A kind of weak/non-basal texture, low anisotropy az61 magnesium alloy and its preparation method

An anisotropic, magnesium alloy technology, applied in the field of weak/non-basal texture, low anisotropy AZ61 magnesium alloy and its preparation, can solve the problems of low production efficiency, poor comprehensive mechanical properties, high cost, and achieve operation The effect of convenience, high forging strain rate and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

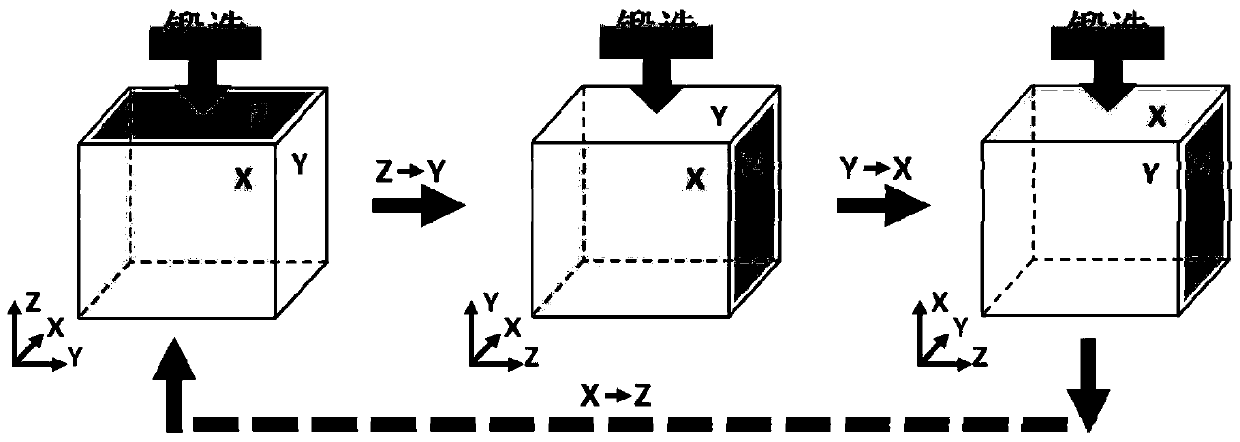

Embodiment 1

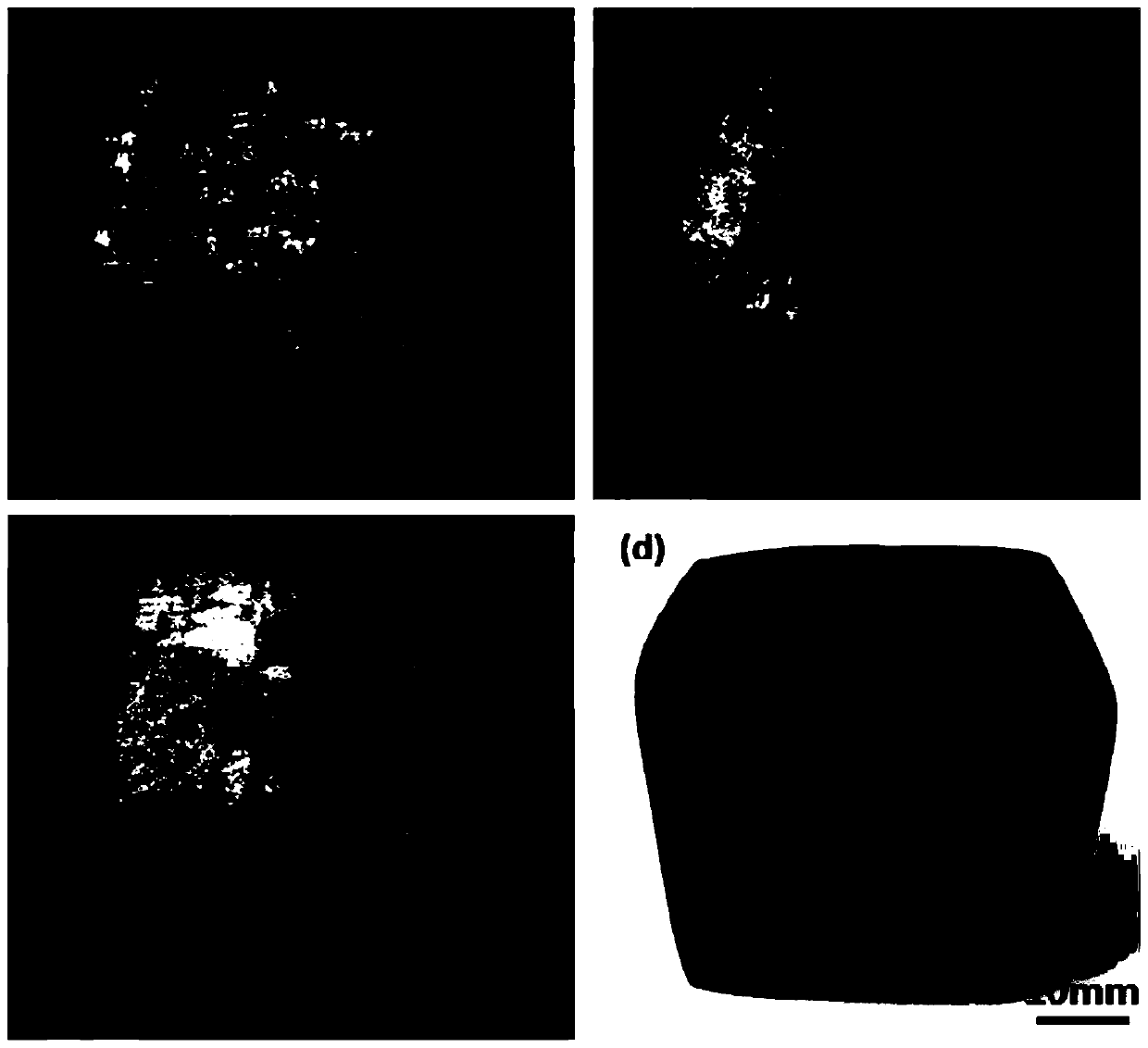

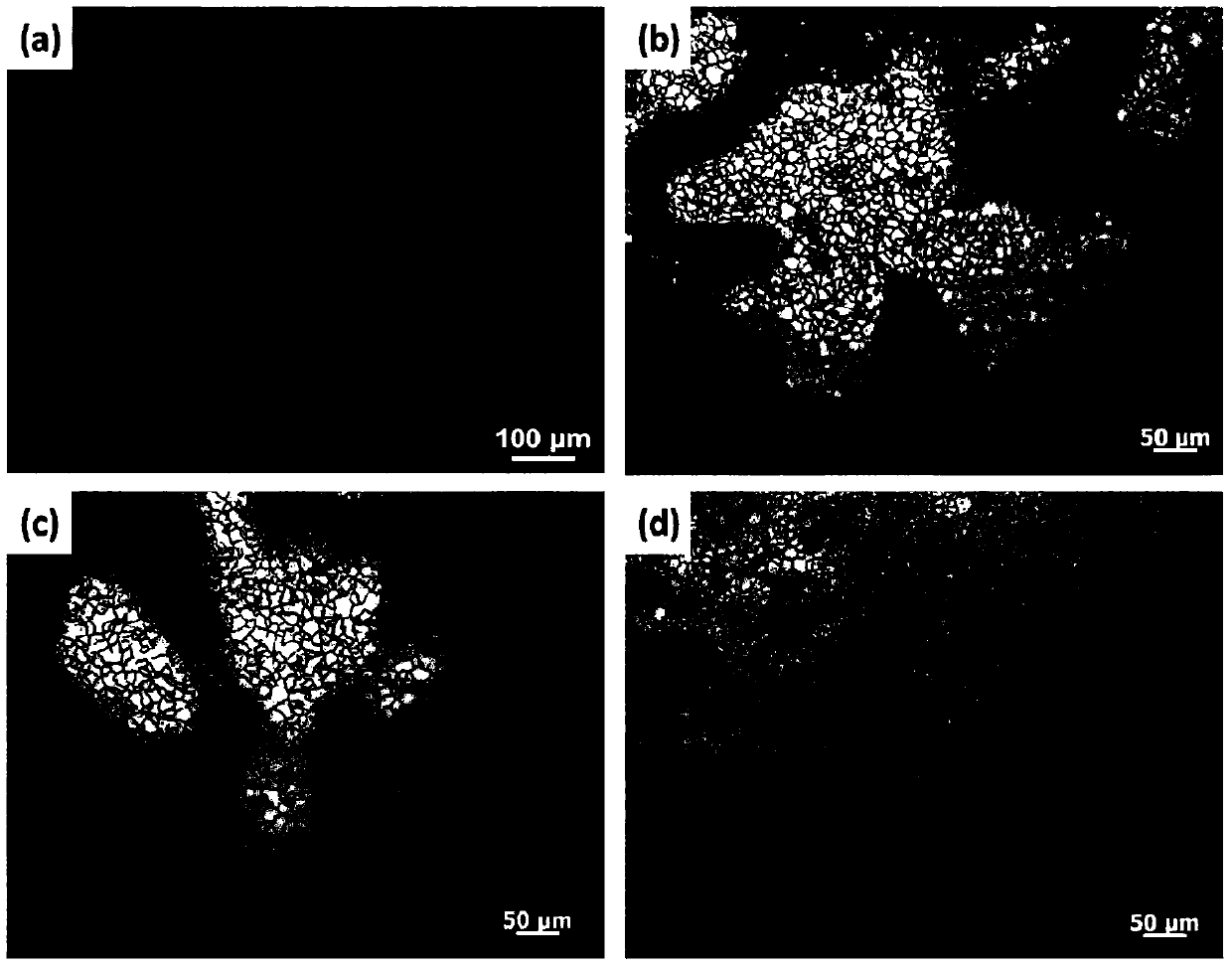

[0039] Select AZ61 magnesium alloy semi-continuous casting as-cast material, cut out three 50mm×50mm×50mm cube block blanks in the ingot, and air-cool after solid solution treatment at 420°C for 16h; On the hammer forging machine, the hammer forging process is carried out, that is, the hammer forging is continuously cycled in the three directions of X, Y, and Z. One hammer forging in one direction is one pass, and the direction is changed every time for hammer forging. The amount of strain in each pass is controlled at 5%, and the average strain rate is 20s -1 , three block blanks were continuously hammered for 30 passes (sample 1), 60 passes (sample 2), and 120 passes (sample 3). The time for 120 passes of hammer forging is 3.5 minutes, the temperature of the sample after forging is between 265°C and 300°C, and the final sample is air-cooled. There is no defect on the surface of the sample after hammer forging, and the size difference of each sample in three directions is no...

Embodiment 2

[0043] Select AZ61 magnesium alloy semi-continuous casting as-cast material, cut out 55mm×55mm×55mm cube block billet in the ingot, and air cool after solid solution treatment at 420°C for 16h; hold at 320°C for 60min, and then hammer forge in industrial air Hammer forging is carried out on the machine, that is, hammer forging is continuously cycled in three directions of X, Y, and Z. One hammer forging in one direction is one time, and the direction is changed every time for hammer forging. The amount of strain in each pass is controlled at 5%, and the average strain rate is 30s -1 , continuous hammer forging 200 times, the time used is 4.5min, the temperature of the sample after forging is 345 ℃, and the final sample is air-cooled. There is no defect on the surface of the sample after hammer forging, and the size of the sample is basically unchanged, see figure 2 (d); fine and uniform equiaxed grains are formed after hammer forging, with an average grain size of 16 μm, wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com