Modular type soil body pressing molding device with soil blocking function

A molding device and modular technology, which is applied in the field of foundation reinforcement treatment and soft soil foundation reinforcement treatment, can solve the problems of high construction cost, long construction period, and inapplicability, so as to reduce the construction period, improve construction efficiency, and quickly drain water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following structural drawings and specific embodiments will further illustrate the present invention.

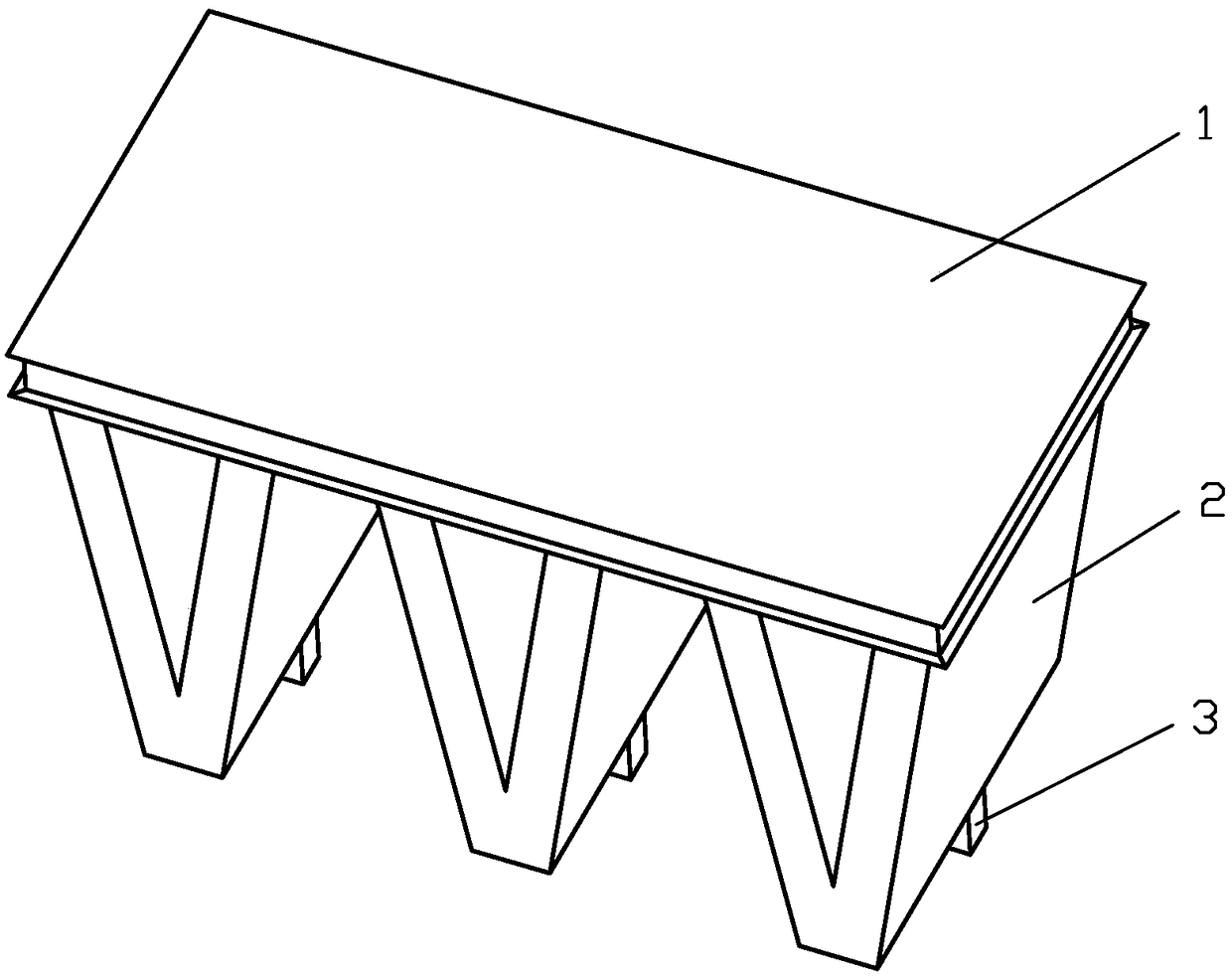

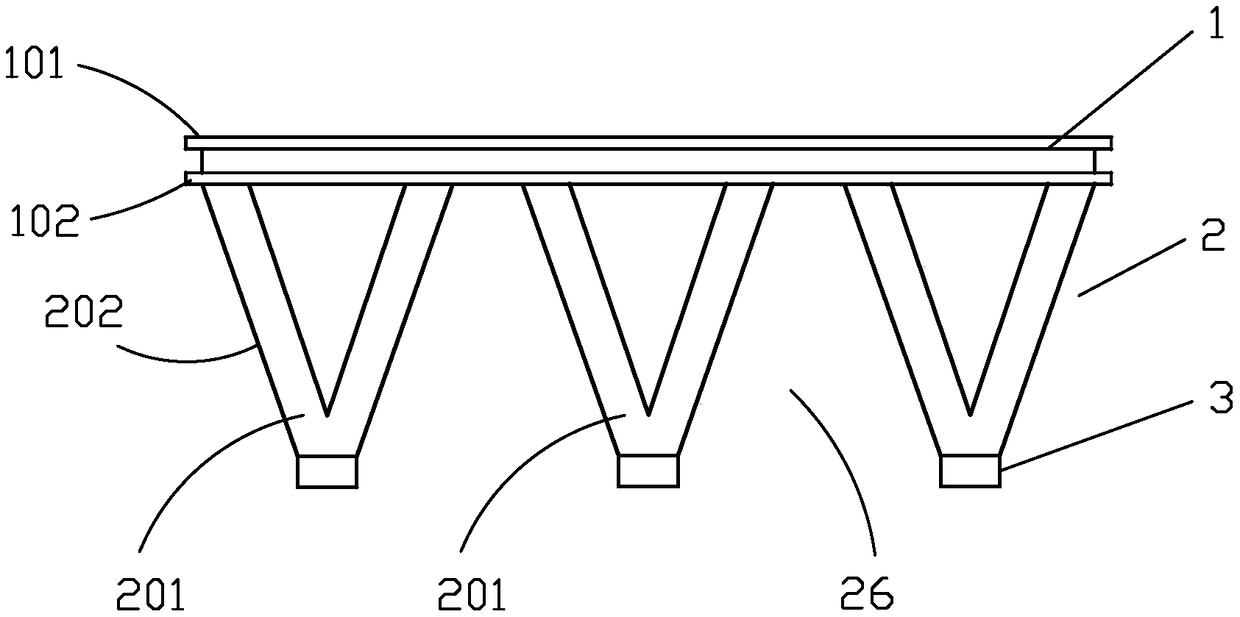

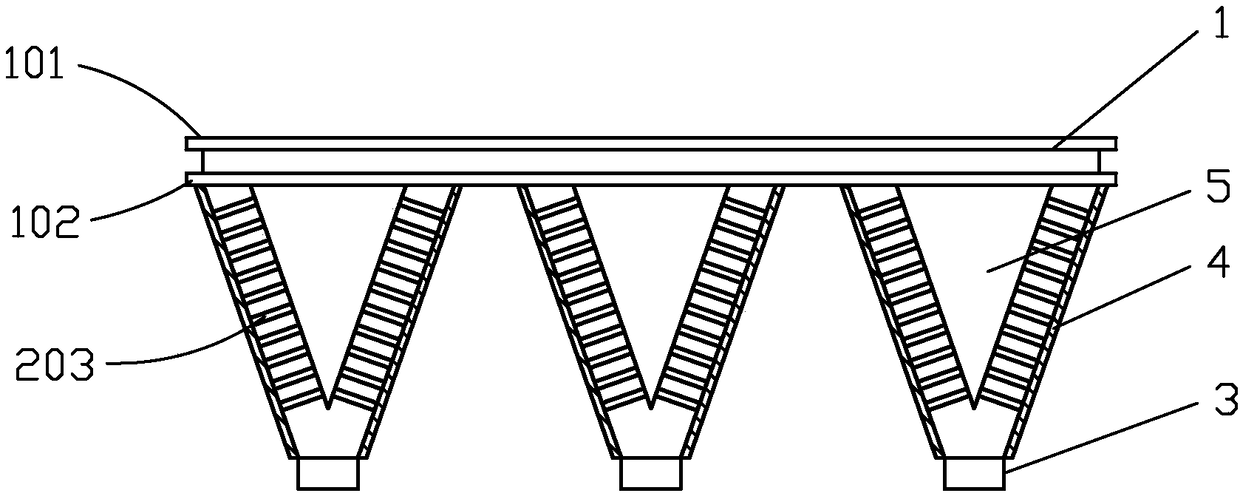

[0060] refer to figure 1 and figure 2 , a modular soil pressure forming device with soil retaining function of the present invention, including a top frame 1, a pressure forming module 2, a soil strength detection device 3 and a baffle 16. The baffle plate 16 will be described later, and the structure of the assembly of the top frame 1 and the pressure forming module 2 will be described here. Based on this structure and the structures of other various embodiments described later, after the baffle plate 16 is arranged around the top frame 1, a complete modular soil pressure molding device with soil retaining function is formed.

[0061] The top frame 1 is rectangular and includes a top plate 101 and a bottom frame 102 . The pressure molding module 2 includes several "V"-shaped convex bodies 201 arranged in parallel. There is a certain distance between adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com