Plastic forming process of integral top cover of nuclear power water chamber and intelligent forging press used by plastic forming process

A technology for plastic forming and forging presses, applied in forging/pressing/hammer devices, mechanical equipment, manufacturing tools, etc., can solve the problems of high processing cost, low forging precision, long manufacturing cycle, etc., and achieve low processing cost, forging The effect of high flexibility and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

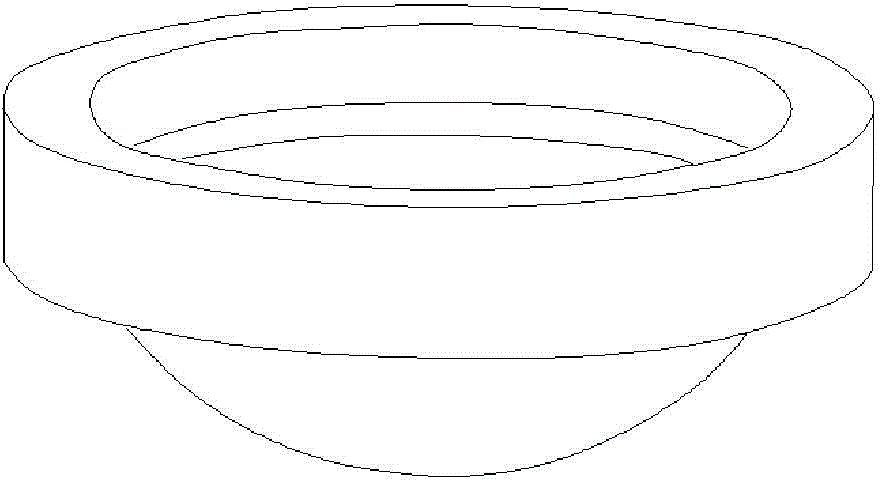

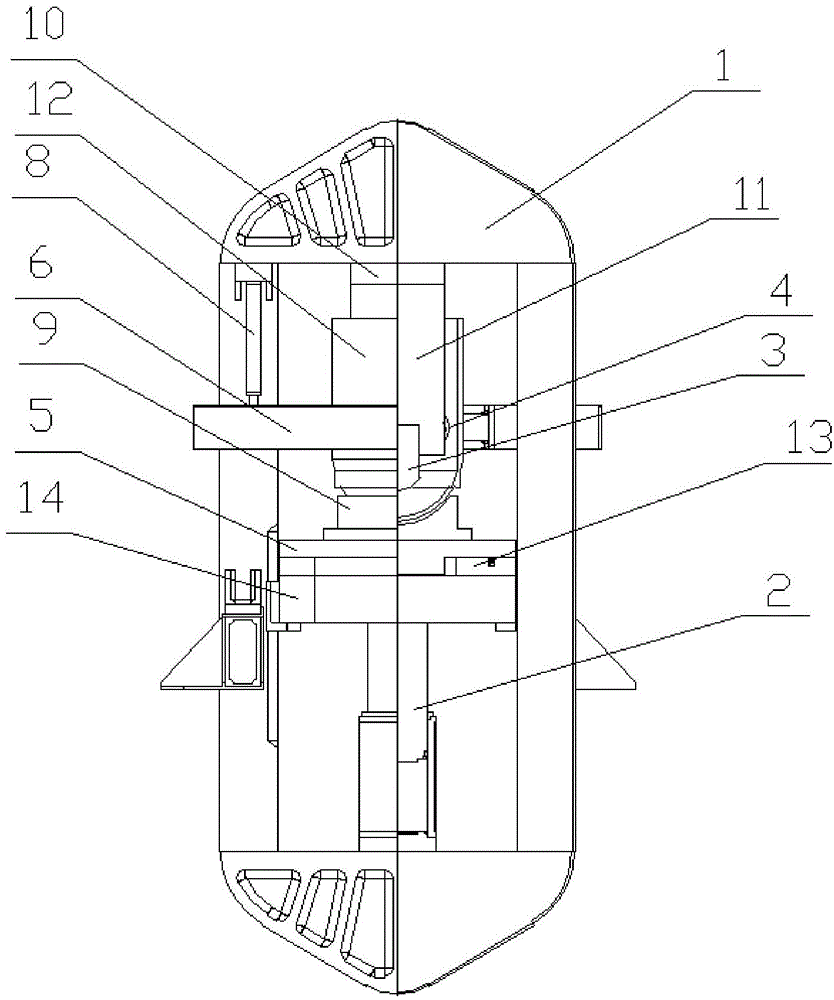

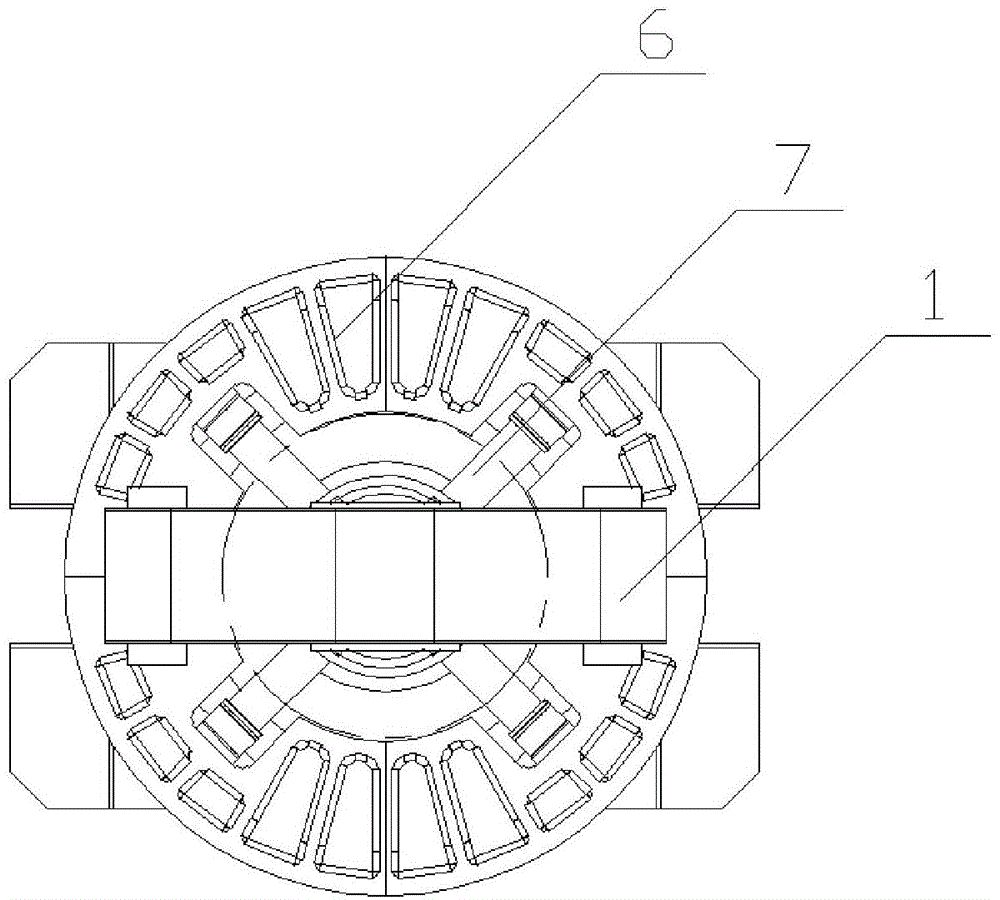

[0022] Embodiment: A kind of plastic forming process of the integral top cover of nuclear power water chamber, the specific steps are as follows:

[0023] Step 1: Carry out three-dimensional modeling of the forging and use finite element analysis software to digitally simulate the plastic deformation of the model to obtain the geometric dimension value of the forging before and after intelligent forging;

[0024] Step 2: Use large-scale LCD (laser cladding deposition) near-net forming to obtain the size and shape of the forging simulated in step 1 before intelligent forging;

[0025] Step 3: Intelligent plastic forming of the top curved surface: Position the billet formed by the LCD on the support device, start the intelligent forging press, and move the main cylinder vertically upward to push the billet to contact and extrude with the intelligent main pressure head 3 of the intelligent forging press, and the intelligent main pressure The head 3 extrudes the billet for plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com