BMS new energy battery positioning and capping device

A new energy and battery technology, applied in the direction of battery assembly, secondary battery manufacturing, transportation and packaging, etc., can solve the problems of high labor intensity, manual capping and low positioning efficiency, so as to reduce labor intensity, reduce practicability, Improve the effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

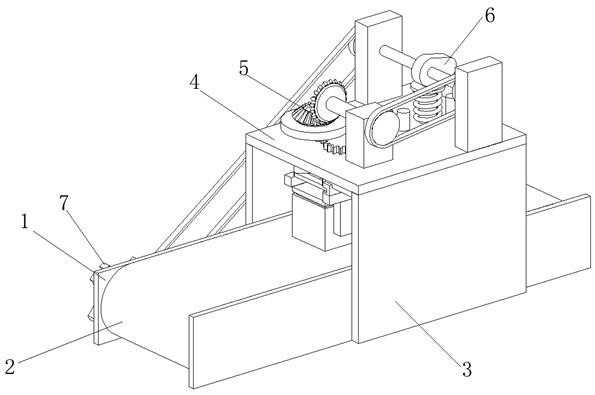

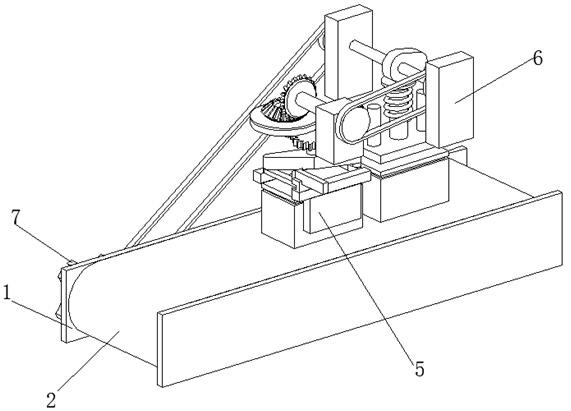

[0034] A positioning and capping device for BMS new energy batteries, such as Figure 1-Figure 6 As shown, the fixed plate 1 is included, and the number of the fixed plates 1 is set to two, and two rollers 2 are rotatably connected between the two fixed plates 1, and the surfaces of the two rollers 2 are connected by a transmission belt, and the two fixed plates 1 The surface of the support plate 3 is welded with a support plate 3, the top of the support plate 3 is welded with a mounting plate 4, the top of the mounting plate 4 is respectively provided with a positioning mechanism 5 and a capping mechanism 6, and the positioning mechanism 5 is located at the front of the capping mechanism 6, and the fixed plate 1 The left side is provided with transmission mechanism 7.

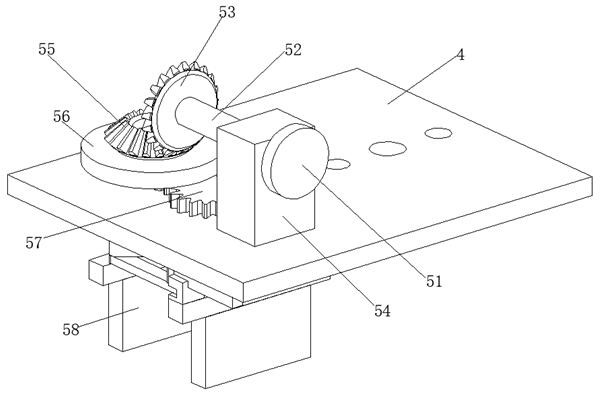

[0035] In this embodiment, the positioning mechanism 5 includes a No. 1 pulley 51, a connecting shaft 52 is welded at the axis of the No. 1 pulley 51, a No. 1 bevel gear 53 is welded to the left end of the con...

Embodiment 2

[0041] Such as Figure 6-Figure 8 As shown, the surface of the No. 2 pulley 61 is connected to the surface of the No. 1 pulley 51 through a belt, the surface of the No. 1 cam 63 is in contact with the upper surface of the push plate 67, and the surface of the transmission shaft 62 is connected in rotation with the inner wall of the support block 64. , the surface of the guide post 68 is slidingly connected with the inner wall of the mounting plate 4, and the two ends of the back-moving spring 66 are in contact with the lower surface of the push plate 67 and the upper surface of the mounting plate 4 respectively. The reason why this device is selected for belt transmission is that the belt has Good elasticity, can ease the impact and vibration during work, the movement is smooth and noiseless, and the belt slips on the wheel when the load is too large, so it can prevent other parts from being damaged and play a role of safety protection. The belt is an intermediate part, and it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com