Split-type steel top steel skirt piston

A split-type, piston technology, used in pistons, engine components, machines/engines, etc., can solve the problems of excessively heavy oil cavity wall, piston ring seal failure, poor heat dissipation effect of steel pistons, etc., to achieve good hardness and strength, improve The effect of heat dissipation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

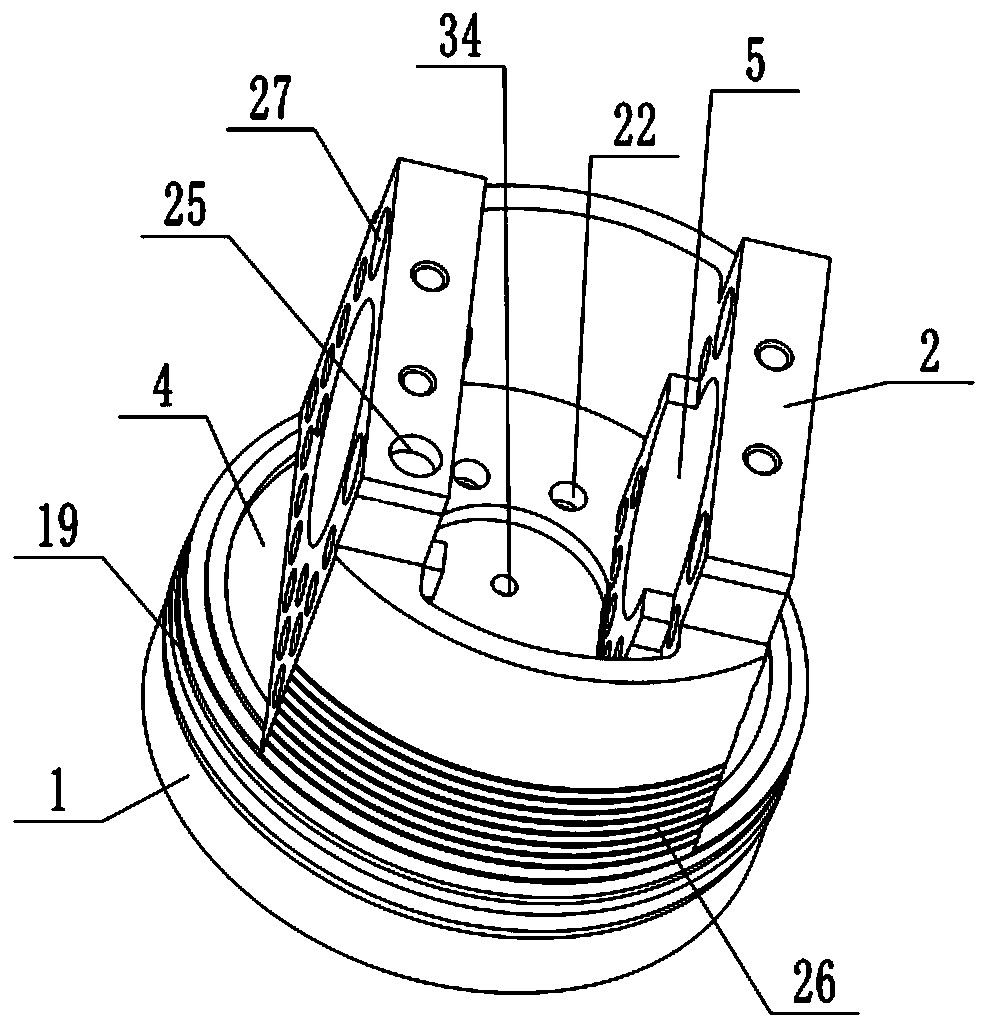

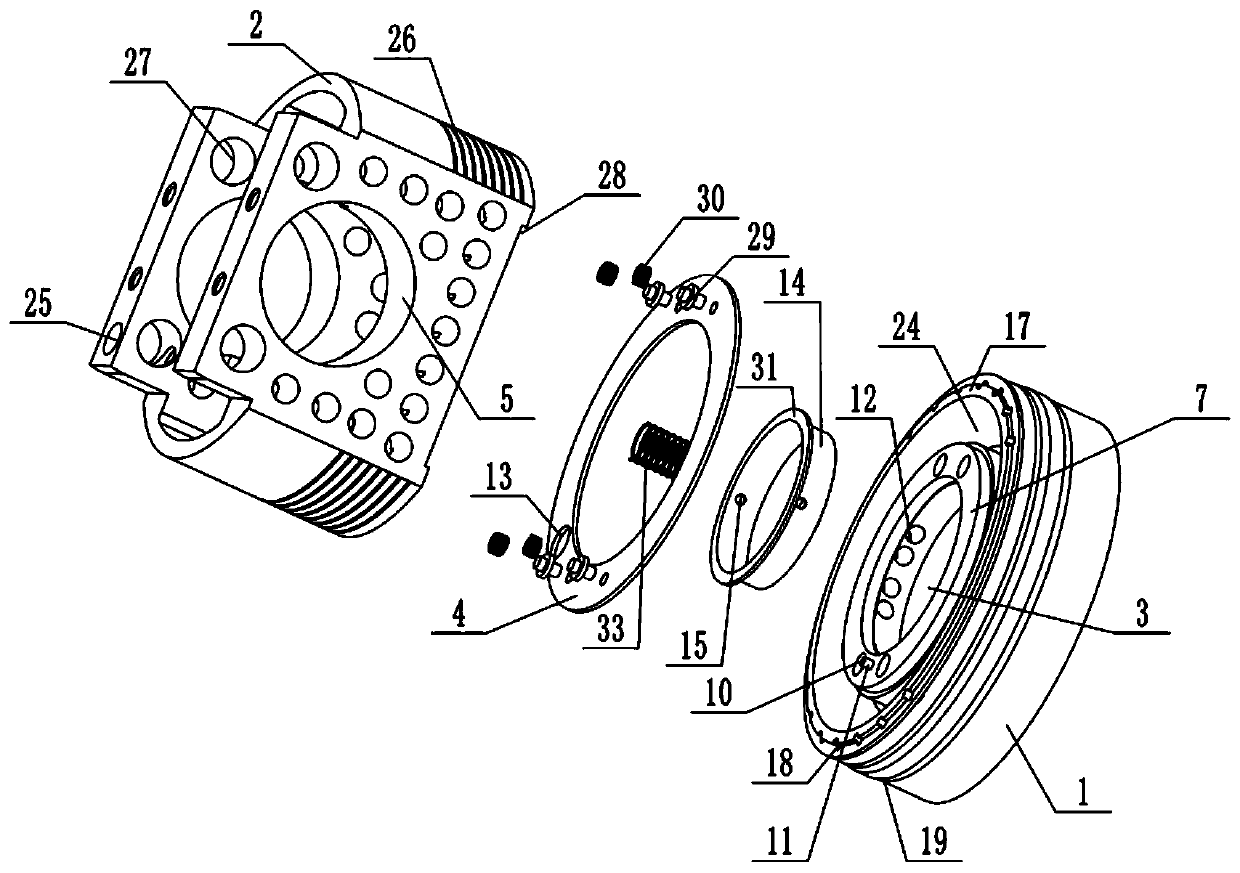

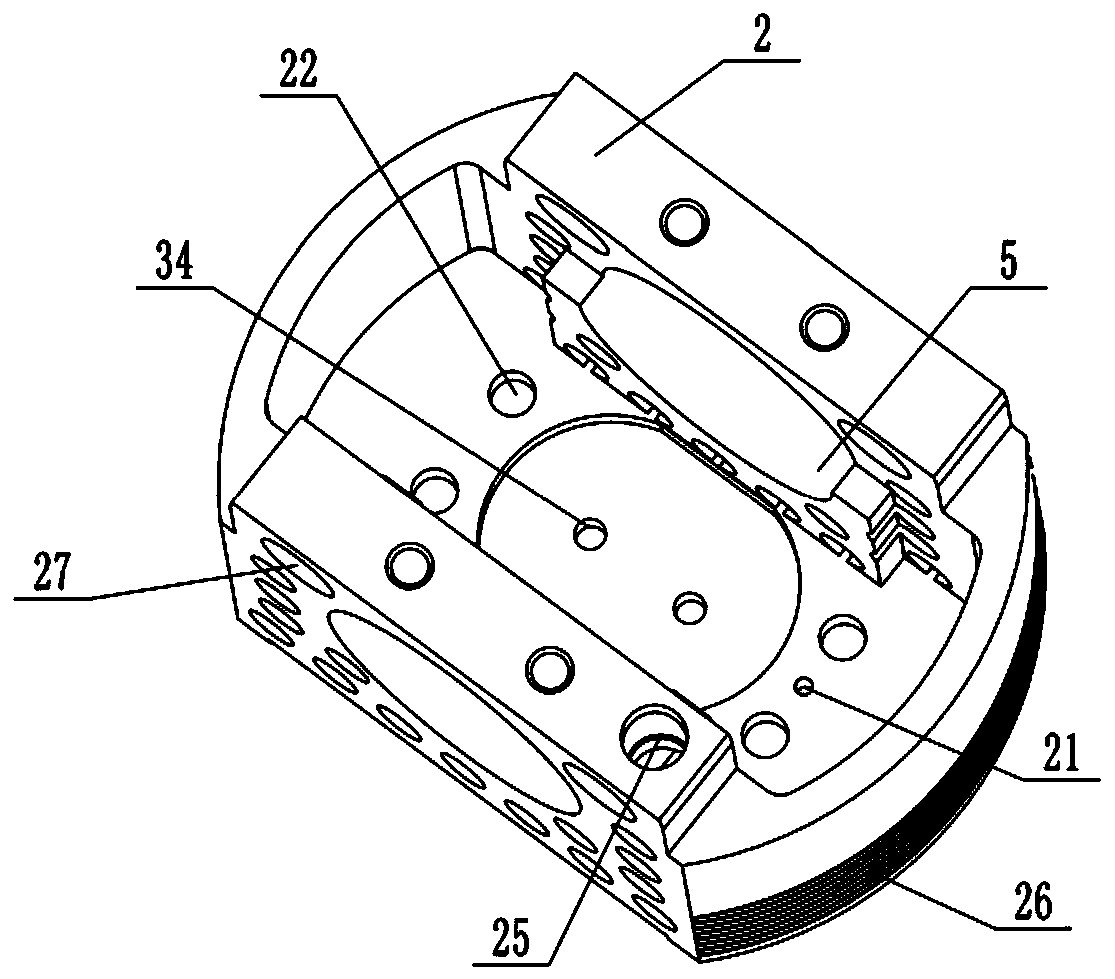

[0034] Embodiment one is basically as attached Figure 1 to Figure 5 Shown:

[0035] The split type steel top and steel skirt piston includes the piston body, the piston body includes the piston steel top 1 and the piston steel skirt 2, the piston steel top 1 is provided with an annular oil cover 4, and the two opposite walls of the piston steel skirt 2 are provided with The piston pin seat 5, the bottom surface of the middle part of the piston steel top 1 is integrally formed with an annular circular platform 7, a cylindrical first oil chamber 3 is formed in the annular circular platform 7, and a circular second oil chamber is formed between the annular circular platform 7 and the piston steel top 1 24. A first step 8 is fixed outside the ring-shaped platform 7, a second step 9 is fixed inside the ring-shaped platform 7, and four first positioning holes 10 are arranged on the top of the ring-shaped platform 7, and every two first positioning holes 10 It is a group, two group...

Embodiment 2

[0041] as attached Figure 6As shown, the difference between the present embodiment and the first embodiment is that the oil inlet hole 25 is opened on the piston pin seat 5 . This setting method is consistent with the oil inlet method of one of the integral pistons at present, which enters the oil chamber from the oil inlet hole 25 provided on the piston pin seat 5. Therefore, when replacing the piston in the existing cylinder, only It is only necessary to replace the original piston with the split-type steel-top and steel-skirt piston, and there is no need to slide other parts, which makes installation and use more convenient.

Embodiment 3

[0043] as attached Figure 7 As shown, the difference between the present embodiment and the first embodiment is that the oil inlet hole 25 is opened in the middle of the circular groove 32 on the oil guide cover 14 . The lubricating and cooling effects of this embodiment are the same as those of Embodiment 1, except that the flow direction of the lubricating oil is opposite. The oil inlet hole 25 enters in the annular round table 7, and enters in the oil chamber through eight through holes 12 of the annular round table 7, and finally, the lubricating oil flows back out from the oil discharge hole on the oil cover 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com