Rotary table of quick-forging hydraulic press

A technology of rotary table and hydraulic press, used in forging/pressing/hammering machinery, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problems of high labor intensity, high cost, inconvenient operation, etc. Accuracy, improved tool life, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

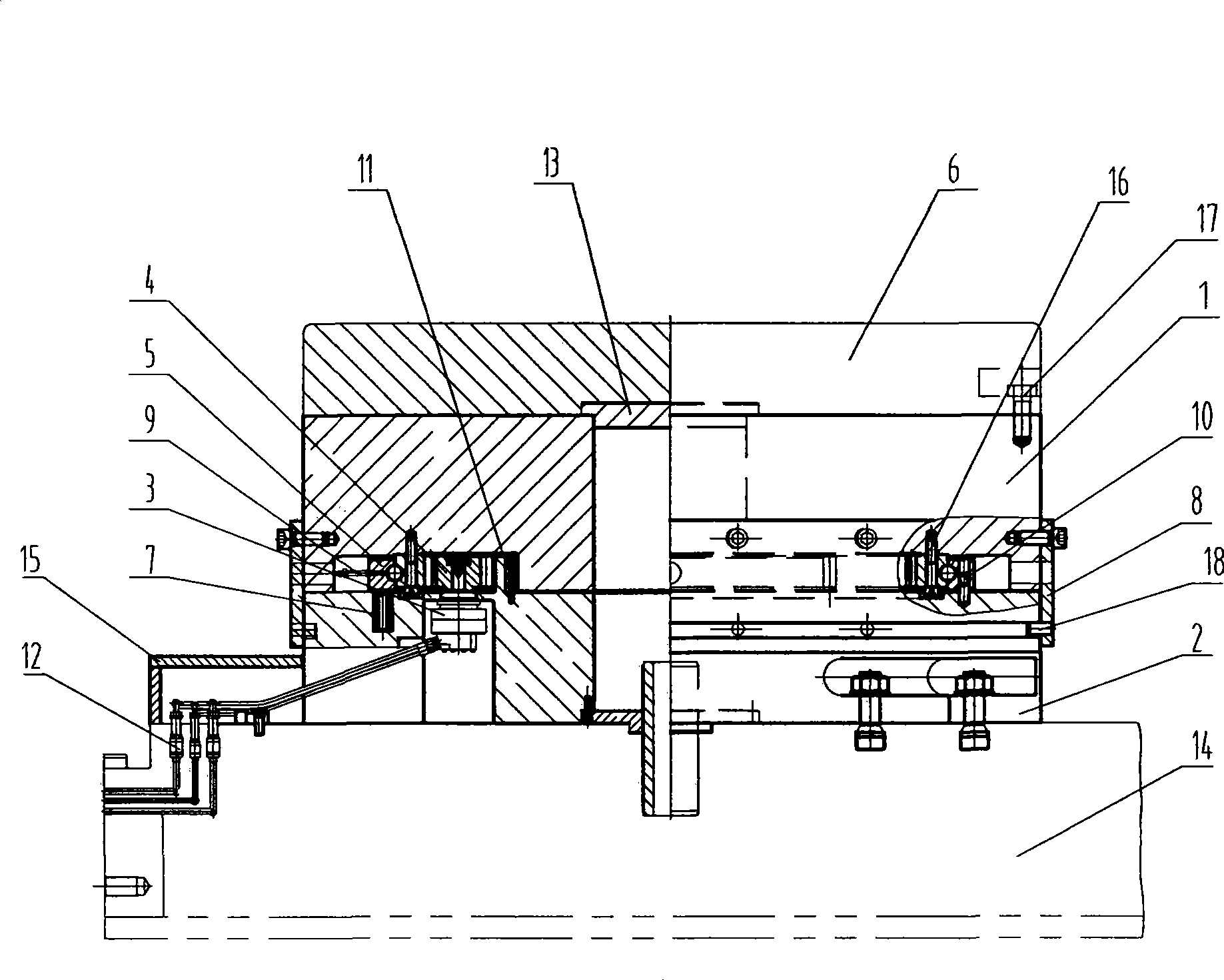

[0010] Such as figure 1 As shown, a rotary workbench of a rapid forging hydraulic press includes: a base 2 arranged on a movable workbench 14 of the hydraulic press, and a worktable 1 connected to the base 2 with bearings. The bearing connection between the worktable 1 and the base 2 is a turntable ball bearing 5, the inner ring of which is connected to the worktable 1 by 36 screws 16, and the outer ring is fixed on the base 2 by 12 pins 10 . A hydraulic motor 3 with a pinion 4 is installed inside the rotary table and fixed to the base 2 , and the pinion 4 meshes with the internal teeth of the turntable ball bearing 5 . The hydraulic motor 3 is driven, and the rotary motion of the worktable is completed through the internal gear meshing transmission of the pinion 4 and the turntable ball bearing 5 . The turntable ball bearing 5 is installed inside the rotary table to keep it away from pollution and heat radiation, which is beneficial to protect the turntable ball bearing.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com