Module type soil pressure applying and forming device and processing method of soft soil foundation

A molding device and processing method technology, which is applied in the field of foundation reinforcement treatment and soft soil foundation reinforcement treatment, can solve the problems of long construction period, high construction cost, and inapplicability, so as to reduce the construction period, improve construction efficiency, and prevent side effects. moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0124] The following structural drawings and specific embodiments will further illustrate the present invention.

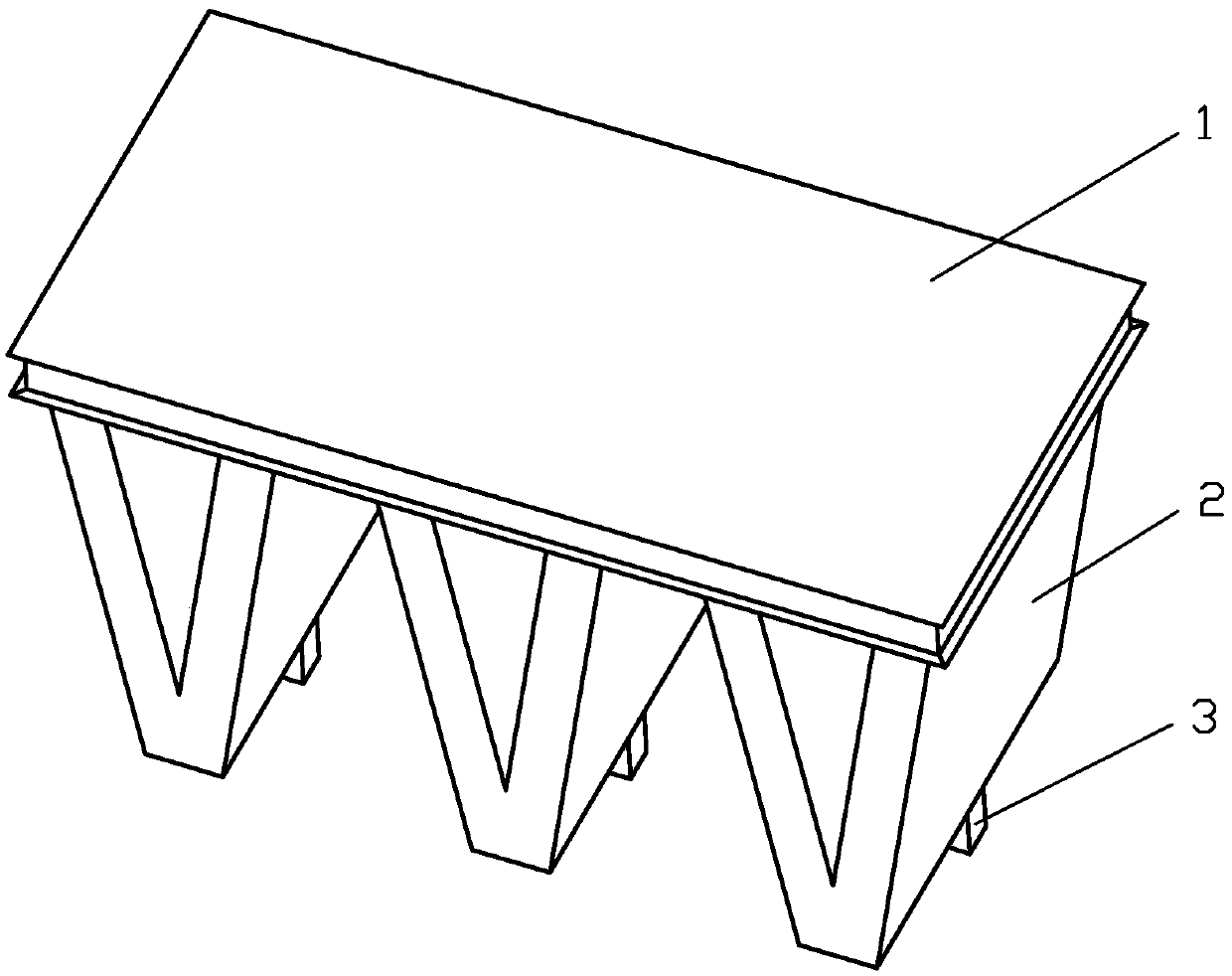

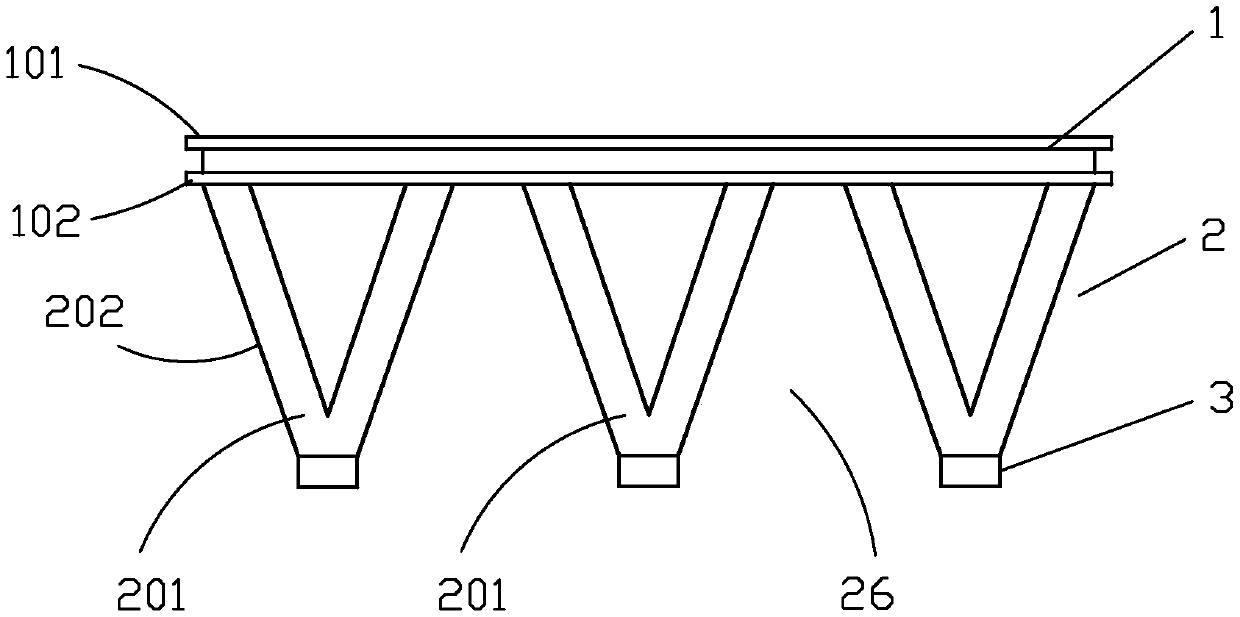

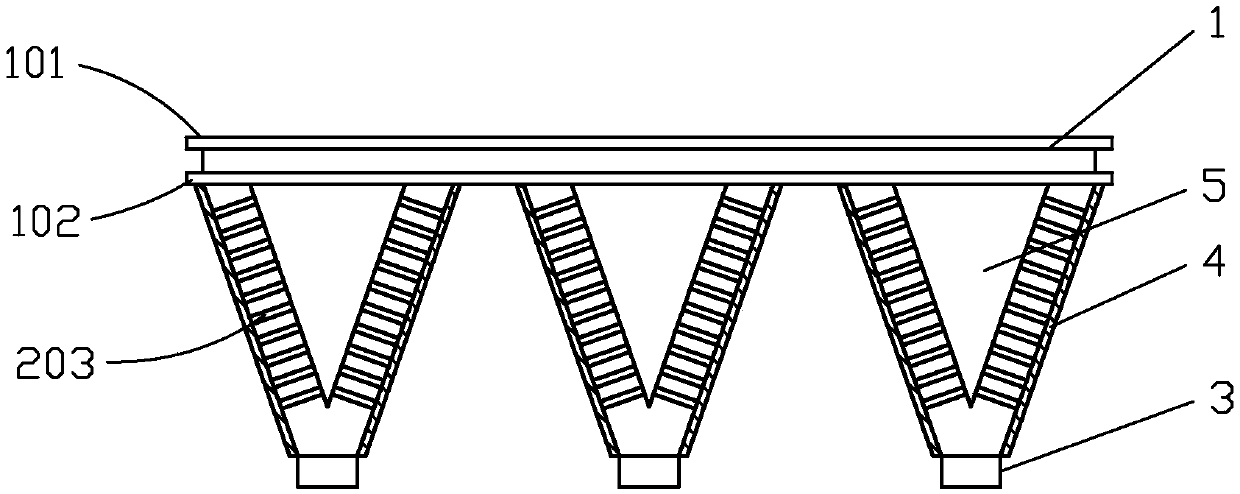

[0125] refer to figure 1 and figure 2 , a modular soil pressure forming device of the present invention, including a top frame 1, a pressure forming module 2 and a soil strength detection device 3. The top frame 1 is rectangular and includes a top plate 101 and a bottom frame 102 . The pressure molding module 2 includes several "V"-shaped convex bodies 201 arranged in parallel. There is a certain distance between adjacent protrusions 201 . The top of the convex body 201 is connected with the top frame. The connection may be welding, or a slot may be provided on the bottom frame 102 of the top frame, and the upper part of the convex body 201 is inserted into the slot to form a detachable connection.

[0126] The soil body strength detection device 3 can be arranged on the bottom and / or the side wall 202 of the convex body 201 . The soil body strength detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com