316LN forged round steel for nuclear power pipeline and preparation method of 316LN forged round steel

A pipe and round forging technology, which is applied in the field of 316LN forged round steel for nuclear power pipes and its preparation, can solve the problems of difficult phase transformation of the structure, deformation of grains, improvement of internal structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

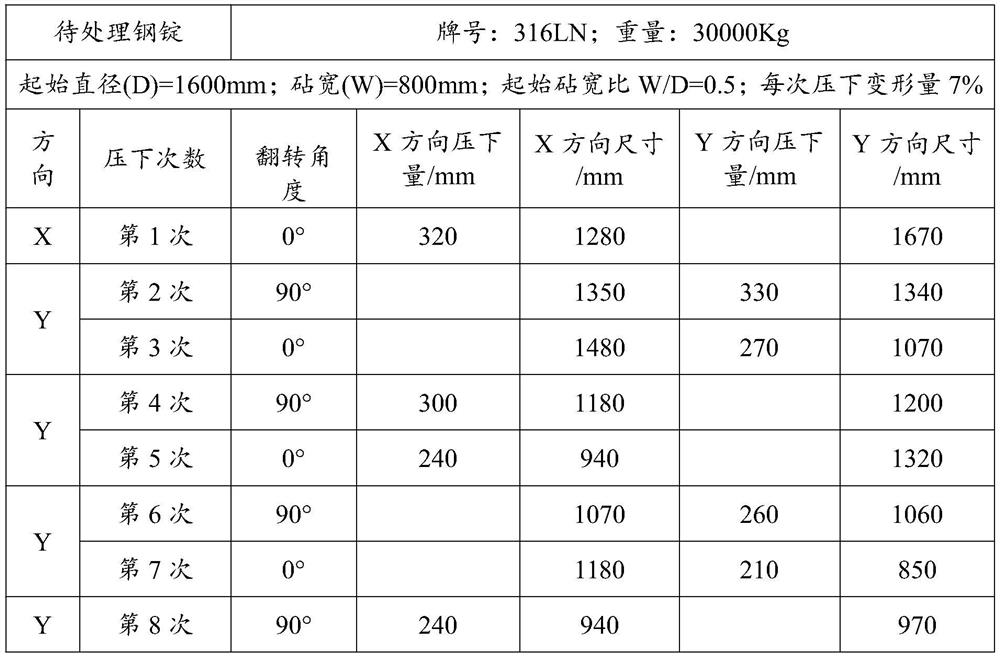

[0024] The invention provides a preparation method of 316LN forged round steel for nuclear power pipelines, comprising: sequentially performing segmental heating, forging and solid solution treatment on the 316LN steel ingot to be processed to obtain 316LN forged round steel for nuclear power pipelines; Formula heating includes a preheating section, a heating section, and a soaking section; the forging includes strong pressing and pressing in sequence; the strong pressing is carried out on an anvil; the total deformation of the strong pressing is more than 70%; The amount of deformation per pressing is 5-8%.

[0025] In the invention, the 316LN steel ingot to be processed is heated in sections to obtain the 316LN steel ingot heat-treated before forging.

[0026] The present invention has no special requirements on the composition of the 316LN steel ingot to be processed, and commercially available 316LN steel well known in the art can be used.

[0027] In the present inventio...

Embodiment 1

[0055] A method for preparing 316LN forged round steel for nuclear power pipelines comprises the following steps: sequentially subjecting 316LN steel ingots to be processed to heating in stages, forging, mold forming and solid solution treatment to obtain 316LN forged round steel for nuclear power pipelines.

[0056] First, the 316LN steel ingot to be treated is refined and ground to remove surface defects, and then heated in stages to obtain a 316LN steel ingot that is heat-treated before forging. Sectional heating consists of preheating section, heating section and soaking section, specifically: the 316LN steel ingot to be processed is loaded into a natural gas heating furnace at room temperature, and the temperature is raised to 550°C at a heating rate of 90°C / h in the preheating section heat preservation temperature, and heat preservation at the temperature of the preheating section for 4 hours, and then raise the temperature to the heat preservation temperature of the heat...

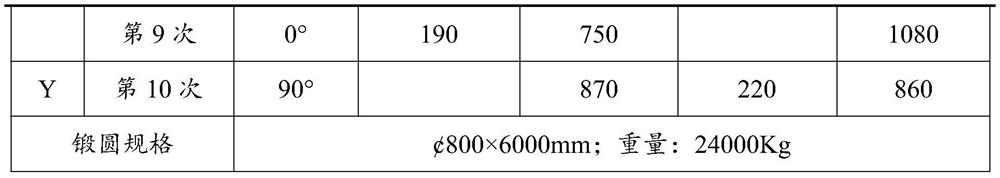

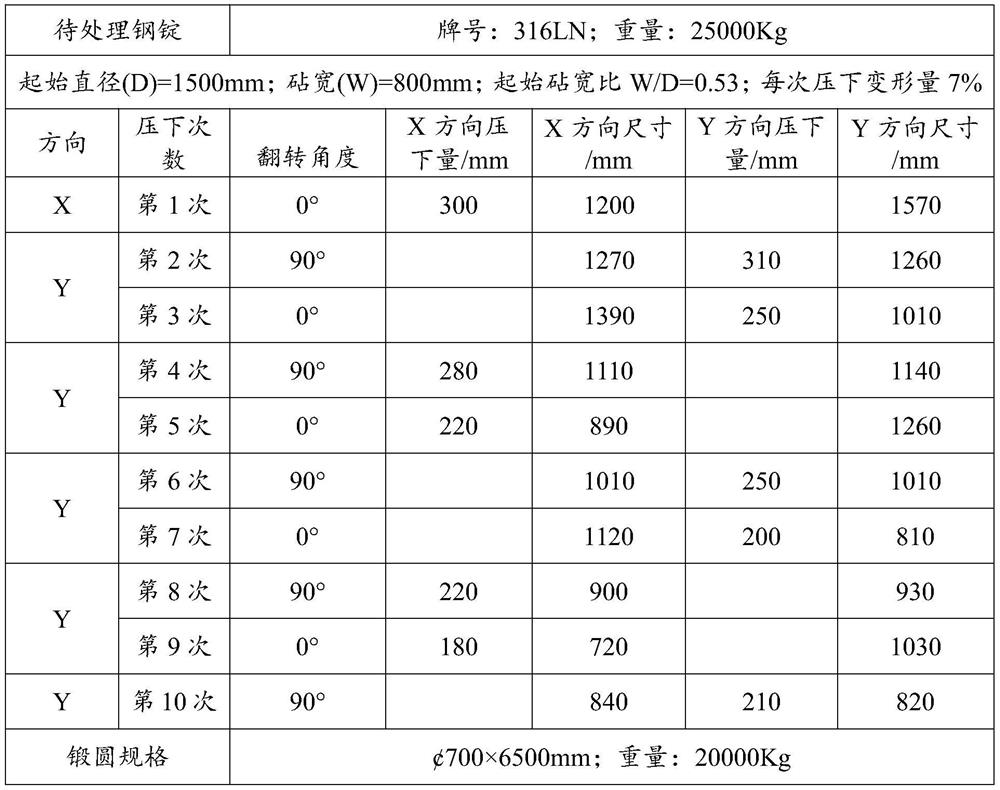

Embodiment 2

[0060] The initial anvil width ratio in the high pressure during forging in Example 1 is replaced by 0.53, and the specific parameters of high pressure during forging are shown in Table 2, and the rest of the technical features are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com