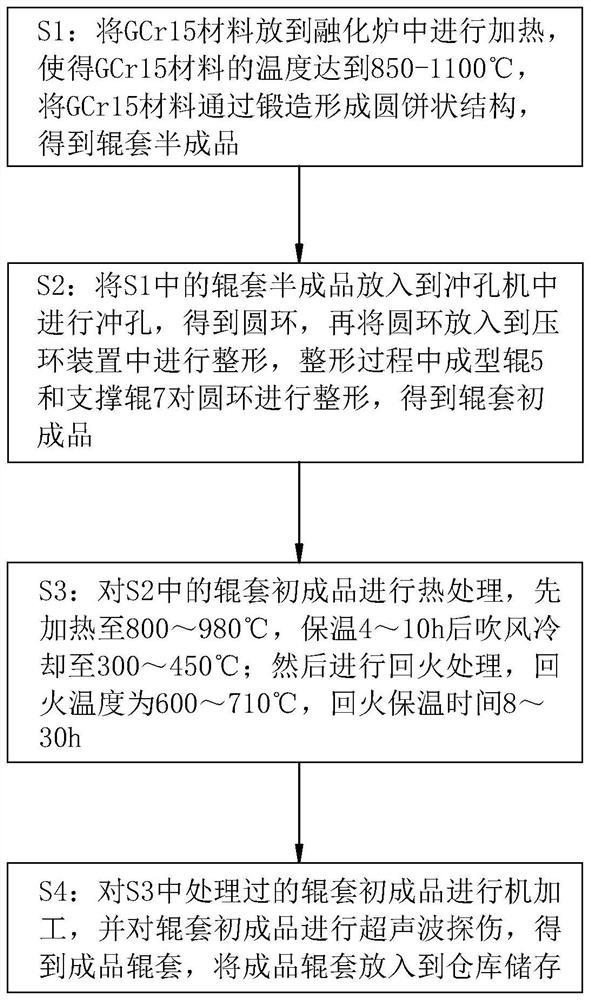

A kind of forging process of gcr15 roller sleeve

A roll sleeve and process technology, applied in the field of roll sleeve forging, can solve the problems of increasing the production cost of the roll sleeve, increasing the forging cost, prolonging the forging time, etc., and achieving the effects of low manufacturing cost, ensuring dimensional accuracy, and simplifying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

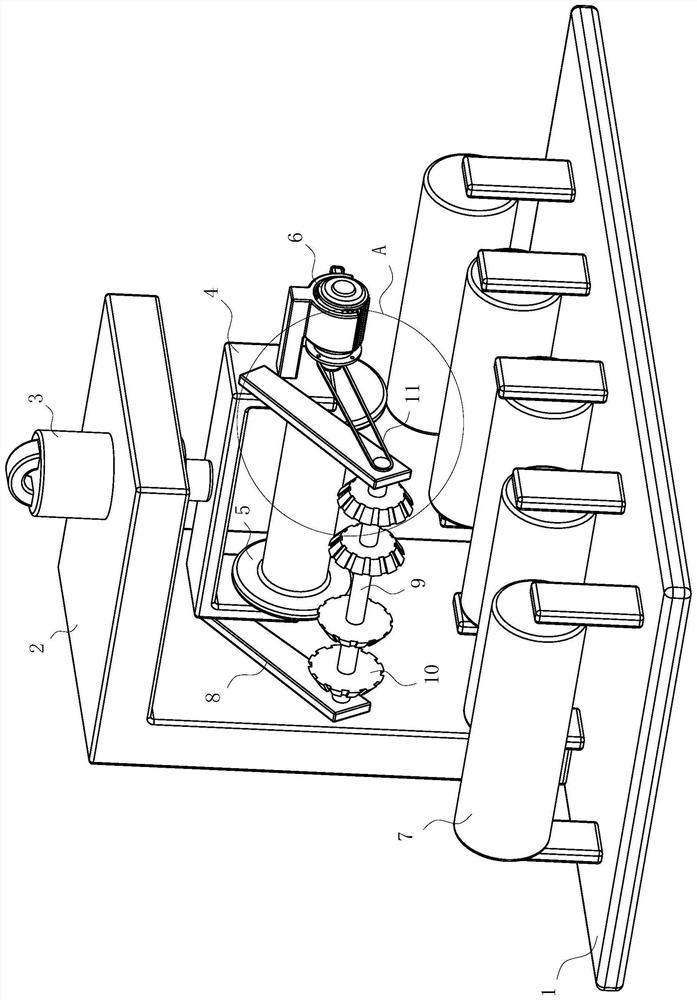

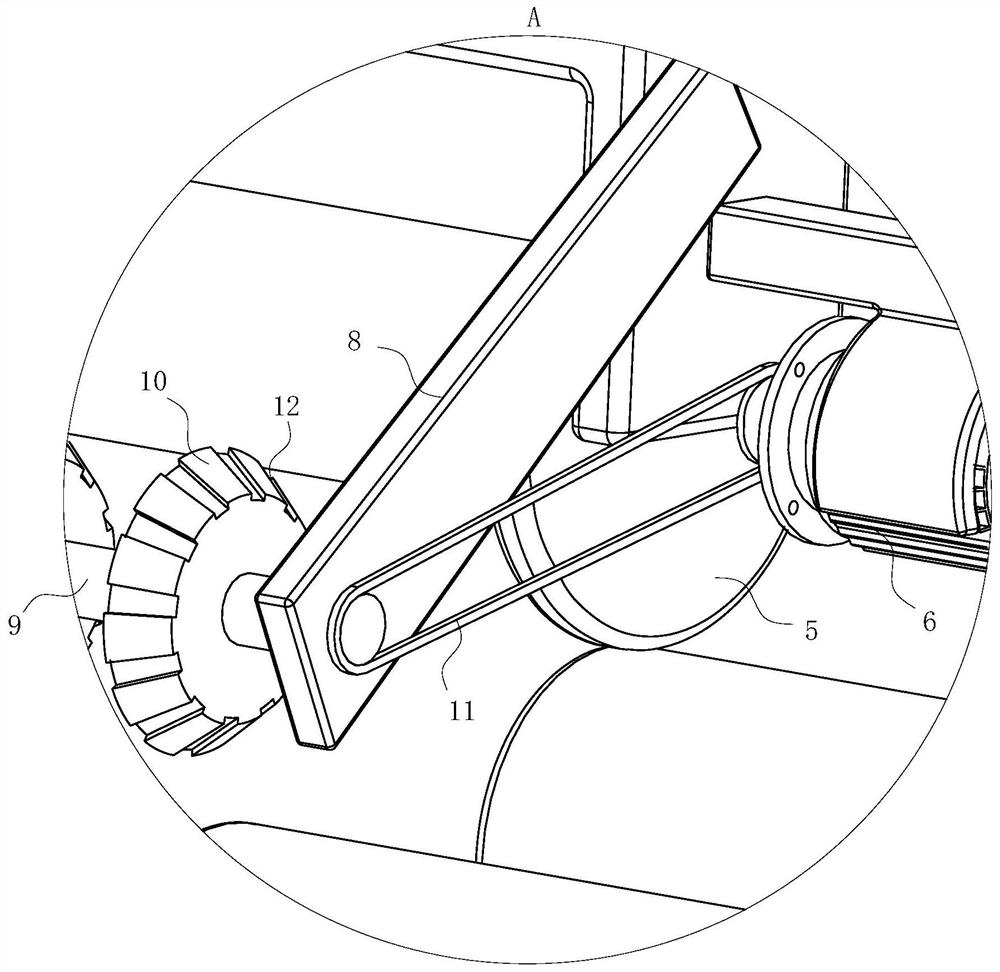

[0035] As a specific embodiment of the present invention, the arc surface of the pre-compression plate 10 is a conical structure, the pre-compression plate 10 is divided into two parts by the midpoint of the connecting rod 9, and the pre-compression plate 10 is close to the connecting rod 9. The diameter value in the direction of the midpoint of the rod 9 is greater than the diameter value far away from the midpoint of the connecting rod 9; during use, the working surface of the pre-compression disc 10 is a conical structure so that the pre-compression disc 10 pushes the inner circle of the ring when it is in contact with the ring. The material is extruded to both ends of the ring, so that the axial length of the ring is elongated; the pretreatment of the pre-pressing plate 10 makes the length of the ring elongated, further reducing the working pressure of the forming roller 5 .

[0036] As a specific embodiment of the present invention, the pre-compression plate 10 is equidis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com