A processing technology of double-ear wedge-shaped clamp shell for electrified railway

A technology for electrified railways and wedge-shaped wire clamps, which is applied to railway car body parts, metal processing equipment, manufacturing tools, etc., and can solve the problems of low mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] A processing technology for a double-ear wedge-shaped clamp shell for electrified railways, the specific steps are as follows:

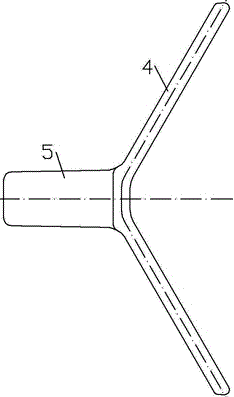

[0043] 1) if Picture 1-1 , 1-2 As shown in and 1-3, the heated raw material is pre-forged, and the pre-forged forging billet has two ears and a solid part connecting the roots of the two ears. The distance between the parts is gradually increased, and the molds used include matching punches and dies, see Figure 8 and Figure 9 On the left side of the punch, the forging face of the punch gradually protrudes from both ends to the middle in the length direction and transitions smoothly in the middle. The die cavity of the die matches the punch. In the length direction, the middle part of the die cavity also has A concave third pit;

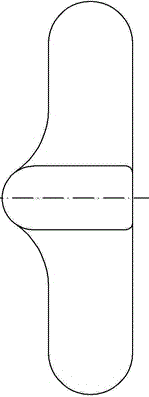

[0044] 2) if diagram 2-1 , 2-2 As shown in 2-3, the second forging is carried out, and the two ears are forged to be on the same plane. The forging billet formed by the second forging is in the shape of ┯ as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com