A screw extrusion sludge distribution machine

A technology of screw extrusion and distributing machine, which is applied in the direction of transportation, packaging, loading/unloading, etc. It can solve the problems of unable to evenly cover the sludge, accelerate the wear of parts, and consume a lot of energy, so as to change the drying surface area and reduce friction , the effect of less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

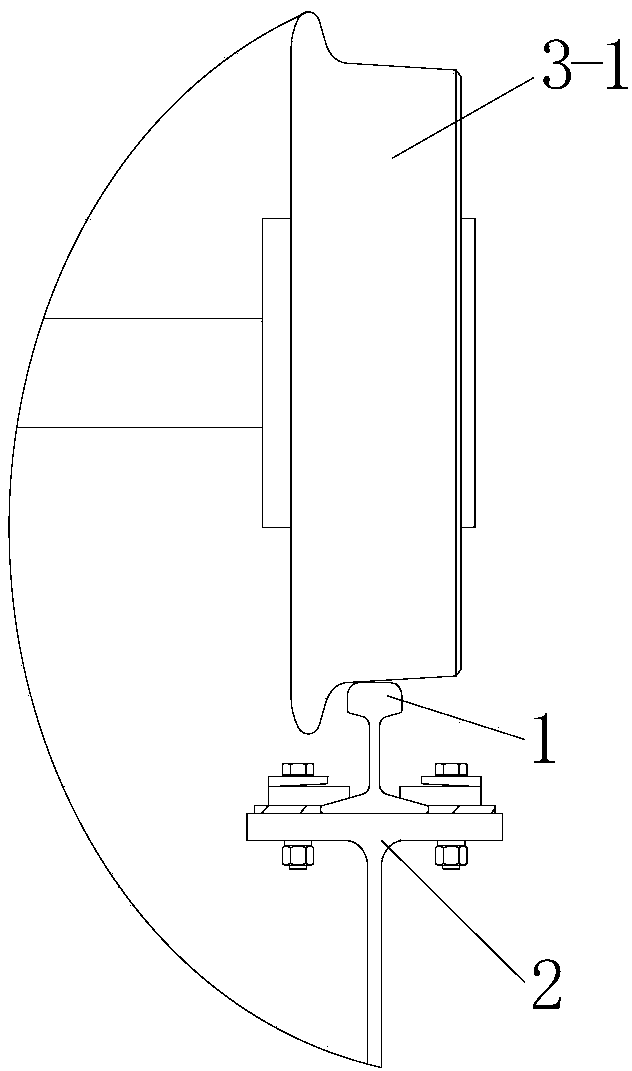

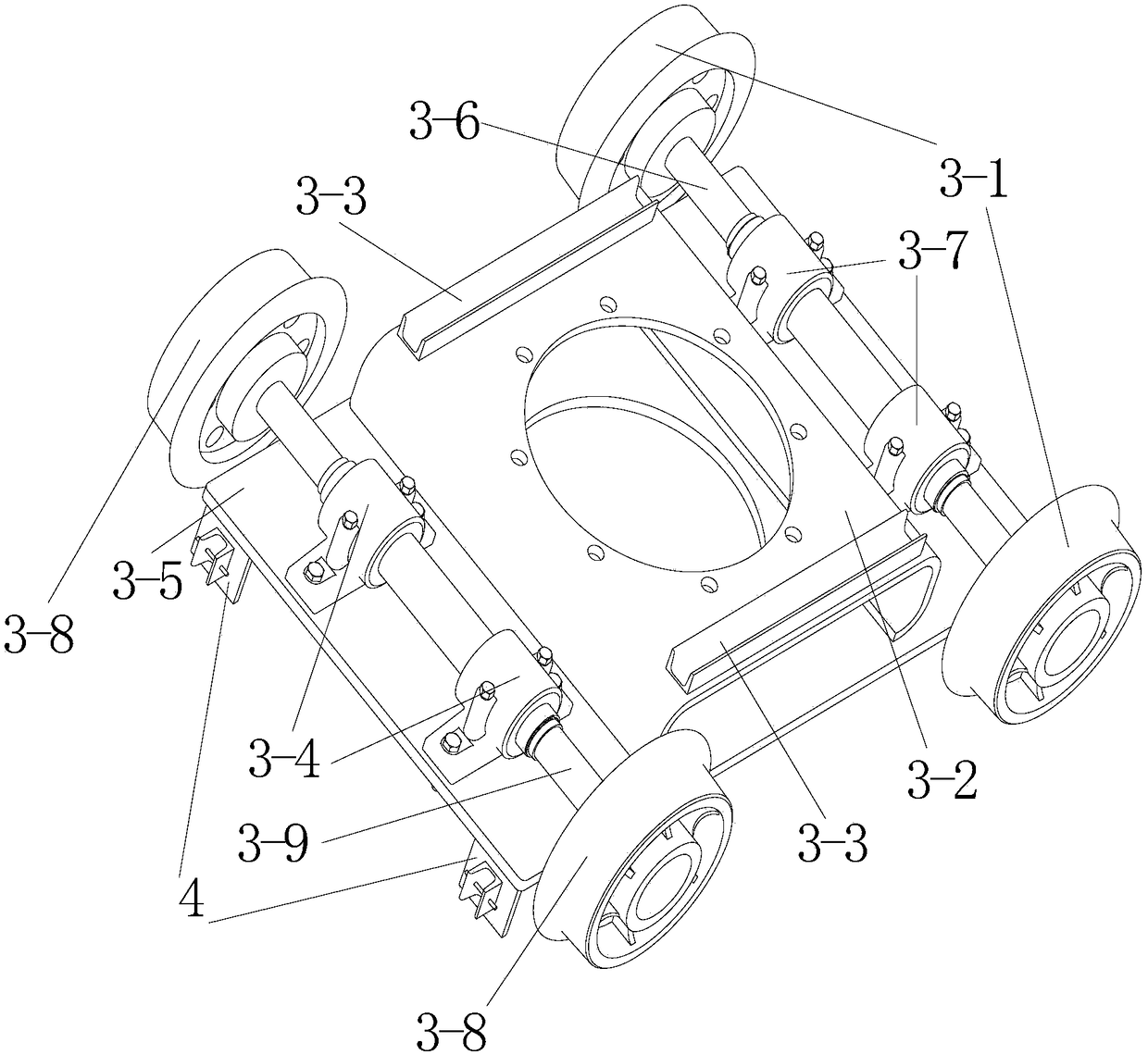

[0031] For the convenience of description, the orientation mentioned below is stipulated as follows: the up and down direction mentioned below is consistent with the up and down direction when the distributing machine is naturally placed; the orientation of the sprocket reducer is the front, that is, the sprocket reducer is in the screw extrusion mechanism. the front of the sprocket reducer; the position of the H-shaped steel corresponding to the sprocket reducer is on the left, that is, the sprocket reducer is on the left side of the screw extrusion mechanism.

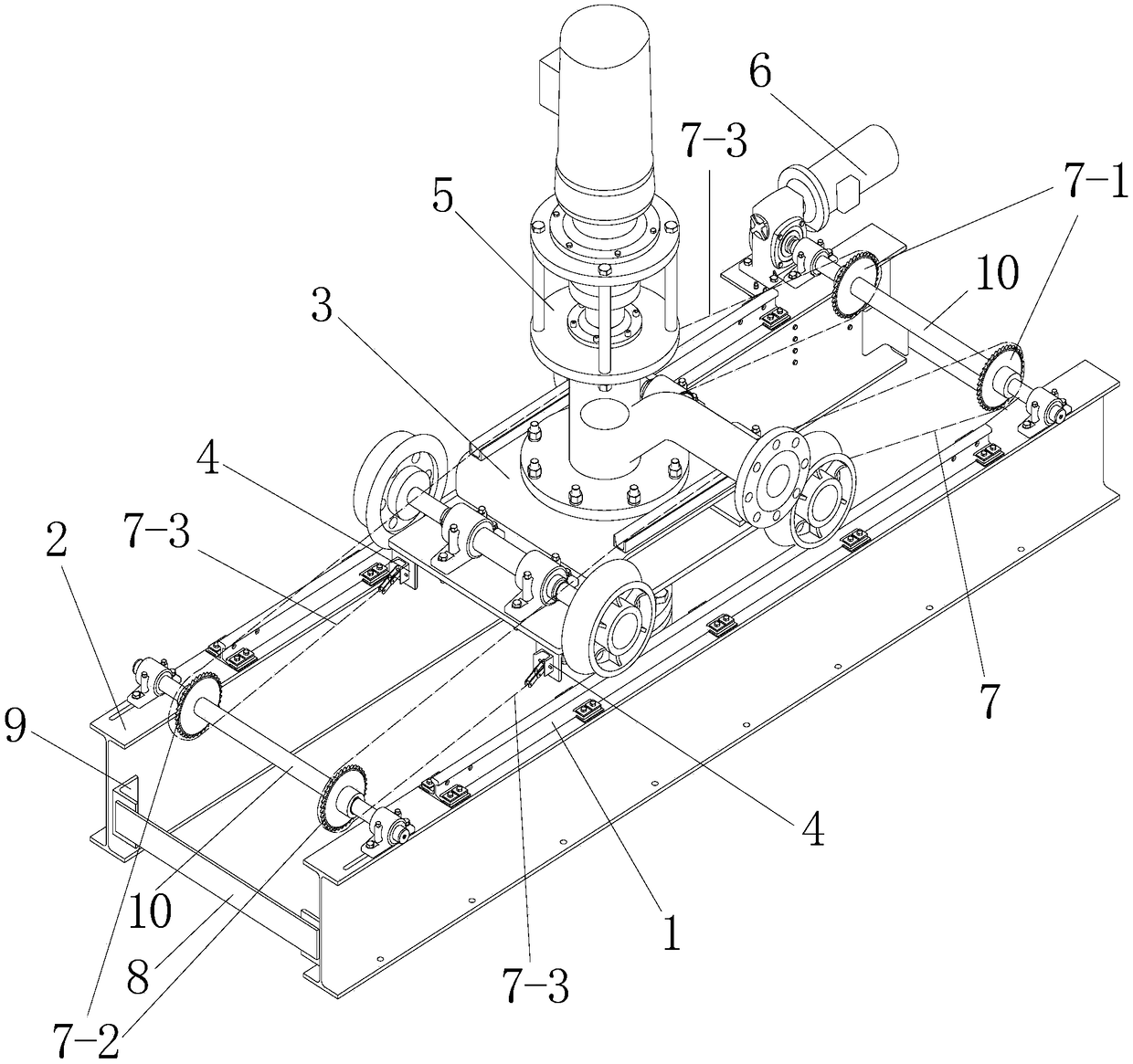

[0032] see figure 1 A screw extruding sludge distributing machine includes a hollow supporting frame, a driving mechanism installed on the supporting frame, a mobile vehicle-mounted mechanism installed on the supporting frame, and a screw extruding mechanism installed on the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com