Material clamping pliers for annular heating furnace material charging and taking device

A technology of annular heating furnace and clamping tongs, which is applied in the field of clamping tongs, can solve the problems of restricting the development of loading and unloading devices for annular heating furnaces, complex structures, and inconvenient maintenance, and achieves improved effective space utilization, low cost, and easy Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

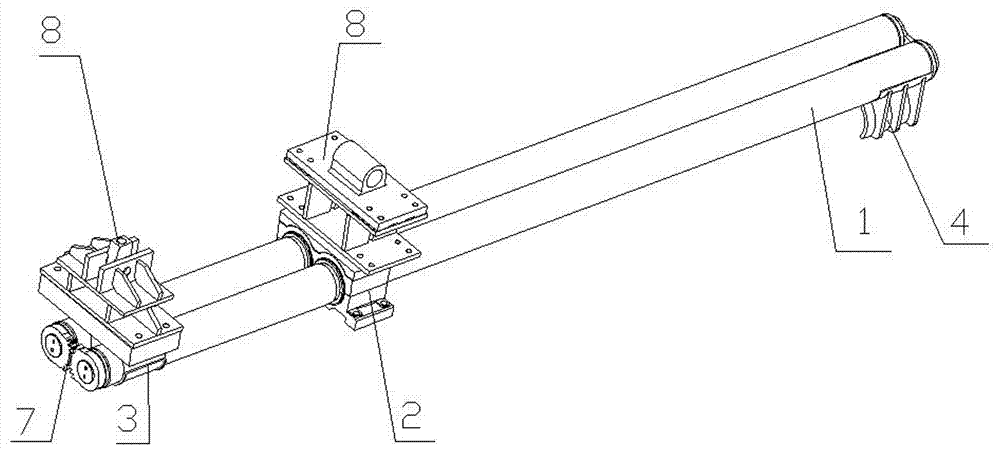

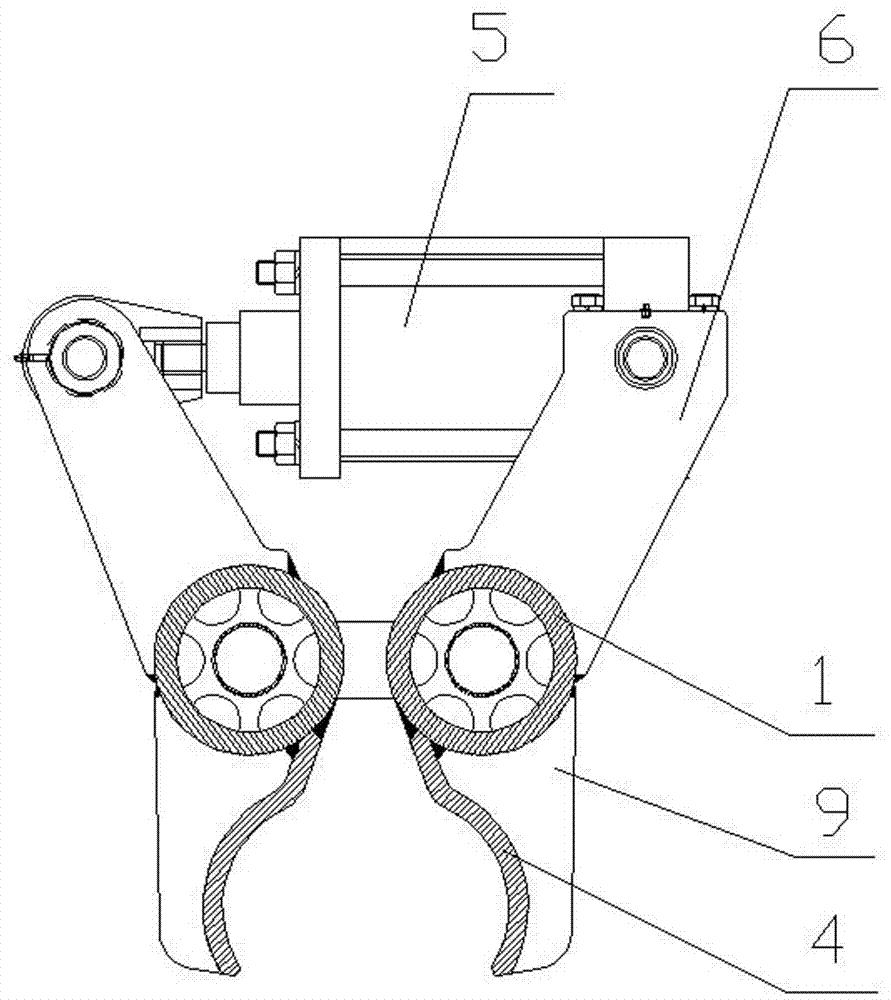

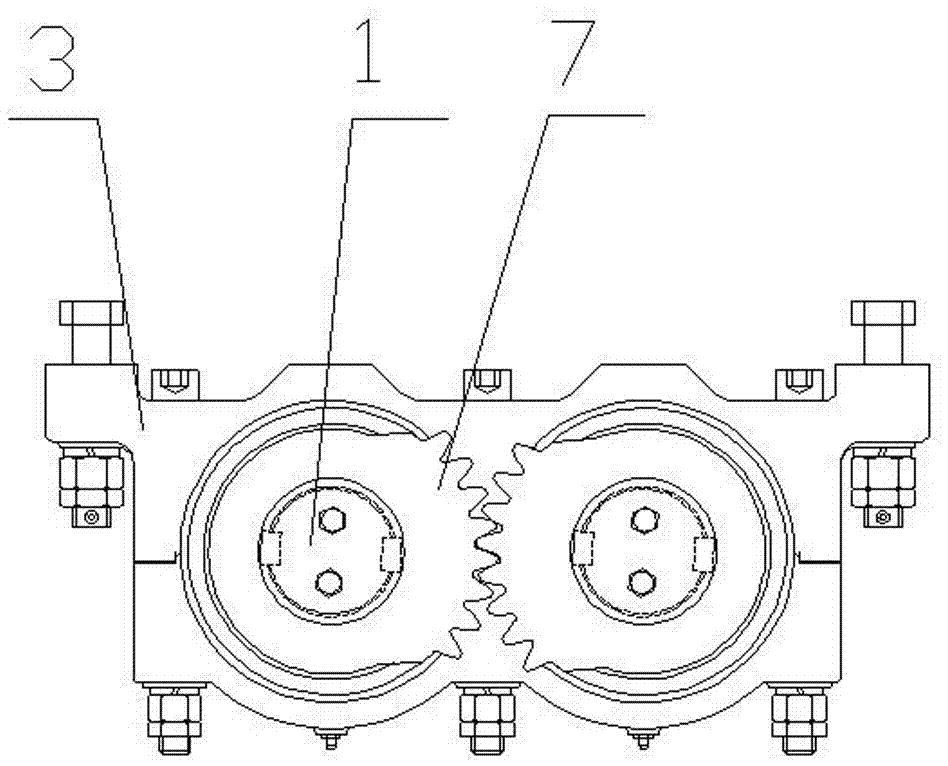

[0024] Such as Figure 1 to Figure 7 As shown, a material clamping tongs used for loading and unloading devices of annular heating furnaces according to the present invention includes two parallel clamp rods 1, and the parts near the middle of the two clamp rods 1 are sleeved on the second double-hole bearing seat 3, two pincer rods 1 are located near the second double-hole bearing seat 3 and one end is sleeved in the second double-hole bearing seat, and the second double-hole bearing seat 3 and the second double-hole bearing seat are equipped with ring-shaped The hinged seat plate 8 that the moving trolley in the loading and unloading device of the heating furnace links to each other. The second double-hole bearing seat 3 is hinged to the mobile trolley on the loading and unloading device of the annular heating furnace through the corresponding hinged seat plate 8, and the hinged seat plate 8 corresponding to the second double-hole bearing seat is hinged to one end of the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com