Patents

Literature

52results about How to "Improve forging precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

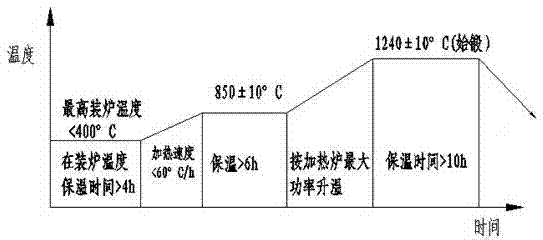

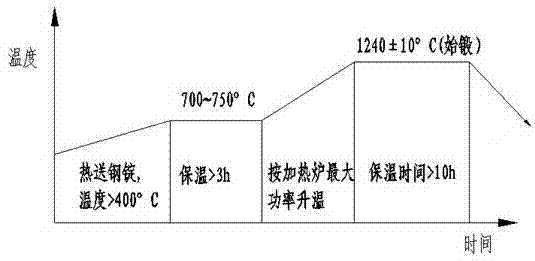

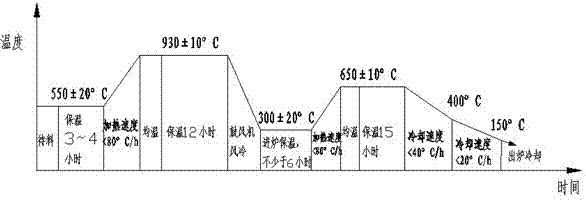

Wind-powered main shaft forging method

ActiveCN102806291AEnsure forging quality requirementsReduce fire consumptionMetal-working apparatusFurnace typesElectricityThermal treatment

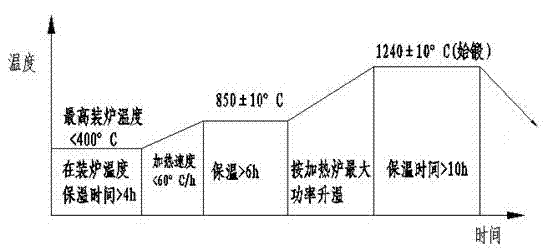

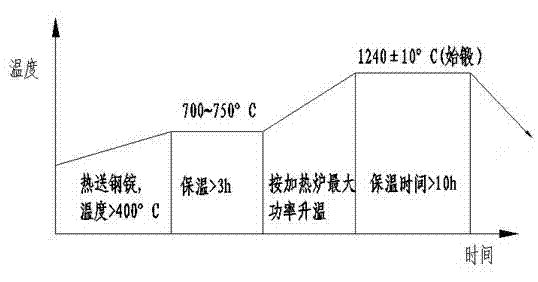

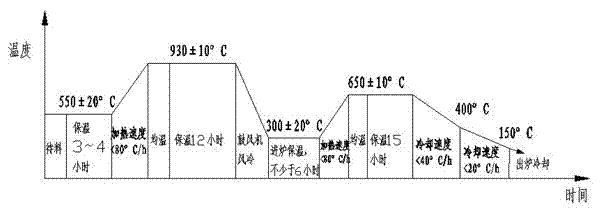

The invention relates to a wind-powered main shaft forging method. The wind-powered main shaft forging method comprises the following steps of inspecting a material; heating the material; taking out a blank which is formed by annealing the material for the first time, pre-forging, upsetting, drawing and printing the blank, performing pre-forging to form the blank, and blanking; finally forging the blank to form a main shaft by annealing for the second time, forging a flange end on a hollow rotary worktable, and drawing the main shaft until a shaft body has forging size; performing re-crystallization normalized tempering thermal treatment by using a one-time thermal loading furnace after forging the wind-powered main shaft; roughly turning the wind-powered main shaft and detecting flaws through ultrasonic wave; hardening and tempering the wind-powered main shaft, and performing nondestructive inspection and physical and chemical inspection on the wind-powered main shaft; finely turning the wind-powered main shaft; and packaging the wind-powered main shaft. The wind-powered main shaft forging method provided by the invention has the characteristics that the efficiency is high, the energy is saved, the cost is reduced, and the forging quality is improved.

Owner:JIANGSU LINGFEI FORGING

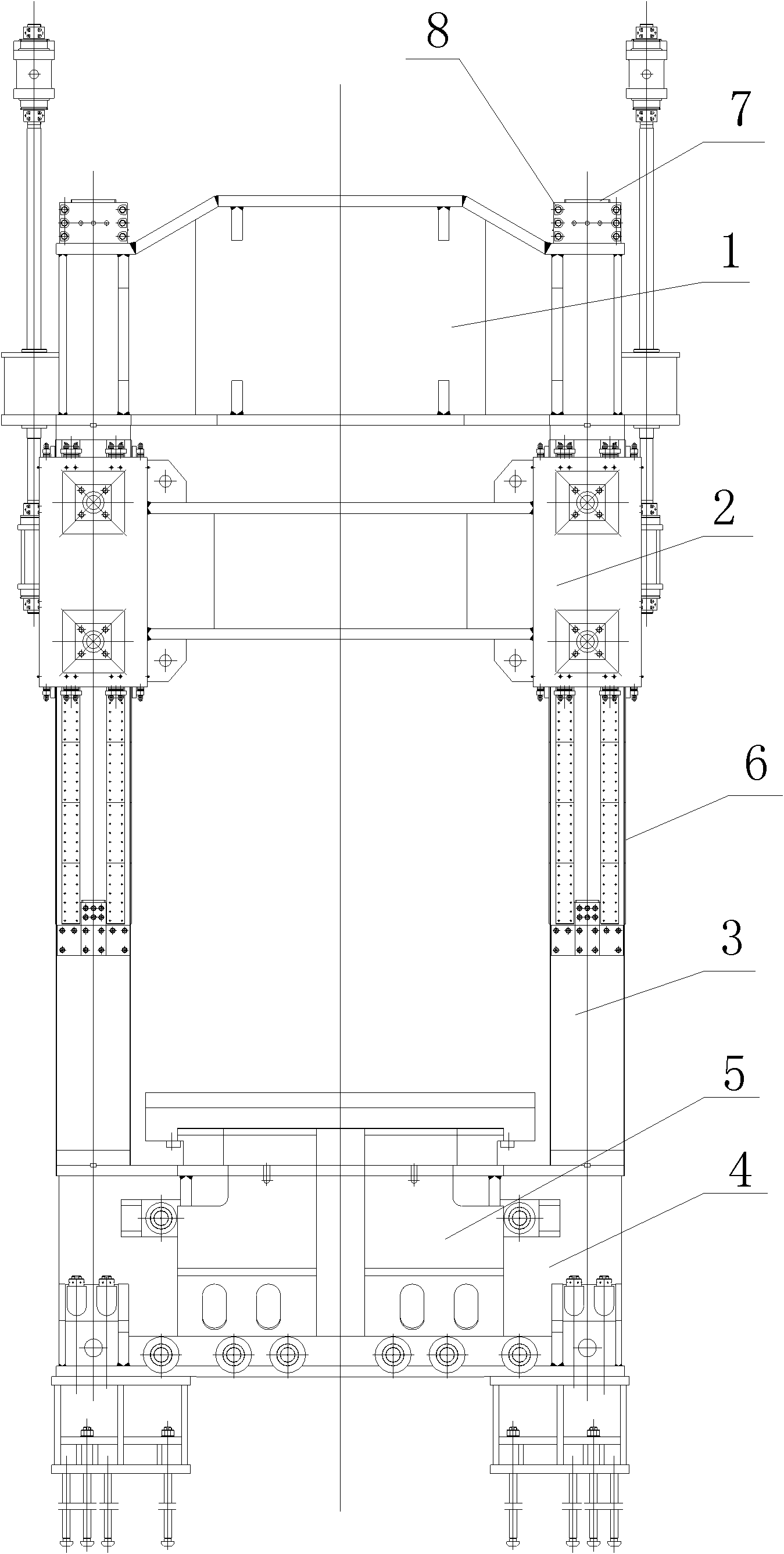

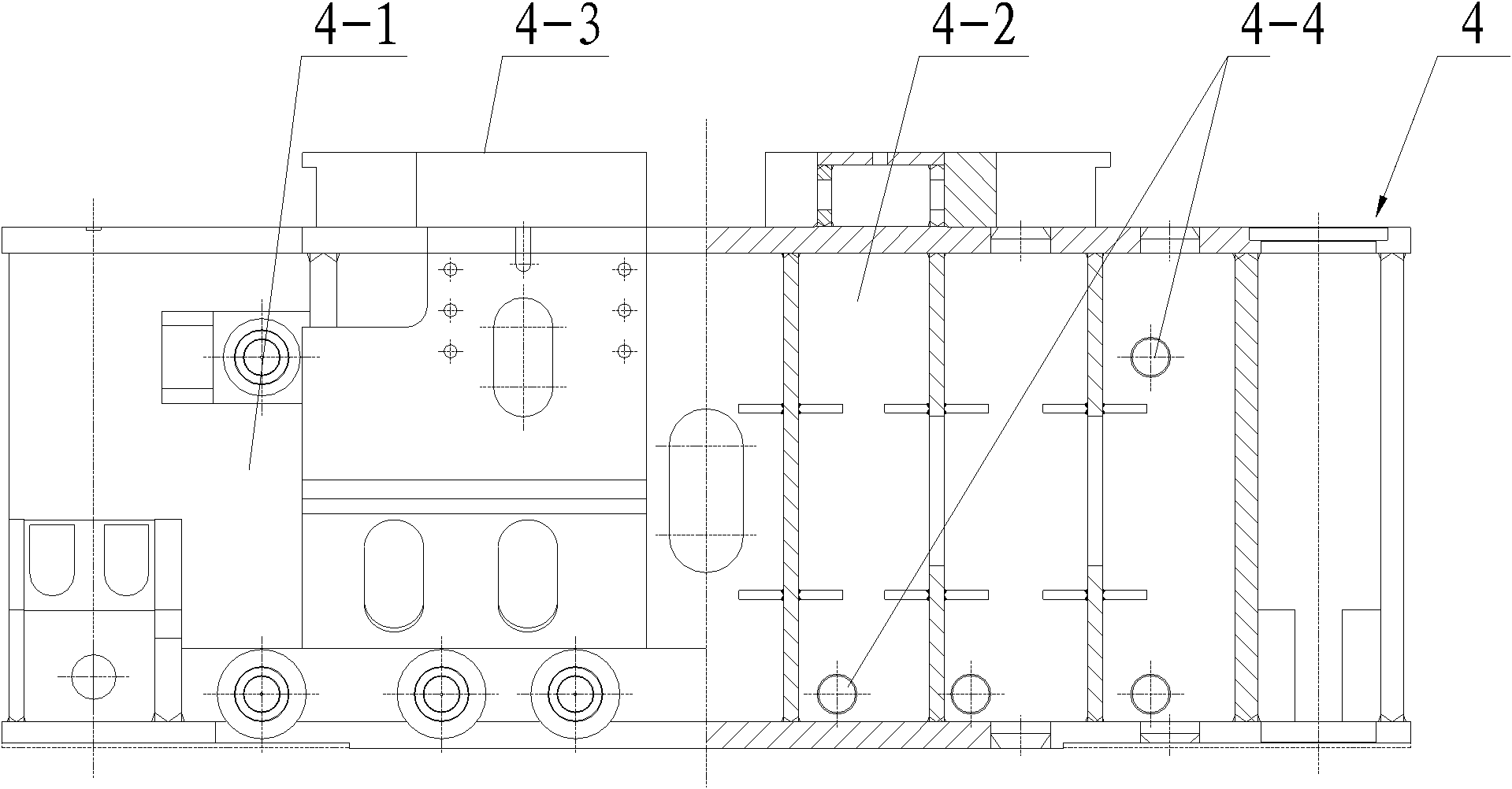

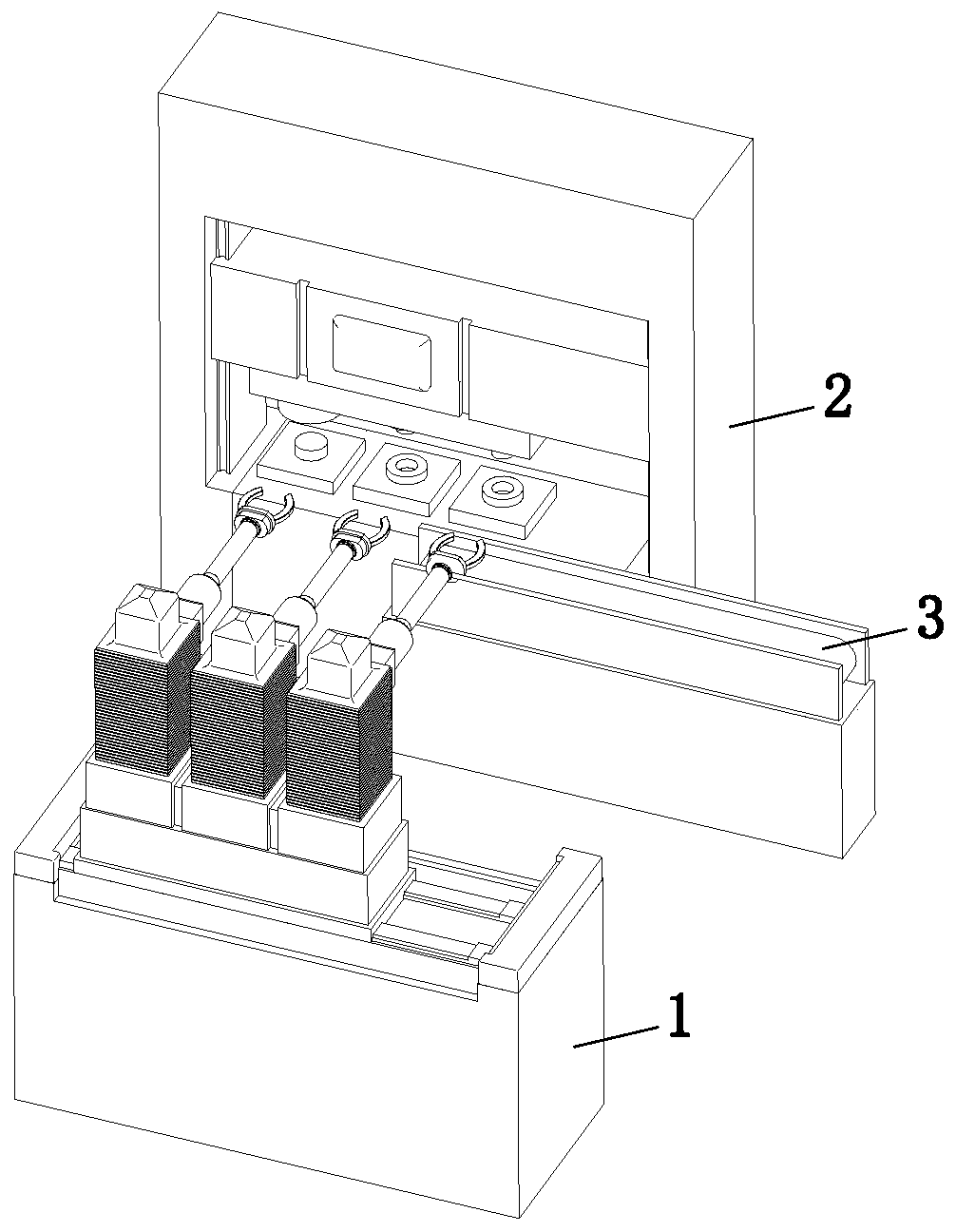

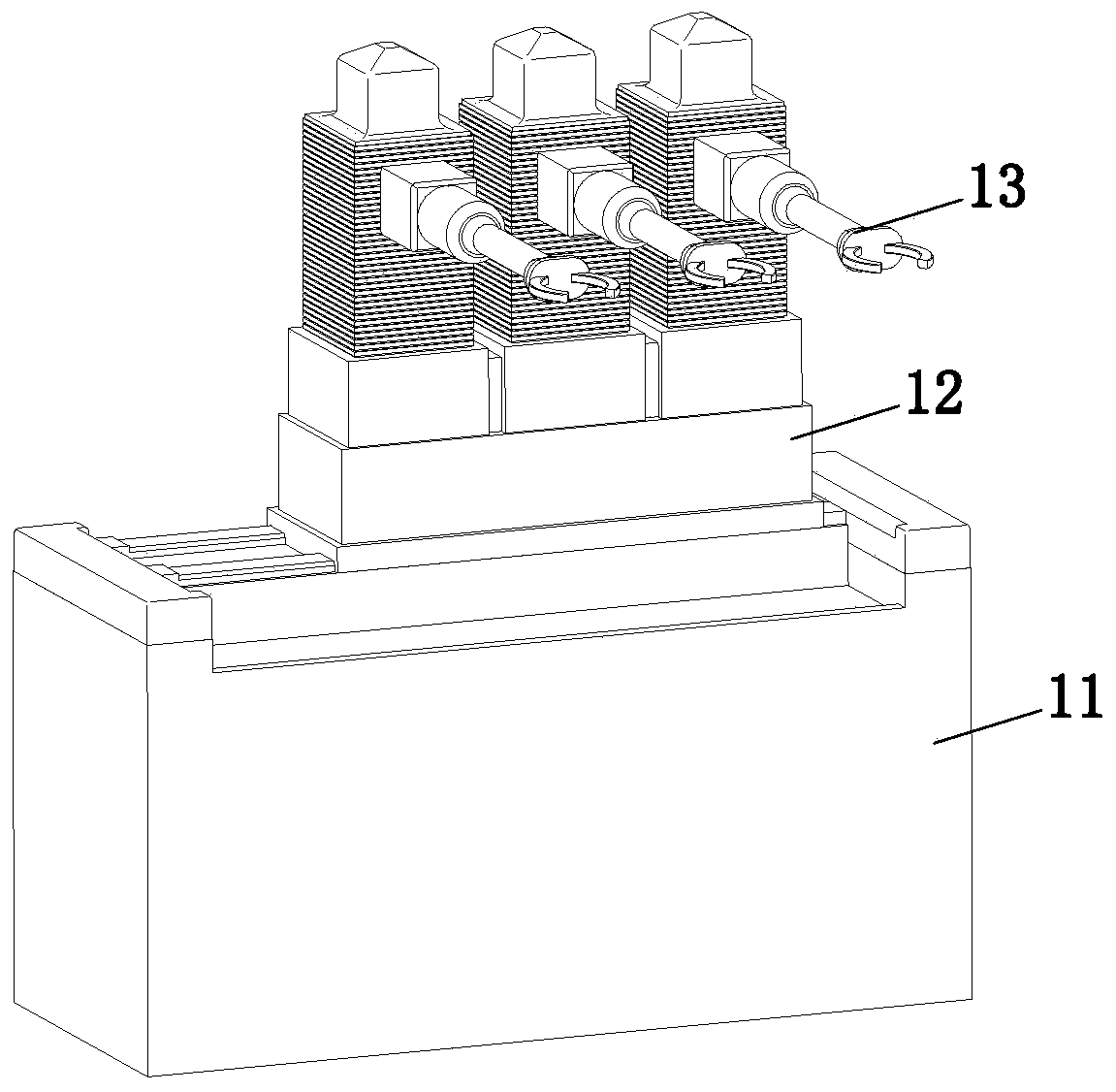

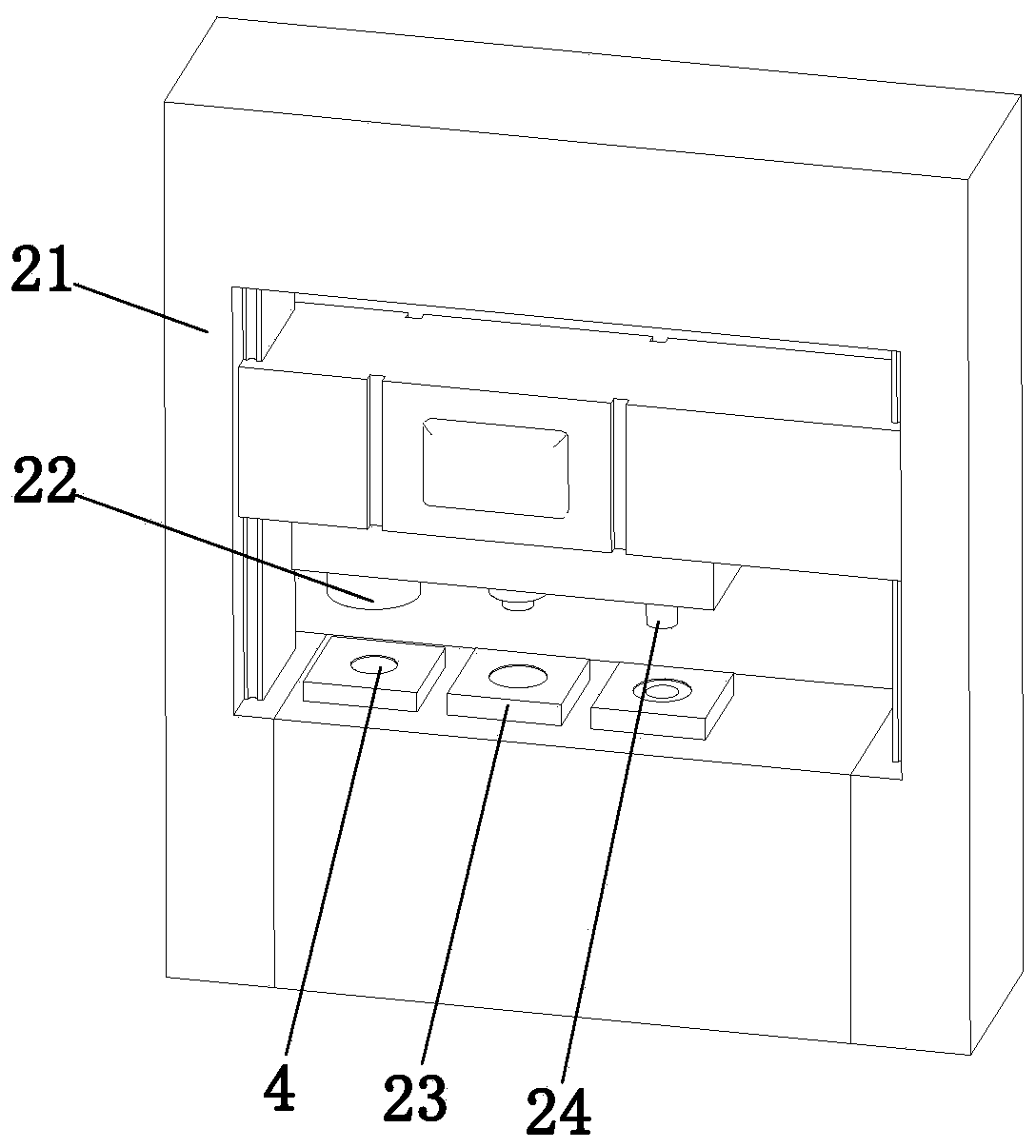

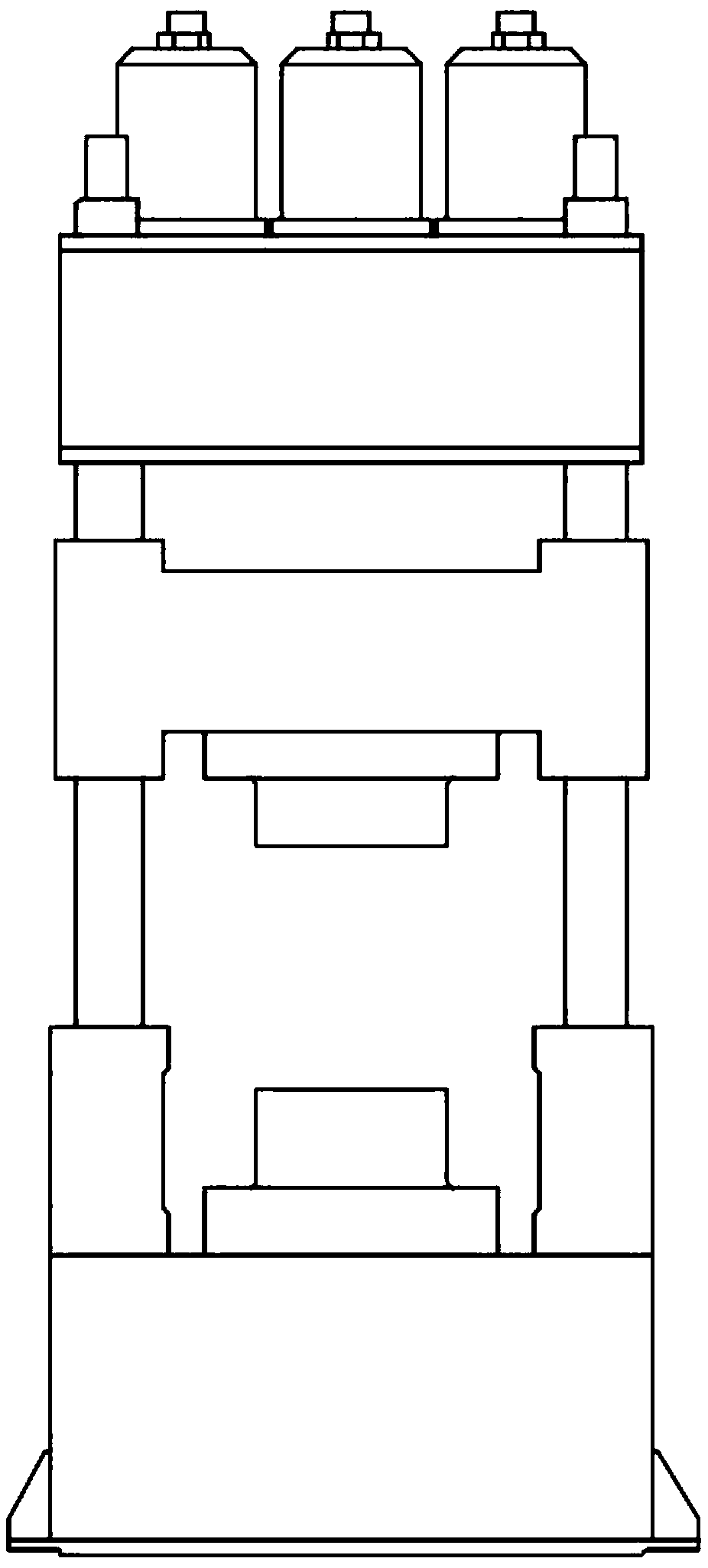

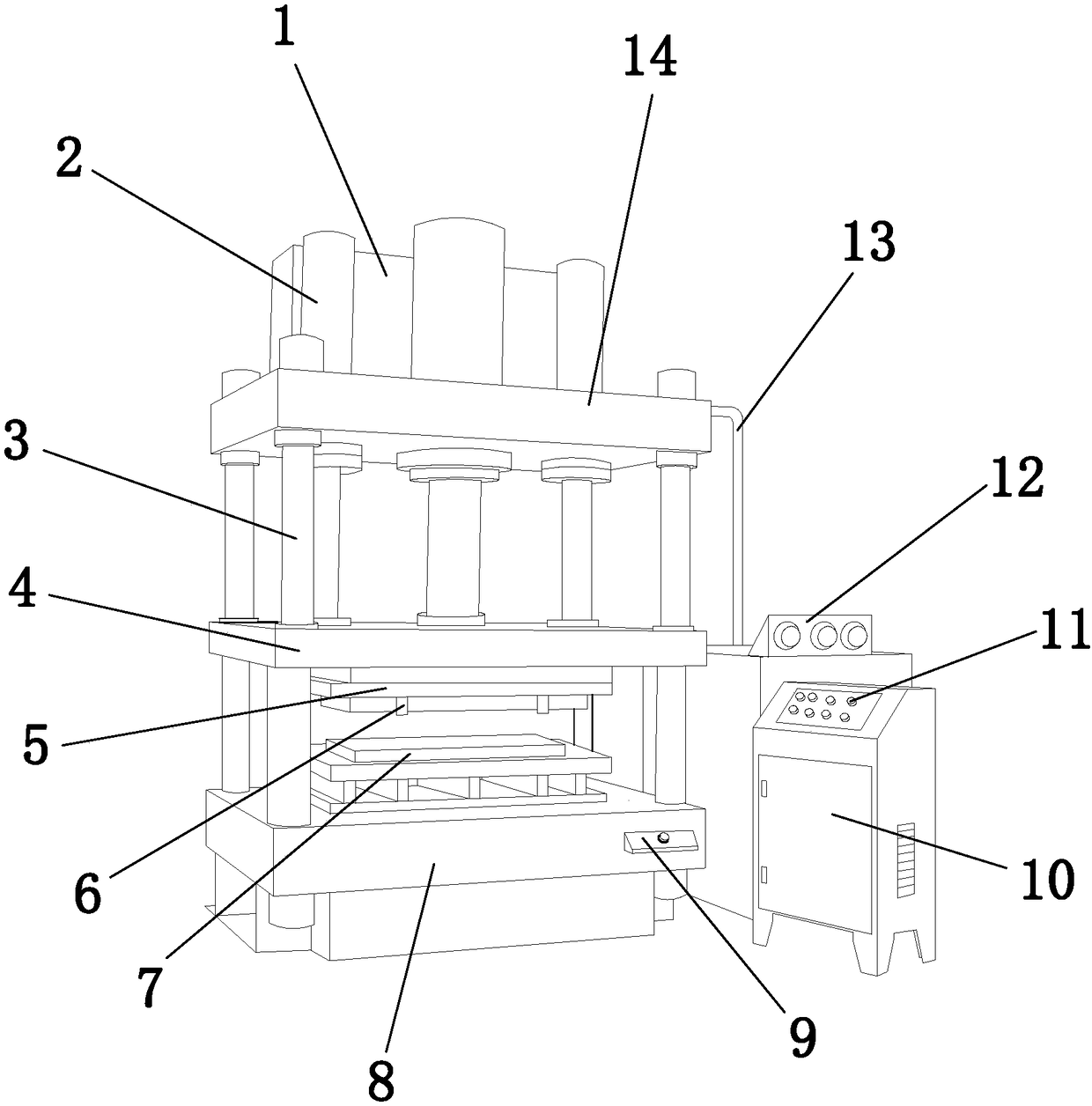

Free hydraulic forging press

InactiveCN102059309AIncrease stiffnessExtended service lifeForging/hammering/pressing machinesForging press drivesHydraulic cylinderPre stress

The invention relates to a free hydraulic forging press comprising a frame press body, a mobile worktable and a hydraulic cylinder, wherein the frame press body comprises an upper cross beam, a sliding block, upright posts and a lower cross beam, and the mobile worktable is connected with the press body. The free hydraulic forging press is characterized in that the frame press body is in an integral pre-stressed structure, that is to say, each upright post is in a hollow structure; a pre-stressed pull rod penetrates through and is arranged in a center hole of each upright post and extends outof the upper cross beam and the lower cross beam; pre-stressed nuts are respectively arranged at the end part of each pre-stressed pull rod; a plunger piston unbalance loading resisting mechanism is arranged on the hydraulic cylinder; a guide device is arranged between the upright post and the sliding block; a stepped mobile mechanism is arranged below the mobile worktable; and a leveling device is arranged below the mobile worktable. The invention has the advantages of large nominal force, strong unbalance loading resistance, long sliding stroke and the like; and the mobile worktable has long moving stroke.

Owner:TIANJIN TIANDUAN PRESS CO LTD

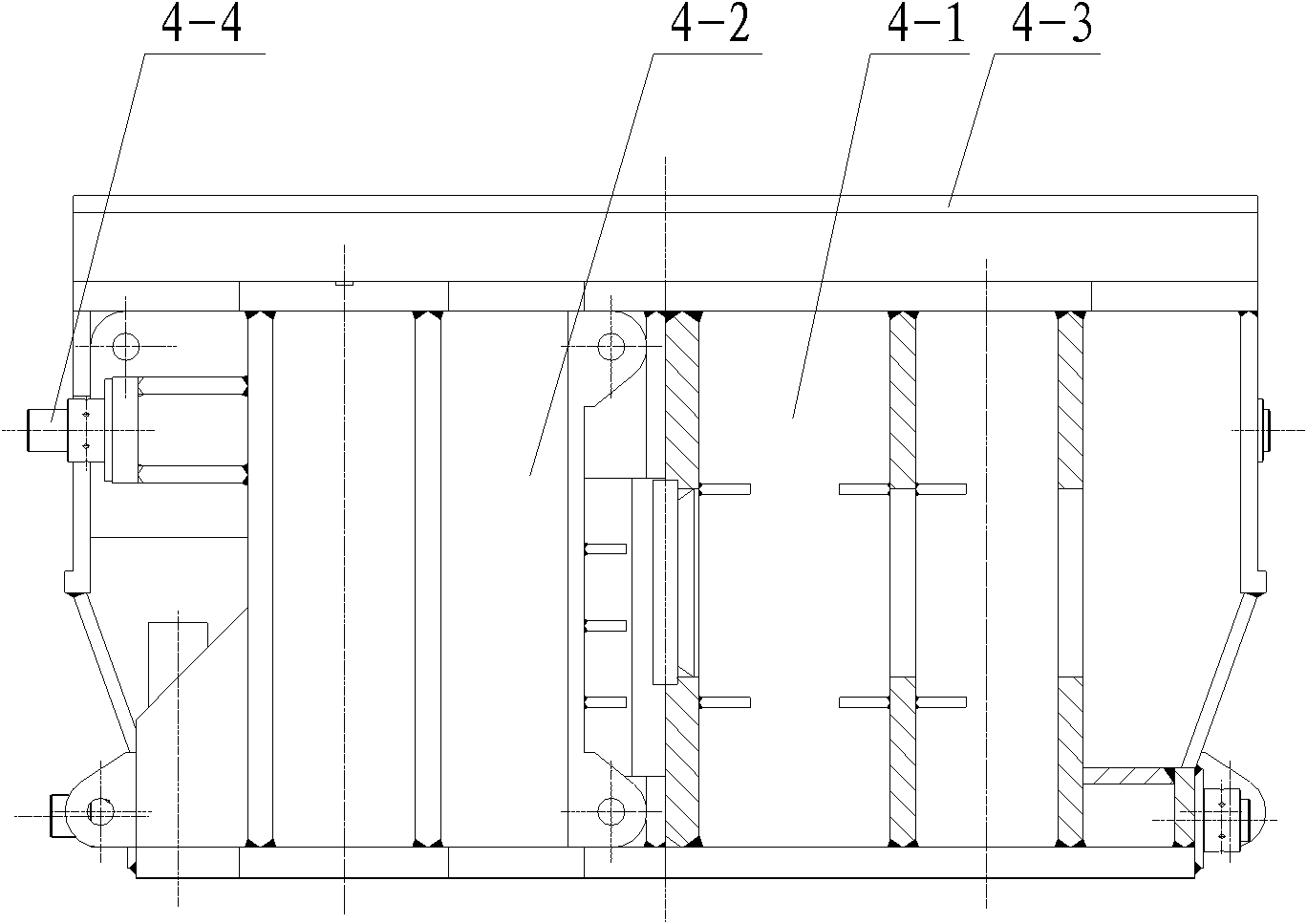

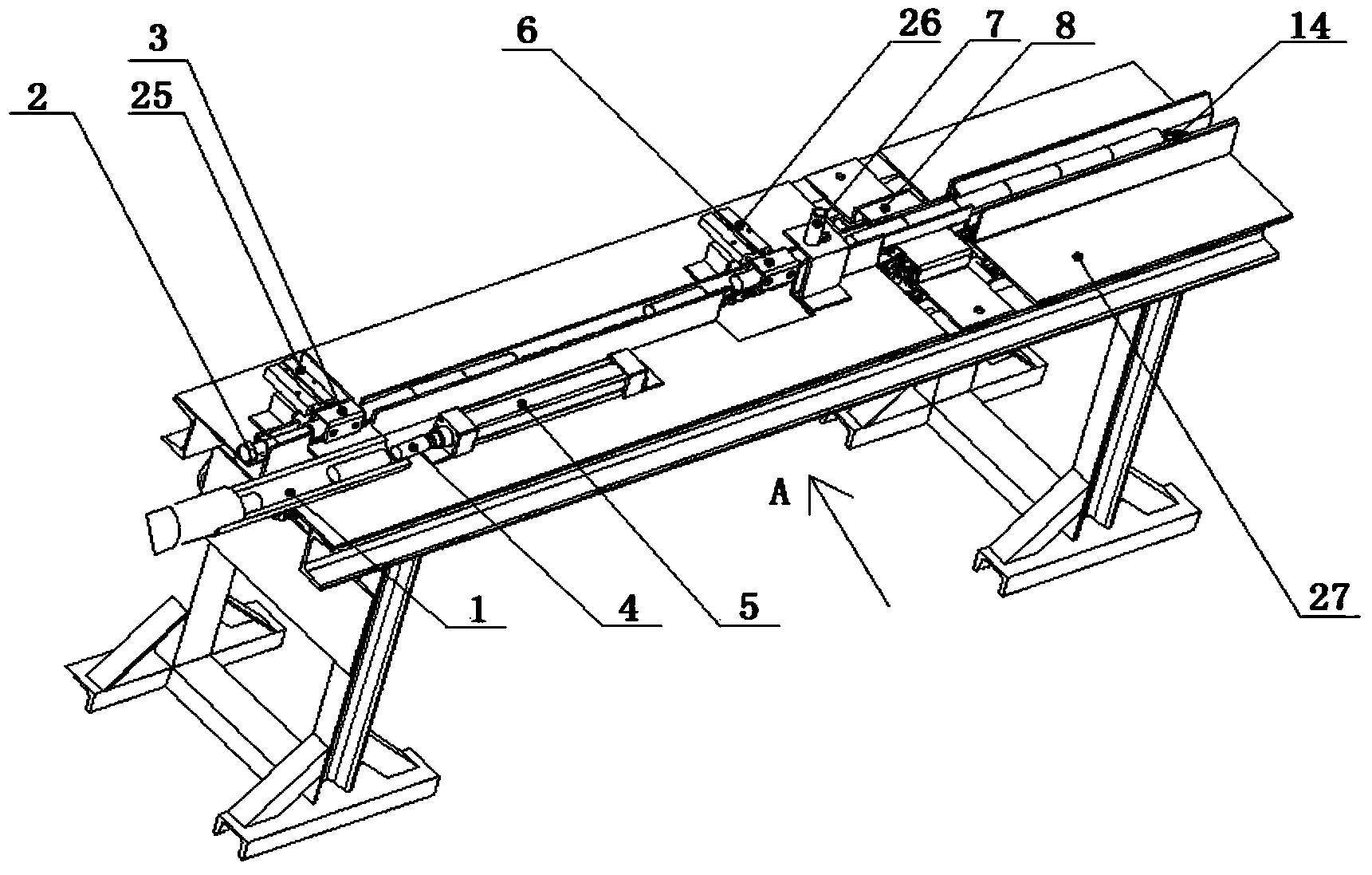

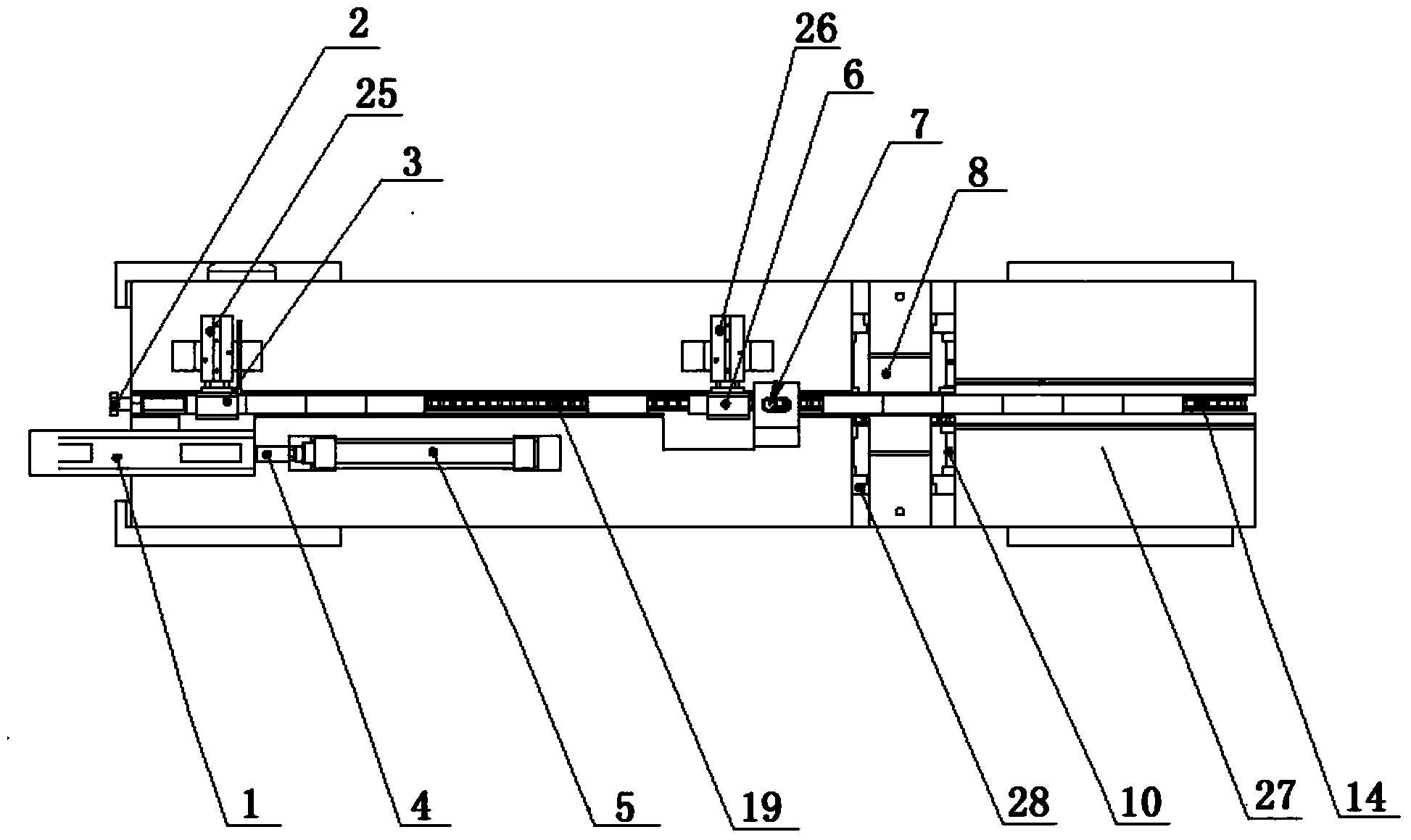

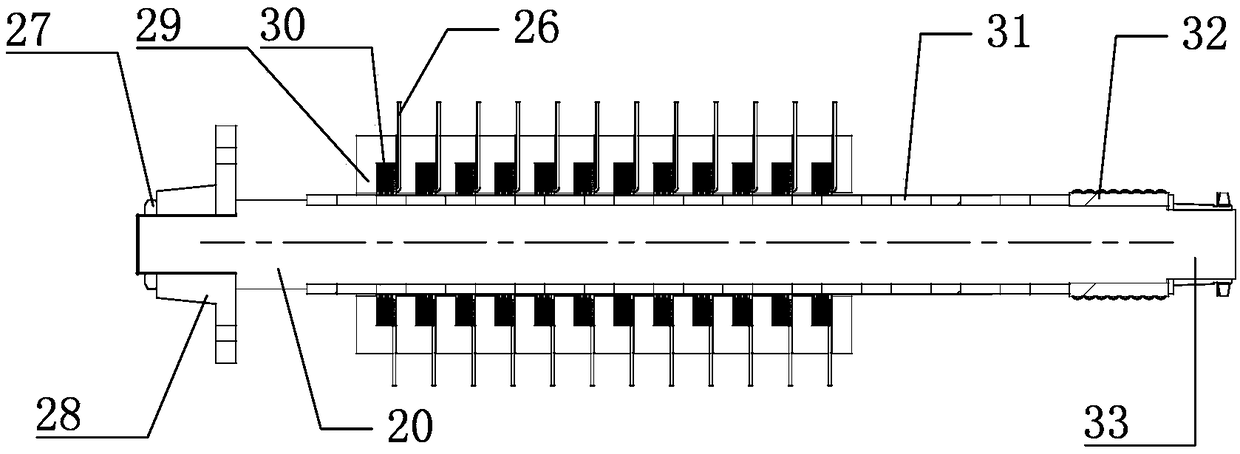

Length detection and automatic feeding and discharging device for short metal bar stocks

InactiveCN103449106AAvoid cloggingGuaranteed continuityConveyorsControl devices for conveyorsEngineeringMetal

The invention discloses a length detection and automatic feeding and discharging device for short metal bar stocks, and belongs to the technical field of mechanical bar stock conveying devices. A transition plate (8) is arranged between a primary chain (14) and a secondary chain (19). A length sensor (7) is arranged above the secondary chain (19). A screening cylinder (26) is fixedly arranged on a bracket (27) on one side of the secondary chain (19), and is perpendicular to the secondary chain (19). A screening cylinder pushing plate (6) is fixedly arranged at the extending end of the screening cylinder (26). A transverse cylinder (25) is arranged on one side of the rear part of the secondary chain (19), and is perpendicular to the secondary chain (19). A transverse cylinder pushing plate (3) is fixedly arranged at the extending end of the transverse cylinder. According to the device, the transition plate, the length sensor, the screening cylinder, the screening cylinder pushing plate, the transverse cylinder, the transverse cylinder pushing plate, a longitudinal cylinder and a longitudinal cylinder pushing plate are additionally arranged, so that the heating continuity and stability of the short metal bar stocks are improved, the forging and pressing accuracy is improved, and high automation degree is ensured.

Owner:XUZHOU HAODING MACHINERY

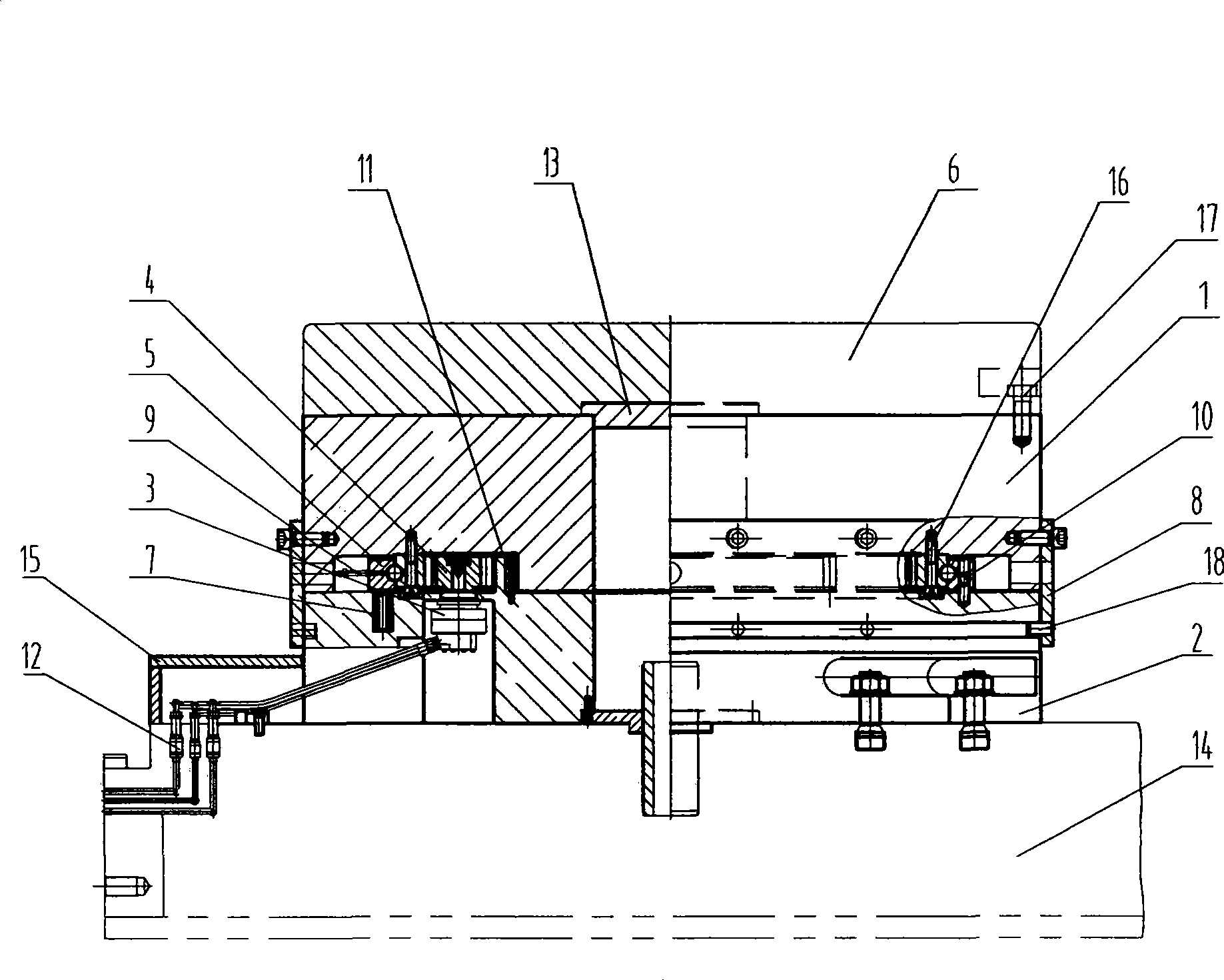

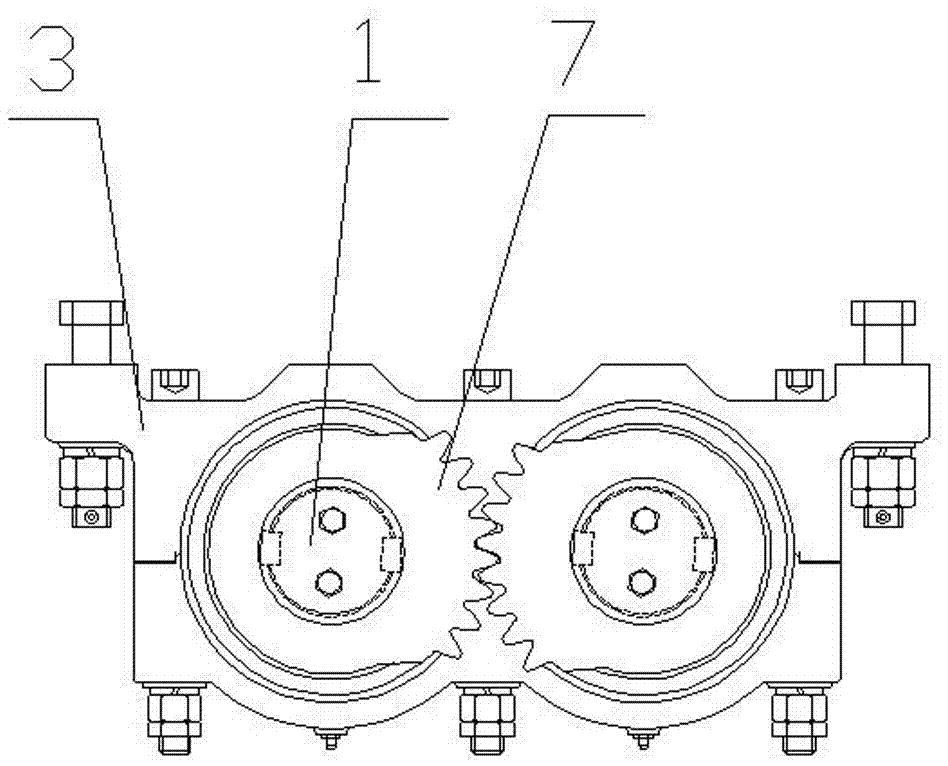

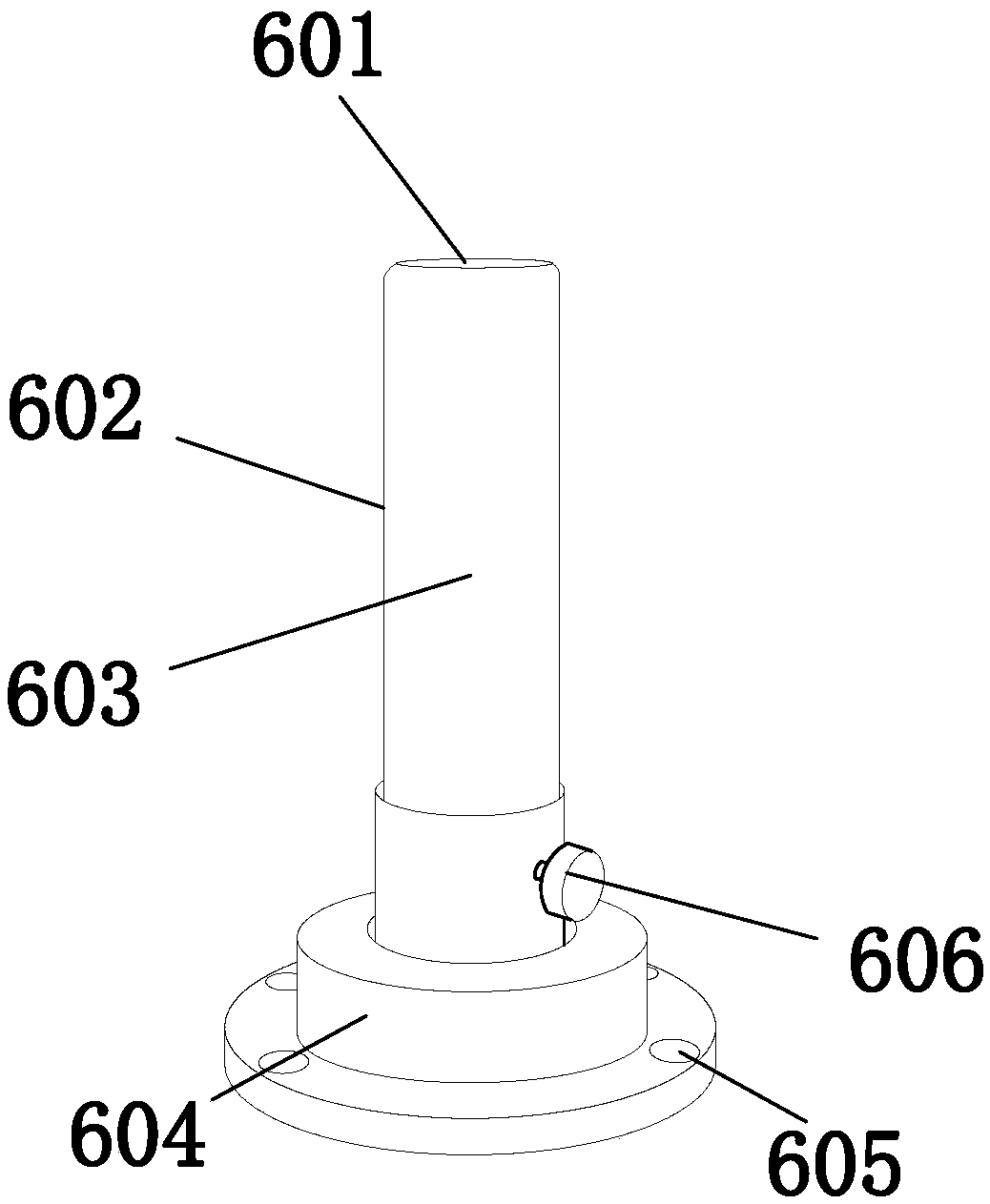

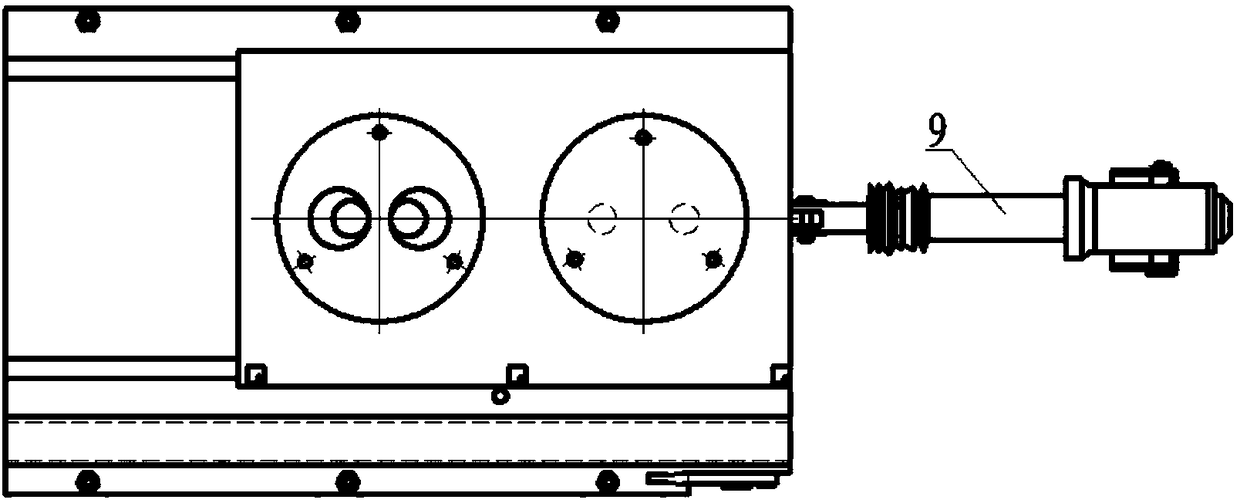

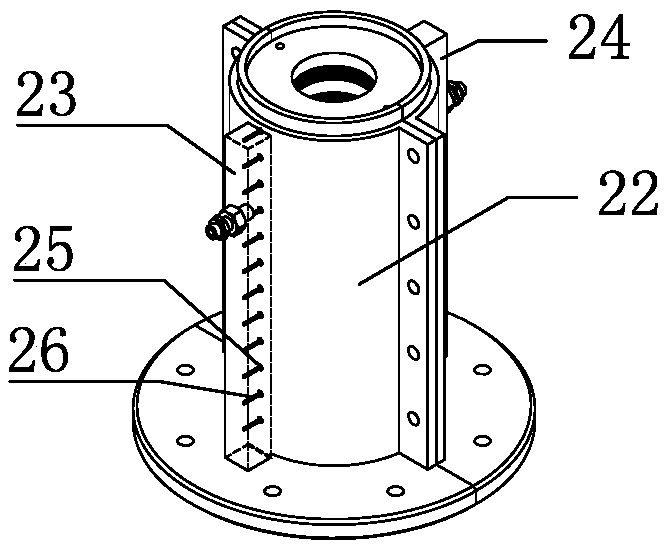

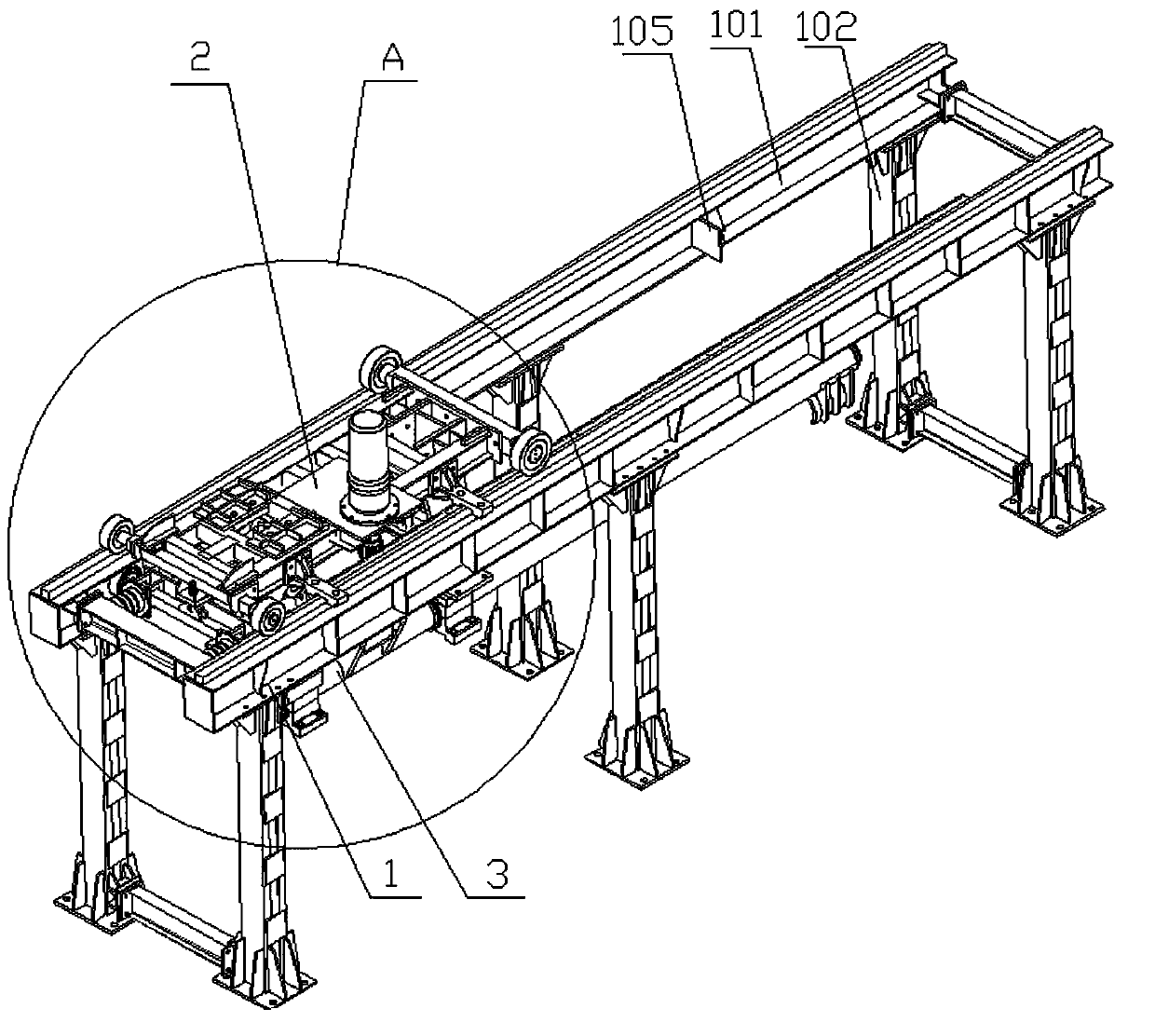

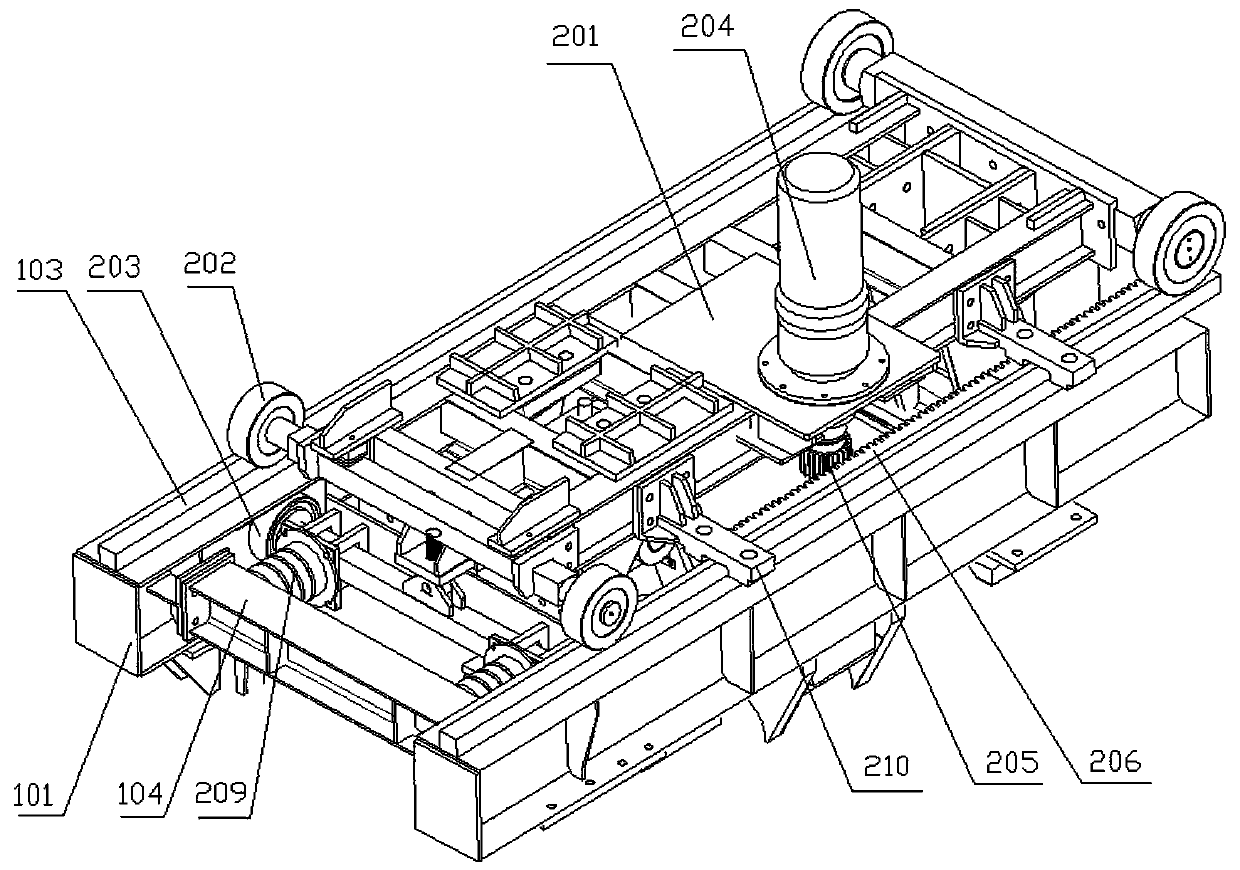

Rotary table of quick-forging hydraulic press

ActiveCN101422806ARealize hydraulic controlSmooth rotationForging/hammering/pressing machinesHydraulic motorAutomatic control

The invention discloses a rotary worktable for a high-speed hydraulic forging press and relates to the forging tool of the hydraulic forging press. The rotary worktable of the prior art is universally manually and pneumatically operated directly on the worktable, the worktable with high weight and high cost is easily damaged, and simultaneously, automated control is hard to realize. A turntable bearing is adopted for connection between the worktable and a base in the invention, so that the inner ring and the worktable are fixed, the outer ring and the base are fixed, a hydraulic motor with a pinion and the base are fixed, and the pinion and the internal tooth of the turntable bearing are engaged. The worktable is provided with a technical liner plate which is positioned by a round pin, a disc spring is installed under the outer ring of the turntable bearing and in the base, and the hydraulic motor is connected with a quick change coupler arranged on the movable worktable. The invention realizes the hydraulic operation of the rotary worktable by the hydraulic motor, and can be automatically controlled, thus improving the production efficiency of the hydraulic machine. The worktable is provided with the technical liner plate which protects the worktable and prolongs the service life of the tool.

Owner:TAIYUAN HEAVY IND

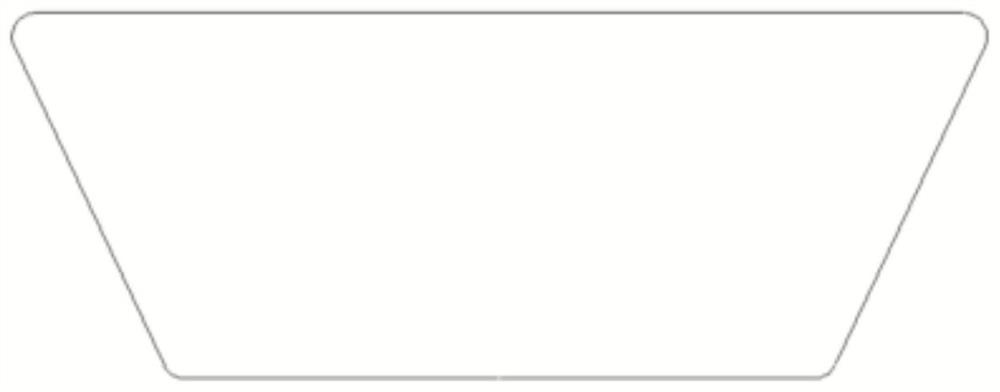

Forging process of aluminum alloy wheel hub

InactiveCN110000320AIncrease profitReduce manufacturing costMetal-working apparatusWheelsUltimate tensile strengthAlloy wheel

The invention discloses a forging process of an aluminum alloy wheel hub. The forging process comprises the following steps that a pre-machined square aluminum alloy blank material is heated to 150 DEG C to 260 DEG C, and heat preservation is carried out for 0.2 hour to 0.5 hour; the square blank material is heated to 300 DEG C to 350 DEG C for the first time, heat preservation is carried out for0.3 hour to 0.5 hour, then second heating is carried out, the temperature ranges from 400 DEG C to 460 DEG C, and heat preservation is carried out for 0.4 hour to 0.6 hour; a mold of a forging machineis pre-heated, wherein the heating temperature ranges from 200 DEG C to 300 DEG C, and heat preservation is carried out for 0.2 hour to 0.4 hour; the square blank material in S20 is placed in the forging mold of the forging machine in S30 to be forged, wherein the forging temperature ranges from 440 DEG C to 480 DEG C, and a hub blank of a disc-shaped structure is formed; and after the hub blankis cooled, edge cutting and polishing are carried out on the hub blank, wear-resisting powder is sprayed, and the finished hub is obtained. According to the forging method, the utilization rate of aluminum alloy is increased, the structural strength is high, and safety is high.

Owner:江苏珀然轮毂有限公司

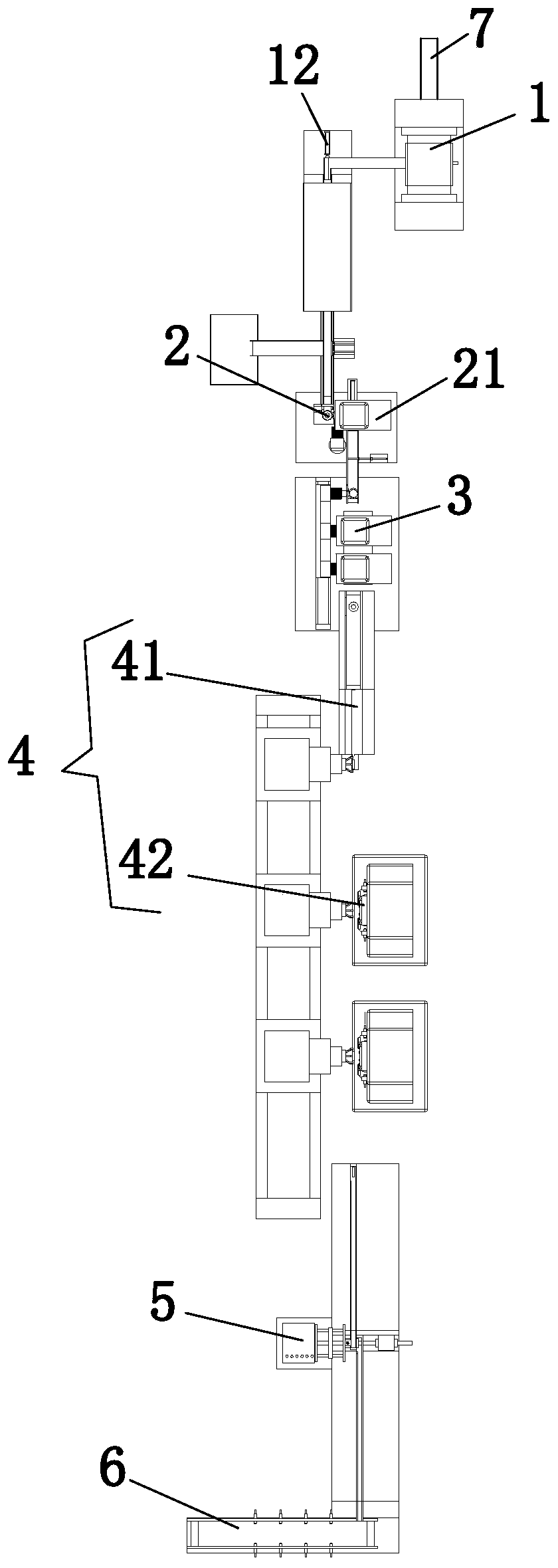

Bearing intelligent precision forging automatic production line

InactiveCN111069517AThere is no poor quality inside and outsideLittle difference in internal and external qualityShaping toolsPerforating toolsProduction linePunching

The invention relates to the technical field of bearing production equipment, in particular to a bearing intelligent precision forging automatic production line which comprises a feeding mechanism, anupsetting mechanism, a punching flattening mechanism, a continuous reaming mechanism, a finishing diameter mechanism and a discharging mechanism, wherein the feeding mechanism comprises a feeding component and a pushing component; the upsetting mechanism comprises an overturning component and an upsetting component; the overturning component is arranged at the tail end of the pushing component; the punching flattening mechanism is arranged by the side of the upsetting component; the continuous reaming mechanism comprises a conveying component and a continuous reaming component; the conveyingcomponent is arranged by the side of the punching flattening mechanism; the continuous reaming component is arranged at the tail end of the conveying component; the finishing diameter mechanism is arranged at the tail end of the continuous reaming component; and the discharging mechanism is arranged at the tail end of the finishing diameter mechanism. The bearing intelligent precision forging automatic production line can realize automatic processing of bearing precision forging, lowers the labor intensity, shortens the blank transferring distance, reduces the temperature differences of different processing parts of the blank, and improves the production efficiency and the bearing precision.

Owner:浙江赛赛轴承有限公司

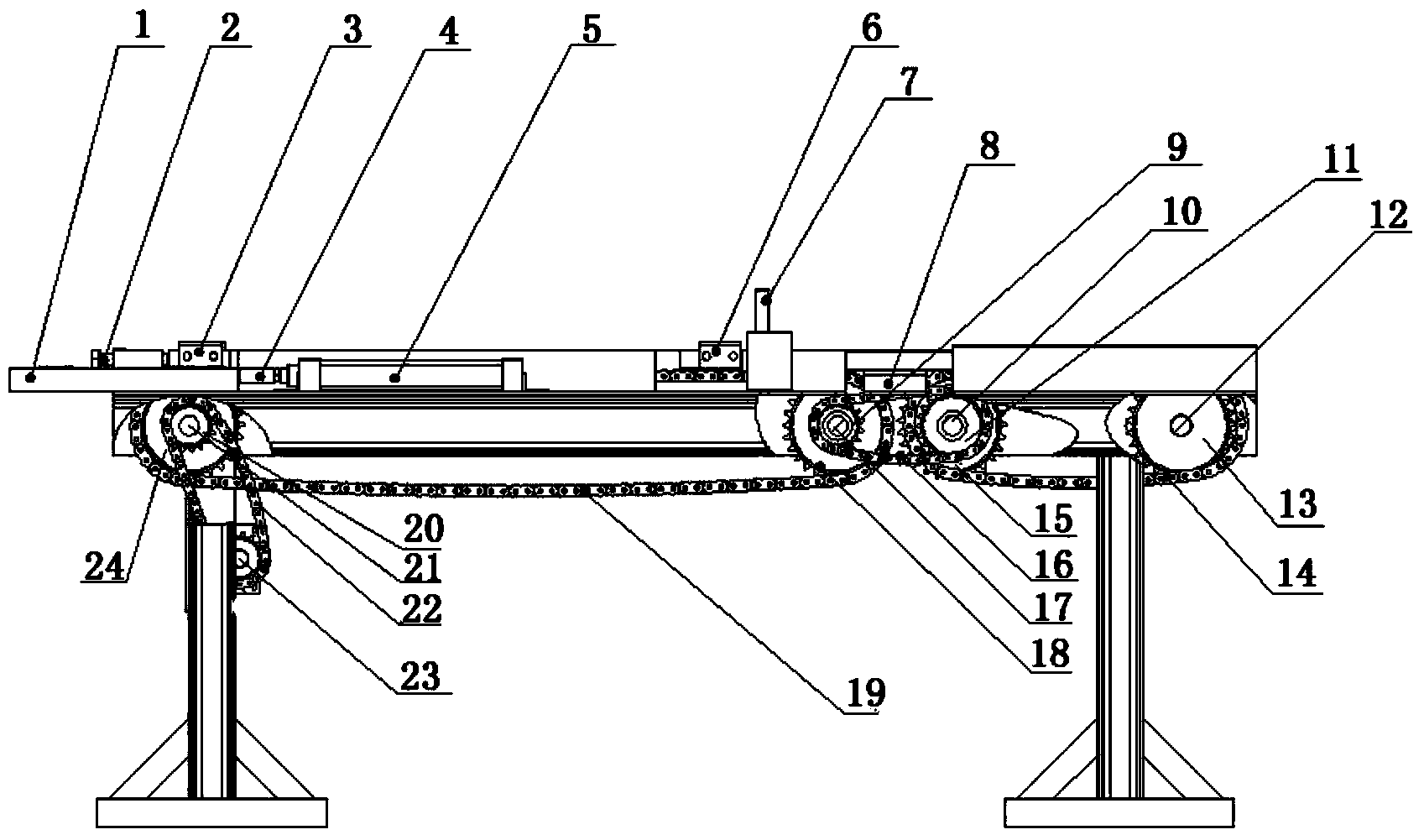

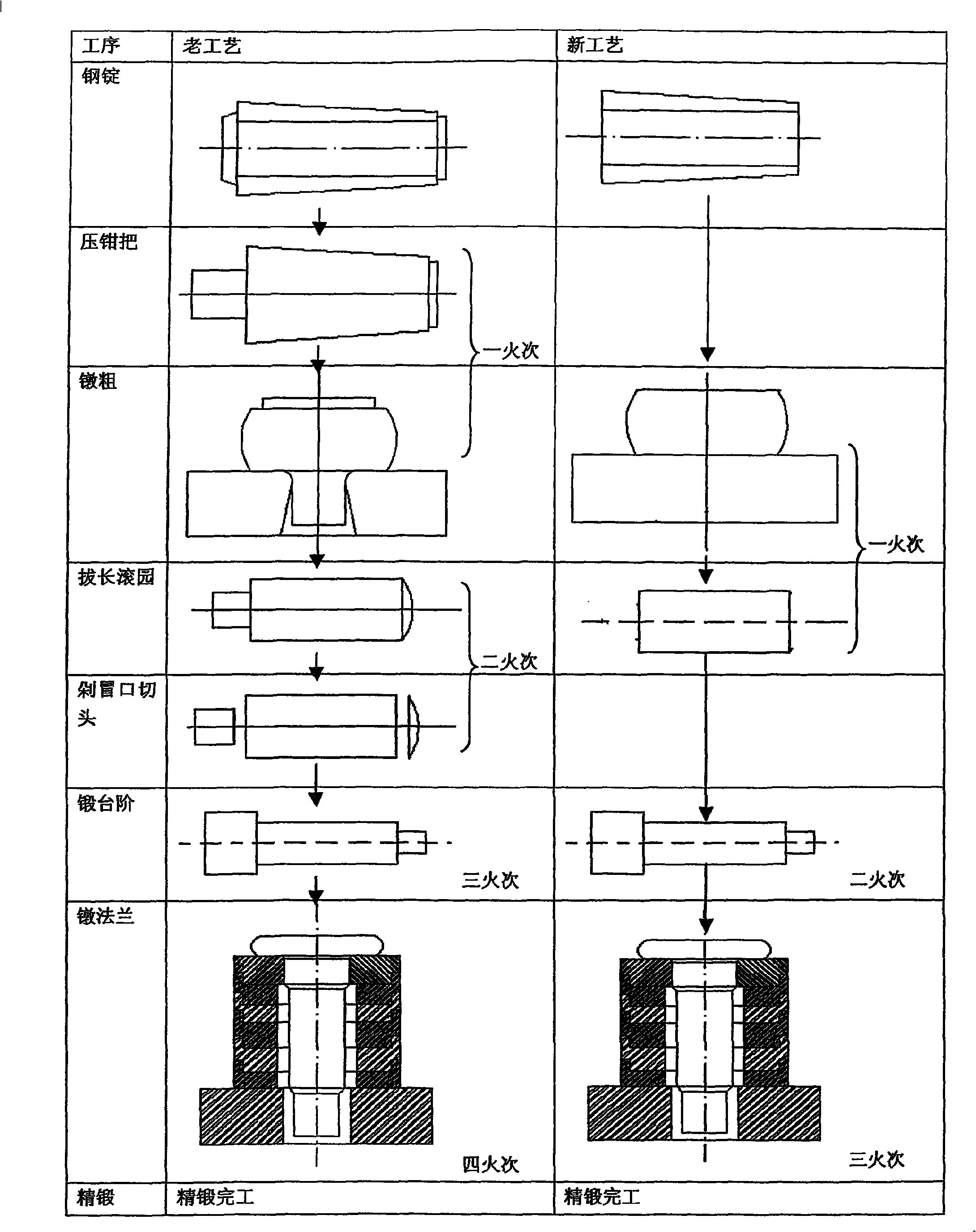

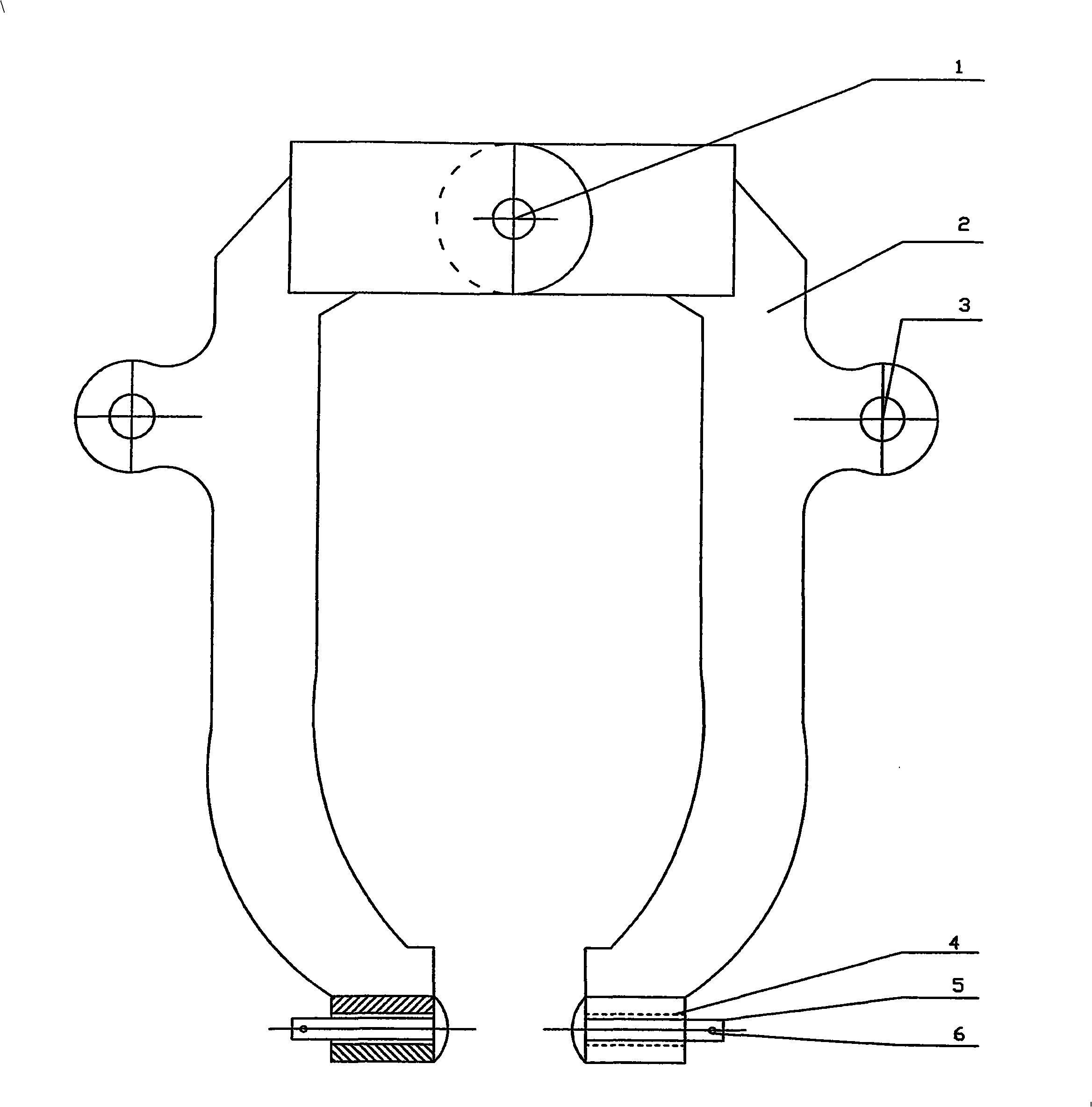

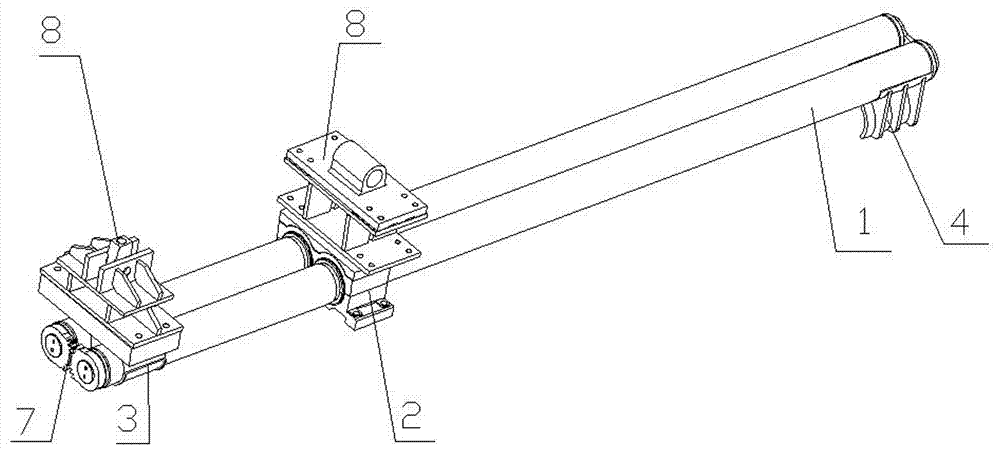

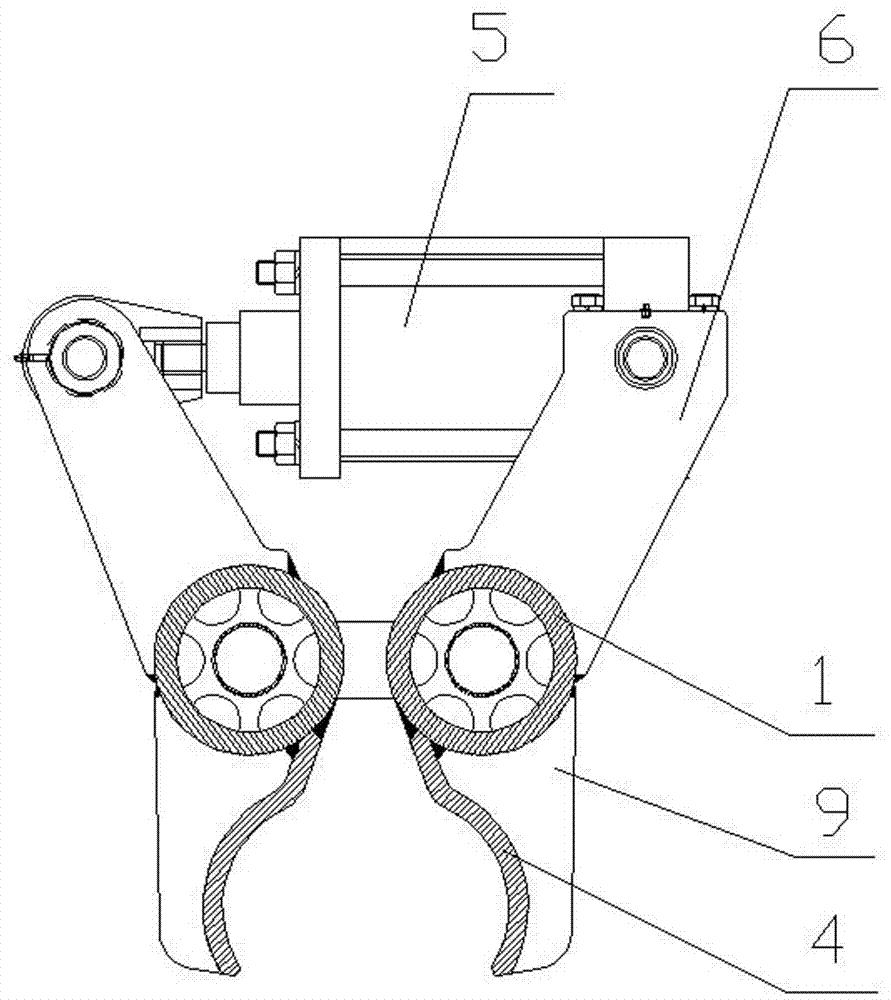

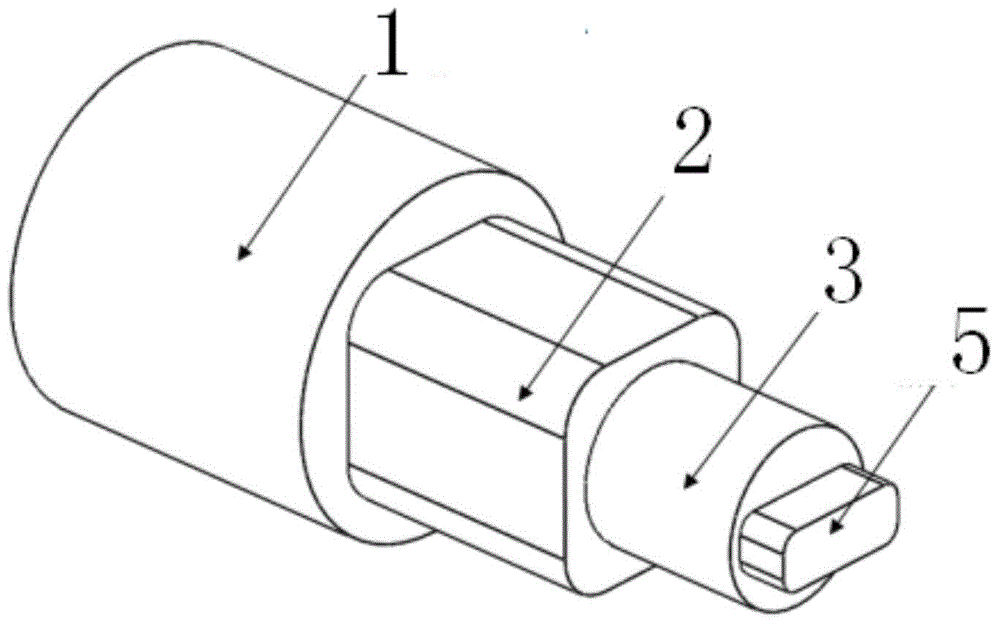

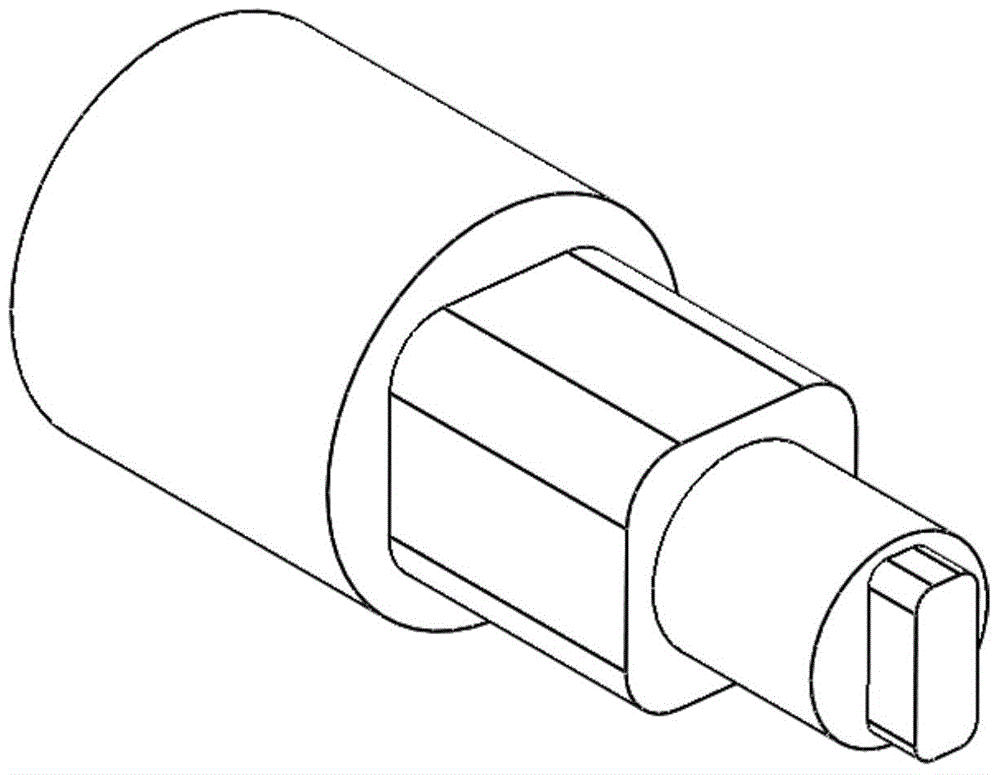

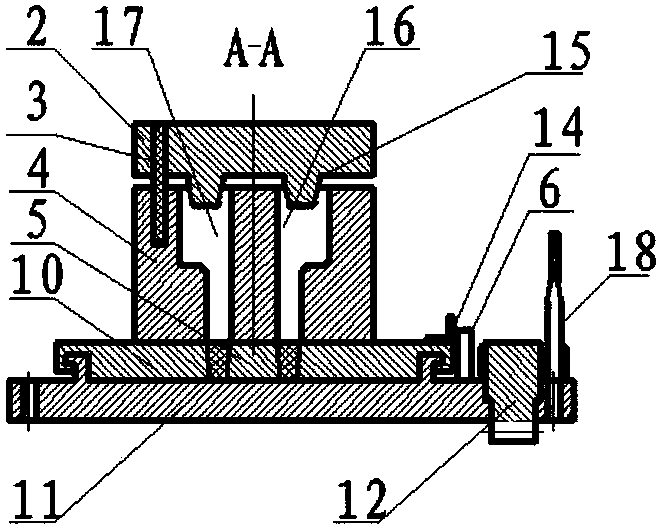

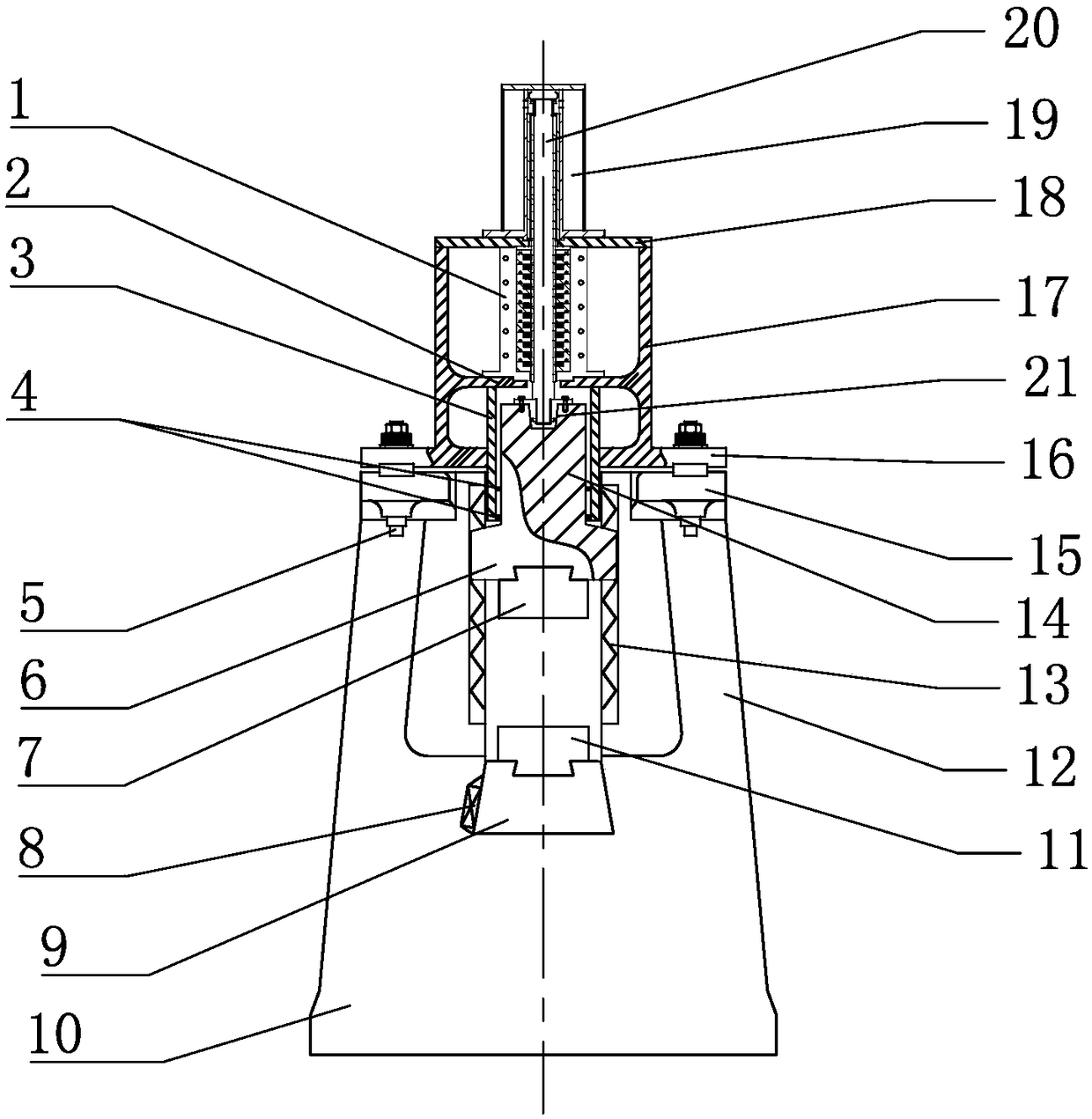

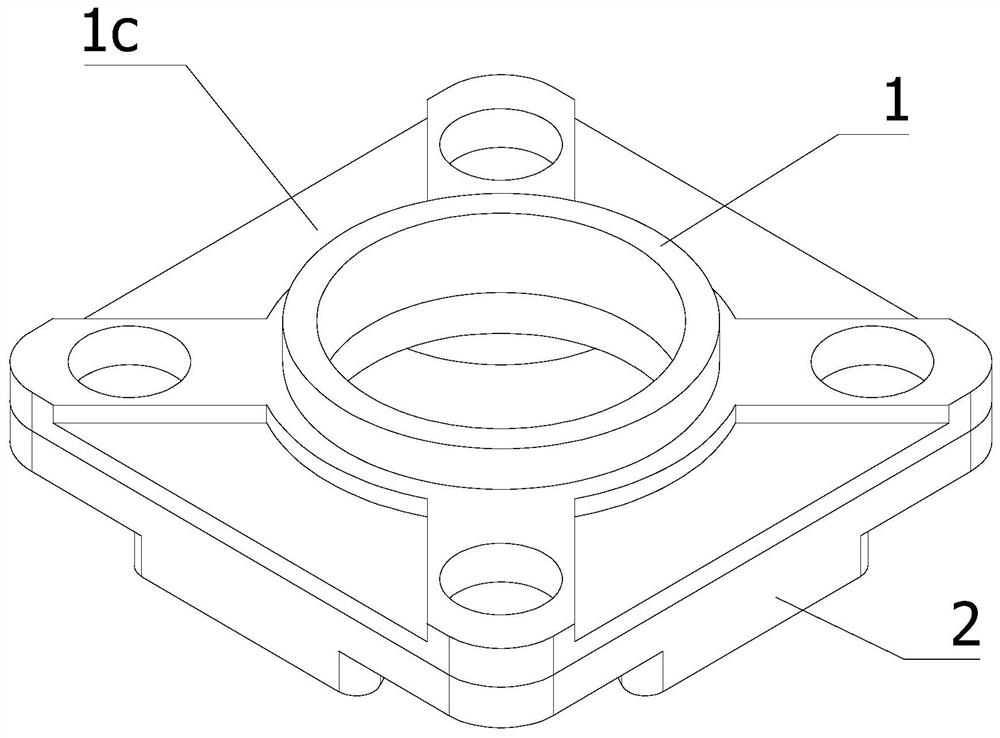

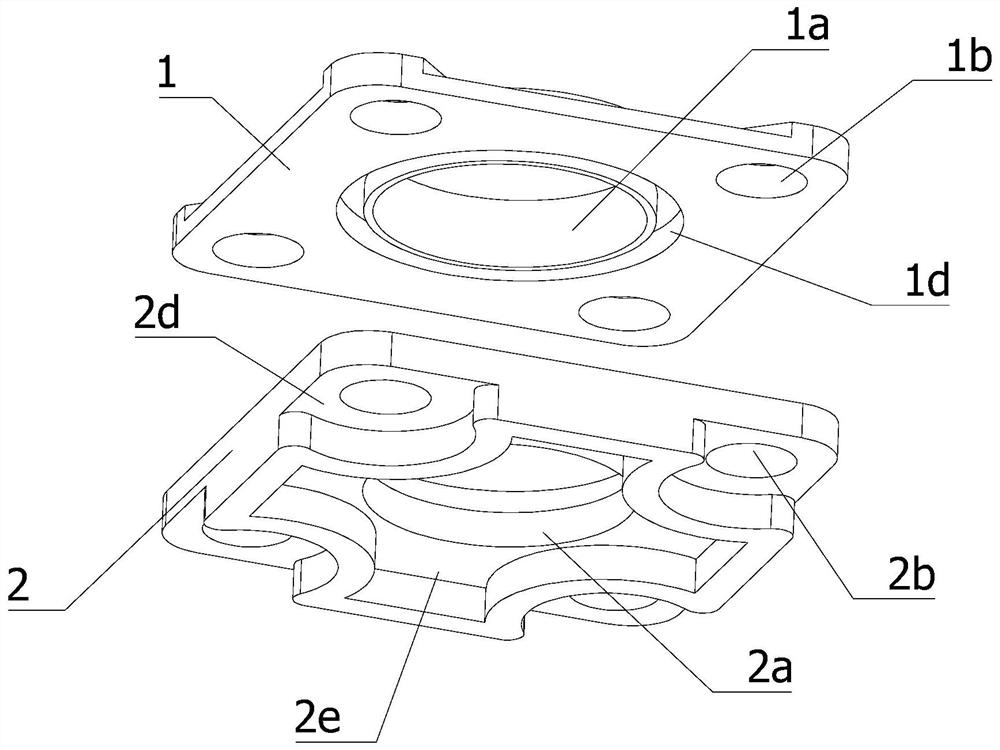

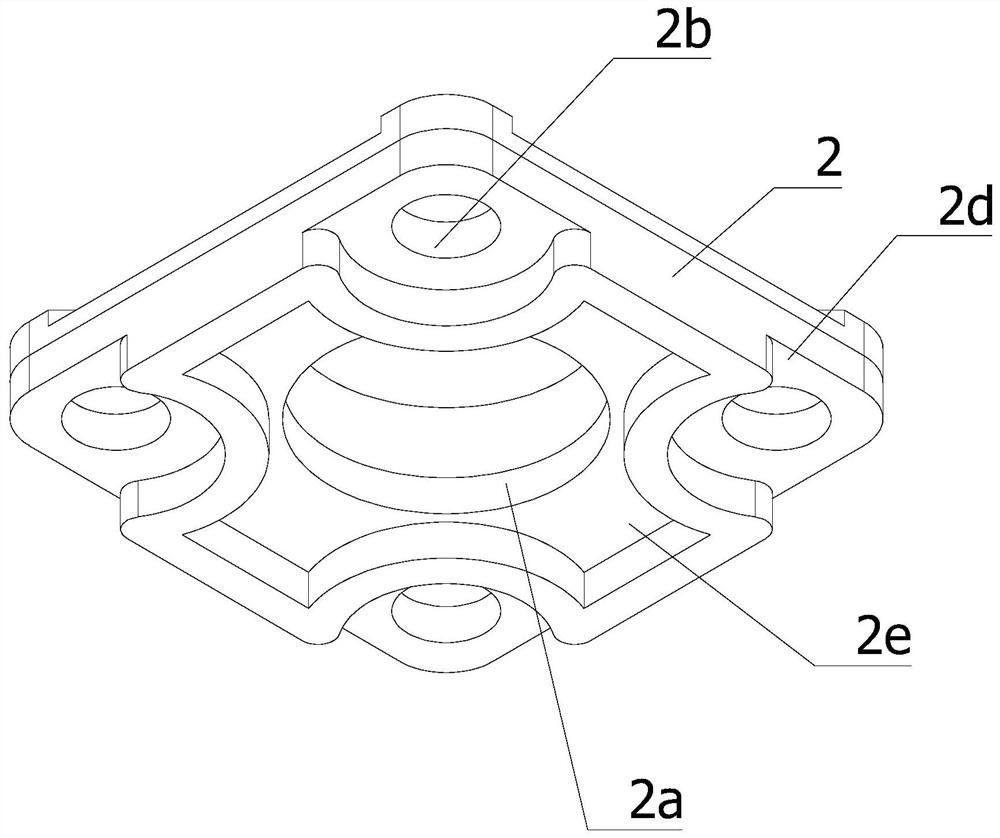

Non-flash groove, non ingot tail smithing method for large-scale wind power principal axle

InactiveCN101293269AGood clamping functionEasy to turn functionForging/hammering/pressing machinesEngine componentsElectricityIngot

The invention relates to a no-riser and no-ingot tail forging method for a large-scale wind power main shaft; before heating and forging, a riser and a ingot tail of a steel ingot are cut off by a saw, then a jaw of pliers of a manipulator is used for clamping the steel ingot without the riser and the ingot tail, and then the processes of upsetting, drawing out, rolling circle, forging steps and upsetting flange are carried out; the jaw of the pliers of the manipulator includes pliers arms (2), sleeve seats (4) and ball-head cylinders (5); the number of the pliers arms (2), the sleeve seats (4) and the ball-head cylinders (5) is two, one piece is at the left and the other piece is at the right, one end of the left pliers arm (2) is articulated with one end of the right pliers arms (2) by a gemel (1), the other ends thereof are respectively provided with the left sleeve seat (4) and the right sleeve seat (4), the left ball-head cylinder and the right ball-head cylinder (5) are respectively pass through the left sleeve seat (4) and the right sleeve seat (4); the ball-head ends of the left ball-head cylinder and the right ball-head cylinder (5) are arranged at the inner sides of the left sleeve seat (4) and the right sleeve seat (4) in a left and right antithetic manner, and the other ends thereof are provided with a fixed pin (6) by inserting along the radial direction. The method of the invention can reduce forging processes, improve production efficiency, shorten forging time and enhance forging precision and forging quality.

Owner:JIANGYIN LEGAO ENERGY EQUIP

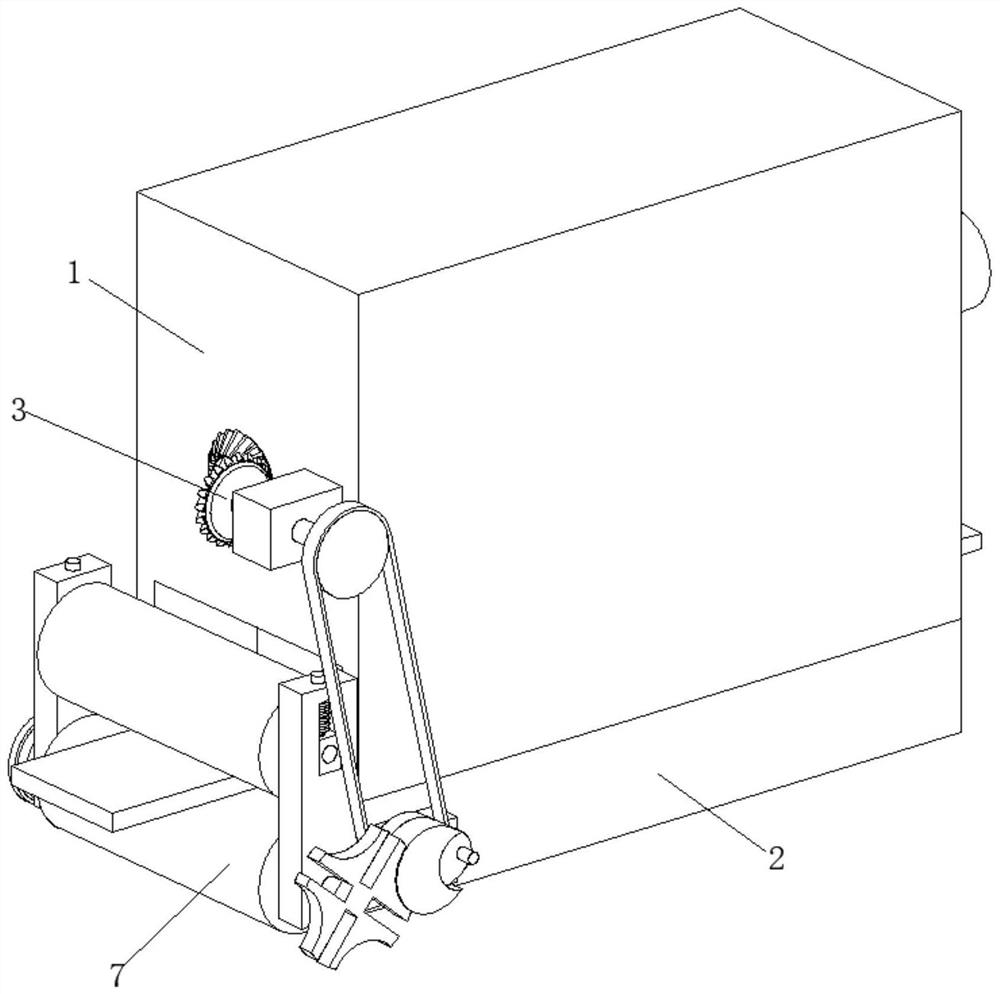

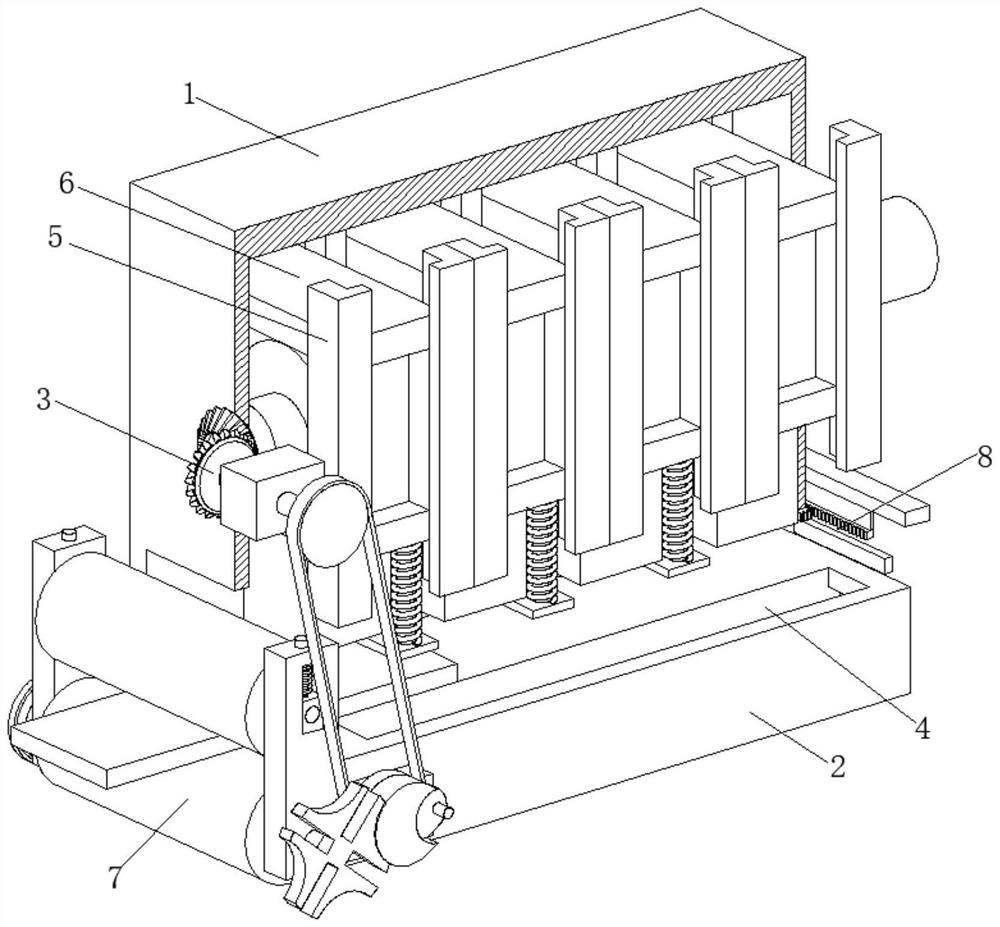

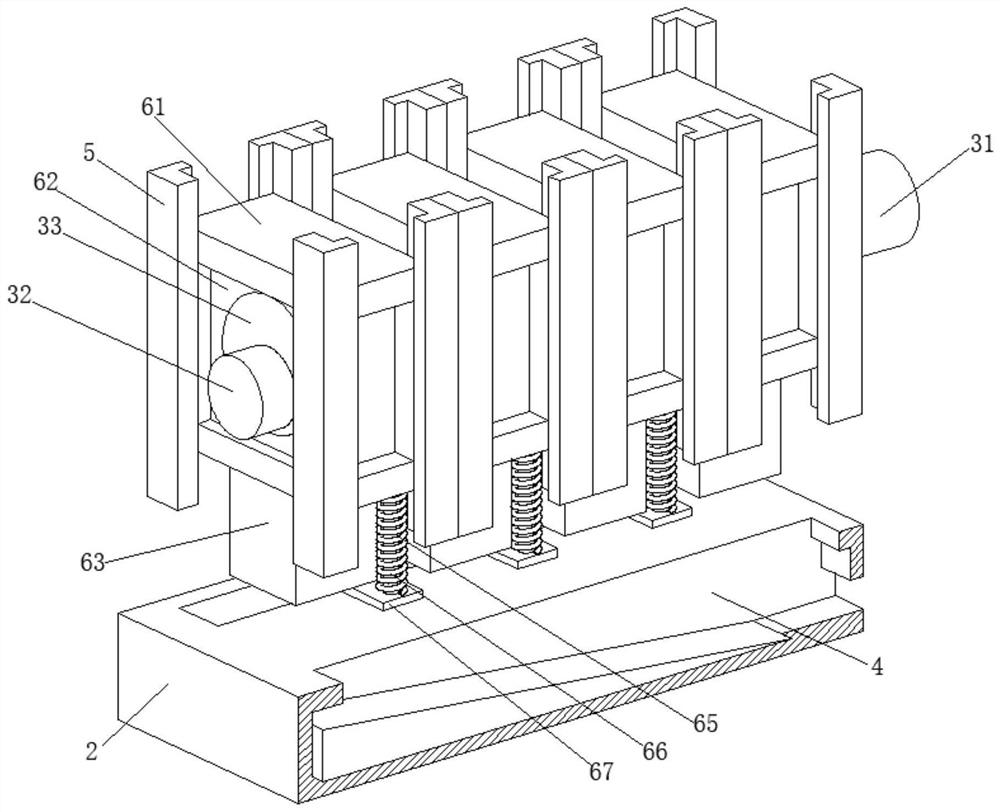

Continuous forging device with automatic cleaning function

ActiveCN112719183AShorten forging timeImprove work efficiencyDrop hammersHammer drivesEngineeringWorkbench

The invention relates to the technical field of forging equipment, and discloses a continuous forging device with an automatic cleaning function. The device comprises a box body, a workbench is welded at the bottom of the box body, a transmission mechanism is arranged at the front part of the box body, two discharge grooves are formed in the top of the workbench, and a plurality of limiting columns are welded on the inner wall of the box body. A forging mechanism is arranged on the surfaces of the limiting columns, a feeding mechanism is arranged at the front part of the workbench, and a cleaning mechanism is arranged at the rear part of the box body. According to the continuous forging device, through cooperative work of the transmission mechanism and the forging mechanism, a steel plate can be continuously forged, so that the situation that forging equipment is replaced after forging is conducted once is avoided, the stroke of the forging equipment is adjusted, forging time can be greatly shortened, the working efficiency is improved, the practicability is greatly improved, the cleaning mechanism can clean the finally forged steel plate, manual cleaning by workers is not needed, and the labor intensity of the workers is reduced.

Owner:山东圣利锻造有限公司

Forging process of gear ring

The invention relates to a forging process of a gear ring. The process includes following steps that: 1) in first firing, an ingot is heated to 1150 DEG C, and the ingot is subjected to heat preservation for 0.5 hour, dead head pressing, chamfering and sprue filing are performed on the ingot; 2) in second firing, re-heating, upsetting and drawing out are performed on the machined ingot; 3) in third firing, re-heating, upsetting, rotary flattening, punching and reaming are performed on the machined ingot; 4) in fourth firing, the machined ingot is re-heated, upsetting is performed on the machined ingot in a mold ring so that the machined ingot can be in a technique size, the mold is removed, and reaming is performed on the machined ingot so that the machined ingot can be in a technique size, and truing is performed, and machining is completed; 5) heat treatment is performed: the machined ingot is heated to 860 DEC C to 880 DEC C, and heat preservation is performed on the machined ingot for 5 to 5.5 hours, and the machined ingot is subjected to air cooling to 520 DEC C, and the machined ingot is heated to 610 DEC C to 630 DEC C, and heat preservation is performed on the machined ingot for 2 to 2.5 hours, and the machined ingot is subjected to air cooling to 260 DEC C. The forging process has high precision. With the forging process adopted, thickness of the wall of the gear ring can be uniform, and the service life of the gear ring can be prolonged.

Owner:JIANGSU JINYUAN FORGE

Gear preliminary forged piece water-spraying descaling device

InactiveCN107537806AEliminate oxidation pitsImprove forging precisionCleaning using liquidsSolenoid valveGear wheel

The invention discloses a device for descaling by spraying water on a preliminary forging of a gear, which belongs to the technical field of gear production. Including the control structure, the circulating water tank, the conveying tunnel on the circulating water tank, the chain conveying structure arranged in the conveying tunnel, the feeding structure arranged at the front end of the chain conveying structure, and the unloading structure arranged at the rear end of the chain conveying structure , at least one spray head arranged in the conveying tunnel, a filtered water tank arranged on the circulating water tank, a high-pressure pump arranged on the circulating water tank and at least one photoelectric sensor arranged on the conveying tunnel, the filtered water tank communicates with the circulating water tank , the filtered water tank is connected to the water inlet of the high-pressure pump through a pipeline, and the water outlet of the high-pressure pump is connected to the sprinkler head through a pipeline with a solenoid valve. The sprinkler head is located directly above the chain plate conveying structure and in front of each sprinkler head Correspondingly, there is a photoelectric sensor below, the photoelectric sensor is flush with the workpiece on the chain plate conveying structure, and the control structure is electrically connected with the photoelectric sensor, high-pressure pump and solenoid valve.

Owner:东风(十堰)精工齿轮有限公司

Bearing automatic finish forging single production line

InactiveCN111036830ARealize singles processingThere is no poor quality inside and outsideShaping toolsPerforating toolsProduction linePunching

The invention relates to the technical field of bearing machining, in particular to a bearing automatic finish forging single production line. The bearing automatic finish forging single production line comprises a material moving mechanism, a machining mechanism and a discharging conveying belt. The material moving mechanism is arranged beside the machining mechanism. The discharging conveying belt is arranged between the material moving mechanism and the machining mechanism. The machining mechanism comprises a high-tonnage punching machine, an upsetting assembly, a punching assembly and a bottom cutting assembly. The upsetting assembly, the punching assembly and the bottom cutting assembly are arranged below the high-tonnage punching machine at equal distance. A stepping beam works to drive three mechanical arms to work synchronously, three blanks are driven to move on the high-tonnage punching machine, single machining of bearing steel rings is achieved, the production line is short, temperature is uniform, product quality is improved, forging temperature is uniform, and production efficiency and forging precision are improved; and due to double mold motion of the punching assembly, the punching assembly can cooperate with the mechanical arms conveniently to discharge the blanks, manual discharging is not needed, automatic work can be achieved on production of the bearing steel rings conveniently, and production efficiency is improved.

Owner:浙江赛赛轴承有限公司

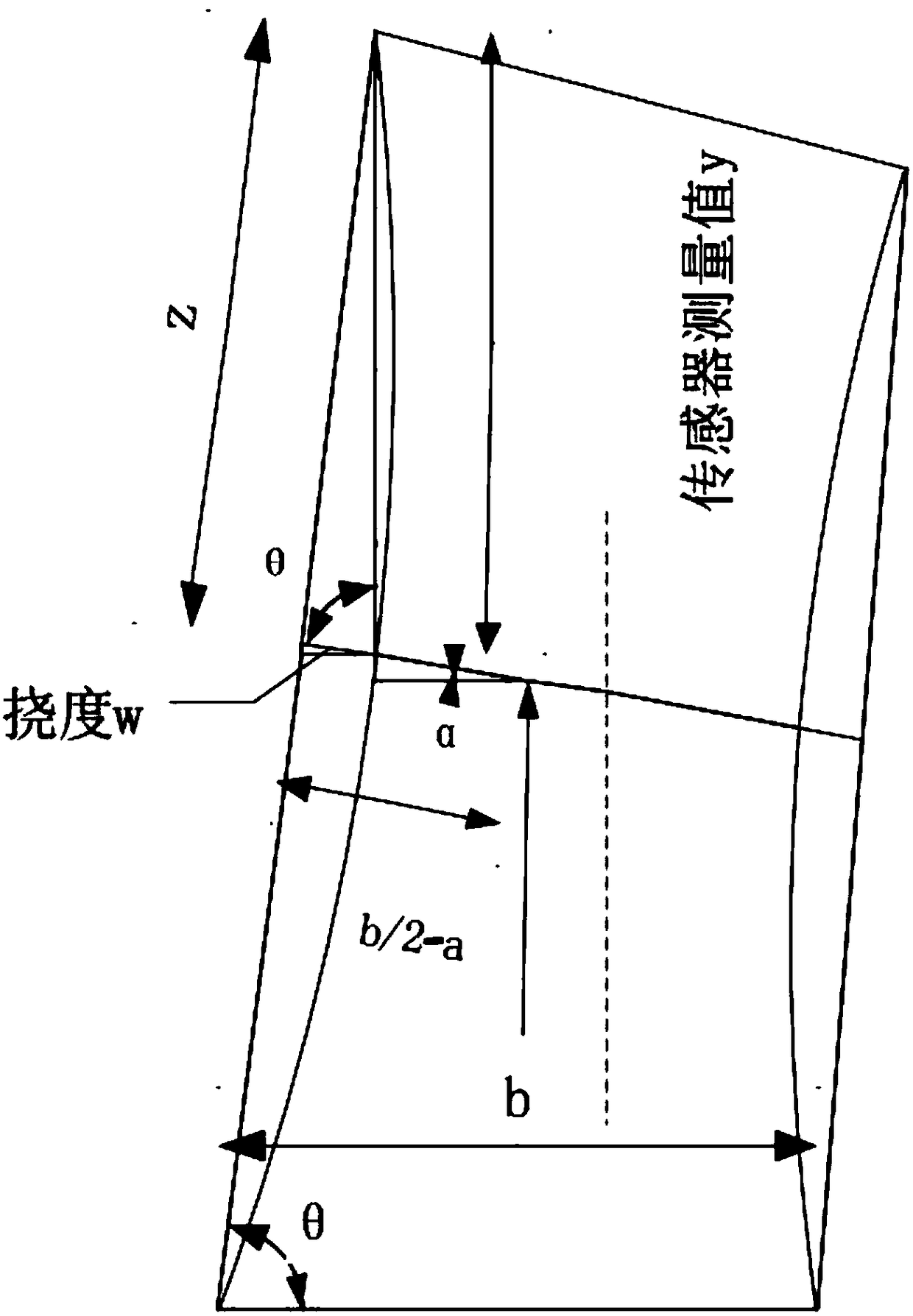

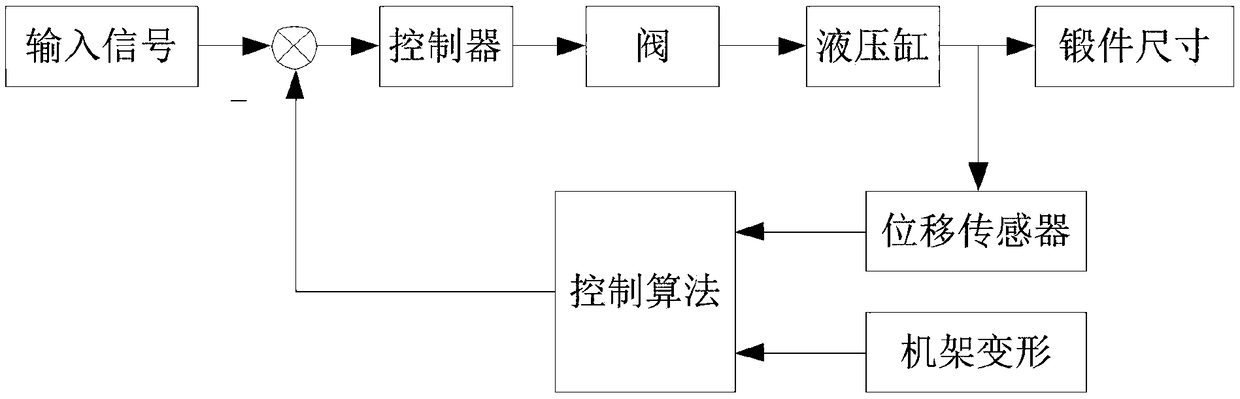

Mechanical deformation compensation control method for forging hydraulic press

ActiveCN108380804AImprove forging precisionForging press drivesElectrical resistance and conductanceStress–strain curve

The invention relates to a mechanical deformation compensation control method for a forging hydraulic press. The mechanical deformation compensation control method is characterized by comprising the working flow that 1), a signal is input to control the opening degree of a servo valve so as to enable movable beams of the press to rapidly descend; 2), after the movable beams are in contact with a forging piece, the movable beams are turned into work, and the frame is deformed by the central force or eccentric load force; 3), the stress strain gauges pasted on the frame are subjected to stress change when the frame is deformed, the resistance values of the strain gauges change, and measured changed electrical signals are fed back to a system; 4), the fed back signals are compared, the signals and the measured values of a displacement sensor are calculated, the actual size of a workpiece is obtained, and the specific calculation method is given below; 5), when forging is completed once, the movable beams return back to the designated position; and 6), the system stops or returns to the first step to carry out the secondary forging. By the adoption of the mechanical deformation compensation control method, the defects of a traditional control method are overcome, the influence of a mechanical body of the forging hydraulic press under the eccentric load working condition on the force deformation in the forging process is fully taken into account, and the forging precision of the forging piece is improved.

Owner:YANSHAN UNIV

Forging process of rotary drilling mast

PendingCN110238334AIncrease profitImprove forging precisionMetal-working apparatusUltimate tensile strengthDrill

The invention discloses a forging process of a rotary drilling mast. The forging process comprises the following steps of heating a rod-shaped steel piece material block, the heated rod-shaped steel piece blocks are placed in a die of a forging machine, carrying out pre-forging and blank making by a forging press along the axis direction of the rod-shaped material block to obtain a cake-shaped and solid prefabricated drill mast blank, punching the center of the prefabricated drill mast blank from a punch to obtain a prefabricated drill mast blank with a through hole; continuously heating the prefabricated drill mast blank, and carrying out multiple expansion on the through hole of the prefabricated drill mast blank with the through hole by a punch on a forging machine; carrying out pressing operation on the prefabricated drill mast subjected to multiple reaming in the step under a forging machine to obtain a pre-formed blank; and the pre-formed blank is heated, and the heated pre-formed blank is subjected to final forging by a forging machine to obtain the rotary drilling mast forging. The forging process is used for improving the utilization rate of the steel, the forging precision is improved, the structural strength is high, and the production efficiency is improved.

Owner:徐州天盈机电有限公司

Material clamping pliers for annular heating furnace material charging and taking device

InactiveCN107571274AStable range of motionImprove applicabilityGripping headsCharge manipulationEngineeringHeating furnace

The invention relates to the field of steel processing equipment, in particular to a pair of material clamping pliers for an annular heating furnace material charging and taking device. The material clamping pliers for the annular heating furnace material charging and taking device comprises two pliers rods, wherein the pliers rods are arranged in parallel. The portions, close to the middle portions, of the pliers rods are arranged in a first double-hole bearing pedestal in a sleeving mode. The ends, close to the first double-hole bearing pedestal, of the pliers rods are arranged in a second double-hole bearing pedestal in a sleeving mode, a clamp is arranged at the other end of each pliers rod, and notches of the clamps are arranged in a face-to-face mode. A driving mechanism which is used for controlling the two pliers rods to rotate so as to control the clamps to be combined and separated is further arranged between the pliers rods. The material clamping pliers for the annular heating furnace material charging and taking device is simple in structure and low in cost, and can meet the material clamping requirement of the annular heating furnace material charging and taking device.

Owner:LUOYANG INST OF SCI & TECH

Intelligent plastic forming process method and intelligent plastic forming equipment used for same

ActiveCN105478641AStrong flexibilityImprove forging precisionForging press detailsManipulatorAutomatic programming

The invention discloses an intelligent plastic forming process method and intelligent plastic forming equipment used for the same. The process method sequentially comprises the steps that three-dimensional modeling and plastic deformation digital simulation are conducted, an automatic programming system with a machine learning function is adopted for completing analysis and programming of the forming step of a forge piece, a steel ingot is heated, closed-die upsetting is conducted on the steel ingot, and plastic forging forming is conducted by squeezing a blank on an intelligent plastic forming hydraulic machine through rolling tools. According to the equipment, intelligent manipulators installed on the intelligent plastic forming hydraulic machine drive intelligent pressing heads to rotate around the axes in the horizontal direction or the vertical direction, and wedging angles larger than zero degree are formed by the squeezing surfaces of the rolling tools on the intelligent pressing heads and the surface of the forge piece; a supporting device can drive the forge piece to rotate and move; a sensing system can obtain data of the temperature of the forge piece, the pressure of the rolling tools on the forge piece and the forge piece metal flowing displacement and send the data to a control system; the control system controls actions of all components. According to the intelligent plastic forming process method and the intelligent plastic forming equipment used for the same, the forging precision is high, materials are saved, no special molds are needed, the forging flexibility is high, and the cost is low.

Owner:JIANGSU YONGNIAN LASER FORMING TECH

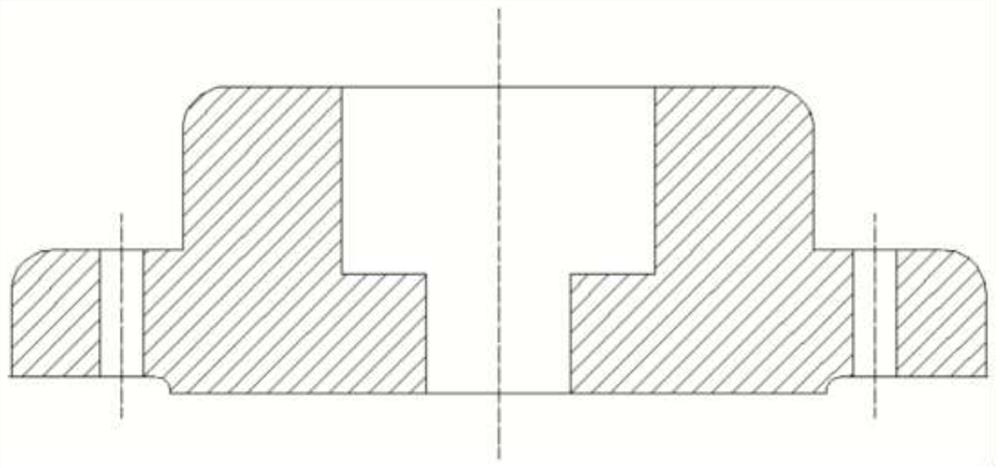

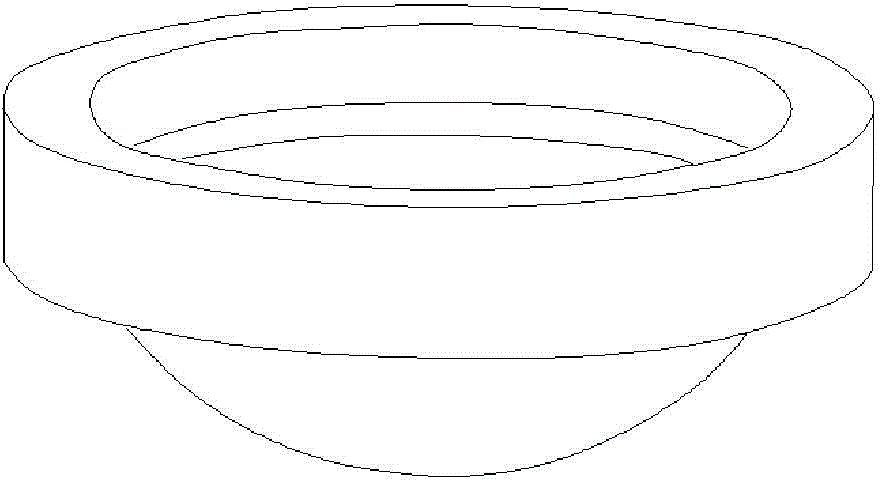

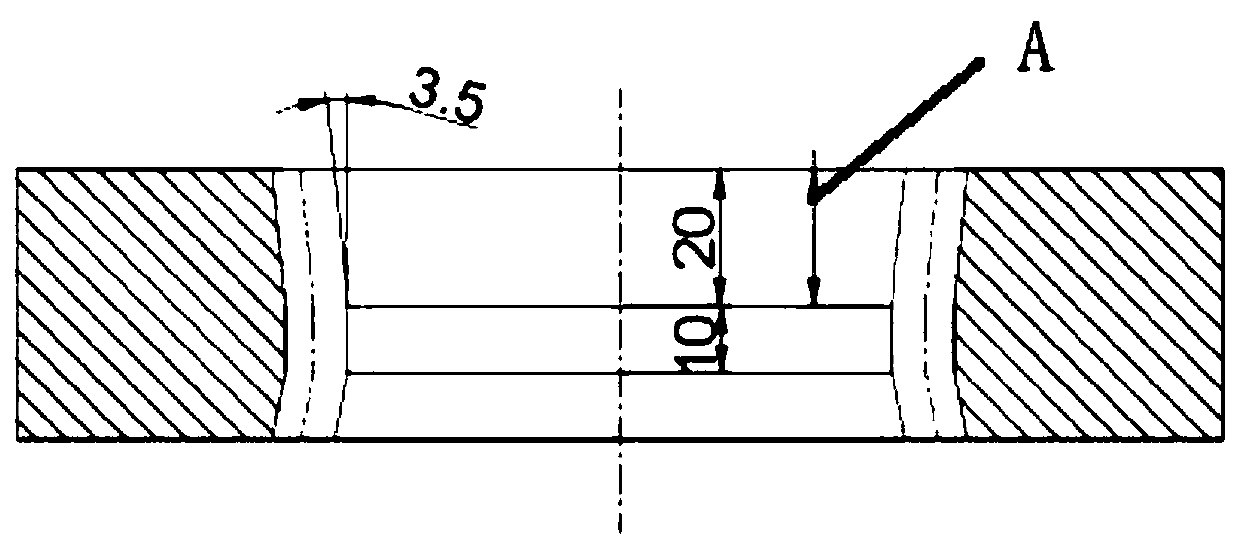

Manufacturing method of CuNi90/10 alloy socket welding flange

ActiveCN111618529ASimple preparation processSave raw materialsMaintainance and safety accessoriesPunchingManufactured material

The invention discloses a manufacturing method of a CuNi90 / 10 alloy socket welding flange. The manufacturing method comprises the following steps that S1, die manufacturing is conducted, specifically,an outer die and a punch are manufactured according to the boundary dimension of the CuNi90 / 10 alloy socket welding flange; S2, heating and blank making are conducted, specifically, a CuNi90 / 10 alloyingot is heated to a forging temperature, the temperature is kept for a certain period of time according to the diameter of the ingot, and the ingot is forged on a forging hammer into a blank capableof being put into the outer die; S4, die preheating is conducted, specifically, the die manufactured in the step S1 is preheated in a heating furnace, and the blank manufactured in the step S2 is putinto the outer die for die pressing until a die cavity is filled with CuNi90 / 10 alloy; S5, punching is conducted, specifically, blind hole punching and through hole punching are sequentially conducted on the die-pressed CuNi90 / 10 alloy through the punch; and S6, cooling is conducted, specifically, after die forging, the CuNi90 / 10 alloy material is withdrawn from the die cavity, cooling treatmentis conducted on the CuNi90 / 10 alloy material, and then the CuNi90 / 10 alloy socket welding flange is obtained through turning. The manufacturing method is reasonable and effective, and has the advantages of raw material saving, small cutting amount, low production cost, high performance of manufactured products and the like.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Large railhead precision forging machine

InactiveCN109261870AGood accuracy retentionImprove forging precisionUpsetting pressesSwagging pressesFuel tankLaser diode

The invention discloses a large railhead precision forging machine. The large railhead precision forging machine structurally comprises a hydraulic oil tank, oil cylinders, vertical columns, a liftingworkbench, a precision forging block, laser locators, a die table, a base, a laser locator controller, a control cabinet, operation keys, a hydraulic station, a hydraulic oil pipe and a top plate, wherein each laser locator comprises a filter lens, a tube body, a laser diode, a fixing seat, mounting holes and a laser angle adjustment valve; in order to achieve the purposes of high forging precision of the large railhead precision forging machine and good precision retainability after the large railhead precision forging machine is pressed, the railhead precision forging machine is provided with the top plate, the lifting workbench and the base, the four vertical columns uniformly and equidistantly arranged at the bottom of the top plate penetrate through the lifting workbench so that thetop plate is connected with the base, thereby forming an integrated movable structure to achieve the good precision retainability after pressing; the precision forging block is provided with the laserlocators, shape positioning is performed on dies of the die table during precision forging, thereby improving the forging precision and improving the production efficiency.

Owner:天津奥特盛业重型锻压有限公司

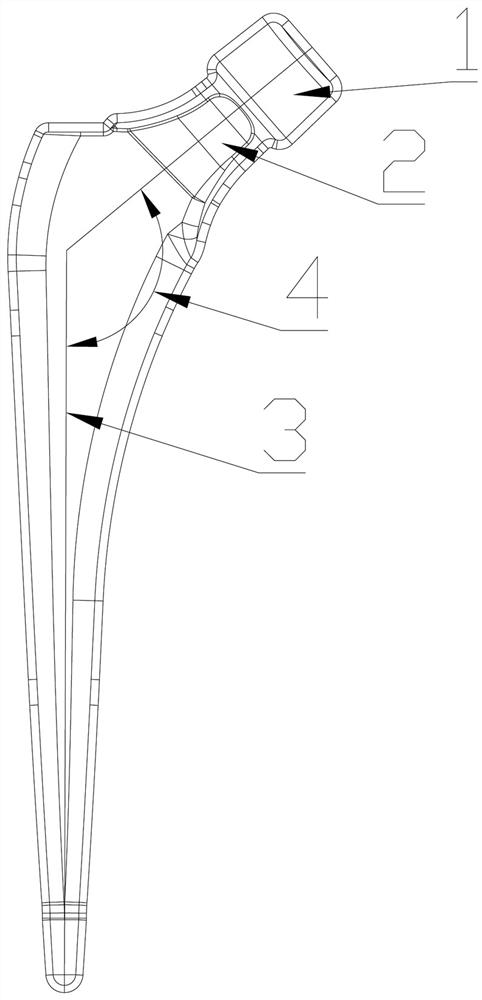

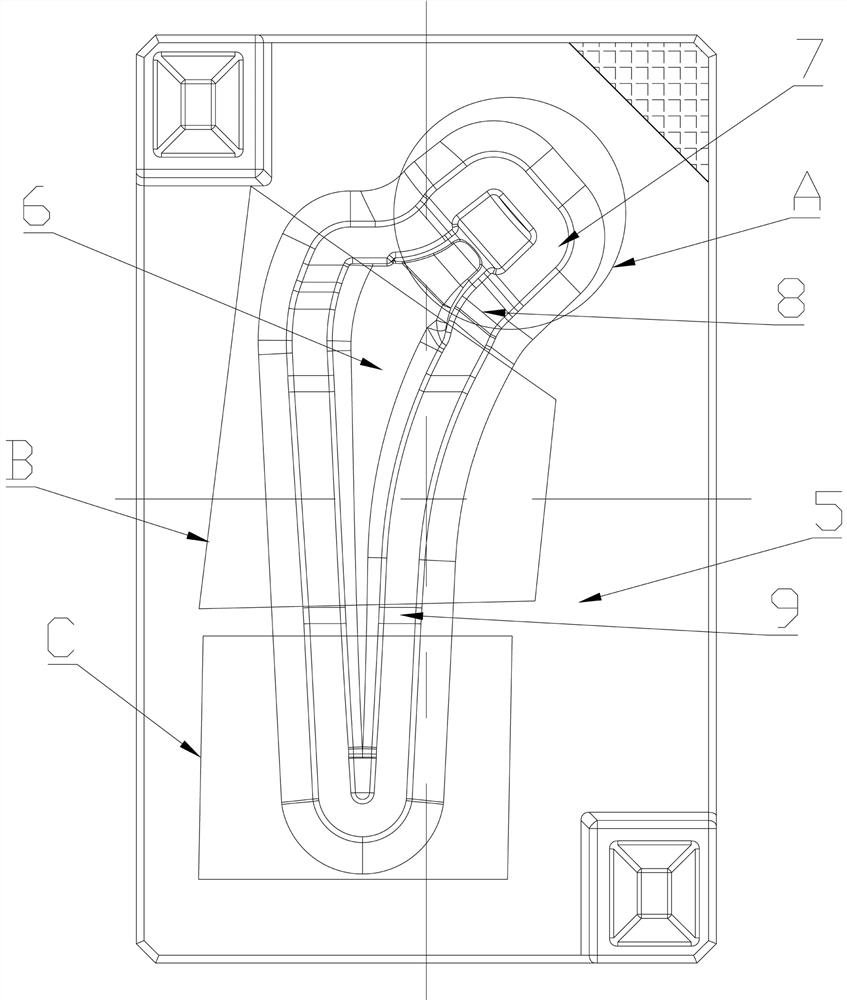

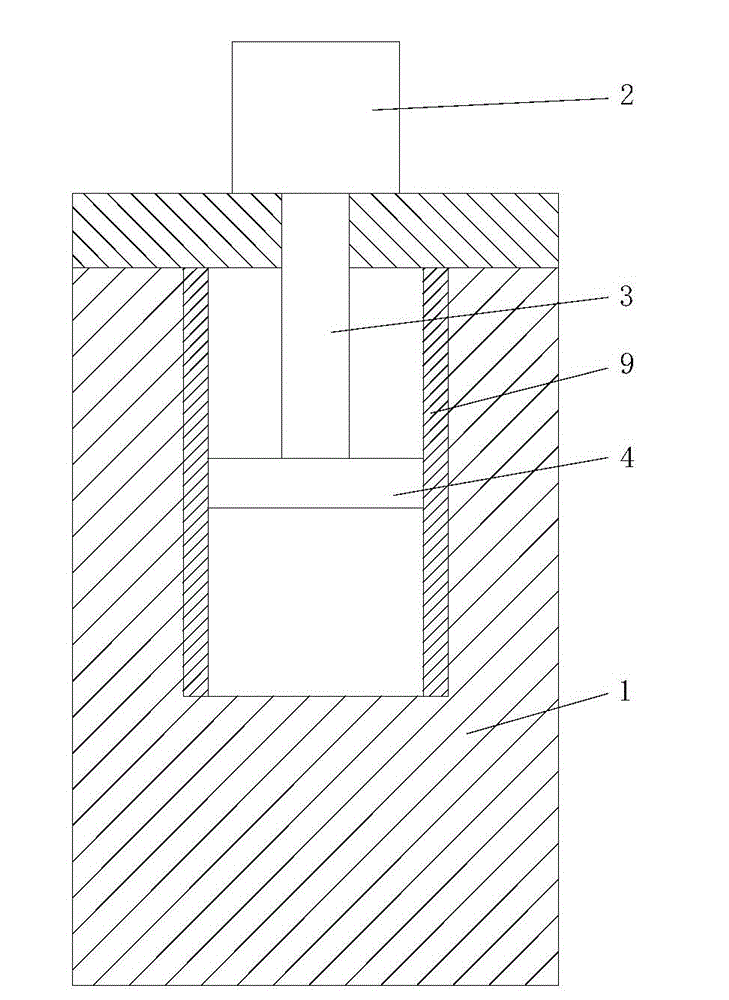

Forging method for alloy femoral component forged part

ActiveCN112247046AHigh dimensional accuracyImprove forging precisionJoint implantsForging/hammering/pressing machinesFemoral boneGonial angle

The invention provides a forging method for an alloy femoral component forged part, which can improve the percent of pass of the angle of an collodiaphyseal angle, improve the dimensional precision ofthe forged part and improve the mechanical property of the forged part so as to ensure the percent of pass of the alloy femoral component forged part and prolong the service life of the alloy femoralcomponent forged part. The forging method comprises the following steps of S1, designing a femoral component die; partitioning a die cavity according to an area of a cross section of the die cavity;and taking a cavity partition with the minimum cross section as a reference partition and reducing the height of a bridge part thereof for other cavity partitions according to a ratio of the cross sections of the other cavity partition and the reference partition; S2, pre-forging a femoral component blank of an alloy material for precision forging; S3, performing flash-cutting, polishing and trimming treatment on the pre-forged femoral component blank; S5, finally forging the collodiaphyseal angle of the heated femoral component blank after pre-bending; and S6, treating the forged femoral component product to obtain a product femoral component.

Owner:无锡航亚科技股份有限公司

All-hydraulic die forging hammer

InactiveCN104550600AIncrease widthExtended service lifeForging press detailsForging press drivesMechanical engineering

The invention relates to an all-hydraulic die forging hammer which comprises a U-shaped lathe bed, wherein the U-shaped lathe bed is provided with an all-hydraulic power head; the all-hydraulic power head comprises a working cylinder; a hammer lever is mounted in the working cylinder; the lower end of the hammer lever is connected with a sliding block; guide grooves are respectively formed in the first side surface and the second side surface, which are contacted with the lathe bed, of the sliding block; each guide groove is internally provided with a groove bottom surface, as well as a first guide surface and a second guide surface arranged on the groove bottom surface, wherein both the first guide surface and the second guide surface are inclined planes; guide rails are arranged on the opposite inner side wall surfaces of the U-shaped lathe bed respectively, and are inserted into the guide grooves to be in sliding fit with the guide grooves. The all-hydraulic die forging hammer has the advantage of high guide precision, and the die forging precision is not affected by a temperature rise.

Owner:CHANGZHOU JINGLING CASTING & FORGING

Plastic forming process of integral top cover of nuclear power water chamber and intelligent forging press used by plastic forming process

ActiveCN104588562AFine grainNo segregation performancePower hammersHammer drivesLiquid-crystal displayNuclear power

The invention discloses a plastic forming process of an integral top cover of a nuclear power water chamber and an intelligent forging press used by the plastic forming process. The plastic forming process comprises the following steps that: three-dimensional modeling is performed, so as to simulate a model, blanks are obtained by using large LCD (liquid crystal display) near-net forming, intelligent plastic forming is performed on the top cambered surface, and annular intelligent plastic forming is performed on the side surface of a cylinder. A vertical rack of the intelligent forging press is fixed on the ground, a movable cross beam is driven to longitudinally slide by a main working cylinder on the vertical rack, a rotary workbench can be rotatably positioned on a movable workbench of the movable cross beam around a vertical rotating shaft, a horizontal rack is driven to longitudinally move by a support cylinder on the vertical rack, a horizontal working cylinder on the horizontal rack corresponds to an intelligent auxiliary pressure head which can horizontally extend, an intelligent main pressure head can longitudinally extend and can be fixedly positioned on the vertical rack, and a sensing system is used for sensing the temperature of forgings, the pressure of the pressure heads and the metal flow information of the forgings. The integral top cover of the water chamber has the advantages of high precision, material saving, short processing cycle, high forging flexibility and low processing cost.

Owner:JIANGSU YONGNIAN LASER FORMING TECH

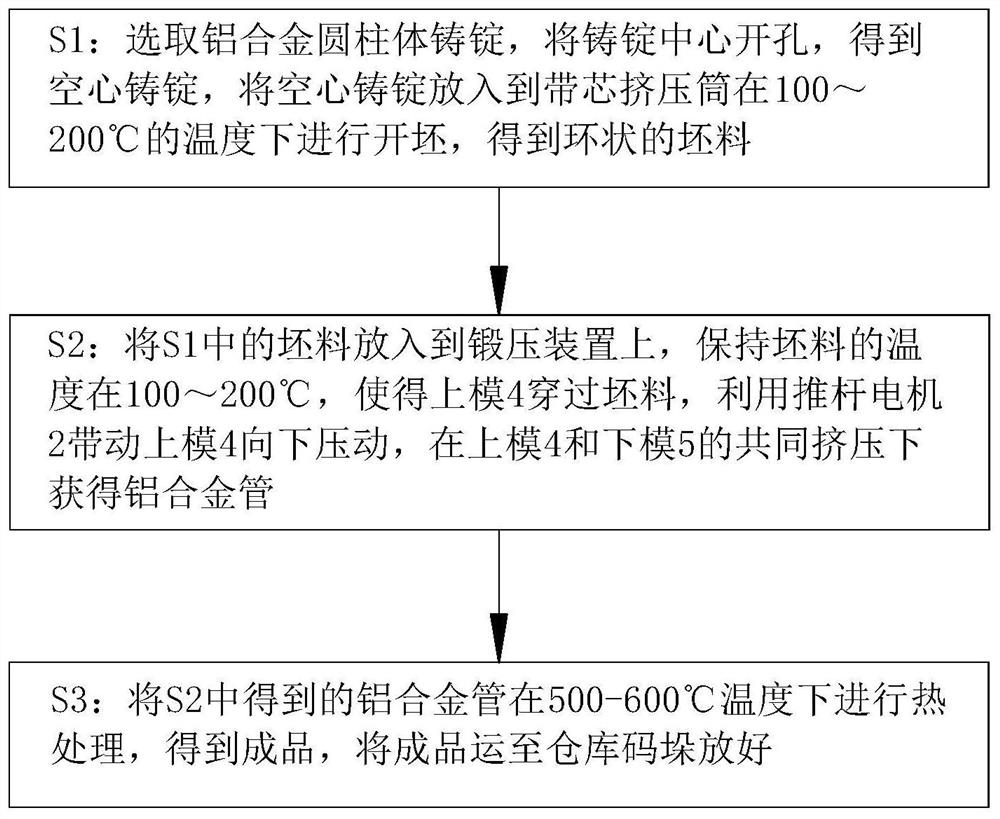

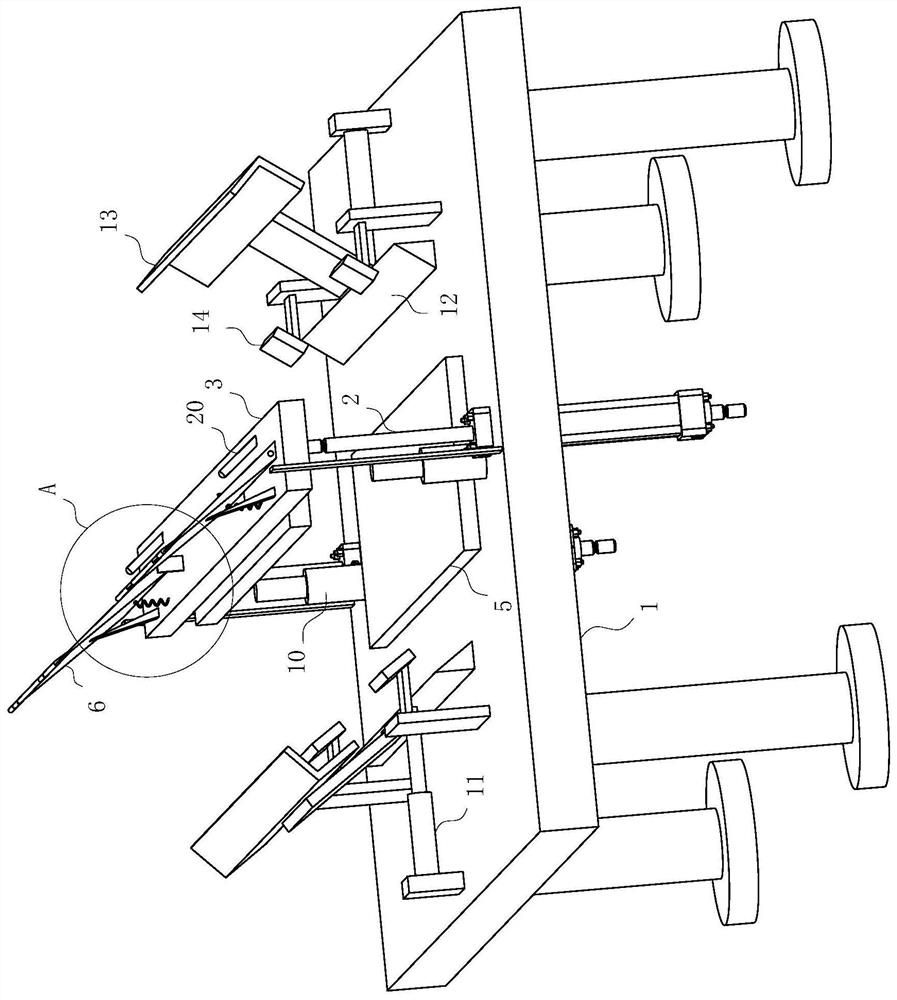

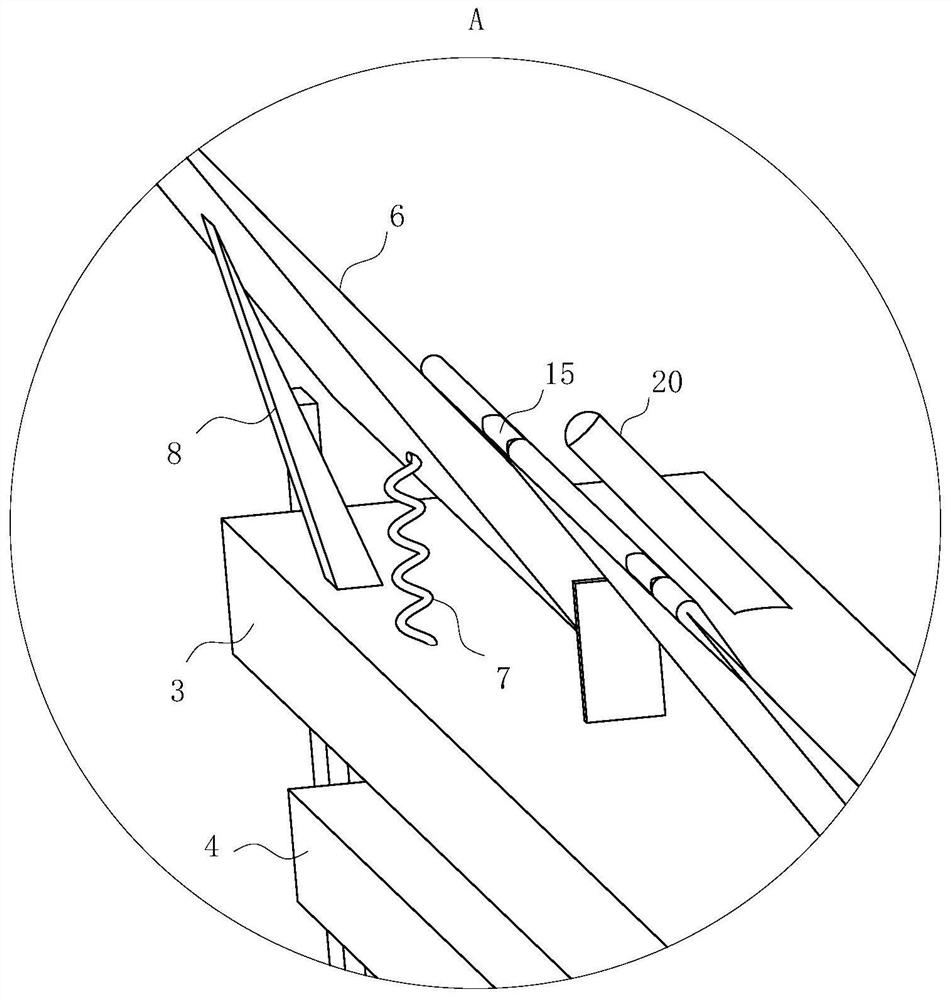

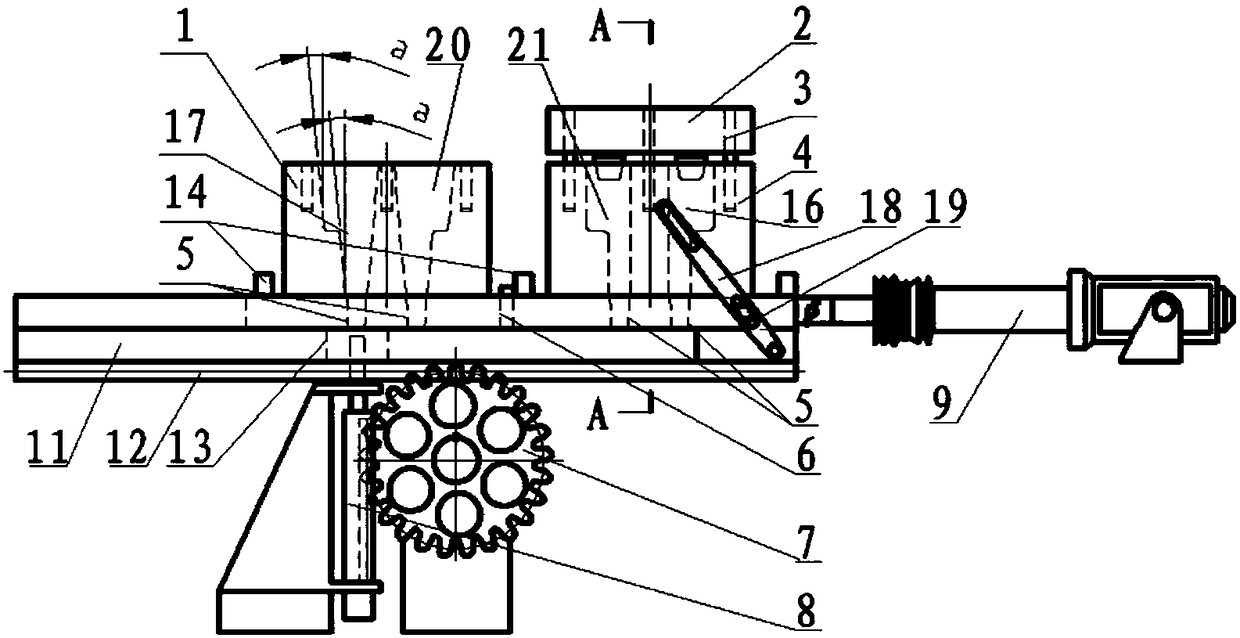

Alloy part forging process

PendingCN112496221AVarious cross sectionsImprove forging efficiencyForging/hammering/pressing machinesElectric machineryEngineering

The invention belongs to the technical field of forging, in particular to an alloy part forging process. A forging device used in the process comprises a worktable, wherein two push rod motors are symmetrically mounted in the middle of the edge of the worktable, a rectangular plate is in clamped connection to the top ends of the push rod motors, an upper die is fixed to the bottom end of the rectangular plate and is used for forging the inner side wall of a blank, a lower die is fixed in a middle position of the top end of the worktable and is used for forging the outer side wall of the blank,and a controller is arranged on the worktable and is used for controlling the forging device to work. By forging a circular tubular product for many times, the circular tubular product becomes a polygonal tube, so that sections of the aluminum alloy tubes are various, and therefore, the forging efficiency of the polygonal aluminum alloy tube is improved favorably and thus, the application range of the aluminum alloy tube is further improved.

Owner:张贺邦

Forklift drive axle half shaft forging technology

InactiveCN105063468ASave gas and electricity consumptionImprove work efficiencyMetal-working apparatusForgingEnergy conservation

The invention discloses a forklift drive axle half shaft forging technology, which comprises a following technological step that a, a bar material steel ingot is cast, and according to weight percentage, the chemical components in the steel ingot are: C which is larger than or equal to 2.25% and smaller than or equal to 2.45%, Si which is larger than or equal to 1.4% and smaller than or equal to 2.4 %, Mn which is larger than or equal to 0.6% and smaller than or equal to 1.4%, P which is larger than or equal to 0.007% and smaller than or equal to 0.125%, S which is larger than or equal to 0.006% and smaller than or equal to 0.026%, Nb which is larger than or equal to 0.01% and smaller than or equal to 0.05%, Al which is larger than or equal to 1.5% and smaller than or equal to 2.20%, Mg which is larger than or equal to 0.25% and smaller than or equal to 0.35%, and the balance Fe. According to the method, the problems that the process is complicated and overloaded, the energy consumption is high, the efficiency is low, the forging precision is low and the like in the traditional forging method are overcome, so that the development trend of future energy conservation and emission reduction is facilitated.

Owner:ANHUI HECHENG MACHINERY

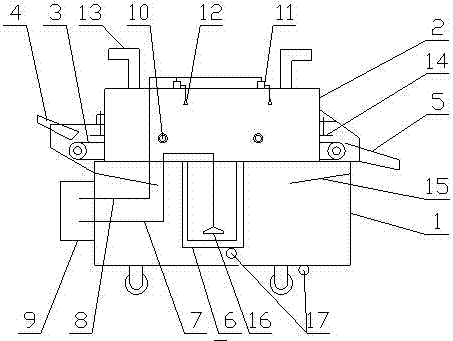

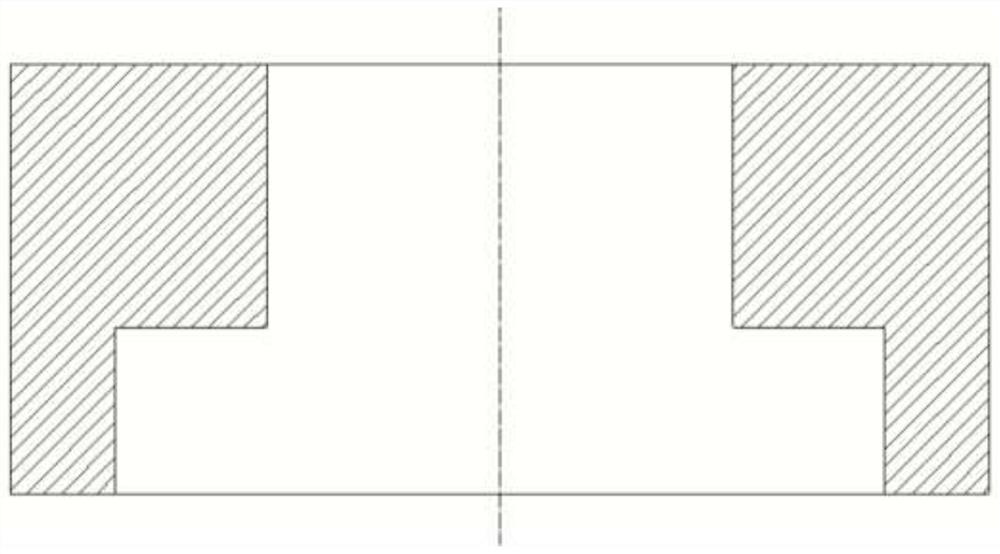

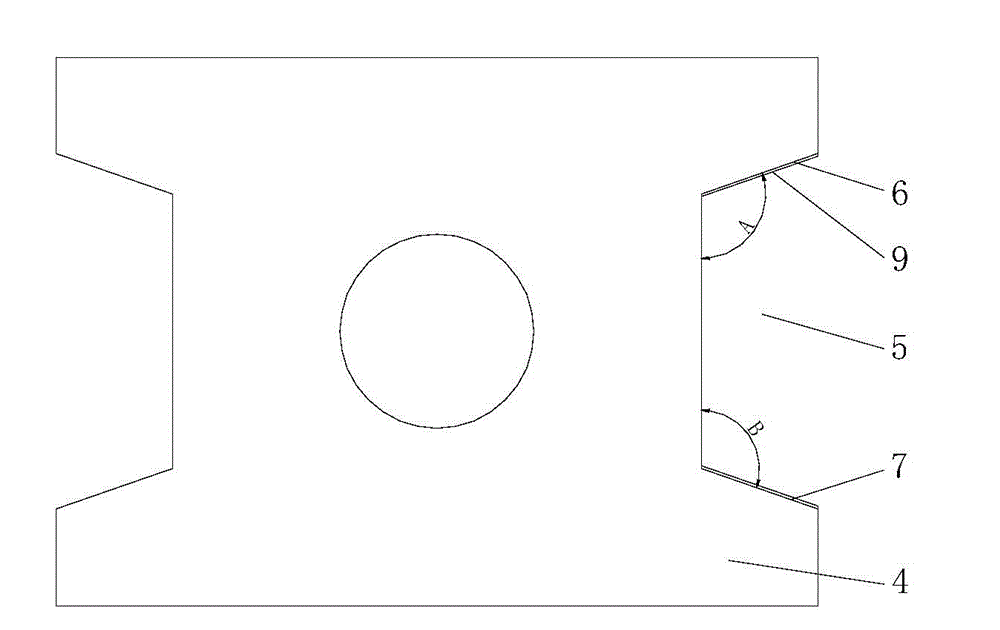

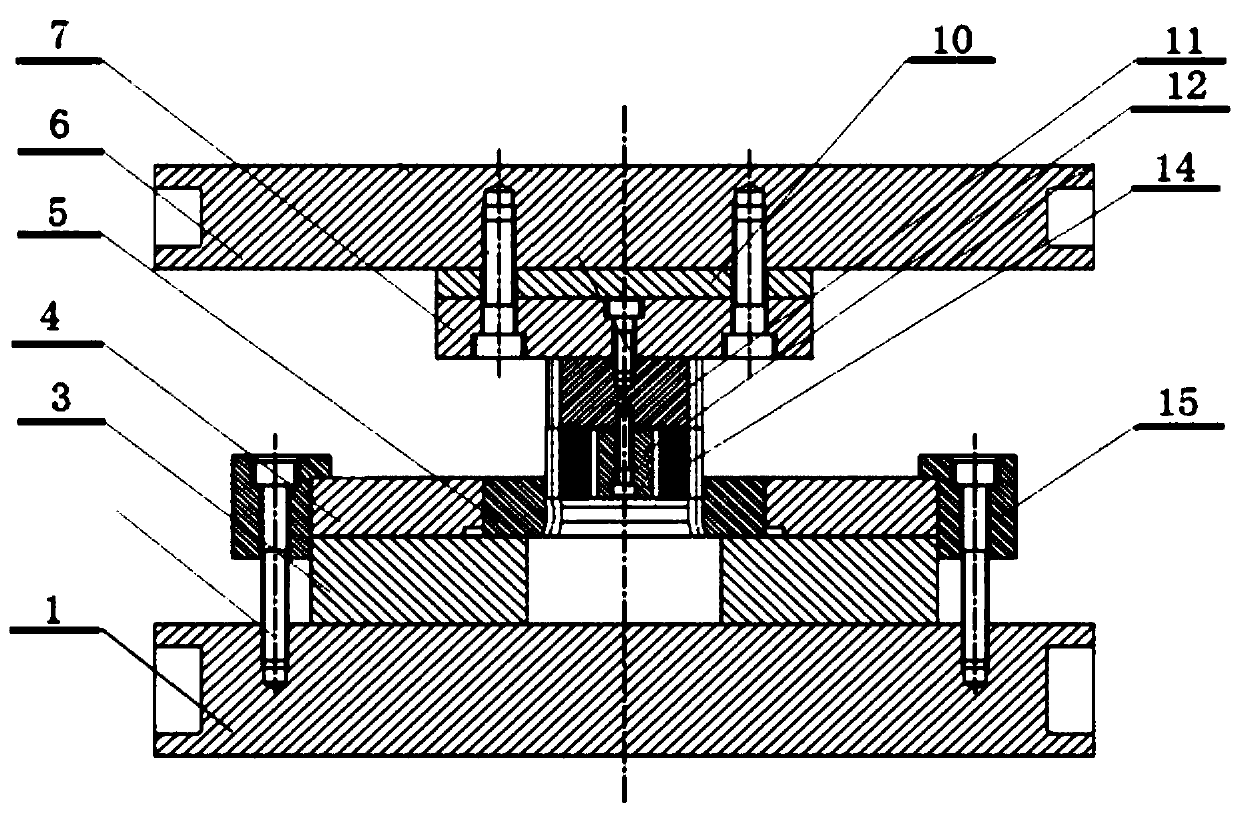

Symmetric outer planetary wheel combined precision forging die

InactiveCN108127065AReduce impact stressReduce distortionForging/hammering/pressing machinesWheelsMachiningForging

The invention relates to dies, in particular to a symmetric outer planetary wheel combined precision forging die. The symmetric outer planetary wheel combined precision forging die comprises an outerdie body, a lower preliminary die, a lower final die, a lower die bottom plate, a guide rail plate, a rack plate, measuring rods, a movable plate, an action mechanism, a gear, a rack jacking rod and ahand pulling plate. The symmetric outer planetary wheel combined precision forging die is characterized in that a groove is formed in the upper die, the position between the upper die and the lower preliminary die and the position between the upper die and the lower final die are guided and limited through the measuring rods, the lower preliminary die and the lower final die are fixed to the lower die bottom plate, the lower die bottom plate is engaged with the guide rail plate, and one end of the lower die bottom plate is fixed to the action mechanism. The rack plate is embedded in the guiderail plate in a falling manner and engaged with the gear. The gear is engaged with the rack jacking rod. The hand pulling plate is fixed to the rack plate and the guide rail plate. After the technical scheme is adopted, the forging precision is high, the quality is good, machining is omitted, and time, labor and materials are saved; and efficiency is high, the problem about trimmings is solved, and the service life of the die is prolonged.

Owner:JIANGSU JINYUAN FORGE

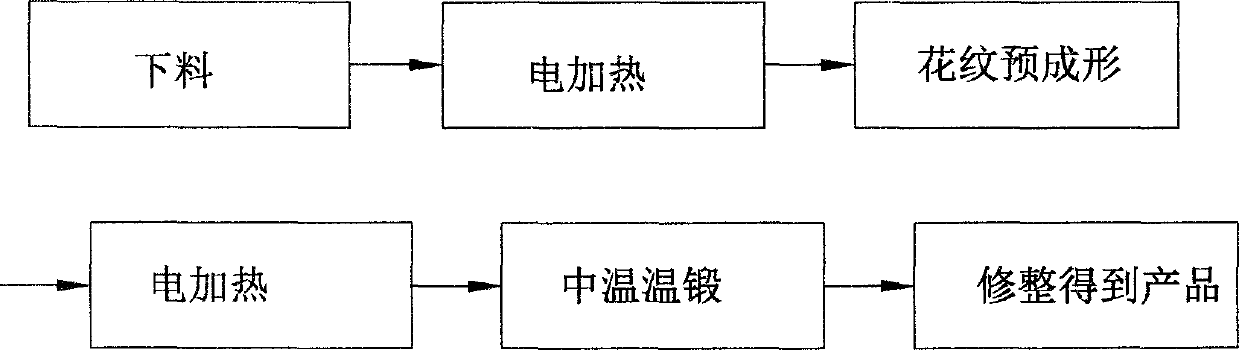

Forging forming process for iron ornamental part product

The invention relates to a forging forming process for an iron ornamental part product. According to the process, low-temperature warm forging pattern preforming is adopted to replace cold forging pattern preforming; moderate-temperature warm forging forming is adopted to replace traditional high-temperature forging forming; electrical heating is adopted to replace fire coal heating; and process flows and the preparation of a mold are reasonably standardized. Compared with the common traditional high-temperature heating forging, by adopting the warm forging forming technology, the surface quality and the heating efficacy of the iron ornamental part product can be remarkably improved, the heating oxidation loss of a material is reduced, and the workshop cost of forging after-treatment is greatly reduced. A low-temperature warm forging and moderate-temperature warm forging forming process is a novel forging forming process with both advantages of high-temperature forging forming and advantages of cold forging forming. According to the forging forming process for the iron ornamental part product, higher forging precision, higher material yield and higher heating and after-treatment efficacy are integrated, and thus, the technical content and the additional value of the iron ornamental part product can be beneficially improved.

Owner:广东鸿图新材料科技有限公司

Wind-powered main shaft forging method

ActiveCN102806291BEnsure forging quality requirementsReduce fire consumptionMetal-working apparatusFurnace typesElectricityThermal treatment

The invention relates to a wind-powered main shaft forging method. The wind-powered main shaft forging method comprises the following steps of inspecting a material; heating the material; taking out a blank which is formed by annealing the material for the first time, pre-forging, upsetting, drawing and printing the blank, performing pre-forging to form the blank, and blanking; finally forging the blank to form a main shaft by annealing for the second time, forging a flange end on a hollow rotary worktable, and drawing the main shaft until a shaft body has forging size; performing re-crystallization normalized tempering thermal treatment by using a one-time thermal loading furnace after forging the wind-powered main shaft; roughly turning the wind-powered main shaft and detecting flaws through ultrasonic wave; hardening and tempering the wind-powered main shaft, and performing nondestructive inspection and physical and chemical inspection on the wind-powered main shaft; finely turning the wind-powered main shaft; and packaging the wind-powered main shaft. The wind-powered main shaft forging method provided by the invention has the characteristics that the efficiency is high, the energy is saved, the cost is reduced, and the forging quality is improved.

Owner:JIANGSU LINGFEI FORGING

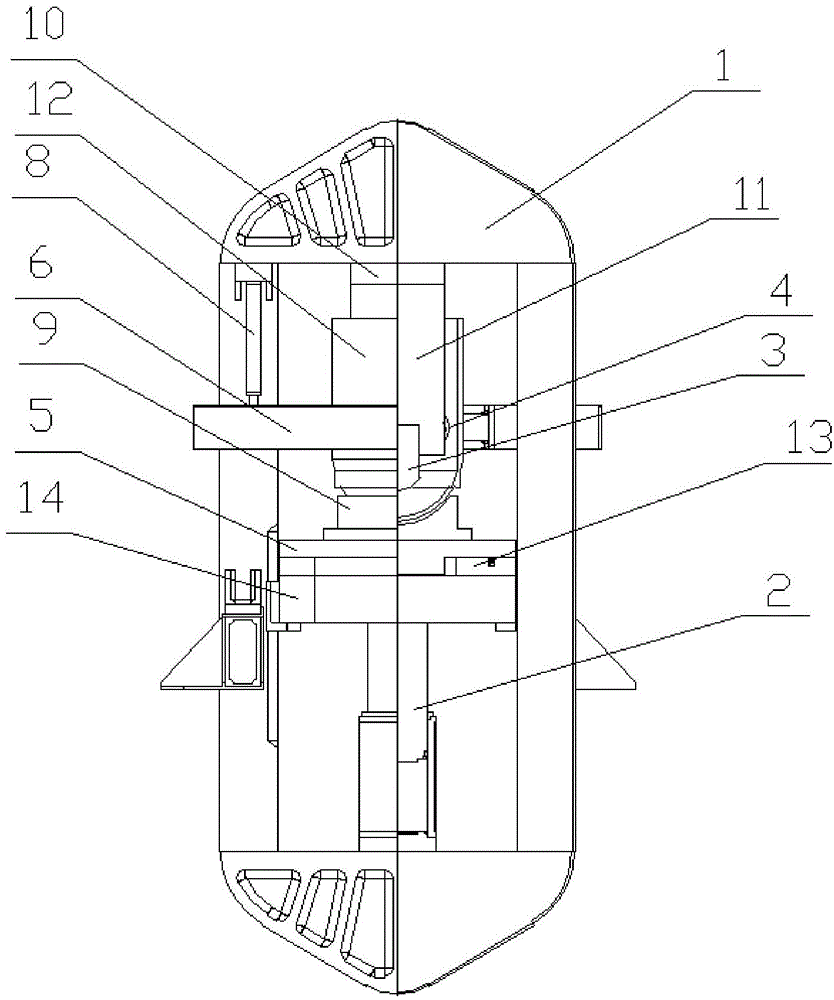

Intelligent direct drive electromagnetic forging hammer

PendingCN108787972AReduce mechanical wear and tearImprove controllabilityPower hammersHammer drivesElectric machineLinear motor

The invention relates to the technical field of forging, in particular to an intelligent direct drive electromagnetic forging hammer. The intelligent direct drive electromagnetic forging hammer comprises a rack, an upper cross beam is connected to the upper portion of the rack, an upper mold and a lower mold are arranged on the inner side of the rack, a cylindrical linear motor is arranged in an inner cavity of the upper cross beam, and comprises a motor shell, a cylindrical stator, and a cylindrical rotor, the stator comprises multiple stator units connected in sequence, each stator unit comprises an iron core and a coil winding, the iron cores are annular, the coil windings are arranged on the inner sides of the annular shapes, and are connected with a power source, each rotor comprisesa rotor screw, a permanent magnet, a ball sleeve and a set sleeve, the permanent magnets are of annular structures with the inner rings provided with threads, the permanent magnets are arranged on therotor screws, the ball guide sleeves are arranged on the tails of the permanent magnets, and the tails are axially locked through the set sleeves. Thrust is directly generated without any replacing device, in the moving process, no mechanical contact can be achieved, transmission parts are not worn, and mechanical losses are greatly reduced.

Owner:郭小红

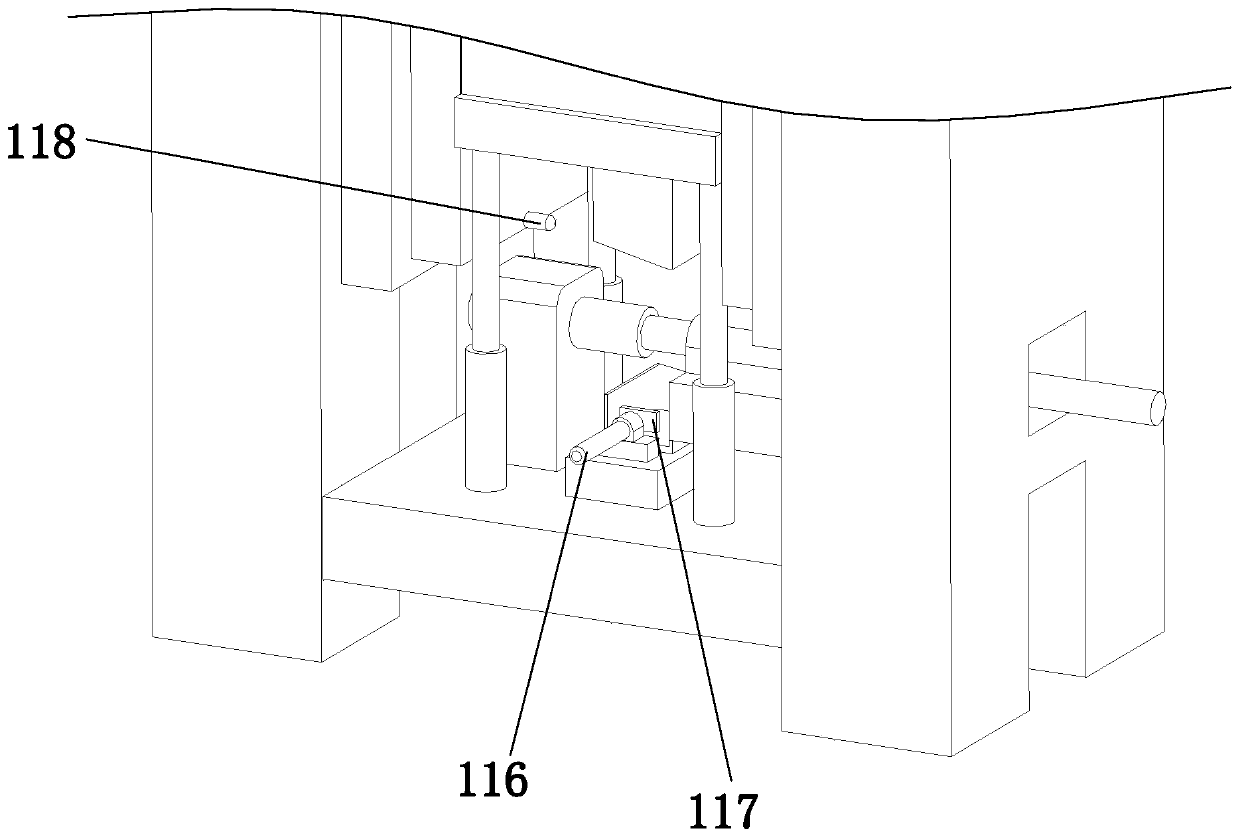

Combined type bearing seat forging device and forging process

PendingCN113751651AImprove processing efficiencyImprove forging precisionForging/hammering/pressing machinesForging press drivesMechanical engineeringAutomotive engineering

The invention relates to the technical field of bearing seat forging, in particular to a combined type bearing seat forging device. The combined type bearing seat forging device comprises a rack, a bearing seat and a connecting seat, and further comprises a first forging mechanism and a second forging mechanism, wherein the first forging mechanism comprises a first driving mechanism and a first die, the first die is installed at the output end of the first driving mechanism, and a die core of the first die is matched with the bearing seat in shape; and the second forging mechanism comprises a second driving mechanism and a second die, the second die is installed at the output end of the second driving mechanism, and a die core of the second die is matched with the connecting seat in appearance. According to the equipment, the machining forming efficiency of the combined bearing seat is greatly improved, the specific die is arranged, and the blank forging precision is improved. The invention further relates to a forging process of the combined bearing seat. According to the forging process of the combined bearing seat, the forging forming efficiency and precision of the combined bearing seat are greatly improved, the forging process has the beneficial effects of being high in efficiency, saving energy and the like, and the production cost is reduced.

Owner:福建精诚锻造有限公司

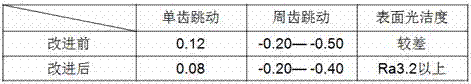

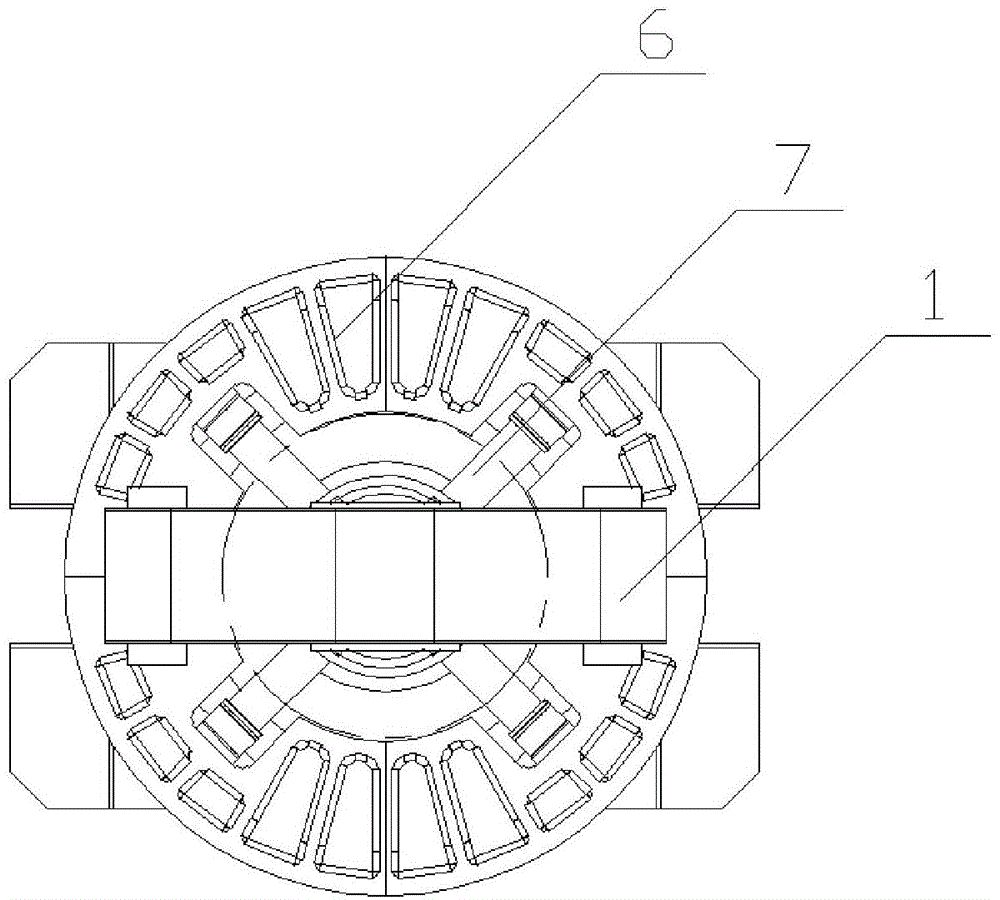

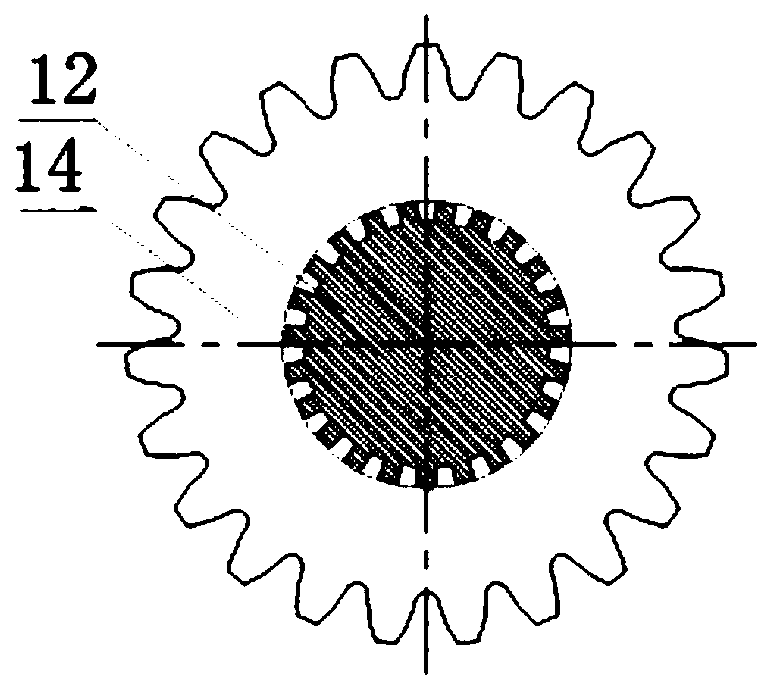

Large-modulus straight toothed spur gear precision forging cold-finish forming method for helicopter and die thereof

ActiveCN110434265AReduce practicalityImprove forging precisionForging/hammering/pressing machinesWheelsGear wheelSpur gear

The invention belongs to the technical field of gear precision forging forming, and particularly relates to a large-modulus straight toothed spur gear precision forging cold-finish forming method fora helicopter and a die thereof. The forming method aims to solve the problems that an existing large-modulus straight toothed spur gear forming method for the helicopter is low in tooth form precision, poor in tooth surface quality and low in die service life. According to the large-modulus straight toothed spur gear precision forging cold-finish forming method for the helicopter, the finishing quantity, the clearance of a punch-matrix, roller radius of a cavity plate, the transition section inclination angle of the cavity plate, and a mandrel structure in the finishing process are adjusted through the design of the punch-matrix and the mandrel structure in the cold-finish process, so that the whole tooth surface finishing is achieved; the mandrel structure is changed on the basis of hollow diverting, so that limitation to diverting is realized, the deformation uniformity of the tooth surface is improved, and the forming load in the finishing process is reduced. The die comprises a pre-tightening cavity plate device and a punch device. The die of the large-modulus straight toothed spur gear precision forging cold-finish forming method for the helicopter is used for the large-modulus straight toothed spur gear precision forging cold-finish forming.

Owner:HARBIN INST OF TECH

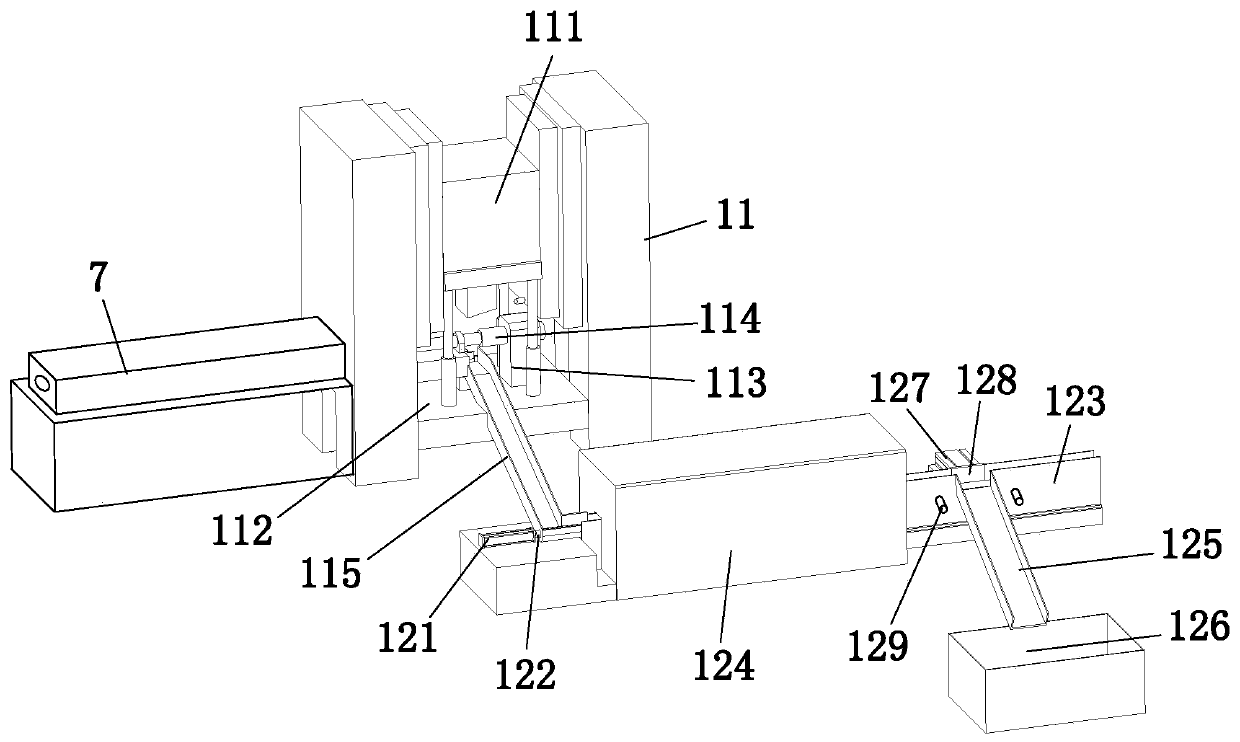

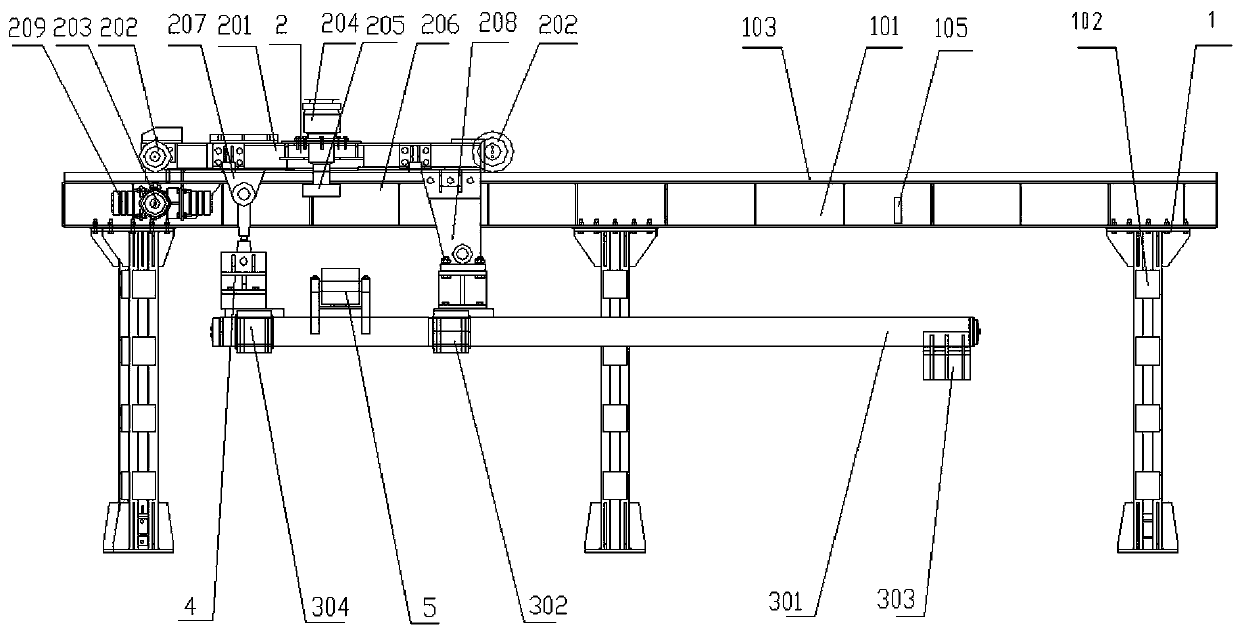

Feeding and discharging device for annular heating furnace

ActiveCN107560437AImprove effective space utilizationReduce shipping timeCharge manipulationEngineeringHeating furnace

The invention relates to the field of steel processing equipment, and particularly relates to a feeding and discharging device for an annular heating furnace. The feeding and discharging device comprises a rack, a trolley and a grabbing mechanism, wherein the trolley is arranged on the rack in a sliding mode, and the grabbing mechanism is arranged on the trolley; the grabbing mechanism comprises two parallel claw beams, the middle parts of the two claw beams sleeve the interior of a first double-hole bearing seat, the top of the first double-hole bearing seat is hinged to the bottom of the trolley, clamping pincers of which notches are opposite are respectively arranged one end of the two claw beams on the same side, the other ends sleeve the interior of a second double-hole bearing seat,a lifting air cylinder is arranged between the second double-hole bearing seat and the trolley, the telescopic end and the cylinder body end of the lifting air cylinder are respectively hinged to thetop of the second double-hole bearing seat and the bottom of the trolley, a clamping cylinder is arranged between the two claw beams, swing arms are respectively hinged to the telescopic end and the cylinder body end of the clamping cylinder, and the other ends of the two swing arms are fixedly connected with the two claw beams respectively. According to the feeding and discharging device, the degree of automation of feeding and discharging processes of the annular heating furnace can be increased, and remote operation control is realized.

Owner:LUOYANG INST OF SCI & TECH

Manufacturing process for shaft coupler

The invention discloses a manufacturing process for a shaft coupler. The manufacturing process comprises the following steps of: a, putting steel ingot into a smelting furnace to heat to 1120 DEG C, clamping the steel ingot by a pressure clamp, performing bottom chewing on the steel ingot and chamfering the steel ingot; b, re-heating the blank obtained in the step a to 1200-1250 DEG C, upsetting the blank, drawing out the blank, cogging down the blank, and controlling a primary forging ratio to 2.0-2.5; c, re-heating the blank obtained in step b to 1100-1150 DEG C, upsetting the blank, drawing out the blank, flattening the end surface of the blank and printing the blank according to a figure number; d, re-heating the blank obtained in step c to 1000-1050 DEG C, and putting the blank into a mould ring to upset and form a rear-end gear blank flange end; e, re-heating the blank obtained in step d to 950-1000 DEG C, drawing out a small shaft end of the blank to a process dimension by a core rod, controlling a shaft end total forging ratio to be greater than or equal to 5, trimming and straightening the blank; f, mounting a semi-finished product obtained in the step e into a processing center to process, firstly processing the outline of the semi-finished product and then processing an inner hole; and g, performing thermal treatment on the semi-finished product obtained in step f, and coating the processed semi-finished product for preservation. The manufacturing process for the shaft coupler disclosed by the invention is long in service life.

Owner:宁波吉威熔模铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com