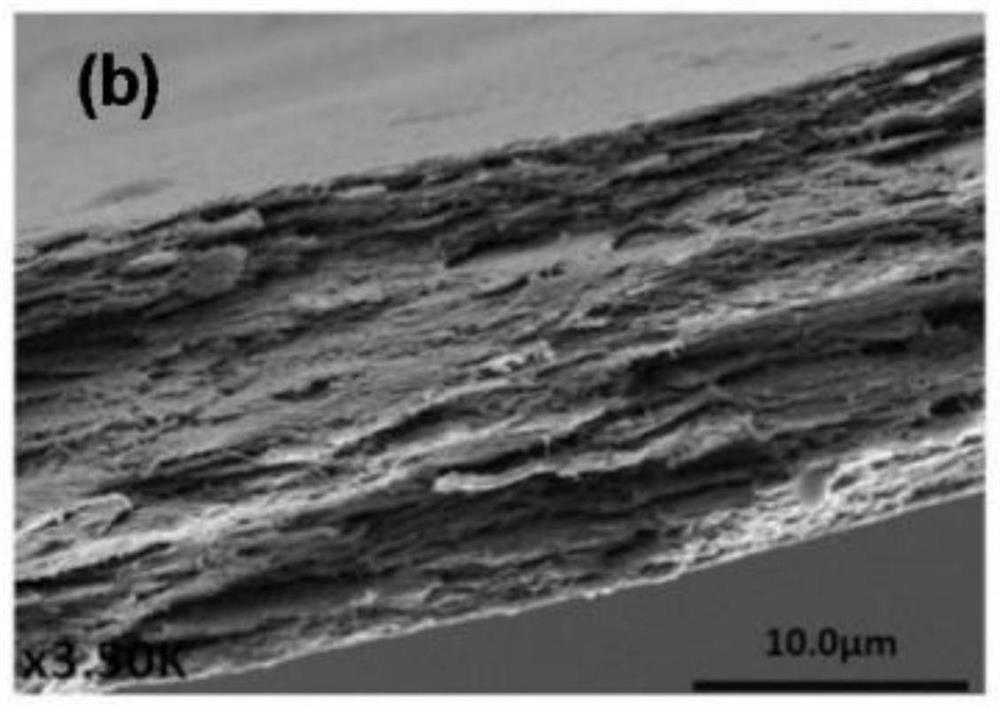

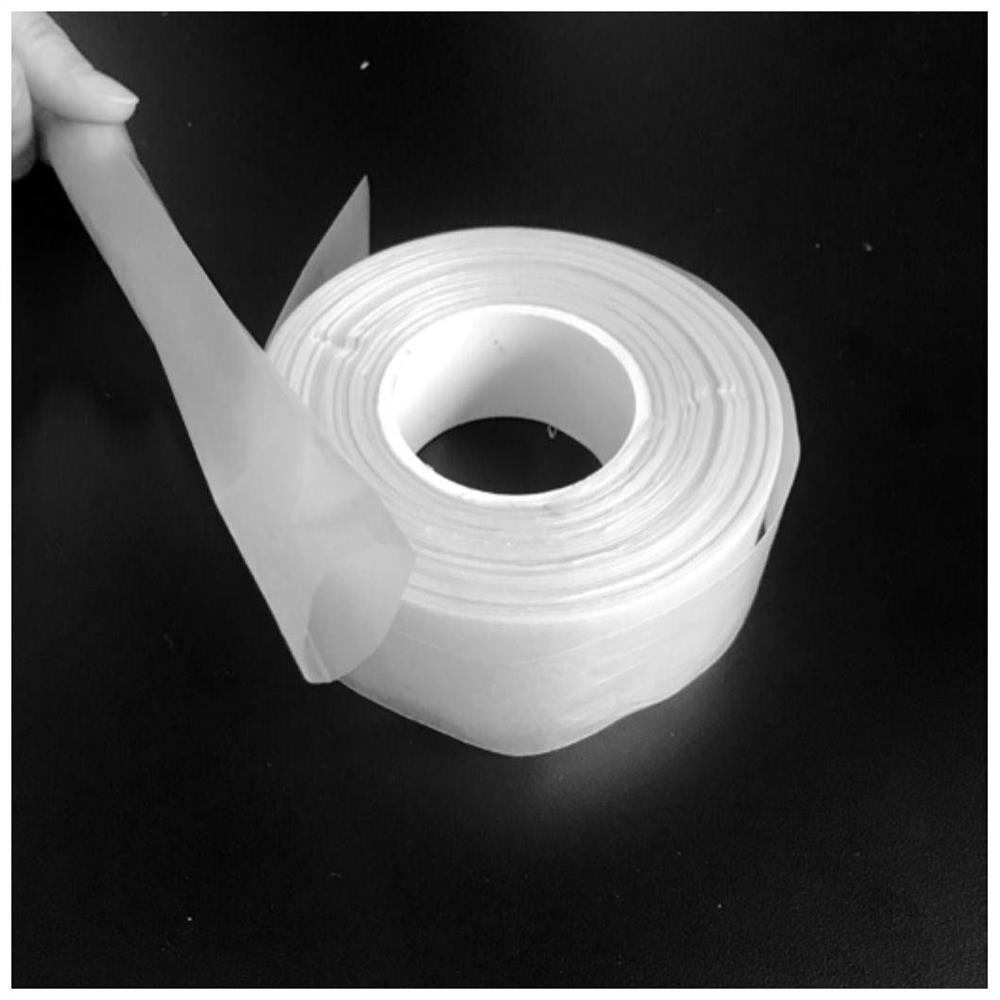

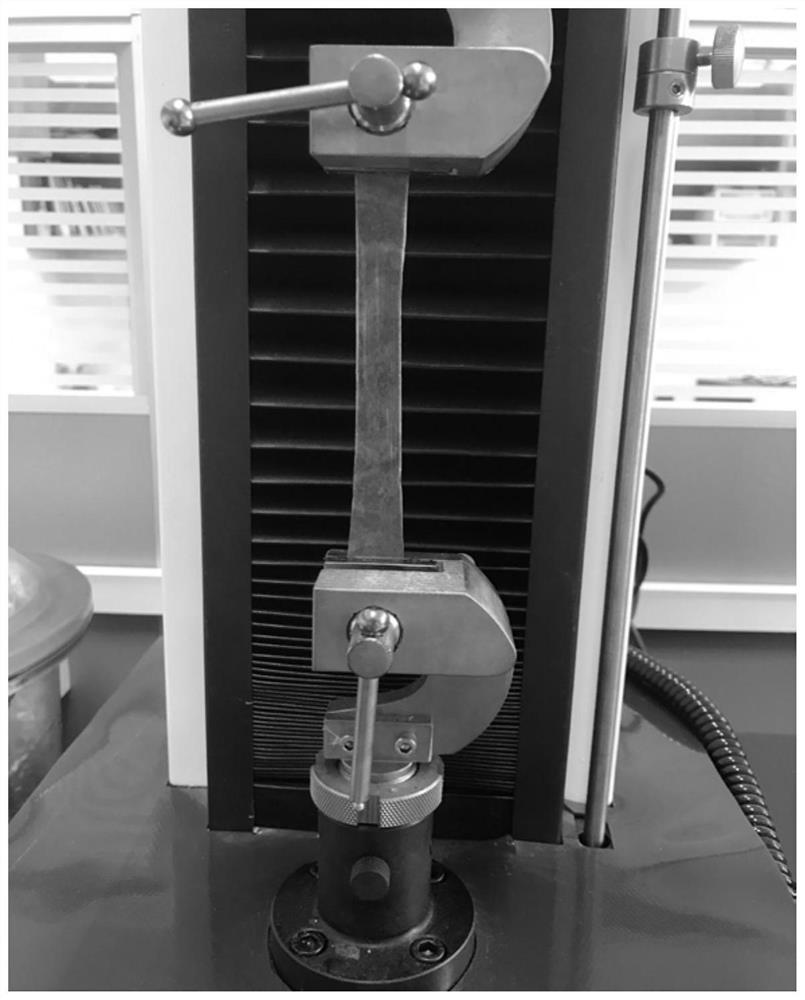

Preparation method of nanocellulose reinforced collagen casing

InactiveCN112931578AQuality improvementImprove mechanical propertiesCellulosic sausage casingsSausage casings by extrusionFiberPolymer science

The invention discloses a preparation method of a nanocellulose reinforced collagen casing, which comprises the following steps: (1) cleaning and splitting the inner layer of cow leather to obtain split leather; (2) carrying out alkali treatment on split leather, conducting cutting to form blocks, and conducting soaking until the pH is neutral; (3) soaking the neutral cow leather in hydrochloric acid, and conducting swelling; (4) scraping collagen fibers on the swelled cow leather, using the collagen fibers to prepare a collagen suspension, and adjusting the pH value of the collagen suspension; (5) preparing nano cellulose by using a physical method, a chemical method or a biological method; (6) adding the nanocellulose suspension into the collagen suspension to obtain a mixed solution A; (7) adding glycerol into the mixed solution A, uniformly conducting stirring to obtain mucilage, and conducting refrigerating; and (8) extruding and spraying the refrigerated mucilage out of a tube, conducting drying, carrying out immobilization treatment, conducting curing and qualitative treatment, and conducting packaging to obtain the casing. By utilizing the advantages of high length-diameter ratio, larger specific surface area and the like of the nanocellulose, the mechanical property of the casing can be improved when the nanocellulose is applied to preparation of the casing.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for Obtaining Artificial Sausage Casing for Foodstuffs, Artificial Casing and Resulting Products Obtained

InactiveUS20130266697A1Maintain physical propertiesGreat dilation capacityContainers for flexible articlesConfectioneryBiomedical engineeringGeometric configuration

Owner:VISCOFAN

Biaxially drawn tubular film comprising three adjacent polyamide-based layers

ActiveUS9265265B2High inherent stabilityMultilayer sausage casingsSynthetic resin layered productsPolyamideEngineering

Owner:KALLE AG +1

Casing preservation salt for air-dried sausages

InactiveCN109953249AImprove performanceAffect food safetyMeat/fish preservationFood ingredient functionsBiotechnologyAlpha-Tocopherol

The invention relates to a casing for air-dried sausages. The casing is characterized by comprising the following components in percentage by weight: 30-40 parts of animal endothelium with a fine grinding mesh number of 200-400 meshes, 10-15 parts of fleece-flower roots, 15-20 parts of swimming bladders, 4-8 parts of sodium carboxymethyl cellulose, 5-10 parts of sweet potato powder, 2-3 parts of D-sodium isoascorbiate, 1-1.5 parts of alliin, 1-2 parts of lycium barbarum polysaccharide, 3-6 parts of polyoxyethylene sorbitan fatty acid ester, 0.5-1.5 parts of nerolyl acetate, 0.5-1 part of citral, 1-3 parts of alpha-tocopherol, 1-2 parts of sodium erythorbate, 1-1.5 parts of ester of adipic acid and 2,3-butanediol, 3-5 parts of fish oil, and 1-1.5 parts of 1,4-dibutyl-6-(1-ethyl pentadecyl)phenol.

Owner:汤萍

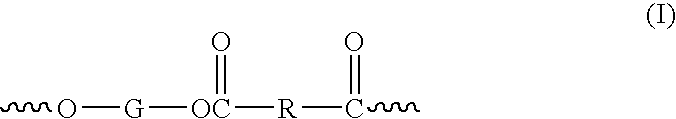

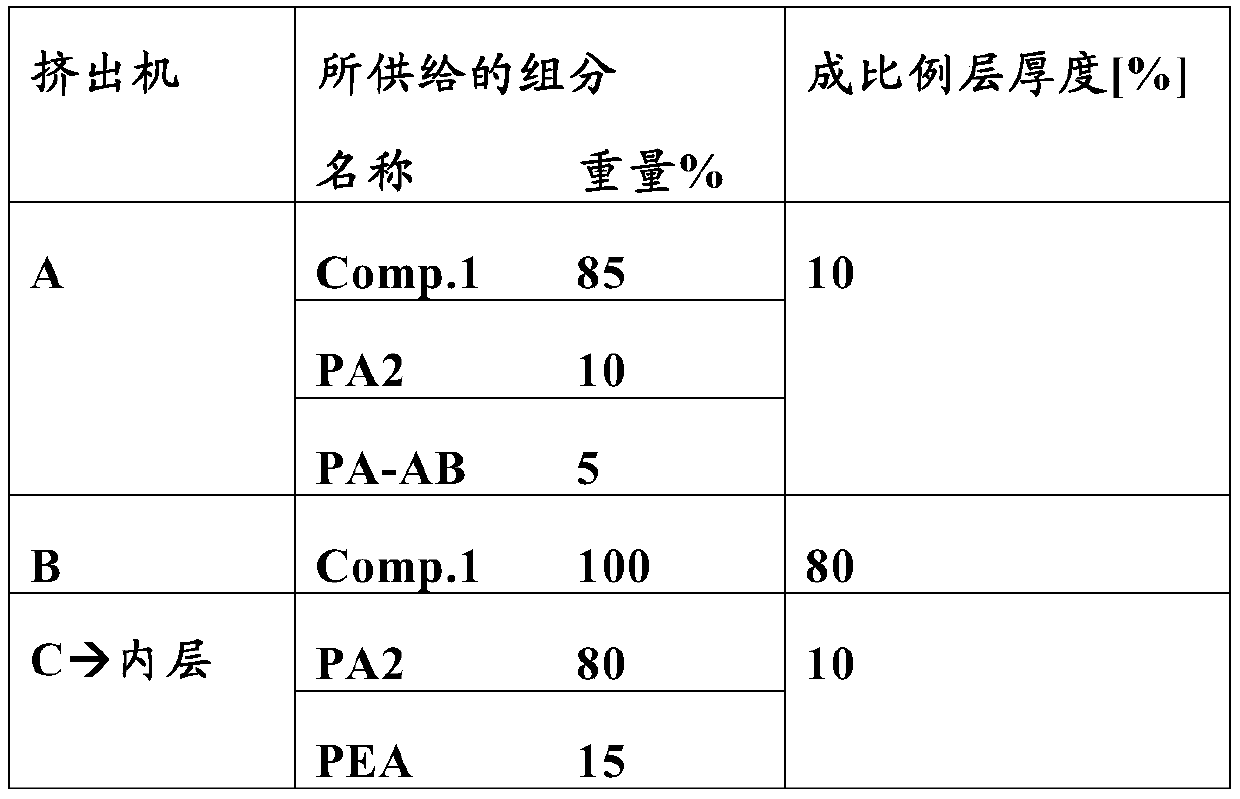

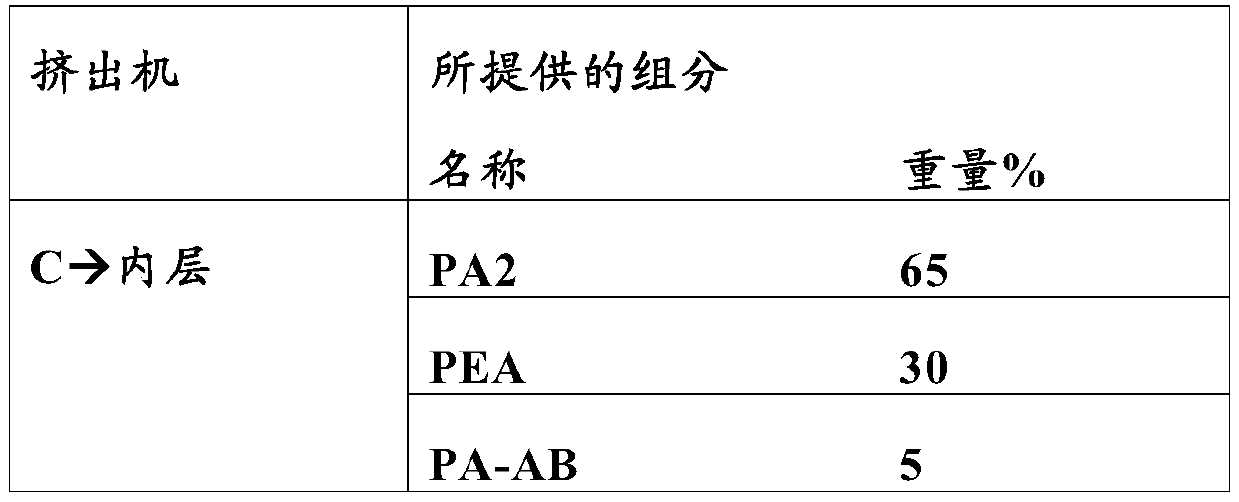

Smoke and water vapor-permeable food casing with optimized bonding properties

A tubular, seamless, water vapor permeable, smokable, biaxially draw-oriented and partially or completely heat-set food casing is provided having at least two layers based on thermoplastic polymers. At least one layer A, which does not form the inside layer, comprises a blend of aliphatic (co)polyamide and at least one hydrophilic polymer, while the inside layer I comprises a blend of aliphatic orisocyclic (co)poly amide and a block copolymer selected from polyether-amide, polyether-ester and polyether-urethane. The casing is produced by a tubular-film blowing process or a process with biaxial tubular-film draw-orientation. The casing is envisaged more particularly as synthetic sausage casing, especially for smoked raw sausage, such as salami.

Owner:KALLE AG

Edible film compositions for processing of meat products

ActiveUS20050238792A1Improve adhesionImproved shine appearanceProtein composition from fishFood ingredientsGelatinPolymer

Novel film compositions are described for use in the processing of meat products, particularly as sausage casings and wrappers for hams and other cured meat products. By combining gelatin and other hydrocolloid film forming polymer materials, edible film compositions are achieved by solution casting which exhibit superior and desirable properties for adhering to the meat product and presenting a shining, appealing surface.

Owner:LIVING CELL RES

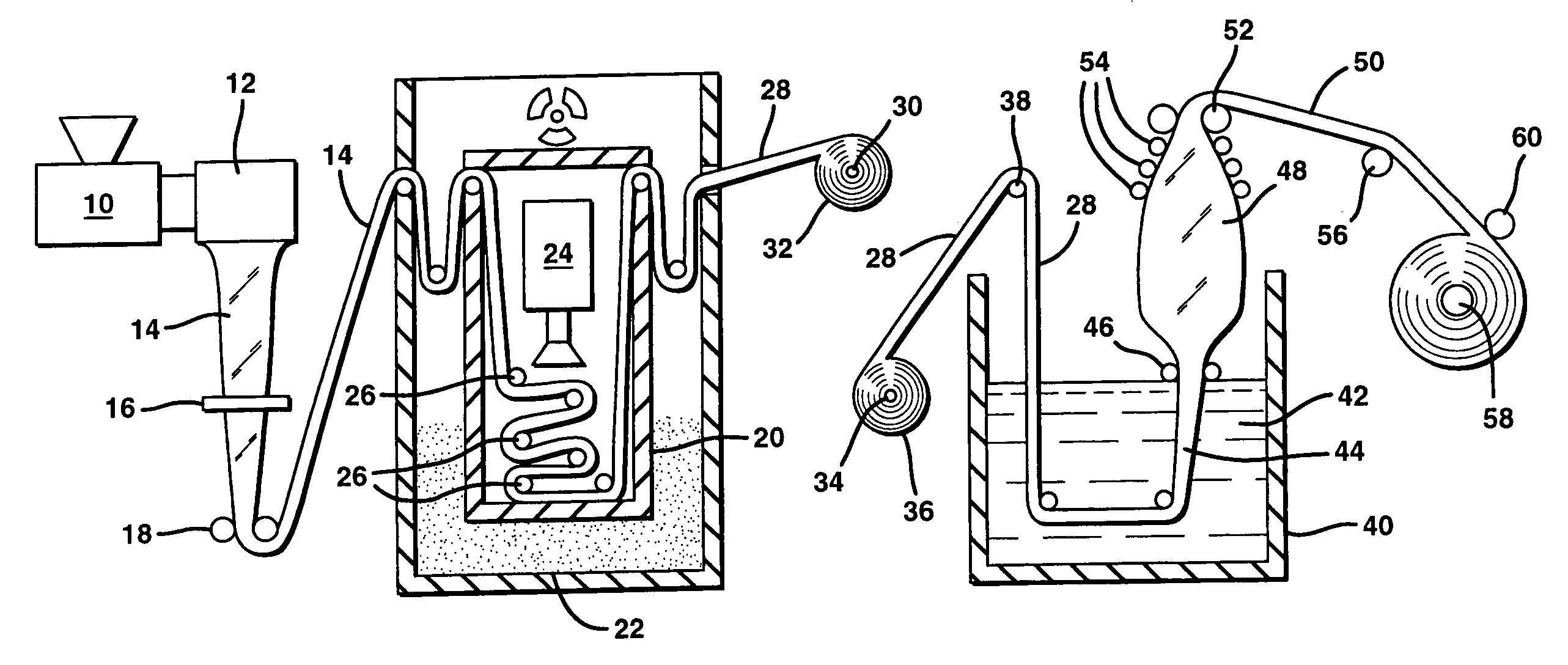

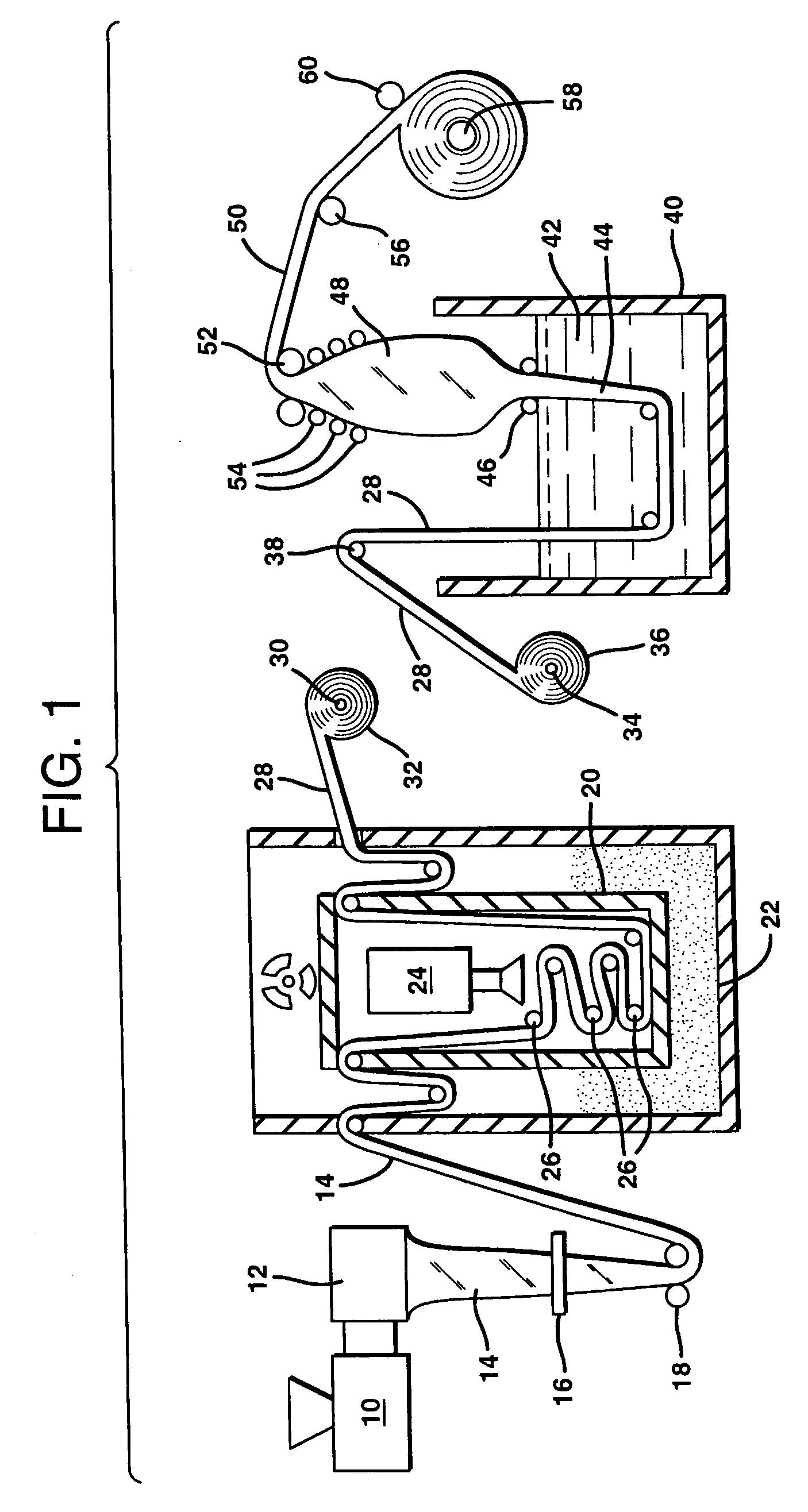

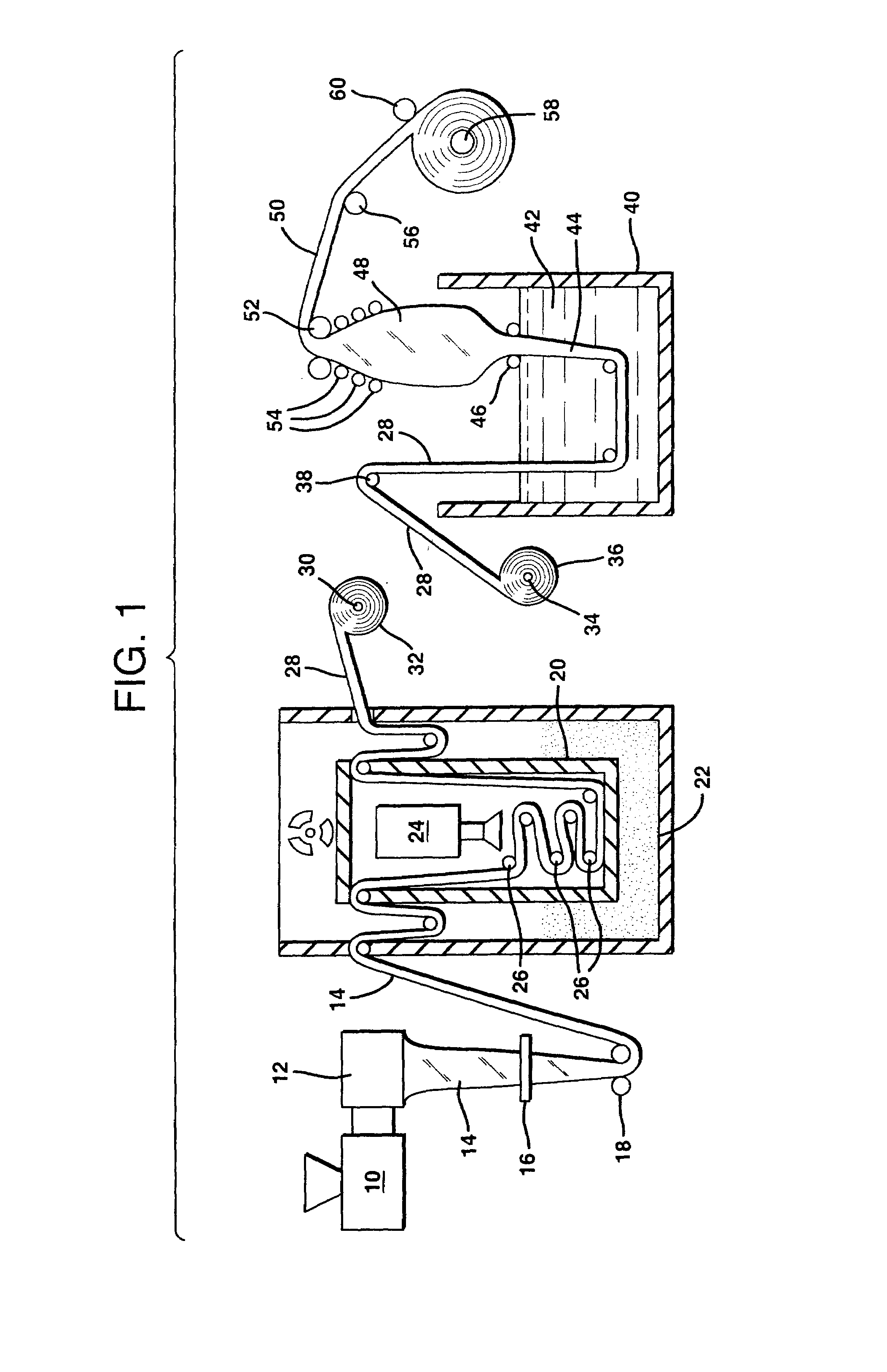

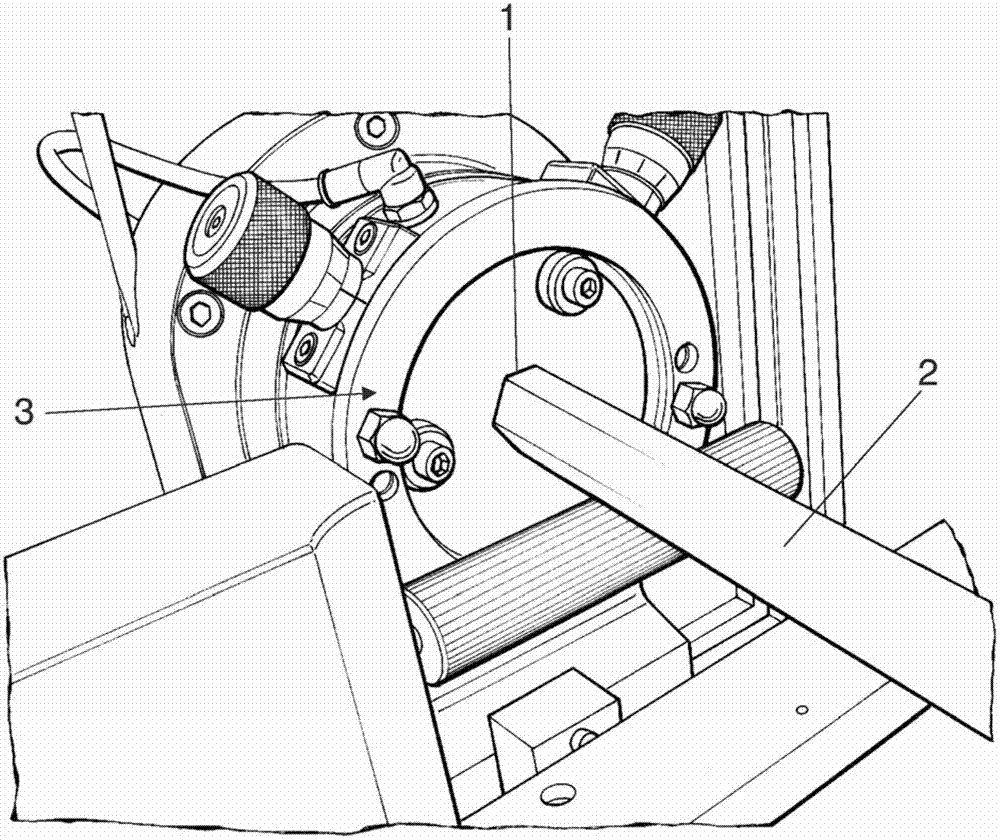

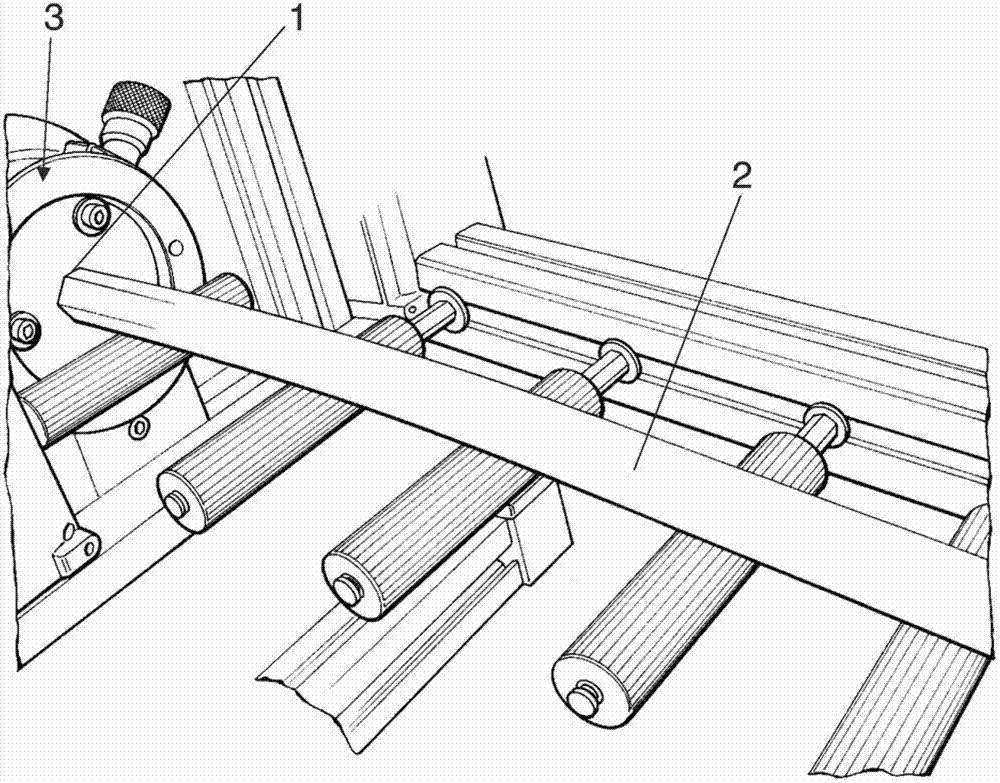

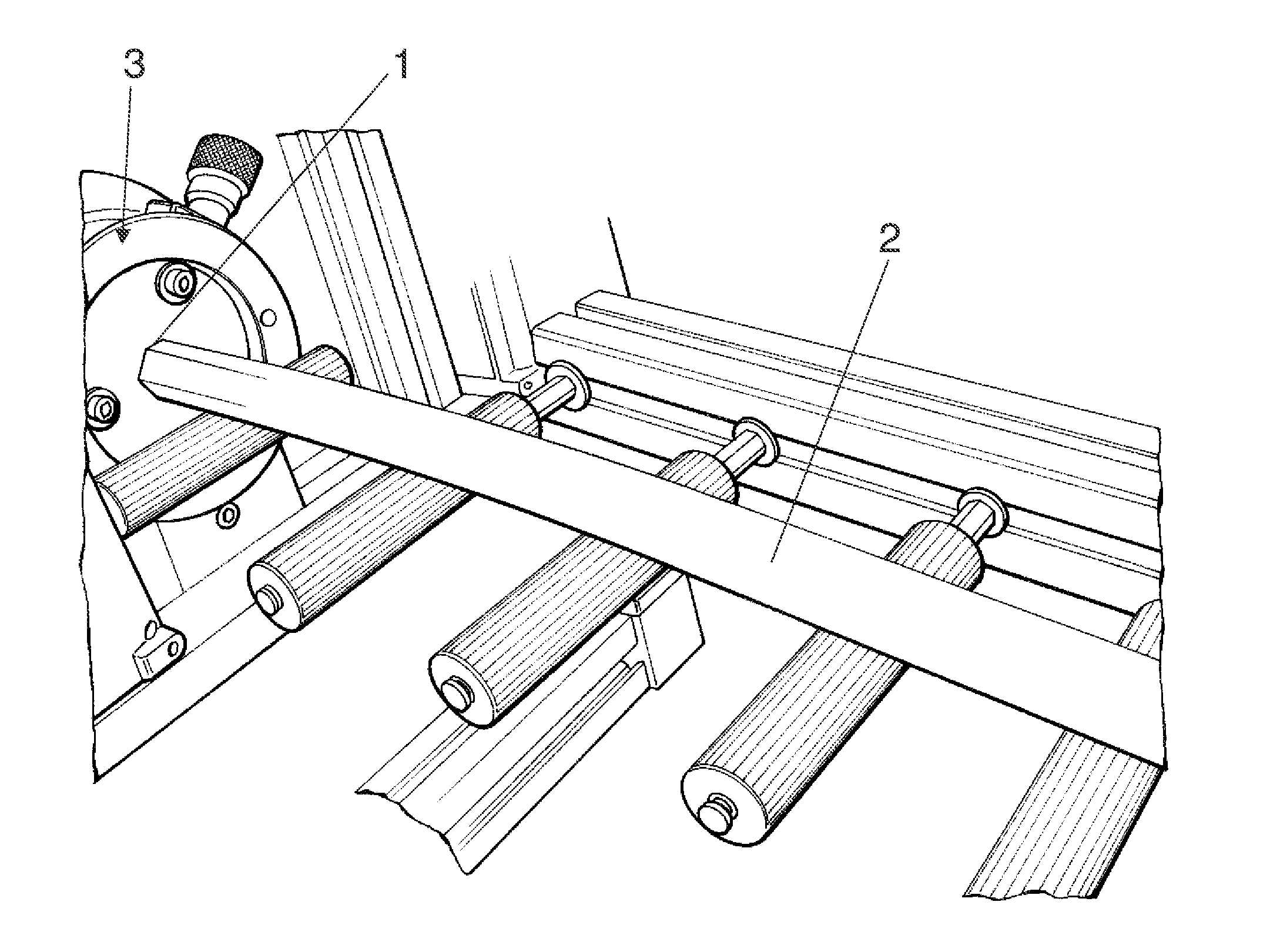

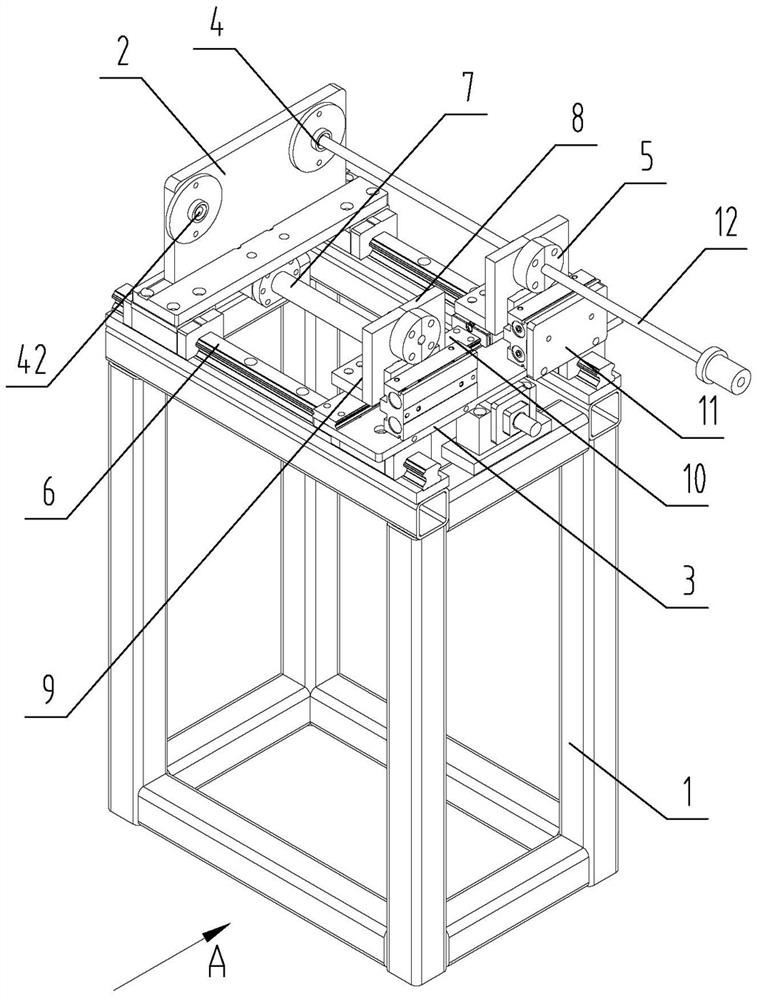

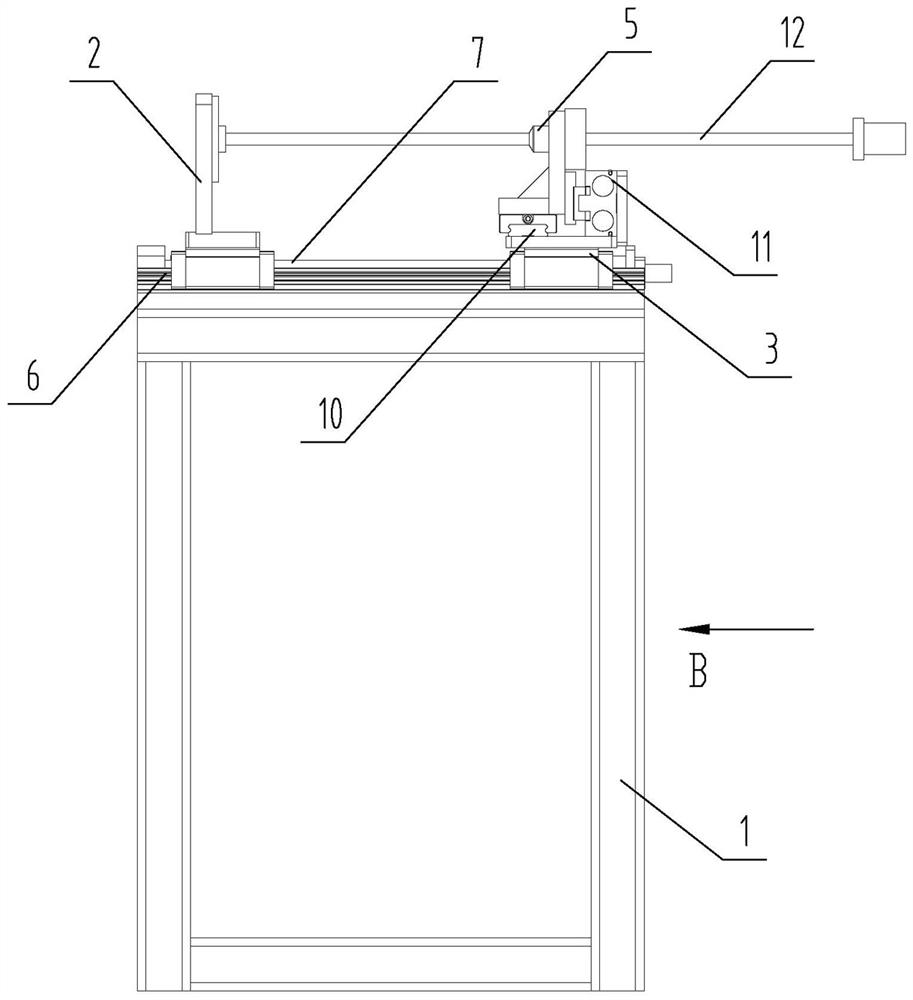

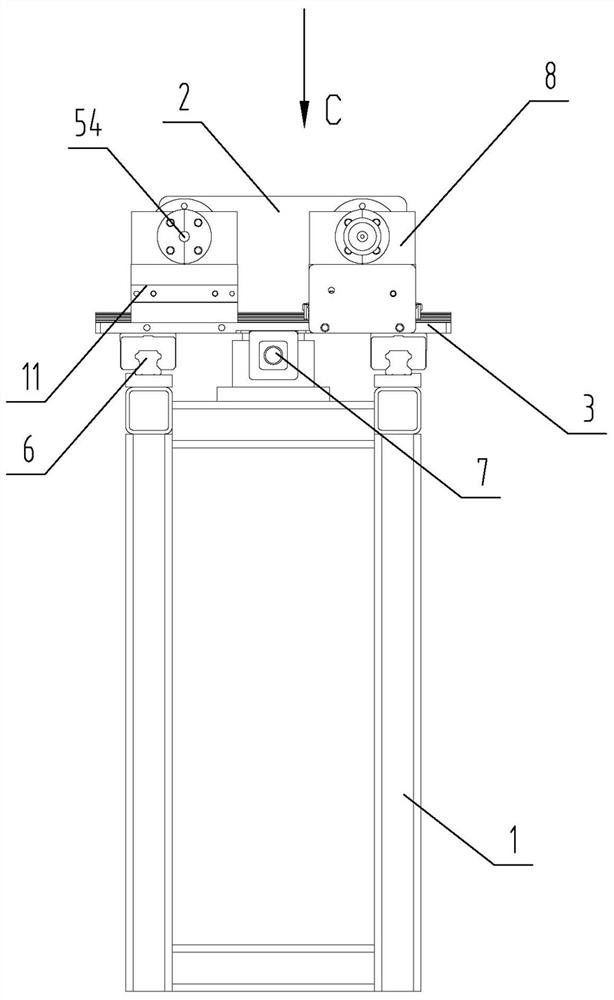

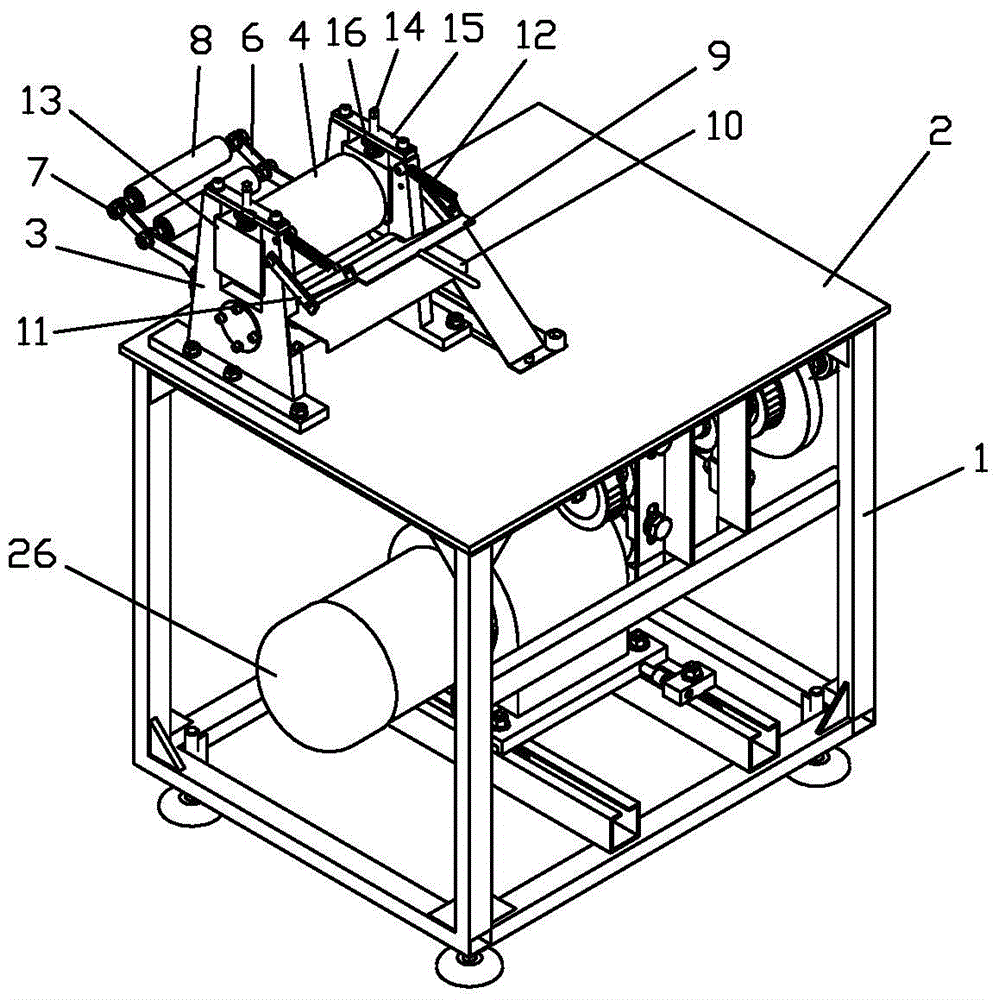

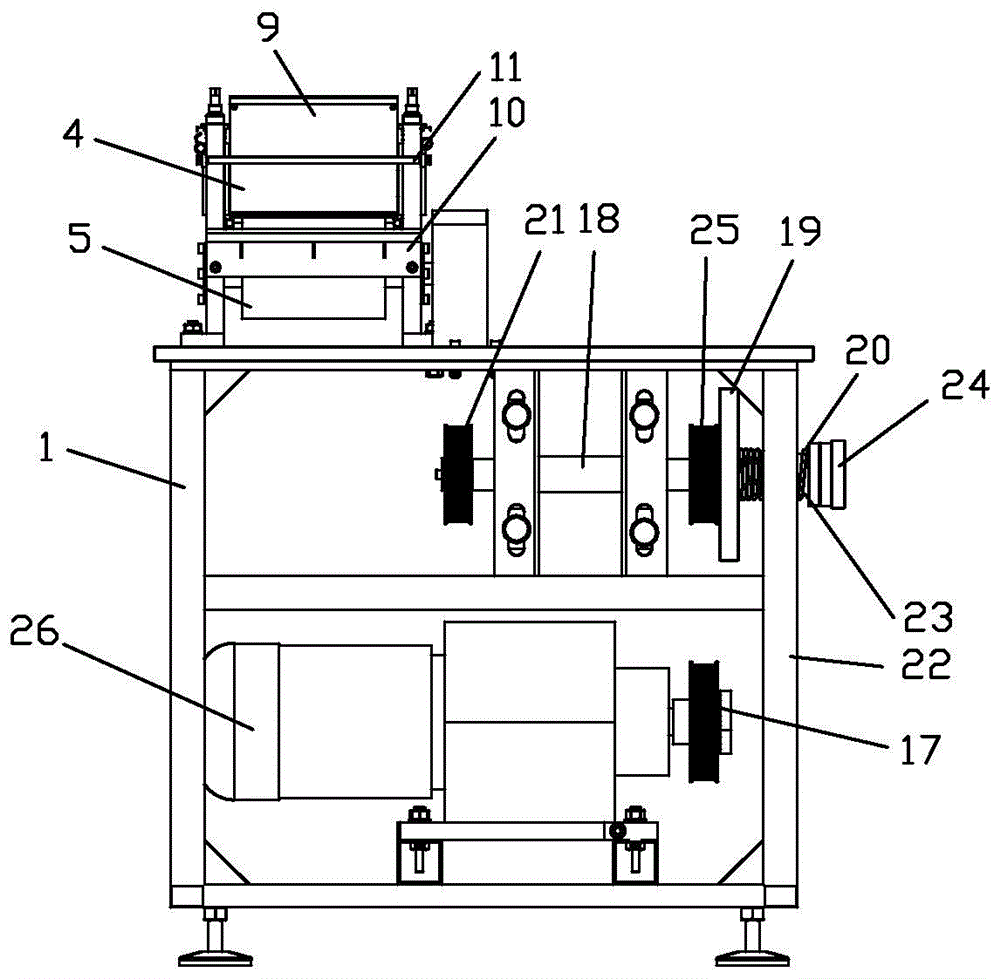

Method and device for extruding and shrinking casing

ActiveCN112825895AImprove shrink qualityImprove compactnessSausage casing manufactureSausage casings by extrusionButt jointIndustrial engineering

The invention discloses a method and device for extruding and shrinking a casing, and belongs to the technical field of casings. The device comprises a rack, and is characterized in that the rack is provided with a first moving support and a second moving support which can move in opposite directions, the first moving support is provided with a first extrusion head, the second moving support is provided with a first plier arm and a second plier arm, the first plier arm and the second plier arm are connected with an opening and closing mechanism, a first split body is arranged on the first plier arm, a first clamping groove is formed in the first split body, a second split body is arranged on the second plier arm, a second clamping groove is formed in the second split body, the second clamping groove can be in butt joint with the first clamping groove to form a clamping hole, and the first split body and the second split body form a second extrusion head; and the second extrusion head and the first extrusion head are distributed oppositely. By means of the device, the two ends of the casing shrinkage pipe can bear extrusion force at the same time to be compacted towards the middle, the compactness of the casing shrinkage pipe can be improved, and disjunction is avoided; and the pipe wall of the casing shrinkage pipe is arched outwards, so that the hole in the casing shrinkage pipe is expanded, and the rod is convenient to separate.

Owner:青岛齐林智信自控技术有限公司

Textured porous barrier transfer casing

ActiveUS20200037622A1Sufficient barrier effectAvoid pollutionContainers for flexible articlesThermoplastic sausage casingsPolymer sciencePolyolefin

The present invention provides a multi-layered coextruded thermoplastic food casing comprising: at least one thermoplastic porous absorbing layer; and at least one layer having a barrier effect for water vapor and / or oxygen, wherein the at least one layer having a barrier effect for water vapor and / or oxygen has an average layer thickness in a range of from 5 to 60 μm over the entire surface area, wherein the at least one thermoplastic porous absorbing layer comprises as a main component at least one thermoplastic polymer material selected from the group consisting of (co)polyamides and (co)polyolefins, wherein the at least one thermoplastic porous absorbing layer comprises areas having a reduced average layer thickness and areas having a non-reduced average layer thickness, wherein the average layer thickness of the at least one thermoplastic porous absorbing layer in areas having a non-reduced average layer thickness is in a range of from 10 to 200 μm, wherein the average layer thickness in areas having a reduced average layer thickness is lower by 7 to 140 μm and is reduced by a range of from 30 to 85% compared to the areas having a non-reduced average layer thickness of the at least one thermoplastic porous absorbing layer, and wherein both areas having a reduced average layer thickness and a non-reduced average layer thickness comprise pores which are able to absorb a functional additive.

Owner:VISCOFAN

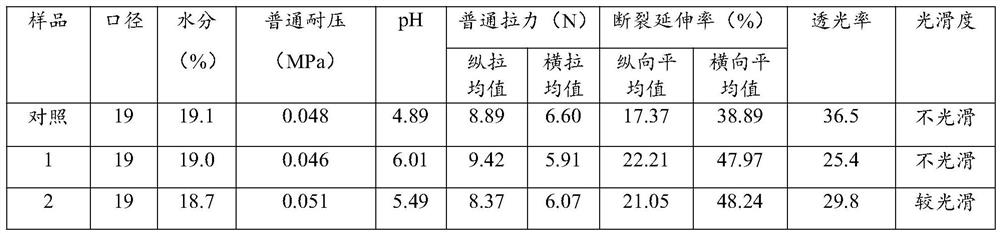

Method for preparing collagen casing by wet method through food synthesis bioengineering technology

ActiveCN112042716AImprove homogenizationHigh transparencySausage casings by extrusionPlasticizerCollagenan

The invention provides a method for preparing a collagen casing by a wet method through a food synthesis bioengineering technology. The method for preparing the collagen casing by the wet method through the food synthesis bioengineering technology comprises the steps that secondary pretreatment is carried out on skin blocks subjected to enzyme A pretreatment by using an ionic liquid / acid double-solvent solution system, homogenizing is carried out by using a high-shear homogenizer, treating is carried out by using a polyhydroxy alcohol food plasticizer, then extrusion molding is carried out, the blocks are immersed in a water bath for shaping, crosslinking and fixing, and finally, a collagen casing product with the thickness of only 0.02mm-0.04mm is obtained through drying The collagen casing prepared by the method is light, thin and uniform in thickness, has good flexibility, has an edible taste similar to that of a natural casing and good mechanical properties, and can be widely applied to various packages of foods as an edible film.

Owner:SICHUAN UNIV

Food casing with permeability to smoke and water vapour and with improved transparency

The present invention relates to a tubular, seamless, biaxially stretched, smoke-permeable and water vapour-permeable, colouristically neutral and transparent, single-layer food casing formed from a mixture including 50 to 95% by weight of aliphatic (co)polyamide, 3 to 40% by weight of at least one vinyl (co)polymer having units of N-vinyl-2-pyrrolidone and 1.5 to 7.0% by weight of at least one aliphatic diol and / or aliphatic polyol, based in each case on the weight of the mixture. The diol and / or polyol is homogeneously distributed in a matrix formed by the aliphatic (co)polyamide. The food casing is produced by an extrusion method with biaxial tube stretching and subsequent heat-setting. It is particularly suitable as synthetic sausage casing, especially for raw sausage, such as salami or mettwurst.

Owner:KALLE AG

Artificial food casing, method for removing and method for manufacturing thereof

ActiveUS9968103B2Easy to detectPrecise positioningThermoplastic sausage casingsPrintable sausage casingsEngineeringArtificial feeding

Owner:VISKOTEEPAK BELGIUM NV

Artificial food casing, method for removing and method for manufacturing thereof

ActiveUS20160143301A1Easy to detectPrecise positioningThermoplastic sausage casingsPrintable sausage casingsEngineering

Owner:VISKOTEEPAK BELGIUM NV

a garment press

InactiveCN104542876BImprove the suppression effectSimple structureSausage casing manufactureSausage casings by extrusionMotor driveEngineering

The invention provides a casing pressing machine. The casing pressing machine comprises a rack, wherein a tabletop is arranged on the rack; two supporting side plates are arranged above the tabletop; a motor is arranged under the tabletop; an upper pressing wheel and a lower pressing wheel are arranged between the two supporting side plates; the motor drives the lower pressing wheel to rotate; a bracket is frontwards extended by the supporting side plates; a roller wheel is arranged on the bracket; a supporting plate and a pressing plate are arranged on one sides, far away from the extended bracket, of the supporting side plates; the supporting plate is hinged with the supporting side plates; the supporting side plates are further provided with supporting rods for supporting the supporting plate; and the pressing plate is located under the supporting plate. According to the casing pressing machine provided by the invention, the pressing effect of casings is good and air in the casings can be pressed out; the casings are guided by the roller wheel and the supporting plate; and the casing pressing machine is more practical, has a simple structure and is easy to maintain and repair.

Owner:广东德福隆生物科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com