Patents

Literature

43results about How to "Reliable Extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

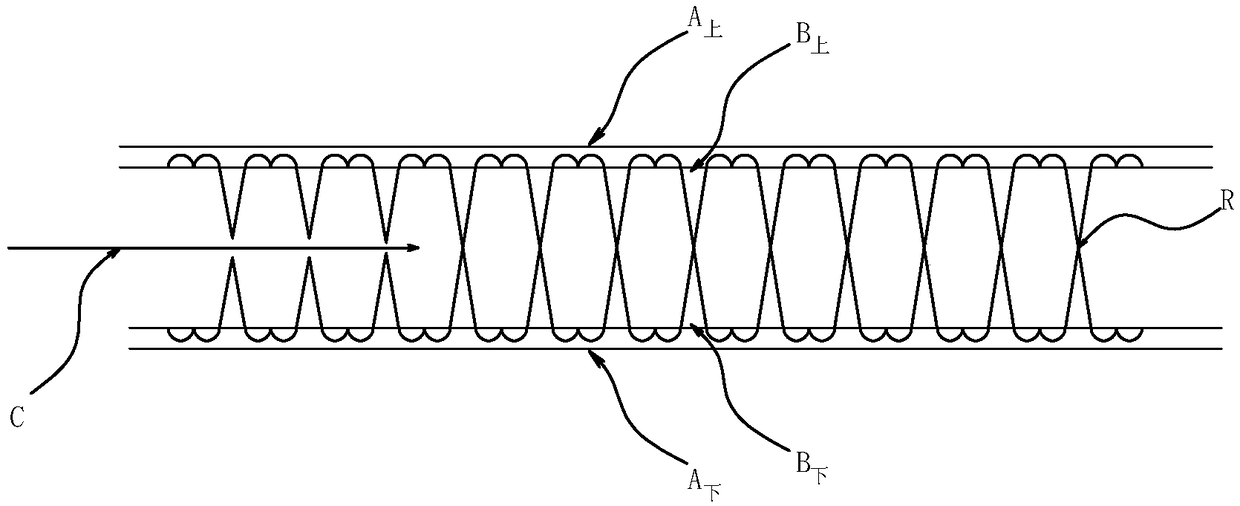

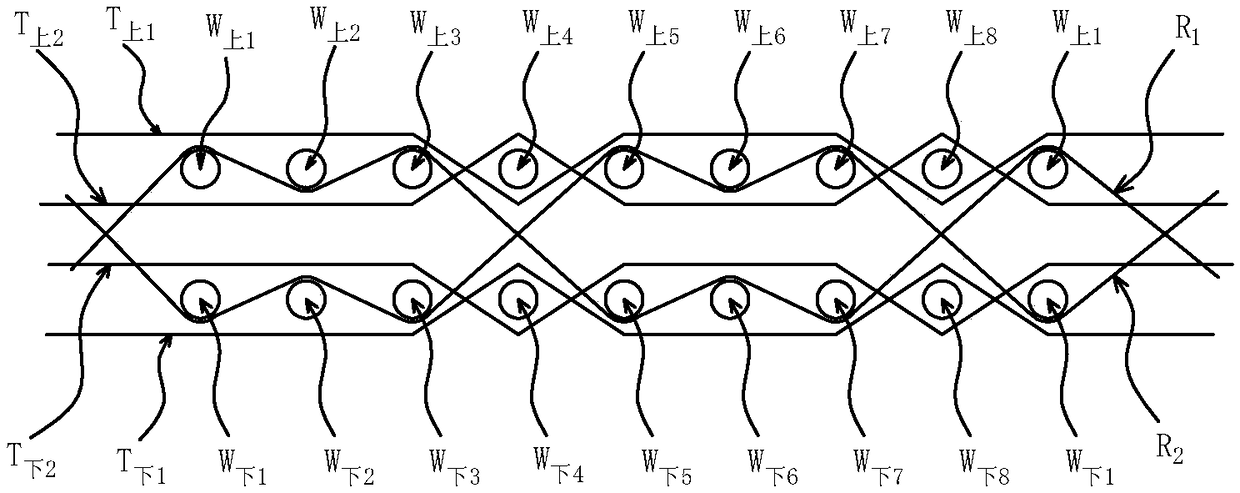

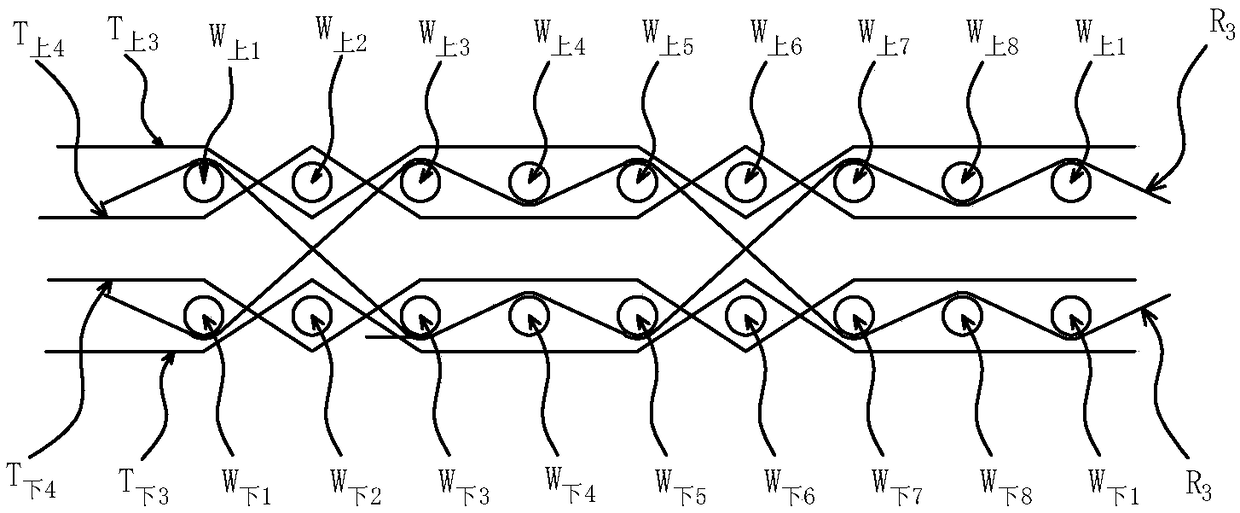

Production process of home textile velvet

ActiveCN109023664AExtrusion stabilityExtruded and consolidated firmlyMulti-ply fabricsNatural fiberFineness

The invention discloses a production process of home textile velvet. The home textile velvet is formed by subjecting a double cloth comprising an upper base fabric, a lower base fabric and a pile warpto velvet pile and arrangement. The pile warp is connected with the upper base fabric and the lower base fabric, and is W consolidated through the upper base fabric and the lower base fabric. The pile warp is a natural fiber yarn. An upper base fabric weft yarn and a lower base fabric weft yarn are both functional yarns. An upper base fabric warp yarn and a lower base fabric warp yarn use naturalfiber yarns and functional yarns. The fineness of the ground warp is not restricted by the fineness of the pile warp. The fineness of the ground warp can be less than that of the pile warp, or can begreater than the fineness of the pile warp. The home textile velvet is very suitable for mass production. The production process can reduce the fineness of the pile warp to achieve a light and elegant purpose while ensuring the density of pile is not exposed to the ground. The home textile velvet comprises all natural fibers contacted by the human body, and functional yarns that are imparted by modern technology and cannot be contacted by the human body, which satisfies people's needs.

Owner:ZHEJIANG INNOVATION TEXTILE CO LTD

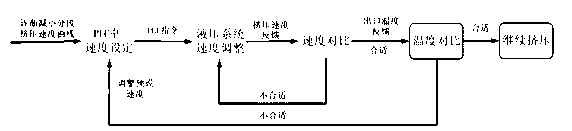

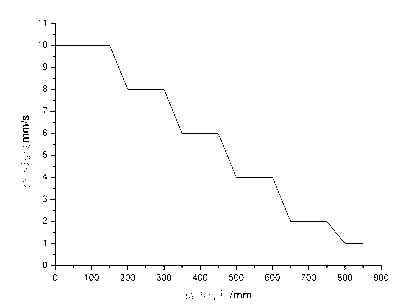

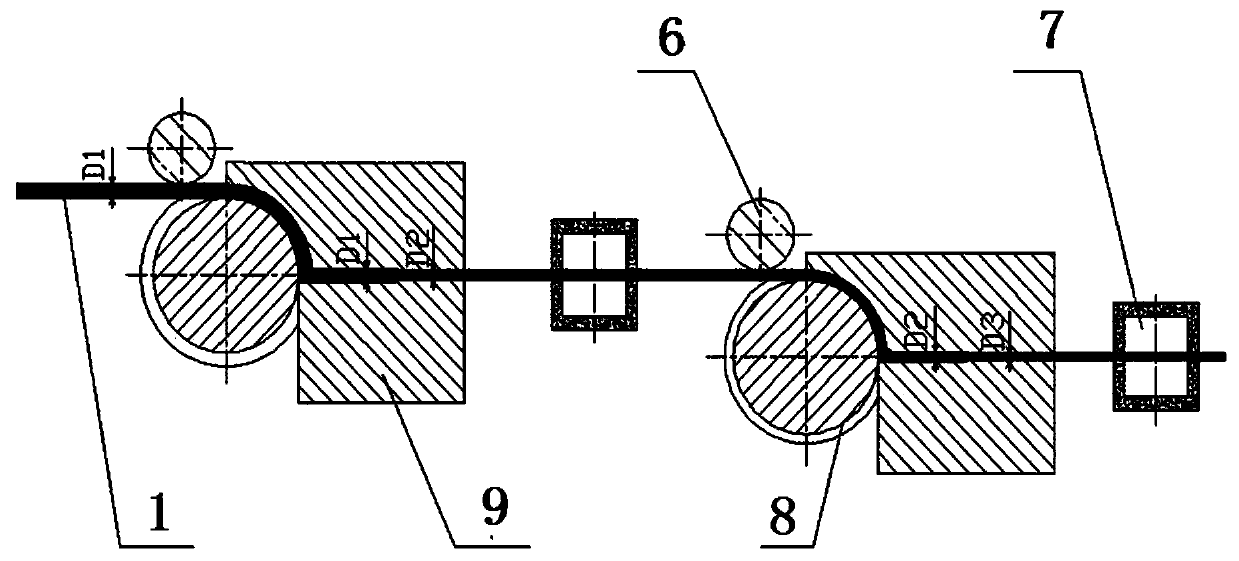

Isothermal extrusion method capable of controlling speed by sections

ActiveCN103100575AExtrusion process safetyReliable ExtrusionExtrusion control devicesProgrammable logic controllerEngineering

The invention relates to the technical field of metallurgy, provides an isothermal extrusion method in an aluminum extruder extruding process, and particularly relates to an isothermal extrusion method capable of controlling the speed by sections. According to the isothermal extrusion method, a PLC (Programmable Logic Controller) is taken as a hardware core; the PLC and a hydraulic system of an extruder are conducted; and a program is programmed into the PLC. The isothermal extrusion method capable of controlling the speed by sections is characterized by being implemented by four steps of inputting the PLC according to a simulated extrusion rod movement speed subsection curve and an extrusion rod movement speed subsection curve, detecting in real time and adjusting in real time. According to the isothermal extrusion method capable of controlling the speeds by sections disclosed by the invention, along the increasing of an extruding route, a manner of gradually reducing the movement speed of an extrusion rod by sections is adopted and an extruded mould is detected; and the method is suitable for actual operation of engineering and can realize an isothermal extrusion process of aluminum and aluminum alloys.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

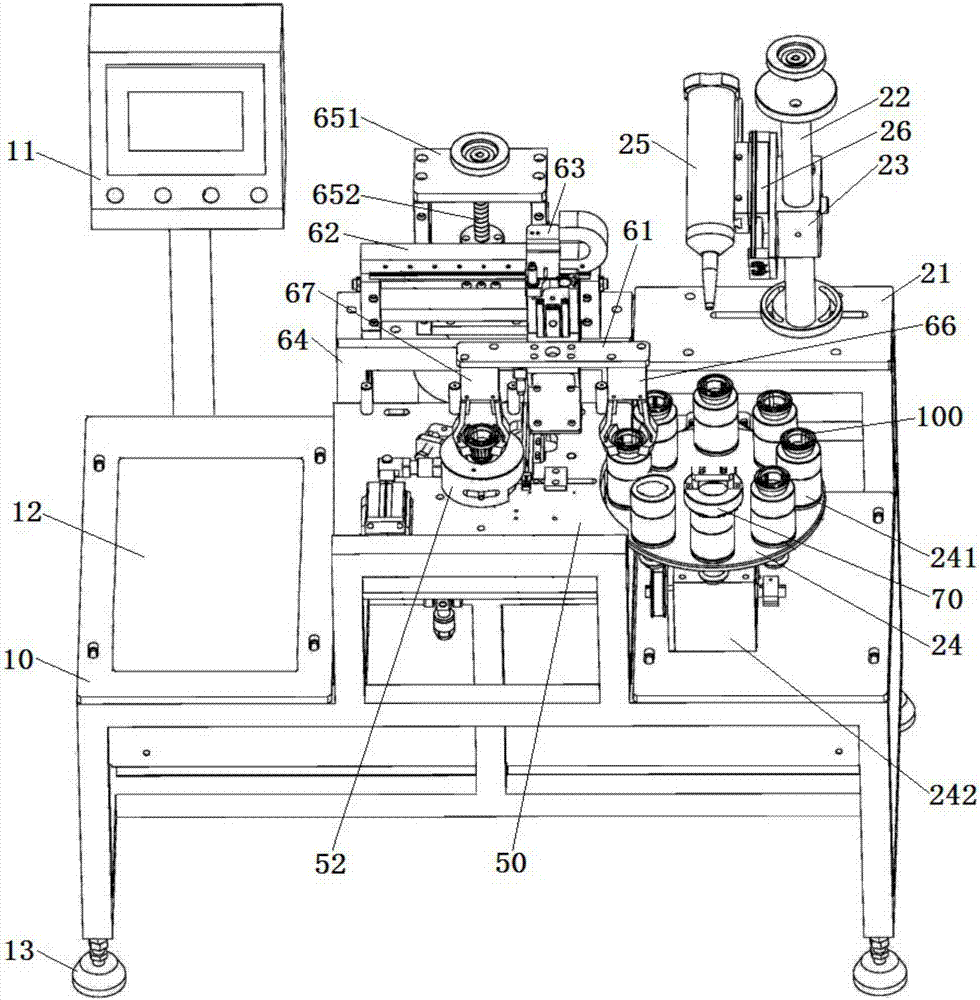

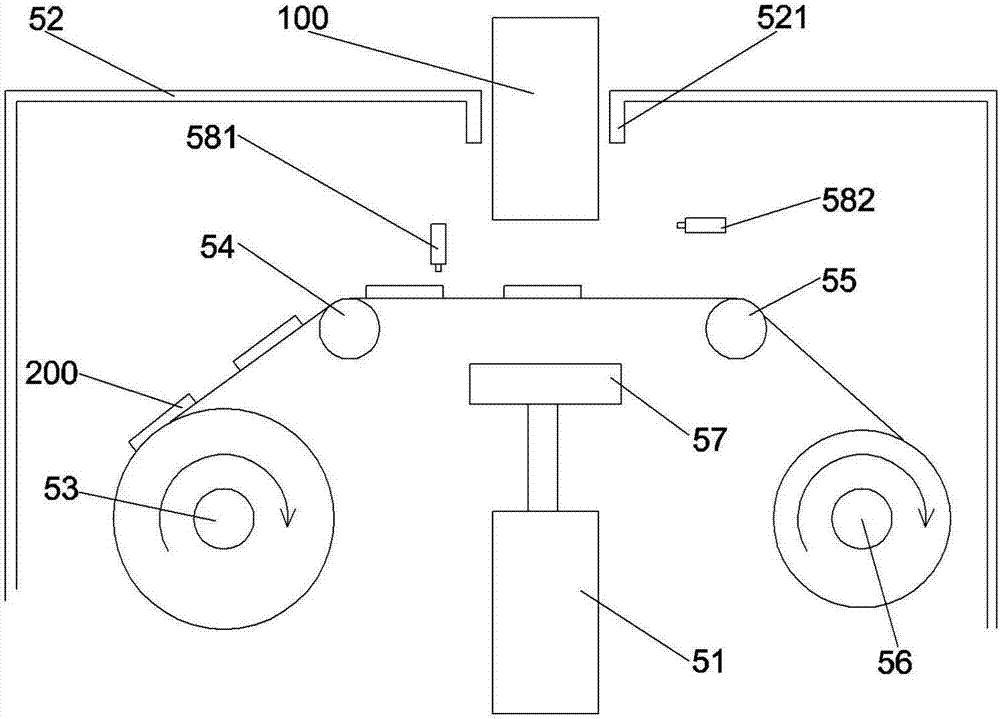

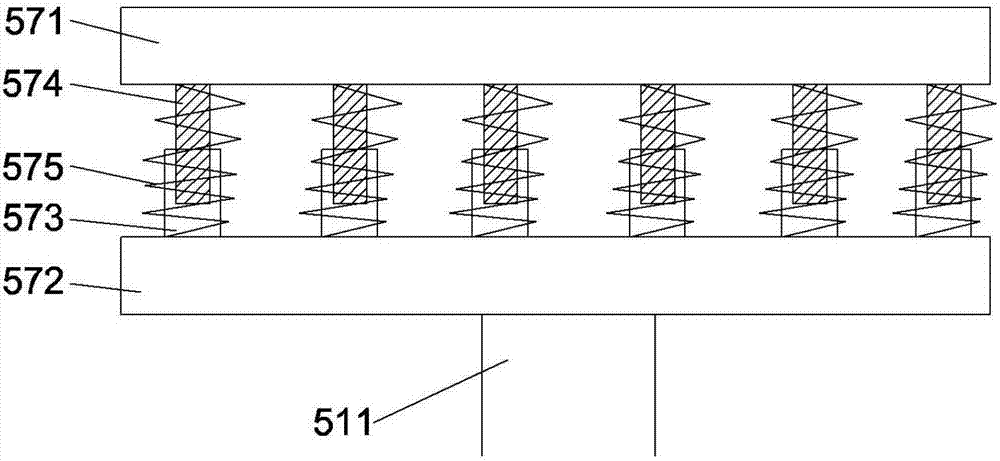

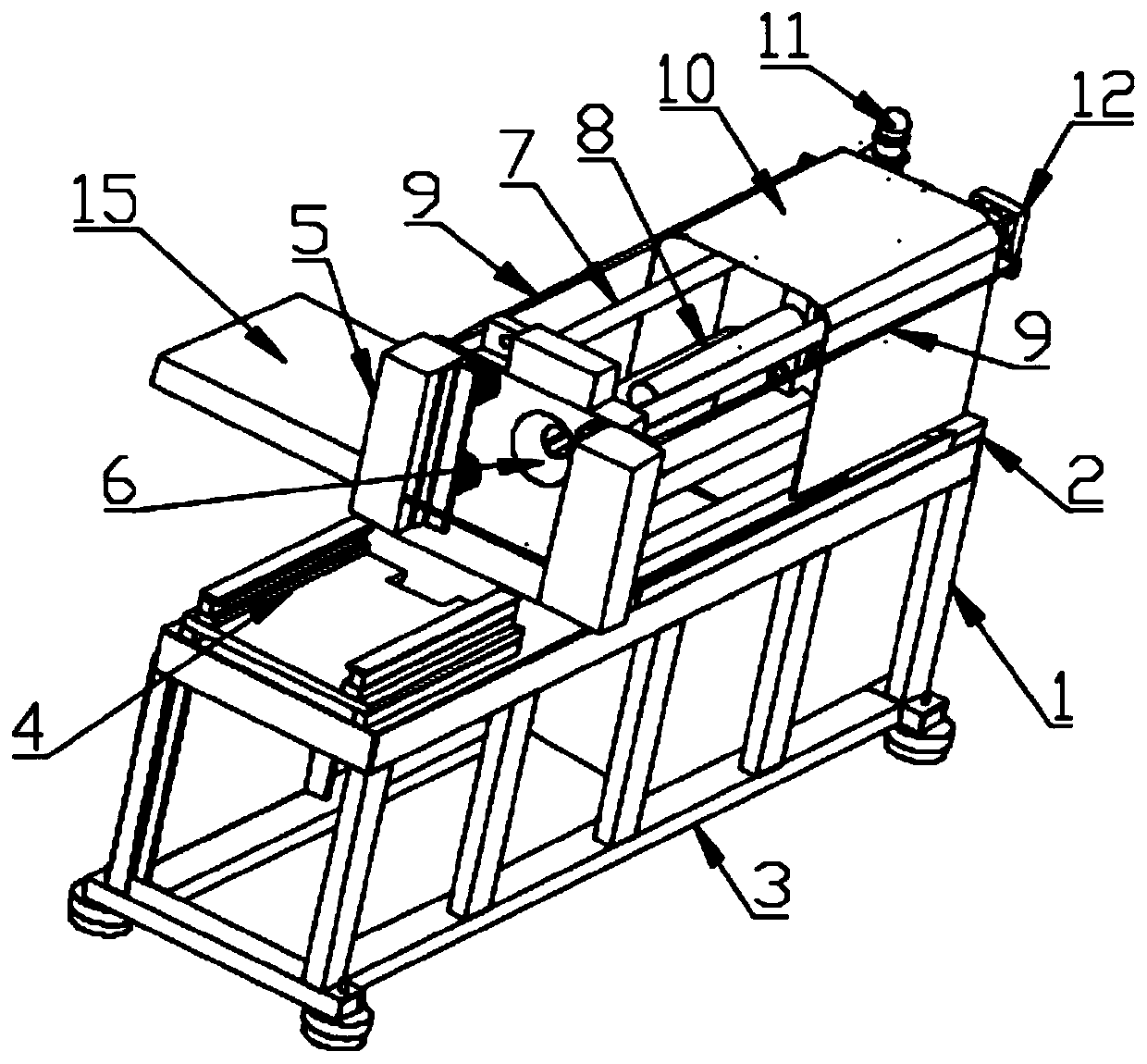

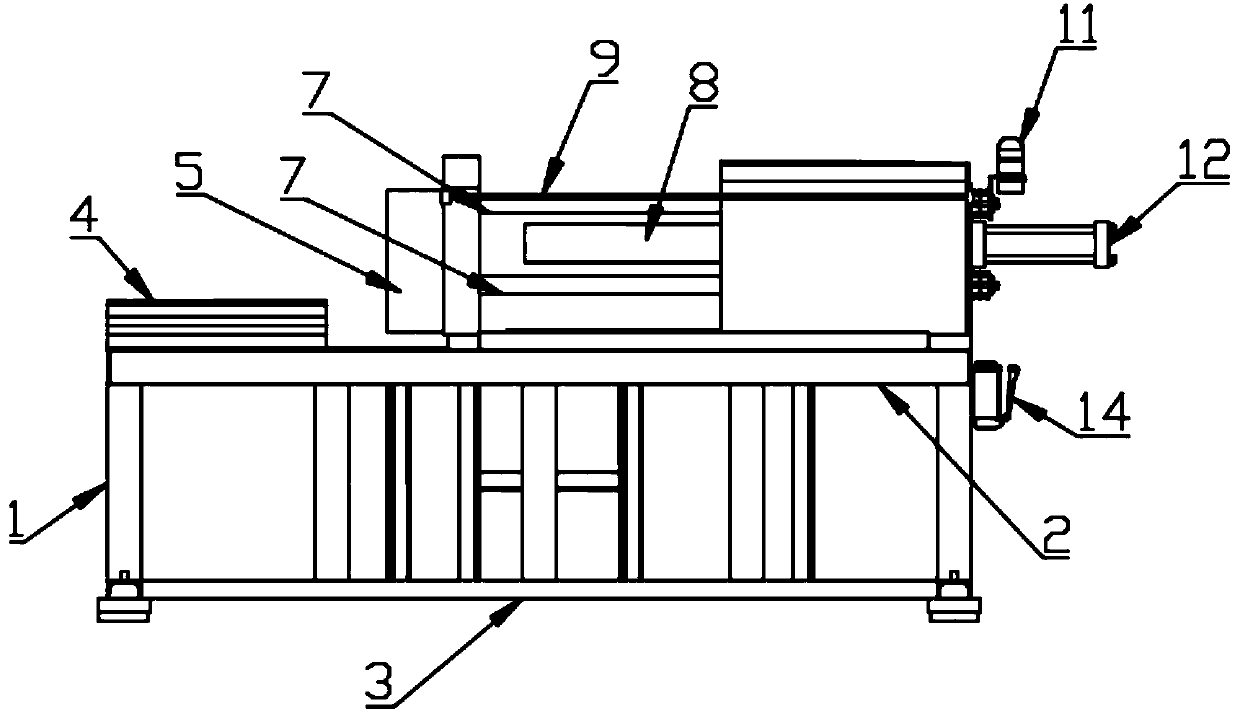

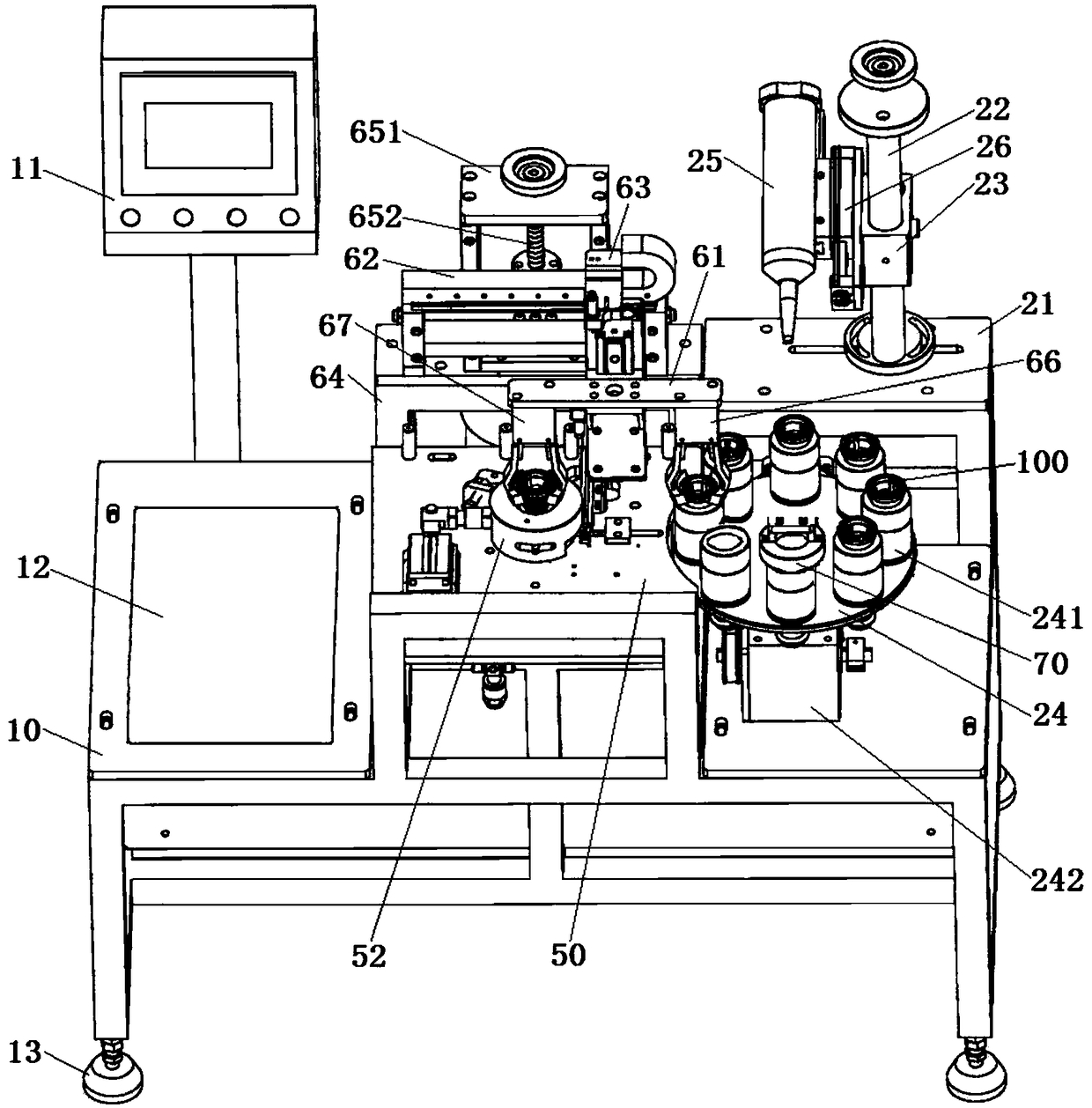

Automated loading and labeling device

ActiveCN107264905AAvoid sliding left and rightEffective squeezeLabelling machinesTransfer mechanismManipulator

The invention discloses an automated loading and labeling device. The automated loading and labeling device comprises a working table, a control mechanism, a loading mechanism, a first labeling mechanism, a second labeling mechanism and a transferring mechanism, wherein the loading mechanism comprises a loading rack, a loading stand column, a mounting sliding block, a loading rotary table and a loading head; the second labeling mechanism comprises a feeding and conveying belt, a driving labeling rotary table, a driven labeling rotary table, a second discharging roll, a second paper collecting roll, shifting rods, an unloading plate, a first guiding plate, a second guiding plate, a U-shaped connecting piece and a pushing cylinder; the first labeling mechanism comprises a label pressing cylinder, a feeding roll, a first guiding roll, a second guiding roll, a paper collecting roll and a paper collecting motor; and the transferring mechanism comprises a transferring arm, a transverse guide track, a lead screw assembly, a sliding table, a transferring rack, a first manipulator and a second manipulator. The automated loading and labeling device is compact in structure; automatic loading, side labeling and bottom labeling of packing boxes can be finished on the device; and the automated loading and labeling device is high in degree of automation and quite convenient to use.

Owner:嘉兴普艾仕自动化科技有限公司

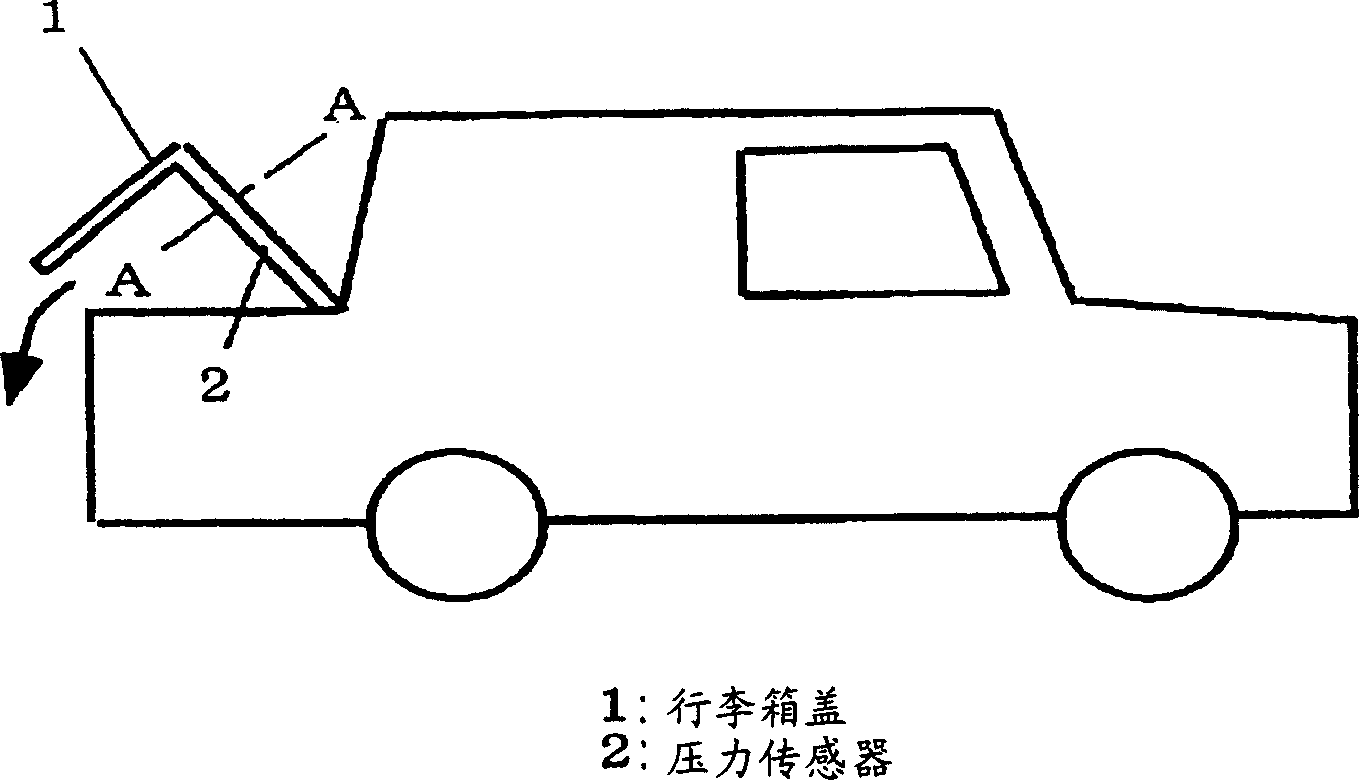

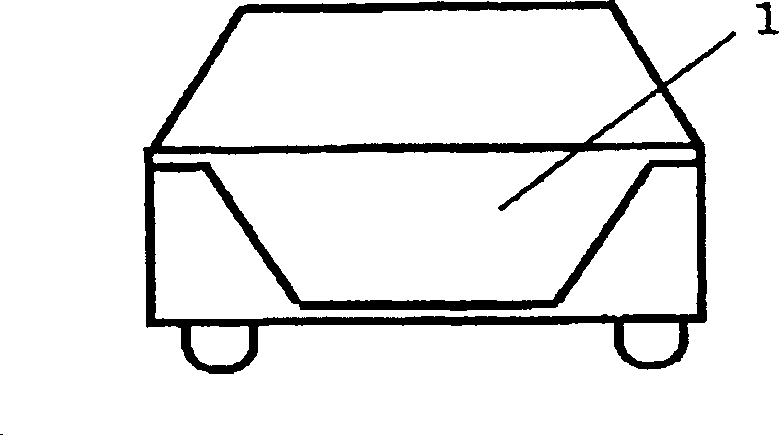

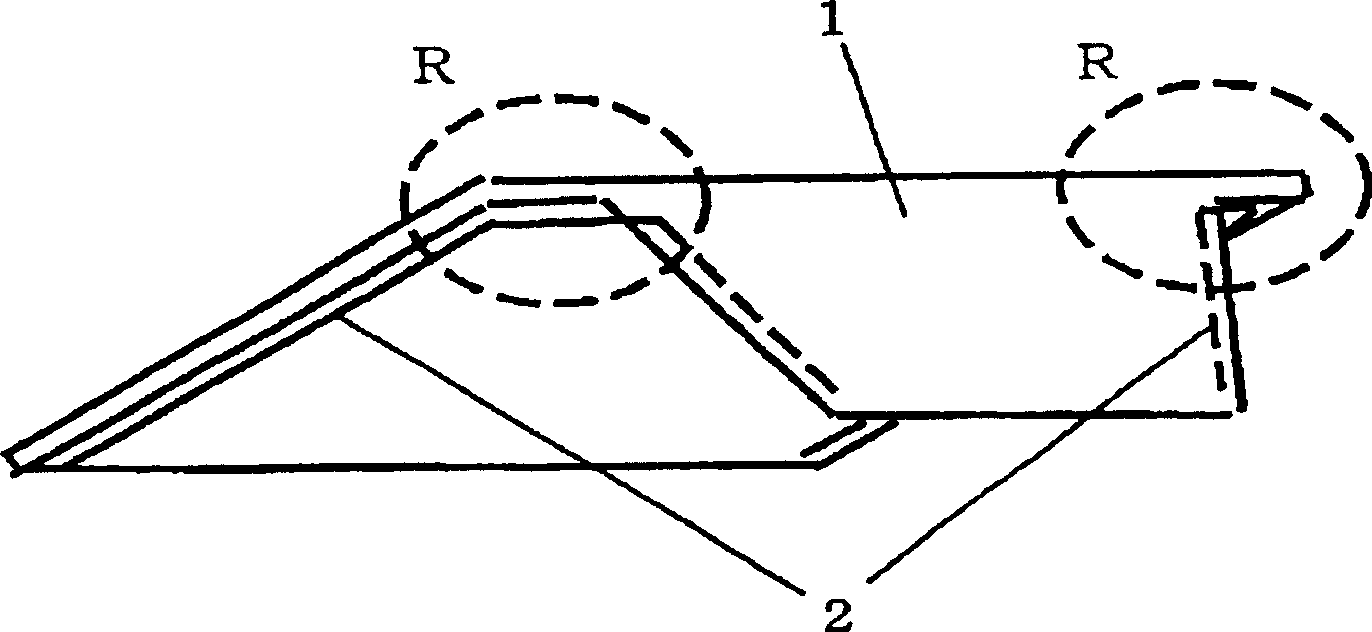

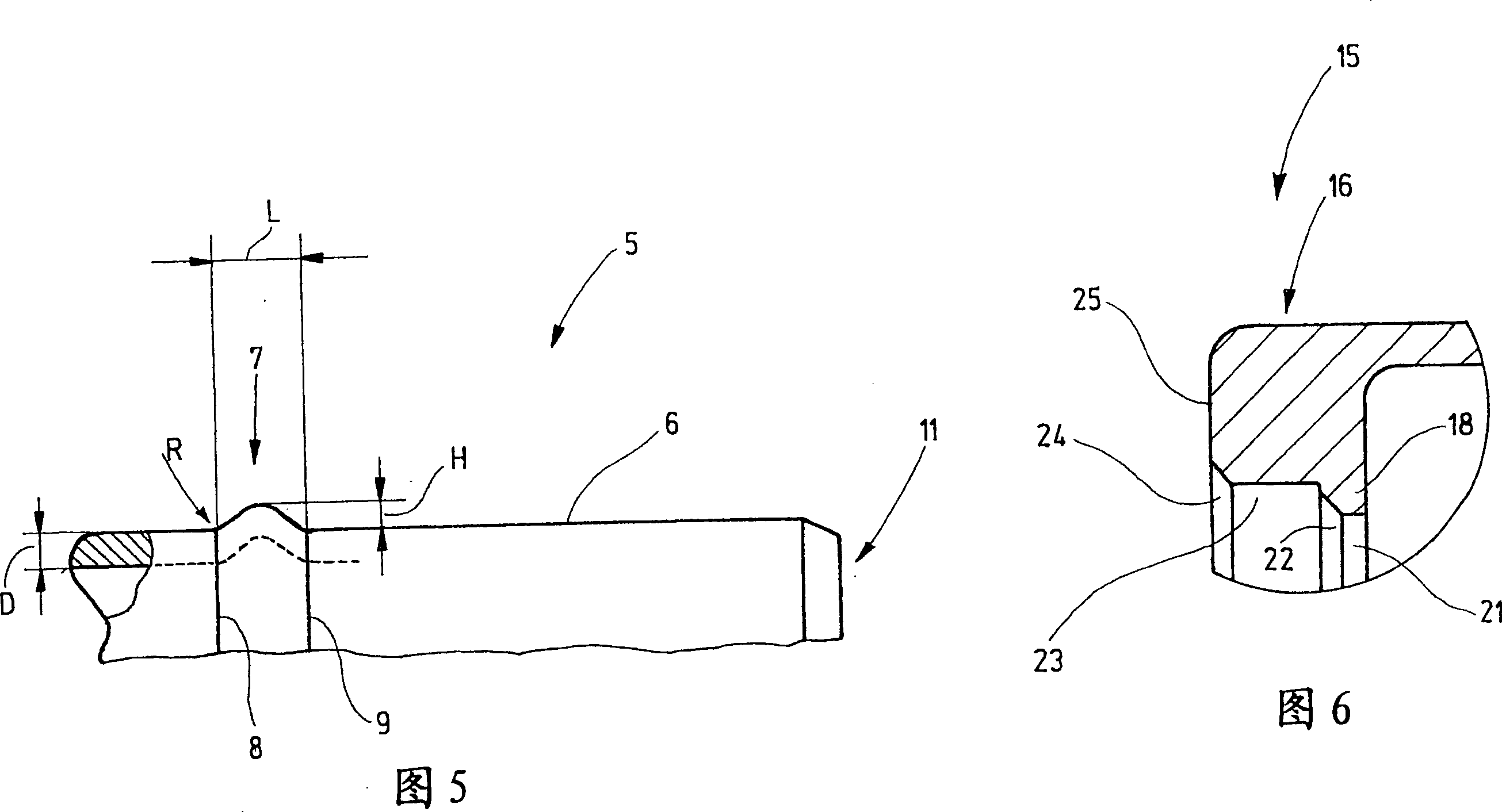

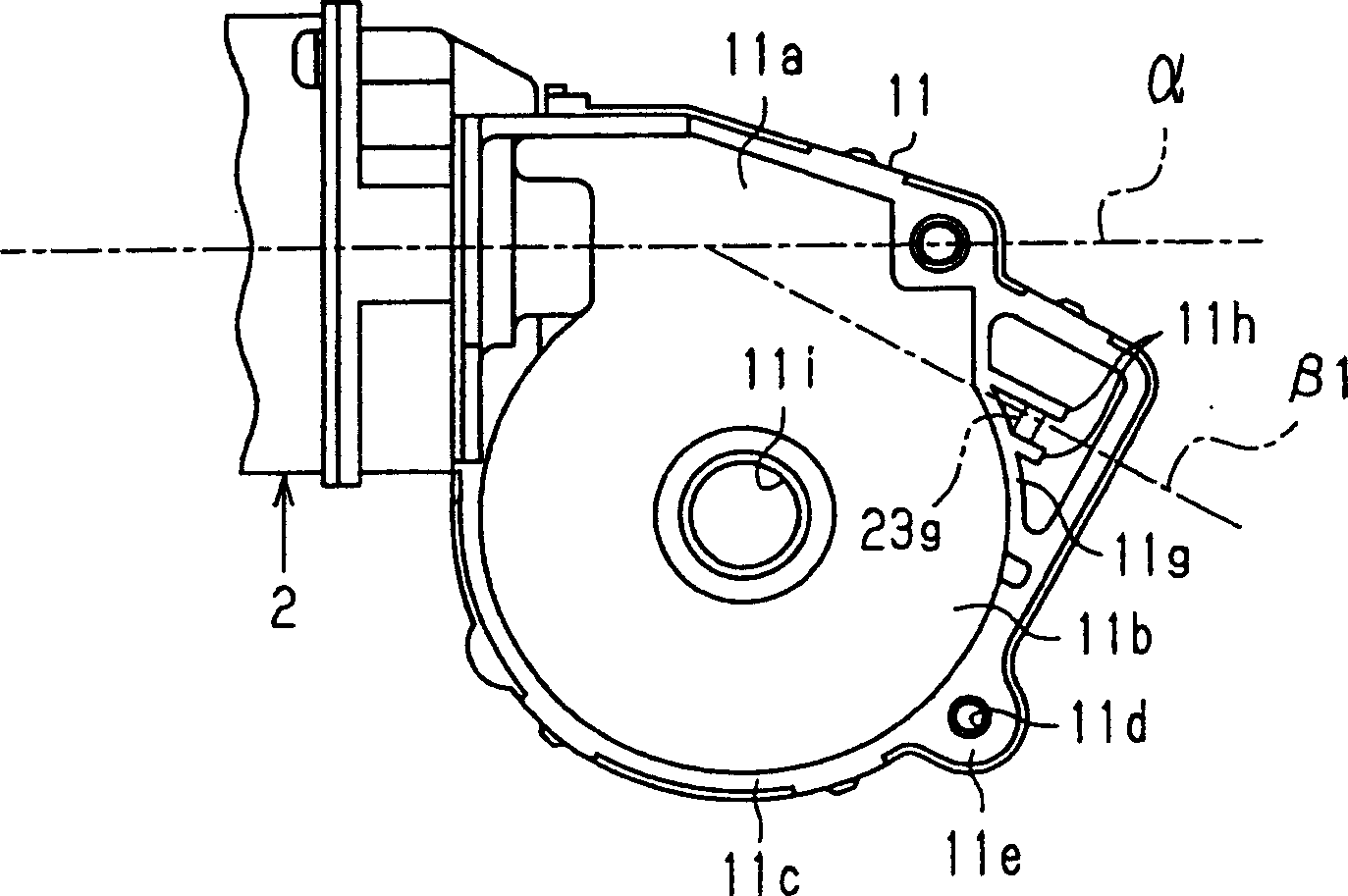

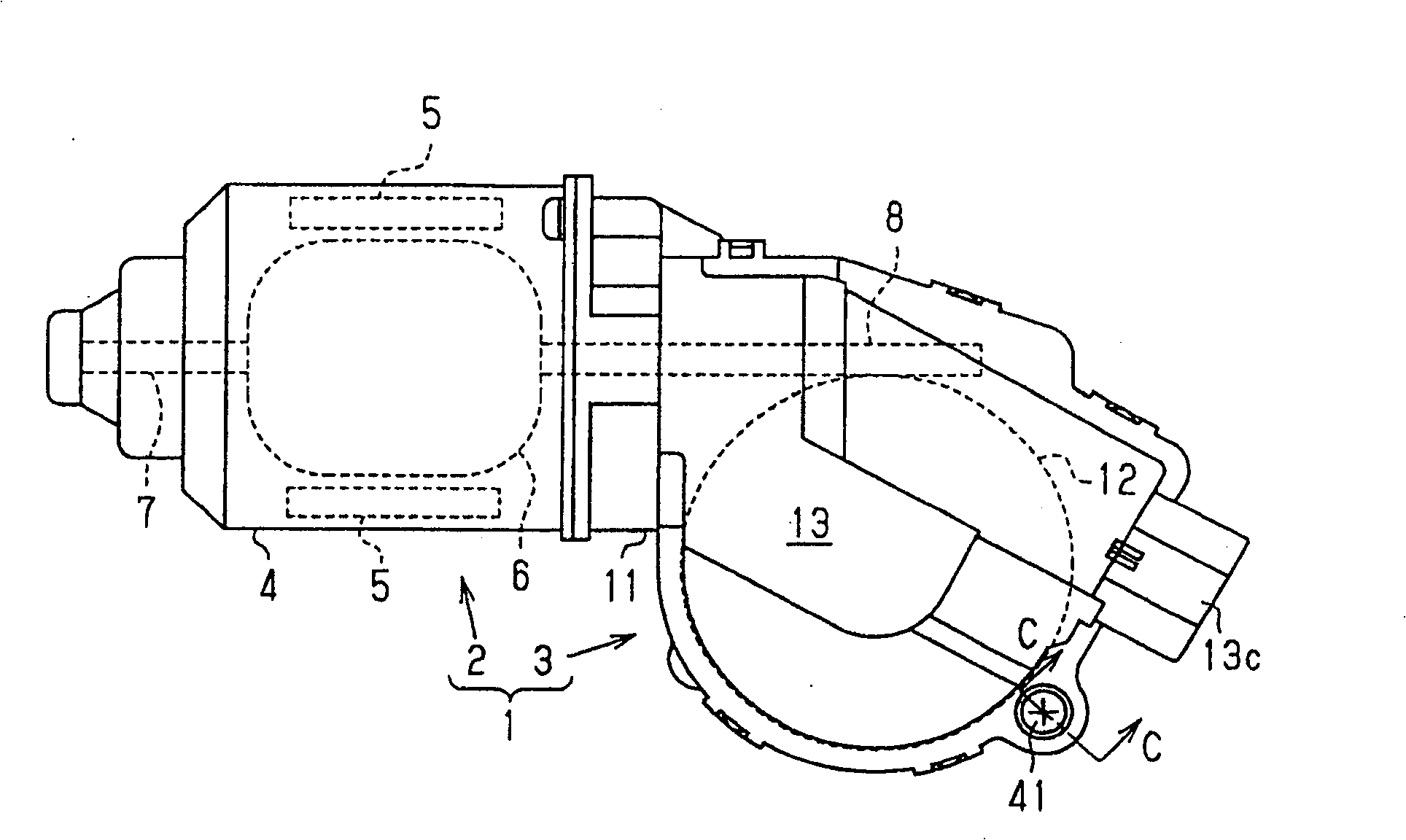

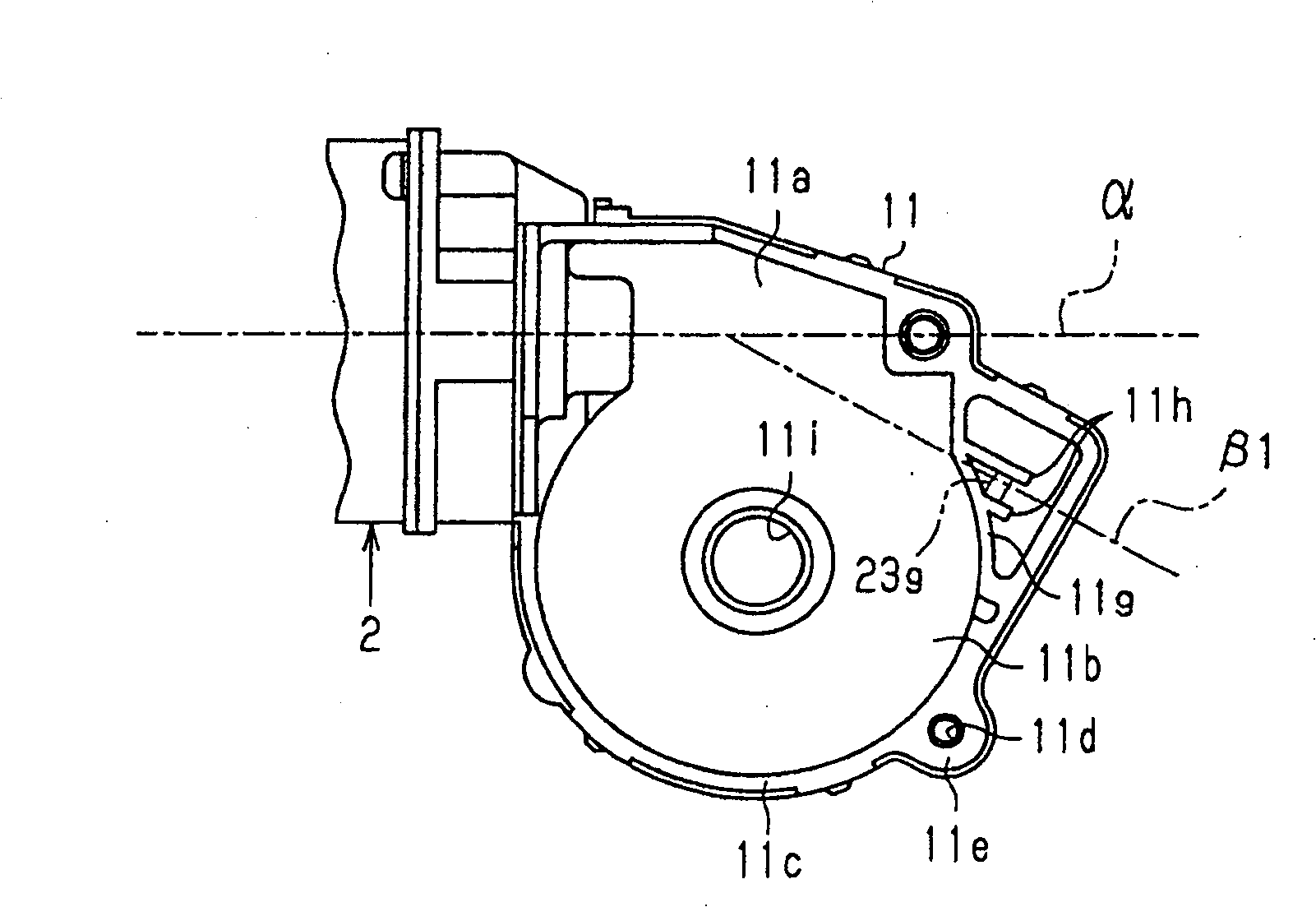

Pinch detection device and opening/closing device

InactiveCN1738955AReliable ExtrusionReliable detectionForce measurement using piezo-electric devicesPower-operated mechanismBiomedical engineeringPressure sensor

A pinch detection device has a pressure sensor (2) flexibly provided along the shape of a trunk lid (1) and determination means (16) for detecting a pinch of an object between an opening (17) and the trunk lid (1) based on an output signal from the pressure sensor (2). Since the pressure sensor (2) is flexibly provided along the shape of the trunk lid (1), a pinch at the trunk lid (1) can be detected.

Owner:PANASONIC CORP

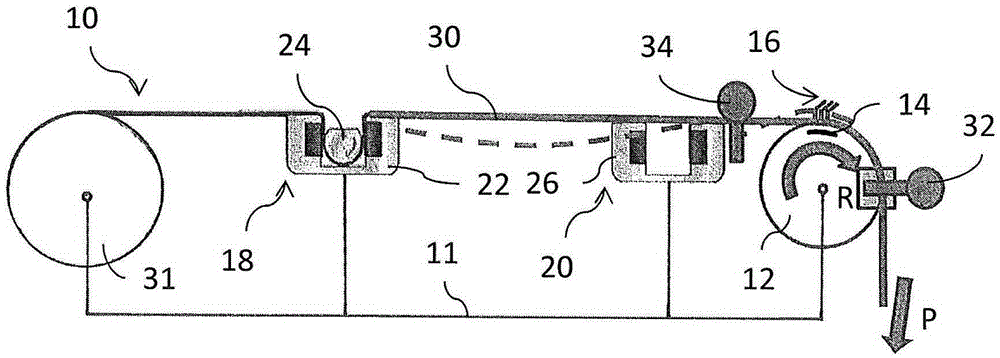

Device for combining several printed webs

InactiveCN1931695AGood effectReliable force transmissionFolding thin materialsArticle deliveryEngineeringMechanical engineering

Owner:M A N ROLAND DRUCKMASCHINEN AG

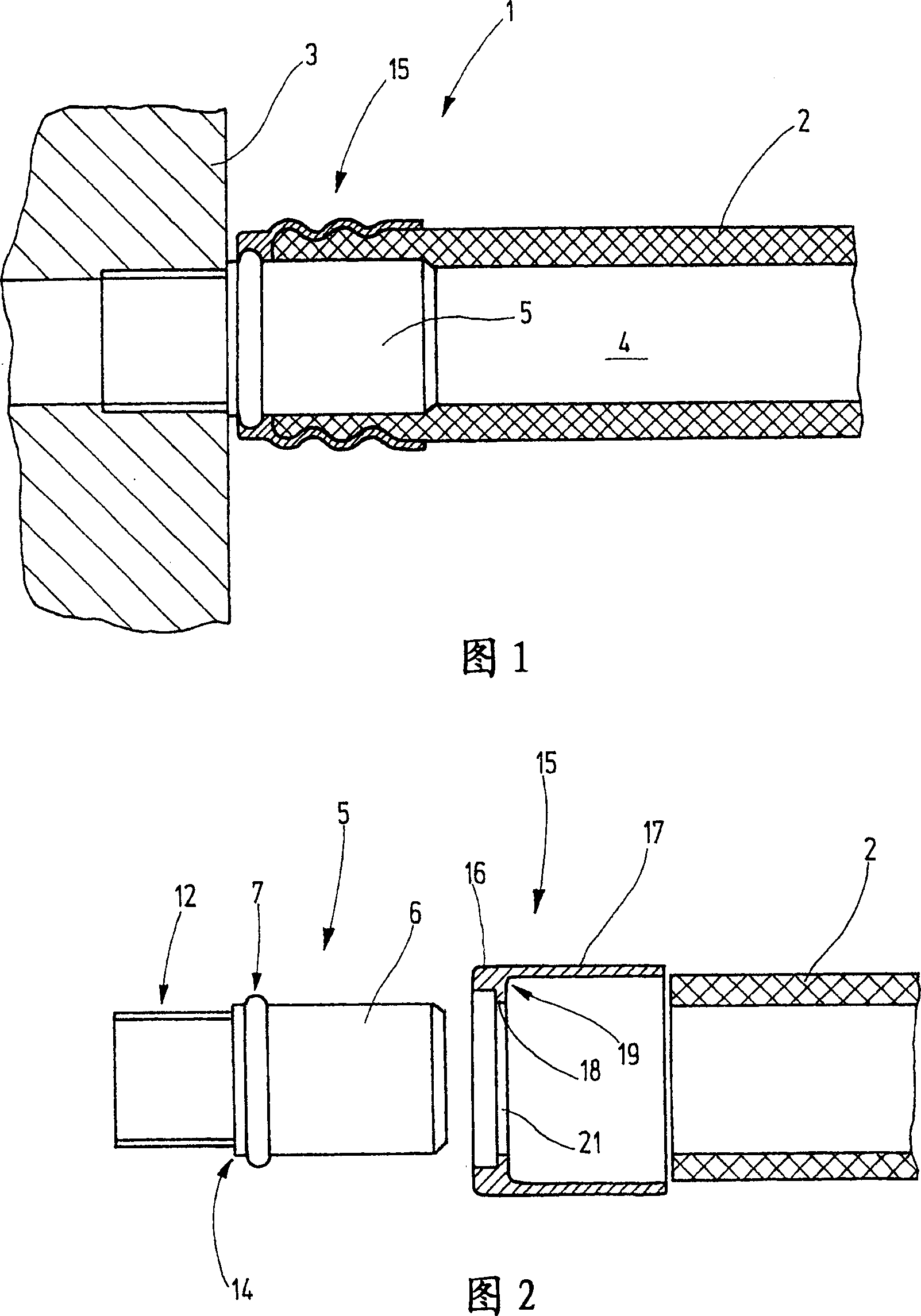

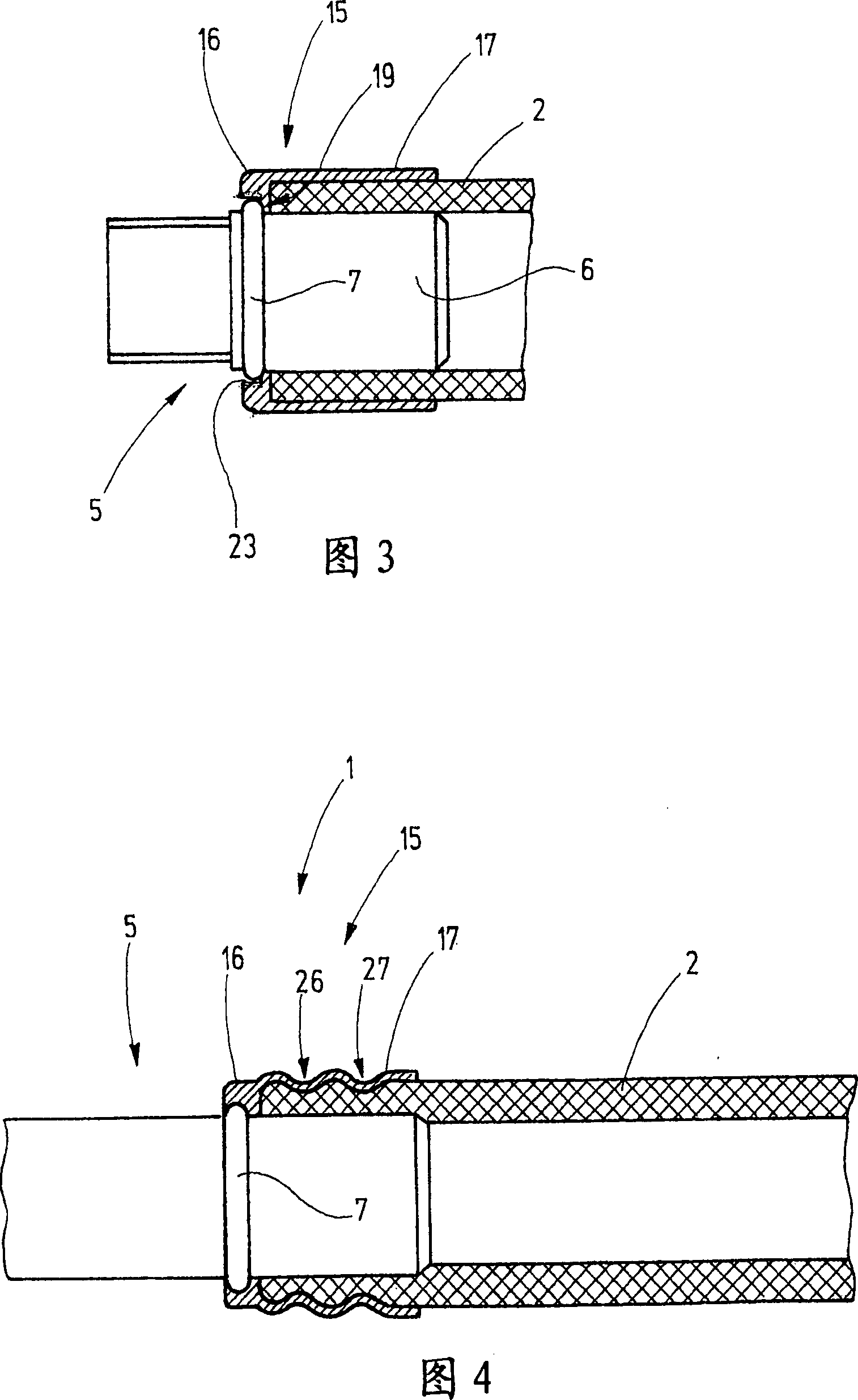

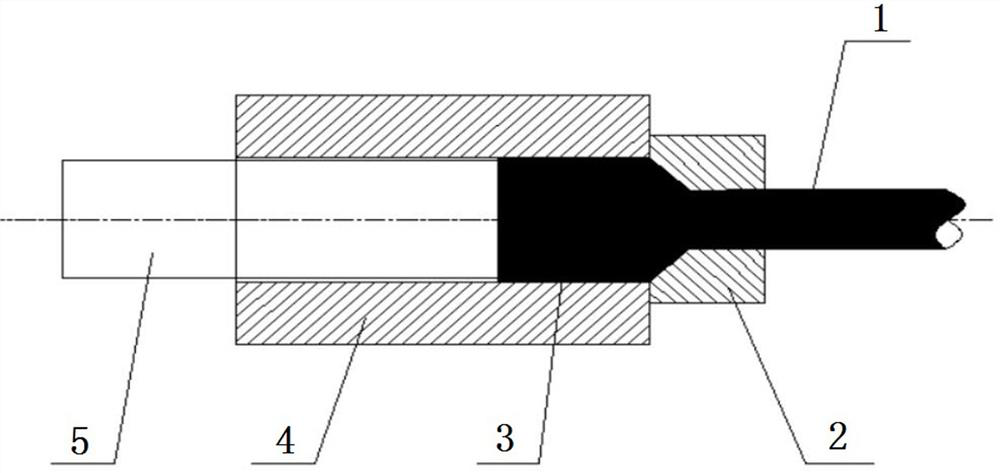

Connecting device

InactiveCN1965191ASimple connectionRealization costHose connectionsNon-disconnectible pipe-jointsAxial lengthEngineering

The invention relates to a connecting device (1) which consists of a connecting nipple (5) having an annular ring (7) and a compression sleeve (15). The aim of the invention is to provide a particularly compact connecting device. For this purpose, the compression sleeve (15) has a connecting area (16) with a substantially square cross-section which is forced onto the annular ring by pressure. The securing area axially fastens the compression sleeve to the connecting nipple (5), however, without engaging behind it, i.e. it is not provided with a section that extends beyond the annular ring (7). The connecting device (1) is therefore especially compact in the axial direction and allows for a bigger sealing length. The overall length of the connecting device (1) is exclusively determined by the length of the peripheral surface (6) serving for sealing in relation to the axial length of the annular ring (7). The connecting device does not require any additional sections engaging behind the annular ring (7).

Owner:EATON FLUID POWER GMBH

Casing structure and motor

ActiveCN1592041AImprove waterproof performanceGuaranteed reliabilitySupports/enclosures/casingsEngineering

Owner:DENSO CORP

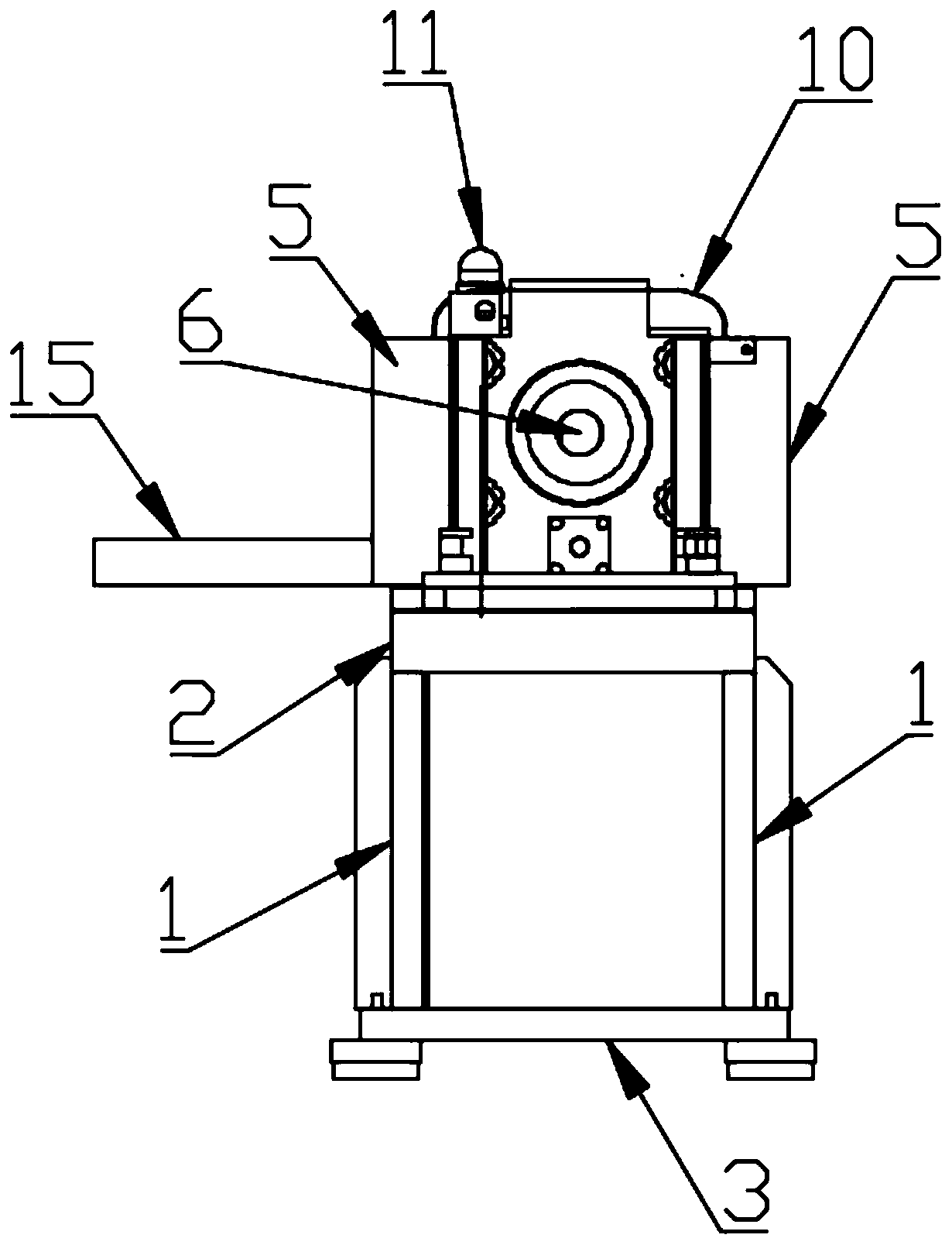

Extruding machine with infrared induction

ActiveCN110624971ANo shakingEfficient extrusion operationsExtrusion diesExtrusion control devicesEngineeringMechanical engineering

The invention provides an extruding machine with infrared induction. The extruding machine comprises a frame, a plurality of infrared induction devices, a controller and an extruding device, wherein the frame comprises a top plate, a bottom plate and support rods; the bottom plate is parallel to the top plate; the two ends of each support rod are perpendicularly and fixedly connected with the topplate and the bottom plate respectively; the extruding device comprises an extruding part, a die part and a feeding part; and the infrared induction devices are respectively arranged on the extrudingpart, the die part and the feeding part. According to the extruding machine, monitoring rods are arranged towards the extruding rod, so that the movement trajectory of the extruding rod is monitored in real time; and when the extruding rod is moved under the extrusion operation of an extrusion driving device, stroke monitoring devices can sense the movement path of the extruding rod, and thus theextrusion operation of the extruding rod can be monitored in real time.

Owner:佛山市三水凤铝铝业有限公司 +1

Tensioning device, knitting machine, necking machine and method for tensioning a number of chain filaments

ActiveCN103388225AReliable knotted connectionIncrease stressLoomsSeaming textilesYarnBiomedical engineering

Owner:STAUBLI SARGANS AG

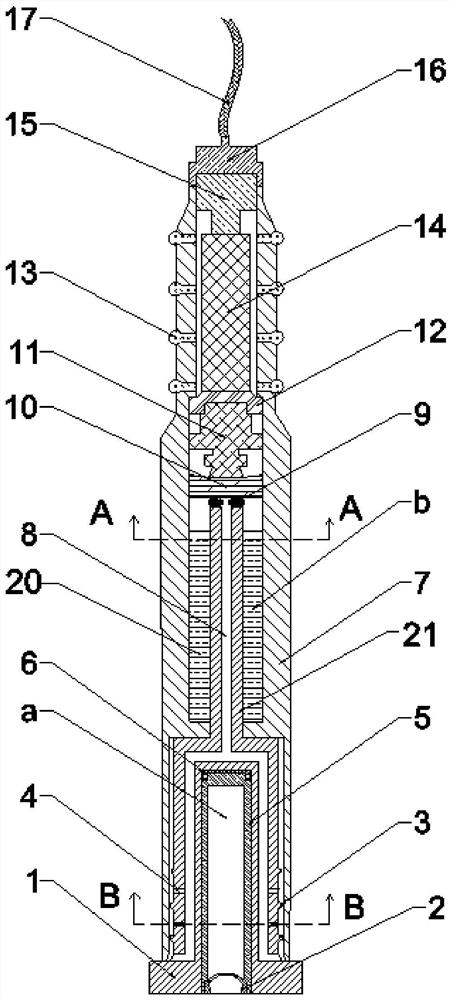

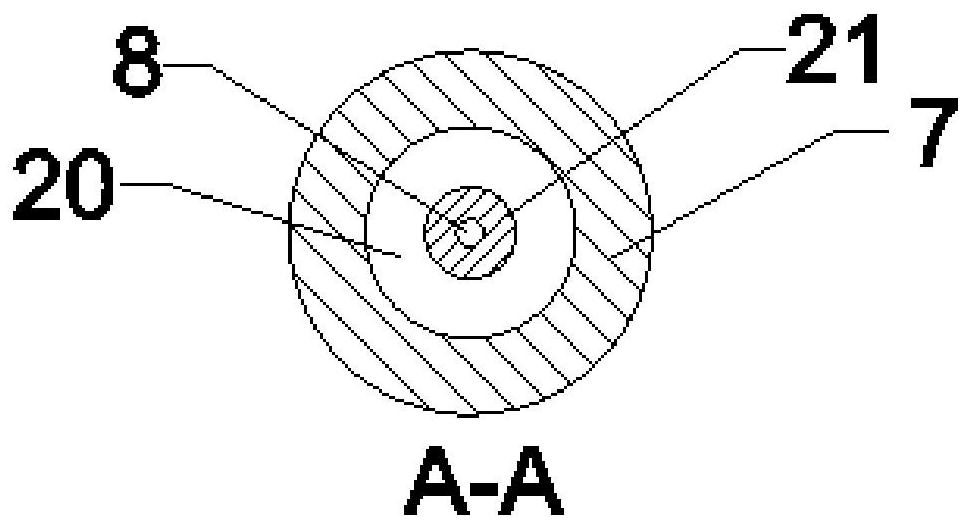

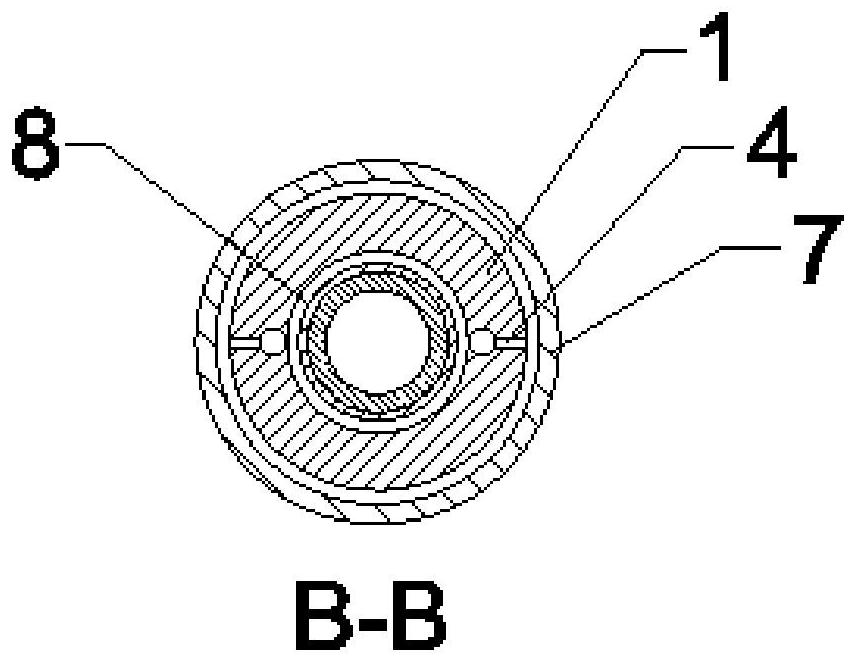

Lunar-based large-depth fidelity coring drilling device

PendingCN111999097AEasy to fixSolve the technical problem of "not getting deep"Withdrawing sample devicesMining engineeringWell drilling

The invention discloses a lunar-based large-depth fidelity coring drilling device, and relates to the technical field of lunar exploration and drilling. The coring device comprises a controller, a coring device outer pipe and a coring drill bit located below the coring device outer pipe, wherein a drilling mechanism is arranged in the coring device outer pipe, and the drilling mechanism comprisesa push rod and a rotating mechanism which are connected with the controller and is used for applying torque and axial bit pressure to the coring drill bit; an inflating mechanism fixedly connected with the coring device outer pipe is arranged at the upper part of the coring device outer pipe; and the inflating mechanism is connected with the controller, so that in the coring process, the controller can control the inflating mechanism to expand in the radial direction of the coring device outer pipe to extrude the well wall, and the coring device outer pipe is centered in the radial direction and fixed in the axial direction through friction force between the inflating mechanism and the well wall. By implementing the technical scheme, the technical problem that existing lunar-based coring cannot achieve large-depth fidelity coring is solved, bit pressure sufficient to penetrate into a lunar rock layer can be applied to the coring drill bit, deep lunar rock is drilled, and large-depth fidelity coring is achieved.

Owner:SHENZHEN UNIV +1

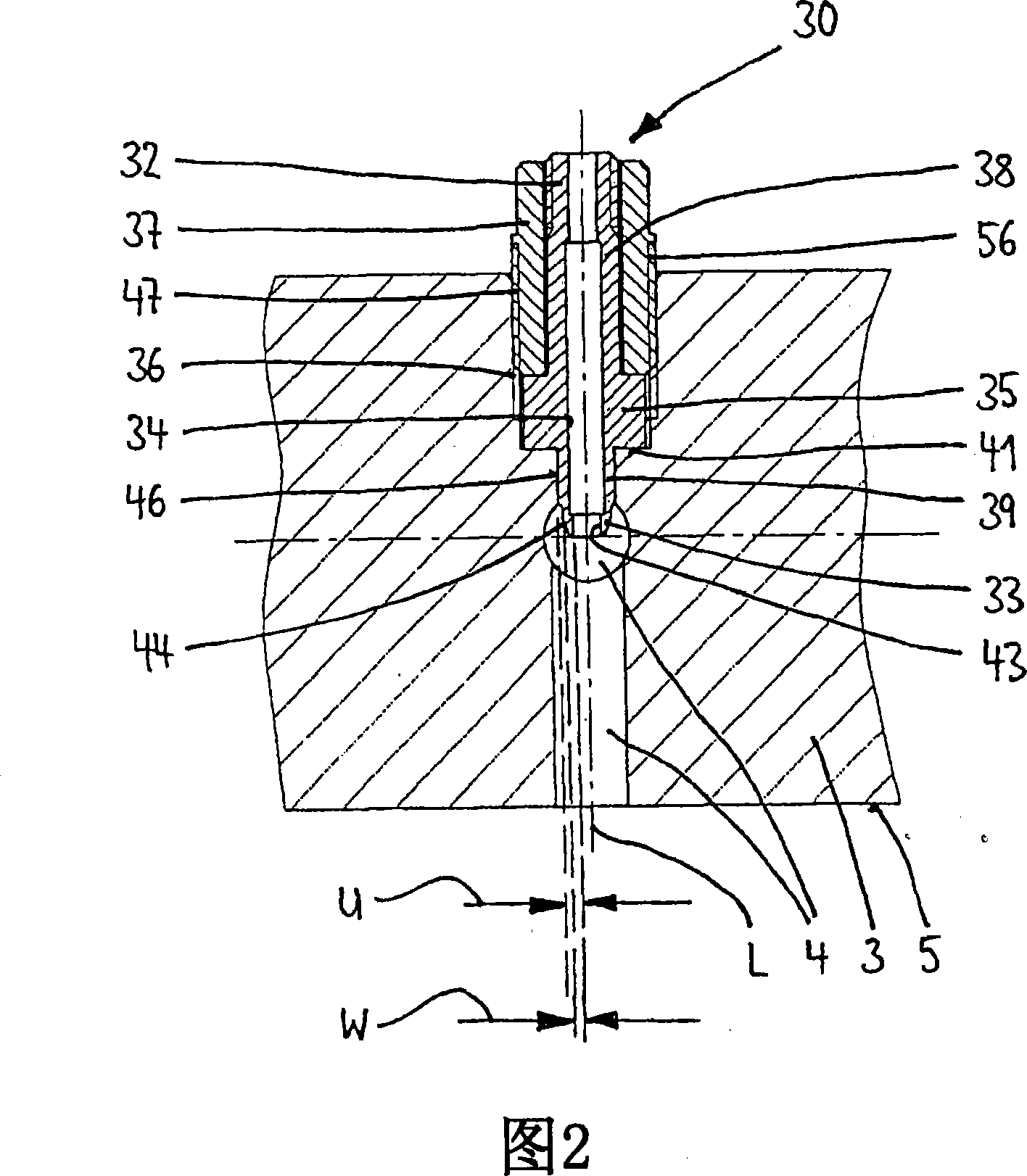

Injection-moulding device with needle valve nozzle and guide bush

Injection molding device (1) with: distribution plate (3) in which at least one flow channel (4) for flowable material is formed; at least one needle closing nozzle by which the nozzle is closing , the flowable material can be fed to the separable mold insert under the guidance of the flow channel; at least one closing needle (20), the closing needle (20) at least partially moves longitudinally through the flow channel and can be in an open and closed position by means of a drive member; and a guide sleeve (30) which allows the closure needle (20) to pass and seals the closure needle (20). The guide sleeve has a region which surrounds the closing needle with little movement play and which is located at least partially in the flow channel. This region thus has a contact surface for the flowable material, which is at least partially located within the flow channel. The flowable material flows around the region and all sides of the interface (44).

Owner:GUENTHER HEISSKANALTECHNIK GMBH

Processing method of decorative plate with three-dimensional patterns and the prepared decorative plate

The invention discloses a processing method of decorative plate with three-dimensional patterns and the prepared decorative plate. The processing method comprises the steps of: (1) heating: heating to soften a decorative plate substrate in an oven at 150-170 DEG C for 1-2 min; (2) three-dimensional pattern stamping: sending the heated decorative plate substrate between a male mold and a female mold of a stamping mold, driving the male mold and female mold for moving towards the decorative plate substrate by a press and punching out the three-dimensional patterns, wherein the stamping force of the press is 75-100 tons, and stamping hold time is 1-2 min; (3) cooling: treating the punched decorative plate substrate with three-dimensional patterns by air or water cooling to a temperature below 45 DEG C; and (4) UV treatment: conducting UV treatment on the surface of the cooled decorative plate substrate.

Owner:刘飞武

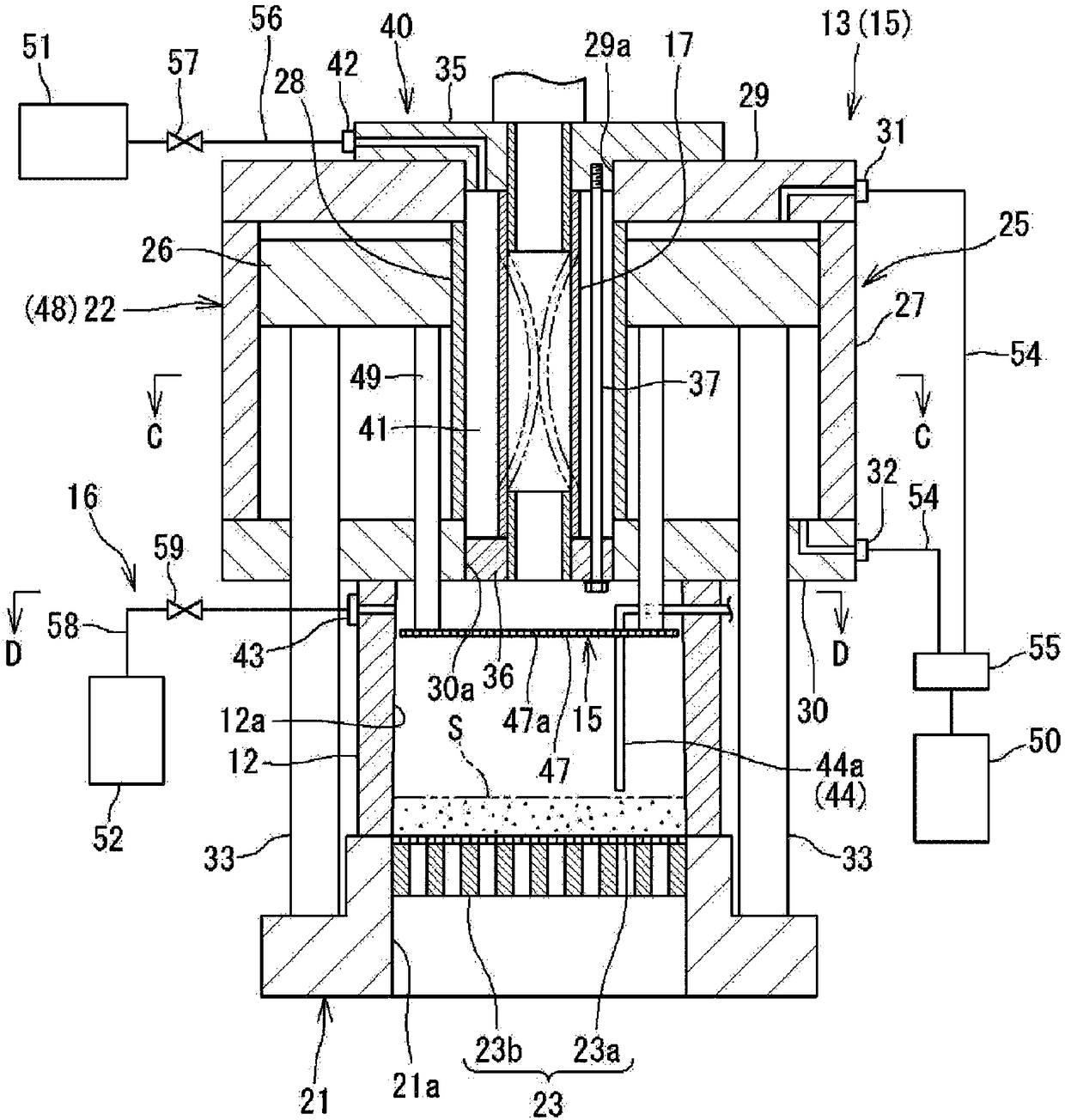

Vacuum vessel, vacuum vessel manufacturing method, vacuum processing apparatus, and electronic device manufacturing method

ActiveCN101752221AEasy to take timeHighly reliable vacuumEngine sealsSemiconductor/solid-state device manufacturingEngineeringElectron

A vacuum vessel includes a pair of bending members which are formed by bending metal plates in predetermined shapes and are bonded to each other to form a closed space inside them. The vacuum vessel also includes a sealing member which seals the gap in the bonding portion between the bending members, and a cubic lattice structure which abuts against the inner surfaces of both the bending members and is accommodated in the closed space. The vacuum vessel further includes a magnet unit. The magnet unit fixes the bending members onto the structure and seals the gap in the bonding portion between the bending members by pressing an O-ring serving as a sealing member along the bonding portion.

Owner:CANON ANELVA CORP

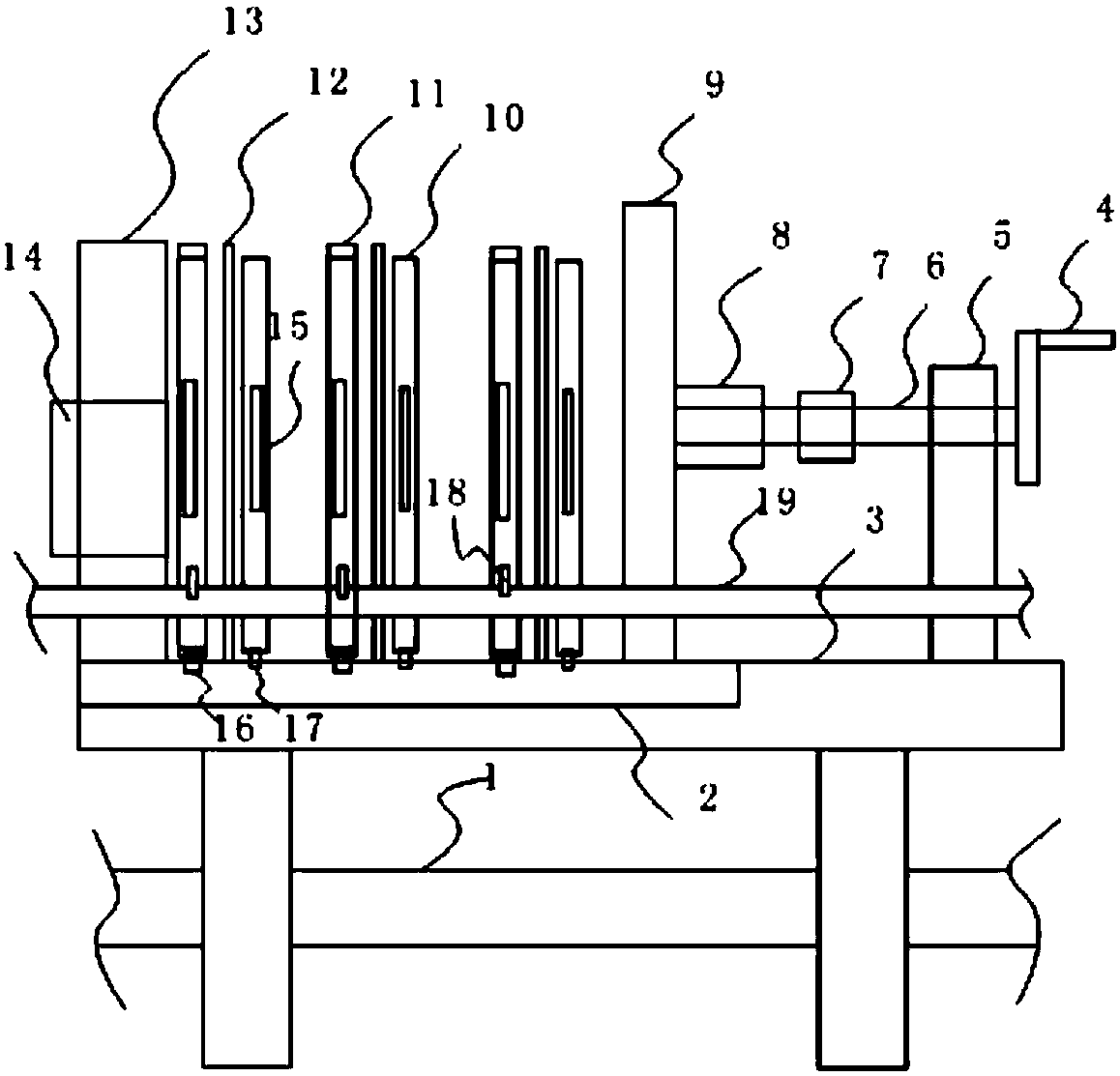

Plate-frame type sludge and slurry filter press

PendingCN107915391ASqueeze out fullySelf-locking and reliableSludge treatment by de-watering/drying/thickeningSludgeControl engineering

The invention relates to the field of sludge treatment equipment, especially to a plate-frame type sludge and slurry filter press. The plate-frame type sludge and slurry filter press comprises a rack,a press filter and a hold-down device. The press filter comprises multiple successively-arranged filter frames, filter cloth and filter boards. A thrust plate is fixedly installed at one end of the rack. A slide rail is arranged below the thrust plate and along the extension direction of the rack. The thrust plate is provided with a feed inlet. Multiple filter frame sliding holders and filter board sliding holders are respectively arranged in a staggered manner on the slide rail. The filter frame sliding holder is provided with a filter frame neck, and the filter board sliding holder is provided with a filter board neck. The filter frames are installed inside the filter frame necks, and the filter boards are installed inside the filter board necks. The filter frames and the filter frame sliding holders are provided with filter board sliding holder abdicators. The hold-down device is arranged at the other end of the rack and comprises a mounting base, a lead screw and a pressure strip,wherein the pressure strip is connected to an end portion of the lead screw through a nut cap; the lead screw passes through the mounting base and is controlled by a handle to rotate; and the lead screw is sleeved with a locknut between the mounting base and the pressure strip. According to the device of the invention, the filter frames and the filter boards are convenient and reliable to installand replace, extrusion is labor-saving, and reliable self-locking can be formed.

Owner:天津远新环保科技有限公司

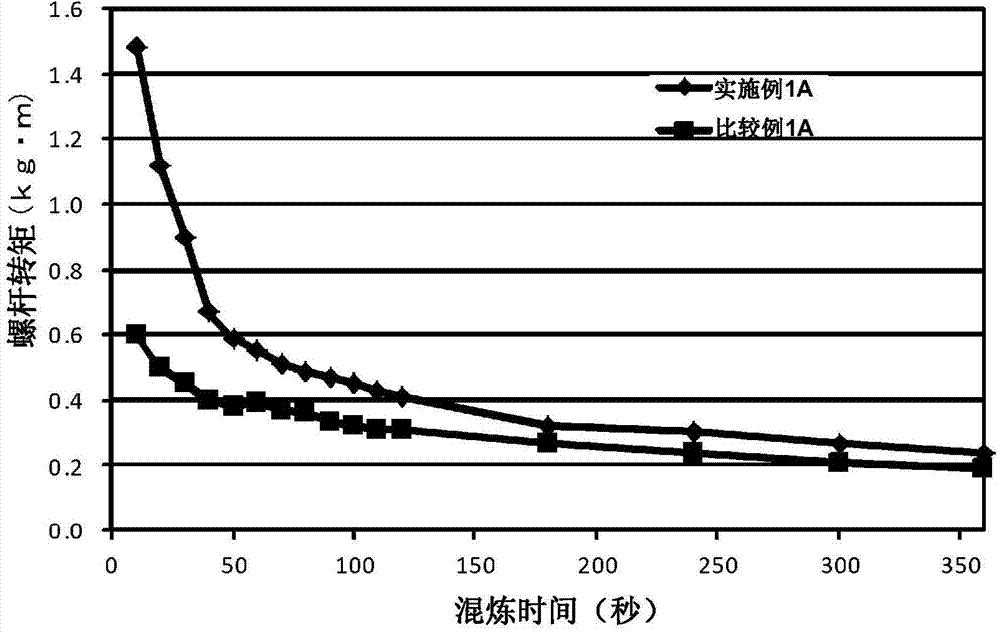

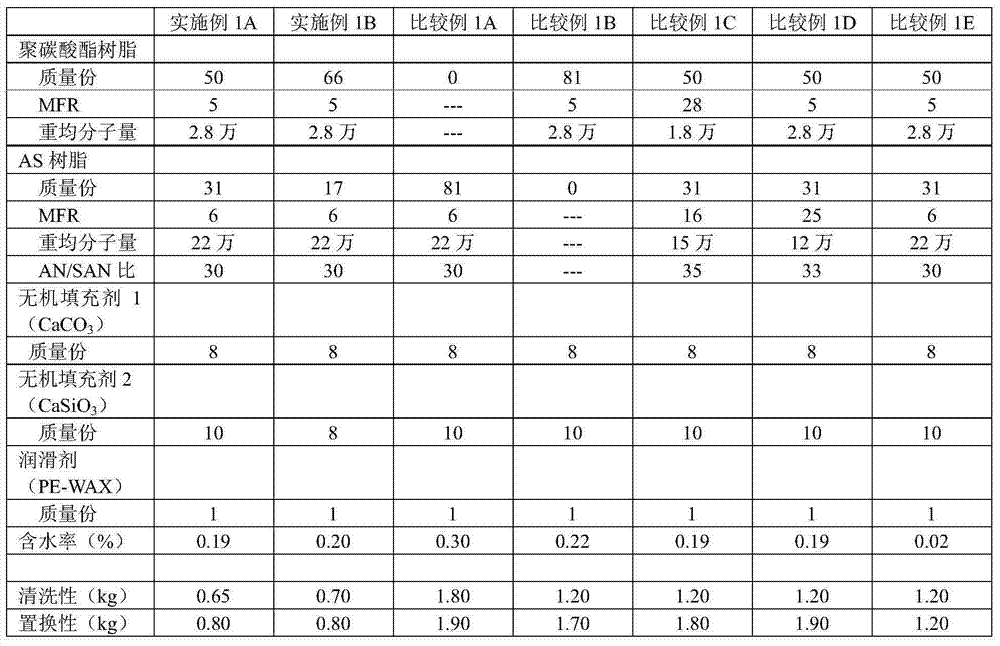

Thermoplastic resin composition for cleaning applications, and cleaning method

A thermoplastic resin composition for cleaning applications comprises (A) 30 to 90 parts by mass of a polycarbonate resin having a melt mass flow rate of 1 to 12g / 10min. as measured under the conditions of a test temperature of 300 DEG C and a nominal load of 1.2 kg, (B) 5 to 70 parts by mass of an acrylonitrile-styrene copolymer having a melt mass flow rate of 4 to 10g / 10min. as measured under the conditions of a test temperature of 220 DEG C and a nominal load of 10 kg, (C) 0.5 to 5 parts by mass of at least one lubricant, and (D) 5 to 40 parts by mass of at least one inorganic filler, and has a water content of 0.1 mass% or more.

Owner:MITSUBISHI GAS CHEM CO INC

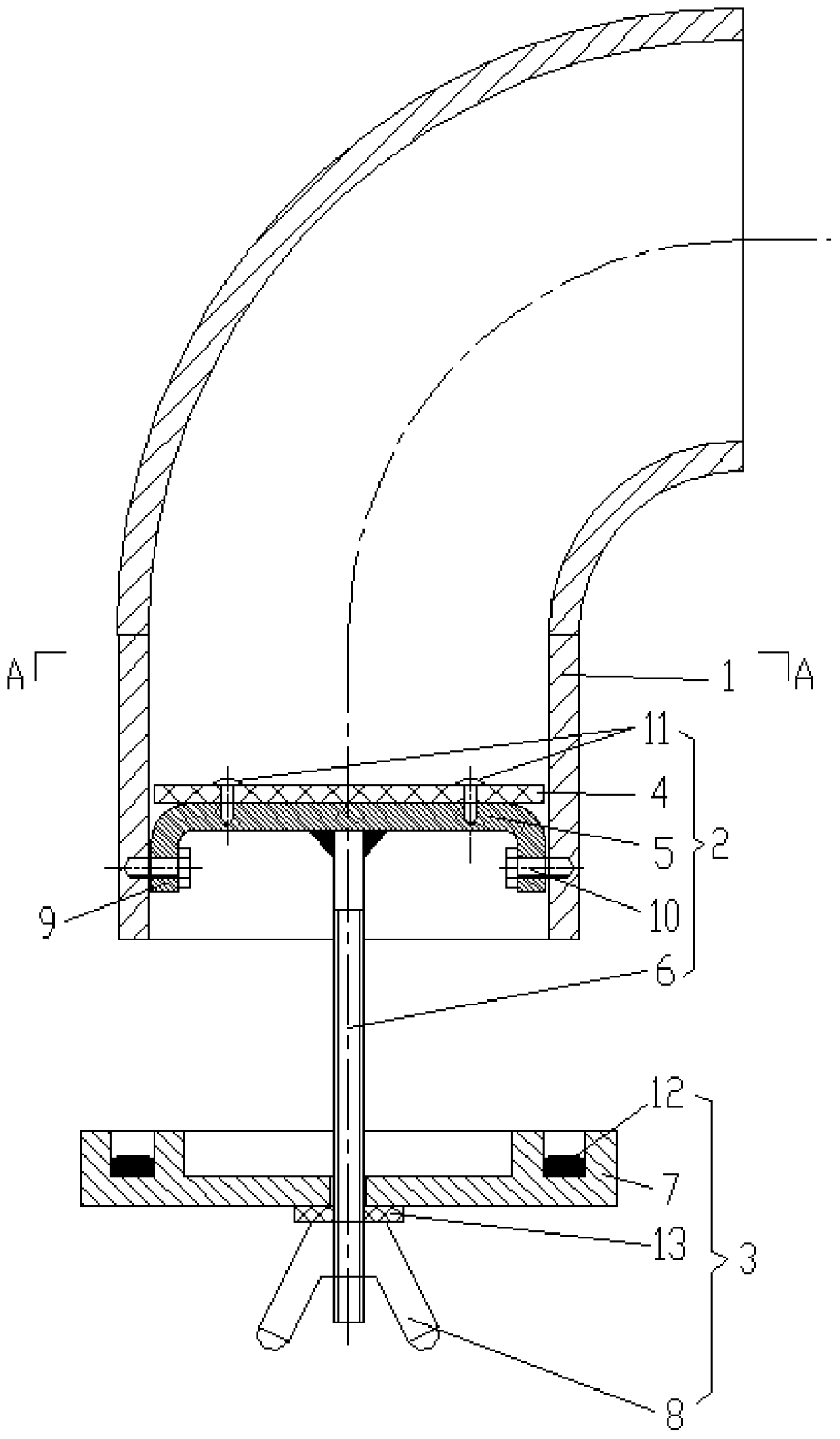

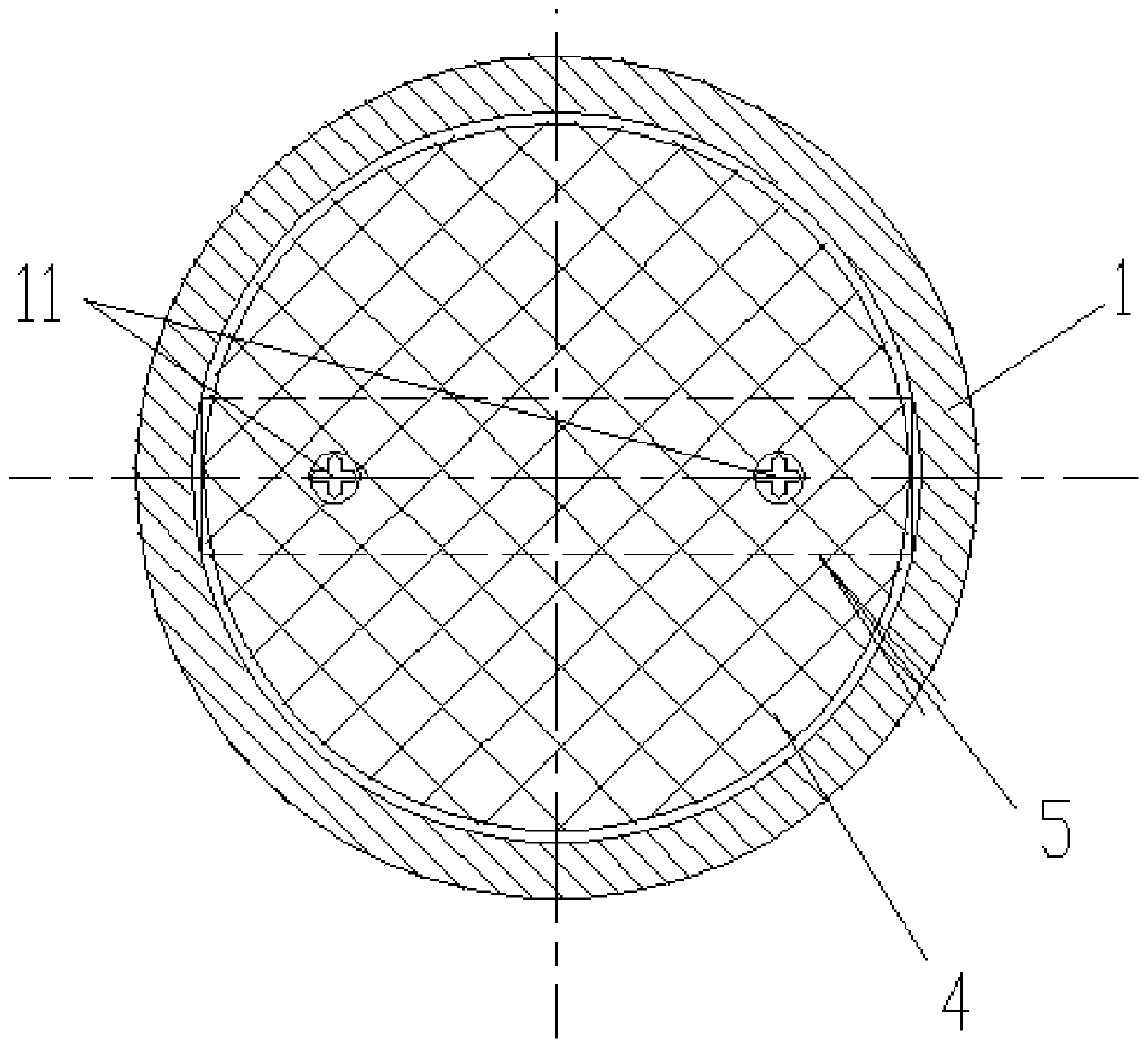

Drooping type circular air pipe air outlet structure with watertight cover and insect-proof net

InactiveCN110254685ASmall footprintReduce construction costsAuxillariesVessel ventillation/heating/coolingWire meshAerospace engineering

The invention relates to the technical field of ventilating ducts, and discloses a drooping type circular air pipe air outlet structure with a watertight cover and an insect-proof net. The drooping type circular air pipe air outlet structure comprises a drooping type circular air outlet pipe, an insect-proof net assembly and a watertight cover assembly, wherein the insect-proof net assembly comprises a disc-shaped steel wire mesh which is matched with an inner hole of the drooping type circular air outlet pipe and a long strip-shaped supporting plate connected to the lower end surface of the disc-shaped steel wire mesh, the two ends of the long strip-shaped supporting plate are fixedly connected with the inner wall of the drooping type circular air outlet pipe, a screw rod which is vertically arranged downwards is fixedly connected to the lower end surface of the long strip-shaped supporting plate, and the watertight cover assembly comprises a watertight cover which is arranged on the outer circle of the screw rod in a sleeving mode and can slide up and down along the outer circle of the screw rod, and a nut which is connected to external threads at the lower end of the screw rod and is used for upwards jacking the watertight cover on the end face of the lower end of the drooping type circular air outlet pipe. According to the drooping type circular air pipe air outlet structure with the watertight cover and the insect-proof net, the insect prevention and waterproof structure of a circular air pipe air outlet is simplified, the occupied space is reduced, and the construction cost is reduced.

Owner:CHENGXI SHIPYARD

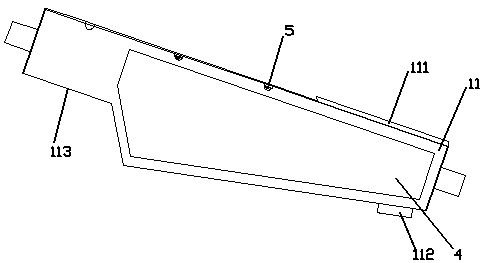

Extrusion mechanism for kitchen garbage

The invention relates to garbage processing, in particular to an extrusion mechanism for kitchen garbage. The extrusion mechanism for kitchen garbage is simple in structure, capable of conveniently extruding garbage, and capable of avoiding blockage and improving processing efficiency. The extrusion mechanism for kitchen garbage comprises a spiral conveyor and a screen cylinder, wherein the spiralconveyor comprises a conveying cylinder and a rotating shaft; the conveying cylinder is obliquely arranged; the top of one end of the conveying cylinder is provided with a feed inlet, and the bottomof the end of the conveying cylinder is provided with a water outlet; the other end of the conveying cylinder is provided with a discharge outlet; spiral blades are arranged on the rotating shaft; thescreen cylinder is arranged in the conveying cylinder; spacing is formed between the spiral blades and the screen cylinder; and one end, at the discharge outlet of the conveying cylinder, of the rotating shaft is provided with separation sheets which are arranged in a staggered manner. According to the extrusion mechanism for kitchen garbage, the occupied area is saved, the discharge reliabilityis improved, and the environmental pollution is avoided.

Owner:江苏中科金汇生态科技有限公司

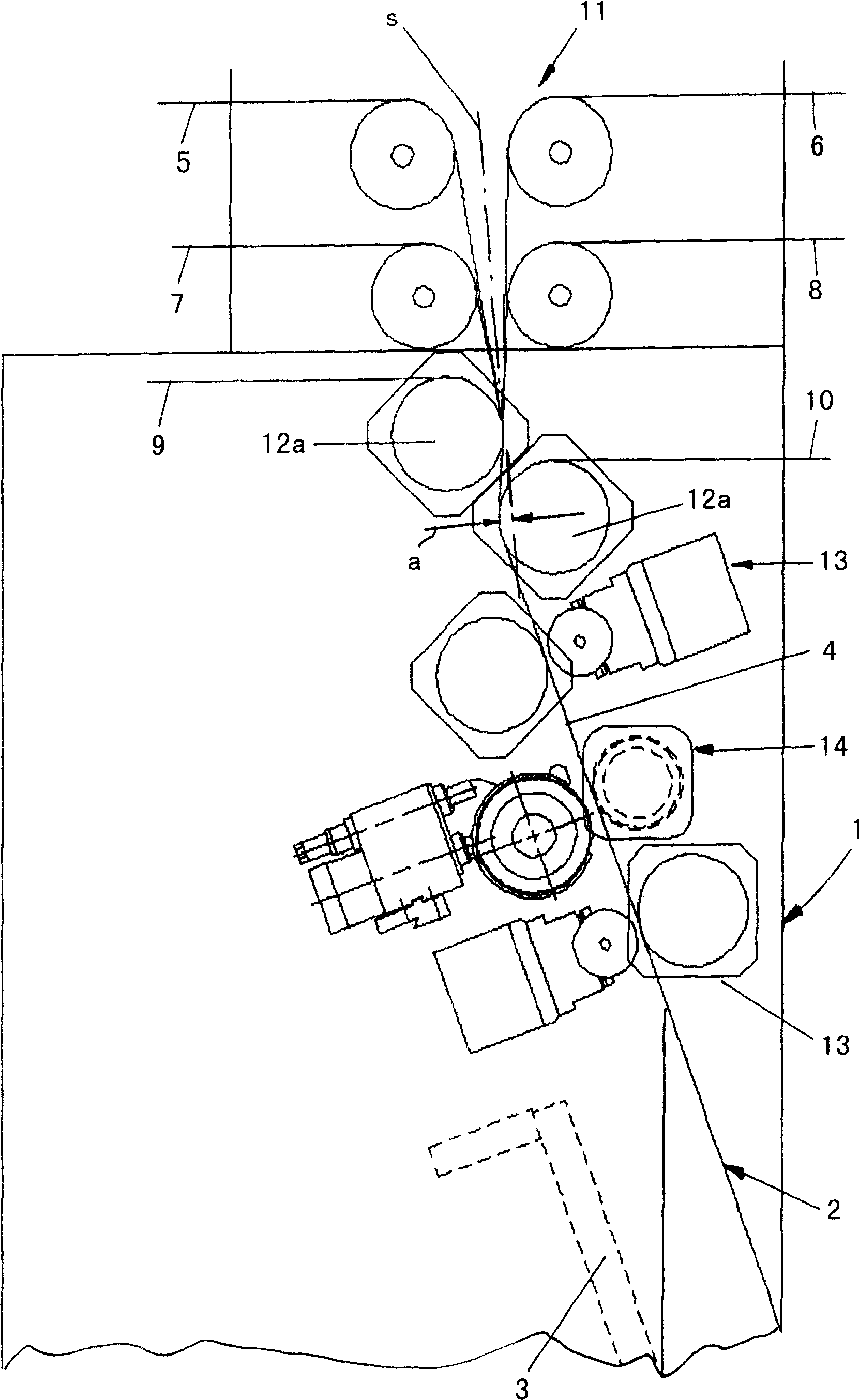

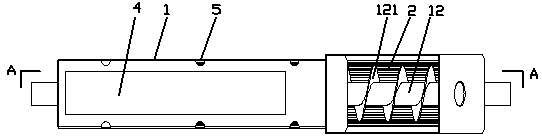

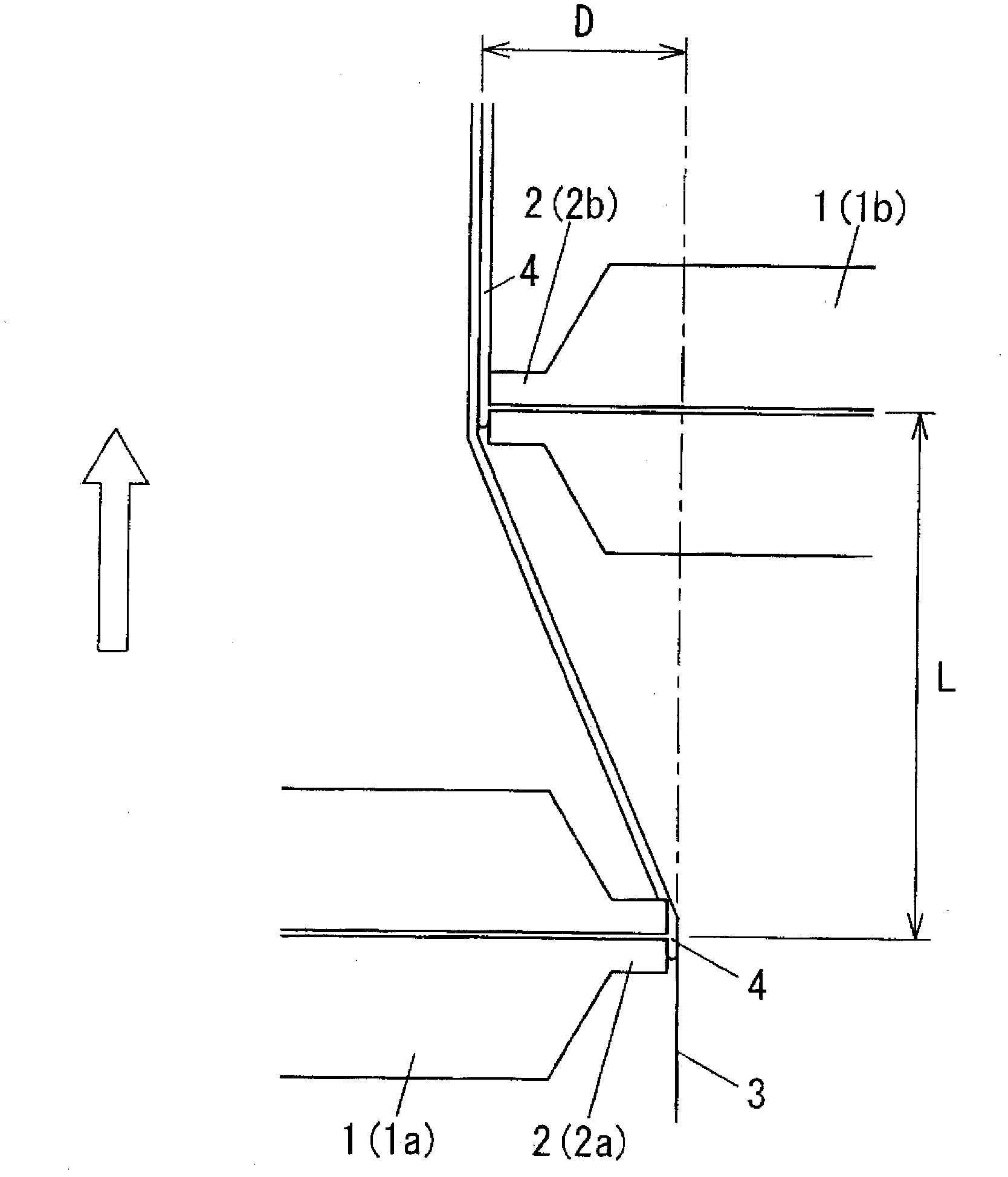

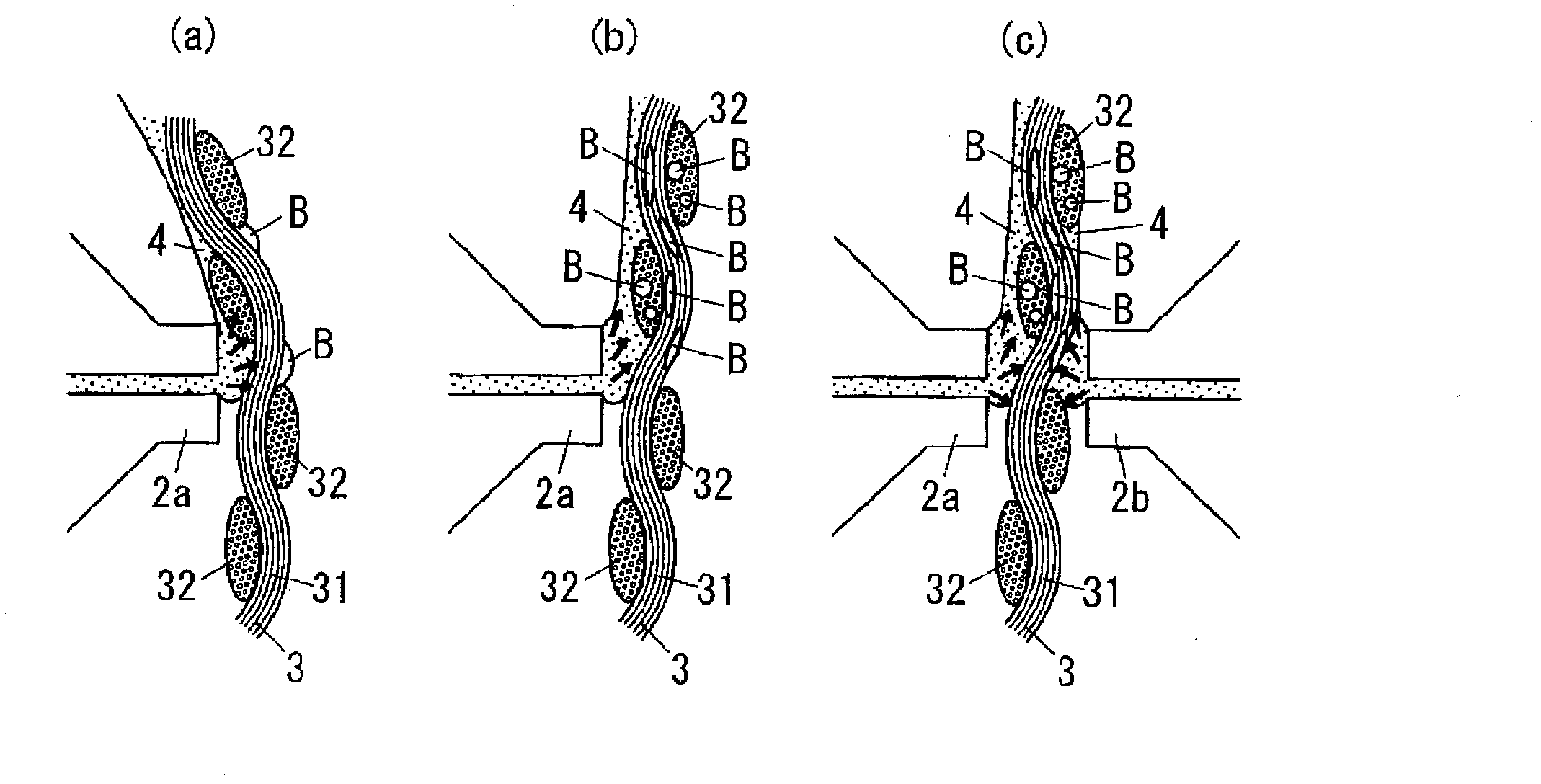

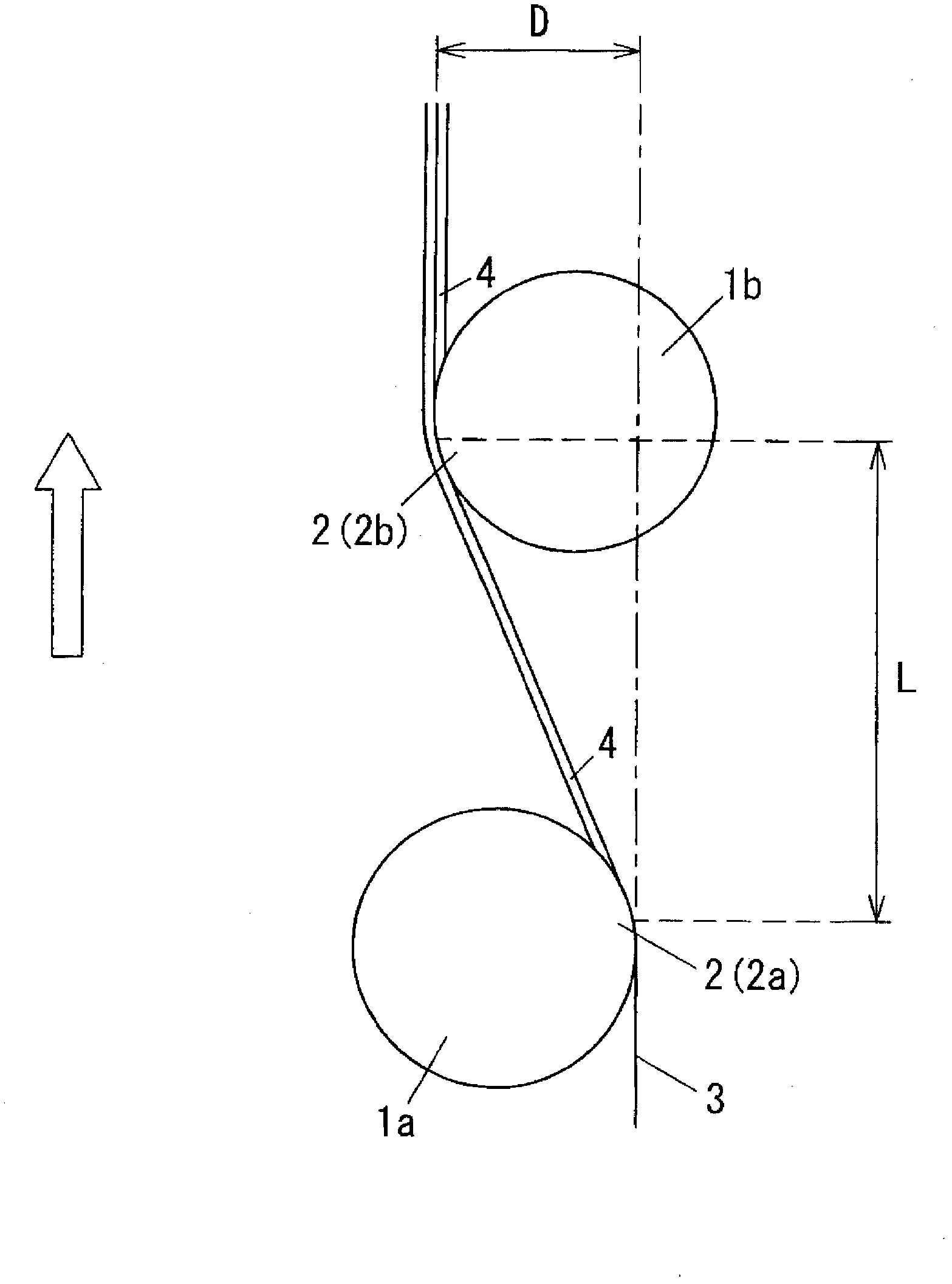

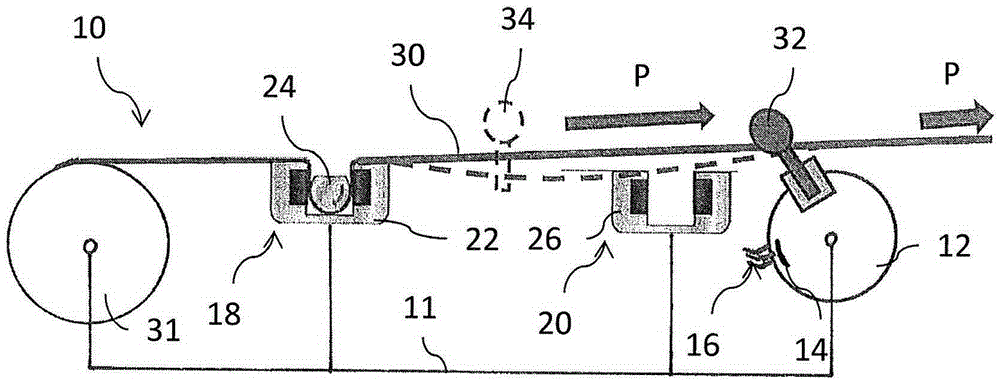

Method for manufacturing prepreg for printed wiring board and device for manufacturing prepreg for printed wiring board

ActiveCN102459430AReliable releaseEasy to adjustPrinted circuit aspectsPrinted circuit manufactureProduction rateEngineering

The present invention has been aimed to propose a process and a device of fabricating a prepreg for a printed circuit board which are capable of controlling respective thicknesses of resin layers on the opposite surfaces of a resultant prepreg, removing air bubbles from the resultant prepreg, and improving productivity. The present invention is a process of resin-coating the opposite surfaces of an elongated substrate sheet 3. The process includes the steps of: feeding the substrate sheet 3 while tensioning the same in a feeding direction along the length of the substrate sheet 3; coating, by the coating head 2 of the first dispenser 1a, one surface of the substrate sheet 3 with the fluid resin 4 while pressing against the one surface to bend the substrate sheet 3; and subsequently coating, by the coating head 2 of the second dispenser 1b, the other surface of the substrate sheet 3 with the fluid resin 4 while pressing against the other surface to bend the substrate sheet 3. A die coater and a roll coater can be used as the first dispenser 1a and the second dispenser 1b.

Owner:PANASONIC CORP

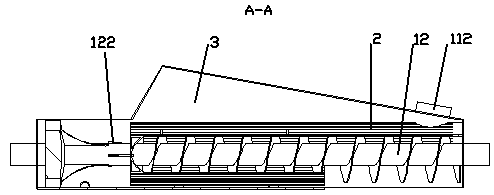

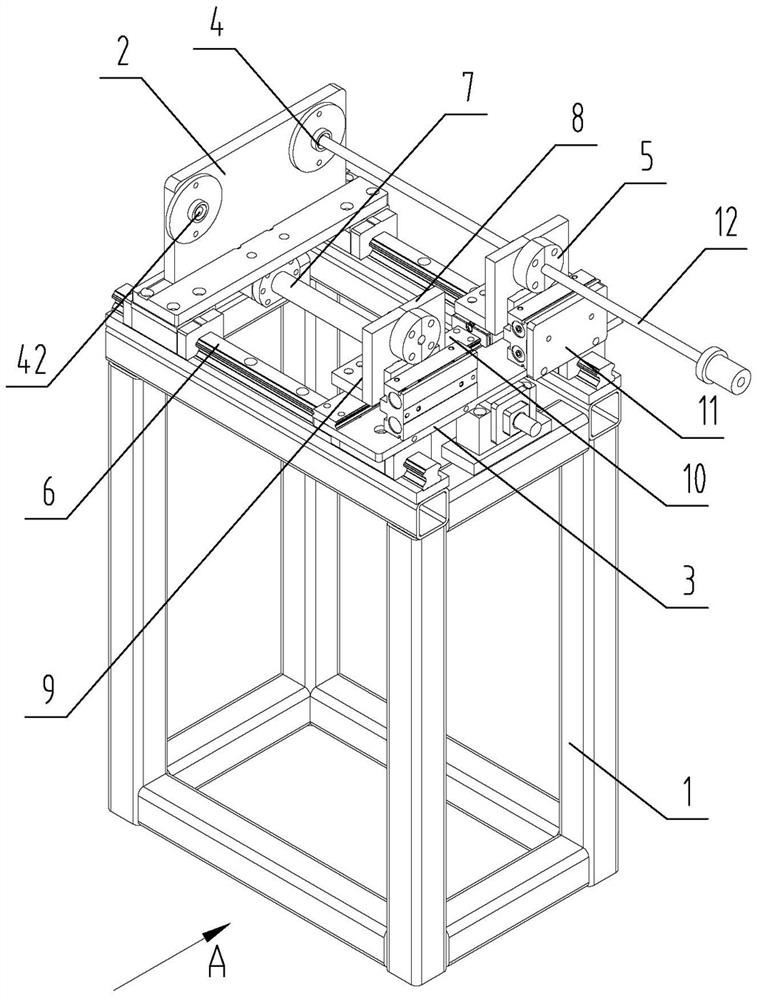

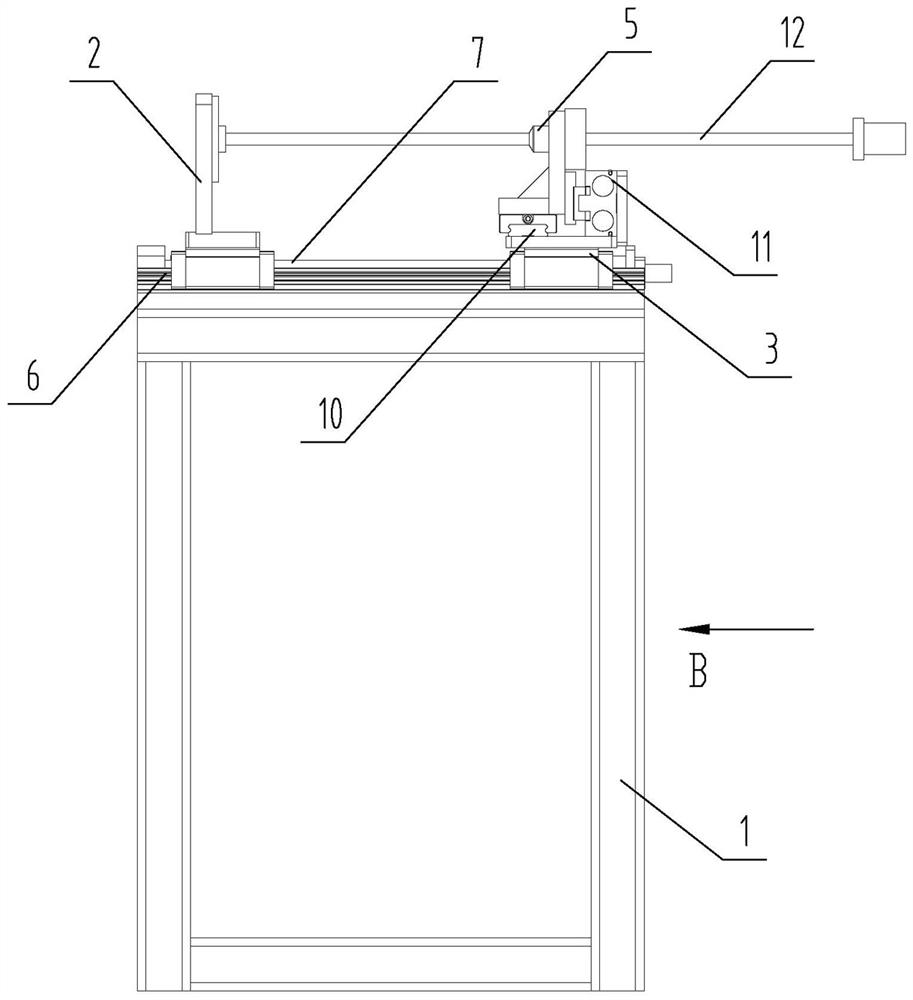

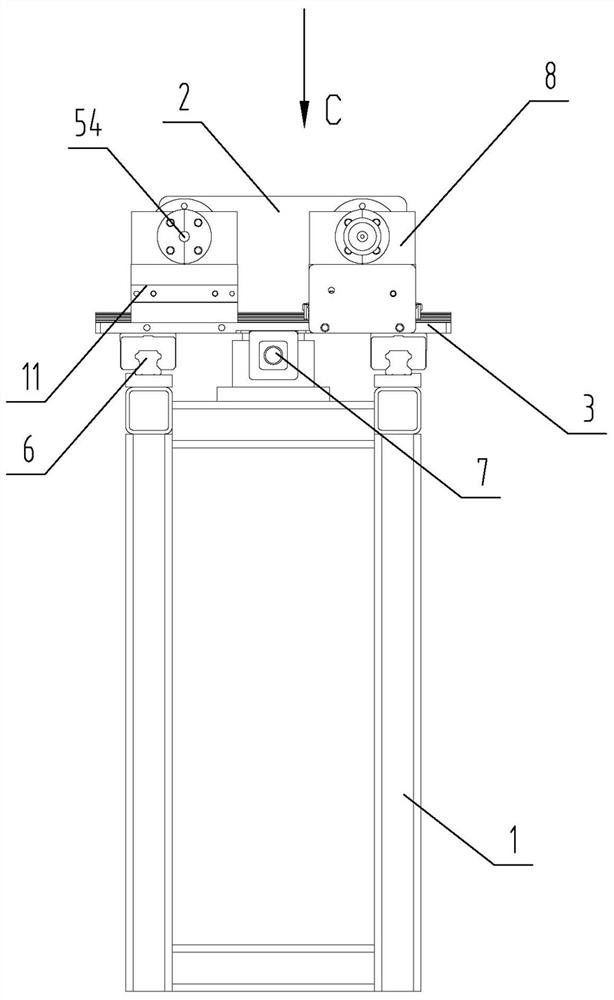

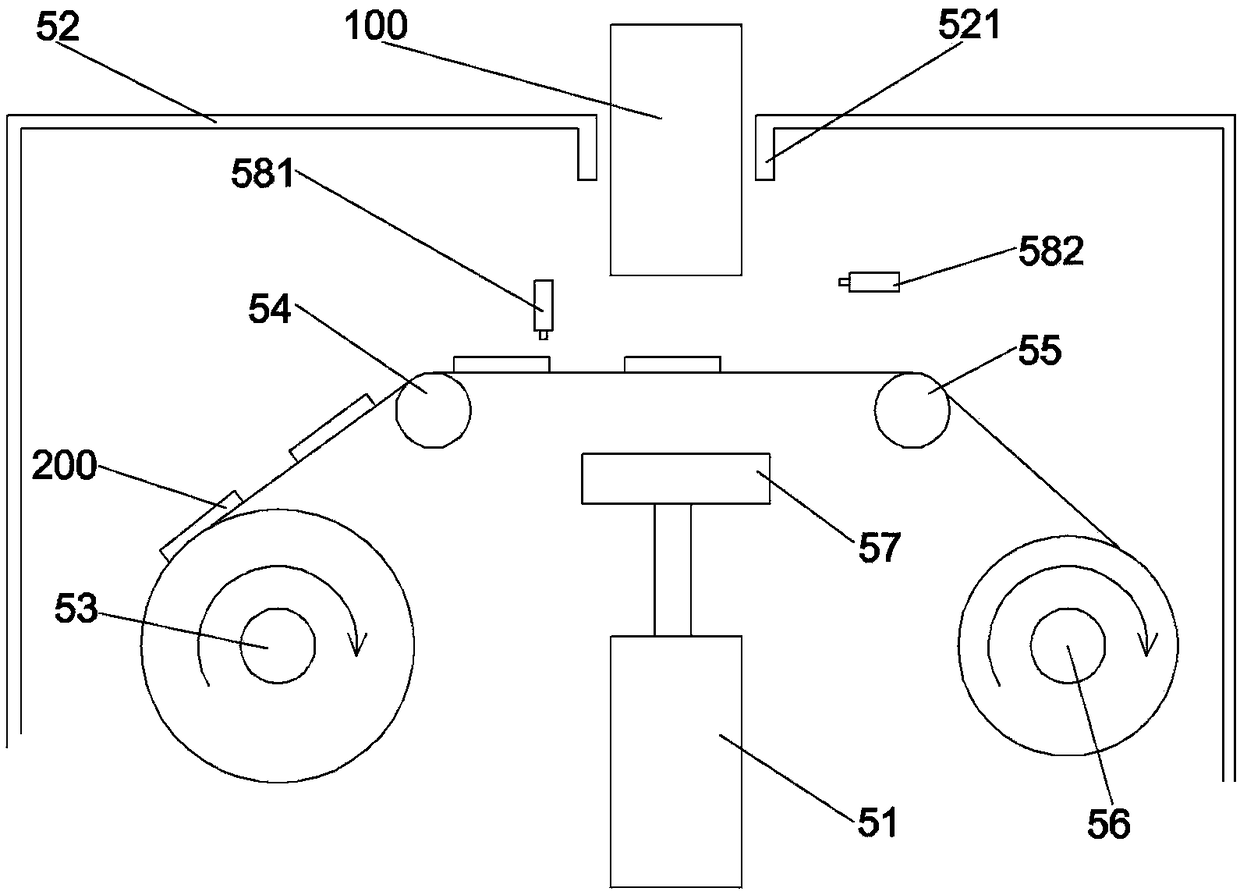

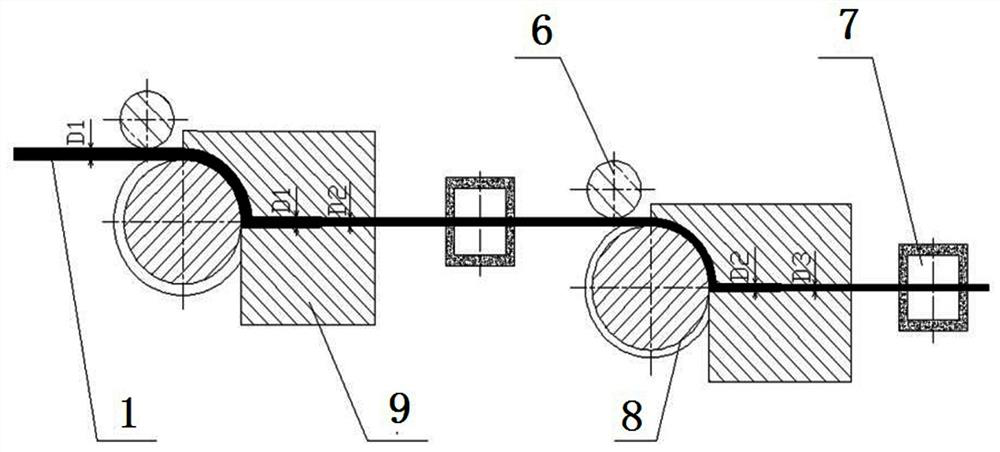

Method and device for extruding and shrinking casing

ActiveCN112825895AImprove shrink qualityImprove compactnessSausage casing manufactureSausage casings by extrusionButt jointIndustrial engineering

The invention discloses a method and device for extruding and shrinking a casing, and belongs to the technical field of casings. The device comprises a rack, and is characterized in that the rack is provided with a first moving support and a second moving support which can move in opposite directions, the first moving support is provided with a first extrusion head, the second moving support is provided with a first plier arm and a second plier arm, the first plier arm and the second plier arm are connected with an opening and closing mechanism, a first split body is arranged on the first plier arm, a first clamping groove is formed in the first split body, a second split body is arranged on the second plier arm, a second clamping groove is formed in the second split body, the second clamping groove can be in butt joint with the first clamping groove to form a clamping hole, and the first split body and the second split body form a second extrusion head; and the second extrusion head and the first extrusion head are distributed oppositely. By means of the device, the two ends of the casing shrinkage pipe can bear extrusion force at the same time to be compacted towards the middle, the compactness of the casing shrinkage pipe can be improved, and disjunction is avoided; and the pipe wall of the casing shrinkage pipe is arched outwards, so that the hole in the casing shrinkage pipe is expanded, and the rod is convenient to separate.

Owner:青岛齐林智信自控技术有限公司

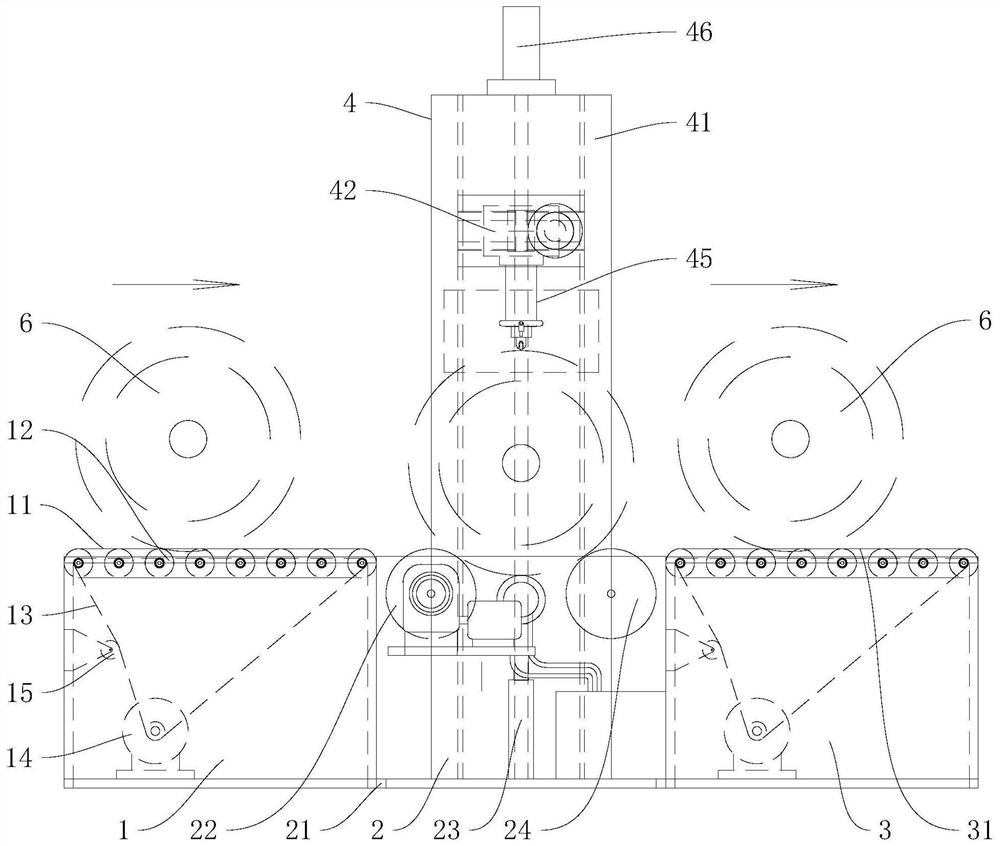

An automatic feeding and labeling device

ActiveCN107264905BAvoid sliding left and rightEffective squeezeLabelling machinesTransfer mechanismManipulator

The invention discloses an automated loading and labeling device. The automated loading and labeling device comprises a working table, a control mechanism, a loading mechanism, a first labeling mechanism, a second labeling mechanism and a transferring mechanism, wherein the loading mechanism comprises a loading rack, a loading stand column, a mounting sliding block, a loading rotary table and a loading head; the second labeling mechanism comprises a feeding and conveying belt, a driving labeling rotary table, a driven labeling rotary table, a second discharging roll, a second paper collecting roll, shifting rods, an unloading plate, a first guiding plate, a second guiding plate, a U-shaped connecting piece and a pushing cylinder; the first labeling mechanism comprises a label pressing cylinder, a feeding roll, a first guiding roll, a second guiding roll, a paper collecting roll and a paper collecting motor; and the transferring mechanism comprises a transferring arm, a transverse guide track, a lead screw assembly, a sliding table, a transferring rack, a first manipulator and a second manipulator. The automated loading and labeling device is compact in structure; automatic loading, side labeling and bottom labeling of packing boxes can be finished on the device; and the automated loading and labeling device is high in degree of automation and quite convenient to use.

Owner:嘉兴普艾仕自动化科技有限公司

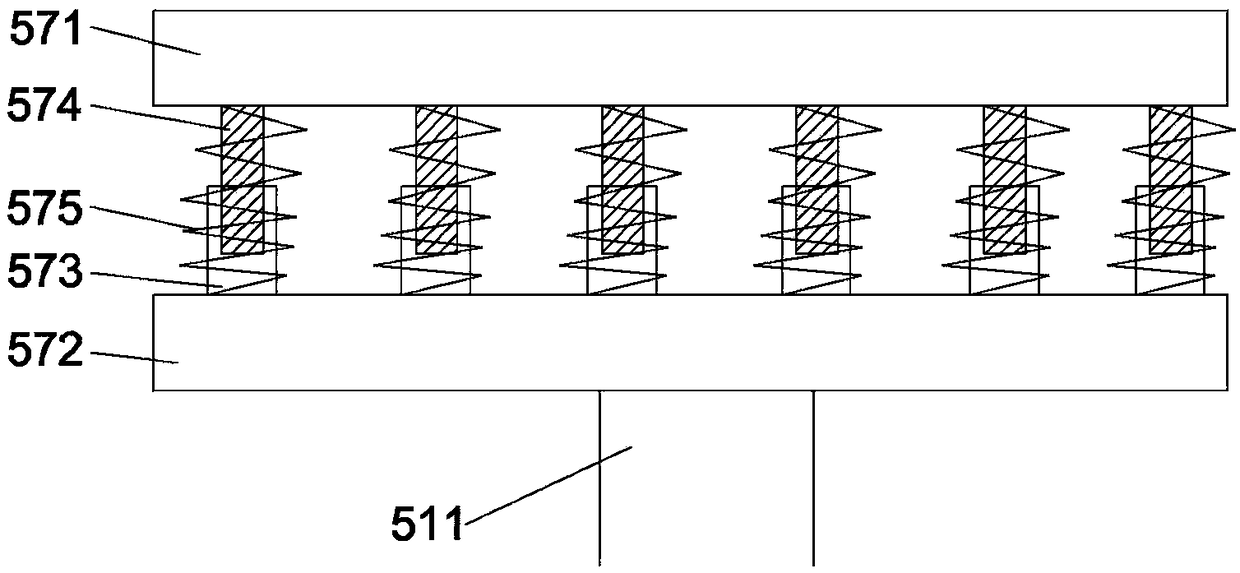

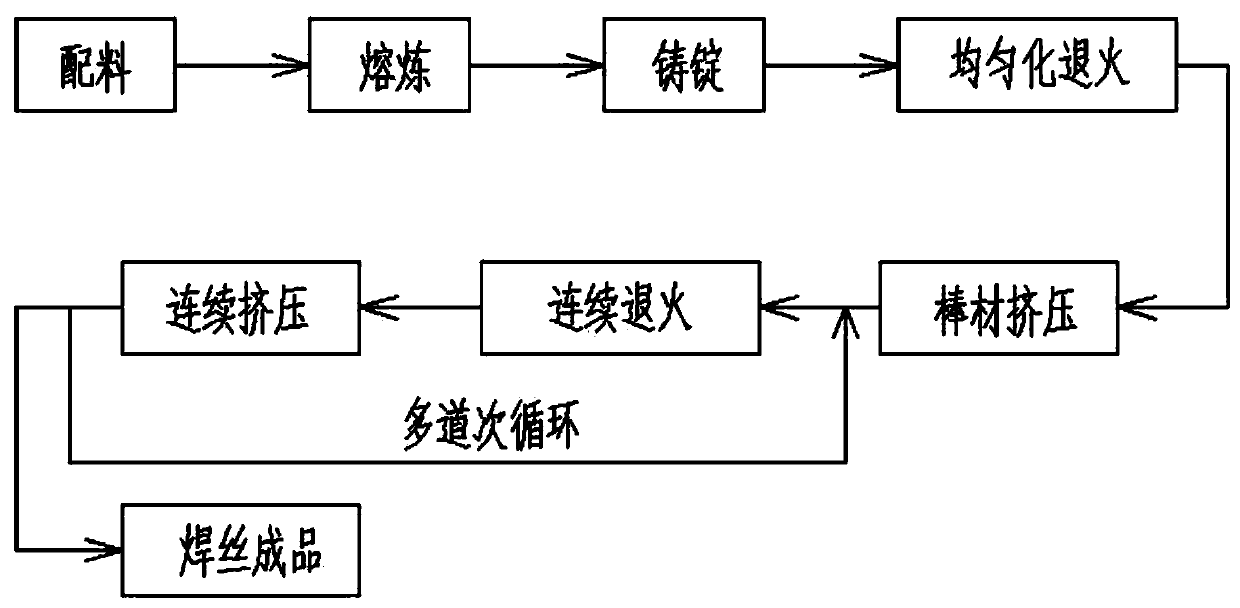

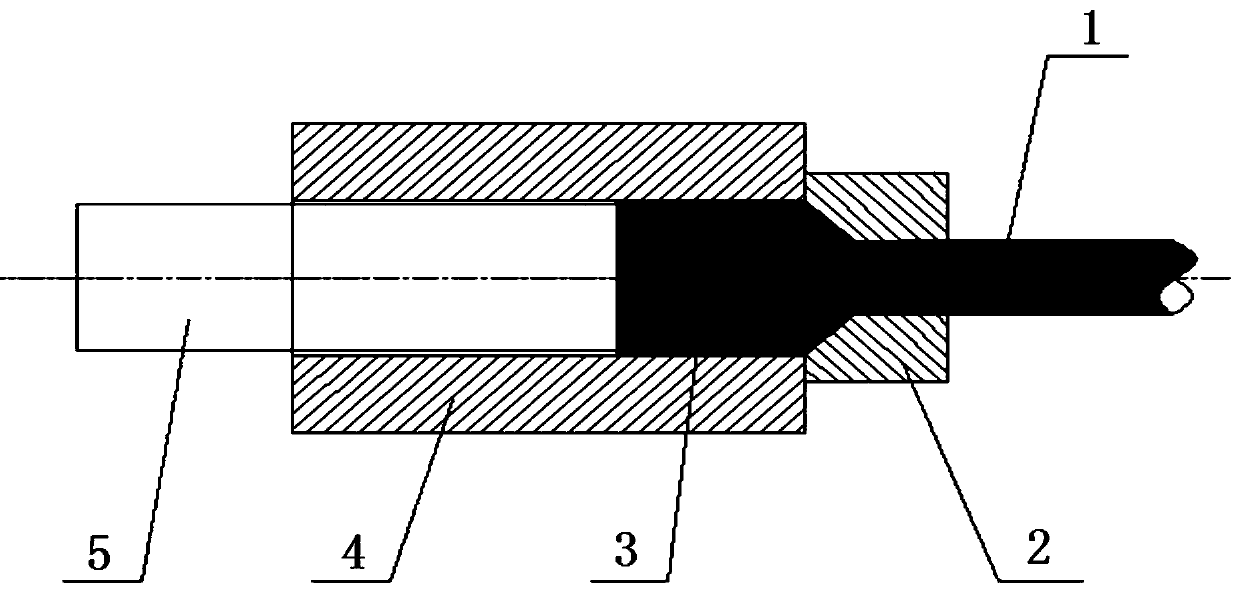

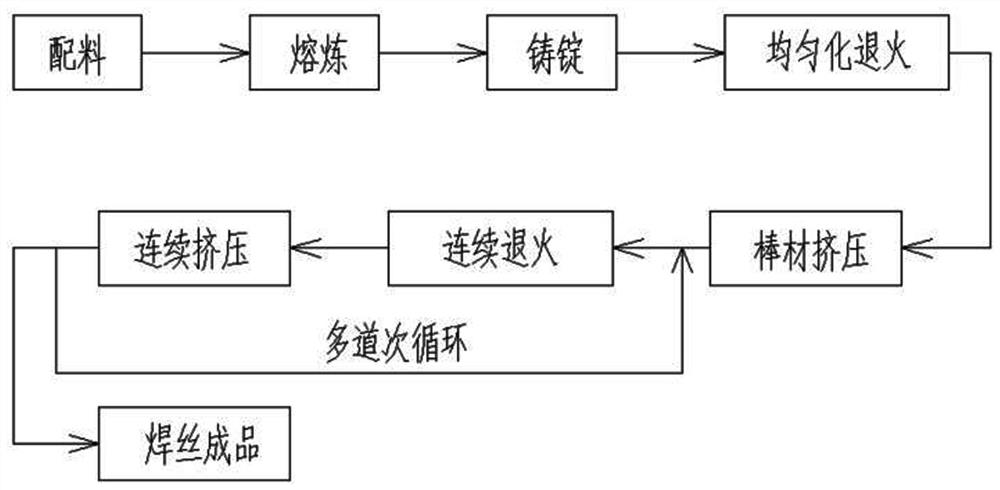

GH4169 alloy welding stick short process preparing method

ActiveCN108672980AExcellent high temperature strengthStrong corrosion resistanceWelding/cutting media/materialsSoldering mediaCorrosionChemical composition

The invention relates to a GH4169 alloy welding stick short process preparing method. Chemical compositions in the method comprise, by weight, 50.0%-55.0% of Ni, 17.0-21.0% of Cr, 5.00%-5.50% of Nb, 2.80%-3.30% of Mo, 0.75%-1.15% of Ti, 0.30%-0.70% of Al, 0.02%-0.06% of C and the balance Fe. Welding stick preparing technological processes mainly include the steps of matching, smelting, ingot casting, homogenizing annealing, bar extrusion, continuous annealing, multi-pass continuous extrusion and the other processes. A prepared alloy welding stick has the excellent high-temperature strength, oxidation resistance, creep resistance and resistance to corrosion and has the good fatigue property and weldability. In particular at the high temperature being 650 DEG C, the mechanical property of the alloy welding stick has the good stability, certain working pressure can be borne under 600 DEG C-1200 DEG C, and the alloy welding stick can be widely applied to welding pieces for blades, turbinediscs, turbine discs and long-service life aerospace engines.

Owner:LANZHOU WEITE WELDING MATERIAL FURANCE BURDEN

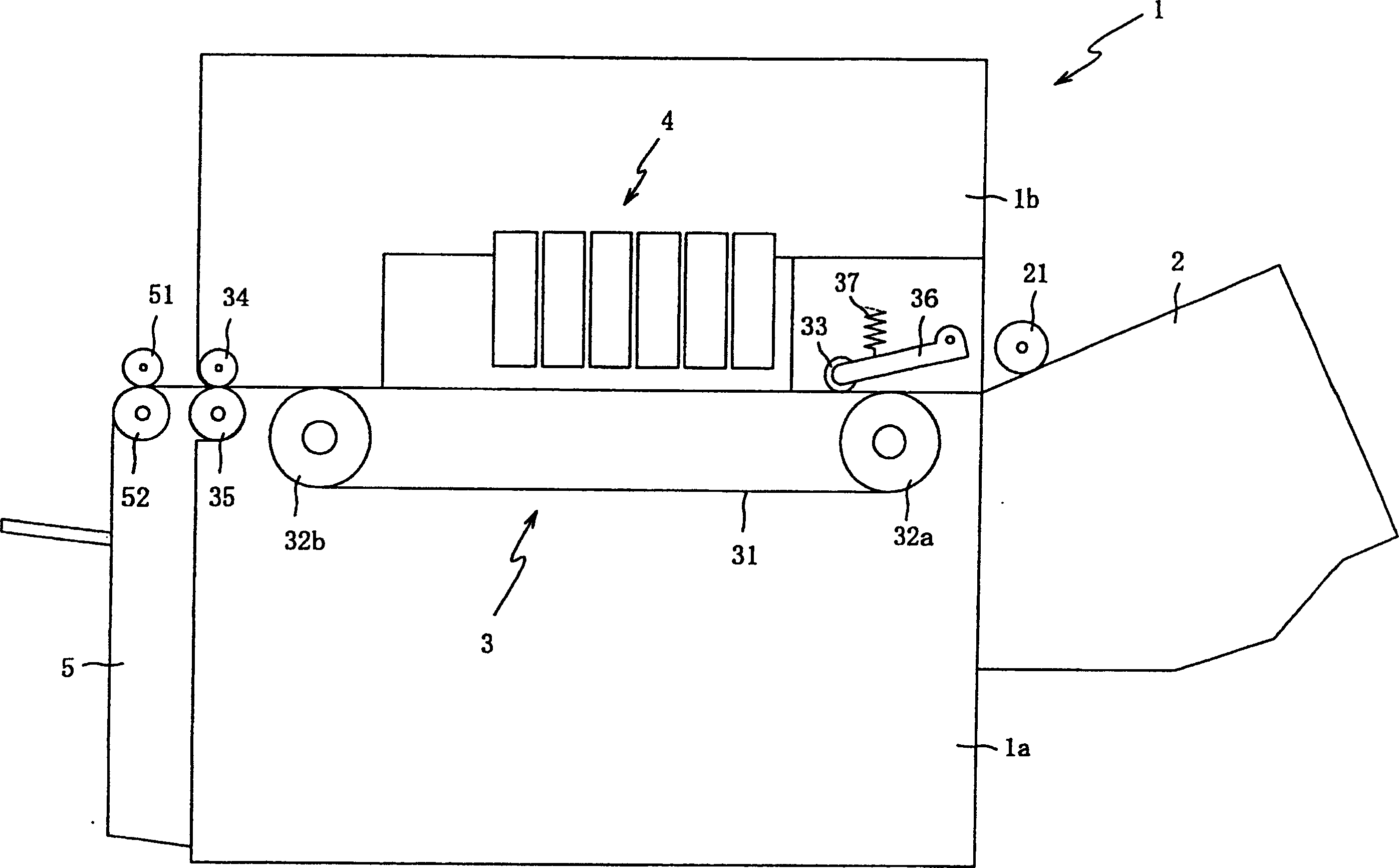

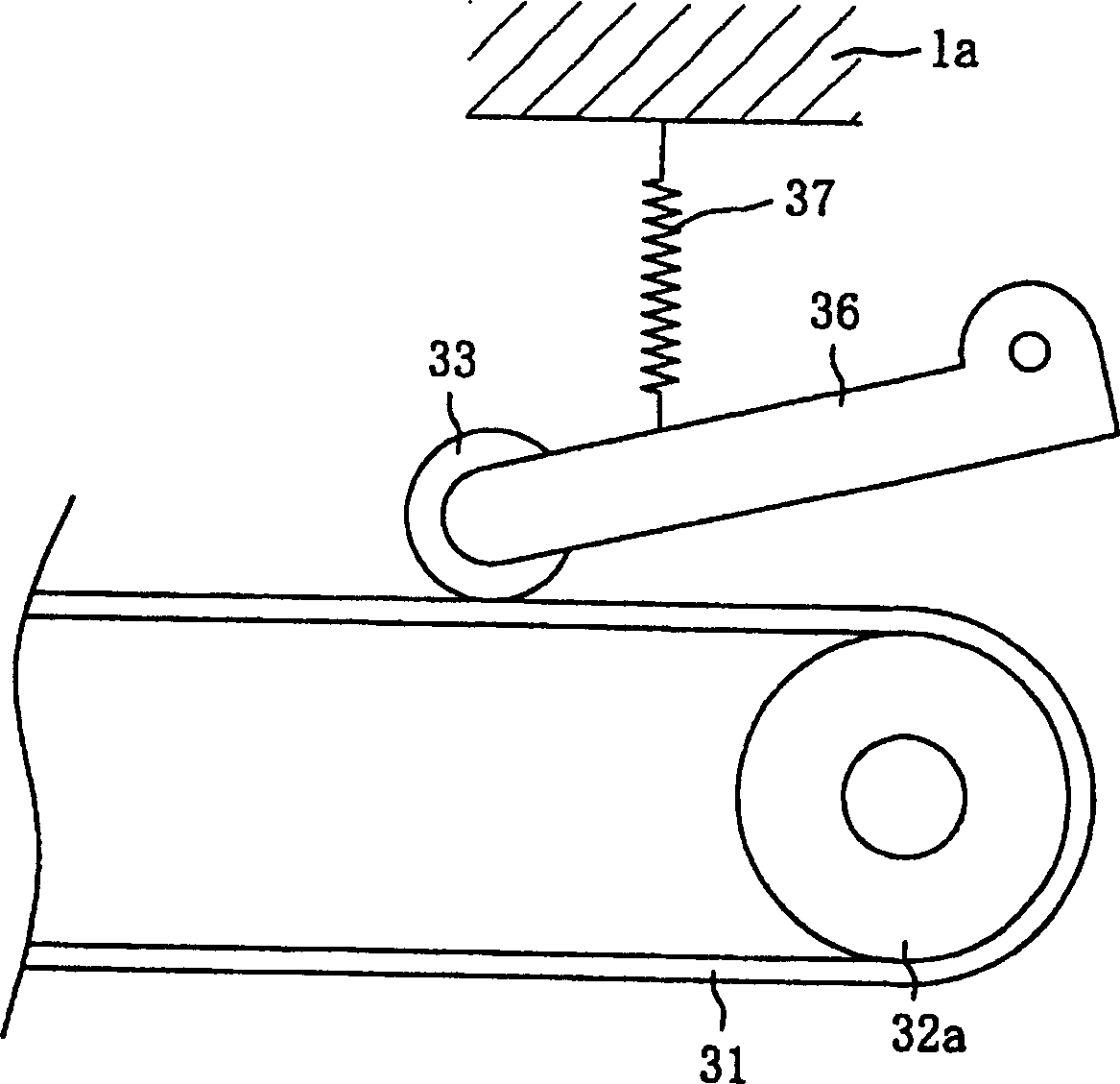

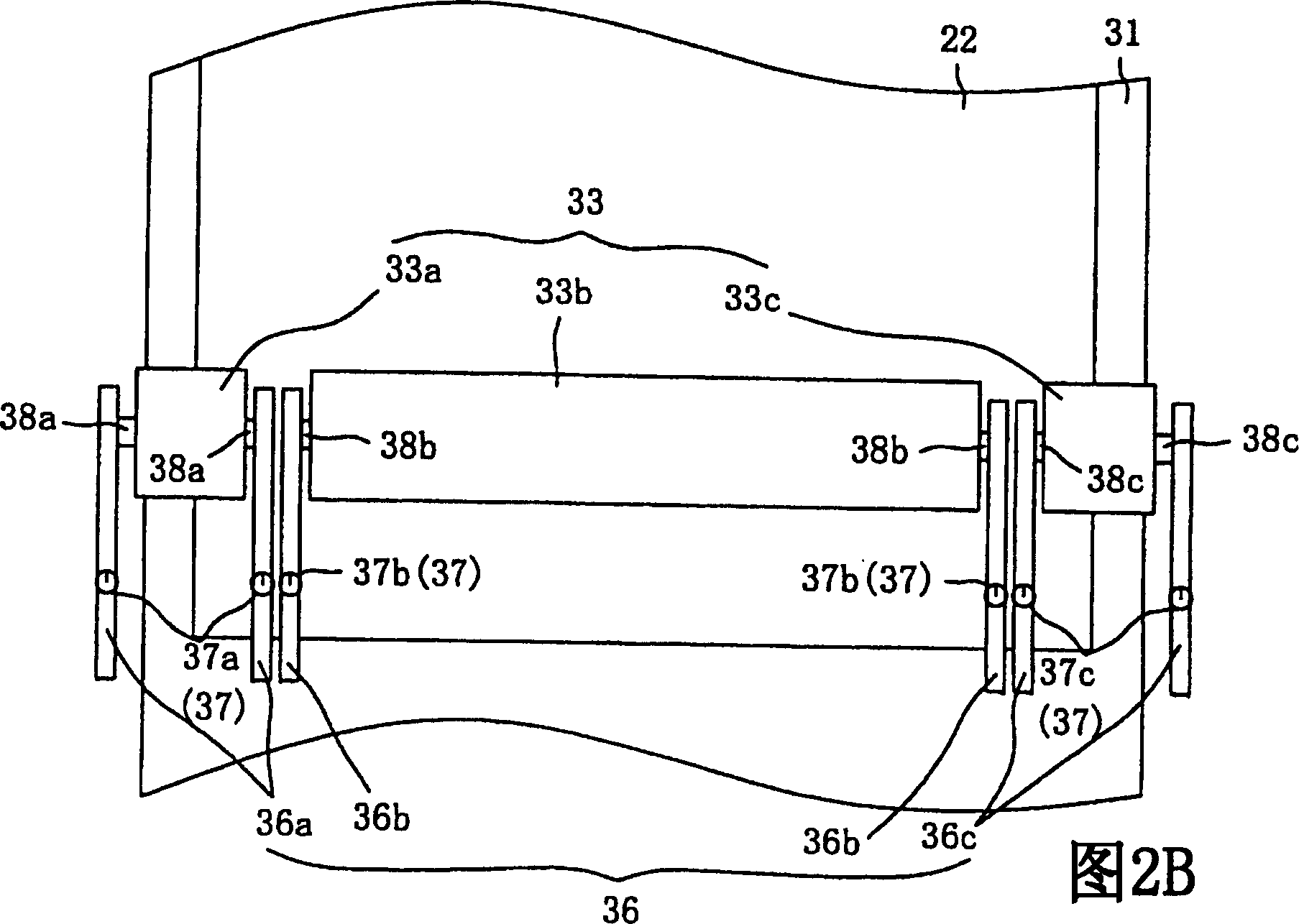

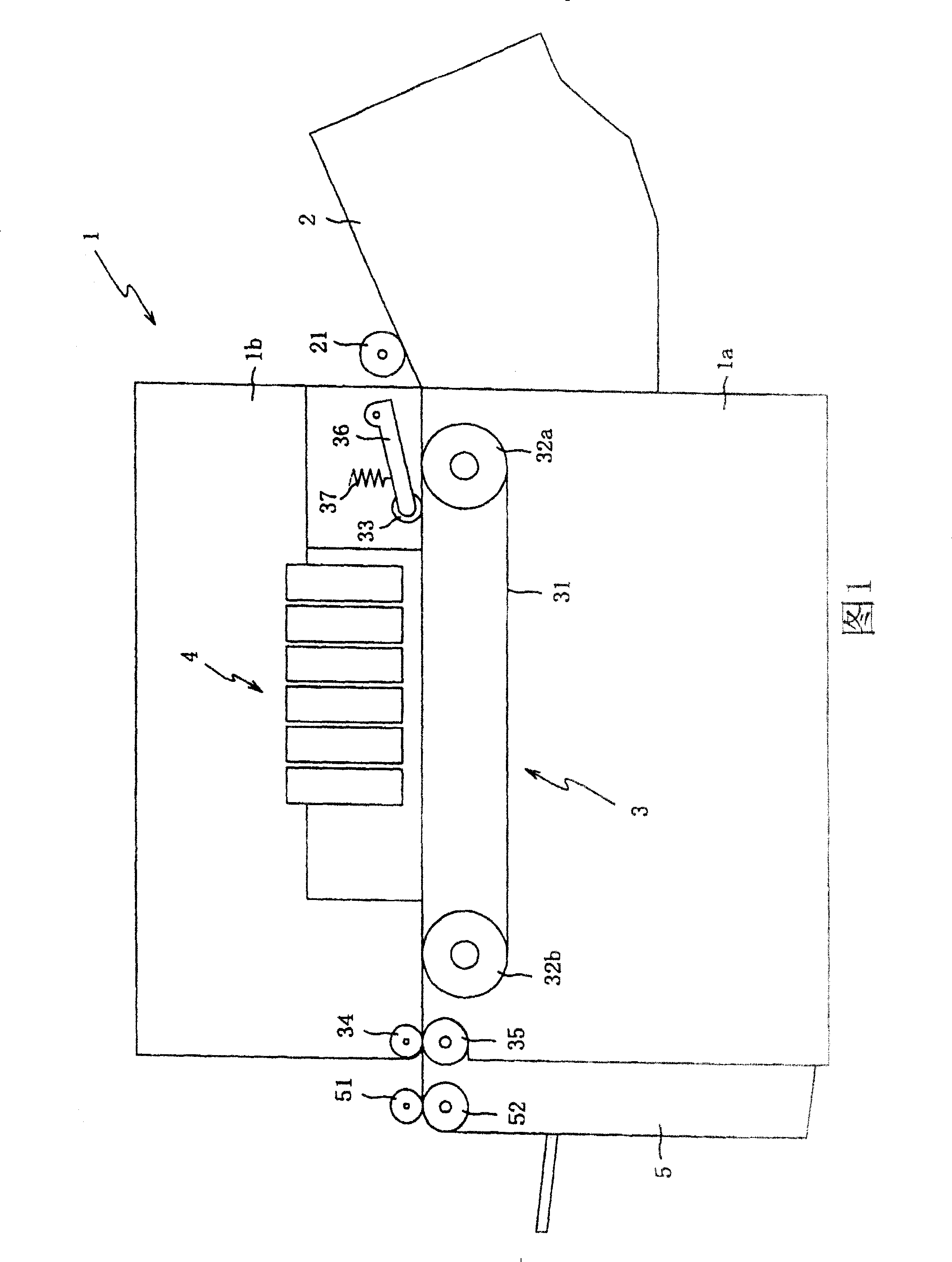

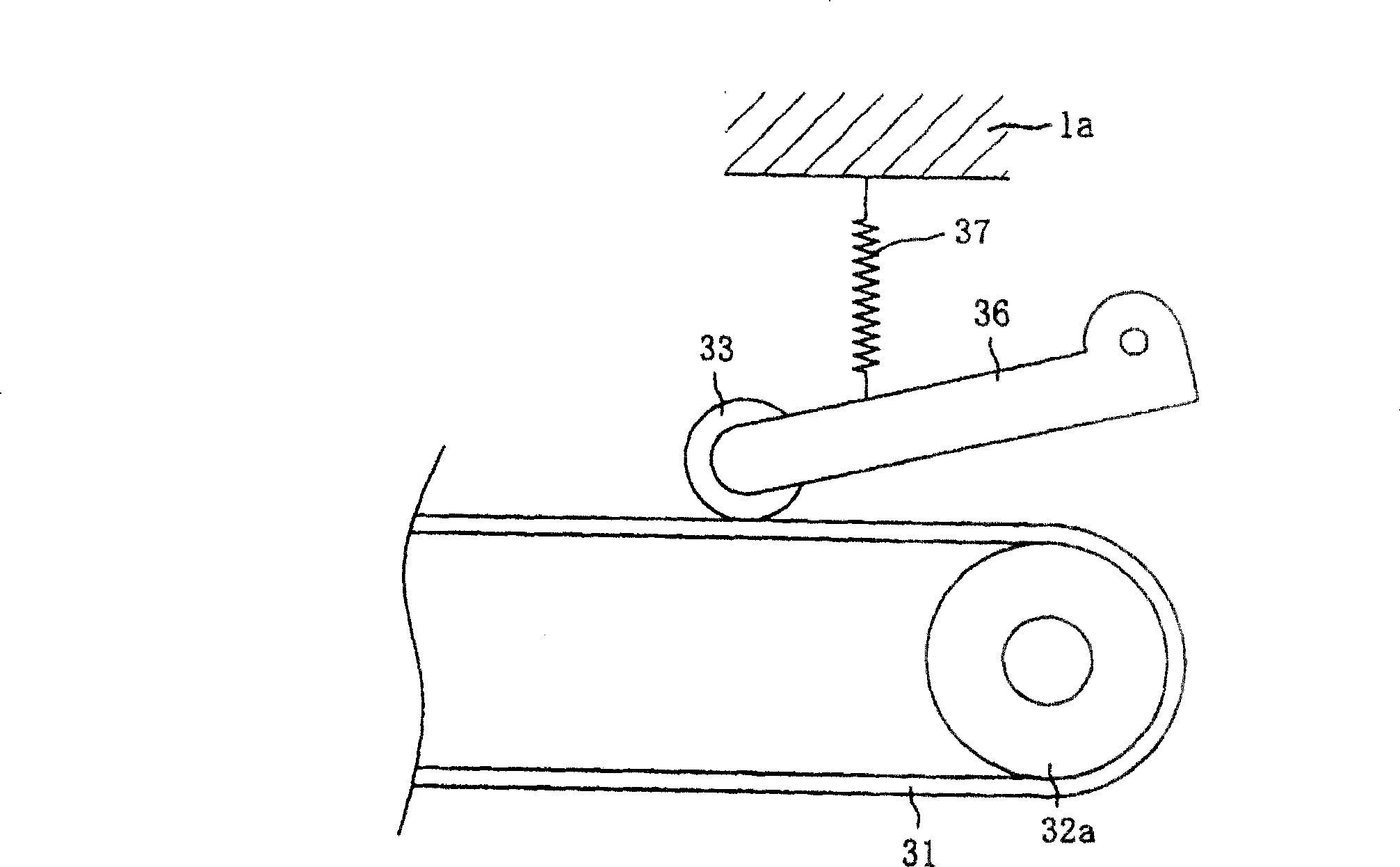

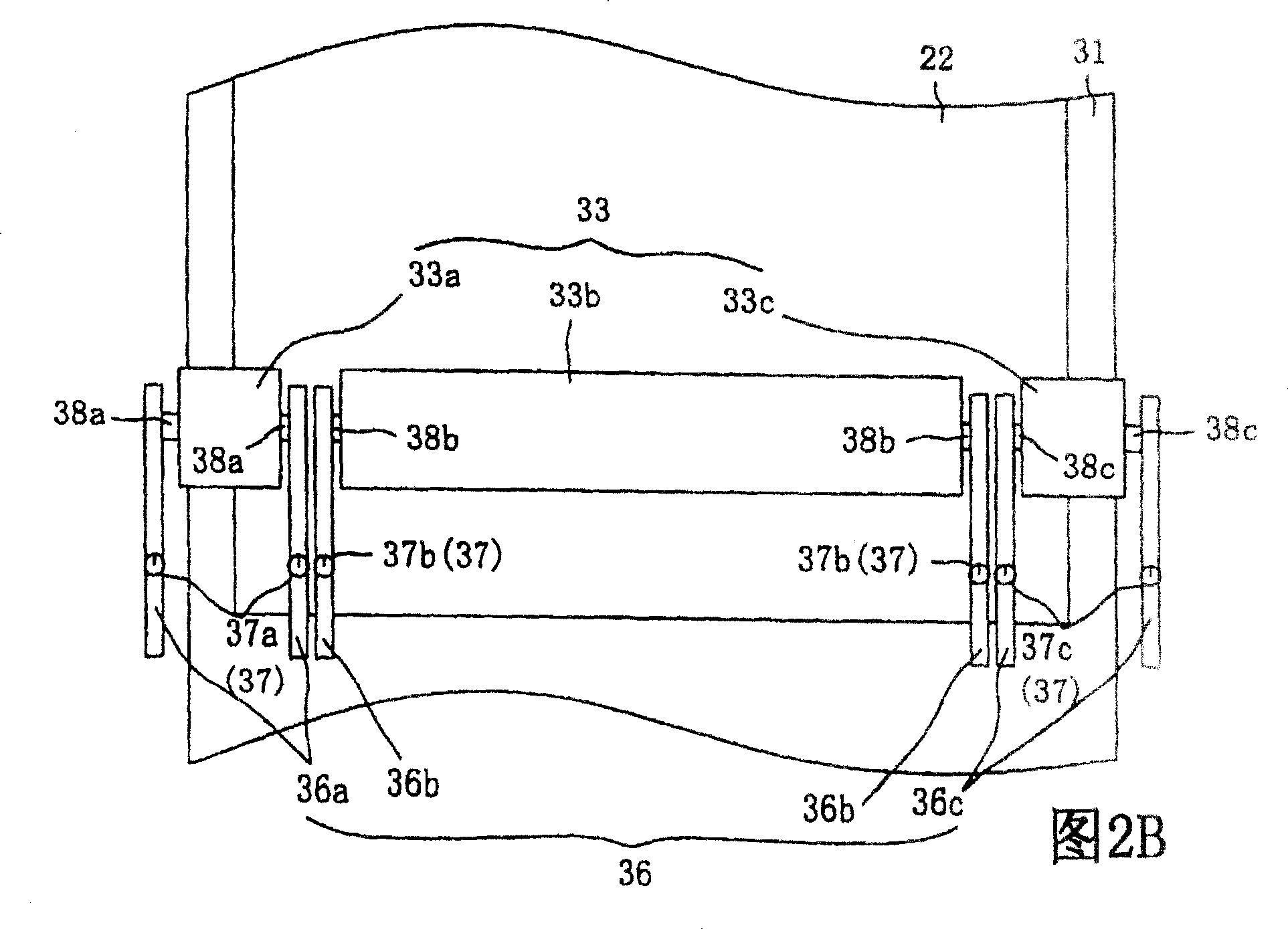

Image forming apparatus

InactiveCN1824516AAvoid distortionSuppression of changes in conveying speedOther printing apparatusArticle feedersImaging equipmentMechanical engineering

Owner:BROTHER KOGYO KK

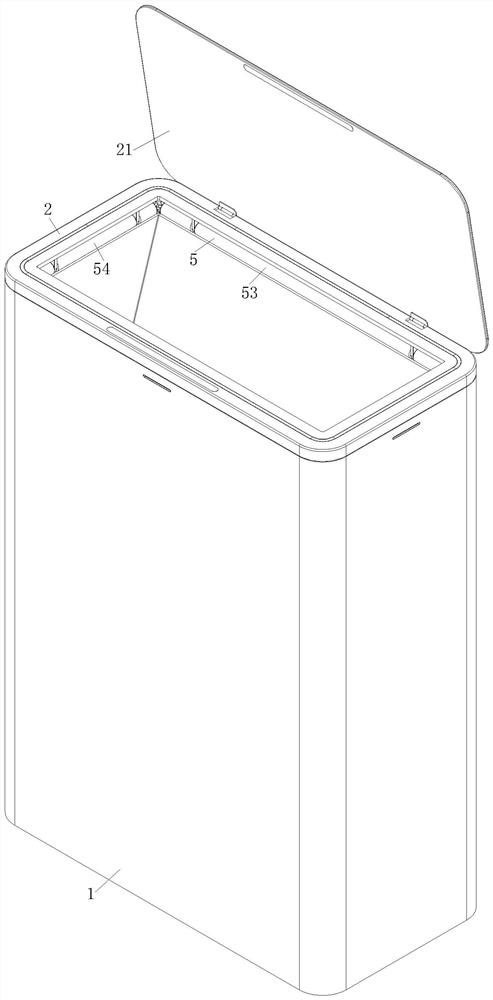

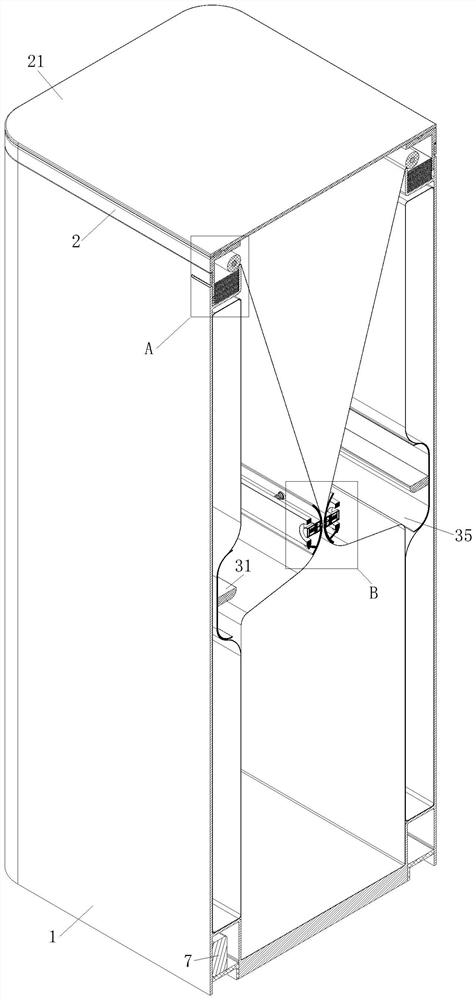

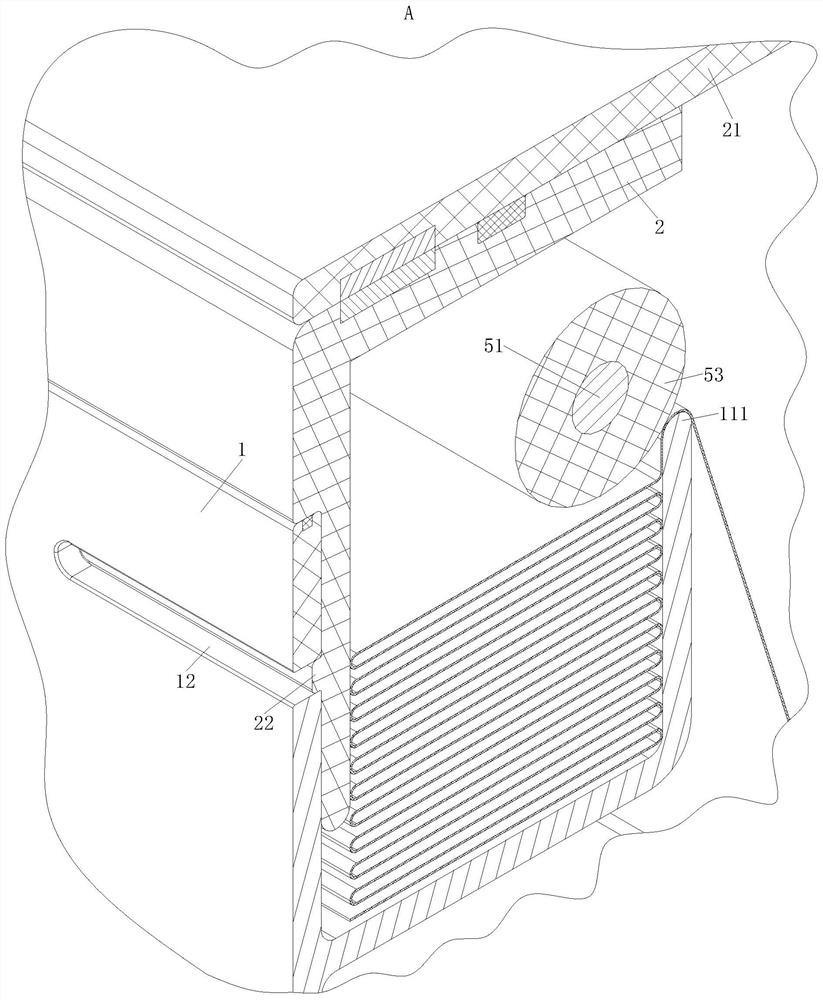

Intelligent garbage can for medical treatment and public health

ActiveCN114313691APrevent proliferationQuality improvementRefuse receptaclesPackaging by pressurising/gasifyingHazardous substancePublic health

The invention belongs to the technical field of garbage cans, and particularly relates to an intelligent garbage can for medical treatment and public health, which comprises a can body, a cover body, a lifting component, an extrusion component, a contraction component and a welding component, according to the garbage bag welding device, a controller enables a contraction part to work, then a garbage bag body in a can body becomes loose, meanwhile, the controller drives a first screw to rotate synchronously, then an extrusion part and a welding part are driven to move through a lifting plate, and meanwhile the controller drives a second screw to rotate through a second motor; the extrusion plates and the welding part are driven to move towards the middle of the can body, then the extrusion plates move to the position above the garbage and extrude the bag body, then the welding part welds the garbage bag body between the extrusion plates, and then the part of medical garbage is stored in a sealed mode. Harmful substances such as viruses and bacteria and peculiar smell are prevented from diffusing into the air when the medical waste is thrown, the air quality is improved, and the health guarantee of medical staff, patients and family members is improved.

Owner:广东创点智能科技有限公司

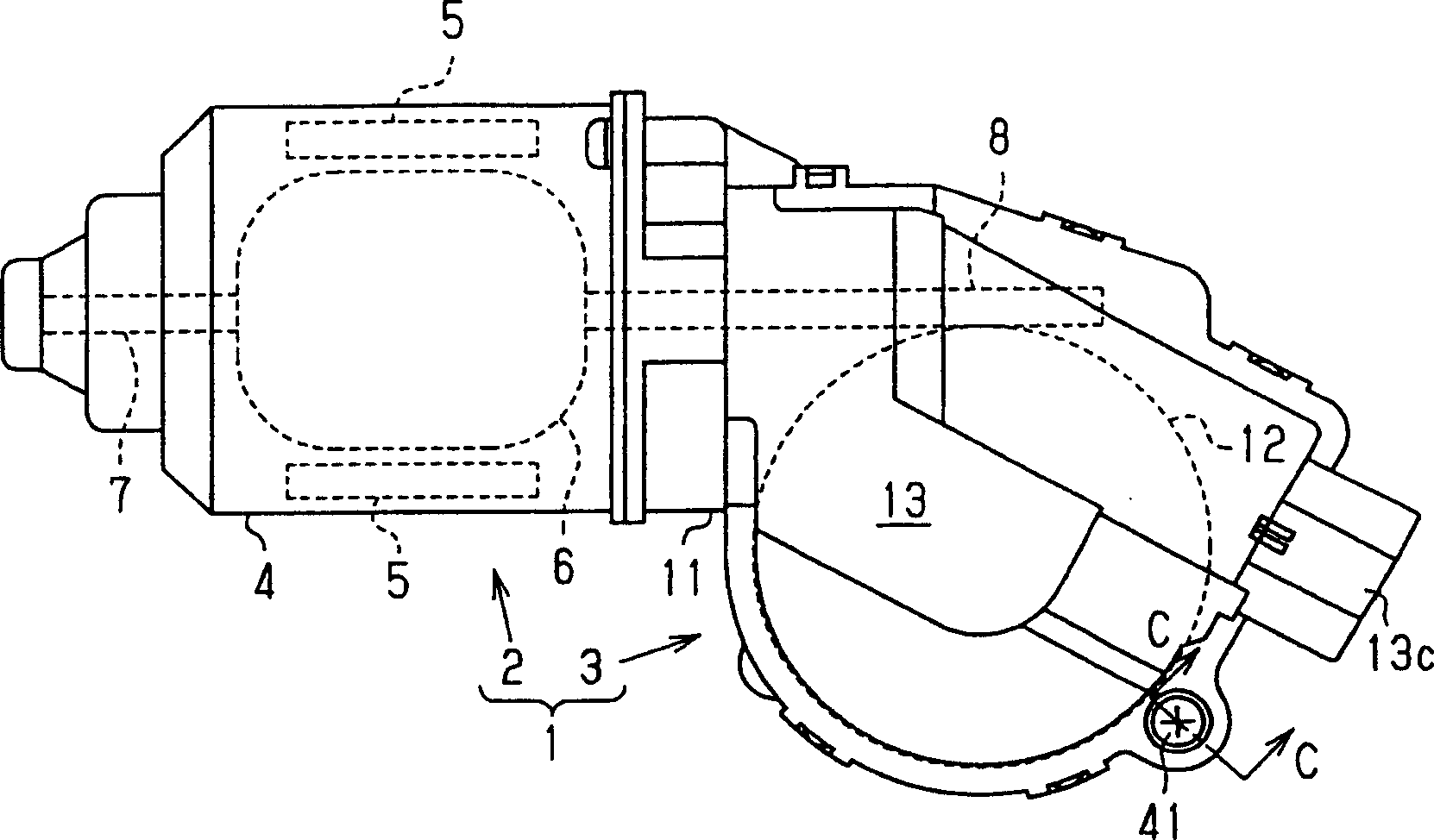

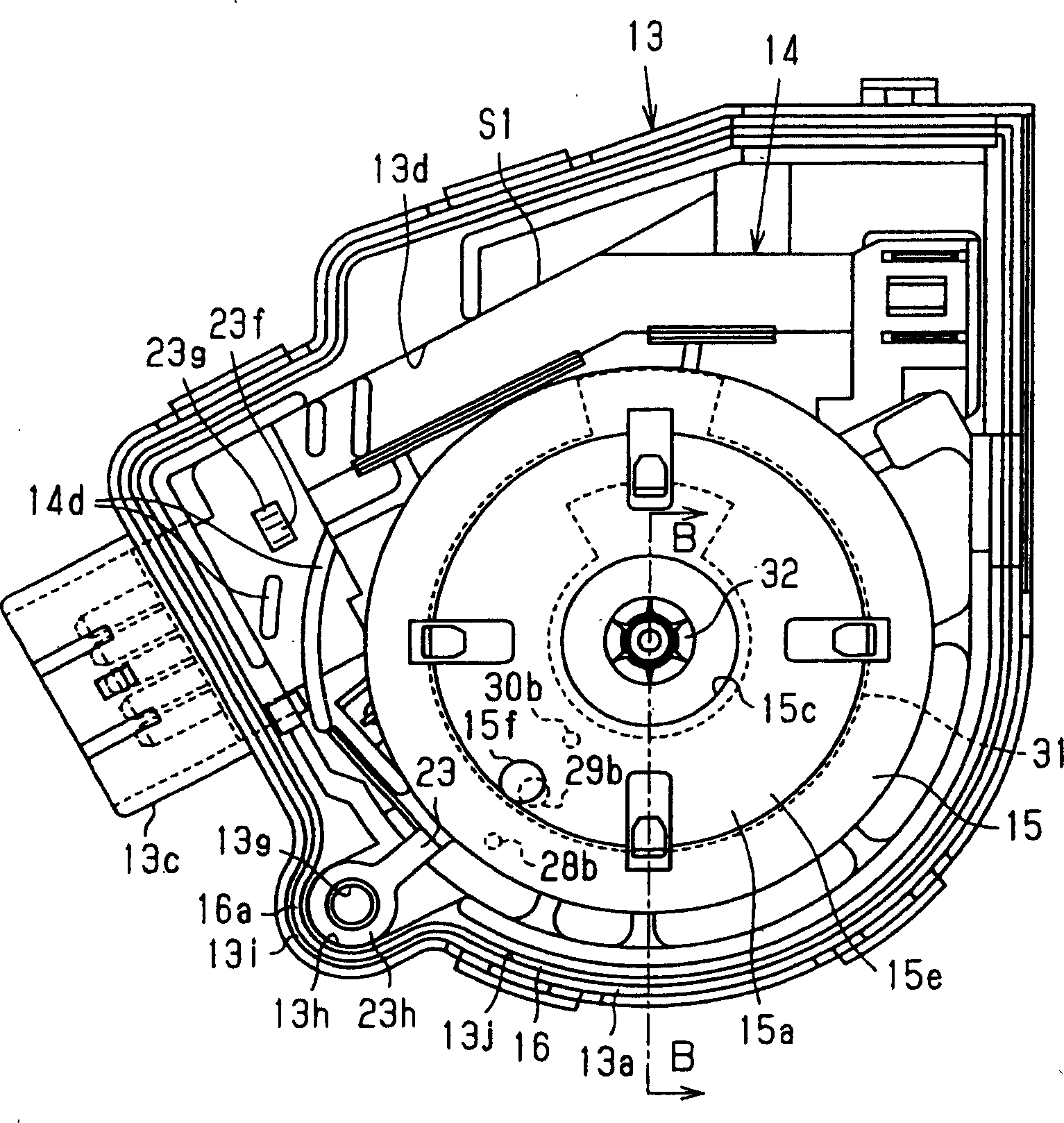

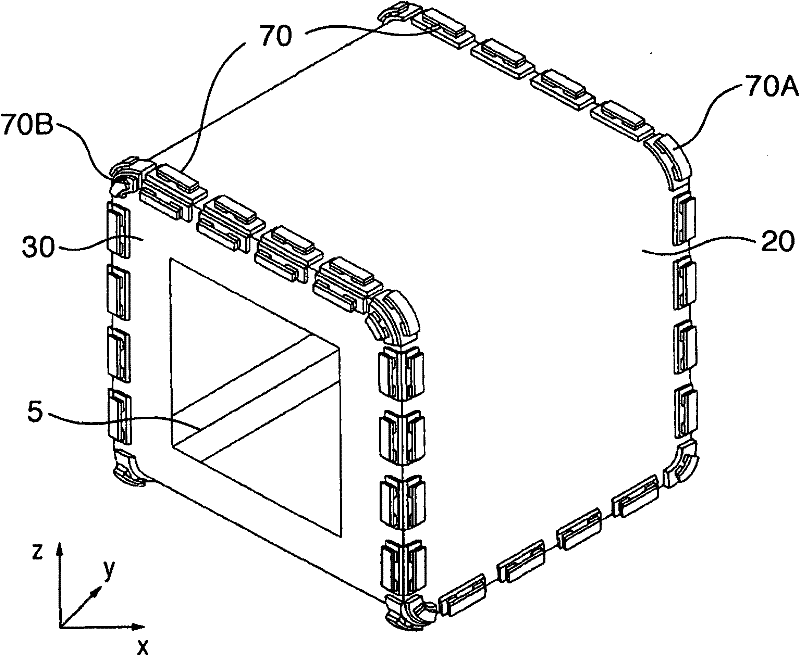

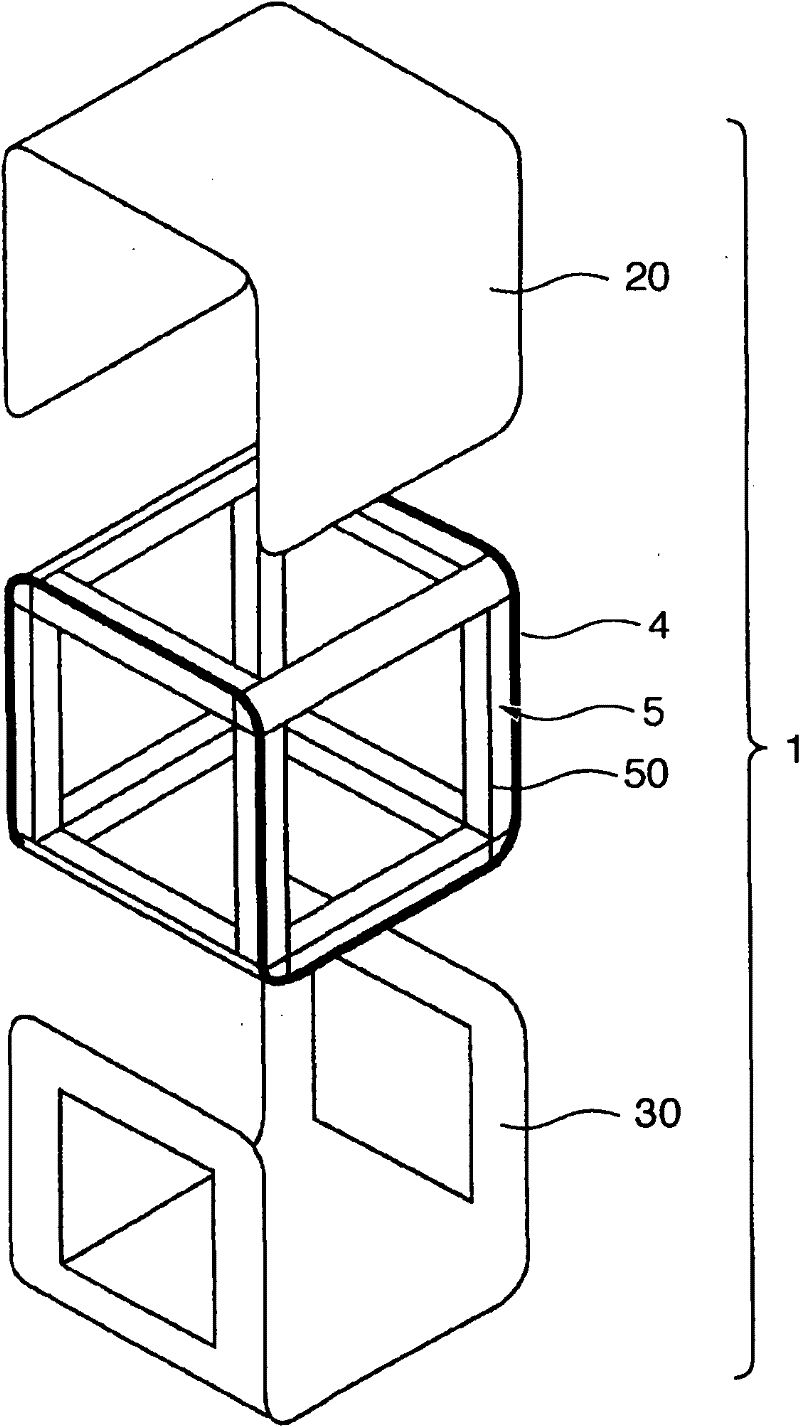

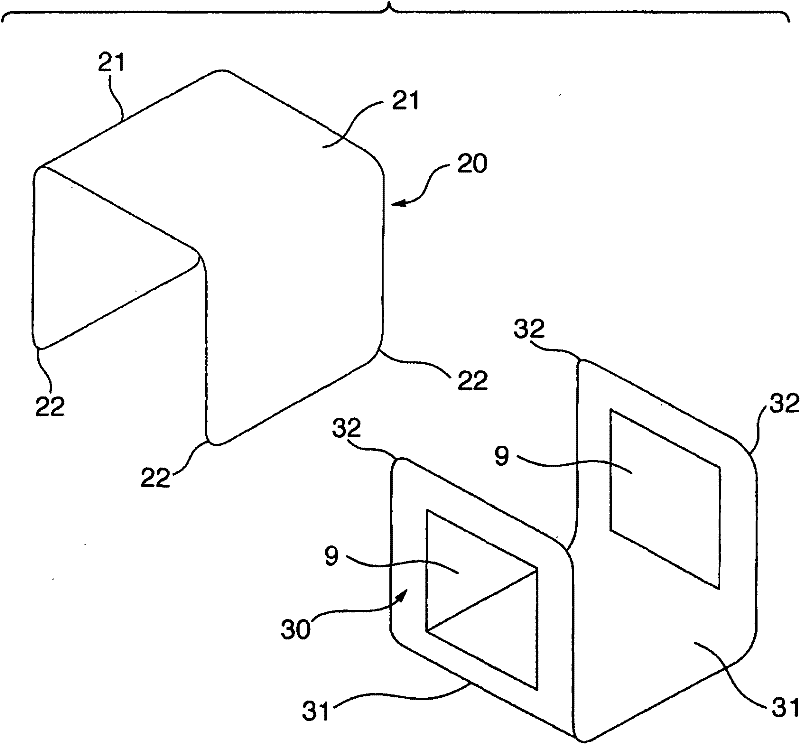

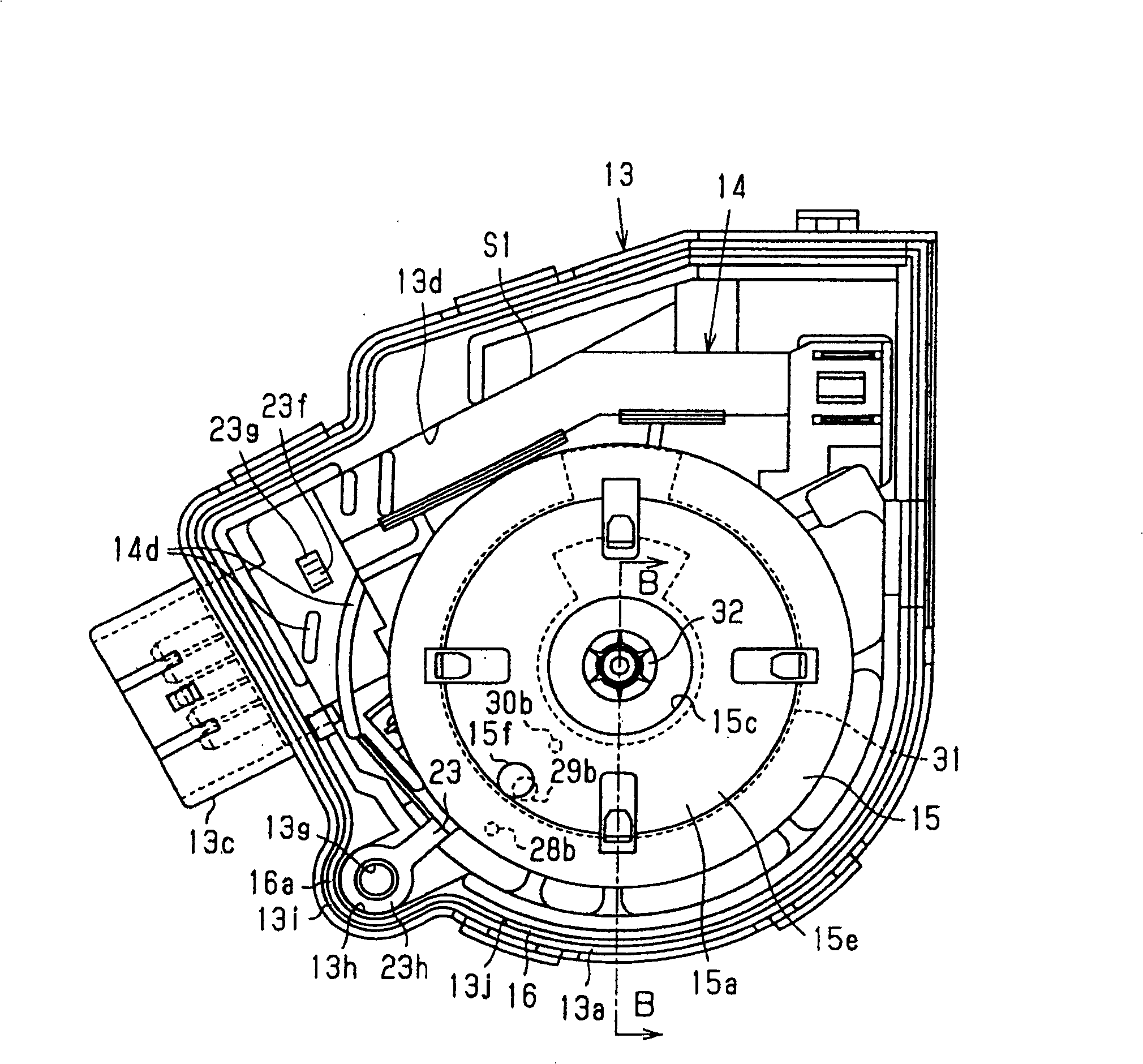

Casing structure and motor

ActiveCN100536283CImprove waterproof performanceGuaranteed reliabilitySupports/enclosures/casingsElectrical connectionEngineering

A casing structure in which the side edge of the box body and the side edge (13a) of the cover (13) of the box are aligned, and are fixed by connecting holes (13g) inserted through them and bolts inserted into the holes , house electrical components including the first fixed contact terminal (23) inside them, and at the same time, configure the common connection portion (23h) of the first fixed contact terminal (23) in a manner surrounding the bolt, and use the box side edge It is clamped with the side edge part (13a) of the cover body. A box body side detour part (13i) bypassing the outside of the connection hole (13g) is formed on the cover body side edge part (13a) at the side edge part of the box body. The seal member (16) between the box-side edge portion and the lid-side edge portion (13a) has a seal-side detour (16a) passing through the box-side detour (13i) and the lid-side detour (13i). Therefore, waterproofness can be improved while ensuring the reliability of the electrical connection of the ground terminal.

Owner:DENSO CORP

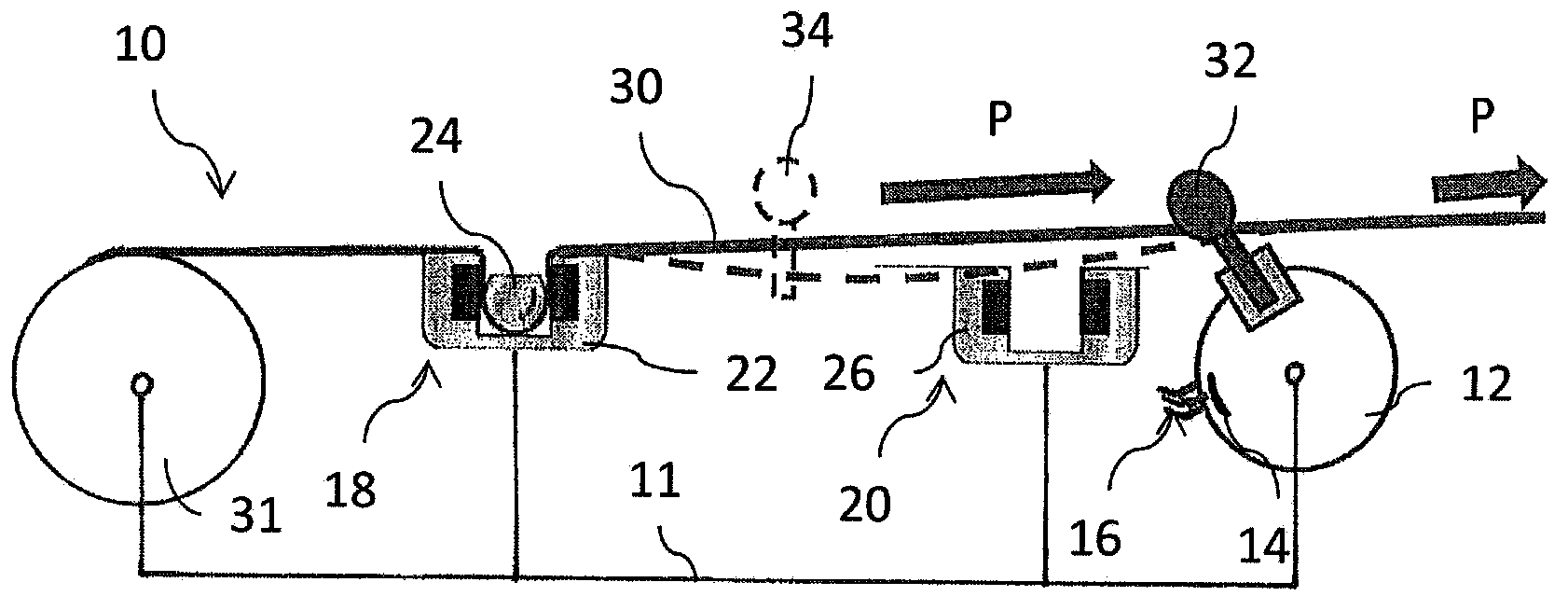

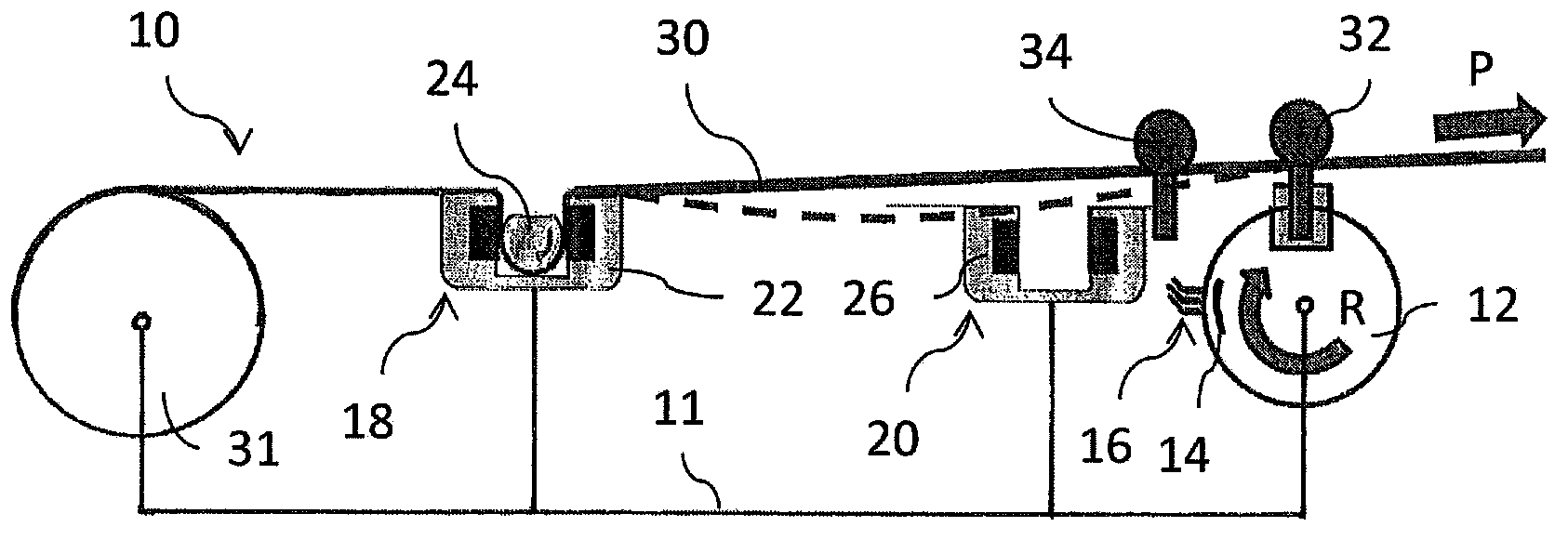

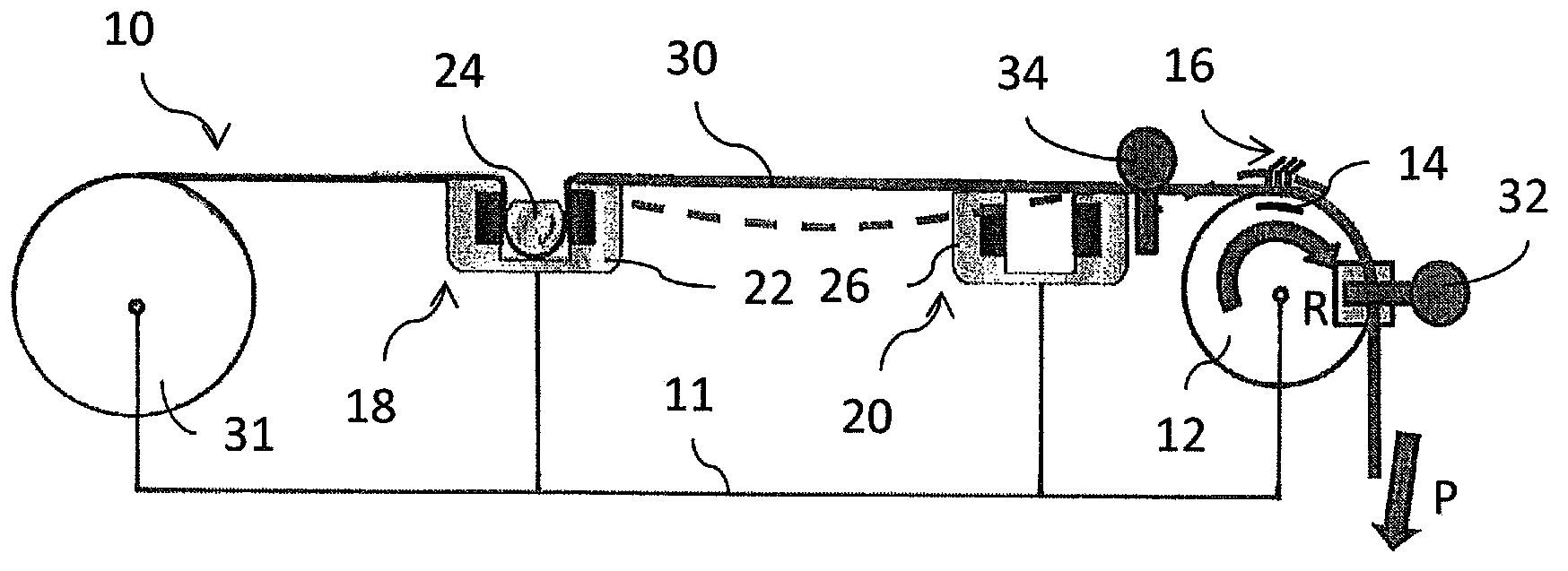

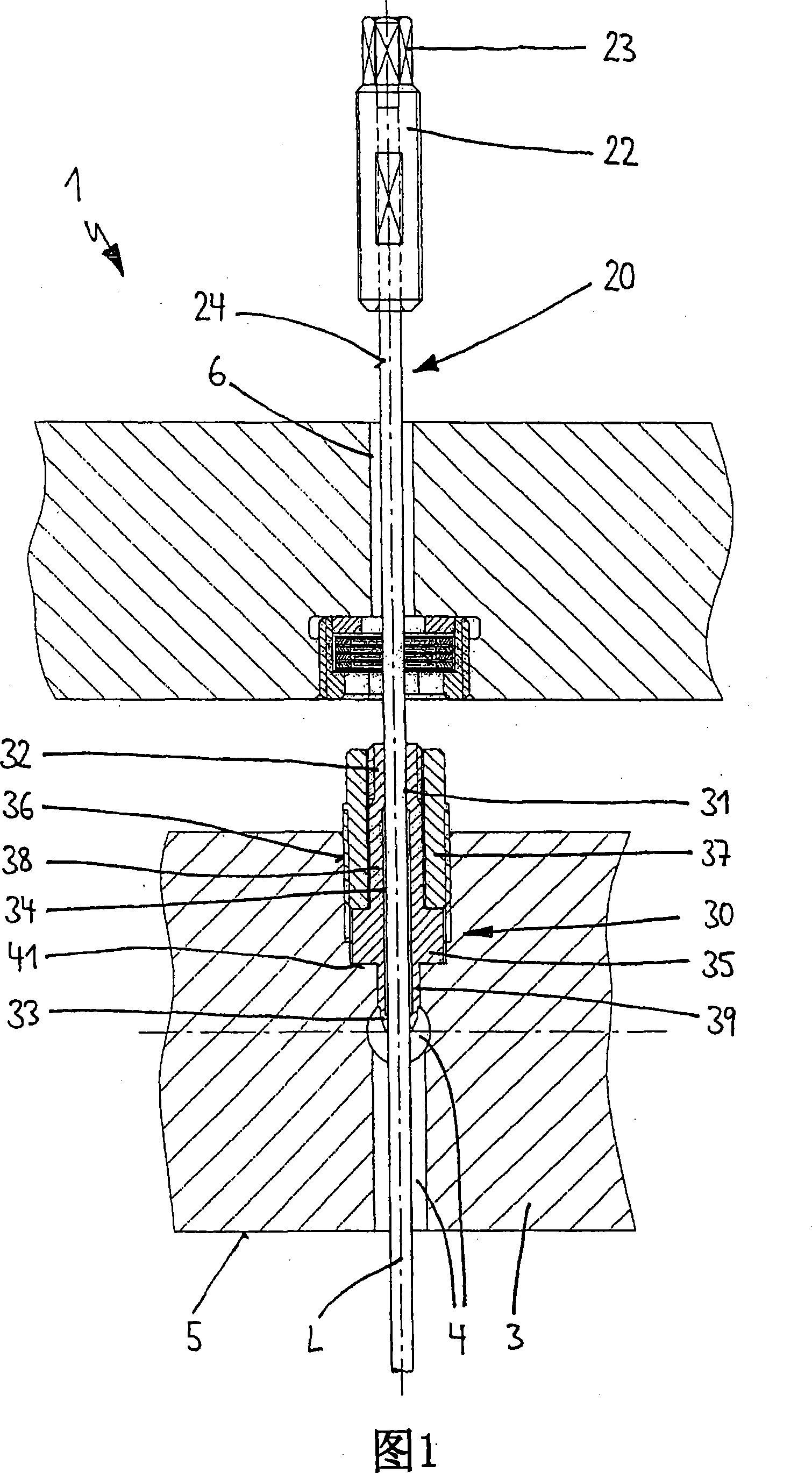

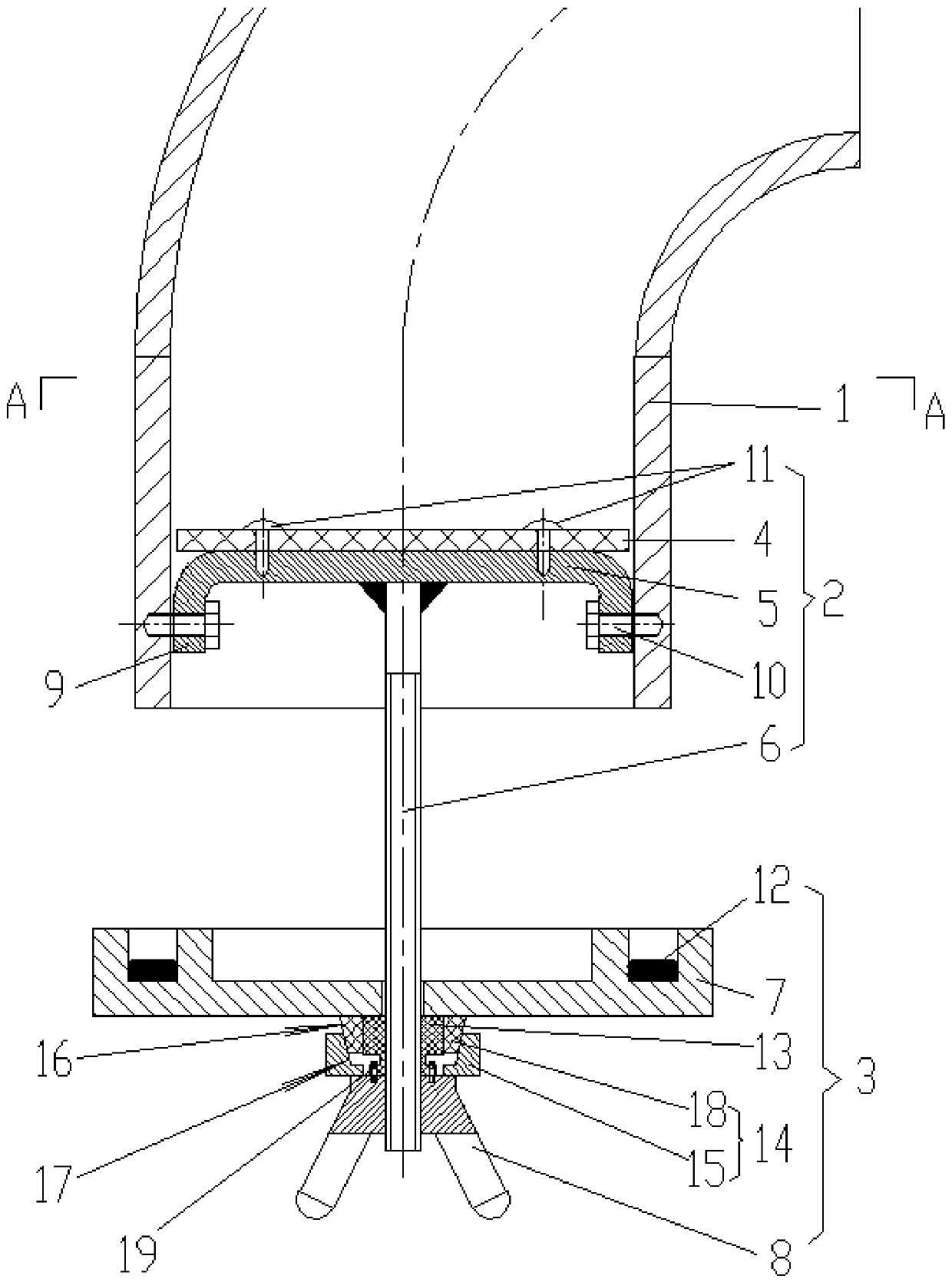

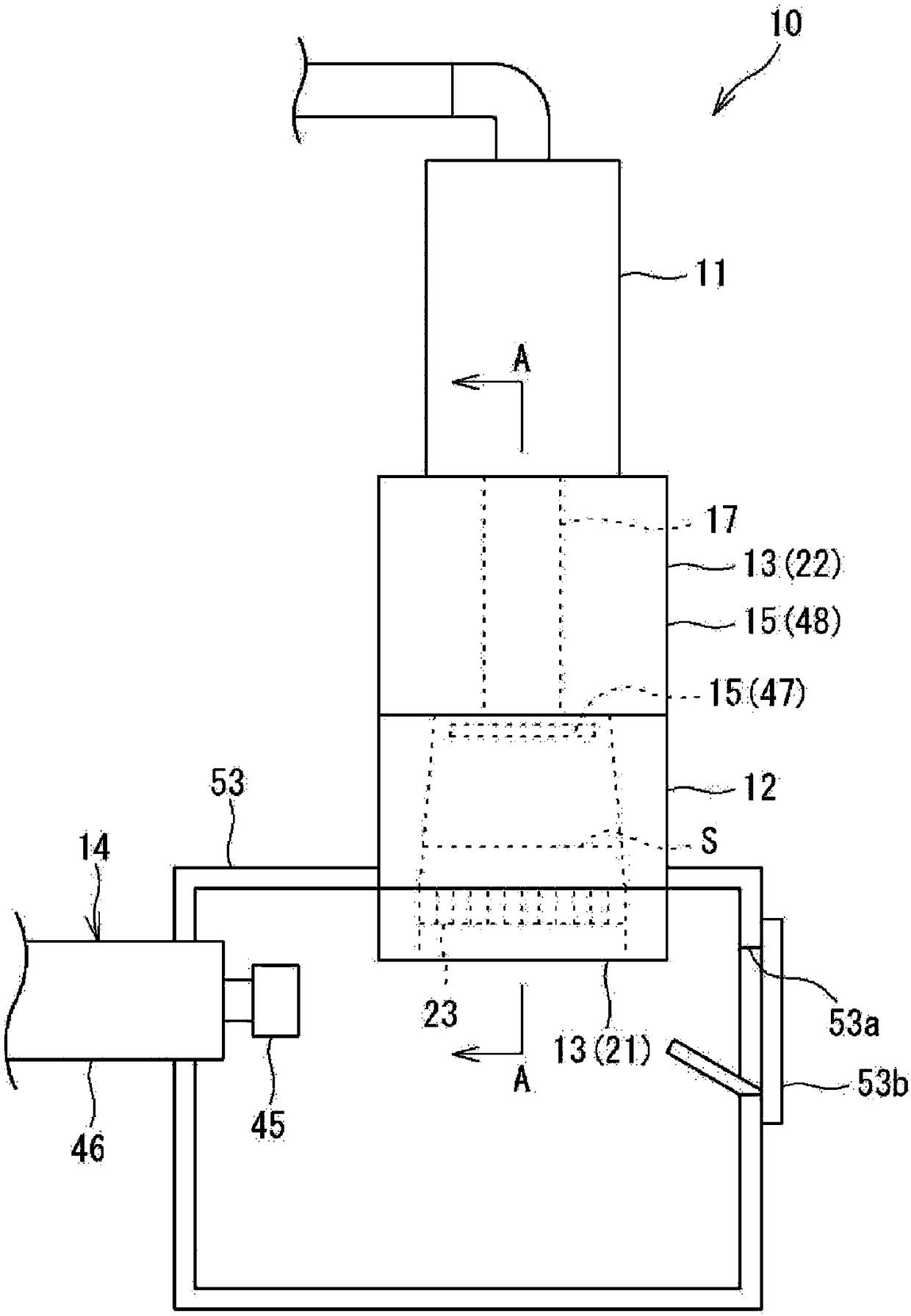

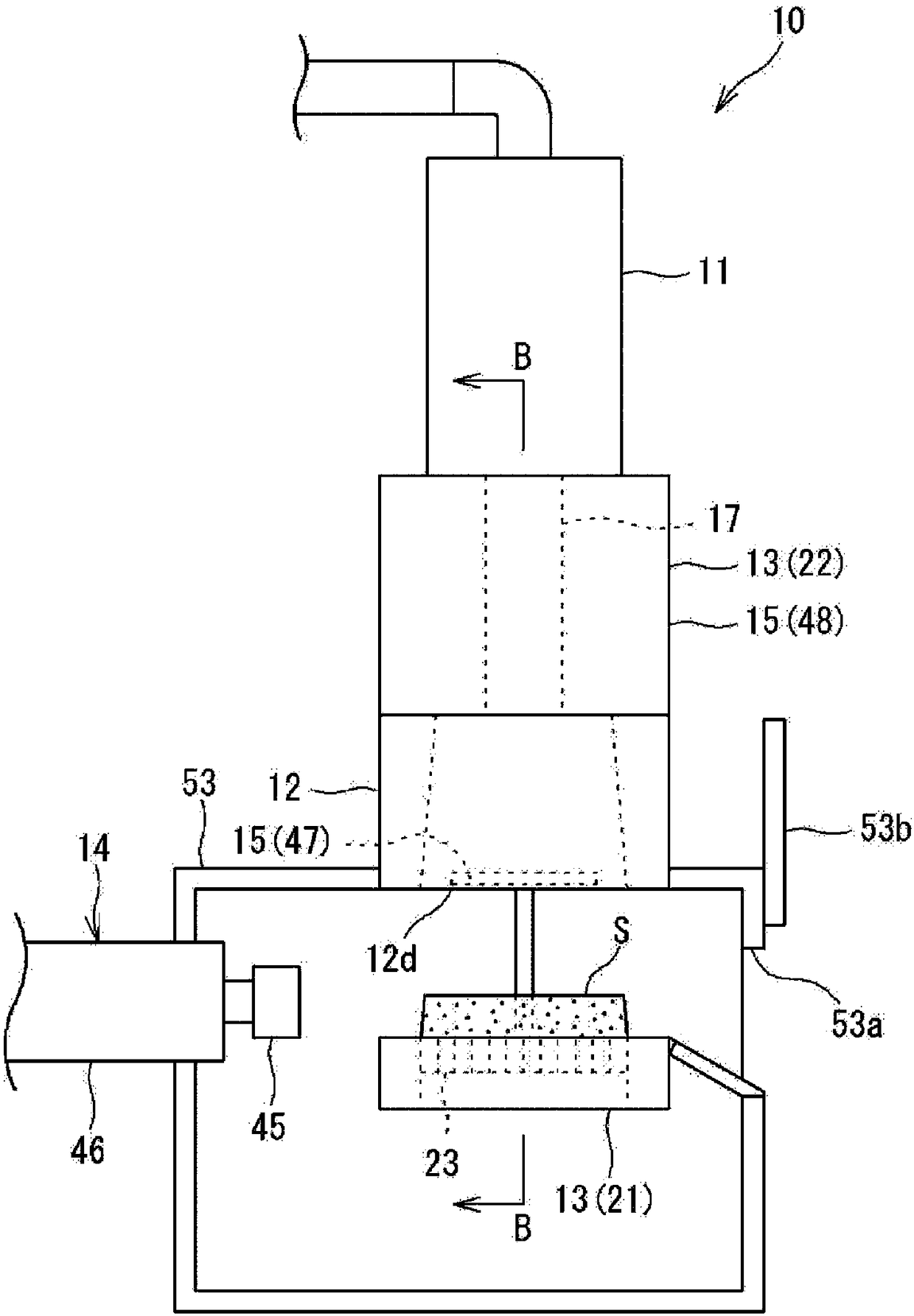

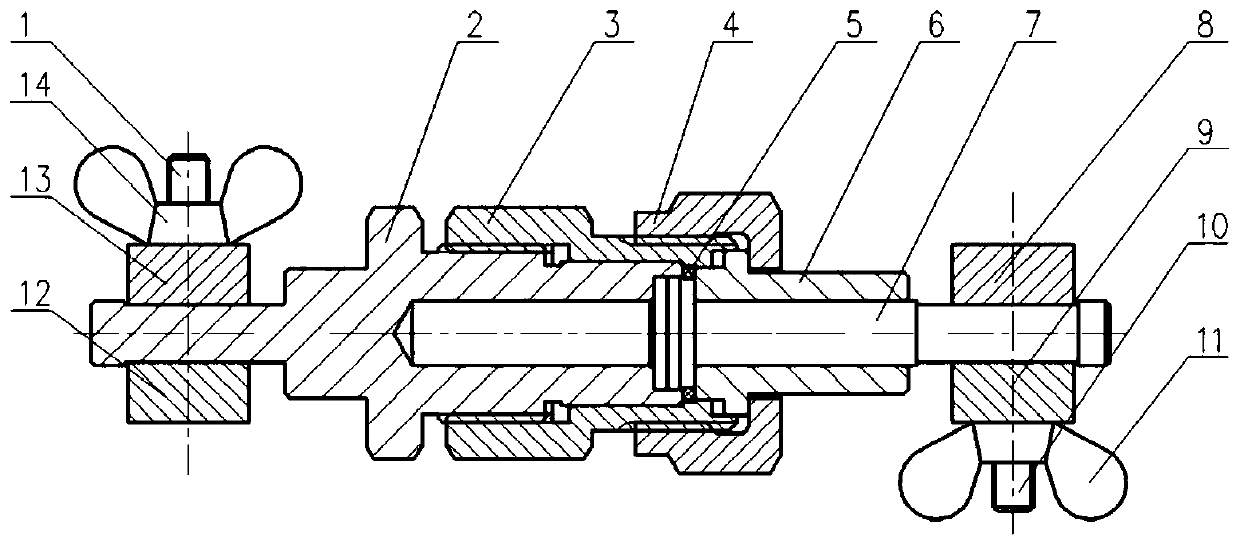

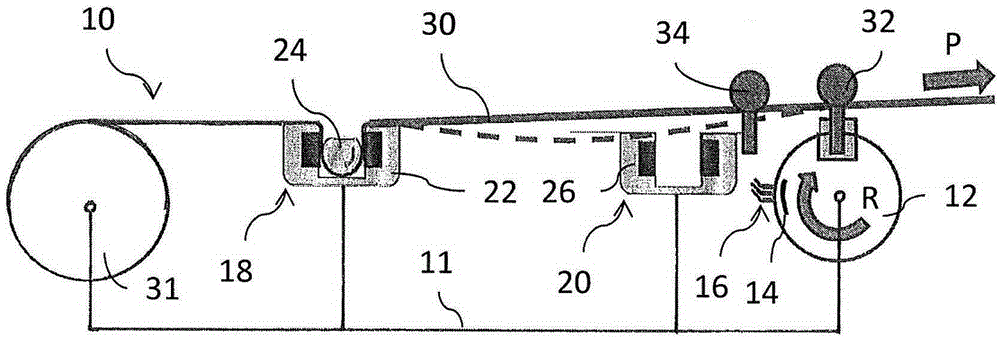

Sludge dehydration and solidification device

ActiveCN107207304BImport smoothlyReliable ExtrusionSludge treatment by de-watering/drying/thickeningSludge processingSludgeSolid-state

The invention provides a sludge dehydration and solidification device, which can reliably take out solidified sludge from a processing container. The deliquification and solidification device (10) of sludge comprises: a processing container (12), which is introduced into the liquid containing sludge, and has a discharge port (12d) at the lower end; a cover body (21), which closes the discharge port (12d), It also has a filter element (23) that allows the liquid introduced into the processing container (12) to pass through and accumulate sludge; an opening and closing drive unit (22) that moves the cover (21) to open and close the discharge port (12d); liquid removal And solidification mechanism (16), the sludge on the filter element (23) is deliquored and solidified; ) to extrude.

Owner:NISSIN MFG CO LTD

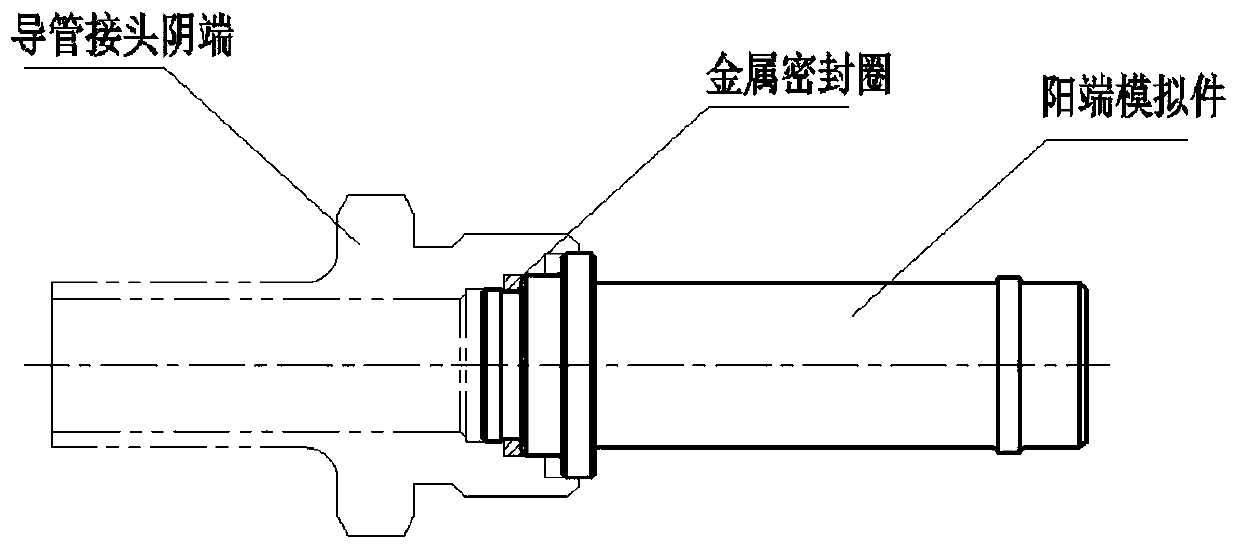

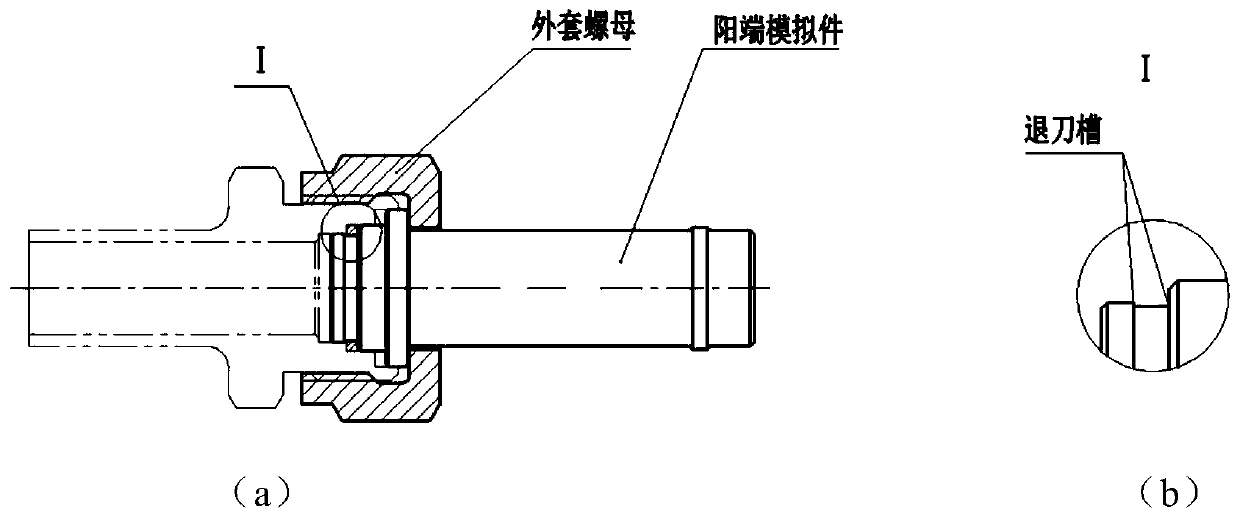

A device and method for quickly removing metal sealing rings of small catheters

ActiveCN107855986BIncrease productivityReduce quality riskMetal-working hand toolsEngineeringGuide tube

The invention relates to a device and method for rapidly taking out a metal sealing ring from a small duct. The device comprises a convex step combination and a concave step combination. The convex step combination consists of a tool coat nut, an ejector shaft, a pull shaft and a pull plate combination, and the concave step combination consists of an ejector sleeve, a pull sleeve and a pull platecombination. Each pull plate combination comprises an upper pressing block, a lower pressing block, a butterfly nut and a stud. When the metal sealing ring is inlaid in a female end of a joint of thesmall duct, the convex step combination is used for taking out the metal sealing ring in the joint of the duct; and when the metal sealing ring is inlaid in a male end of the joint of the small duct,the concave step combination is used for taking out the metal sealing ring in the joint of the duct. By the device, the metal sealing ring which is inlaid in any of the female end and the male end ofthe joint of the small duct can be taken out rapidly, the metal sealing ring can be nondestructively separated from the device, production efficiency of installation and maintenance of the small ductis improved, quality risks are reduced, and potential quality hazards are eliminated.

Owner:CAPITAL AEROSPACE MACHINERY +1

Image forming apparatus

InactiveCN100460218CPreventing Image Quality DeteriorationAvoid distortionOther printing apparatusArticle feedersEngineeringImaging equipment

Owner:BROTHER KOGYO KK

A short process preparation method of gh4169 alloy welding wire

ActiveCN108672980BImprove high temperature strengthAntioxidant is goodWelding/cutting media/materialsSoldering mediaCombustion chamberOxidation resistant

The invention relates to a GH4169 alloy welding stick short process preparing method. Chemical compositions in the method comprise, by weight, 50.0%-55.0% of Ni, 17.0-21.0% of Cr, 5.00%-5.50% of Nb, 2.80%-3.30% of Mo, 0.75%-1.15% of Ti, 0.30%-0.70% of Al, 0.02%-0.06% of C and the balance Fe. Welding stick preparing technological processes mainly include the steps of matching, smelting, ingot casting, homogenizing annealing, bar extrusion, continuous annealing, multi-pass continuous extrusion and the other processes. A prepared alloy welding stick has the excellent high-temperature strength, oxidation resistance, creep resistance and resistance to corrosion and has the good fatigue property and weldability. In particular at the high temperature being 650 DEG C, the mechanical property of the alloy welding stick has the good stability, certain working pressure can be borne under 600 DEG C-1200 DEG C, and the alloy welding stick can be widely applied to welding pieces for blades, turbinediscs, turbine discs and long-service life aerospace engines.

Owner:LANZHOU WEITE WELDING MATERIAL FURANCE BURDEN

Tensioning device, weaving machine, closing machine and method for tensioning a plurality of warp yarns

ActiveCN103388225BTension evenly and reliablyPrevent disengagementLoomsSeaming textilesYarnElectrical and Electronics engineering

The device (10) has a clamp (18) which is adapted to the warp yarns (30) of a warp thread layer to be fixed locally to a frame (11). A tensioner (12) is formed along the longitudinal direction of the tensioner arranged through a penetration pin (16). The surface of the tensioner are arranged to face ends of the penetration pin in relation to the normal direction of the surface of the tensioner. The warp yarns are brought into contact ends of the penetration pin in a direction opposite to the clamp. Independent claims are included for the following: (1) a vintage machine; (2) a threading machine; and (3) a method for tensioning warp yarns in clamping device.

Owner:STAUBLI SARGANS AG

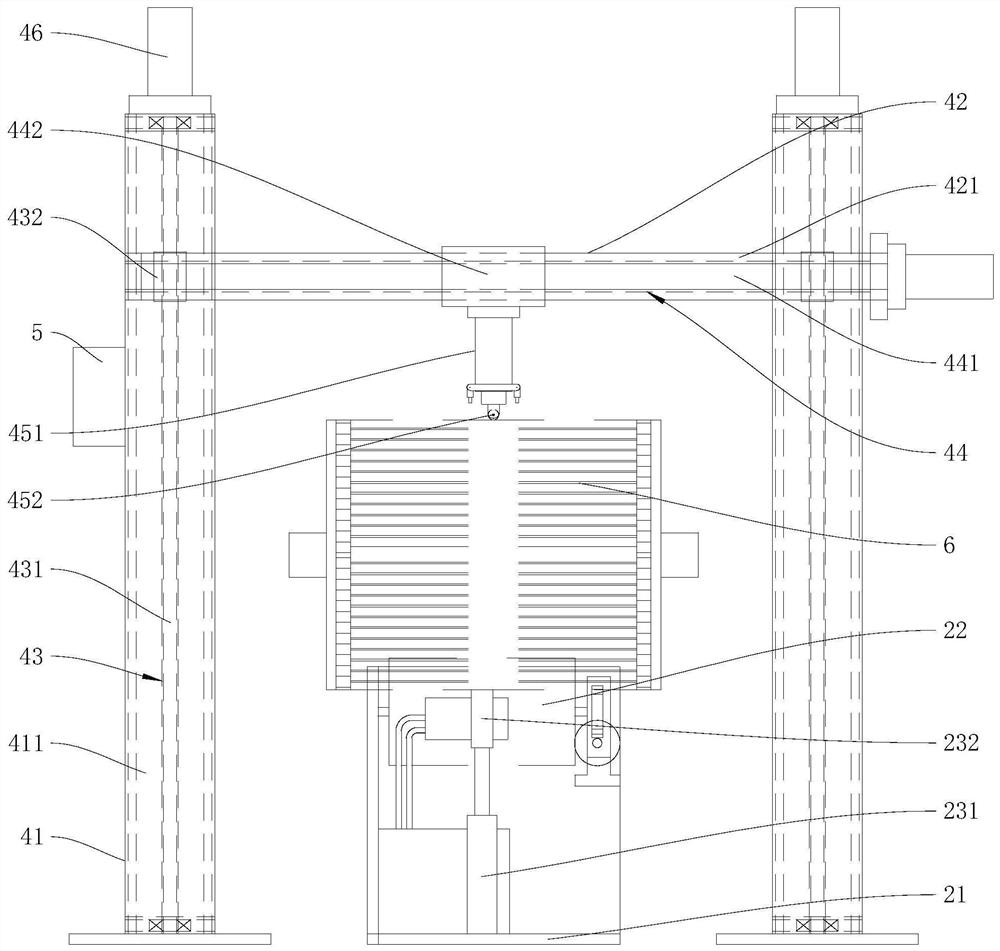

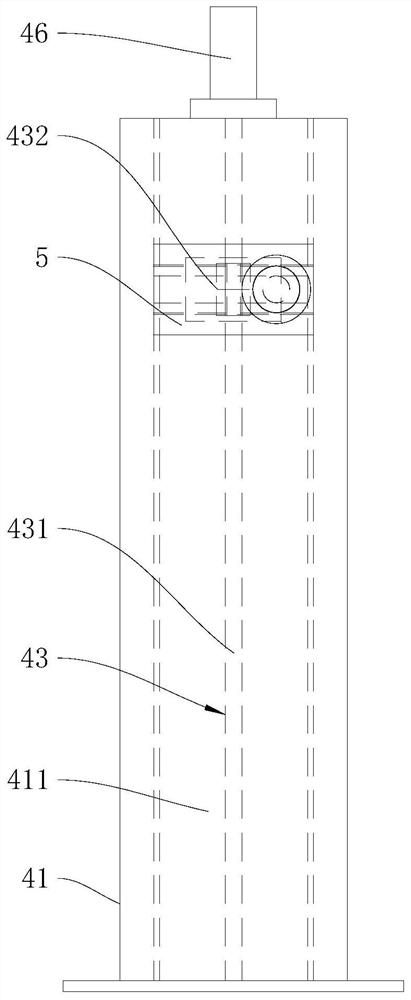

An automatic tensioning device for copper bars of traction motors

ActiveCN113746278BAchieve extrusionReliable ExtrusionManufacturing stator/rotor bodiesElectric machineEngineering

The invention provides an automatic tensioning device for a copper strip of a traction motor, which belongs to the technical field of motor manufacturing and maintenance, and includes a conveying device, a supporting device, a receiving device and a tensioning device. The supporting roller, the driving roller and the supporting roller are respectively arranged close to the conveying device and the receiving device, and the jacking mechanism is used to support the motor rotor to fall on the driving roller and the supporting roller and to lift the motor rotor to the supporting roller and fall on the receiving device , the tensioning device includes a column, a beam, a vertical moving mechanism, a horizontal moving mechanism and a tensioning head. The automatic tensioning equipment for traction motor copper bars provided by the present invention positions and supports the motor rotor by means of driving rollers, support rollers and a jacking mechanism, and the tensioning head is driven by the vertical moving mechanism and the horizontal moving mechanism to move along the length direction of the motor rotor And quickly and reliably complete the extrusion of the copper bar, complete the transportation of the motor rotor, and improve the work efficiency.

Owner:CRRC TANGSHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com