A metal-organic framework-zirconia fiber composite material and its preparation method and application

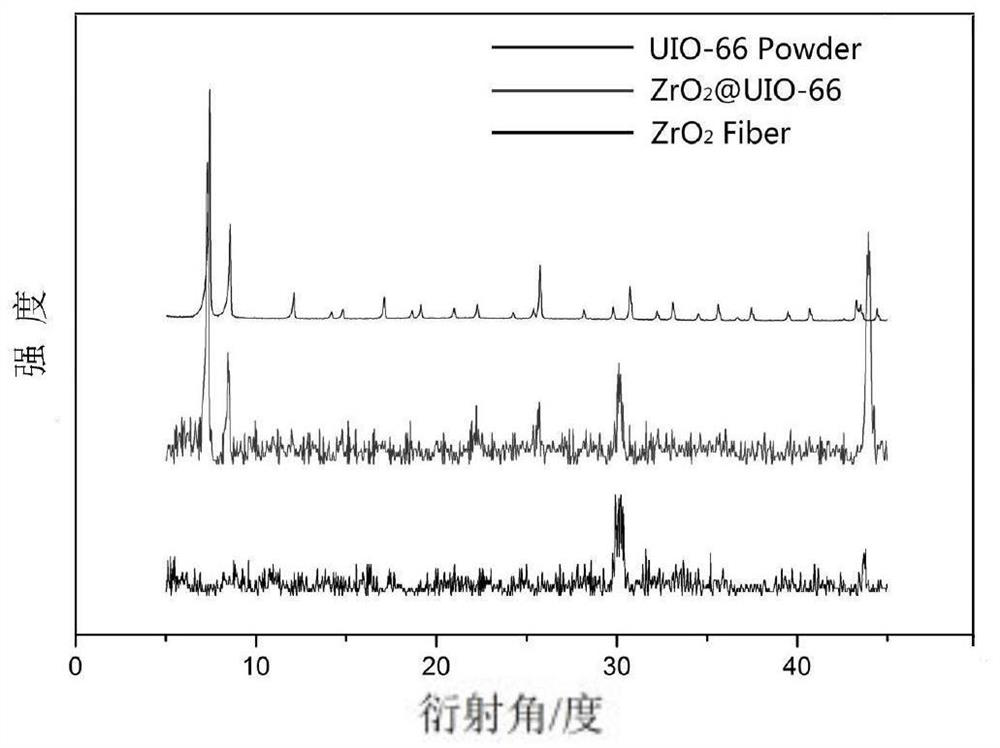

A metal-organic framework and zirconia fiber technology, applied in the field of composite materials, can solve the problems of difficult to guarantee the stability of composite materials, low mass fraction of MOFs, and large volume of substrates, and achieve excellent thermal stability and chemical stability. Good reusability, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

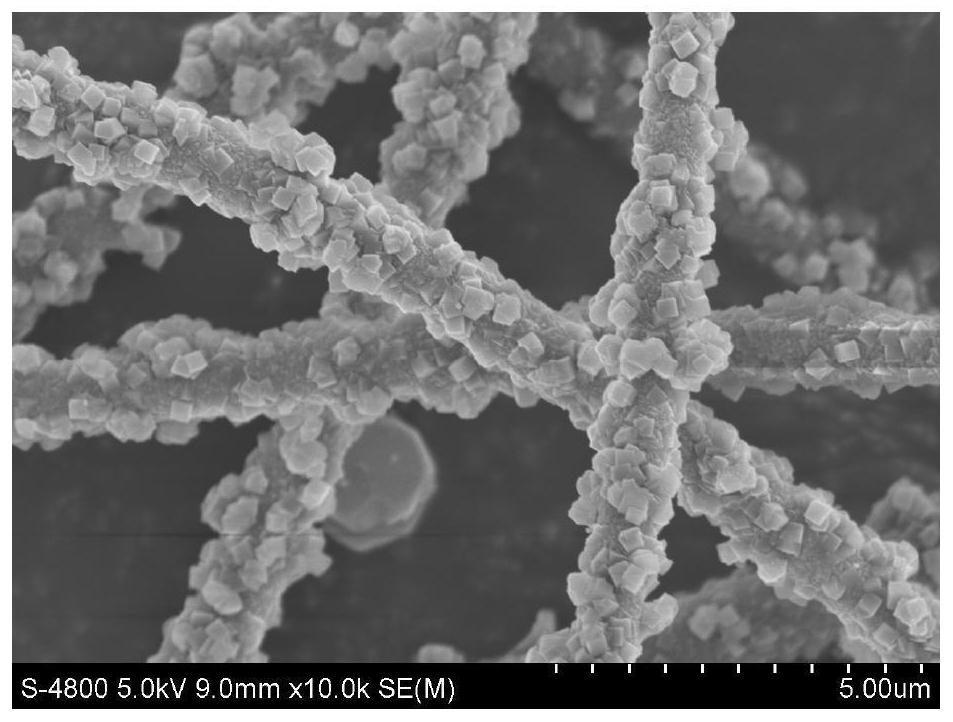

[0051] A preparation method of UIO-66-zirconia fiber composite material, comprising the steps of:

[0052] (1) Weigh PAZ, yttrium nitrate hexahydrate, PEO, and methanol in a weight ratio of 100:20:1:200, fully mix and dissolve at 30°C under stirring conditions, and obtain a clear PAZ precursor spinning sol;

[0053] (2) Add the PAZ precursor spinning sol obtained in step (1) into the syringe, use a stainless steel needle (type 23G) with an inner diameter of 0.33mm, and advance at a speed of 1.2mL / h at a spinning temperature of 20°C , the spinning humidity is 30%, the spinning voltage is 10kV, the electrospinning is carried out, the receiving distance is 20cm, and the zirconia precursor fiber is collected;

[0054] (3) Put the zirconia precursor fiber obtained in step (2) on the setter in the program-controlled sintering furnace, raise the temperature to 600°C at a heating rate of 1°C / min, keep it for 2h, and remove the zirconia precursor fiber. Organic matter, natural cooling...

Embodiment 2

[0058] The preparation of the UIO-66-zirconia fiber composite material was the same as in Example 1, except that the methanol in step (1) was replaced with ethanol.

Embodiment 3

[0060] The preparation of UIO-66-zirconia fiber composite material is the same as in Example 1, except that in step (1), PAZ, yttrium nitrate hexahydrate, PVP, methyl alcohol are weighed, and the weight ratio is 100:0:2: 200, fully mixed and dissolved at 30°C under stirring conditions to obtain the PAZ precursor spinning sol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com