Patents

Literature

45results about How to "Shorten forging time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

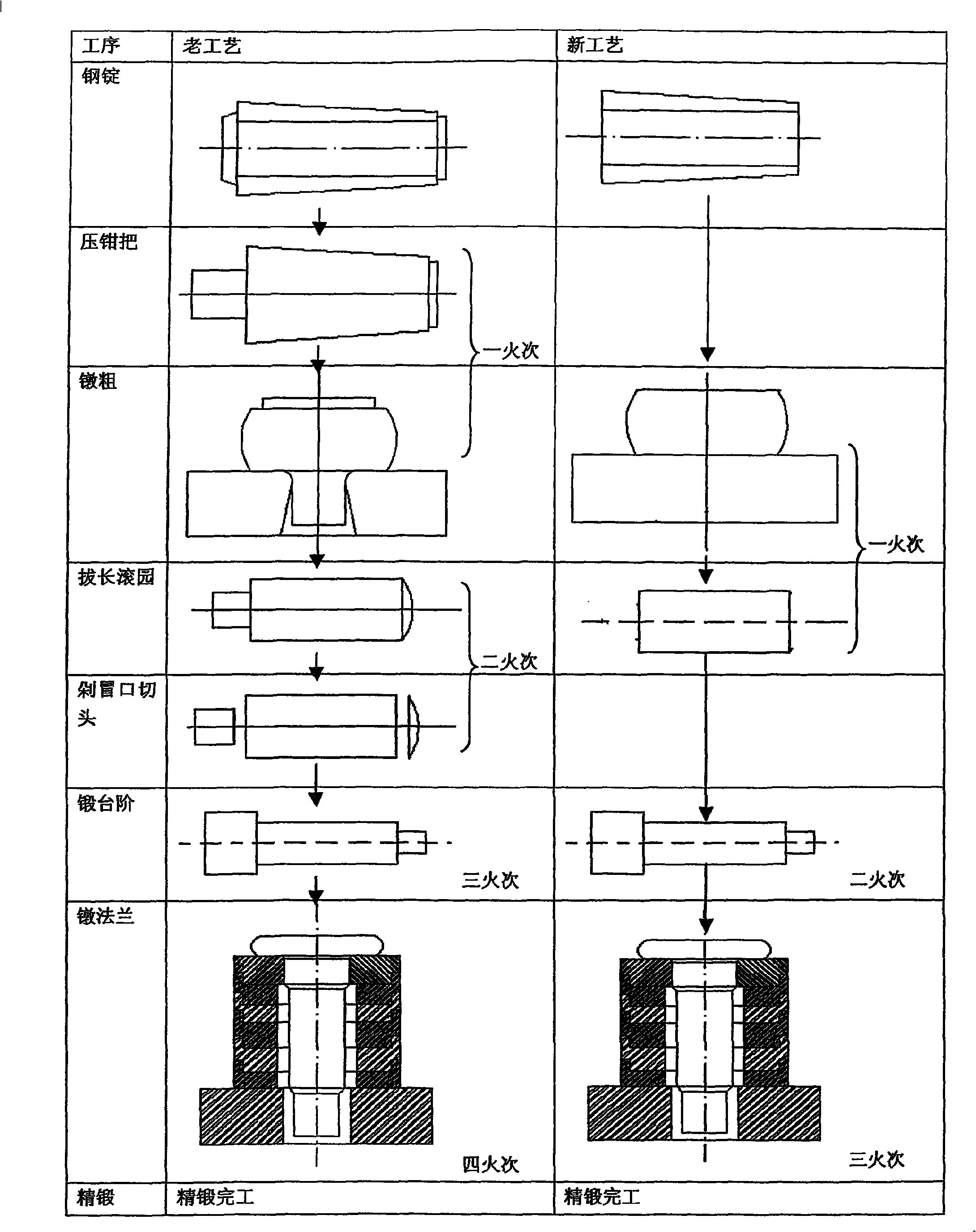

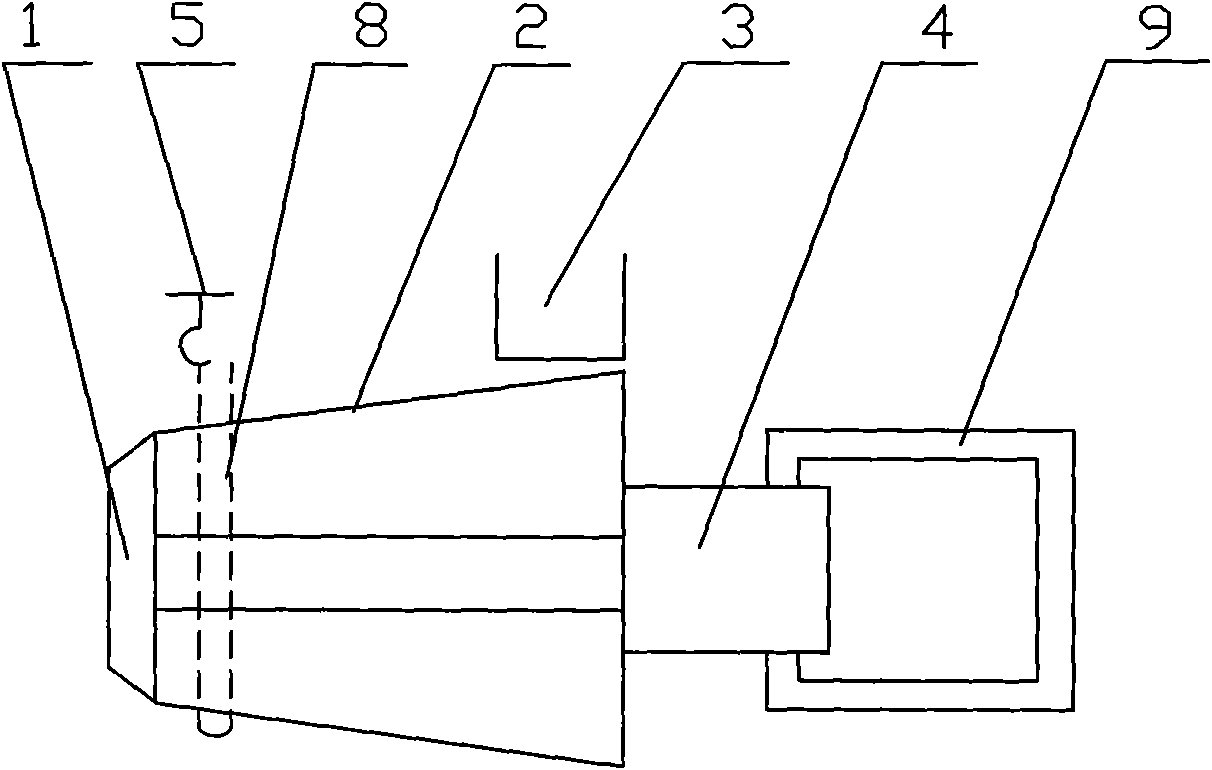

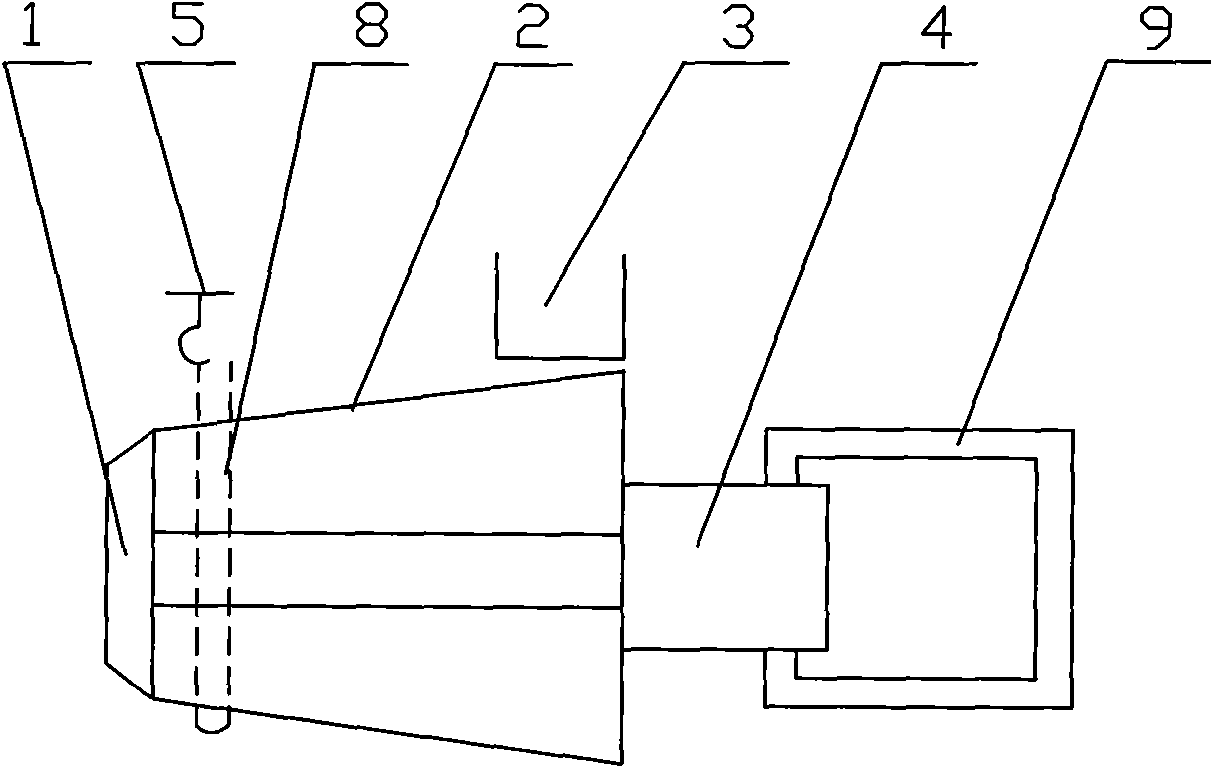

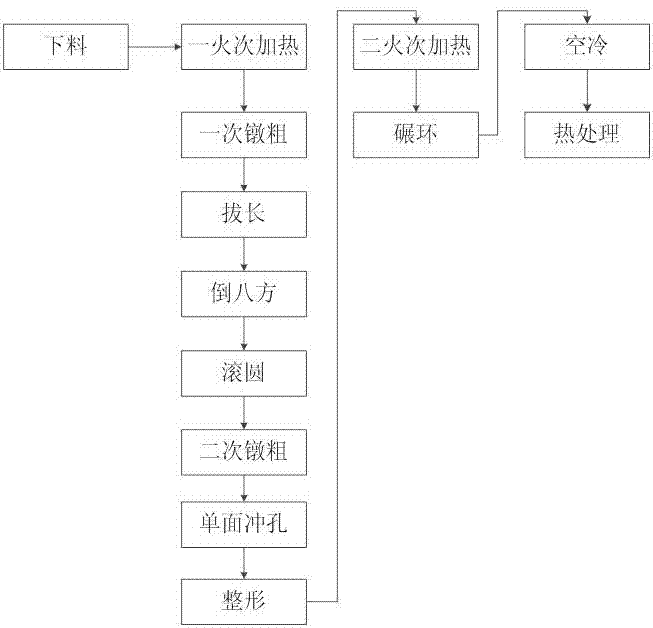

Wind-powered main shaft forging method

ActiveCN102806291AEnsure forging quality requirementsReduce fire consumptionMetal-working apparatusFurnace typesElectricityThermal treatment

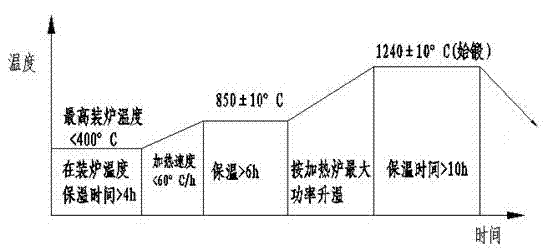

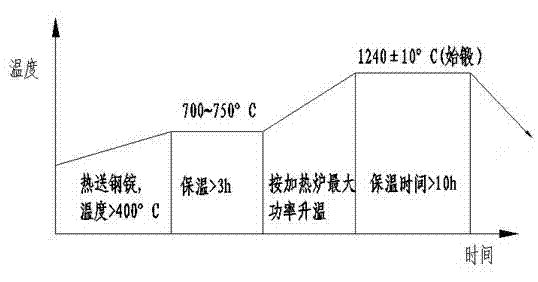

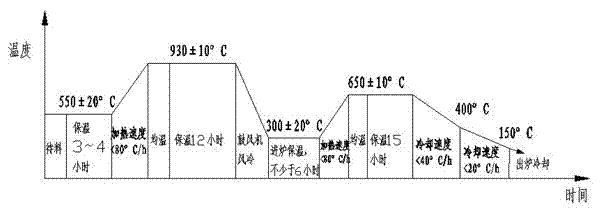

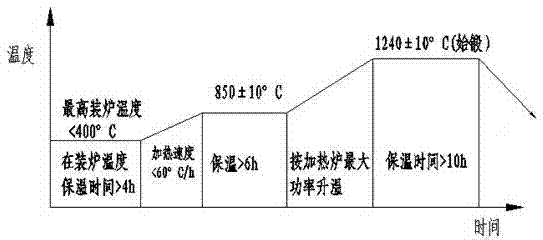

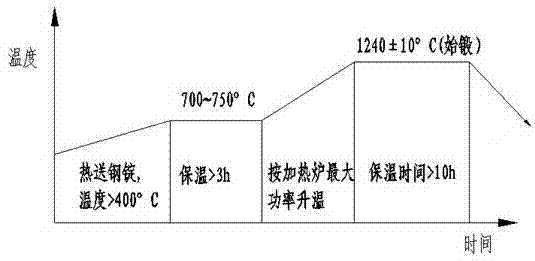

The invention relates to a wind-powered main shaft forging method. The wind-powered main shaft forging method comprises the following steps of inspecting a material; heating the material; taking out a blank which is formed by annealing the material for the first time, pre-forging, upsetting, drawing and printing the blank, performing pre-forging to form the blank, and blanking; finally forging the blank to form a main shaft by annealing for the second time, forging a flange end on a hollow rotary worktable, and drawing the main shaft until a shaft body has forging size; performing re-crystallization normalized tempering thermal treatment by using a one-time thermal loading furnace after forging the wind-powered main shaft; roughly turning the wind-powered main shaft and detecting flaws through ultrasonic wave; hardening and tempering the wind-powered main shaft, and performing nondestructive inspection and physical and chemical inspection on the wind-powered main shaft; finely turning the wind-powered main shaft; and packaging the wind-powered main shaft. The wind-powered main shaft forging method provided by the invention has the characteristics that the efficiency is high, the energy is saved, the cost is reduced, and the forging quality is improved.

Owner:JIANGSU LINGFEI FORGING

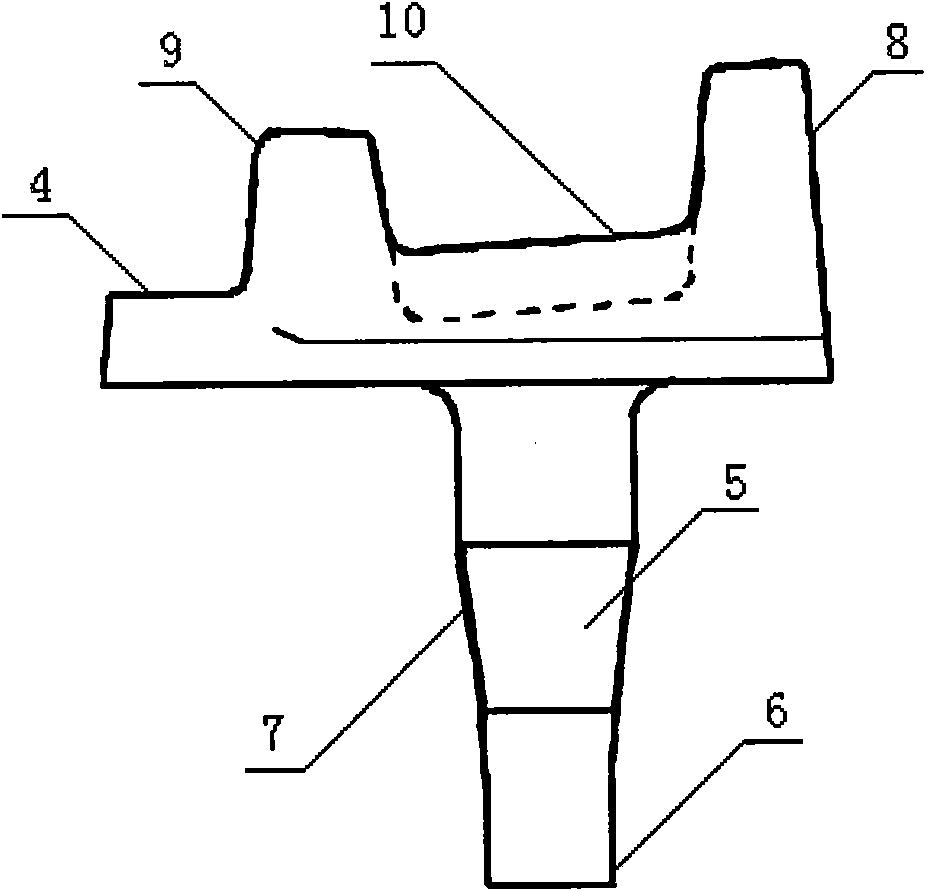

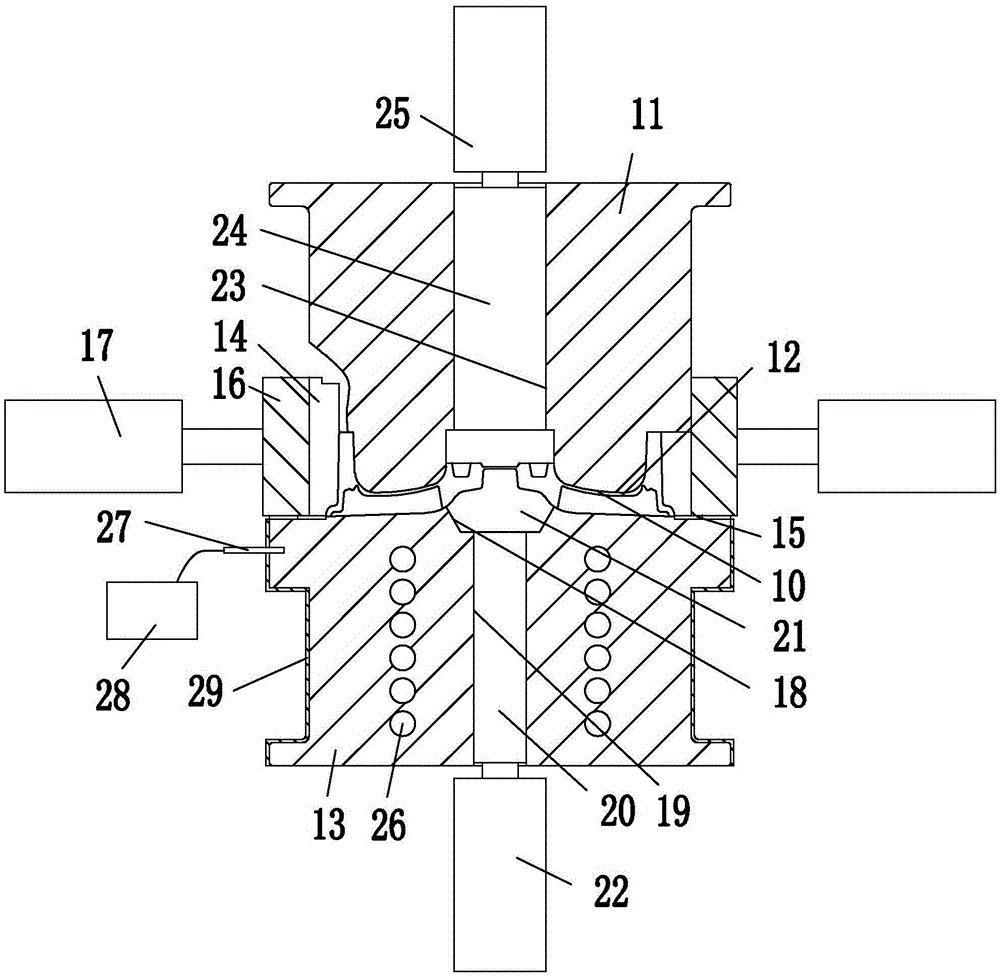

Closed forging technique for steering knuckle

ActiveCN101972835AReduce investmentAchieve flash-free forgingMetal-working drilling toolsRailway componentsControl theoryScrew press

The invention discloses a closed forging technique for a steering knuckle, belongs to automotive steering knuckle forging in the machining field, and overcomes the defects of need of procedures, such as trimming and the like, large metal consumption, low use ratio of a material and the like. The steering knuckle is forged on an electric straight direct drive spindle press by the closed forging technique; an extrusion blanking mould and a final forging mould both have a closed structure; a rod part of the steering knuckle is placed on an upper mould, and an ear part is placed on a lower mould; extrusion blanking and final forging forming can be tried; required blow energy is determined by actually debugging, a procedure of the blow energy is stored and used in the process of mass production; and in a series of technical schemes, the flashless forging of the steering knuckle is realized by three forging process steps, the procedures, such as preforging, trimming, revising and the like are saved, the use ratio of a forging material of the steering knuckle is increased, mould input is reduced, working efficiency is improved, and production cost is reduced.

Owner:HUBEI TRI RING FORGING

Forging method of single-throw crank shaft

InactiveCN102989942AUniform deformationImprove pass rateMetal-working apparatusEngine componentsCrankHeating furnace

The invention discloses a forging method of a single-throw crank shaft. The forging method of the single-throw crank shaft comprises the following steps: a step a of pouring a cylindrical blank material, wherein the cylindrical blank material comprises chemical components, by weight percent: 0.12-0.40% of C, 0.42-1.0% of Mn, 0.7-1.5% of Si, 0.09-0.15% of V, 0.15-0.22% of Ti, 0.4-1.4% of Cr, 0.6-1.5% of Ni, 0.18-0.30% of Mo, 0.4-0.8% of Li, 0.04-0.08% of Nb, 0.18-0.24% of Al, 0.18-0.45% of Mg, no greater than 0.033% of P, no greater than 0.030% of S and the balance of Fe; and a step b of forging, wherein the sep b comprises the following steps: at first, heating the selectively-used cylindrical blank material to an initial forging temperature by adopting an intermediate frequency heating furnace; next, rolling the heated blank material in a cross wedge rolling mill through a cross wedge rolling die into a rough blank and forming shaft rod parts of two ends; subsequently, putting the rolled rough blank in a bending die for bending; and finally, upsetting and extruding the bent rough blank in an upsetting forging concave die in two directions for shaping. With the adoption of a quenching and tempering heat treatment technology for the single-throw crank shaft provided by the invention, the high temperature normalizing and the forging are caused to organically form a continuous production line; and therefore, the defects of the prior art are overcome, the energy resource is saved, the heat treatment quality is improved, the production period is shortened, the production cost is lowered and the radiation pollution to a workshop environment is reduced.

Owner:CHANGLI FORGING

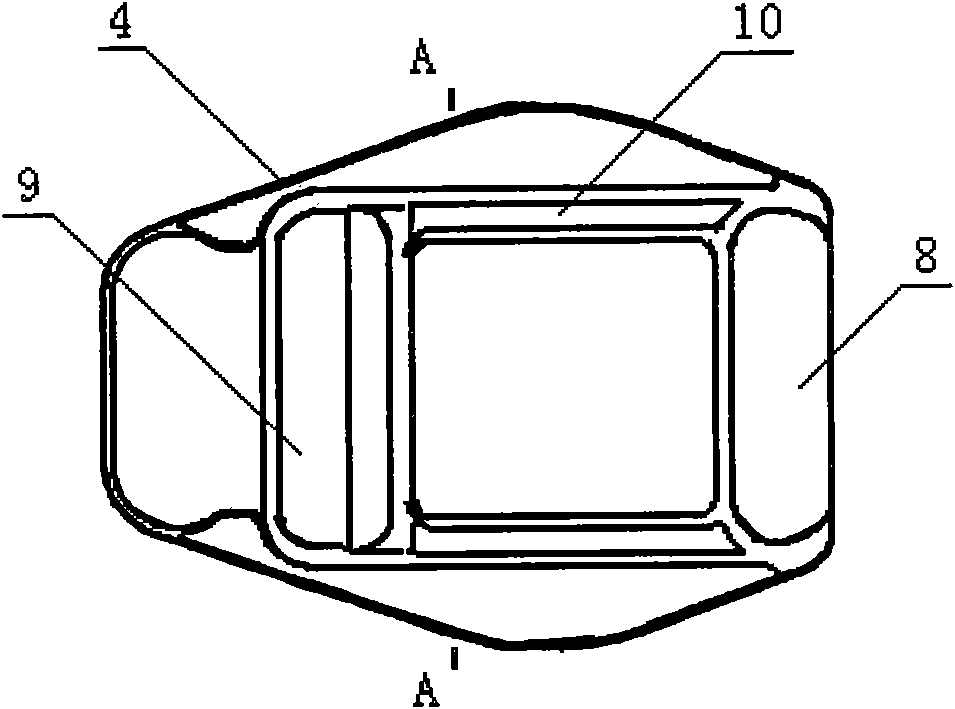

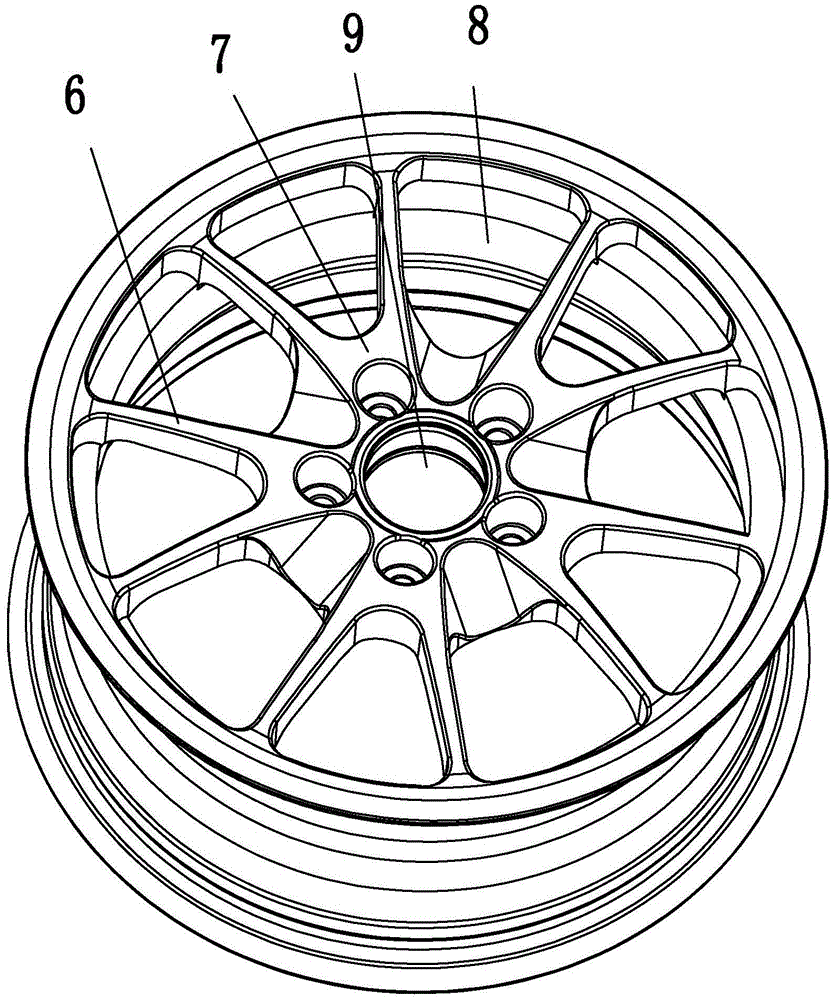

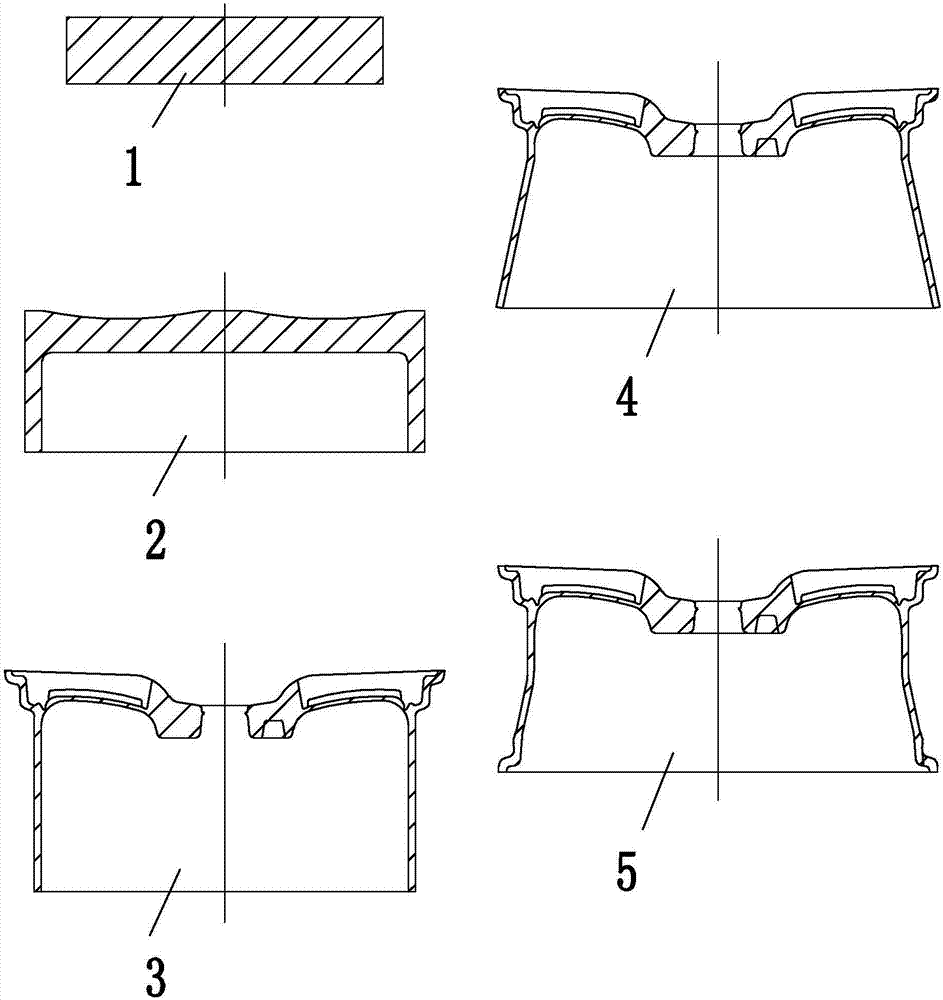

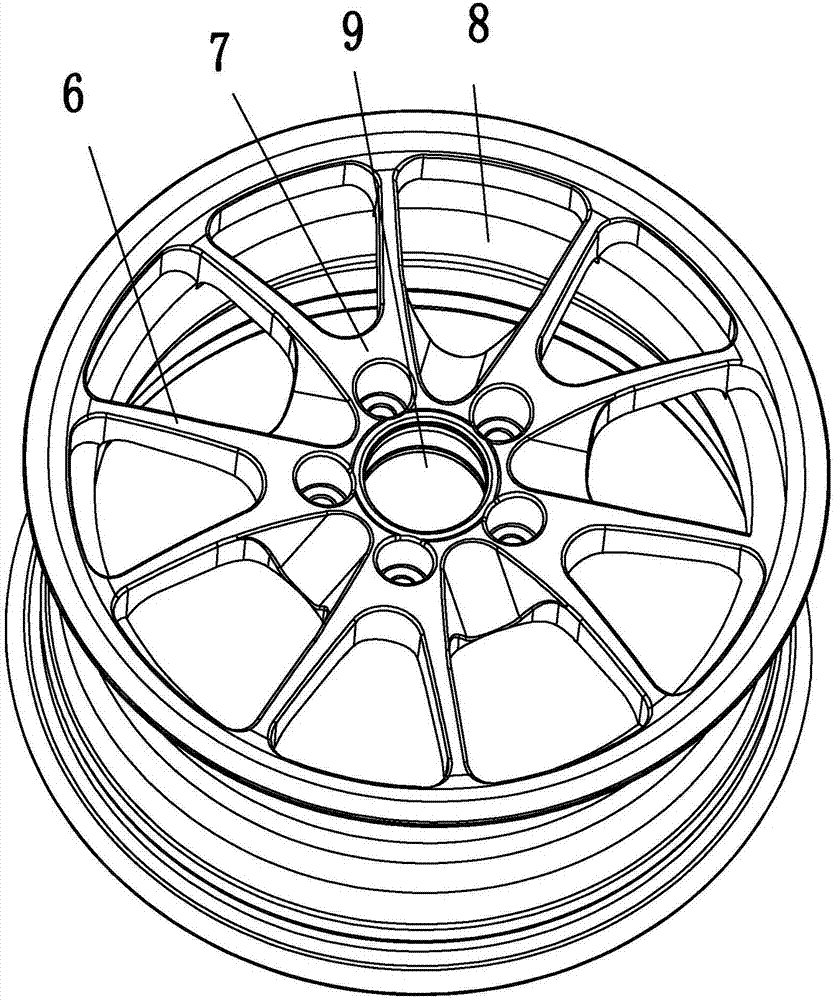

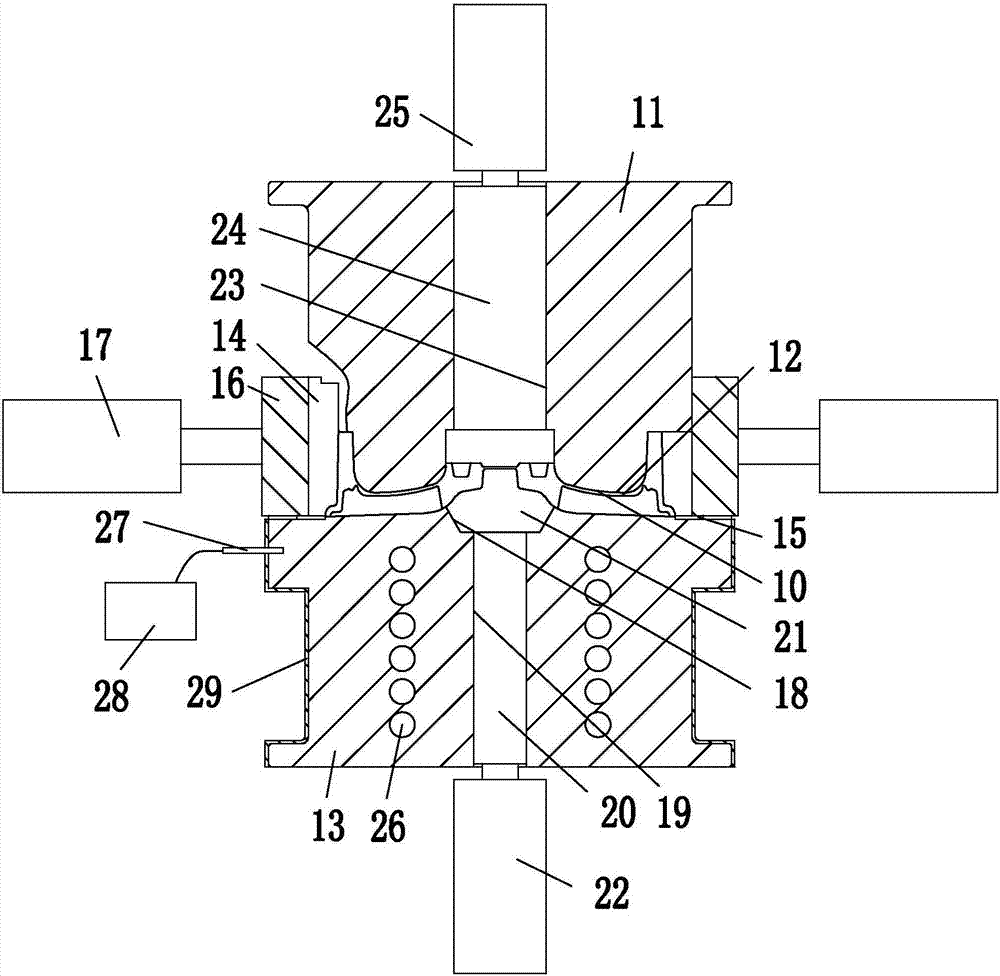

Forging method for magnesium-alloy automobile hub

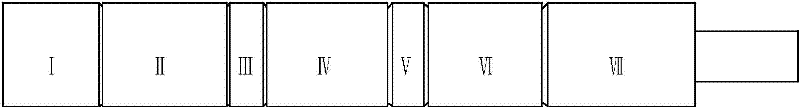

ActiveCN105665610AShorten forging timeIncrease productivityForging/hammering/pressing machinesForging press drivesSizingHeating furnace

The invention relates to the forging field, and aims to provide a forging method for a magnesium-alloy automobile hub. The forging method for the magnesium-alloy automobile hub comprises the following steps: step I, heating a magnesium alloy rod in a heating furnace; step II, pre-forging the magnesium alloy rod; step III, carrying out pre-profiling forging on disc-shaped blank; step IV, carrying out fine-profiling forging on a pre-profiled hub; step V, carrying out fine-shaping forging on a fine-profiled hub; step VI, transferring the fine-shaped hub to a transfer table for heating through a position transfer device, wherein a heating temperature is controlled to 320 DEG C to 450 DEG C; and step VII, carrying out rim extrusion sizing on the fine-shaped hub. The forging method for the magnesium-alloy automobile hub is relatively high in production efficiency; and the magnesium-alloy automobile hub is compact in texture, is uniform in component, and is relatively high in mechanical strength.

Owner:刘兴军

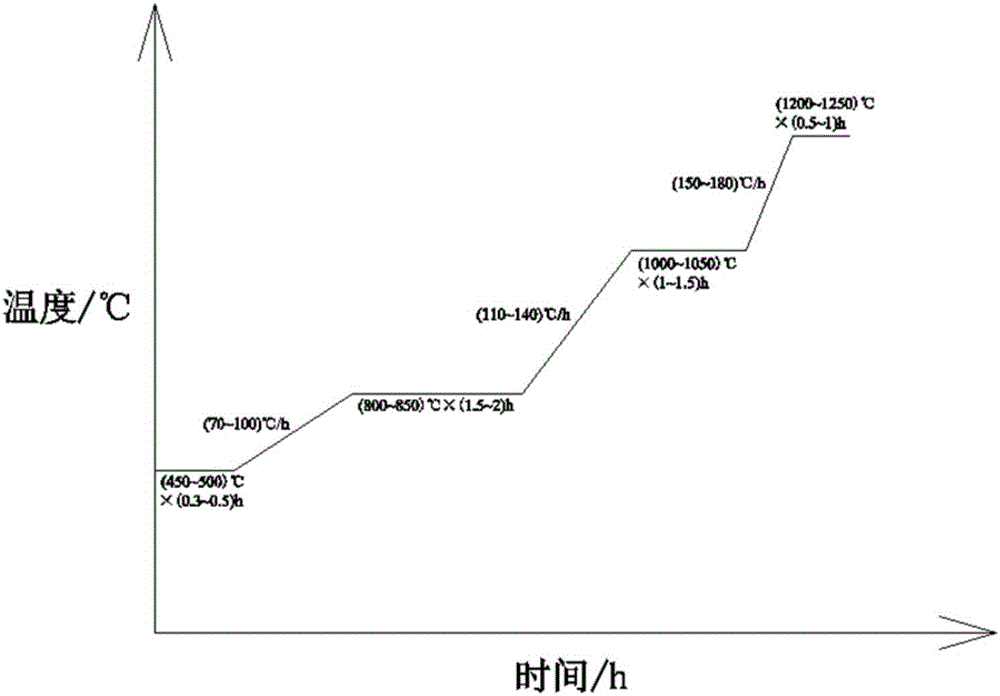

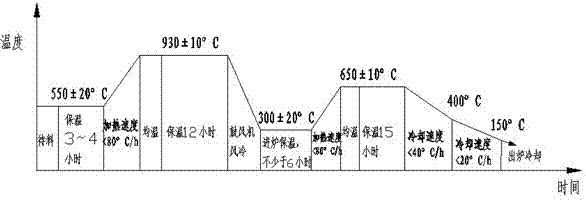

Fe-Mn austenite non-magnetic steel forging method

ActiveCN106048208AImprove uniformityGuaranteed uniformityMetal-working apparatusFurnace typesThree stageTemperature difference

The invention discloses a Fe-Mn austenite non-magnetic steel forging method, and belongs to the technical field of forging. The forging method comprises a heating process and a screw down process, wherein the heating process is characterized in that casting blank steel ingots are delivered to a soaking furnace in a hot manner, the surface temperature of the casting blank steel ingots is greater than 330 DEG C, the temperature in a preheating stage is controlled to be 400-550 DEG C and is kept for 0.2-0.7 h when heating is carried out, and heating is carried out in three stages; and the screw down process is characterized in that the blanks are forged to preheat a device before casting blank steel ingots are forged to make the surface temperature of flat anvils be greater than 250 DEG C, a layer of asbestos is paved on the surface of the casting blank steel ingots after the casting blank steel ingots are discharged from the furnace, forging is rapidly carried out, the initial forging temperature is greater than 1100 DEG C, and the finish forging temperature is greater than 900 DEG C. Compared with present forging technologies, the method disclosed in the invention has the advantages of reduction of the temperature difference between the surface and the core, basically consistent grain size, substantial improvement of the temperature and the microstructure uniformity, no cracks in the forging process, shortening of the crack cleaning time, forging time shortening, and effective increase of the forging efficiency.

Owner:武汉钢铁有限公司

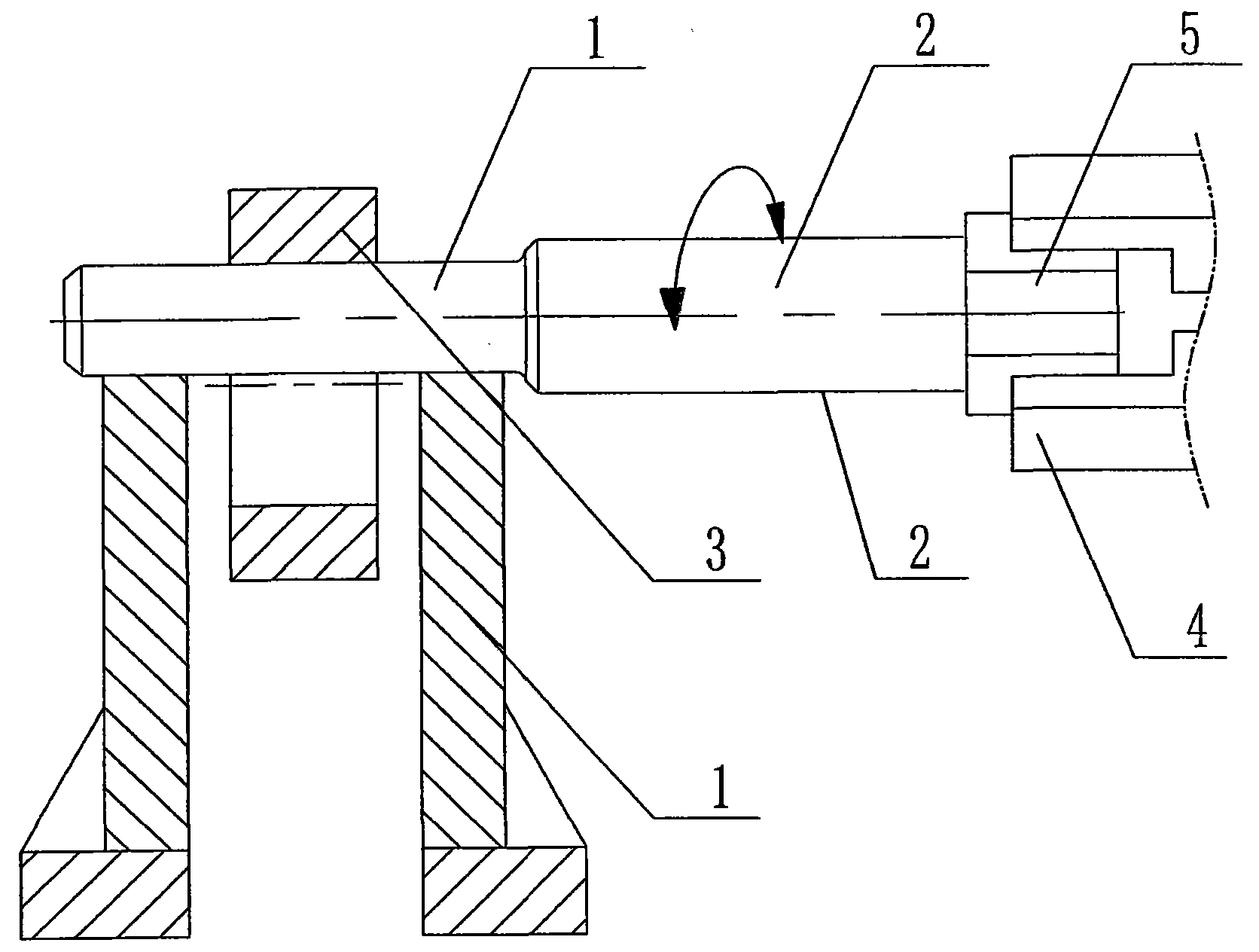

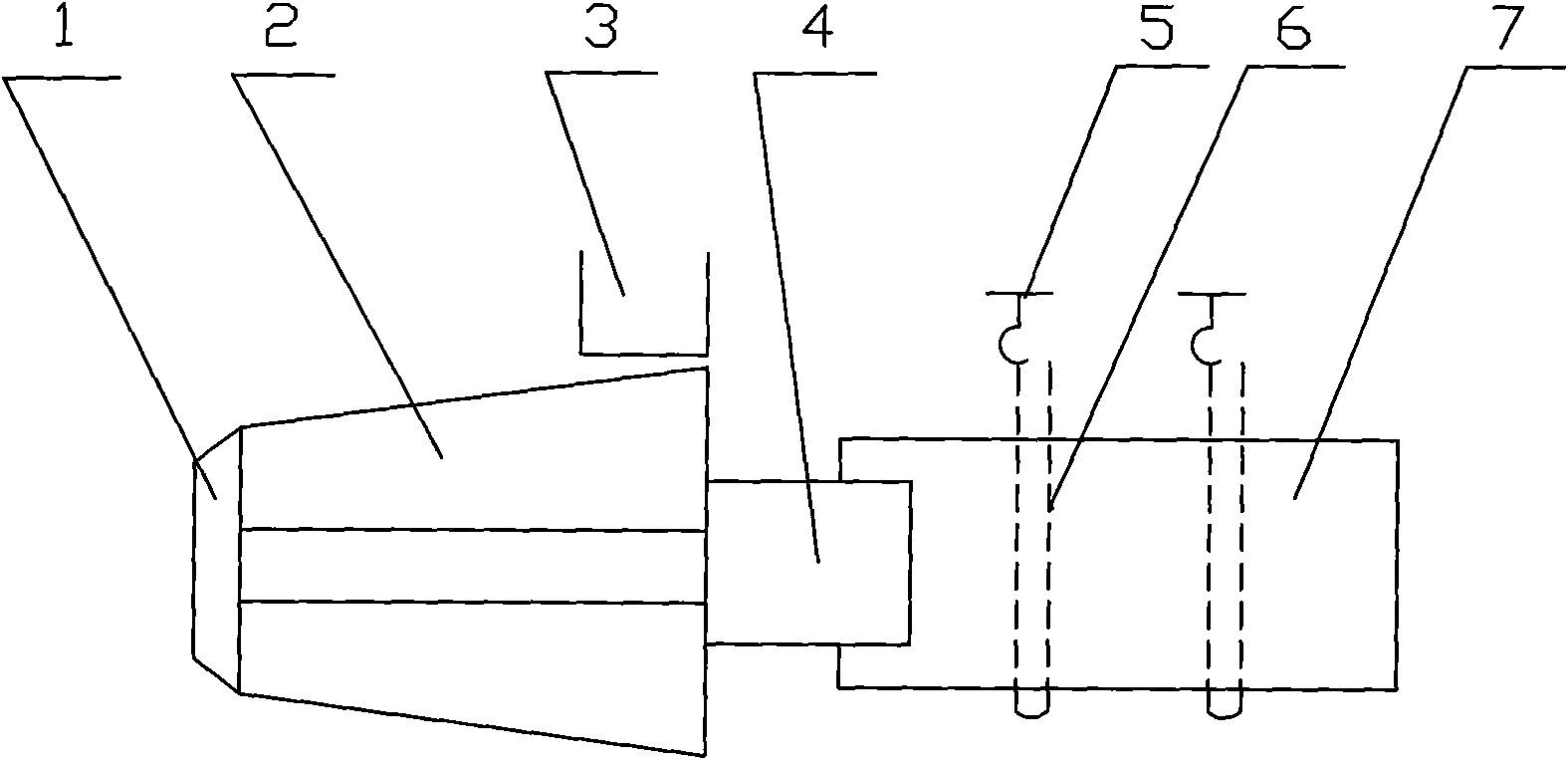

Non-flash groove, non ingot tail smithing method for large-scale wind power principal axle

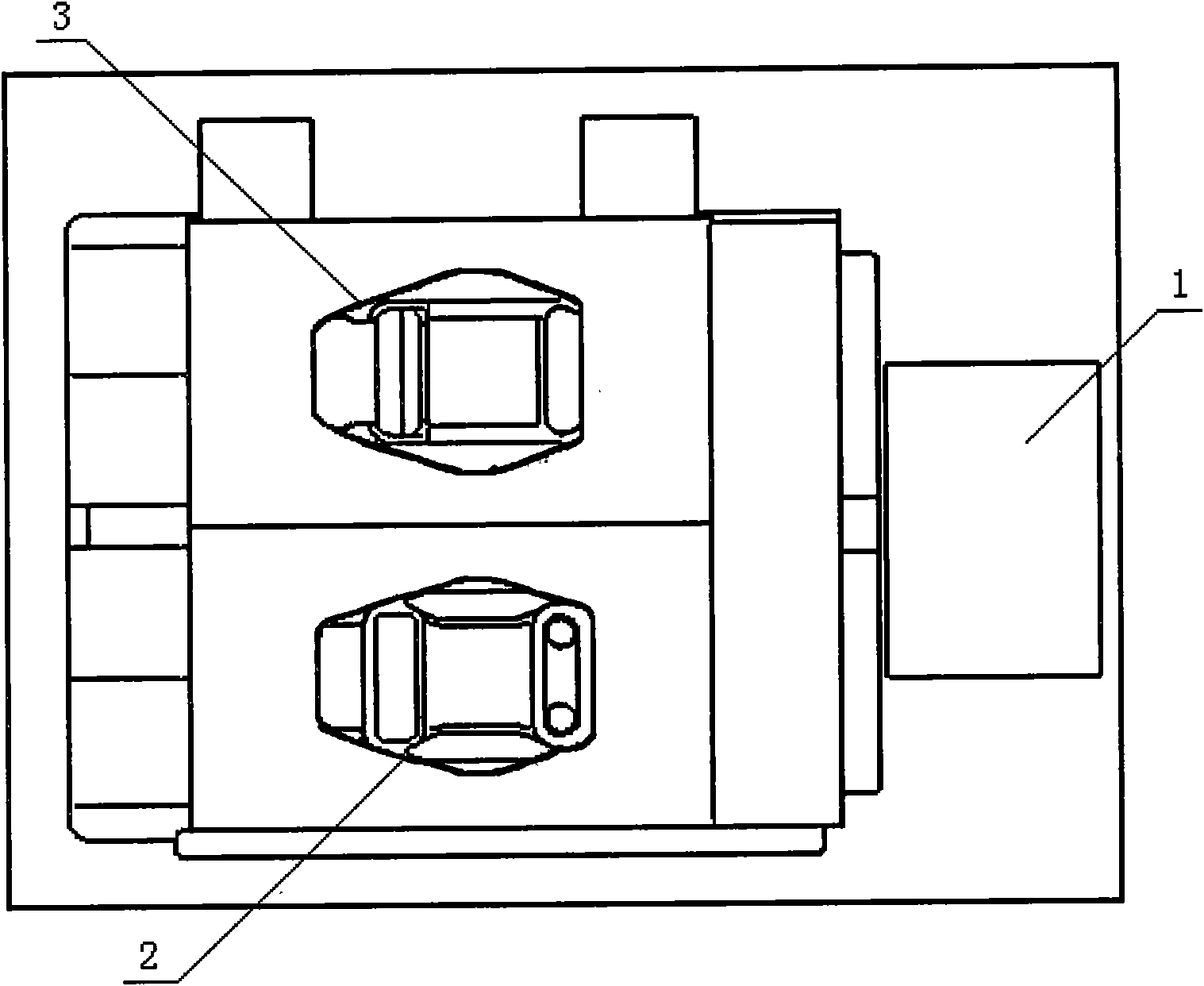

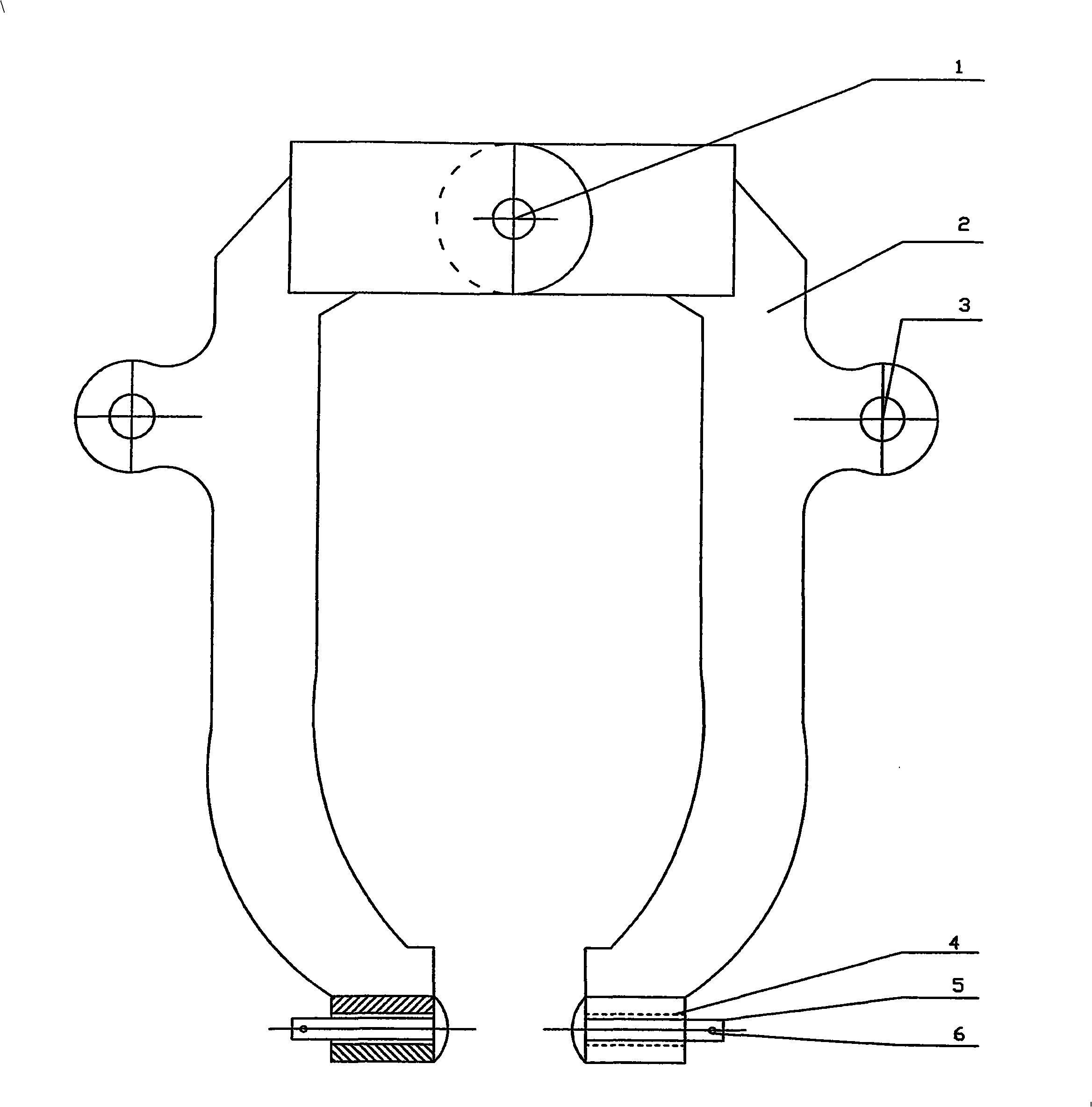

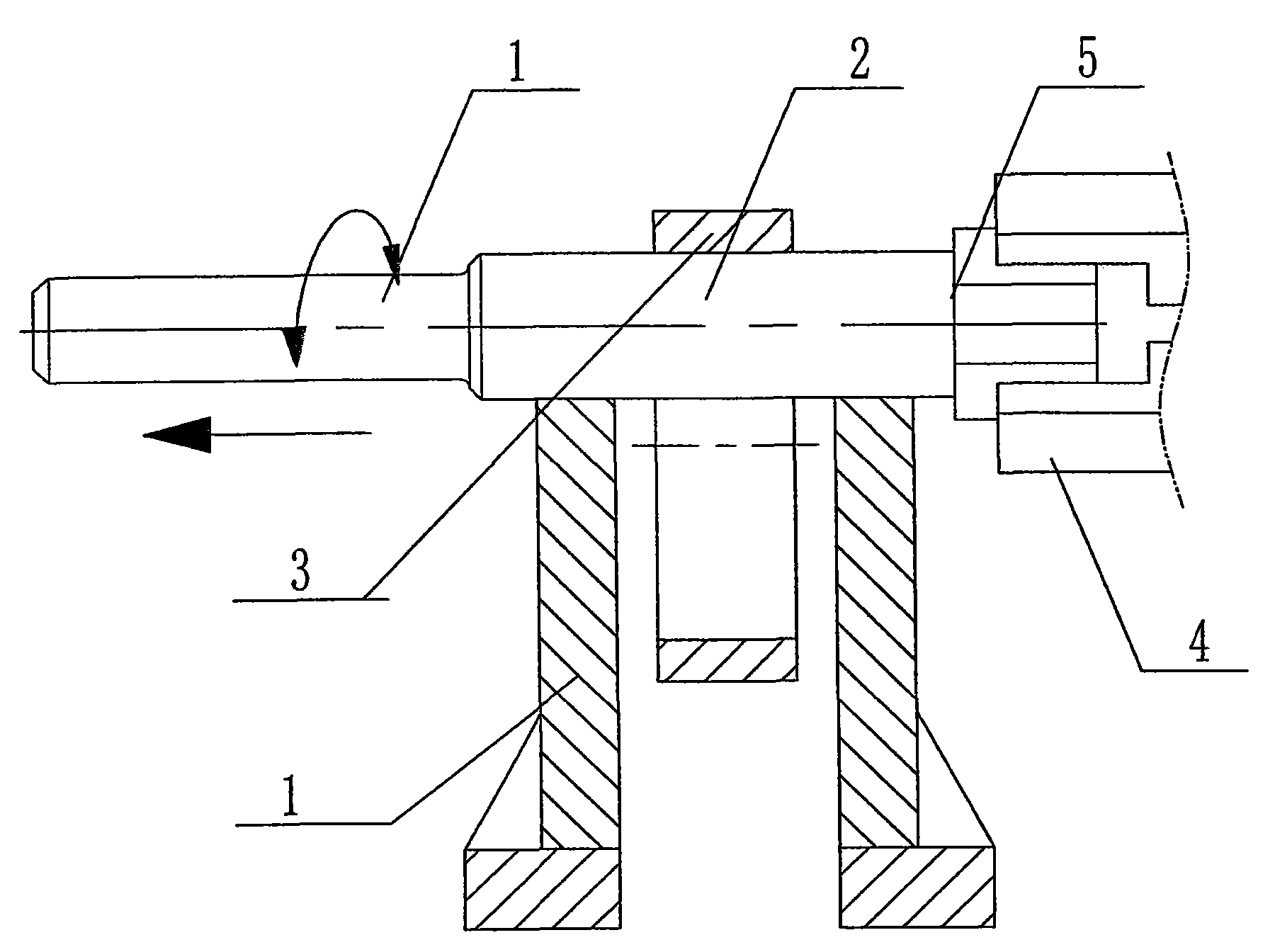

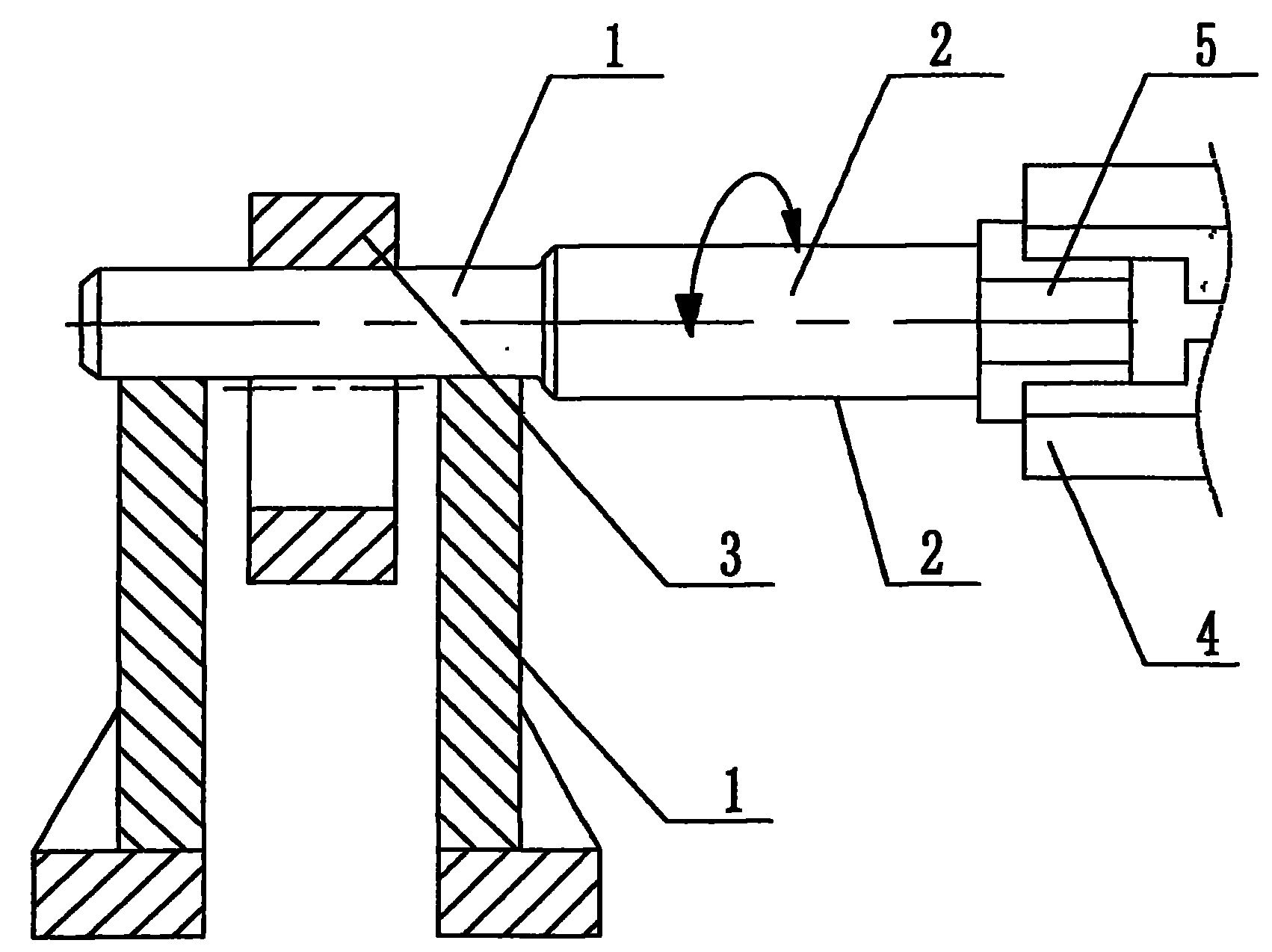

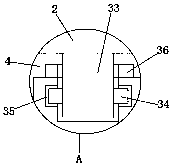

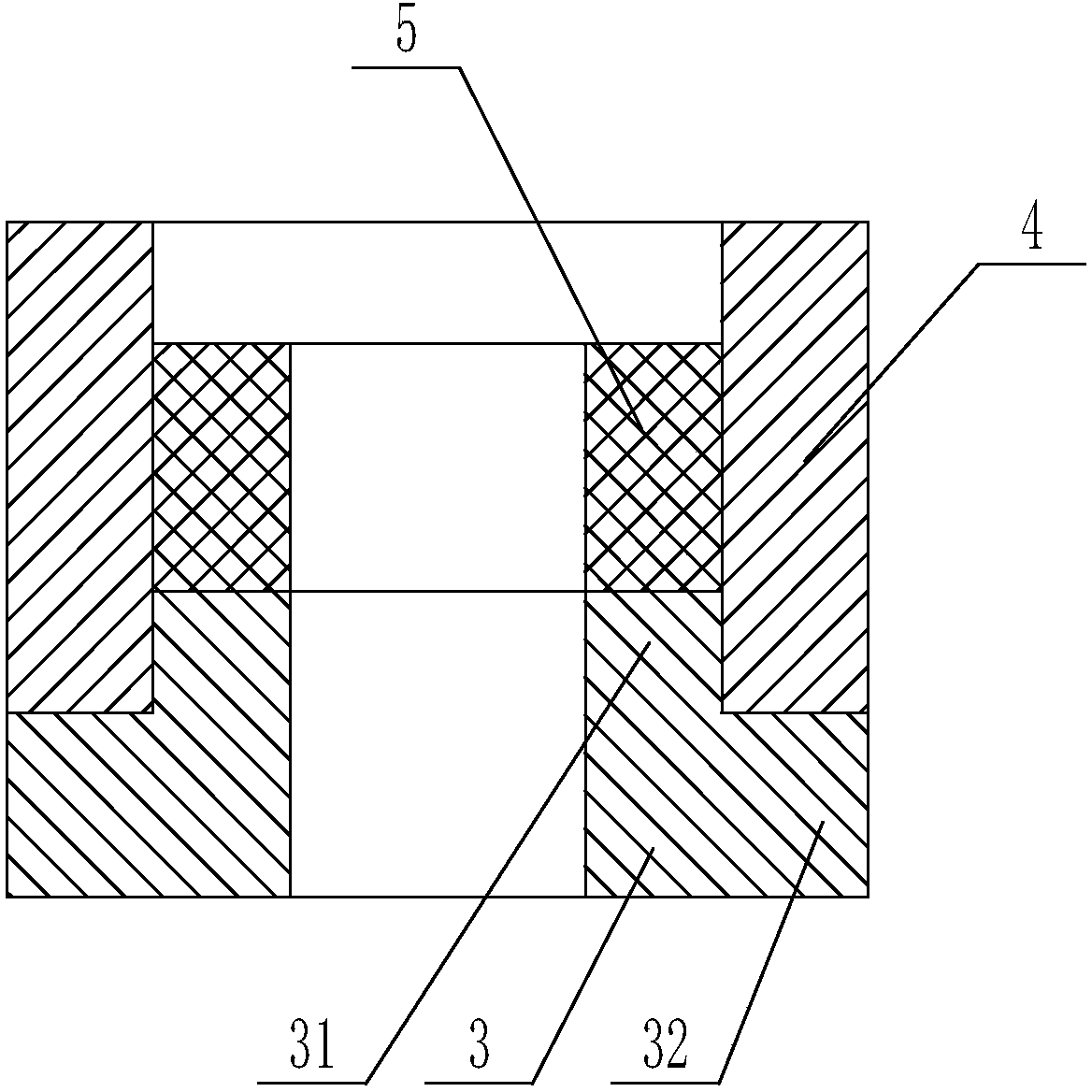

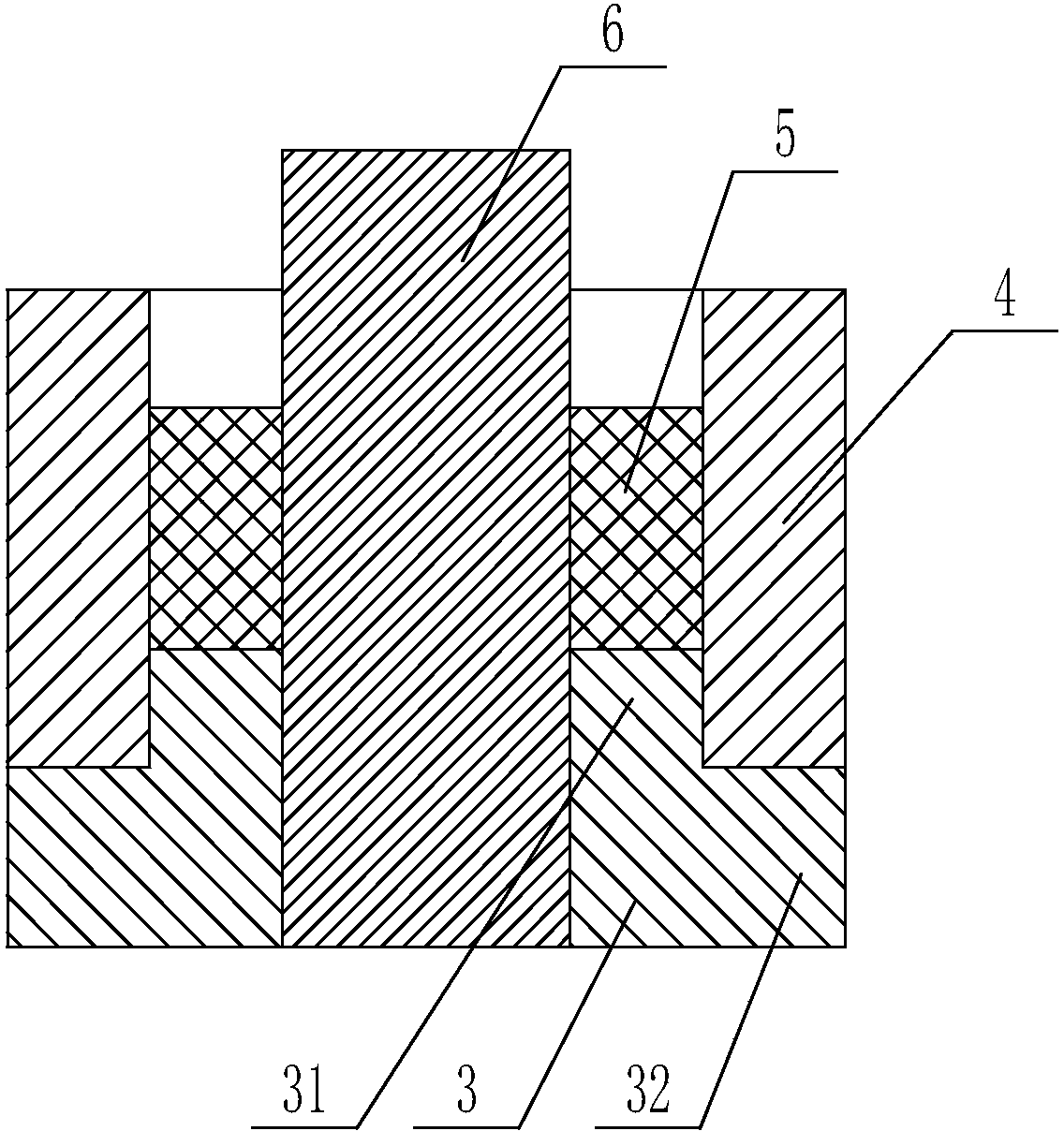

InactiveCN101293269AGood clamping functionEasy to turn functionForging/hammering/pressing machinesEngine componentsElectricityIngot

The invention relates to a no-riser and no-ingot tail forging method for a large-scale wind power main shaft; before heating and forging, a riser and a ingot tail of a steel ingot are cut off by a saw, then a jaw of pliers of a manipulator is used for clamping the steel ingot without the riser and the ingot tail, and then the processes of upsetting, drawing out, rolling circle, forging steps and upsetting flange are carried out; the jaw of the pliers of the manipulator includes pliers arms (2), sleeve seats (4) and ball-head cylinders (5); the number of the pliers arms (2), the sleeve seats (4) and the ball-head cylinders (5) is two, one piece is at the left and the other piece is at the right, one end of the left pliers arm (2) is articulated with one end of the right pliers arms (2) by a gemel (1), the other ends thereof are respectively provided with the left sleeve seat (4) and the right sleeve seat (4), the left ball-head cylinder and the right ball-head cylinder (5) are respectively pass through the left sleeve seat (4) and the right sleeve seat (4); the ball-head ends of the left ball-head cylinder and the right ball-head cylinder (5) are arranged at the inner sides of the left sleeve seat (4) and the right sleeve seat (4) in a left and right antithetic manner, and the other ends thereof are provided with a fixed pin (6) by inserting along the radial direction. The method of the invention can reduce forging processes, improve production efficiency, shorten forging time and enhance forging precision and forging quality.

Owner:JIANGYIN LEGAO ENERGY EQUIP

Method for producing reinforced platinum material

[Problems]Providing a strengthened platinum material with the use of melt-sprayed platinum alloy powder and through a simpler working process, which ensures strength of weld and is excellent in high temperature creep property. [Means for Solving the Problems]In a method for producing a strengthened platinum material, comprising the steps of: adding an organic solvent and wet-milling a platinum alloy powder obtained by melt-spray; degassing the milled platinum alloy fine powder by heating; sintering the fine powder; and forging the fine powder, wherein the method further comprises subjecting a sintered body formed by the sintering to oxidation treatment; and subjecting the sintered body to compression molding.

Owner:TANAKA PRECIOUS METAL IND

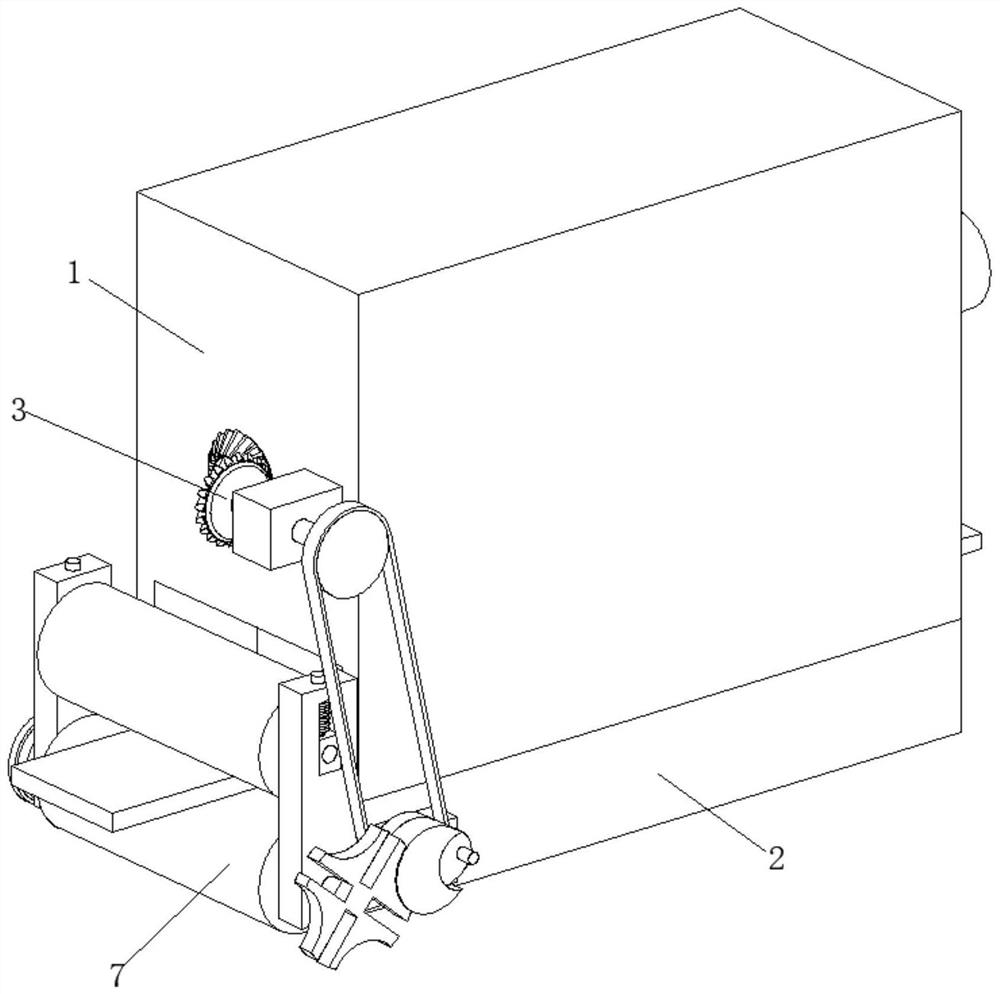

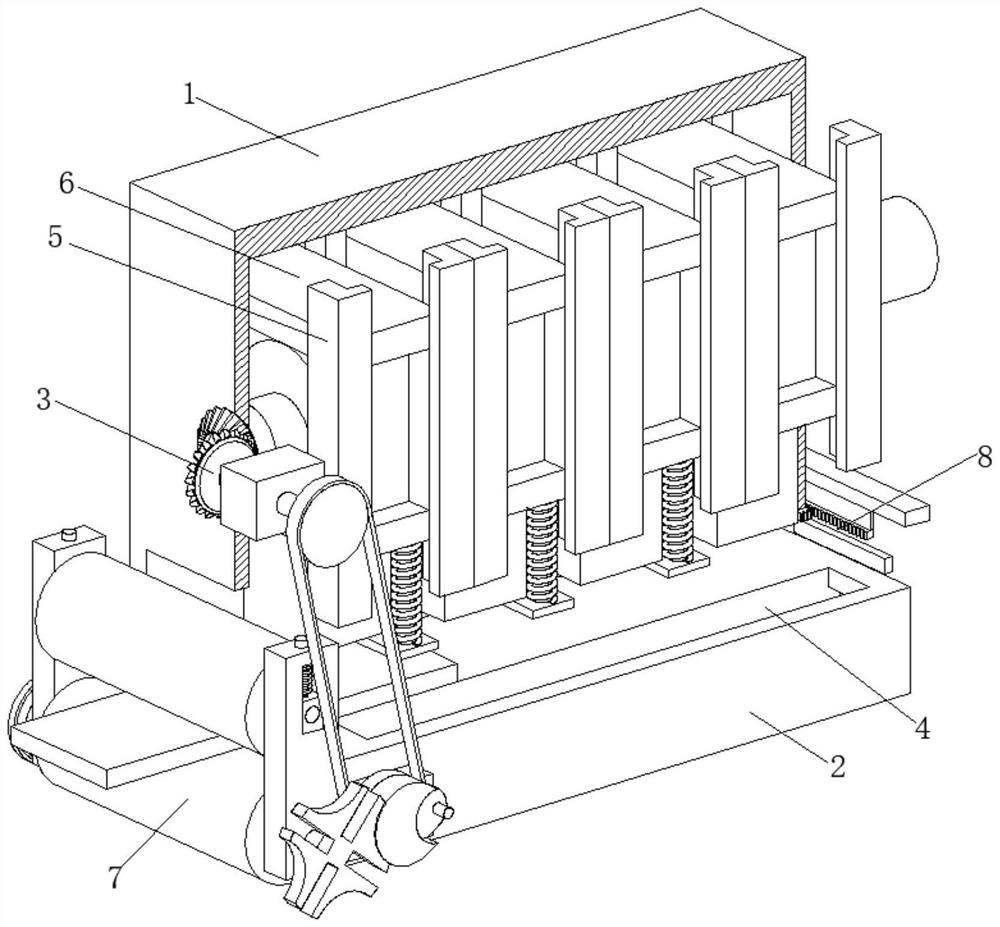

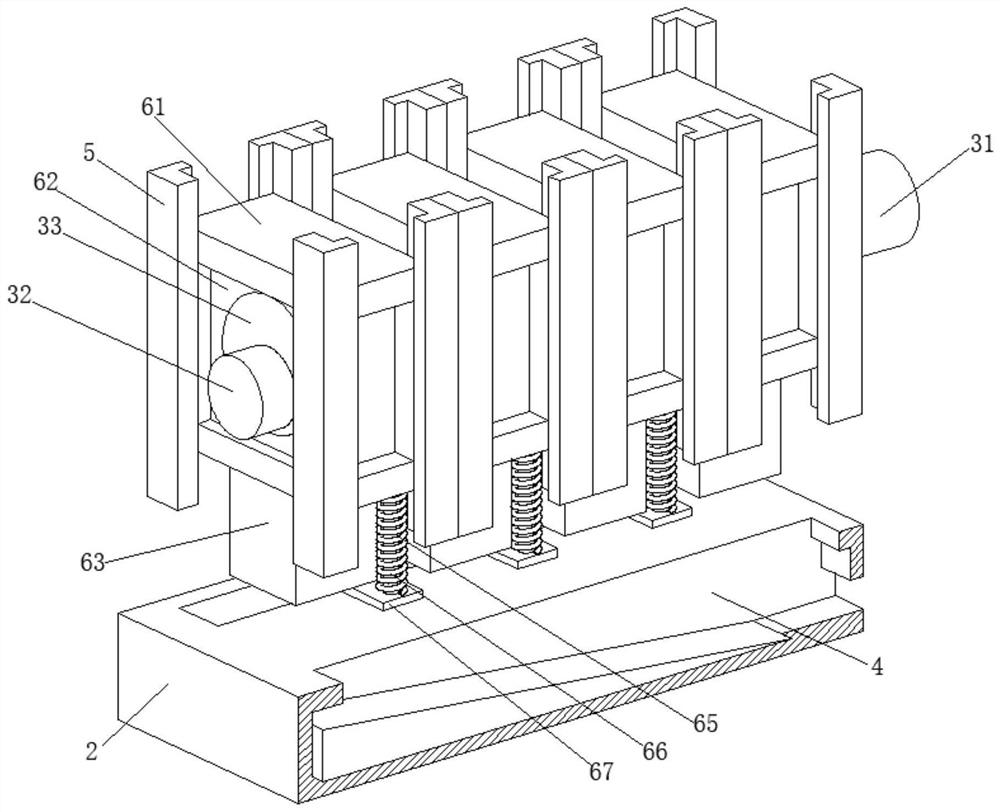

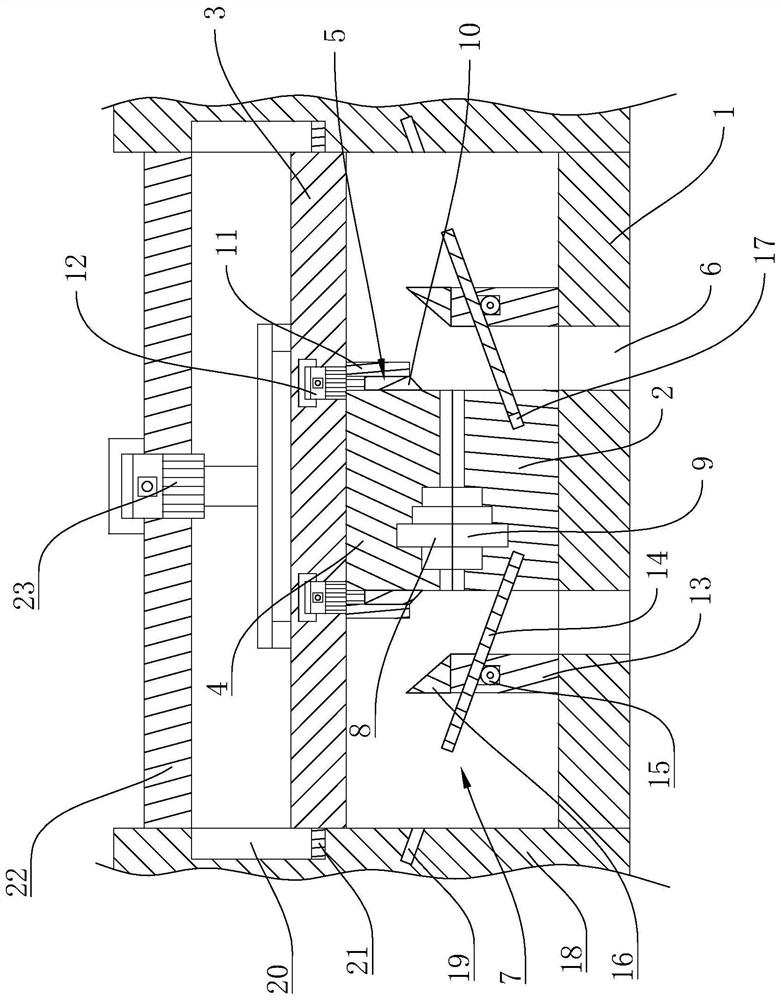

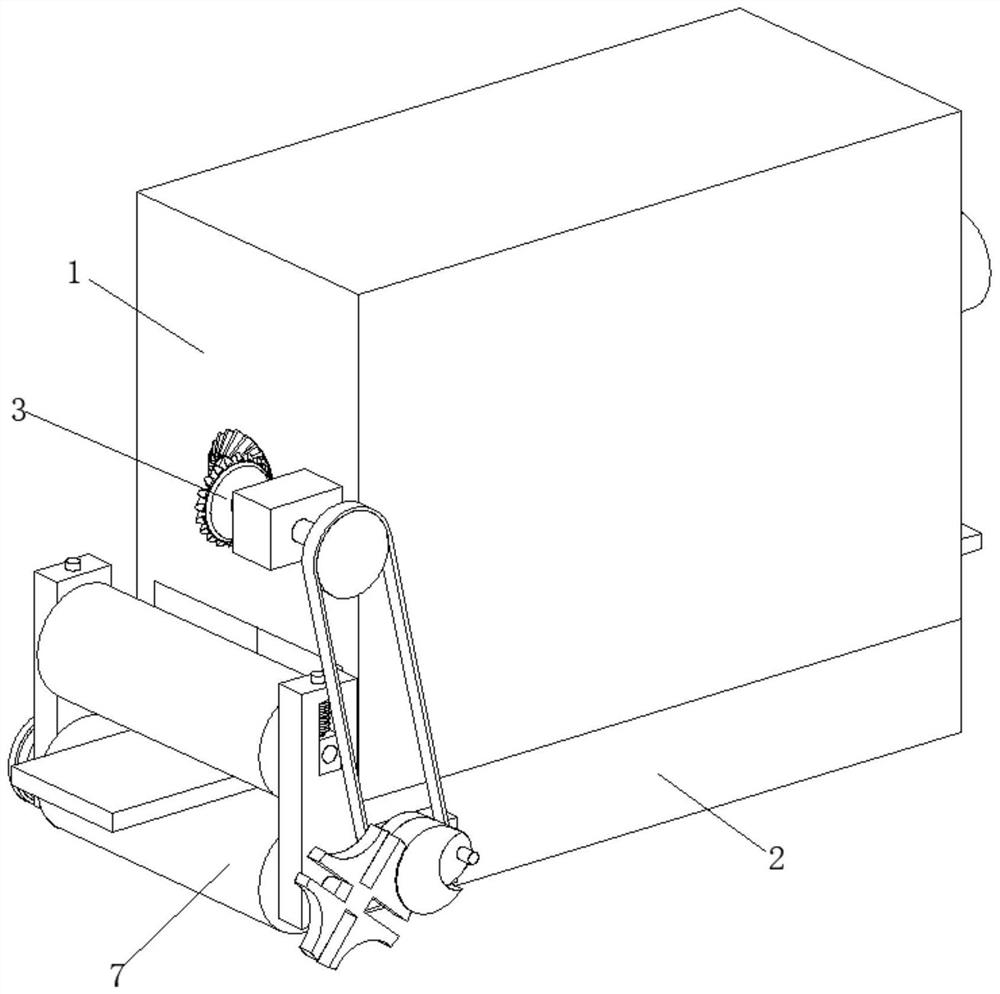

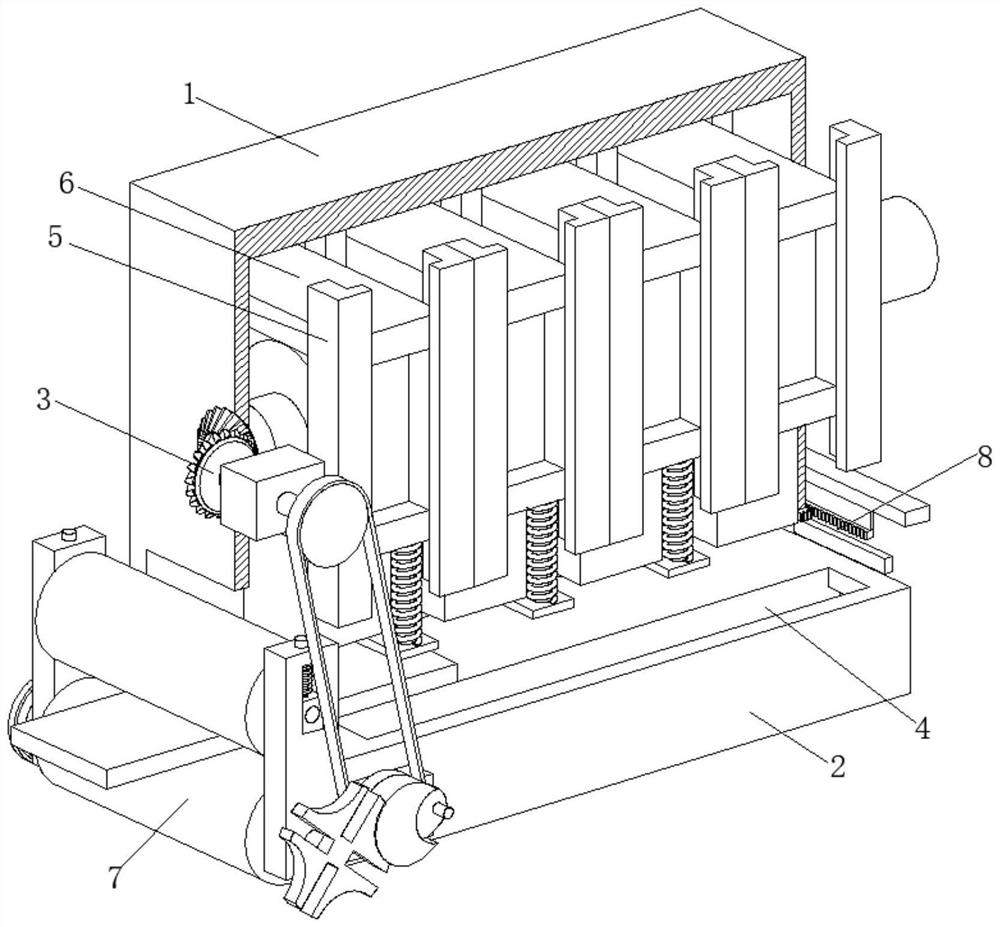

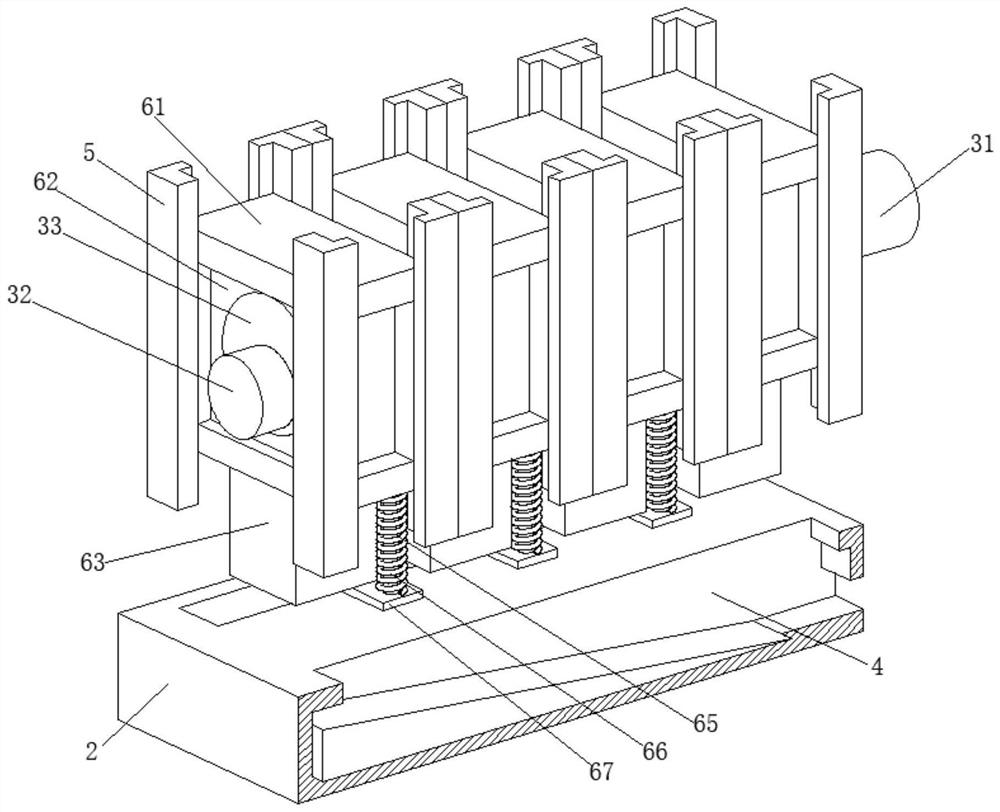

Continuous forging device with automatic cleaning function

ActiveCN112719183AShorten forging timeImprove work efficiencyDrop hammersHammer drivesEngineeringWorkbench

The invention relates to the technical field of forging equipment, and discloses a continuous forging device with an automatic cleaning function. The device comprises a box body, a workbench is welded at the bottom of the box body, a transmission mechanism is arranged at the front part of the box body, two discharge grooves are formed in the top of the workbench, and a plurality of limiting columns are welded on the inner wall of the box body. A forging mechanism is arranged on the surfaces of the limiting columns, a feeding mechanism is arranged at the front part of the workbench, and a cleaning mechanism is arranged at the rear part of the box body. According to the continuous forging device, through cooperative work of the transmission mechanism and the forging mechanism, a steel plate can be continuously forged, so that the situation that forging equipment is replaced after forging is conducted once is avoided, the stroke of the forging equipment is adjusted, forging time can be greatly shortened, the working efficiency is improved, the practicability is greatly improved, the cleaning mechanism can clean the finally forged steel plate, manual cleaning by workers is not needed, and the labor intensity of the workers is reduced.

Owner:山东圣利锻造有限公司

Forging method for six-throw crankshaft

InactiveCN102380564ASimple processSimple and efficient operationMetal-working apparatusEngine componentsEngineeringCrankshaft

The invention relates to a forging method for a six-throw crankshaft. The method comprises the following steps of: a), after upsetting a forge piece, drawing the forge piece to be flat and square, stamping the top and the bottom of the forge piece by using a triangular knife according to the number of the sections of the six-throw crankshaft needing to be forged, and stamping the forge piece into the same sections as the six-throw crankshaft; b), drawing the longer section of the six-throw crankshaft by using a short anvil according to the length of the six-throw crankshaft needing to be forged, and then integrally drawing the overall forge piece to a required size; c), twisting a corresponding section of the drawn forge piece to obtain a blank of the six-throw crankshaft needing to be forged; and d), performing precision-forging finishing on the blank of the six-throw crankshaft to obtain the six-throw crankshaft needing to be forged. The method is suitable for forging the six-throw crankshaft.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

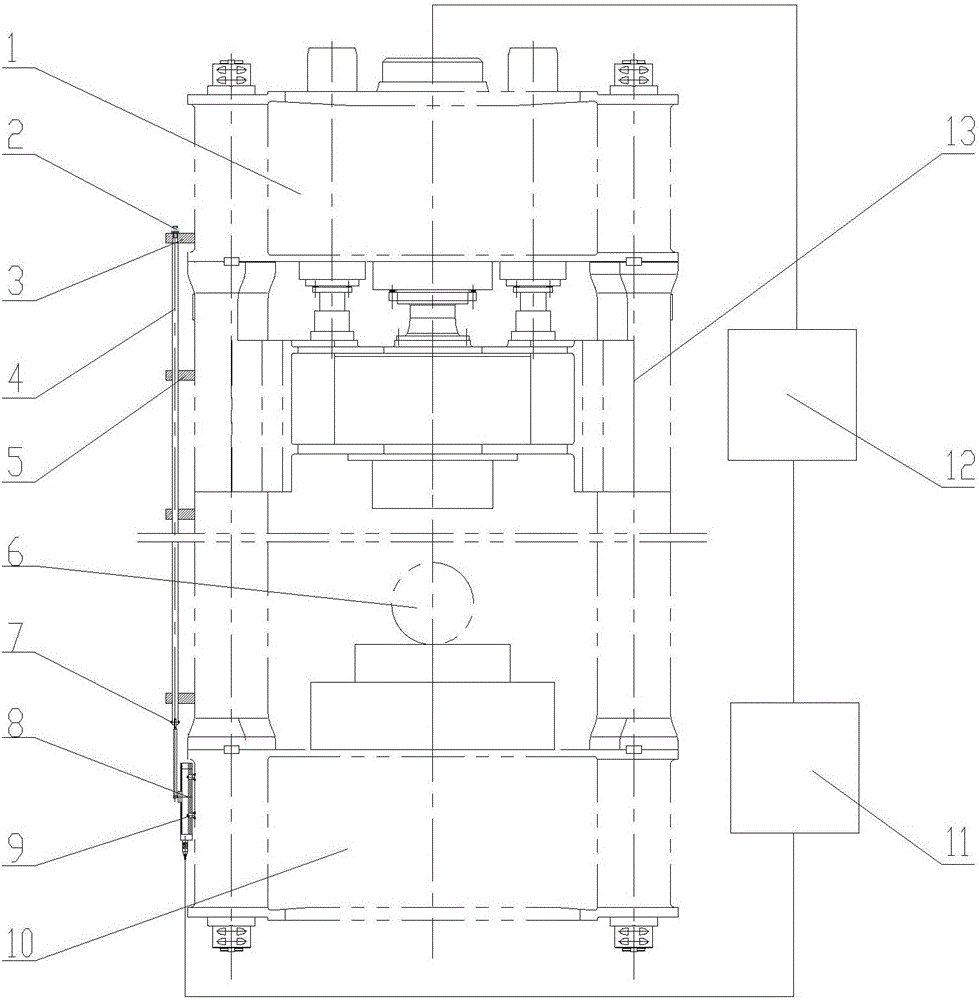

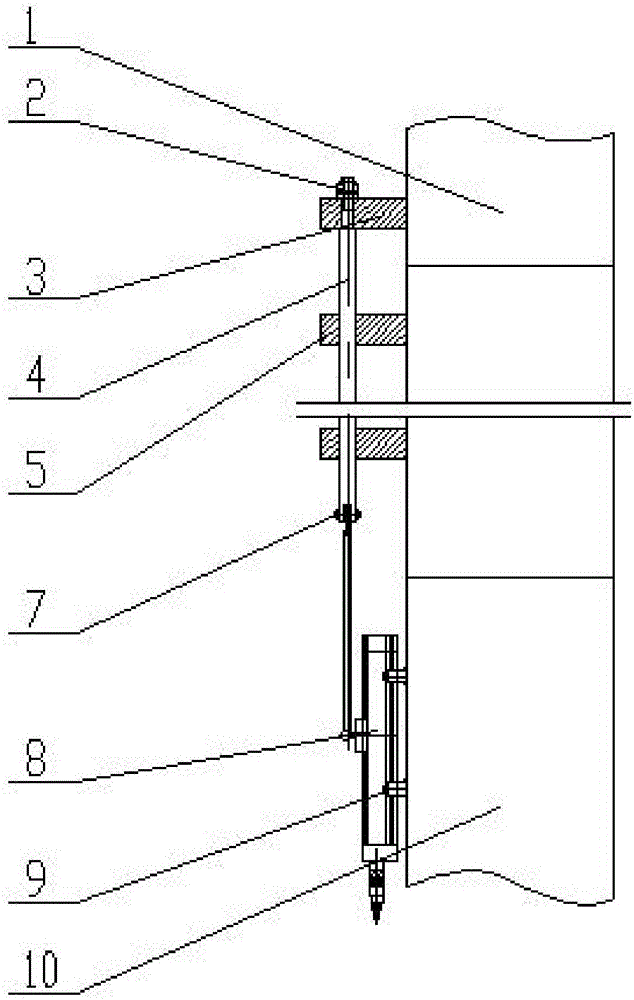

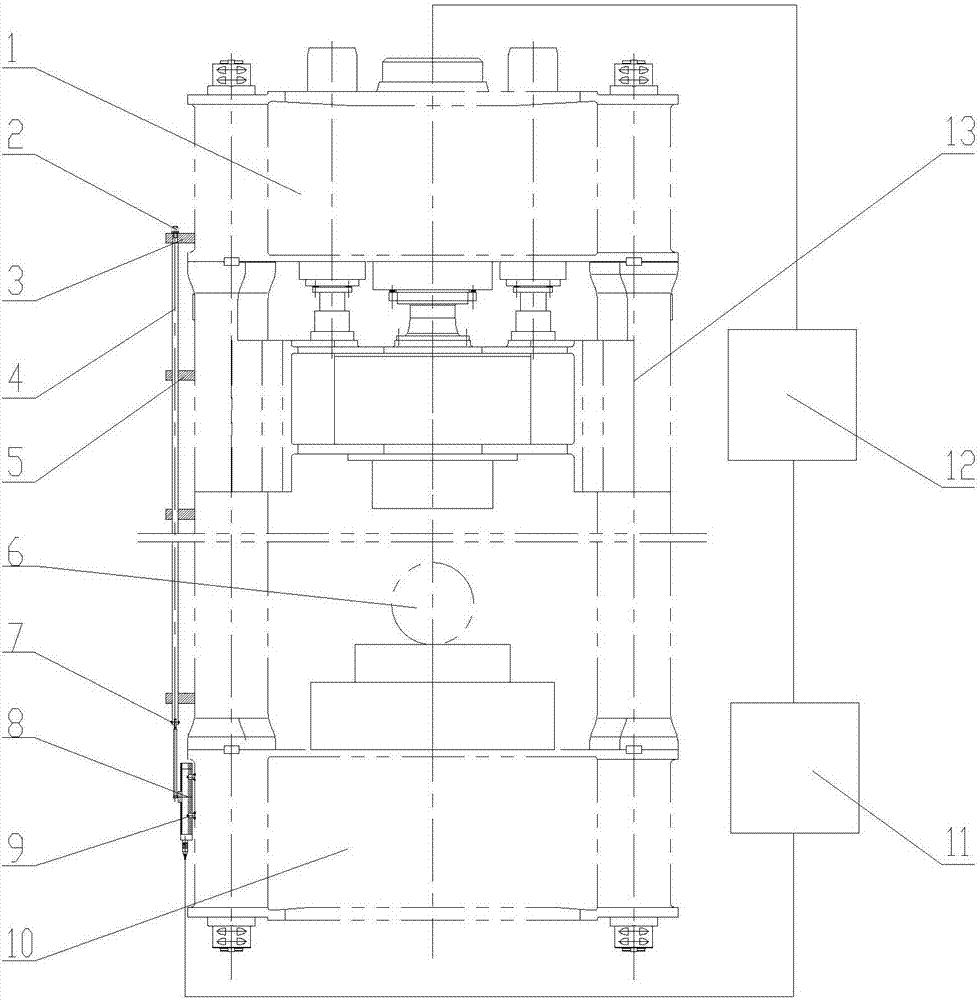

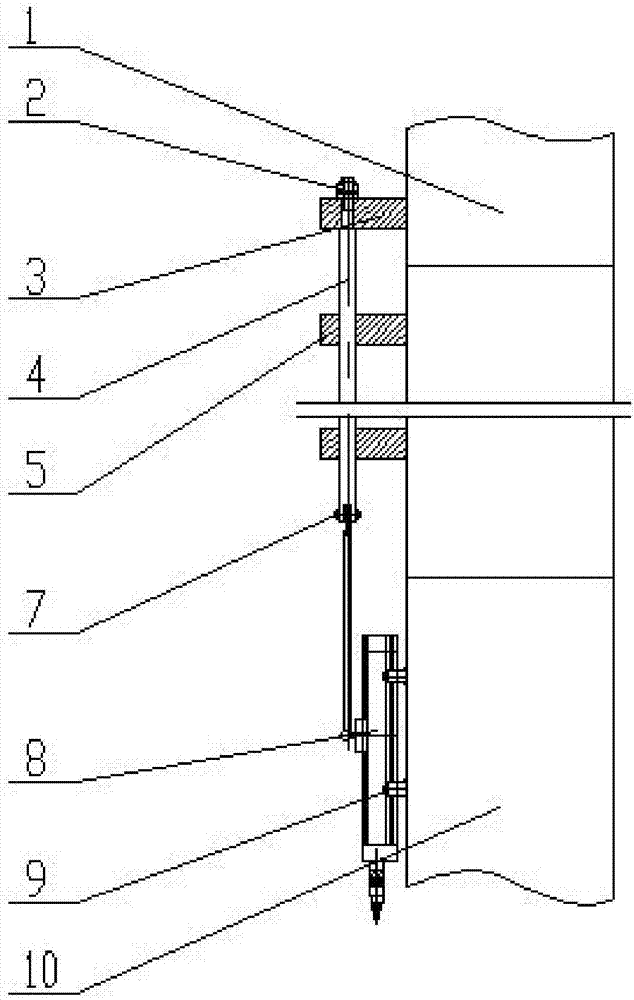

Large hydraulic machine size compensation system

ActiveCN105903875AIncrease productivityShorten forging timeForging press drivesElectrical controlControl theory

A large hydraulic machine size compensation system comprises a displacement sensor fixed to a lower beam through a fixing support; a sliding block on the displacement sensor is connected with the lower end of a fixing rod through a pin shaft; the upper end of the fixing rod is fixedly connected with an upper beam through an upper fixing block; the upper fixing block and the fixing rod are fastened through lock nuts; the signal output of the displacement sensor is connected with the input of an electrical control system; the output of the electrical control system is connected with the input of a hydraulic control system; forging on a forge piece is completed through the hydraulic control system; the displacement sensor is used for measuring direct displacement changes of the upper beam and the lower beam; the displacement sensor is used for transmitting the real-time deformation amount of a framework to the electrical control system so that forging size correction can be performed; the hydraulic system is controlled to complete forging on the forge piece; it is achieved that actual forging size and the set size are within actual control precision; the size precision of the forge piece is improved; and the overall forging time is shortened, and therefore the production efficiency is improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Magnesium alloy automobile wheel forging method

ActiveCN105665610BDense tissueUniform tissueForging/hammering/pressing machinesForging press drivesHeating furnaceUltimate tensile strength

The invention relates to the forging field, and aims to provide a forging method for a magnesium-alloy automobile hub. The forging method for the magnesium-alloy automobile hub comprises the following steps: step I, heating a magnesium alloy rod in a heating furnace; step II, pre-forging the magnesium alloy rod; step III, carrying out pre-profiling forging on disc-shaped blank; step IV, carrying out fine-profiling forging on a pre-profiled hub; step V, carrying out fine-shaping forging on a fine-profiled hub; step VI, transferring the fine-shaped hub to a transfer table for heating through a position transfer device, wherein a heating temperature is controlled to 320 DEG C to 450 DEG C; and step VII, carrying out rim extrusion sizing on the fine-shaped hub. The forging method for the magnesium-alloy automobile hub is relatively high in production efficiency; and the magnesium-alloy automobile hub is compact in texture, is uniform in component, and is relatively high in mechanical strength.

Owner:刘兴军

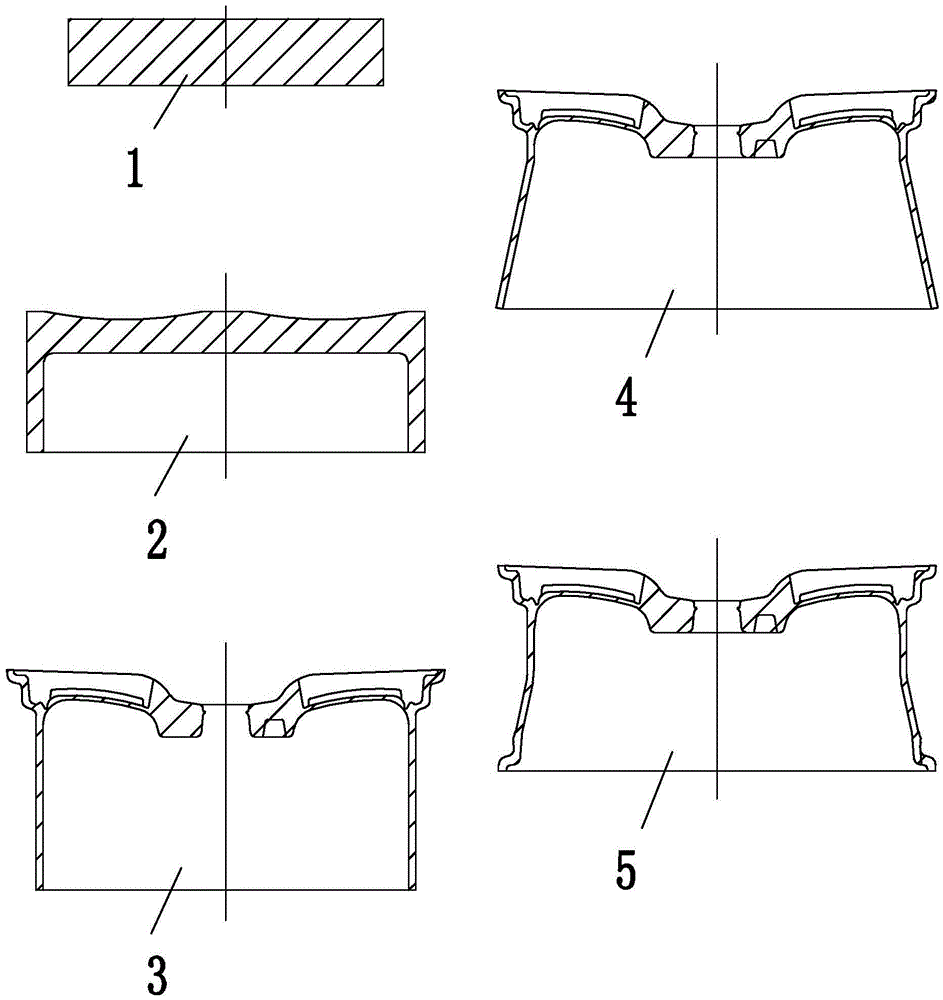

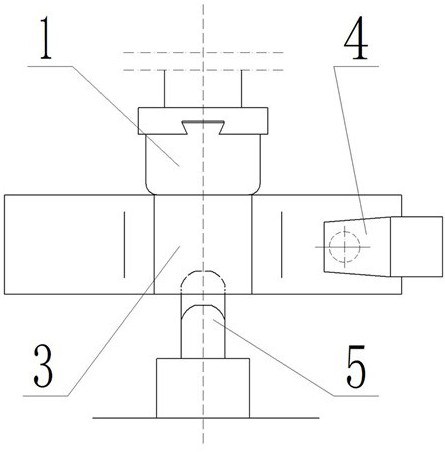

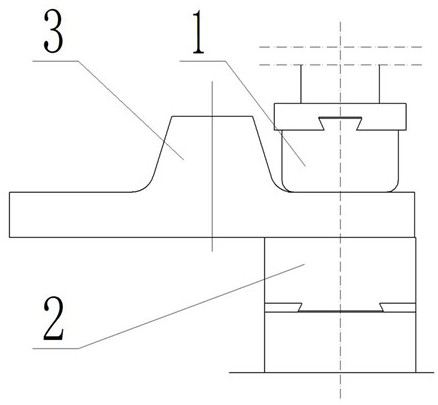

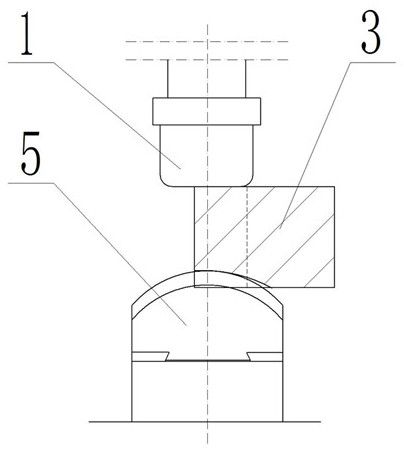

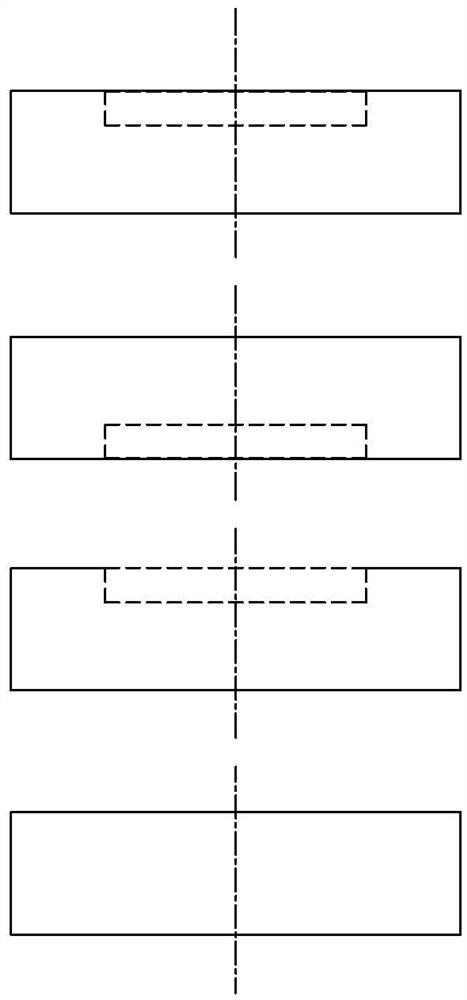

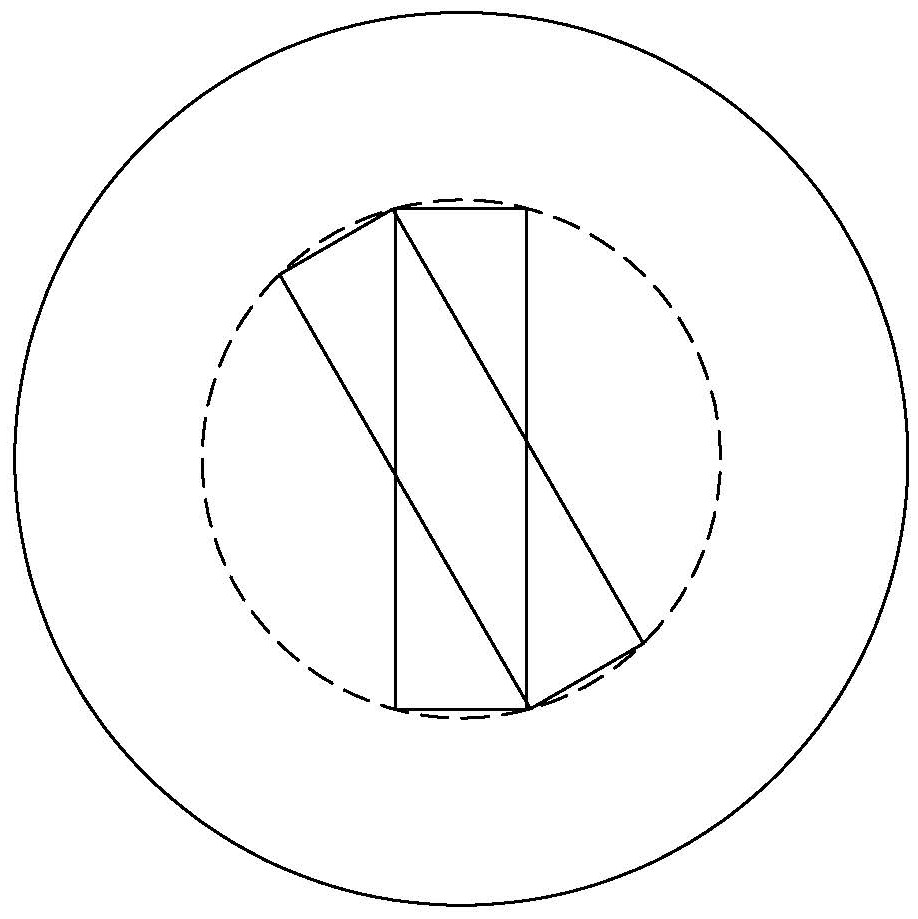

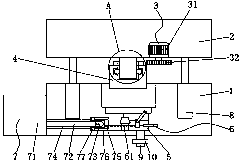

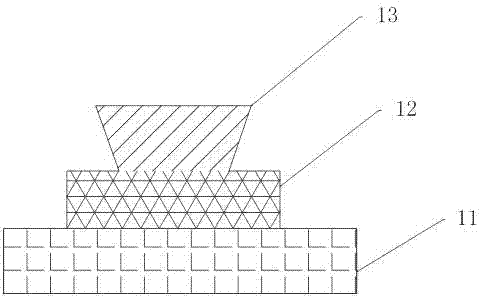

Shoulder core forging die for 3T/5T swager

InactiveCN102029344AShorten forging timeReduce energy consumptionForging/hammering/pressing machinesEngineeringEnergy consumption

The invention relates to a shoulder core forging die for a 3T / 5T swager and is mainly used for forging core forgings. The shoulder core forging die comprises a support (1), a core (2) and a jaw (4), wherein the core (2) is divided into two straight sections from the front to the rear along a length direction; the front straight-section core has a smaller diameter and is called a small diameter section (2.1); the rear straight-section core has a larger diameter and is called a large diameter section (2.2); the tail of the large diameter section (2.2) is an octagon (5); the core (2) is transversely shelved on the support (1); and the jaw (4) is arranged at the octagonal end of the core (2). During production, the front small diameter section core is used for performing primary expanding, and the rear large diameter section core is directly used for performing secondary expanding. Therefore, the forging time can be greatly shortened, and the energy consumption is also reduced.

Owner:JIANGYIN NANGONG FORGING

A Size Compensation System for Large Hydraulic Press

ActiveCN105903875BIncrease productivityShorten forging timeForging press drivesElectrical controlEngineering

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

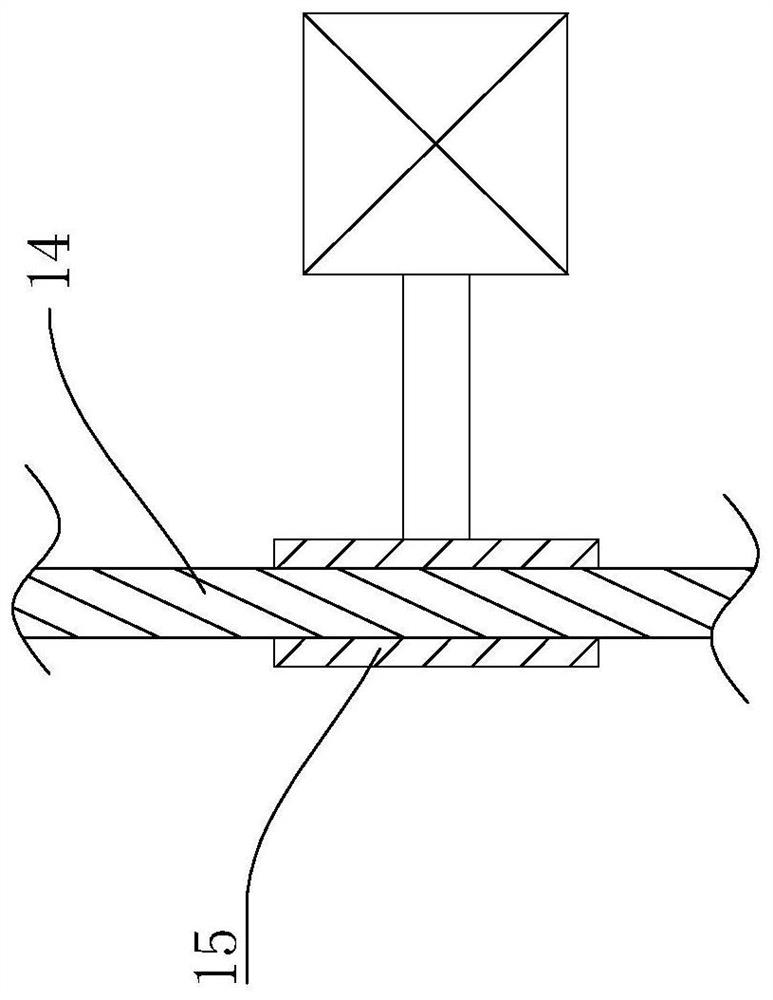

Method for forging by using tilting gear and manipulation trolley instead of sleeve for turning steel ingot

InactiveCN102049454ALarge clamping forceThe operation process is easy to controlMetal-working apparatusIngotEngineering

The invention relates to the field of metallurgy forging, in particular to a method for forging by using a tilting gear and a manipulation trolley instead of a sleeve for turning steel ingot. The method comprises the following steps of: 1) arranging the tilting gear at the tail or the head of the steel ingot, and clamping the cap at the head of the steel ingot by using a manipulator of the manipulation trolley; and 2) hooking the tilting gear by using a main hook of a crown wheel and making the tilting gear and the manipulator of the manipulation trolley simultaneously turn the steel ingot. Compared with the prior art, the method has the advantages that: the operating process of the method is easily controlled, the clamping force on the steel ingot is large, the operation is simple and convenient, the forging time is saved, and the working efficiency is improved.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

Crank throw forming and forging process

PendingCN114309429AGood forging formabilitySmall machining allowanceForging/hammering/pressing machinesEngine componentsPhysicsCrank

The invention relates to a crank throw forming forging process which comprises a forging machine, a manipulator, an anvil replacing die, a reverse buckling bending die, a core die, an upper anvil, a lower anvil, a workbench and a forged piece. Firstly, a prefabricated forge piece with a boss arranged in the middle is pressed to be thin and drawn out, then a male die, a trapezoidal die and a female die are arranged below the boss, a concave anvil replacing die and an arc anvil replacing die are arranged above the boss, multi-angle left-right moving and overturning forging is conducted on the boss, forging of a curved neck cylindrical blank is completed, then reverse forging bending is conducted through a reverse buckling bending die, and the curved neck cylindrical blank is formed. And two wings of the prefabricated forge piece are bent and folded together, then a series of core molds with different thickness differences at the two ends are used for pressing, meanwhile, the boss head is forged into the quadrangular crank throw head, and finally the crank throw forge piece is finished to the set size. The forging die has the advantages of being good in forming degree, small in machining allowance, short in forging time, small in material loss and low in production cost.

Owner:ZHONGJUXIN OCEAN ENG EQUIP CO LTD +1

Forging method of large medium-thickness cake-like forging

InactiveCN111618218AEasy to loosenEasy to crackMetal-working apparatusIndustrial engineeringRaw material

The invention discloses a forging method of a large medium-thickness cake-like forging. On the premise of guaranteeing product quality, the heating number of forging can be reduced, the loss in heat treatment of raw materials is saved, forging time is shortened, and production cost is lowered. According to the forging method, the forging is heated to expected temperature, indenting is performed, and an outer edge is rotatably and flatly pressed. The forging method is characterized in that the indenting is double-surface continuous indenting, that is, after one surface is indented, the forgingis immediately turned over by 180 degrees to indent the other surface; and finally, rotatable flat-pressing, outer circle rolling, flattening of the two indented surfaces and forming are performed.

Owner:WUXI HONGDA HEAVY IND

Wind-powered main shaft forging method

ActiveCN102806291BEnsure forging quality requirementsReduce fire consumptionMetal-working apparatusFurnace typesElectricityThermal treatment

The invention relates to a wind-powered main shaft forging method. The wind-powered main shaft forging method comprises the following steps of inspecting a material; heating the material; taking out a blank which is formed by annealing the material for the first time, pre-forging, upsetting, drawing and printing the blank, performing pre-forging to form the blank, and blanking; finally forging the blank to form a main shaft by annealing for the second time, forging a flange end on a hollow rotary worktable, and drawing the main shaft until a shaft body has forging size; performing re-crystallization normalized tempering thermal treatment by using a one-time thermal loading furnace after forging the wind-powered main shaft; roughly turning the wind-powered main shaft and detecting flaws through ultrasonic wave; hardening and tempering the wind-powered main shaft, and performing nondestructive inspection and physical and chemical inspection on the wind-powered main shaft; finely turning the wind-powered main shaft; and packaging the wind-powered main shaft. The wind-powered main shaft forging method provided by the invention has the characteristics that the efficiency is high, the energy is saved, the cost is reduced, and the forging quality is improved.

Owner:JIANGSU LINGFEI FORGING

Method for forging fuel feed pump driving gear for forklift

The invention discloses a method for forging a fuel feed pump driving gear for a forklift. According to the method, a steel ingot comprises, by weight, 0.25-0.35% of C, 0.5-1.3% of Mn, 1.5-2.5% of Si, 0.02-0.06% of Al, 0.085-0.12% of Ti, 1.2-2.4% of Cr, 0.16-0.26% of Zn, a trace amount to 0.30% of Nd, 0.2-0.4% of Li, 0.04-0.08% of Cu, a trace amount to 0.025% of Re, smaller than or equal to 0.025% of P, smaller than or equal to 0.030% of S, and the balance Fe. By the adoption of the method, the defects of the prior art are overcome, energy is saved, heat treatment quality is improved, the production cycle is shortened, production cost is reduced, and radiation pollution to a workshop is reduced.

Owner:安徽蓝博旺机械集团精密液压件有限责任公司

Rotary machining die for forge piece machining

InactiveCN111215569ARapid coolingReduce mistakesForging/hammering/pressing machinesGear wheelElectric machinery

The invention discloses a rotary machining die for forge piece machining. The rotary machining die for forge piece machining comprises a fixed die, a movable die, a rotating assembly, a forging hammer, a mounting groove, a die separating assembly, a cooling assembly, a first hydraulic rod, a water outlet pipe and a valve, and the rotating assembly is fixed to the outer wall of the bottom end of the movable die; and the rotating assembly comprises a motor, a first gear, a fixing rod, a first sliding block, a first sliding groove and a second gear, the fixing rod is welded and fixed to the outerwall of the middle of the bottom end of the movable mold, and the first sliding block is welded and fixed to the outer wall of one side of the fixing rod. According to the rotary machining die for forge piece machining, a rotating device is adopted for machining a curved surface structure, the rotating angle can be adjusted more finely through the motor, errors are reduced, the quality of a forgepiece is improved, a cooling device is further adopted, the forge piece can be rapidly cooled, the forging time is shortened, the production efficiency is improved, finally, a die separating device is utilized, therefore, the forge piece is separated from the die, the manual operation is reduced, and the working efficiency is improved.

Owner:张本松

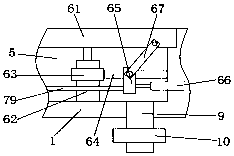

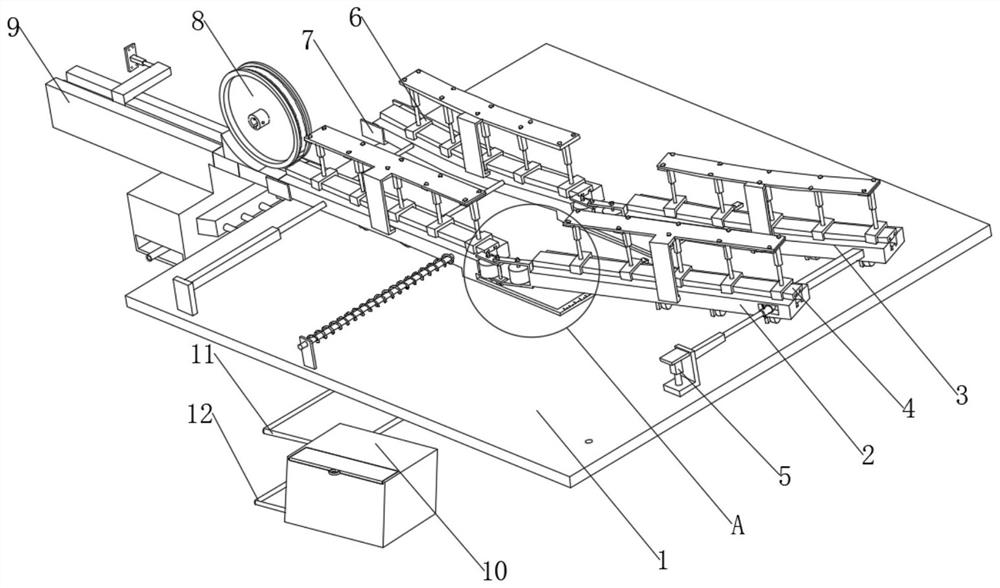

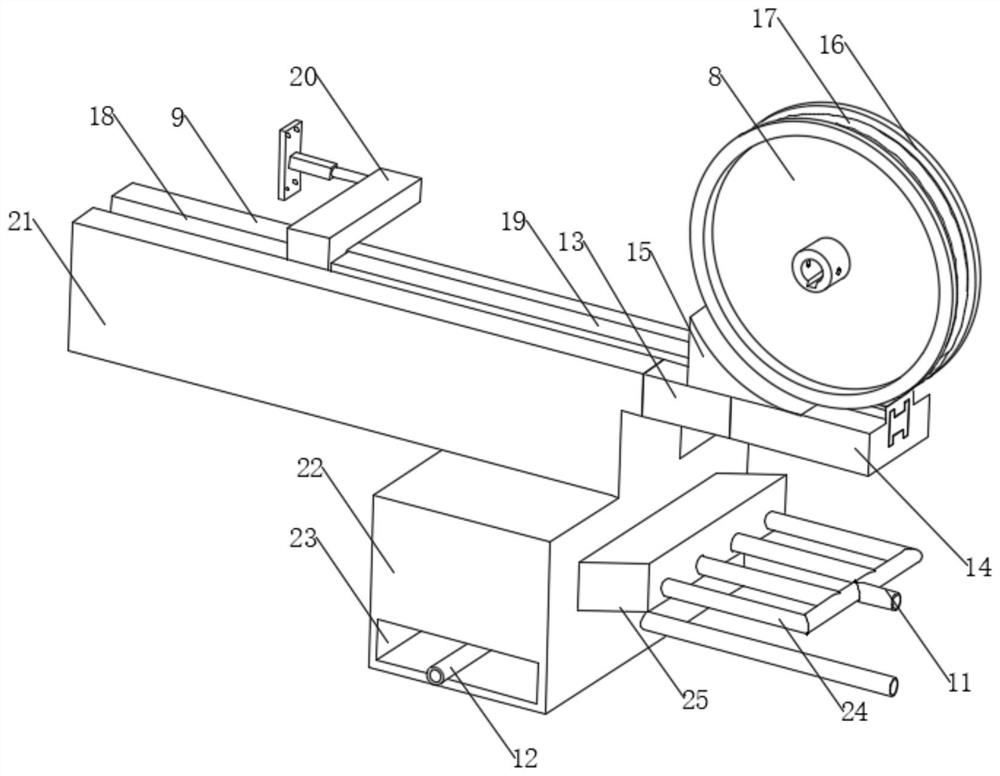

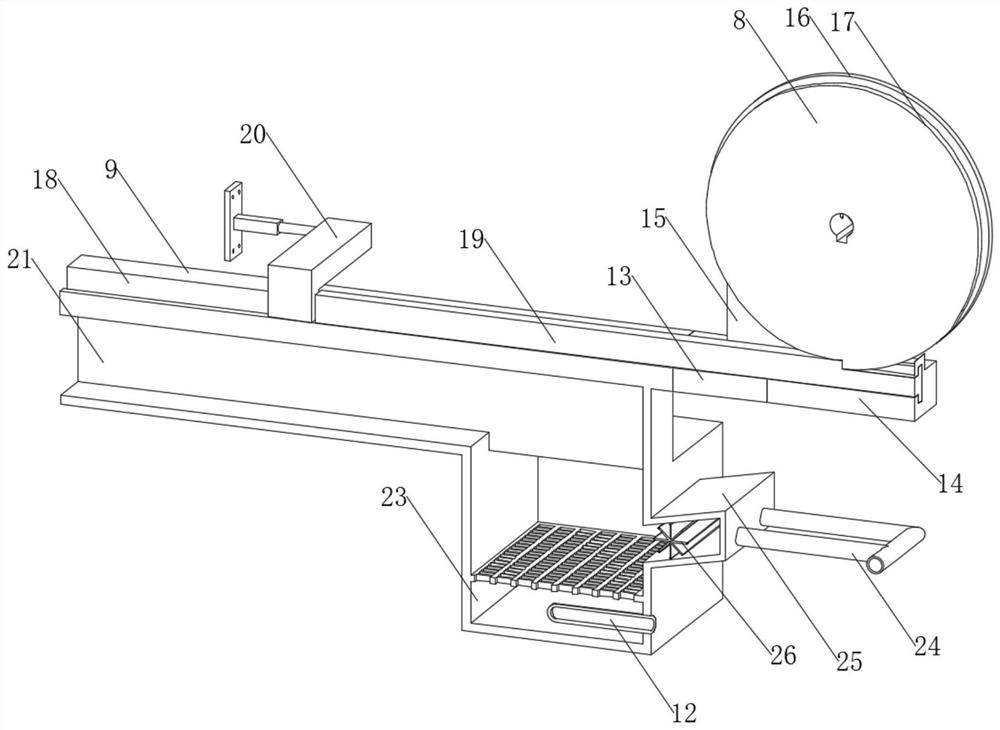

Gearbox shaft forge piece machining equipment and machining method thereof

PendingCN113560476AShorten forging timeImprove mechanical propertiesForging/hammering/pressing machinesForging press detailsMachiningIndustrial engineering

The invention belongs to the technical field of shaft forge piece forging, and particularly relates to gearbox shaft forge piece machining equipment and a machining method thereof. The gearbox shaft forge piece machining equipment comprises a machining base, the machining base is provided with a thermal correction shaft forging piece lower die, an upper die fixing plate capable of doing reciprocating rectilinear motion in the vertical direction is arranged above the thermal correction shaft forging piece lower die, and a thermal correction shaft forging piece upper die is arranged at the bottom of the upper die fixing plate. Through the arrangement of a flash removal cutter, a cutter limiting plate and a rim charge blocking and communicating plate, the shaft forging piece is subjected to thermal correction, meanwhile, flash of the shaft forging piece is automatically cut off through the flash removal cutter, the forging time of the shaft forging piece is shortened, the mechanical performance of the shaft forging piece is improved, and the service life of the shaft forging piece is prolonged; and through moving the rim charge blocking and communicating plate, the flash on the edge blocking and communicating plate can enter a discharging groove, the flash is automatically discharged through the discharging groove, the flash does not need to be manually cleaned, operation is easy and convenient, and the automation degree and the production efficiency are high.

Owner:ZHEJIANG JIAJIE AUTOMOBILE DESIGN CO LTD

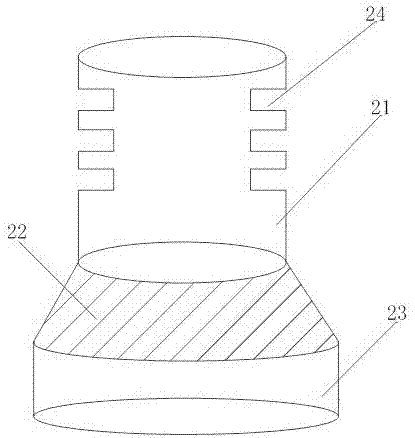

A method for forging the inner and outer rings of fan variable speed bearings

ActiveCN105537863BImprove efficiencyInfluence of internal organizational structureBearing componentsForging/hammering/pressing machinesEngineering

Owner:四川民盛特钢锻造有限公司

Forging method for six throw crankshaft

ActiveCN103071751BUniform deformationLess prone to dead zonesEngine componentsChemical compositionMetallurgy

The invention discloses a forging method for a six throw crankshaft, comprising the step of pouring cylindrical blank. The cylindrical blank comprises the following chemical compositions in percentage by weight: 0.12-0.40 percent of C, 0.42-2.0 percent of Mn, 0.7-1.5 percent of Si, 0.09-0.15 percent of V, 0.11-0.22 percent of Ti, 0.4-1.4 percent of Cr, 0.4-1.5 percent of Ni, 0.15-0.30 percent of Mo, 0.4-0.8 percent of Li, 0.04-0.08 percent of Nb, 0.15-0.20 percent of Al, 0.15-0.50 percent of Mg, wherein the weight percentage of P is less than or equal to 0.030 percent, the weight percentage of S is less than or equal to 0.030 percent, and Fe accounts for the rest amount. According to the forging method for the six throw crankshaft, the defects in the prior art are overcome, energy sources are saved, the quality of heat treatment is improved, the production cycle is shortened, the production cost is reduced, and the radiation pollution to the workshop environment is reduced.

Owner:CHANGLI FORGING

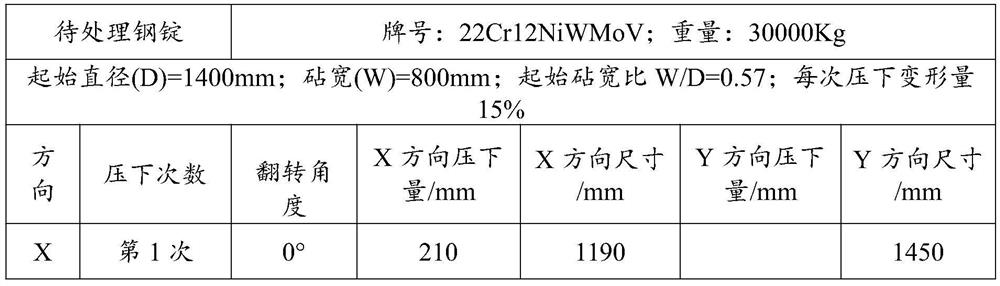

22Cr12NiWMoV forged round steel for gas turbine and preparation method thereof

PendingCN113953422AShorten forging timeReduce manufacturing costMetal-working apparatusMetallic materialsIngot

The invention provides 22Cr12NiWMoV forged round steel for a gas turbine and a preparation method thereof, and belongs to the technical field of metal material machining. The preparation method of the 22Cr12NiWMoV forged round steel for the gas turbine comprises the step of sequentially carrying out sectional heating, forging and post-forging heat treatment on a 22Cr12NiWMoV steel ingot to be treated so as to obtain the 22Cr12NiWMoV forged round steel for the gas turbine. According to the method, by adopting a pre-forging segmented heating mode and controlling forging parameters during forging, the prepared 22Cr12NiWMoV forged round steel for the gas turbine can have excellent room-temperature and high-temperature mechanical properties, meanwhile, crystal grains are fine, few non-metallic inclusions exist, and the preparation method is simple, easy to implement and low in cost.

Owner:浙江大隆特材有限公司

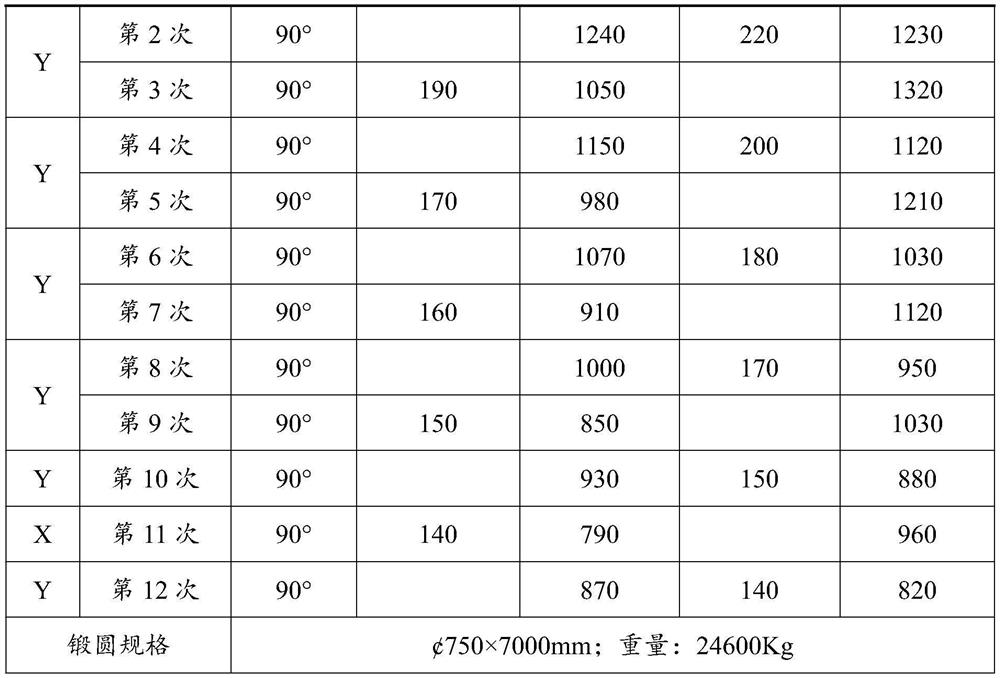

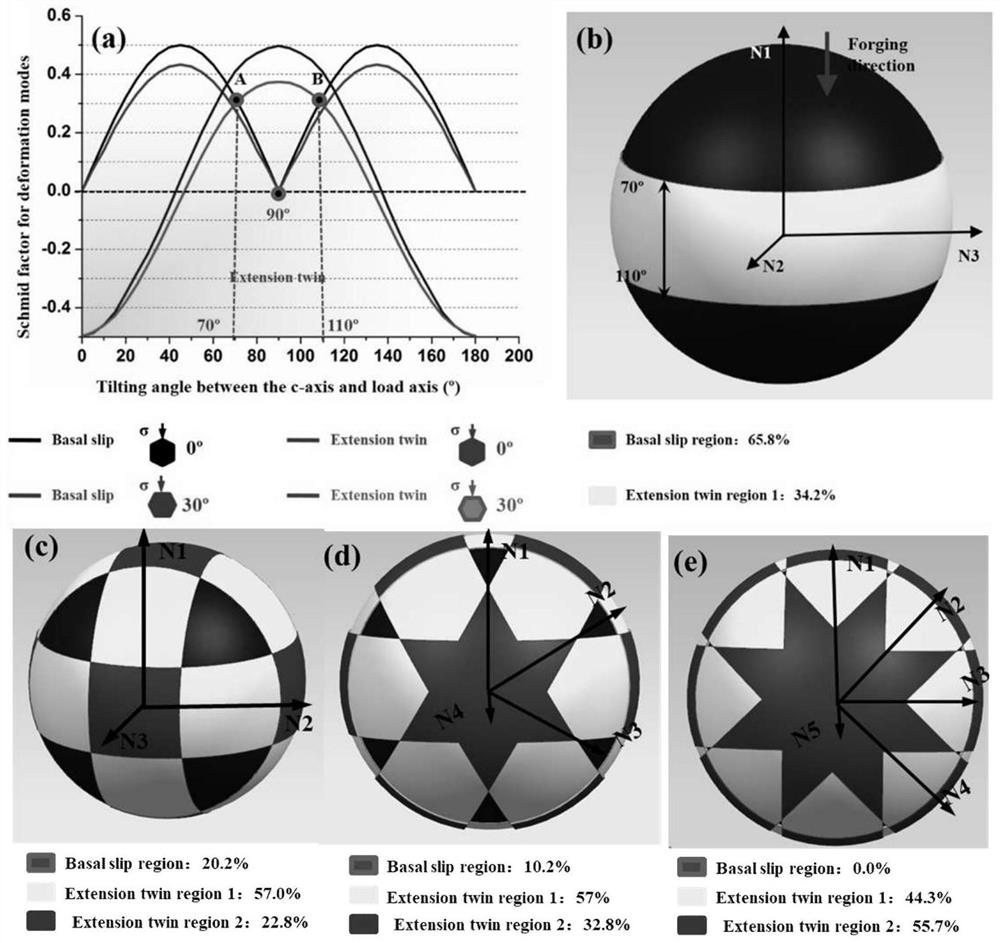

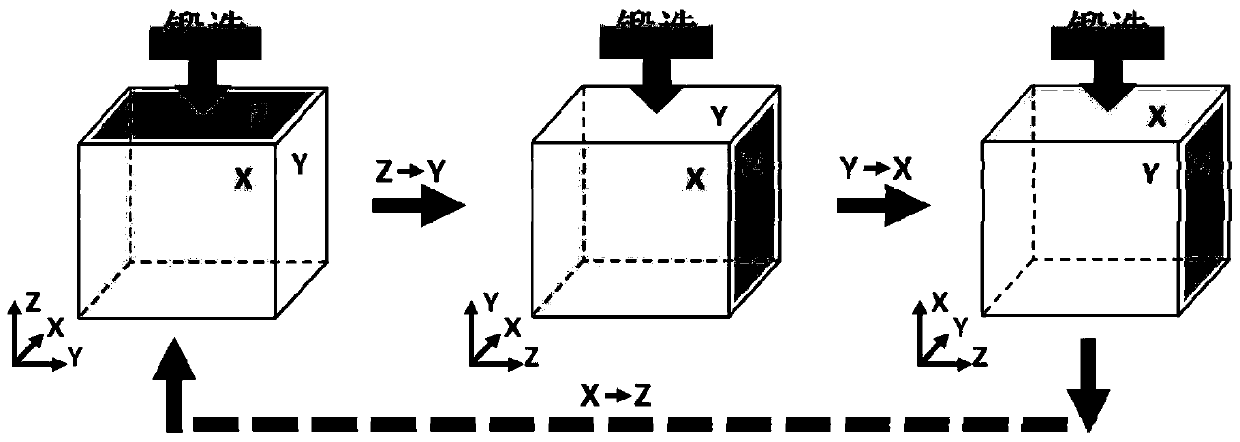

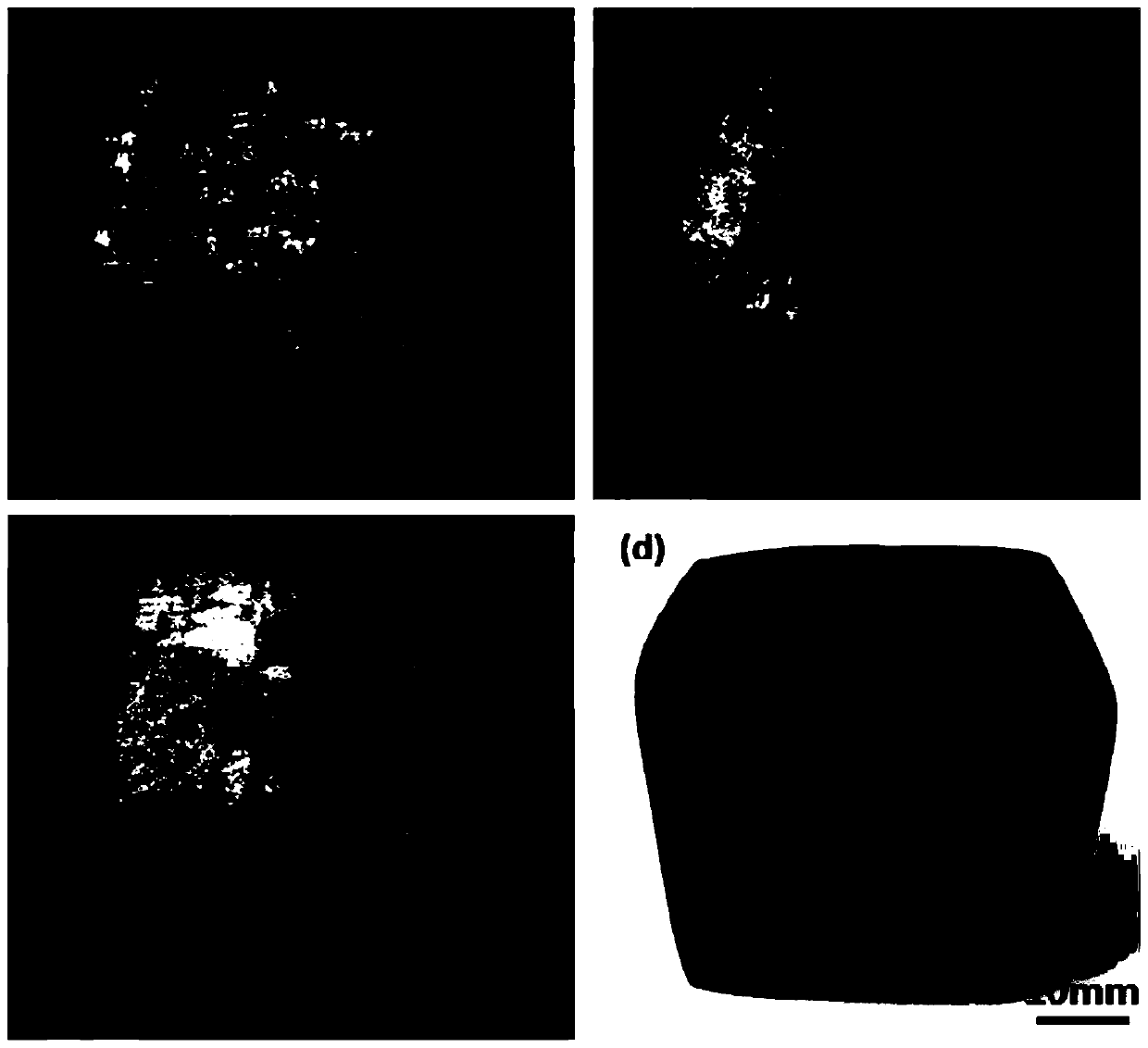

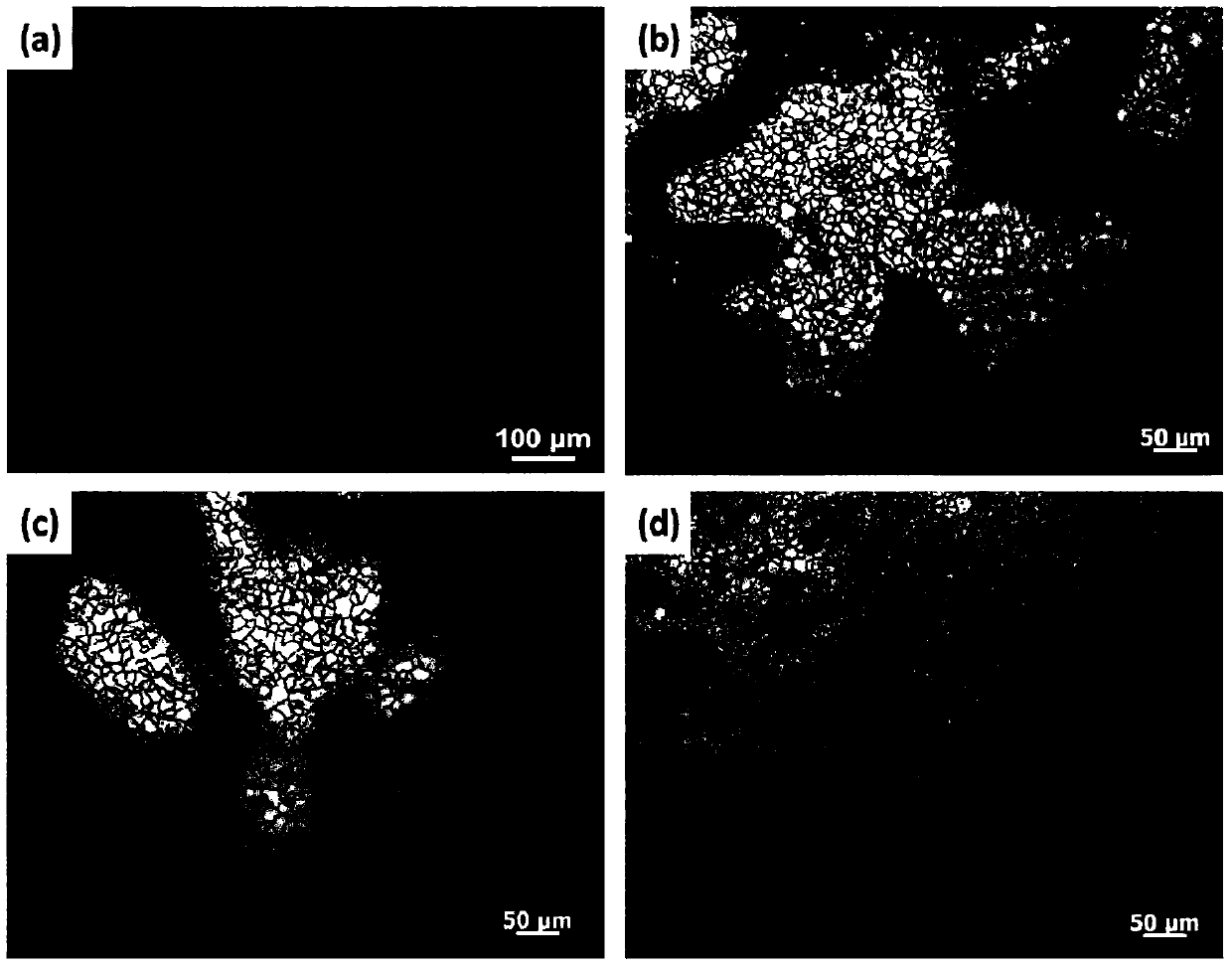

Forging process of nearly-isotropic, high-strength and high-plasticity Mg-Gd-Y-Zr alloy material

PendingCN114505428AImprove mechanical propertiesPromote marketizationMetal-working apparatusOctahedronMetallic materials

The invention discloses a forging process of a near-isotropic, high-strength and high-plasticity Mg-Gd-Y-Zr alloy material, and belongs to the technical field of metal material plastic processing. The process comprises the following steps of: cutting a solid-solution Mg-(0.1-16) Gd-(0.1-12) Y-(0-1.0) Zr (wt.%) alloy into block ingot blanks in a certain shape (a hexahedral cube or other inequilateral hexahedrons (3 axial directions), a hexagonal prism, an equilateral or inequilateral octahedron (4 axial directions), a cylinder or equilateral or inequilateral polyhedrons (5 axial directions and more)); and the block is subjected to circulating high-speed hammering and forging at a certain temperature in the multiple axial directions (the axial directions are larger than or equal to 3) of the block, forging is conducted for 30 passes or above in the multiple axial directions, annealing is conducted for 5-600 min, then forging continues, and after forging is conducted for several times continuously, the total pass reaches 100 passes or above. The Mg-Gd-Y-Zr alloy material forged by the method has a weak texture, and has the advantages of near isotropy, high strength and high plasticity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

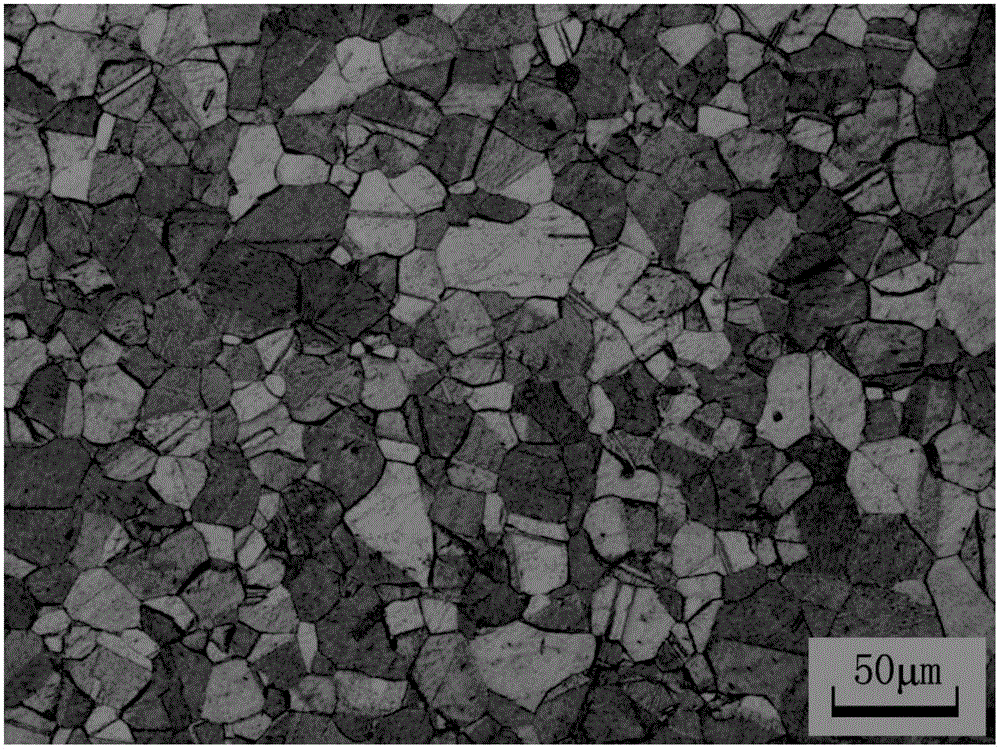

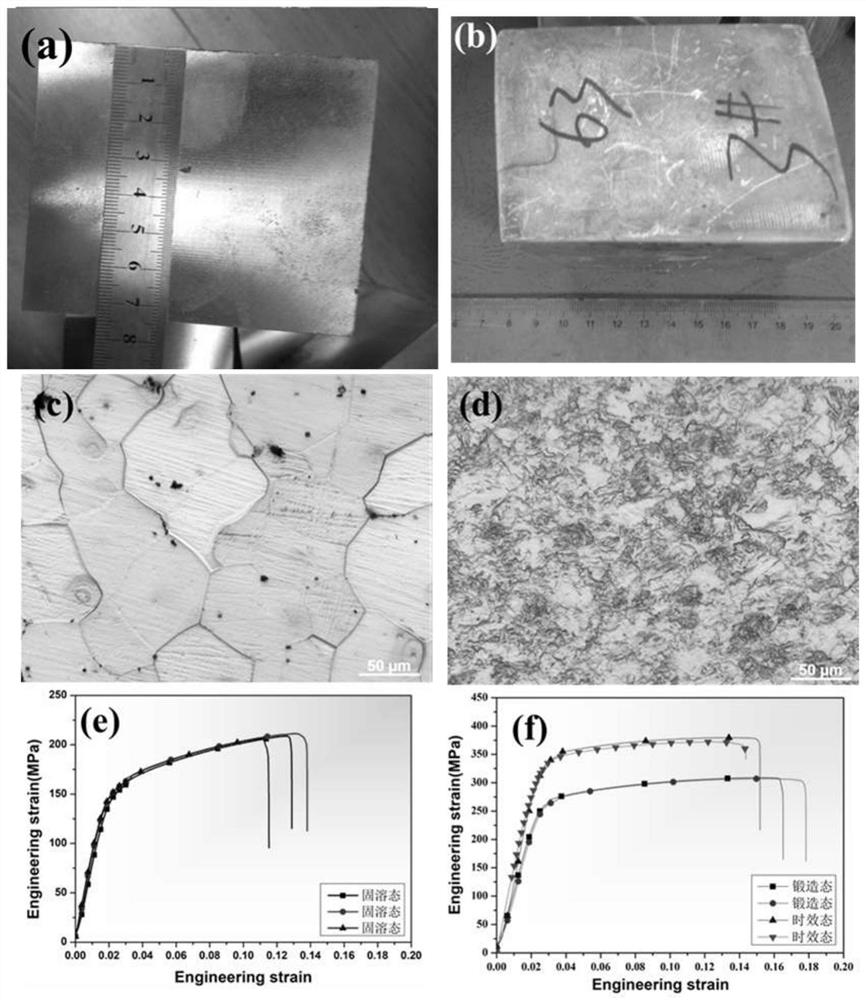

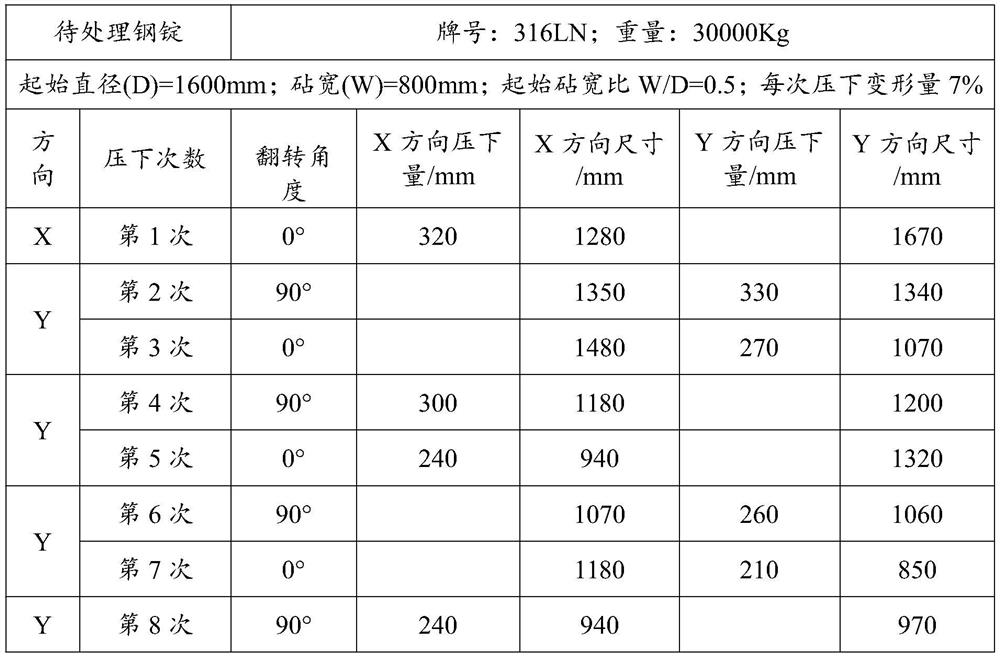

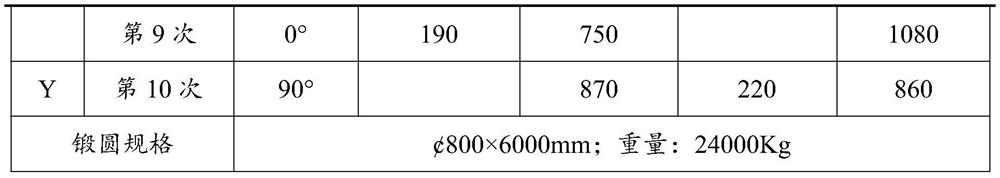

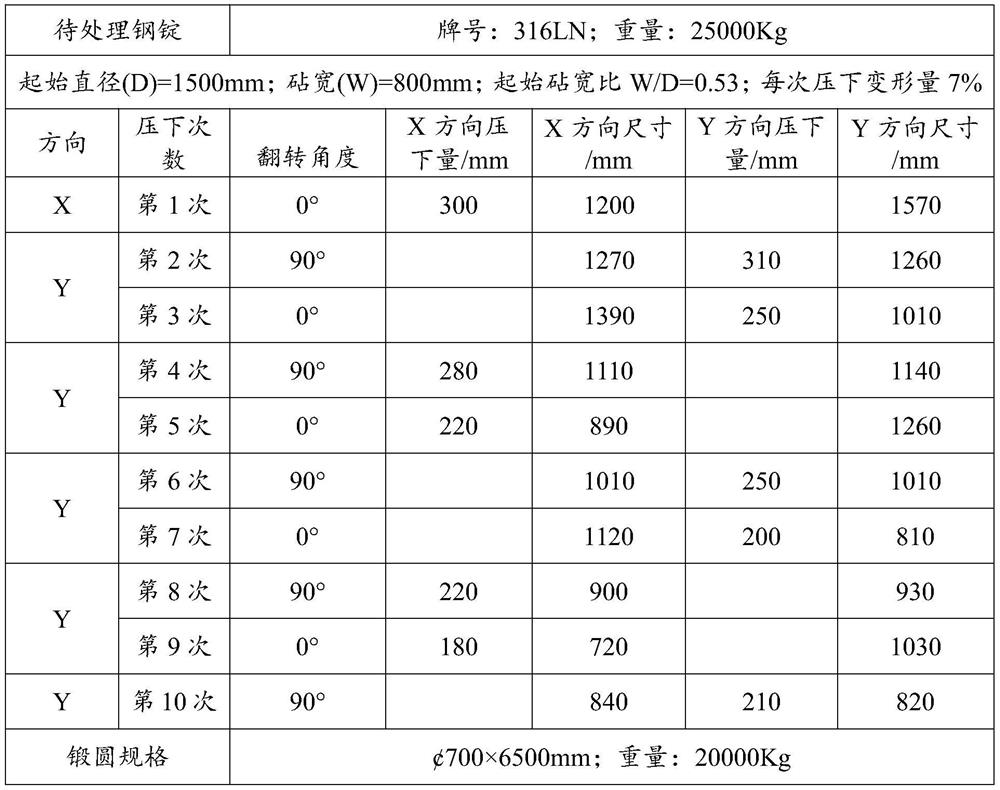

316LN forged round steel for nuclear power pipeline and preparation method of 316LN forged round steel

PendingCN113953421AReduce weightShorten forging timeMetal-working apparatusSolution treatmentNuclear engineering

The invention provides 316LN forged round steel for a nuclear power pipeline and a preparation method of the 316LN forged round steel, and belongs to the technical field of metal material machining. The preparation method of the 316LN forged round steel for the nuclear power pipeline comprises the following steps that a 316LN steel ingot to be treated is sequentially subjected to sectional type heating, forging and solution treatment, and the 316LN forged round steel for the nuclear power pipeline is obtained. According to the 316LN forged round steel for the nuclear power pipeline and the preparation method, by adopting a pre-forging segmented heating mode, controlling forging parameters during forging and finally adopting a solid solution strengthening mechanism, the prepared 316LN forged round steel for the nuclear power pipeline has excellent mechanical performance and corrosion resistance, meanwhile, grains are small, non-metallic inclusions are few, and the preparation method is simple, easy to implement and low in cost.

Owner:浙江大隆特材有限公司

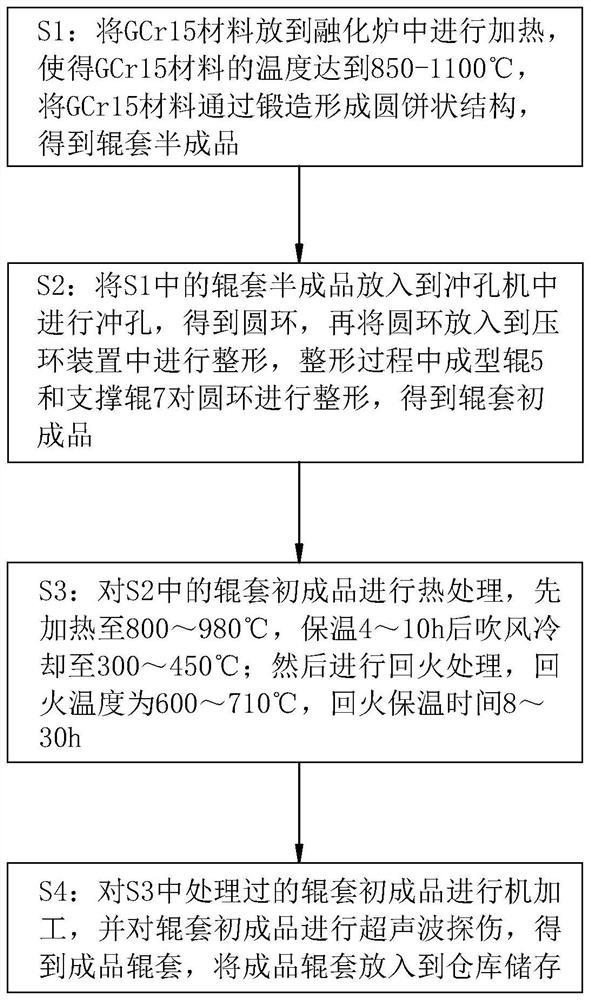

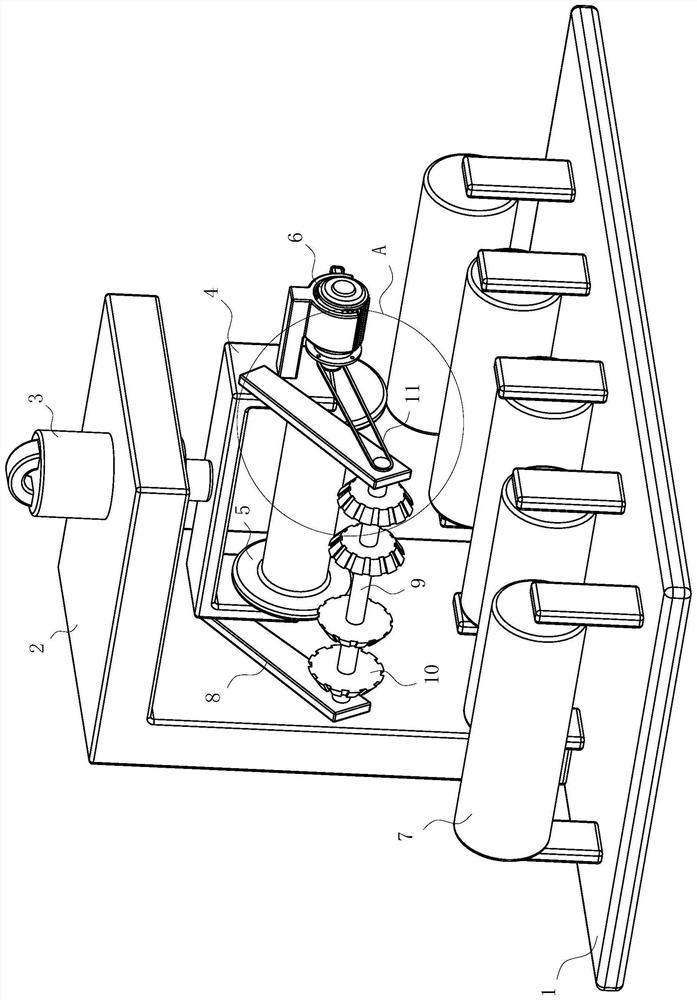

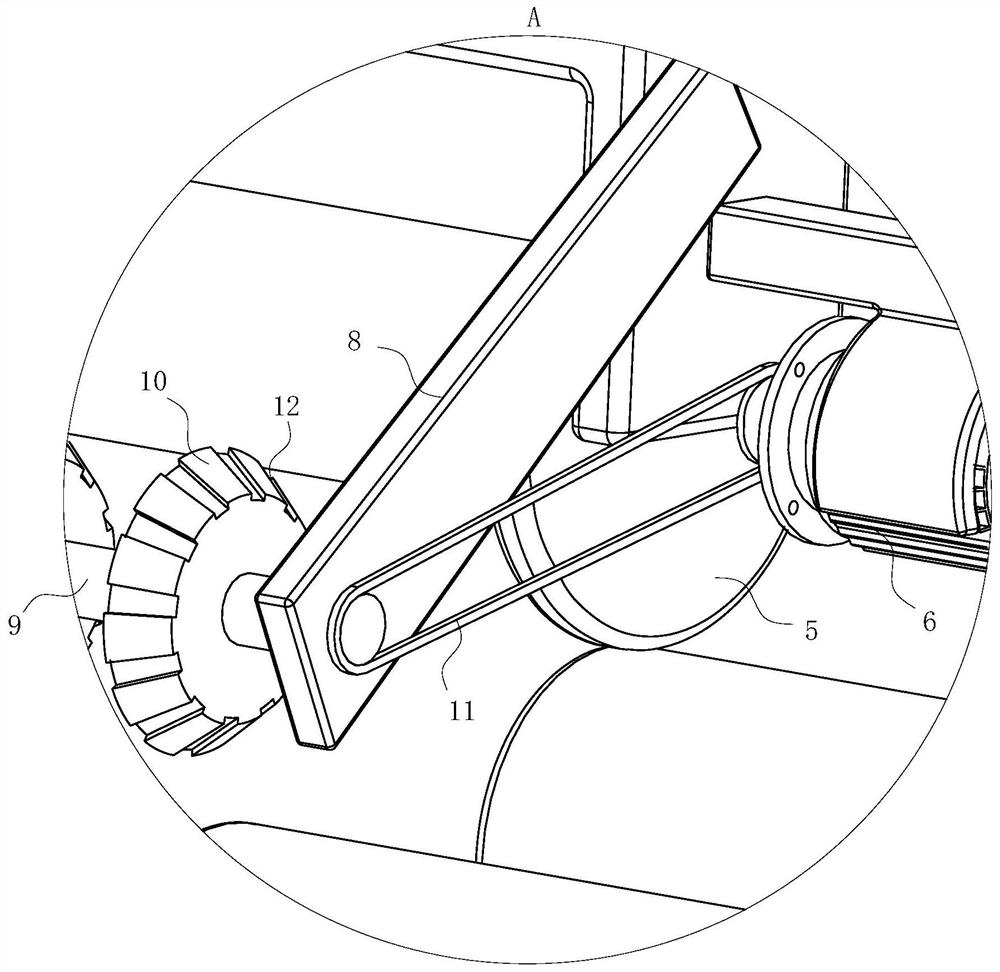

A kind of forging process of gcr15 roller sleeve

ActiveCN111673025BShorten forging timeGuaranteed dimensional accuracyMetal-working apparatusEngine componentsHydraulic cylinderRing device

The invention belongs to the technical field of roller sleeve forging, and specifically relates to a forging process of a GCr15 roller sleeve. The pressing ring device used in the process includes a bottom plate, a bracket is fixed at the top of the bottom plate, and a hydraulic cylinder is fixed at the top of the bracket. The output shaft end of the hydraulic cylinder is fixed with a mounting frame, the bottom of the mounting frame is rotatably mounted with a rotating shaft, the surface of the rotating shaft is fixed with a forming roller, the side wall of the mounting frame is fixed with a drive motor, and the output of the drive motor The shaft end is fixedly connected with the rotating shaft, and more than two plate groups are fixed on the top of the bottom plate, and each plate group includes two rectangular plates; the present invention obtains the primary product of the roller sleeve after pressing and shaping the perforated ring, which is The process steps are reduced, the forging time of the roller sleeve is saved, and the dimensional accuracy of the roller sleeve is also ensured. At the same time, the present invention has simple structure, low manufacturing cost, and simplifies the equipment required for the production of the roll sleeve, thus reducing the requirement for the production of the roll sleeve. cost.

Owner:定襄县同立重工有限公司

Mould for forging shaft coupling

ActiveCN102699253BContinuous fiberGuaranteed mechanical propertiesForging/hammering/pressing machinesCouplingMaterials science

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

Forging Mechanism for Continuous Forging Point Rail and Preparation Technology of Forging Point Rail

ActiveCN111570691BQuality improvementReduce stressForging/hammering/pressing machinesIndustrial engineeringFlange

The invention discloses a forging mechanism for continuous forging point rails and a preparation process for forging point rails, comprising: a preheating rail for accommodating the point rails to be forged, the preheating rails can maintain the temperature of the forging point rails during the forging process Hot forging is carried out at a temperature above 800°C, and there is also a forging wheel for forging the point rail to be forged. The way of flange extrusion makes the force-bearing area of the point rail to be forged large, and the force is uniform, continuous extrusion molding, easy to quickly form , the equipment loss is small, and the forging time is reduced. The invention also discloses a preparation process for a forging point rail, which includes the following steps: S1: heat treatment; S2: forging; S3: shaping; S4: unloading; S5: cooling; S6: Straightening; S7: Grinding. The invention can forge V-shaped, curved, straight forging materials, one end is bent and the other end is straight, and has a wide range of applications.

Owner:ANHUI ZHONGZHI RAIL TRANSPORTATION EQUIP MFG CO LTD

A continuous forging device with automatic cleaning function

ActiveCN112719183BShorten forging timeImprove work efficiencyDrop hammersHammer drivesWorkbenchIndustrial engineering

The invention relates to the technical field of forging equipment, and discloses a continuous forging device with an automatic cleaning function, which includes a box body, a workbench is welded to the bottom of the box body, and a transmission mechanism is arranged at the front of the box body. The top of the workbench is provided with two discharge troughs, the inner wall of the box is welded with several limit posts, the surface of the limit posts is provided with a forging mechanism, and the front part of the workbench is provided with a For the mechanism, the rear part of the box is provided with a cleaning mechanism. The present invention can continuously forge the steel plate through the cooperation of the transmission mechanism and the forging mechanism, so that it is not necessary to replace the forging equipment after forging once and adjust the stroke of the forging equipment. The forging time is greatly reduced, the work efficiency is increased, and the practicability is greatly increased. The cleaning mechanism can clean the steel plate after the final forging, so that workers do not need to clean it manually, which reduces the labor intensity of the workers.

Owner:山东圣利锻造有限公司

A kind of weak/non-basal texture, low anisotropy az61 magnesium alloy and its preparation method

ActiveCN105483580BPowerful industrial production and processingShort production processSolution treatmentCenter shift

The invention discloses an AZ61 magnesium alloy with weak / non-basal plane texture and low anisotropy and a preparation method thereof, belonging to the technical field of plastic processing of magnesium alloys. The as-cast AZ61 magnesium alloy is subjected to solution treatment, and at a deformation temperature of 250-350°C, it is hammered continuously in three axial directions orthogonal to each other by using an industrial air hammer forging machine. Each time, the direction of each hammer forging is changed, the strain in each pass is 3-10%, the average strain rate of hammer forging is 15-200s‑1, and the hammer forging is continuous for 20-250 passes. After hammer forging, the grain size of the sample is 12-30 μm, the peak texture strength is less than 6, and the deviation angle of the peak texture position relative to the pole figure center is greater than 30°; in all directions of the sample, the yield strength σy, tensile strength σb, and elongation δ are all Not less than 90MPa, 270MPa and 20% respectively.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com