Forging method for six-throw crankshaft

A technology for six-turn crankshafts and forgings is applied in the forging field of six-turn crankshafts, which can solve the problems of low qualification rate, complex shape, easy quality problems, etc., to save energy and cost, reduce scrap rate, and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The forging method of the six-flip crankshaft of the present invention will be further described in detail through specific examples below.

[0014] The forging method of crankshaft with six turns comprises the steps:

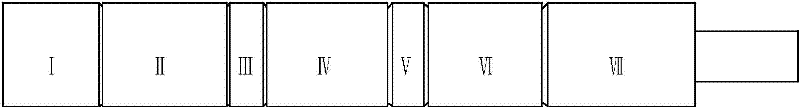

[0015] a) After upsetting the forging, pull it out to a flat square, and then use a triangular knife to stamp the forging up and down according to the number of segments of the six-turn crankshaft to be forged, and stamp the forging with the same number of segments as the six-turn crankshaft, that is, I ~paragraph VII, get as image 3 Forgings shown;

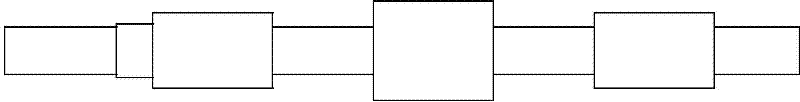

[0016] b) According to the length of the six-turn crankshaft to be forged, use the short anvil to pre-draw the long and short parts (sections III and V), and then pull the entire forging to the required size;

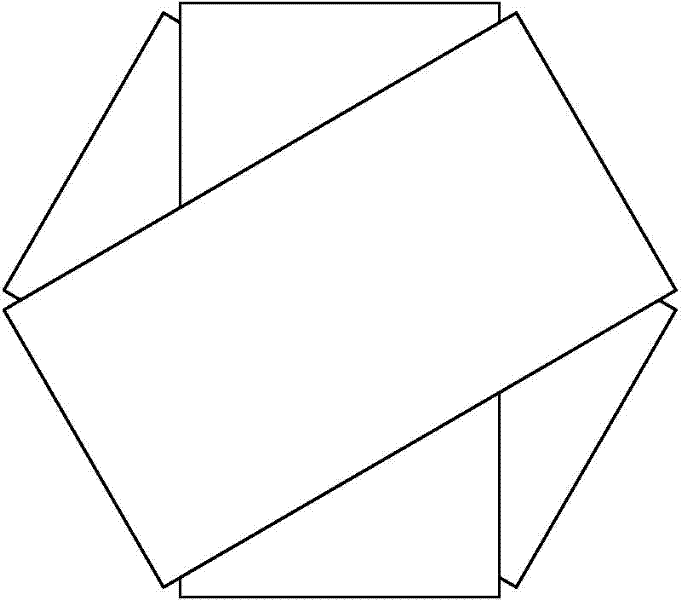

[0017] c) Twist the corresponding sections (sections II and VI) of the forged piece after drawing to obtain the required forged six-turn crankshaft blank;

[0018] d) Finishing the six-throw cran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com