Method and device for extruding and shrinking casing

A sausage casing and shrinking technology, applied in sausage casings, making sausage casings, sausage casing extrusion, etc., can solve the problem of reducing the size of the hole in the casing shrinking tube, uneven density of the casing shrinking tube, and affecting the downstream enema link. Use and other problems to achieve the effect of improving the quality of the sleeve, reliable extrusion, and ensuring accurate action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

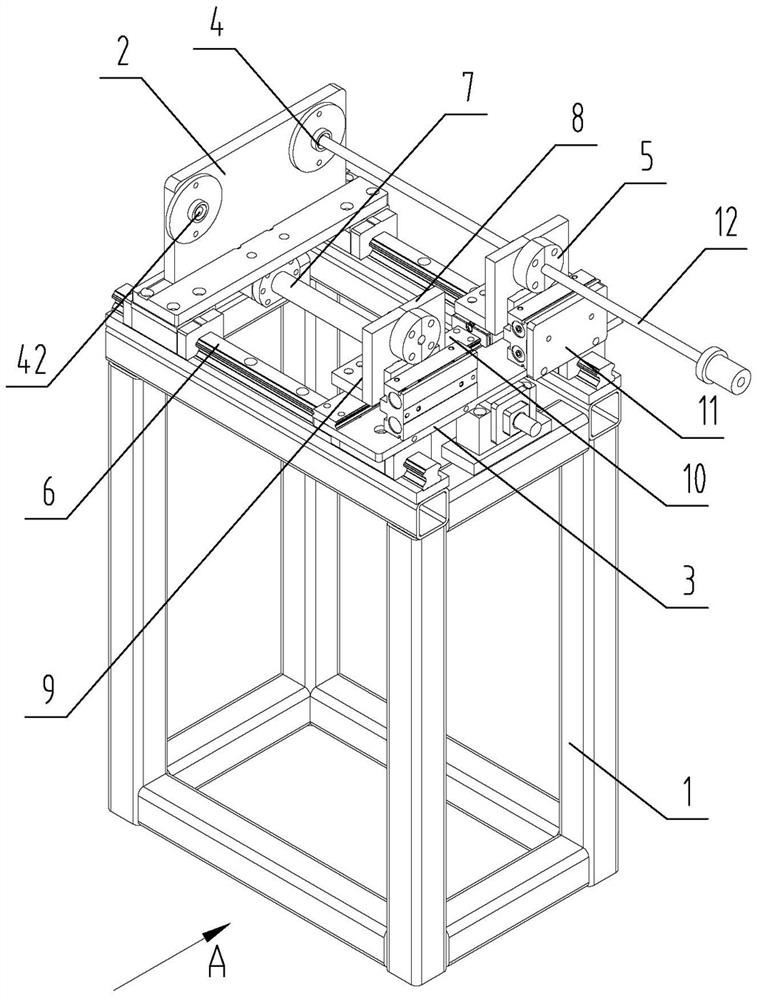

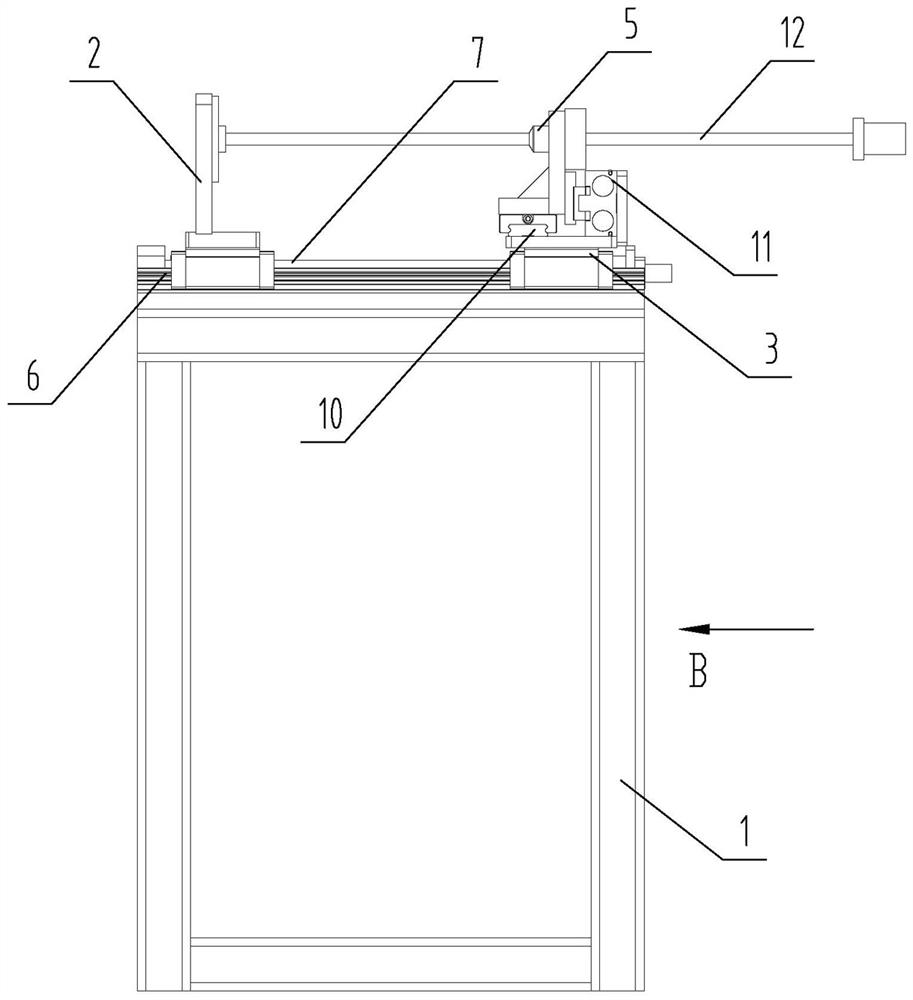

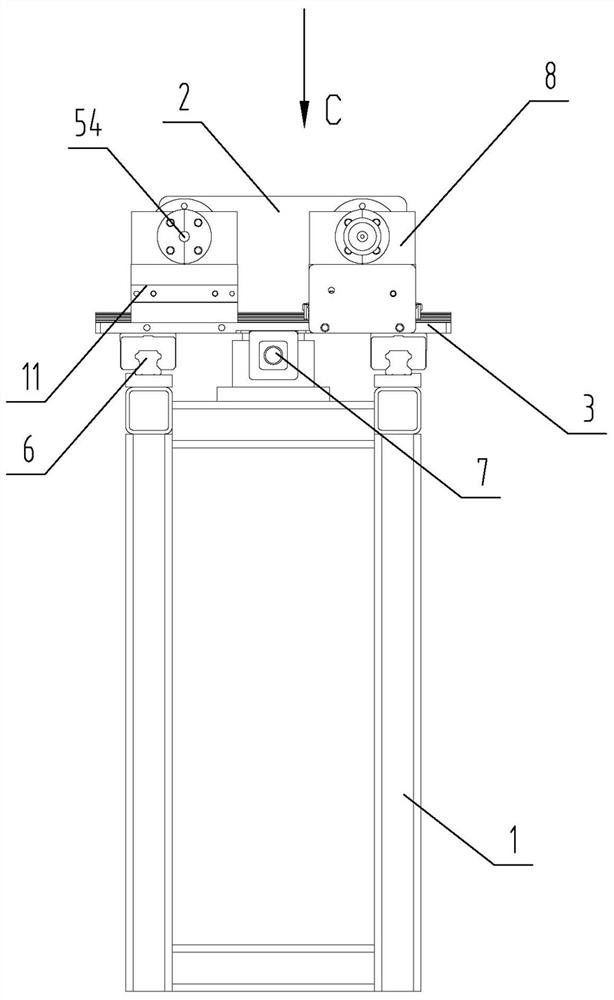

[0034]The present invention will be further described in further detail below with reference to the accompanying drawings.

[0035]In the present invention, the reference casing is defined as the front end in the moving direction of the casing, that is, the casing entry end is defined as the rear end.

[0036]The main idea of the present invention is to provide a first extrusion head and a second extrusion head showing a relative-shaped distribution, and a jack is opened in the first extrusion head, the second extrusion head is formed, the second extrusion After the head is closed, there is a card hole, the card hole and the jack coaxial setting, the steps of extruding the casing are as follows:

[0037](1) Initiation: Open the second extrusion head, set the casing set of casings on the receiving lever into the position between the first extrusion head and the second extrusion head, and the end of the receiving rod enters the jack, The two squeezing head is closed, and the receiving rod is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com