an eye drop bottle

A technology of eye drops bottle and bottle body, which is applied in medical containers, ophthalmic treatment, pharmaceutical packaging, etc., and can solve the problems of poor appearance and large volume of packaging bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

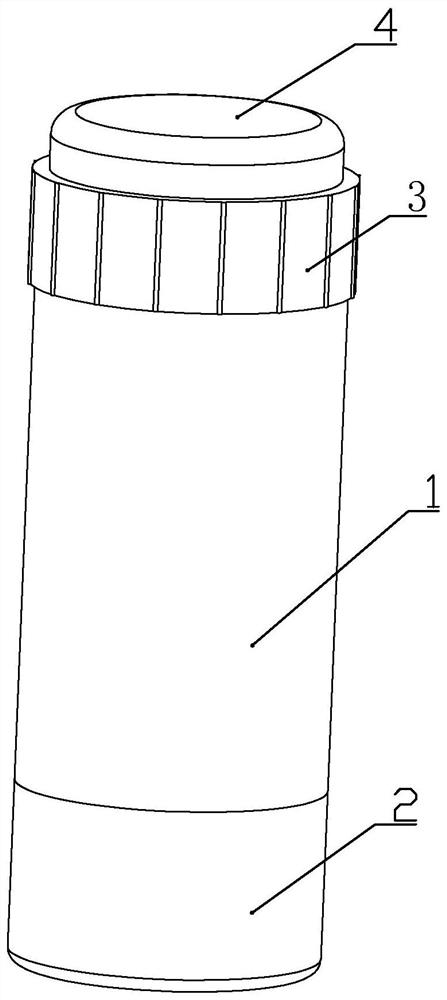

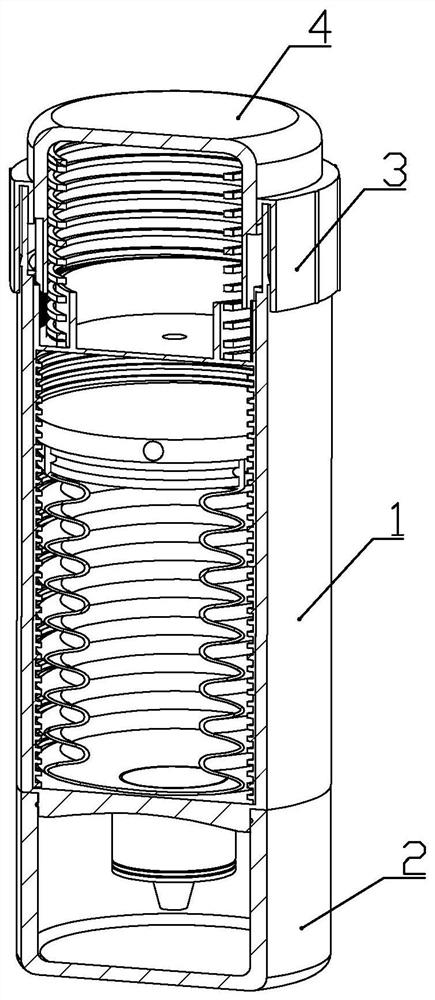

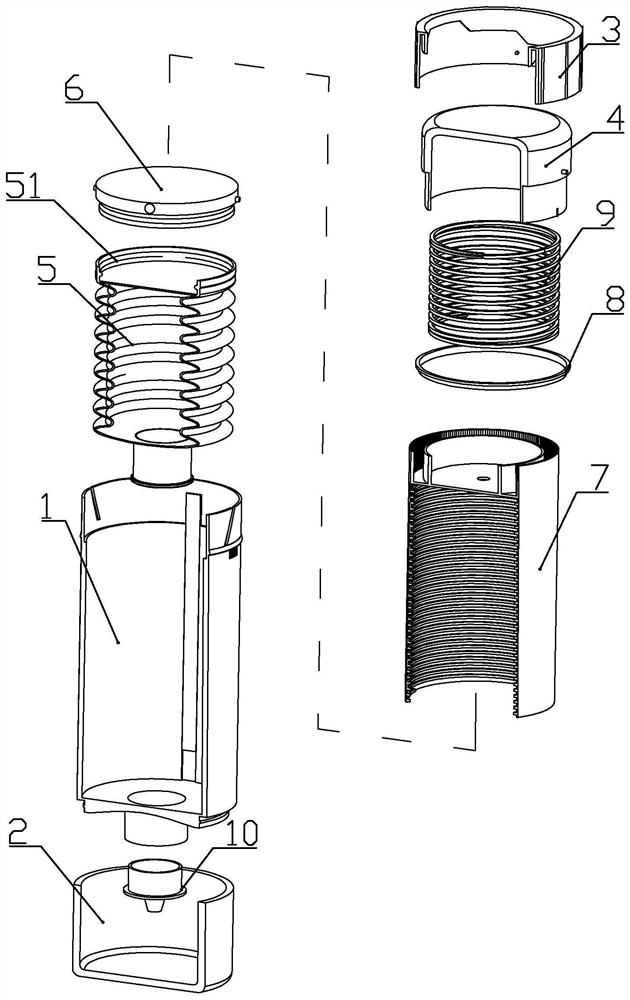

[0040] according to Figure 1 to Figure 9 As shown, the present embodiment is an eye drop bottle, which includes an outer bottle body 1 , a bottle cap 2 connected to the front end of the outer bottle body, and a drip tip 10 plugged in at the front end of the outer bottle body 1 .

[0041] A corrugated silicone liner 5 is plugged into the outer bottle body 1 , and a connecting sleeve 51 is formed on the upper end of the silicone liner 5 .

[0042] The upper end of the silicone liner 5 is connected with an inner liner extruding portion 6 , and the lower end of the inner liner extruding portion is formed with an inner liner connecting portion 61 fixedly connected with the connecting sleeve 51 .

[0043] The inner wall of the outer bottle body 1 is formed with a bar-shaped iron plate slot 121, and a bar-shaped iron plate 12 is vertically inserted in the bar-shaped iron plate slot; The permanent magnets 63 that the bar-shaped iron sheets 12 attract each other.

[0044] The outer ...

Embodiment 2

[0058] This embodiment makes the following improvements on the basis of Embodiment 1: the inner circumference of the upper end of the adjustment knob 3 is formed with a connecting ring, and the inner circumference of the connecting ring is formed with a ring inserted into the inner wall of the upper end of the outer bottle body to limit the movement of the button part 4 The retaining ring 31 of the range.

[0059] The retaining ring 31 is formed with a first step for preventing the guide protrusion from moving in the guide groove and more than one second step for adjusting the movement range of the guide protrusion along the guide groove. The first step It is equal to the length of the second step along the circumferential direction of the retaining ring.

[0060] One first step and more than one second step are distributed in a step shape along the circumferential direction of the retaining ring, and the adjacent first step, the second step, or the adjacent two second steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com