Closed forging technique for steering knuckle

A closed-joint and process technology, which is applied in the technical field of forging production of automobile steering knuckles, can solve the problems of large metal consumption and low material utilization rate, and achieve the effects of high material utilization rate, lower production cost and saving forging time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described.

[0030] 1. Cutting: Use GB4025C band saw machine to cut φ140 round bar with a length of 275±1mm; Heating: Use KGPS800-1 medium frequency induction heating furnace to heat the round bar to the temperature required for the forging process;

[0031] 2. Die forging:

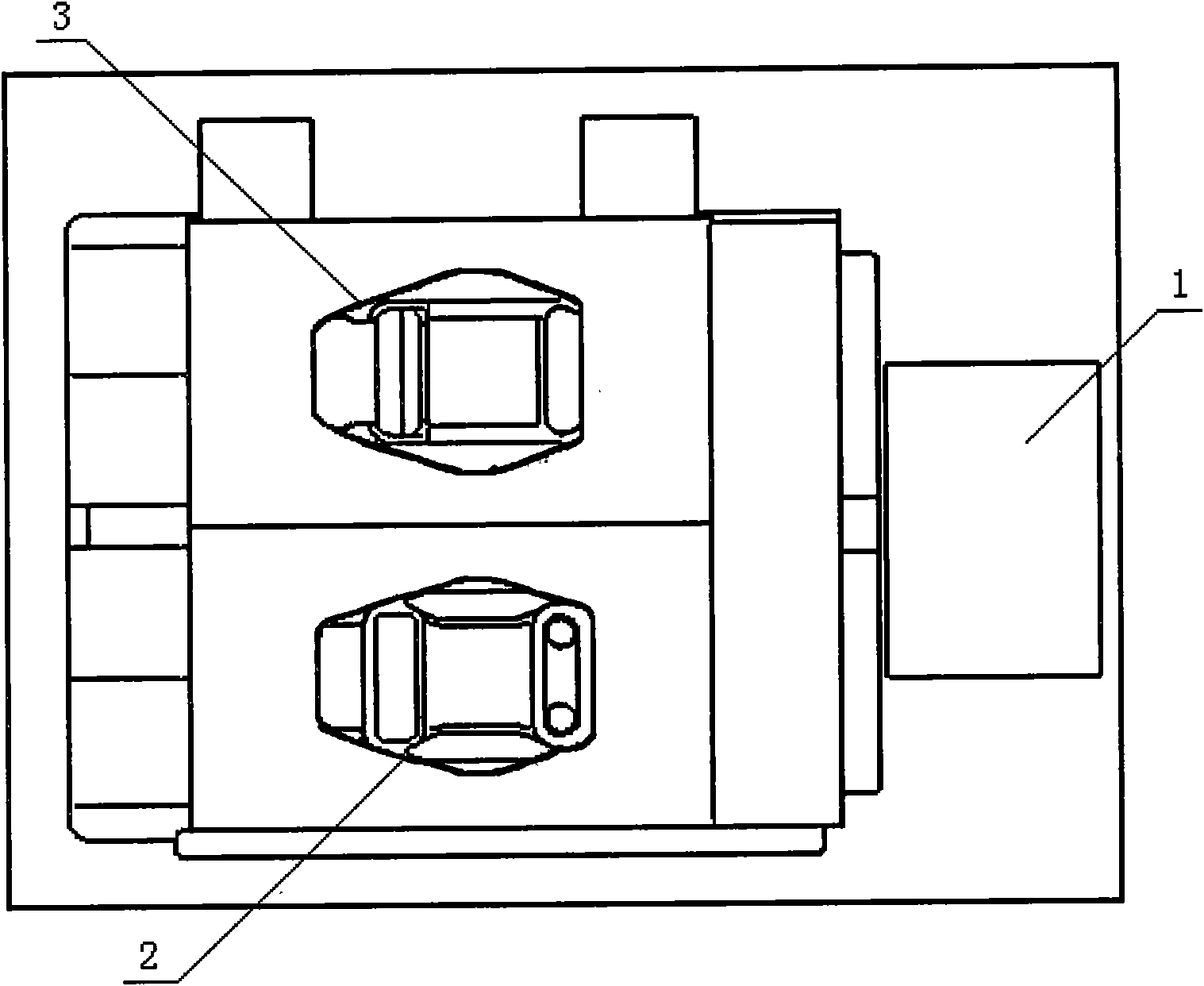

[0032] 1) Upsetting: upsetting the heated round bar on the upsetting table 1 and removing the oxide scale generated during heating at the same time, the length of the upsetting billet is 210±5mm, and the shape is like a drum;

[0033] 2) Extrusion billet: the upsetting billet is placed in the extrusion billet mold to extrude the billet;

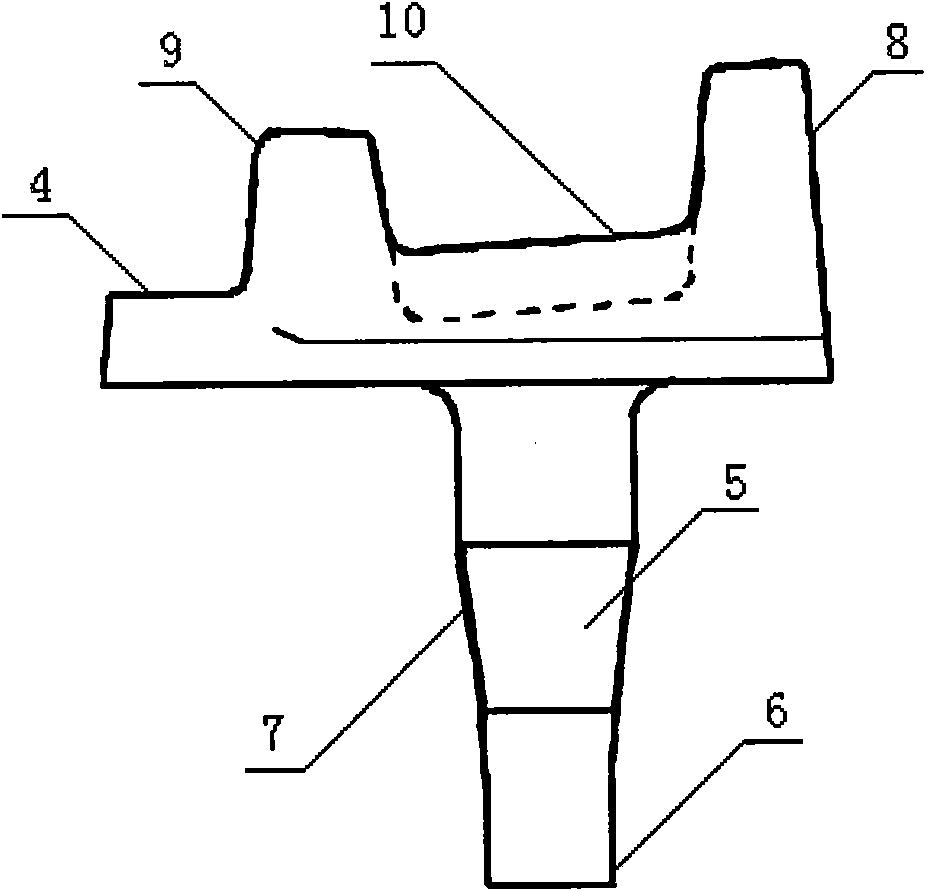

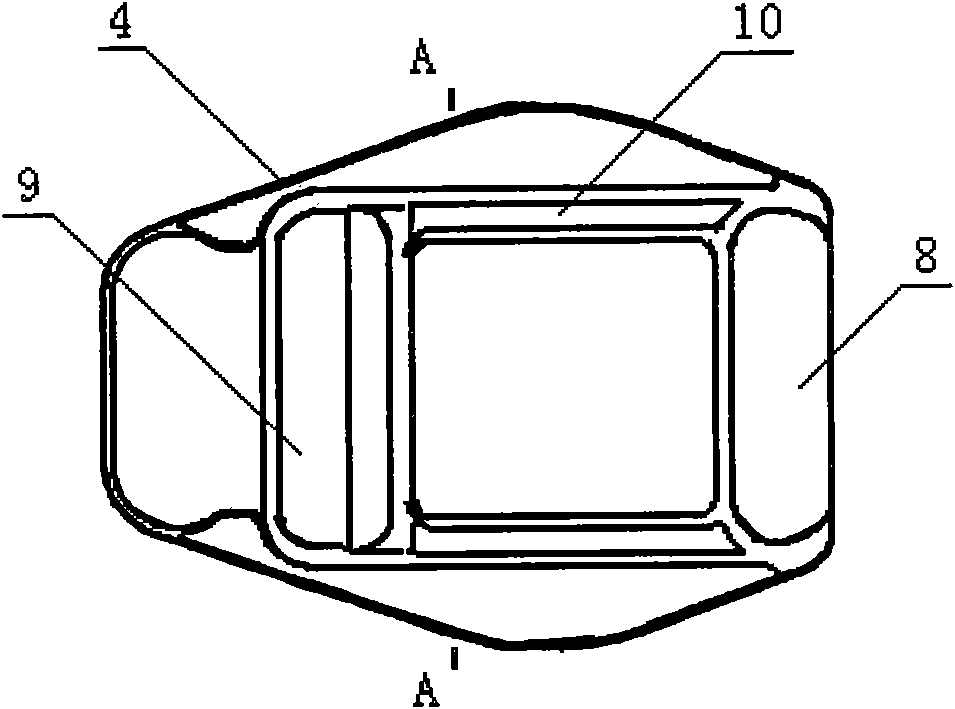

[0034] The billet after extrusion, the extrusion billet mold, and its partial cross-sectional view are as follows: Figure 7 to Figure 11 As shown, the closed forging process is adopted, and the forging is carried out on an electric direct-drive screw press. The extrusion billet die and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com