22Cr12NiWMoV forged round steel for gas turbine and preparation method thereof

A gas turbine and round forging technology, which is applied to metal processing equipment, etc., can solve the problems of large volume, difficulty in forging, and many impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of 22Cr12NiWMoV forged round steel for gas turbine, comprising:

[0023] The 22Cr12NiWMoV steel ingot to be processed is sequentially subjected to segmental heating, forging and post-forging heat treatment to obtain 22Cr12NiWMoV forged round steel for gas turbines; the segmental heating includes a preheating section, a heating section and a soaking section; the forging includes sequentially The strong pressure and the pressure side; the strong pressure is carried out on the chopping board; the total deformation of the strong pressure is more than 70%; the overlapping amount of each pressing during the strong pressure is 8~12% of the width of the chopping board.

[0024] In the invention, the 22Cr12NiWMoV steel ingot to be processed is heated in sections to obtain the heat-treated 22Cr12NiWMoV steel ingot before forging.

[0025] The present invention has no special requirements on the composition of the 22Cr12NiWMoV st...

Embodiment 1

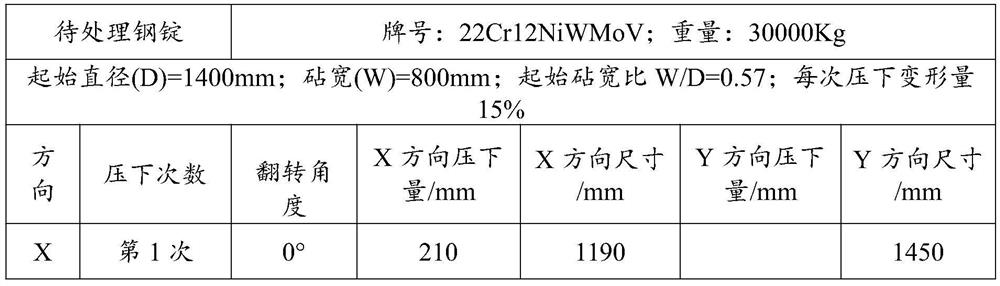

[0058] A method for preparing 22Cr12NiWMoV forged round steel for gas turbines, comprising the following steps: sequentially subjecting a 22Cr12NiWMoV steel ingot to be processed to heating in stages, forging, mold forming, and post-forging heat treatment to obtain 22Cr12NiWMoV forged round steel for gas turbines.

[0059] Firstly, the 22Cr12NiWMoV steel ingot to be treated is refined and ground to remove surface defects, and then heated in sections to obtain the 22Cr12NiWMoV steel ingot heat-treated before forging. Sectional heating is divided into preheating section, heating section and soaking section, specifically: put the 22Cr12NiWMoV steel ingot to be processed into a natural gas heating furnace at room temperature, and raise the temperature to 860℃ at a heating rate of 90℃ / h in the preheating section heat preservation temperature, and heat preservation at the temperature of the preheating section for 7 to 12 hours, and then raise the temperature to the heat preservation ...

Embodiment 2

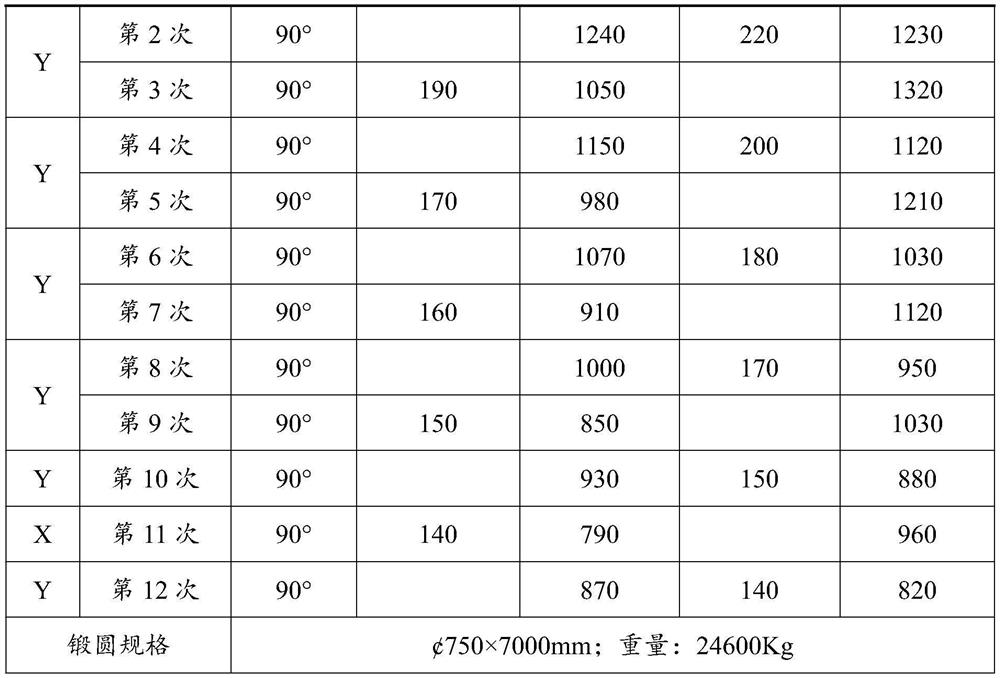

[0063] The initial anvil width ratio in the strong pressure during forging in Example 1 is replaced by 0.62, and the specific parameters of the strong pressure during forging are shown in Table 2, and the rest of the technical features are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com