Particle plate forming device

A sheet forming and particle technology, which is applied to home appliances, other home appliances, flat products, etc., can solve the problems of low labor efficiency and high skill level requirements of operators, and achieve convenient operation, reduced investment, and good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

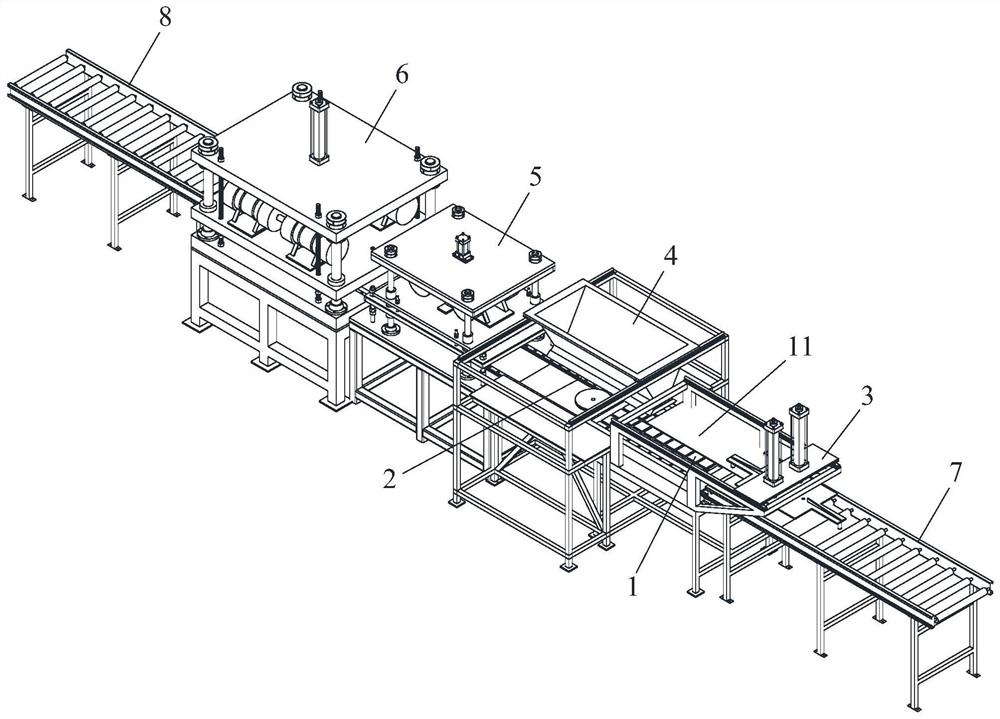

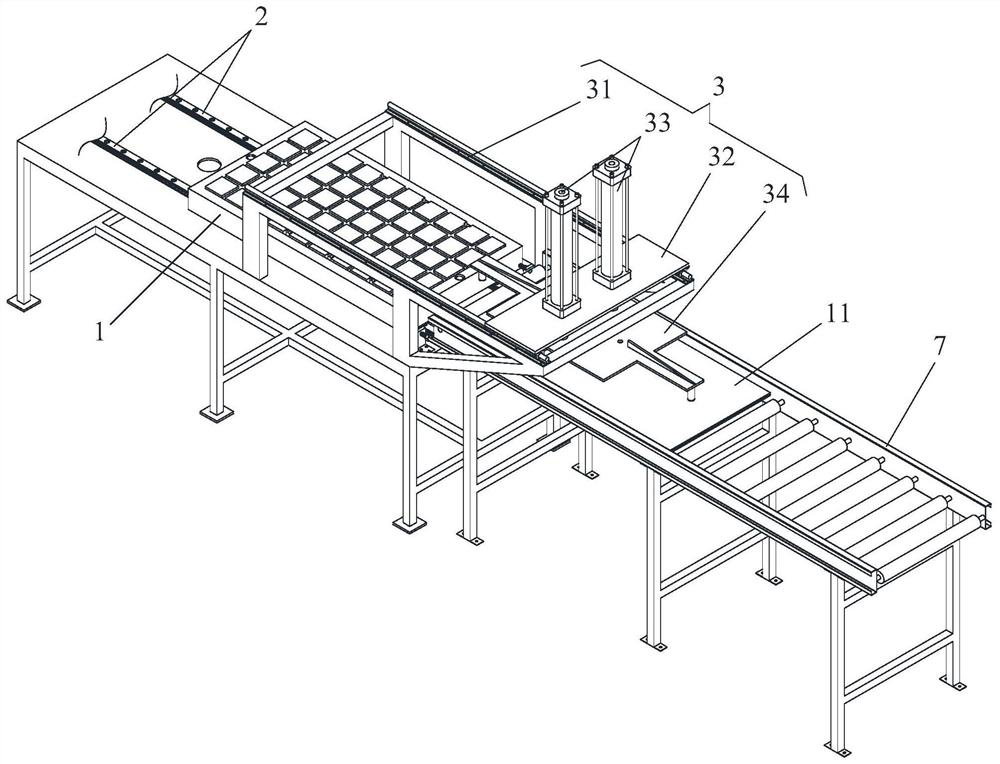

[0069] Such as Figures 1 to 11 As shown, a particle sheet forming device according to the present invention includes a cavity mold 1, a conveying guide rail 2, a pallet transfer mechanism 3, a material distribution mechanism 4, a pressing mechanism 5, a vibration forming mechanism 6, and a first sliding guide rail 7 , the second slide rail 8 and the frame, the frame is installed with the first slide rail 7, the transfer rail 2, the pallet transfer mechanism 3, the cloth mechanism 4, the press-in mechanism 5 , the vibration forming mechanism 6 and the second sliding guide rail 8 .

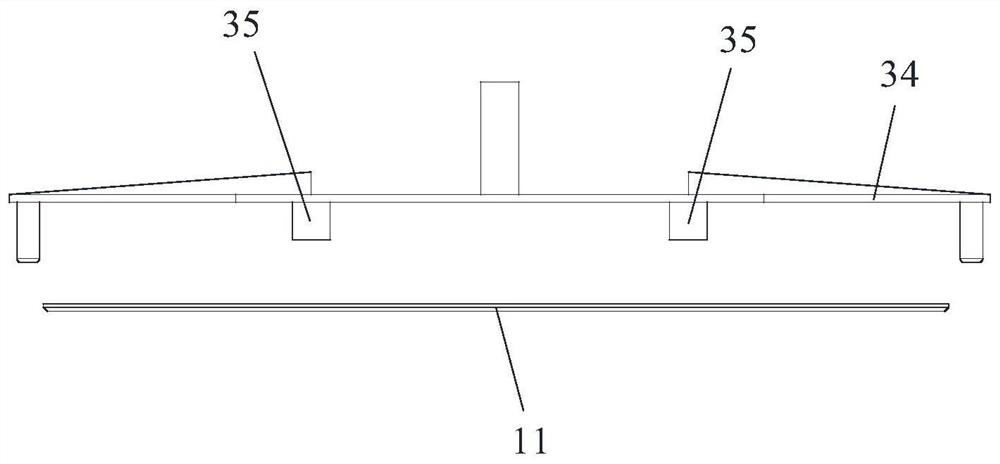

[0070] The cavity mold 1 is used to carry the pallet 11, and arrange the gel particles 12 to form the particle board.

[0071] Such as figure 2 As shown, the pallet transfer mechanism 3 is used to install the pallet 11 into the cavity mold 1; specifically, the pallet transfer mechanism 3 includes a slider slide rail 31 and a slide rail 31 slidingly fitted therewith. block 32, the slider rail 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com