A magnetic reversing locking mechanism

A locking mechanism and magnetic technology, applied in the direction of manipulators, generators/motors, electrical components, etc., can solve the problems of increasing system complexity and cost of use, and achieve high space utilization, compact volume, and eliminate heating problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

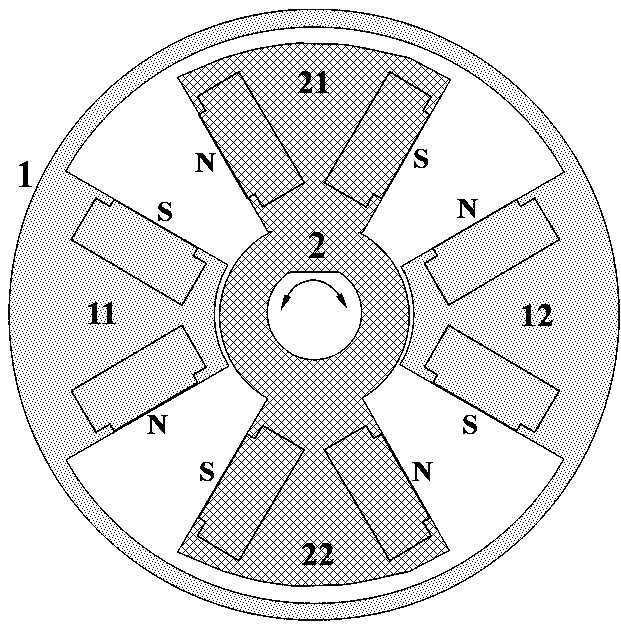

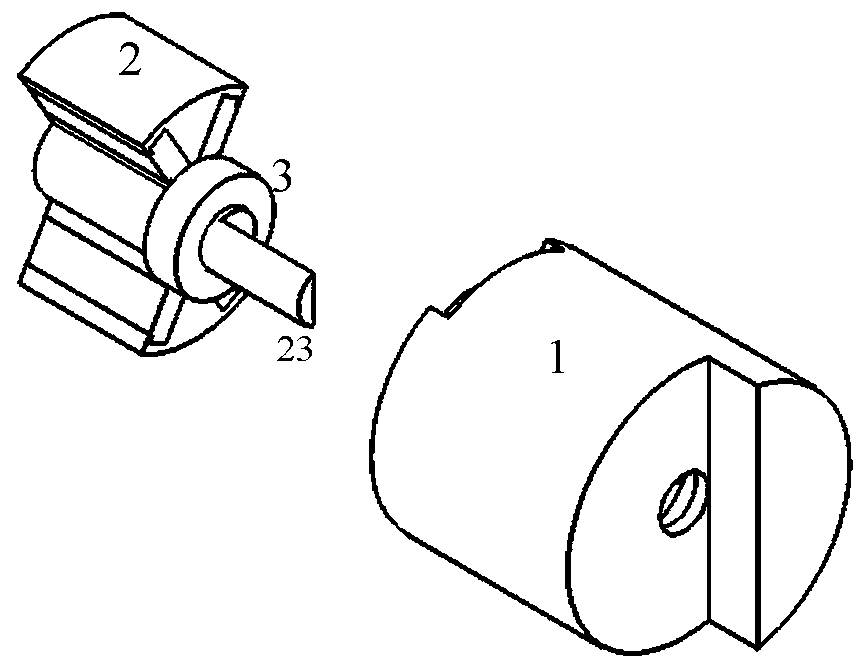

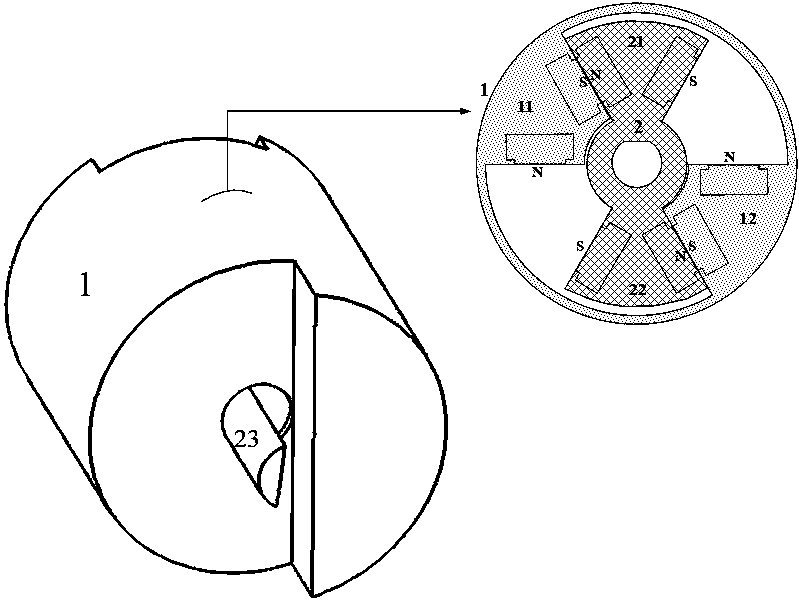

[0022] Example 1, an on-off pinch valve, see Figure 2-4 , Including the stator 1, the rotor 2 and the bearing 3; wherein the stator 1 and the rotor 2 each have two magnetic pole pairs, and the magnetic pole pairs are fan-shaped, evenly distributed along the circumference.

[0023] The on-off pinch valve includes a first state ( image 3 ) And the second state ( Figure 4 ), where the first state is the released state and the second state is the clamped state;

[0024] In the first state, the N pole in the first magnetic pole pair 21 of the rotor 2 is attached to the S pole in the first magnetic pole pair 11 of the stator 1, and the N pole in the second magnetic pole pair 22 of the rotor 2 is in contact with the stator 1 The S pole of the second magnetic pole pair 12 is attached; the attraction force between the two pairs of attaching surfaces generates a counterclockwise torque relative to the rotor shaft 23 to maintain the pinch valve in a released state.

[0025] In the second st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com