Patents

Literature

36results about How to "Squeeze out fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

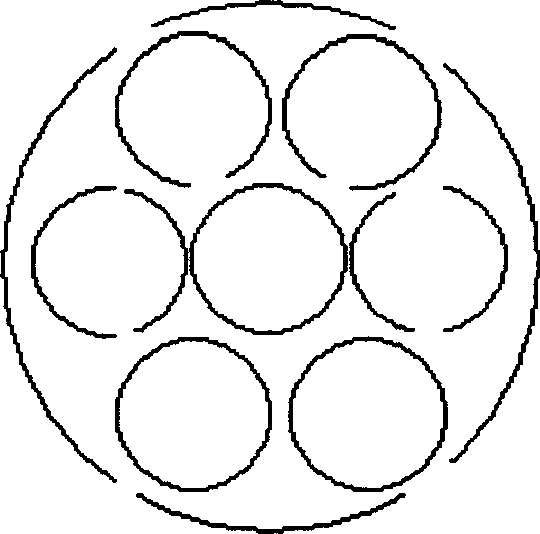

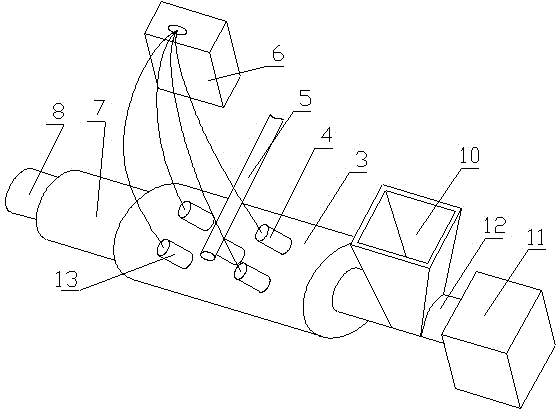

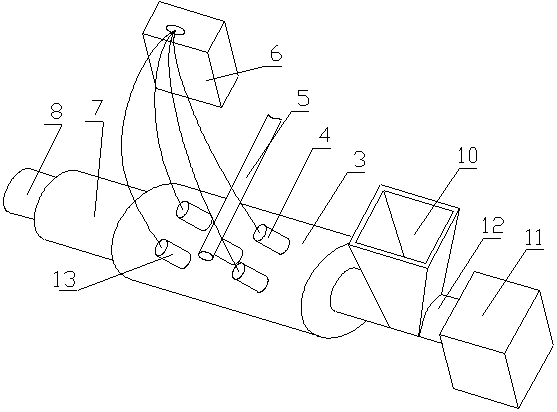

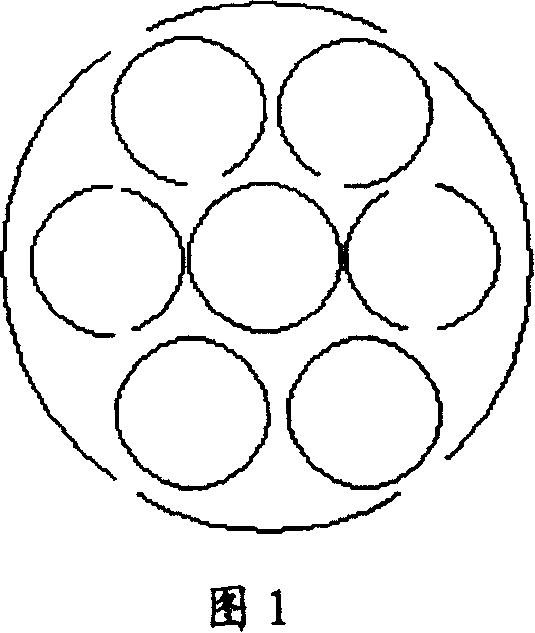

Weaving method for captive balloon cable of polyethylene fiber with ultra-high molecular weight

InactiveCN1807753APass awayImprove wear resistanceRope making machinesBalloon aircraftsYarnWinding machine

This invention discloses a superhigh molecular weight polyethene fabric captive balloon cable crochet method, which includes joining yarn, joining small sections, immersing rosin, weaving and other steps, wherein the joining yarn and joining small sections steps use seven sections twist, immersing rosin right after joining small sections, and after weaving into the cable, pulling in advance, which improves the resistant draw intension and wear-resisting intension. This invention is fit for the situation which has a high demand for the weight and intension, for example the cable for winding machine.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

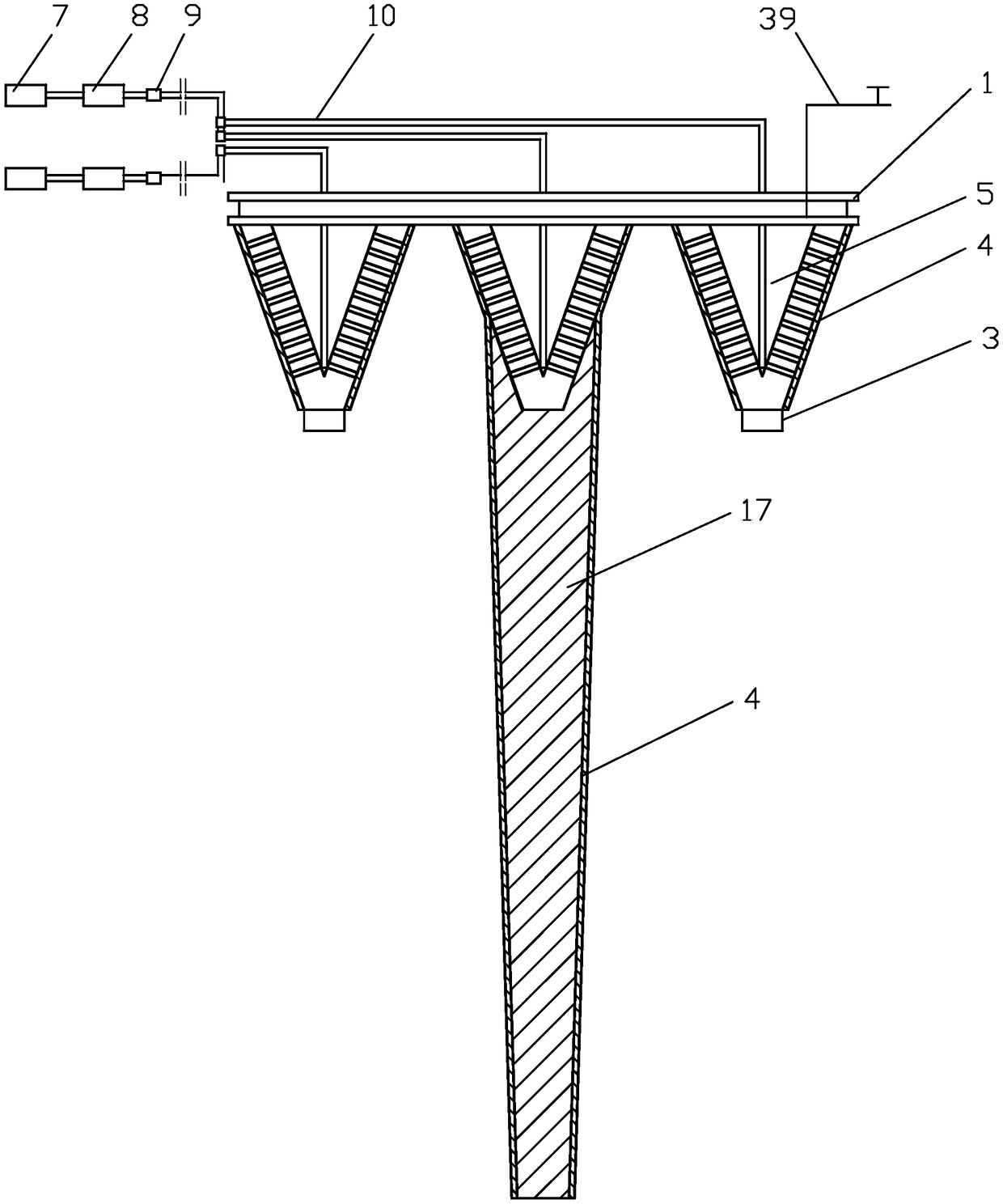

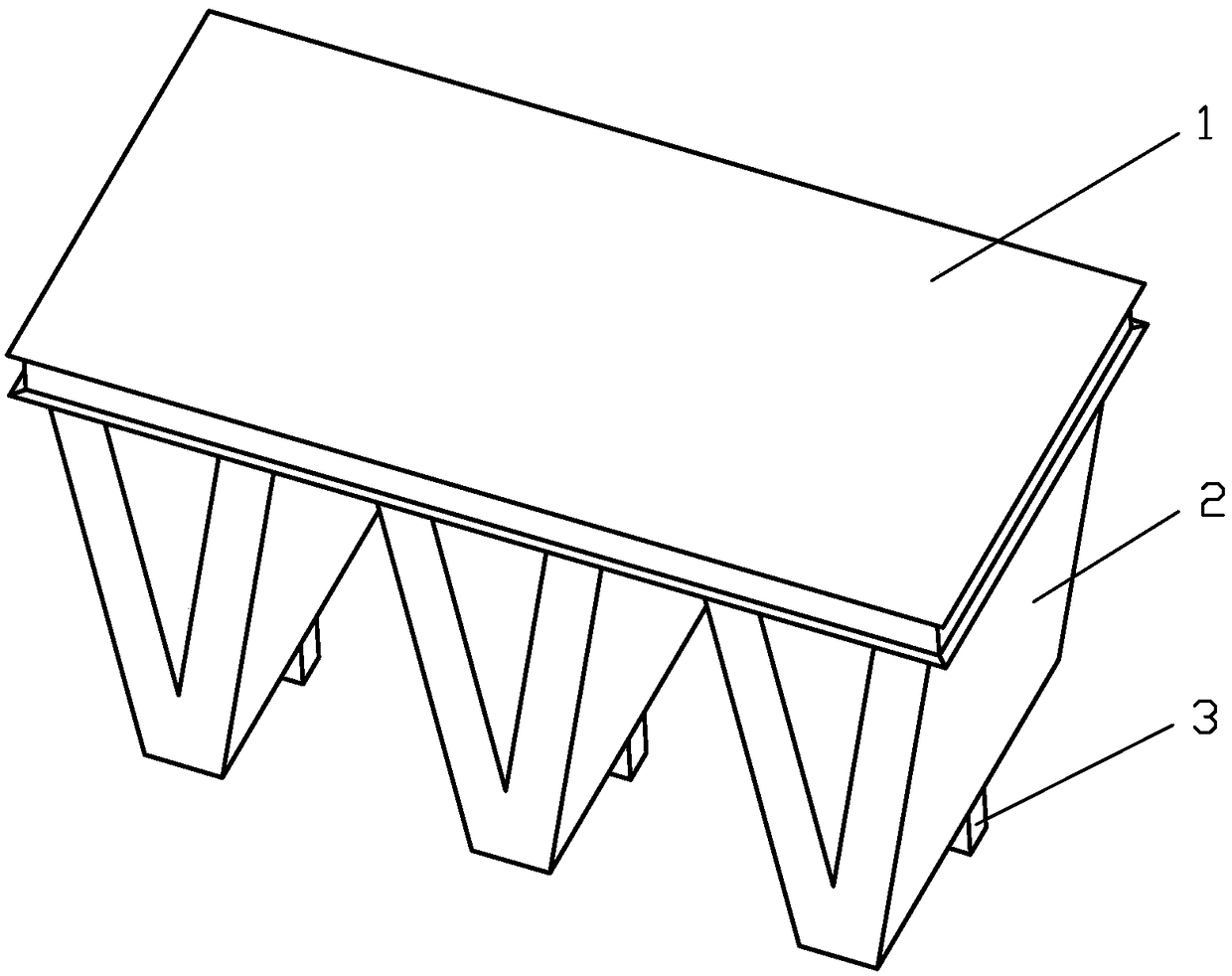

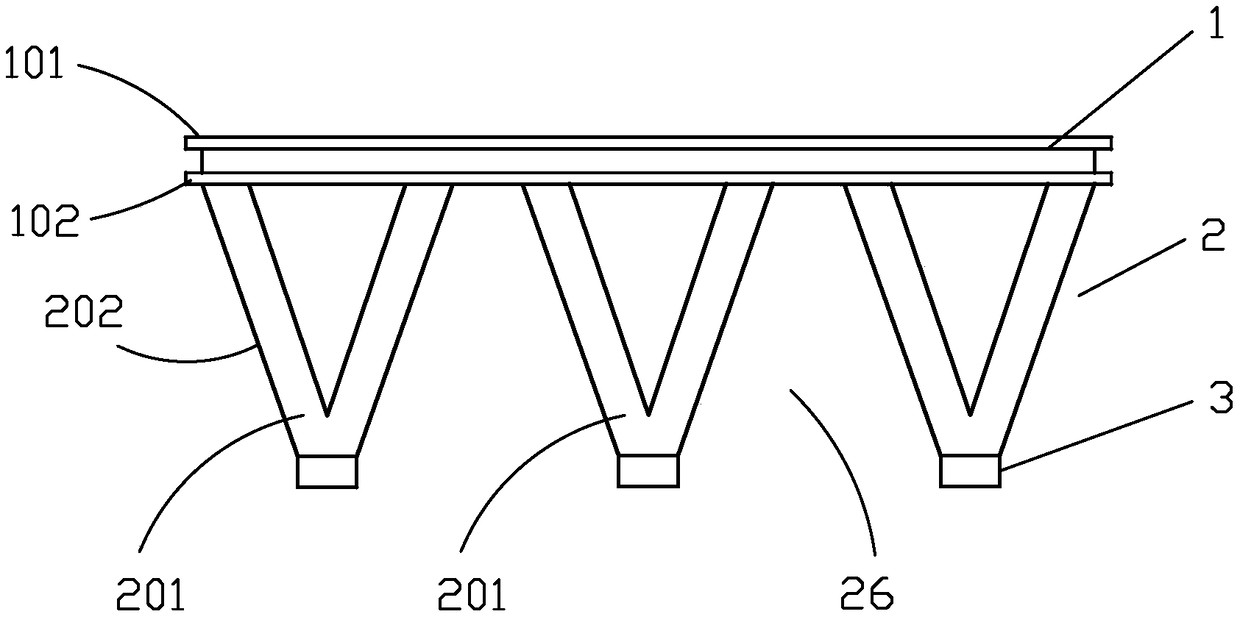

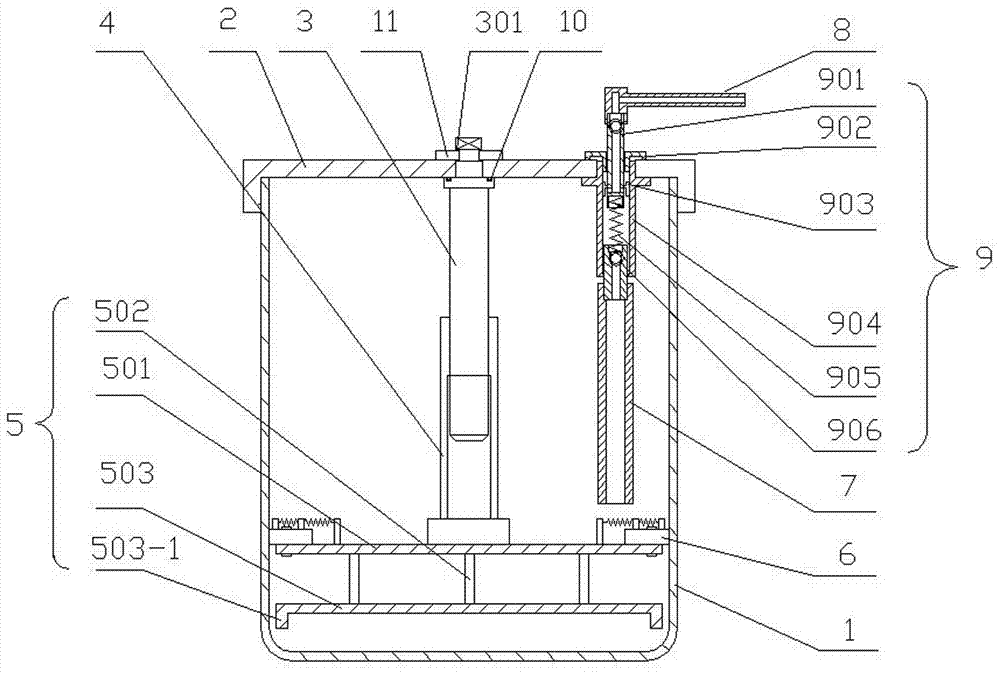

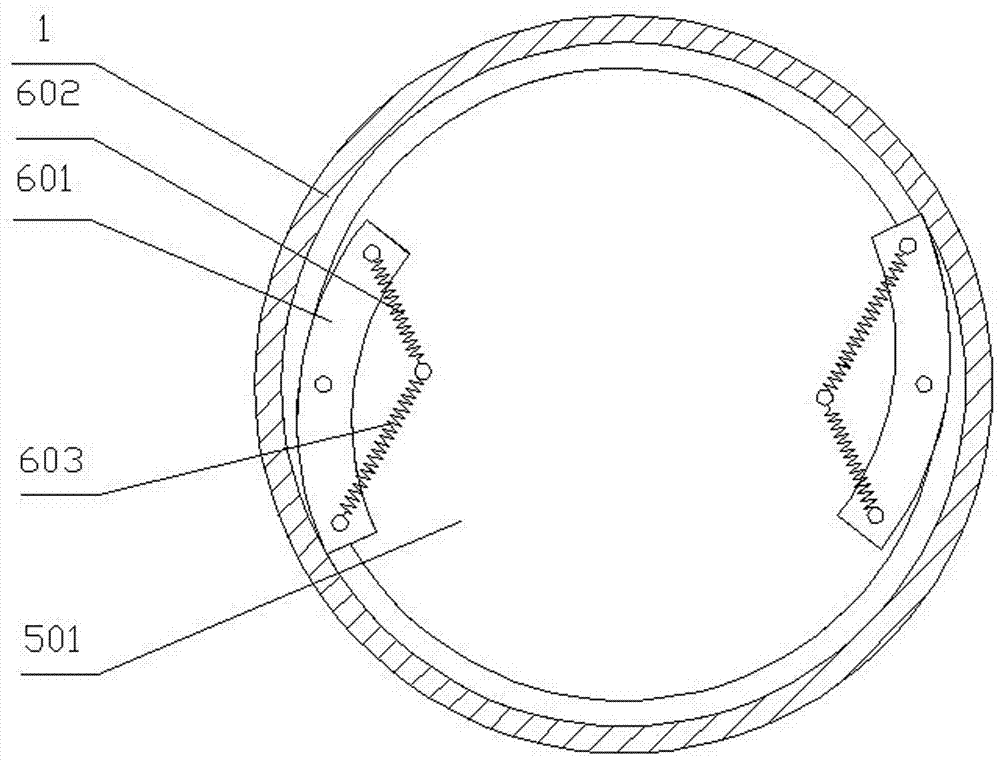

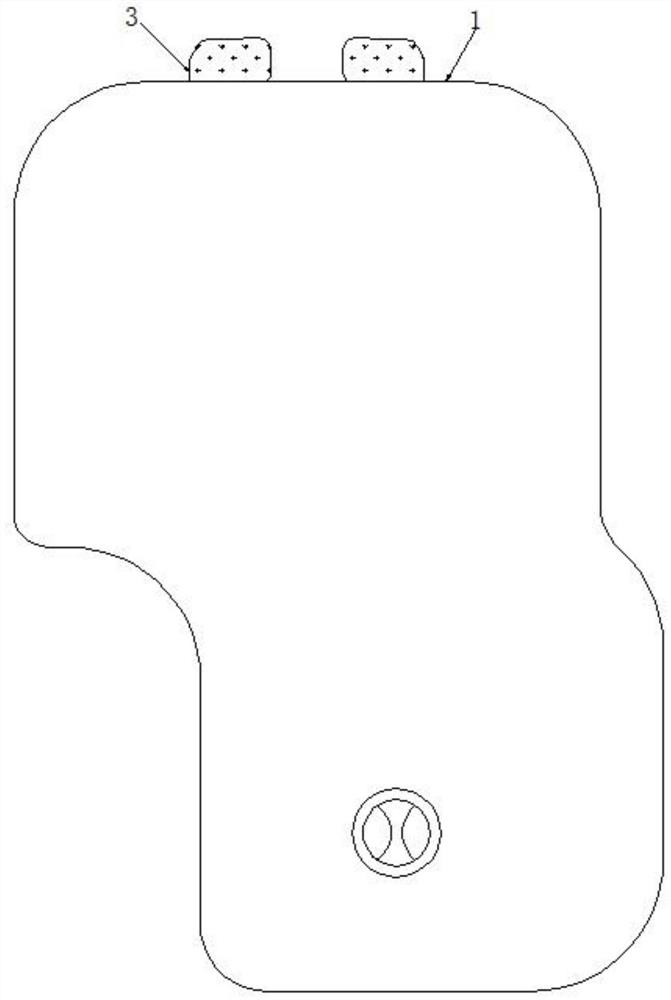

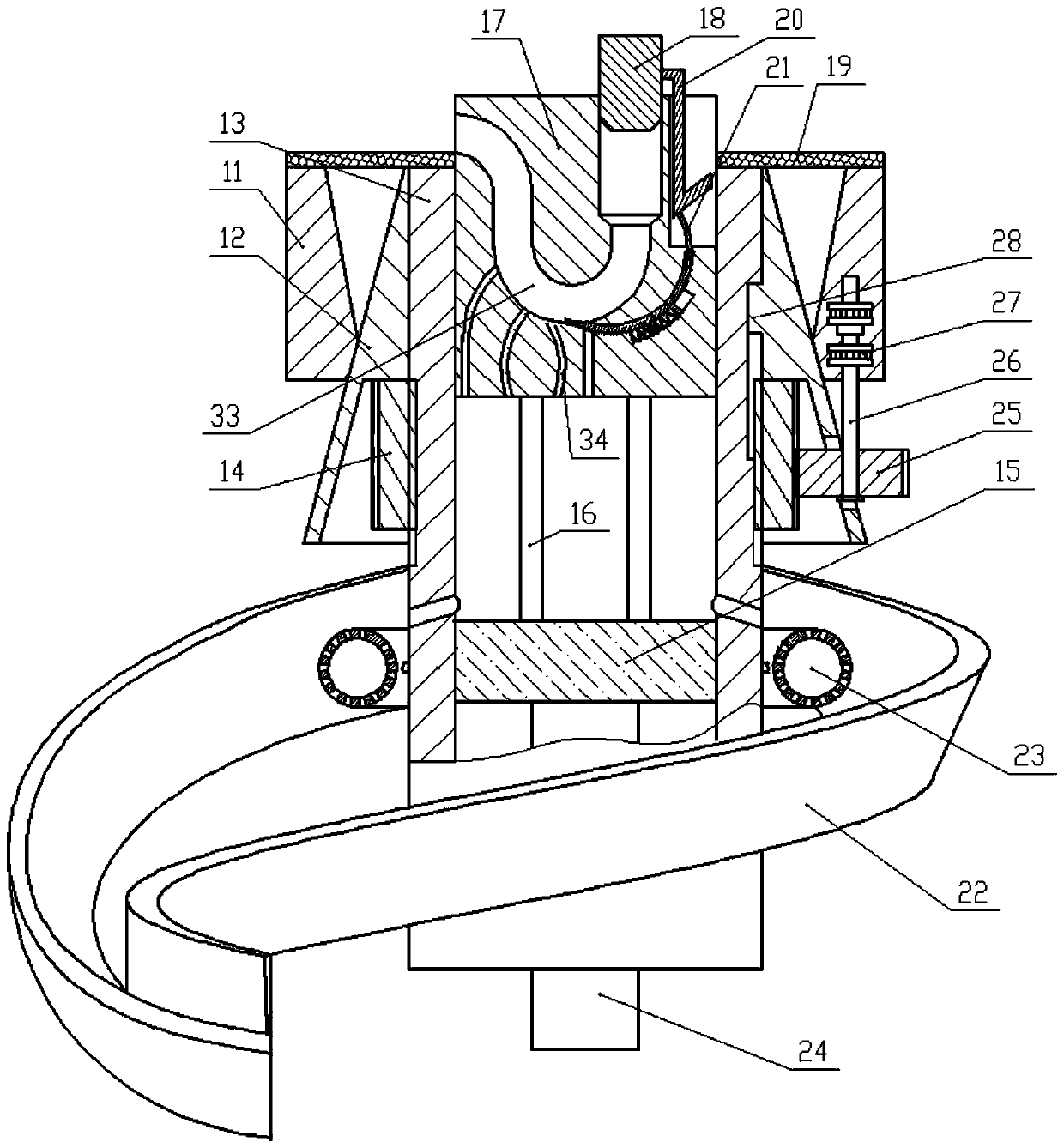

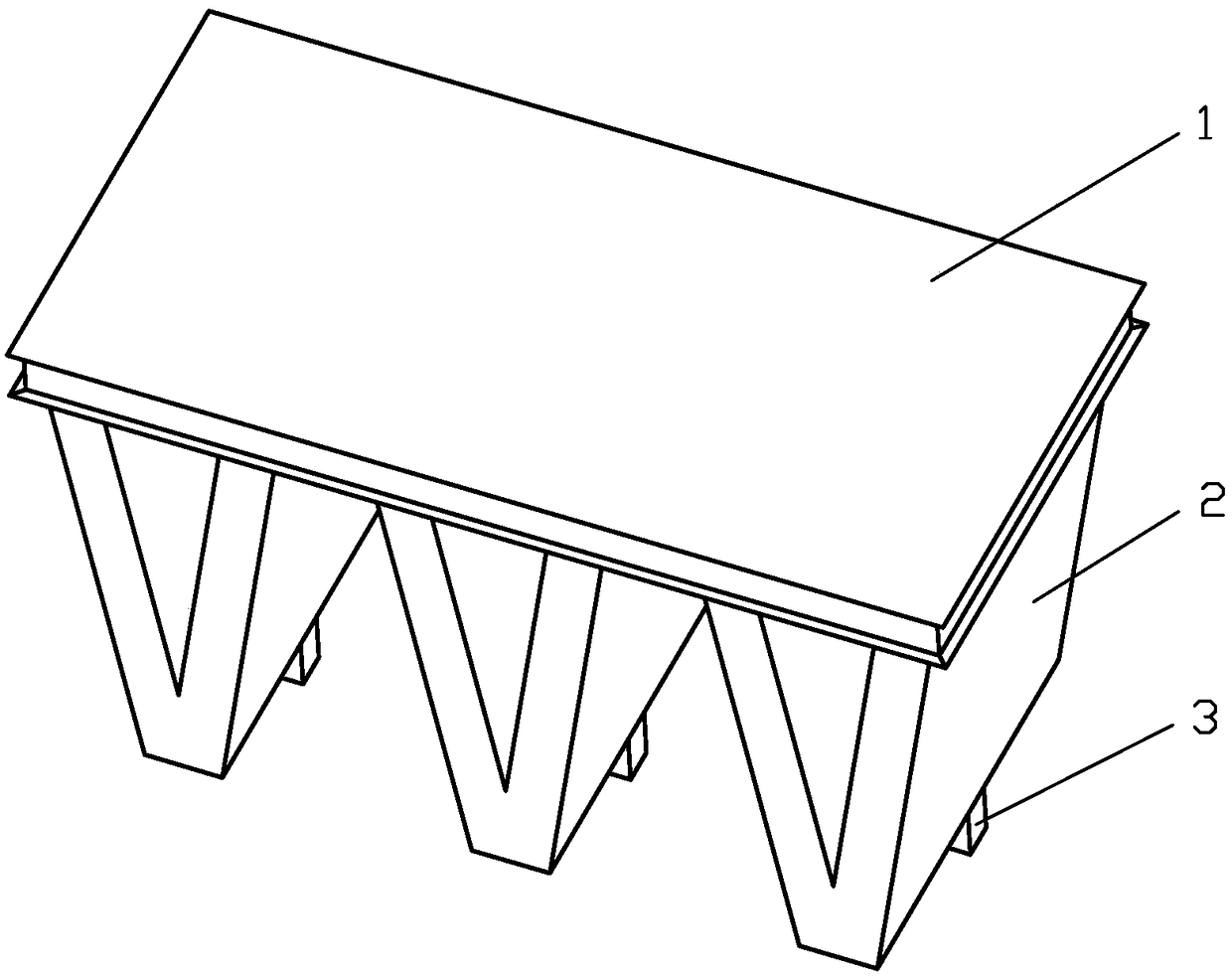

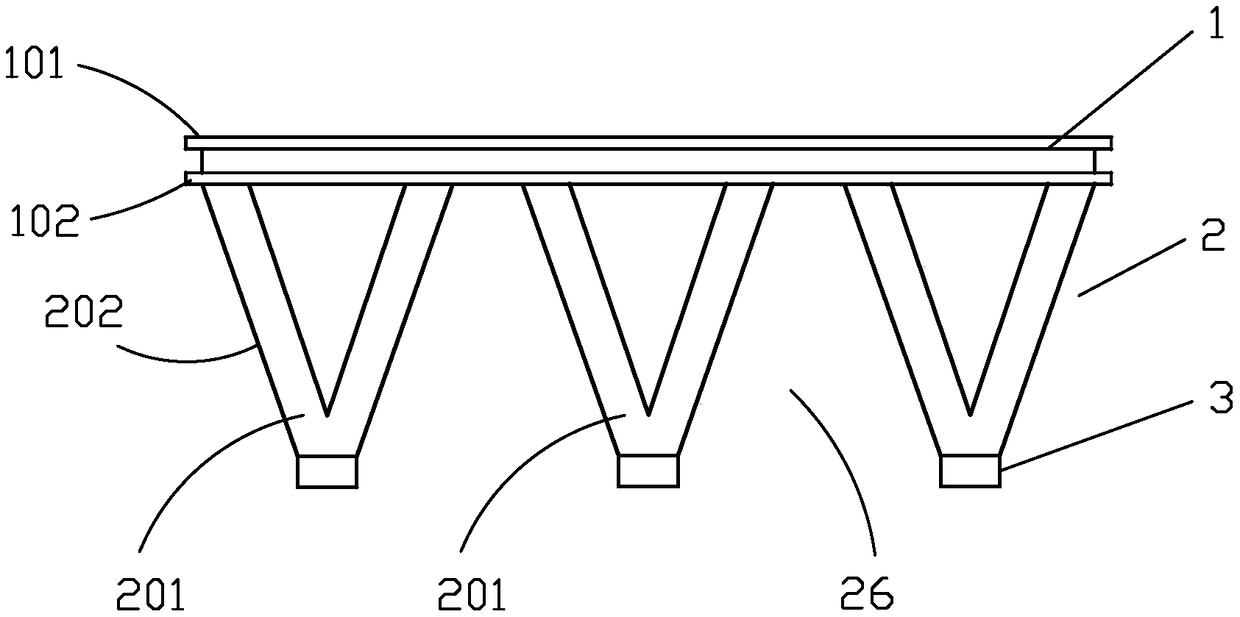

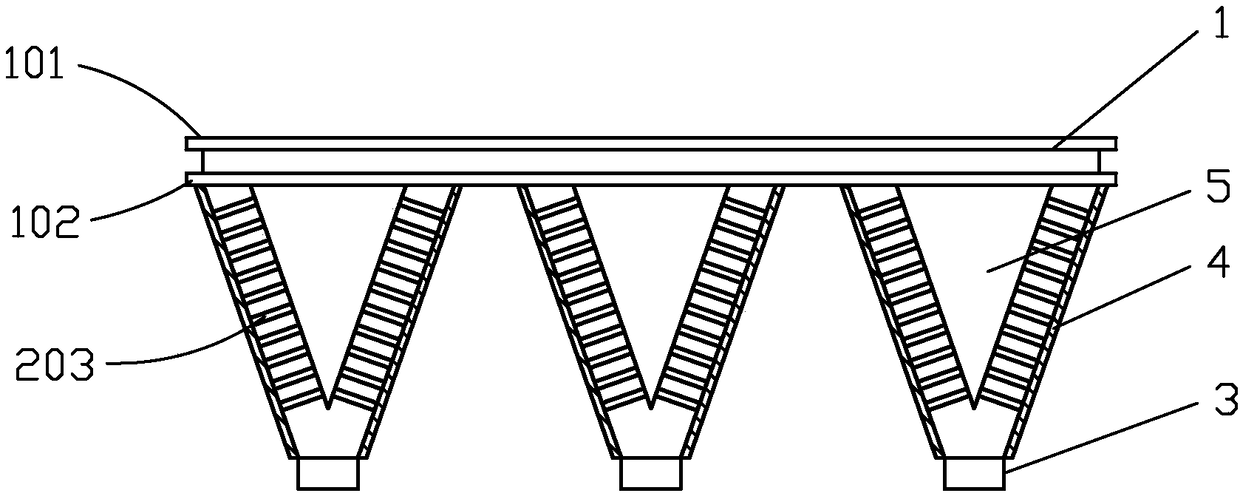

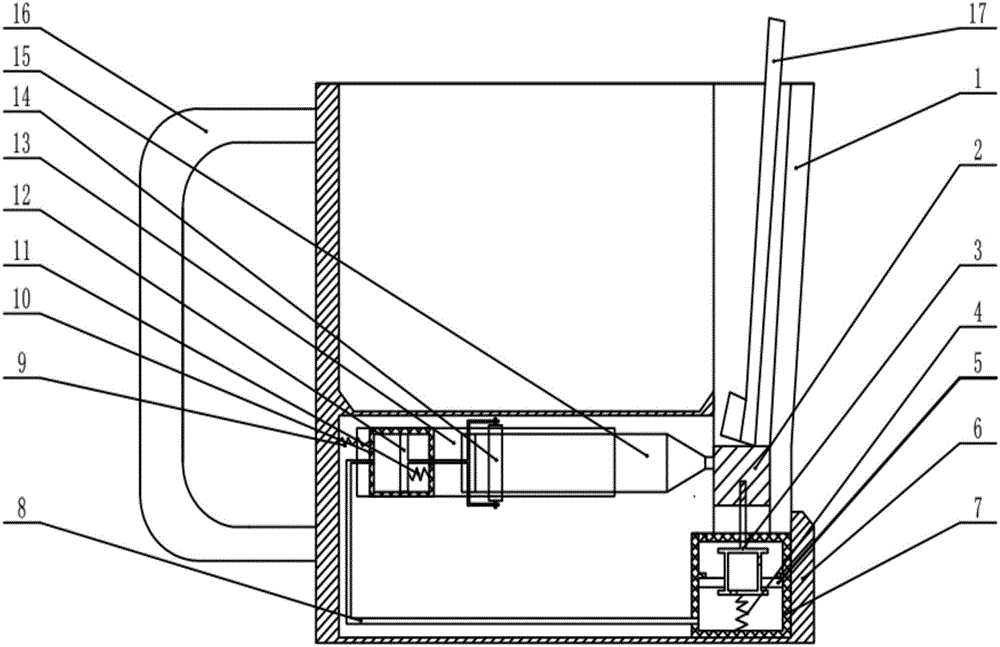

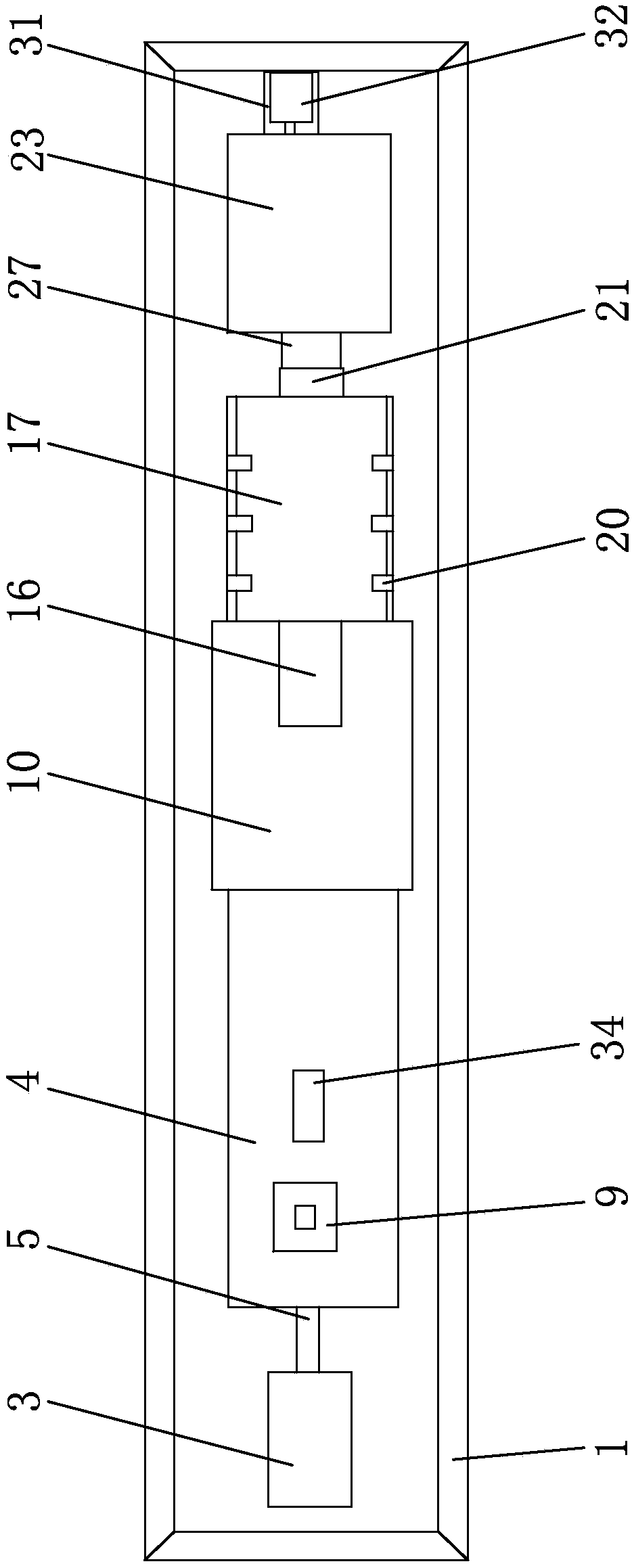

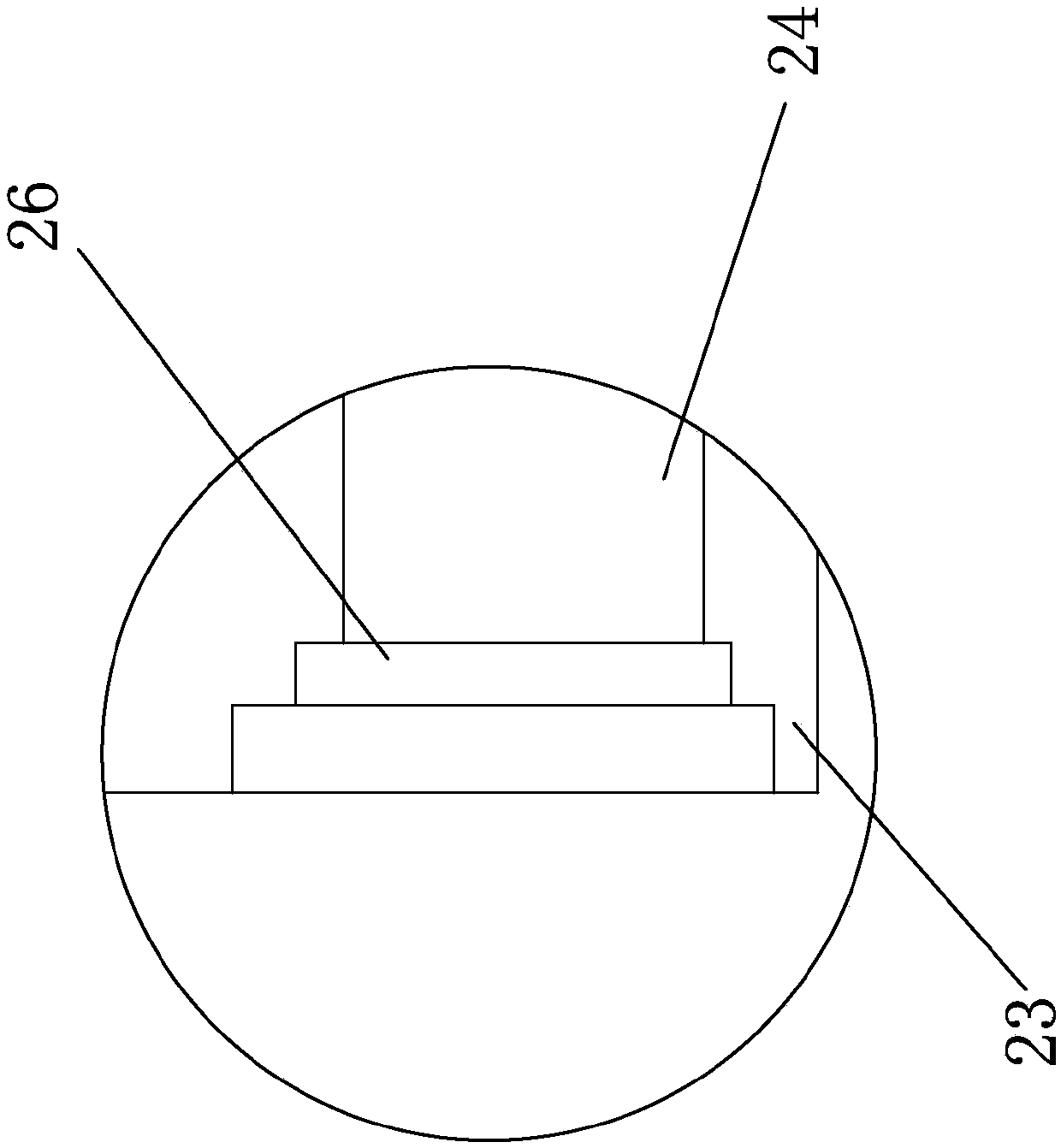

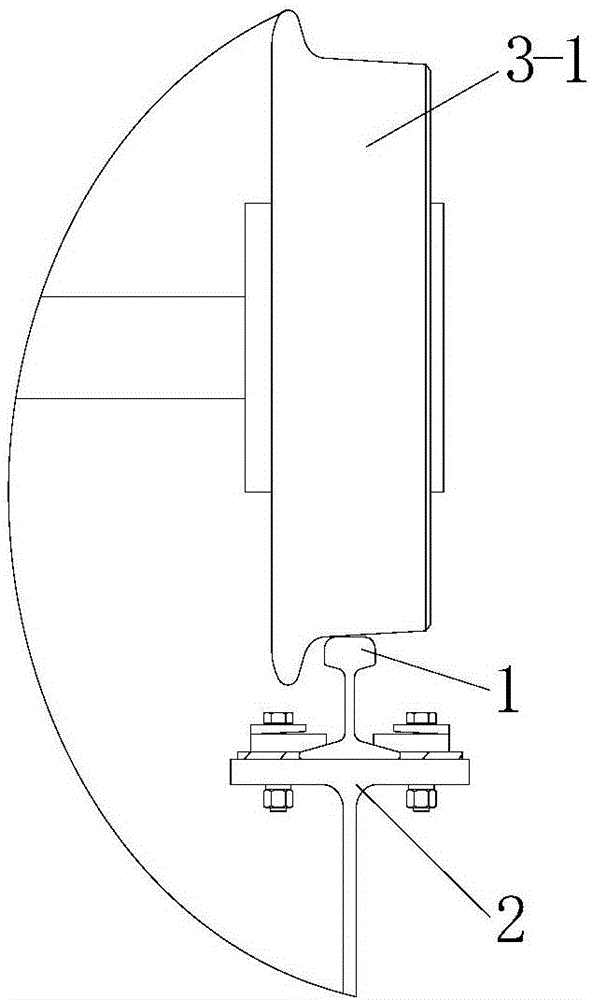

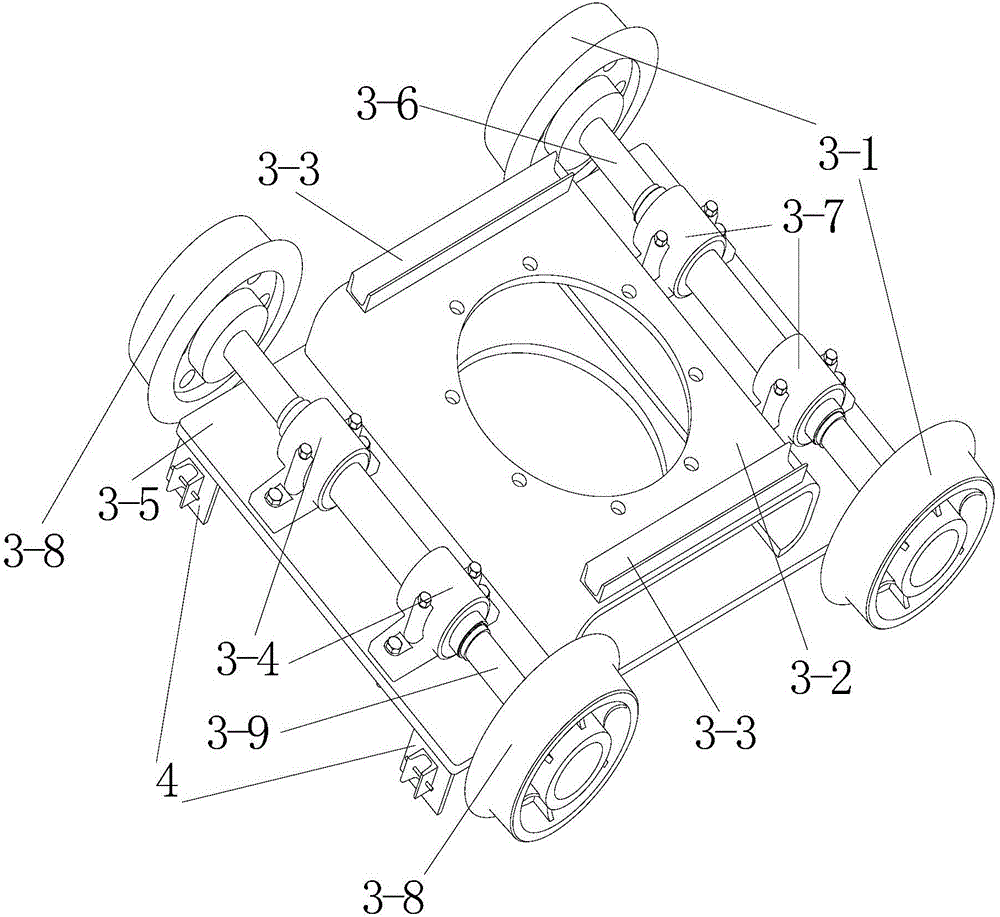

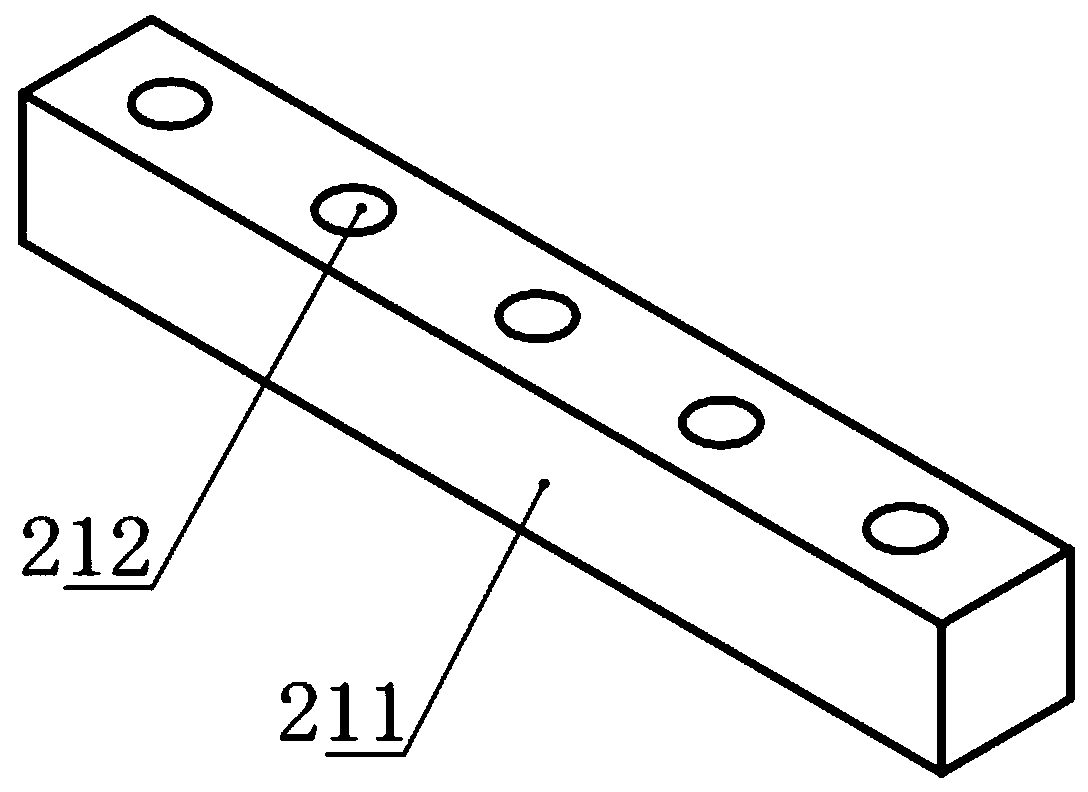

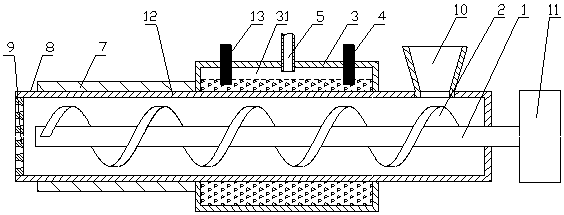

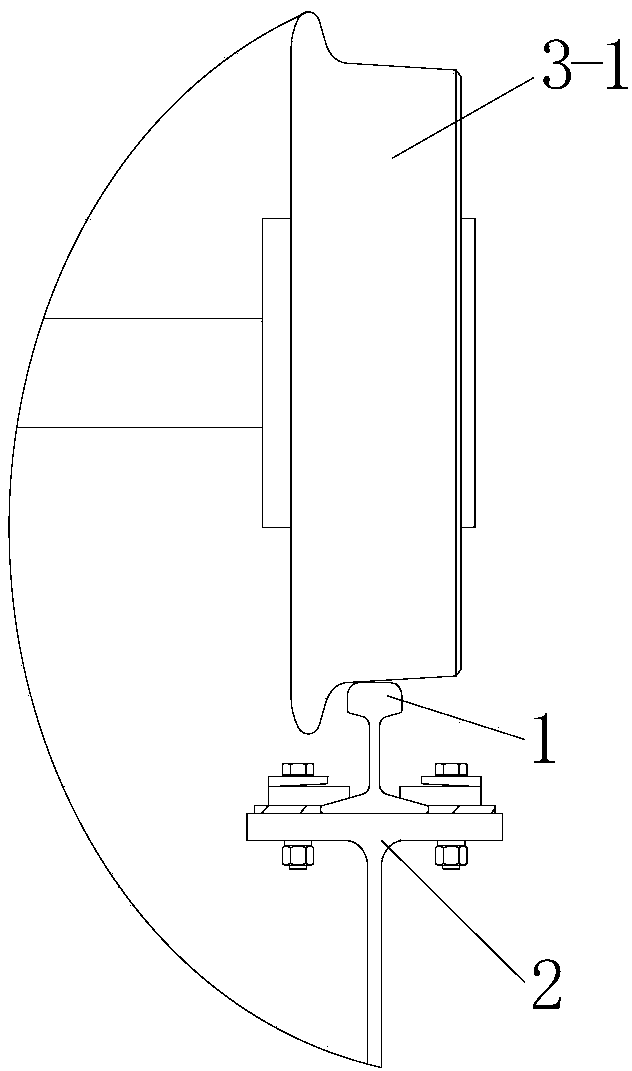

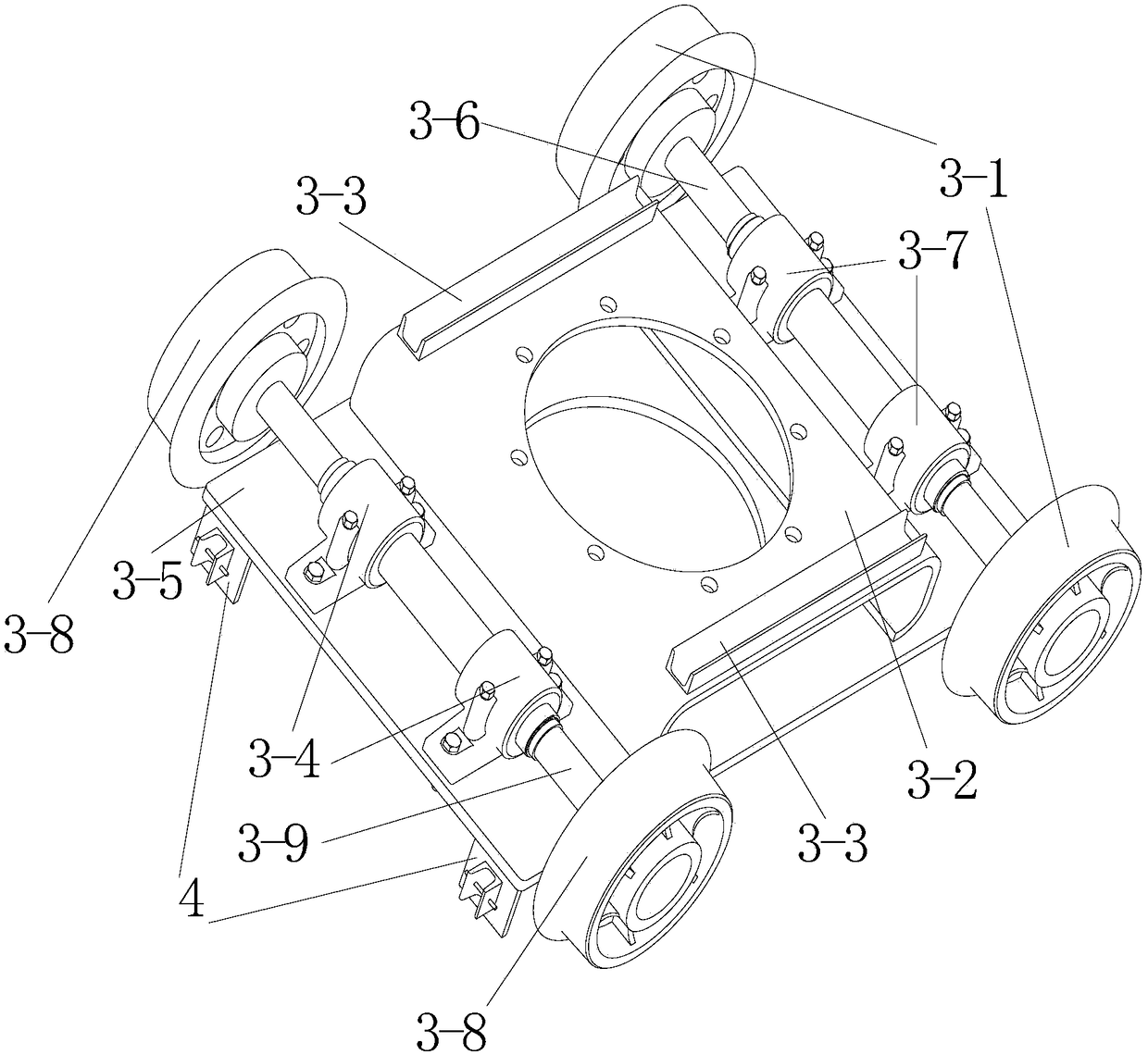

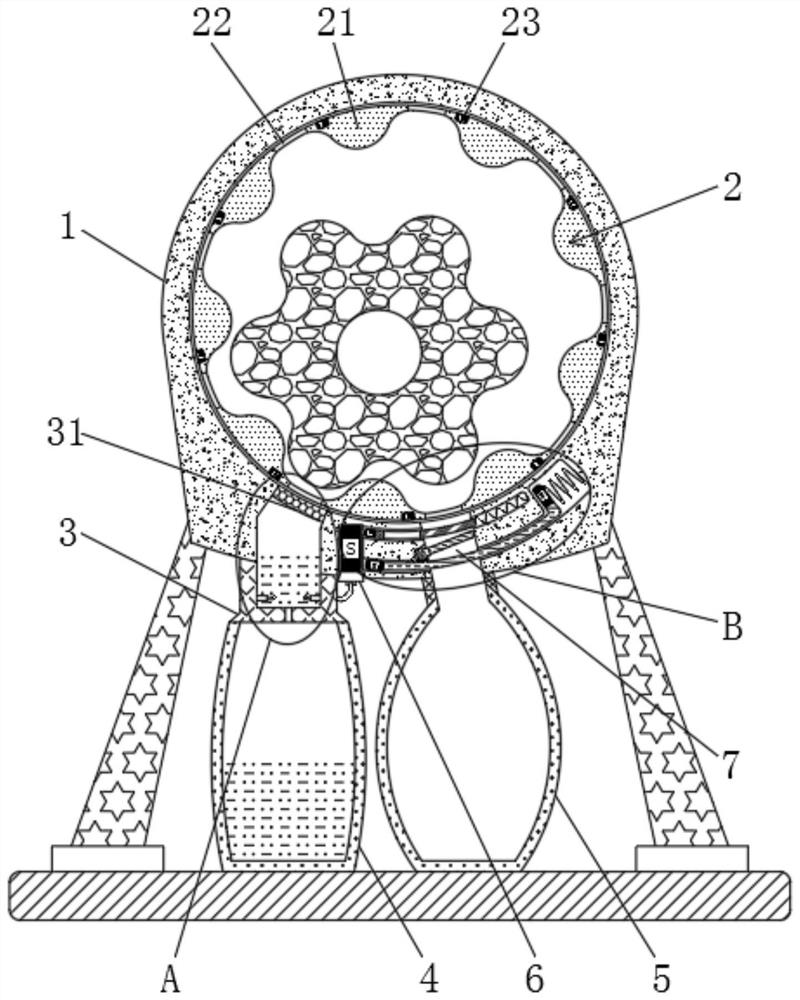

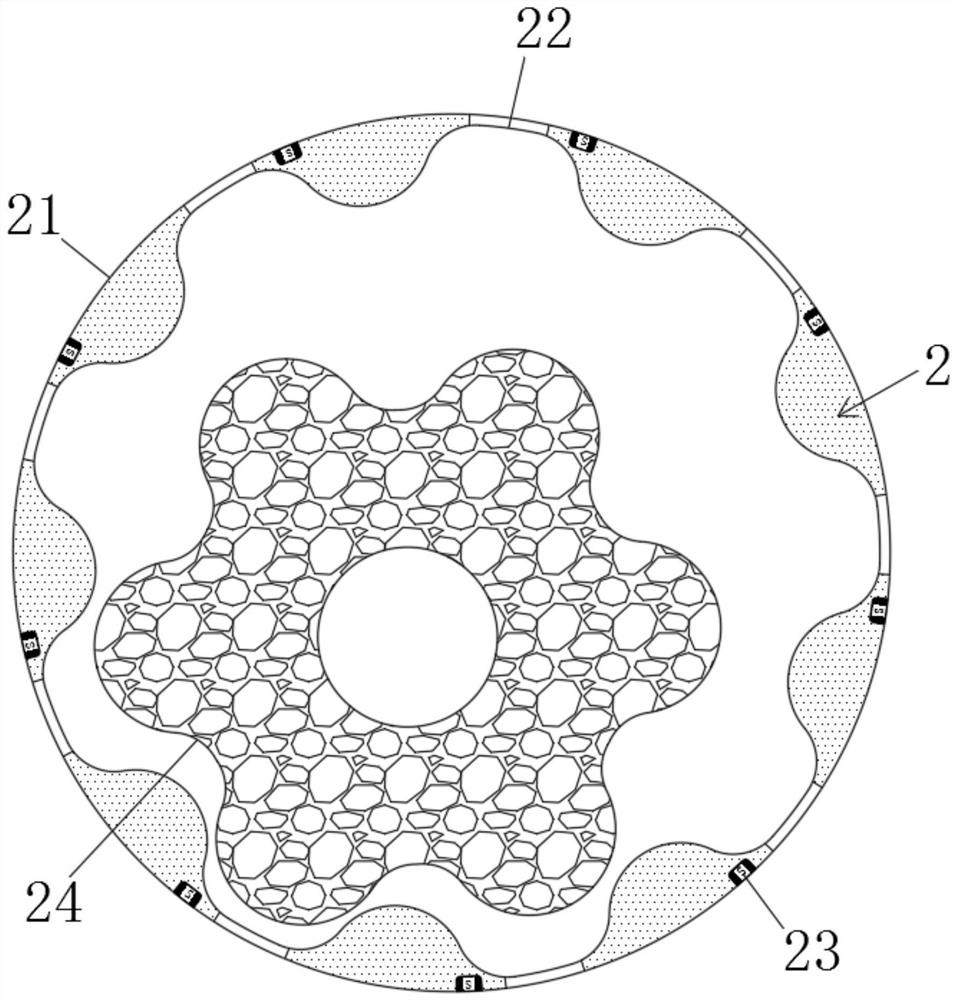

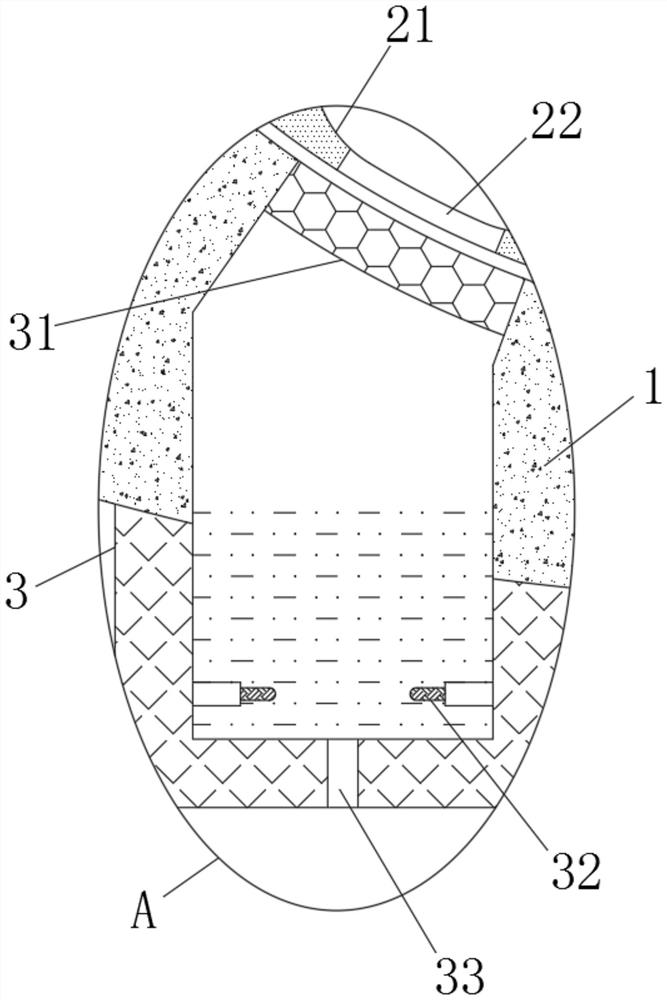

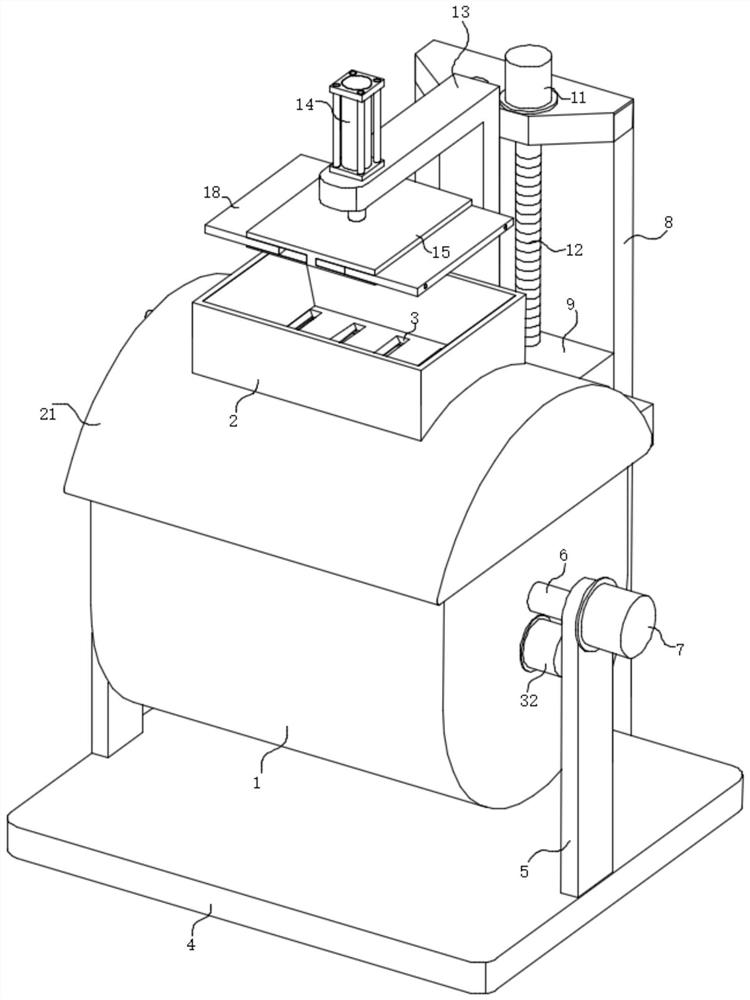

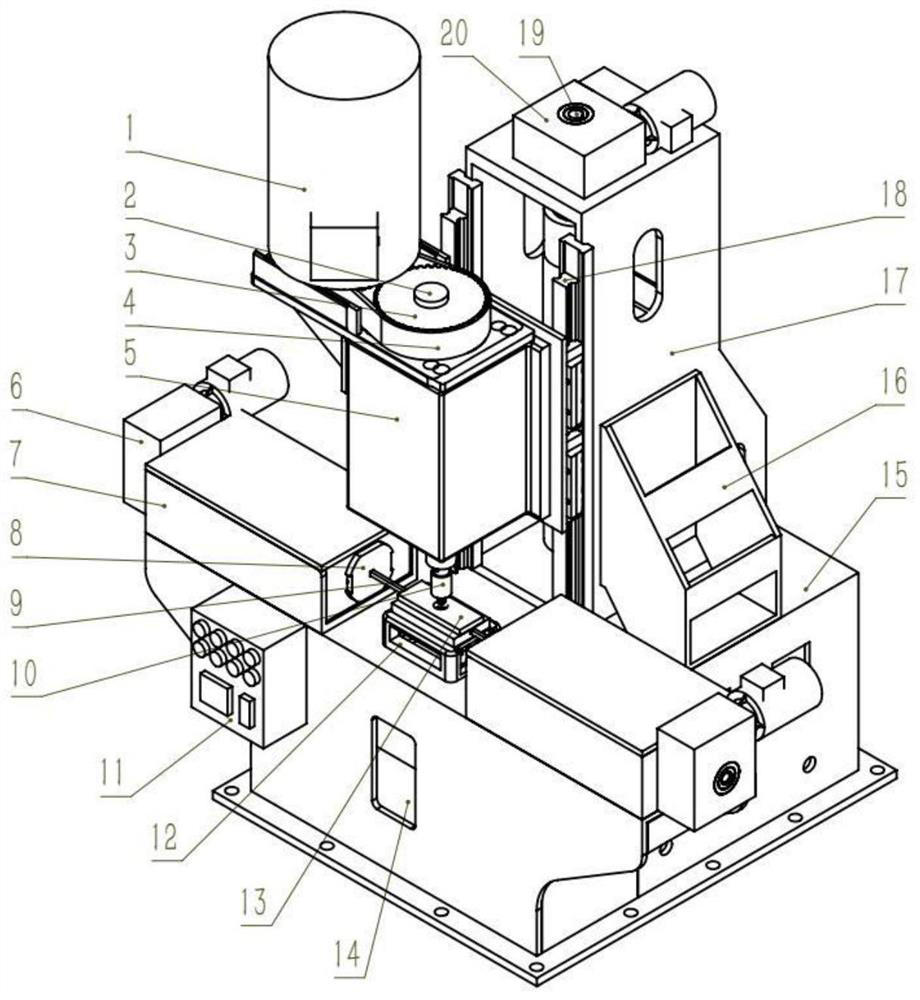

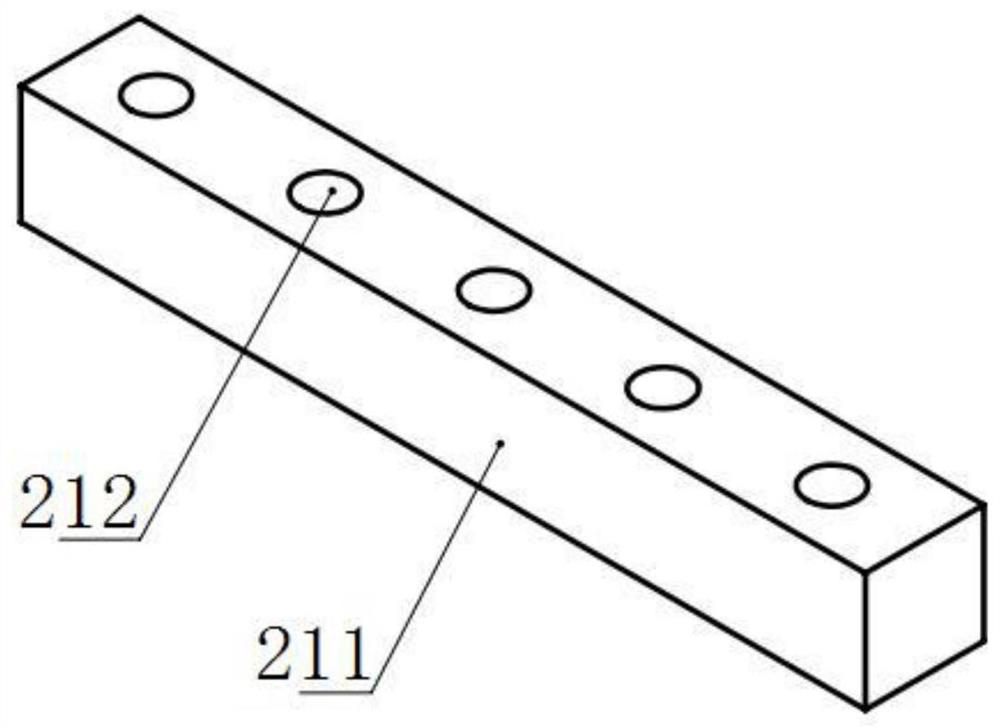

Modular soil compaction molding device applicable for treatment of deep and shallow soft soil foundations

InactiveCN108330948APlay a blocking rolePrevent sideways movementSoil preservationEngineeringUltimate tensile strength

The invention discloses a modular soil compaction molding device applicable for treatment of deep and shallow soft soil foundations. The modular soil compaction molding device comprise an upper frame,a compaction molding module and a soil strength detection device, and is characterized in that the compaction molding module comprises a plurality of convex bodies; the top of the module is connectedto the upper frame, and the part, coming into contact with soil, of the compaction molding module is further provided with a filter device; and the bottom of the compaction molding module is furtherprovided with a vertical pile body. The soil is blocked by the convex bodies at the bottom of the compaction molding module, and prevented from offsetting so that the soil is centralized in spaces among the convex bodies and extruded fully, and the effects of quick drainage and compaction are achieved. Moisture extruded from the soil is discharged through the filter device, and the construction efficiency is improved greatly; and the construction period is shortened, and the construction cost is reduced.

Owner:ZHEJIANG JIA YUAN CIVIL ENG CO LTD

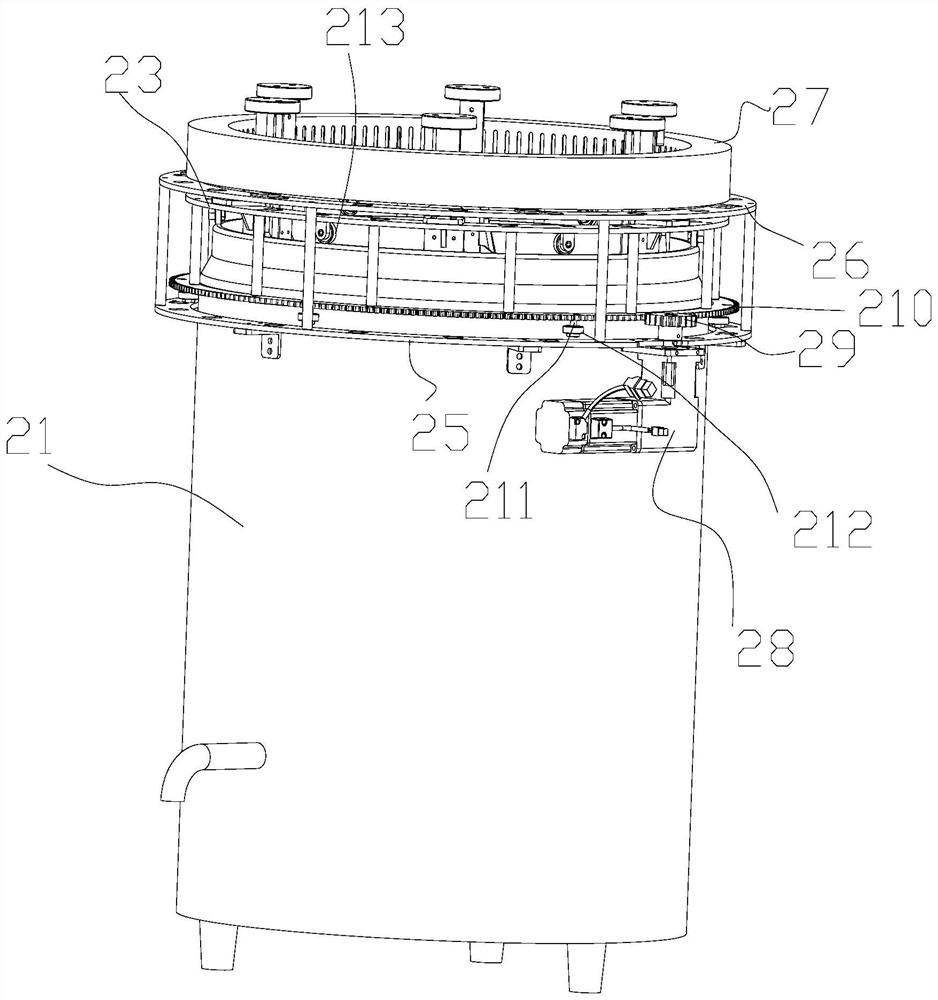

Brewing device for grape wine

The invention relates to the field of a wine brewing device and specifically relates to a brewing device for grape wine. The brewing device comprises a cylindrical bottle body and a bottle cap arranged at an opening of the bottle body, wherein an extruding mechanism and a liquid draining mechanism are arranged on the bottle cap; the extruding mechanism comprises a screw rod, a nut sleeve and a filtering sieve; the screw rod vertically penetrates through the bottle cap; the nut sleeve is matched with and arranged at the lower end of the screw rod; the filtering sieve is fixed at the lower end of the nut sleeve; a brake which is used for preventing the nut sleeve and the filtering sieve from coaxially rotating along with the screw rod is arranged on the filtering sieve. The brewing device for grape wine can fully squeeze the wine liquid from the grape skin, the wine liquid can be led out conveniently, safely and sanitarily.

Owner:LUOYANG INST OF SCI & TECH

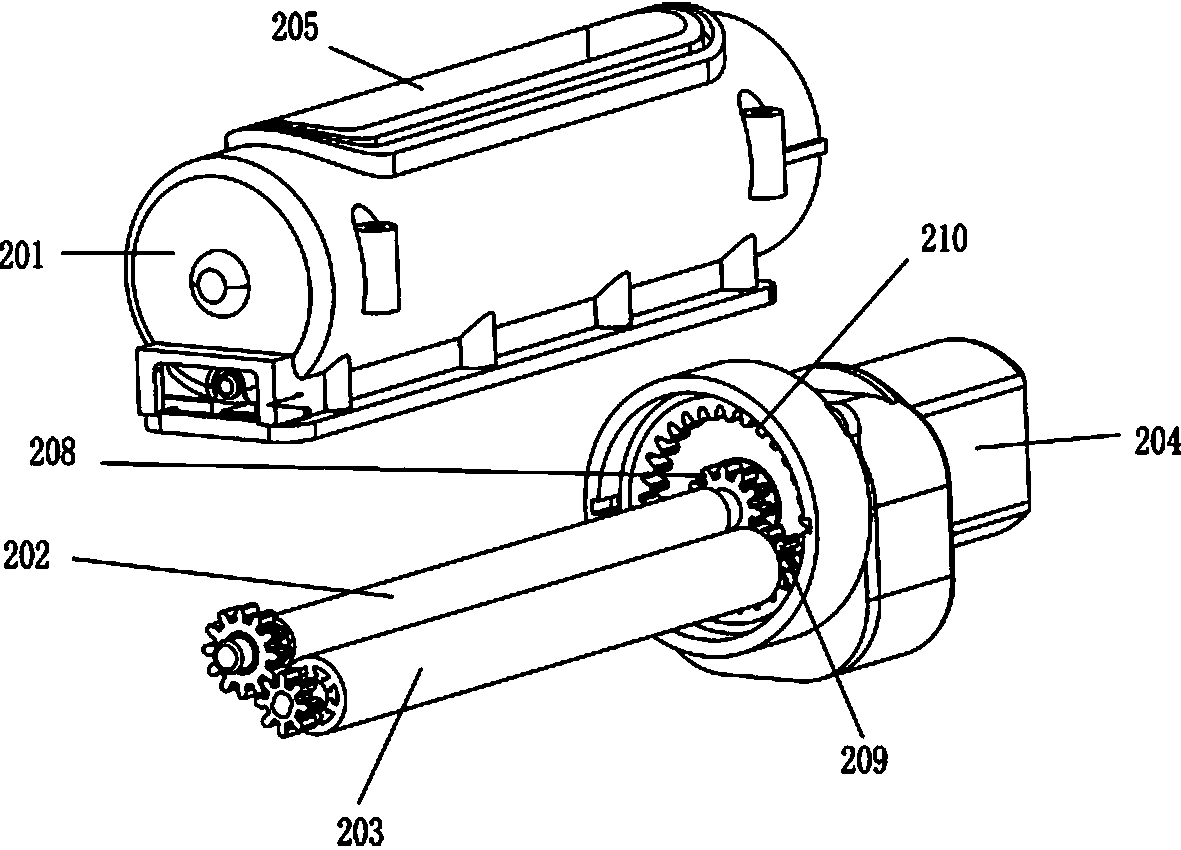

Stirring extrusion type hair dyeing comb

PendingCN111513447ASufficient stockQuantitative extrusionTransportation and packagingMixersPolymer scienceHair Colorants

Owner:DONG GUAN KONG ELECTRIC ELECTRICAL APPLIANCES CO LTD

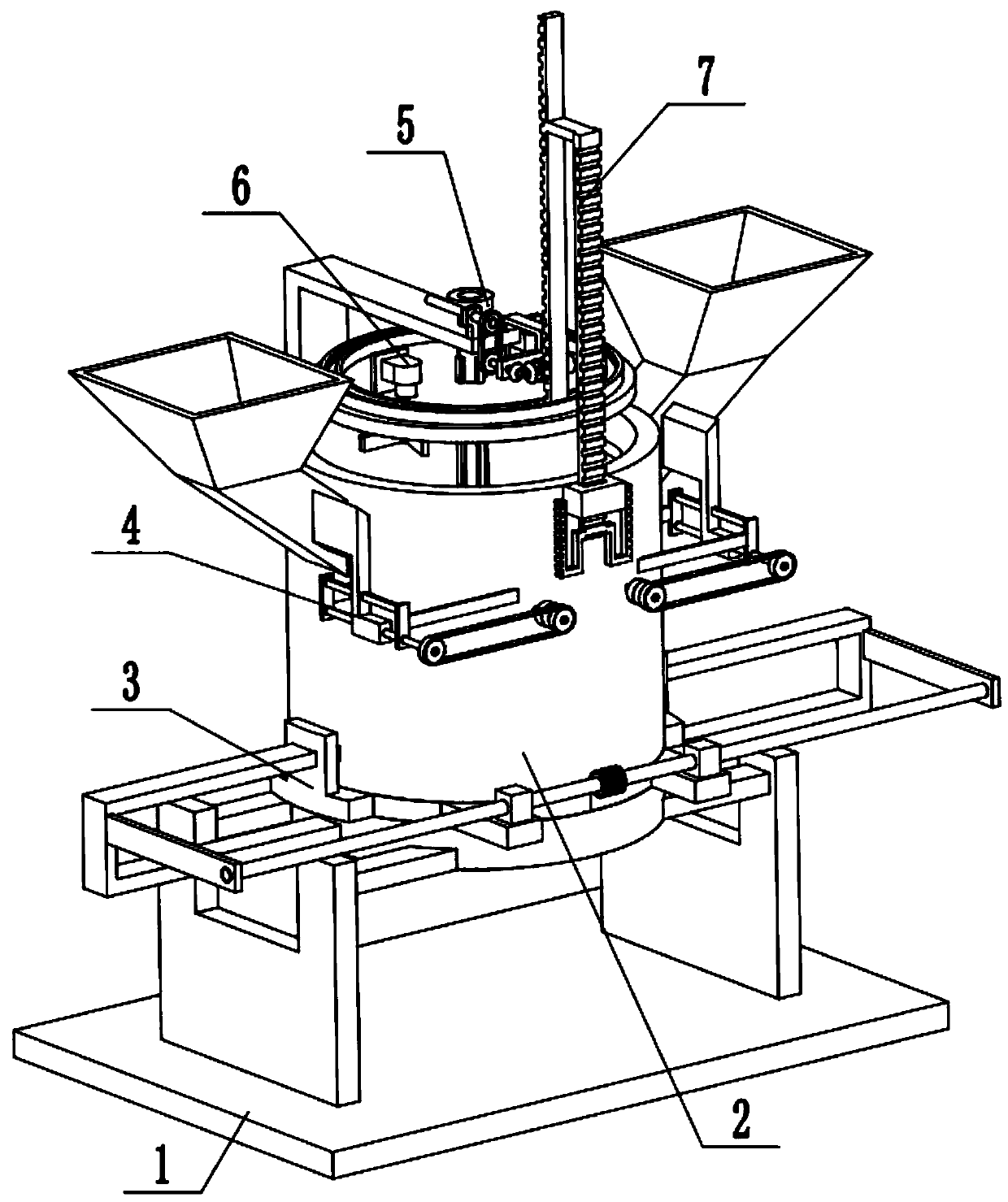

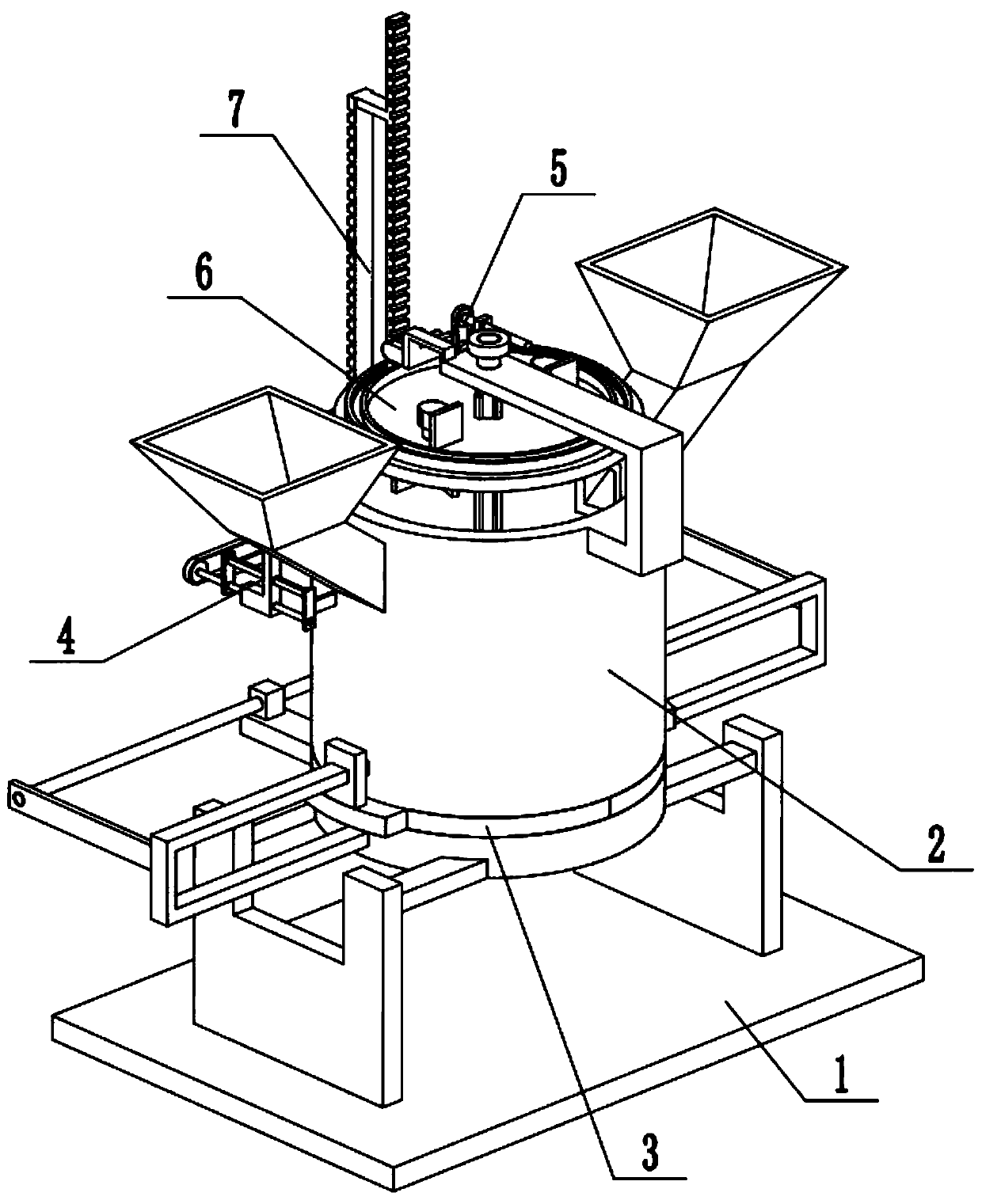

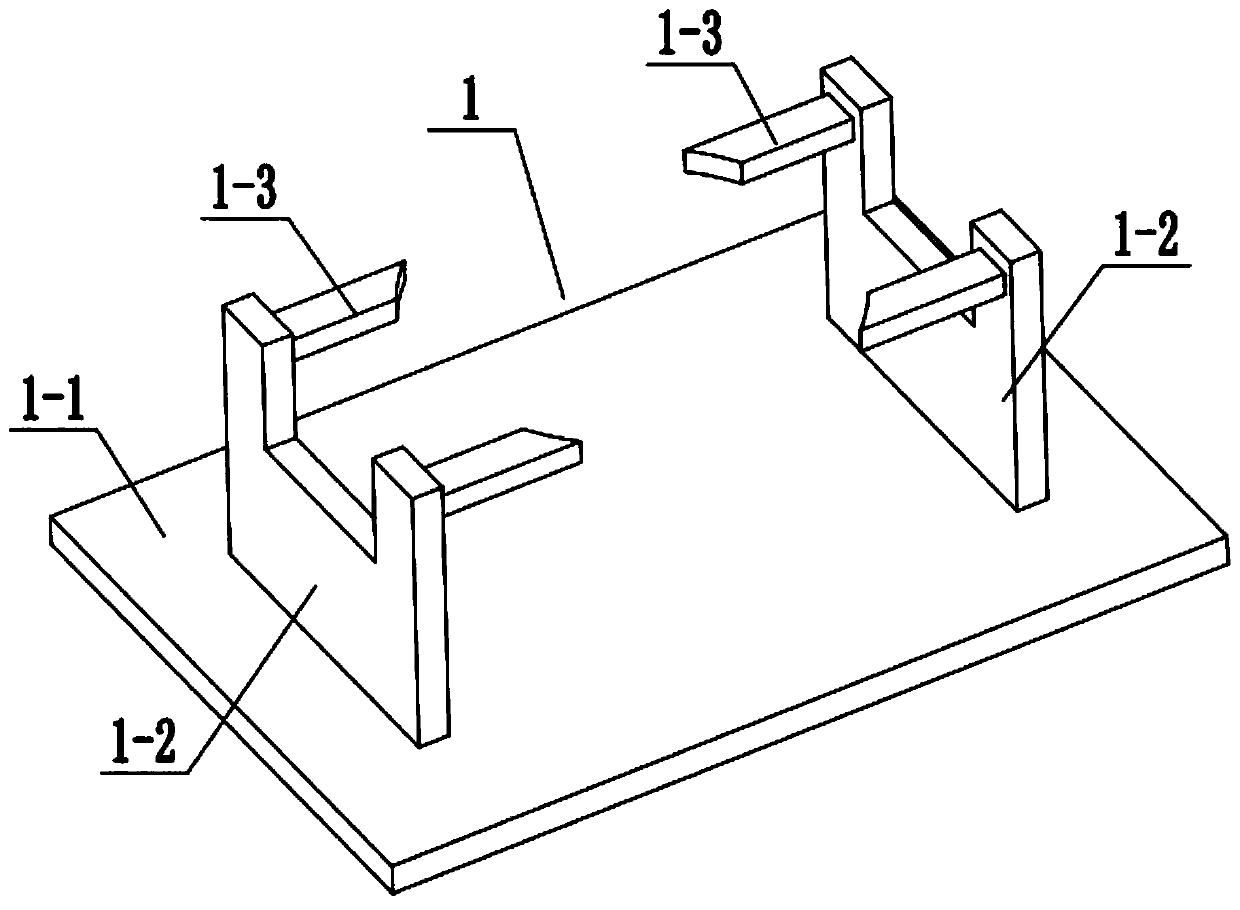

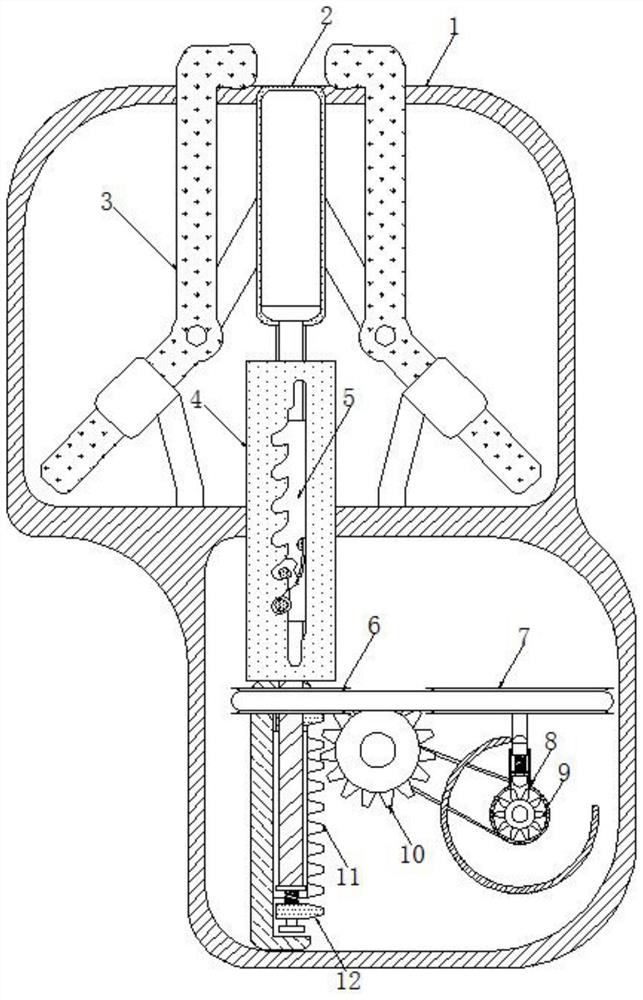

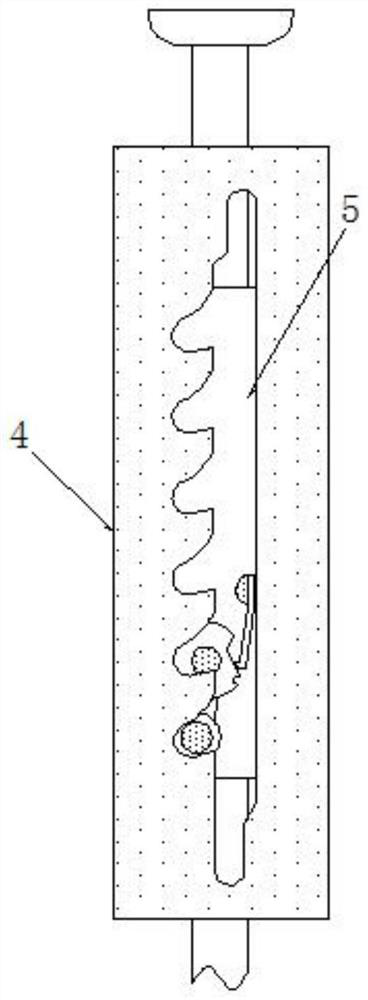

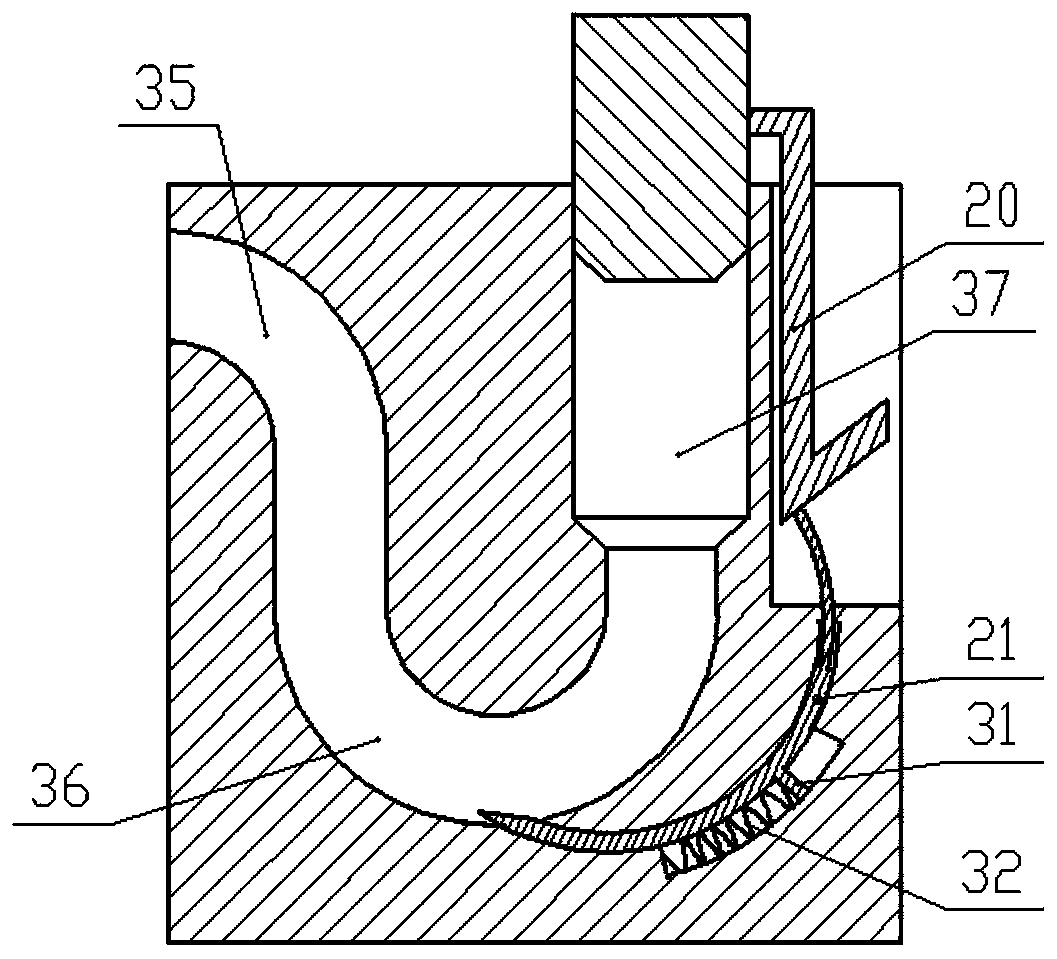

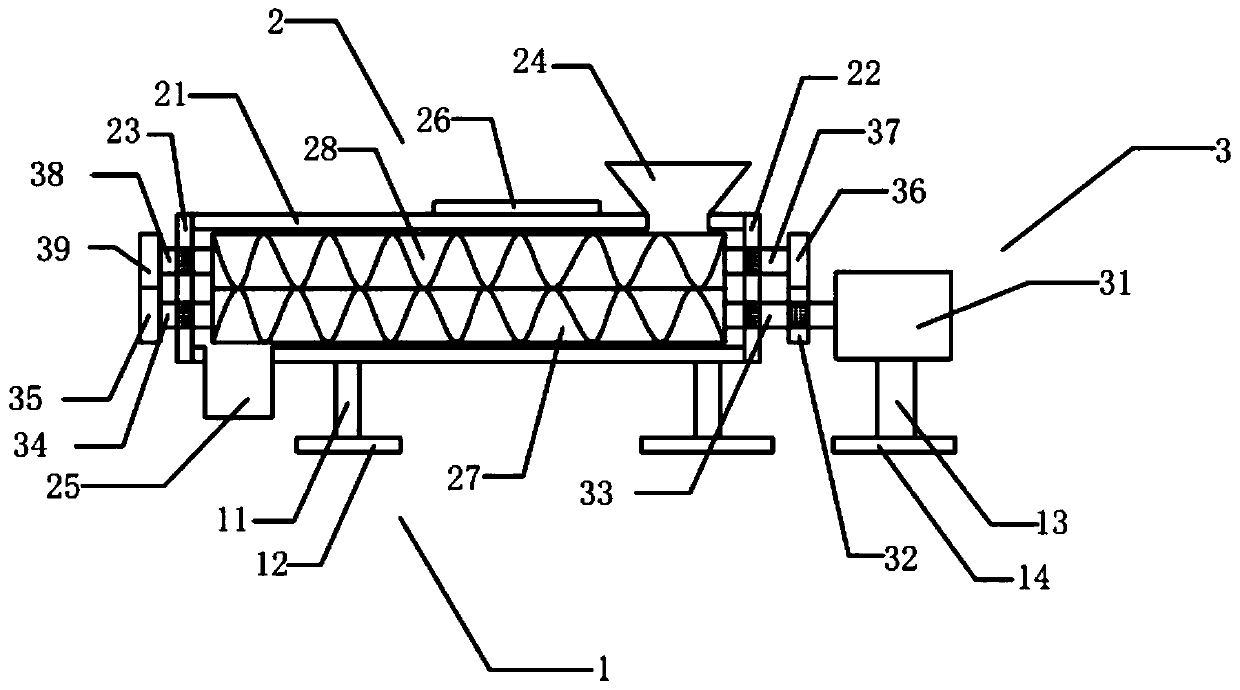

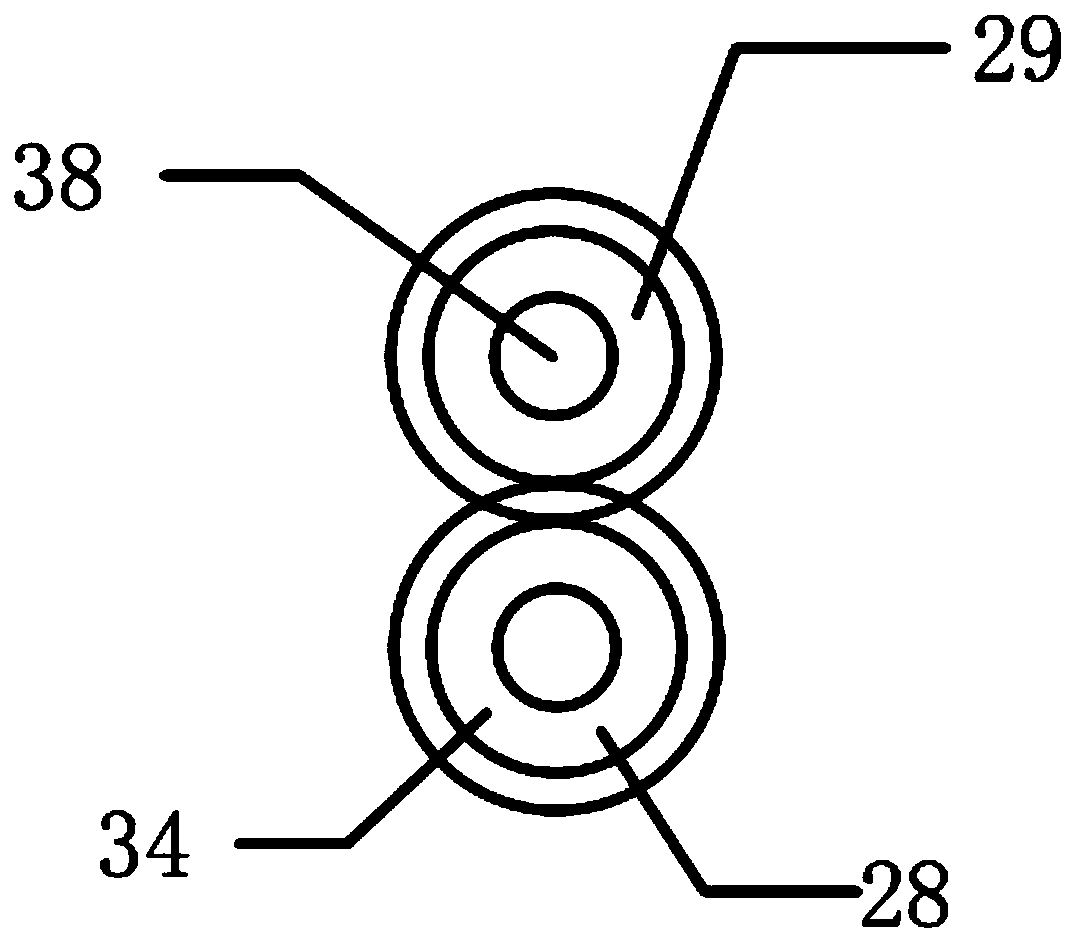

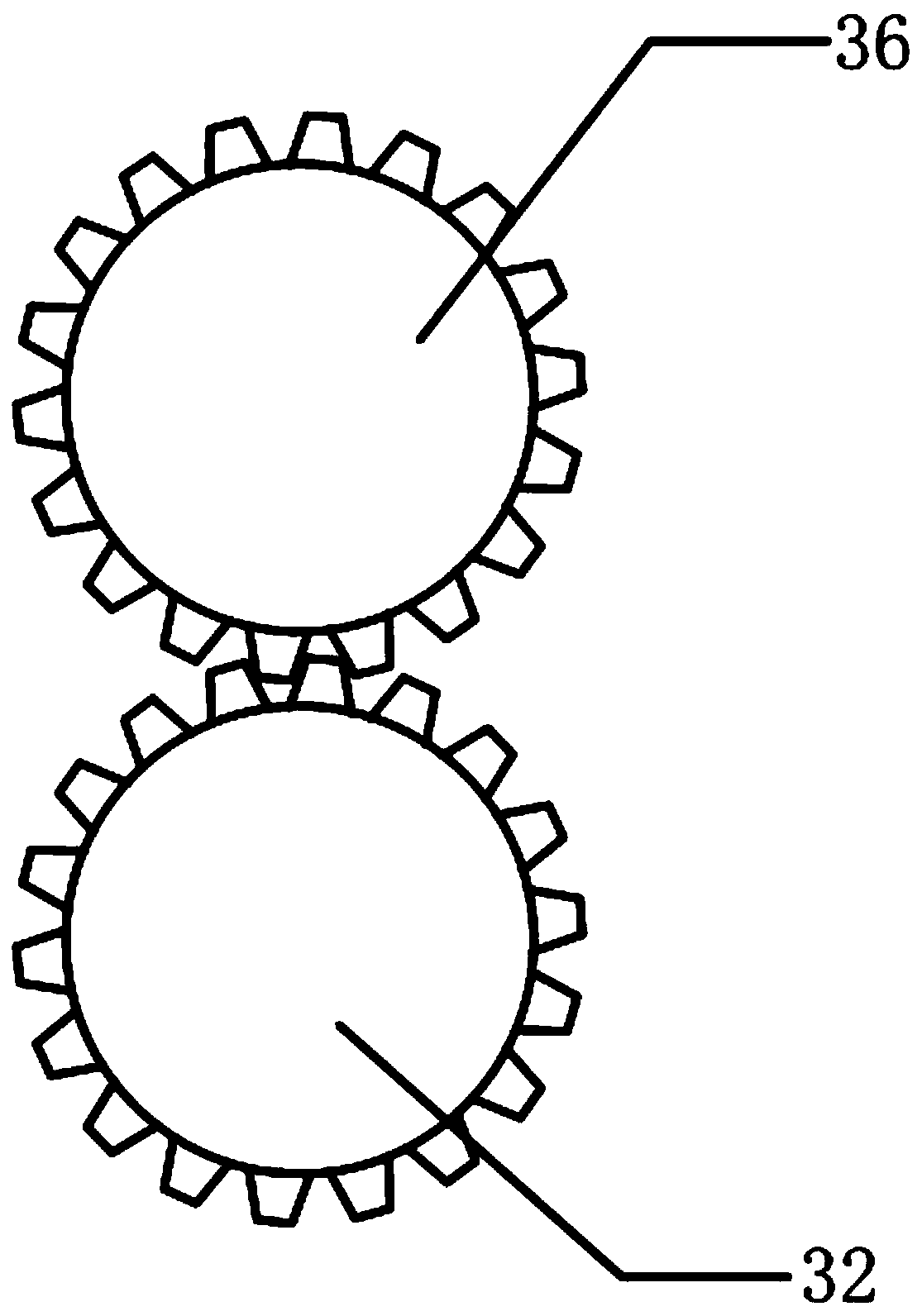

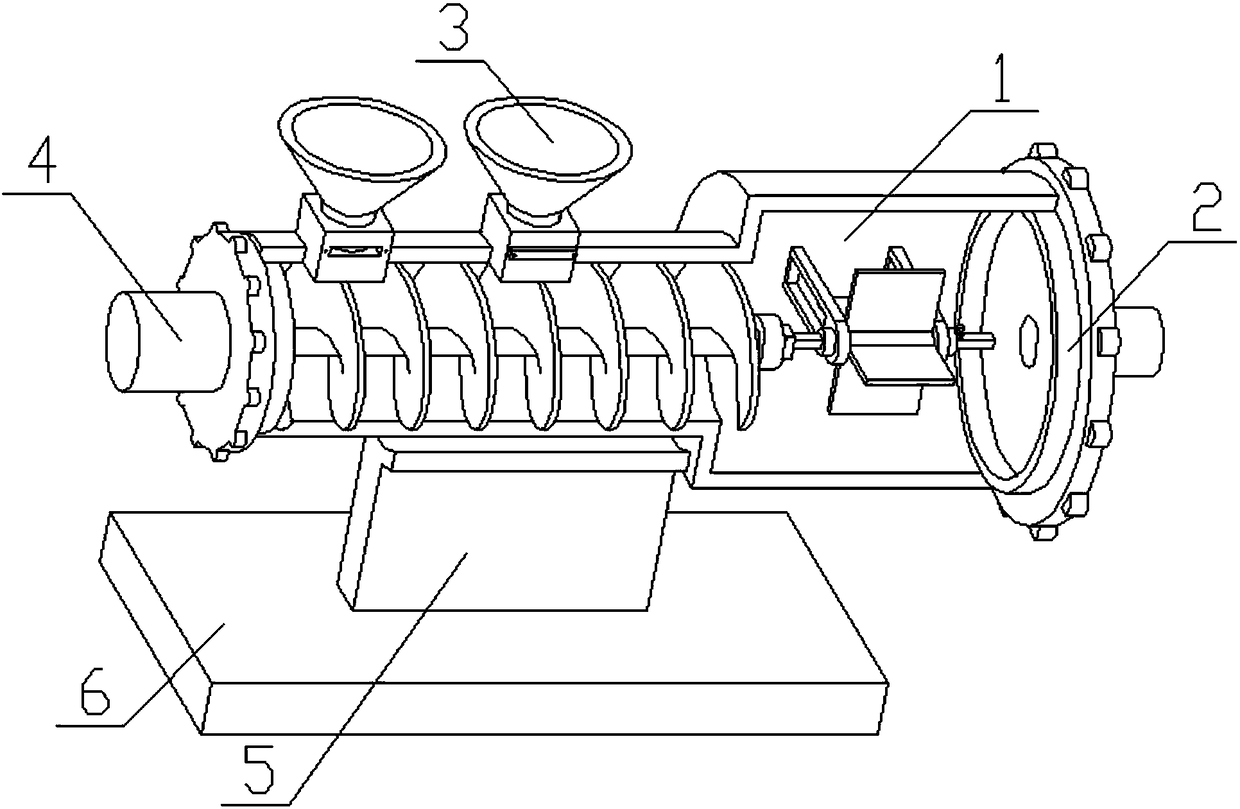

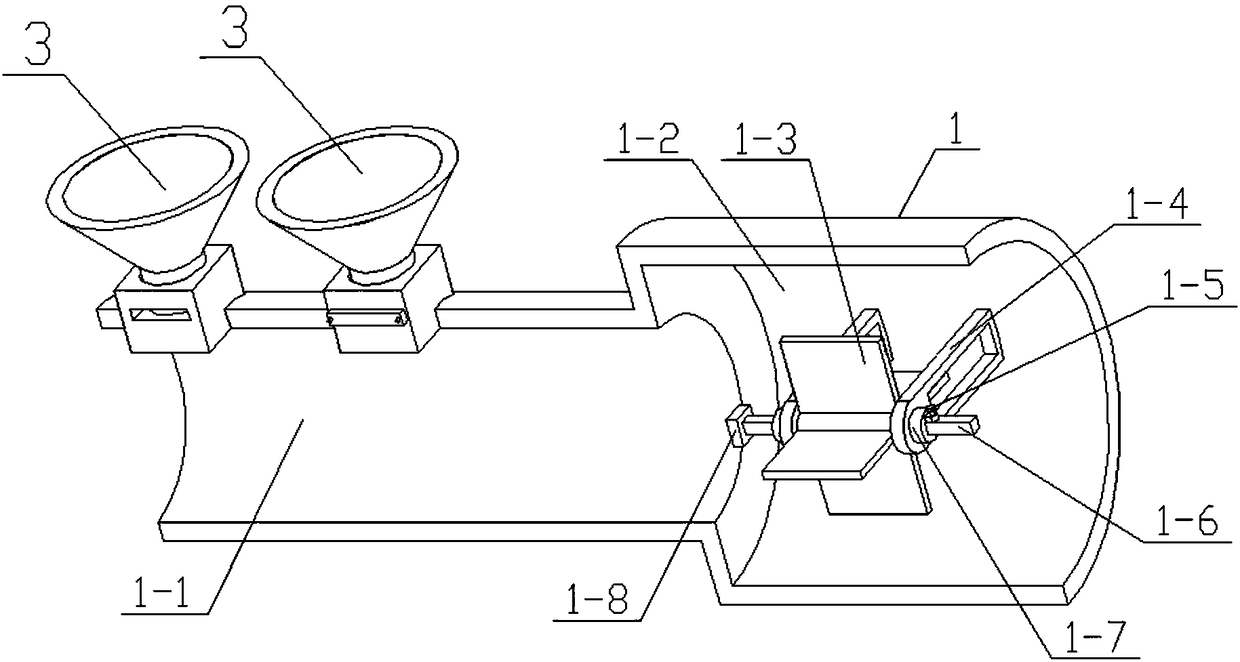

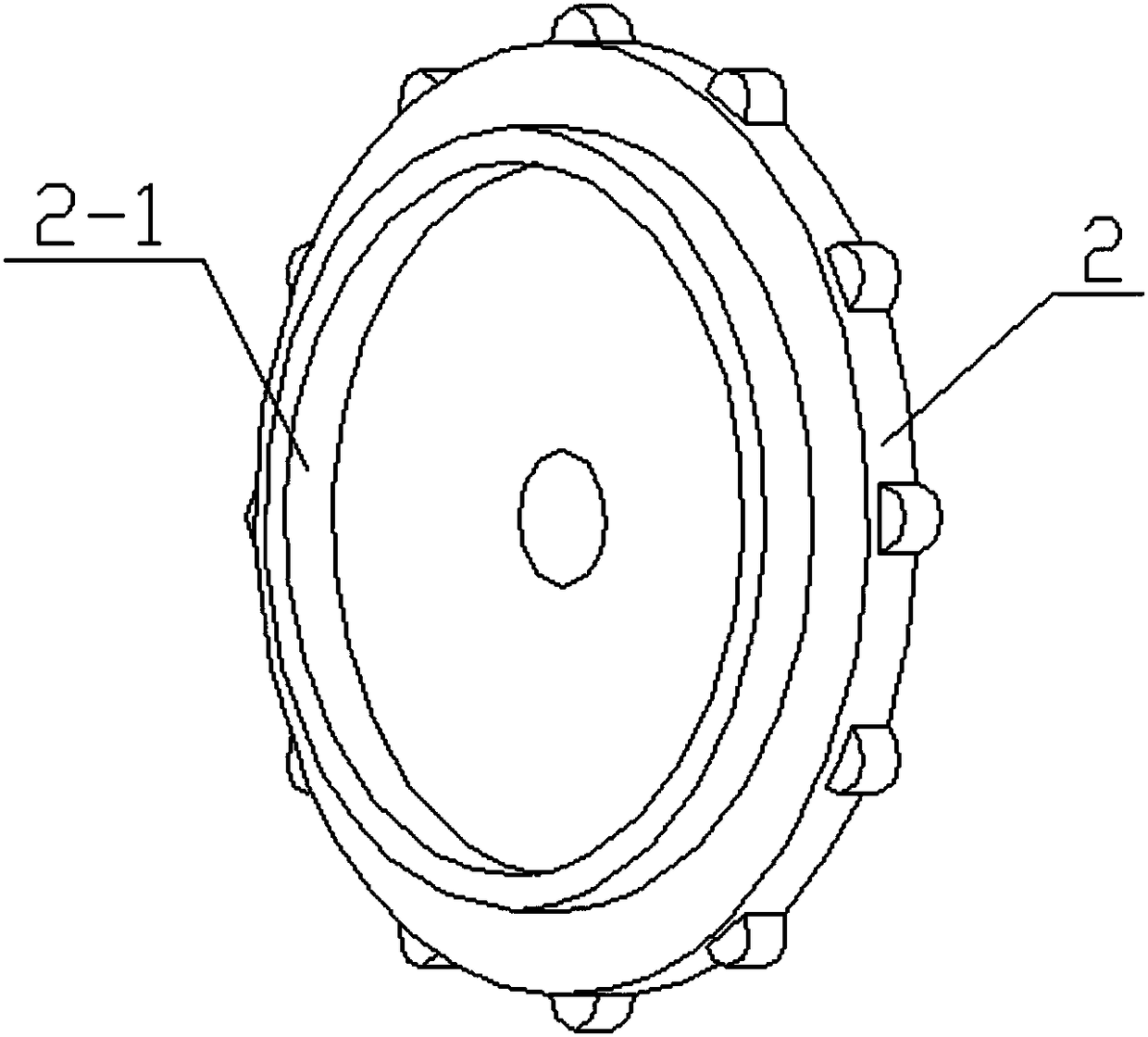

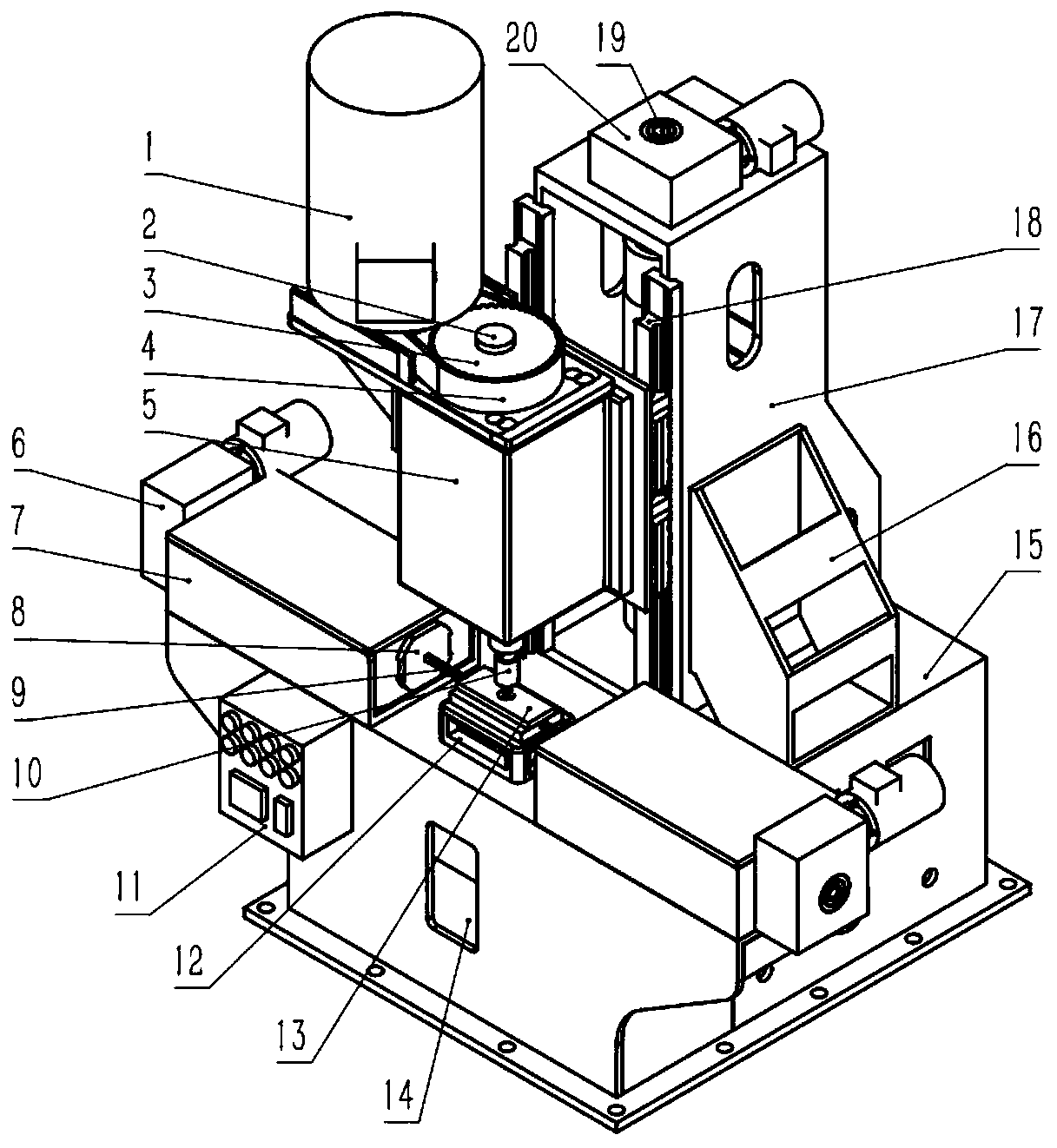

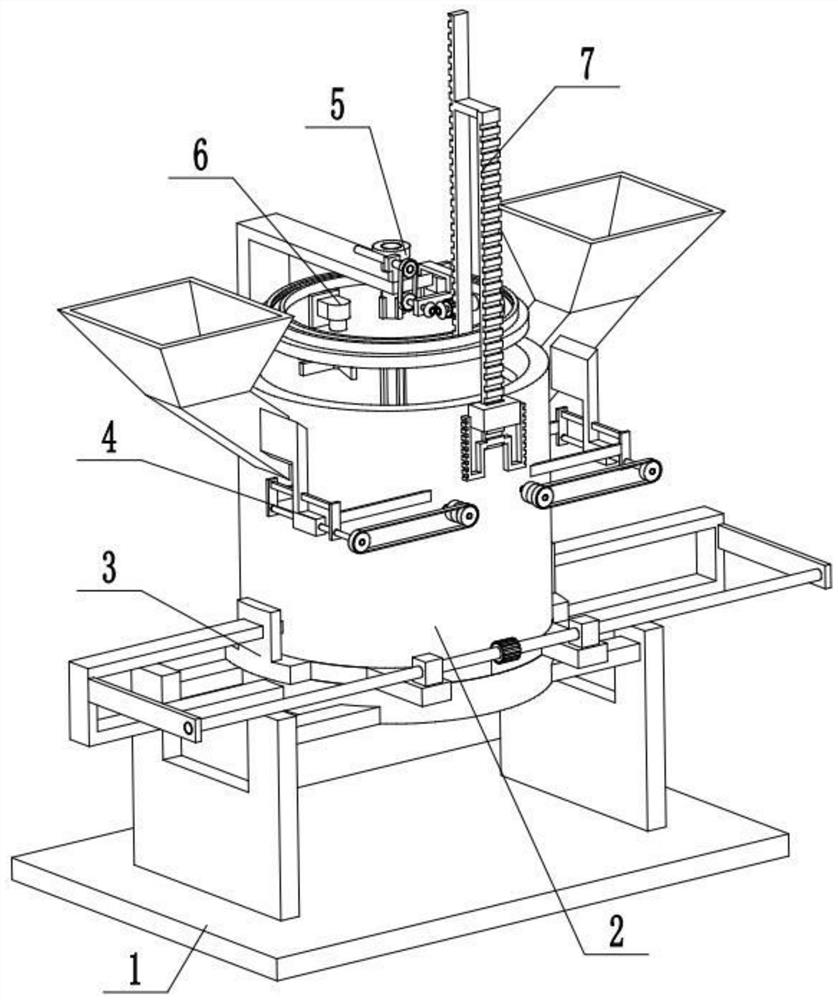

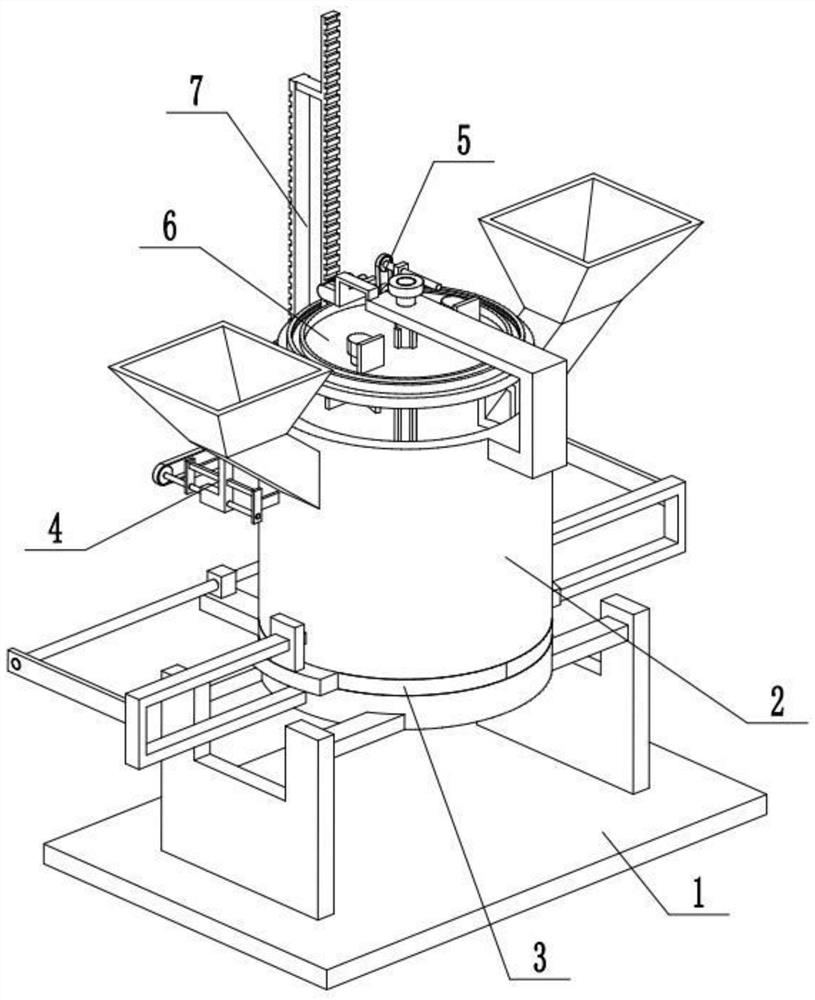

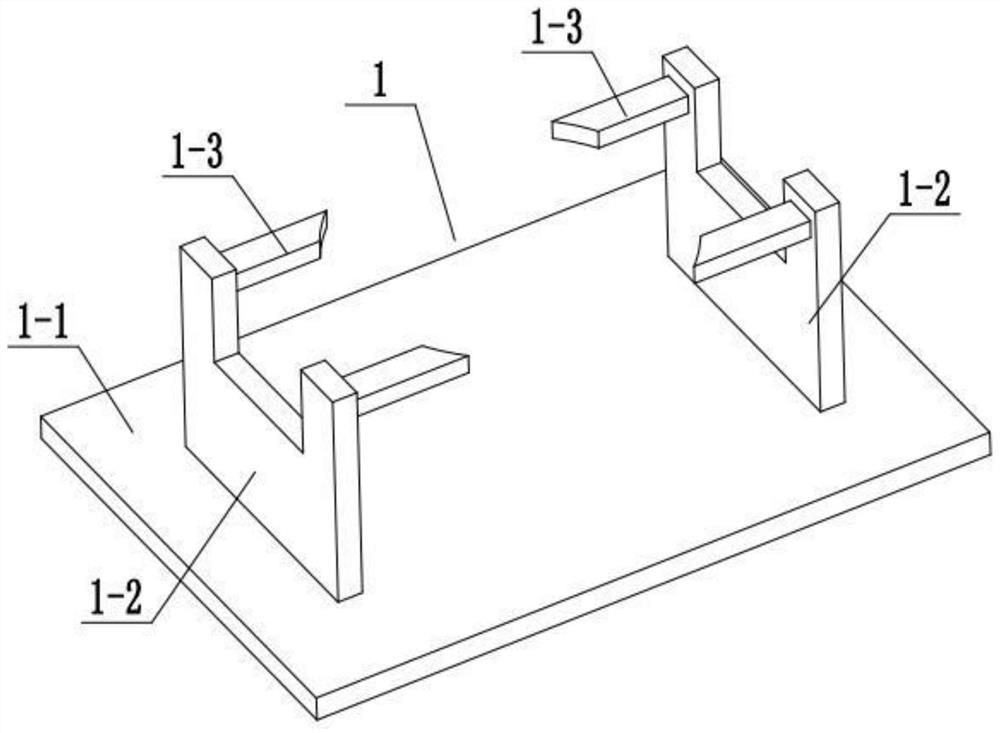

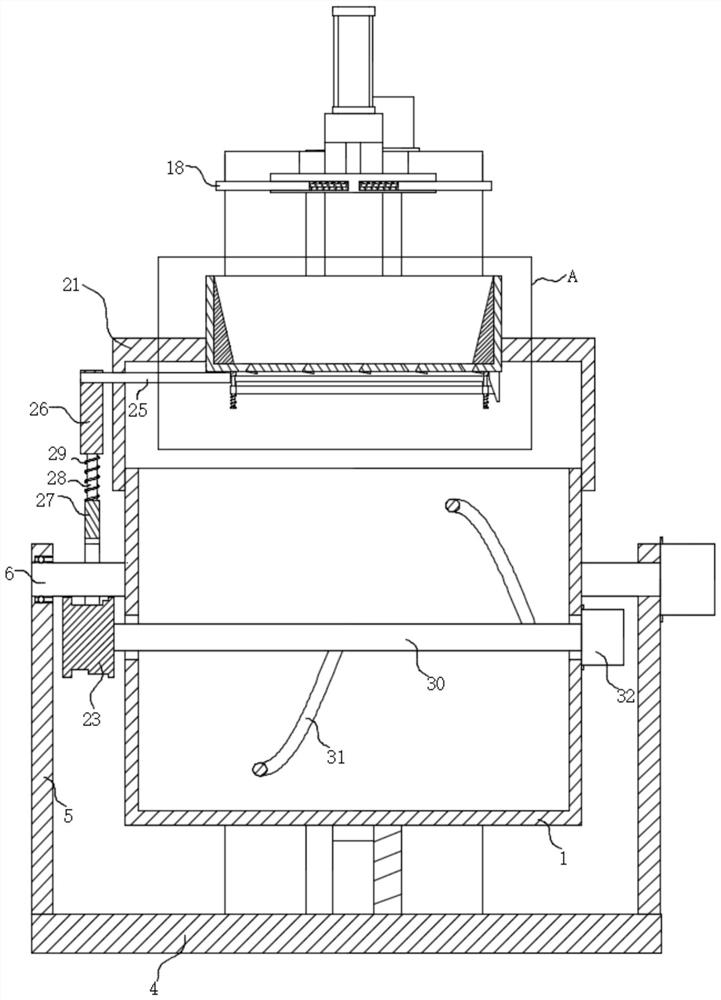

Equipment for extracting skin-moisturizing and wrinkle-resistant cosmetic

ActiveCN110548581ASqueeze out fullyShred fully and comprehensivelyGrain treatmentsWrinkle skinEngineering

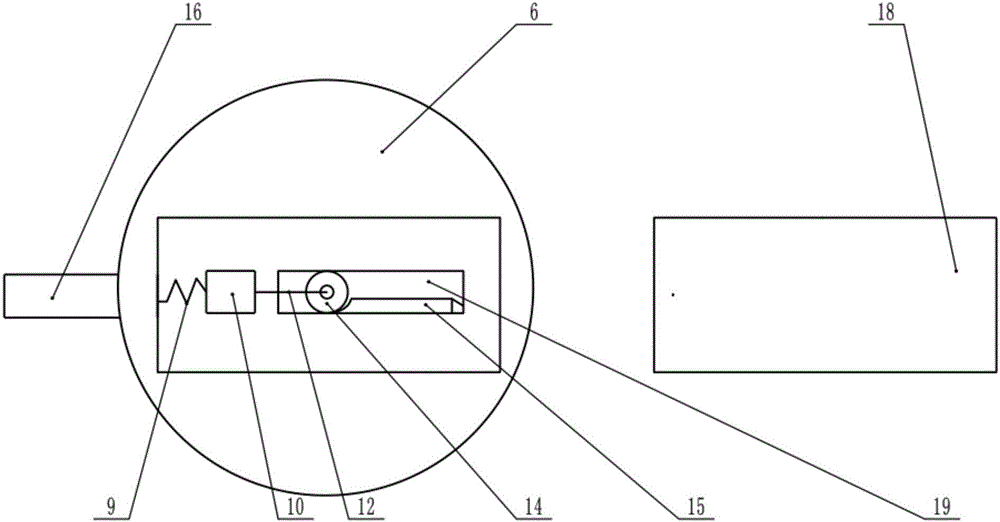

The invention provides equipment for extracting a skin-moisturizing and wrinkle-resistant cosmetic and relates to the technical field of extraction equipment for cosmetic production. The equipment forextracting the skin-moisturizing and wrinkle-resistant cosmetic comprises a bottom frame, an extraction cylinder assembly, a movable baseplate mechanism, intermittent feeding control mechanisms, a power output mechanism, an extruding crushing mechanism and a reciprocating control mechanism. The equipment for extracting the skin-moisturizing and wrinkle-resistant cosmetic has the beneficial technical effects that automatic intermittent feeding can be conducted, thus it is guaranteed that plants in every extruding period are quantitative, thus it is guaranteed that plants in every extruding period can be crushed fully and comprehensively, and it is guaranteed that juice in the plants is extruded fully; and meanwhile, residues can be discharged automatically by the device. The extraction cylinder assembly is fixedly connected to the bottom frame. The movable baseplate mechanism is arranged at the lower end of the extraction cylinder assembly. Two intermittent feeding control mechanisms are arranged symmetrically on two sides of the extraction cylinder assembly. The power output mechanism is fixedly connected to the upper end of the extraction cylinder assembly. The extruding crushingmechanism is connected to the power output mechanism in a sliding-fit manner.

Owner:江西登云健康美业互联有限公司

Oral external ointment discharging device capable of automatically fixing and quantitatively pushing ointment

InactiveCN112023232AIncrease linkageConvenient extrusion operationDentistryMedical devicesPoulticeEngineering

The invention relates to the technical field of oral devices, and discloses an oral external ointment discharging device capable of automatically fixing and quantitatively pushing an ointment. The device comprises a shell; a material pipe is fixedly connected to the interior of the shell; an ejector rod moves up and down to enable vertical rods of two clamping rods to get close to each other and then get away from each other, and the tubular ointment is automatically fixed, so that ointment squeezing operation is facilitated, the situation that an ointment tube moves and consequently the ointment cannot be effectively extruded is avoided, and after the ointment is used, the ointment tube can be released and conveniently replaced; and a first rotating disc rotates to enable a push rod at the top of a movable plate to move upwards gradually at equal intervals and then move downwards smoothly, and the ointment tube is pressurized automatically, so that the situations that during manual extrusion, extrusion force is not easy to control, the extrusion amount is easily too large or too small, extrusion is not thorough enough, and a large amount of the ointment in the ointment tube cannotbe used are avoided, the ointment is quantitatively discharged, the ointment in the ointment tube is fully extruded, and the utilization rate of the ointment is increased.

Owner:刘保华

Waste incineration device

ActiveCN111578286ASqueeze fullySqueeze out fullyDirt cleaningIncinerator apparatusDust controlEnvironmental engineering

The invention discloses a waste incineration device which comprises a vertical smoke inlet pipe connected into a flue. An installing shaft is coaxially fixed into the position close to an outlet end of the smoke inlet pipe. A valve rod is axially and slidingly installed in the installing shaft. A dustproof cover on the valve rod comprises a gravity center body and a dust blocking cover ring whichare integrally connected. The gravity center body is fixedly connected with the valve rod. A pre-pressing device comprises an outer sleeve, an inner sleeve and a flow guide cover cylinder. The flow guide cover cylinder axially and slidingly sleeves the inner sleeve. A compression cylinder, a supporting rod, a bottom plate and a hydraulic supporting shaft are sequentially arranged in the inner sleeve from top to bottom. The hydraulic supporting shaft is used for supporting the bottom plate and pushing the bottom plate to move up and down. The bottom plate is connected with the compression cylinder through the supporting rod. A compression channel for compressing waste is formed in the compression cylinder. The waste incineration device can primarily collect dust obtained after comprehensivewaste incineration, lays a firm foundation for further thorough removal of dust, and can efficiently and smoothly compress and squeeze waste before incineration.

Owner:XIAN JUYUAN INFORMATION TECH CO LTD

High-temperature-resistant polyethylene composite material and preparation process thereof

InactiveCN110655703AImprove flame retardant performanceImprove high temperature resistanceFiberCarbon fibers

The invention discloses a high-temperature-resistant polyethylene composite material and a preparation process thereof. The polyethylene composite material is prepared from the following raw materialsin parts by weight: 80-100 parts of polyethylene, 7.5-9 parts of an antioxidant, 8-10 parts of a modified flame retardant, 6-8 parts of a lubricant, 8.5-10 parts of titanium dioxide, 12-14 parts of carbon fibers and 6-9 parts of a plasticizer. According to the invention, the modified flame retardant is added in the preparation process which has very good flame retardance, and a large amount of carboxyl groups at the same time, carboxyl groups have relatively high polarity, so that the volatility resistance and the high-temperature resistance of the material are improved; the carbon fibers arehigh-strength high-modulus fibers with a carbon content of 90% or more, and have good high temperature resistance; titanium dioxide can be converted into rutile state from anatase state at high temperature, the material high temperature resistance can be better improved, and the high temperature resistance of the polyethylene composite material is further improved by mixing the modified flame retardant with the carbon fibers and titanium dioxide powder.

Owner:安徽瑞琦塑胶科技有限公司

Modular type soil body pressing molding device with soil blocking function

InactiveCN108360497APrevent sideways movementImprove compactnessIn situ soil foundationSoil preservationEngineeringUltimate tensile strength

Owner:ZHEJIANG JIA YUAN CIVIL ENG CO LTD

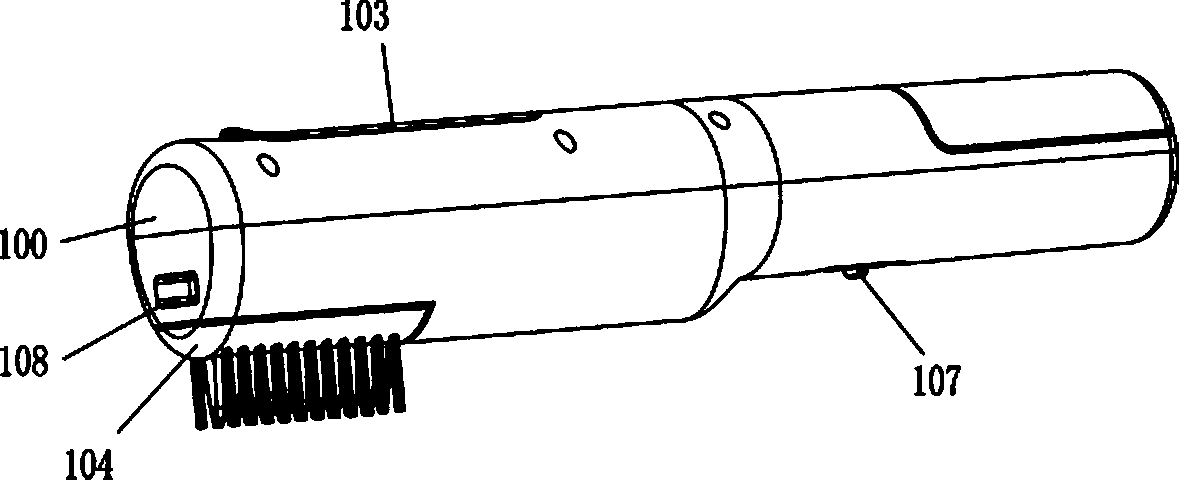

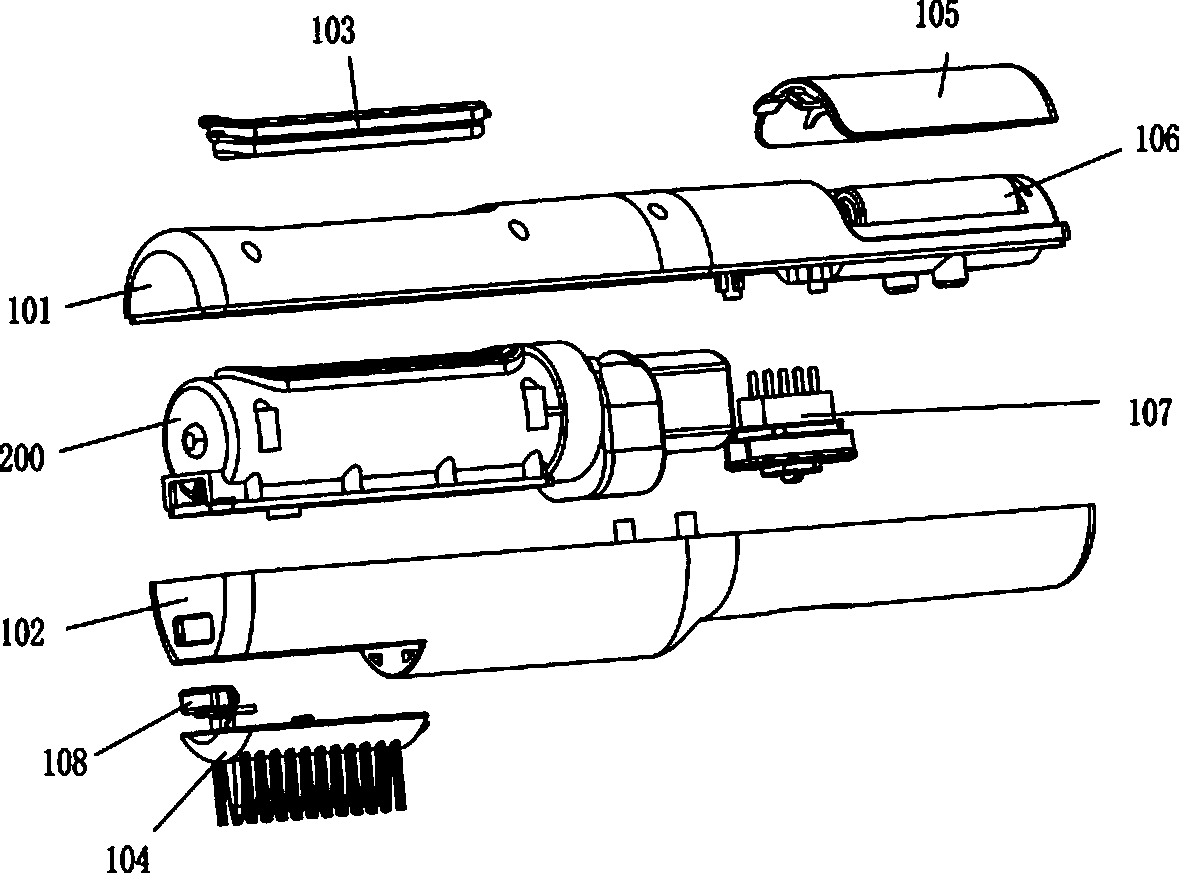

Tooth brushing cup capable of squeezing toothpaste

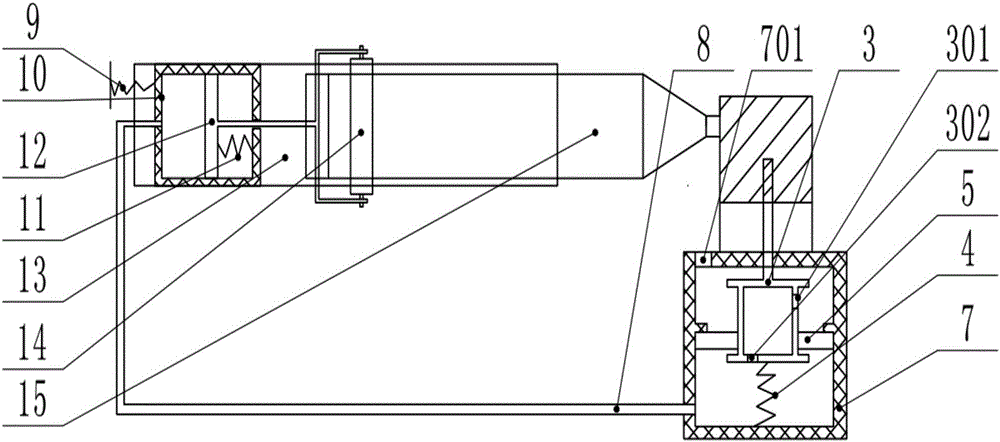

ActiveCN106419696ASqueeze out fullyReduce wasteArticle unpackingHolders and dispensersPressure transmissionToothpaste

The invention provides a tooth brushing cup capable of squeezing toothpaste, in particular to a scheme achieving the purpose that a toothbrush cup has a toothpaste squeezing function based on the air pressure principle and belongs to the field of daily necessities. The tooth brushing cup capable of squeezing the toothpaste is composed of a toothbrush containing shell, a sliding block, a hollow sliding body, a hollow sliding body spring, a large piston, a cup shell, a large air cylinder, an air guide tube, a small air cylinder spring, a small air cylinder, a small piston spring, a small piston and roller frame assembly, a small air cylinder sliding groove, a roller, a cup handle, a bottom face cover plate and a roller sliding groove. The tooth brushing cup has the advantages that a toothbrush is inserted into the toothbrush containing shell, the roller is driven to squeeze the toothpaste through air pressure transmission, when the toothpaste needs to be squeezed, pressing can be carried out through the sliding block under the toothbrush, and convenience and fastness are achieved. The toothpaste is fully squeezed through the roller, and toothpaste waste is reduced. By means of air pressure transmission, the toothpaste can be squeezed with small efforts based on the Pascal principle in the process of squeezing the toothpaste.

Owner:新昌县佛虑机械配件厂

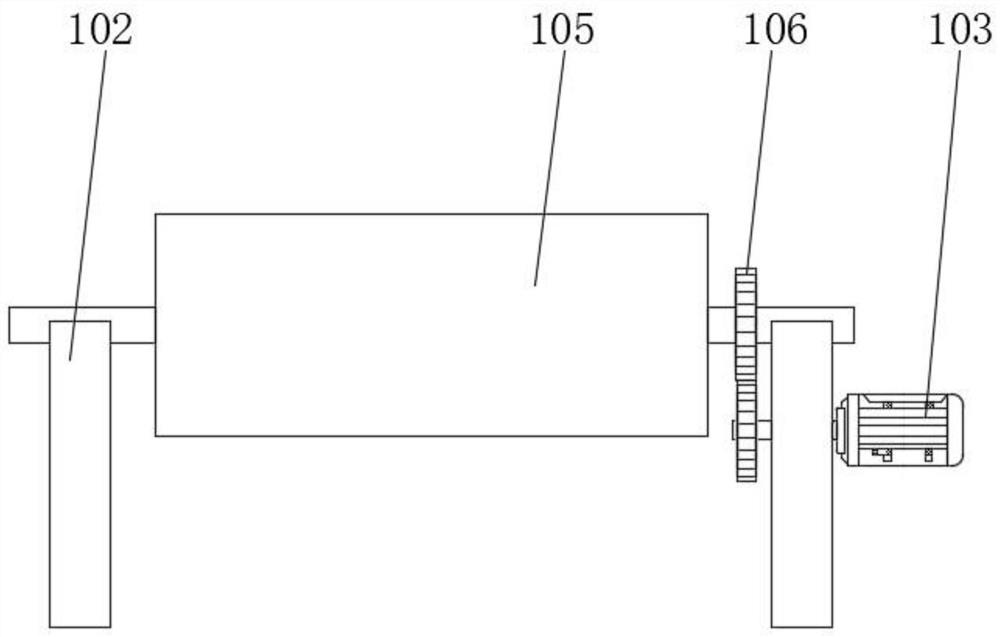

Polyethylene pipeline production equipment

PendingCN107639801AImprove cooling effectReduce cooling effectTubular articlesElectrical connectionCooling chamber

The invention provides polyethylene pipeline production equipment which comprises a base, a vacuum cooling chamber, a sprinkling chamber and a segmenting chamber. Castors are arranged at the bottom ofthe base, a first motor is arranged at the left end of the top of the base, a material barrel is arranged at the left end of the top of the base and arranged on the right side of the first motor, a feeding bucket and a controller are both arranged at the top outside the material barrel, the controller is arranged on the right side of the feeding bucket, the first motor and the controller are in electrical connection, a screw is arranged in the material barrel, the left end of the screw extends to the outside of the material barrel to be movably connected with an output end of the first motor,a fixing plate is arranged on the right side wall in the material barrel, and the right end of the screw is movably connected with the fixing plate through a first bearing. The polyethylene pipelineproduction equipment is mounted on the base and can be moved due to arrangement of the castors, and multiple processing procedures are set in the equipment.

Owner:海宁亚大塑料管道系统有限公司

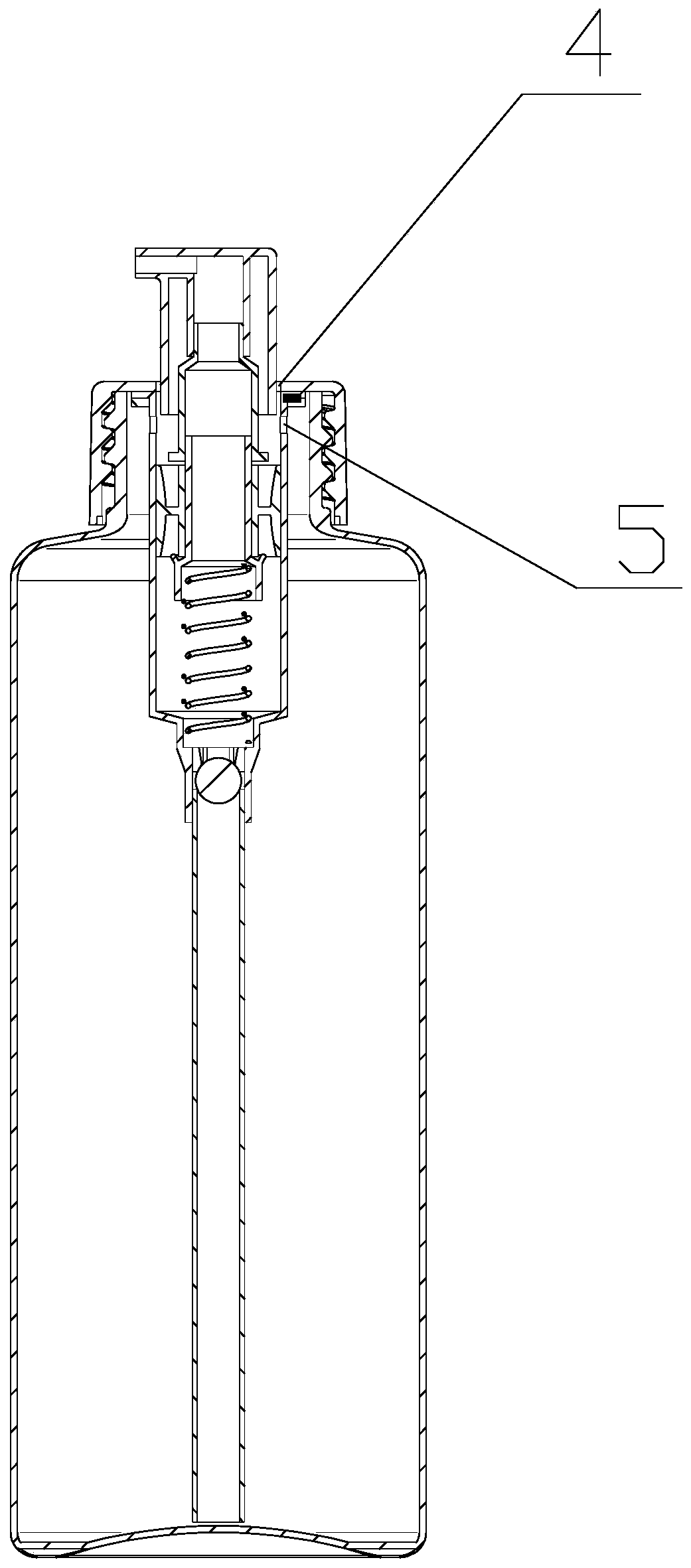

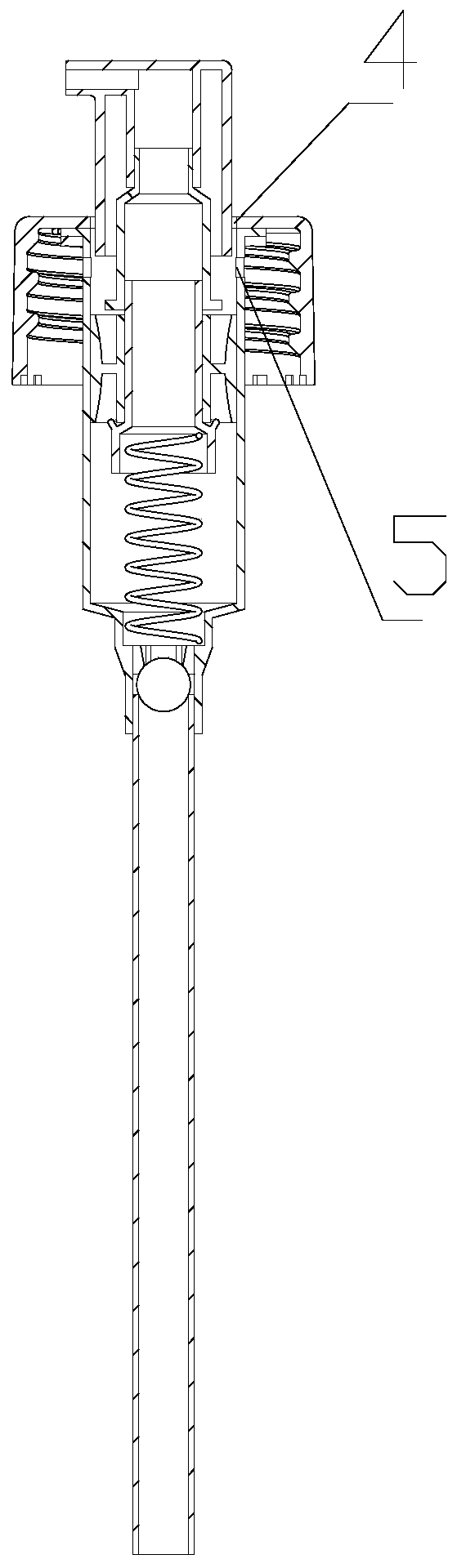

Pressing bottle with bag

The invention discloses a pressing bottle with a bag. The pressing bottle with the bag comprises the inner bag, a bottle body and a pump head connected with the bottle body; the inner bag is positioned in the bottle body; an opening of the inner bag is connected with an opening of the bottle body; a through hole communicating with the outside is formed in the bottle body; the minimum elastic modulus of the material of the bottle body is not lower than 850 MPa, and the material of the inner wall of the bottle body is not bonded with EVOH; the inner bag comprises an EVOH layer and an LDPE layer;the EVOH layer and the LDPE layer are bonded through an adhesive; the EVOH layer is positioned on the outermost side of the inner bag; and the air does not enter the inner bag from outside the bottlebody during the processes of the pressing and the rebounding of the pump head. The pressing bottle with the bag is less in using residue and good in user experience; contents in the bottle can be isolated, the quality of the contents is improved, and the shelf life of the contents is prolonged; the design is unique, the structure is simplified, the cost is low, the shape and the size of the bottle body are controllable, and the bottle body is attractive and elegant; and after the pressing bottle is used, the bottle body is separated from the inner bag, no content residue exists in the bottlebody, and the bottle body can be directly recycled, so that the energy is saved, the environment is protected, and the pressing bottle has great application prospects.

Owner:精英模具制品(上海)有限公司

Novel extruding machine and using method thereof

The invention discloses a novel extruding machine and a using method thereof. The novel extruding machine comprises a material barrel, an extrusion opening cover, a feeding hopper and a motor assembly; the material barrel comprises an extrusion barrel, a stirring barrel, stirring blades, stirring shaft supports, a fastening screw, a square sliding rod, a stirring shaft and a square insertion block, the extrusion barrel and the stirring barrel are both of cylinder structures and are connected in a welding manner, the stirring barrel is located at the right end of the extrusion barrel, the two stirring shaft supports are welded to the inner wall of the stirring barrel, the stirring shaft is rotationally connected between the two stirring shaft supports through a bearing, the multiple stirring blades are welded to the stirring shaft, and the fastening screw is in threaded connection to the right end of the stirring shaft.

Owner:俞云飞

Combined type multi-functional vermicelli machine

ActiveCN104957473AIncrease temperatureImprove extrusion efficiencyFood shapingFood preparationProcess engineeringMechanical engineering

The invention discloses a combined type multi-functional vermicelli machine, and belongs to vermicelli machines in the technical field of food processing equipment. The invention aims to provide the combined type multi-functional vermicelli machine which provides a constant temperature range value for ageing vermicelli, so that the ageing degree of the vermicelli is controlled to be in a better range. The technical scheme lies in that the combined type multi-functional vermicelli machine comprises a machine frame and a powder sleeve, wherein a screw rod is mounted in the powder sleeve in a sleeving manner, and screwing-in vanes are arranged on the screw rod; a feed hopper is arranged at the feed end of the powder sleeve, a discharging mold is arranged at the tail end of the discharge end of the powder sleeve, a tail heater is arranged outside the discharge end of the powder sleeve in a sleeving manner, and a constant-temperature sleeve is arranged outside the powder sleeve in a sleeving manner; a heater and a temperature sensor are arranged on the constant-temperature sleeve, and the heater and the temperature sensor are respectively and electrically connected with an external control cabinet; the vermicelli machine is communicated with a steam pot through a steam conduit. The combined type multi-functional vermicelli machine disclosed by the invention is suitable for producing the vermicelli.

Owner:叙永县鸿艺粉业有限公司

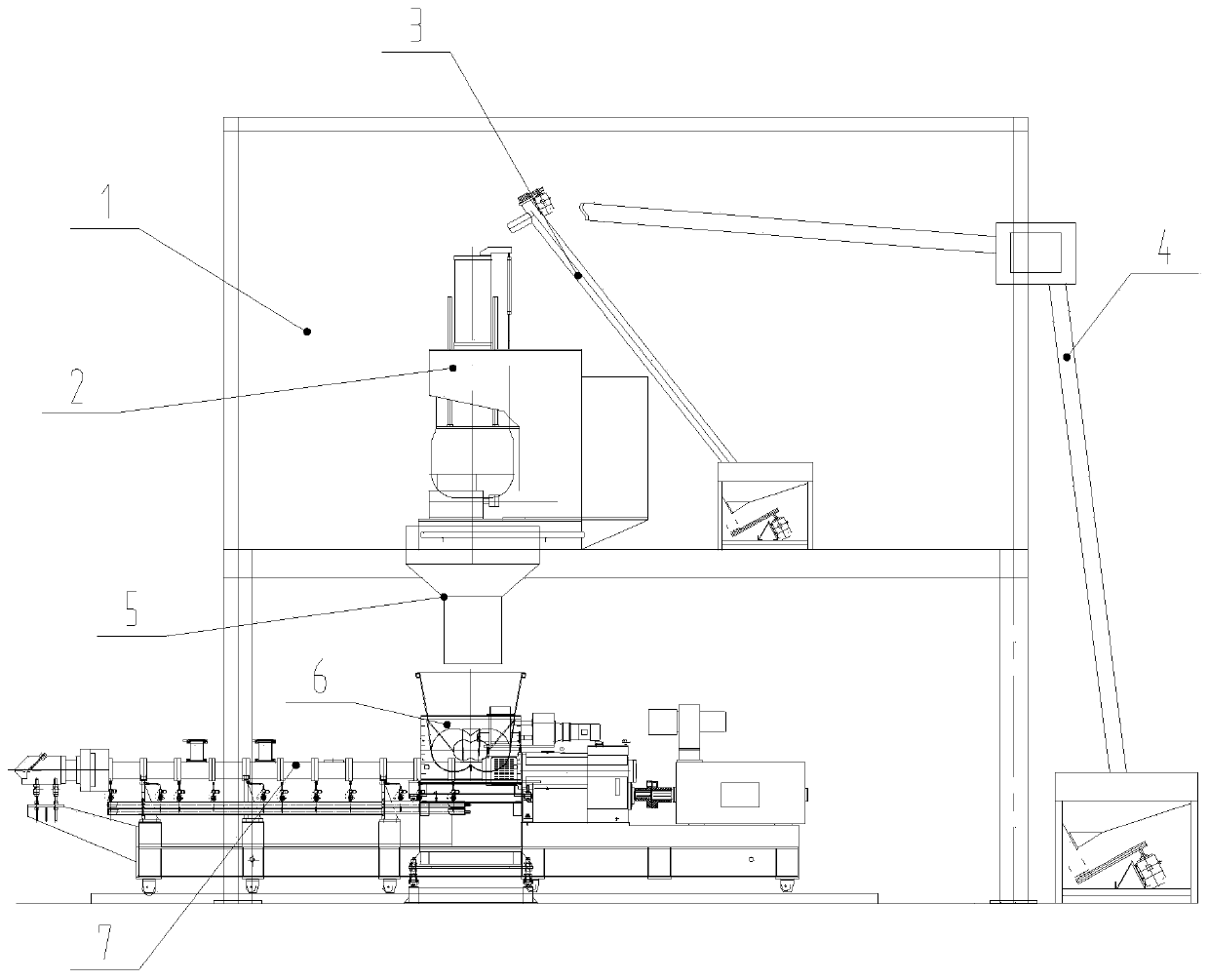

Drying system for sludge treatment

ActiveCN106630534AImprove drying efficiencyAvoid crowdingSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentSludgeThermal insulation

The invention relates to a drying system for sludge treatment. The drying system comprises a casing, a sludge feeding device, a plurality of chain plate conveying devices, a guiding device, a thermal insulation device and a sludge output device, wherein the sludge feeding device is located above a sludge inlet of the casing, and the sludge output device is located below a sludge outlet of the casing; the plurality of chain plate conveying devices arranged in the casing are sequentially arranged from top to bottom, and sludge falls onto lower chain plate conveying devices from upper chain plate conveying devices with rotation of the chain plate conveying devices; the guiding device and the thermal insulation device which are arranged in the casing divide the inside of the casing into a drying chamber and a cooling chamber, the plurality of chain plate conveying devices are located in the drying chamber, and at least one chain plate conveying device is located in the cooling chamber; the guiding device for guiding hot air is placed at the bottom of the drying chamber and located above the thermal insulation device. The drying system can efficiently dry sludge and belongs to the technical field of sludge treatment.

Owner:GUANGZHOU UNIVERSITY

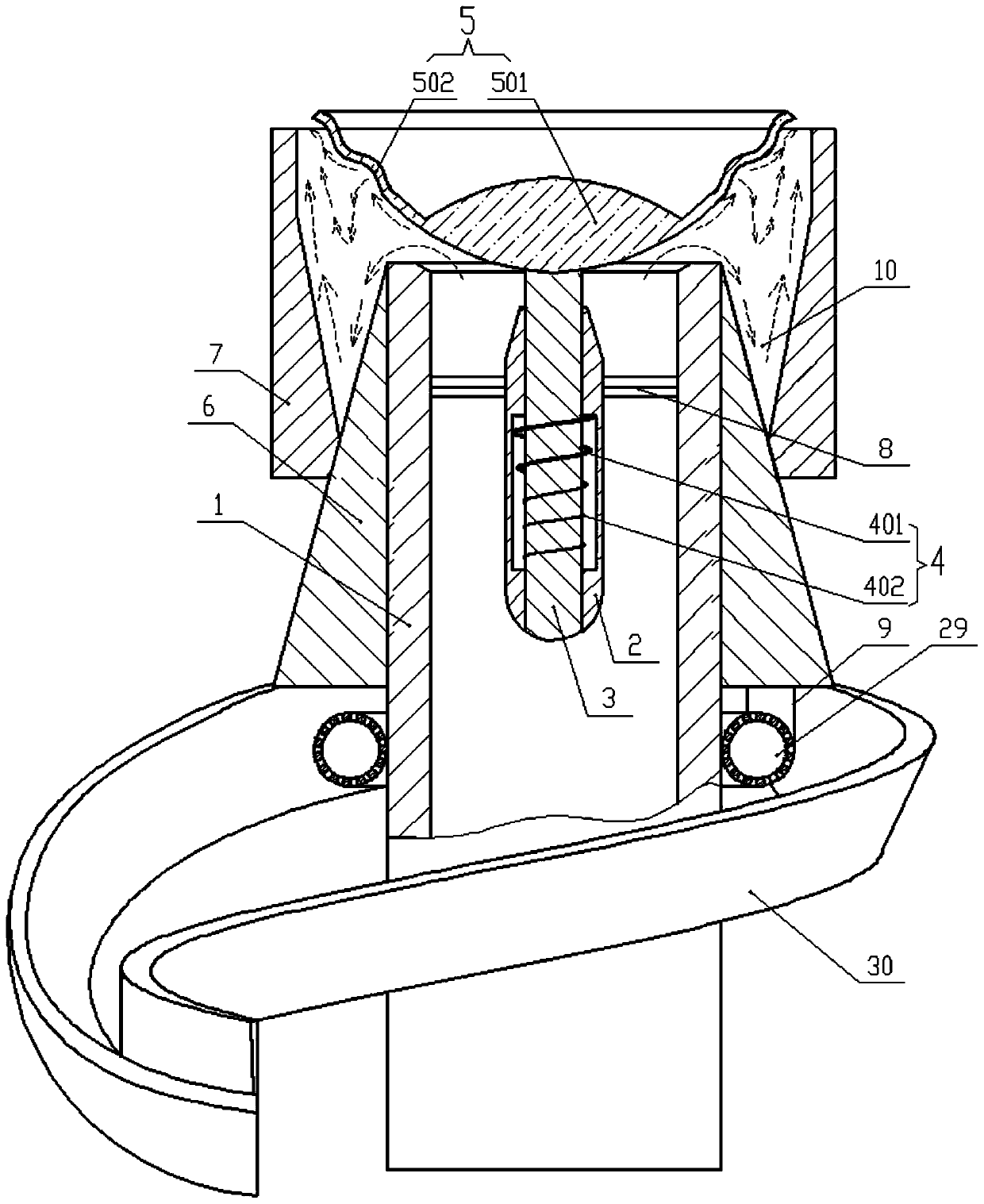

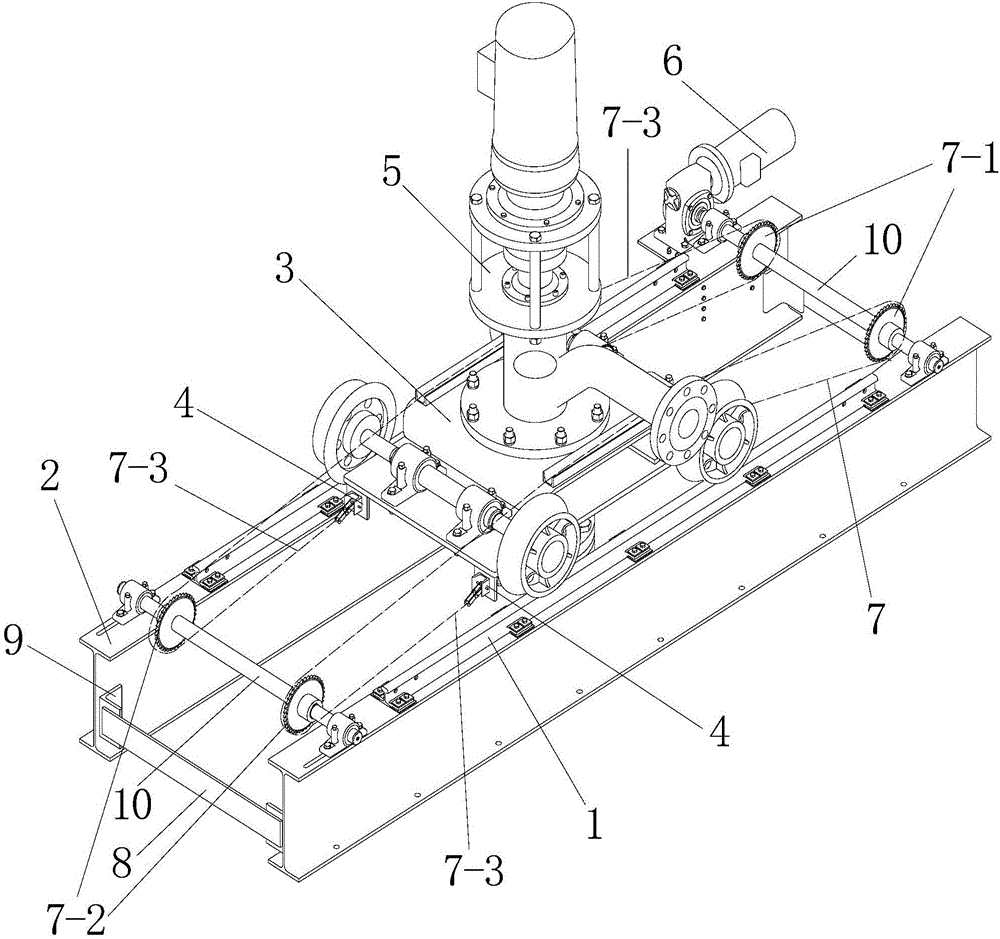

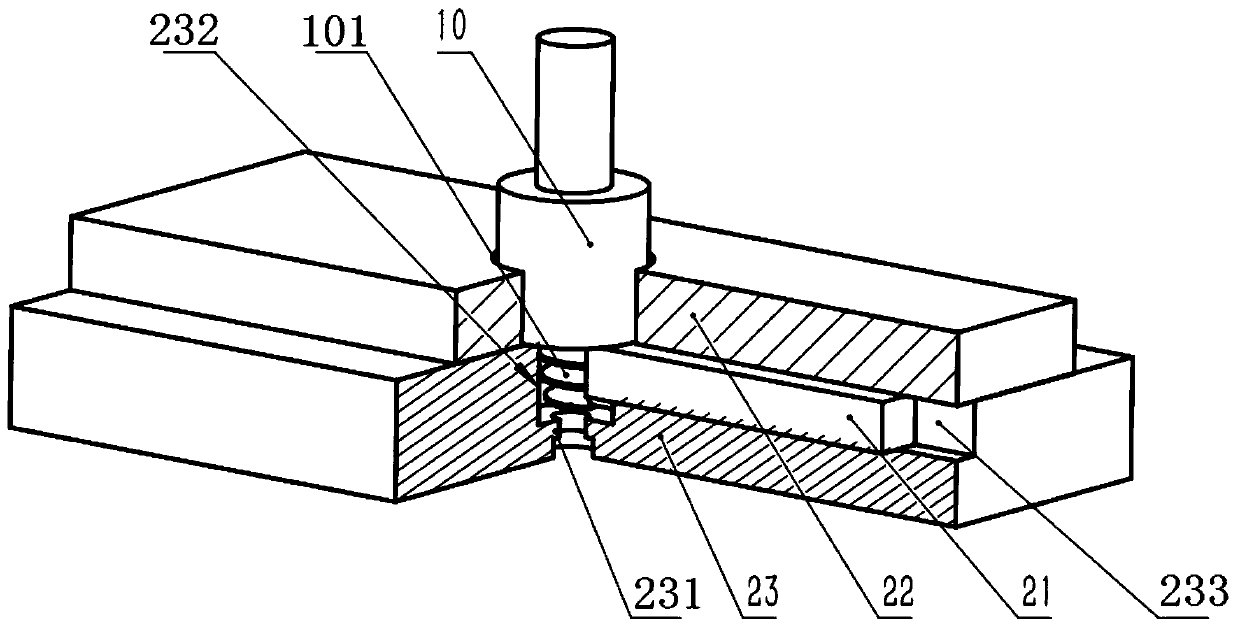

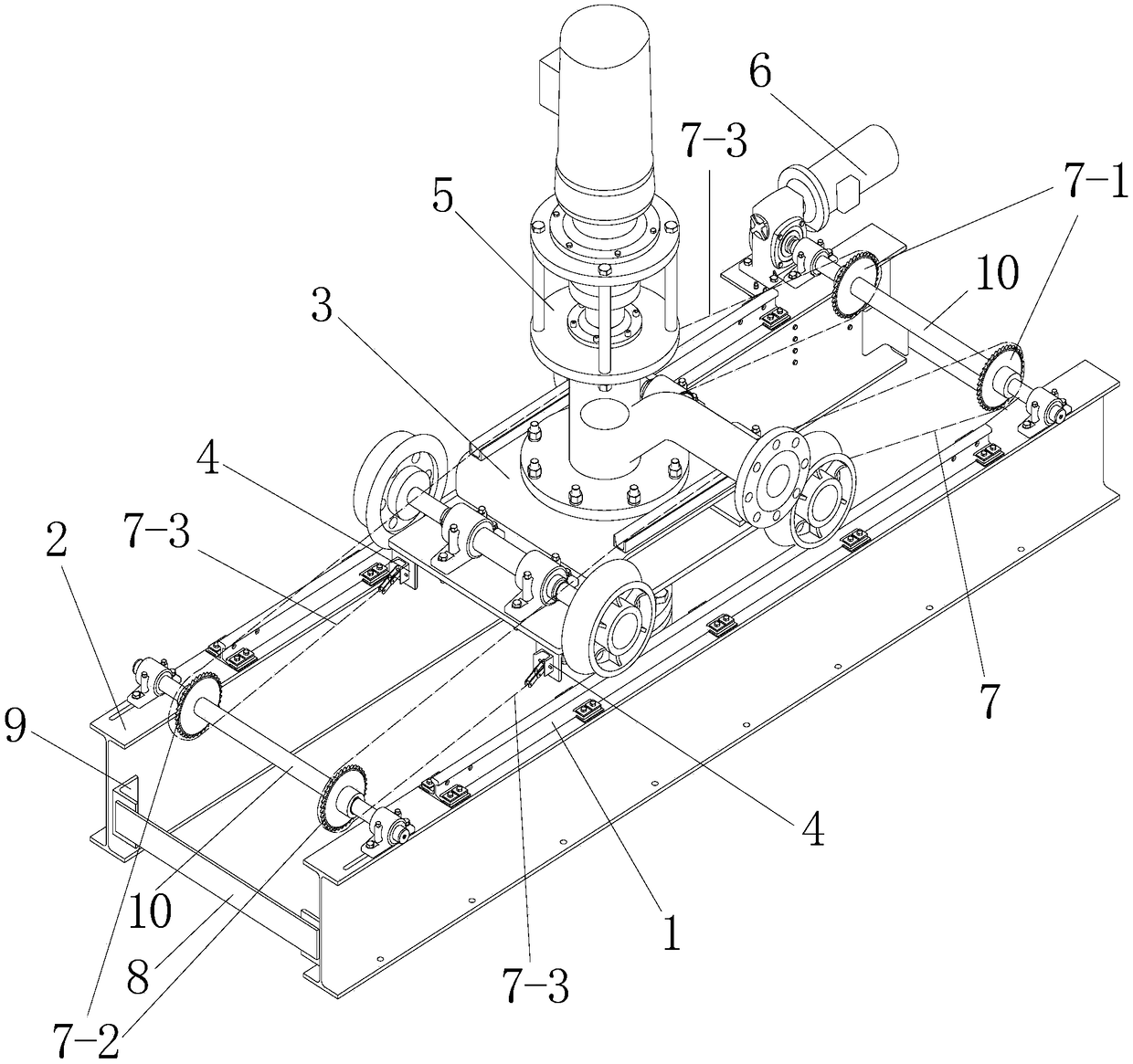

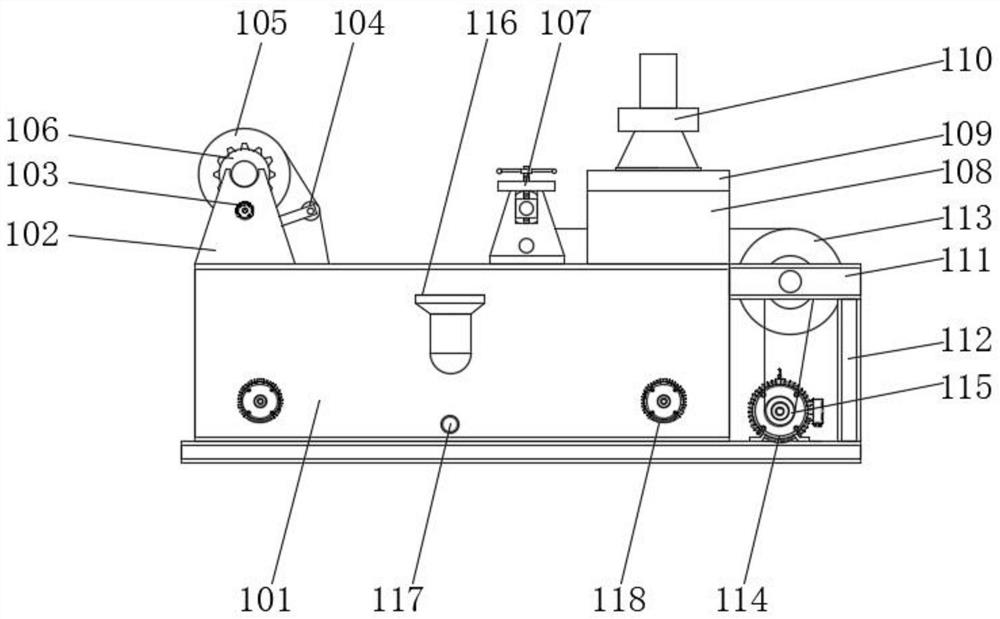

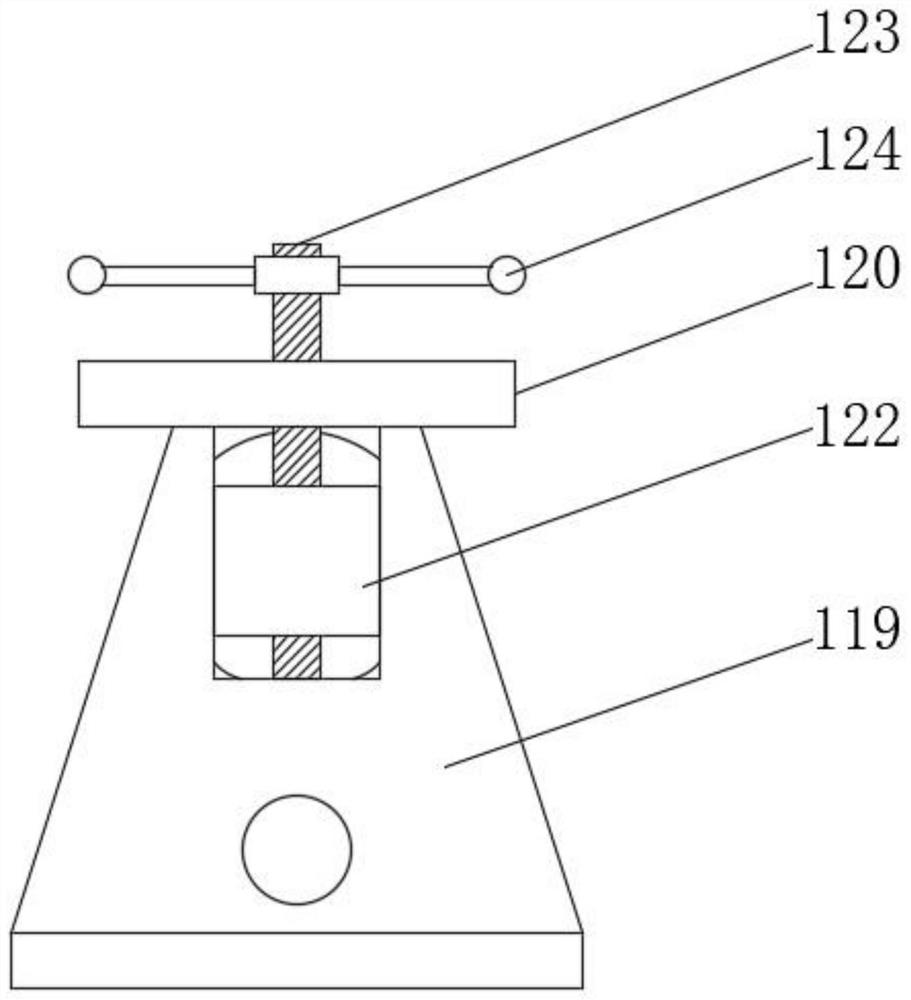

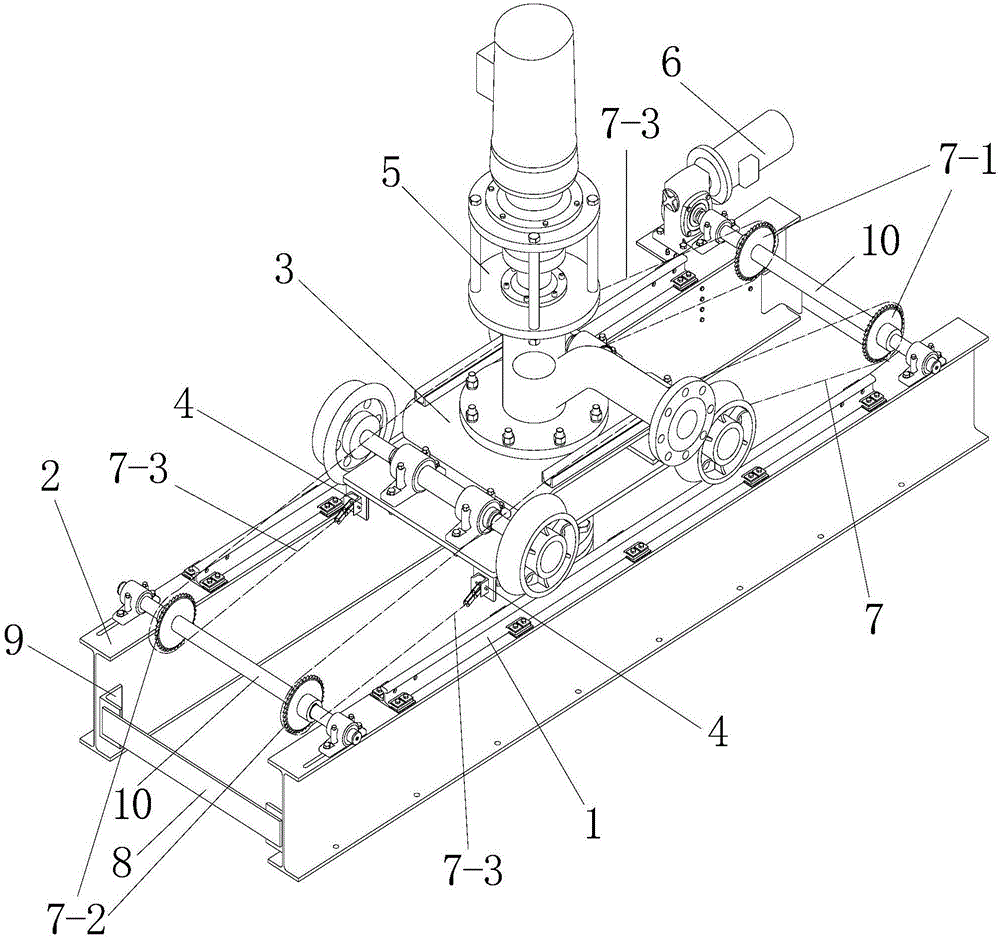

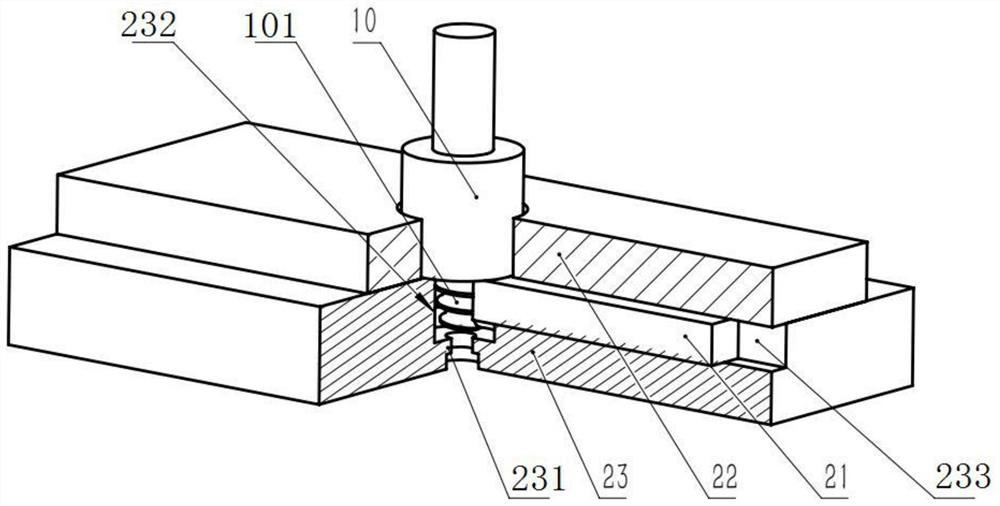

Stirring friction extrusion method and device based on stirring needle

The invention discloses a stirring friction extrusion device based on a stirring needle. A base is provided with a die assembly, an extrusion assembly and a lifting assembly. The die assembly comprises a die and a cover plate. A feeding trough is arranged between the die and the cover plate. A preformed body is arranged in the feeding trough. The feeding trough communicates with a die stirring zone. The position, corresponding to a die outlet at the bottom of a die, of the base is provided with a cavity. The extrusion assembly comprises a box body, a horizontal first screw rod rotationally arranged in the box body, a movable sliding block and a first driving device. The movable sliding block is provided with an extrusion rod directly facing the feeding trough. The lifting assembly comprises a bracket, a second screw rod, a sliding block and a second driving device. A spindle box is fixedly connected with the sliding block. The spindle box is provided with a third driving device capableof driving a spindle to rotate. The bottom end of the spindle is connected with a stirring head directly facing the die stirring zone. The stirring head is provided with the stirring needle. Throughthe stirring friction extrusion method and device based on the stirring needle, sufficient stirring, mixing and extrusion forming of composites are achieved.

Owner:NANCHANG HANGKONG UNIVERSITY

A kind of extracting equipment for moisturizing and anti-wrinkle cosmetics

ActiveCN110548581BSqueeze out fullyShred fully and comprehensivelyGrain treatmentsEngineeringCosmetics

The invention relates to the extraction equipment for skin-moisturizing and anti-wrinkle cosmetics, which relates to the technical field of extraction equipment for cosmetics production, including a bottom frame, an extraction cylinder assembly, a movable bottom plate mechanism, an intermittent feeding control mechanism, a power output mechanism, an extrusion crushing mechanism and a reciprocating control mechanism Mechanism, the beneficial technical effect is that the present invention can automatically feed intermittently, thereby ensuring that the plants in each extrusion cycle are quantitative, thereby ensuring that the plants in each extrusion cycle can be fully and comprehensively crushed, ensuring that the plants in the extrusion cycle The juice is fully pressed out, and the device can automatically discharge the residue. The extraction cylinder assembly is fixedly connected to the bottom frame, the movable floor mechanism is set at the lower end of the extraction cylinder assembly, and there are two intermittent feeding control mechanisms, and the two intermittent feeding control mechanisms are symmetrically arranged on both sides of the extraction cylinder assembly, and the power output The mechanism is fixedly connected to the upper end of the extracting cylinder assembly, and the extruding and crushing mechanism is slidably connected to the power output mechanism.

Owner:江西登云健康美业互联有限公司

Combined multifunctional vermicelli machine

ActiveCN104957473BIncrease temperatureImprove extrusion efficiencyFood shapingElectricityAgricultural engineering

The invention discloses a combined multifunctional vermicelli machine, which belongs to the vermicelli machine in the technical field of food processing equipment. The degree of ripening is controlled in a good range. Its technical scheme is as follows: including the frame and the powder sleeve, the powder sleeve is equipped with a screw rod, and the screw rod is provided with a screw blade; the feeding end of the powder sleeve is provided with a feed hopper, and the powder sleeve There is a discharge mold at the end of the discharge end of the barrel, a tail heater is set on the discharge end of the powder sleeve, and a thermostatic sleeve is provided on the powder sleeve; a heater and a temperature sensor are provided on the thermostatic sleeve. Both the heater and the temperature sensor are electrically connected to the external control cabinet; and the fan machine communicates with the steam tank through the steam conduit. The invention is applicable to a vermicelli machine for producing vermicelli.

Owner:叙永县鸿艺粉业有限公司

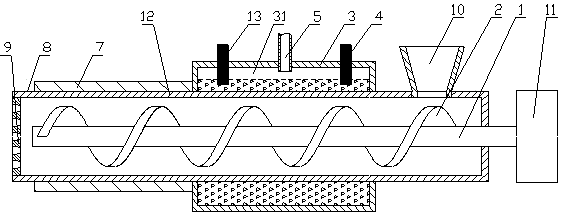

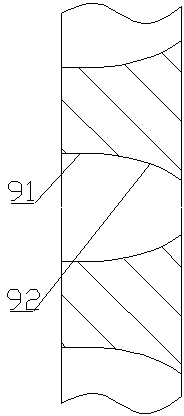

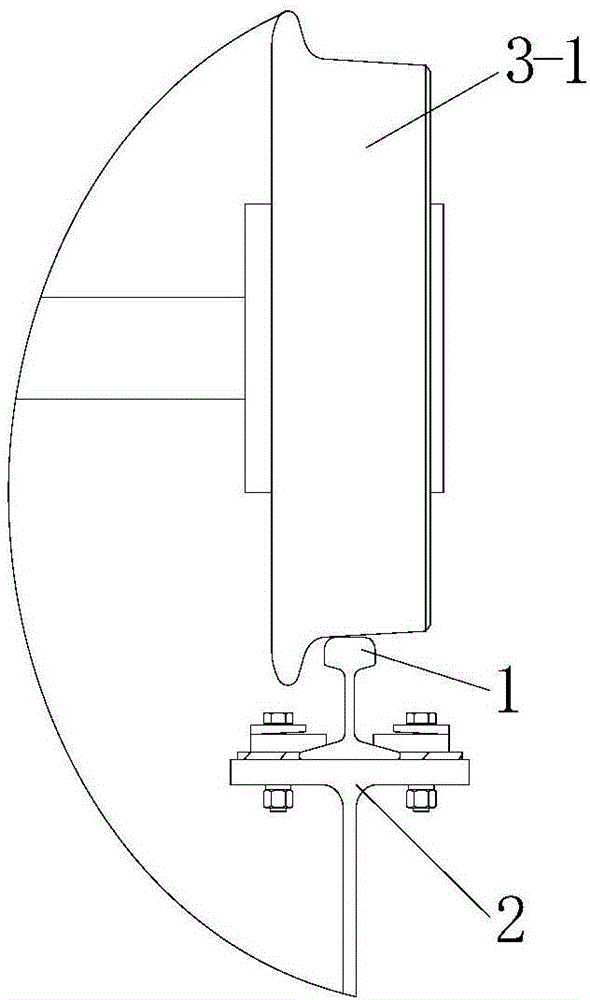

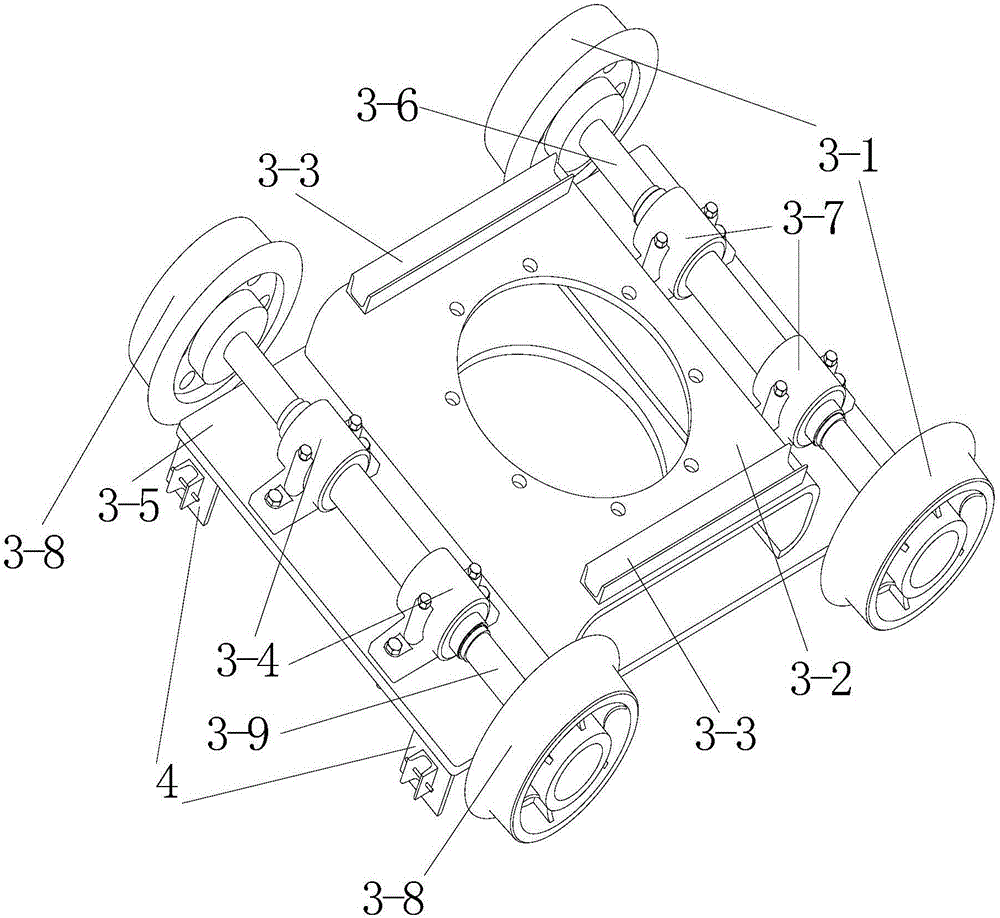

A screw extrusion sludge distribution machine

The invention relates to a screw extruding sludge distributing machine, comprising a supporting frame, a driving mechanism installed on the supporting frame, a mobile vehicle-mounted mechanism installed on the supporting frame, and a screw extruding mechanism installed on the vehicle-mounted mechanism; The driving mechanism that drives the vehicle-mounted mechanism to reciprocate along the support frame is connected to the vehicle-mounted mechanism; the support frame is provided with an open space for sludge to fall; the screw extrusion mechanism with the function of extruding sludge downward is located in the support frame above the open space. The barrel is installed on the vehicle-mounted mechanism, the screw is placed inside the barrel, the screw drive device for driving the screw to rotate is installed on the upper part of the barrel, and the feed pipe connected to the inside of the barrel is installed on the barrel, the extruder The machine head is arranged at the lower end of the barrel, and the lower end of the extruder head is provided with a detachable fifth flange. The distributing machine can not only crush, shape and extrude the sludge, but also spread the extruded sludge evenly on the drying unit, belonging to the technical field of sludge treatment.

Owner:GUANGZHOU UNIVERSITY

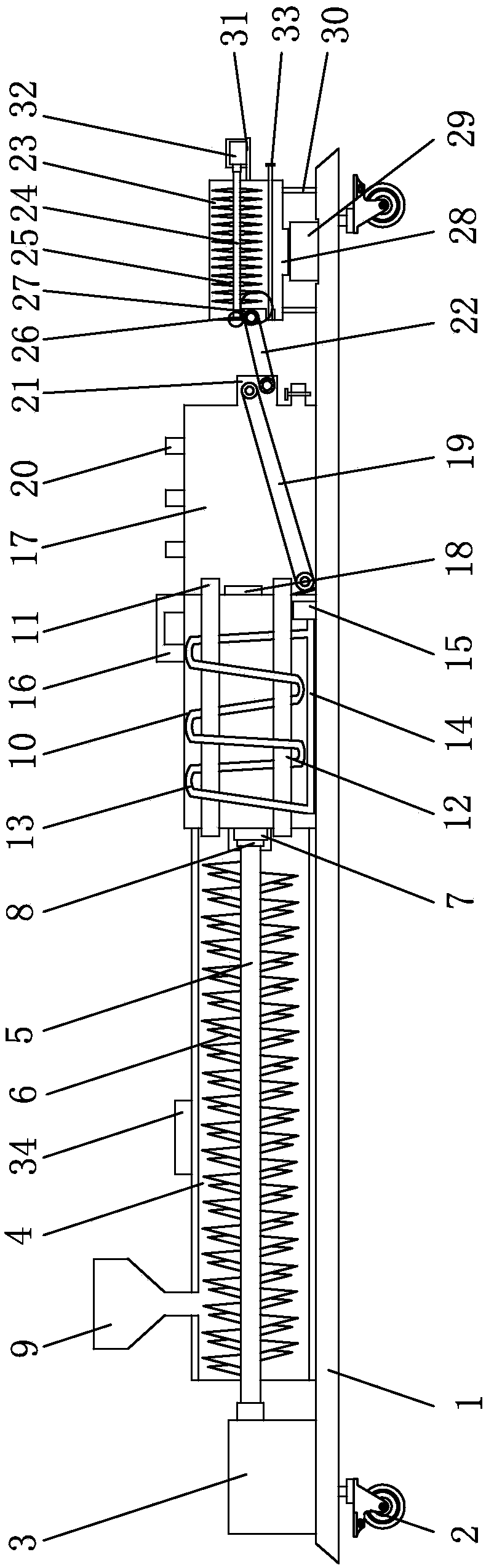

Liquid medicine extraction device capable of automatically controlling deslagging according to amount of extruded liquid medicine

InactiveCN114131987ASqueeze out fullyAvoid dischargeGrain treatmentsPressesEngineeringMechanical engineering

The invention relates to the technical field of biological medicine, and discloses a liquid medicine extraction device capable of automatically controlling deslagging according to the amount of extruded liquid medicine, the liquid medicine extraction device comprises a fixed cylinder, the inner rear wall of the fixed cylinder is rotatably connected with a grinding mechanism, the left side of the bottom of the fixed cylinder is welded with a blanking pipe and an electromagnet, and the bottom of the blanking pipe is welded with a liquid medicine collection box; and a dreg falling hole is formed between the fixing cylinder and the medicine dreg collecting box, and an arc-shaped baffle is connected to the inner left wall of the dreg falling hole in an inserted mode. The hole diameter of the through hole in the bottom of the discharging pipe is small, so that liquid medicine always exists in the discharging pipe, the liquid medicine in the discharging pipe serves as a conductor between the two conducting strips at the moment, then a closed loop is formed between the electromagnet and the two conducting strips, the electromagnet is powered on to generate magnetism, and a first magnetic device is attracted; and then a first magnetic device drives an arc-shaped baffle to move leftwards to close a residue falling hole, so that the medicine residues in the rotating cylinder are prevented from being discharged from the residue falling hole, and the effect that the medicine residues are fully extruded in the grinding mechanism is achieved.

Owner:上海旎丽美医药科技有限公司

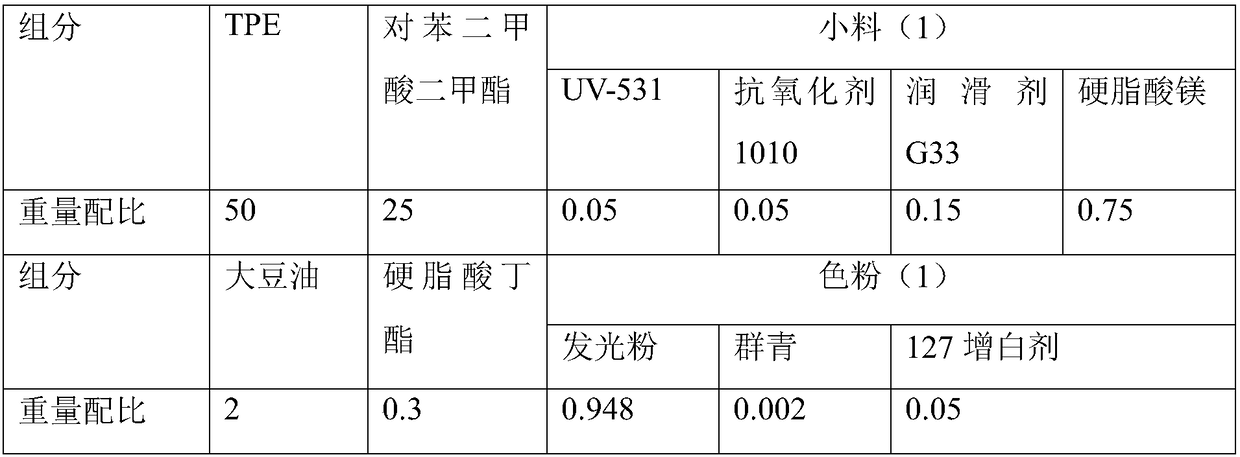

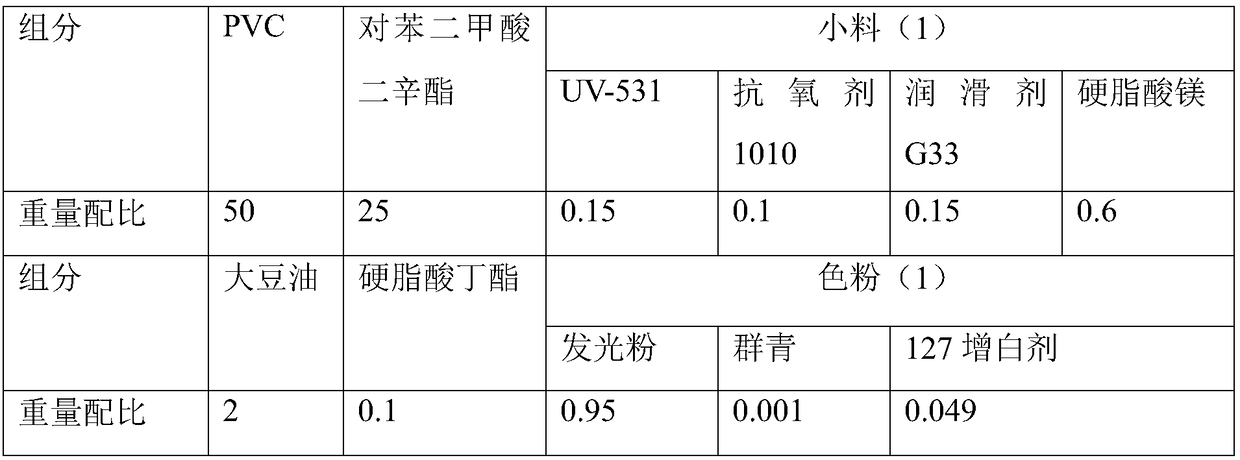

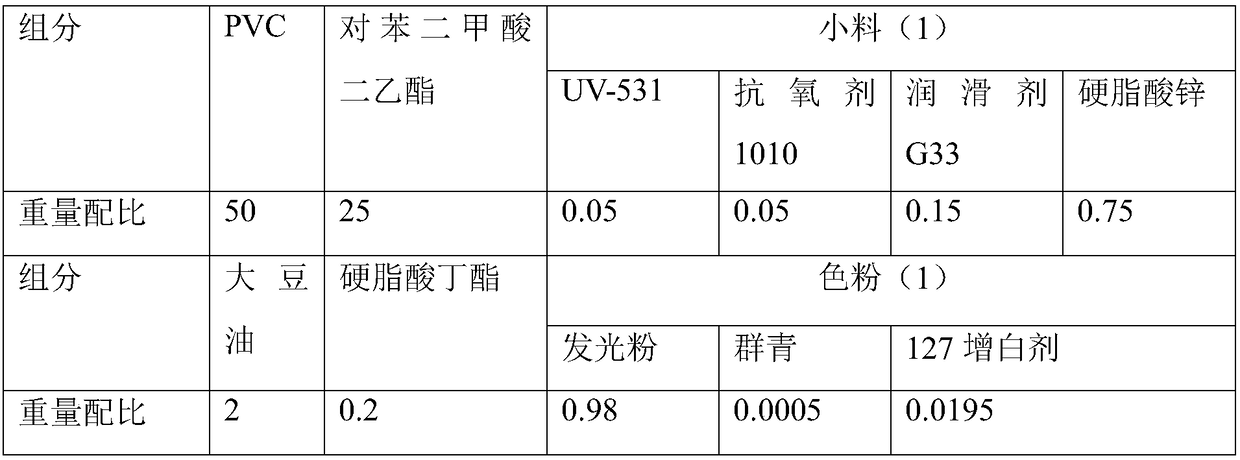

Light balancing conductor material and preparation method thereof

The invention discloses a light balancing conductor material which at least comprises, by weight, 40-60 parts of transparent resin, 21-31 parts of plasticizers, 2-6 parts of soybean oil, 0.1-0.3 partof butyl stearate, 0.1-2.0 parts of auxiliary materials and 0.1-2.0 parts of toners. The auxiliary materials comprise, in weight percent, 5-20% of antioxidants, 5-20% of ultraviolet absorbents, 5-20%of lubricating agents and 50-75% of stabilizers. The toners comprises, in weight percent, 95-98% of luminescent powder, 0.05-0.2% of ultramarine and 1-5% of 127 brightening agents. According to the material, adjustment and control of luminous flux and color rendering property of a light source penetrating the light balancing conductor material can be effectively improved, less lighting energy consumption is only needed on the premise of the same luminous flux, and the material has the advantages of efficient energy and environmental friendliness. The invention further discloses a preparation method of the light balancing conductor material.

Owner:郭晶晶 +1

Extrusion device adopting permanent magnetic transmission

PendingCN107825753AReduce lossAvoid deformation or breakageCooling/ventillation arrangementSupports/enclosures/casingsMotor shaftTime of use

The invention discloses an extruding device using a permanent magnet drive, which comprises an extruding cylinder, an annular limiting groove is opened on the inner side wall of the extruding cylinder, and one end of the extruding cylinder is provided with a limiting groove. The limit plate matched with the groove, the right end of the extrusion barrel is fixedly connected with a protective shell, the inside of the protective shell is fixedly installed with a first permanent magnet motor, and the rotating shaft of the first permanent magnet motor runs through the extrusion barrel The side plate extends to the inside of the extrusion cylinder and is connected to the limit plate through the first coupling. One side of the limit plate is fixedly connected with the extrusion rod, and the outer surface of the extrusion rod is welded with Fan blades arranged in a spiral shape. By using the permanent magnet motor instead of the ordinary motor, the present invention can ensure the power transmission performance during use, reduce the loss of the transmission shaft, prevent the transmission shaft from being deformed or broken, and help prolong the service life of the transmission shaft.

Owner:丁锋燕

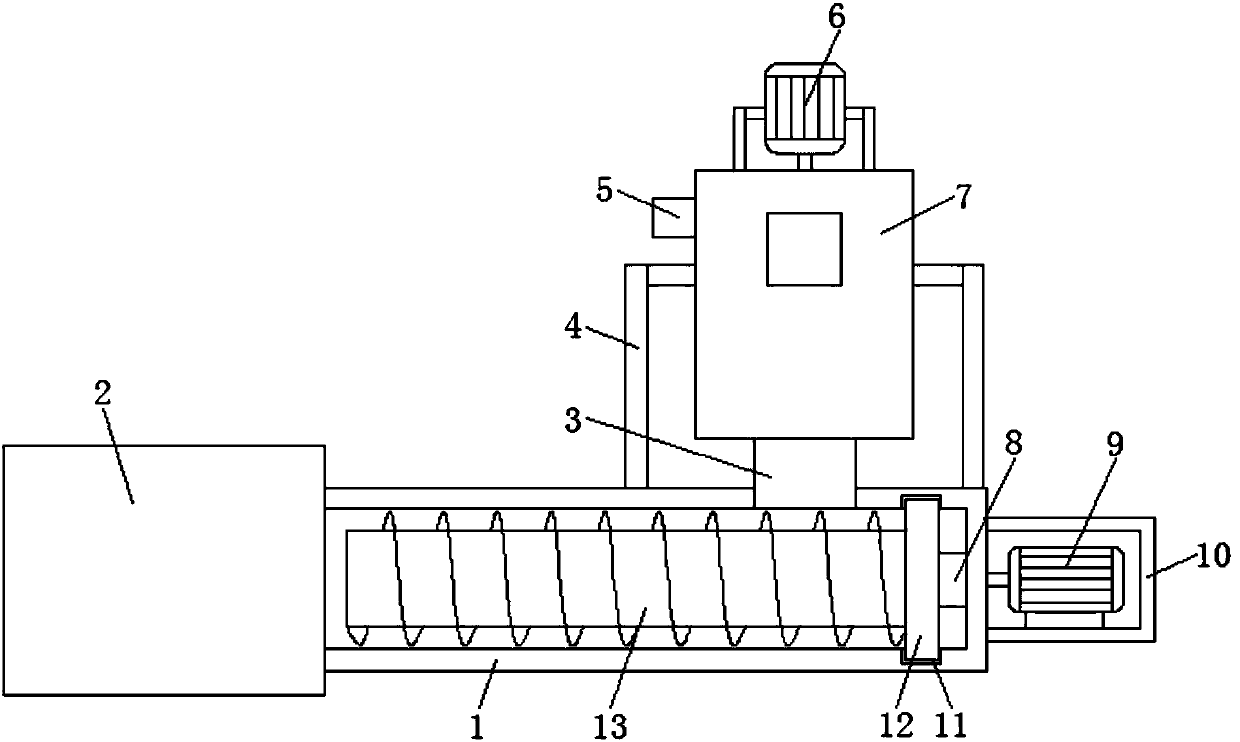

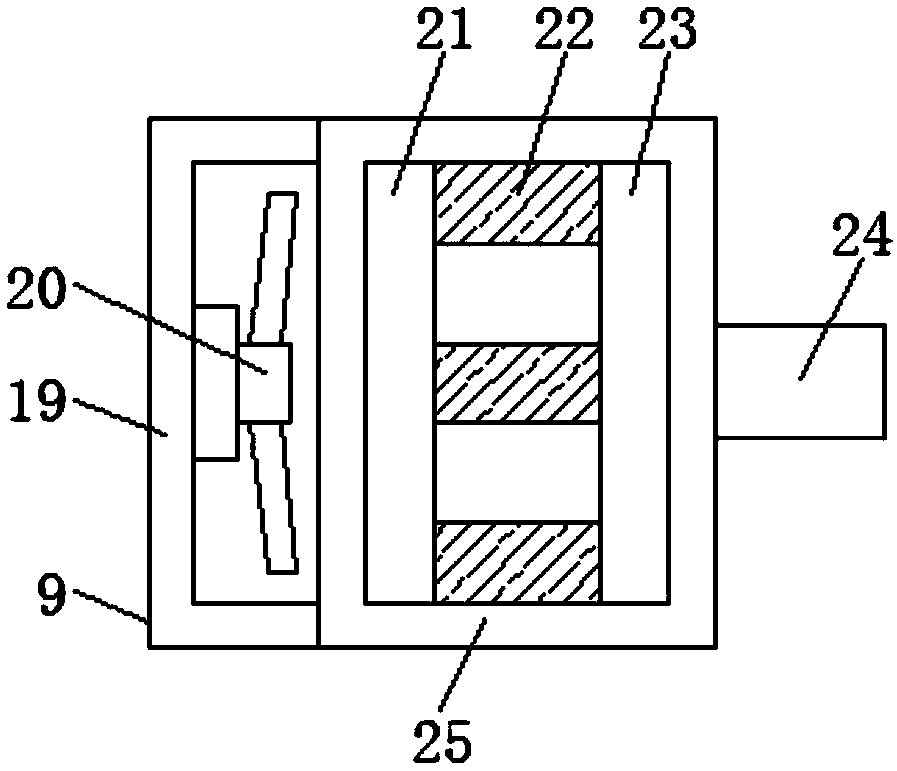

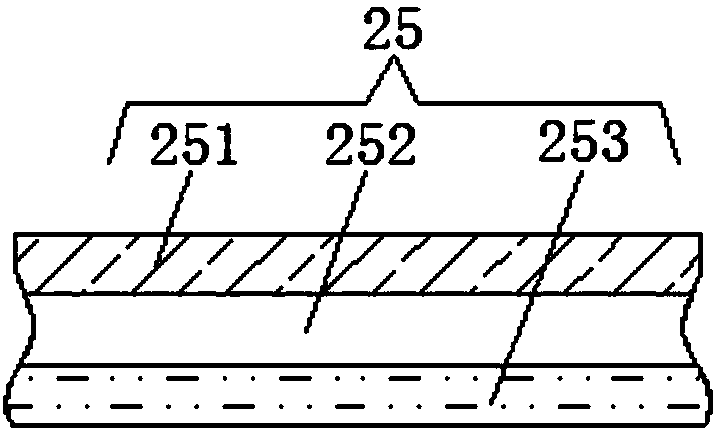

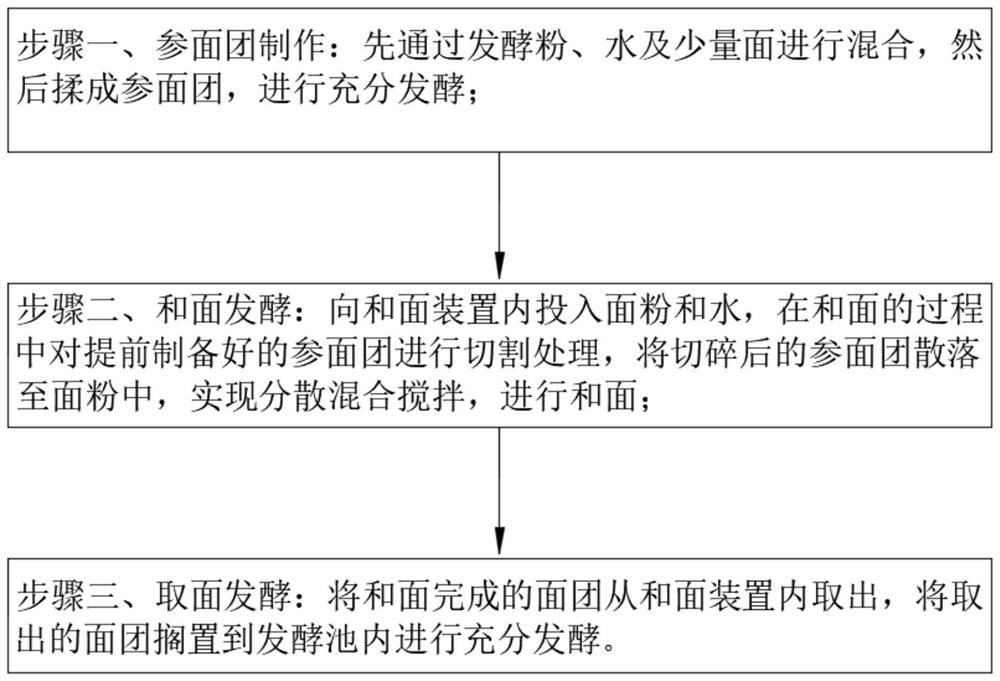

Microbial fermentation process for food processing

PendingCN113545381AAccelerated fully fermented doughEvenly distributedMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsChemistryBiology

The invention relates to the technical field of microbial fermentation, in particular to a microbial fermentation process for food processing, which comprises the following steps: step 1, baking dough preparation: baking powder, water and a small amount of flour are firstly mixed and then kneaded into dough for fully fermenting; a baking dough extruding mechanism extrudes out the baking dough through an extruding opening, so that dispersed baking dough sections are formed, the baking dough sections in contact with the extruding opening are subjected to gap cutting under the synchronous action of a dough crushing device, so that single baking strips are formed, the baking strips can be dispersed and fall into a dough kneading pool, and the baking strips can be uniformly mixed and stirred with flour and water, so that the baking dough can be uniformly distributed into the formed dough, the fully fermented baking dough can uniformly ferment the later formed dough, and rapid fermentation treatment of the dough is facilitated.

Owner:冯成金

Weaving method for captive balloon cable of polyethylene fiber with ultra-high molecular weight

InactiveCN100376744CPass awayImprove wear resistanceRope making machinesBalloon aircraftsYarnWinding machine

This invention discloses a superhigh molecular weight polyethene fabric captive balloon cable crochet method, which includes joining yarn, joining small sections, immersing rosin, weaving and other steps, wherein the joining yarn and joining small sections steps use seven sections twist, immersing rosin right after joining small sections, and after weaving into the cable, pulling in advance, which improves the resistant draw intension and wear-resisting intension. This invention is fit for the situation which has a high demand for the weight and intension, for example the cable for winding machine.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

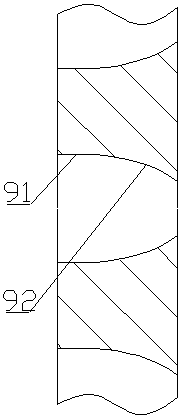

Processing technology of composite fabric with good anti-wrinkle effect

InactiveCN113152085APrevent slippingHigh recoveryWrinkle resistant fibresVegetal fibresPolyesterPolymer science

The invention discloses a processing technology of a composite fabric with a good anti-wrinkle effect. The processing technology comprises the following steps of uniformly mixing cotton fibers, bamboo fibers, polyester fibers and modal fibers, spinning and forming to obtain gray cloth, and then singeing, desizing, boiling off, bleaching and mercerizing the gray cloth to obtain composite gray cloth, then placing the composite gray cloth in an anti-wrinkle finishing liquid to be treated, so that macromolecular chain segments are prevented from slipping when cellulose fibers are subjected to external force, the recovery performance is improved, and the anti-wrinkle performance of the composite fabric is improved. According to the processing technology, anti-wrinkle finishing equipment is used for carrying out anti-wrinkle treatment on the composite gray cloth, the anti-wrinkle finishing equipment is high in automation degree, the composite gray cloth can be efficiently subjected to anti-wrinkle treatment, the anti-wrinkle effect is good, and meanwhile the production efficiency of the composite fabric with the good anti-wrinkle effect is improved.

Owner:安徽弋尚纺织科技有限公司

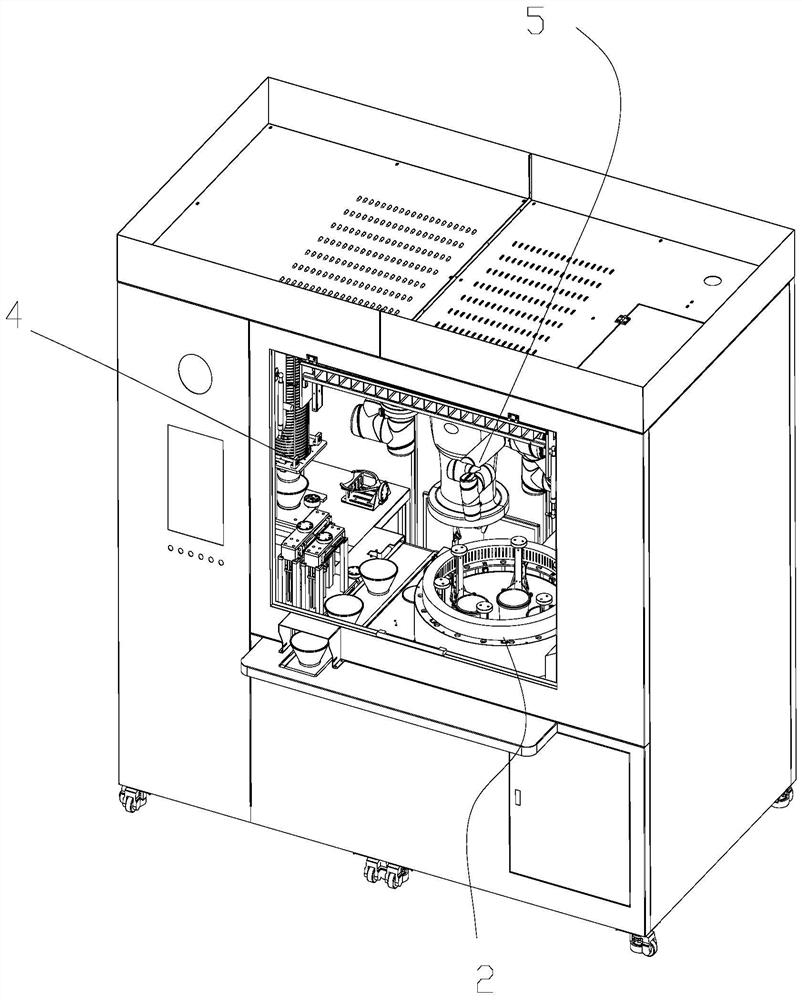

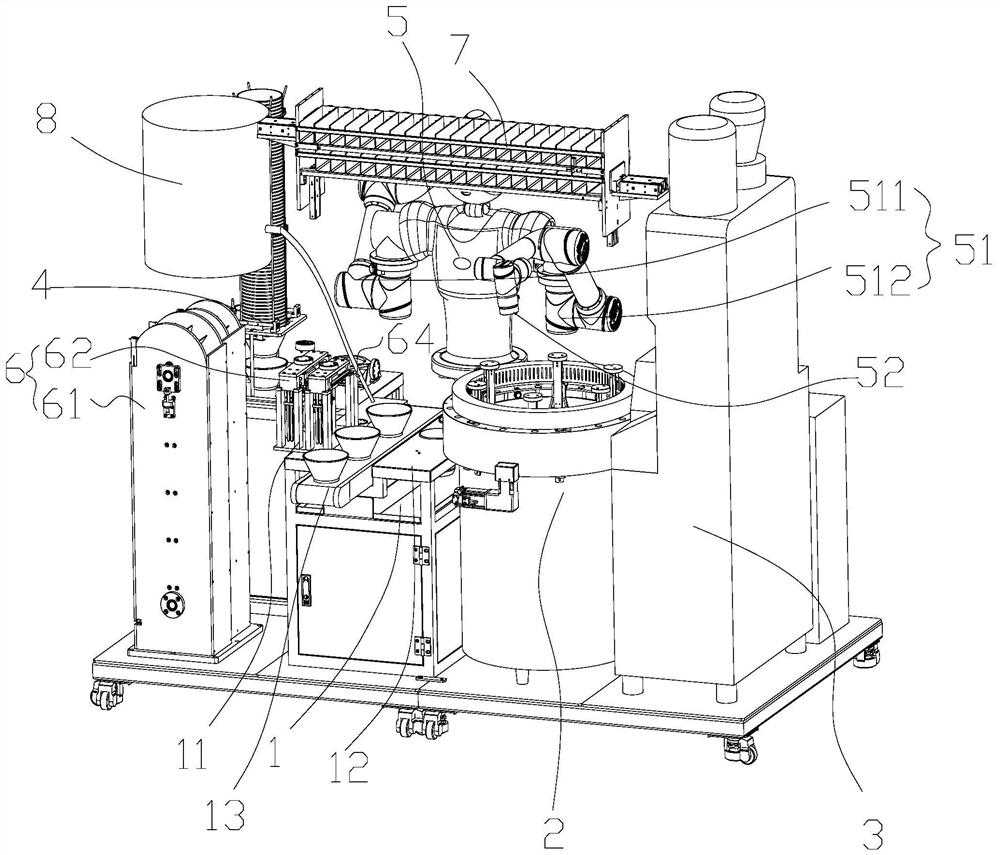

Food cooking machine

PendingCN113349629AReasonable structure layoutHighly corporatedWater-bath cooking vesselsCooking insertsTransfer mechanismProcess engineering

The invention relates to the technical field of food cooking equipment, in particular to a food cooking machine, which comprises: a food cooking mechanism, wherein the food cooking mechanism comprises a pot body, and the pot body is internally provided with a container for holding food to be cooked; a staple food supply mechanism used for inputting staple food to be cooked into the container; a bowl supply mechanism for supplying bowls one by one; a transfer mechanism used for transferring among a plurality of set positions; a sauce supply mechanism comprising a material bag supply mechanism, a cutting knife for cutting a material bag and a clamping and extruding mechanism for taking and extruding the material bag; a side dish supply mechanism comprising a plurality of material grids circularly moving to a material taking and placing position, wherein the transfer mechanism transfers the material grids containing the side dishes to the position above the container and pours the side dishes into the container; and a soup supply mechanism used for injecting soup into the bowls. According to the food cooking mechanism, the structural arrangement is reasonable, the matching degree of all the mechanisms is high, the overall working efficiency is high, and it is guaranteed that food materials are healthy and sanitary.

Owner:遨博(北京)智能科技股份有限公司

Polyvinyl chloride insulated cable material suitable for high-speed production of automobiles and preparation method of polyvinyl chloride insulated cable material

InactiveCN109096653AWell mixedEasy extrusionPlastic/resin/waxes insulatorsAntioxidantPolyvinyl chloride

The invention relates to a polyvinyl chloride insulated cable material suitable for high-speed production of automobiles and a preparation method of the polyvinyl chloride insulated cable material. Active components of the polyvinyl chloride insulated cable material consist of the following raw materials in parts by weight: 45-50 parts of PVC resin powder, 1-3 parts of oxidized polyethlene wax, 25-35 parts of a plastifier TOTM, 1-3 parts of a lubricant G16, 2-5 parts of a calcium zinc stabilizer, 15-20 parts of nanometer level calcium carbonate, 0.5-1 part of an antioxidant, 0.5-1 part of a surface treating agent, 1-3 parts of zinc stearate and 0.5-1 part of a coupling agent. The PVC soft resin powder and the oxidized polyethlene wax are pre-stirred, so that the polymerizing degree of mixed materials is higher, besides, when the temperature of substrates is lower than that of squeezed materials, the melting state is reached quickly, and high-speed squeezing is facilitated; and the antioxidant is added, so that after the materials are squeezed for shaping, under the adverse use condition, the antioxygenic property of products can be greatly improved, and the safety property of the products in the use course can be higher.

Owner:山东寰宇线缆有限公司

Screw extrusion type sludge distributing machine

The invention relates to a screw extrusion type sludge distributing machine. The machine comprises a supporting frame, a driving mechanism mounted on the supporting frame, a movable vehicle-mounted mechanism mounted on the supporting frame and a screw extrusion mechanism mounted on the vehicle-mounted mechanism; the driving mechanism for driving the vehicle-mounted mechanism to reciprocate linearly along the supporting frame is connected with the vehicle-mounted mechanism; an open space for falling of sludge is arranged in the supporting frame; the screw extrusion mechanism having a downward sludge extruding function is located above the open space of the supporting frame; a barrel is mounted on the vehicle-mounted mechanism; a screw is arranged inside the barrel; a screw driving device for driving the screw to rotate is mounted at the upper part of the barrel; a feeding pipe communicating with the inside of the barrel is mounted on the barrel; an extruding machine head is arranged at the lower end of the barrel; and a detachable fifth flange is arranged at the lower end of the extruding machine head. The distributing machine can mash, mold and extrude the sludge, can evenly disperse the extruded sludge on a drying unit at the same time and belongs to the technical field of sludge treatment.

Owner:GUANGZHOU UNIVERSITY

A friction stir extrusion method and device based on a stirring needle

Owner:NANCHANG HANGKONG UNIVERSITY

Mixed extrusion system and mixed extrusion method for production of A2 or B1-grade fireproof plate

PendingCN109719920AIncrease extrusion speedImprove efficiencyFlat articlesProcess controlRaw material

The invention discloses a mixed extrusion system and mixed extrusion method for production of an A2 or B1-grade fireproof plate. The mixed extrusion system is adopted in the mixed extrusion method. The mixed extrusion system comprises an internal mixer, a main extruder, a feeder and a screw feeder. The feeder is arranged on the upstream portion of the internal mixer. The discharging end of the feeder is connected with a feed opening of the internal mixer to be used for supplying a raw material for producing an A2 or B1-grade fireproof core layer into the internal mixer. A discharging opening is formed in the bottom of the internal mixer and is connected with a feeding opening of the screw feeder. A discharging opening of the screw feeder communicates with a feeding opening of the main extruder. A core layer sheet forming mold used for extruding and forming the fireproof core layer is arranged at the discharging end of the main extruder. By means of the mixed extrusion system, the A2 orB1-grade core layer can be produced better, the production efficiency is improved, process control is simpler, and the core layer is denser.

Owner:张家港市弘扬机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com