Mould for forging shaft coupling

A technology of couplings and molds, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of increasing difficulty, increasing difficulty of operation, waste of raw materials, etc., to improve the quality of materials Utilization rate, reduction of forging time, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The mold for forging a shaft coupling of the present invention will be further described in detail through specific examples below.

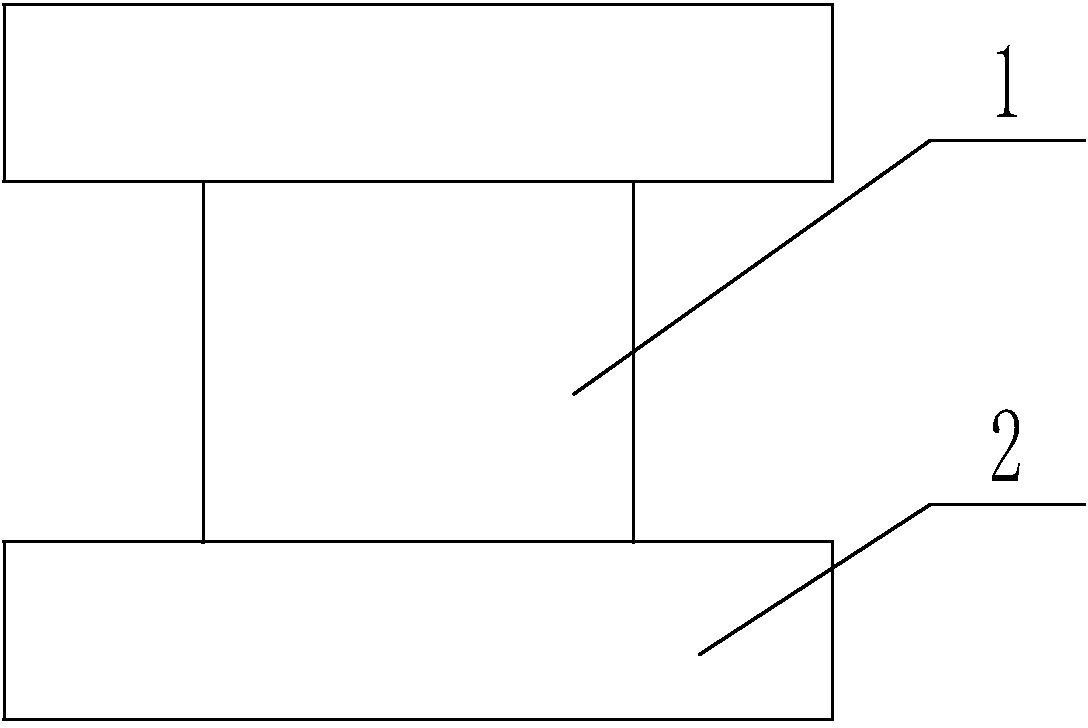

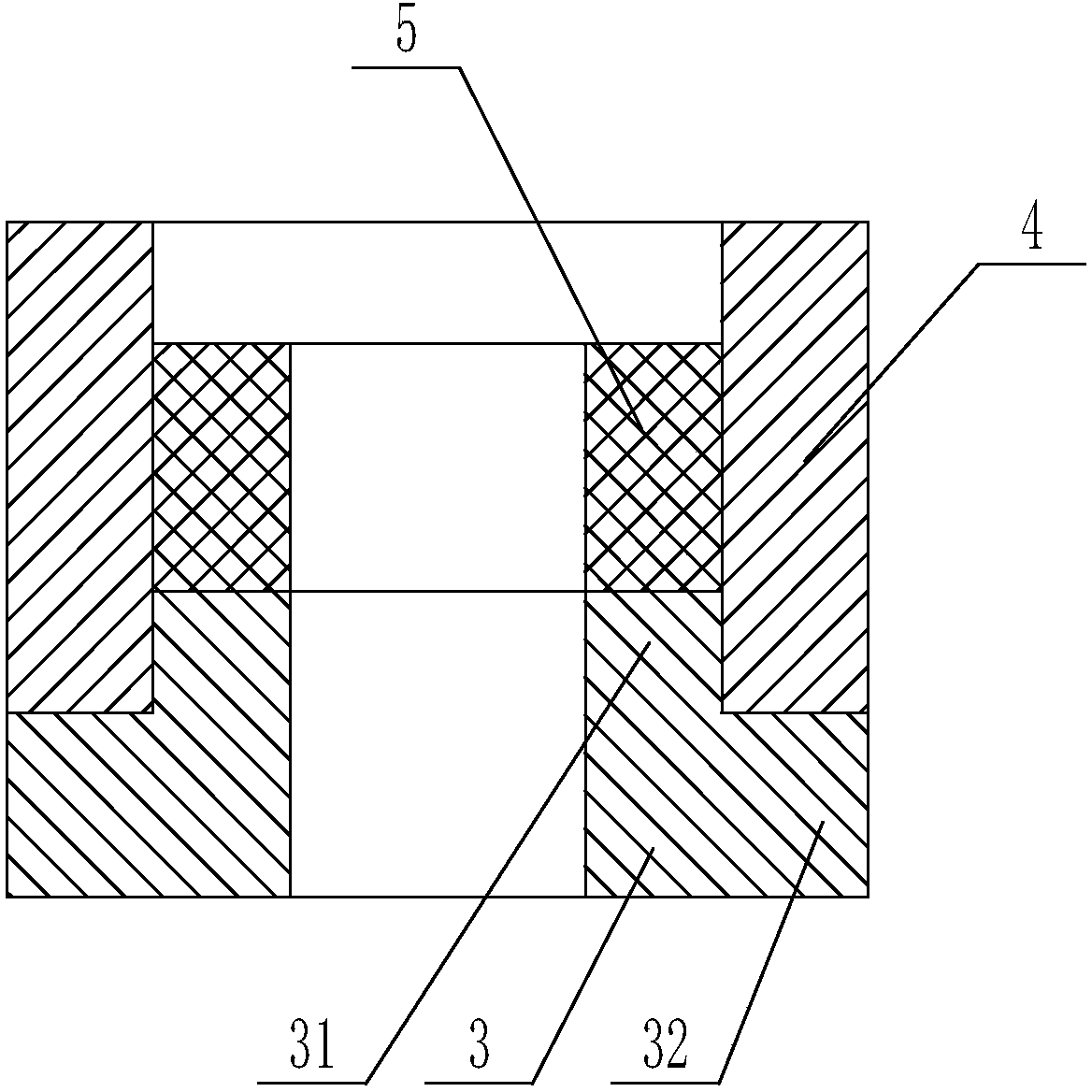

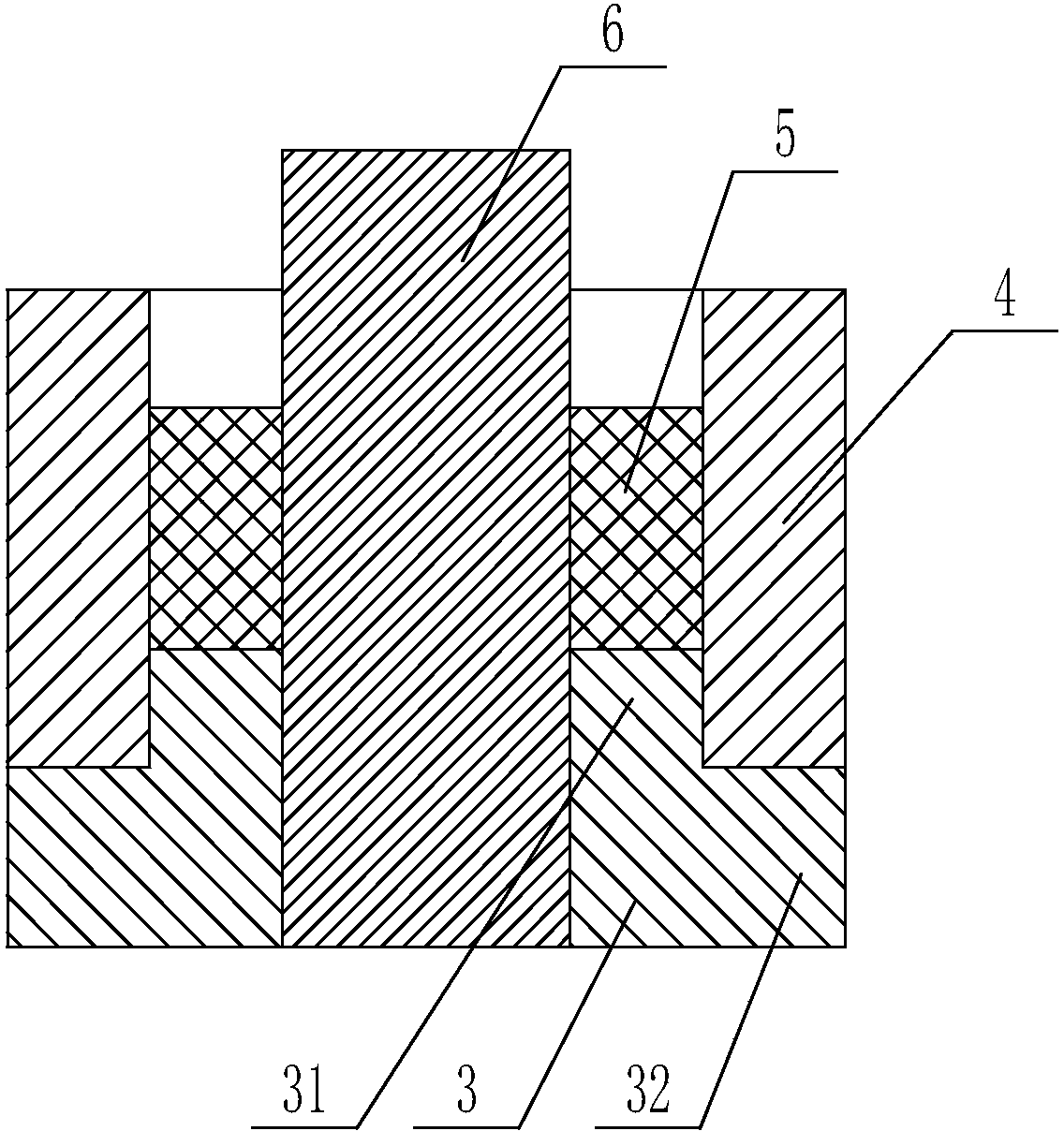

[0015] Such as figure 2 As shown, the mold for forging the coupling includes a lower mold 3, an outer mold 4 and an inner mold 5. The lower mold 3 includes a small ring body 31 and a large ring body 32 arranged concentrically from top to bottom, The external diameter of large torus 32 is greater than the external diameter of small torus 31, and the internal diameter of large torus 32 is equal to the internal diameter of small torus 31, and described outer mold 4 is a torus, and the outer mold 4 Outer diameter equals the outer diameter of big torus 32, and the inner diameter of outer mold 4 equals the outer diameter of little torus 31, and described internal mold 5 is a torus, and the outer diameter of inner mold 5 is equal to little torus 31, the inner diameter of the inner mold 5 is equal to the inner diameter of the small torus 31, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com