A kind of preparation method of continuous magnesium aluminum spinel fiber

A magnesia-aluminum spinel and fiber technology, which is applied in the field of inorganic refractory materials, can solve the problems of difficulty in large-scale equipment, large fiber diameter, short fiber length, etc., and achieves the effects of simple equipment, low environmental requirements, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

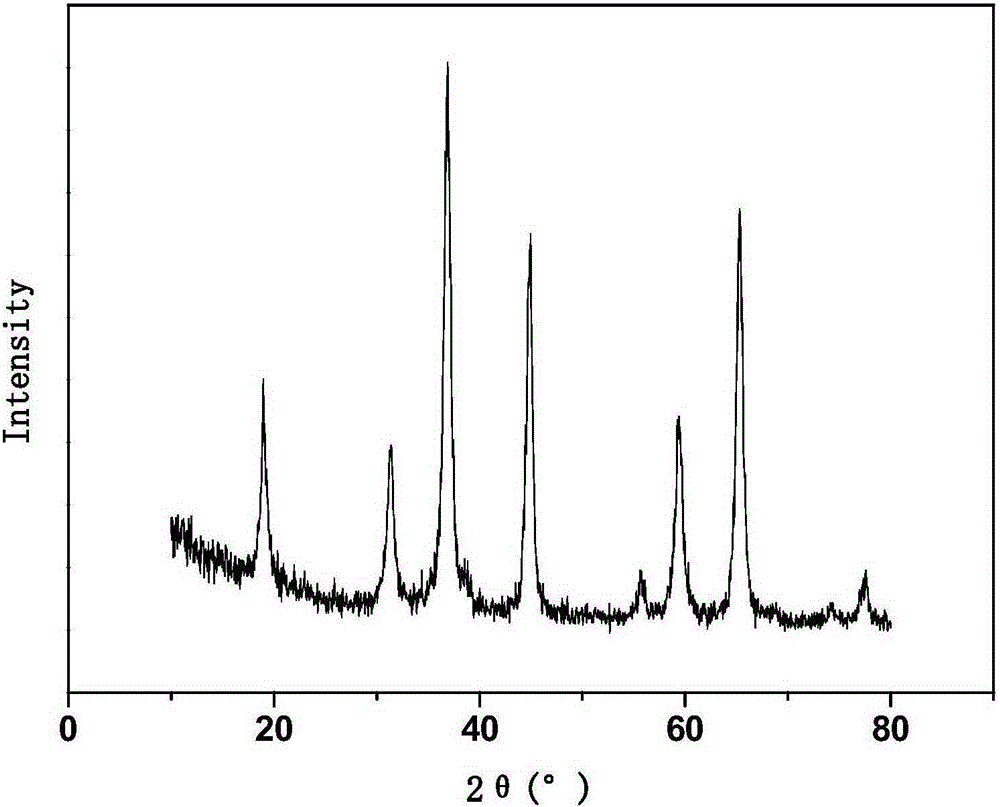

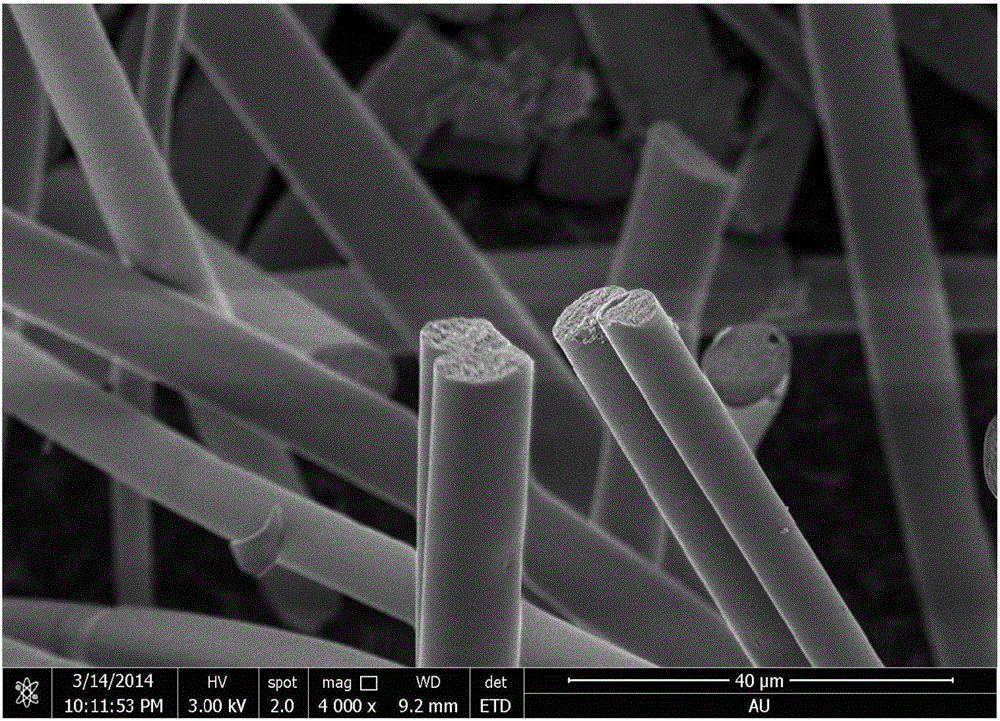

Embodiment 1

[0027] Take 15g of anhydrous AlCl 3 Dissolve in 200ml of water, add 15g of aluminum powder to the solution after hydrolysis is complete, place the mixed solution in a reflux condensing device, heat to a slight boil under normal pressure, control the reflux time for 1.5h, filter out the insoluble matter to obtain polychlorinated Aluminum sol. Get 32.6g basic magnesium carbonate and 120g citric acid and dissolve in 400ml water, stir at room temperature until the solution is transparent and clear to obtain a magnesium citrate solution. Mix the above-prepared polyaluminum chloride sol with the magnesium citrate sol, stir at room temperature until the mixed solution is clear, and add 20ml of acetic acid as a stabilizer to the solution. The solution was pressure-distilled at 80°C to remove excess water until MgAl with a viscosity of 50 Pa·s was obtained. 2 o 4 Sol spinning solution. The spinning solution is injected into the ultra-high-speed centrifugal spinning device, and unde...

Embodiment 2

[0029] Take 15g of anhydrous AlCl 3 Dissolve in 200ml of water, add 15g of aluminum powder to the solution after hydrolysis is complete, place the mixed solution in a reflux condensing device, heat to a slight boil under normal pressure, control the reflux time for 2 hours, filter out the insoluble matter to obtain polyaluminum chloride Sol. Get 32.6g basic magnesium carbonate and 140g citric acid and dissolve in 400ml water, stir at room temperature until the solution is transparent and clear to obtain a magnesium citrate solution. Mix the above-prepared polyaluminum chloride sol with the magnesium citrate sol, stir at room temperature until the mixed solution is clear, and add 25ml of acetic acid as a stabilizer to the solution. The solution was distilled under pressure at 75°C to remove excess water until MgAl with a viscosity of 50 Pa·s was obtained. 2 o 4 Sol spinning solution. The spinning solution is injected into the ultra-high-speed centrifugal spinning device, an...

Embodiment 3

[0031] Take 30g of anhydrous AlCl 3 Dissolve in 400ml of water, add 30g of aluminum powder to the solution after complete hydrolysis, place the mixed solution in a reflux condensing device, heat to a slight boil under normal pressure, control the reflux time for 2 hours, filter out the insoluble matter to obtain polyaluminum chloride Sol. Get 65.2g basic magnesium carbonate and 250g citric acid and dissolve in 800ml water, stir at room temperature until the solution is transparent and clear to obtain a magnesium citrate solution. Mix the above-prepared polyaluminum chloride sol with the magnesium citrate sol, stir at room temperature until the mixed solution is clear, and add 50ml of acetic acid as a stabilizer to the solution. The solution was pressure-distilled at 80°C to remove excess water until MgAl with a viscosity of 50 Pa·s was obtained. 2 o 4 Sol spinning solution. The spinning solution is injected into the ultra-high-speed centrifugal spinning device, and at a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com