Patents

Literature

101results about How to "Reduce the number of placements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

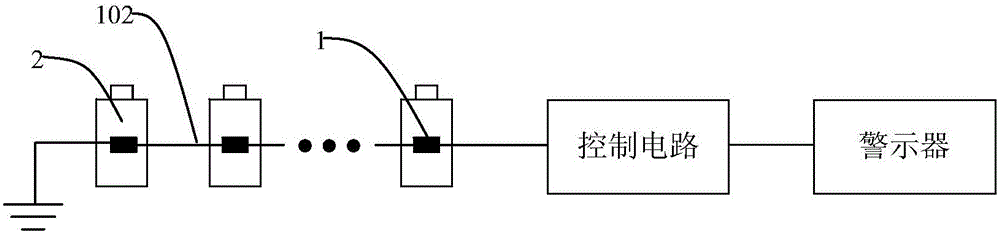

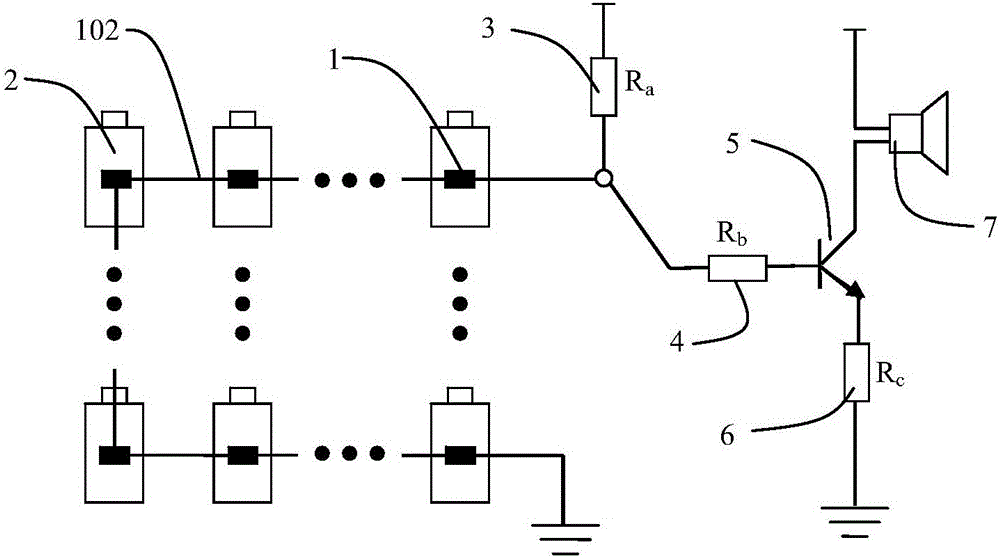

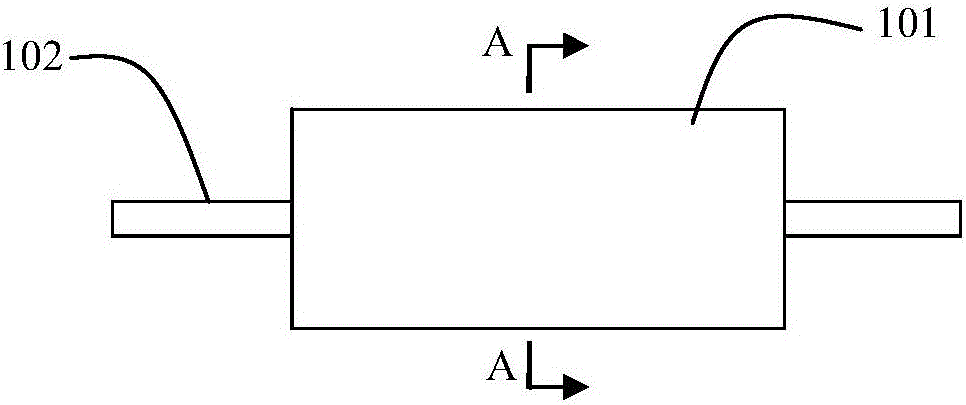

Power battery thermorunaway automatic alarm device and method

ActiveCN106205029ASimple structureEasy wiringCircuit monitoring/indicationDifferent batteries chargingPower batteryHeat management

The invention relates to a power battery thermorunaway automatic alarm device and method used for monitoring and alarming thermorunaway of power battery single bodies. The automatic alarm device comprises multiple fuse elements and further comprises a control circuit and a warning indicator, and all the fuse elements are arranged on all the battery single bodies or battery packs formed by two or more battery single bodies and fuse when surface temperature of a certain battery single body or battery pack reaches a certain threshold value; all the fuse elements are sequentially connected in series to form a fuse element string, one end of the fuse element string is sequentially connected with the control circuit and the warning indicator, the other end of the fuse element string is grounded, and the control circuit uses the audion connection characteristics when the fuse elements fuse for controlling the warning indicator to act to automatically give an alarm. The automatic alarm device is simple in structure, low in cost and high in practicability, achieves real-time monitoring of thermorunaway of the battery single bodies connected in parallel or series in the power battery packs and improves safety and reliability of heat management on the power battery packs.

Owner:BEIHANG UNIV

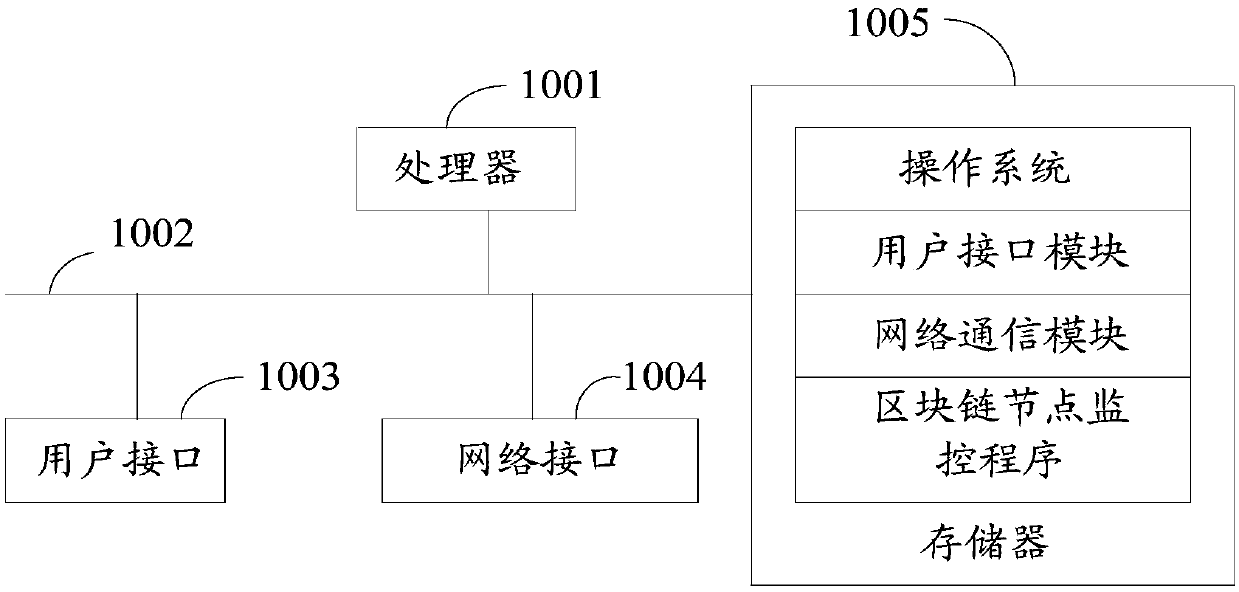

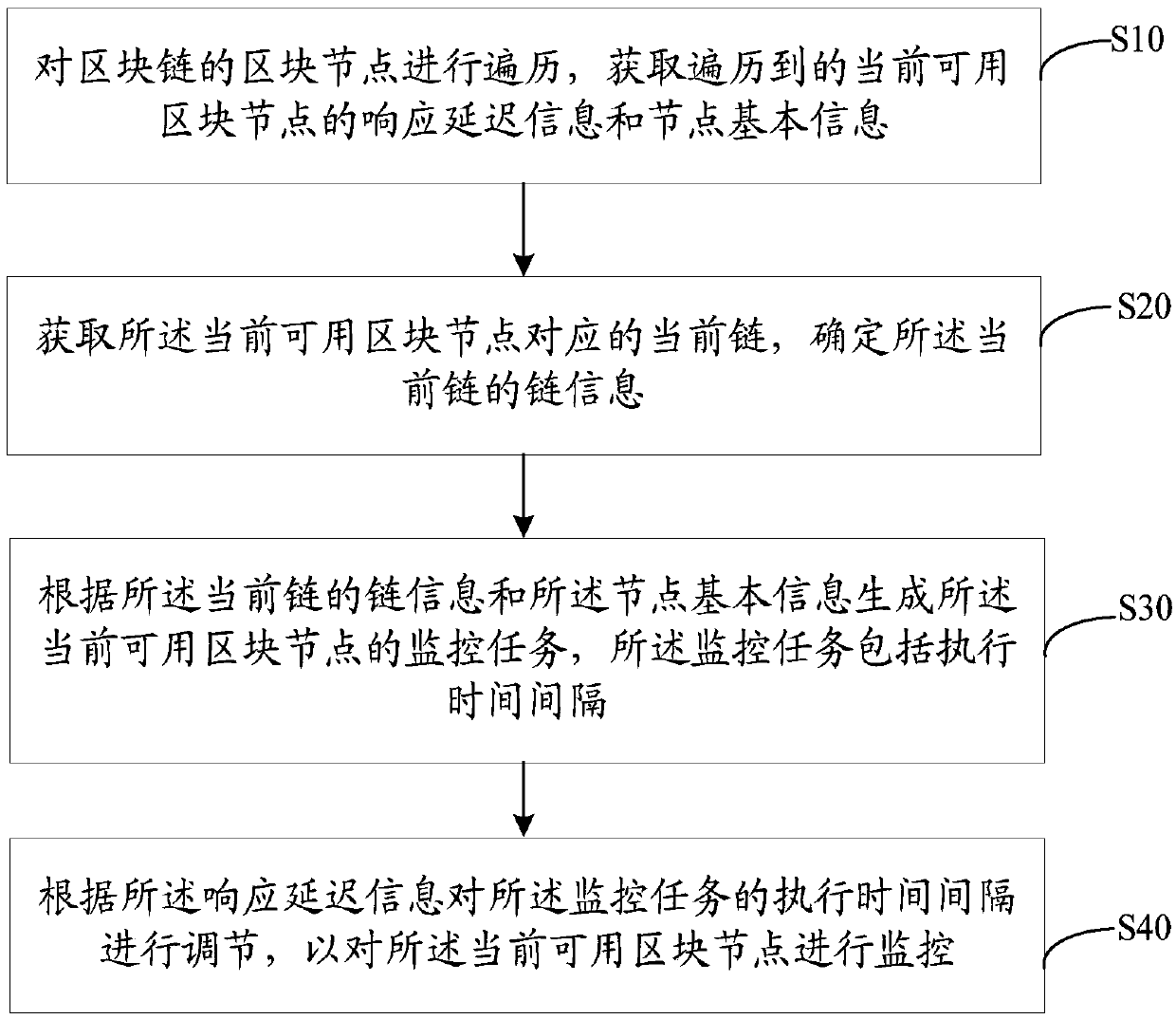

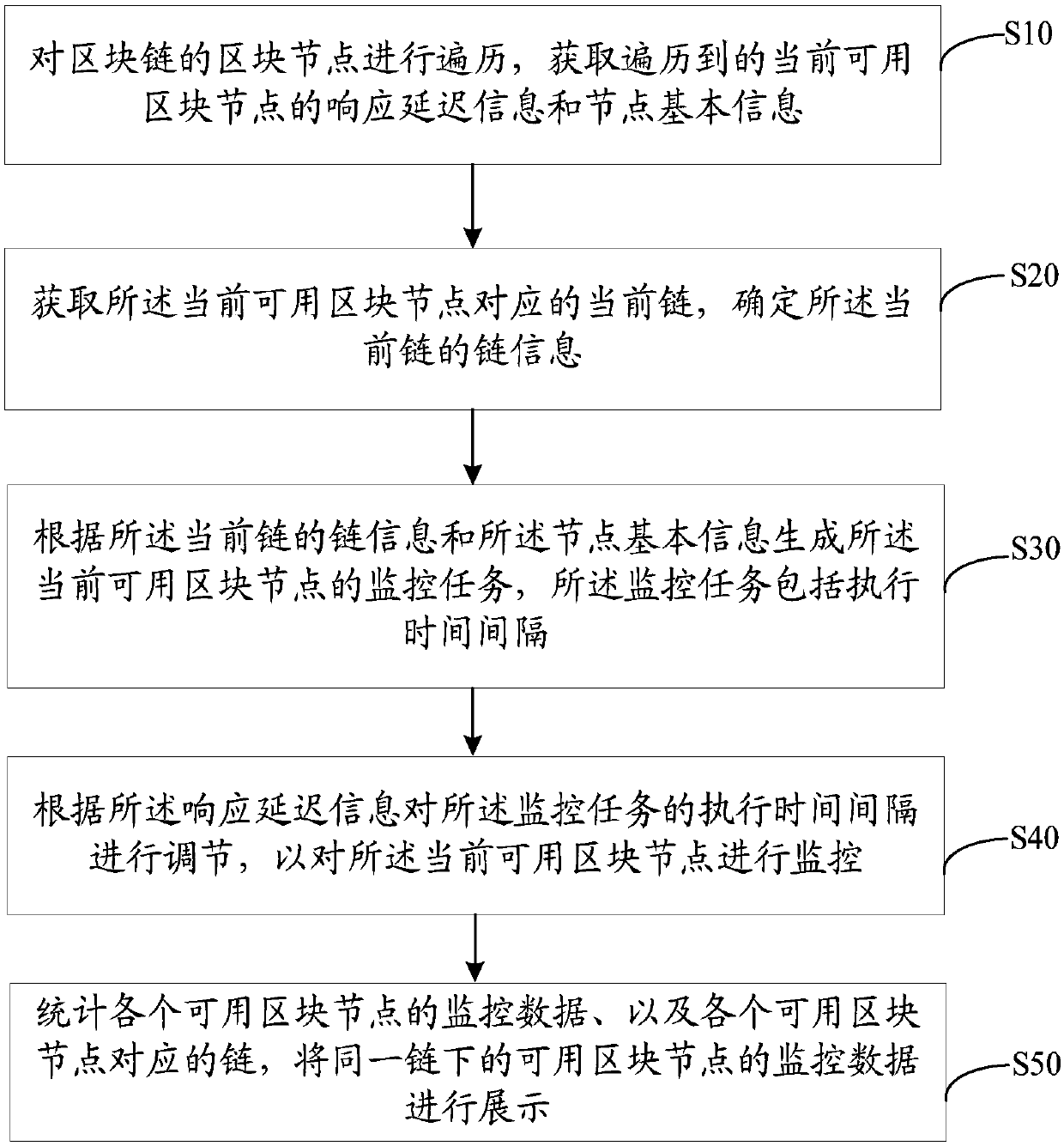

Block chain node monitoring method, device and system, and computer storage medium

ActiveCN109639751AReduce the number of placementsReduce occupancyTransmissionOccupancy rateResponse delay

The invention belongs to the technical field of the block chain, and discloses a block chain node monitoring method, device and system, and a computer readable medium. The method comprises the following steps: firstly traversing a block nodes of the block chain, acquiring traversed response delay information and node basic information of the current available block node; acquiring the current chain corresponding to the current available block node, and determining the chain information of the current chain; generating a monitoring task of the current available block node according to the chaininformation of the current chain and the node basic information, wherein the monitoring task comprises execution time interval; and finally adjusting the execution time interval of the monitoring task according to the response delay information, thereby monitoring the current available block node. The placing number of the logic code of the block node in the block chain monitoring process can bereduced, the occupancy rate of the block node resource is reduced, and the problem that the load is excessively high in the period of monitoring the block chain running state is solved.

Owner:PING AN TECH (SHENZHEN) CO LTD

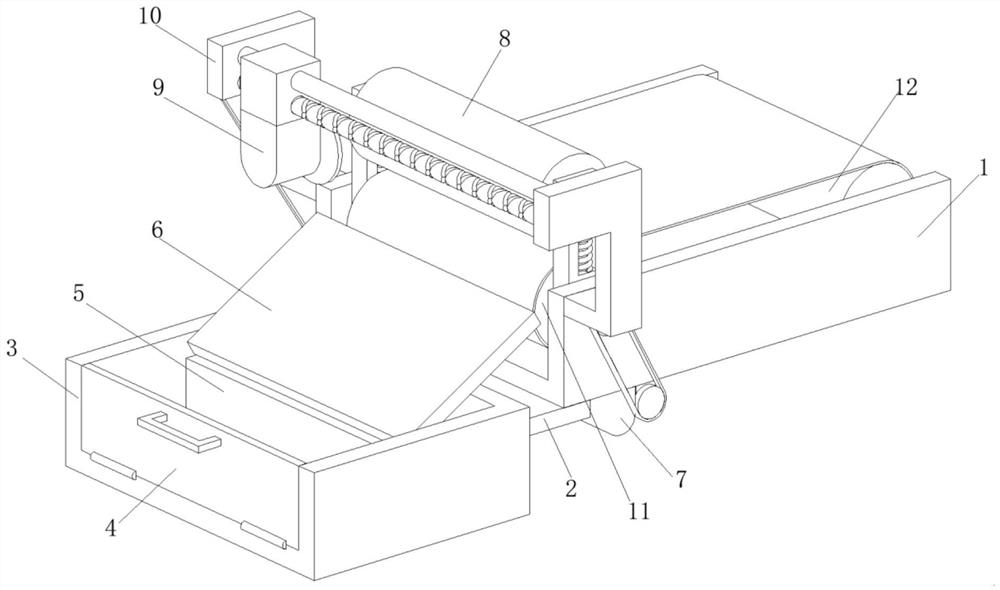

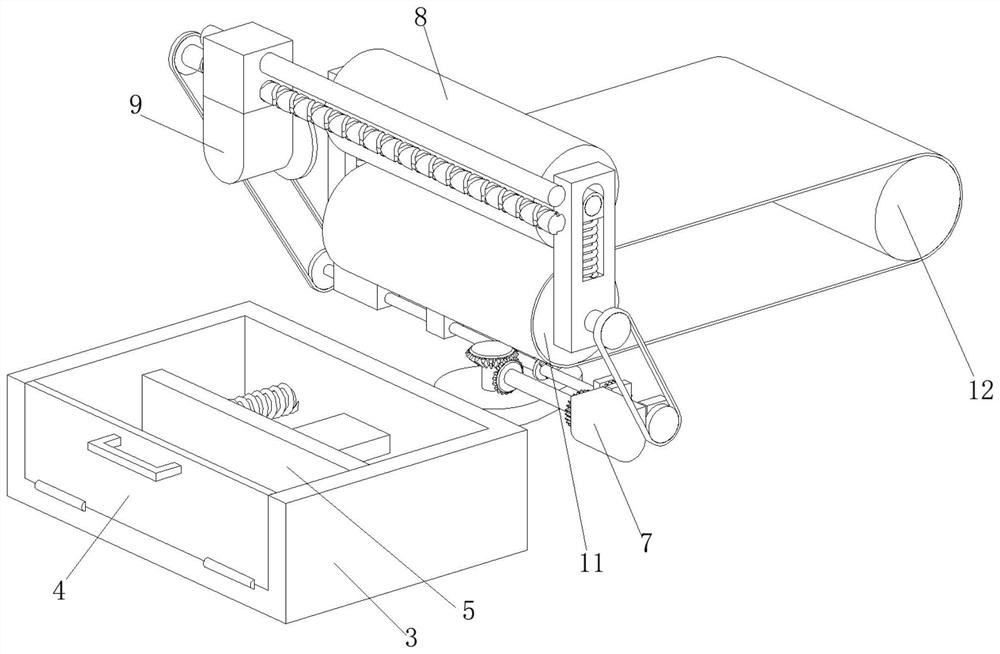

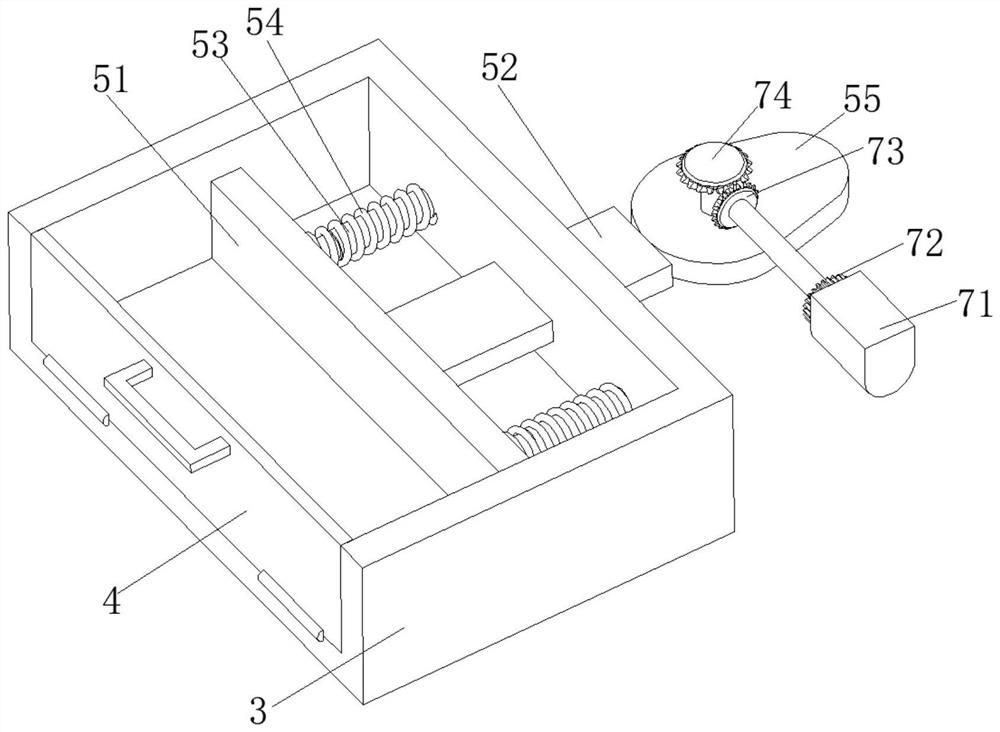

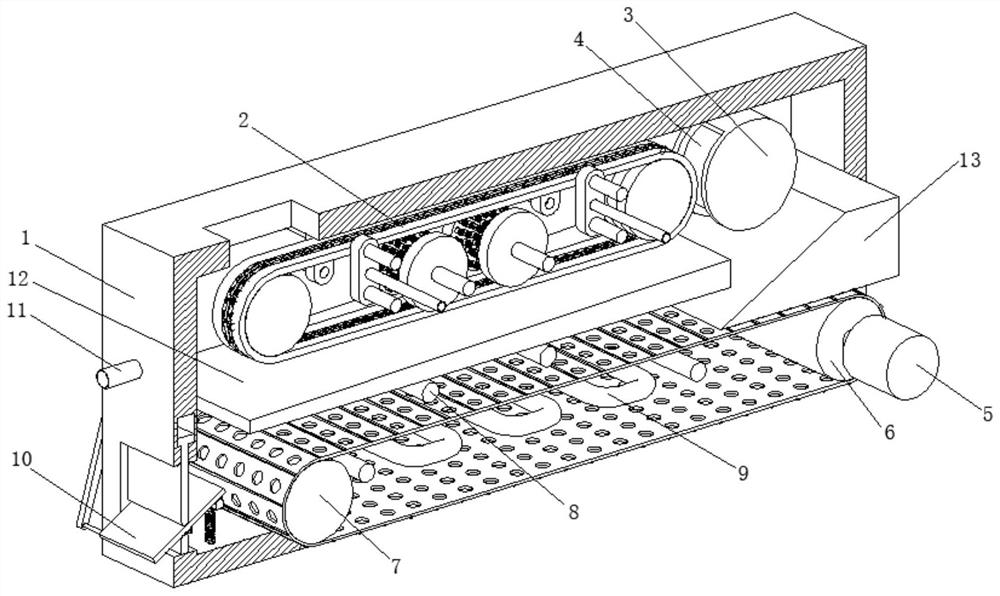

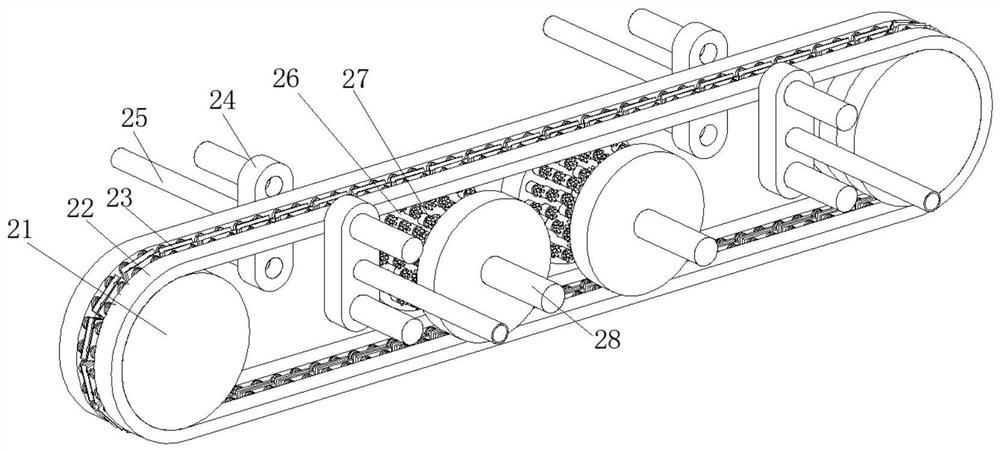

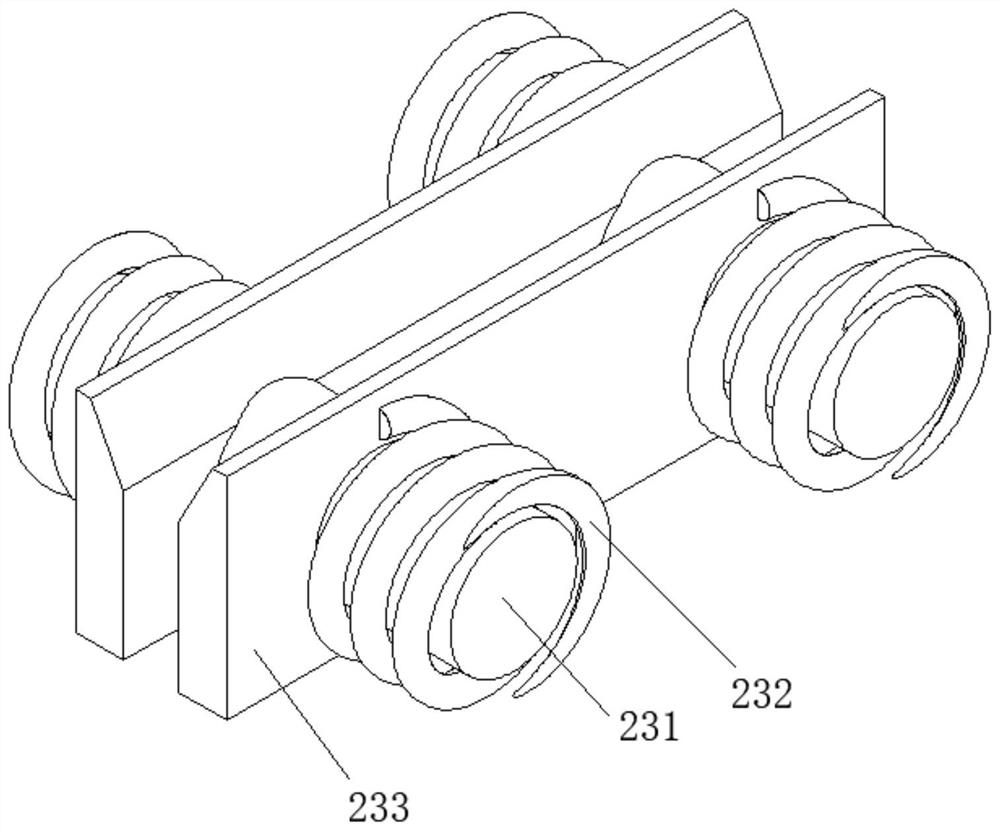

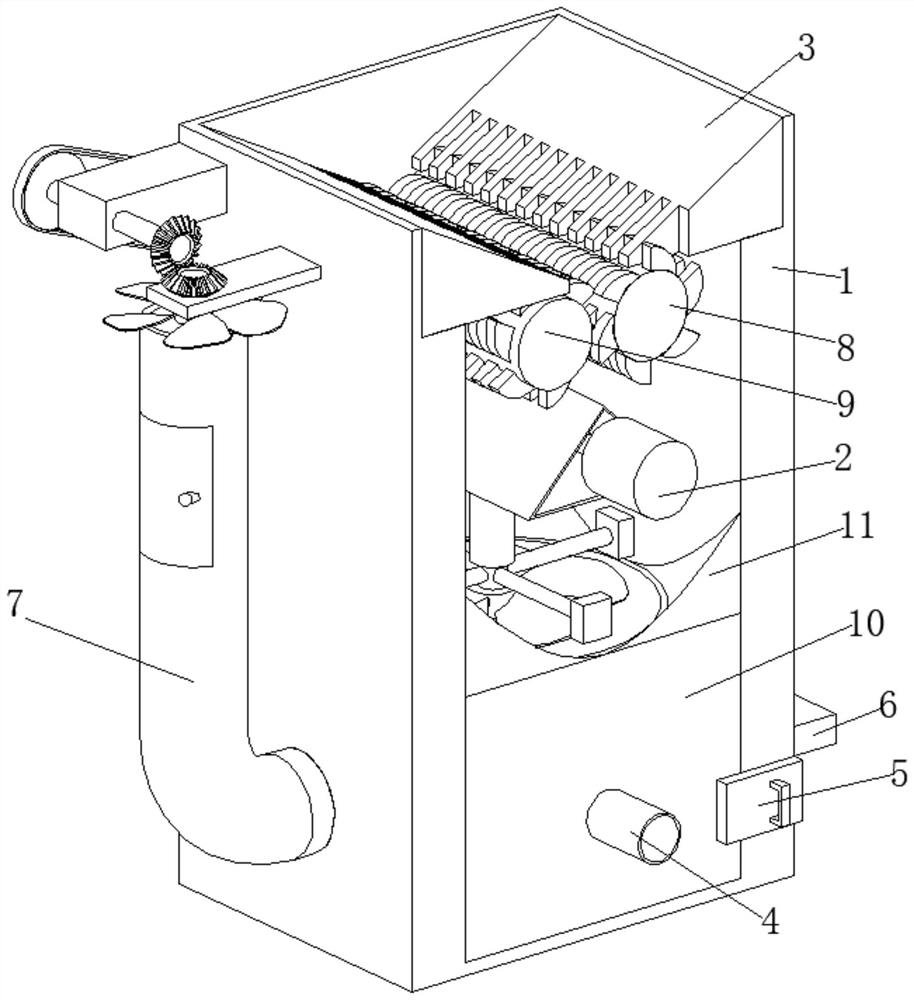

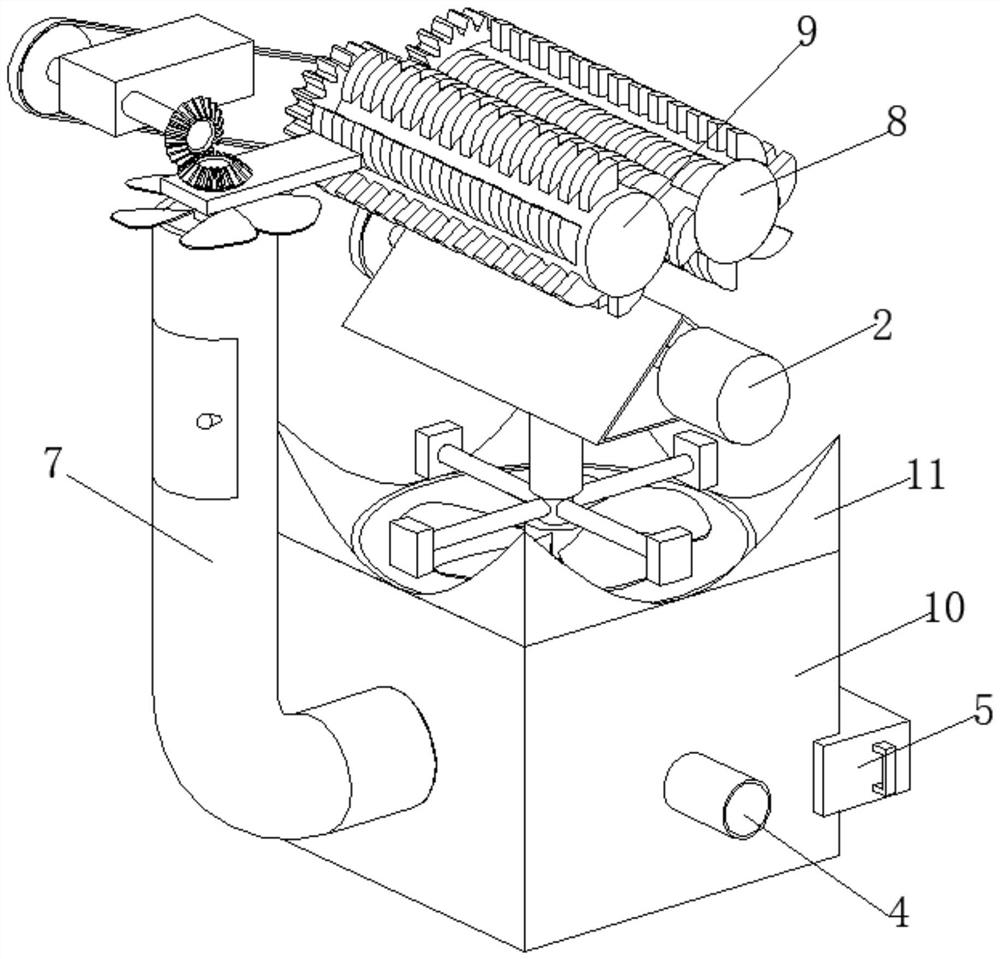

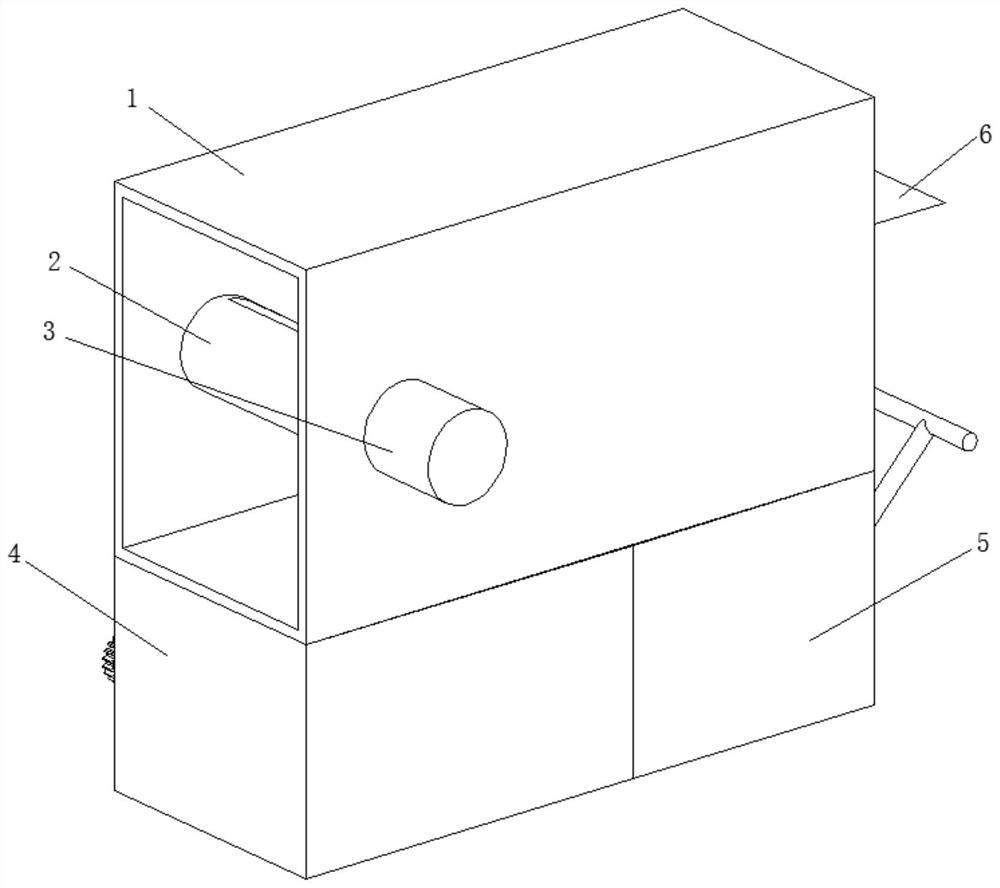

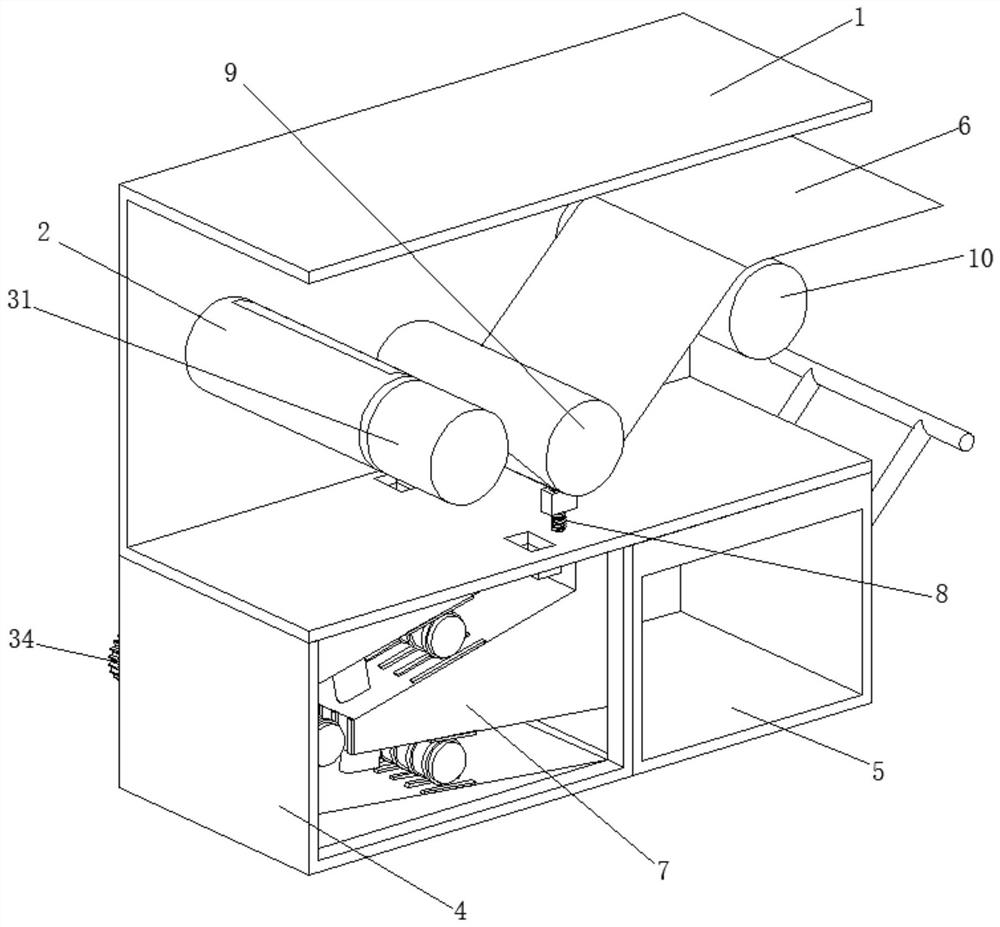

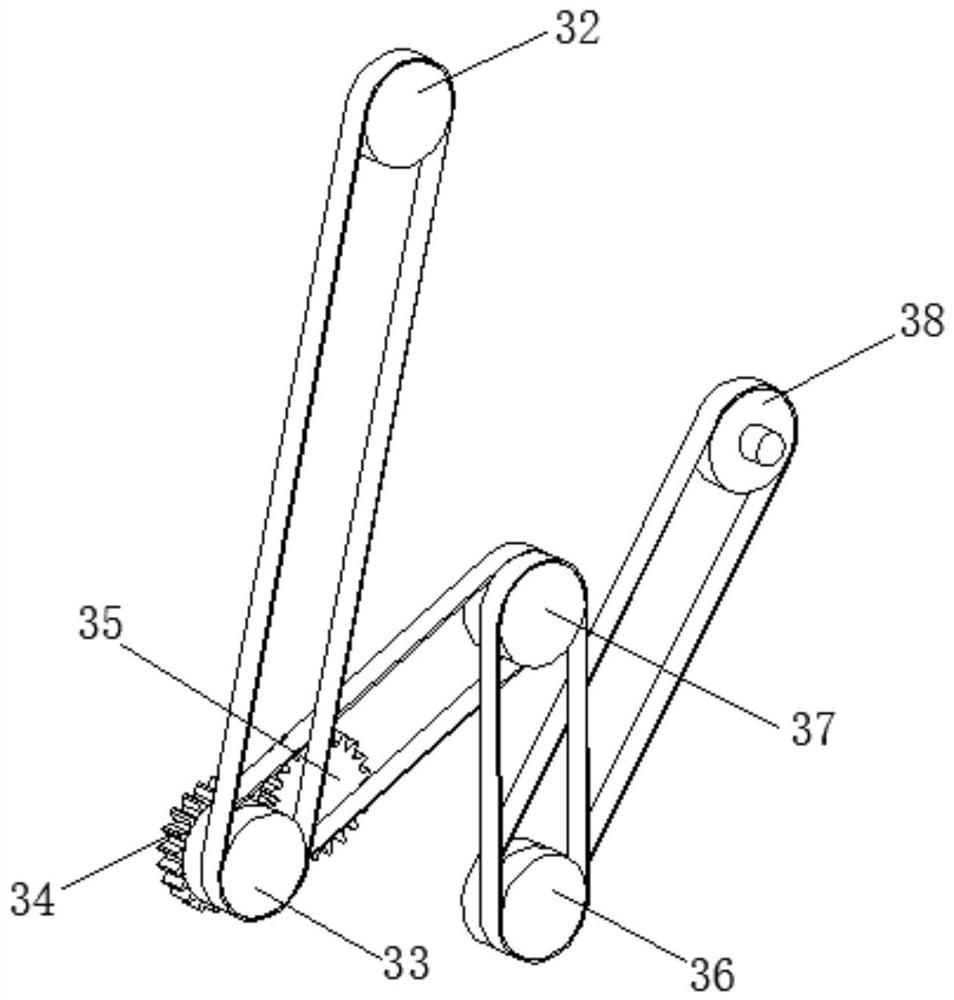

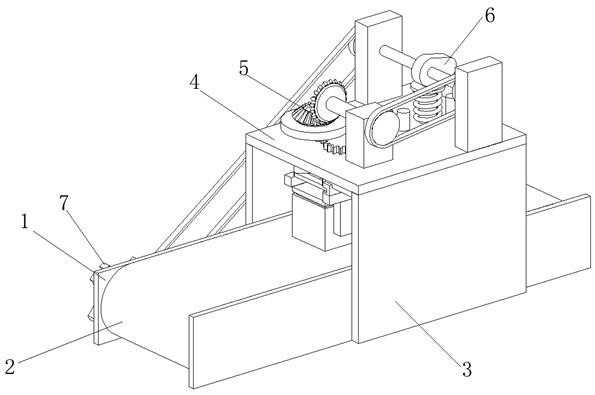

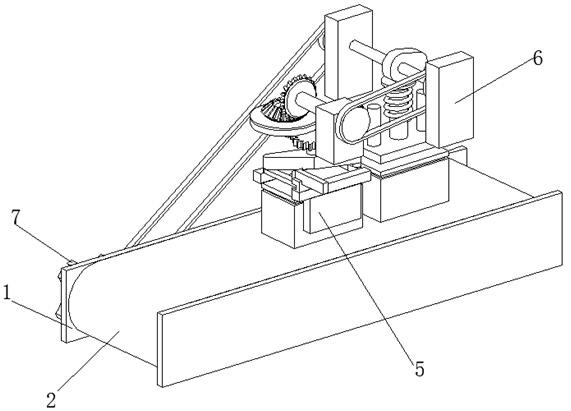

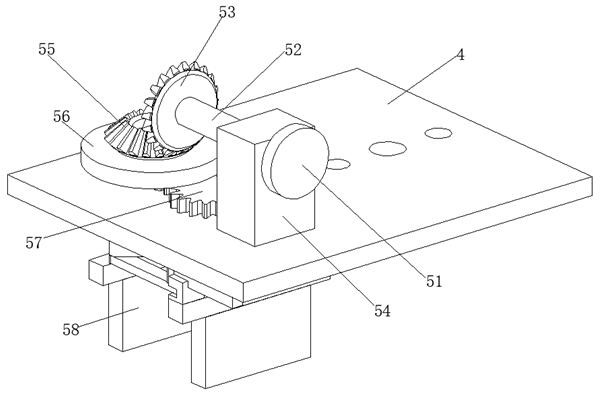

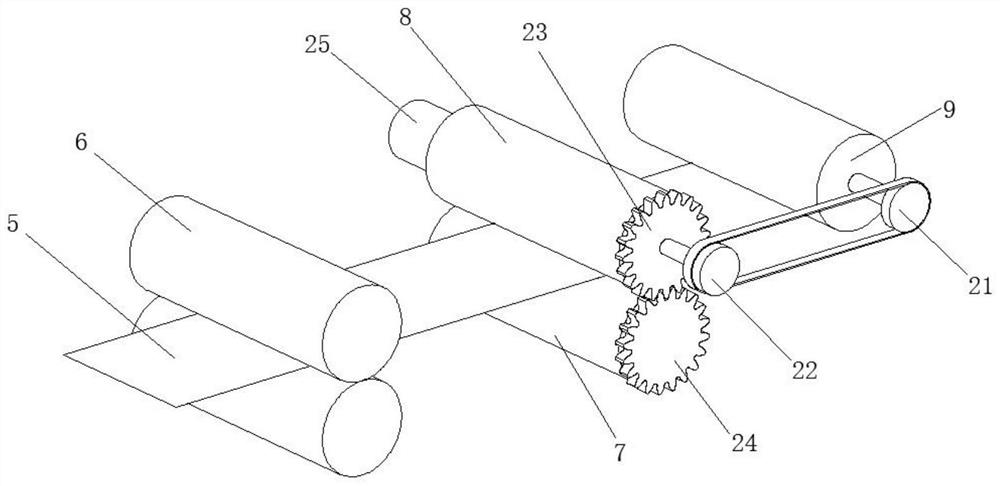

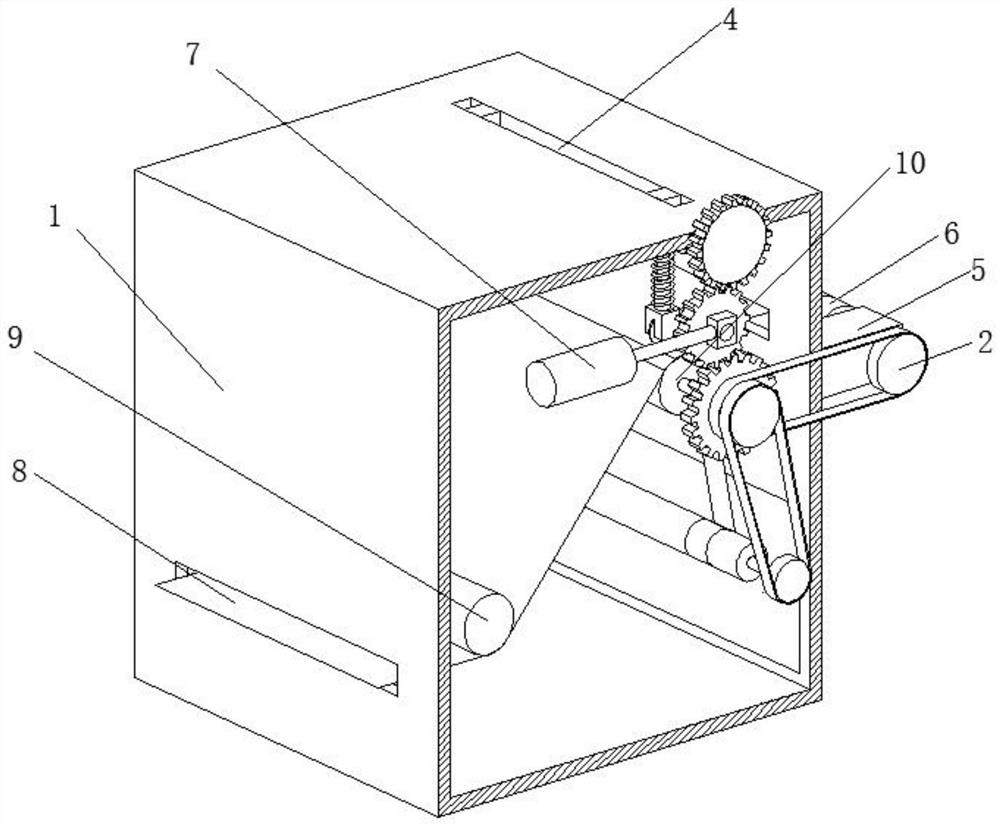

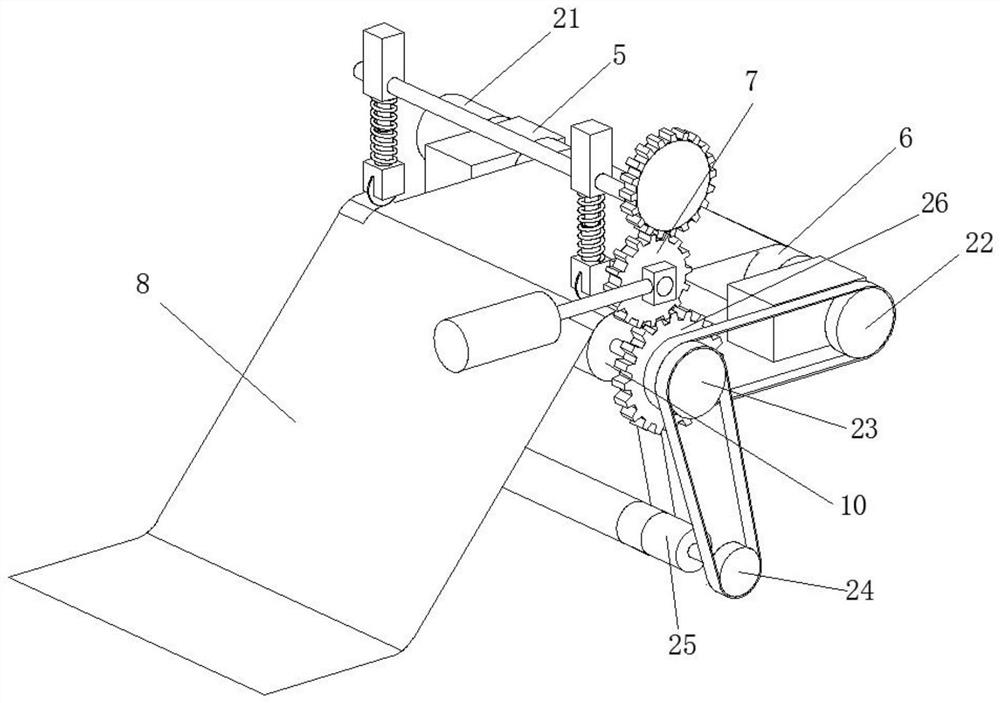

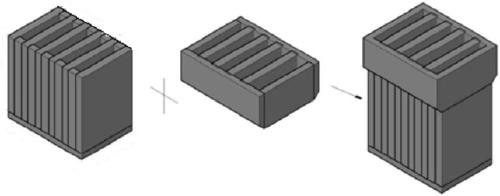

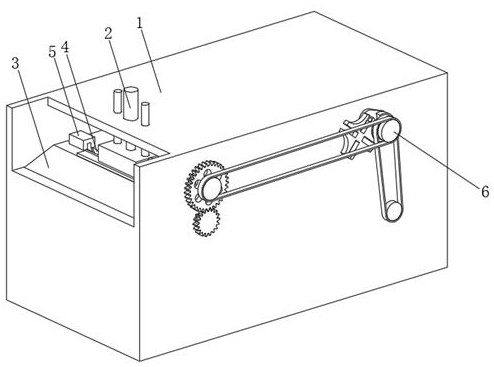

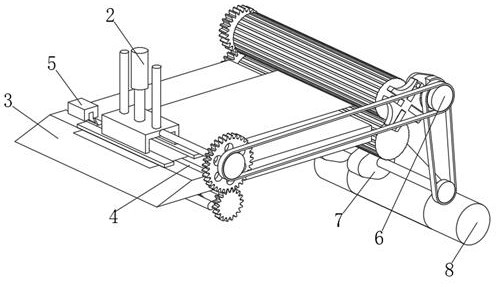

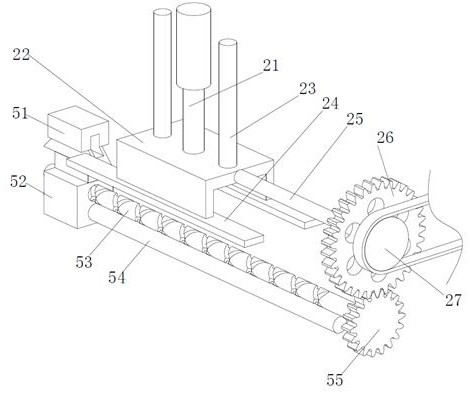

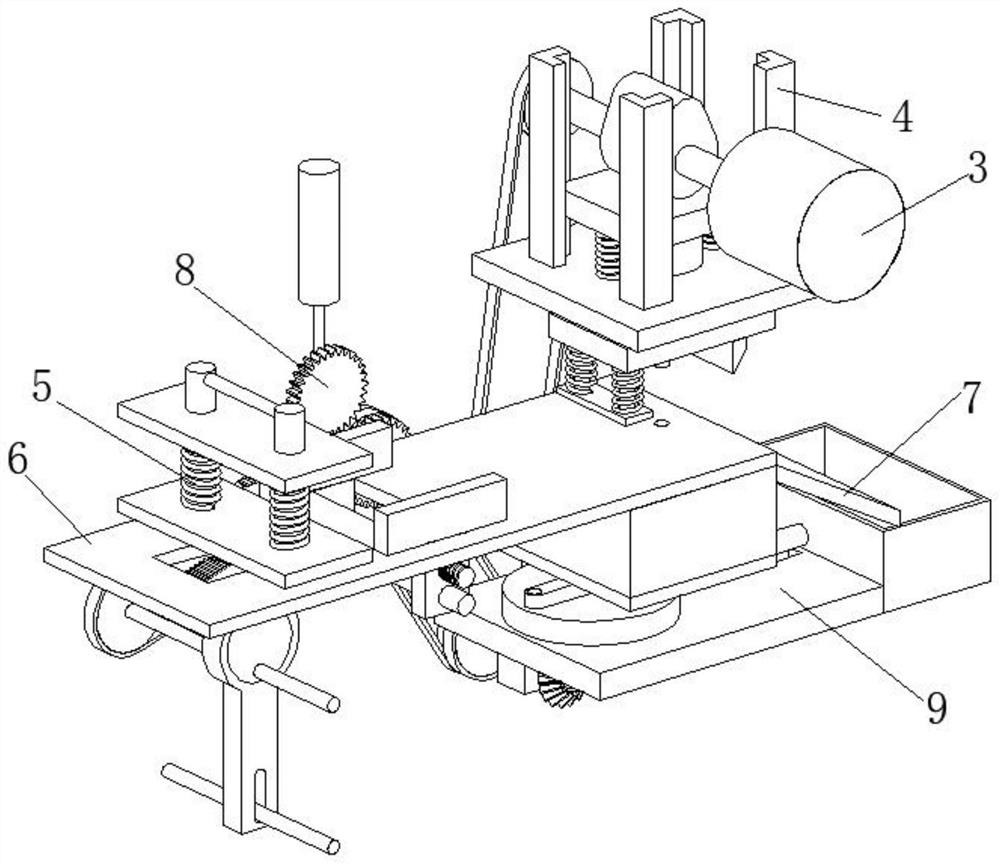

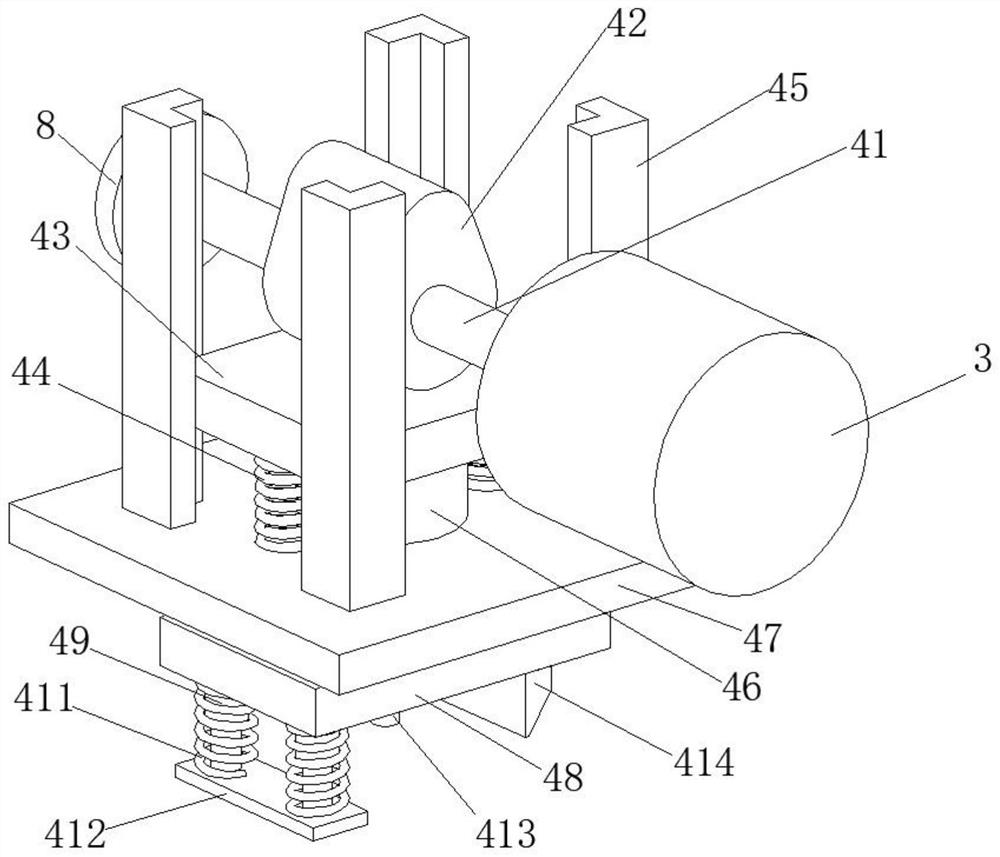

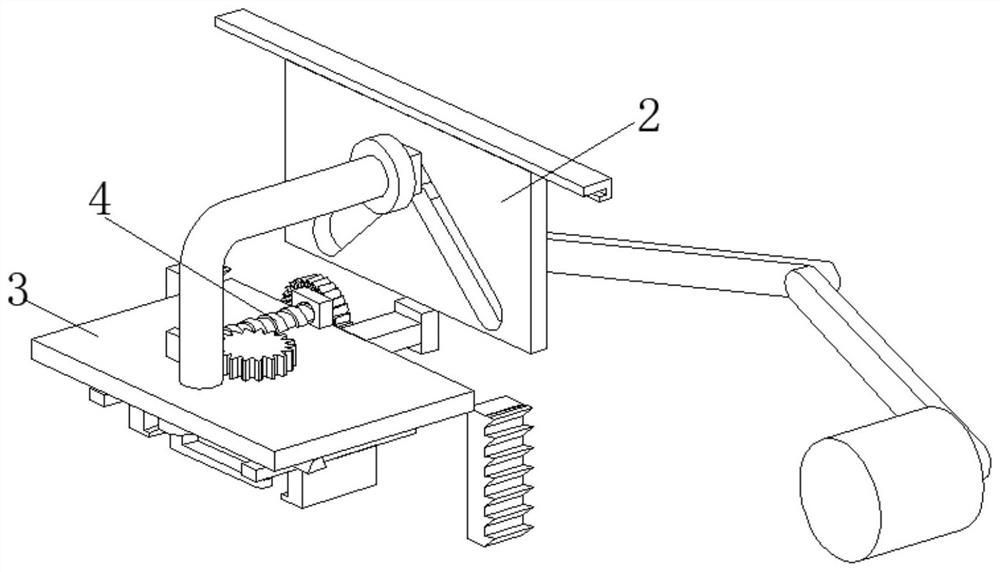

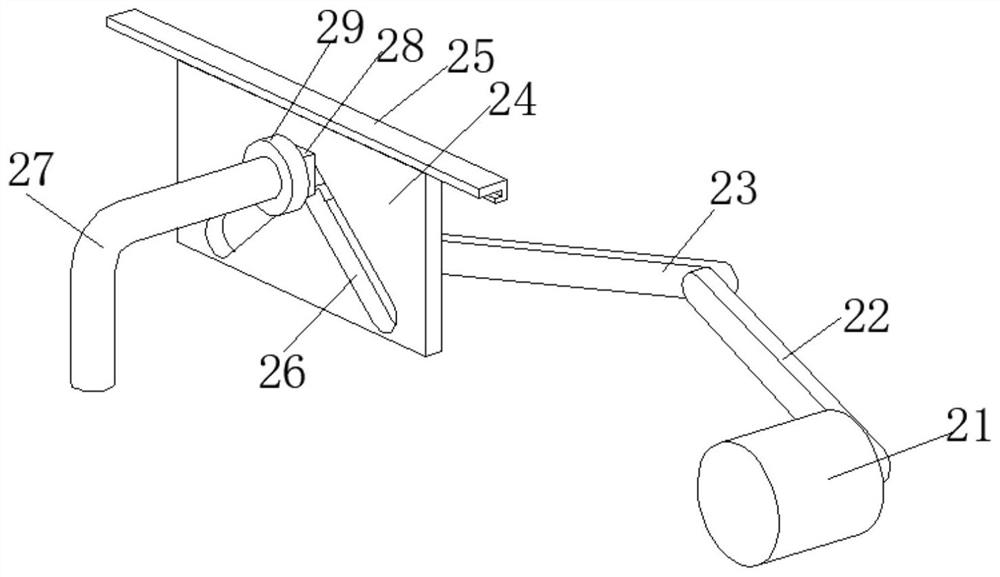

Cutting and slitting device for composite board and using method of cutting and slitting device

ActiveCN112976073AReduce damage rateReduce occupancyMetal working apparatusStructural engineeringComposite plate

The invention relates to the technical field of cutting equipment, and discloses a cutting and slitting device for a composite board and a using method of the cutting and slitting device. The cutting and slitting device comprises a frame, a connecting plate is welded to the bottom of the frame, a collecting box is fixedly installed on the front portion of the connecting plate, a rotating door is movably connected to the front portion of the collecting box, and a collecting mechanism is arranged in the collecting box; and an inclined plate is clamped to the inner wall of the collecting box, a transmission mechanism is arranged at the bottom of the frame, a front roller and a rear roller are rotatably connected to the inner wall of the frame through connecting rods correspondingly, a fixing mechanism is arranged at the top of the front roller, supporting plates are welded to the two sides of the frame correspondingly, and a cutting mechanism is arranged between the two supporting plates. By means of the collecting mechanism and the transmission mechanism, cut plates can be collected and stacked in order, the damage rate of the plates can be reduced, the space of the collected plates can be reasonably distributed, and occupied space is reduced.

Owner:深圳市广德盛科技有限公司

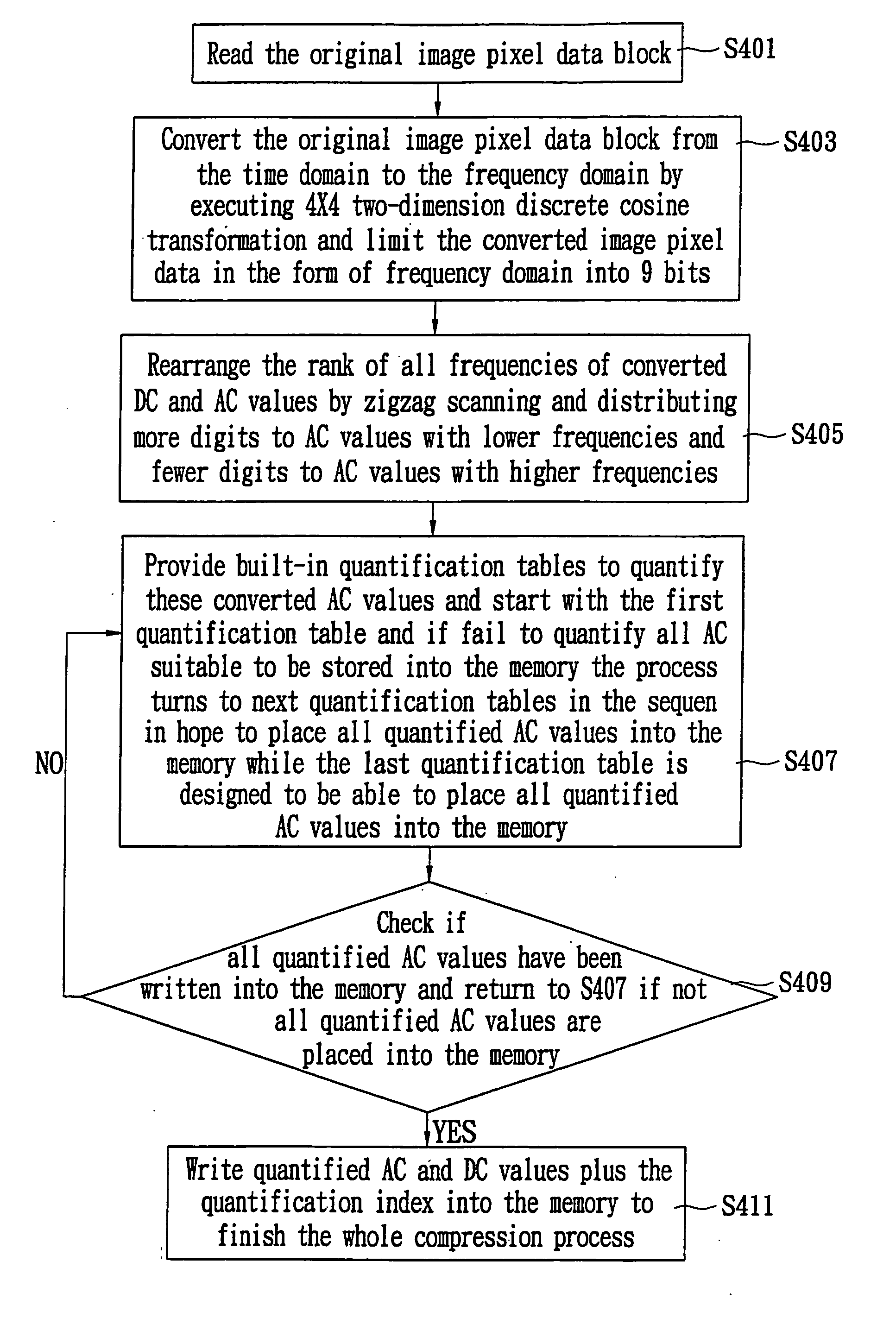

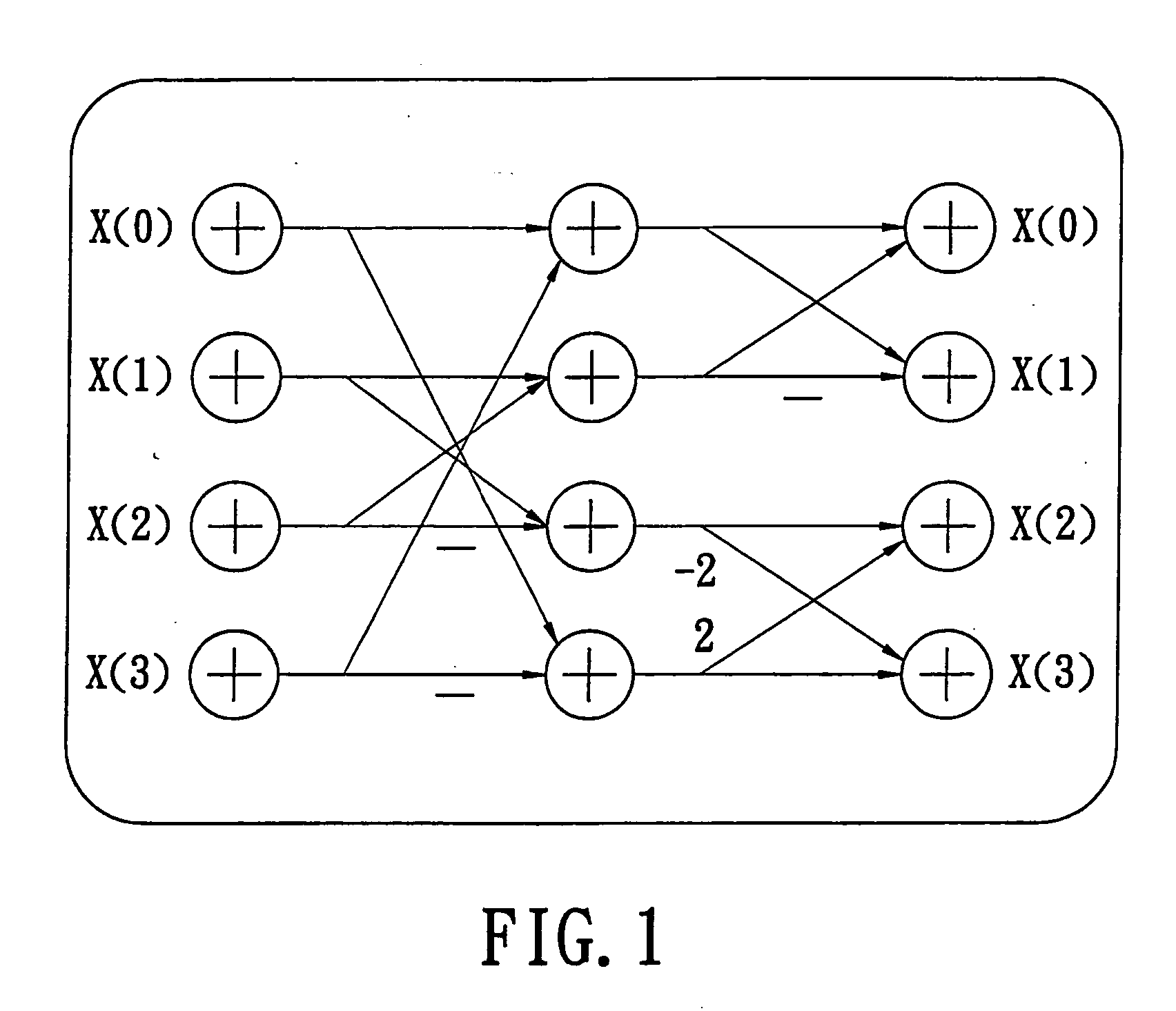

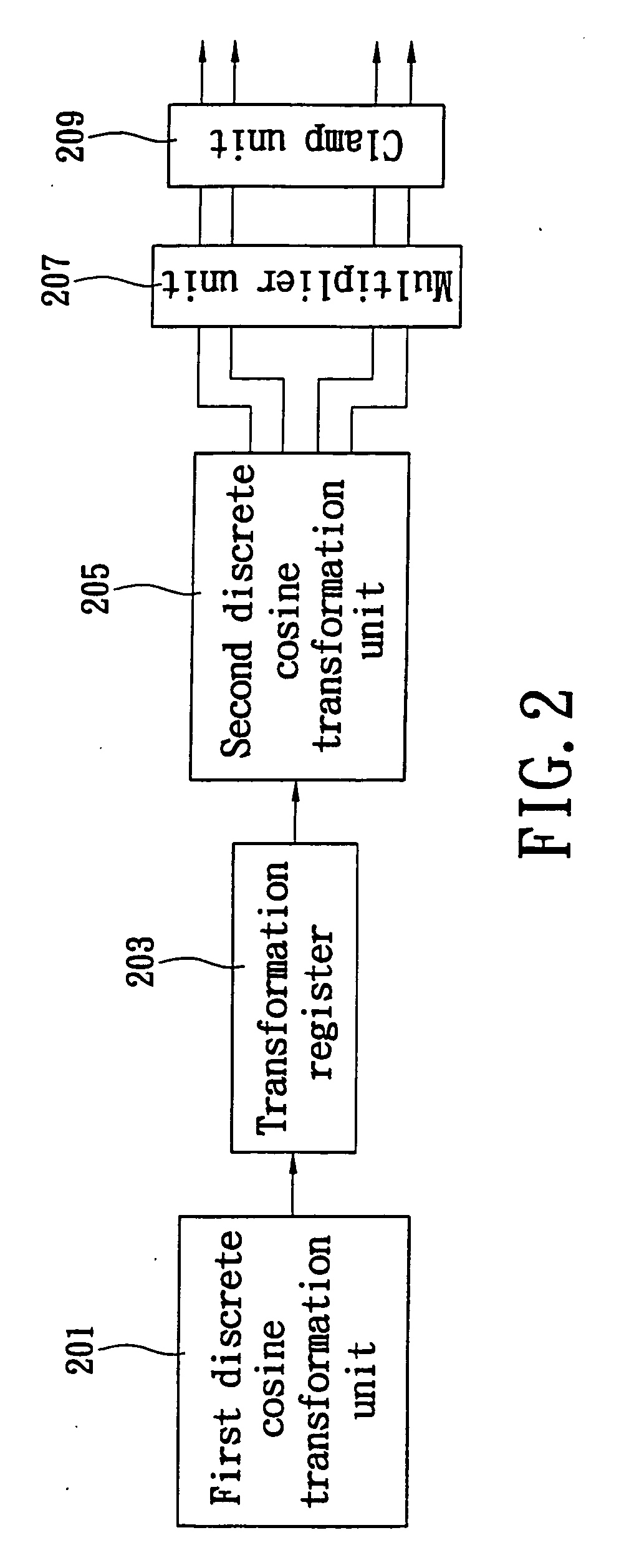

Image processing method and two-dimension discrete cosine transformation device using the same

InactiveUS20070065035A1Reduce the number of placementsCharacter and pattern recognitionDigital video signal modificationPattern recognitionData limitations

An image processing method and a two-dimension discrete cosine transformation device using the same method are provided. The method includes steps of reading an image pixel data block, converting the data of the image pixel data block in the form of a frequency domain, limiting the converted data in the form of the frequency domain into a first predetermined number of bits, rearranging original DC values and original AC values, distributing the number of bits of the original DC values and the original AC values, quantifying the original DC values and the original AC values, and storing the quantified DC values and AC values into a memory. The device using the aforementioned method includes a first one-dimension cosine transformation unit connected to a transformation register further connected to a second one-dimension cosine transformation unit and a multiplier unit for receiving outputs from the second one-dimension cosine transformation unit.

Owner:ALICORP

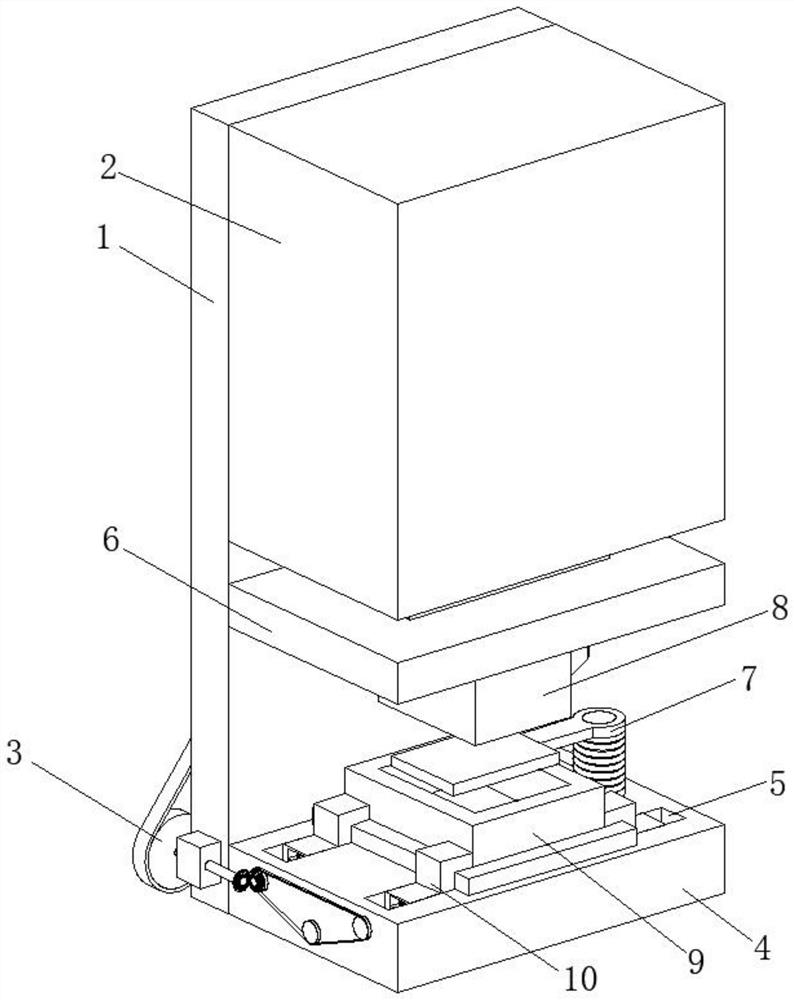

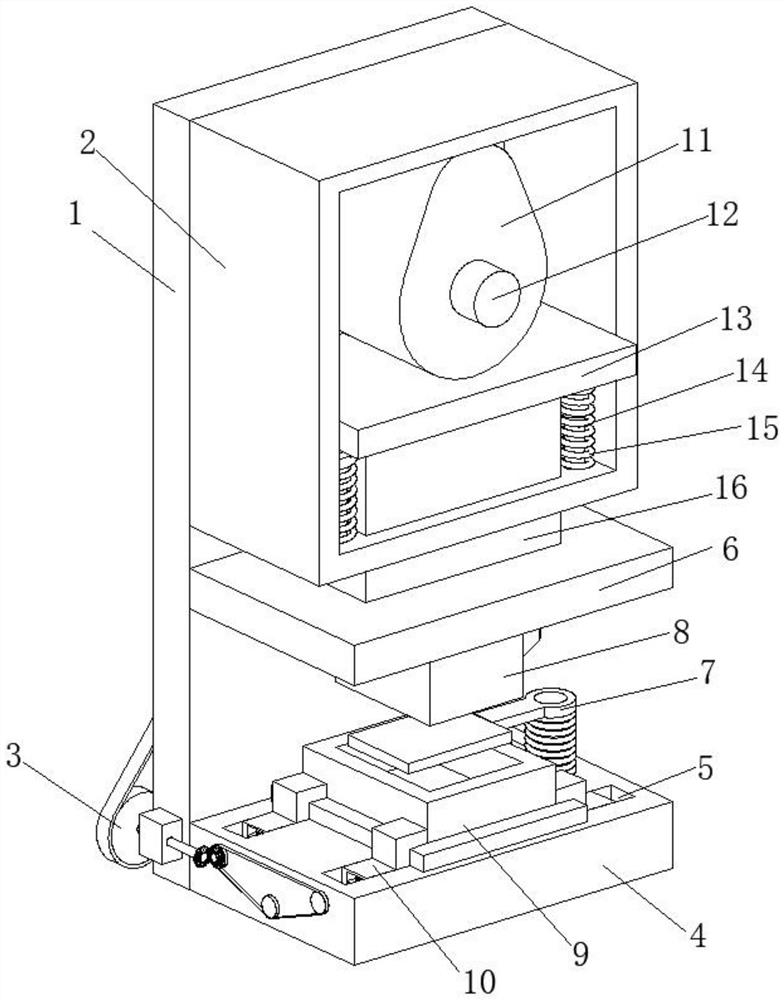

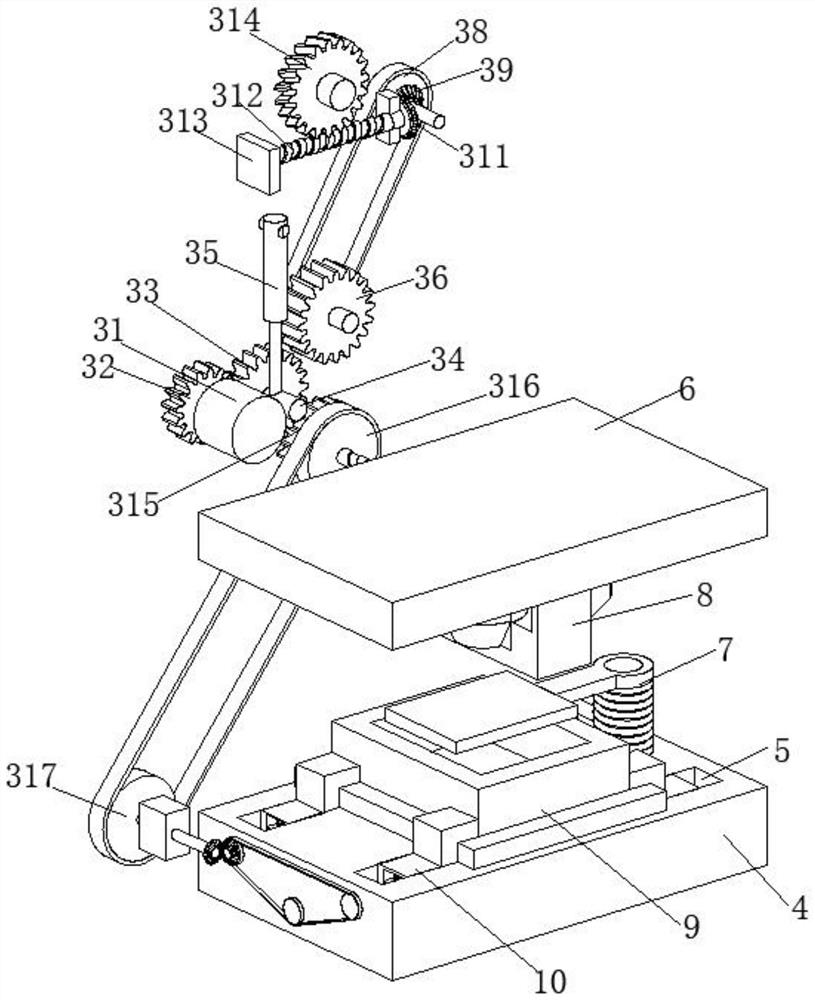

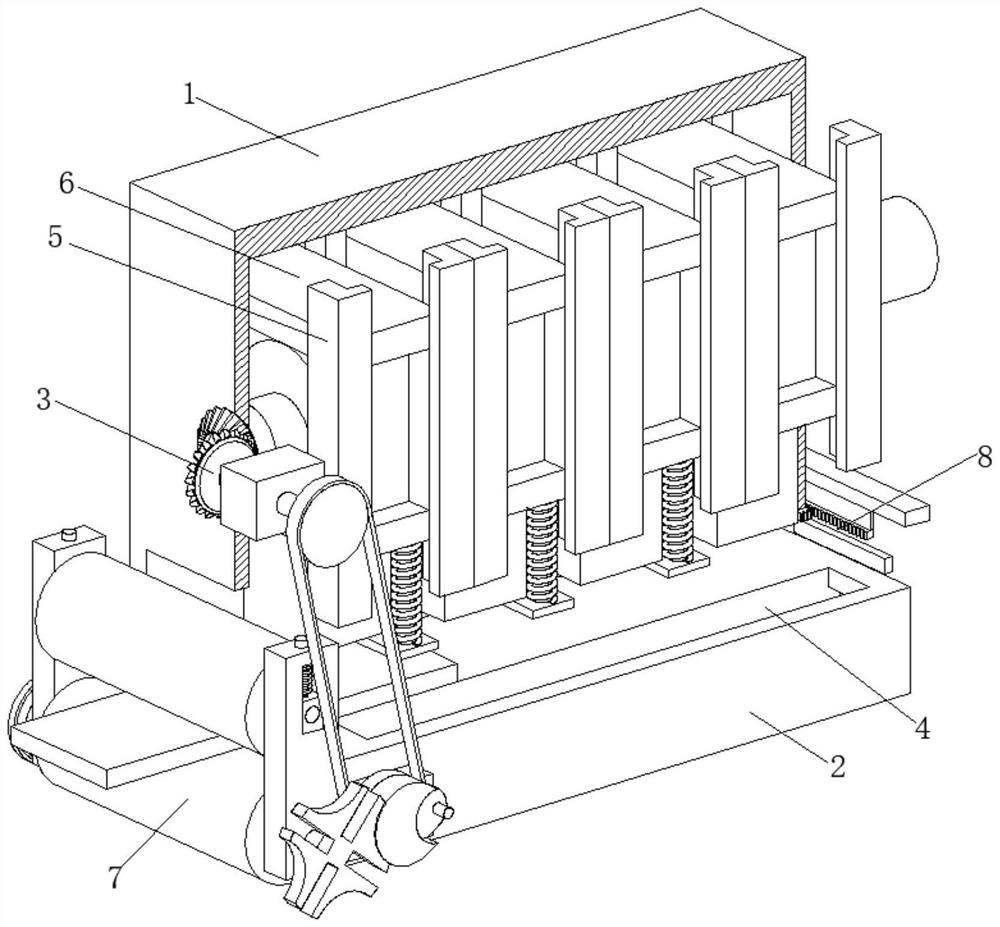

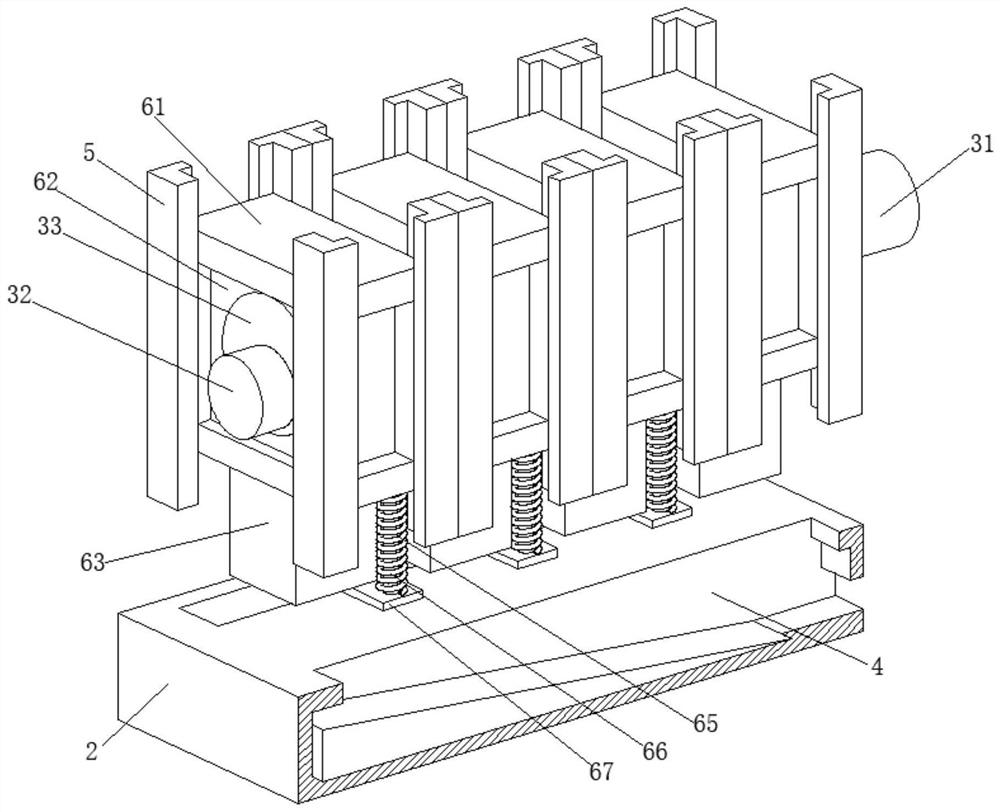

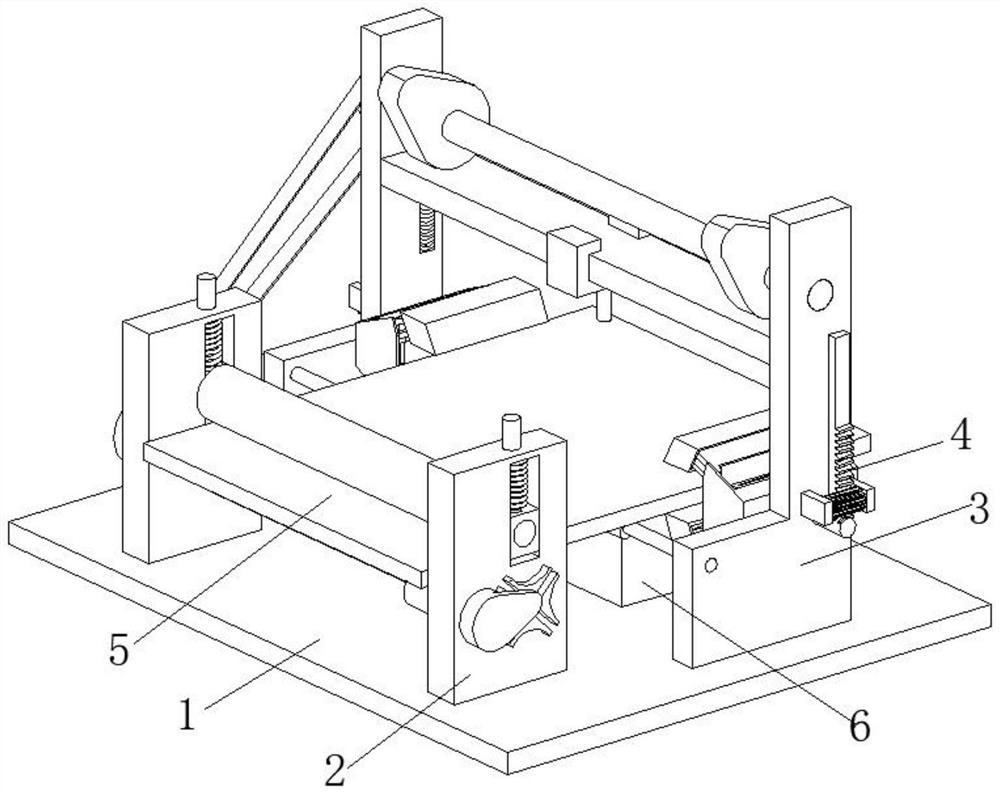

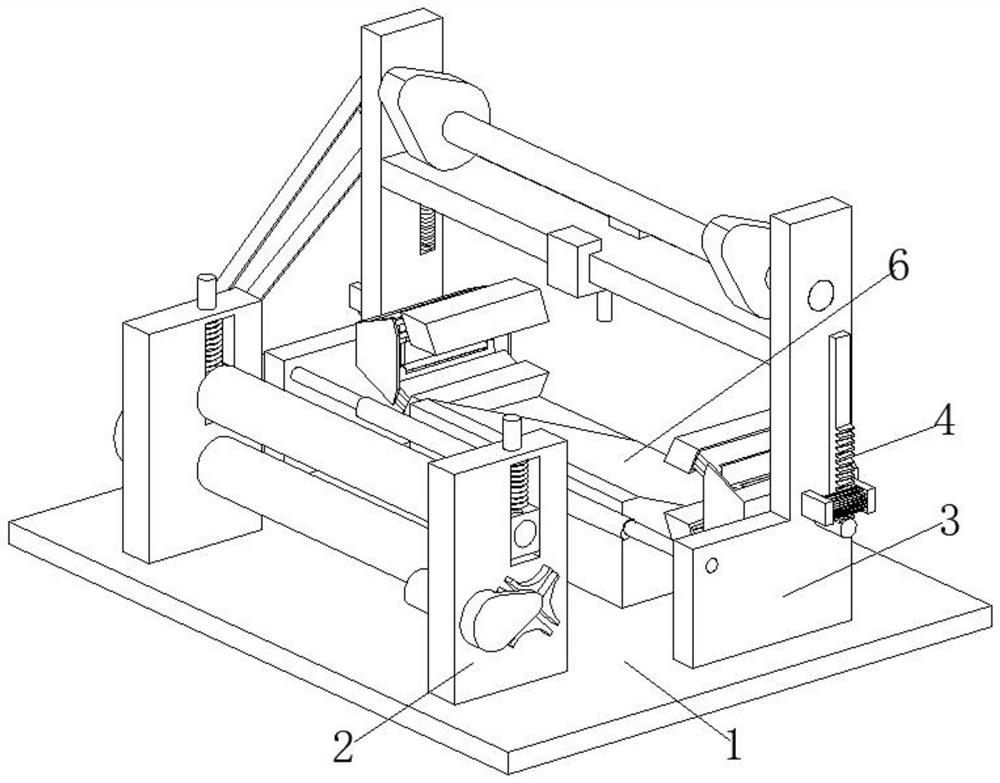

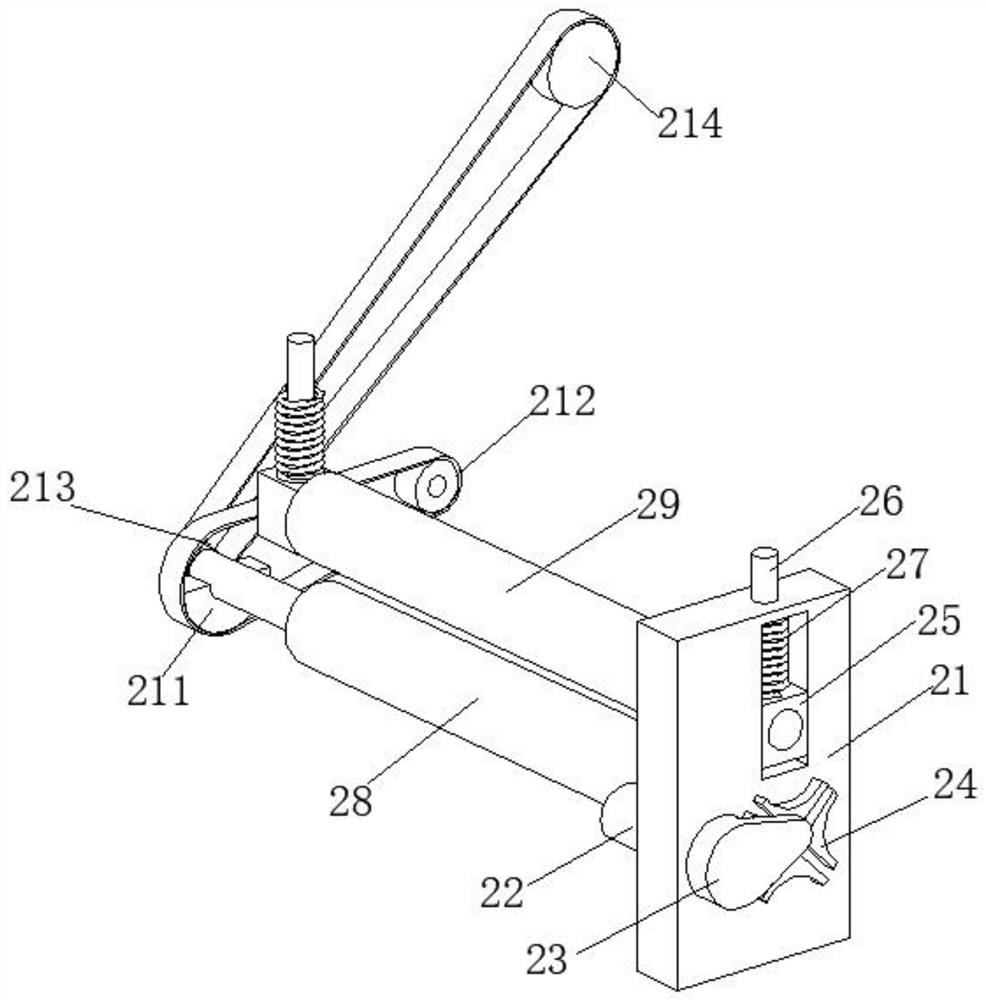

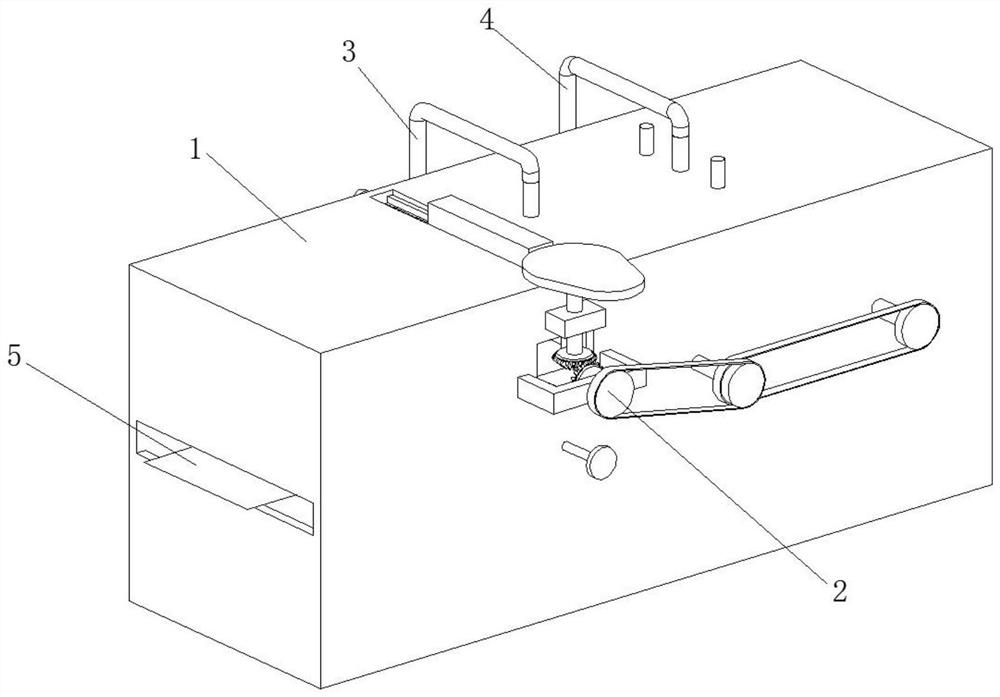

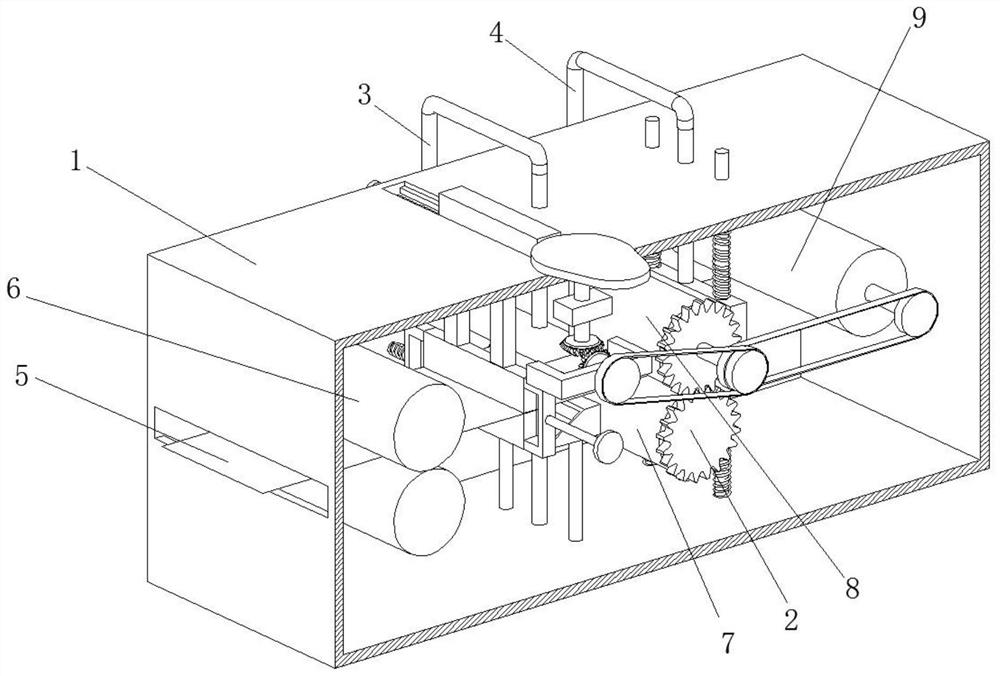

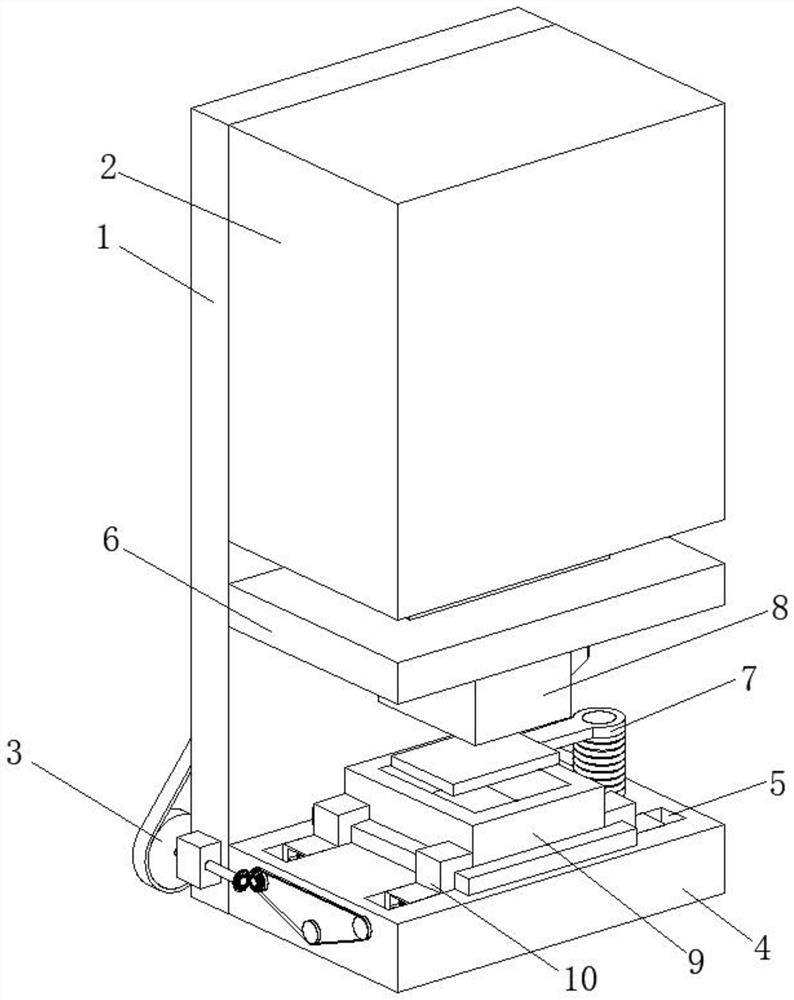

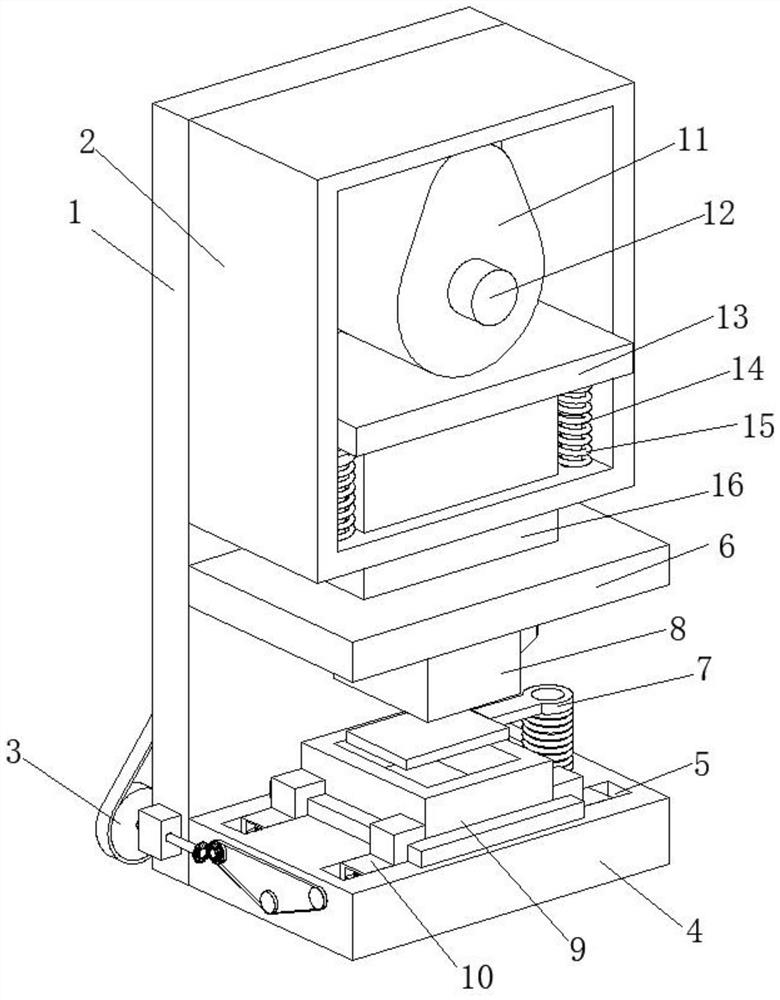

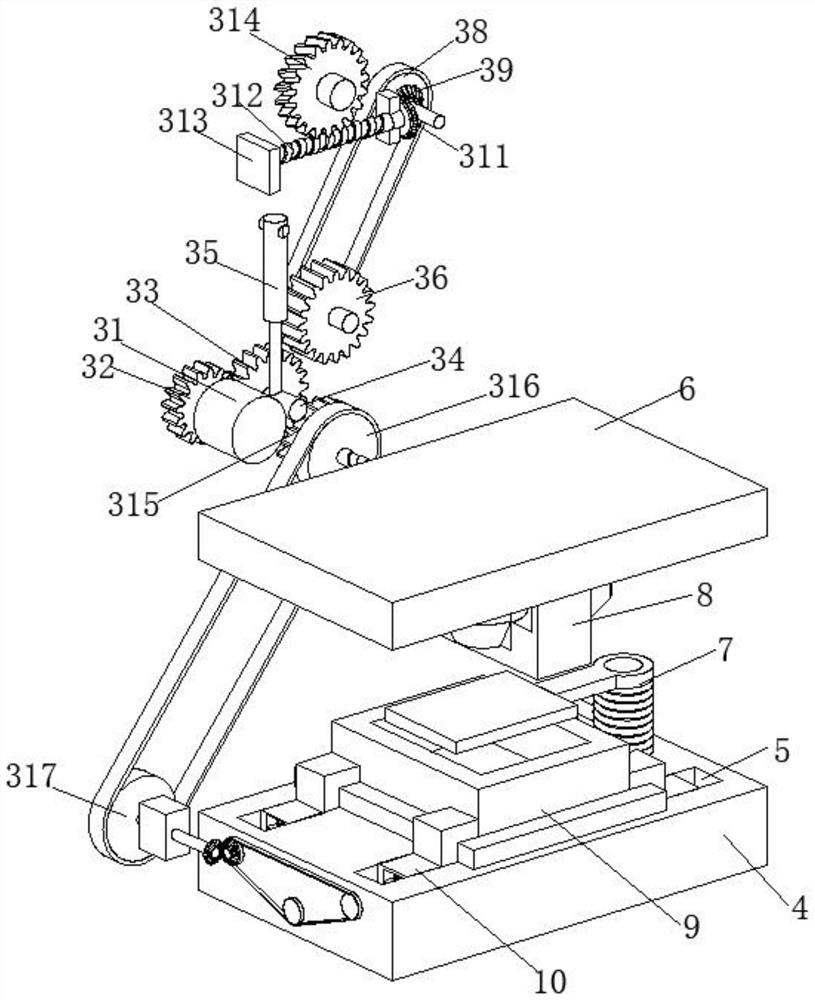

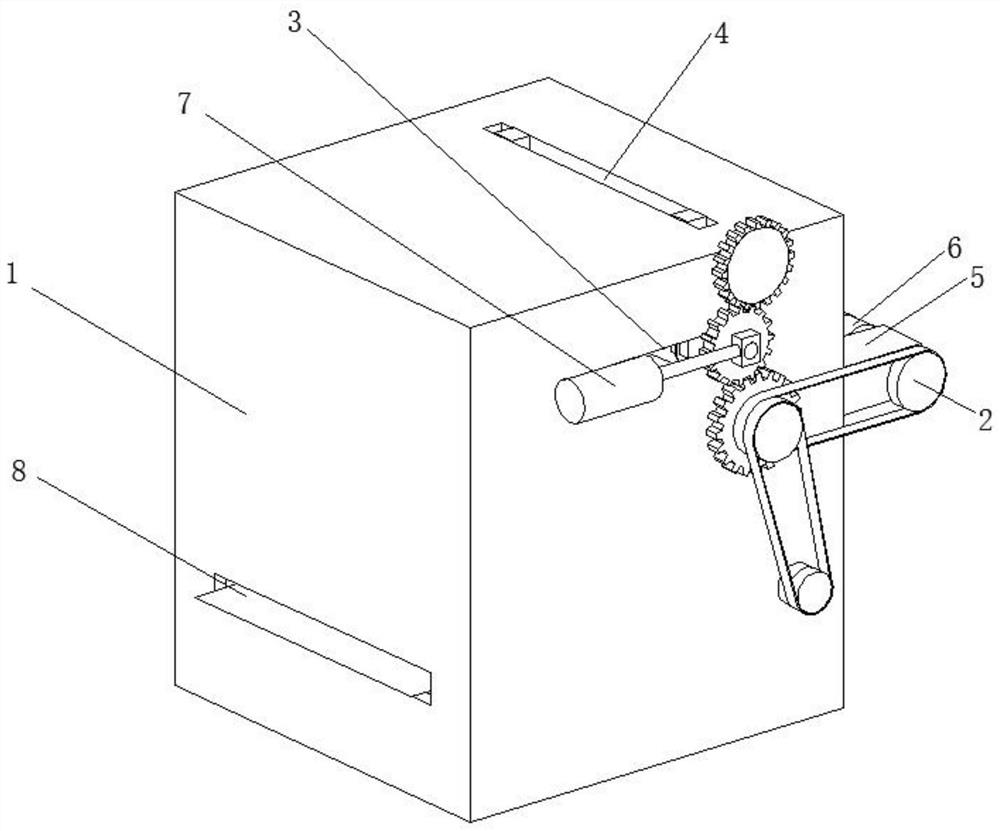

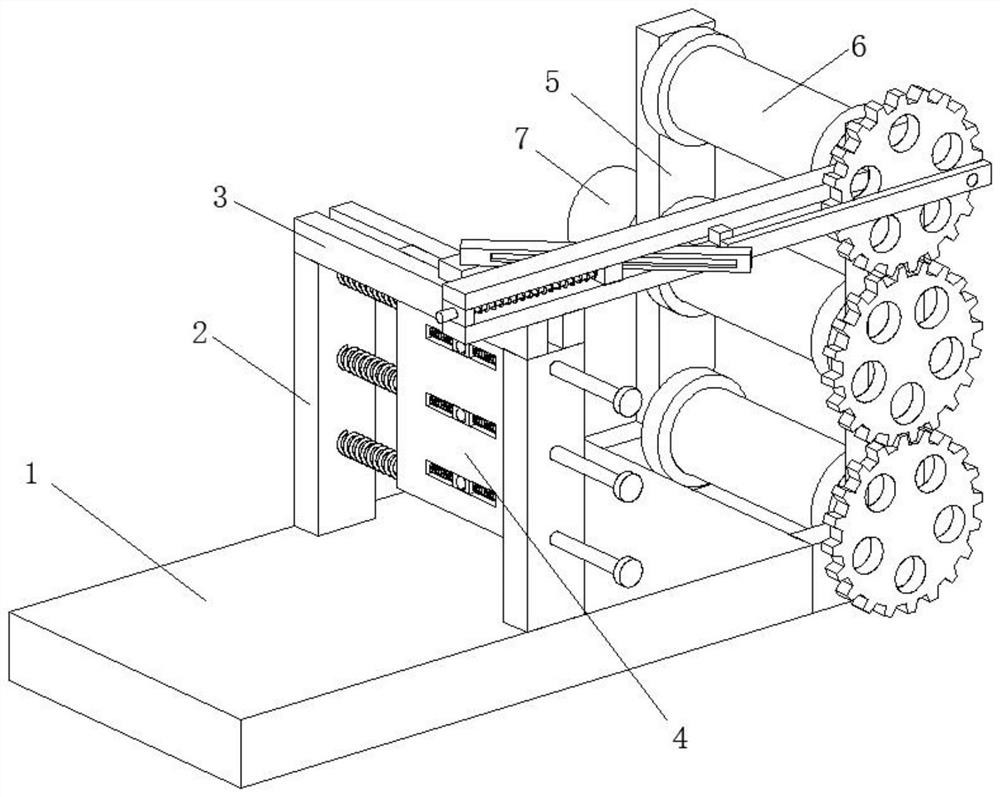

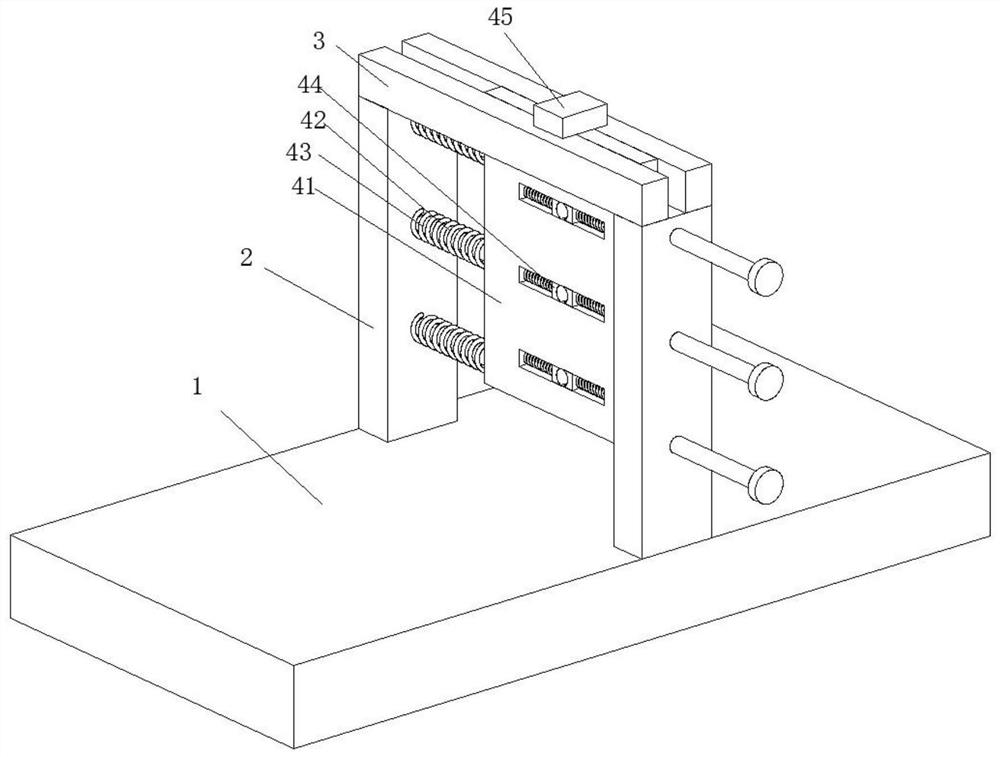

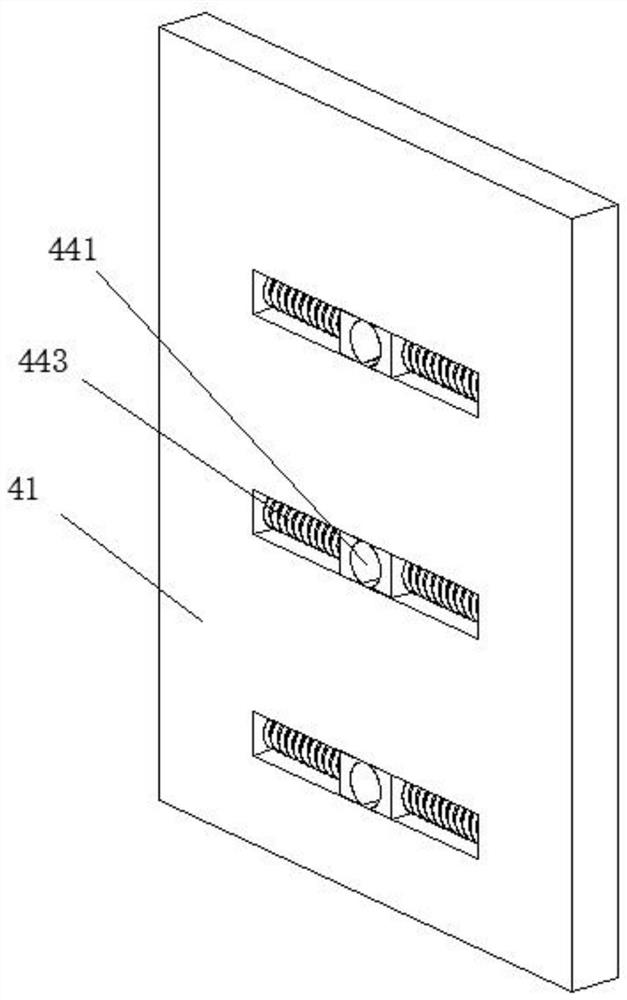

Stamping die capable of being rapidly fixed

The invention relates to the technical field of stamping dies, and discloses a stamping die capable of being rapidly fixed. The stamping die comprises a supporting plate, the right side of the supporting plate is connected with a box body and a workbench through bolts, the workbench is located below the box body, the left side of the supporting plate is provided with a transmission mechanism, the top of the workbench is provided with two sliding grooves, a fixing mechanism is arranged on the right side of the supporting plate, a feeding mechanism is arranged at the top of the workbench, the feeding mechanism is located between the two sliding grooves, an upper die is arranged at the bottom of the fixing mechanism, a lower die is fixedly installed at the top of the workbench, and clamping mechanisms are arranged on the inner walls of the sliding grooves. According to the stamping die, a mold on the workbench can be automatically clamped and fixed through the transmission mechanism, the fixing mechanism and the clamping mechanisms, so that manual clamping and fixing of workers are not needed, the clamping time can be greatly shortened, the working efficiency is improved, the labor intensity of the workers is reduced, and the practicability is greatly improved.

Owner:金城宝五金(深圳)有限公司

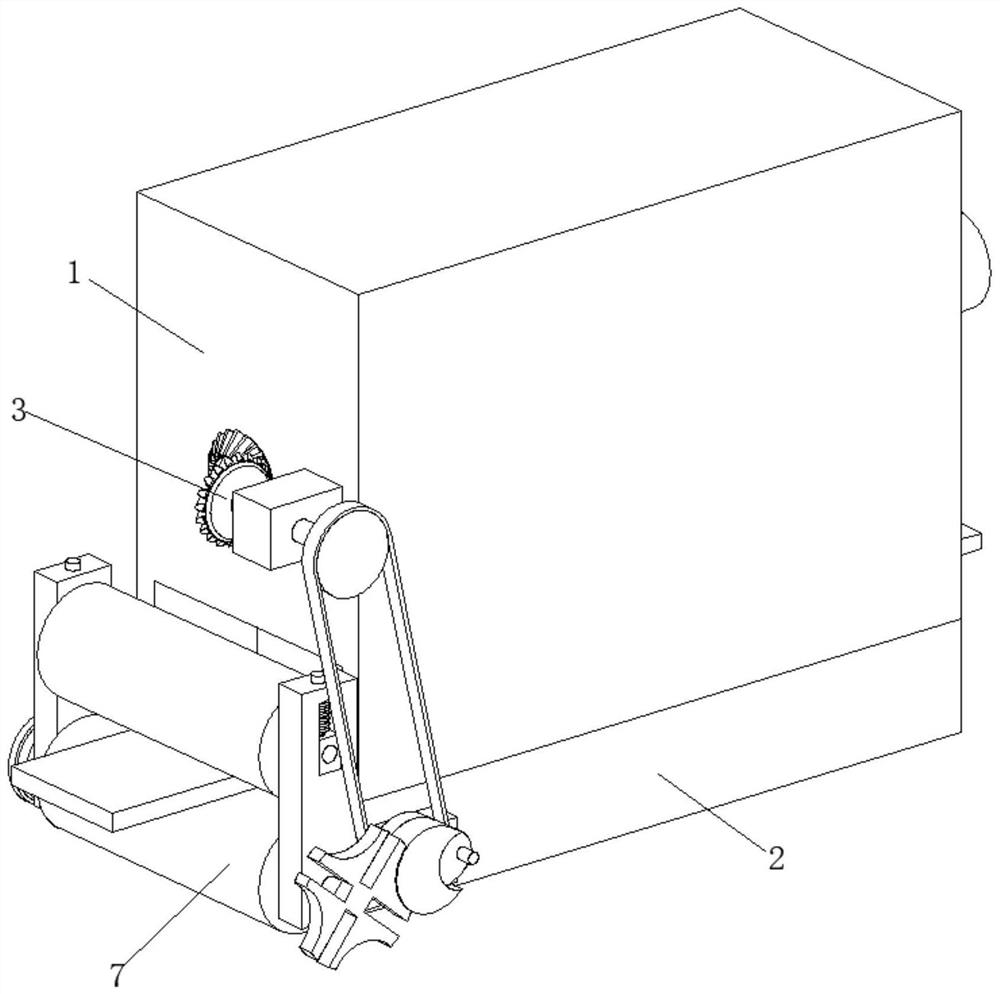

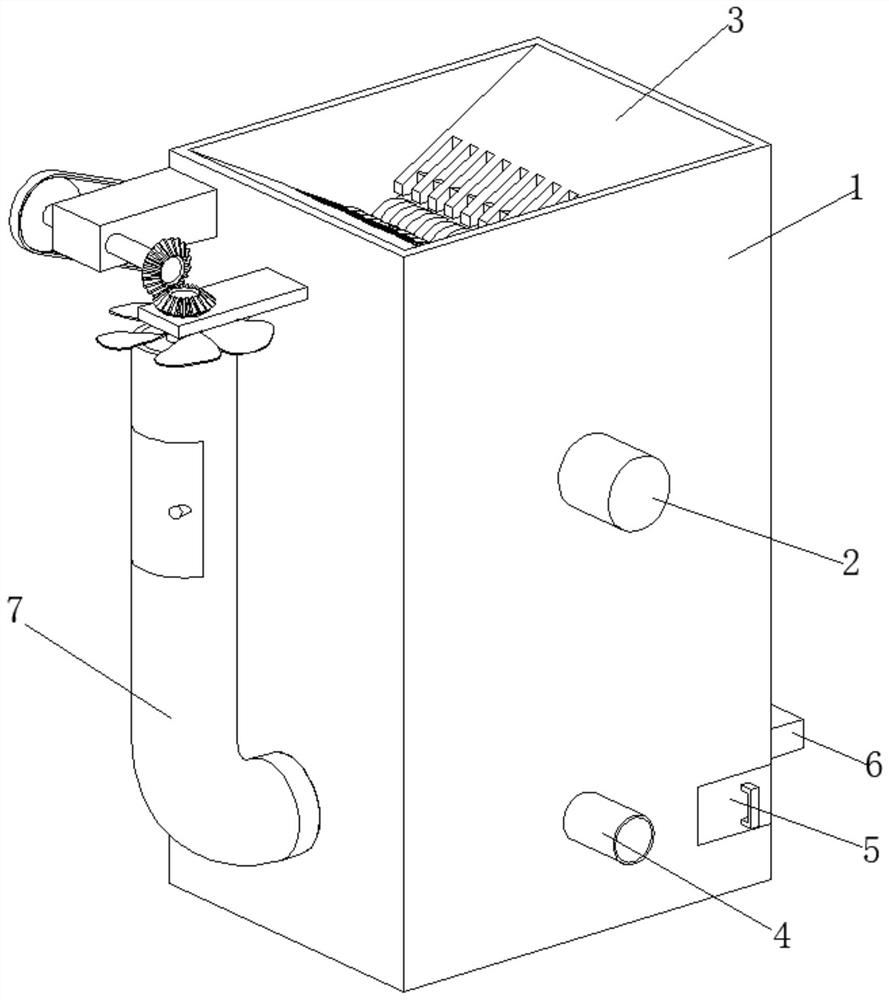

Continuous forging device with automatic cleaning function

ActiveCN112719183AShorten forging timeImprove work efficiencyDrop hammersHammer drivesEngineeringWorkbench

The invention relates to the technical field of forging equipment, and discloses a continuous forging device with an automatic cleaning function. The device comprises a box body, a workbench is welded at the bottom of the box body, a transmission mechanism is arranged at the front part of the box body, two discharge grooves are formed in the top of the workbench, and a plurality of limiting columns are welded on the inner wall of the box body. A forging mechanism is arranged on the surfaces of the limiting columns, a feeding mechanism is arranged at the front part of the workbench, and a cleaning mechanism is arranged at the rear part of the box body. According to the continuous forging device, through cooperative work of the transmission mechanism and the forging mechanism, a steel plate can be continuously forged, so that the situation that forging equipment is replaced after forging is conducted once is avoided, the stroke of the forging equipment is adjusted, forging time can be greatly shortened, the working efficiency is improved, the practicability is greatly improved, the cleaning mechanism can clean the finally forged steel plate, manual cleaning by workers is not needed, and the labor intensity of the workers is reduced.

Owner:山东圣利锻造有限公司

Disinfection and classification equipment for anesthesiology department and use method thereof

ActiveCN112517381AReduced risk of punctureReduce labor intensitySievingScreeningAnesthetic departmentProcess engineering

The invention discloses disinfection and classification equipment for the anesthesiology department. The disinfection and classification equipment comprises a classification box, the rear portion of the classification box is connected with a cleaning box through bolts, the bottom of the classification box and the bottom of the cleaning box are connected with a drying box and a disinfection box through bolts correspondingly, and a plurality of supporting plates are inserted into the inner wall of the classification box; and a water outlet pipe is communicated with the interior of the cleaning box, a transmission mechanism is arranged at the front part of the cleaning box, connecting mechanisms are arranged at the rear parts of the cleaning box and the disinfection box, and a drying mechanism is arranged in the drying box. According to the disinfection and classification equipment, used needles and syringes can be separated and classified through the classification box, and then the syringes can be classified again according to the sizes during drying, so that manual separation by medical staff is not needed; and the separated syringes can be automatically cleaned and transported into the disinfection box through the transmission mechanism to be disinfected, so that manual cleaning and transportation by the medical personnel are not needed, the labor intensity is reduced, and theworking efficiency is improved.

Owner:洛阳嘉泽医疗科技有限公司

High-speed intelligent laser cutting equipment and application method thereof

PendingCN113385832AReduce labor intensityRealize continuous processingLaser beam welding apparatusLaser cuttingMachining

The invention relates to the technical field of laser cutting, and discloses high-speed intelligent laser cutting equipment. The equipment comprises a mounting plate, wherein a feeding mechanism and a cutting mechanism are arranged at the top of the mounting plate, and a limiting mechanism is arranged on the surface of the cutting mechanism. According to the high-speed intelligent laser cutting equipment andan application method thereof, through cooperative work of the feeding mechanism, the cutting mechanism and the limiting mechanism, continuous machining of the device can be achieved, assistance of workers beside is not needed, so that the production and machining speed of the device can be greatly increased; the intelligent automation degree of the device is high, and much labor cost can be saved; the limiting mechanism can automatically clamp and fix a workpiece, the situation that the cutting size does not conform to the technology due to shaking during cutting is prevented, the labor intensity of the workers can be reduced, and the practicability of the device is greatly improved; and the feeding mechanism can be automatically adjusted according to the thickness of a machined workpiece, and the practicability is improved.

Owner:孙明元

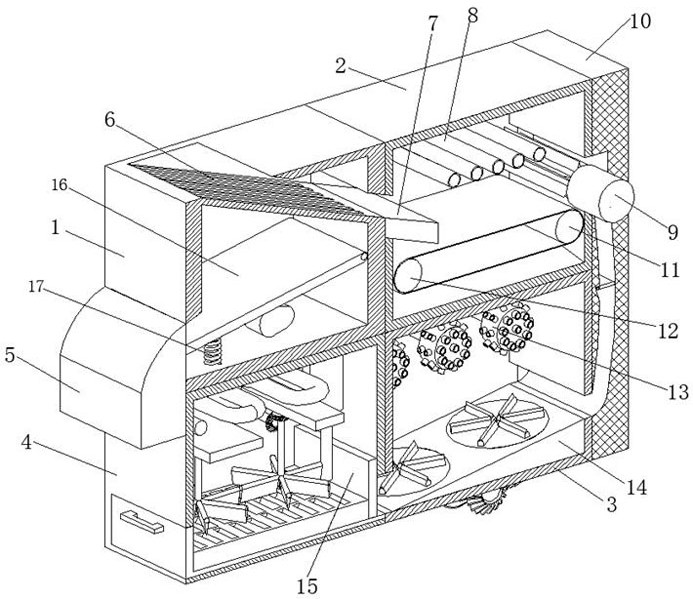

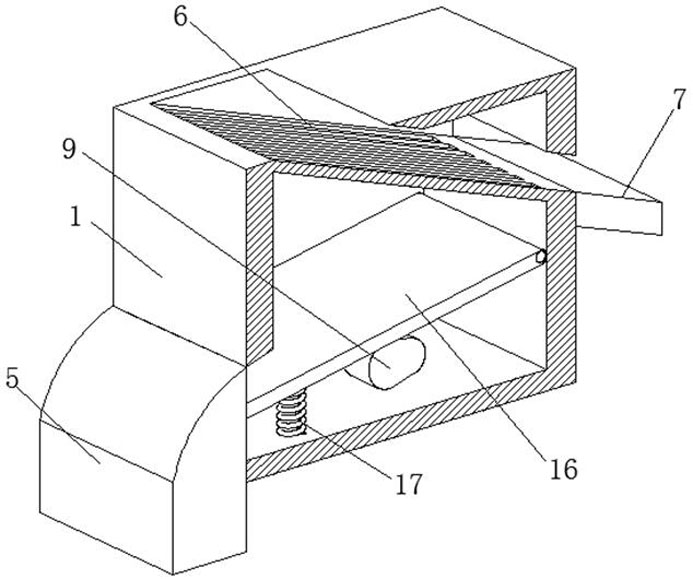

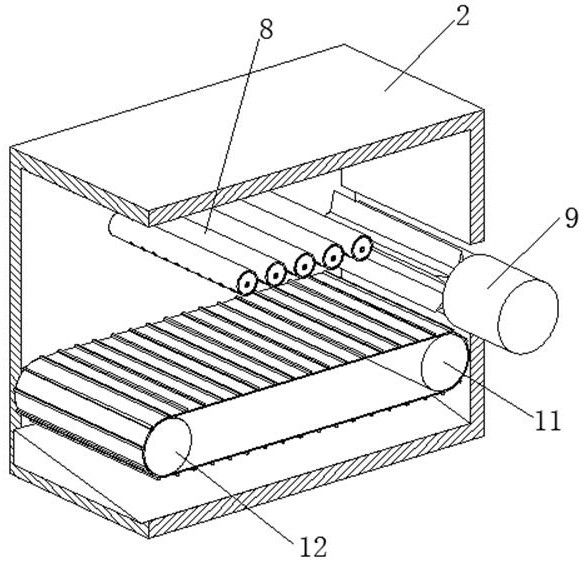

Cleaning and maintaining mechanism for medical apparatus and instruments

ActiveCN112691957AReduce labor intensityReduce the risk of infectionCleaning using toolsDrying machines with progressive movementsMedicineUltraviolet lights

The invention relates to the technical field of medical apparatus and instruments, and discloses a cleaning and maintaining mechanism for medical apparatus and instruments. The cleaning and maintaining mechanism for the medical apparatus and instruments comprises a box body, a cleaning mechanism is arranged in the box body, a shell is welded to the top wall in the box body, a magnet is rotatably connected to the inner wall of the shell, and a transmission mechanism is arranged on the right side of the box body. A transmission roller and a driven roller are rotationally connected to the inner wall of the box body, an ultraviolet lamp and a heating pipe are fixedly connected to the inner wall of the box body, a discharging mechanism is arranged on the front portion of the box body, and an inclined plate and an inclined block are welded to the inner wall of the box body. According to the cleaning and maintaining mechanism for the medical apparatus and instruments, scalpels and operating forceps can be automatically cleaned through the cleaning mechanism and the transmission mechanism, manual cleaning is not needed, the risk that the scalpels and the operating forceps are scratched by apparatus and instruments is reduced, the safety is high, the labor intensity of medical staff is reduced, and the cleaned medical apparatus and instruments can be dried and disinfected through the ultraviolet lamp and the heating pipe, thus integration of cleaning, drying and disinfecting is achieved.

Owner:QINGDAO MUNICIPAL HOSPITAL

Medical waste treatment equipment with cleaning function

InactiveCN112902179AReduce the risk of contact infectionImprove work efficiencyElectrostatic separationBlast-producing apparatusMedical wasteEnvironmental engineering

The invention relates to the technical field of waste treatment, and discloses medical waste treatment equipment with a cleaning function. The equipment comprises a box body, wherein a transmission mechanism is arranged on the right side of the box body, two sliding blocks are welded on the inner wall of the box body, the right side of the box body communicates with a feeding pipe, the feeding pipe is positioned below the transmission mechanism, a sliding block is slidably connected to the inner wall of the rear portion of the box body, an electromagnet is fixedly installed on the rear portion of the box body, a purification mechanism is arranged on the front portion of the box body, a first smashing roller and a second smashing roller are rotatably connected to the inner wall of the box body, a treatment box is fixedly installed on the bottom wall inside the box body, and an inclined block is welded to the top of the treatment box. According to the equipment, cleaning liquid is injected into the feeding pipe, and then the inner wall of the treatment box can be automatically cleaned through the transmission mechanism, so that manual cleaning by workers is not needed, the risk of contact infection is reduced, and the working efficiency is further improved.

Owner:邵欠欠

Non-woven fabric cutting leftover material recycling and smashing device

ActiveCN112495539AEasy to crushImprove crushing effectPlastic recyclingGrain treatmentsStructural engineeringNonwoven fabric

The invention relates to the technical field of non-woven fabrics, and discloses a non-woven fabric cutting leftover material recycling and smashing device. The non-woven fabric cutting leftover material recycling and smashing device comprises a box body, wherein the inner wall of the box body is rotatably connected with a winding drum, a transmission roller and a guide roller separately; a transmission mechanism is arranged at the right side of the box body; a recycling box is welded on the bottom of the box body; the bottom of the box body is in sliding connection with a collecting box; thesurfaces of the winding drum, the transmission roller and the guide roller are movably connected with cloth; a smashing mechanism is arranged inside the recycling box; and an edge cutting mechanism isarranged on the bottom wall inside the box body. According to the non-woven fabric cutting leftover material recycling and smashing device disclosed by the invention, the transmission mechanism, theedge cutting mechanism and the smashing mechanism are matched to operate, so that leftover materials are directly smashed after the cloth is subjected to edge cutting, and as a result, the problem that the leftover materials are accumulated and are difficult to recycle and clear during recycling is prevented; and the collecting box can be used for boxing and collecting the smashed leftover materials, so that the leftover materials are conveniently transported after being smashed.

Owner:浙江百联无纺科技有限责任公司

BMS new energy battery positioning and capping device

ActiveCN112537623AIncrease investmentEasy transferAssembling battery machinesFinal product manufactureNew energyStructural engineering

The invention relates to the technical field of BMS, and discloses a BMS new energy battery positioning and capping device. The BMS new energy battery positioning and capping device comprises two fixing plates, two rollers are rotatably connected between the two fixing plates, the surfaces of the two rollers are in transmission connection through a conveying belt, and supporting plates are weldedto the surfaces of the two fixing plates; and a mounting plate is welded to the tops of the supporting plates, a positioning mechanism and a capping mechanism are arranged at the top of the mounting plate correspondingly, and a transmission mechanism is arranged on the left side of each fixing plate. A battery box can be automatically positioned and straightened through the positioning mechanism,so that operation is convenient when the battery box is conveyed to the next procedure to be capped; and the situation that the battery box is not straight, consequently, a top cover cannot be completely closed, and then the rework rate is increased and the cost investment is increased is prevented, the battery box obtained after positioning can be automatically capped through the capping mechanism, manual capping of workers is not needed, and the working efficiency is improved.

Owner:南京金邦动力科技有限公司

Textile device capable of conveniently flattening and rolling textile fabric

PendingCN112141775AAchieve cleanupAvoid dirtMechanical cleaningPressure cleaningTextile technologyMechanical engineering

The invention relates to the technical field of textiles, and discloses a textile device capable of conveniently flattening and rolling textile fabric. The textile device comprises a box body, whereina transmission mechanism is arranged on the right side of the box body, a dust collection mechanism and an ironing mechanism are correspondingly arranged on the left side of the box body, and the dust collection mechanism is located in front of the ironing mechanism; and a transmission roller, a lower roller, an upper roller and a rolling roller are rotationally connected to the inner wall of thebox body, wherein the rolling roller is located behind the transmission roller, and cloth is movably connected to the surfaces of the transmission roller, the lower roller, the upper roller and the rolling roller. According to the textile device capable of conveniently flattening and rolling the textile fabric, through cooperated operation between the transmission mechanism and the dust collection mechanism, the cloth can be cleaned, so that the cloth is prevented from being rolled together with dust during rolling, and the cloth is further prevented from being contaminated; and in addition,the cloth with wrinkles can be ironed by the ironing mechanism, so that the situations that finished cloth is uneven and then unqualified products are produced due to the fact that the cloth with thewrinkles get rolled are prevented.

Owner:ZHEJIANG MEILAIYA TEXTILE

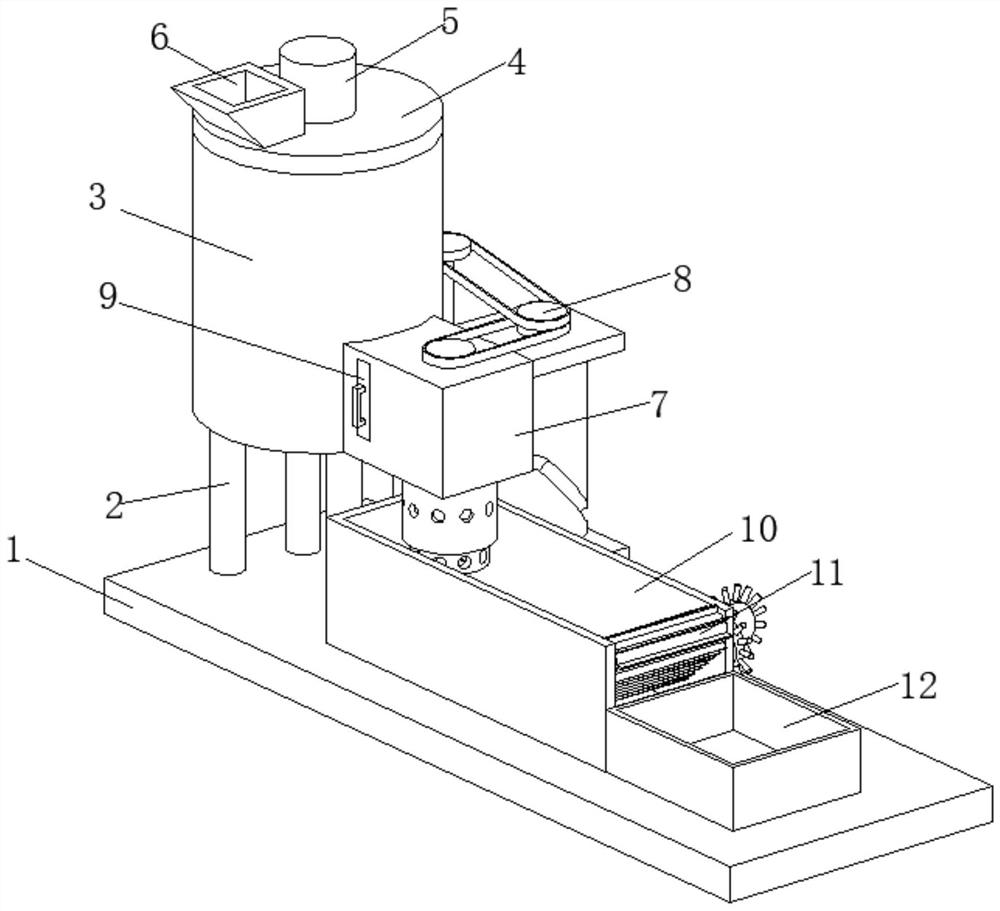

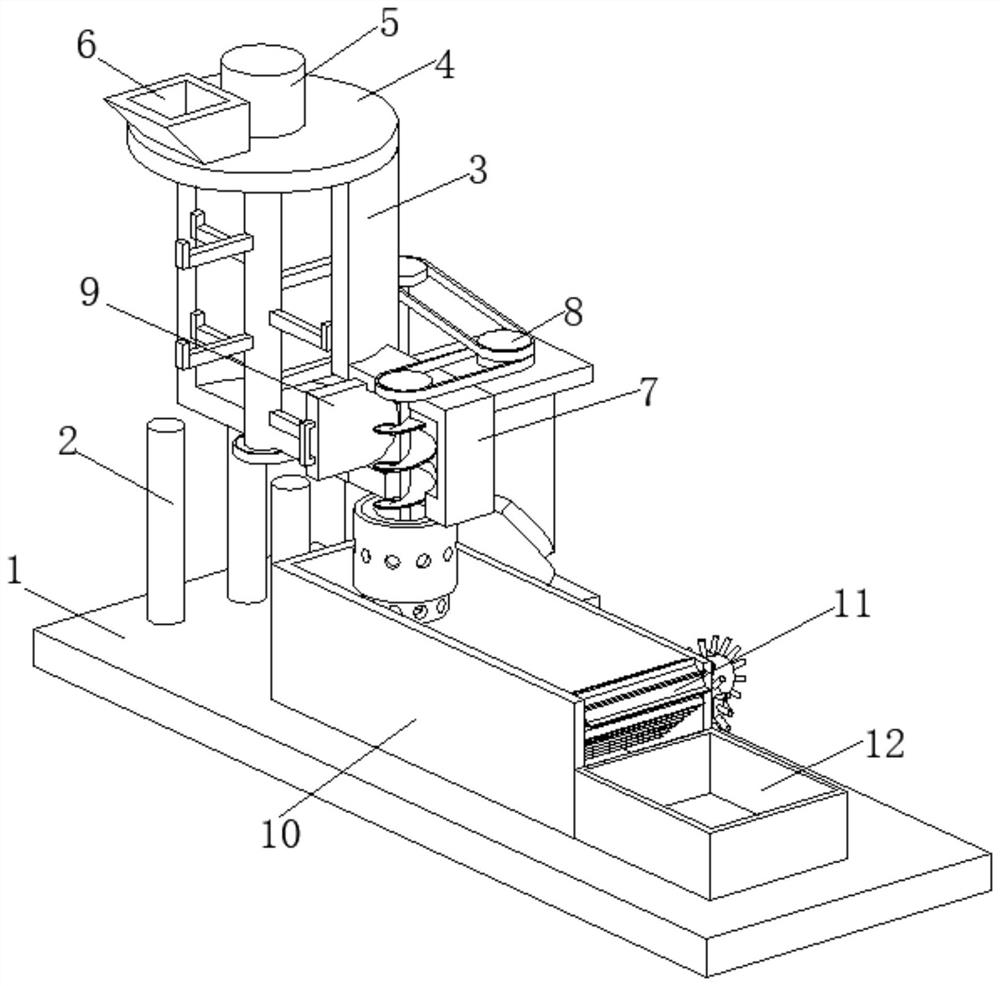

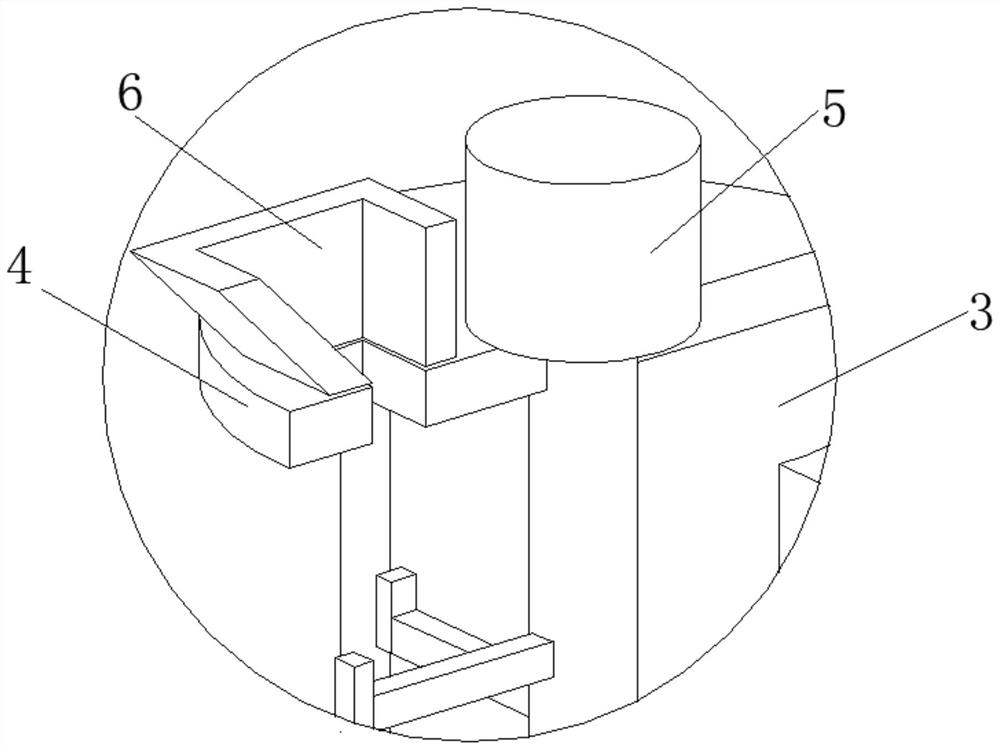

Ball food forming and processing equipment

PendingCN113349236AReduce investmentReduce labor intensityHollow article cleaningGrain treatmentsWork productivityIndustrial engineering

The invention relates to the technical field of food processing, and discloses ball food forming and processing equipment. The equipment comprises a base, four supporting columns are welded to the top of the base, a tank body is welded to the top ends of the supporting columns, a top cover is connected to the top of the tank body through bolts, a smashing mechanism is arranged at the top of the top cover, the top of the top cover communicates with a feeding frame, the surface of the tank body communicates with a connecting block, a transmission mechanism is arranged at the top of the connecting block, a pulling plate is slidably connected to the inner wall of the connecting block, the top of the base is connected with a box body and a collecting box through bolts, the added meat or food can be automatically smashed through the smashing mechanism and the transmission mechanism, balls are squeezed, so that the integrated design of meat mincing and ball squeezing is achieved, one working procedure is reduced, the cost investment can be reduced, the working efficiency is greatly improved, manual ball squeezing by workers is not needed, and the labor intensity of the workers is greatly reduced.

Owner:王彦玺

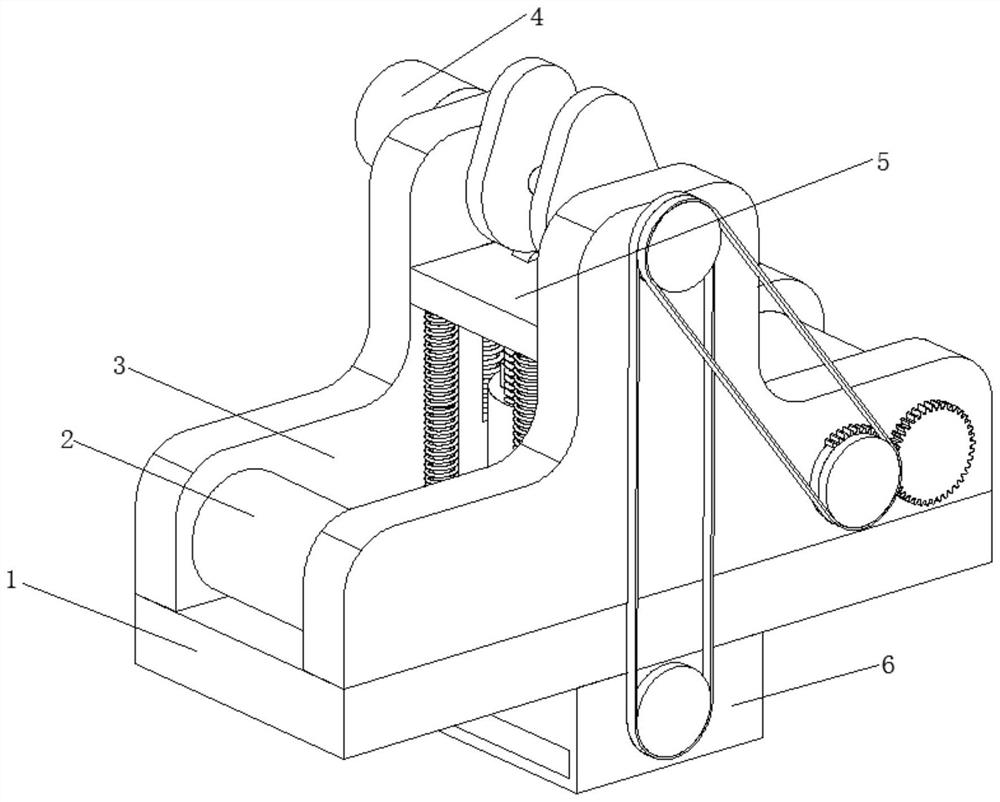

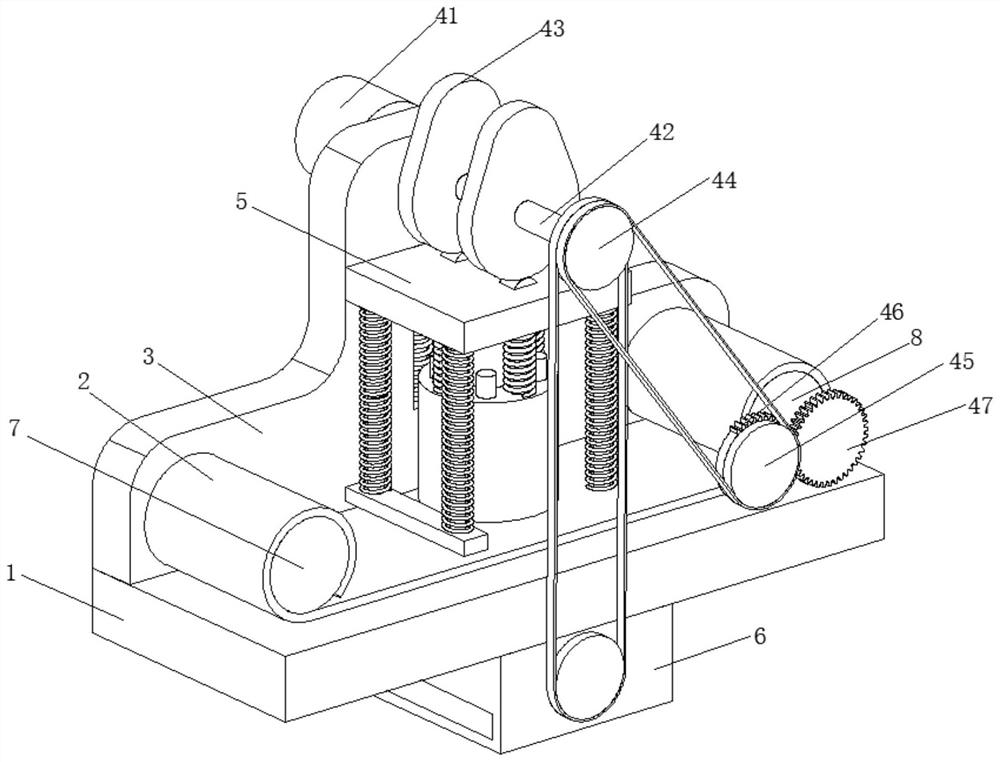

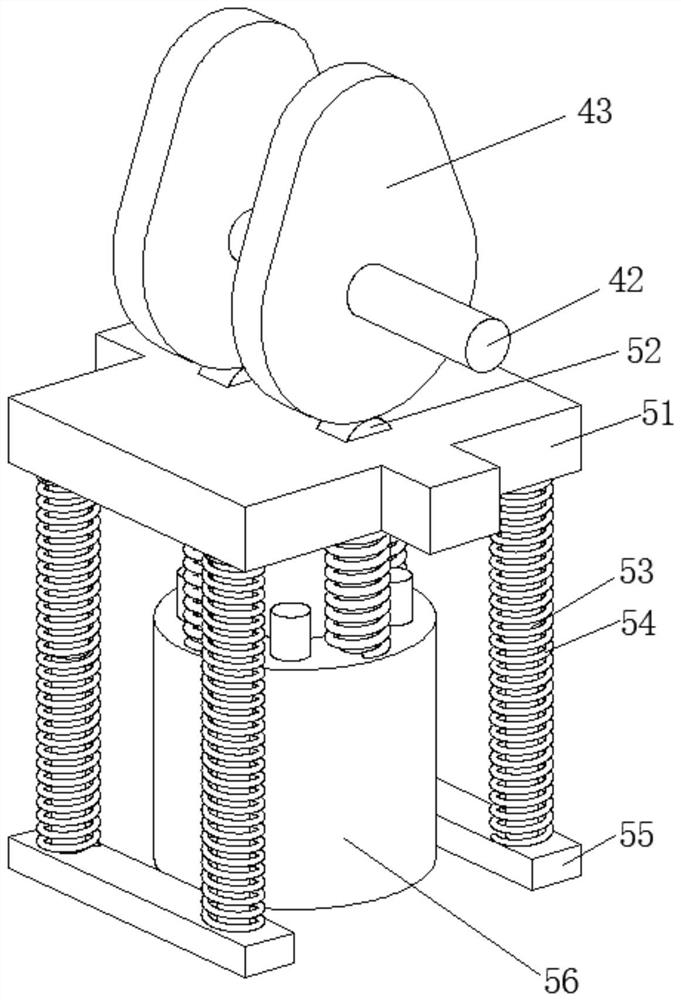

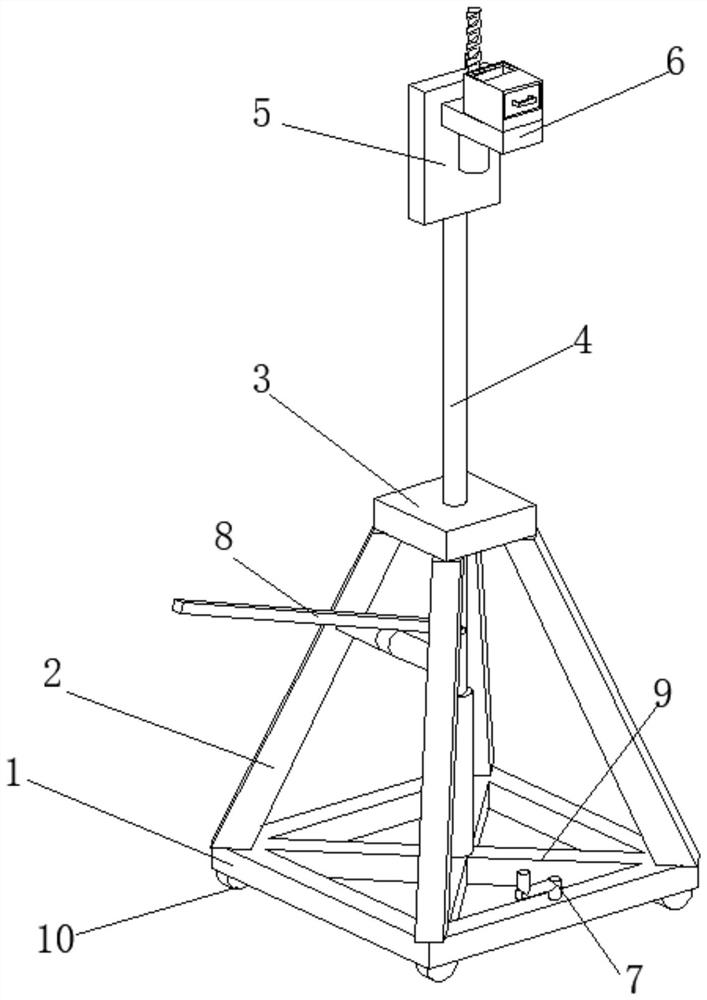

Small material crane and working method thereof

ActiveCN112758818ASmall footprintImprove space utilizationTravelling gearCranesMarine engineeringBolt connection

The invention relates to the technical field of cranes, and discloses a small material crane. The small material crane comprises a box body, a fixing rod is rotatably connected to the inner wall of the box body, a storage box is welded to the left end of the fixing rod, a cargo boom is slidably connected to the inner wall of the storage box, an electric hoist is connected to the upper surface of the storage box through a bolt, a storage mechanism is arranged on the lower surface of the cargo boom, a handle is welded to the rear portion of the box body, a top cover is rotationally connected to the top of the box body, a transmission mechanism is arranged on the inner wall of the box body and located in front of the fixing rod, a transmission rod is rotationally connected to the inner wall of the box body and located below the transmission mechanism, and rolling wheels are arranged at two ends of the transmission rod. According to the small material crane and a working method thereof, the crane can be folded and stored through the storage mechanism, so that the occupied space of the crane can be reduced when the crane is not used, and the reasonable utilization space can be increased.

Owner:上海甲佳智能科技有限公司

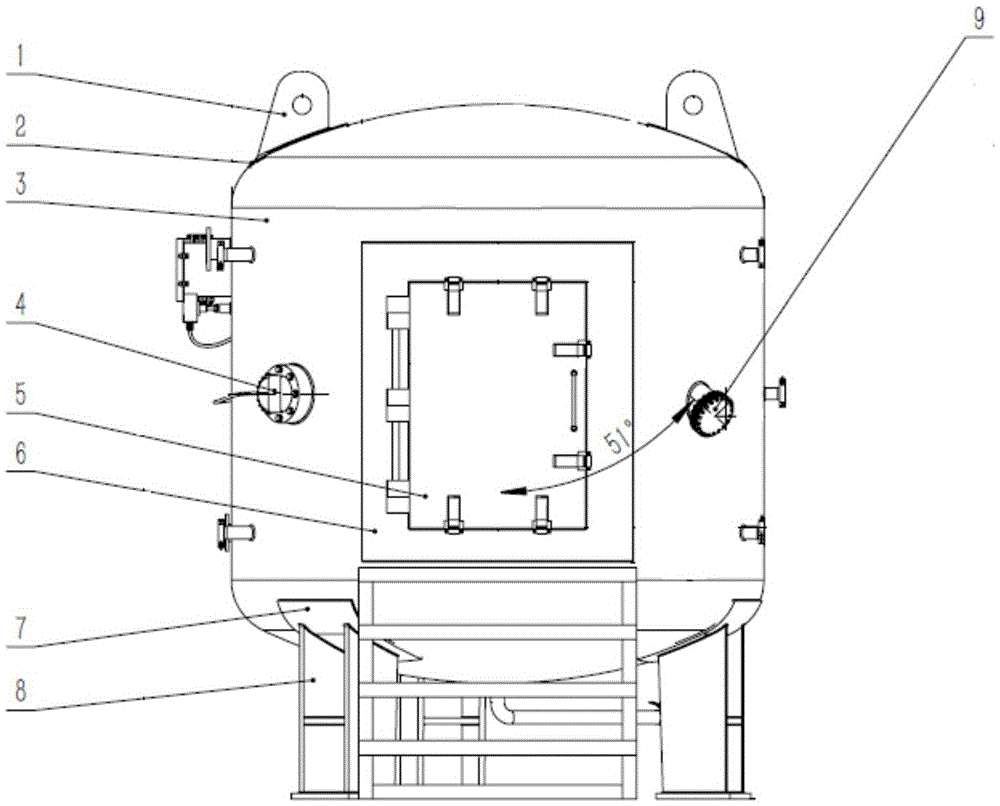

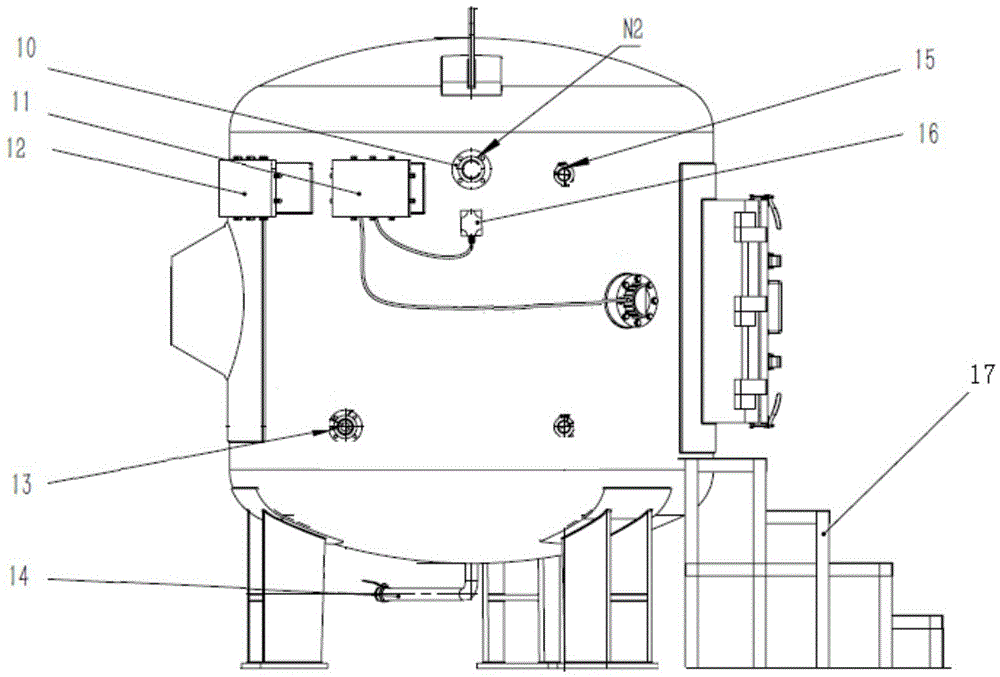

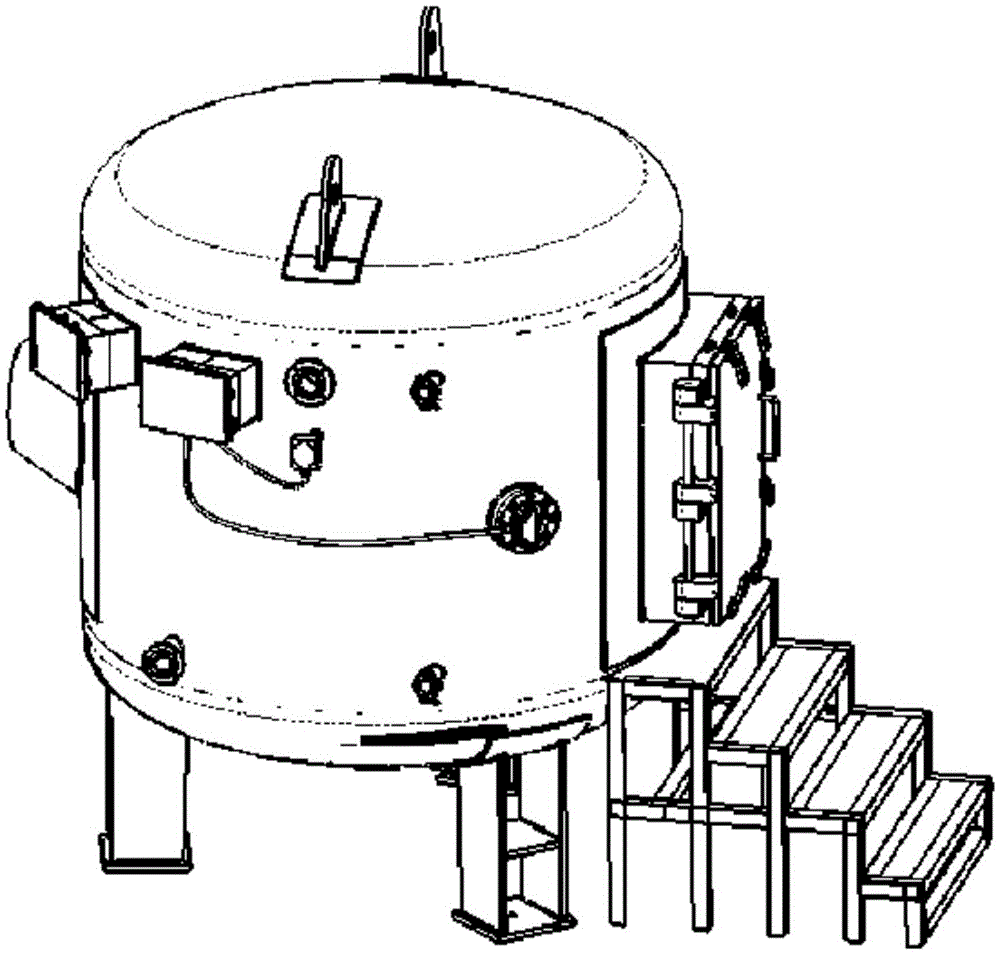

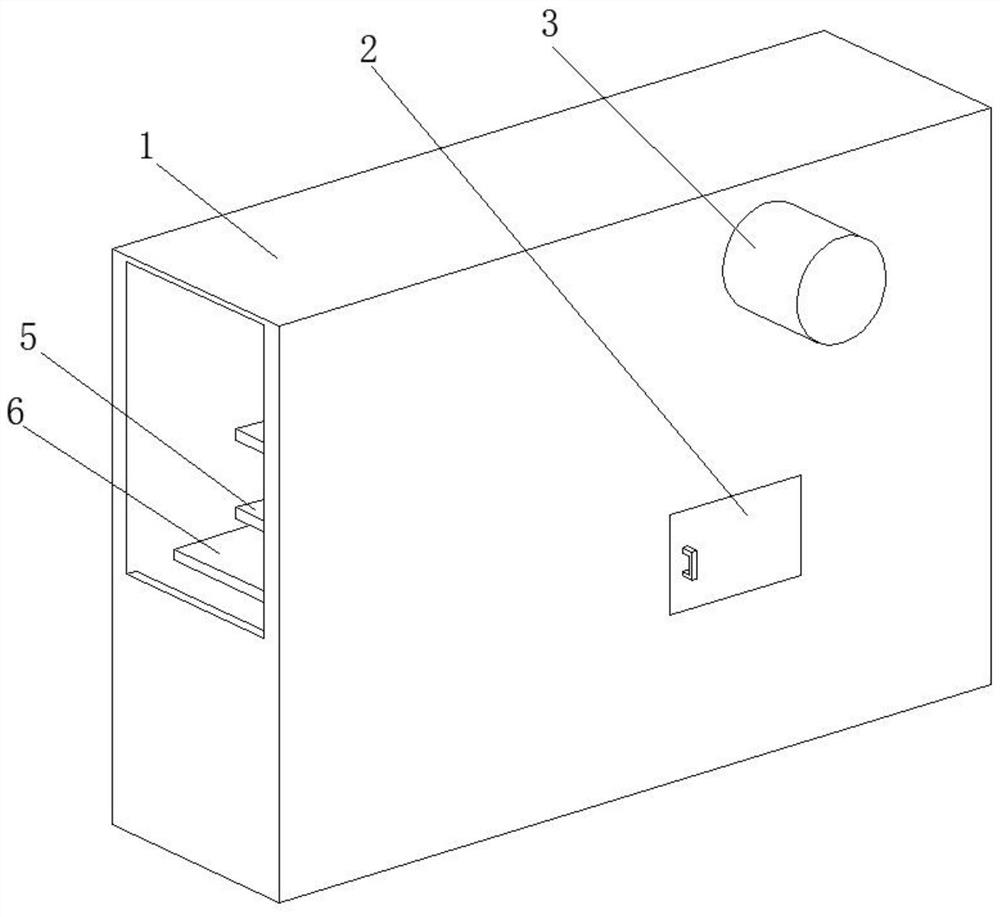

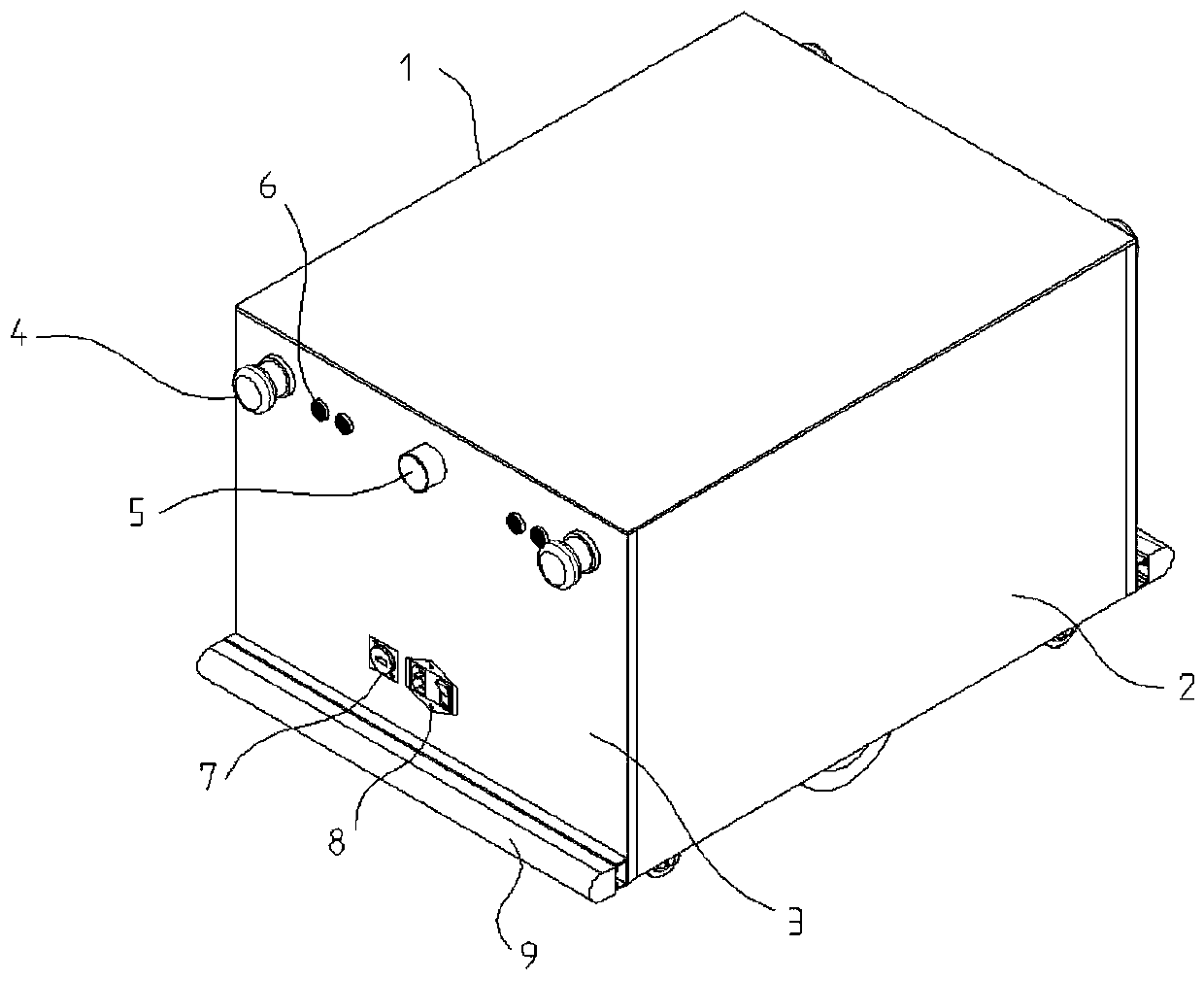

Micro multifunctional environment climate simulation device for high voltage tests

InactiveCN106814264AReduce testing costsImprove test efficiencyEnvironmental/reliability testsEngineeringVacuum pump

The invention provides a micro multifunctional environment climate simulation device for high voltage tests. The device comprises a tank, and a temperature adjusting device, a spraying device and a vacuum-pumping device which are mounted on the tank, and further comprises a weather monitoring device and a central control system, wherein the weather monitoring device is mounted on the tank and is used for monitoring weather data in the tank and feeding back the weather data to the central control system, and the central control system is arranged outside the tank and is used for receiving the weather data fed back by the weather monitoring device and regulating the temperature adjusting device, the spraying device and the vacuum-pumping device according to the weather data so as to simulate the environment climate in the tank in accordance with demands. The device is advantaged in that environment parameters can be precisely controlled, multiple types of climate conditions can be simulated, precise control on multiple weather parameters can be realized, the device can be applied to air gap and surface discharge characteristics and mechanism researches, problems of difficulty in precise control on indoor environment factors of the environment climate and high test cost in the prior art are solved, and test efficiency and accuracy are substantially improved.

Owner:CHINA ELECTRIC POWER RES INST +1

Method capable of quickly fixing stamping die

The invention relates to the technical field of stamping dies, and discloses a method capable of rapidly fixing a stamping die. The method comprises the following steps that the die with an upper die and a lower die in a die assembly state is placed on a workbench, is roughly placed in the middle position and does not need to be accurately placed, the die can slide on the workbench, a motor drives a rotating shaft to rotate through a transmission mechanism, the rotating shaft drives a cam to rotate, the cam drives a top plate to move downwards, the top plate drives a telescopic column and a reset spring to contract, meanwhile, the top block is driven to move downwards, the top block drives a fixing plate to move downwards, the fixing plate drives a positioning column to move downwards, and through a chamfer below the positioning column, when the positioning column moves downwards to penetrate through the inner wall of the upper die, the whole die can be driven to conduct position adjustment, so that the die is moved to the center of the workbench; and after the die moves to a proper position, the upper die is fixed by two clamping plates, and the lower die is fixed by a clamping mechanism, so that the rapid fixation of the die is realized. According to the method, manual clamping and fixing of workers are not needed, and the clamping time can be greatly shortened.

Owner:佑达光电科技(苏州)有限公司

Shaping and edge cutting equipment of textile machinery

PendingCN112173798AAvoid curlAvoid flyingSevering textilesHeating/cooling textile fabricsTextile technologyStructural engineering

The invention relates to the technical field of textile, and discloses shaping and edge cutting equipment of textile machinery. The shaping and edge cutting equipment comprises a box body, wherein a transmission mechanism is arranged on the right side of the box body, a sliding groove is formed in the right side of the box body, a sliding rail is arranged at the top of the box body, supporting blocks are welded to the rear part of the box body, a winding roller is rotationally connected between the two supporting blocks, an edge cutting mechanism is arranged on the right side of the box body,cloth is fixedly connected to the surface of the winding roller, a shaping mechanism is arranged on the inner wall of the box body, and a supporting roller is rotationally connected to the inner wallof the box body. According to the shaping and edge cutting equipment, the edge cutting distance can be adjusted through the cooperative use of the transmission mechanism and an adjusting mechanism, sothat the cloth with different edge cutting sizes can be adapted, and then the application range of the device is greatly increased; and the shaping mechanism can prevent the phenomenon that the edgeof the cut edge of the cloth is curled after the edge is cut, so that the cloth with the cut edge is unqualified, and unnecessary loss is caused.

Owner:ZHEJIANG MEILAIYA TEXTILE

Paving bricks for glass kiln and production process thereof

ActiveCN109095902AGood high temperature resistance, corrosion resistanceImproved thermal shock stabilityGlass furnace apparatusGlass productionSodium carbonateTitanium dioxide

The invention provides paving bricks for a glass kiln and a production process thereof. The paving bricks are prepared from the following raw materials in parts by weight: 30-50 parts of natural zircon sand, 30-50 parts of aluminum oxide powder, 1-3 parts of sodium carbonate, 1-5 parts of fluorite powder, 2-8 parts of silica powder and 8-16 parts of titanium dioxide. By controlling the proportionof the components reasonably and selecting an insulating material reasonably, the prepared paving bricks have excellent performance. In the embodiment process, the sand form of the prepared sand is improved. 15 paving bricks can be produced at one time in one insulating oven after the sand form is improved. The paving bricks are good in quality and high in percent of pass. In the production process, the paving bricks need not to be melted frequently, so that scattering of a feed liquid is reduced, the casting time is shortened and the production efficiency is improved.

Owner:江苏徐耐新材料科技股份有限公司

Intelligent new textile material cutting device for textiles

ActiveCN112482006AReduce labor intensityImprove work efficiencyMechanical cleaningPressure cleaningTextile technologyMechanical engineering

The invention relates to the technical field of textiles, and discloses an intelligent new textile material cutting device for textiles. The intelligent new textile material cutting device comprises abox body, wherein a fixing mechanism is arranged at the top of the box body, a supporting plate is arranged on the inner wall of the box body, a sliding groove is formed in the top of the supportingplate, a cutting mechanism is arranged on the inner wall of the sliding groove, a transmission mechanism is arranged on the right side of the box body, a dust removal mechanism is arranged in the boxbody, a winding drum is arranged on the inner wall of the box body, and the winding drum is located on the rear portion of the supporting plate. Cloth can be automatically cut from left to right or from right to left through the cutting mechanism, and therefore manual cutting by workers is not needed, the working efficiency is greatly improved, the labor intensity of workers is reduced, the practicability is greatly improved, the cloth can be pressed and fixed through the fixing mechanism before being cut, and the problem that a cut is uneven or not cut off due to the fact that the cloth movesin a cutting process is solved.

Owner:山东圣豪家纺有限公司

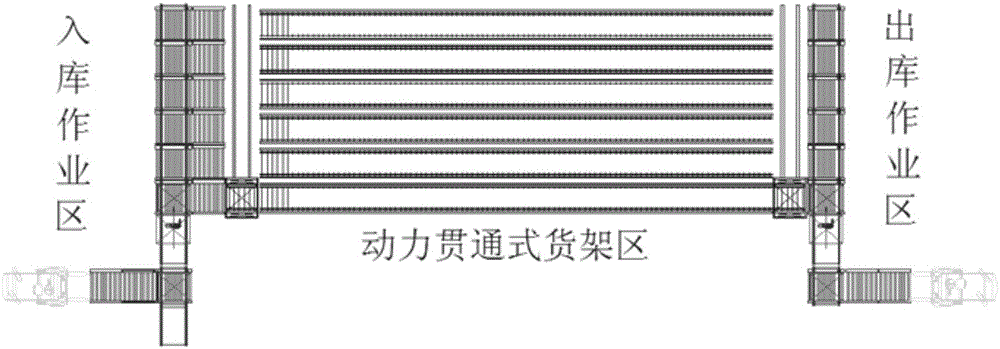

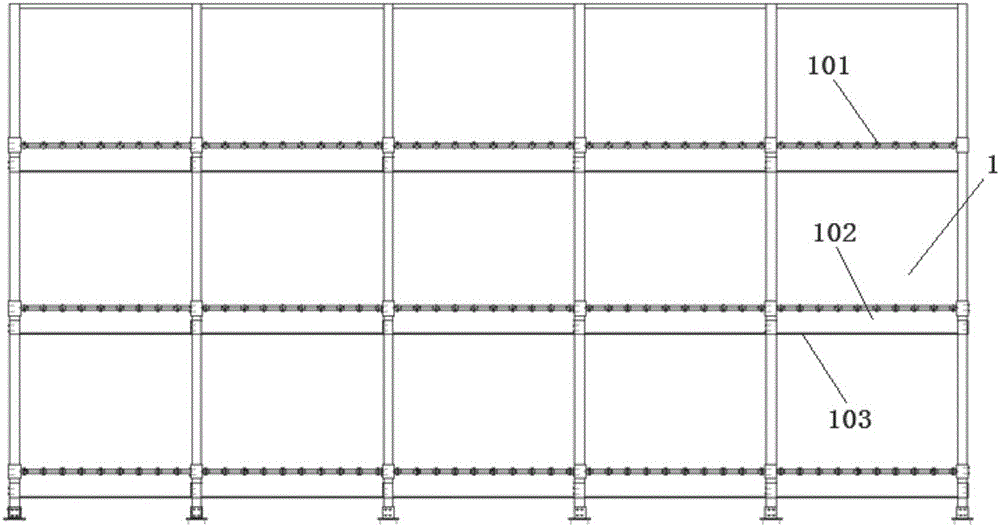

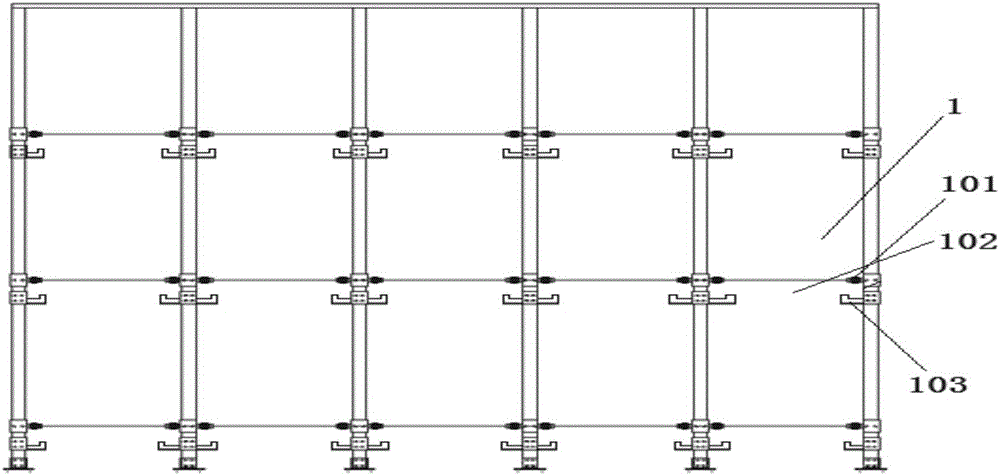

A high-density forward-moving agile storage and sorting system and its working method

InactiveCN104443993BImprove space utilizationSave physical spaceStorage devicesPhysical spaceHigh density

The invention relates to a high-density forward-movement prompt storage and sorting system and a working method of the high-density forward-movement prompt storage and sorting system. The high-density forward-movement prompt storage and sorting system comprises a power drive-through type goods shelf, lifting shuttle vehicles and push type self-propelled railway vehicles, wherein the lifting shuttle vehicles are arranged on the two sides of the power drive-through type goods shelf and used for lifting trays to the inlet sides or the outlet sides of goods aisles; the push type self-propelled railway vehicles place the trays on tray conveying mechanisms to put goods into storage; the push type self-propelled railway vehicles operate to the positions below the trays in rail mechanisms and move the trays to the lifting shuttle vehicles to deliver the goods from storage. Compared with a traditional roadway stacking goods shelf, the system saves physical space and increases the space utilization rate of a stereoscopic warehouse; meanwhile, the high-density forward-movement prompt storage and sorting system is high in automation degree, saves manpower and material resources, shortens working time and improves working efficiency.

Owner:SHANDONG UNIV

Automatic feeding and punching device

ActiveCN112605244AReduce investmentImprove practicalityMetal-working feeding devicesPositioning devicesElectric machineryIndustrial engineering

The invention relates to the technical field of punching equipment, and discloses an automatic feeding and punching device. The automatic feeding and punching device comprises a box body, a rotating door is rotatably connected to the inner wall of the right side of the box body, a motor is connected to the right side of the box body through bolts, and a punching mechanism, an adjusting mechanism and a collecting mechanism are arranged in the box body. A fixed plate and an inclined plate are welded to the inner wall of the box body, and a transmission mechanism is arranged on the left side of the box body. The widths and the thicknesses of punched plates can be adjusted by an integrated mode through the adjusting mechanism, and therefore the automatic feeding and punching device can be suitable for plates of different types, the application range of the device can be widened, and the practicability is improved. Meanwhile, the plates can be driven to be fed, and manual feeding is not needed. Compared with the prior art, the automatic feeding and punching device has the advantages that labor input is reduced, the plates can be cut while punching is conducted through the punching mechanism, the plates do not need to be moved to the next procedure to be machined, one procedure can be omitted, and then cost and investment are reduced.

Owner:台山市佳淳实业有限公司

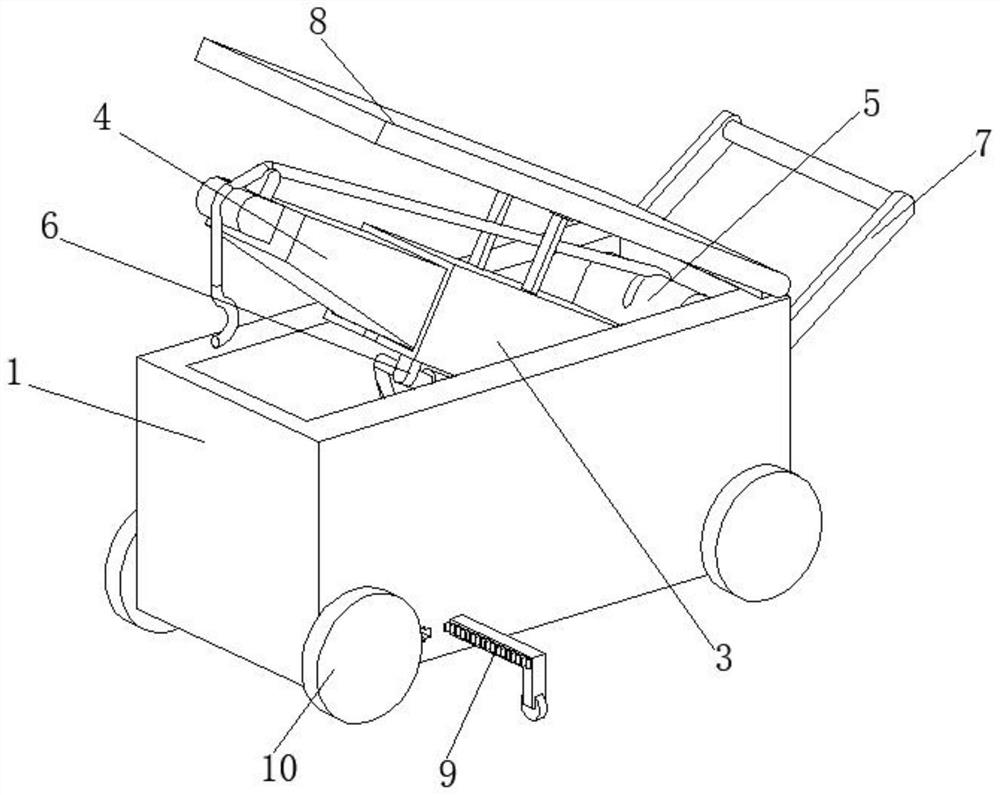

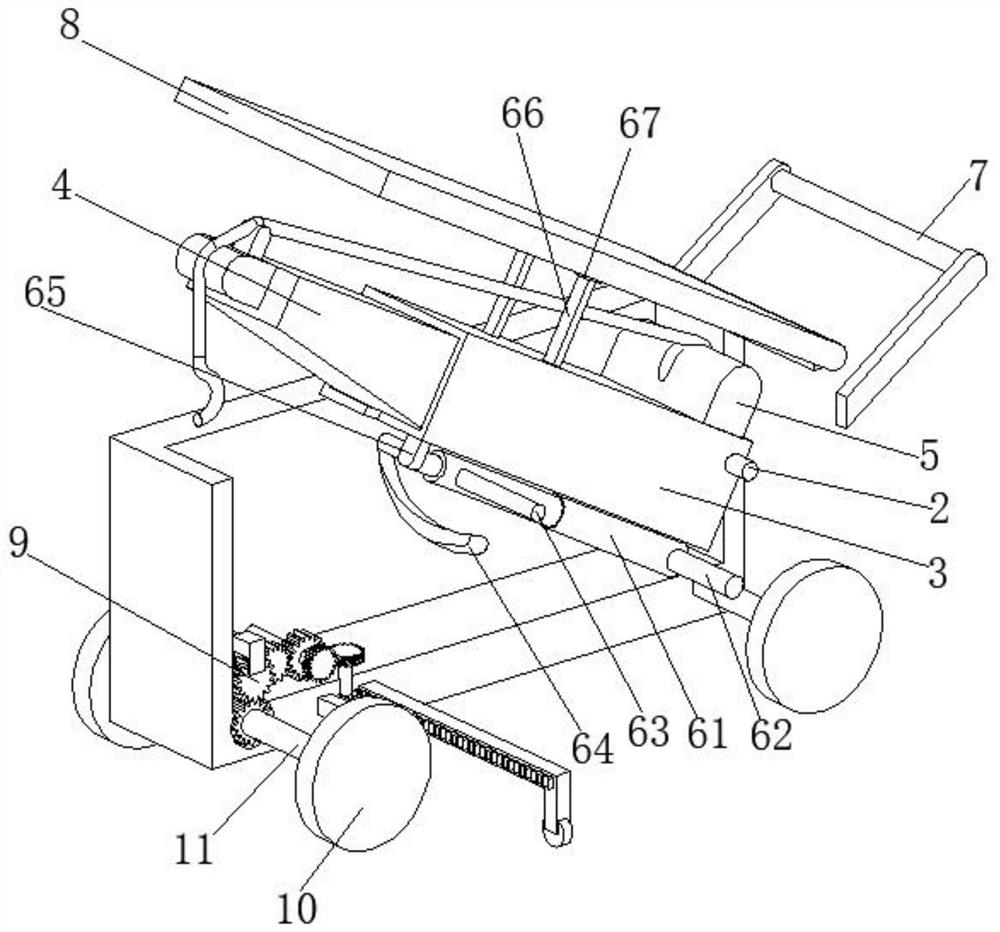

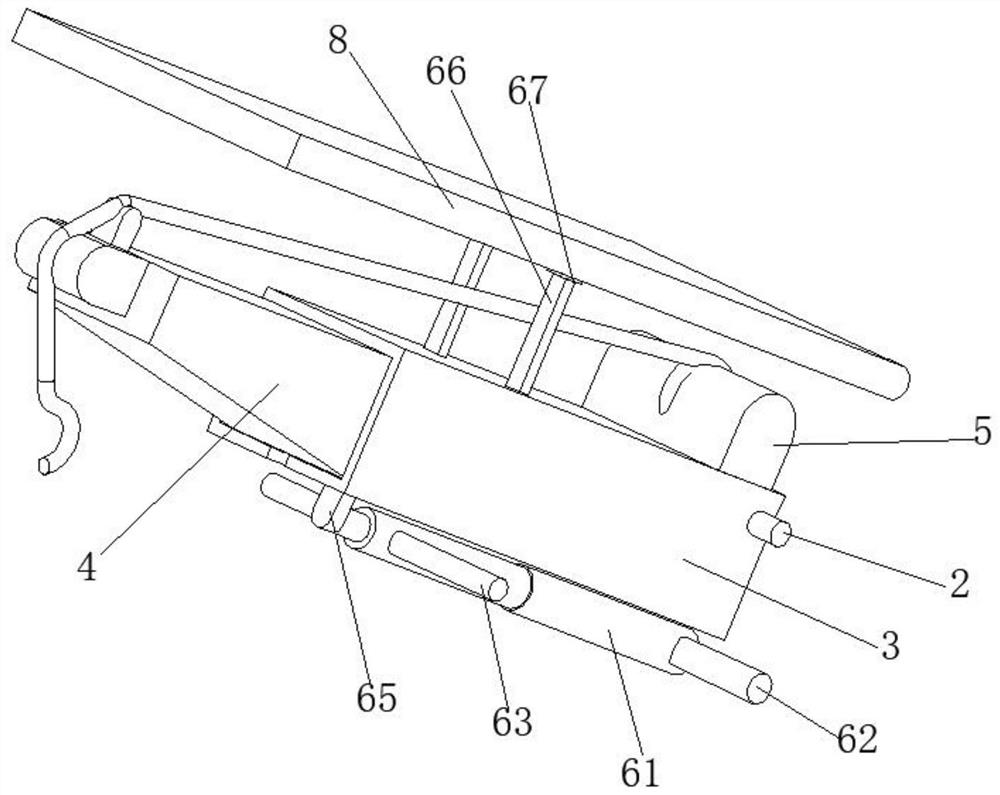

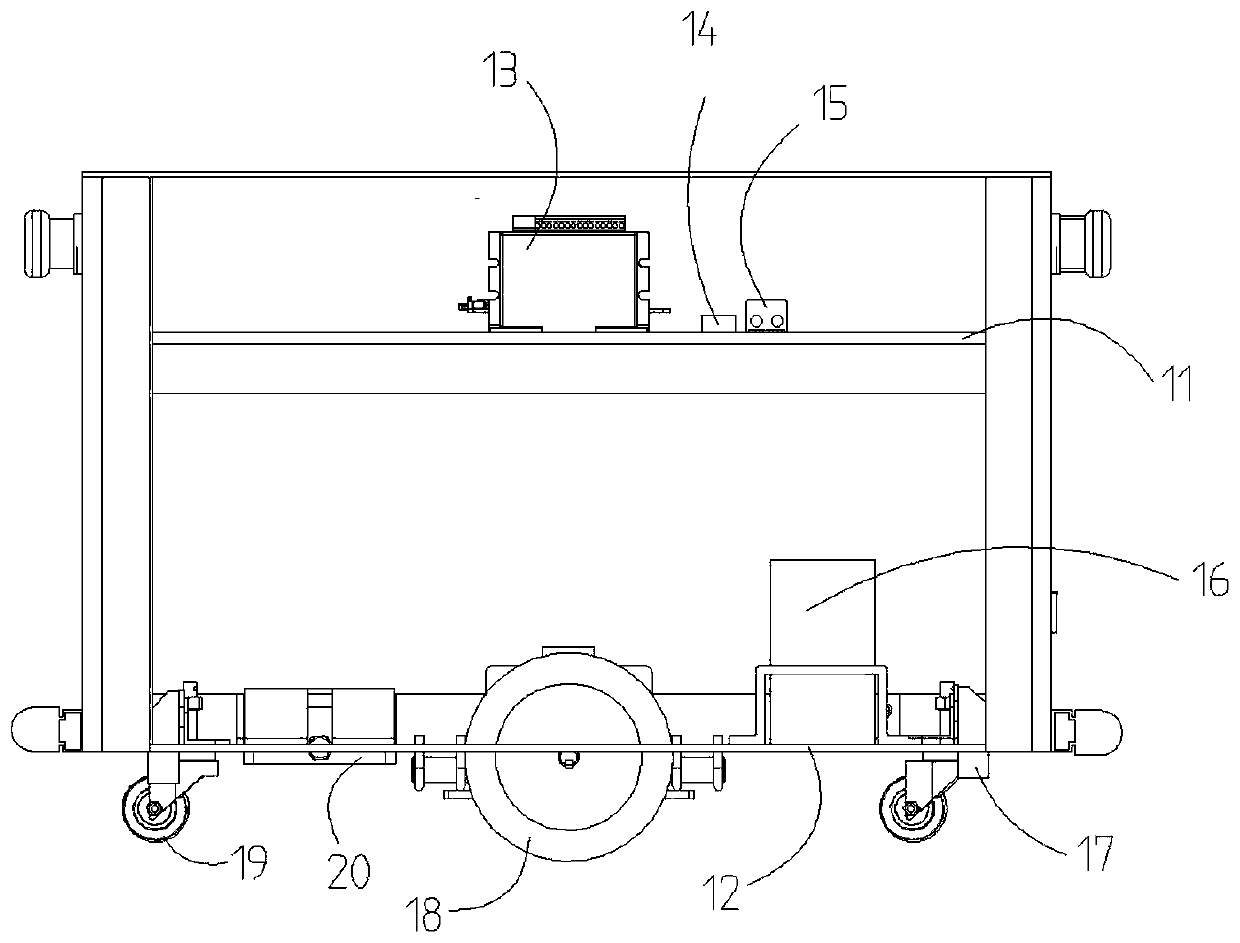

Blood sampling test tube carrying AGV

PendingCN111361662AReduce the number of placementsShorten the lengthPosition/course control in two dimensionsVehiclesDrive wheelElectric machinery

A blood sampling test tube carrying AGV comprises an AGV trolley and a test tube carrying device, and the test tube carrying device is arranged above the AGV trolley; the AGV trolley comprises a vehicle body, a driving wheel and a driven wheel which are arranged below the vehicle body, and magnetic sensors arranged on the front side and the rear side below the vehicle body; the test tube carryingdevice comprises a bottom plate, a first lifting plate, a middle plate, a second lifting plate and a test tube material bin which are sequentially arranged from bottom to top; the lifting motion of the first lifting plate in the vertical direction is realized by driving a trapezoidal screw rod through a large motor; the bottom surface of the left side of the test tube material bin is hinged to thetop surface of the left side of the second lifting plate; a cam mechanism is arranged between the test tube material bin and the second lifting plate, and the dumping action of the test tube materialbin is realized by adopting the cam mechanism; and a turnover plate used for dumping test tubes is arranged on the left side of the test tube material bin, and the turnover action of the turnover plate is achieved in a motor direct drive mode. The blood sampling test tube carrying AGV can realize carrying and automatic loading and unloading of the blood sampling test tubes, and is simple in structure and convenient to use.

Owner:ZHEJIANG UNIV OF TECH

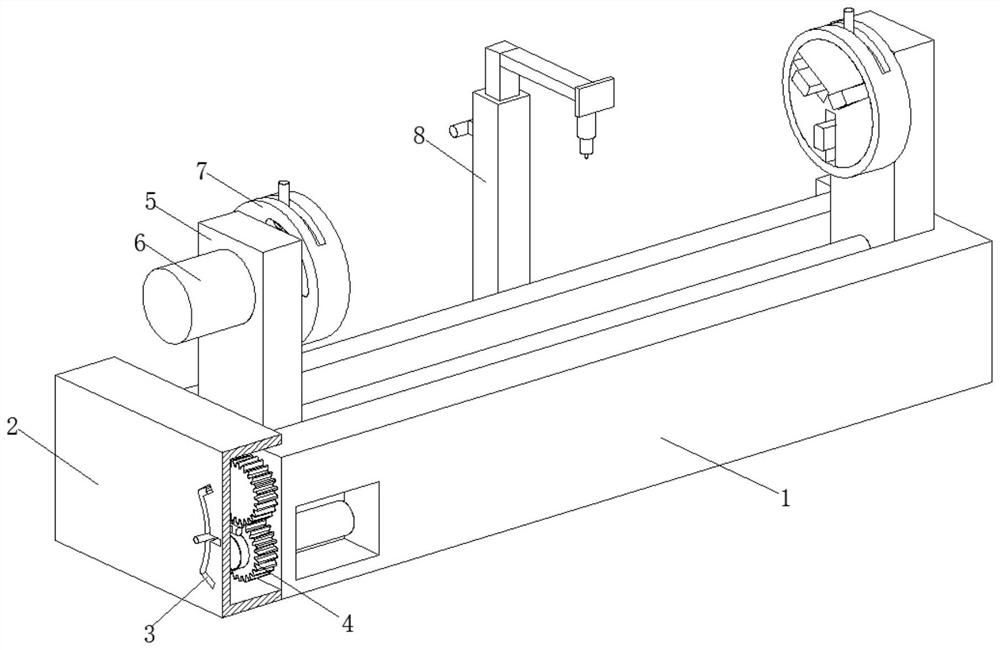

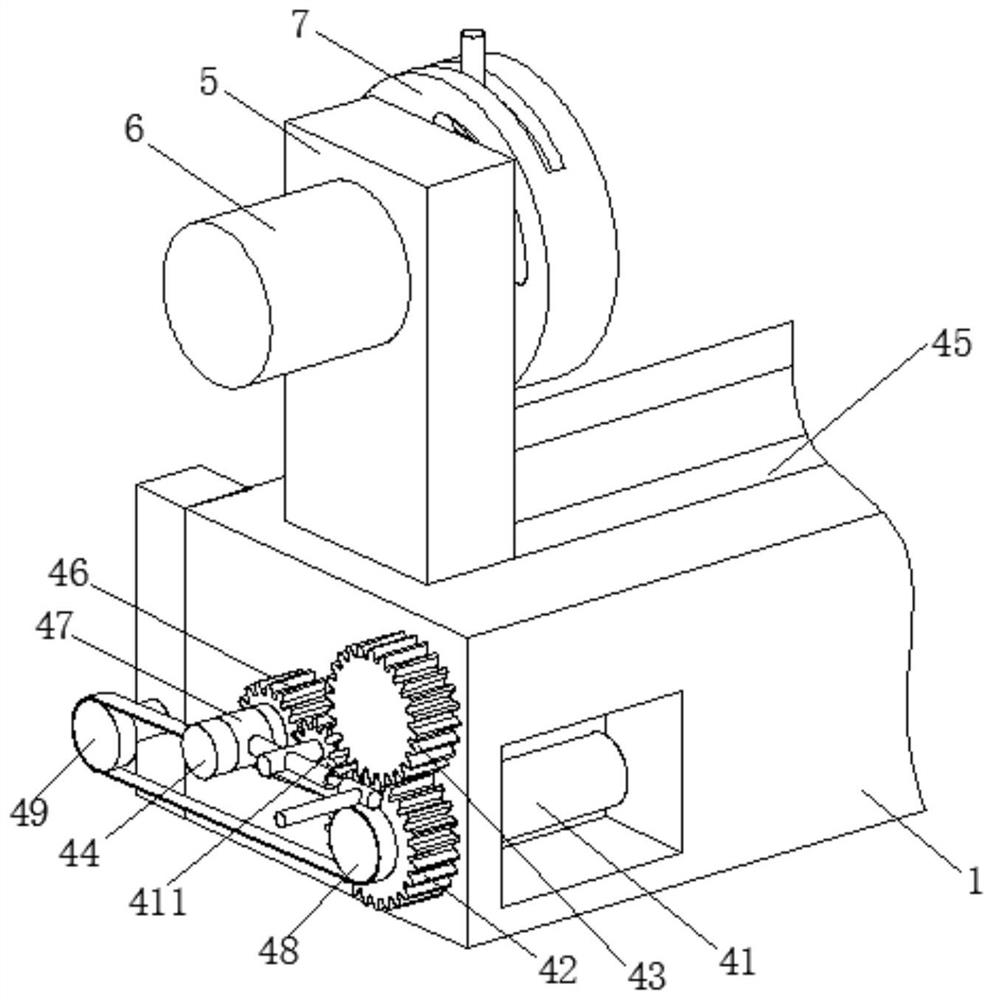

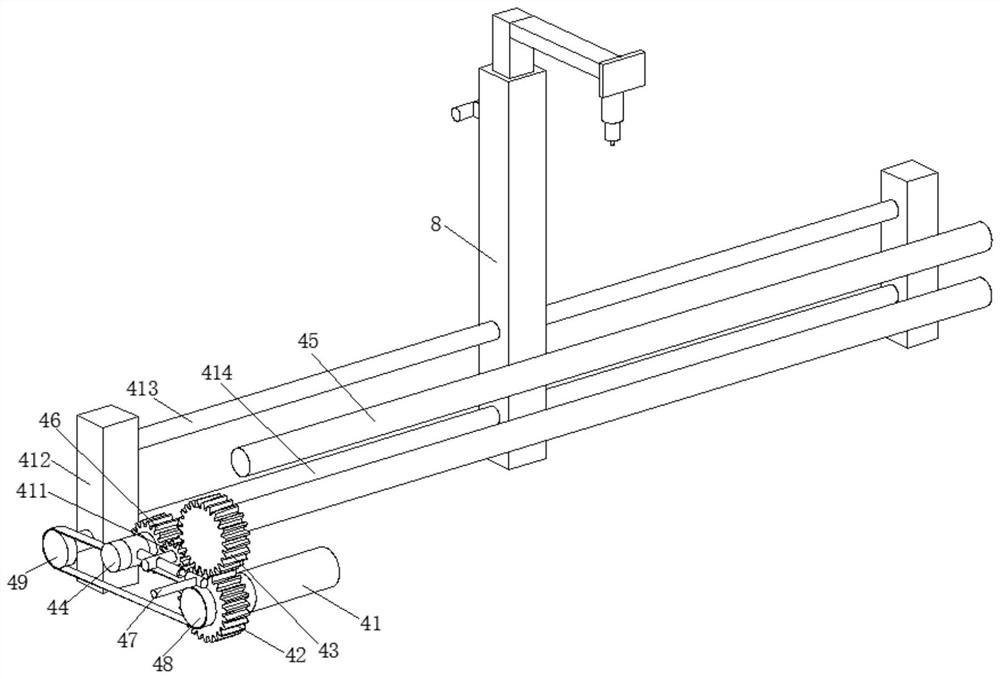

Mining machinery wheel shaft deflection measurement device

InactiveCN112484685AReduce the burden onExtended service lifeMeasurement devicesWorkbenchBolt connection

The invention relates to the technical field of deflection measurement, and discloses a mining machinery wheel shaft deflection measurement device which comprises a workbench, a protection box is connected to the front portion of the workbench through bolts, a clamping groove is formed in the front portion of the protection box, and a transmission mechanism is arranged in the protection box. Two supporting blocks are slidably connected to the inner wall of the workbench, motors are connected to the front portions of the supporting blocks through bolts, clamping mechanisms are arranged on the rear portions of the supporting blocks, and a detection mechanism is arranged on the left side of the workbench.Through cooperative use of the transmission mechanism and the supporting blocks, wheel shafts with different lengths can be clamped, so that the clamping mechanism can adapt to axles with different lengths, the application range of the clamping mechanism is widened, the axles can be clamped through the clamping mechanism, the clamping mechanism can adapt to the axles with different diameters and can be reinforced, the application range can be further widened, and the axles with largeweight can be clamped.

Owner:德清凯晶光电科技有限公司

Blanking device of reinforced backflow hollow-square-shaped HY fiber felt in flat heat pipe

PendingCN112371830AReduce labor intensityIncrease productivityMetal-working feeding devicesGrain treatmentsFiberStructural engineering

The invention relates to the technical field of fiber felt material post-treatment forming preparation, and discloses a blanking device of a reinforced backflow hollow-square-shaped HY fiber felt in aflat heat pipe. The blanking device comprises a workbench, two side plates are welded to the top of the workbench, a transmission mechanism is arranged at the left sides of the side plates, and a blanking mechanism is arranged between the two side plates; and a collecting mechanism is arranged at the bottom of the workbench, a discharging roller and a winding roller are rotationally connected between the two side plates correspondingly, and the surface of the discharging roller and the surface of the winding roller are both movably connected with a fiber felt body. According to the blanking device, the transmission mechanism and the blanking mechanism are used in a matched manner, so that the fiber felt can be directly and continuously blanked and automatically fed, manual cutting production by workers is not needed, the production efficiency can be greatly improved, and the labor intensity of the workers is reduced; and the collecting mechanism can be used for crushing and collectingleftover materials, the leftover materials can be conveniently recycled, and waste can be prevented.

Owner:德清宏业晶体纤维有限公司

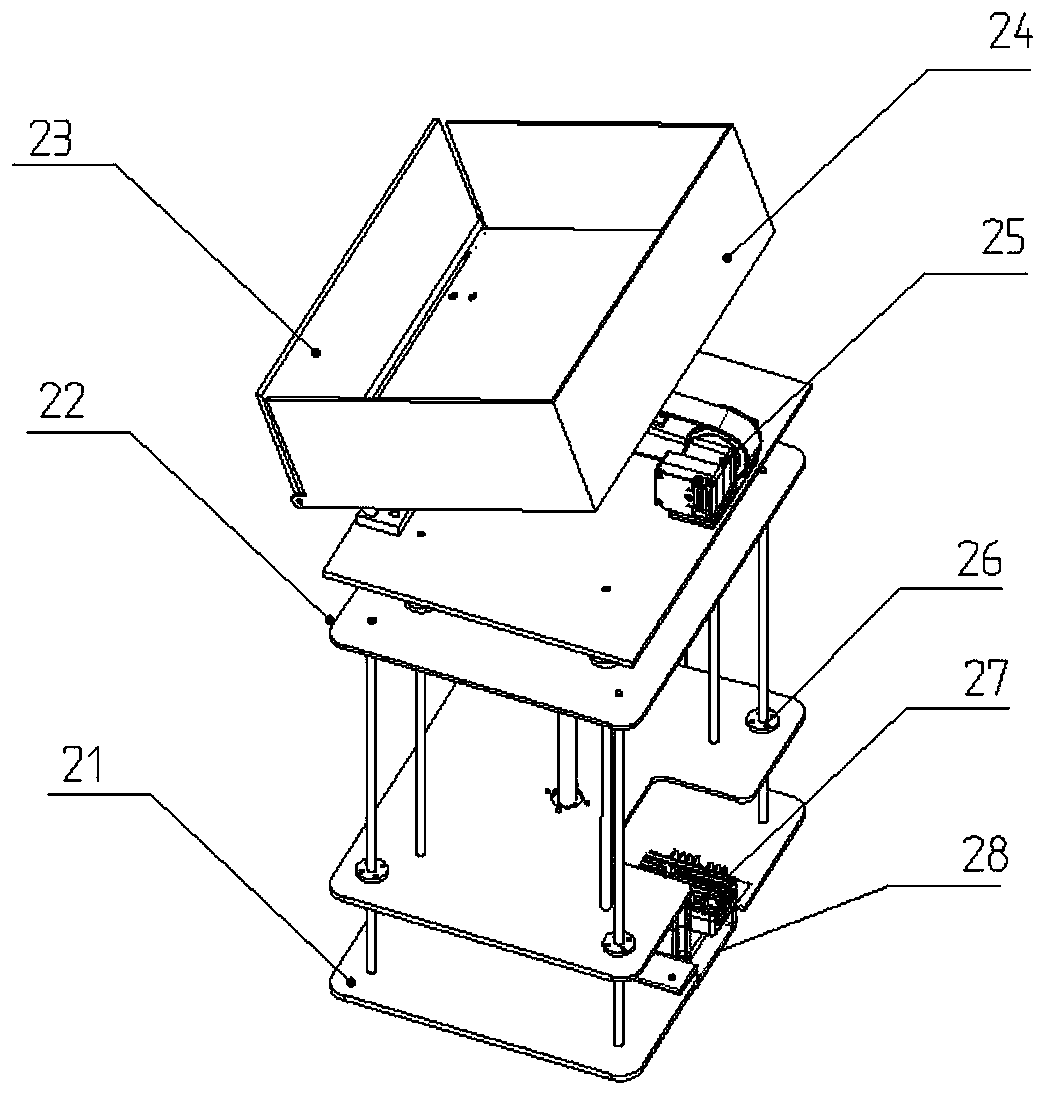

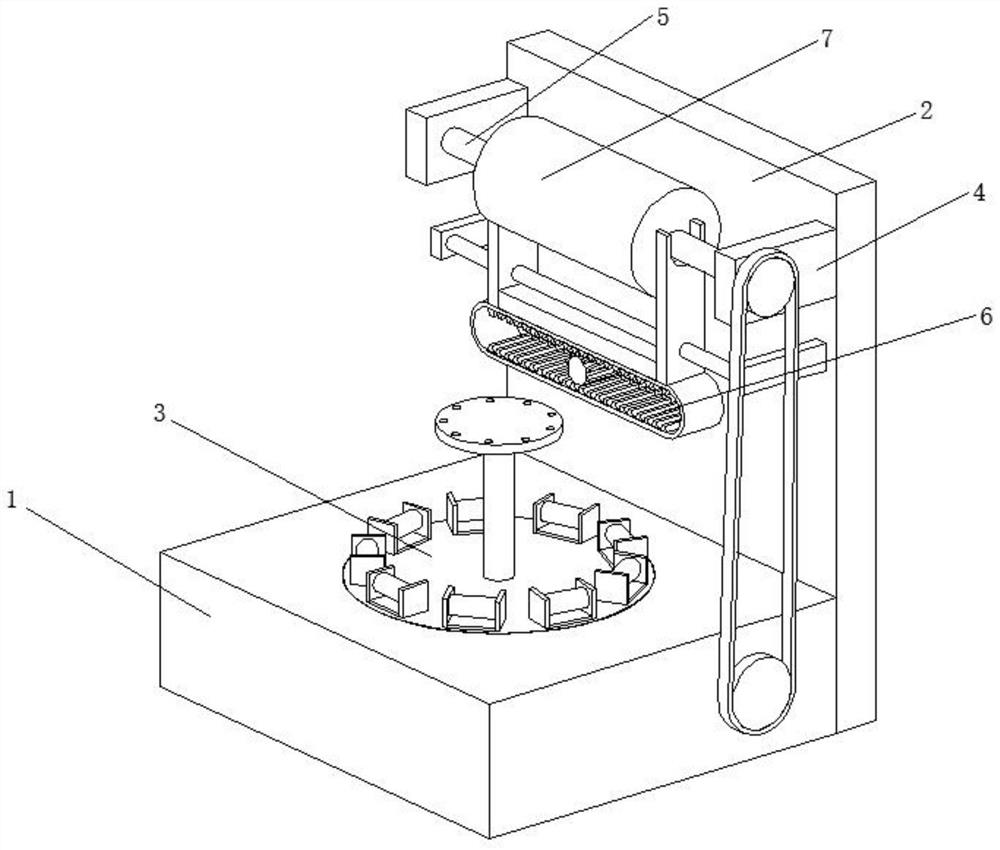

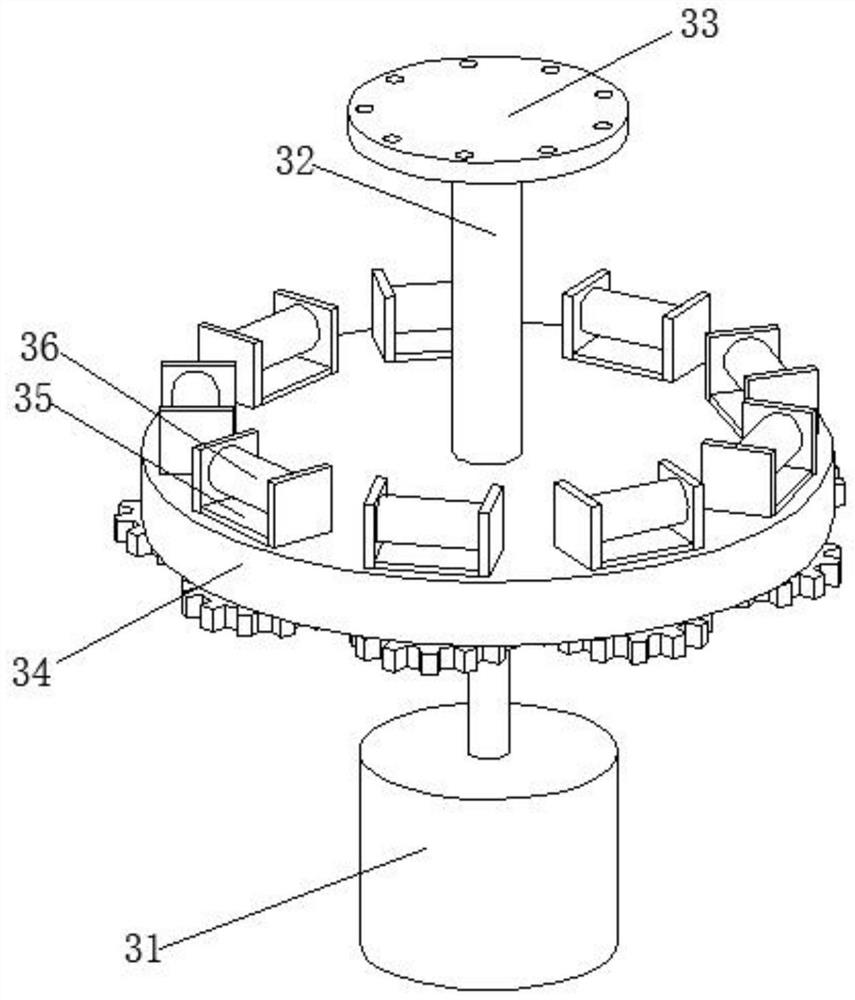

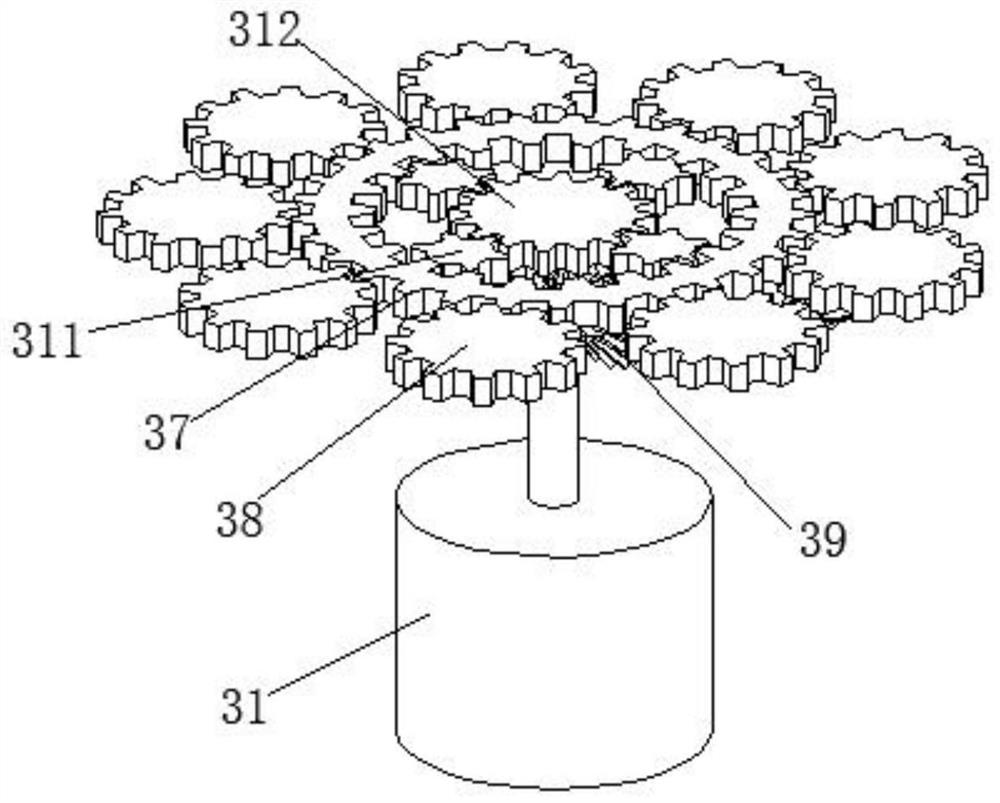

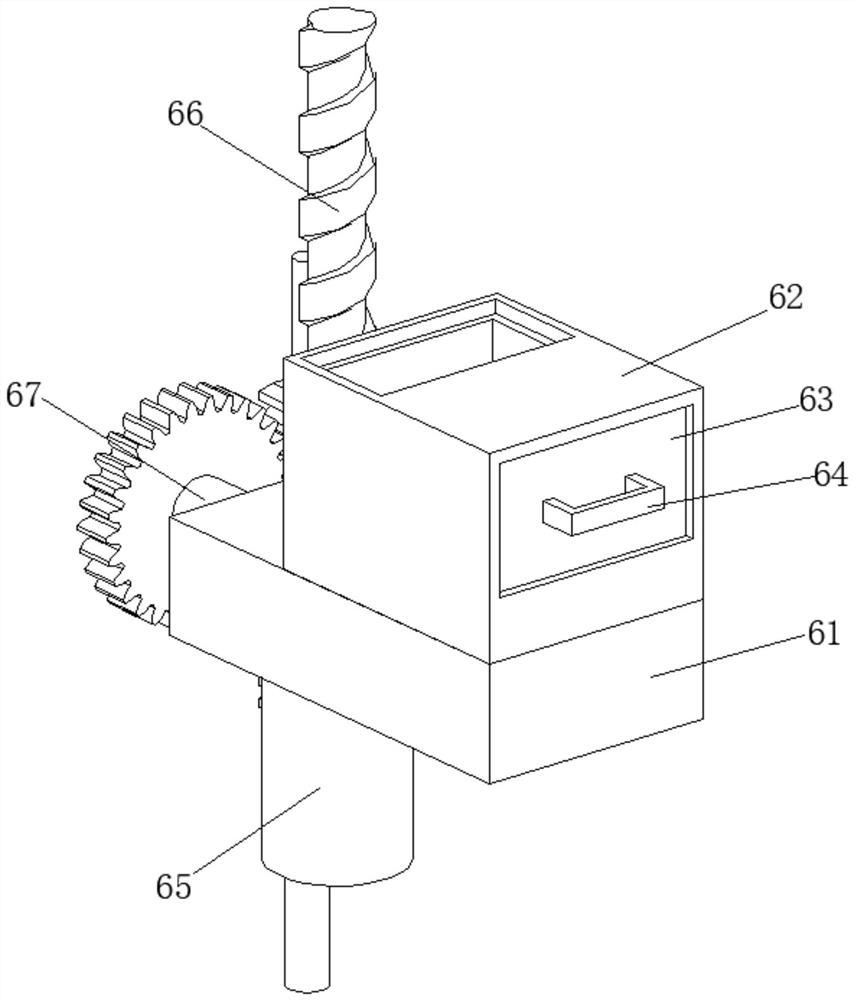

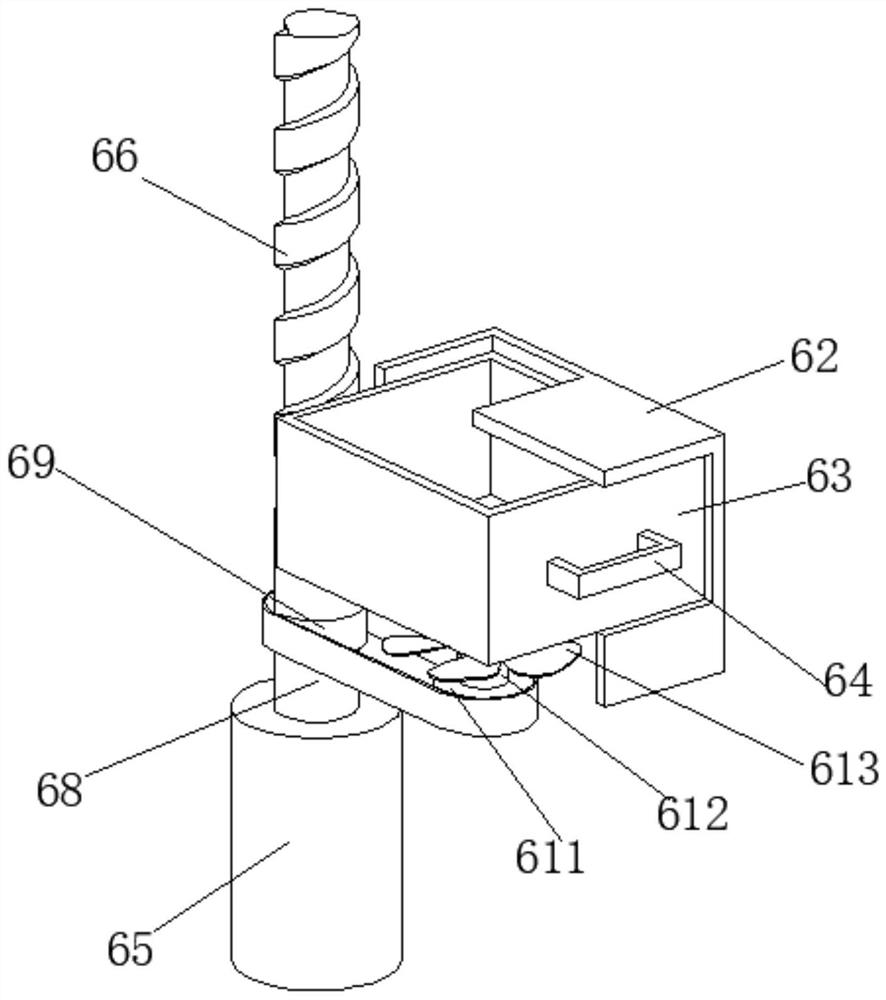

Rapid taking and placing device for power battery module

InactiveCN113370832APrevent fallingAvoid damageCharging stationsVehicular energy storagePower batteryElectrical battery

The invention relates to the technical field of power batteries, and discloses a rapid taking and placing device for a power battery module. The device comprises a mounting plate, a working mechanism is arranged on the rear portion of the mounting plate, a limiting mechanism is arranged on the front portion of the mounting plate, and an adjusting mechanism is arranged on the surface of the limiting mechanism. According to the rapid taking and placing device for the power battery module, through cooperative use of the working mechanism, the limiting mechanism and the adjusting mechanism, a battery can be straightened while the device clamps the battery, so the battery can be conveniently clamped subsequently, and the situation that the battery is damaged due to the fact that the battery deviates and then falls off after being clamped is prevented; through a supporting spring between an inner plate and an outer plate in the limiting mechanism, the device can adapt to batteries of different sizes when clamping the batteries, when the sizes of the batteries are large, the device can clamp the batteries excessively, but the inner plate and the outer plate can displace, the batteries are prevented from being damaged by clamping, and the application range of the device is greatly widened.

Owner:重庆新知创科技有限公司

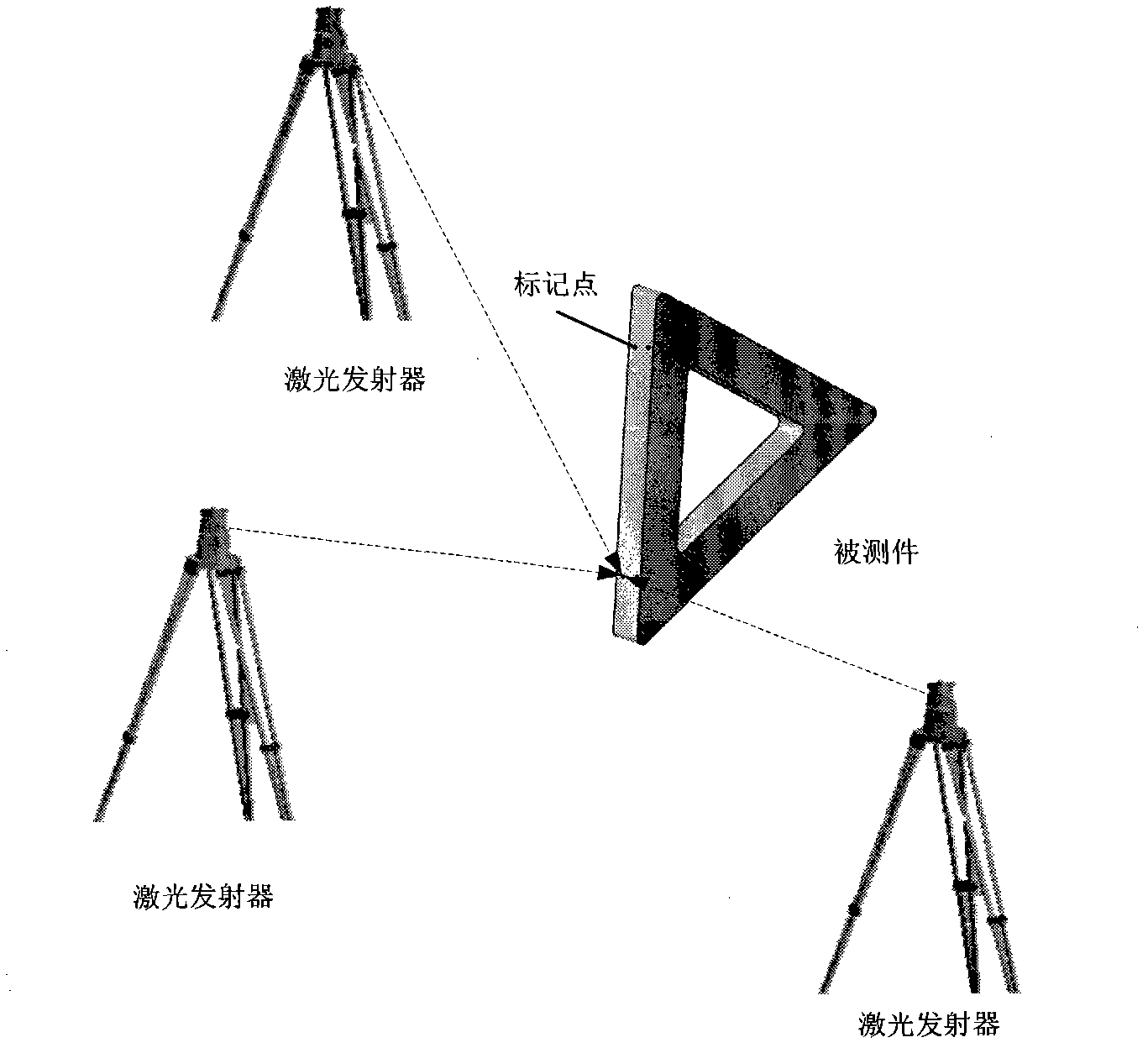

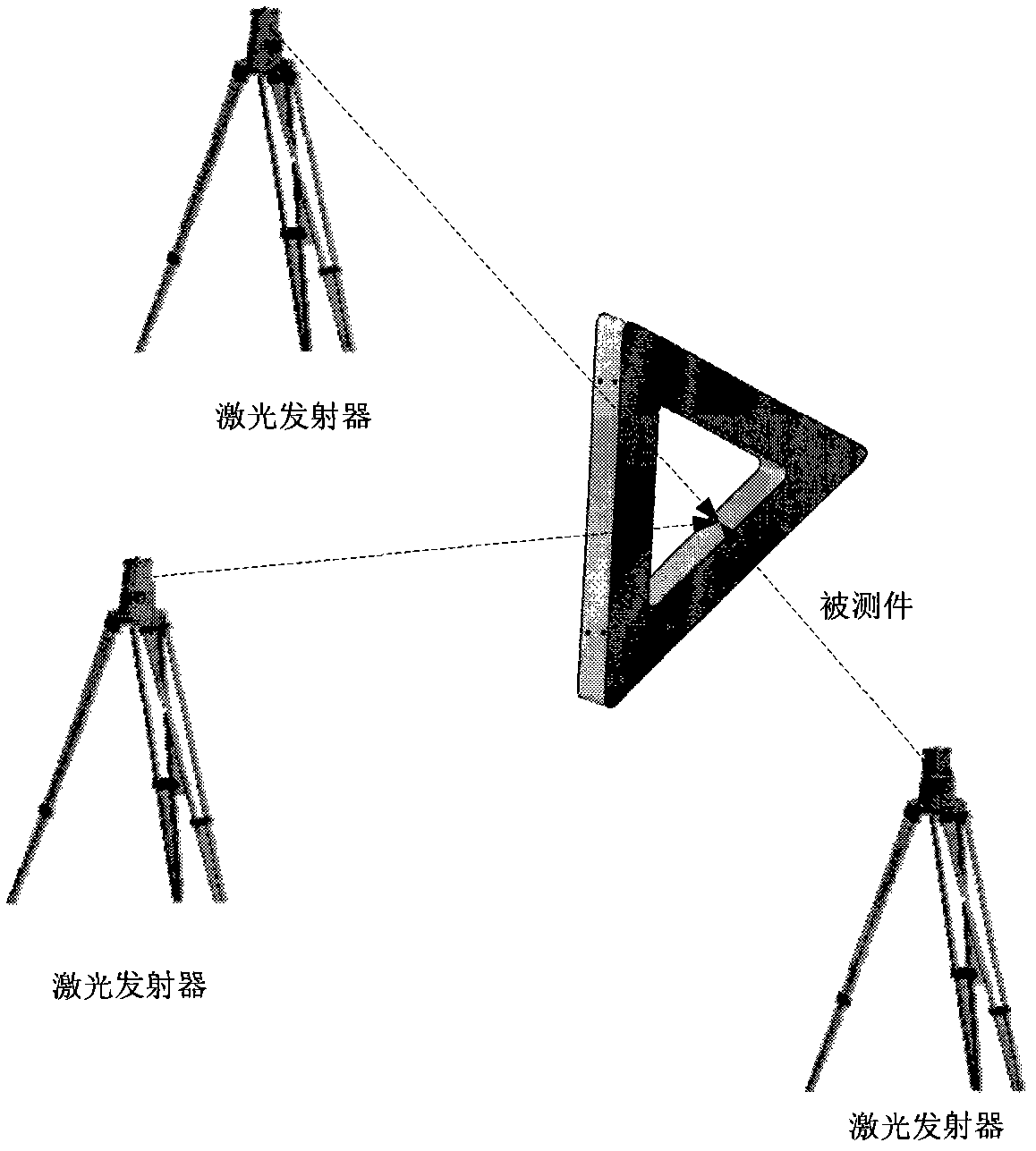

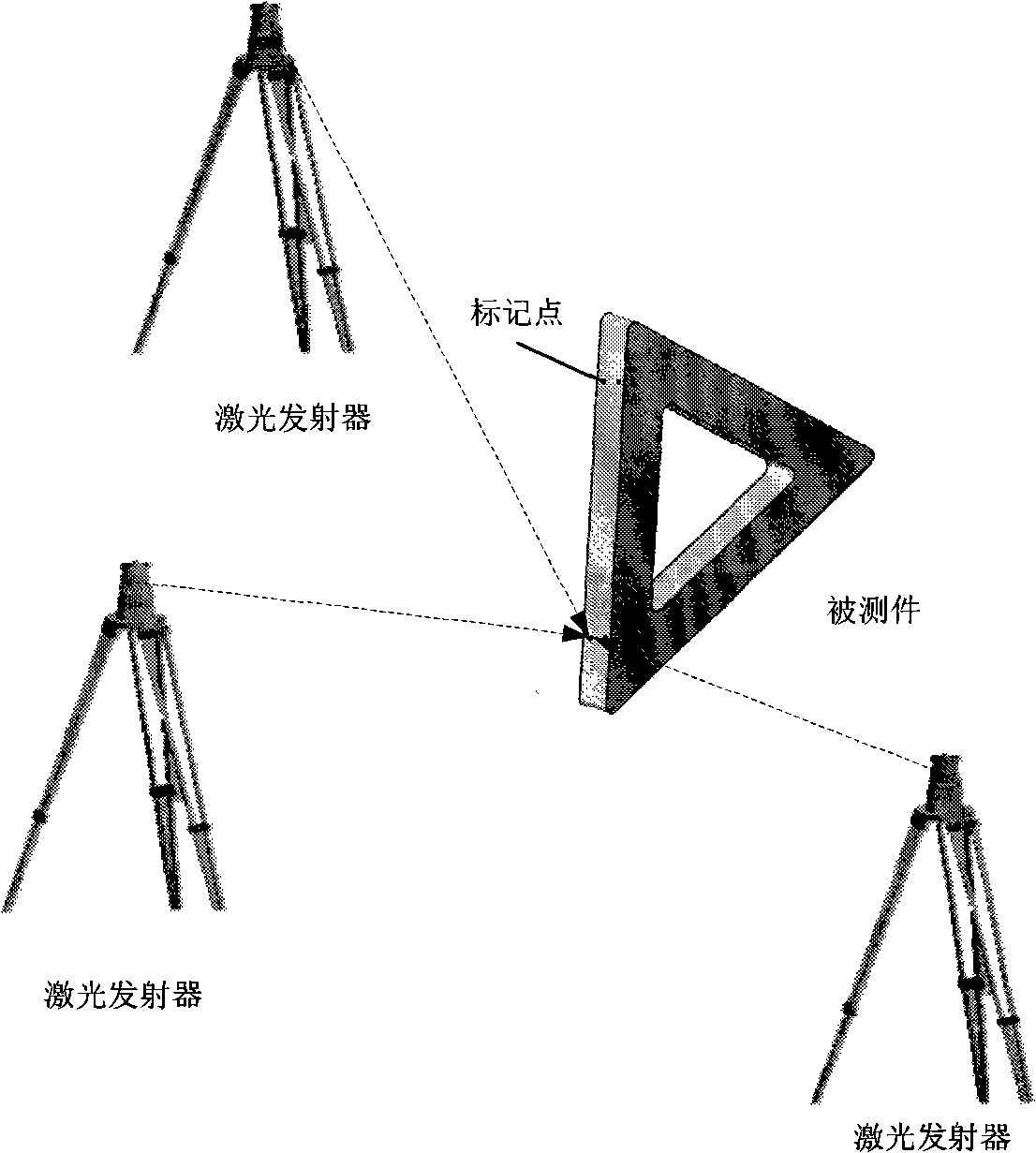

Method for estimating measurement accuracy of local global positioning system (GPS) based on tested triangular piece

ActiveCN102375145AReduce the number of placementsImprove evaluation efficiencySatellite radio beaconingGps measurementMeasurement point

The invention relates to a method for estimating the measurement accuracy of a local global positioning system (GPS) based on a tested triangular piece. The method comprises the following steps of: designing a measurement accuracy estimation tested triangular piece, arranging measuring points on the surface of the triangular piece, measuring all the measuring points by using a high-accuracy three-coordinate measuring machine, and calculating the distances among all the measuring points and the included angles among all fitting surfaces; arranging a measuring field of the local GPS, measuring all the measuring points, and calculating the distances among all the measuring points and the included angles among all the fitting surfaces; and estimating the measurement accuracy of the local GPS according to a measuring result. In the method, the length and angle measurement accuracy of the local GPS can be estimated simultaneously; a plurality of groups of measurement values can be acquired after the tested triangular piece is placed at any position, so that the placement frequency of the tested triangular piece can be reduced, and estimation efficiency is improved; and the measurement accuracy of the local GPS is estimated by a method for comparing and measuring the local GPS and high-accuracy measuring equipment, so that the influence of system errors on the estimation of the measurement accuracy in the conventional estimation method can be eliminated.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Yarn twisting device for spinning

ActiveCN112342651AThere will be no phenomenon of inconsistencyBeautify the appearanceContinuous wound-up machinesYarnTextile technology

The invention relates to the technical field of spinning, and discloses a yarn twisting device for spinning. The yarn twisting device comprises a workbench, a mounting plate is welded to the rear partof the workbench, a yarn twisting mechanism is arranged in the workbench, two supporting plates are welded to the front part of the mounting plate, a rotating shaft is movably connected between the two supporting plates, a winding roller is movably connected with the surface of the rotating shaft, and a winding mechanism is arranged on the front part of the mounting plate. Multiple strands of yarns can rotate while twisting and rotating through the yarn twisting mechanism and the winding mechanism, so that each yarn is twisted when being wound tightly, the phenomenon of different thicknessesafter yarn twisting can be avoided, the appearance is beautified, and unqualified products are reduced; and nine strands of spinning yarns can be twisted at most at the same time, the application range of the yarn twisting device is widened, the twisted yarns are wound in a left-right reciprocating motion mode, and then the yarns are prevented from being wound in the winding process.

Owner:ZHEJIANG MEILAIYA TEXTILE

Textile thread positioning device of textile machine

InactiveCN112173863AAvoid entanglementImprove work efficiencyFilament handlingElectric machineryIndustrial engineering

The invention relates to the technical field of textile machines, and discloses a textile thread positioning device of a textile machine. The textile thread positioning device comprises a workbench, two support plates are correspondingly welded at the top of the workbench, two baffle plates are correspondingly welded at the tops of the support plates, a positioning mechanism is arranged between the two support plates, two supporting columns are welded to the rear portion of the workbench, a winding mechanism is arranged between the two supporting columns, and a motor is connected to the left sides of the supporting columns through bolts. Through cooperative work of the positioning mechanism and a transmission mechanism, threads can be separated for winding, the situation that the device cannot continue to work due to intertwining of the textile threads during winding can be prevented due to the fact that the threads are wound left and right repeatedly, friction borne by the textile threads in the winding process can be reduced through a guide device, the risk of breakage of the textile threads during winding is reduced, and the quality of the textile threads after winding of the textile threads is greatly improved.

Owner:ZHEJIANG MEILAIYA TEXTILE

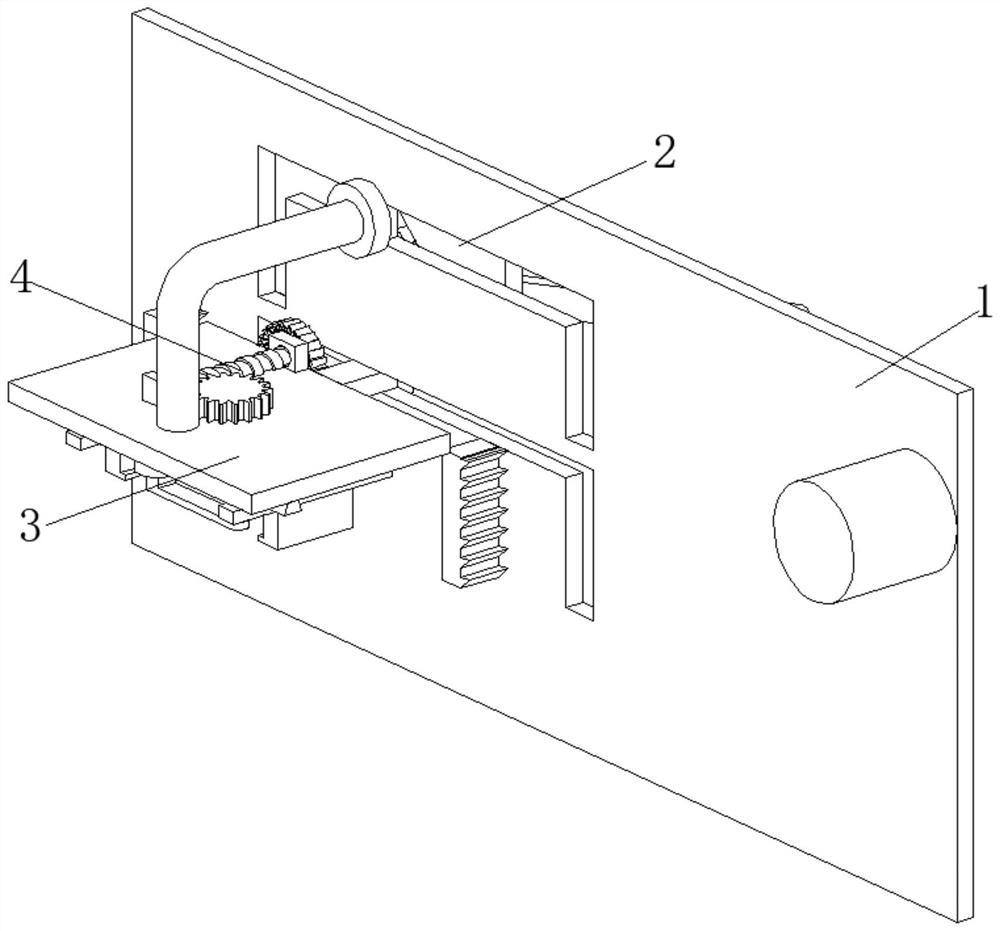

Multi-angle punching device capable of being operated by single person

ActiveCN114378333AReduce investmentImprove work efficiencyWork benchesPortable drilling machinesPunchingBolt connection

The invention relates to the technical field of punching devices, and discloses a single-person operable multi-angle punching device which comprises a mounting fixing seat, four supporting columns are fixedly mounted at the top of the mounting fixing seat, a supporting plate is fixedly mounted at the tops of the four supporting columns, and a vertically arranged supporting rod is slidably connected to the supporting plate; a mounting plate is welded to the top end of the supporting rod, a working mechanism is arranged on one side of the mounting plate, a fixing mechanism is arranged in the mounting fixing seat, a transmission mechanism is arranged on the surface of the supporting column, a connecting rod is welded to the mounting fixing seat, and universal wheels are connected to the bottom of the mounting fixing seat through bolts. Through cooperative use of the working mechanism and the transmission mechanism, the angle of the punching device can be adjusted by one person, the application range of the device is greatly enlarged, only one person is needed for operation during punching, the punching device is very convenient and rapid, the investment of labor cost can be reduced, and the working efficiency is greatly improved.

Owner:CHINA CONSTR EIGHTH ENG DIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com