Patents

Literature

34results about How to "Full pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding structure and method of target and backing plate

InactiveCN101537533AFull pressureSmall sizeVacuum evaporation coatingSputtering coatingTitaniumMaterials science

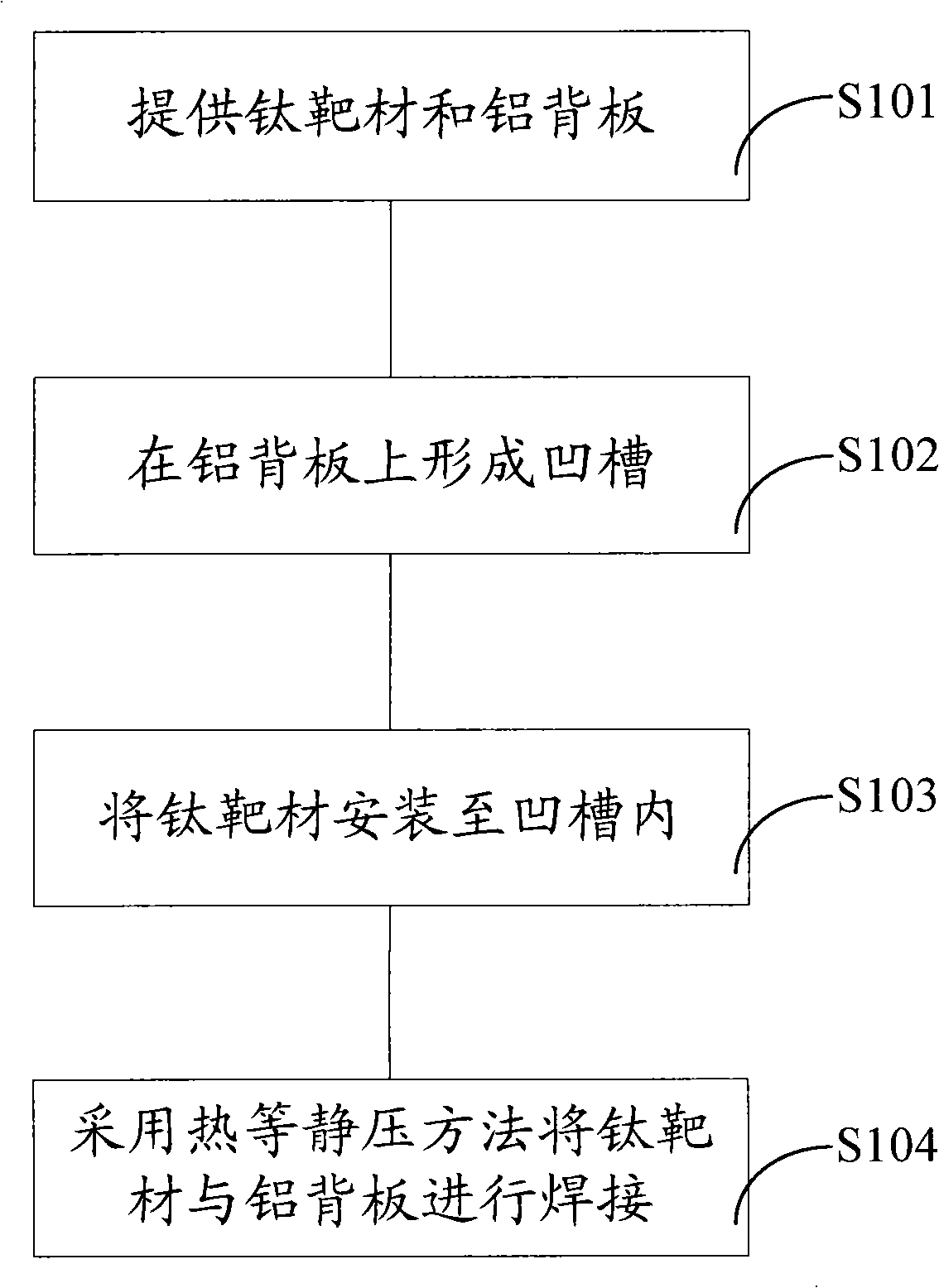

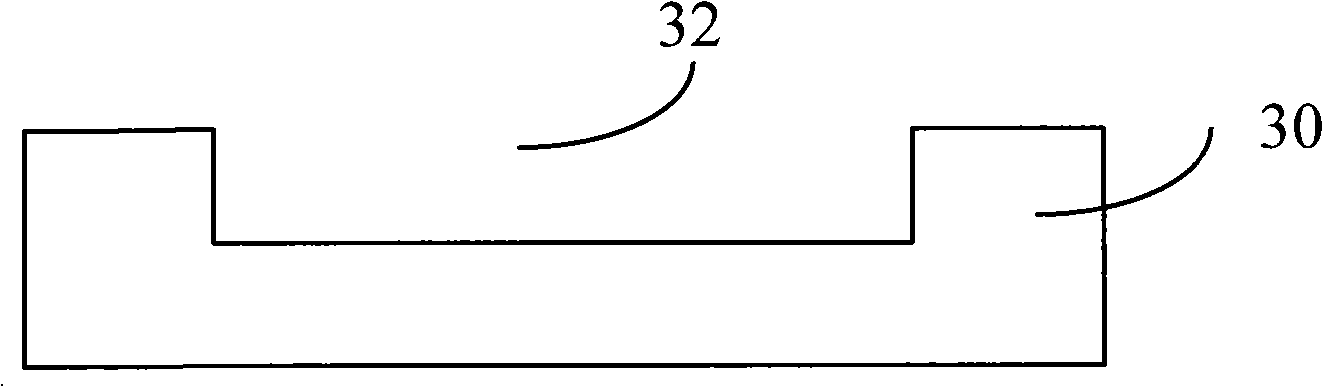

The invention relates to a welding structure and a method of a target and a backing plate, wherein the welding method of the target and the backing plate includes the steps of: providing a titanium target and an aluminum backing plate; forming a groove on the aluminum backing plate; mounting the titanium target in the groove; and adopting a hot isostatic pressing method to weld the titanium target and the aluminum backing plate. The invention greatly reduces the use amount of welding materials and simultaneously, the technology does not affect the tissue structure of the target and causes the quality of the target to meet the final use requirement.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

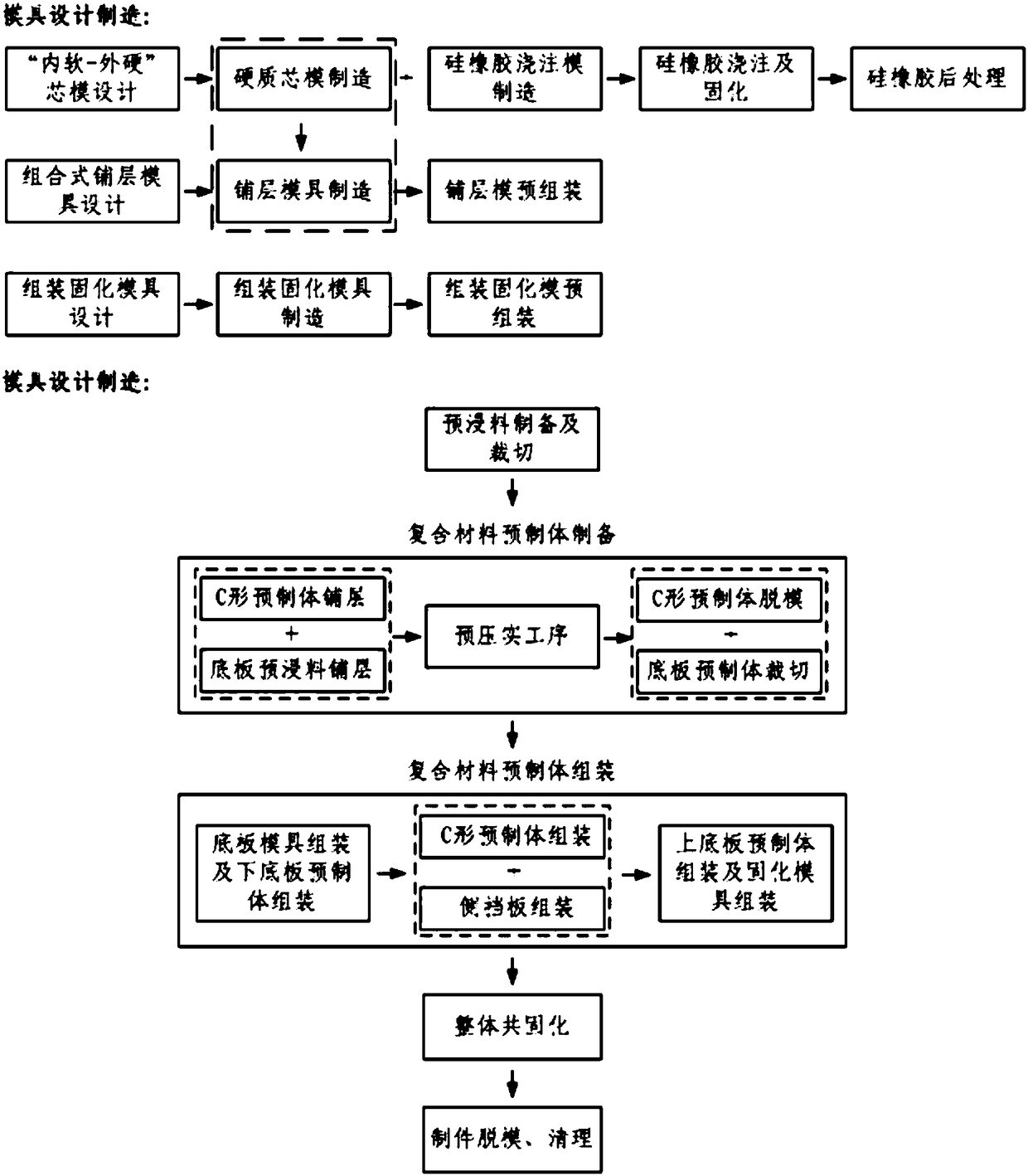

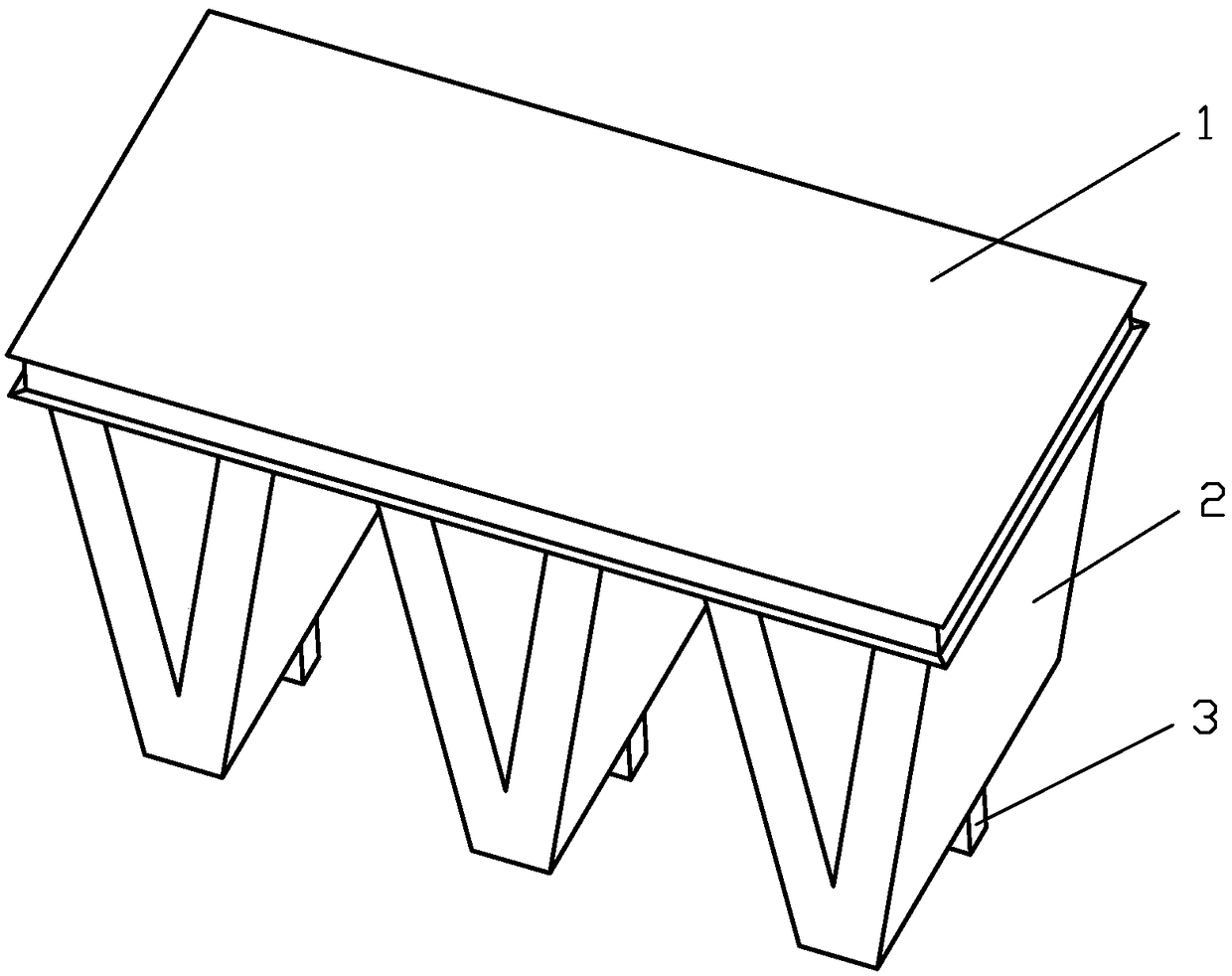

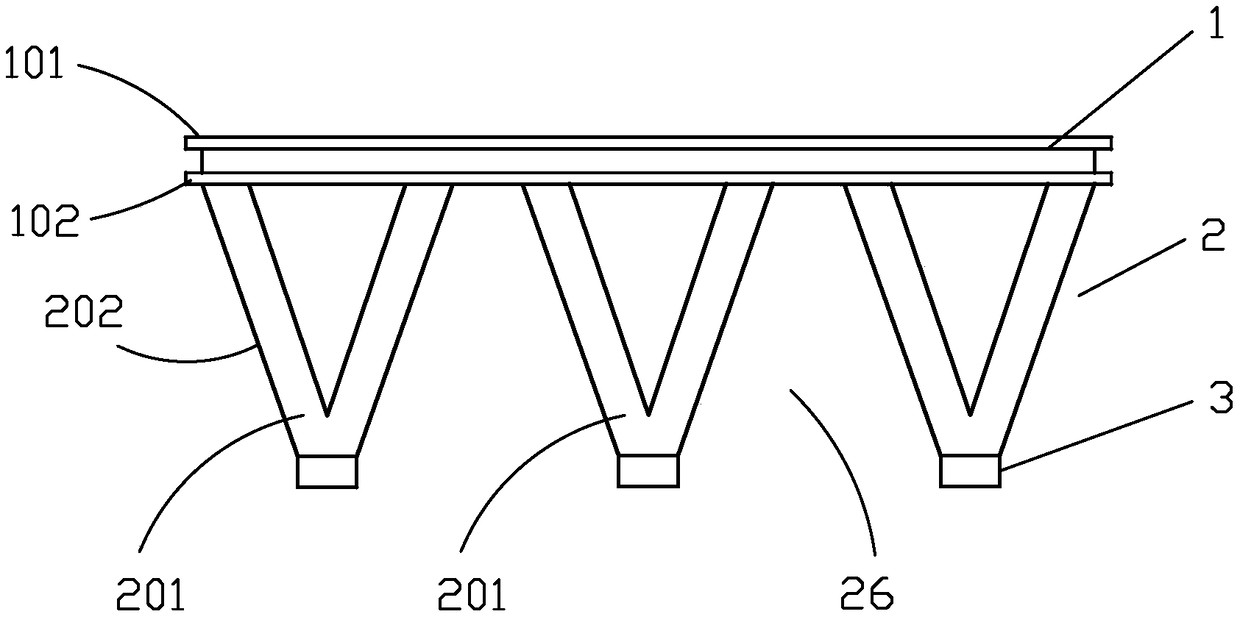

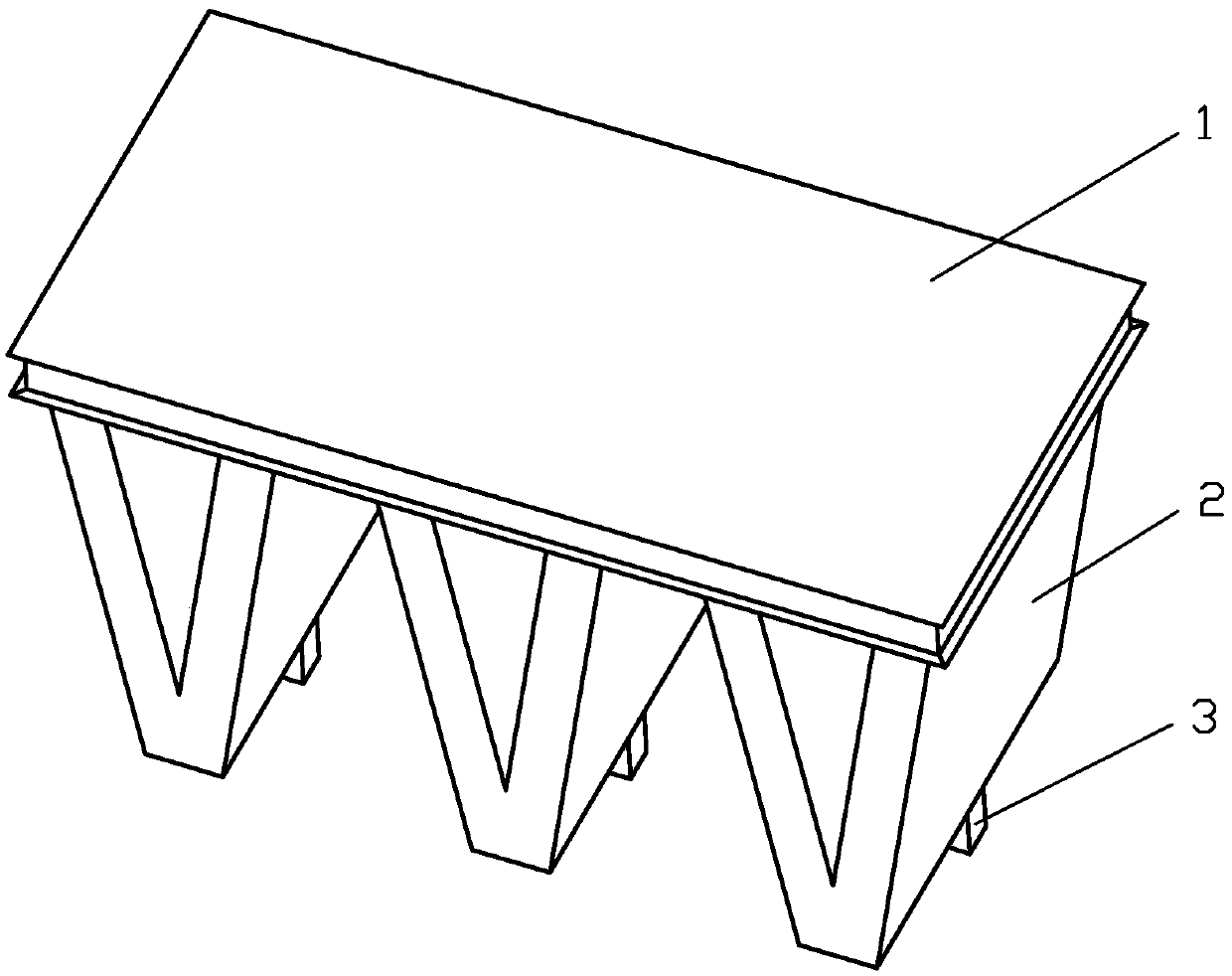

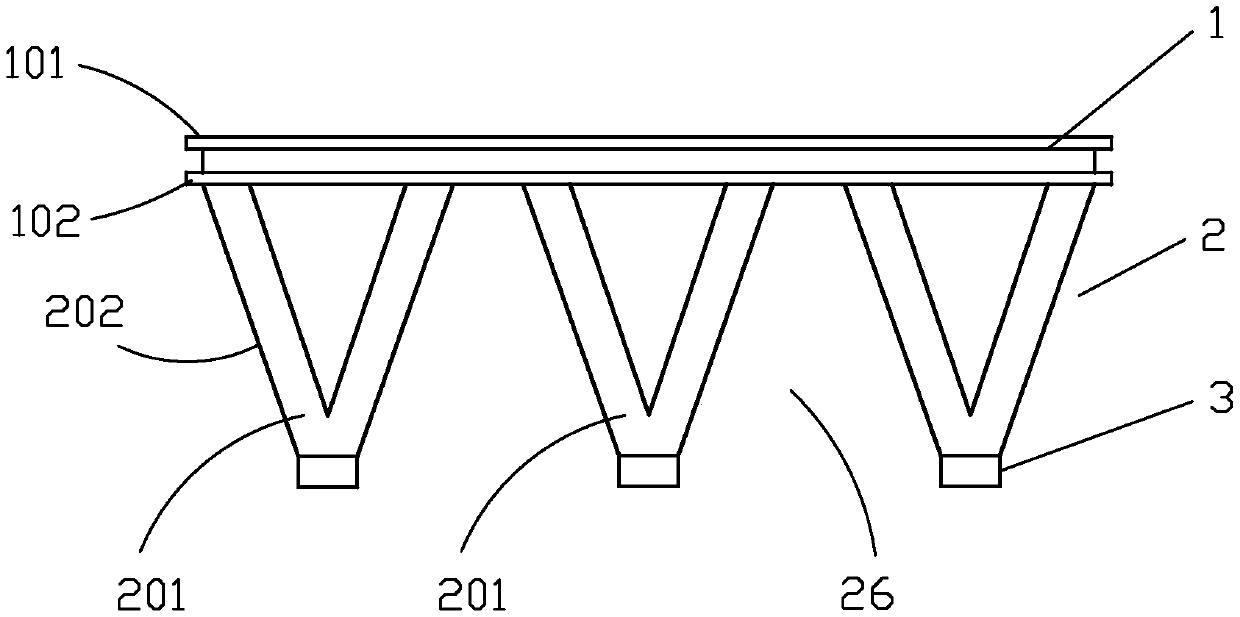

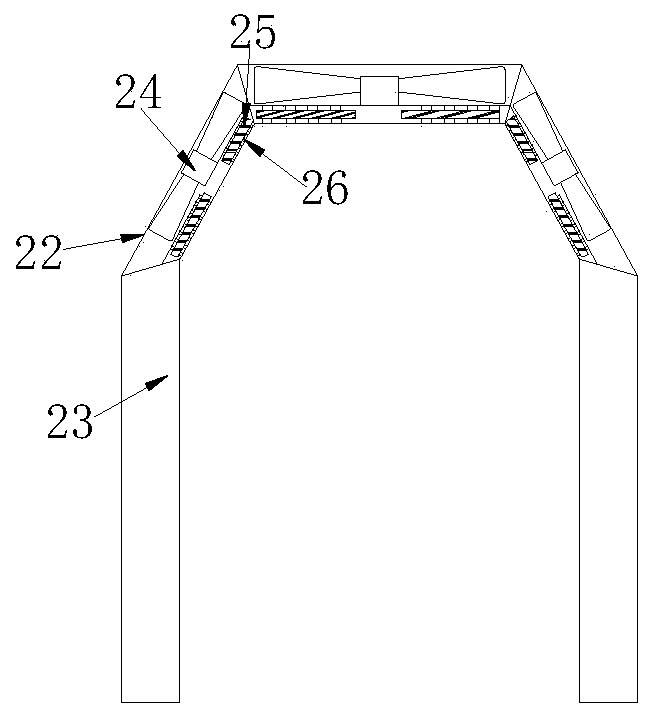

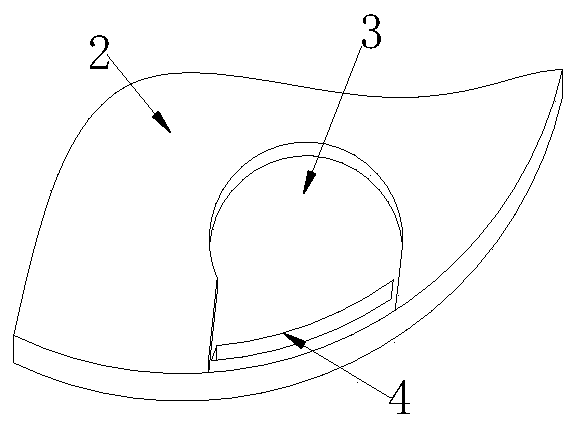

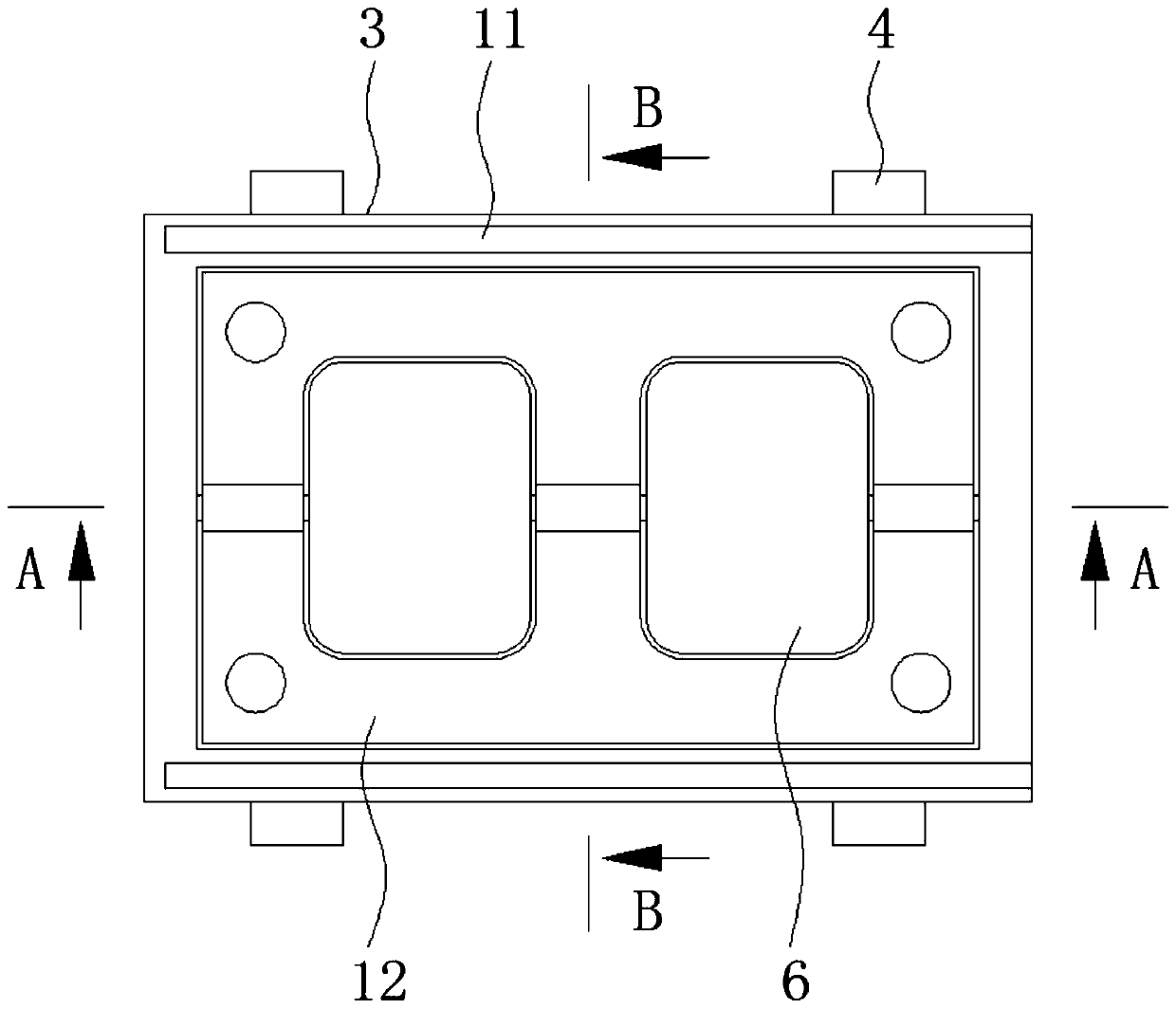

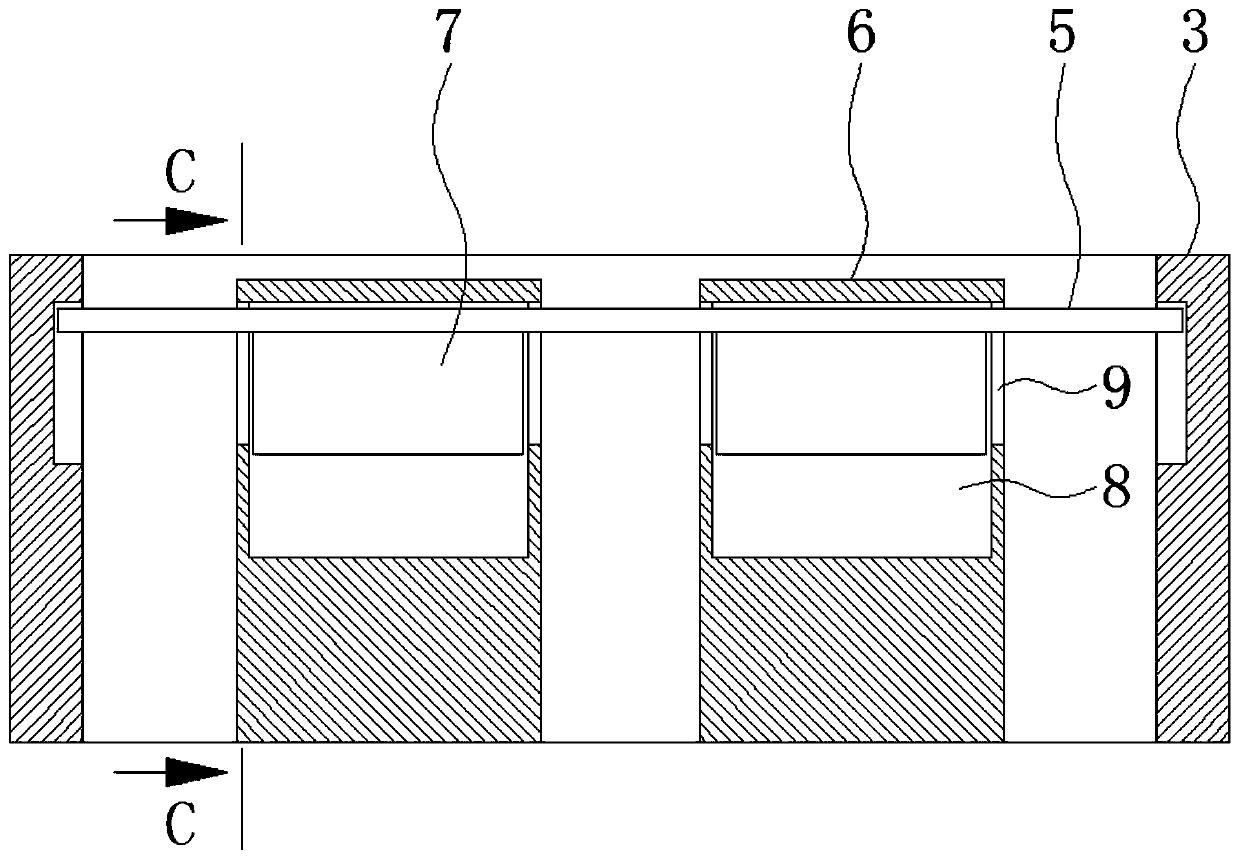

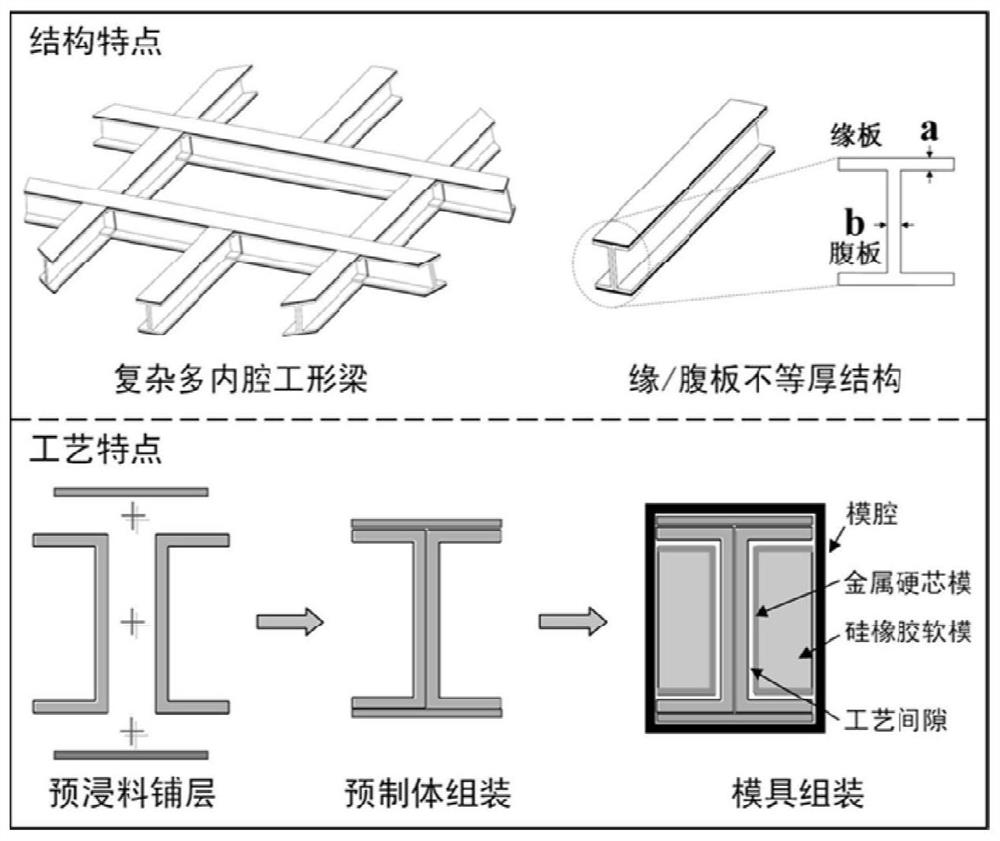

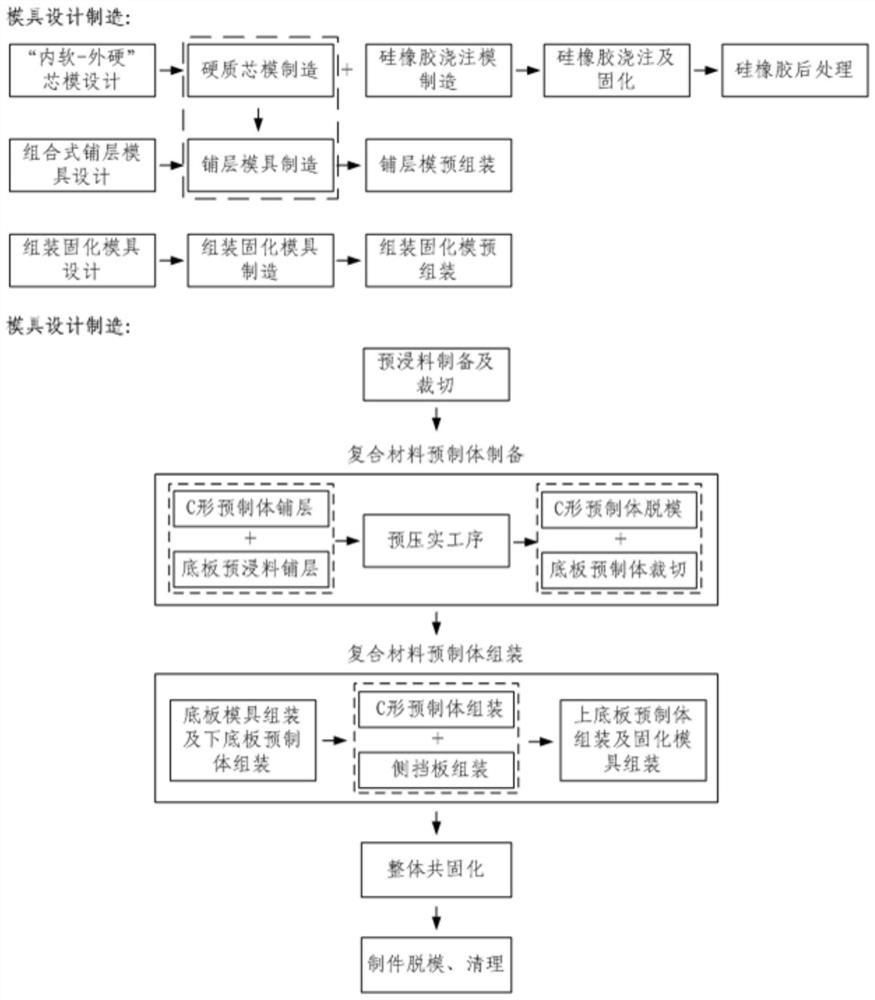

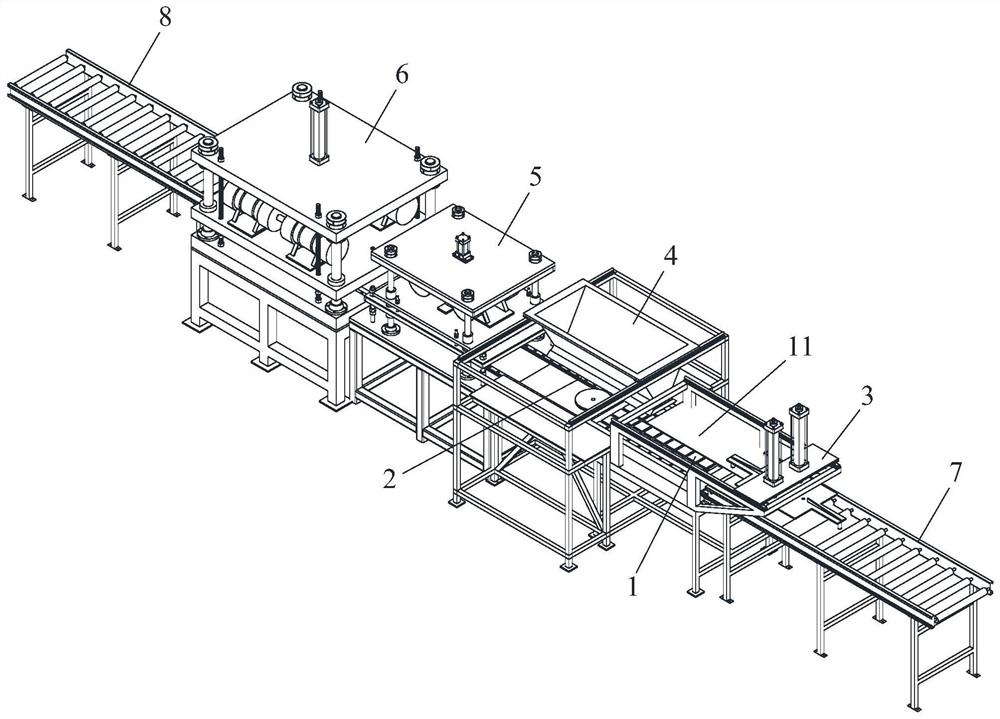

Multi-cavity I-beam and high-precision soft mold forming and defect control method thereof

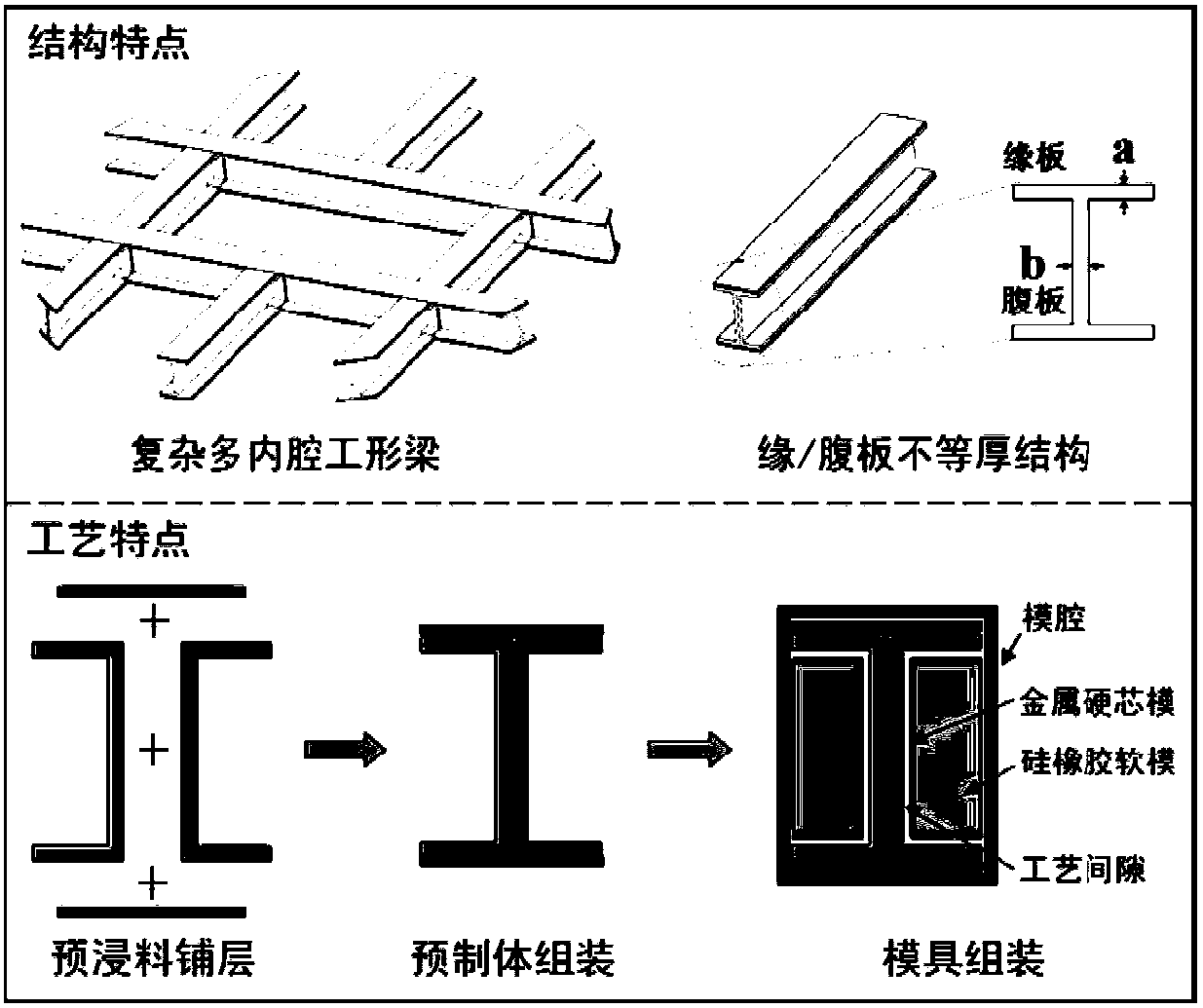

The invention provides a multi-cavity I-beam and a high-precision soft mold forming and defect control method thereof. Aiming at structural features of multiple cavities, multiple molded surfaces, unequal thickness of marginal / web plates and high precision of molded surfaces inside cavities, silicone rubber soft mold pressurization is adopted to achieve the overall co-curing molding of the I-beamwith a complex structure. The multi-cavity I-beam comprises at least two main beams and at least six secondary beams, the main beams and the secondary beams are in the same plane, the main beams are not intersected with each other, the secondary beams located between the main beams are used for connecting the main beams, and the secondary beams located outside the main beams are used for connecting with the outside; equitable distribution of pressure in the X / Y / Z direction is achieved by adopting silicone rubber soft mold process gap compensation design, and the problem of unequal thickness pressurization of the marginal / web plates is solved; an internal soft-external hard pressure equalization design method is utilized to avoid the pressure deviation caused by uneven expansion of a soft mold, and the dimensional accuracy and internal defects of the molded surfaces inside the cavities are improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

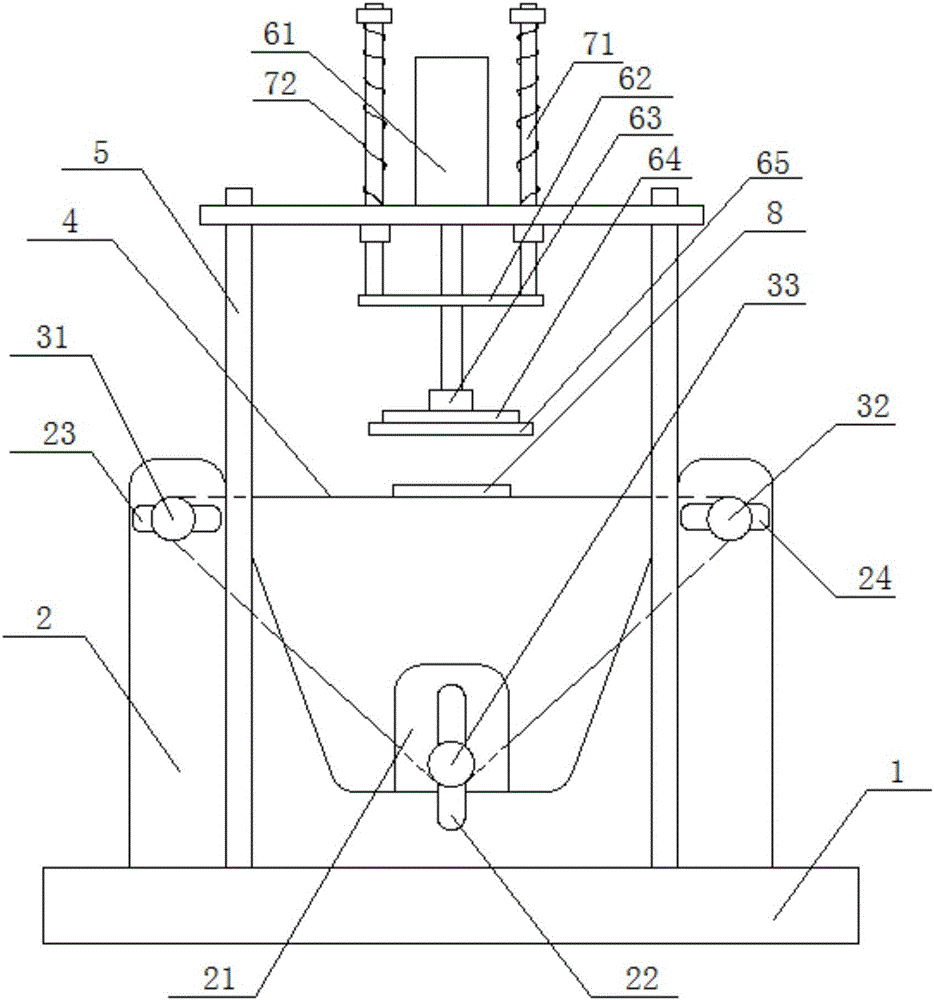

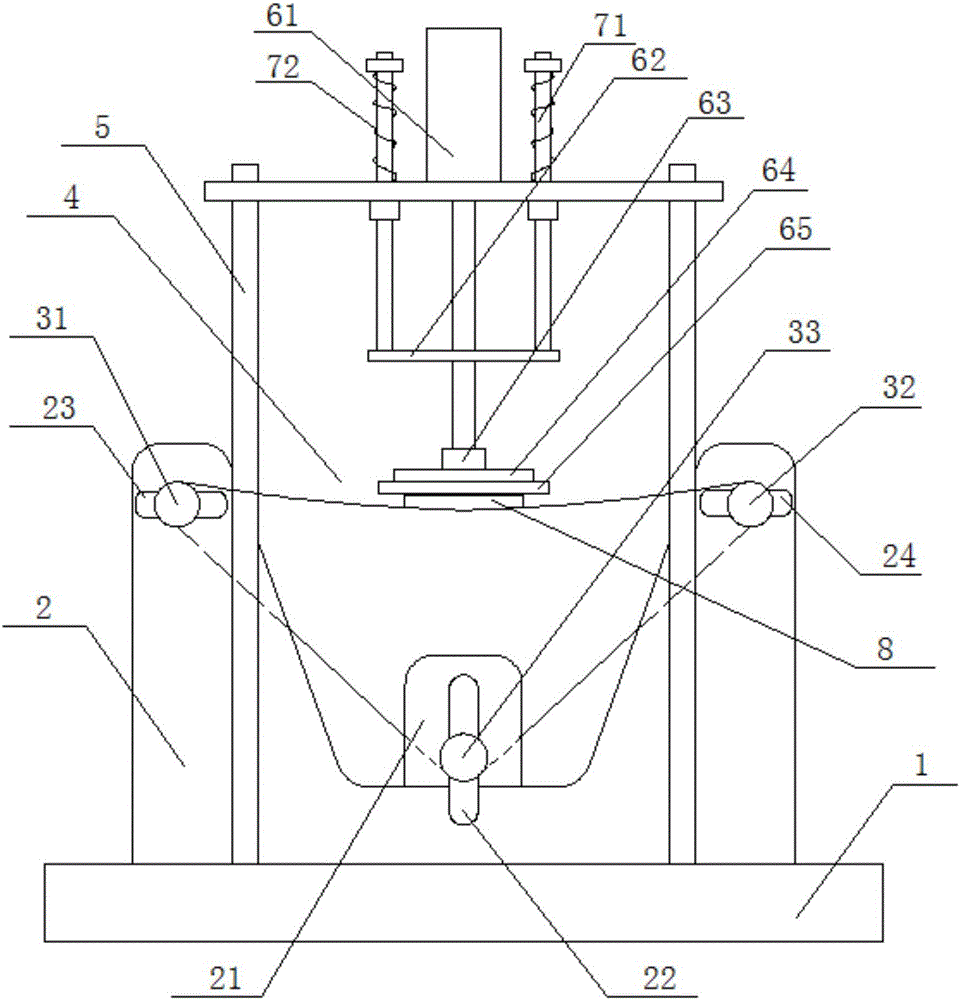

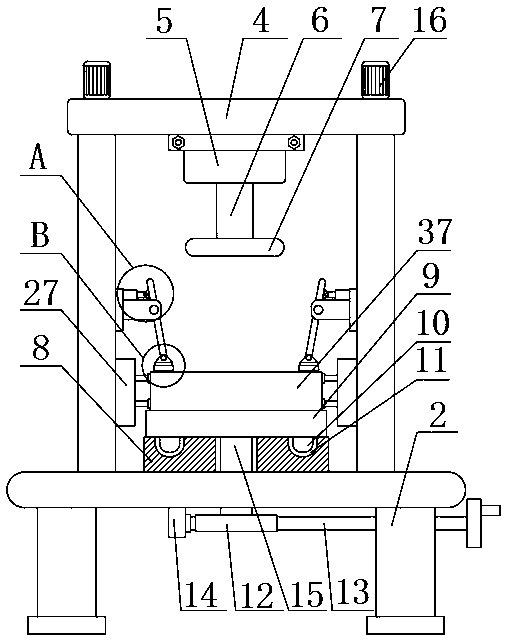

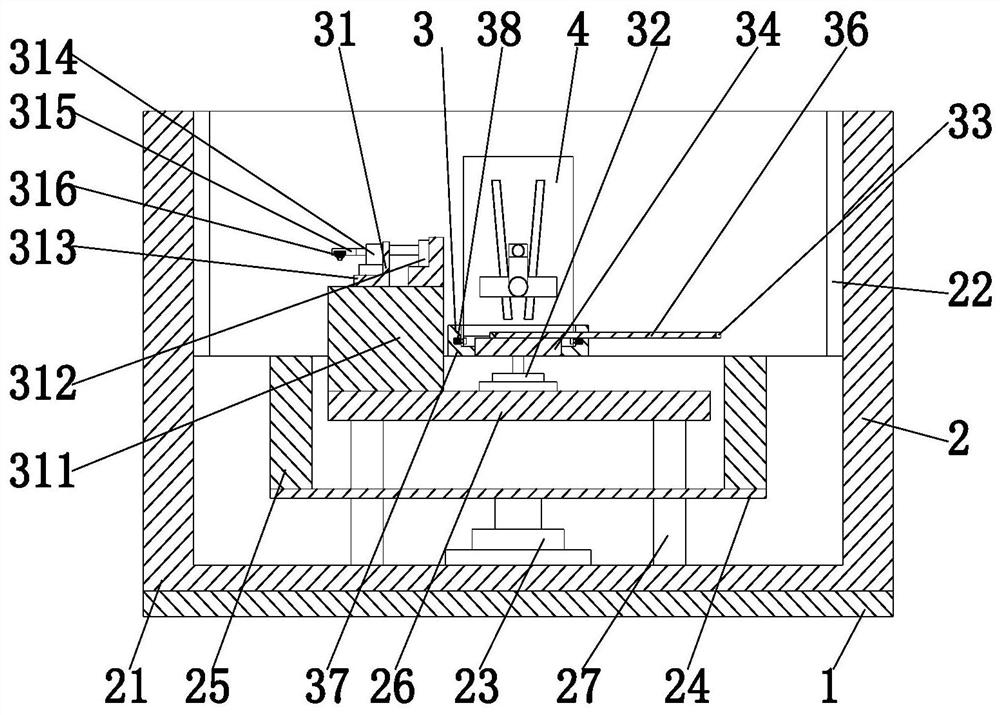

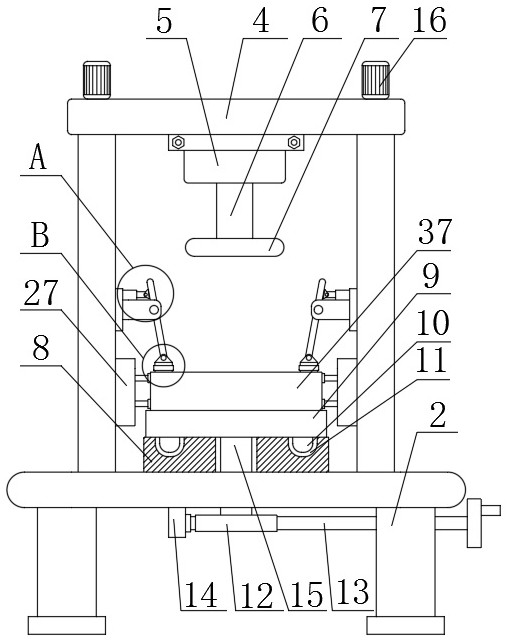

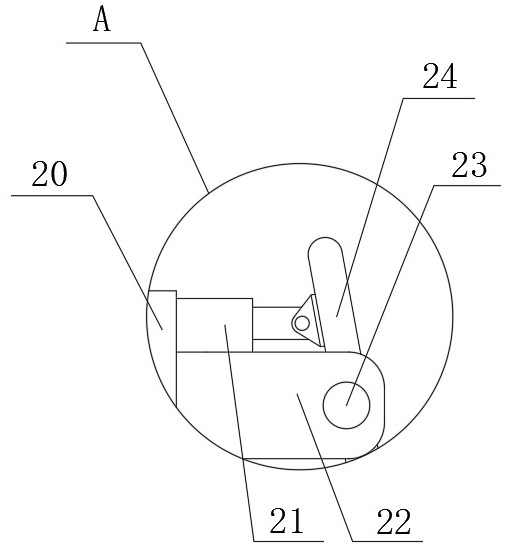

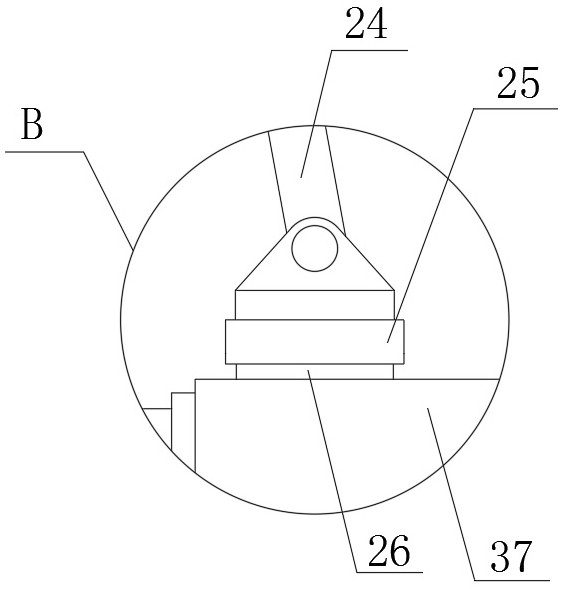

Detection device for cellphone compressive performance detection

InactiveCN106790896ASimple device structureEasy to operateSubstation equipmentSupport beltTesting equipment

The present invention belongs to the field of cellphone performance detection devices, and particularly relates to a detection device for cellphone compressive performance detection. The detection device comprises a base, a body and an elastic support belt. The body is fixedly installed on the base. The body is provided with a support mechanism for installation of the support belt. The base is provided with a fixing rack. A drive mechanism is installed on the fixing rack. The drive mechanism is above the support belt. The drive mechanism is provided with a pressure head. The drive mechanism drives the pressure head to move downward to press a cellphone placed on the support belt. The detection device has the beneficial effects that the elastic support belt and the pressure head cooperate with each other so as to simulate external flexible pressure on the cellphone, so that the compressive performance of the cellphone is detected accurately; and the detection device has a simple structure, is convenient to operate, detects automatically, reduces labor intensity, and improves detection efficiency.

Owner:重庆哈迪斯科技有限公司

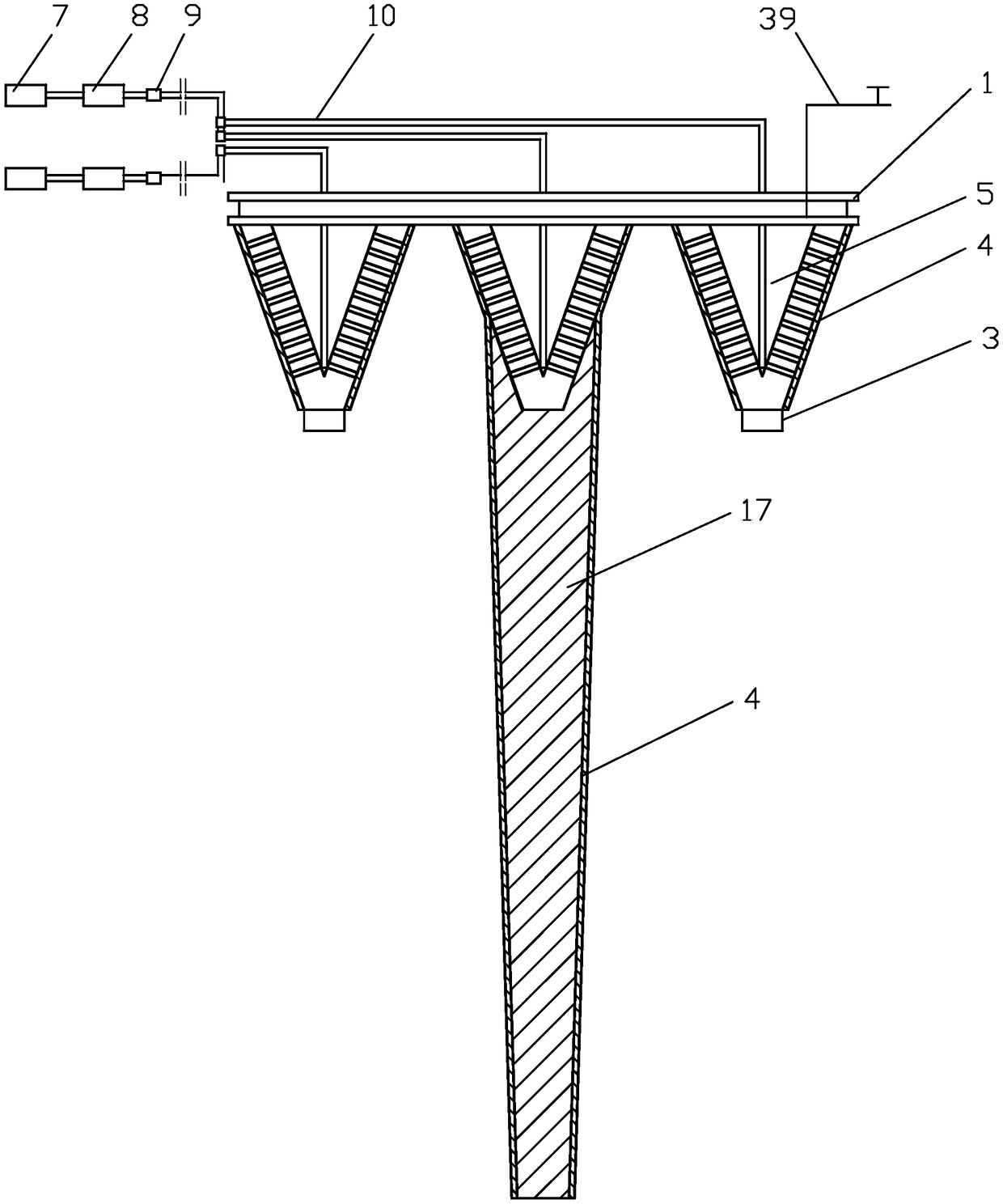

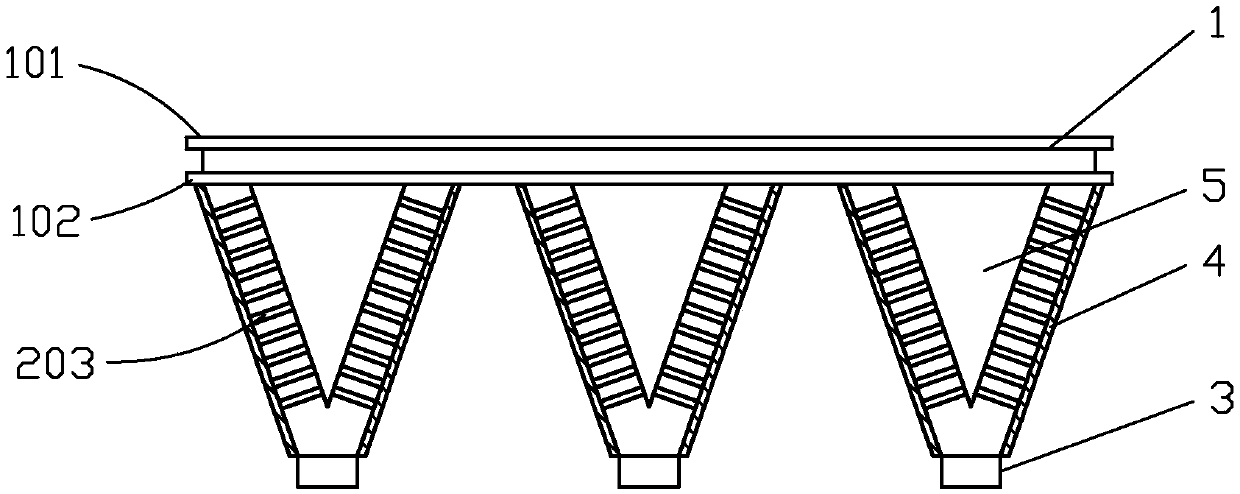

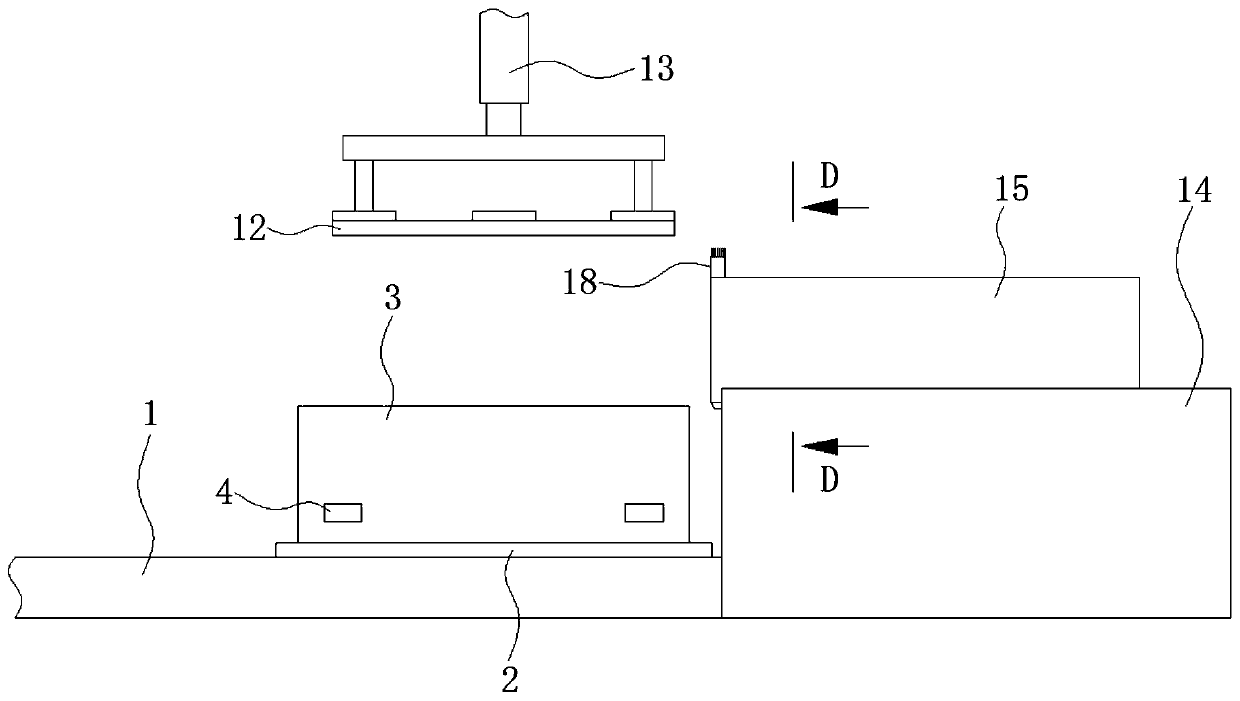

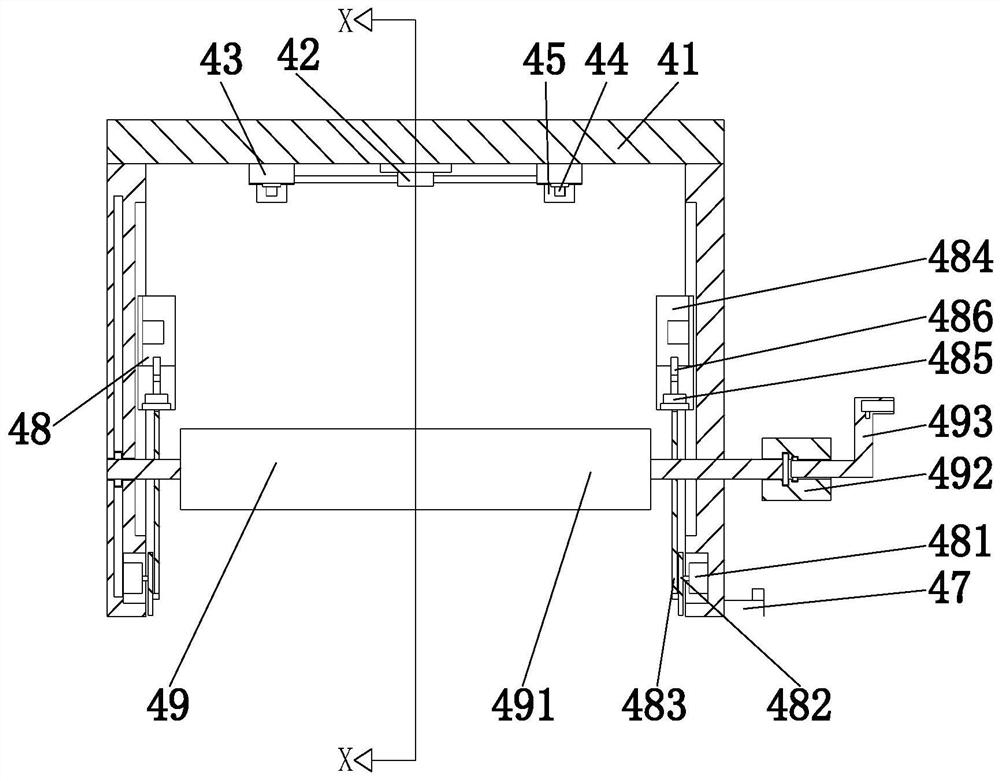

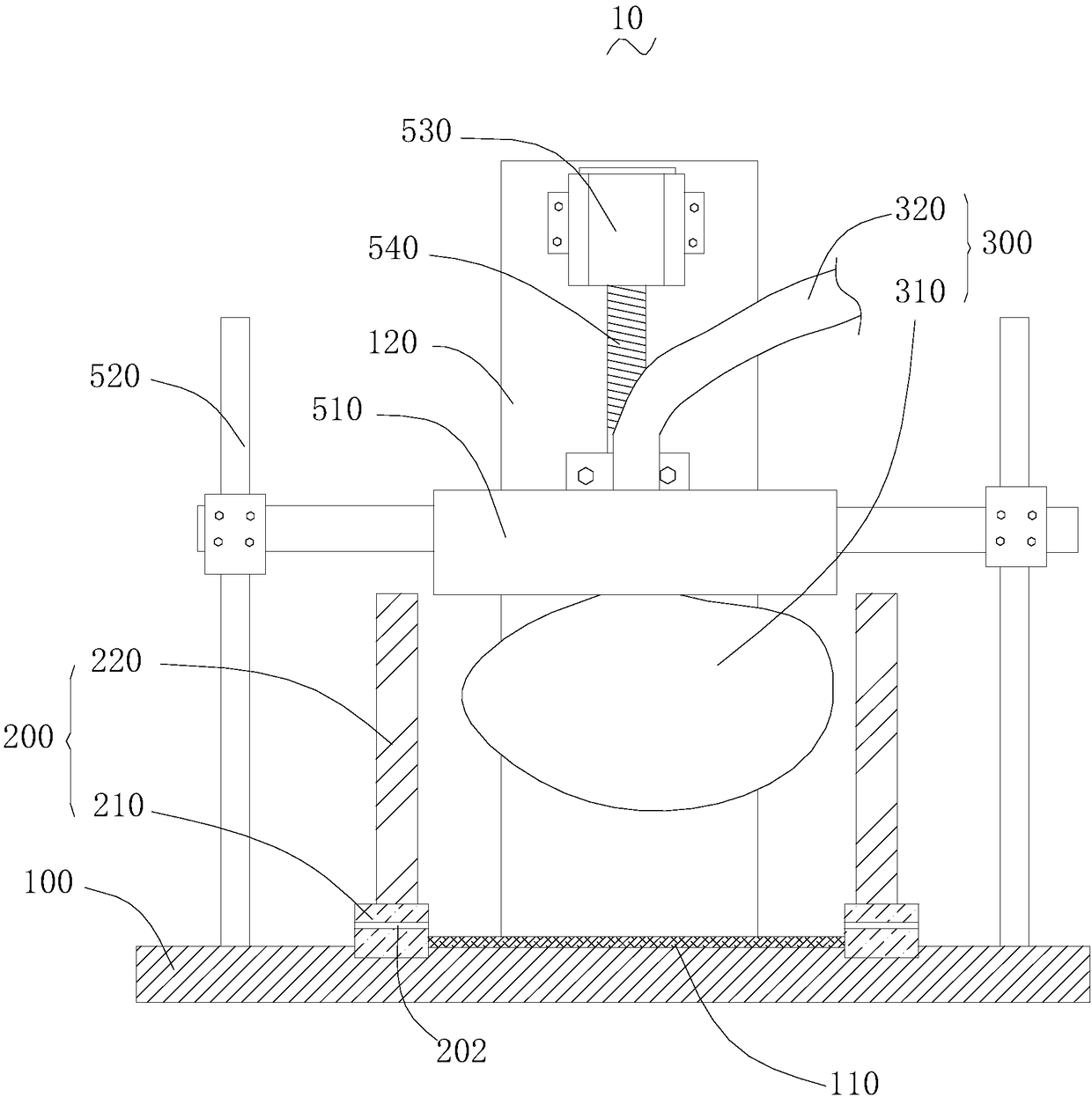

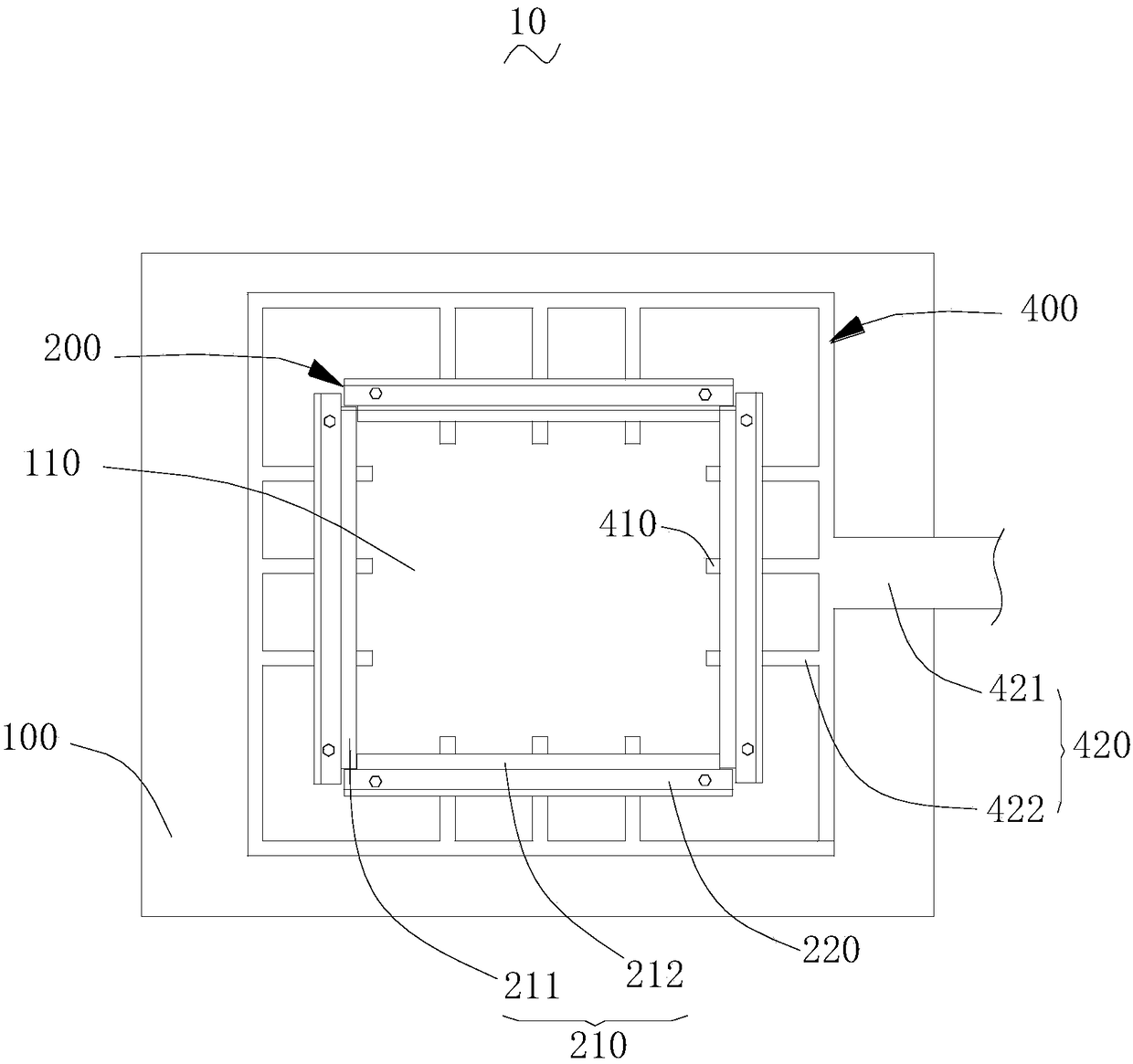

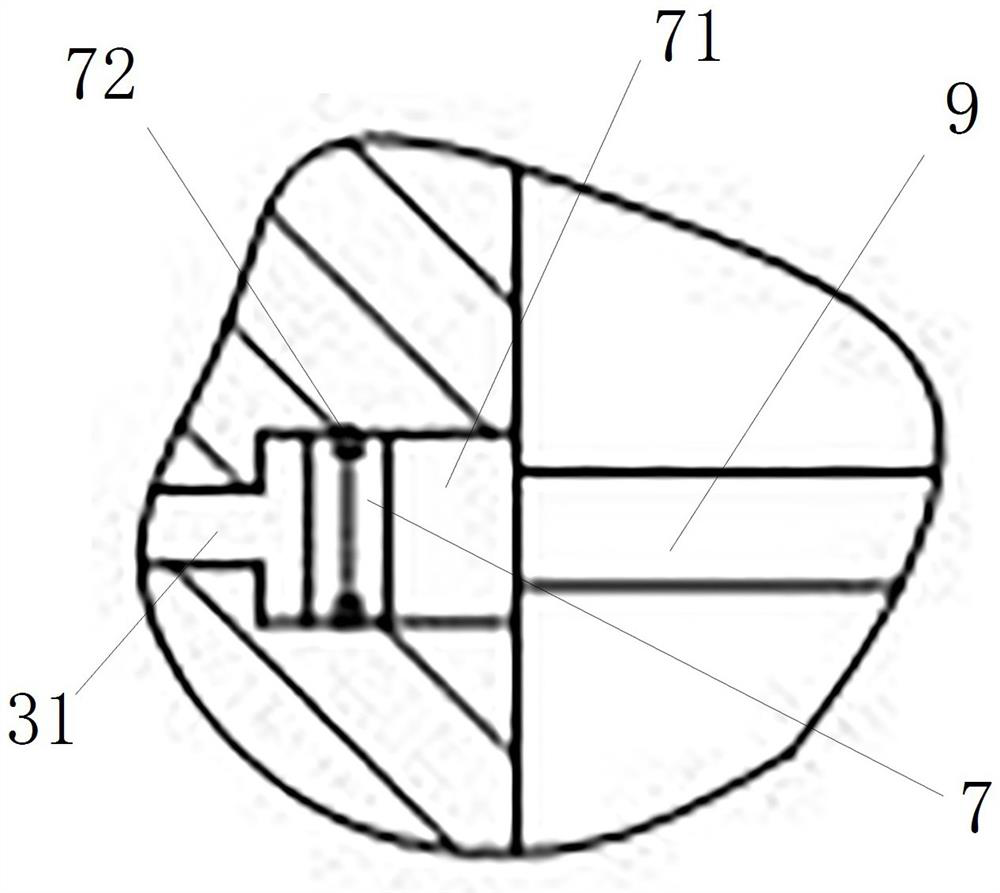

Modular soil compaction molding device applicable for treatment of deep and shallow soft soil foundations

InactiveCN108330948APlay a blocking rolePrevent sideways movementSoil preservationEngineeringUltimate tensile strength

The invention discloses a modular soil compaction molding device applicable for treatment of deep and shallow soft soil foundations. The modular soil compaction molding device comprise an upper frame,a compaction molding module and a soil strength detection device, and is characterized in that the compaction molding module comprises a plurality of convex bodies; the top of the module is connectedto the upper frame, and the part, coming into contact with soil, of the compaction molding module is further provided with a filter device; and the bottom of the compaction molding module is furtherprovided with a vertical pile body. The soil is blocked by the convex bodies at the bottom of the compaction molding module, and prevented from offsetting so that the soil is centralized in spaces among the convex bodies and extruded fully, and the effects of quick drainage and compaction are achieved. Moisture extruded from the soil is discharged through the filter device, and the construction efficiency is improved greatly; and the construction period is shortened, and the construction cost is reduced.

Owner:ZHEJIANG JIA YUAN CIVIL ENG CO LTD

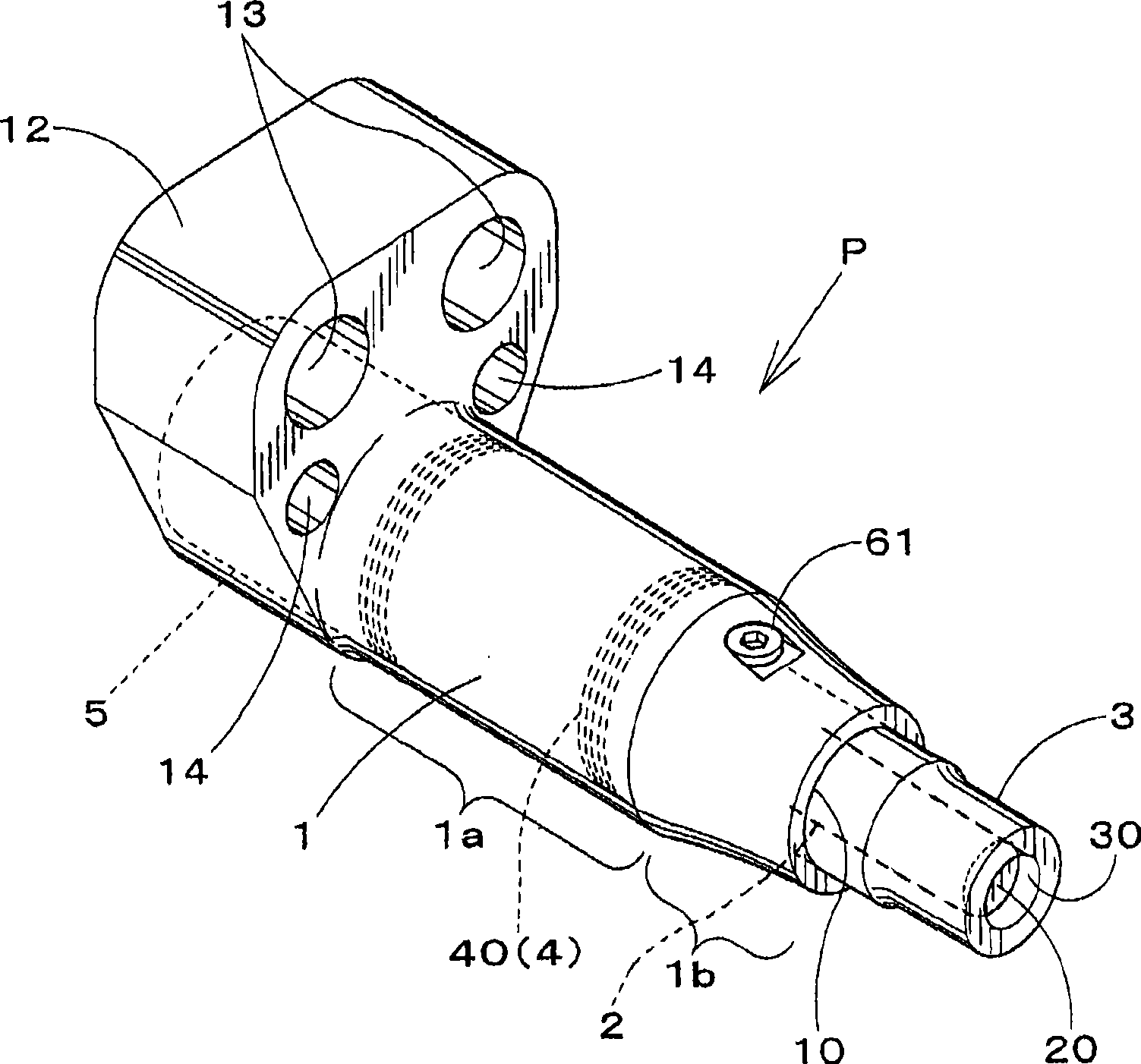

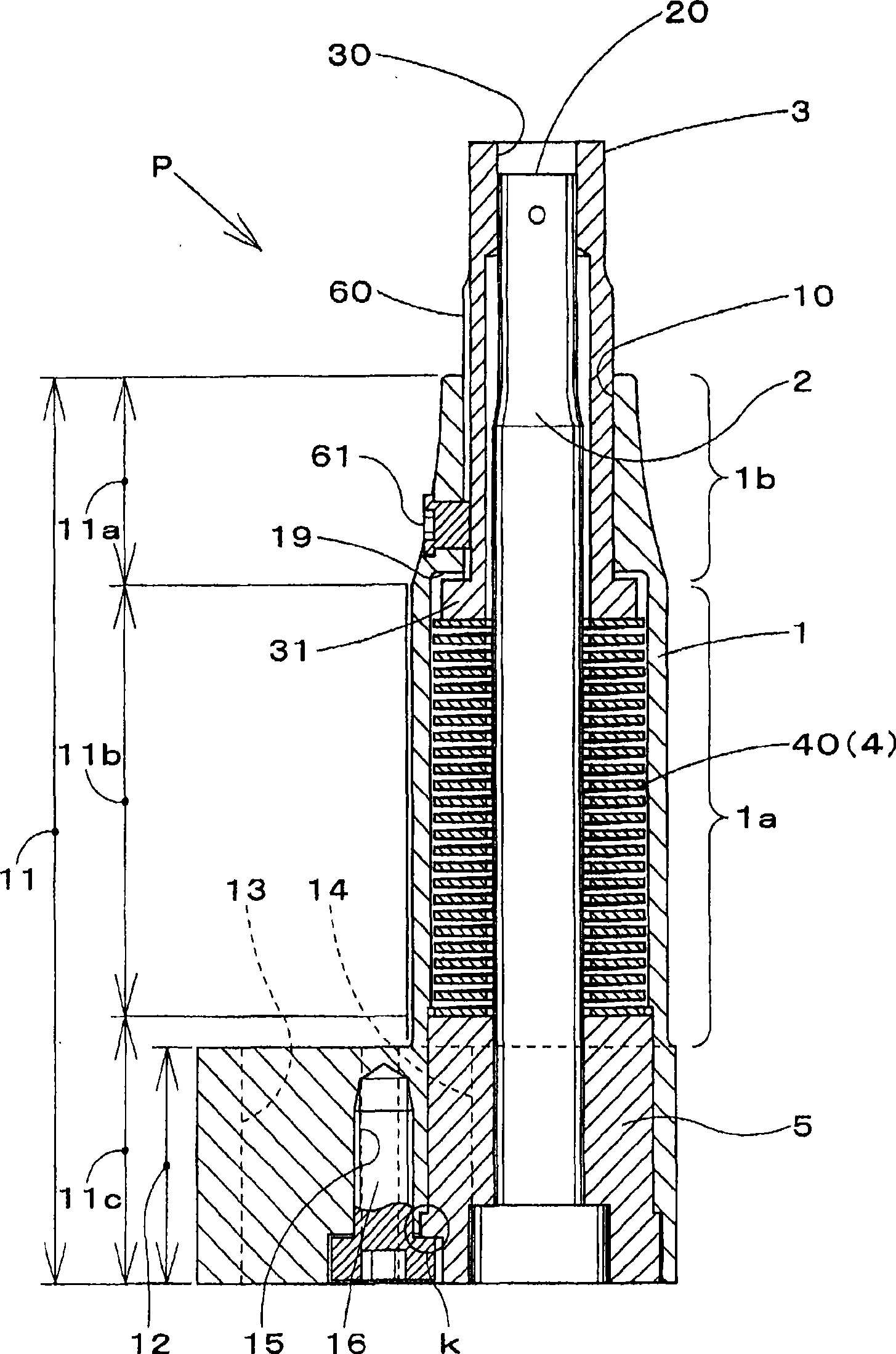

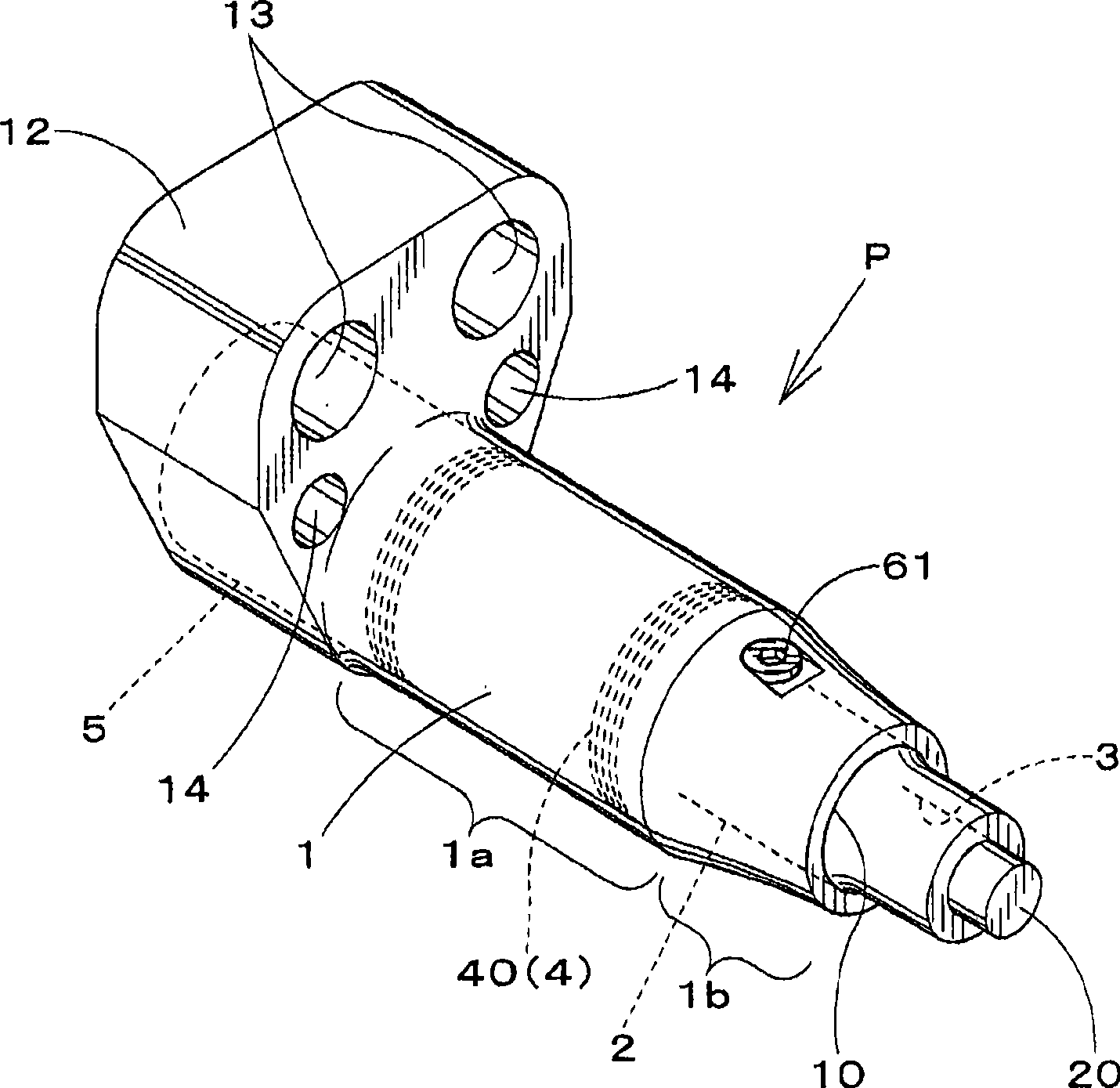

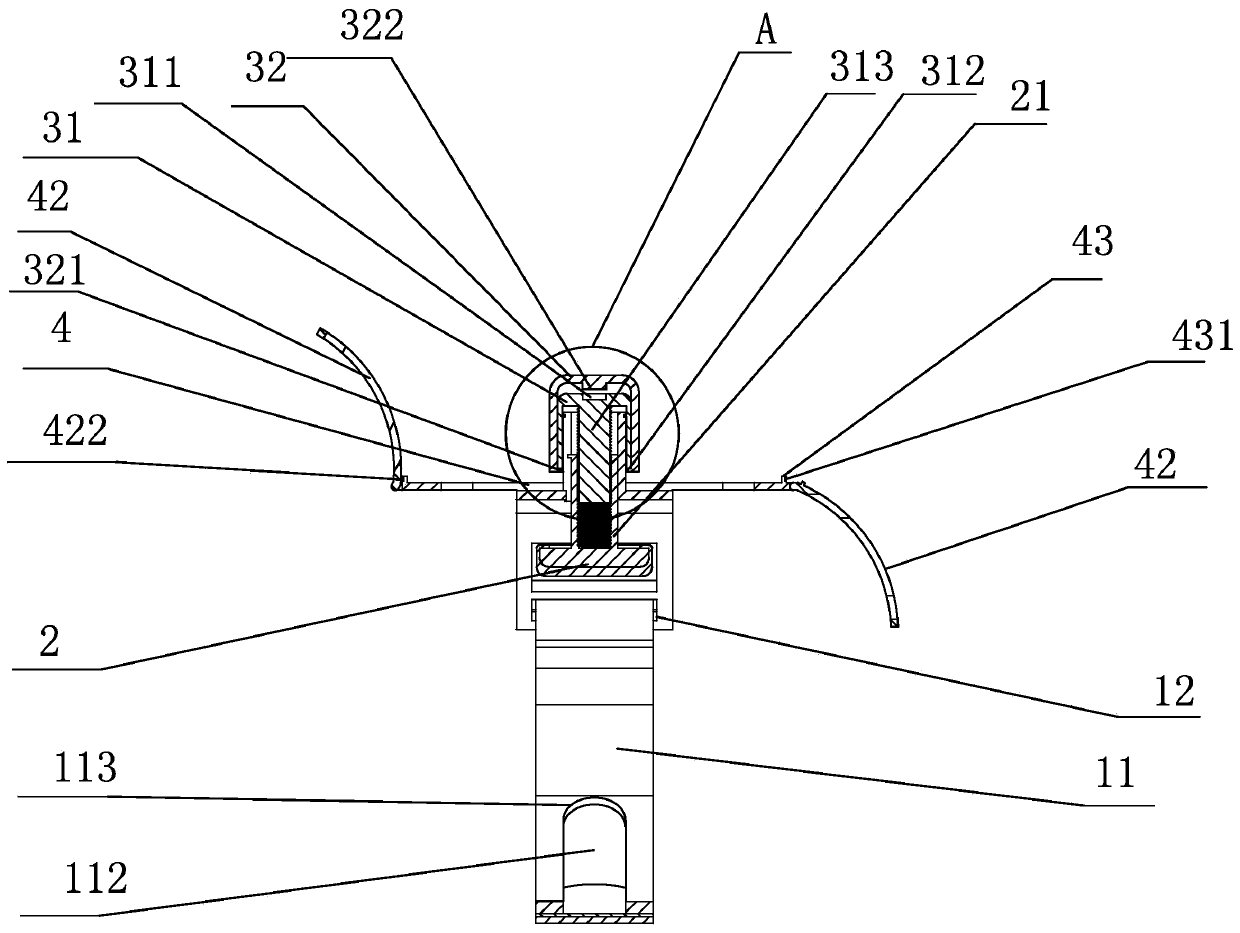

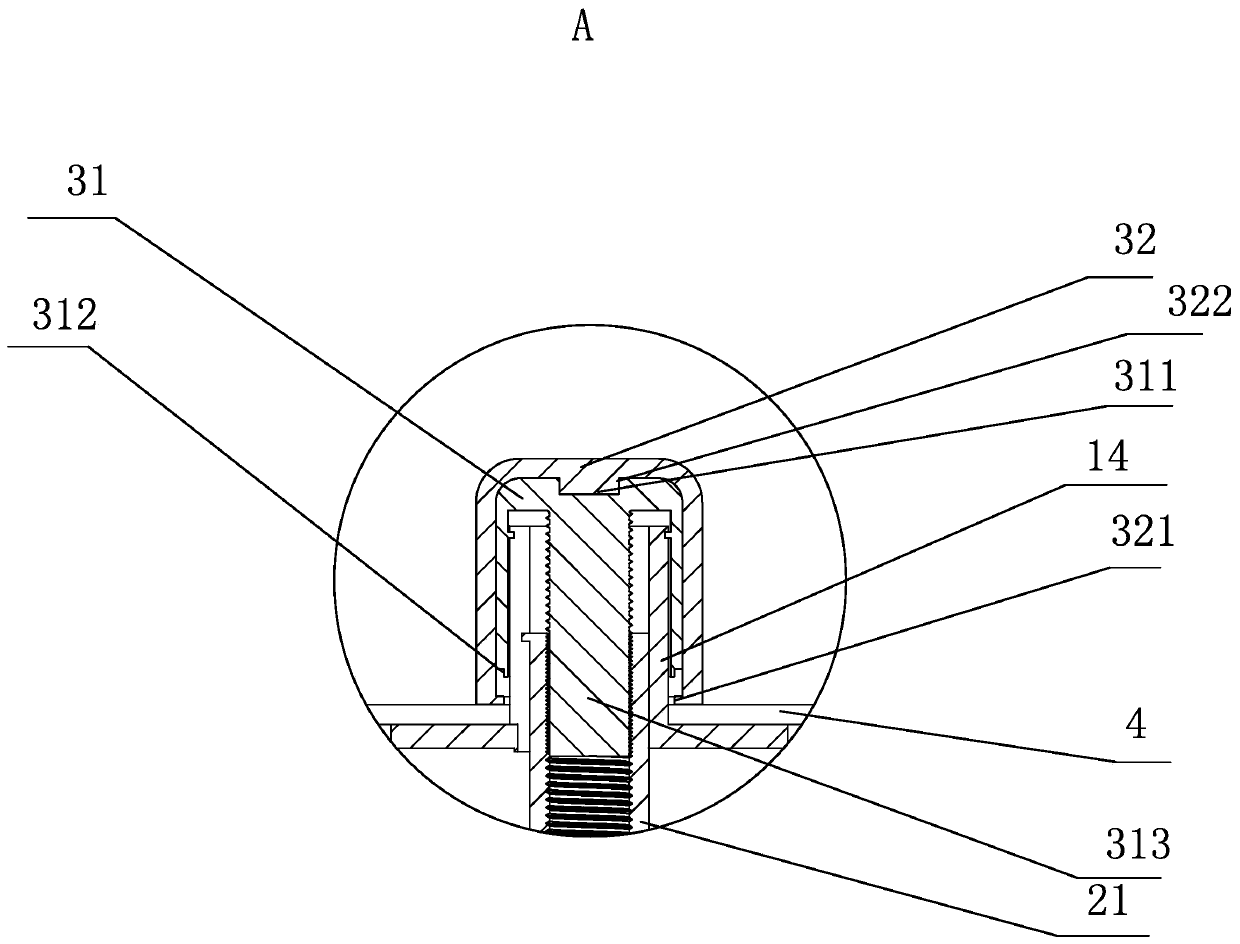

Puncher

InactiveCN101450358ASolution to short lifeFull pressurePerforating toolsStripping-off devicesComing outEngineering

The invention relates to a puncher; a piercing punch (2) is unmovably and loosely inserted in a cylindrical cover (1) having a one-end opening hole (10) while a tip end face (20) projects from the one-end opening hole (10). A cylindrical stripper (3) is provided between the cover (1) and the piercing punch (2) while the stripper (3) can be pulled out from the one-end opening hole (10). The stripper (3) is made to project more than the piercing punch (2) from the one-end opening hole (10) by an urging means (4). Then, pushing into the stripper (3) against the urging force of the urging means (4) makes the distal end face of the piercing punch (2) project from a through hole (30) bored at the projecting end of the stripper (3). A come-out prevention means for preventing the stripper from coming out from the cover is provided at the cover detachably.

Owner:UMIX

Module type soil pressure applying and forming device and processing method of soft soil foundation

InactiveCN108677911APlay a blocking rolePrevent sideways movementSoil preservationEngineeringUnit structure

The invention discloses a module type soil pressure applying and forming device. The module type soil pressure applying and forming device comprises a top frame, a pressure applying forming module anda soil body strength detecting device, wherein the pressure applying forming module comprises a plurality of convex bodies, and the top of the pressure applying forming module is connected with the top frame. The invention further discloses a processing method of a soft soil foundation, and is used for extruding, draining and forming a soil body by adopting the module type soil pressure applyingand forming device. The device can be integrally manufactured and can also be manufactured in a unit splicing mode. Different functional components can be added on each unit according to needs. The manufacturing mode of unit splicing is adopted, and the size of each unit is small, so that the manufacturing is simpler, and the manufacturing difficulty and the manufacturing cost can be reduced. Moreover, the units can be used as standard sizes or as a series of products, and each series of unit structures are the same in size, so that splicing is carried out according to design or construction requirements, and the design and the use are more flexible.

Owner:HANGZHOU YONGCHUANG INFRASTRUCTURAL ENG SCI & TECHCAL CO LTD

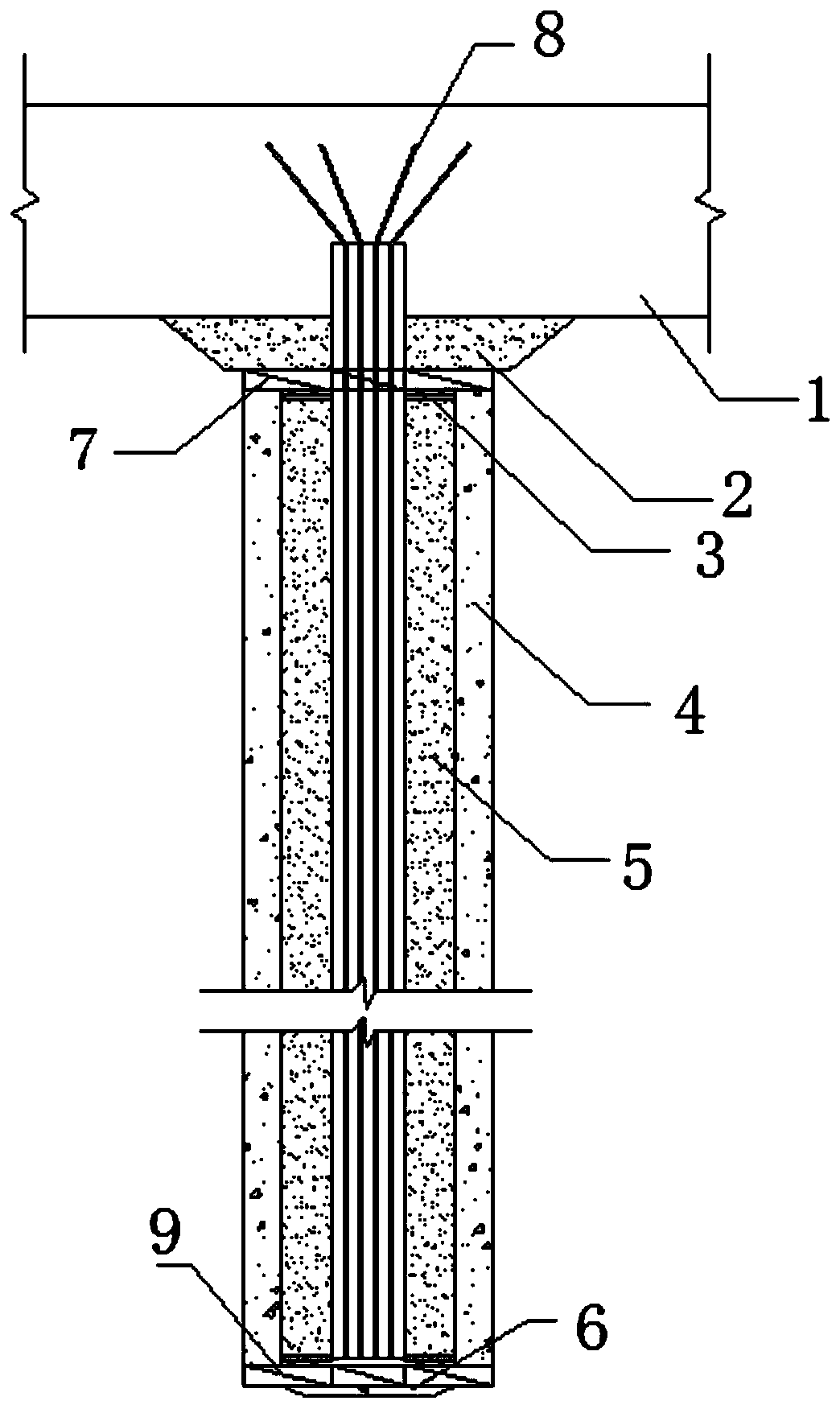

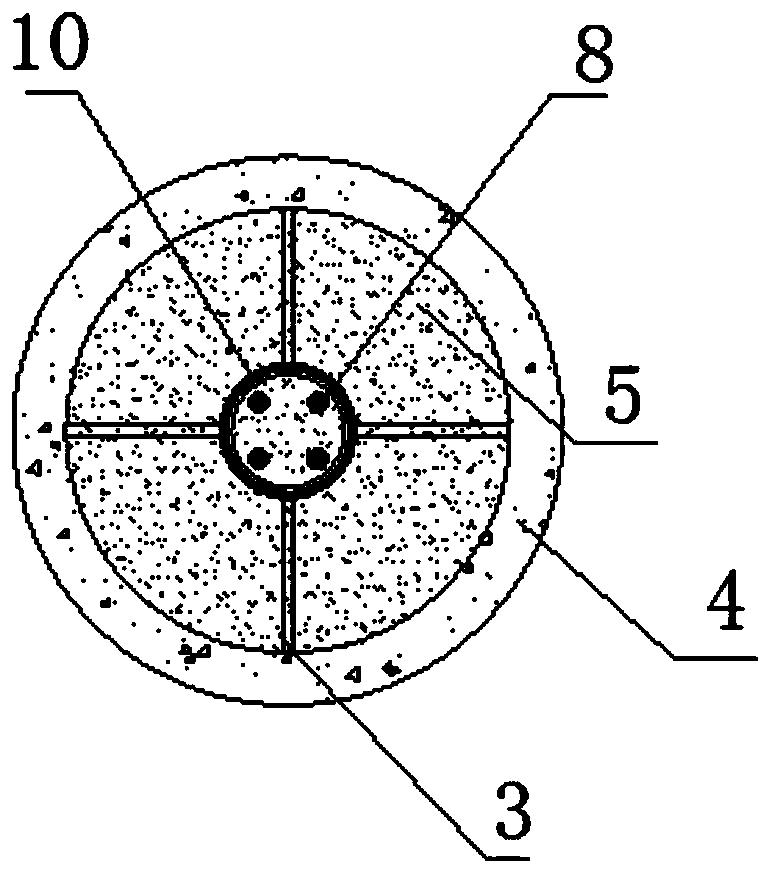

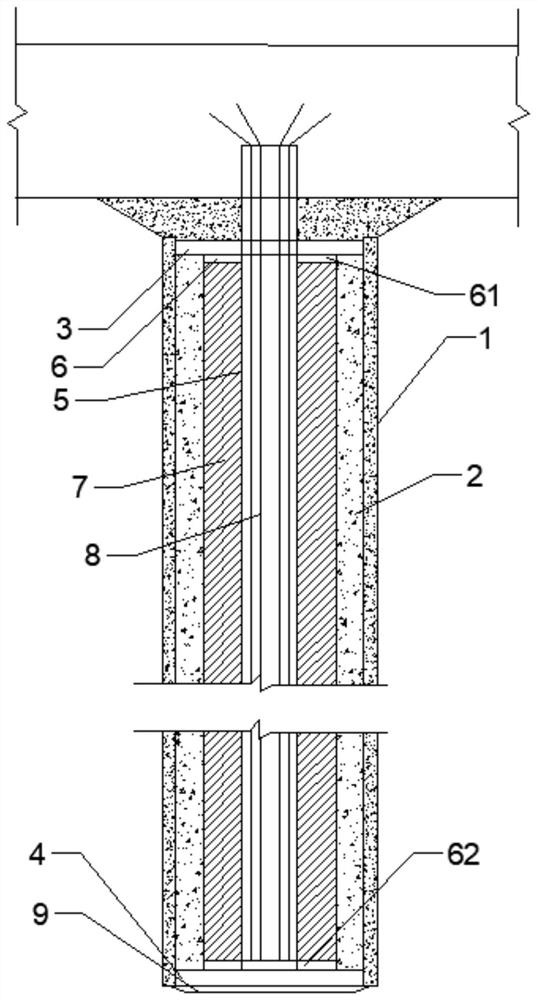

Combined reinforced anti-pull anchor rod device and construction method thereof

PendingCN110847167ANo emissionsNo pollution in the processBulkheads/pilesPre stressArchitectural engineering

The invention relates to the technical field of buildings, in particular to a combined reinforced anti-pull anchor rod device and a construction method thereof. The combined reinforced anti-pull anchor rod device can be widely applied to floating resisting of buildings (structures), comprehensive pipe galleries and underground construction foundations, and can also be applied to foundation pit andside slope supporting engineering. According to the combined reinforced anti-pull anchor rod device, positioning supports are fixed to an upper end plate and a lower end plate of a concrete precast pile correspondingly, core pipes are arranged on positioning holes of the positioning supports, and a plurality of rod ribs are arranged in the core pipes; the concrete precast pile is constructed through a static pressure or hammering method, zero emission is achieved in the construction process, a concrete pile body and a composite anchoring body are stable and reliable in quality, high in construction efficiency and convenient to operate, the single anti-pull bearing capacity is high, on-site passing is convenient, and the comprehensive cost is reduced; the concrete precast pile is a bearingbody of a composite anchor rod and is also a protection layer of the rod rib, the rod rib can be effectively protected from being corroded by a corrosive medium in underground water and soil, dan thedurability of the anchoring body is improved; and the rod rib can be stretched to exert prestress.

Owner:研建创科(北京)科技有限公司

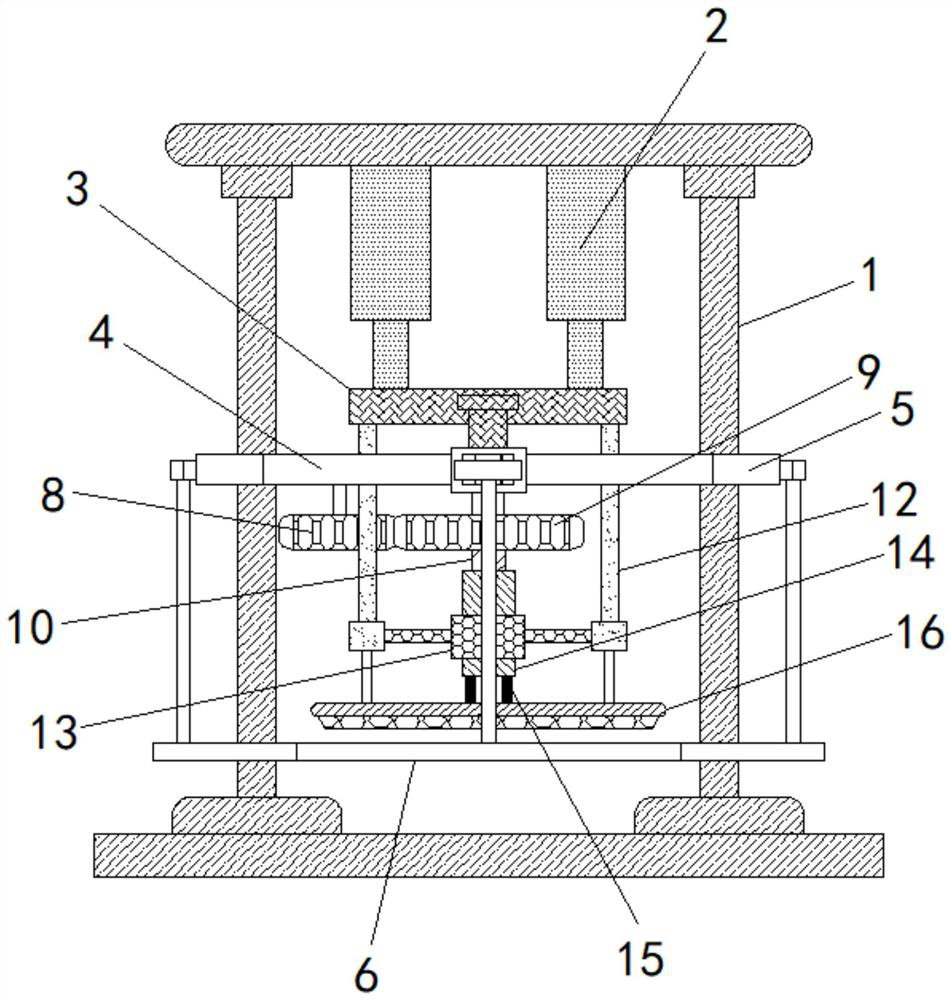

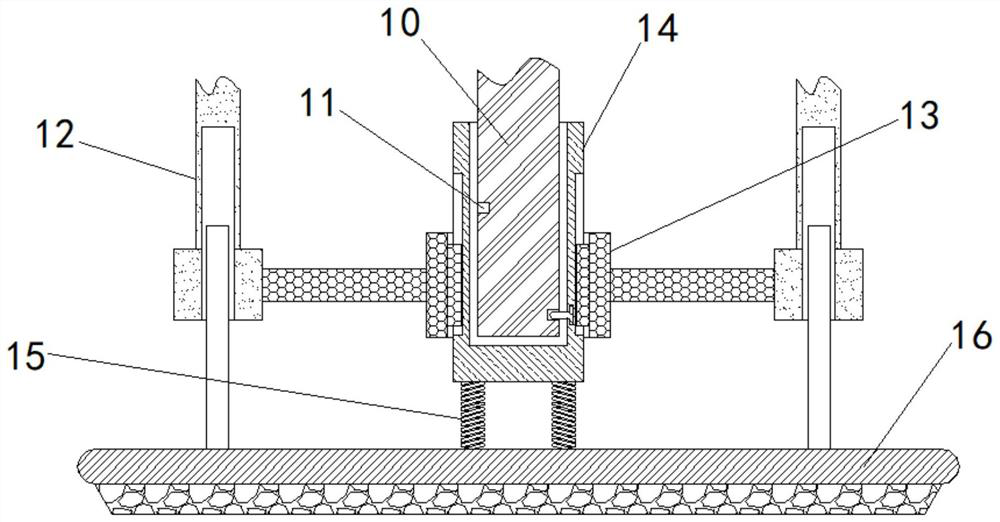

Energy-saving plate-shaped stamping part

ActiveCN111036752AFull pressureAvoid displacementShaping toolsMetal-working feeding devicesHydraulic cylinderStamping

The invention relates to an energy-saving plate-shaped stamping part, which comprises a base, a top base, a workbench and a height adjusting mechanism, wherein supporting columns are fixedly connectedto the periphery of the bottom end of the base, and the top end of the base is fixedly connected with the top base by means of a connecting plate; the bottom end of the top base is fixedly connectedwith a hydraulic cylinder, and a piston rod of the hydraulic cylinder is fixedly connected with a stamping die by means of bolts; the workbench is fixedly connected to the base, a lower die base is arranged at the top end of the workbench, and a workpiece body is arranged on the lower die base; the height adjusting mechanism is connected to the connecting plate; and the height adjusting mechanismcomprises a motor, a threaded rod, a strip-shaped notch, an adjusting block and a nut. According to the energy-saving plate-shaped stamping part, the distance between hinge bases can be adjusted according to the height of the stamped workpiece body, the workpiece body can be fully pressed by means of a pressing plate, displacement of the machined part during stamping is avoided, stamping errors are reduced, the precision of the machined workpiece body is guaranteed, resource waste is avoided, and materials are saved.

Owner:TAIZHOU HUIJIN ELECTRONIC CO LTD

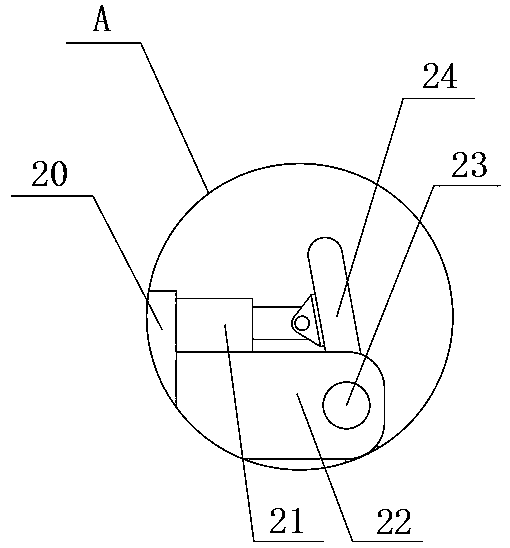

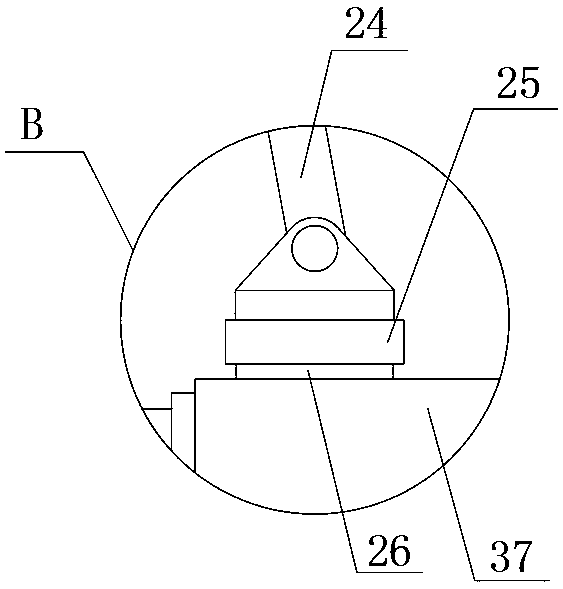

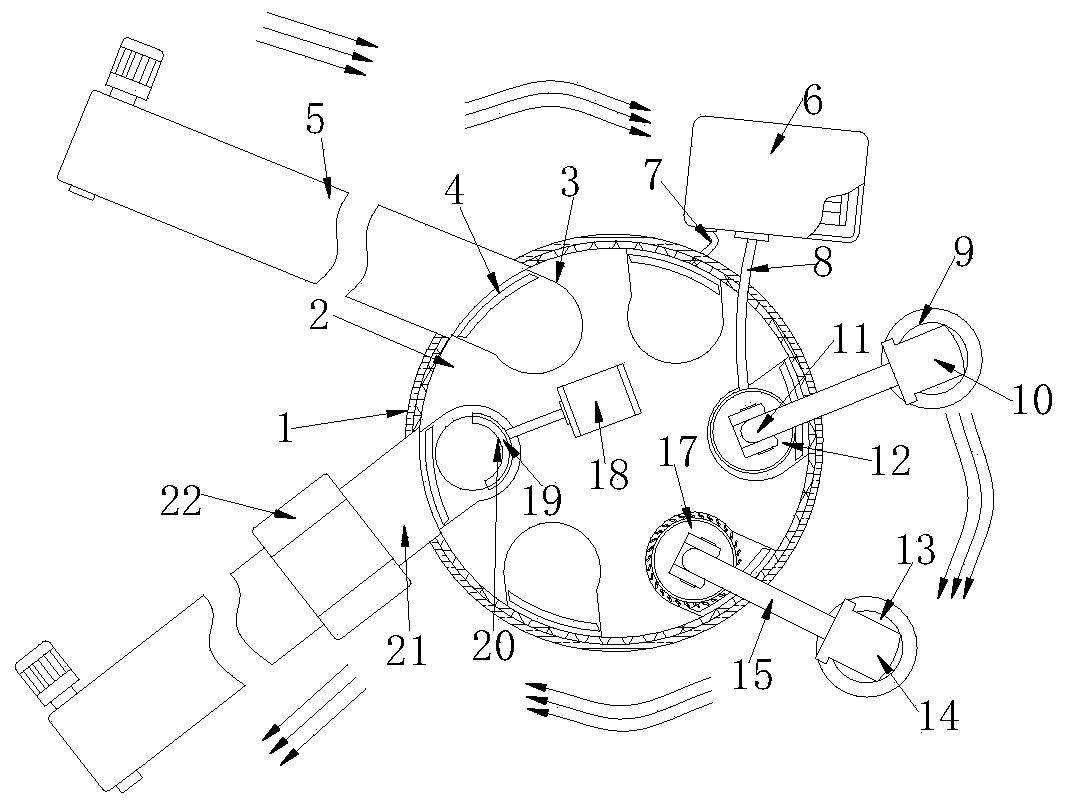

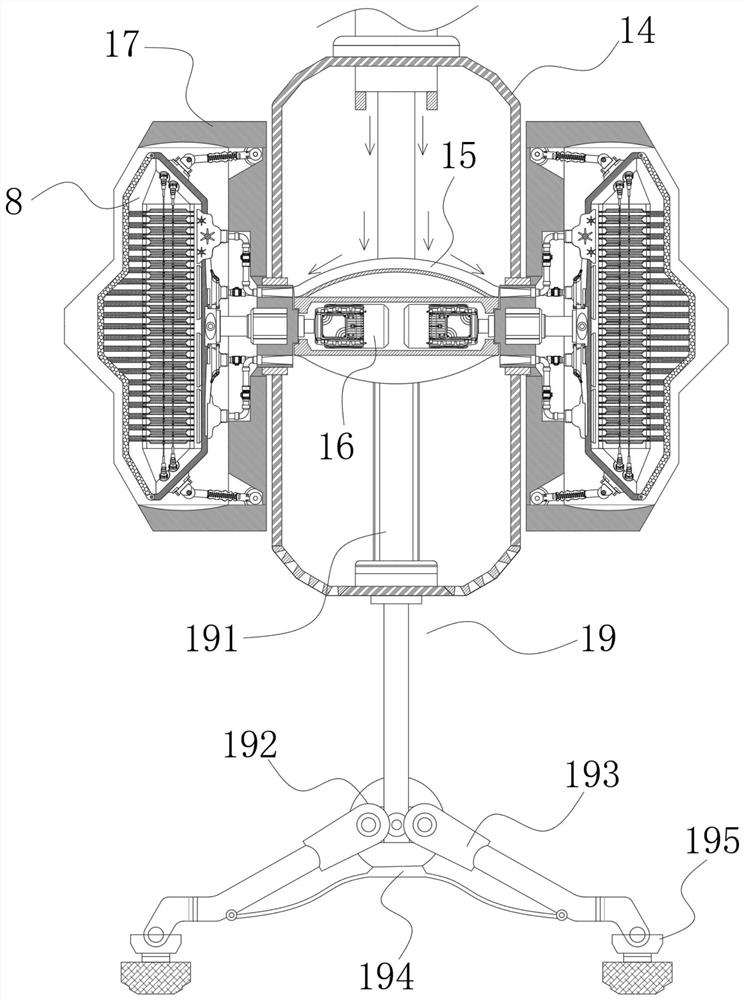

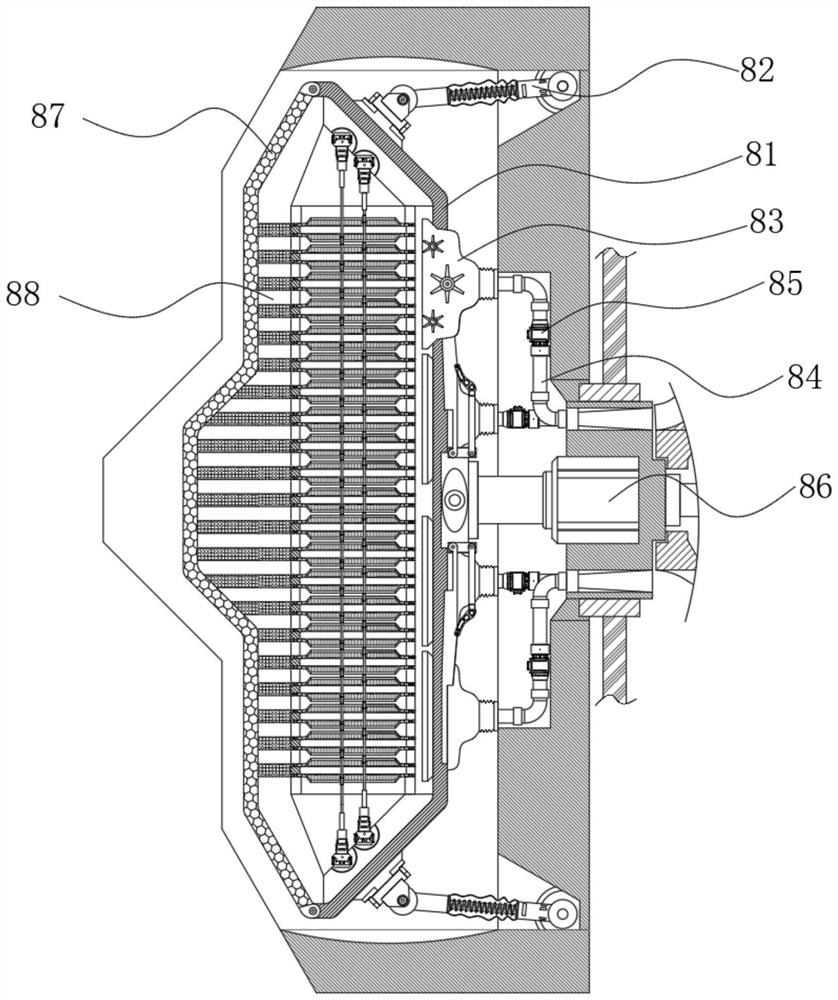

Autonomous cooling polishing and grinding robot

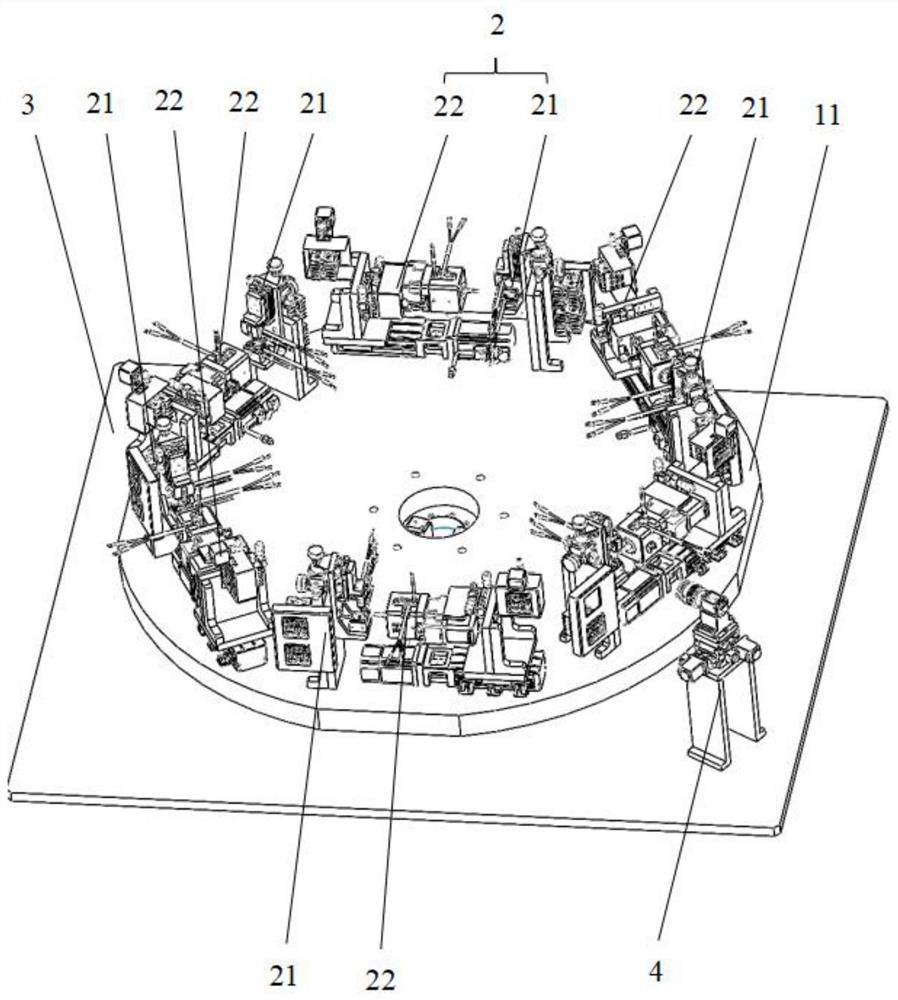

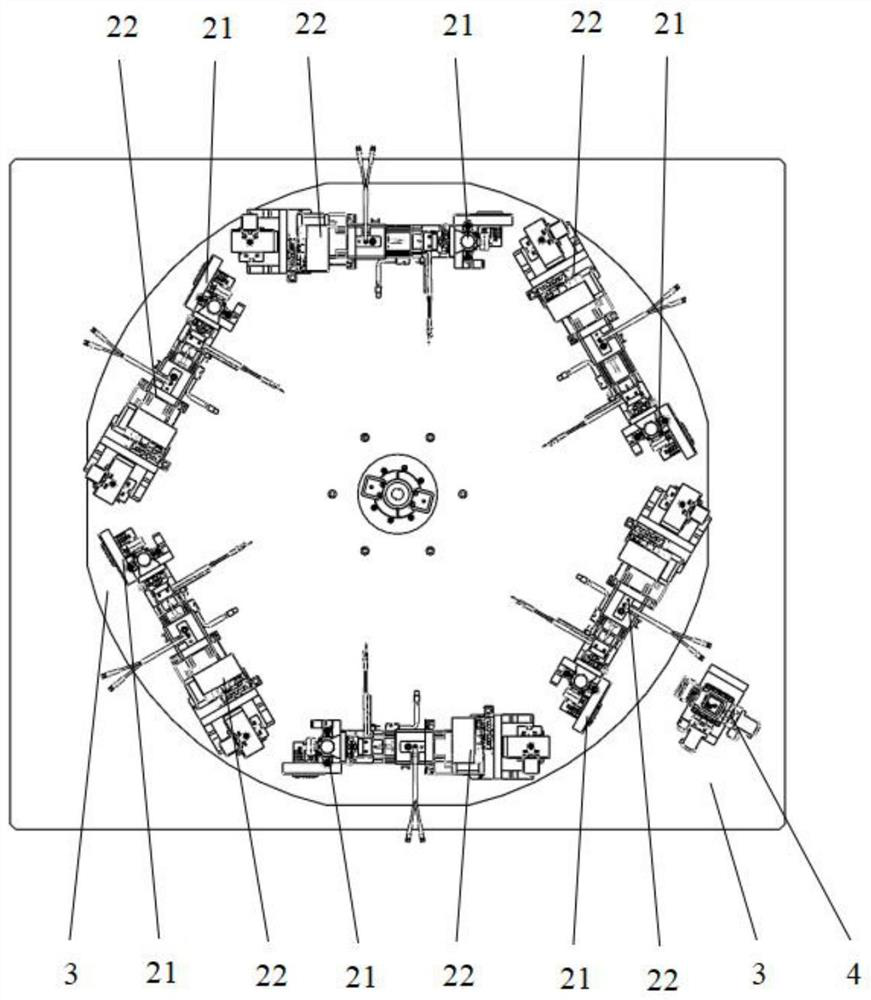

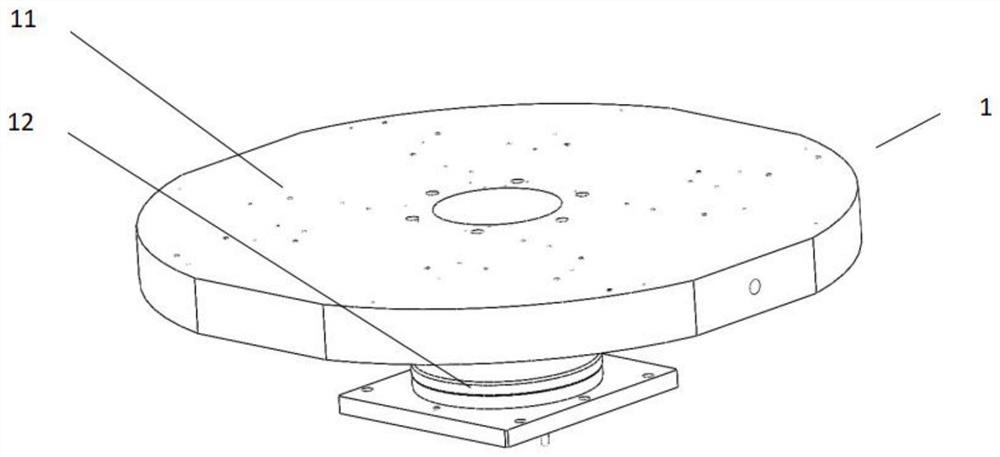

InactiveCN111531558AFacilitate automatic processingImprove polishing efficiencyDrying gas arrangementsGrinding feedersPhysicsGrinding

The invention belongs to the technical field of workpiece machining, and particularly relates to an autonomous cooling polishing and grinding robot. The autonomous cooling polishing and grinding robotcomprises a rotary disc, a first base is installed on one side of the rotary disc, a first telescopic rod is installed on the upper surface of the first base, a first rotary plate is fixedly connected to the outer side wall of the first telescopic rod, a grinding part is rotationally connected to the bottom face of the end face of the first rotary plate, and a fixed barrel is installed on the bottom face of the rotary disc. A cleaning part which rotates rapidly sweeps away chippings on a workpiece, the cleaning effect is achieved, and finally, when the cleaning part rotates to a second conveying belt, a sensor detects the existence of the workpiece, an electric push rod descends to drive an air cylinder to descend, a telescopic shaft of the air cylinder drives a push plate to stretch out,the workpiece in a containing groove is pushed to the second conveying belt, and the second conveying belt completes the conveying process of the ground workpiece. In conclusion, automatic process operation is formed for polishing and grinding of the workpiece, automatic machining is facilitated, and the polishing and grinding efficiency is improved.

Owner:CHONGQING ACAD OF METROLOGY & QUALITY INST

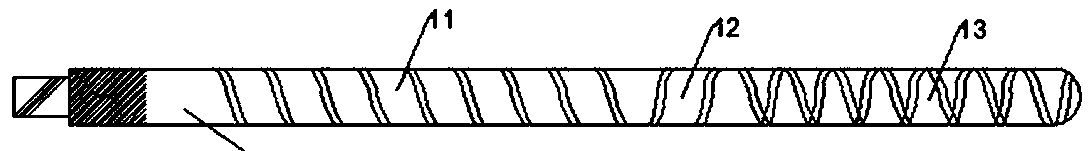

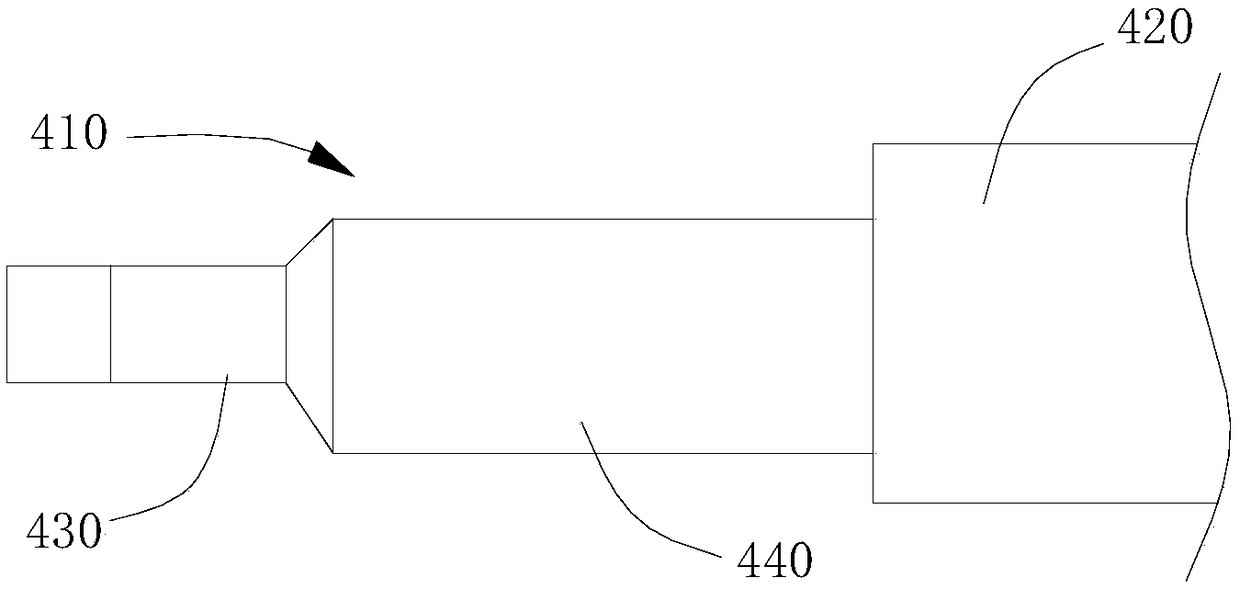

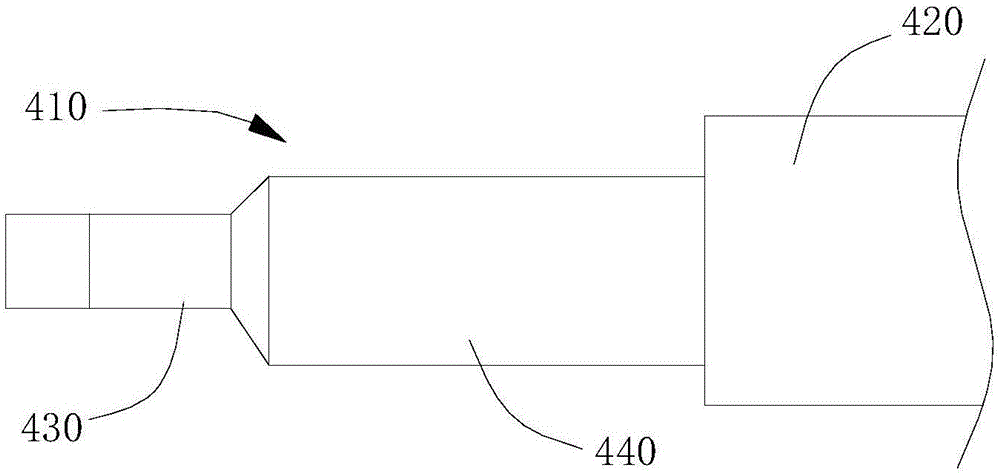

Screw for extruder, and extruder

PendingCN107745501AStirring effect is goodFull pressureDomestic articlesSoft materialsMechanical engineering

The invention discloses a screw for an extruder, and the extruder. The screw for the extruder is sequentially divided into a stirring-pressing section with a single forward thread groove, a spacing section with a single reverse thread groove or an annular groove, and a reverse pressing section with double forward-reverse thread grooves according to the different spiral directions of surface threads, wherein the thread groove in the tail end of the reverse pressing section communicates with the end surface of the screw. The screw for the extruder is good in extrusion effect, greatly applicableto extrusion forming for a soft material, and free from no discharge or breakage.

Owner:SHENZHEN FUSAI ENERGY TECH

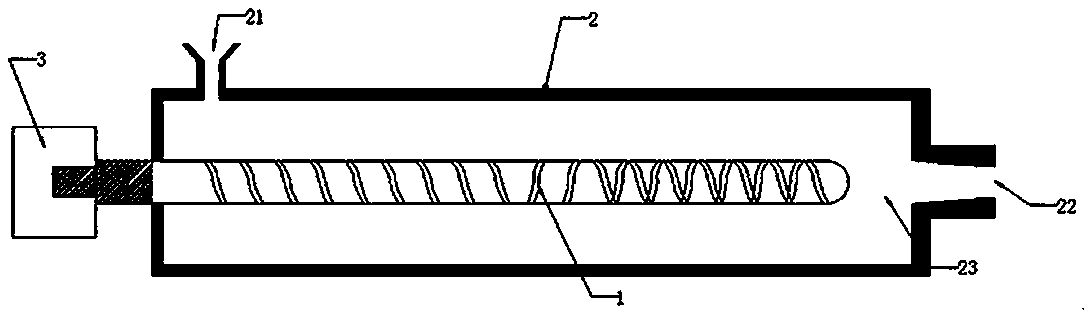

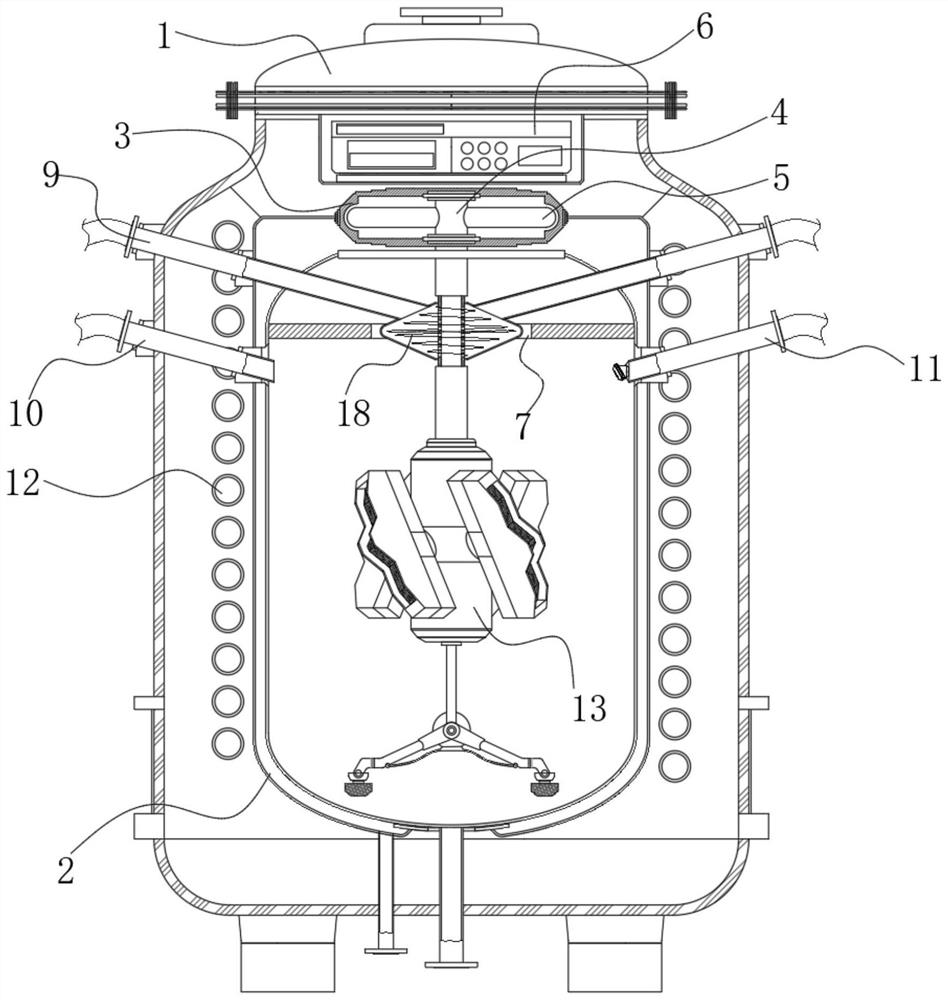

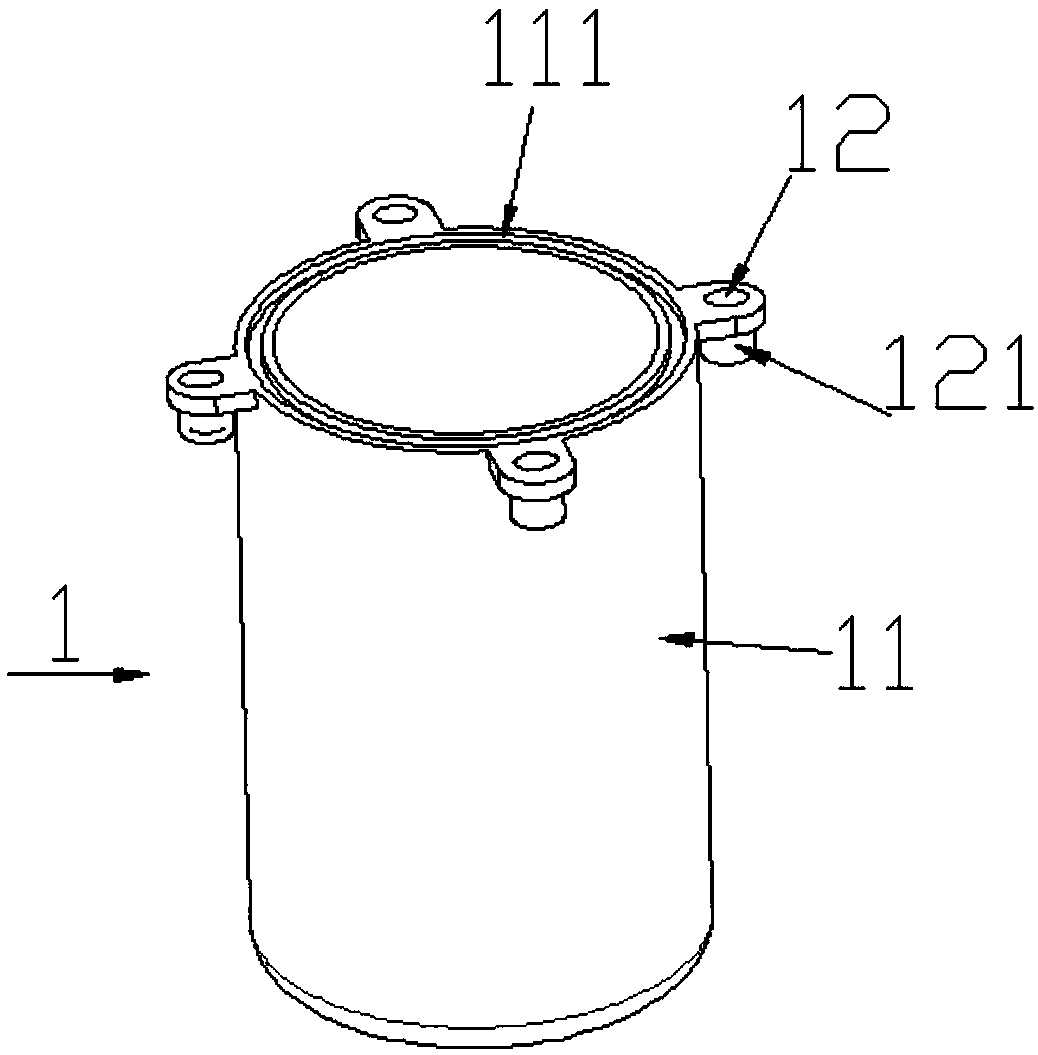

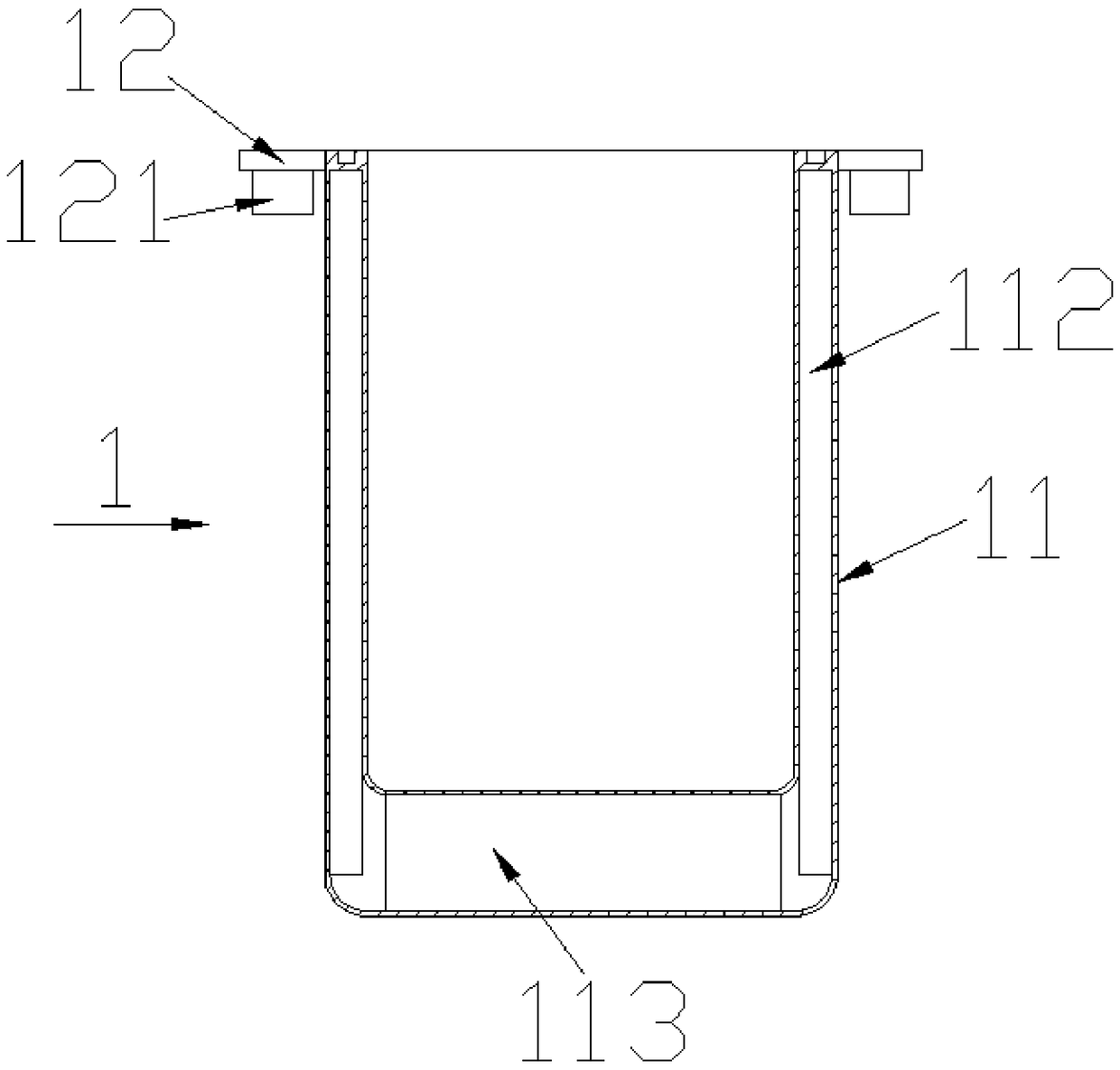

High-pressure reaction kettle with magnetic stirring function for organic reaction

InactiveCN113368788AIncrease seal coverageImprove reaction efficiencyRotary stirring mixersTransportation and packagingMetallurgyEngineering

The invention discloses a high-pressure reaction kettle with a magnetic stirring function for organic reaction, the high-pressure reaction kettle comprises a reaction tank, a stirring shaft, a magnetic stirrer, a magnetic rotor, a liquid guide pipe, a solid feeding pipe and a stirring device, the reaction tank is arranged in the reaction kettle, and a heating pipe is spirally wound on the outer side of the reaction tank; a chromium plating box is fixed to the upper end of the reaction tank, the upper end of the stirring shaft is embedded into the chromium plating box, the magnetic rotor transversely penetrates through a shaft body at the top end of the stirring shaft and is arranged in the chromium plating box, the magnetic stirrer is arranged on the chromium plating box, a mixing support is installed in the reaction tank, and amixing box is installed in the center of the mixing support. The liquid guide pipe penetrates through the reaction kettle and the reaction tank shell and is communicated with the upper side wall of the mixing box, a liquid discharge pipe is mounted at the bottom end of the reaction tank, the solid feeding pipe and the gas guide pipe respectively and independently penetrate through the reaction kettle shell and are communicated with the inner cavity of the reaction tank, and a stirring device is mounted at the lower end of the stirring shaft.

Owner:LULIANG UNIV

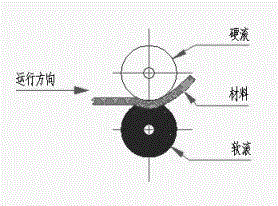

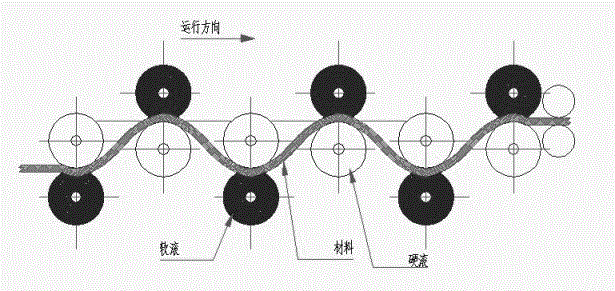

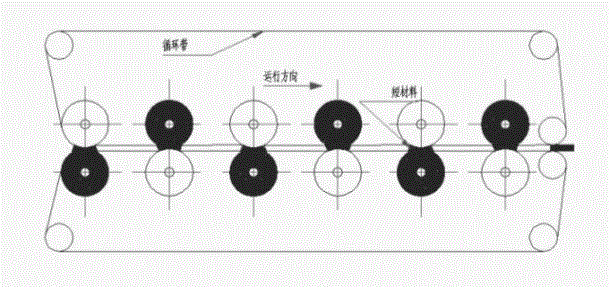

Soft and hard roller continuous cyclic bending method and device

InactiveCN102744902ASmooth processingGuarantee the quality of workmanshipMaterial nanotechnologyRotary pressMicro nanoResultant force

The invention relates to a soft and hard roller continuous cyclic bending method and a device. The device is mainly composed of soft rollers and hard rollers, the soft rollers and the hard rollers have different rigidities, strips and short materials are subjected to bending deformation by means of resultant forces of the soft rollers and the hard rollers, and the materials can be subjected to two-way cyclic bending by means of the pressing of multiple groups of the soft and hard rollers, so that processing efficiency of the materials is greatly improved, and usability of the processed materials is also greatly improved. The soft and hard roller continuous cyclic bending method can be used for preparing ultrafine nano-crystalline materials, porous materials, relevant microstructures and micro-nano space structures of material matrix surfaces and insides. The device is concise in structure, accurate in control, high in production efficiency, low in manufacturing cost, reliable in performance and applicable to industrial applications.

Owner:罗凯

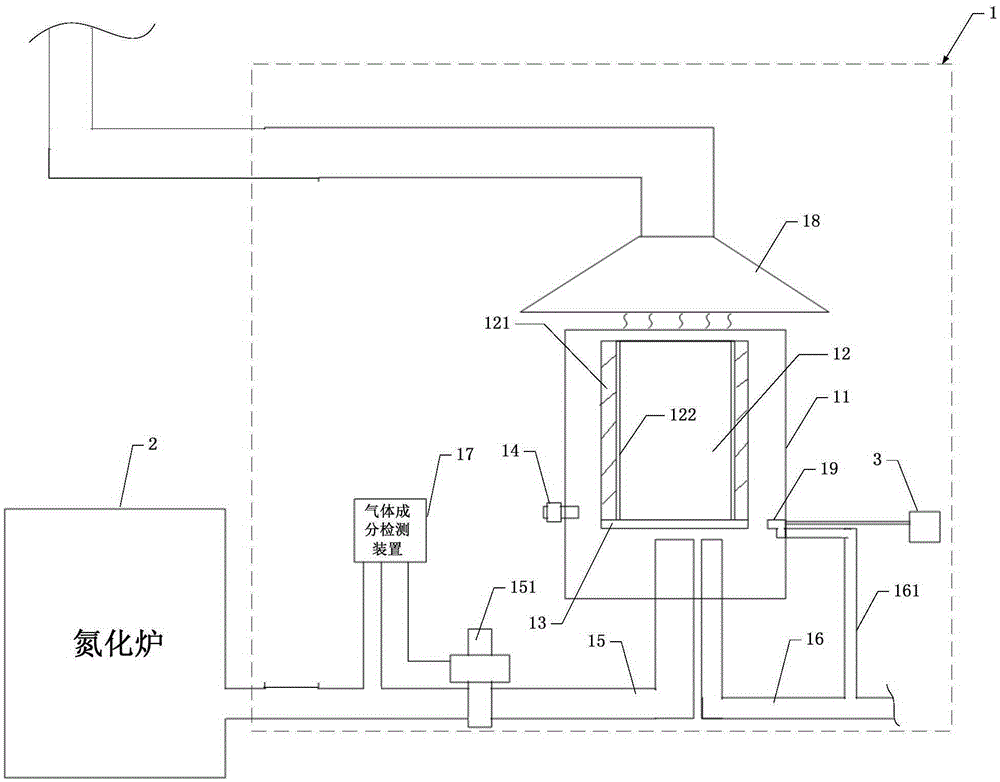

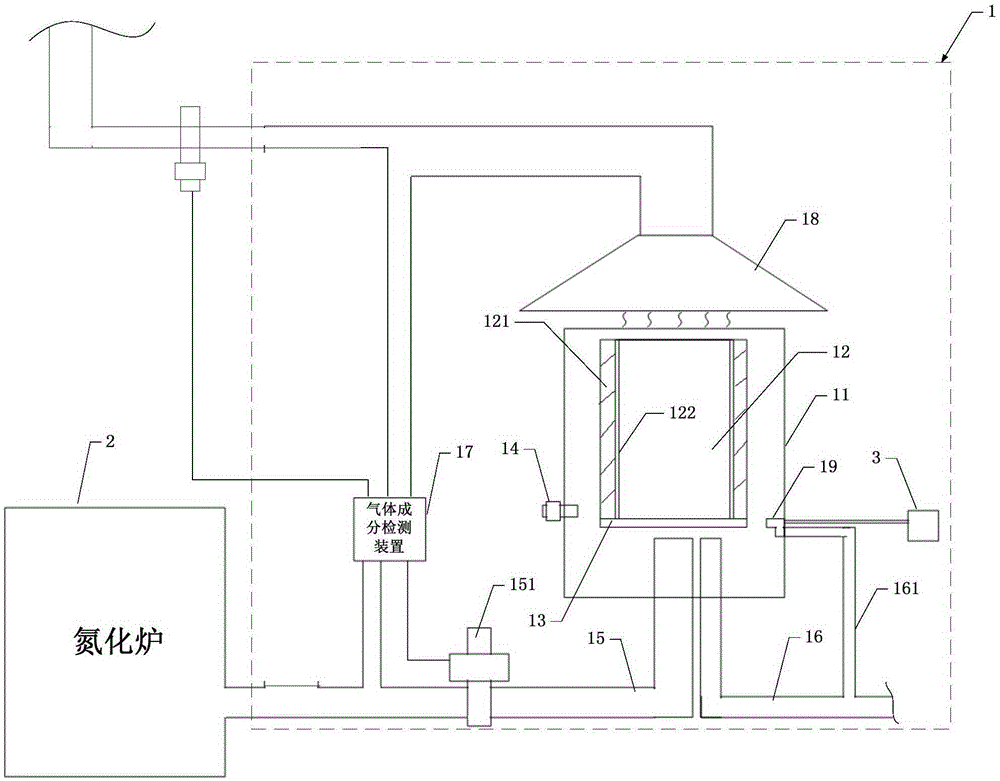

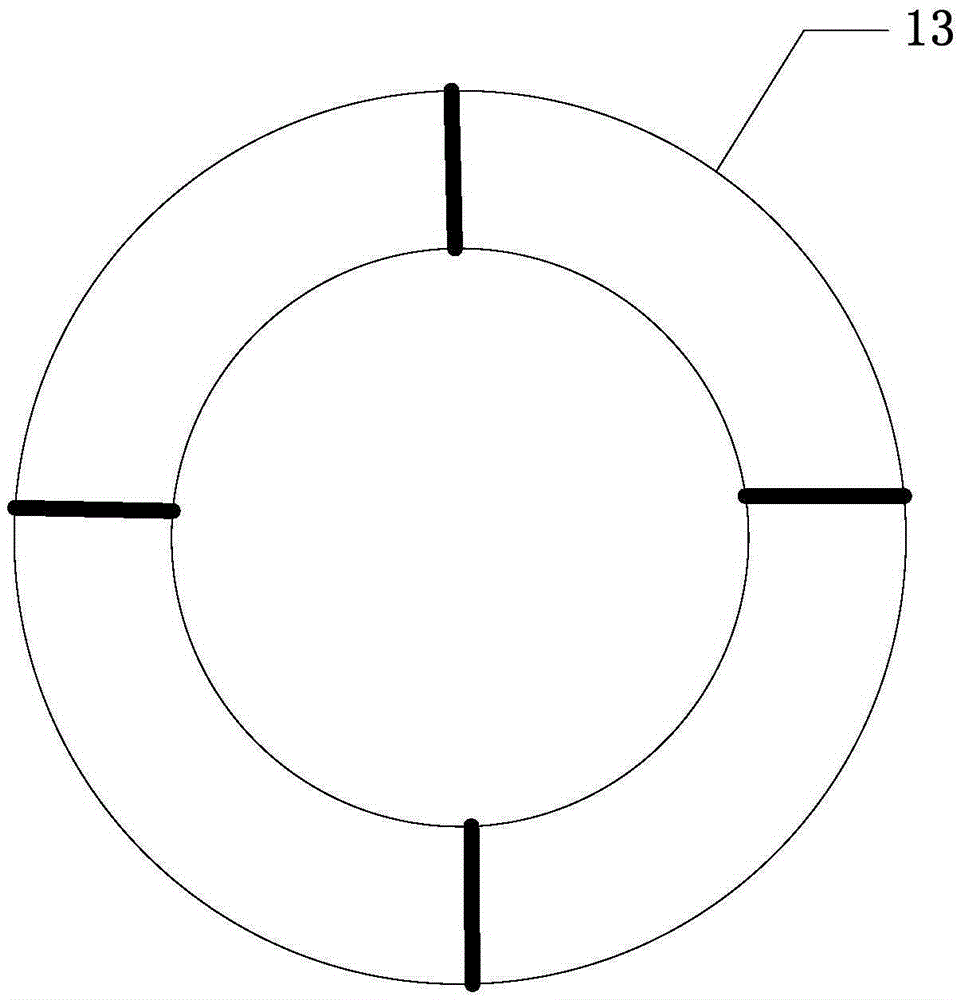

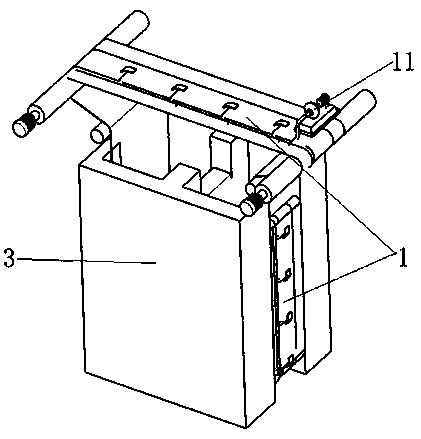

A waste gas treatment equipment for nitriding furnace

ActiveCN103742929BFull pressureGuaranteed temperatureSolid state diffusion coatingIncinerator apparatusCombustion chamberExhaust fumes

Owner:TONGFU HEAT TREATMENT KUNSHAN +1

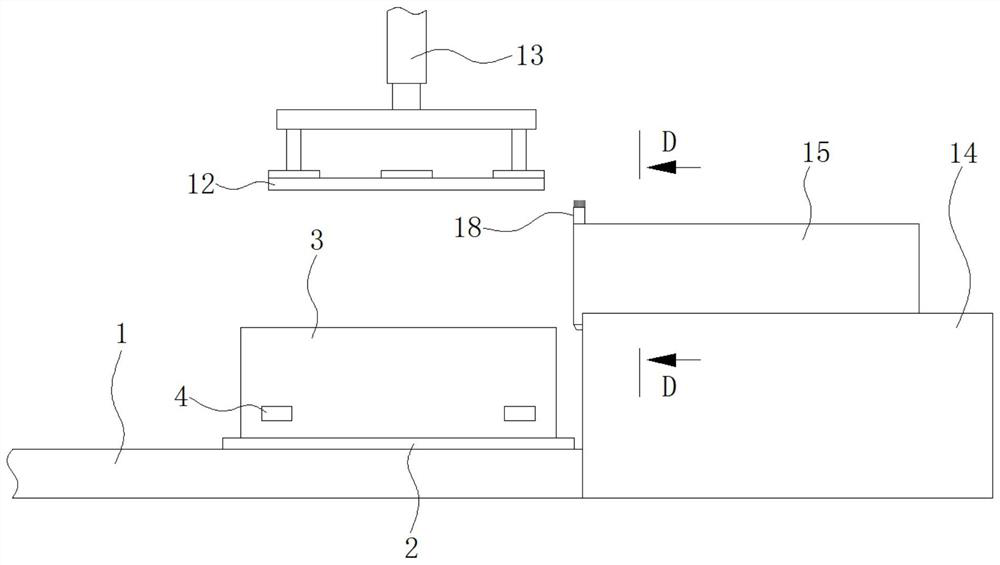

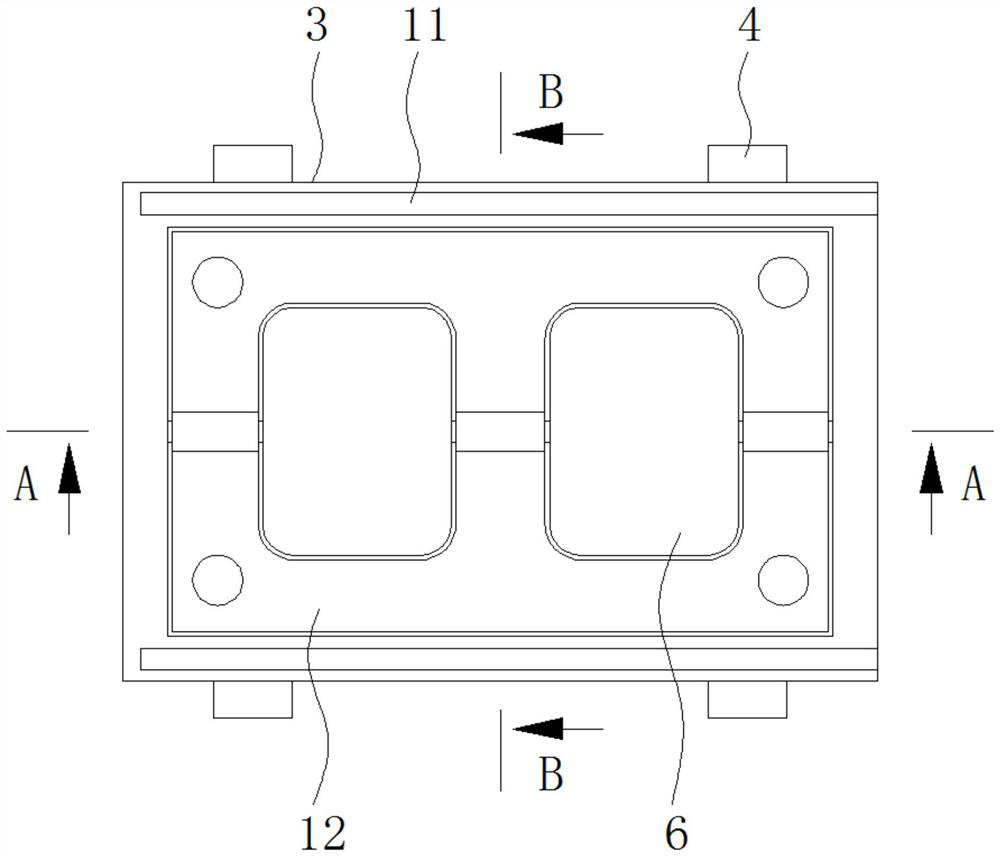

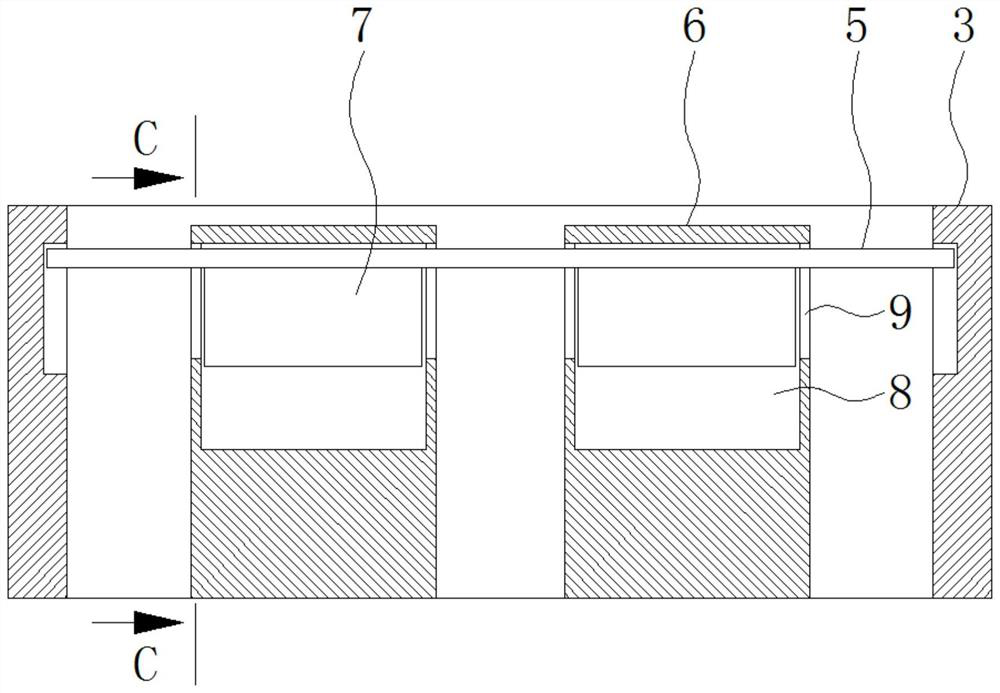

Environment-friendly intelligent manufacturing device of high-density hollow brick

ActiveCN110480797AHigh densityAvoid easy loose phenomenonFeeding arrangmentsAuxillary shaping apparatusHigh densityManufacturing technology

The invention provides an environment-friendly intelligent manufacturing device of a high-density hollow brick and relates to the technical field of hollow brick intelligent manufacturing. The environment-friendly intelligent manufacturing device of the high-density hollow brick comprises a sliding rail. A holding plate is connected to the top of the sliding rail in a sliding manner. A shaping frame is placed at the top end of the holding plate. Lifting frames are fixedly installed at the front end and the back end of the shaping frame. A connection rod is connected into the shaping frame in asliding manner. The periphery of the connection rod is connected with hollow columns in a sliding manner. The bottom end of the connection rod is fixedly provided with sliding blocks. Grooves are formed in the hollow columns. The environment-friendly intelligent manufacturing device of the high-density hollow brick achieves all-around pressing on raw materials, avoids the phenomenon that the rawmaterials at the bottom of the connection rod cannot be pressed and improves the density of the hollow brick; and meanwhile, the raw materials are quantitatively fed, so that raw material waste and circular conveyance of the redundant raw materials are avoided, and therefore better energy conservation and environment protection are achieved.

Owner:临泉县睿鑫建材股份有限公司

Fireproof plate fireproof layer processing equipment

InactiveCN111636246AReduced use of drive motorsReduce manufacturing costMechanical paper treatmentPhysical paper treatmentManufacturing engineeringIndustrial engineering

The invention relates to fireproof plate fireproof layer processing equipment which comprises a bottom rack, a drying rotating mechanism, a moving rotating mechanism and a clamping rolling mechanism.The following problems existing in the processing course of the fireproof layer of the decorative plate can be solved: a, in majority of traditional machining operation processes, kraft paper is directly dried after being soaked and thus the kraft paper is wrinkled in drying process, and subsequent extrusion forming operation is affected; b, the existing equipment also has a technology for drivingand pressing the kraft paper in the drying process, but in the driving and pressing process, the kraft paper clamping part cannot be effectively driven and pressed, and the kraft paper clamping partpossibly has a wrinkle phenomenon after being dried.

Owner:李根

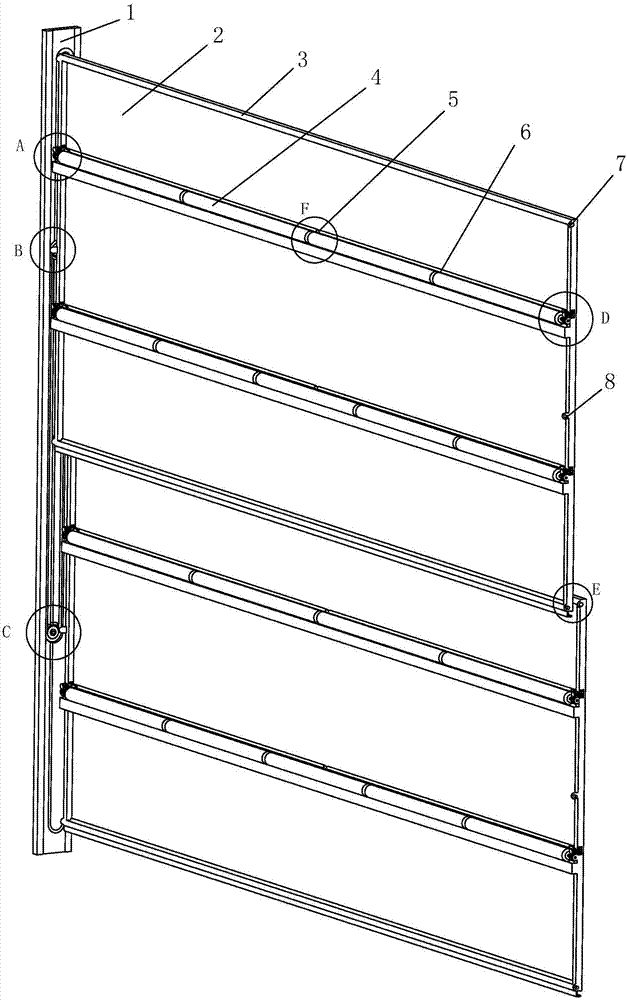

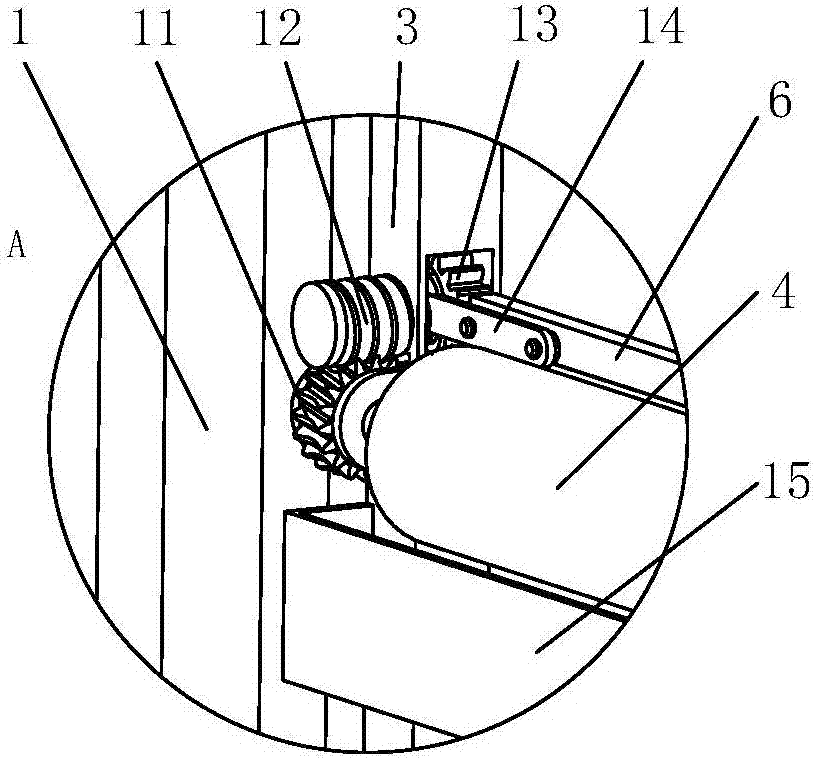

Vertically-sliding efficient self-cleaning blackboard

InactiveCN107139610AFlexible pressure distributionFull pressureBoard cleaning devicesWriting boardsEngineeringOrbit

The invention discloses a vertically-sliding efficient self-cleaning blackboard characterized by comprising an orbit fixing device, a multi-dimensional driving device, a board surface ash wiping device, an ash removing device and an ash collecting cavity; an upper roller, a lower roller and a chain connecting rod on a blackboard frame are respectively mounted in an upper orbit, a lower orbit and a chain slot on each of a left outer frame and a right outer frame by the orbit fixing device to operate; the multi-dimensional driving device is a combined driving mechanism composed of a gear bar, a gear as well as a worm wheel and a worm; the obverse side of a blackboard is pressed by an ash wiping roller on the board surface ash wiping device due to the mutual connection and rotation of a universal coupling, a roller rotating shaft and a turbine and the pressing of a seat pressing spring against a supporting seat; the ash removing device is used for converting the rotation of the gear into rapid horizontal movement of an ash removing hairbrush by a cam connecting piece sliding in a cam slot; and the ash collecting cavity is arranged below. Self-cleaning can be completed by only downwards pulling an inner side blackboard required to be used, and the vertically-sliding efficient self-cleaning blackboard is efficient, convenient, remarkable in cleaning effect and incapable of affecting the normal teaching process.

Owner:ANHUI UNIV OF SCI & TECH

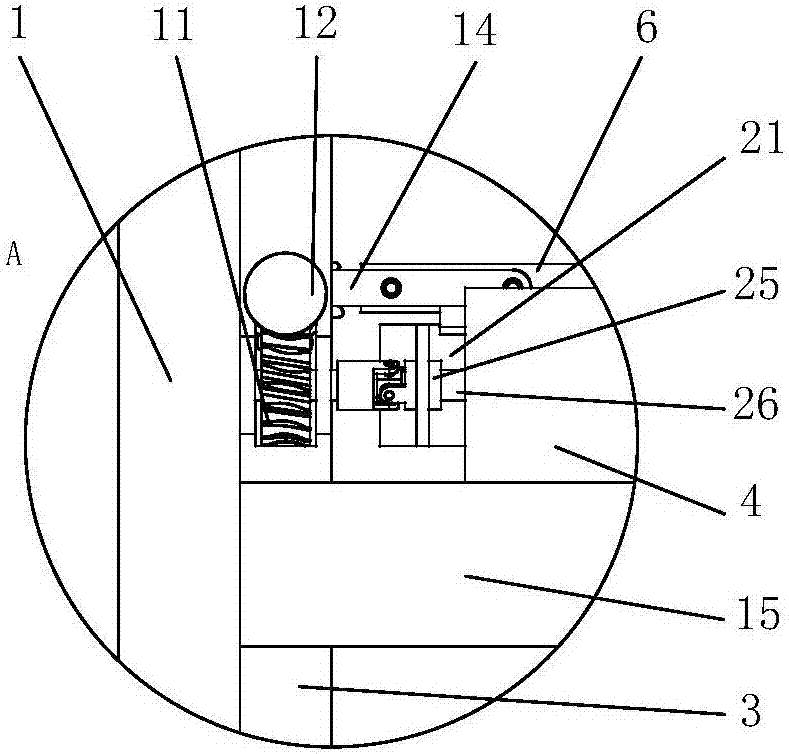

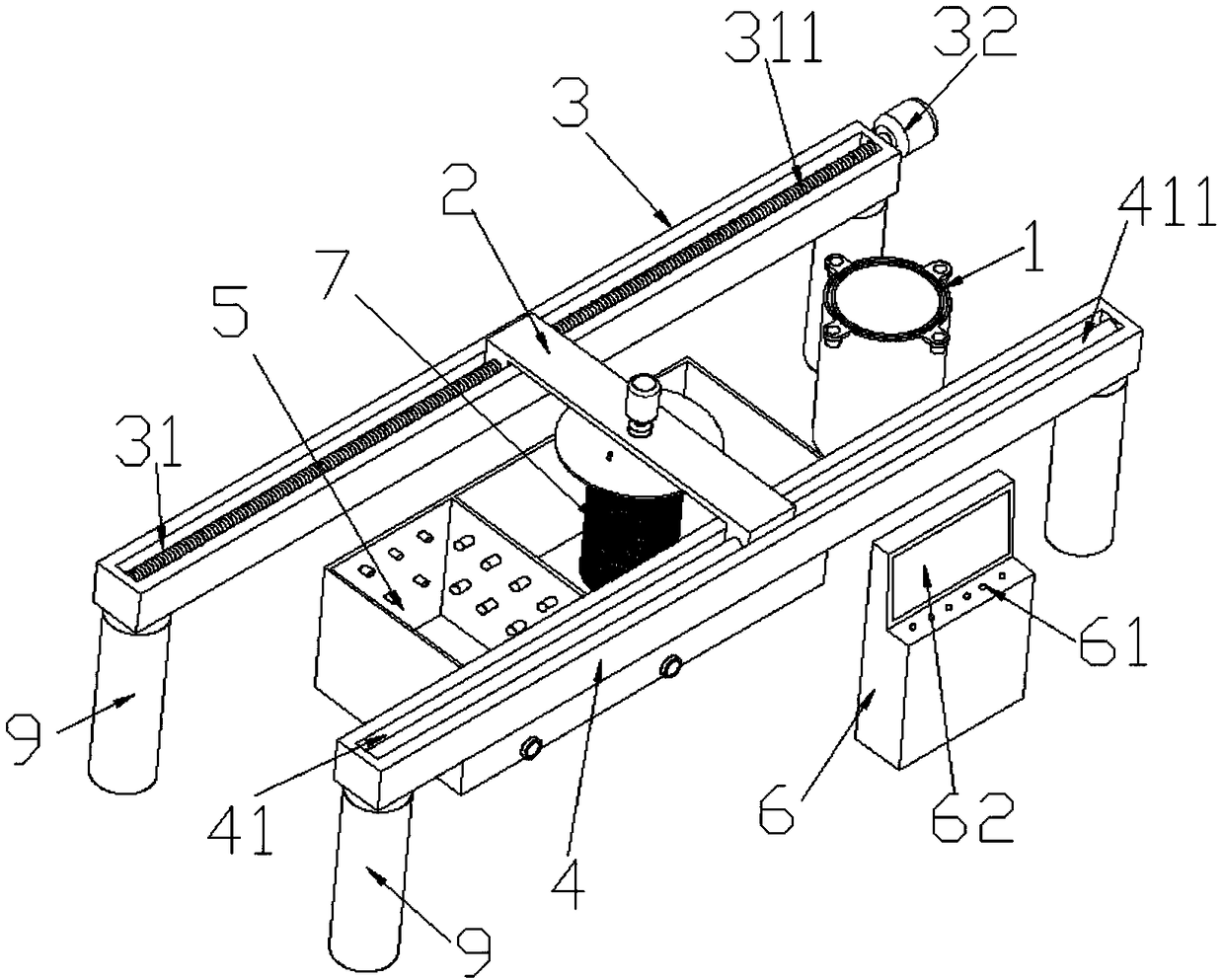

Cooking cleaning device for extraction of bamboo fibers

The invention relates to a cooking cleaning device for extraction of bamboo fibers, which includes: a cooking barrel, a sliding cover assembly, a left slide rail, a right slide rail, a cleaning box, acontrol cabinet and an arrangement frame. The device greatly reduces labor intensity and is high in production efficiency.

Owner:湖州友星木业有限公司

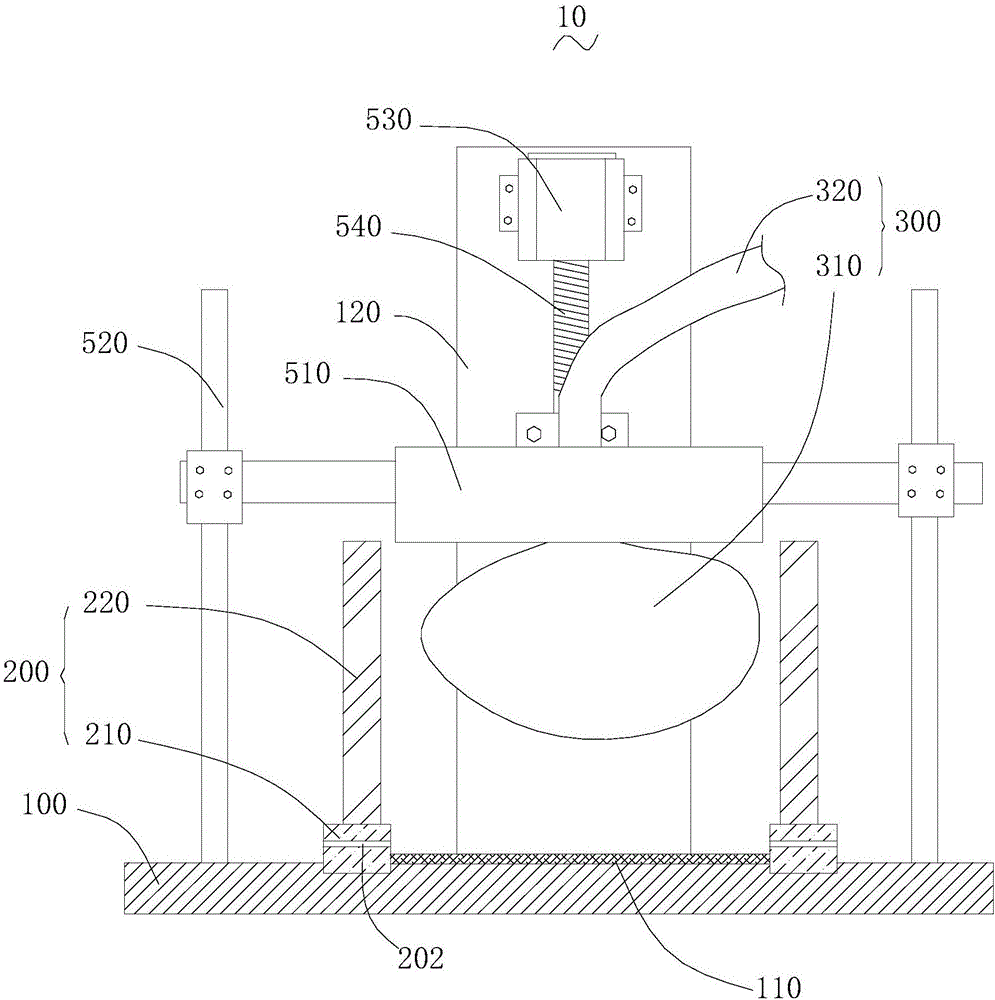

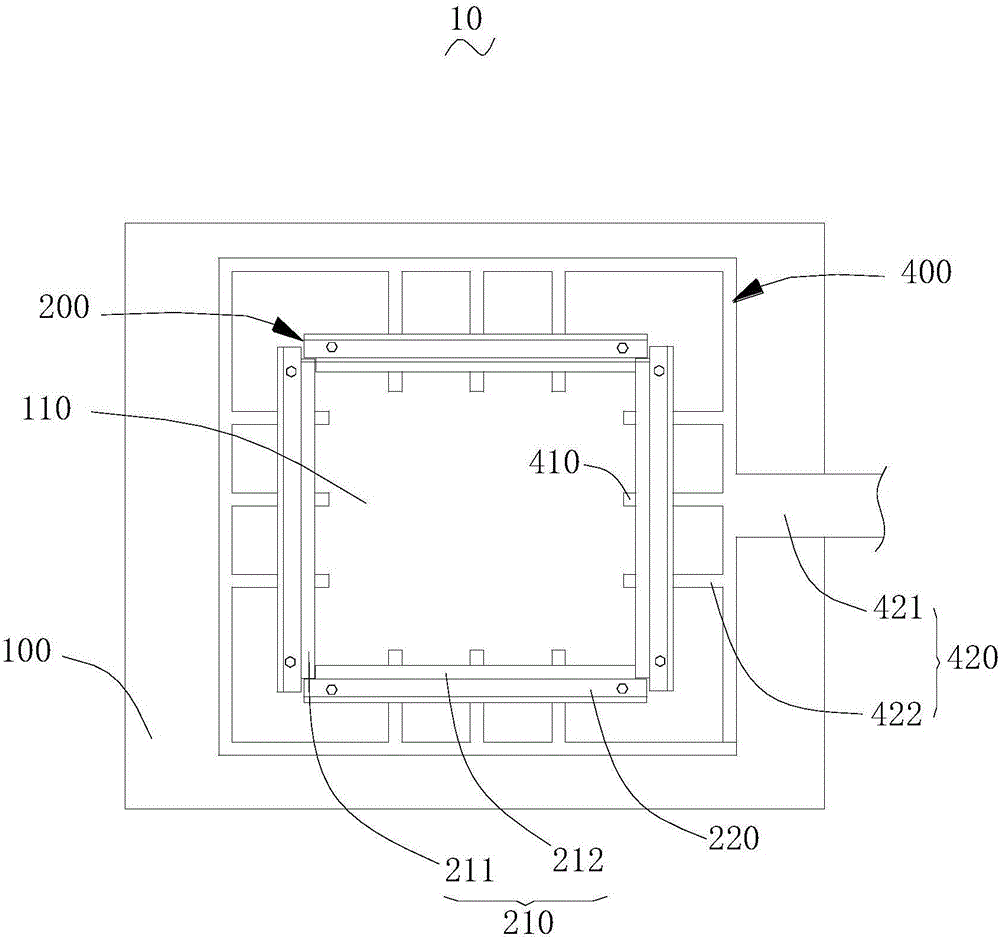

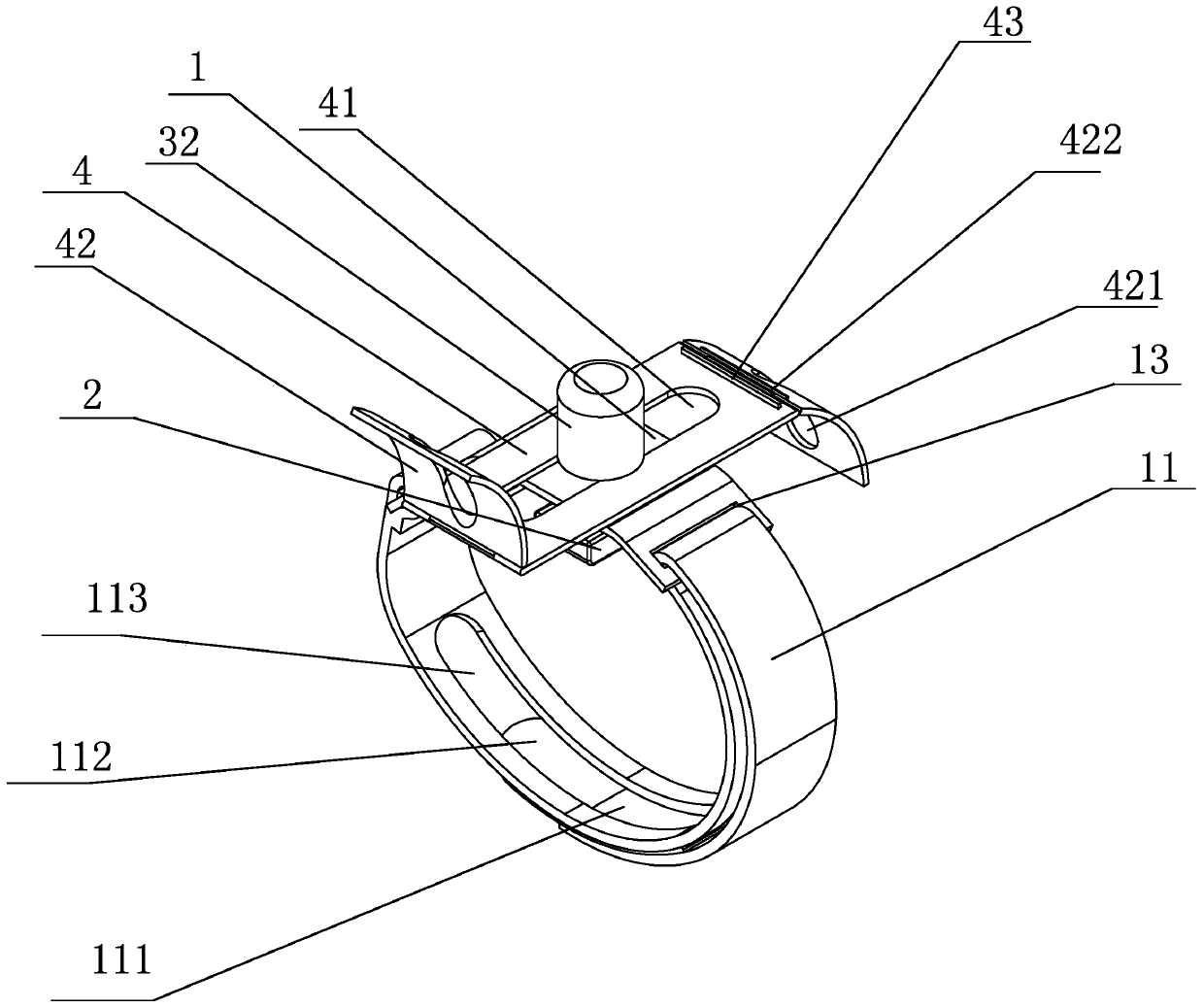

A pressure-maintaining device and pressure-maintaining equipment for earphone shell wiring assembly

ActiveCN113858110BImprove assembly efficiencyImprove assembly stabilityElectrical transducersWork holdersFluid controlEngineering

Owner:SUZHOU JQS INFO TECH CO LTD

An energy-saving plate stamping part

ActiveCN111036752BFull pressureAvoid displacementShaping toolsMetal-working feeding devicesHydraulic cylinderElectric machinery

The invention relates to an energy-saving plate stamping part, which comprises a base; support columns are fixedly connected around the bottom of the base, and the top of the base is fixedly connected to the top base through a connecting plate; the top base; the bottom end of the top base is fixedly connected There is a hydraulic cylinder, and the piston rod of the hydraulic cylinder is fixedly connected with a stamping die through bolts; a workbench; the workbench is fixedly connected to the base, and the top of the workbench is provided with a lower mold base, and a workpiece body is arranged on the lower mold base; Adjustment mechanism: The height adjustment mechanism is connected to the connecting plate. The height adjustment mechanism includes a motor, a threaded rod, a strip notch, an adjustment block and a nut. The workpiece body is pressed and held to avoid displacement of the workpiece during stamping processing, which reduces the error of stamping, ensures the precision of the processed workpiece body, does not cause waste of resources, and saves materials.

Owner:TAIZHOU HUIJIN ELECTRONIC CO LTD

printing press

The invention relates to a printing machine. The printing machine comprises a workbench, a bearing plate, a fixing frame, a pressing mechanism and a driving mechanism; the bearing plate is arranged on the workbench; the fixing frame comprises a first frame and a second frame which is fixedly connected with the first frame; the pressing mechanism comprises an air pump, an air delivery pipe and an inflation thin film; the air pump communicates with the air delivery pipe; the inflation thin film communicates with the air delivery pipe and is movably arranged in the fixing frame; the driving mechanism comprises a fixing block, guide rails and a driving motor; the guide rails are fixedly arranged on the workbench; and the fixing block is arranged on the guide rails in a sliding manner. The air pump is used for inflating air for the inflation thin film for enabling the inflation thin film to evenly apply pressure on printing stock on the bearing plate; and the inflation thin film is limited by the fixing block and the fixing frame for being prevented from being exposed, so that the inflation thin film can fully apply pressure on the printing stock, printing ink can be evenly printed on the printing stock, and the printing effect is better.

Owner:江西大海彩印包装有限公司

Water pressure type edible vegetable oil squeezing device

The invention relates to a water pressure type edible vegetable oil squeezing device, and belongs to the technical field of vegetable oil squeezing equipment. The invention aims to provide the water pressure type edible vegetable oil squeezing device which is composed of a conveyor belt, an oil bag, an oil collecting bottle, a water tank, a motor, a pressure sensor and a pressure display screen, the device utilizes the principle of a traditional mechanical oil press which the pressure is used to enable oil plants to squeeze oil, and the water pressure is taken as a pressure source; oil plant bags containing the oil plants which pretreated in advance are place on the conveyor belt, the conveyor belt conveys the oil plant bags into the water tank with a certain water level height, the oil plants in the soft oil plant bags are extruded by utilizing the water pressure generated by water, the oil is enable to seep out, and the squeezed oil is stored in the oil collecting bottle; and the motor solves the problem of driving the conveyor belt, the conveyor belt solves the problems of conveying the oil plant bags and the oil collecting bottle, and the pressure sensor and the pressure display screen solve the water pressure detection and visualization problems. The oil squeezing device is simple to operate, energy-saving and safe, and superior to a traditional oil squeezing device.

Owner:3S IMPERIAL FOOD JIANGXI PROV

A multi-cavity I-shaped beam and its high-precision soft mold forming and defect control process method

The invention provides a multi-cavity I-beam and a high-precision soft mold forming and defect control method thereof. Aiming at structural features of multiple cavities, multiple molded surfaces, unequal thickness of marginal / web plates and high precision of molded surfaces inside cavities, silicone rubber soft mold pressurization is adopted to achieve the overall co-curing molding of the I-beamwith a complex structure. The multi-cavity I-beam comprises at least two main beams and at least six secondary beams, the main beams and the secondary beams are in the same plane, the main beams are not intersected with each other, the secondary beams located between the main beams are used for connecting the main beams, and the secondary beams located outside the main beams are used for connecting with the outside; equitable distribution of pressure in the X / Y / Z direction is achieved by adopting silicone rubber soft mold process gap compensation design, and the problem of unequal thickness pressurization of the marginal / web plates is solved; an internal soft-external hard pressure equalization design method is utilized to avoid the pressure deviation caused by uneven expansion of a soft mold, and the dimensional accuracy and internal defects of the molded surfaces inside the cavities are improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

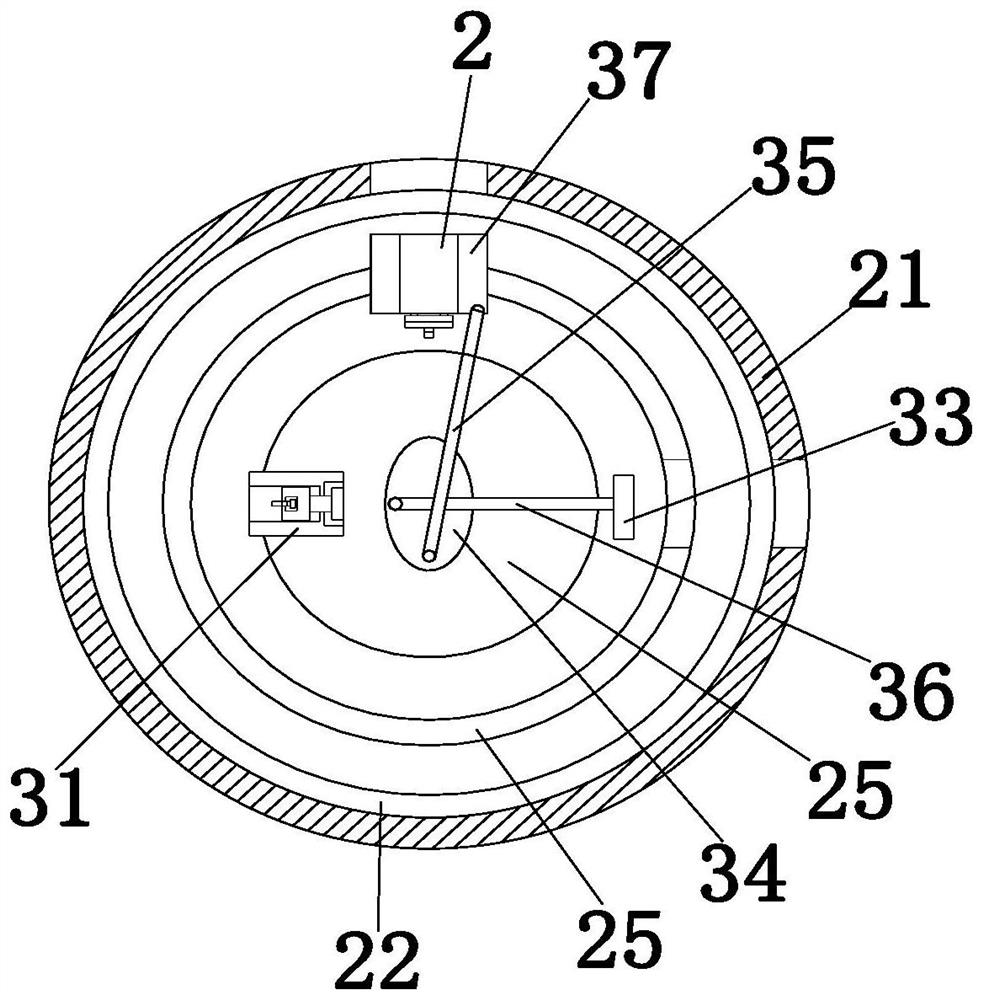

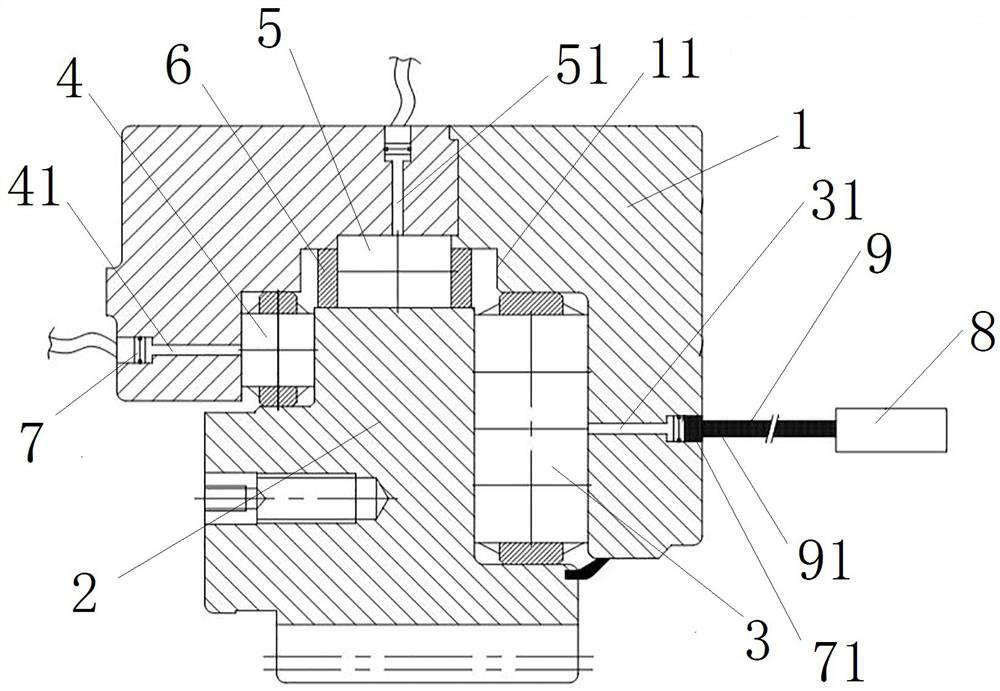

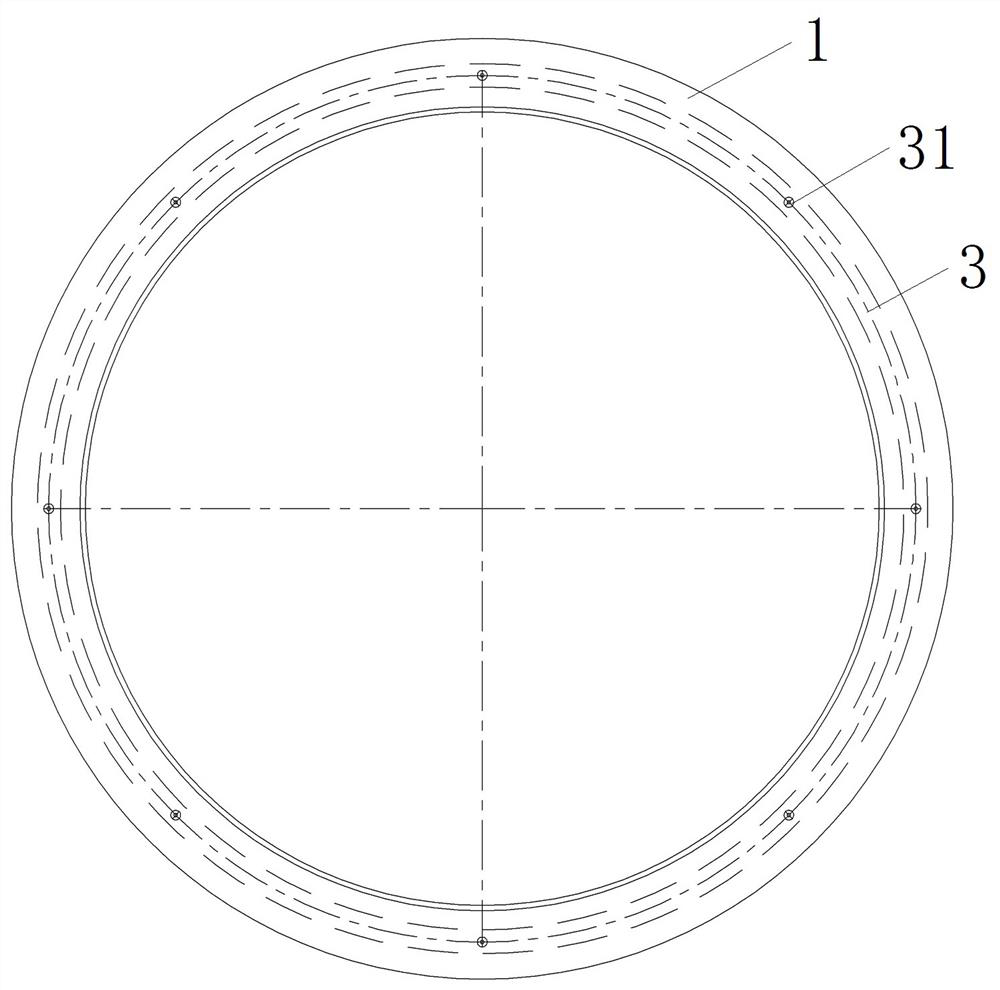

Bearing system with oil film pressure detection function

PendingCN113738771AEasy to operateOptimize layoutRolling contact bearingsBearing assemblyEngineeringMechanical engineering

The invention relates to a bearing system with an oil film pressure detection function. The bearing system comprises an outer ring and an inner ring, both the outer ring and the inner ring are provided with roller paths, and rollers are arranged between the roller paths of the outer ring and the inner ring; capillary holes are formed in the outer ring and / or the inner ring and extend in the inside-outside direction, piston cavities are formed in the outer ends of the capillary holes, pistons are arranged in the piston cavities, the inner ends of the capillary holes communicate with the roller paths, so that when the rollers move to the capillary holes, oil film pressure between the rollers and the outer ring and / or the inner ring is transmitted to the pistons, and oil pressure sensor detection interfaces are arranged at the outer open ends of the piston cavities and used for being connected with the oil pressure sensors so as to detect the oil pressure of the sides, back to the capillary holes, of the pistons. The oil film pressure between the rollers and the outer ring and / or the inner ring is converted into the oil pressure of the sides, back to the capillary holes, of the pistons, the oil pressure measured by the oil pressure sensors is processed so that the oil film pressure between the rollers and the outer ring and / or the inner ring can be obtained, and the oil film pressure in the bearing running process can be accurately measured.

Owner:HENAN UNIV OF SCI & TECH

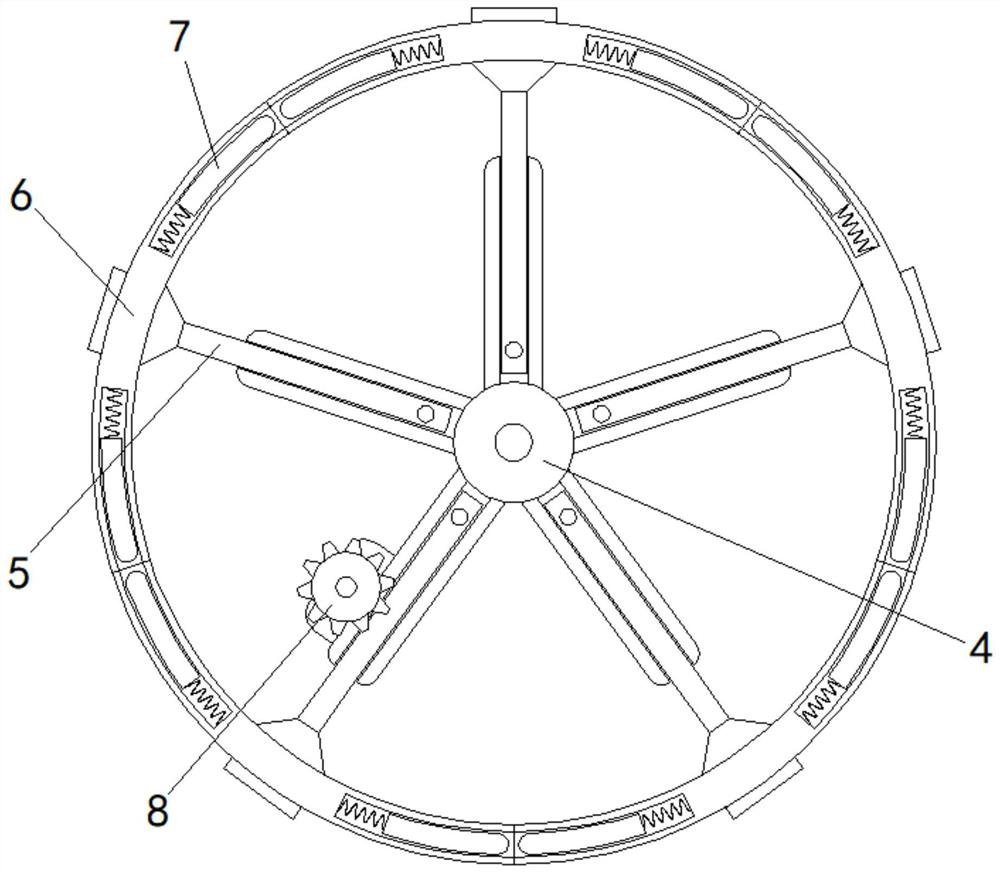

Household bed sheet ironing device making fabric convenient to comprehensively flatten

InactiveCN112030500AEasy to flattenFull pressureIroning apparatusTextiles and paperHome useGear wheel

The invention relates to the technical field of household appliances, and discloses a household bed sheet ironing device making a fabric convenient to comprehensively flatten. The household bed sheetironing device comprises a frame, symmetrical telescopic columns are fixedly arranged at the top of the frame, the lower ends of the telescopic columns are fixedly connected with a bearing plate, thelower end of the bearing plate is fixedly connected with a radiation disc, sliding strips are evenly arranged on the radiation disc, flattening strips are fixedly connected to the lower ends of the outer sides of the sliding strips, elastic strips are slidably connected to inner cavities of the two ends of each flattening strip, and a driving gear is rotatably connected to the rear portion of theradiation disc. According to the household bed sheet ironing device making the fabric convenient to comprehensively flatten, the extension of the sliding strips is controlled through a transmission gear, so that the flattening strips and the elastic strips are driven to radially expand; and a tension spring is arranged between an ironing plate and a sliding cylinder in a matched manner, so that ato-be-ironed area of the fabric is comprehensively flattened, and the ironing effect on the fabric is improved.

Owner:温州飒盟贸易有限公司

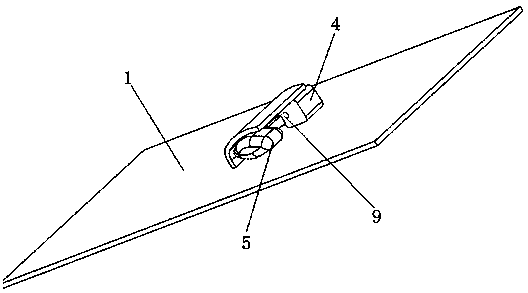

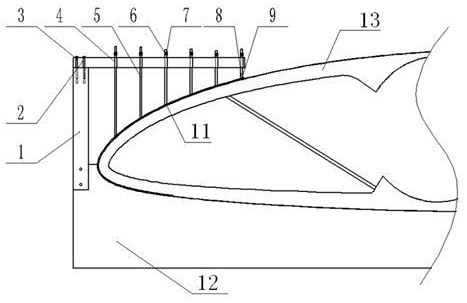

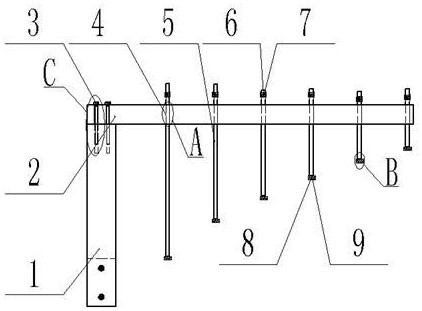

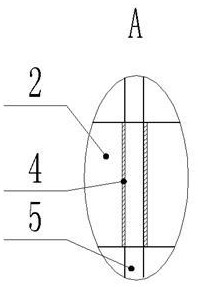

A flexible pressure tooling and method for controlling assembly damage at the leading edge of an unmanned aerial vehicle

The invention discloses a flexible pressure application tool for controlling the assembly damage of the front edge of an unmanned aerial vehicle, comprising: a first support block, a second support block, a screw, a wire thread sleeve, a screw rod, a first nut, a second nut, and foam glue and soft foam. The first support block is connected with the assembly tooling; the second support block is connected with the first support block by screws; the wire screw sleeve is installed at the corresponding position of the first support block and the second support block; the screw rod is installed on the wire screw The two nuts are installed on the screw rod; the soft foam is attached to the lower end of the screw rod through foam glue. Except for the support block which is machine-added, all finished parts are used as tooling components, which are low in cost and easy to assemble; the screw has an adjustable function, which makes the tooling flexible and can adapt to different airfoils and different sizes; the tooling is in contact with the leading edge The position adopts a soft foam structure, which can effectively control the structural damage of the leading edge and protect the leading edge while realizing the bonding and pressure of the ultra-thin leading edge and the rib.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

An environmentally friendly and intelligent manufacturing device for high-density hollow bricks

ActiveCN110480797BHigh densityAvoid easy loose phenomenonFeeding arrangmentsAuxillary shaping apparatusEnvironmental resource managementBrick

The invention provides an environmentally friendly intelligent production device for high-density hollow bricks, and relates to the technical field of intelligent production of hollow bricks. The environmentally friendly and intelligent production device for high-density hollow bricks includes a slide rail, the top of the slide rail is slidably connected to a placement plate, a shaping frame is placed on the top of the placement plate, and landing gear is fixedly installed at the front and rear ends of the shaping frame , the inside of the shaped frame is slidably connected with a connecting rod, the periphery of the connecting rod is slidably connected with a hollow column, the bottom end of the connecting rod is fixedly mounted with a slider, and a groove is opened inside the hollow column. The environmentally friendly and intelligent production device for high-density hollow bricks realizes all-round pressing of raw materials, avoids the phenomenon that the raw materials at the bottom of the connecting rod cannot be pressed, improves the density of hollow bricks, and adds quantitative raw materials to avoid waste of raw materials. As well as the circulation transmission of redundant raw materials, it is more energy-saving and environmentally friendly.

Owner:临泉县睿鑫建材股份有限公司

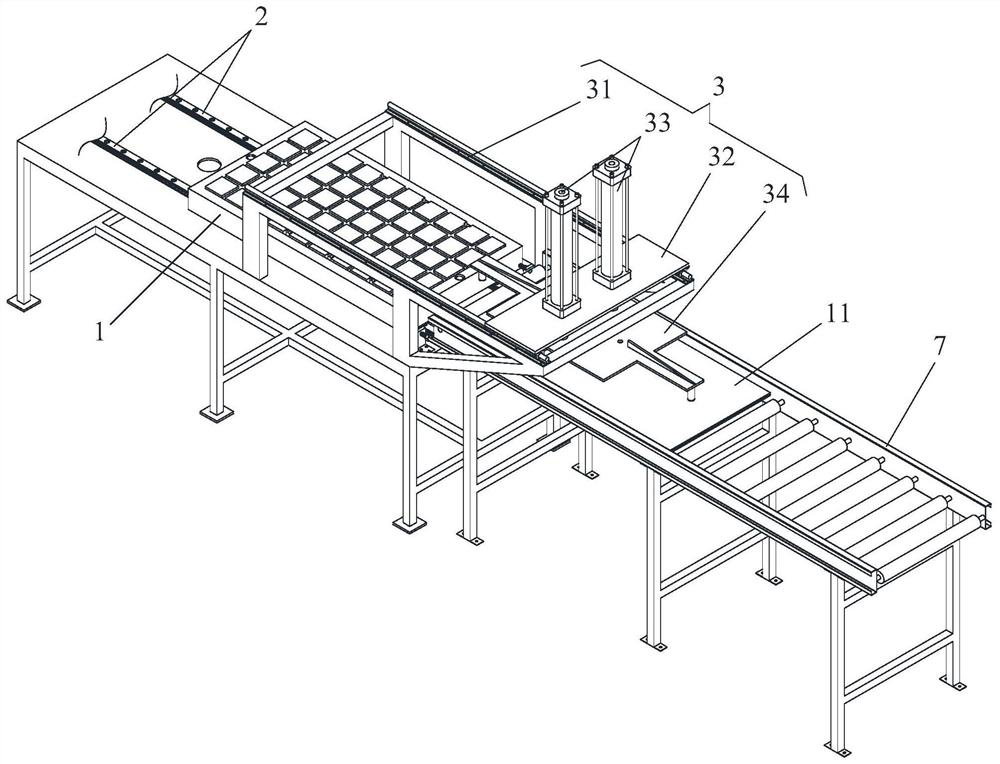

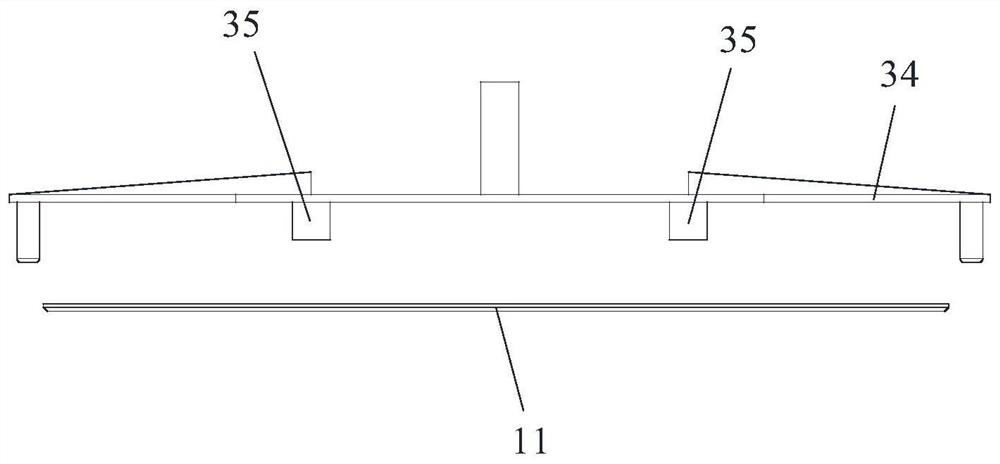

Particle plate forming device

ActiveCN113478715AReduce the number of inputsEasy to operateWaste based fuelFlat articlesMolding machineMaterial distribution

The invention discloses a particle plate forming device. Particle material plates are formed through a cavity mold, the size and form and position errors of products are obviously relieved, the amount of gel particles arranged in the cavity mold can be adjusted through cooperation of a material distribution mechanism and the cavity mold, the material use amount for manufacturing particle products is guaranteed, products in batches are balanced in weight and good in consistency, and the surfaces of gel particles can be flattened while the material distribution mechanism distributes materials; the gel particles are subjected to vibration pressing forming through a vibration forming mechanism, particle materials can be fully and evenly pressed downwards, the compactness of products is guaranteed, and the product quality is high; the gel particles are distributed in the cavity mold at a time, the arrangement frequency of the gel particles is reduced, a reinforcing net is directly pressed into the gel particle layer, the production action of the particle material is simplified, and the production efficiency is improved; and after forming, a supporting plate and the particle product are taken out of the cavity mold, the input number of the cavity mold is reduced, operation of the cavity mold is facilitated, and line production is fast.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

Printing machine

The invention relates to a printing machine. The printing machine comprises a workbench, a bearing plate, a fixing frame, a pressing mechanism and a driving mechanism; the bearing plate is arranged on the workbench; the fixing frame comprises a first frame and a second frame which is fixedly connected with the first frame; the pressing mechanism comprises an air pump, an air delivery pipe and an inflation thin film; the air pump communicates with the air delivery pipe; the inflation thin film communicates with the air delivery pipe and is movably arranged in the fixing frame; the driving mechanism comprises a fixing block, guide rails and a driving motor; the guide rails are fixedly arranged on the workbench; and the fixing block is arranged on the guide rails in a sliding manner. The air pump is used for inflating air for the inflation thin film for enabling the inflation thin film to evenly apply pressure on printing stock on the bearing plate; and the inflation thin film is limited by the fixing block and the fixing frame for being prevented from being exposed, so that the inflation thin film can fully apply pressure on the printing stock, printing ink can be evenly printed on the printing stock, and the printing effect is better.

Owner:江西大海彩印包装有限公司

Stiff composite pile body anchor rod device and construction technology

The invention discloses a stiff composite pile body anchor rod device. The stiff composite pile body anchor rod device comprises an anchor rod body and cement soil arranged on the periphery of the anchor rod body. A prefabricated concrete pile body is arranged in the cement soil, an upper end plate and a lower end plate are correspondingly and fixedly arranged at the upper end and the lower end of the prefabricated concrete pile body, a core pipe is arranged in the concrete pile body, the core pipe is arranged on the end plates in a penetrating mode, positioning supports used for fixing the core pipe are fixedly arranged on one side of the upper end plate and one side of the lower end plate, a grouting body is arranged between the concrete pile body and the core pipe in a filling mode, and a plurality of rod ribs are installed in the core pipe. The rod ribs can be made into free sections or non-free sections according to actual conditions, the problem that a traditional anchor rod and an uplift pile are insufficient in durability is solved, the stress mode of the rod body is improved, and the durability of the composite anchor rod is improved; and meanwhile, the stiff composite pile body anchor rod device has the advantages of being high in construction speed, high in bearing capacity, low in engineering cost and the like.

Owner:JIAN YAN FOUND ENG +1

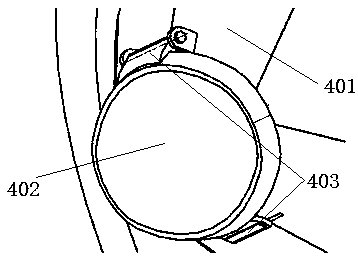

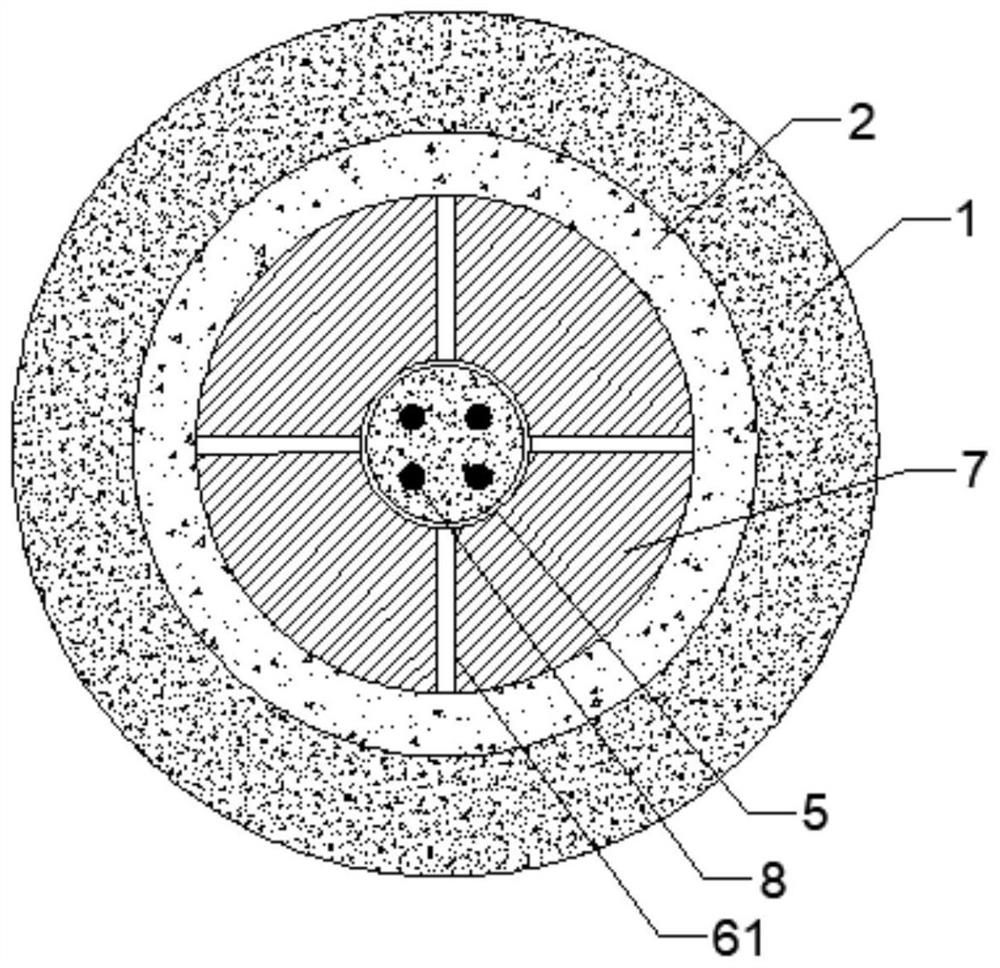

Purlicue artery compression hemostat

The invention provides a purlicue artery compression hemostat. The hemostat comprises a stress plate, a compression plate is arranged below the stress plate, one end of the stress plate is provided with a fixing groove, an elastic belt used for fixing the palm of a patient is arranged on the fixing groove, the other end of the stress plate is provided with a limiting groove, one end of the elasticbelt is fixedly connected to the fixing groove, the other end of the elastic belt is an adhesive end and is provided with an adhesive buckle, the position close to the adhesive end of the elastic belt is provided with a clamping connection groove that the thumb of a patient can insert into, the adhesive end passes through the limiting groove and fits the elastic belt body through the adhesive buckle to form fixed connection with the palm of the patient, and the stress plate is also provided with a fixing piece used for fixing the index finger of the patient, so that the index finger and the thumb form an L shape. The hemostat can be adjusted according to the sizes of hands of different patients, so that the re-bleeding of a puncture point caused by the mismatch of equipment and a palm isavoided, and the bleeding caused by the random move of the palm of the patient can be avoided.

Owner:WENZHOU PEOPLES HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com