Feeding and discharging device for annular heating furnace

A ring-shaped heating furnace and trolley technology, applied in lighting and heating equipment, furnaces, furnace components, etc., can solve the problems of difficulty in fully controlling the furnace pressure of the heating furnace, difficult for staff to operate for a long time, and affecting product quality. The effect of improving effective space utilization, reducing transportation time, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

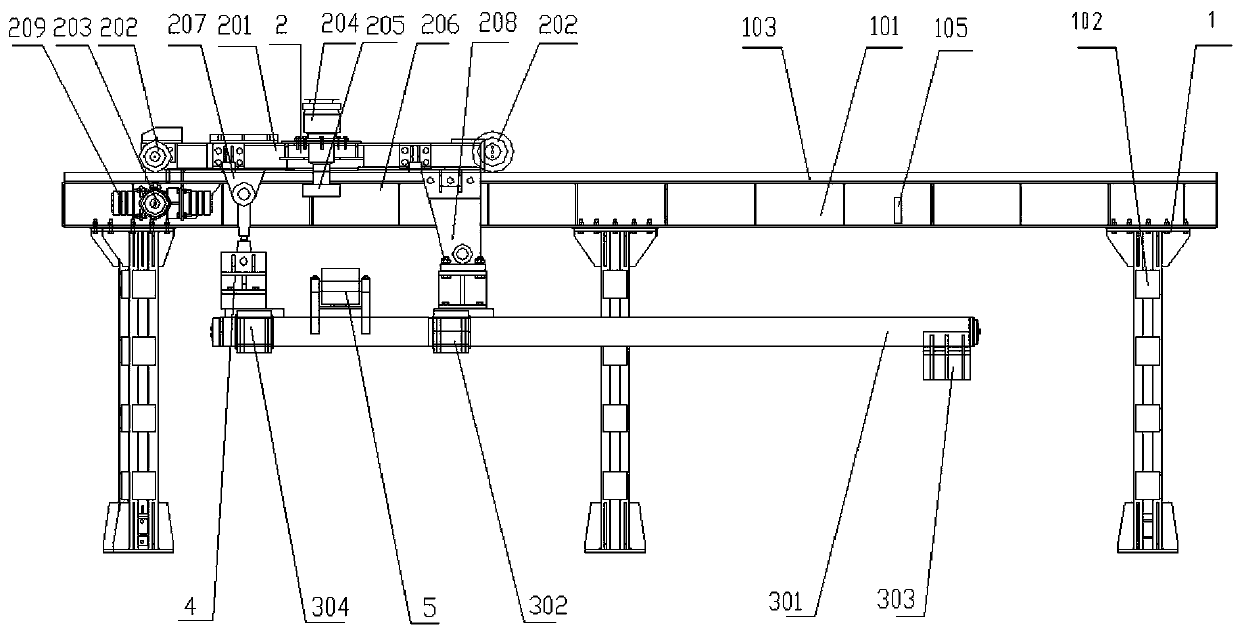

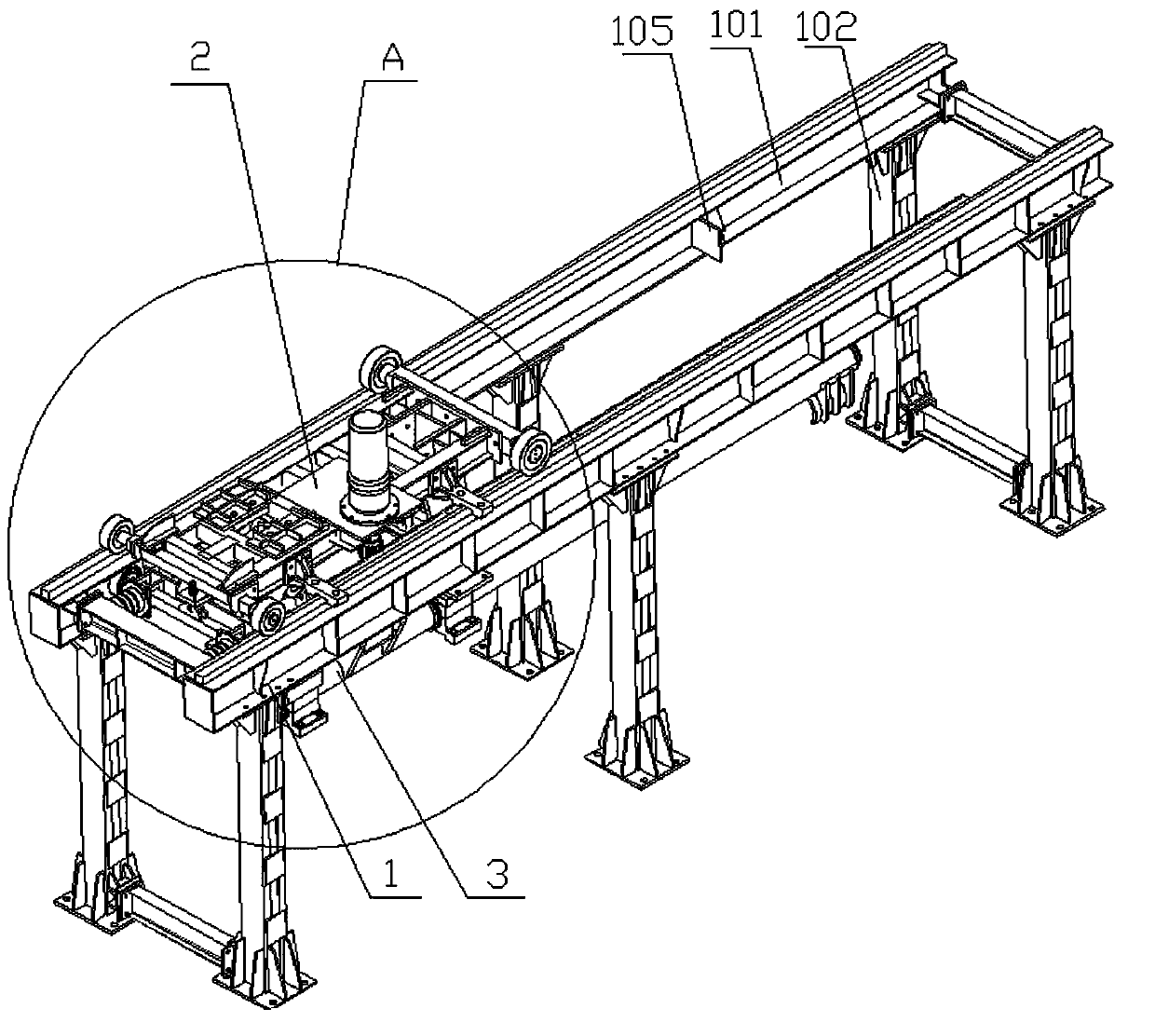

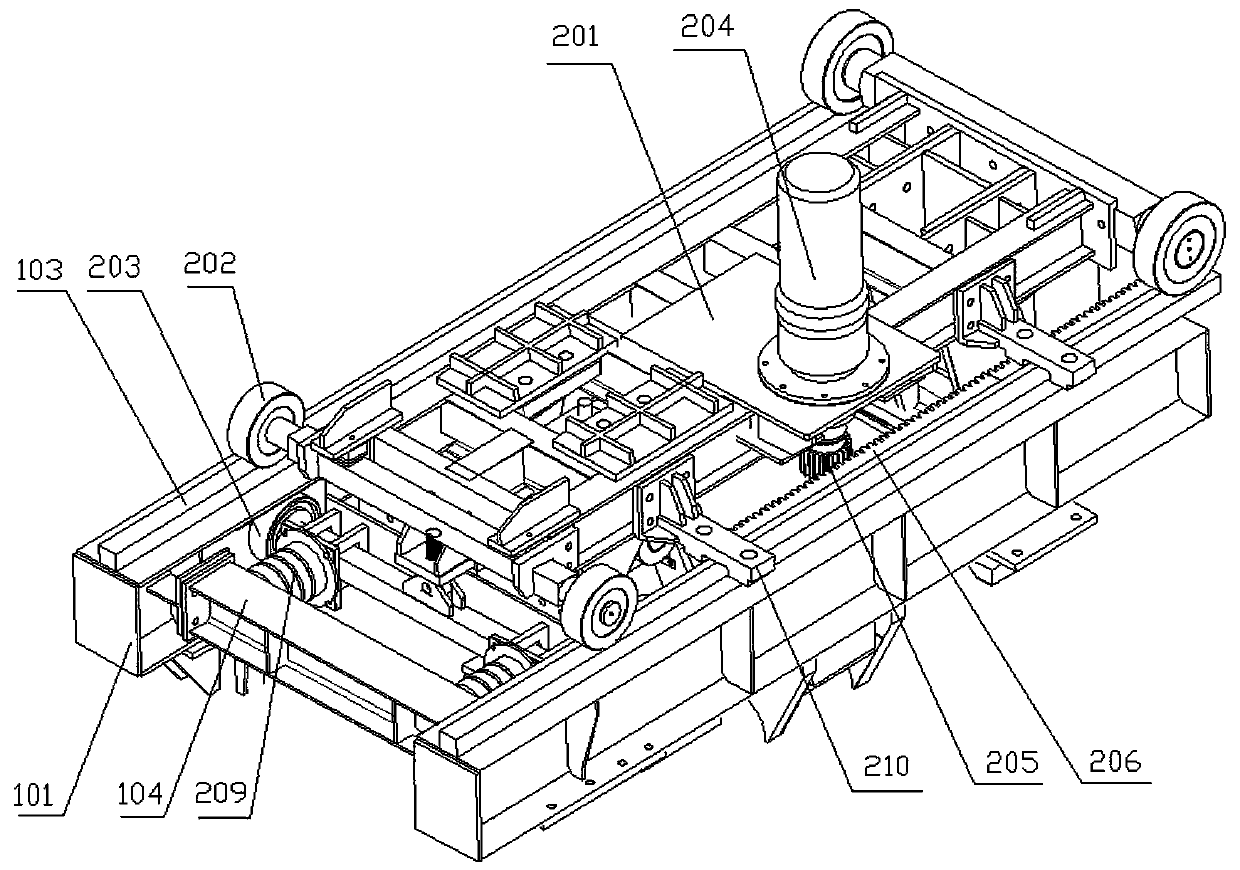

[0026] Such as Figure 1 to Figure 6 As shown, a loading and unloading device for an annular heating furnace of the present invention includes a frame 1 , a trolley 2 slidably arranged on the frame 1 , and a grabbing mechanism 3 disposed on the trolley 2 . The frame 1 is arranged at the loading and unloading port of the annular heating furnace, and the movement track of the trolley 2 is toward or away from the loading and unloading opening of the annular heating furnace. After grabbing the billet from the unloading rack by the gripping mechanism 3, the billet is put into the annular heating furnace with the sliding of the trolley 2 on the frame 1 and its own lifting, or taken out from the annular heating furnace.

[0027] The frame 1 includes two horizontal and parallel beams 101, the lower parts of the two beams 101 are respectively provided with three supporting columns 102 at even intervals, and the upper parts of the two beams 101 are provided along the length direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com