Fe-Mn austenite non-magnetic steel forging method

An austenitic, non-magnetic steel technology, applied in the field of Fe-Mn series austenitic non-magnetic steel forging, can solve problems such as shortening forging time, and achieve shortened forging time, reduced temperature difference, temperature and microstructure uniformity improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Optional Fe-Mn series austenitic non-magnetic steel, its chemical composition includes C: 3.2%, Si: 0.42%, Mn: 20%, P: 0.010%, S: 0.003%, Al: 1.8%, Nb: 0.015 %, V: 0.014%, the balance is Fe. The billet is an octagonal ingot, the size of the tail of the ingot mold is 680mm, the size of the head of the fixed mold is 750mm, the size of the lower part of the riser is 660mm, the size of the upper part of the riser is 660mm, the length of the ingot body is 1600mm, the length of the ingot tail is 170mm, the height of the riser is 270mm, and the total length of the ingot is 2050mm. Weighing about 6t, the cross-sectional size required for forging is 210×1100mm. Its forging method includes heating process and pressing process:

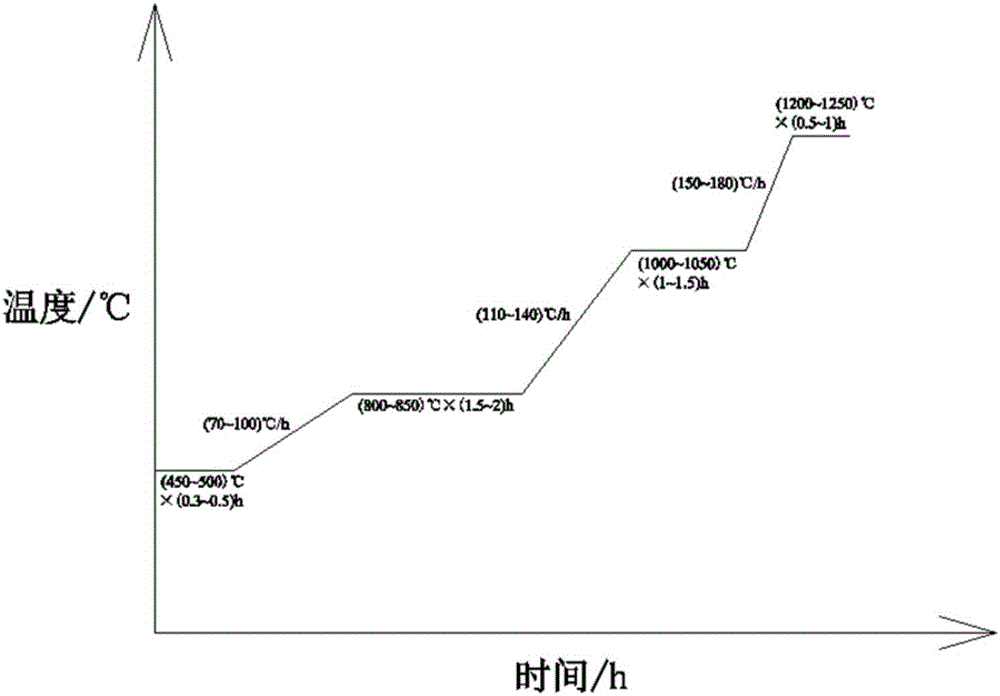

[0037] (1) During the heating process, the cast slab steel ingot is delivered hot, and the surface temperature of the hot delivered steel ingot is 385°C; when heating, it is put into the furnace at a low temperature, and the temperature in the preheating...

Embodiment 2

[0040] Optional Fe-Mn series austenitic non-magnetic steel, its chemical composition includes C: 3.0%, Si: 0.48%, Mn: 18.4%, P: 0.008%, S: 0.002%, Al: 2.2%, Nb: 0.015 %, V: 0.015%, the balance is Fe. The billet is a square ingot, the size of the tail of the ingot mold is 430mm, the size of the head of the ingot mold is 565mm, the size of the lower part of the riser is 535mm, the size of the upper part of the riser is 535mm, the length of the ingot body is 1300mm, the height of the riser is 160mm, the total length of the ingot is 1500mm, and the weight is about 3t. The cross-sectional dimension of the forging is 150×150mm. Its forging method includes heating process and pressing process:

[0041] (1) During the heating process, the cast slab steel ingot is delivered hot, and the surface temperature of the hot delivered steel ingot is 380°C; when heating, it is put into the furnace at a low temperature, and the temperature in the preheating section is 500°C. After holding for 0...

Embodiment 3

[0044] Optional Fe-Mn series austenitic non-magnetic steel, its chemical composition includes C: 4.0%, Si: 0.5%, Mn: 23%, P: 0.01%, S: 0.002%, Al: 1.2%, Nb: 0.01 %, V: 0.02%, the balance is Fe. The billet is a square ingot, the size of the tail of the ingot mold is 430mm, the size of the head of the ingot mold is 565mm, the size of the lower part of the riser is 535mm, the size of the upper part of the riser is 535mm, the length of the ingot body is 1300mm, the height of the riser is 160mm, the total length of the ingot is 1500mm, and the weight is about 3t. The cross-sectional dimension of the forging is 150×150mm. Its forging method includes heating process and pressing process:

[0045] (1) During the heating process, the cast slab steel ingot is delivered hot, and the surface temperature of the hot delivered steel ingot is 350°C; when heating, it is put into the furnace at a low temperature, and the temperature in the preheating section is 450°C. After holding for 0.5h, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com