Mechanical deformation compensation control method for forging hydraulic press

A technology of compensation control and mechanical deformation, which is applied to the driving device of the forging press, etc., can solve the problems such as the influence of the forging precision of the press, and achieve the effect of improving the forging precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

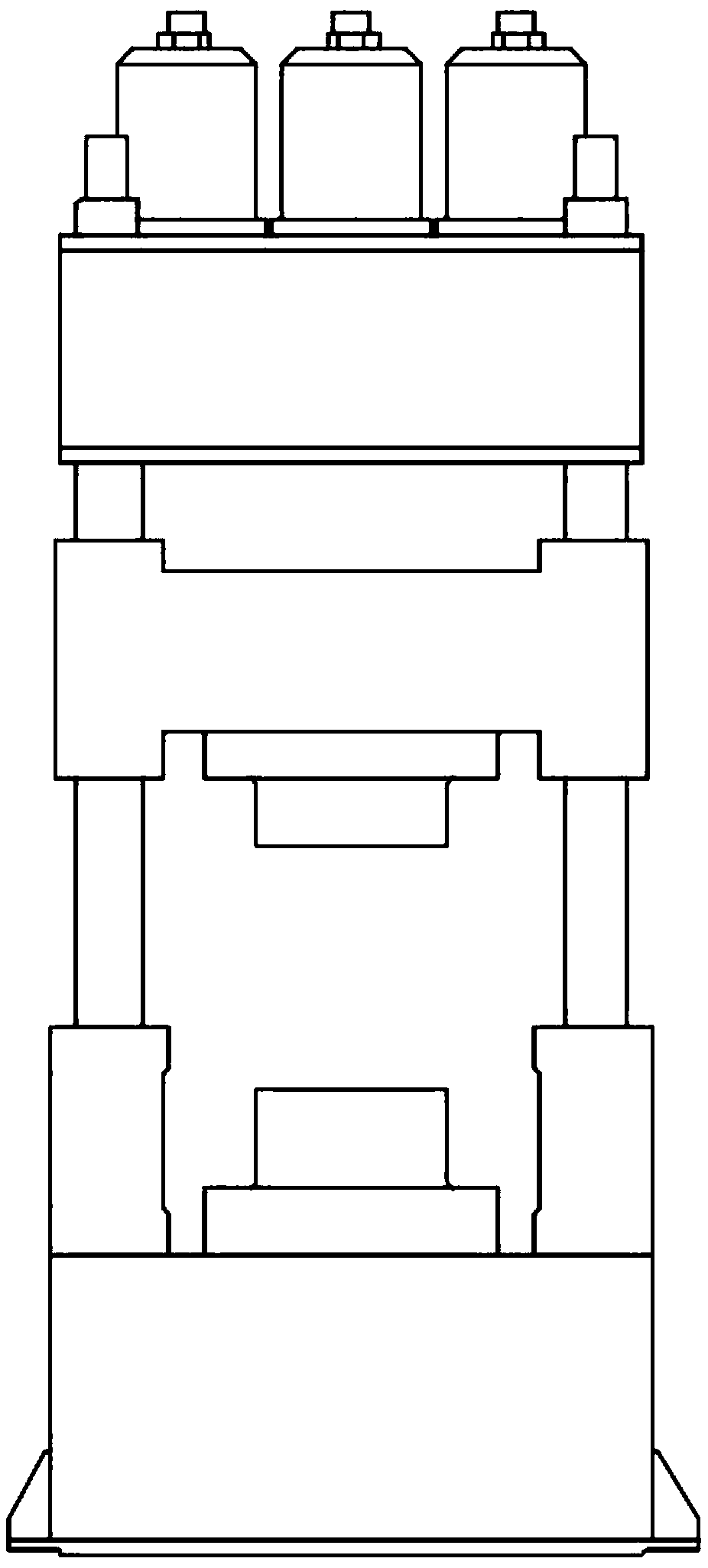

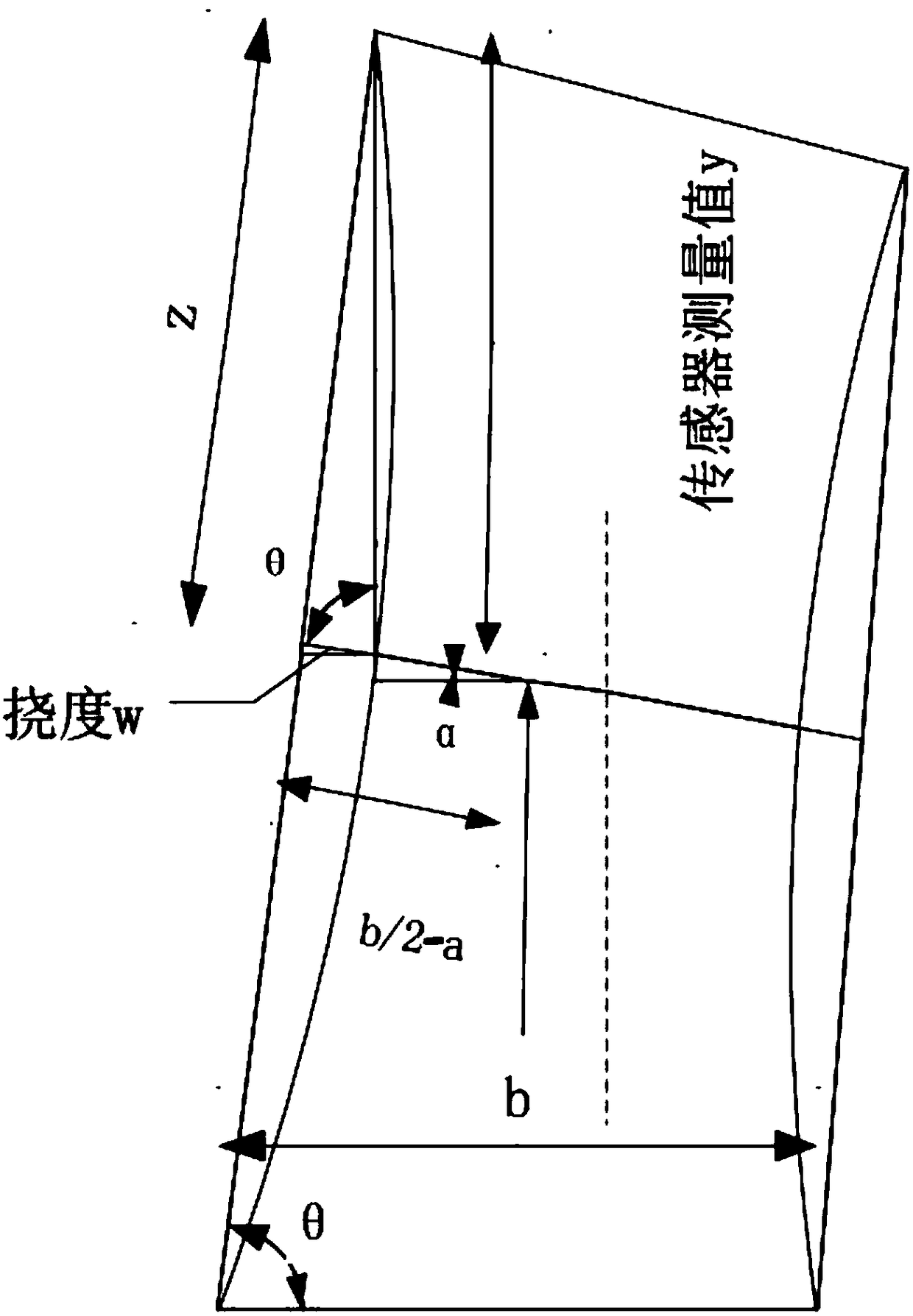

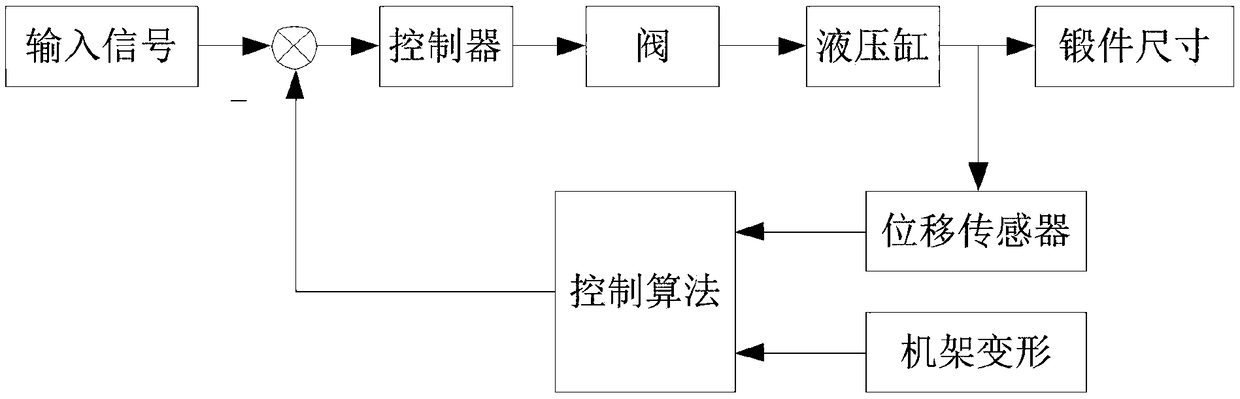

[0047] exist figure 1 , figure 2 and image 3 In the schematic diagram of the present invention shown,

[0048] The technical scheme adopted in the present invention:

[0049] The method is to use the stress strain gauge to convert the stress and deformation caused by the deformation of the mechanical structure into an electrical signal through the stress strain gauge, and feed it back to the control system. Through calculation, the difference between the measured values of the sensor is compensated, thereby improving the forging accuracy of the forging. Deformation: During the working process of the forging hydraulic machine, after the cutting board contacts the forging and pressurizes, the forging generates deformation reaction force during the deformation process, which acts on the upper and lower cutting boards respectively; while the main cylinder drives the movable beam, it also receives the reaction given by the movable beam The force acts on the upper beam and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com