Patents

Literature

260 results about "Steel piston" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

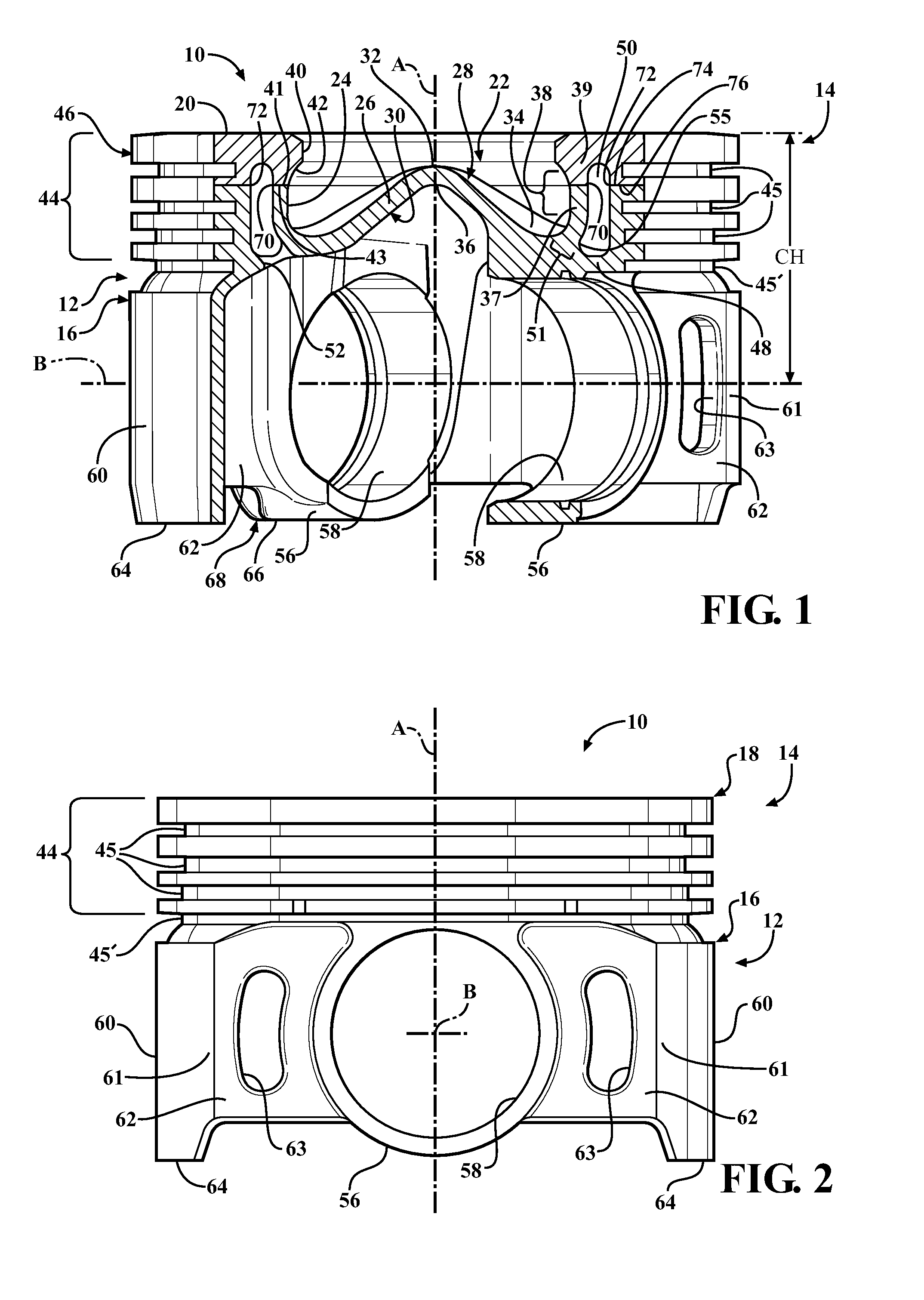

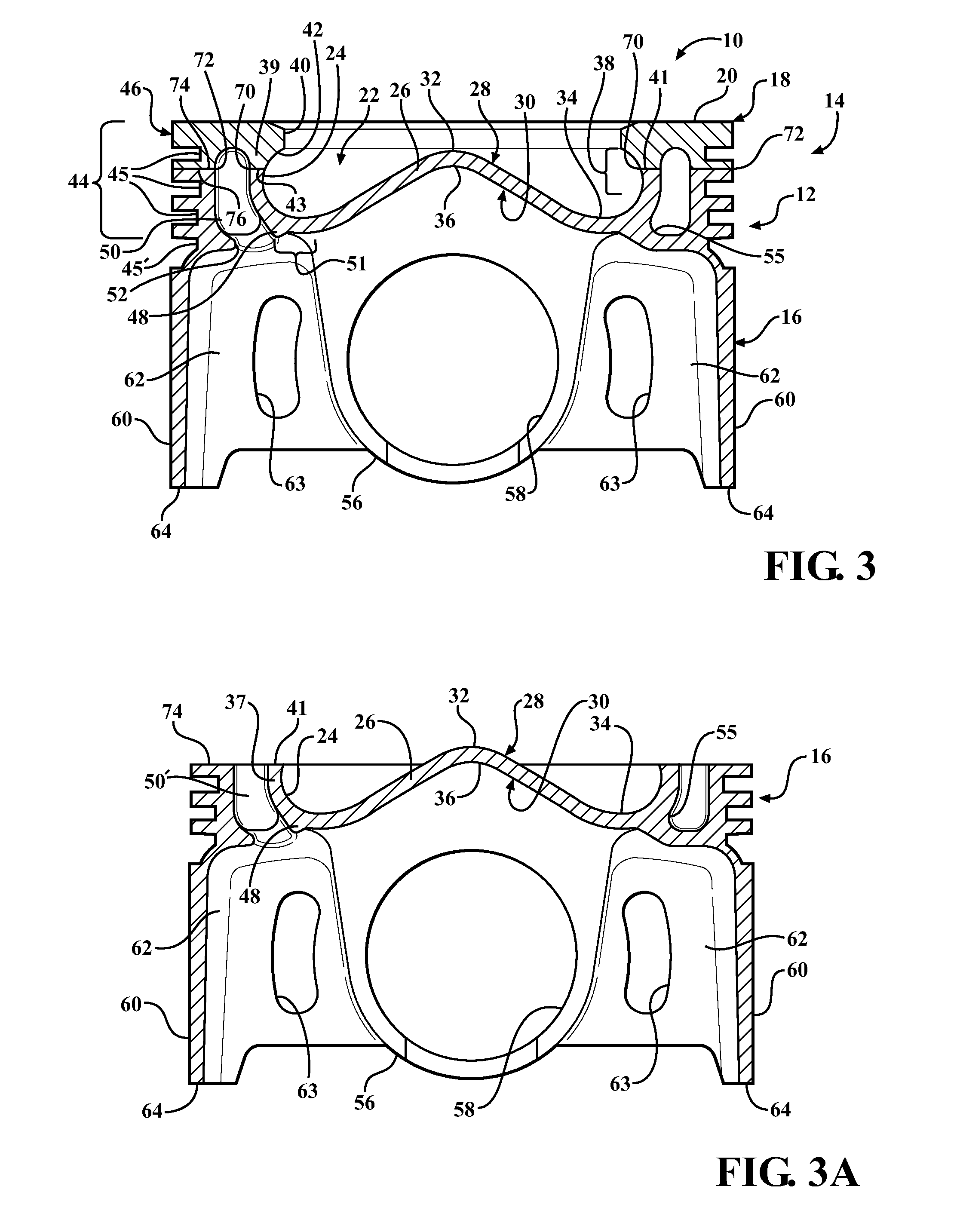

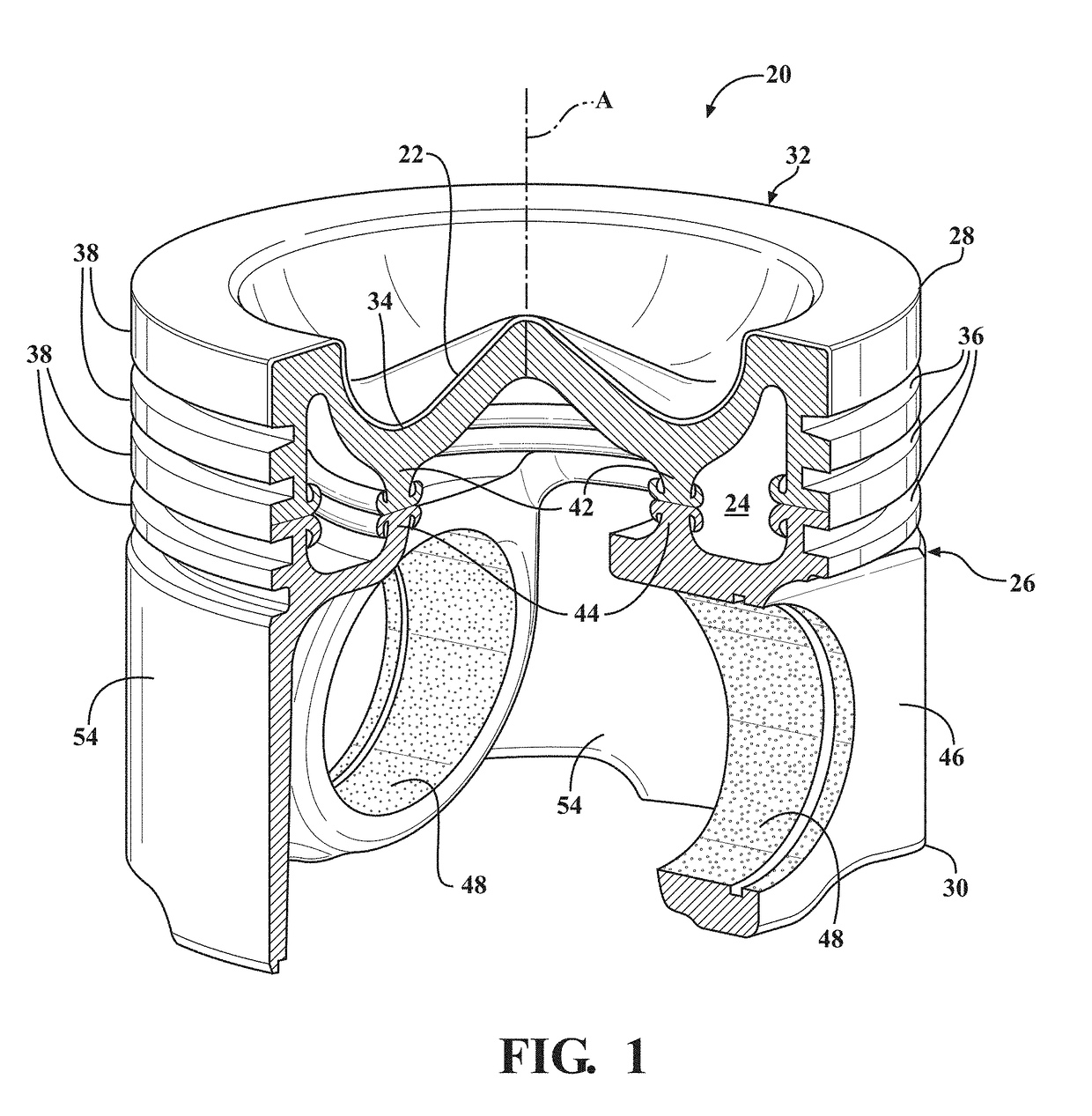

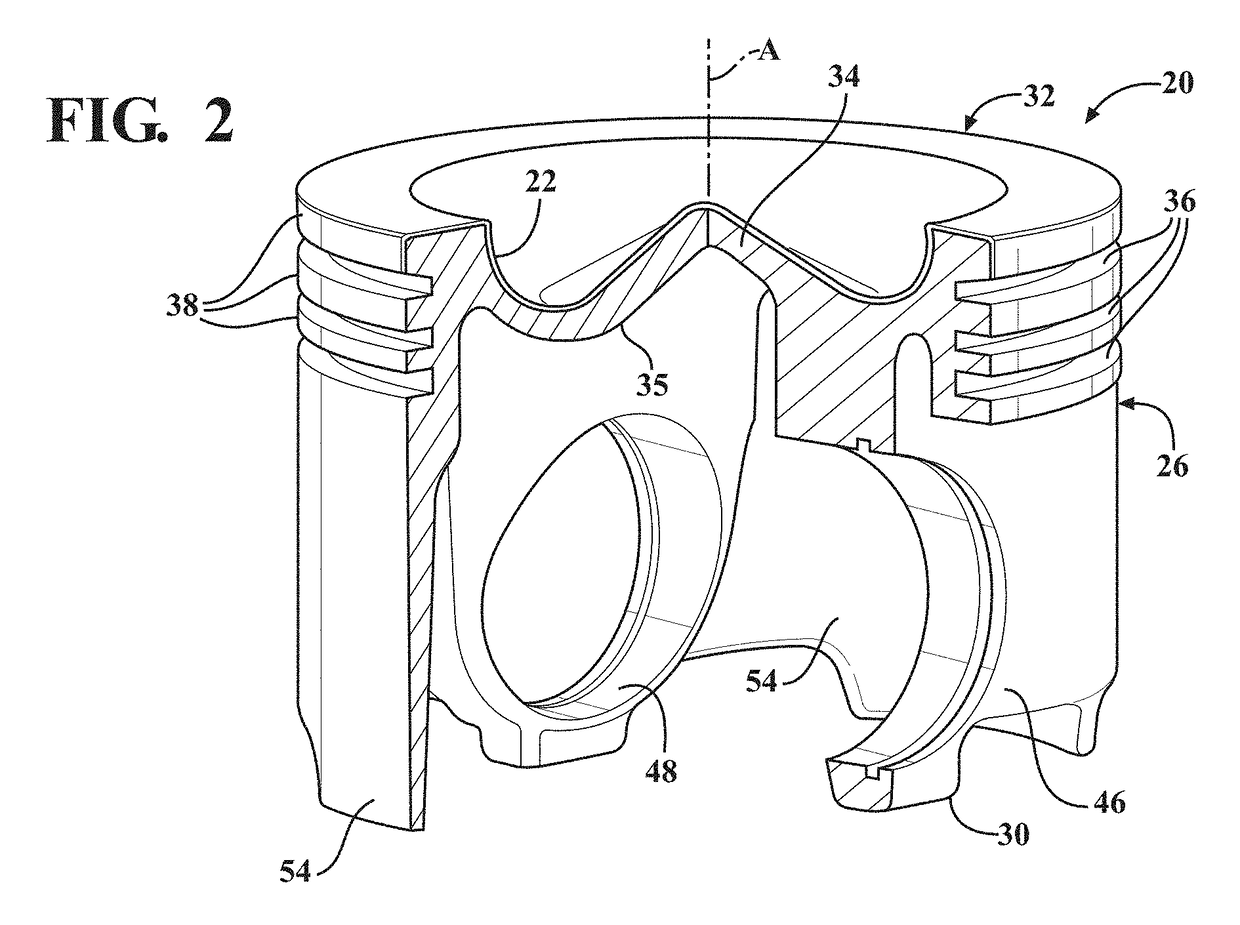

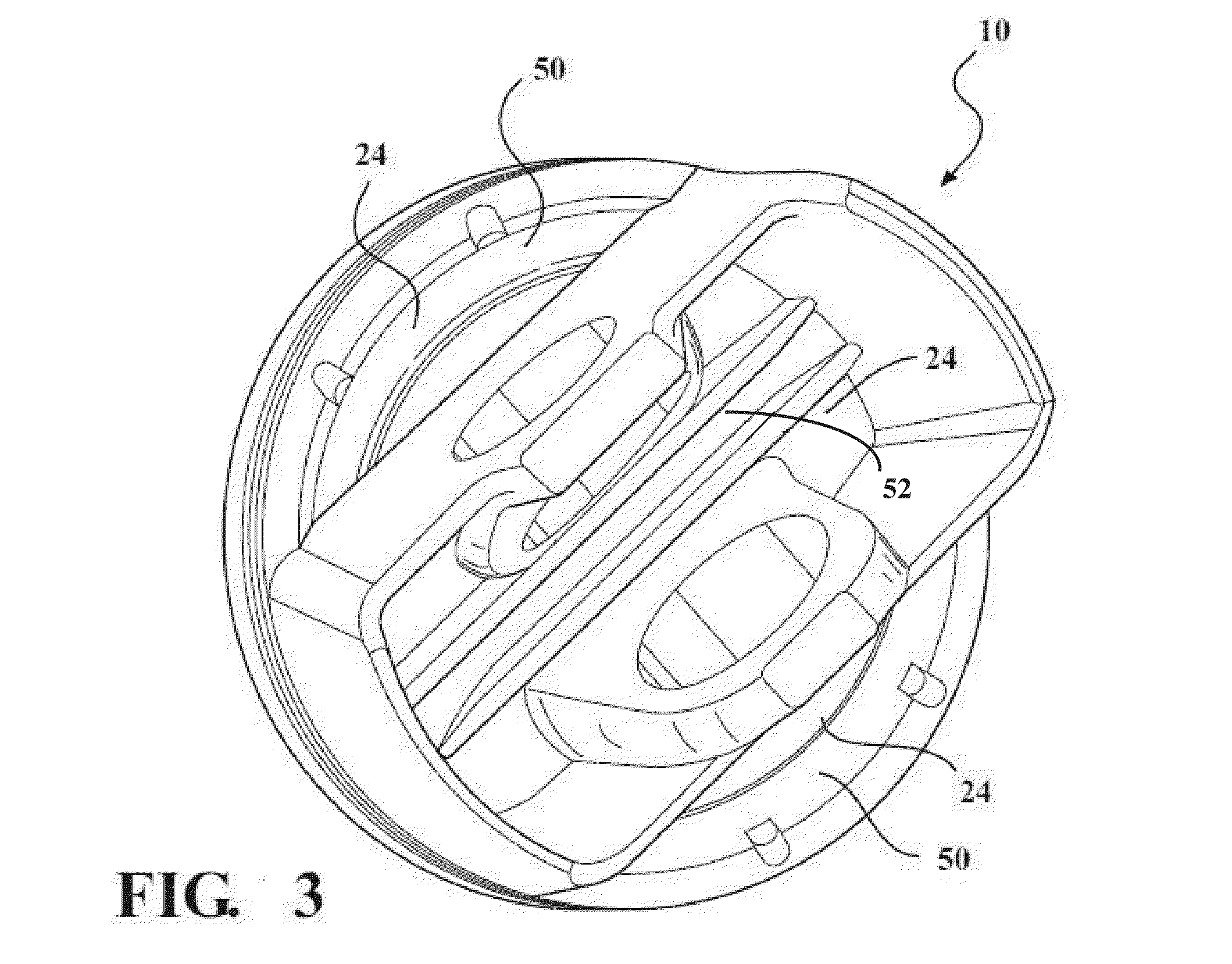

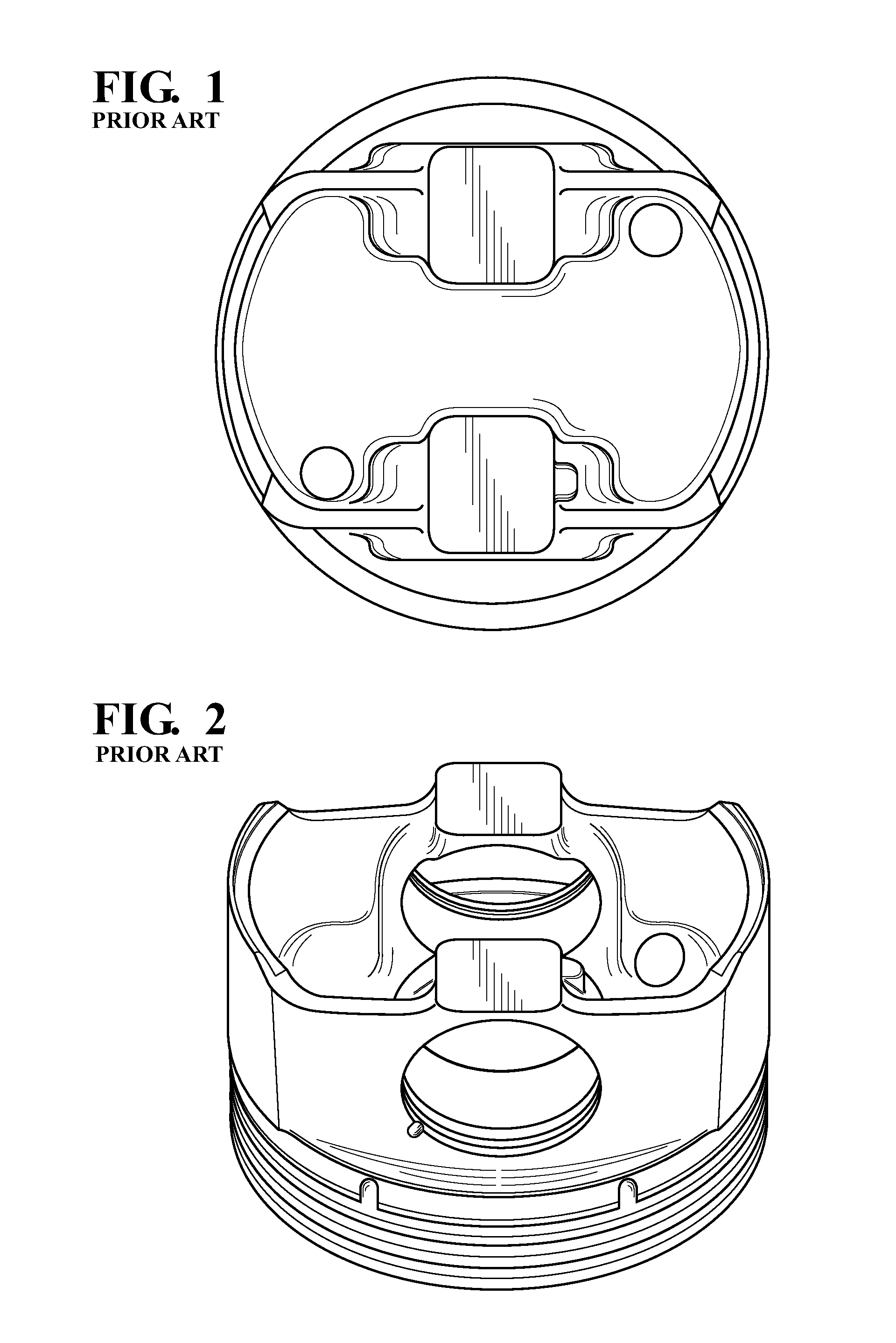

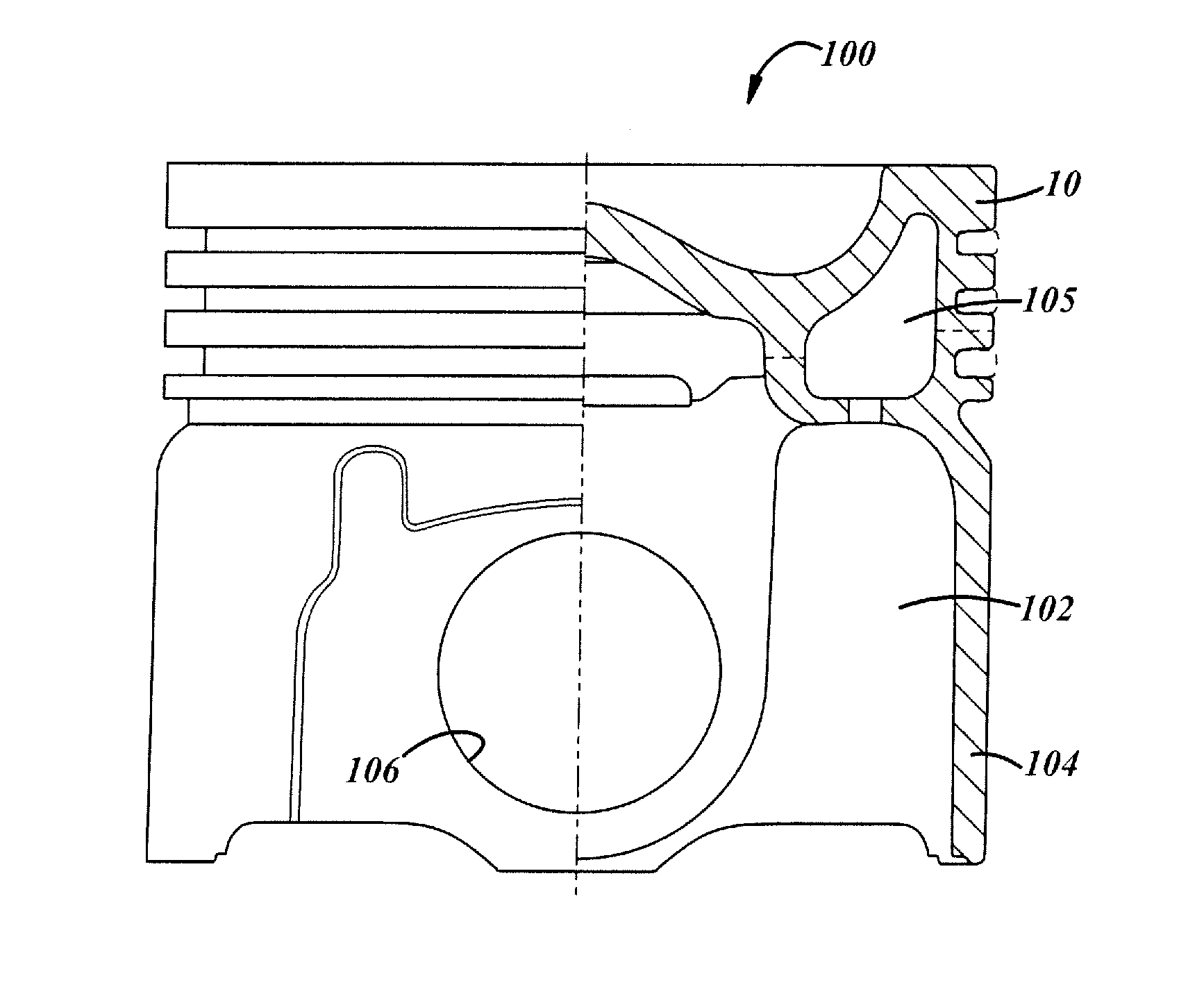

Steel piston with cooling gallery and method of construction thereof

ActiveUS20120037112A1High strengthIncreased durabilityInternal combustion piston enginesPistonsCombustionEngineering

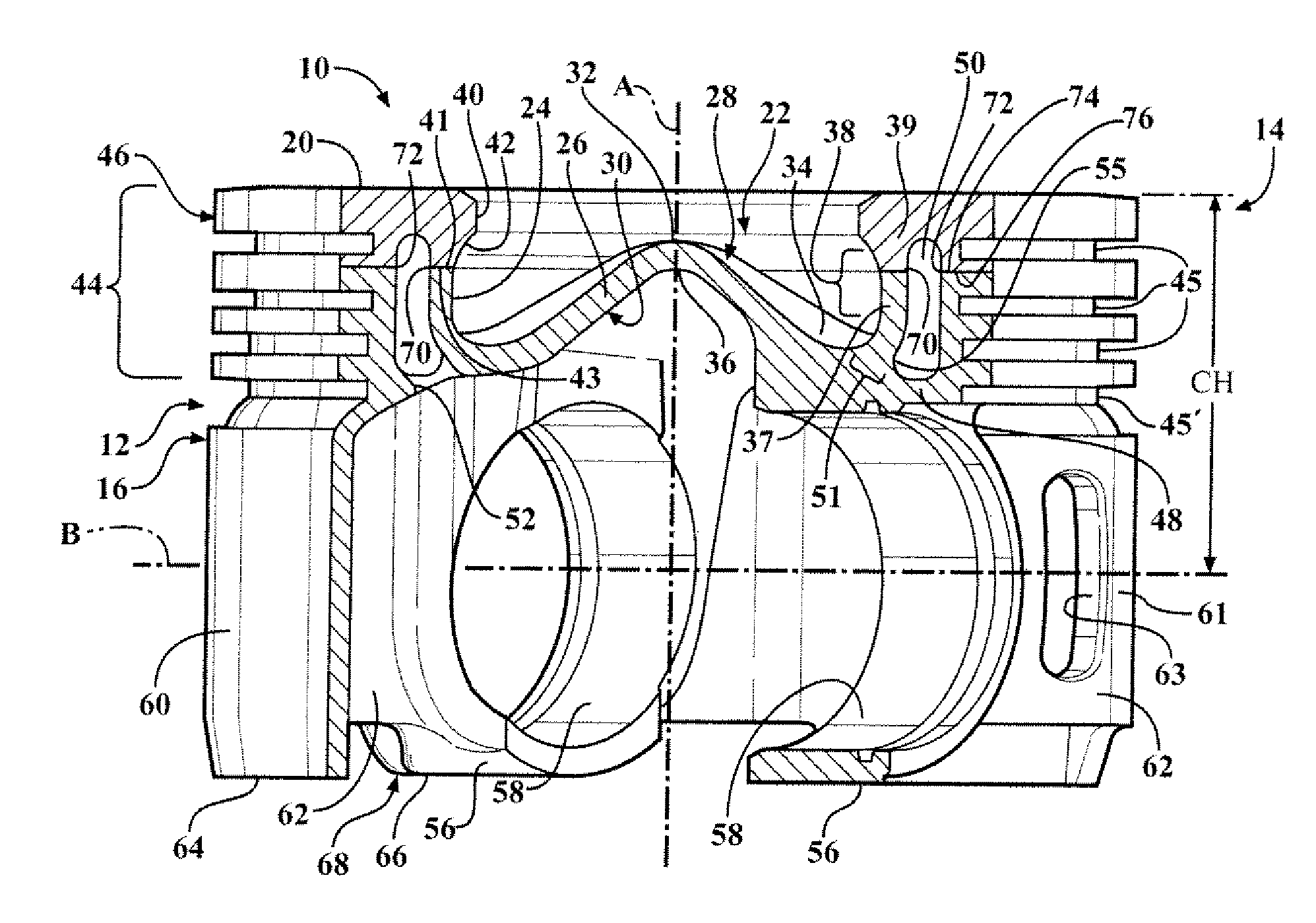

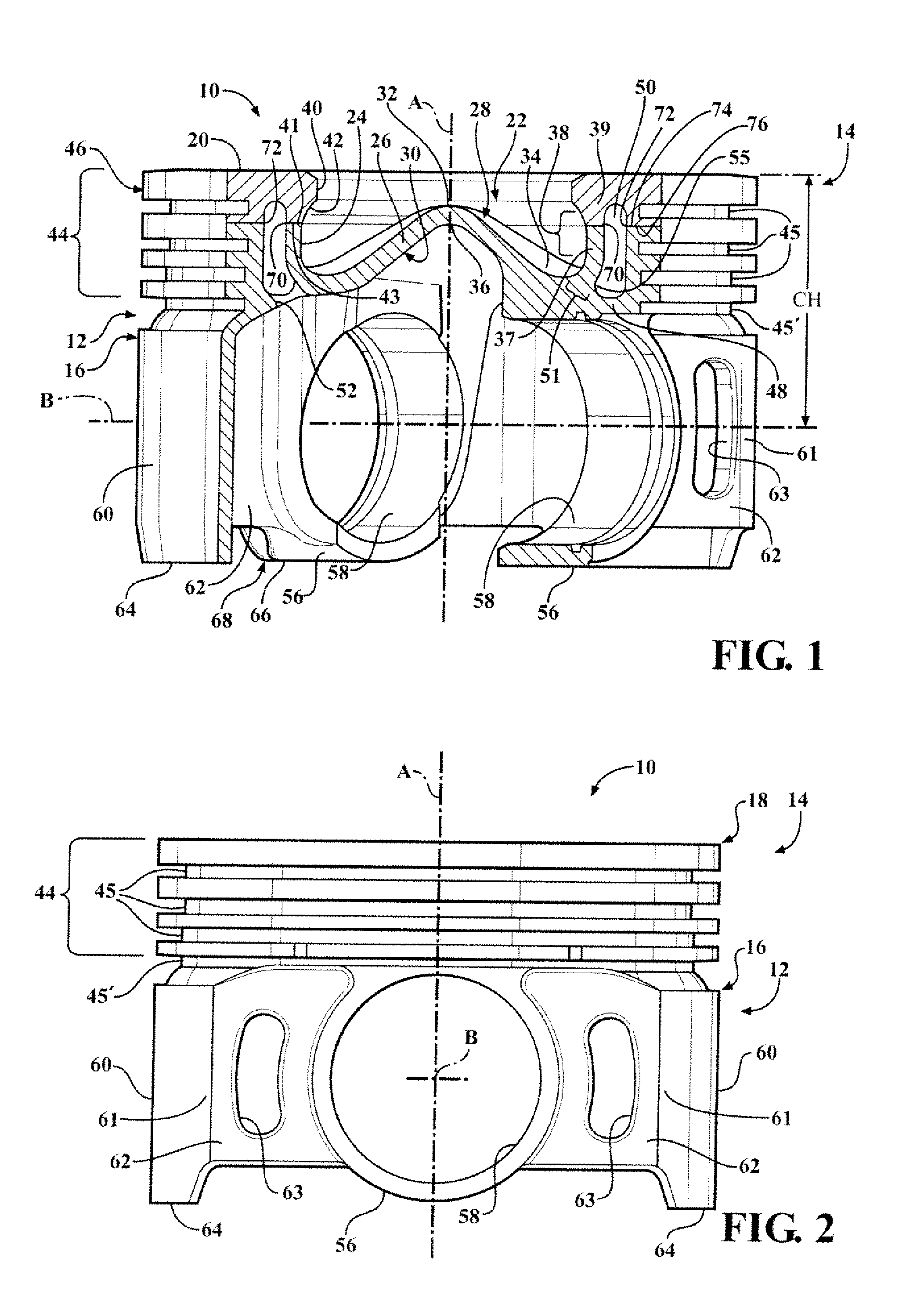

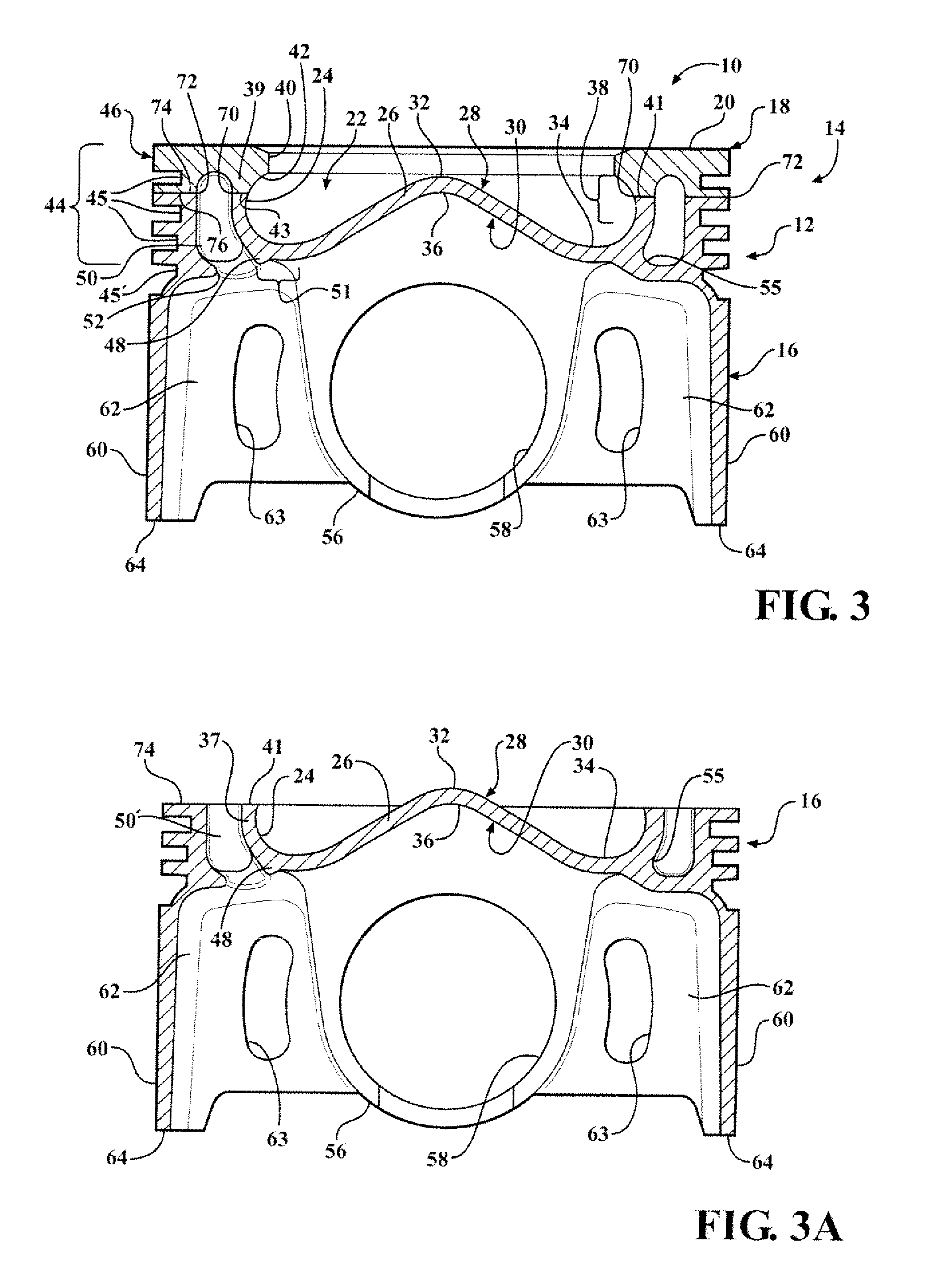

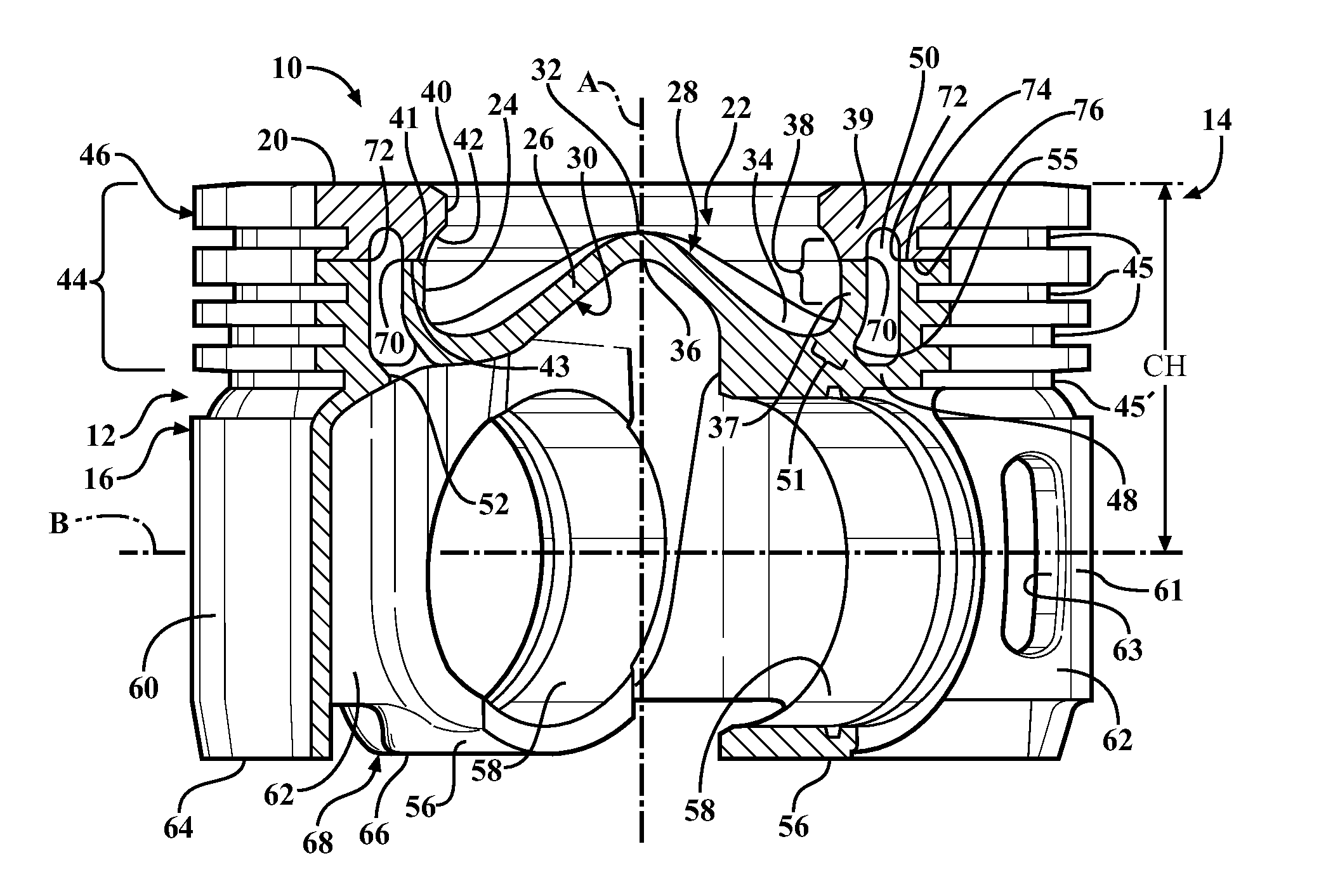

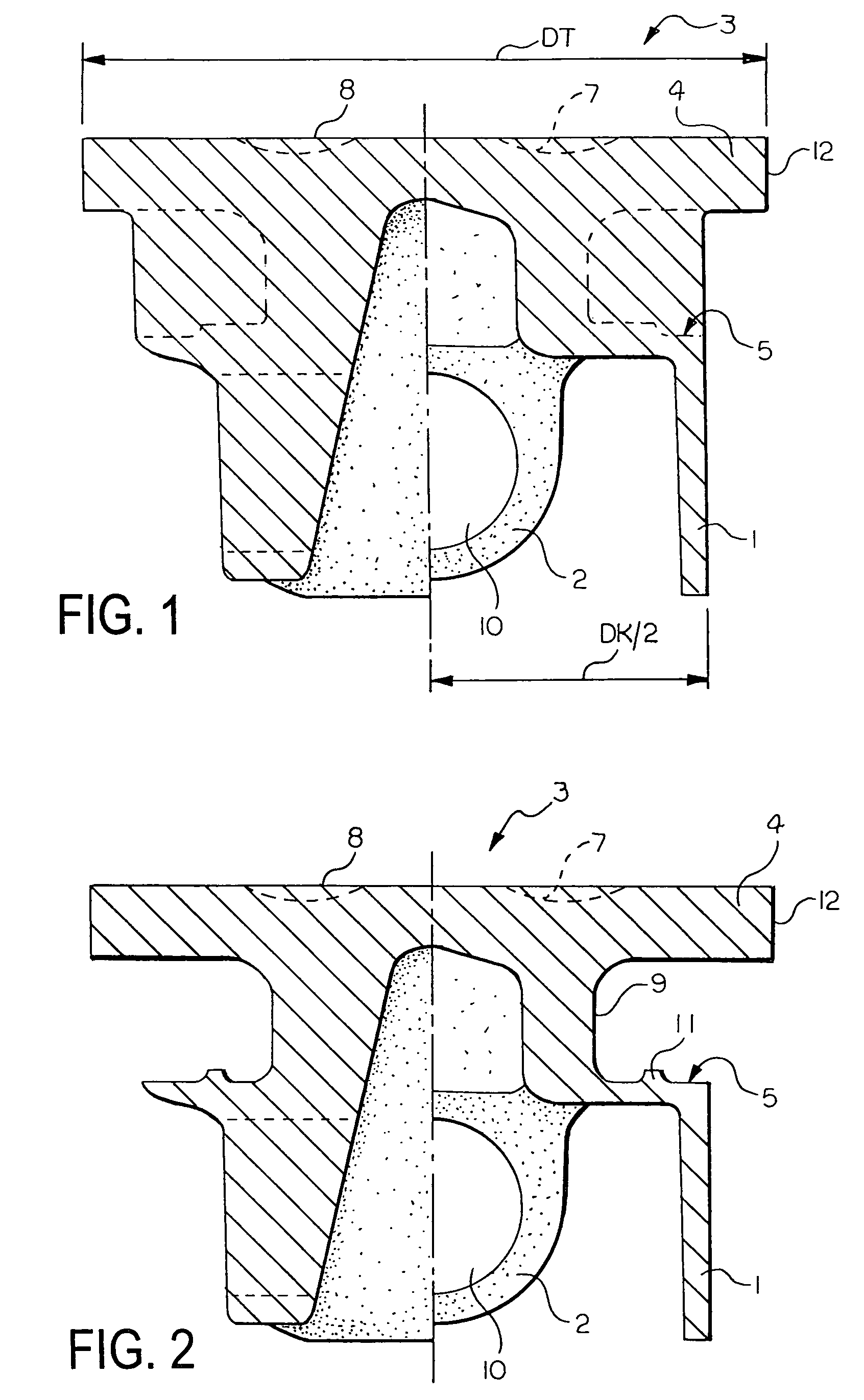

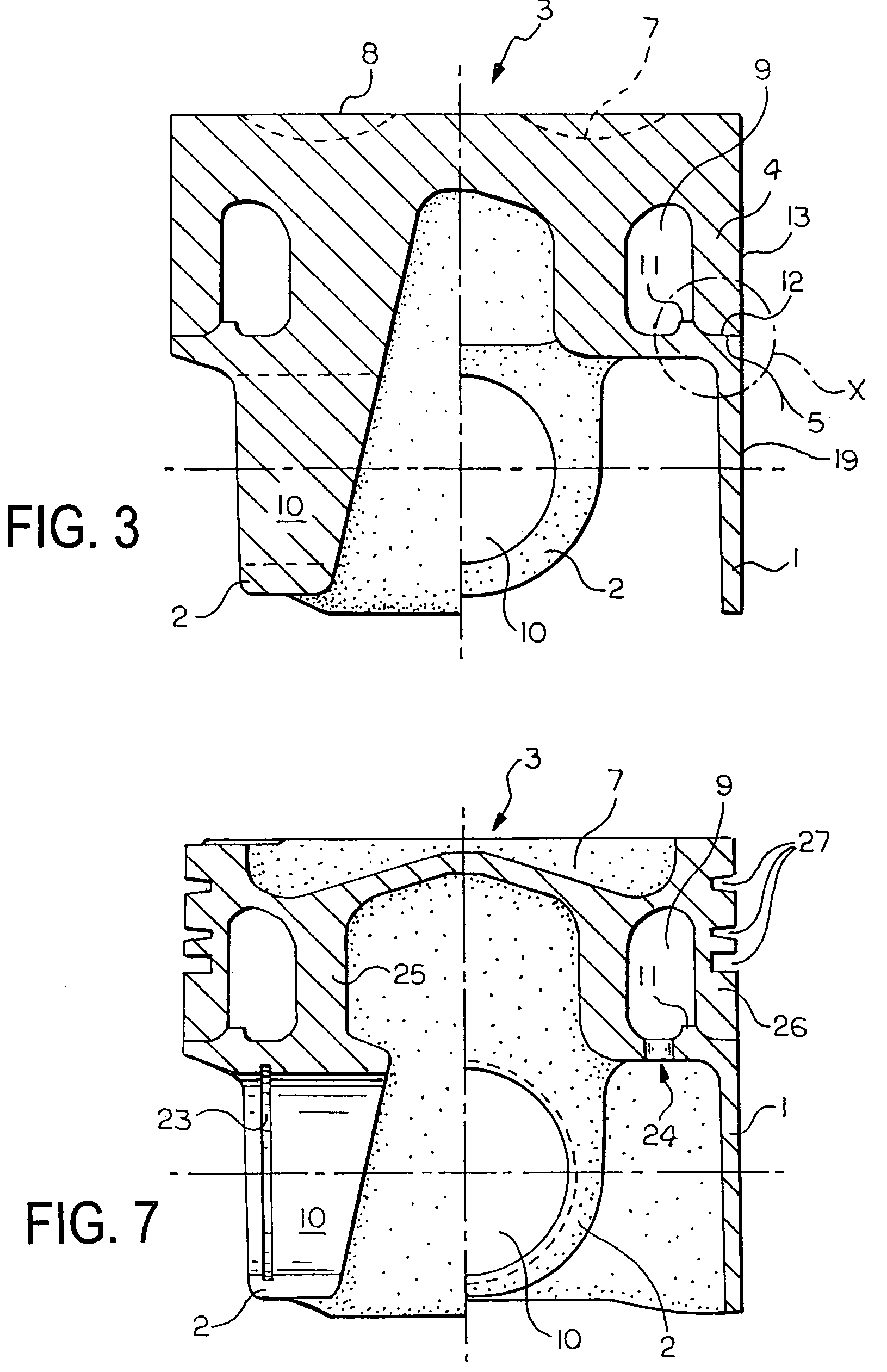

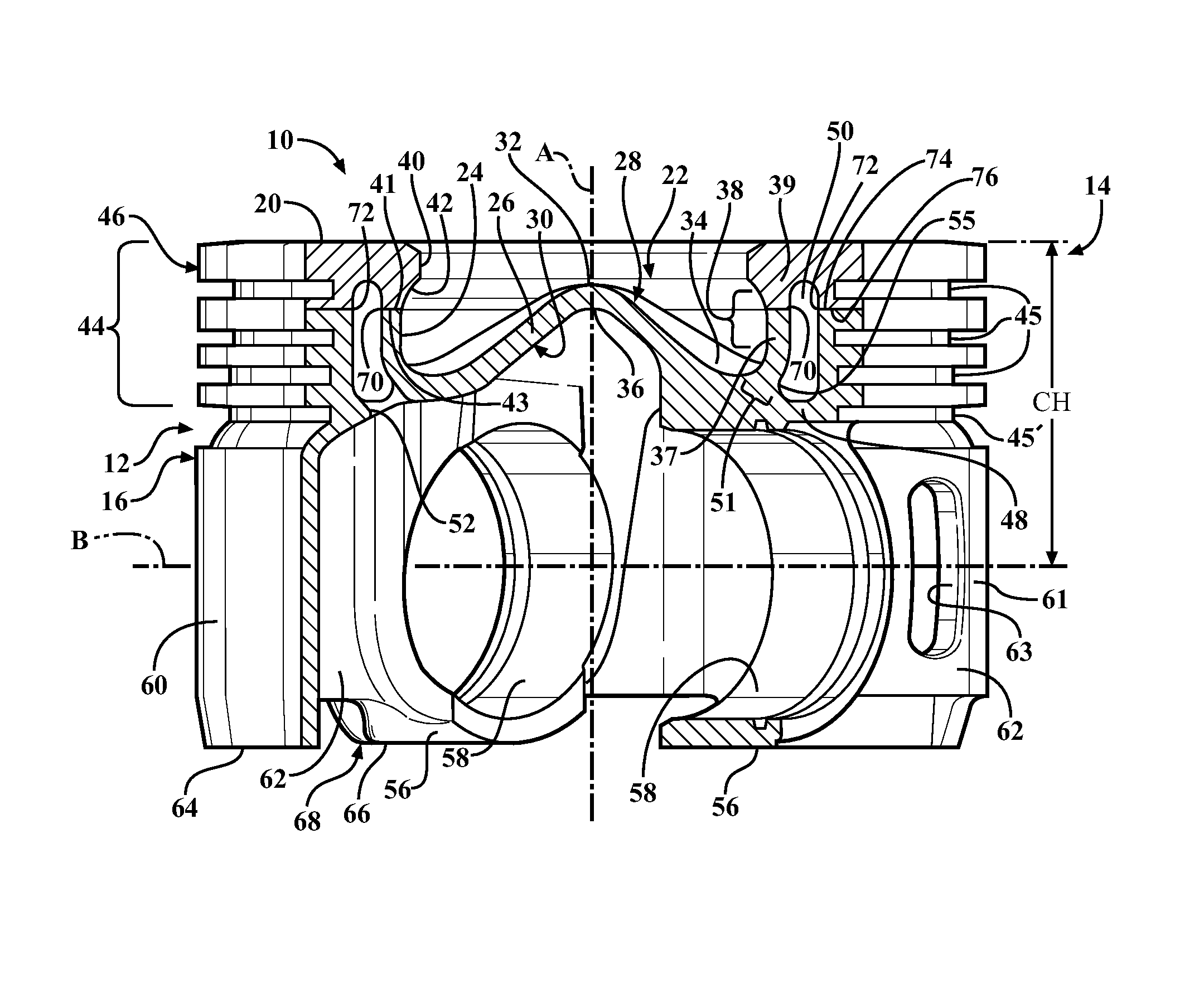

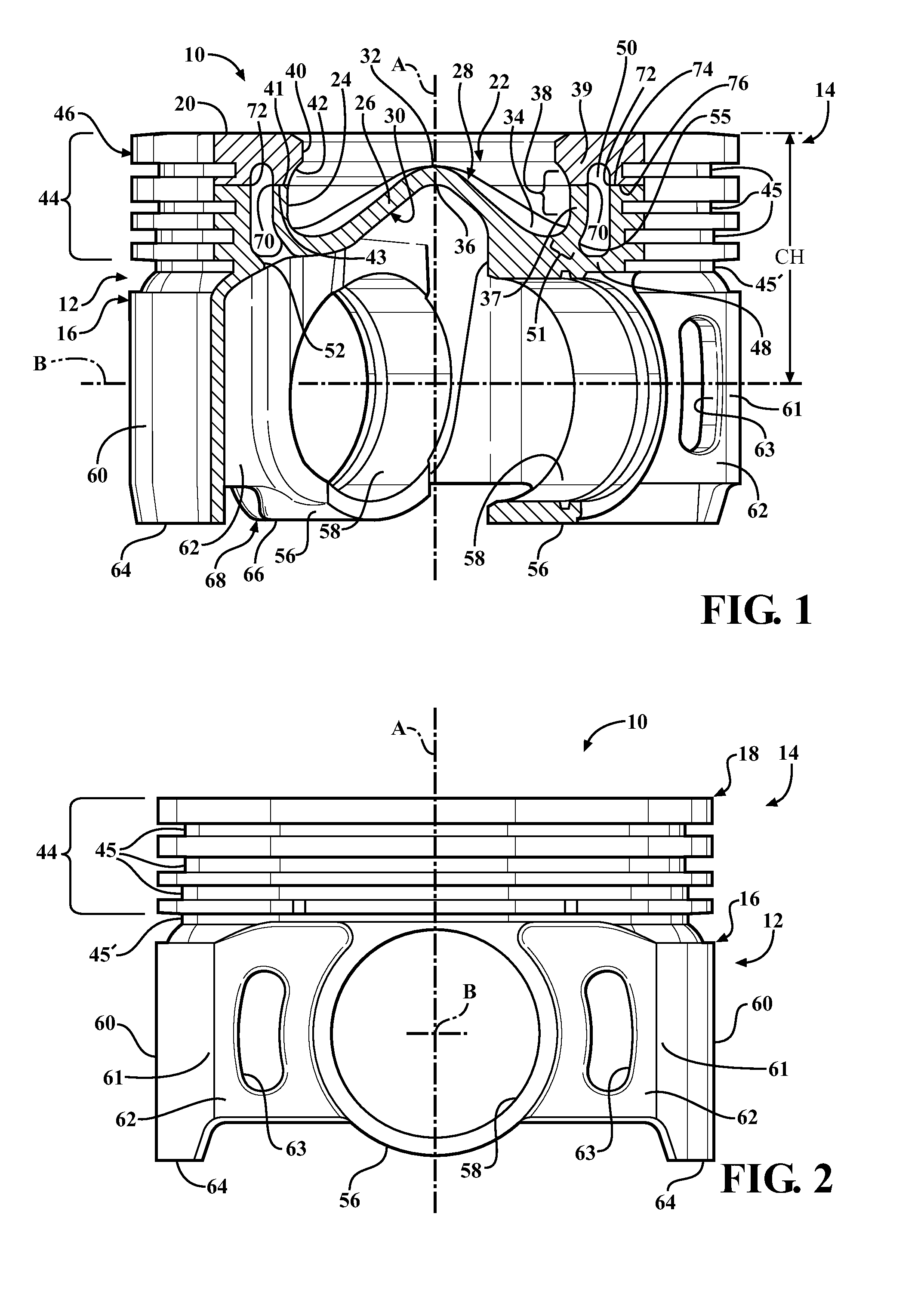

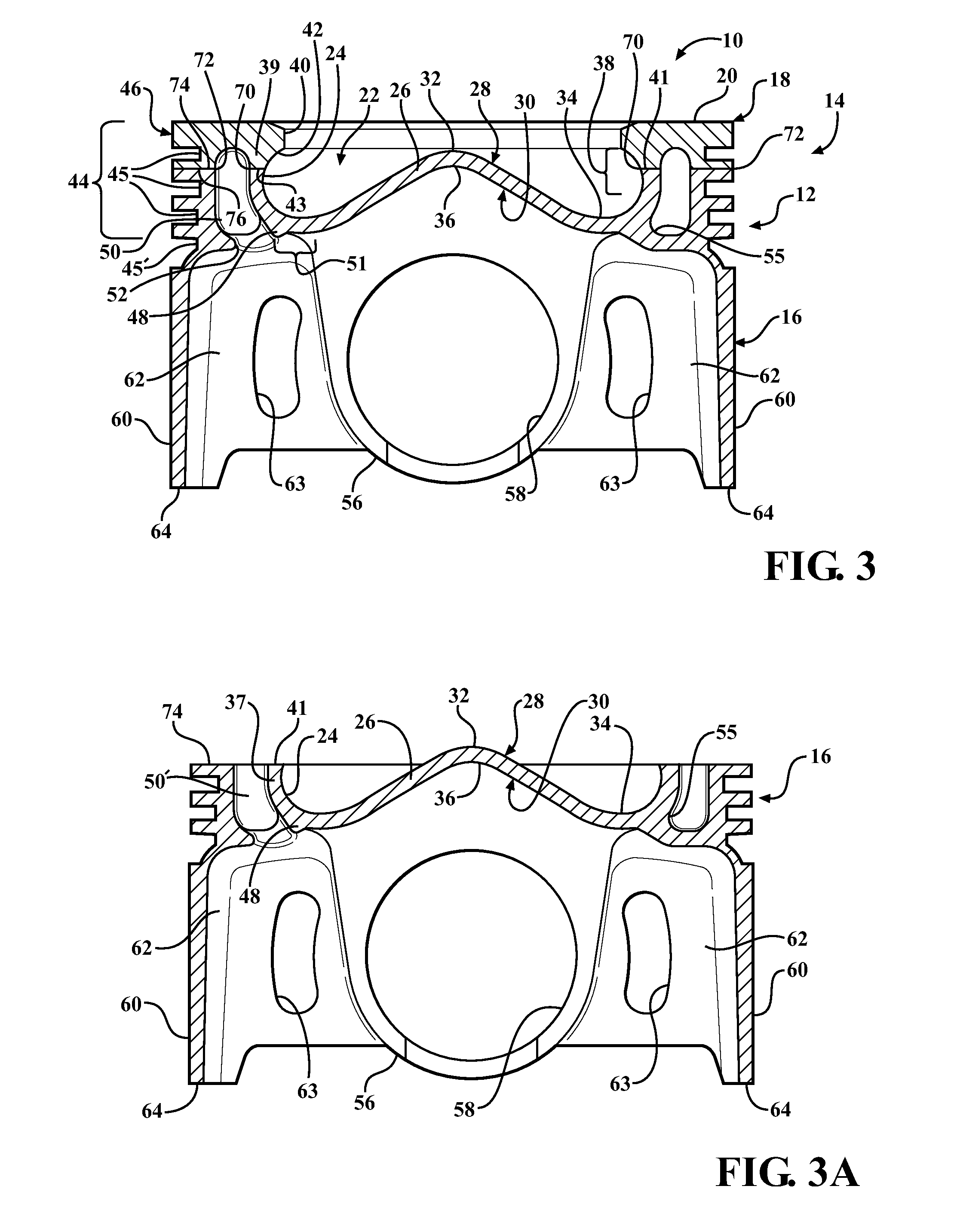

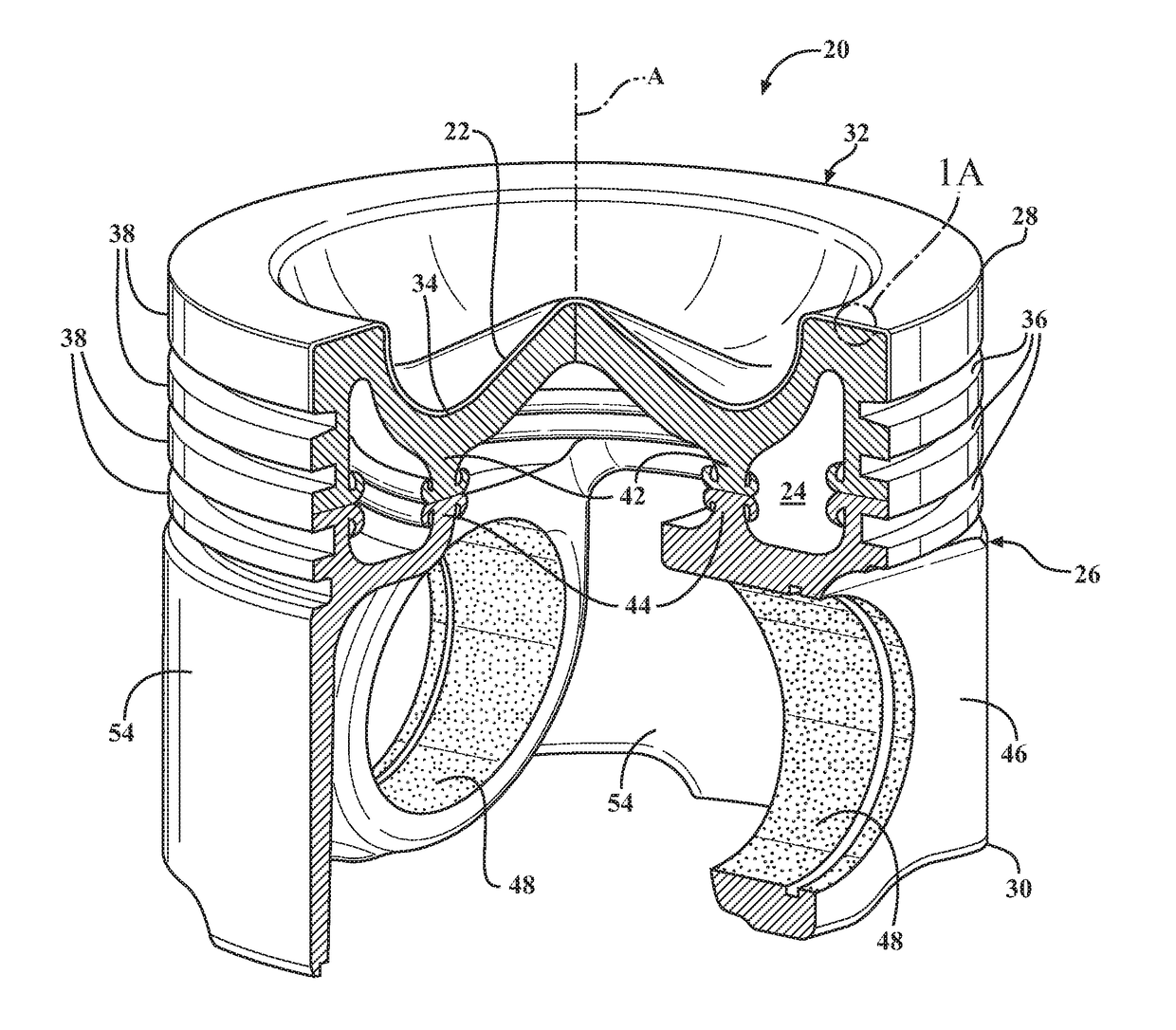

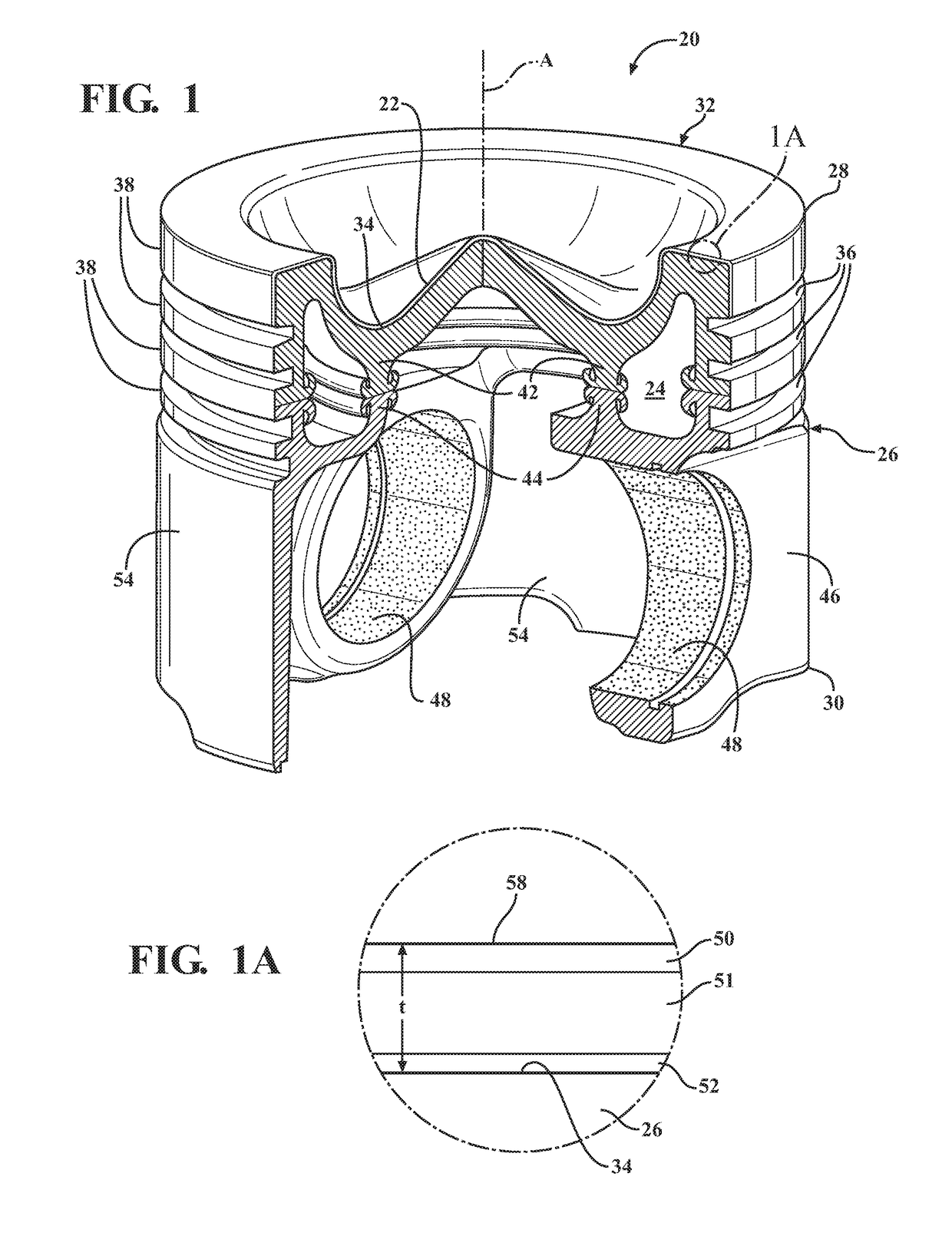

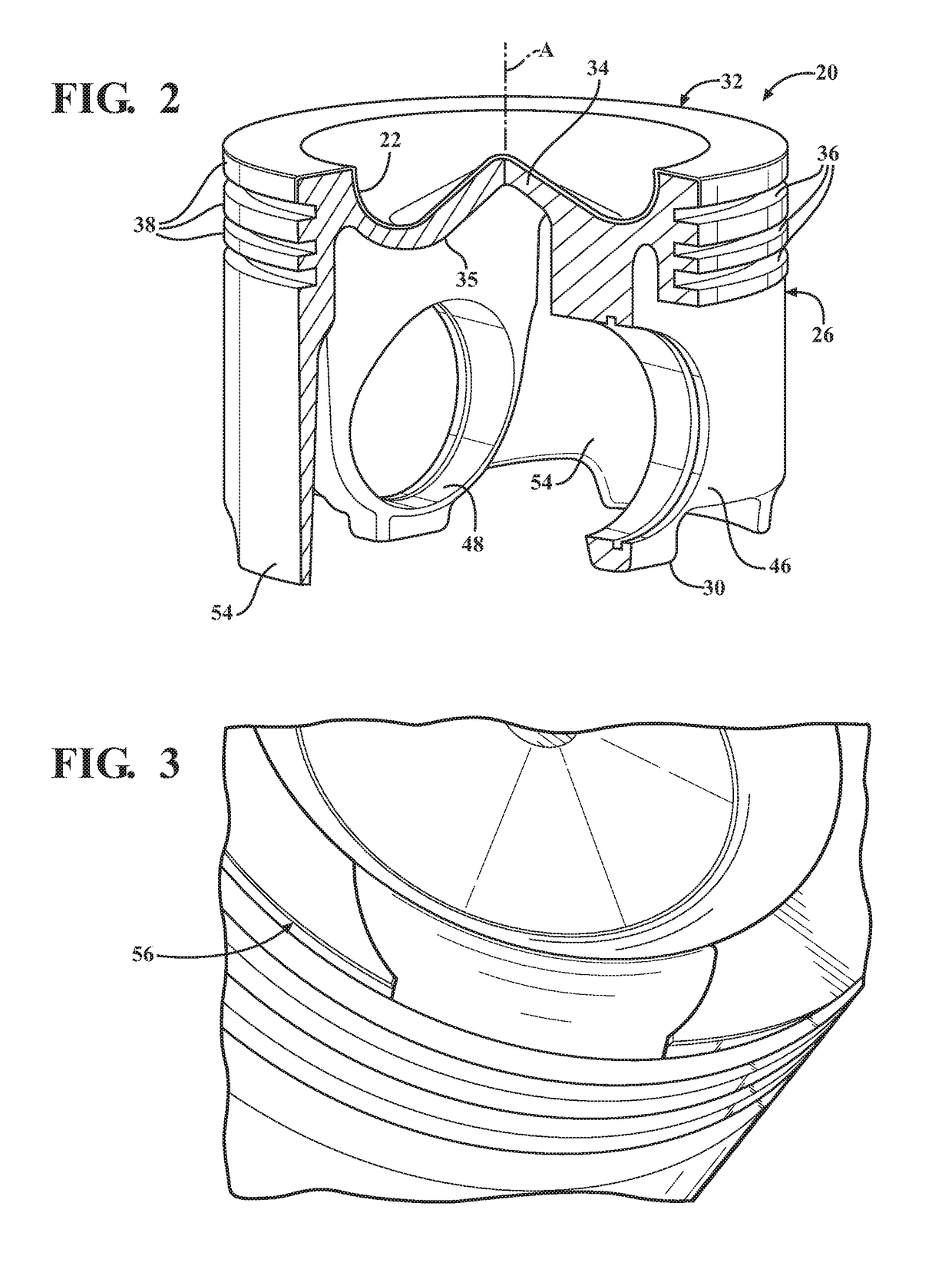

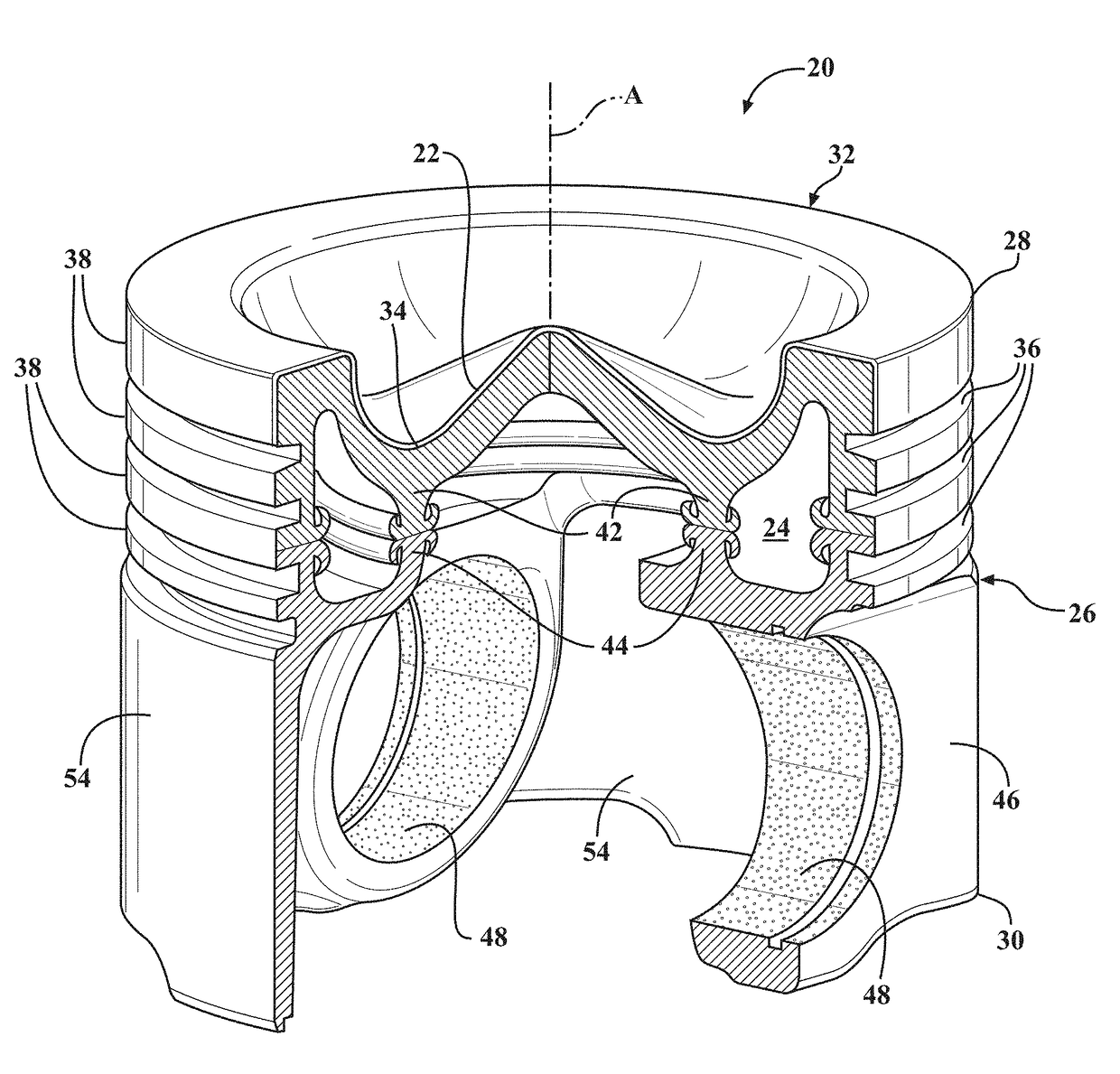

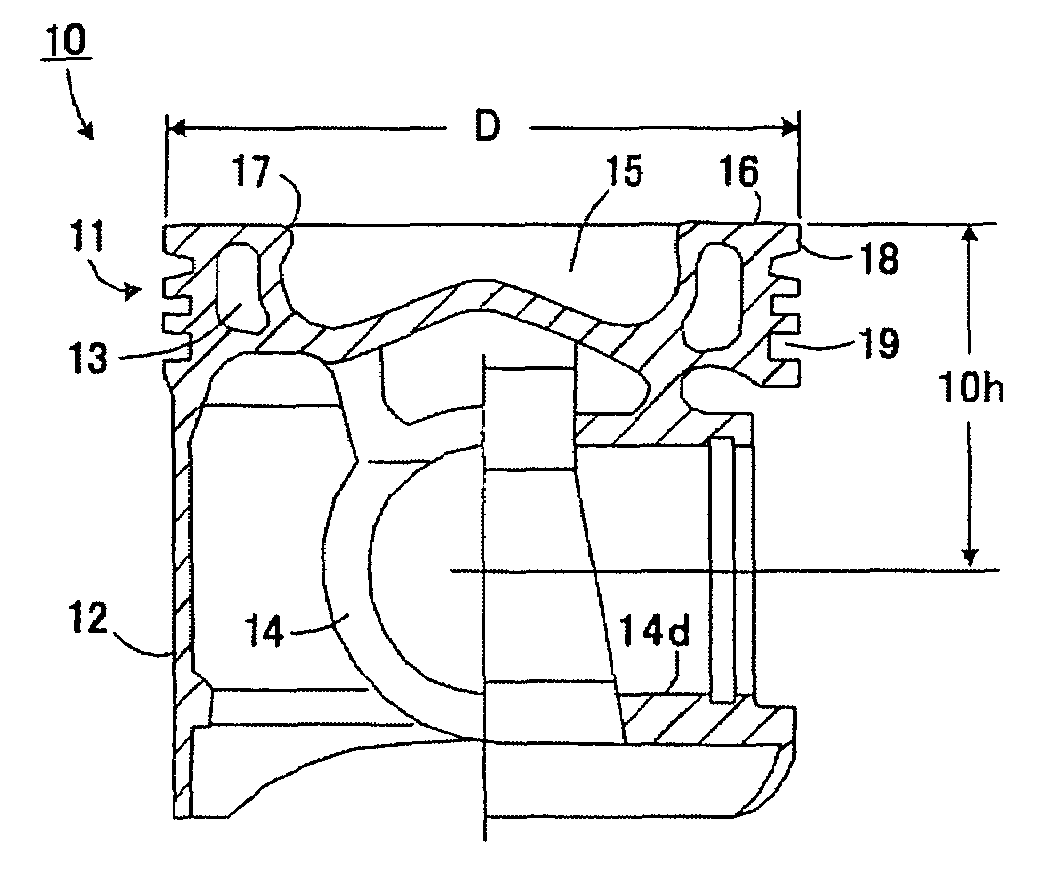

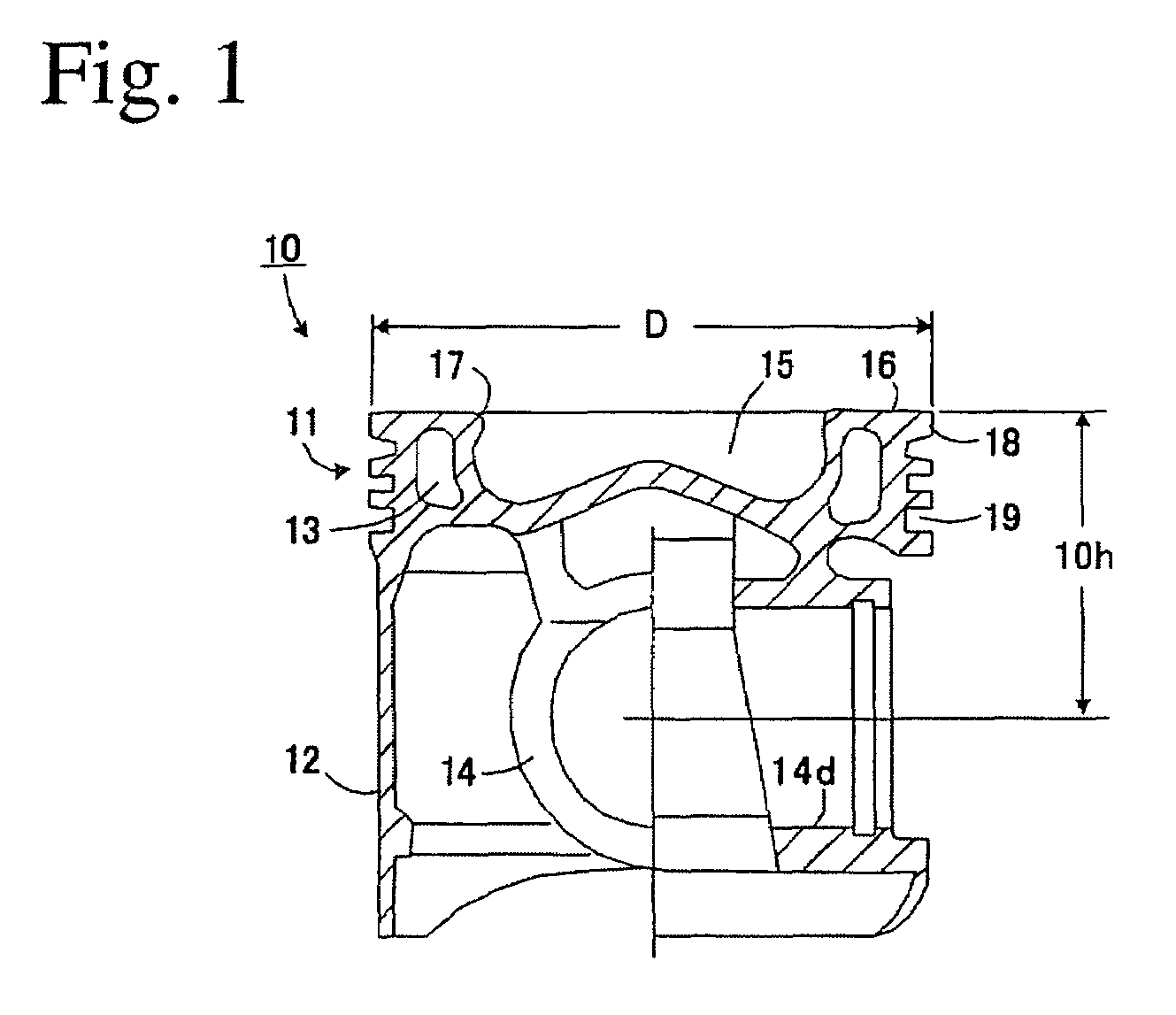

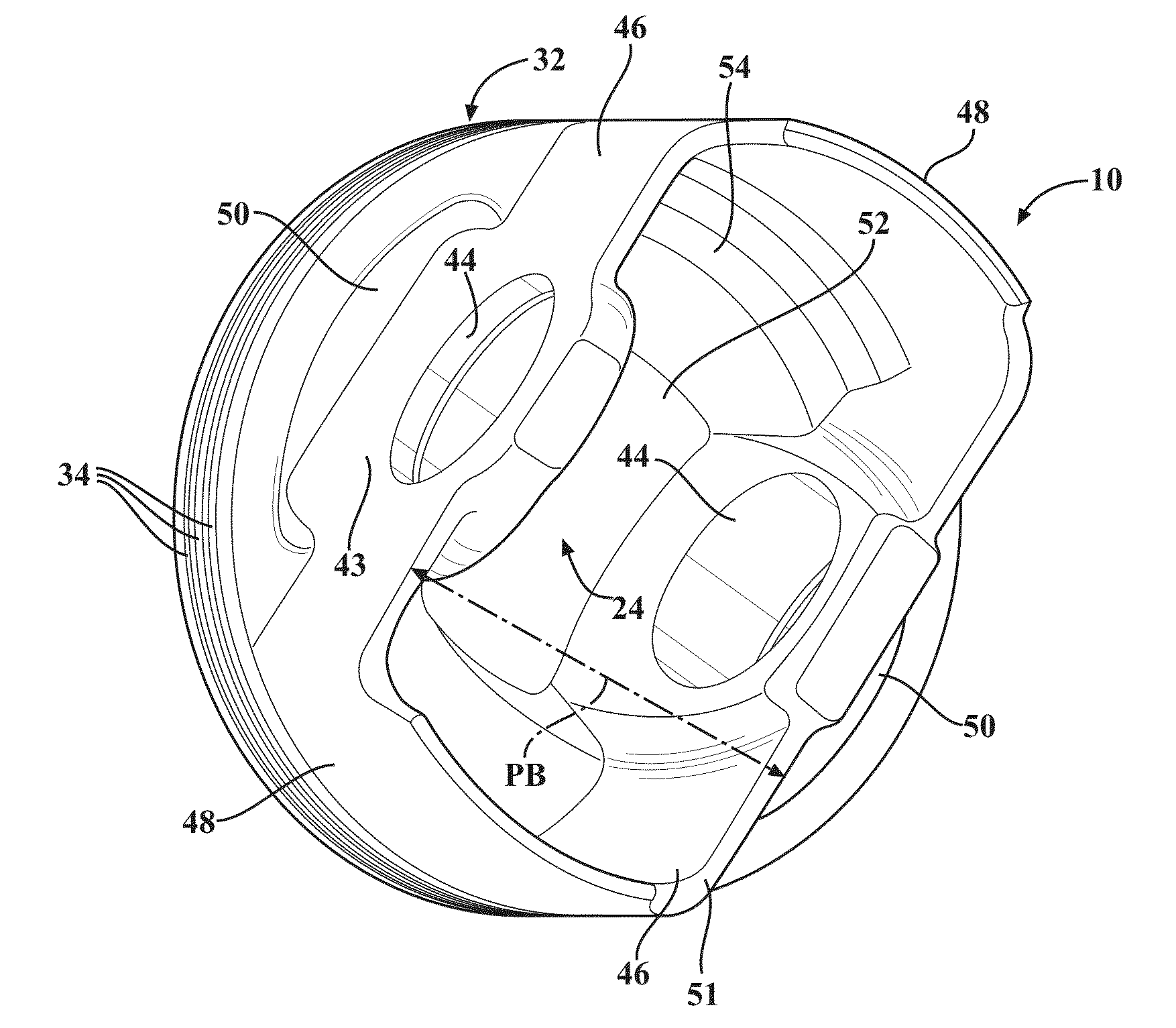

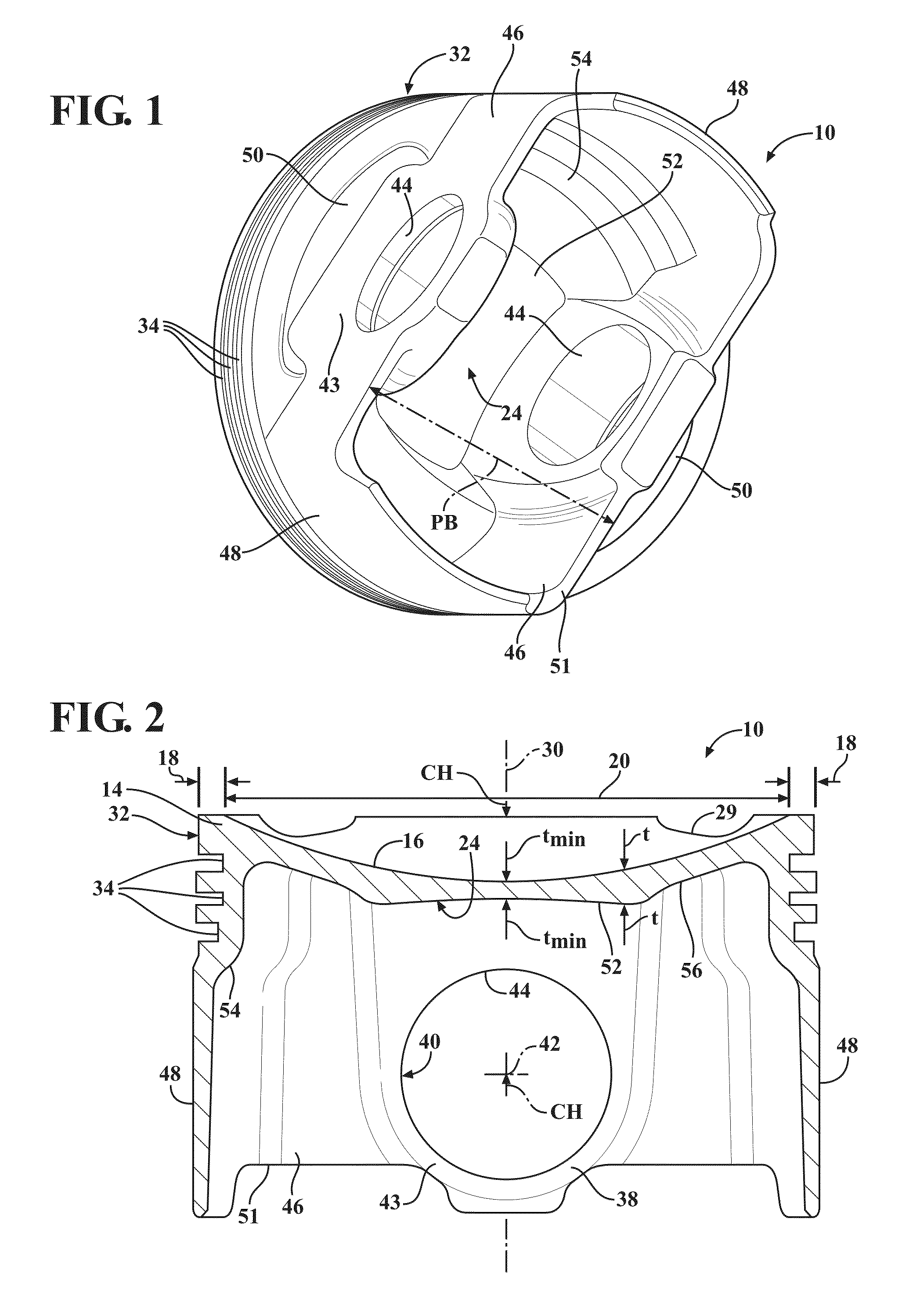

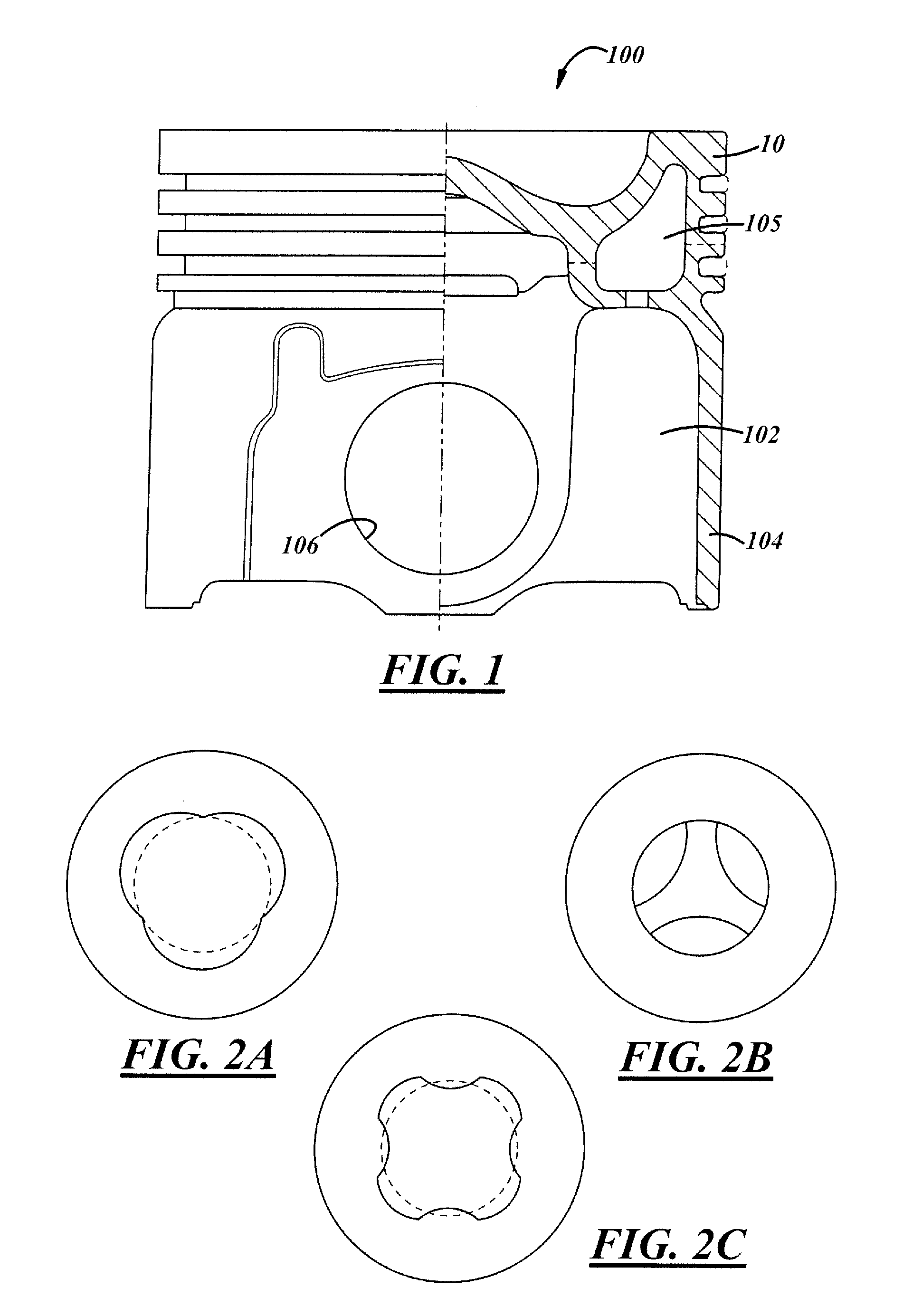

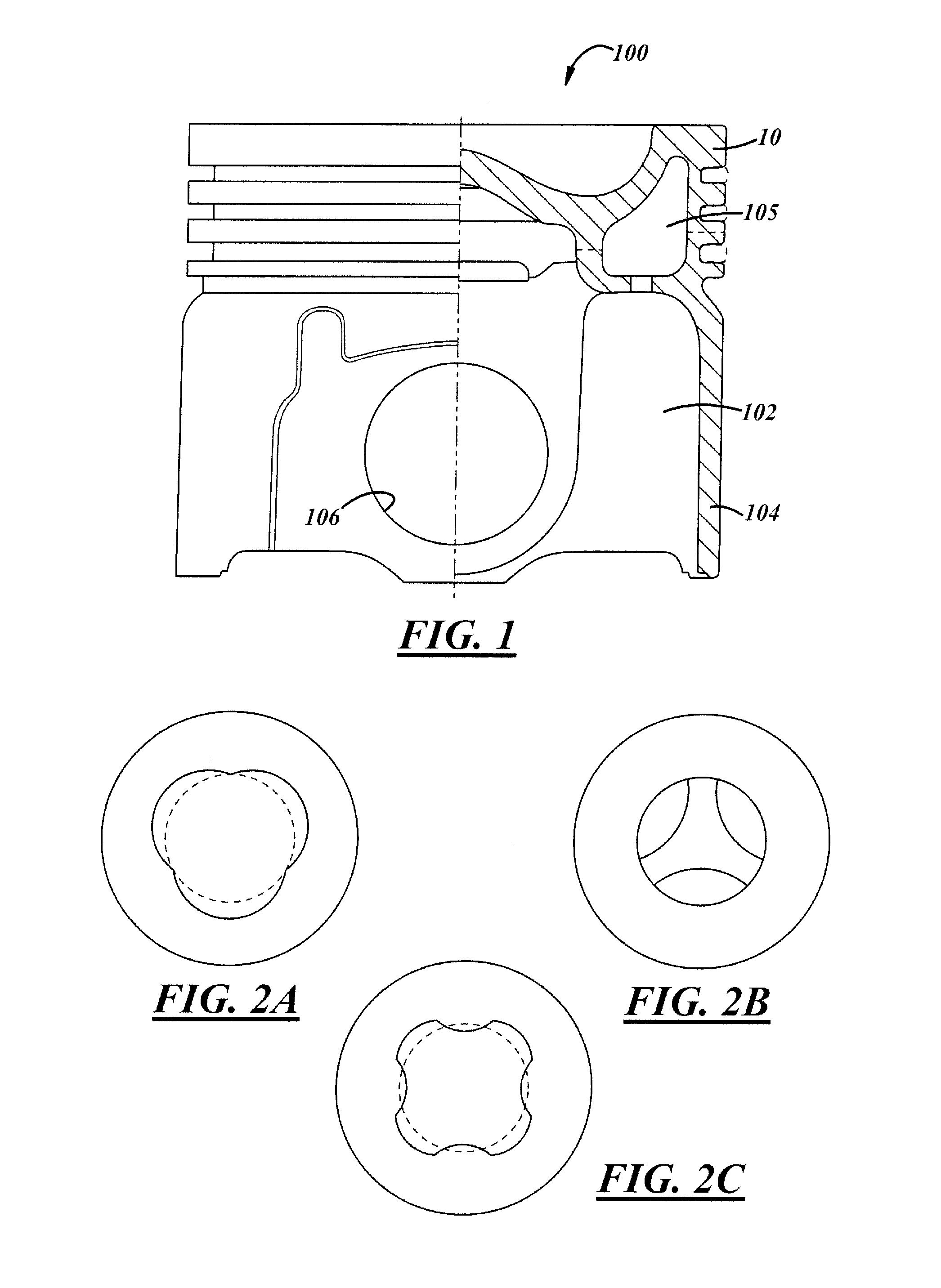

A piston and method of construction is provided. The piston includes a top part fixed to a bottom part. The top part has an uppermost surface with annular inner and outer upper joining surfaces depending therefrom. The bottom part has a pair of pin bosses with pin bores aligned with one another along a pin bore axis; a pair of upwardly extending annular inner and outer lower joining surfaces and a combustion bowl wall. Inner and outer weld joints fix the inner and outer upper and lower joining surfaces to one another. An annular cooling gallery is formed laterally between the upper and lower joining surfaces. The inner weld joint joining the top part to the bottom part is located within the combustion bowl wall and configured to minimized the compression height of the piston.

Owner:TENNECO INC

Steel piston with cooling gallery and method of construction thereof

ActiveUS20110107997A1High strengthIncreased durabilityValve arrangementsMachines/enginesCombustionEngineering

A piston and method of construction is provided. The piston includes a top part fixed to a bottom part. The top part has an uppermost surface with annular inner and outer upper joining surfaces depending therefrom. The bottom part has a pair of pin bosses with pin bores aligned with one another along a pin bore axis; a pair of upwardly extending annular inner and outer lower joining surfaces and a combustion bowl wall. Inner and outer weld joints fix the inner and outer upper and lower joining surfaces to one another. An annular cooling gallery is formed laterally between the upper and lower joining surfaces. The inner weld joint joining the top part to the bottom part is located within the combustion bowl wall and configured to minimized the compression height of the piston.

Owner:TENNECO

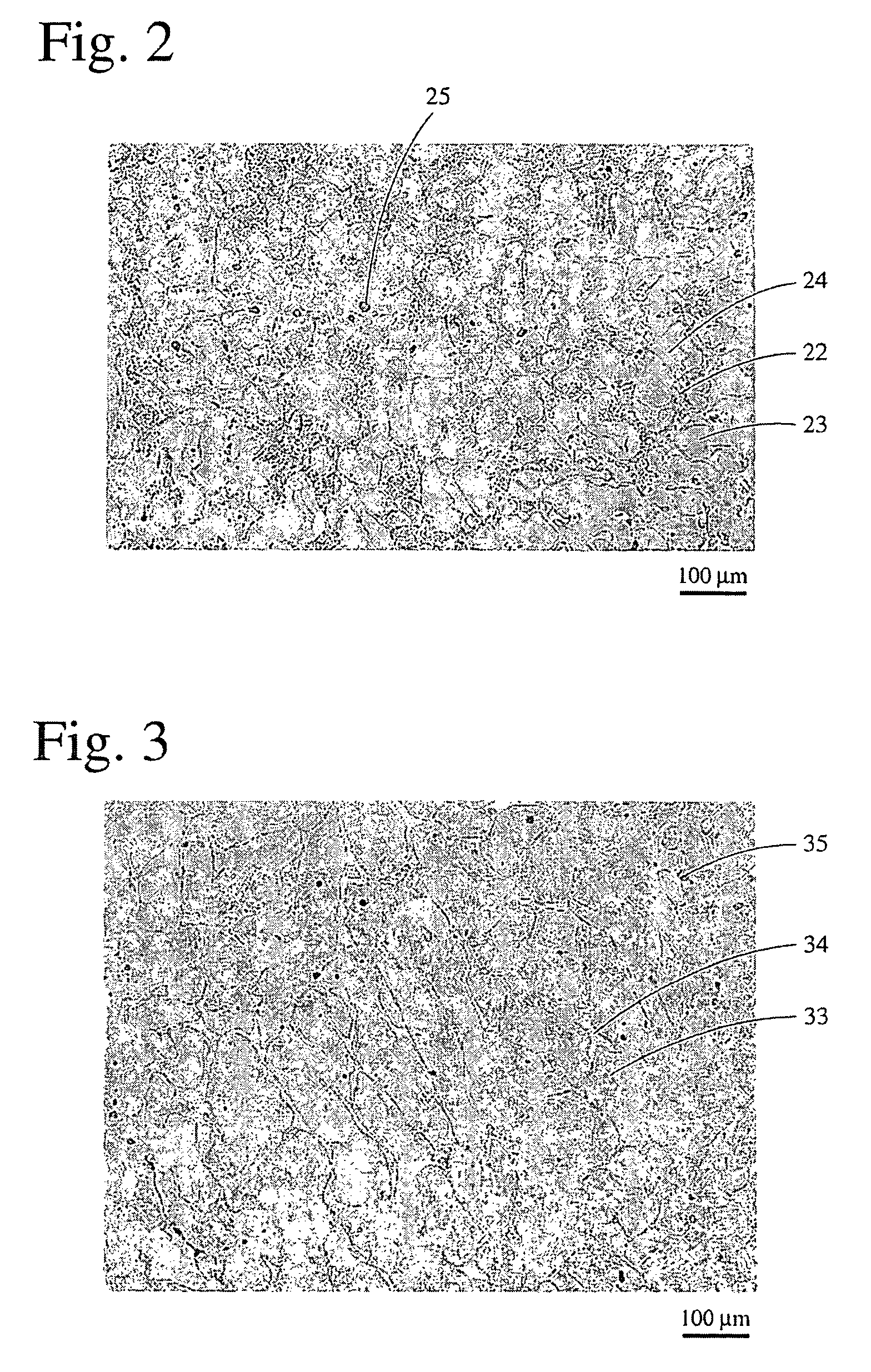

Internal engine piston and its production method

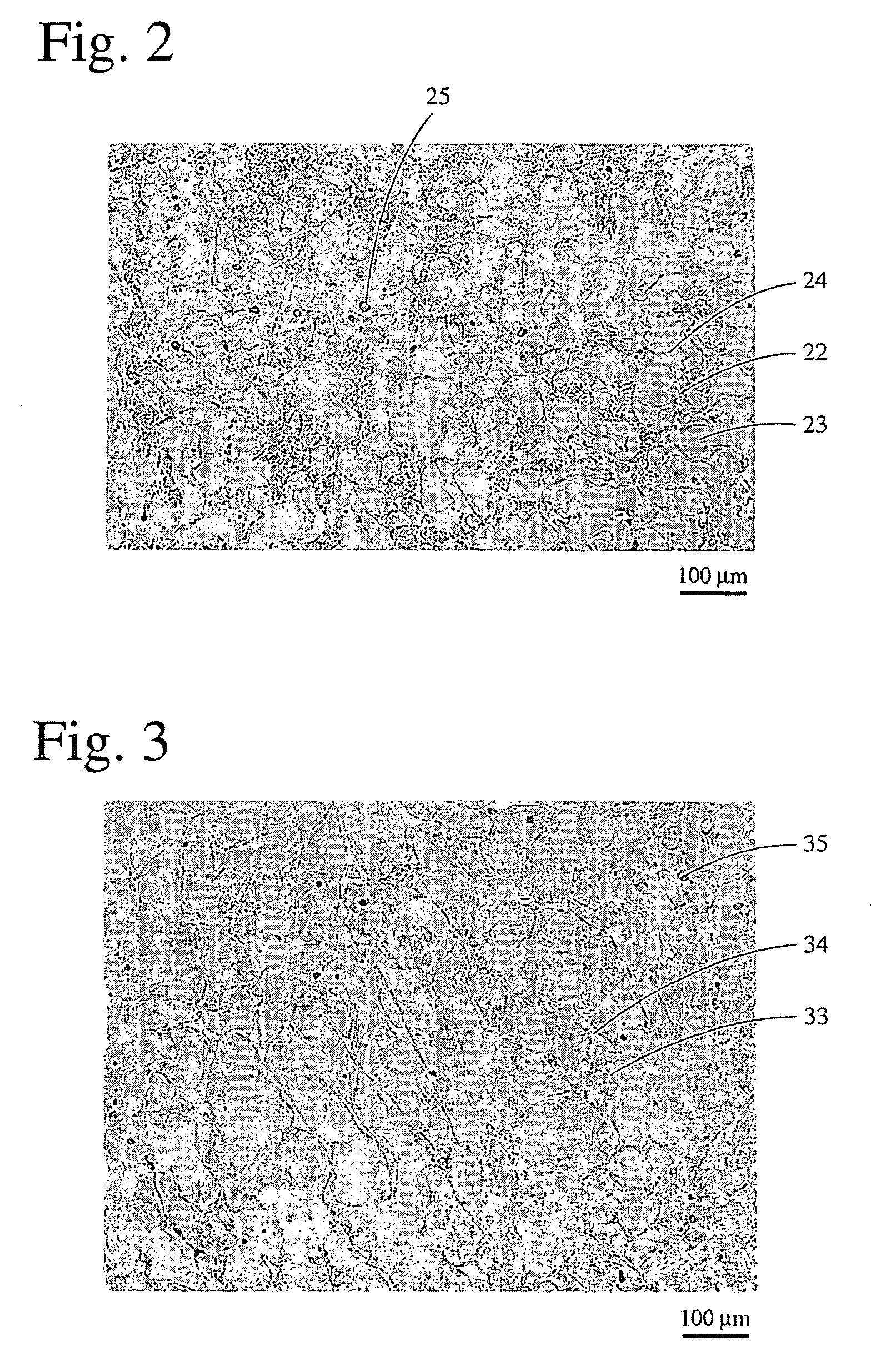

ActiveUS20060191508A1Inhibit adhesionImproved seizure resistanceValve arrangementsInternal combustion piston enginesMetallurgyInternal combustion engine

An integrally cast steel piston for internal engines, the cast steel having (a) a composition comprising 0.8% or less of C, 3% or less of Si, 3% or less of Mn, 0.2% or less of S, 3% or less of Ni, 6% or less of Cr, 6% or less of Cu, and 0.01-3% of Nb, the balance being substantially Fe and inevitable impurities, or (b) a composition comprising 0.1-0.8% of C, 3% or less of Si, 3% or less of Mn, 0.2% or less of S, 10% or less of Ni, 30% or less of Cr, 6% or less of Cu, and 0.05-8% of Nb, the balance being substantially Fe and inevitable impurities, by mass.

Owner:HITACHI METALS LTD +1

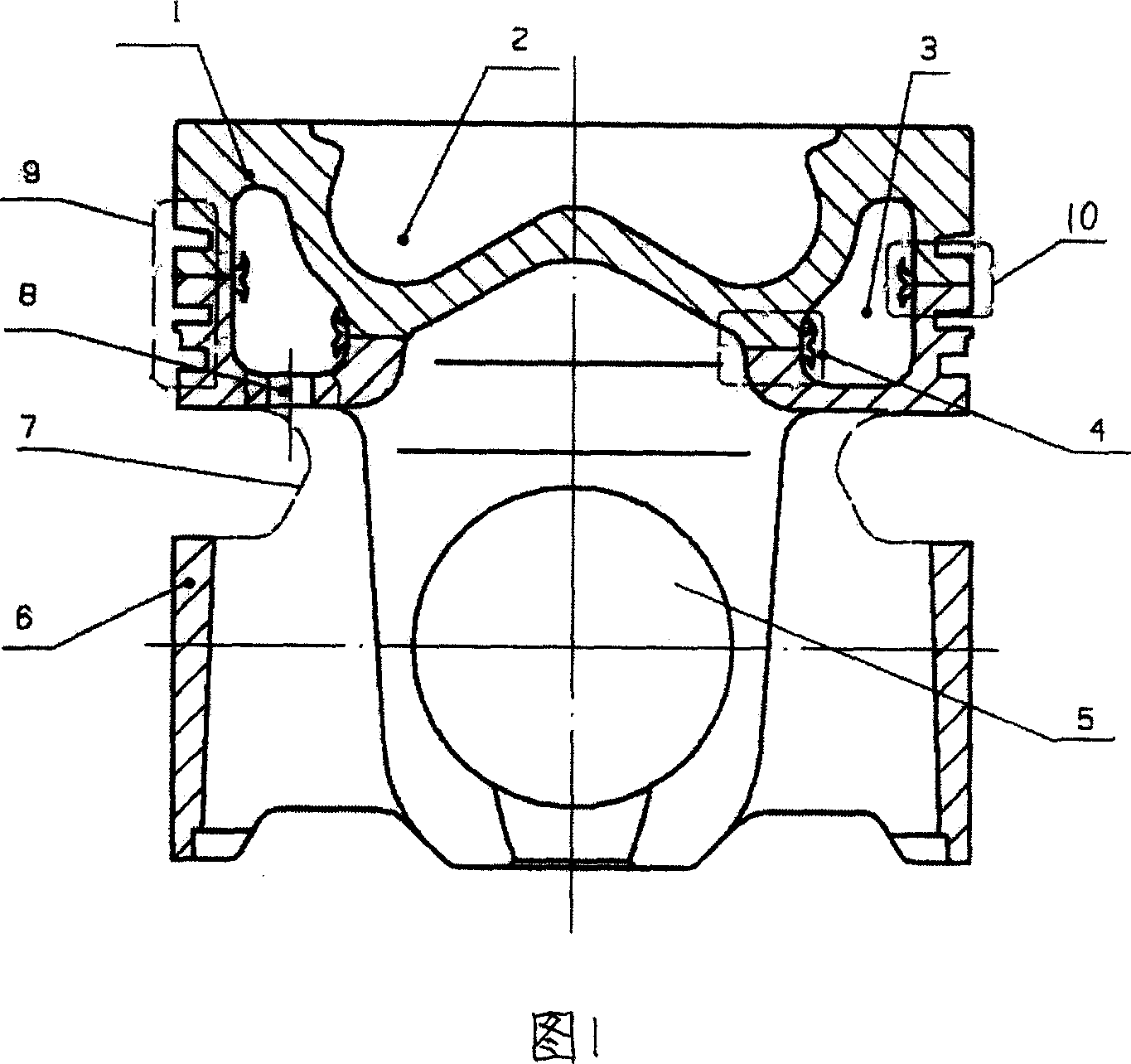

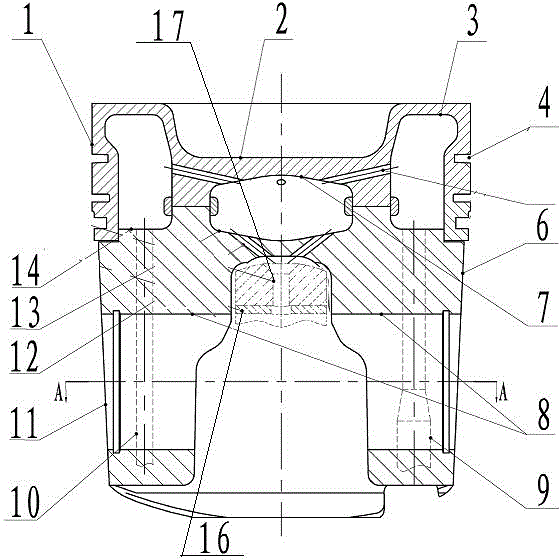

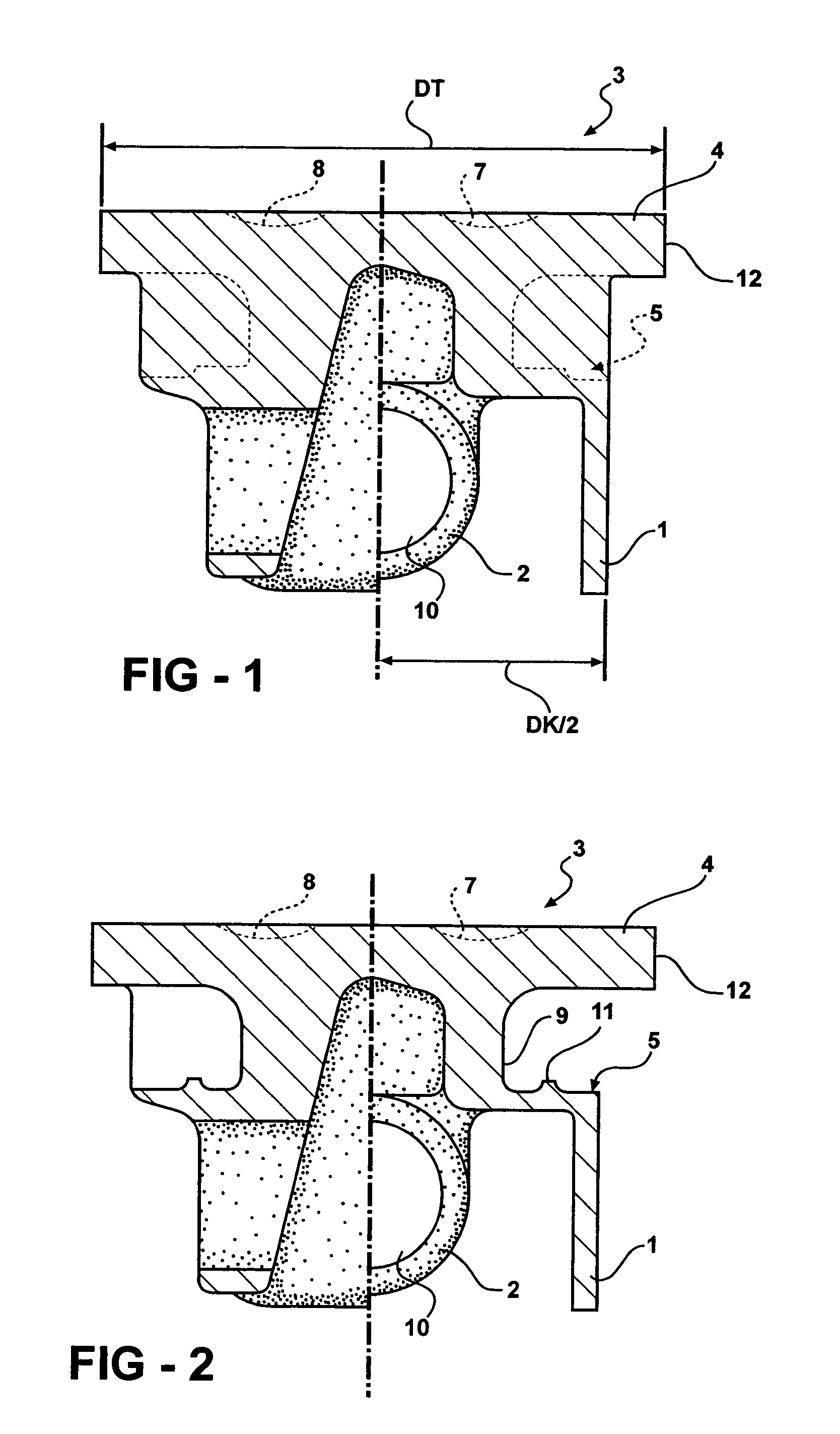

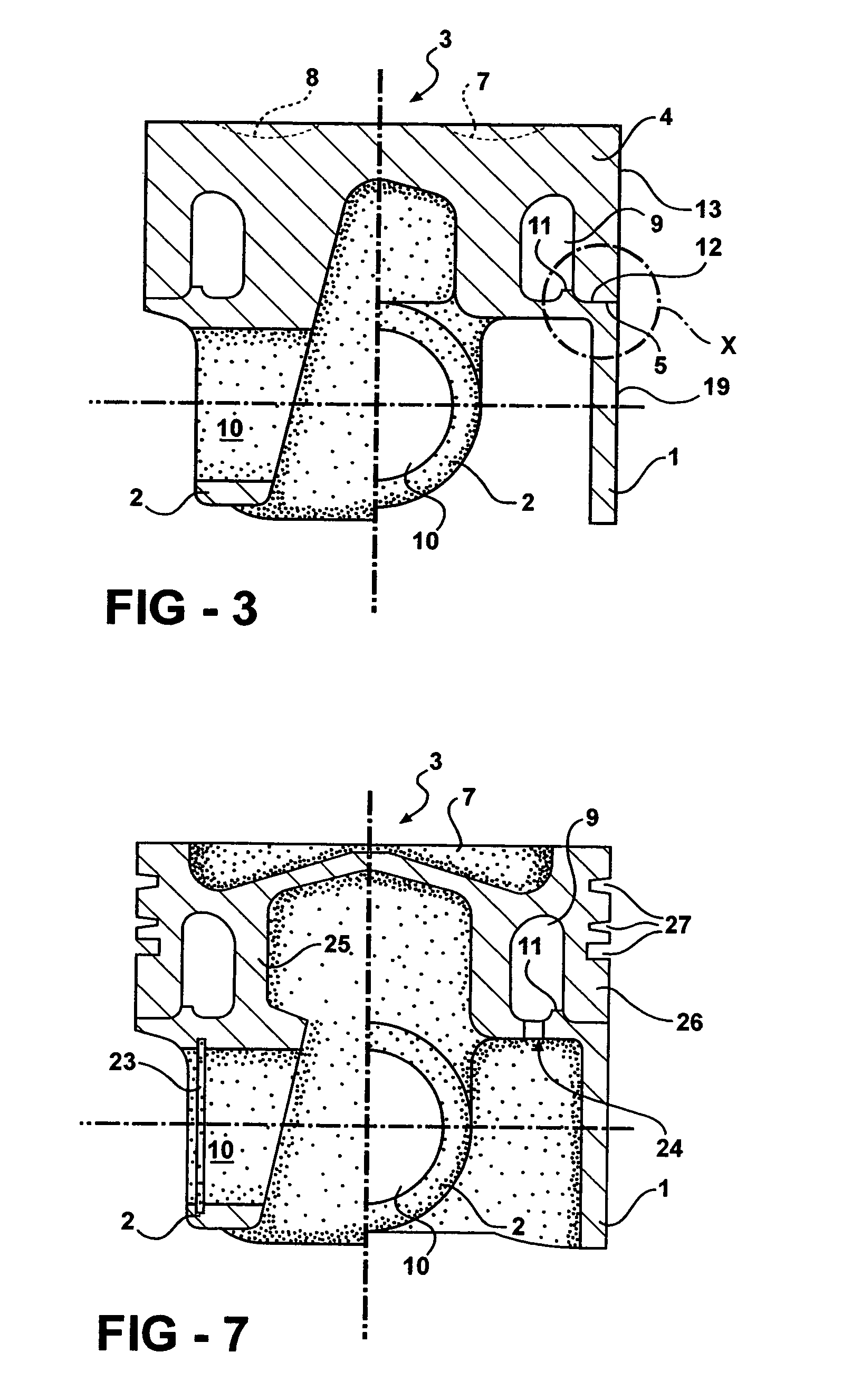

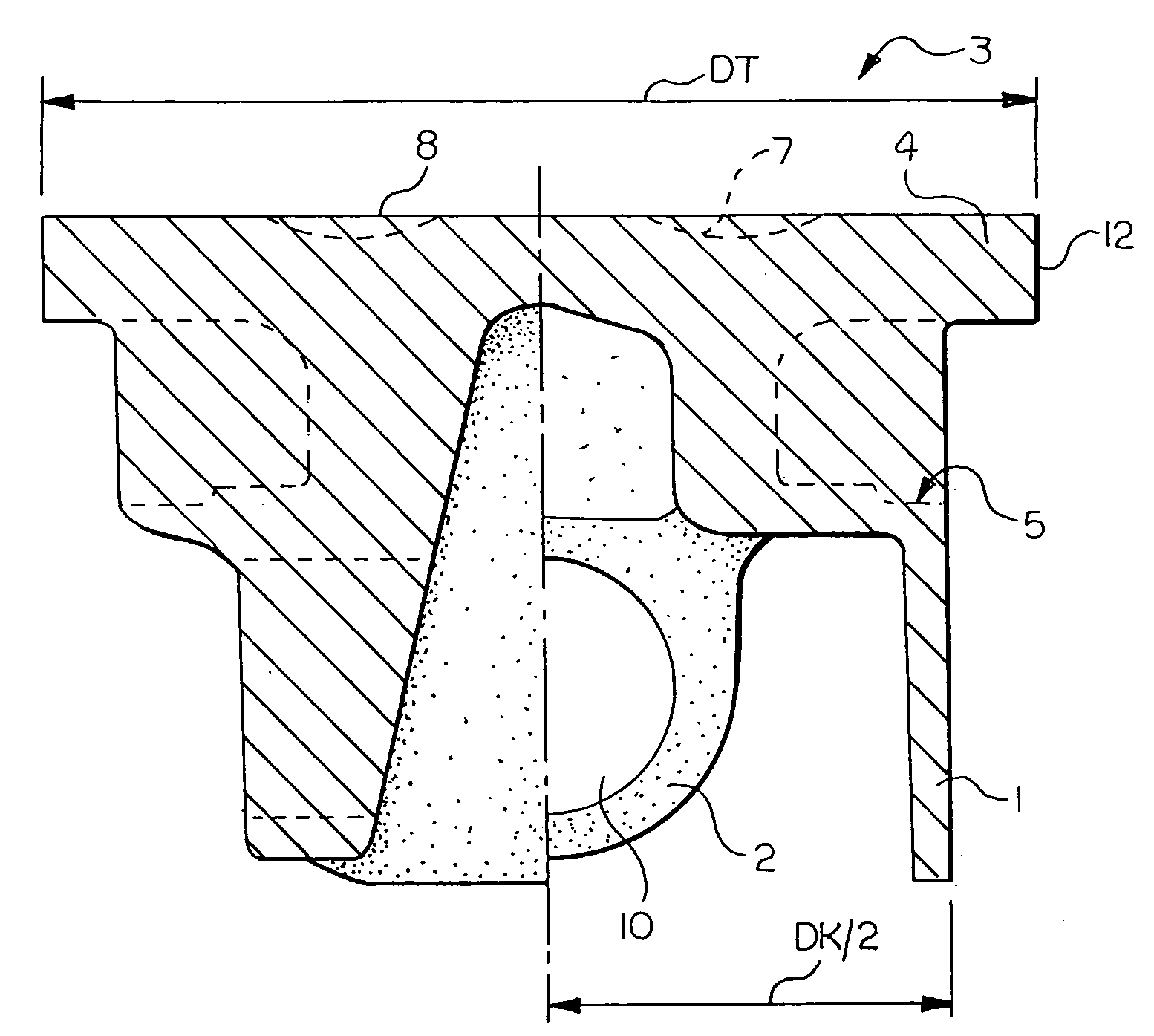

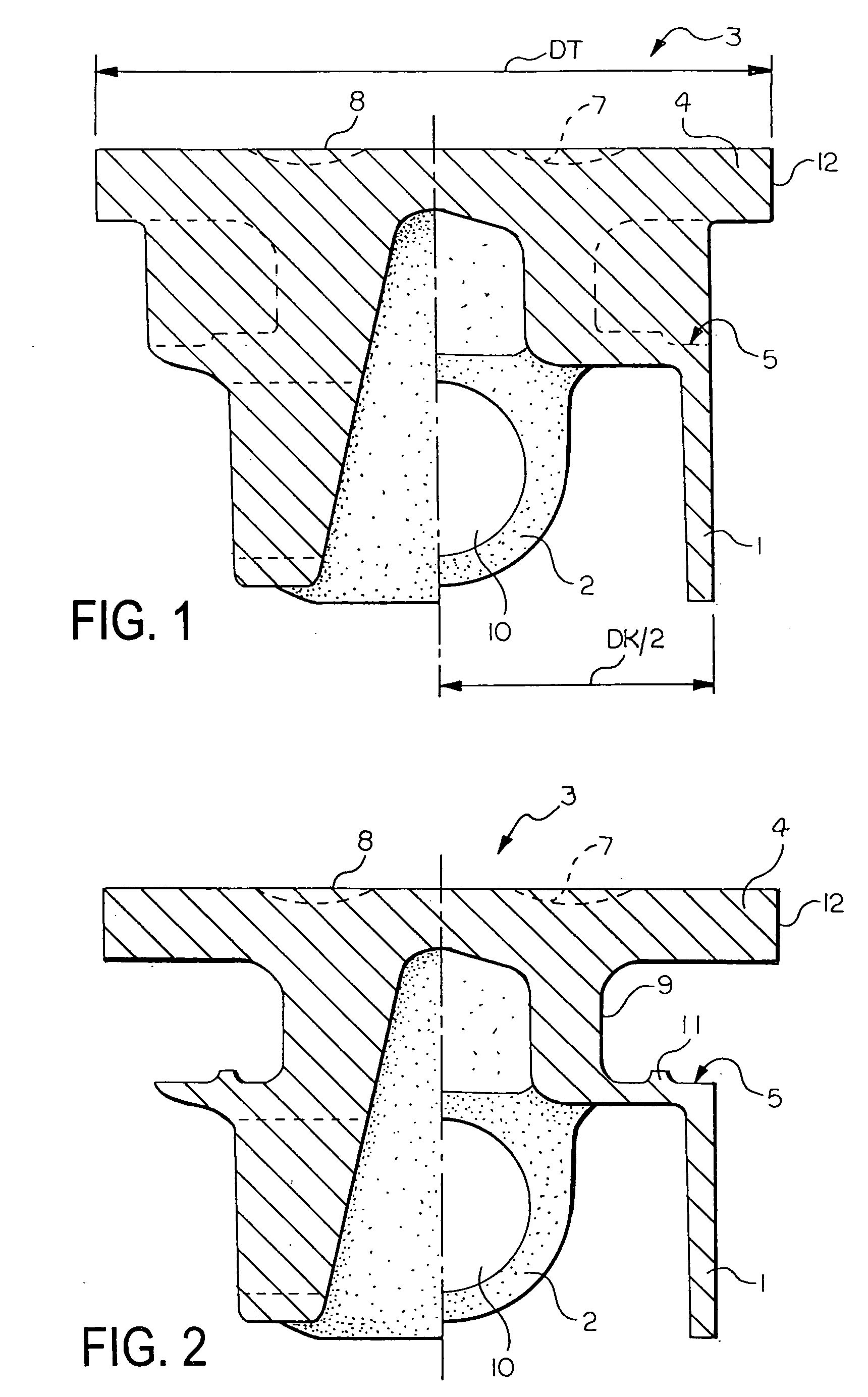

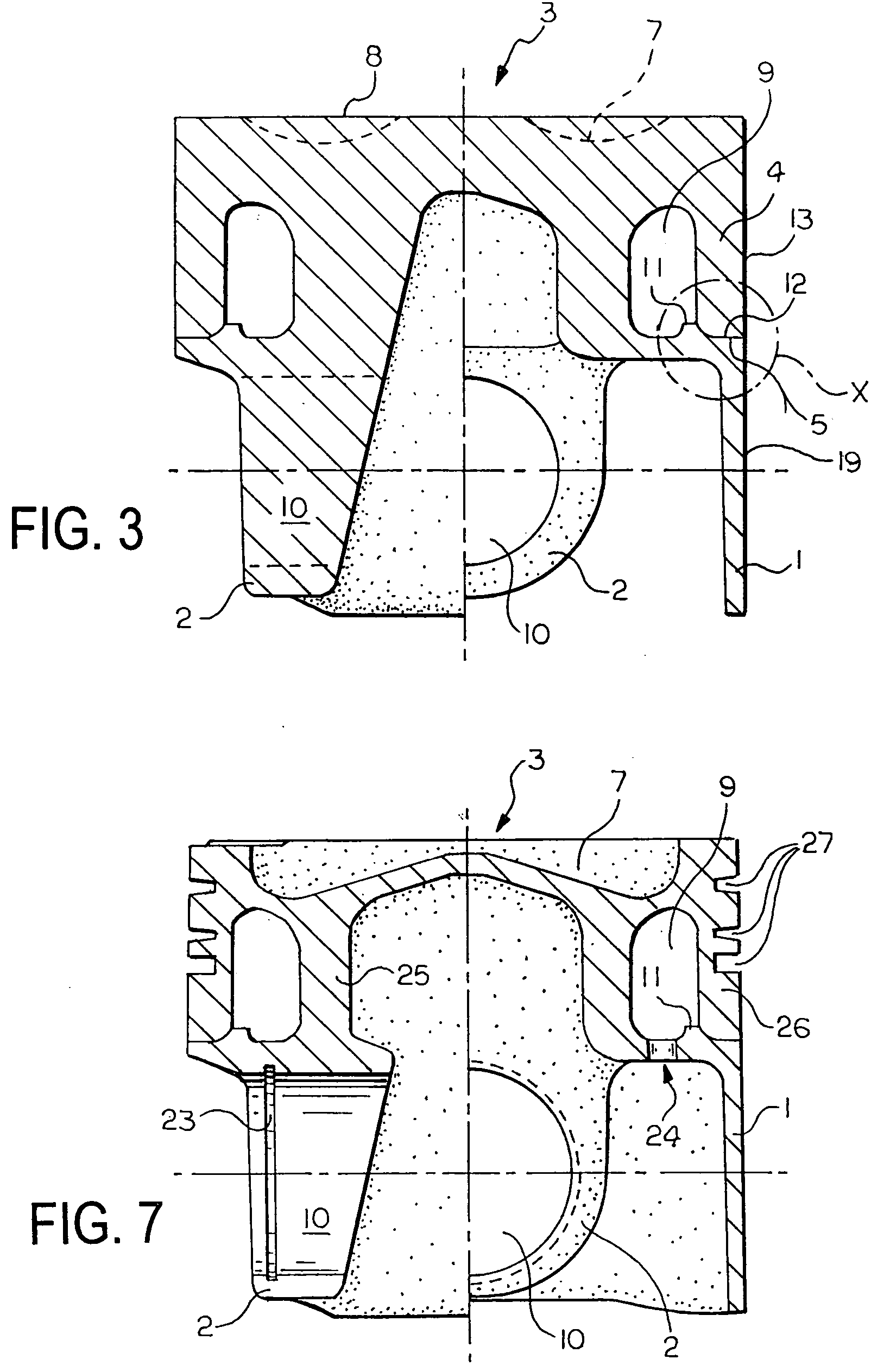

Single-piece forged-steel piston with inner oil cooling chamber and a method for manufacturing thereof

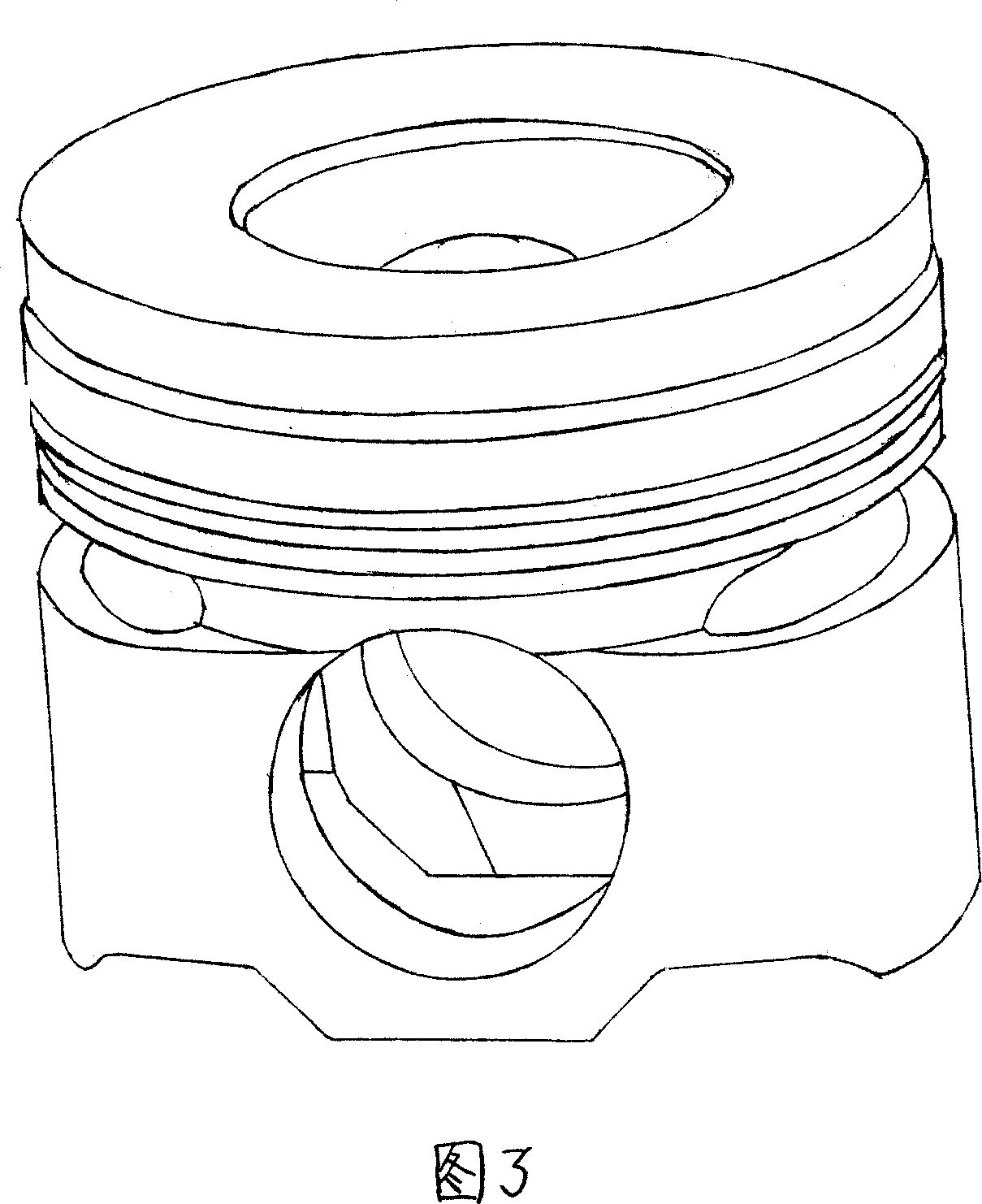

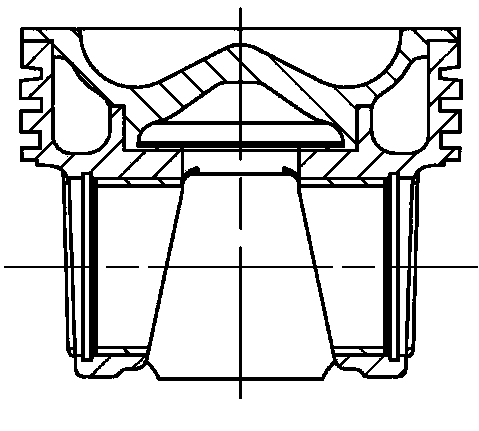

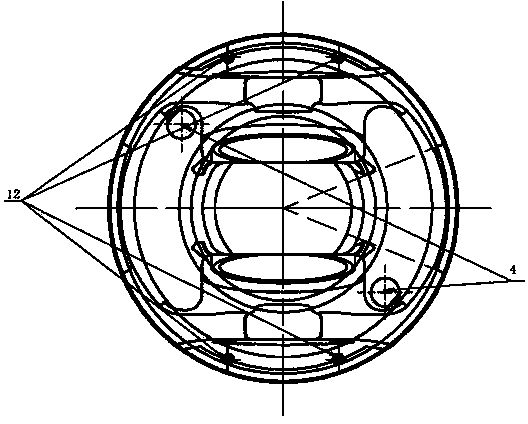

InactiveUS20090020007A1Simple structureEasy to makeValve arrangementsPlungersPiston ringCooling chamber

A laser-welded single-piece forged-steel piston with an enclosed inner oil cooling chamber having the advantages of simple structure and easy manufacturing process, and capable of satisfying the requirement of engines for high power, high rigidity, and low discharge development, and its manufacturing process. The laser-welded single-piece forged-steel piston of the invention comprises a piston body member and a piston ring member, wherein the piston body member is welded together with the piston ring member through laser welding procedure, an enclosed inner oil cooling chamber is formed between the piston body member and the piston ring member, and is connected with the piston inner cavity by means of at least two oil inlet / outlet holes, and a pin hole is opened at the lower portion of the piston body member.

Owner:LIN FENGHUA +3

Welded forged steel integrated piston and its producing method

InactiveCN1944994AImprove structural rigidityReduce weightMachines/enginesPistonsFriction weldingCombustor

The present invention is welded integral forged steel piston and its manufacturing process. The manufacturing process includes the following steps: forging the head blank and the skirt blank; separate heat treatment of the head blank and the skirt blank; coarse machining the head blank and the skirt blank; friction welding the head and the skirt together; machining the ring slot, combustor, pin hole, excircle and oil outlet in the piston; and final surface phosphorizing or graphitizing treatment of the piston. The present invention has raised manufacturability, high integral structural rigidity, lowered weight and low machine oil consumption compared with available integrally cast piston.

Owner:SHANDONG BINZHOU BOHAI PISTON

One-piece steel piston

A one-piece steel piston that is made from a piston blank that includes a portion that configured and designed to be displaced to form a cooling gallery and ring belt. The piston blank can be formed by a casting or forging process. The portion that is designed and configured to be displaced is a flange that extends radially at the top of the piston blank. The flange is bent downward so that a peripheral edge of the flange contacts a top portion of the piston skirt. The peripheral edge of the flange and the top portion of the skirt can be welded together or provided with inter-engaging structures.

Owner:KS KOLBENSCHMIDT US

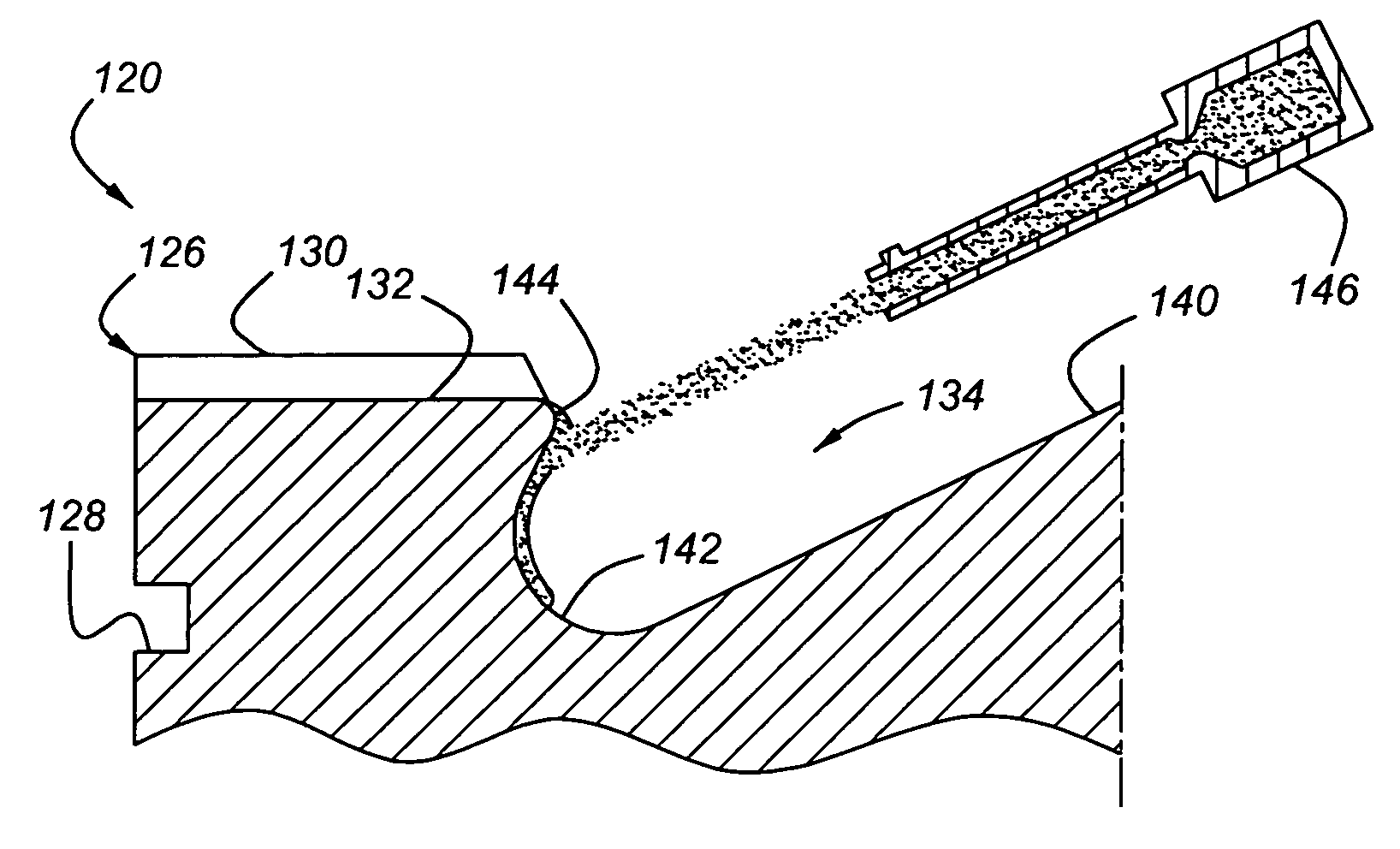

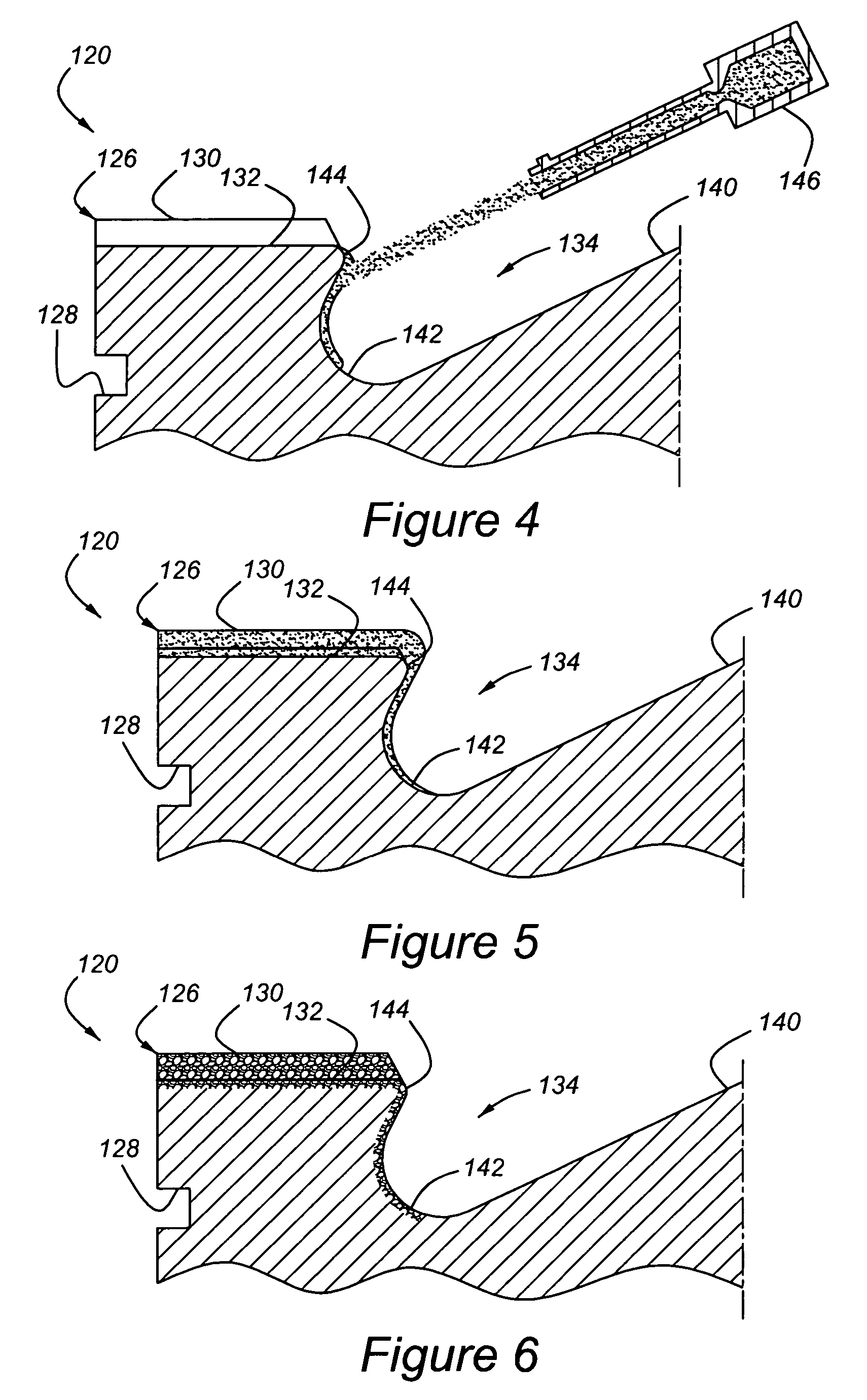

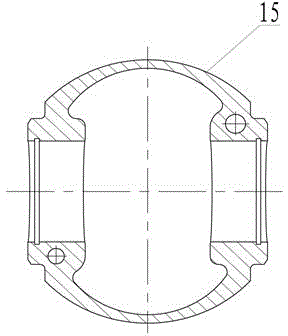

Thermal oxidation protective surface for steel pistons

ActiveUS7458358B2Promote oxidationIncrease resistanceValve arrangementsMolten spray coatingThermal sprayingHigh energy

A piston (120) and method for making a piston (120) for a fuel-injected diesel engine adapted to withstand the damaging effects of fuel injection plume-induced oxidation in the regions of the piston bowl (134) and rim (130). The surfaces of the piston crown (126) targeted by the fuel injection plume (138) are first coated with a corrosion-resistant and oxidation-resistant composition applied as a slurry or by a thermal spraying technique, such as HVOF or plasma spraying. Thereafter, a high energy industrial laser beam irradiates the as-sprayed coating to increase its density, while simultaneously reforming its microstructure so as to fuse, alloy, and materially bond the coating material with the underlying steel substrate, thereby resulting in a durable protective surface for the steel piston crown (126).

Owner:FEDERAL MOGUL WORLD WIDE LLC

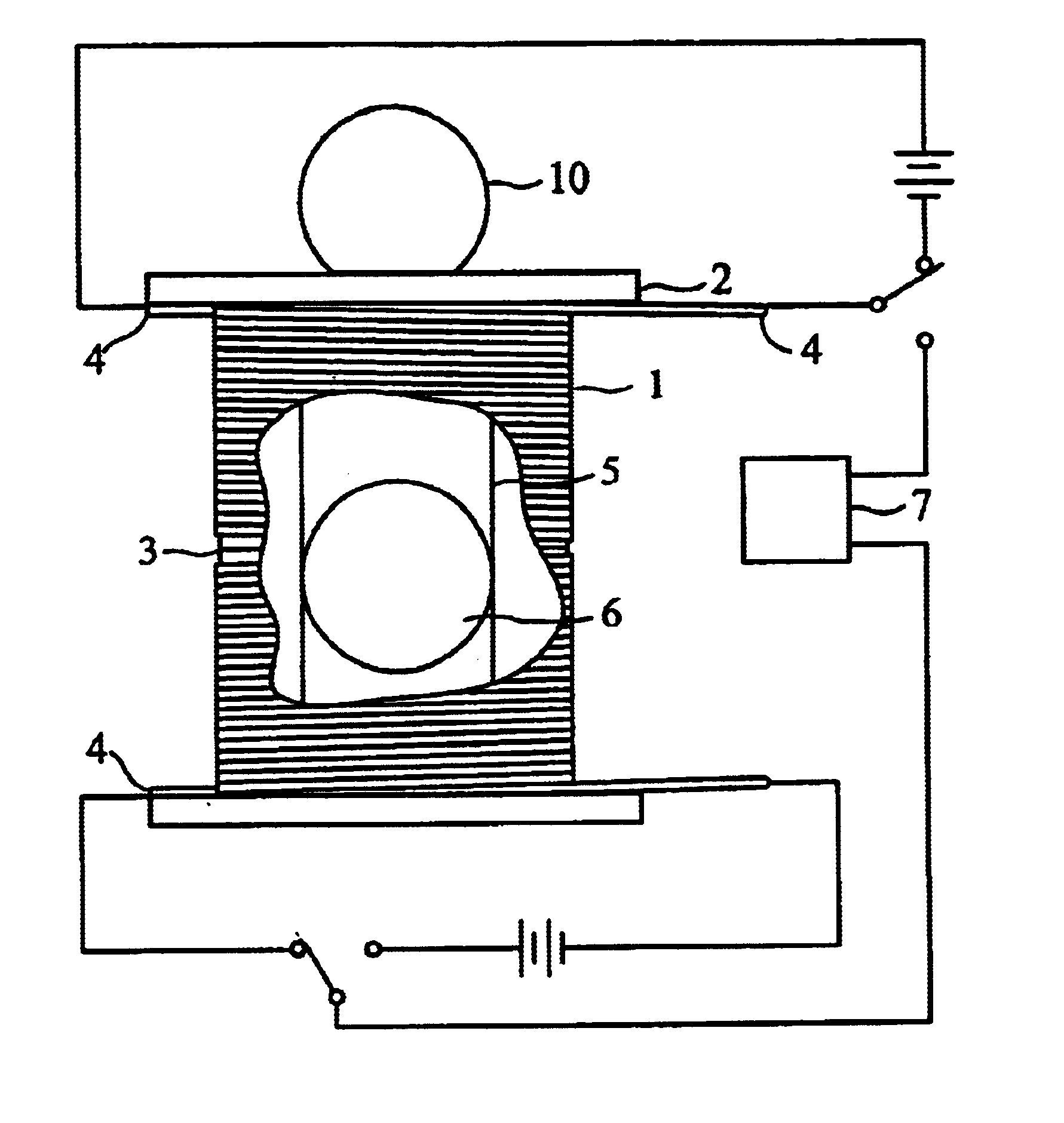

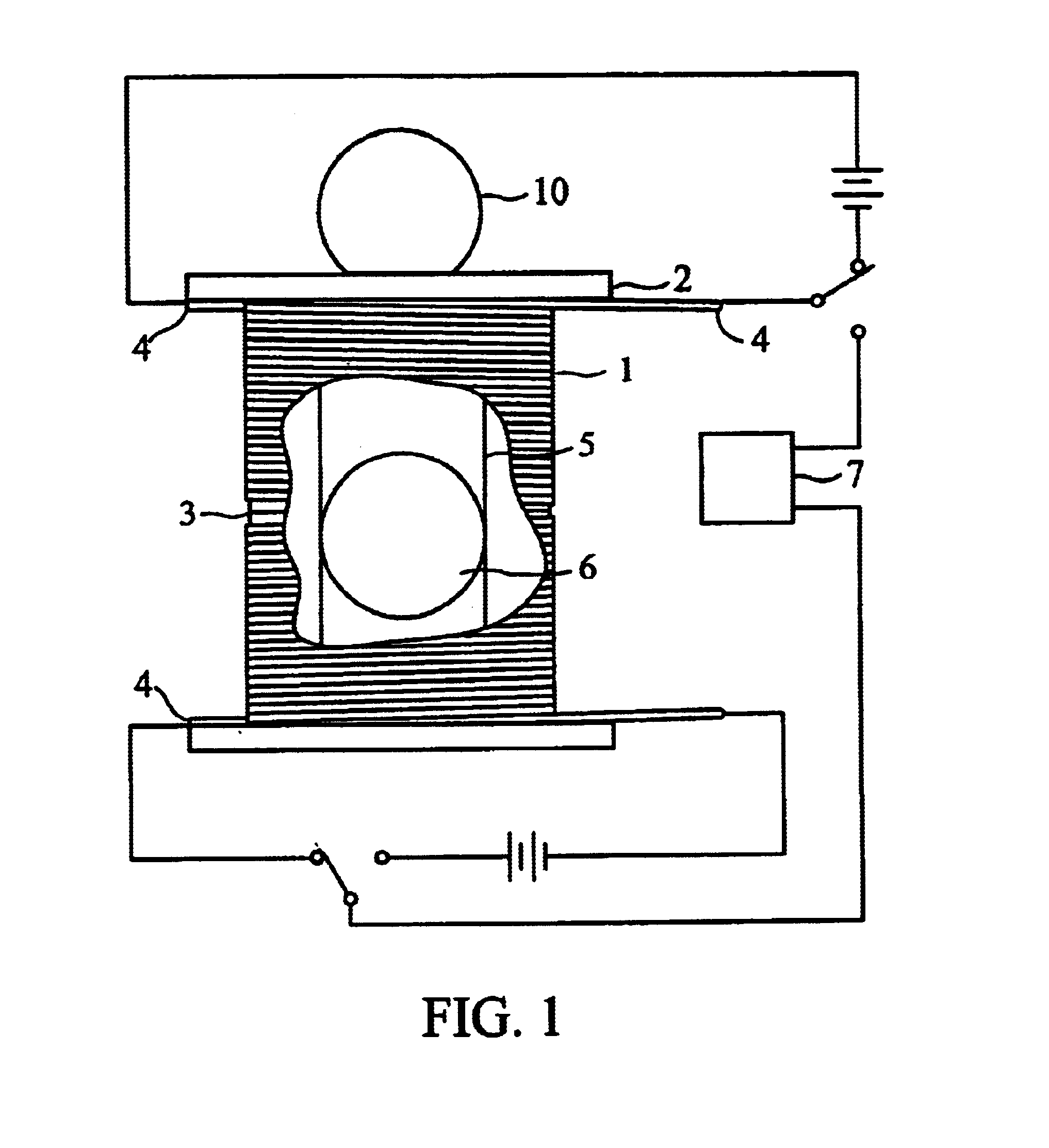

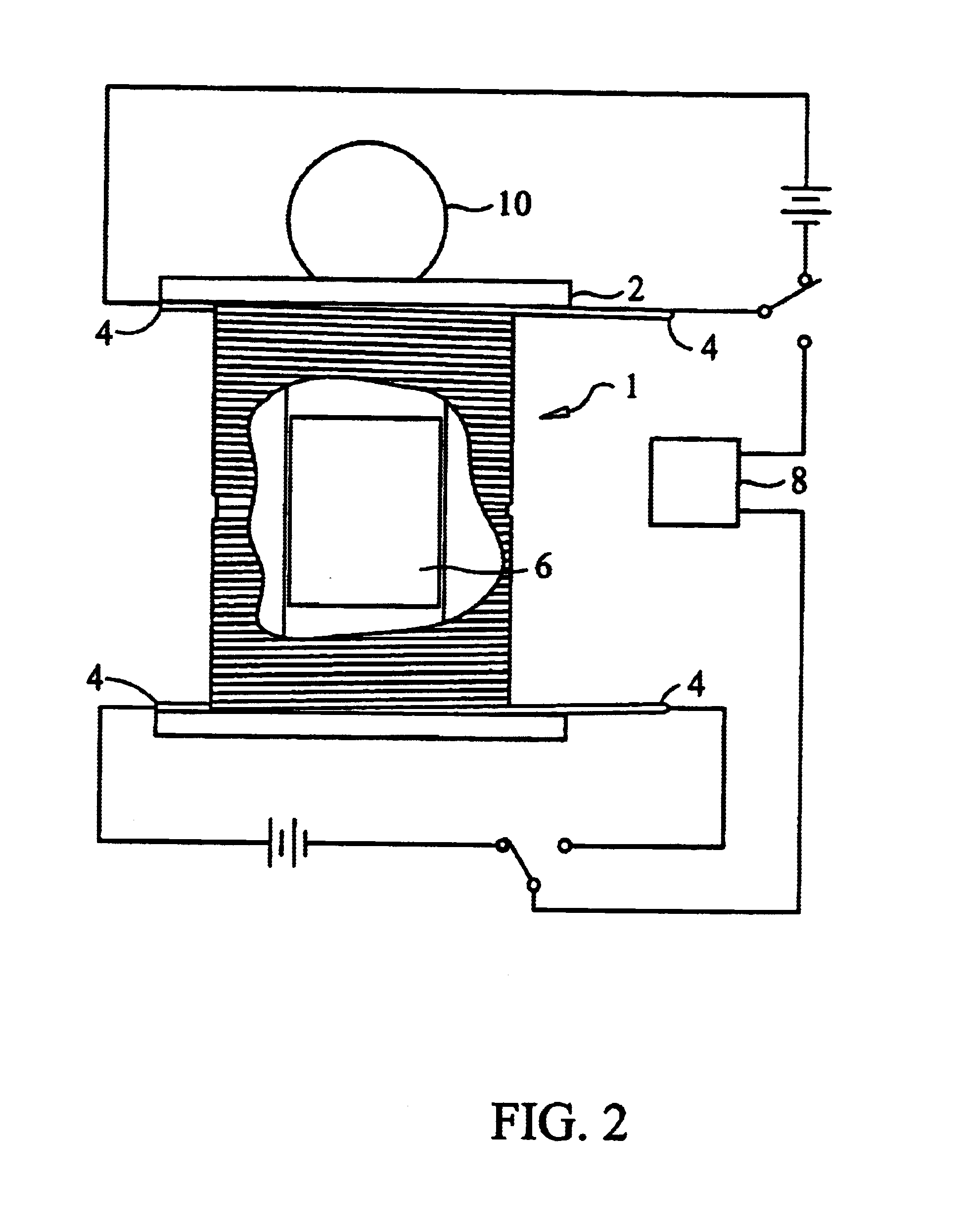

Brushless electric motor

A prime mover using a split coil for magnetically inducing movement of a steel piston. The magnetic effects are emphasized in higher reciprocating movement by the proximate introduction of a permanent magnet. The prime mover is sparkless, brushless, quiet, low friction, and can operate on a wide array of voltages, including high frequency very low voltage signals.

Owner:CORDIALE FR J +1

Steel piston with cooling gallery and method of construction thereof

ActiveUS8807109B2Enhanced strength and durabilityIncreased compressive loadValve arrangementsMachines/enginesCombustionMechanical engineering

Owner:TENNECO INC

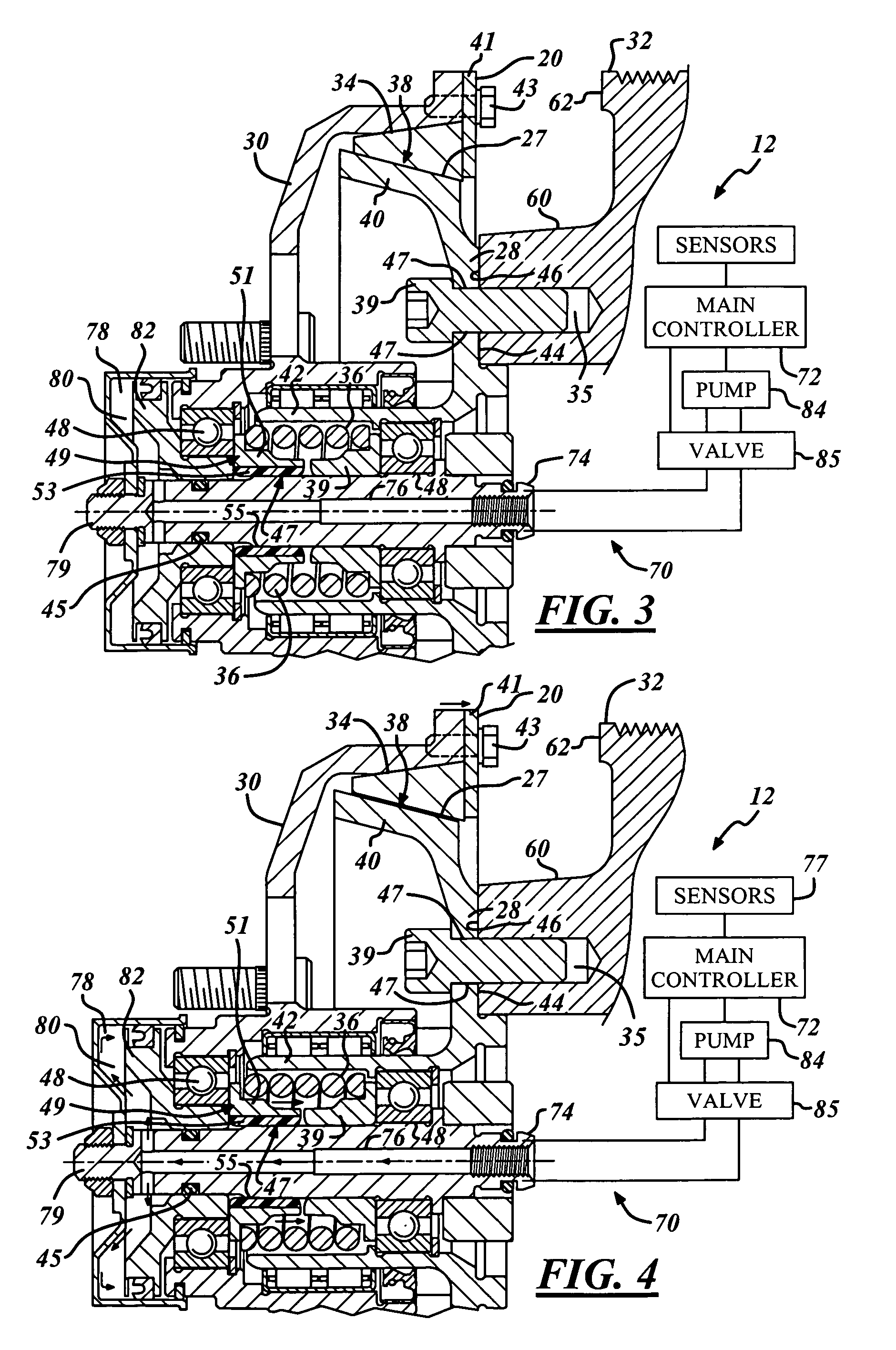

Bi-assembly spring end cap for vehicle on/off fan drive to improve seal life, reduce vibration input loading to ball bearings and reduce component cost

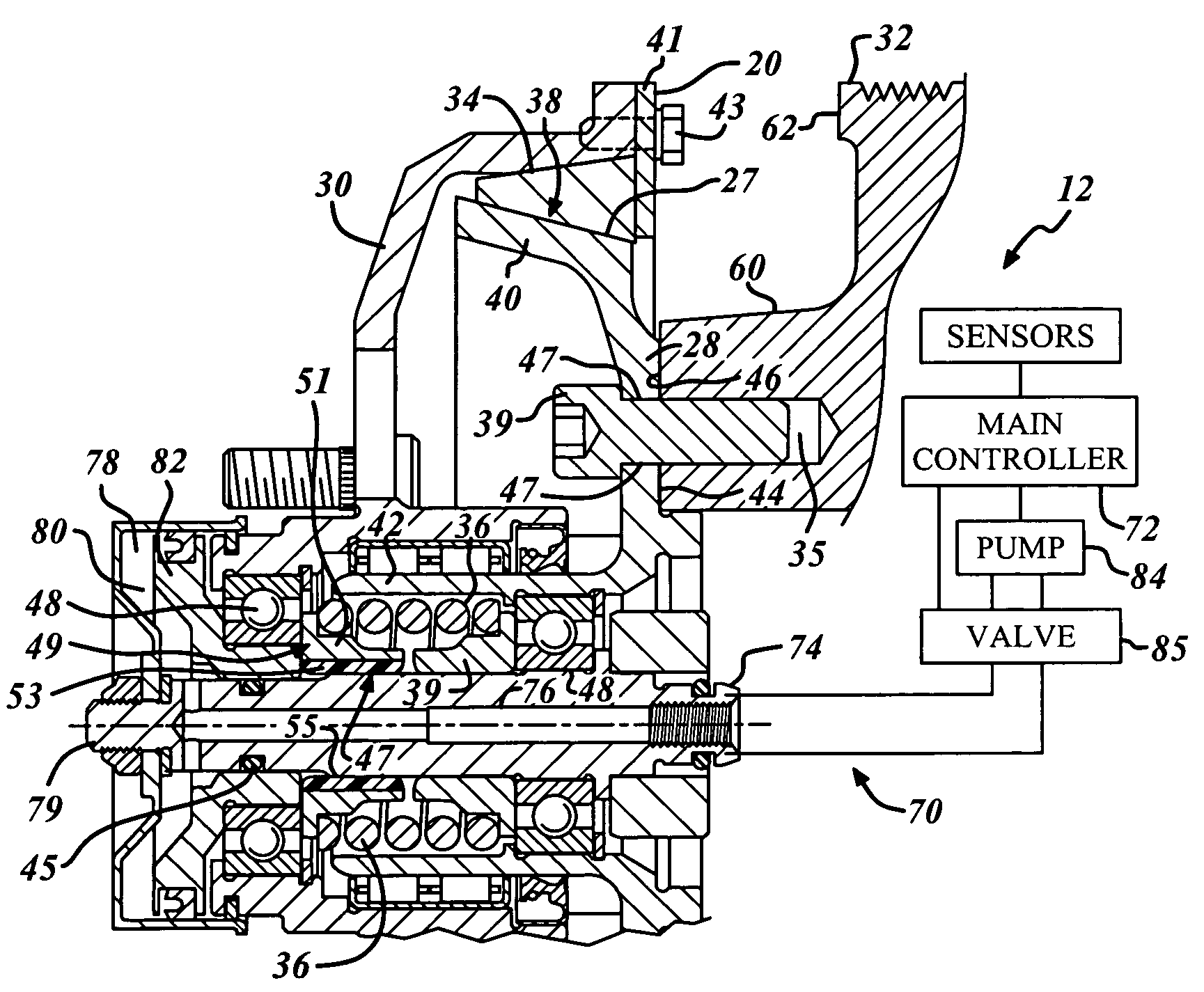

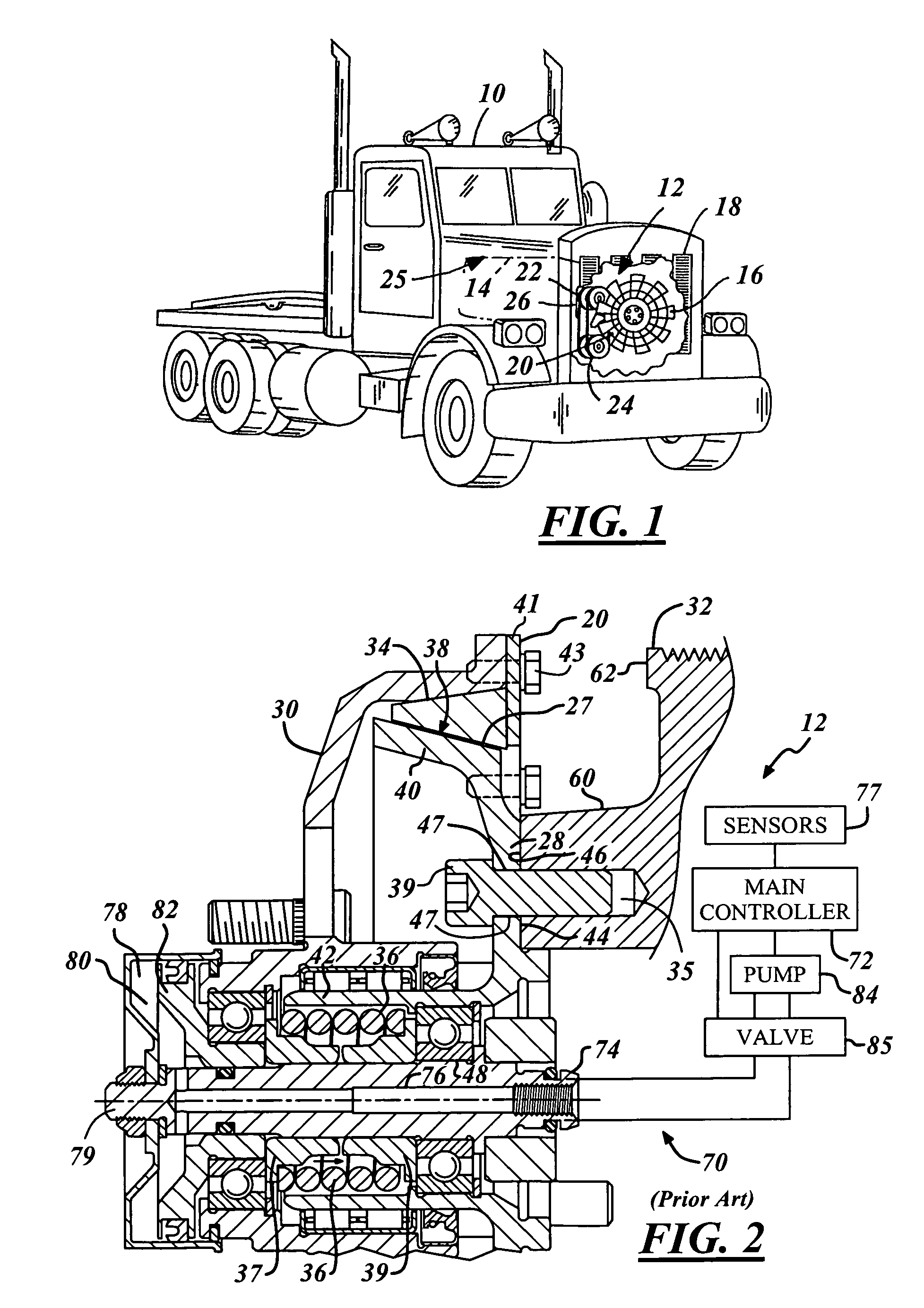

ActiveUS7137362B1Avoid corrosionReduce vibrationCoolant flow controlFluid actuated clutchesBall bearingEngineering

An on / off clutch assembly is disclosed having a two component spring end cap. The spring end cap includes a steel cap portion and a non-metallic portion. The non-metallic portion extends along the entire length of the steel cap portion and is located between the steel cap portion and the piston rod. The new design insulates the steel piston rod from the steel spring end cap. This results in reduced corrosion of seals within the clutch assembly and contributes to improved conditions for bearings within the clutch assembly.

Owner:BORGWARNER INC

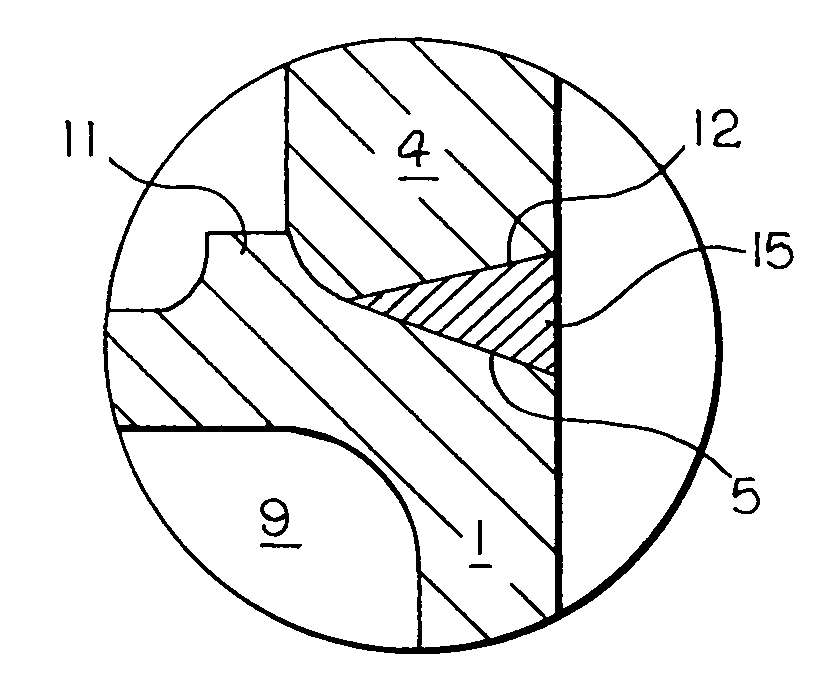

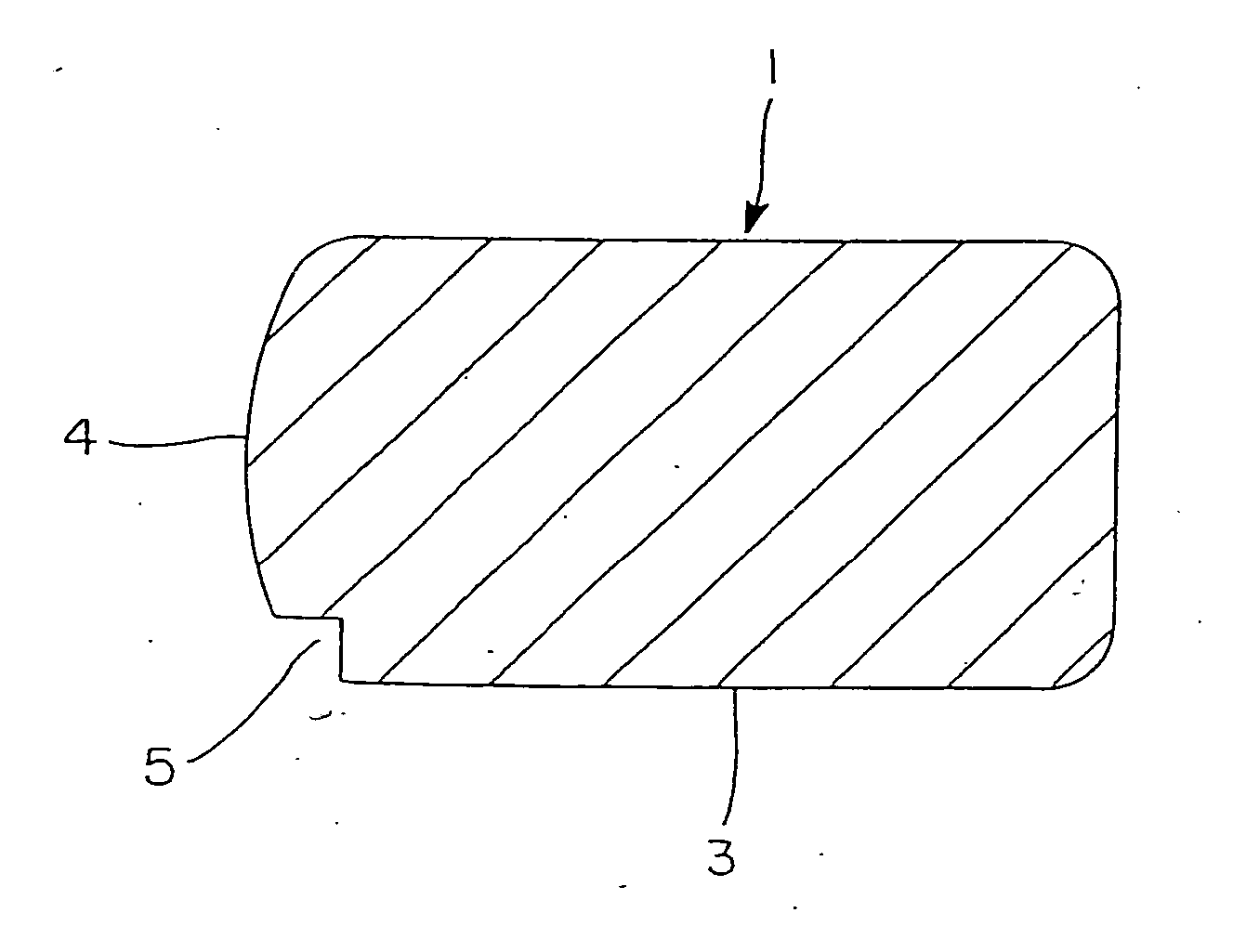

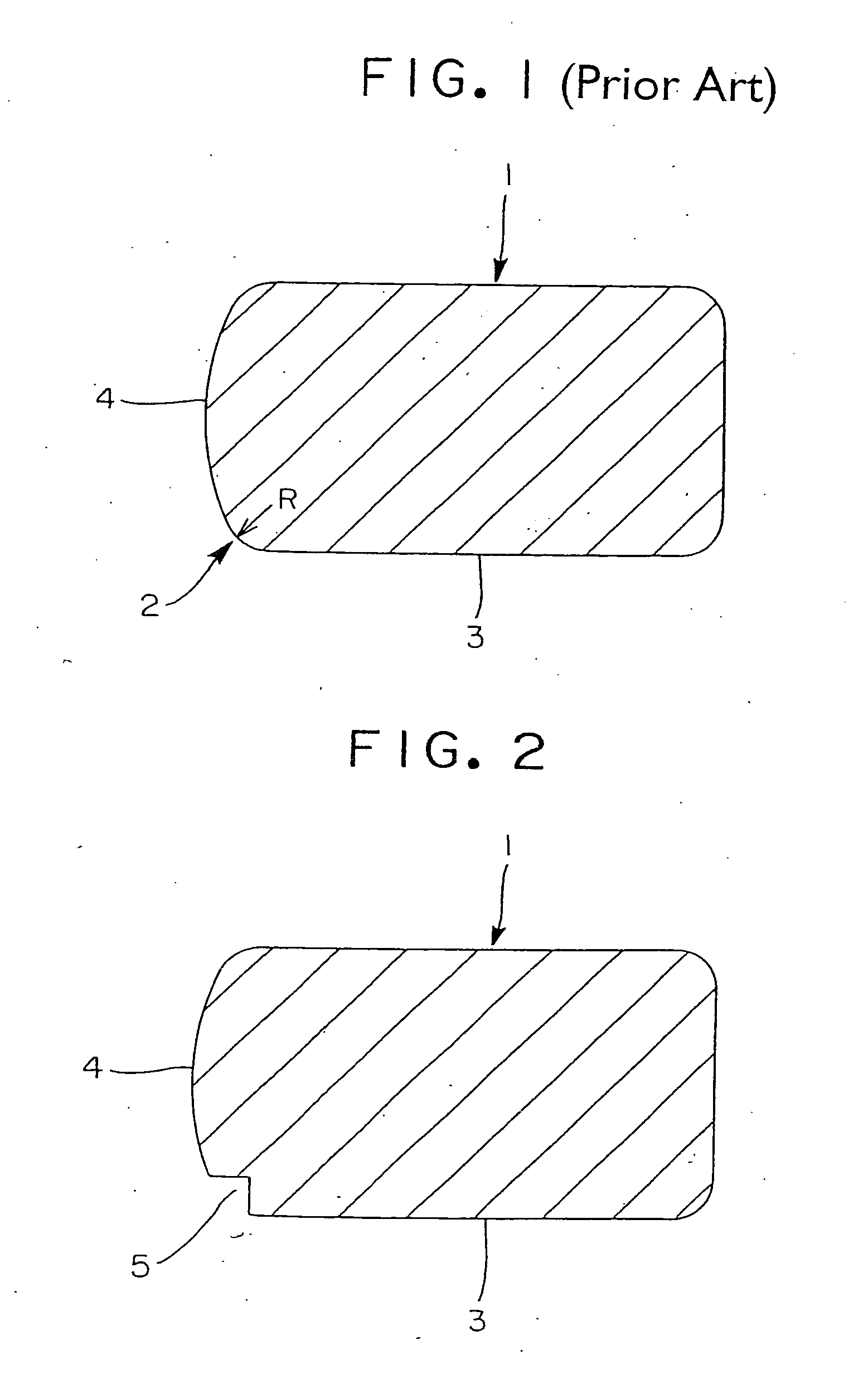

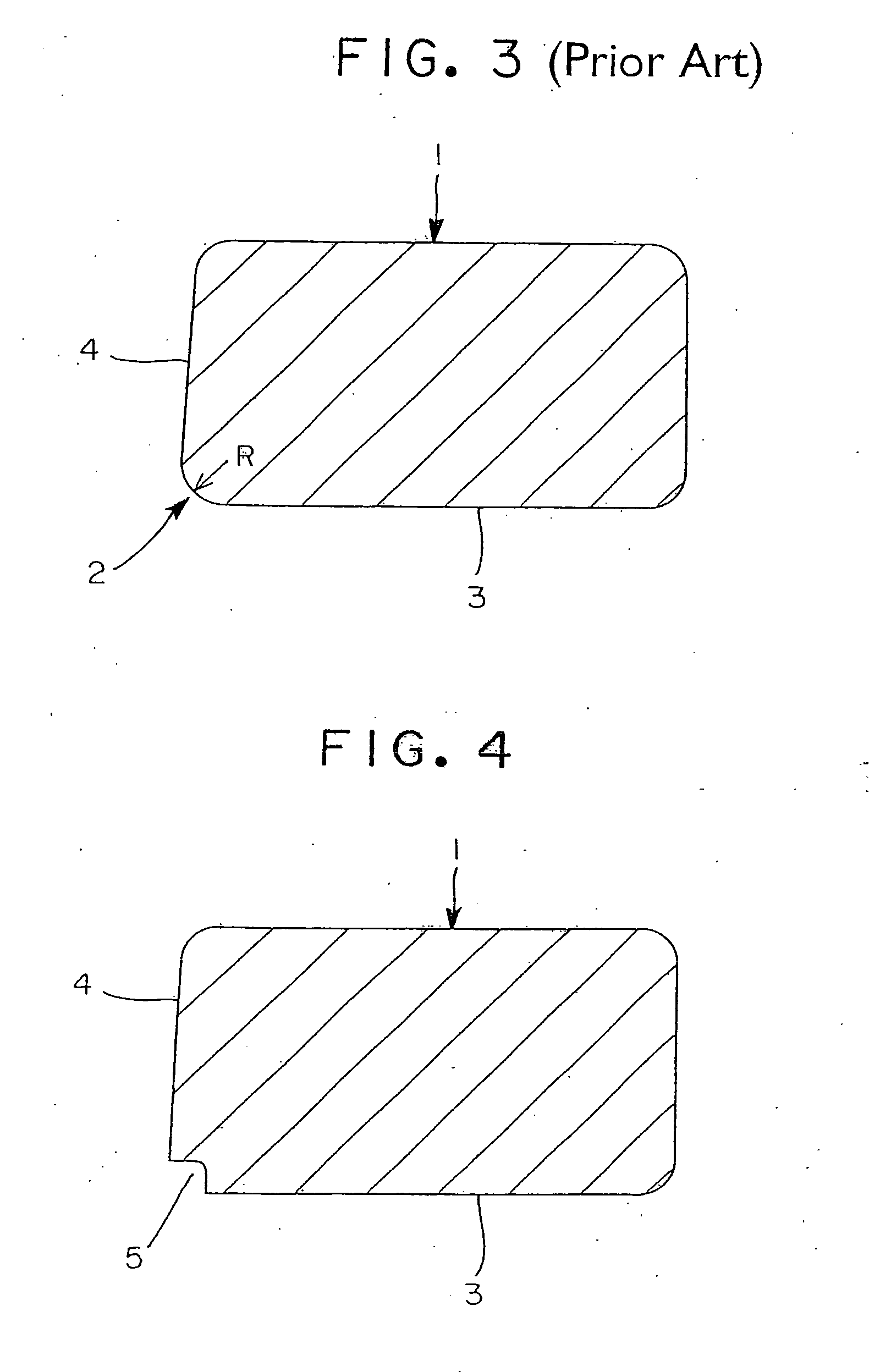

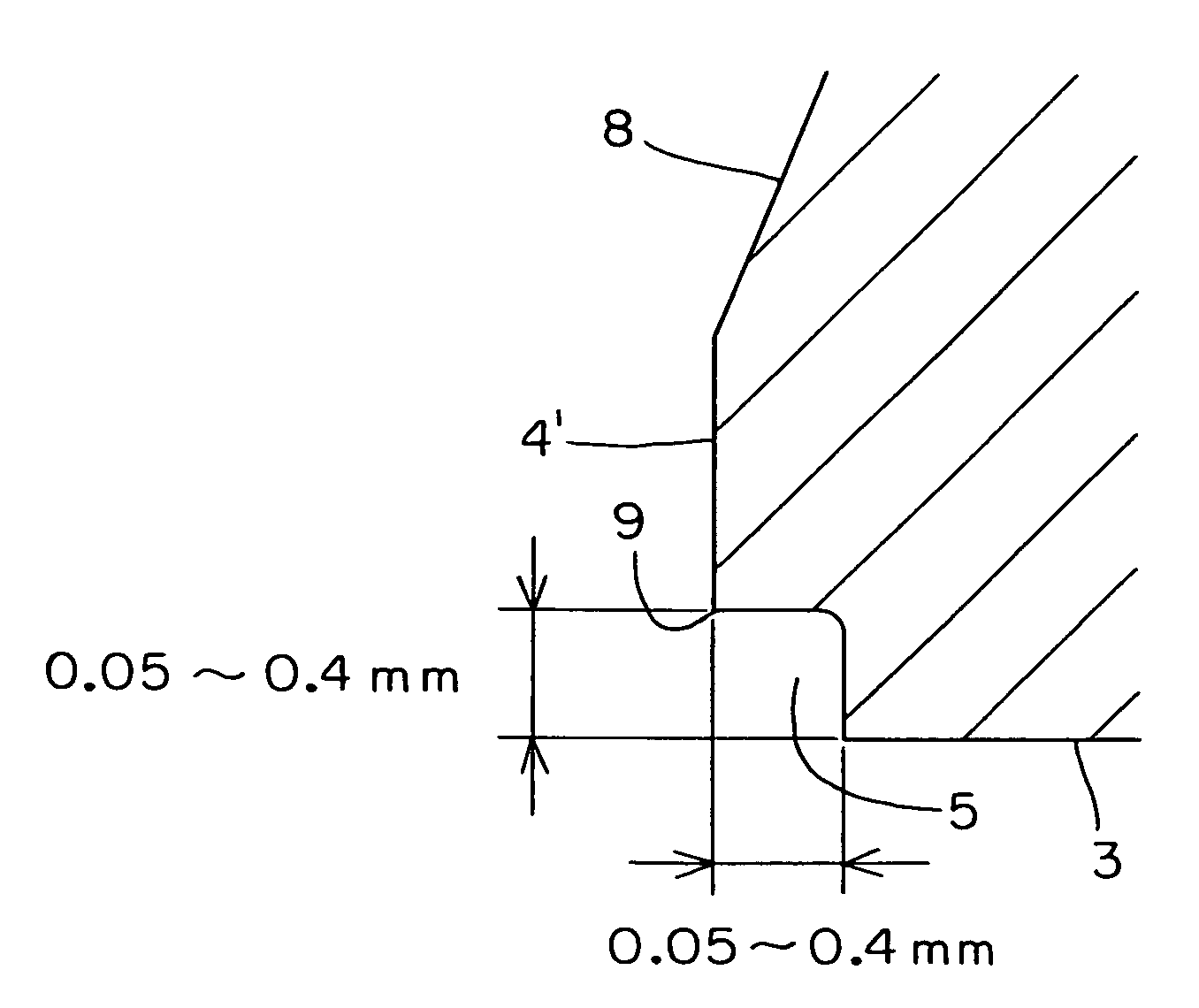

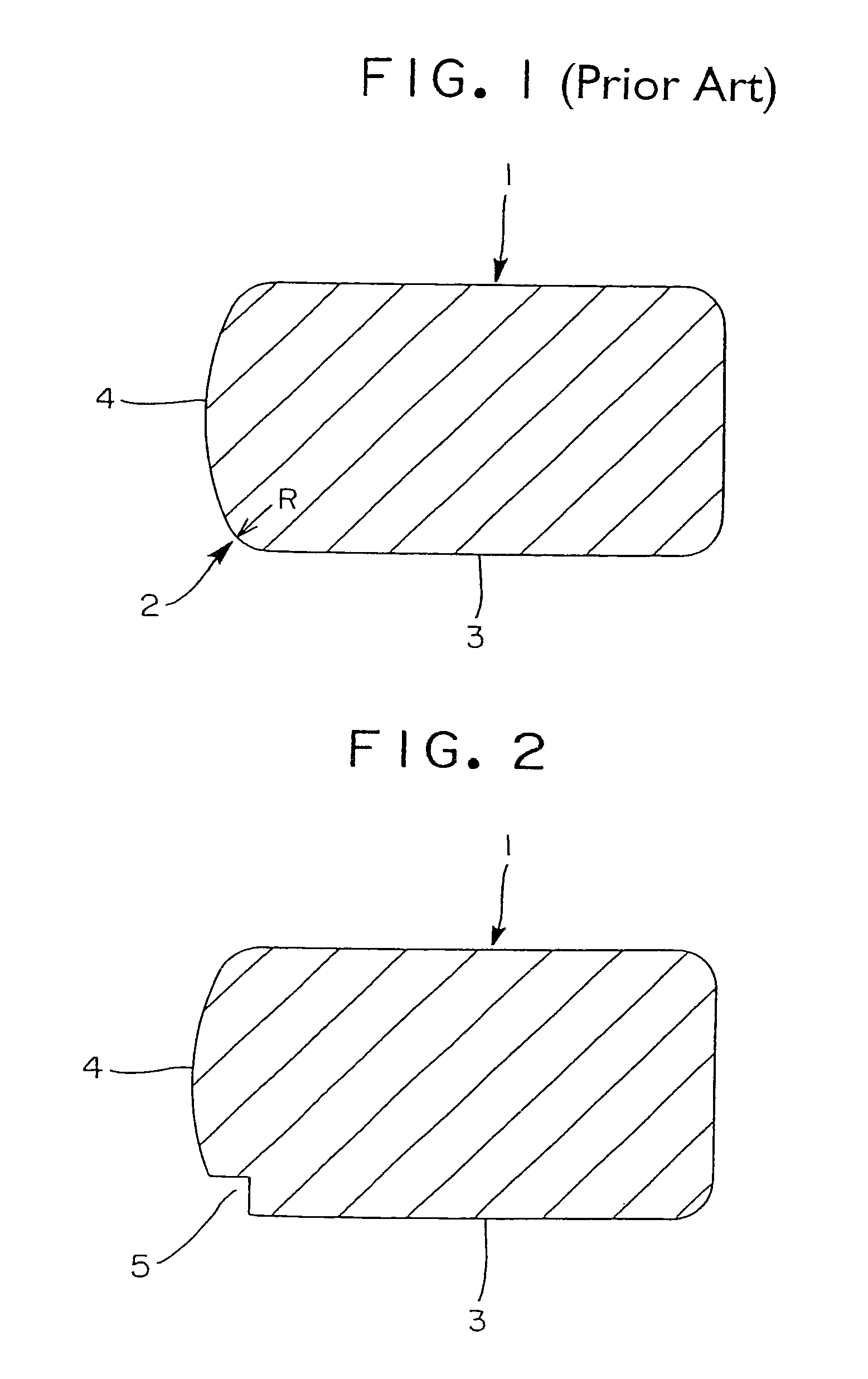

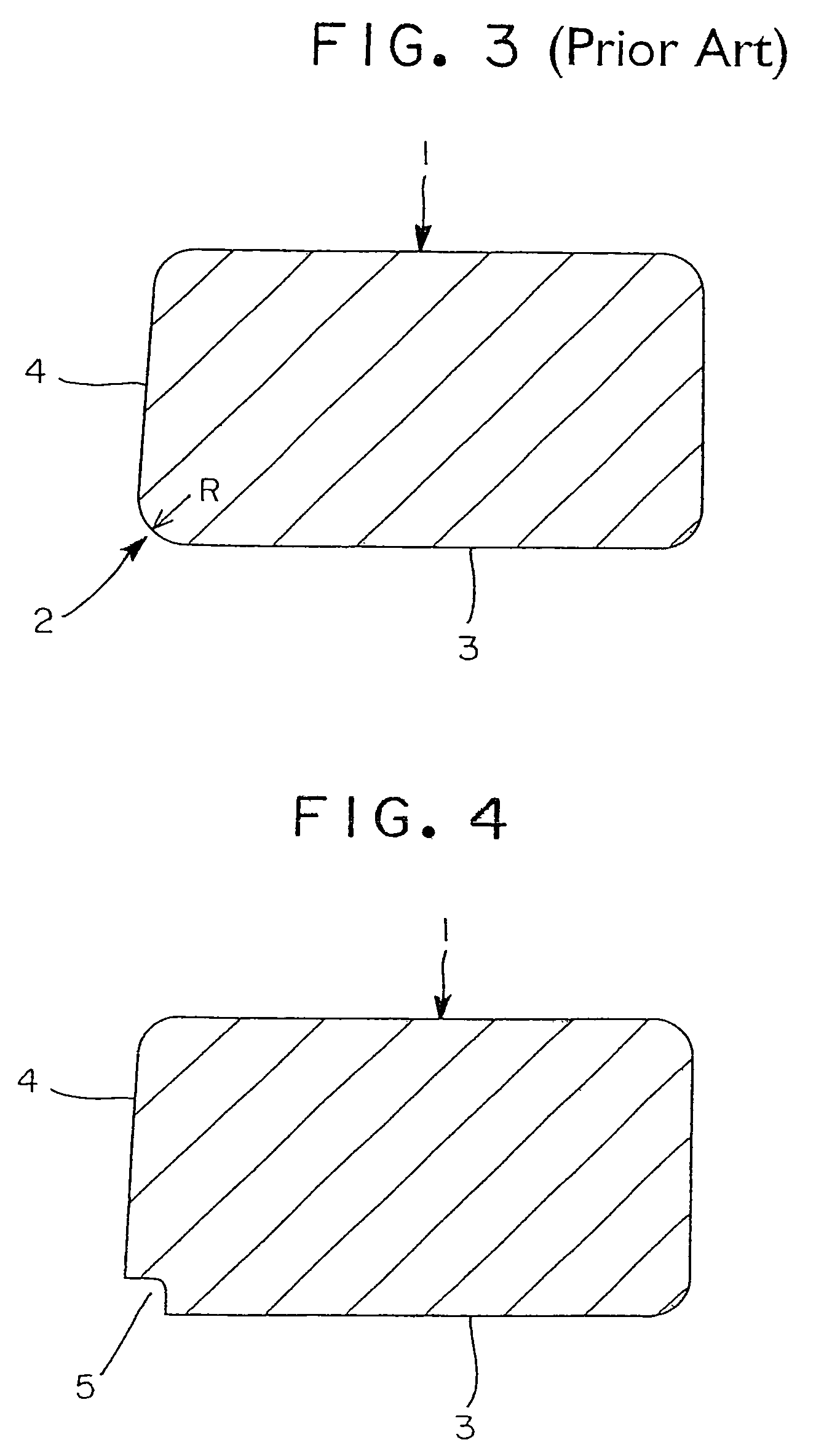

Steel piston ring

In a corner portion (2) defined between an outer peripheral surface (4) and a lower-side surface (3) of a steel piston ring (1), a groove (5, 6) having either an approximately quadrangular shape with a length of one side of 0.05 to 0.4 mm or an approximately quarter circular shape having a radius of 0.05 to 0.4 mm is formed. A sharp edge (9) formed by the groove (5, 6) performs an oil scraping function and the groove (5, 6) works to reduce an oil pressure of a second land or a third land clearance between the cylinder bore and the piston.

Owner:RIKEN CO LTD

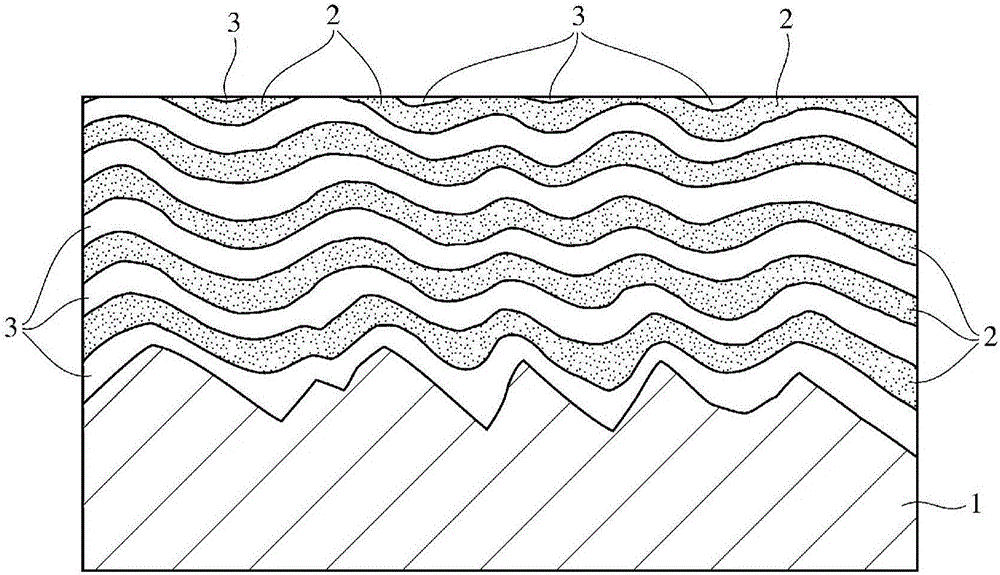

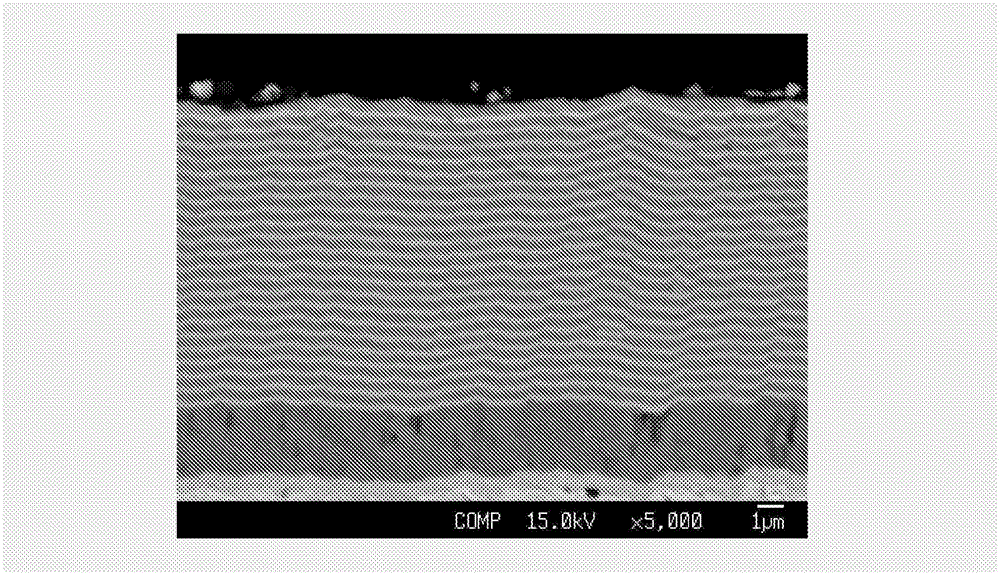

Thermally insulated steel piston crown and method of making using a ceramic coating

A piston for a diesel engine is provided. The piston includes a thermal barrier coating applied to a crown formed of steel. A layer of a metal bond material is first applied to a combustion surface of the crown, followed by a gradient structure including a mixture of the metal bond material and a ceramic material, followed by a layer of the ceramic material. The ceramic material includes at least one of ceria, ceria stabilized zirconia, yttria stabilized zirconia, calcia stabilized zirconia, magnesia stabilized zirconia, and zirconia stabilized by another oxide. The thermal barrier coating is applied by a thermal spray process or HVOF. The thermal barrier coating has a porosity of 2% by vol. to 25% vol., based on the total volume of the thermal barrier coating, a thickness of less than 1 mm, and a thermal conductivity of less than 1.00 W / m·K.

Owner:TENNECO

Steel piston crown and/or combustion engine components with dynamic thermal insulation coating and method of making and using such a coating

ActiveUS20180128166A1Improved thermal barrier coatingMolten spray coatingMachines/enginesThermal insulationInternal combustion engine

A piston for an internal combustion engine is provided. The piston includes a thermal barrier coating applied to a crown formed of steel. According to one embodiment, a bond layer of a metal is applied to a combustion surface of the crown, followed by a mixed layer of metal and ceramic with a gradient structure, and then optionally a top layer of metal. The thermal barrier coating can also include a ceramic layer between the mixed layer and top layer, or as the outermost layer. The ceramic includes at least one of ceria, ceria stabilized zirconia, yttria, yttria stabilized zirconia, calcia stabilized zirconia, magnesia stabilized zirconia, and zirconia stabilized by another oxide. The thermal barrier coating is applied by thermal spray, HVOF, or wire arc spraying. The thermal barrier coating preferably has a thickness less than 200 microns and a surface roughness Ra of not greater than 3 microns.

Owner:TENNECO

Steel piston ring

In a corner portion (2) defined between an outer peripheral surface (4) and a lower-side surface (3) of a steel piston ring (1), a groove (5, 6) having either an approximately quadrangular shape with a length of one side of 0.05 to 0.4 mm or an approximately quarter circular shape having a radius of 0.05 to 0.4 mm is formed. A sharp edge (9) formed by the groove (5, 6) performs an oil scraping function and the groove (5, 6) works to reduce an oil pressure of a second land or a third land clearance between the cylinder bore and the piston.

Owner:RIKEN CO LTD

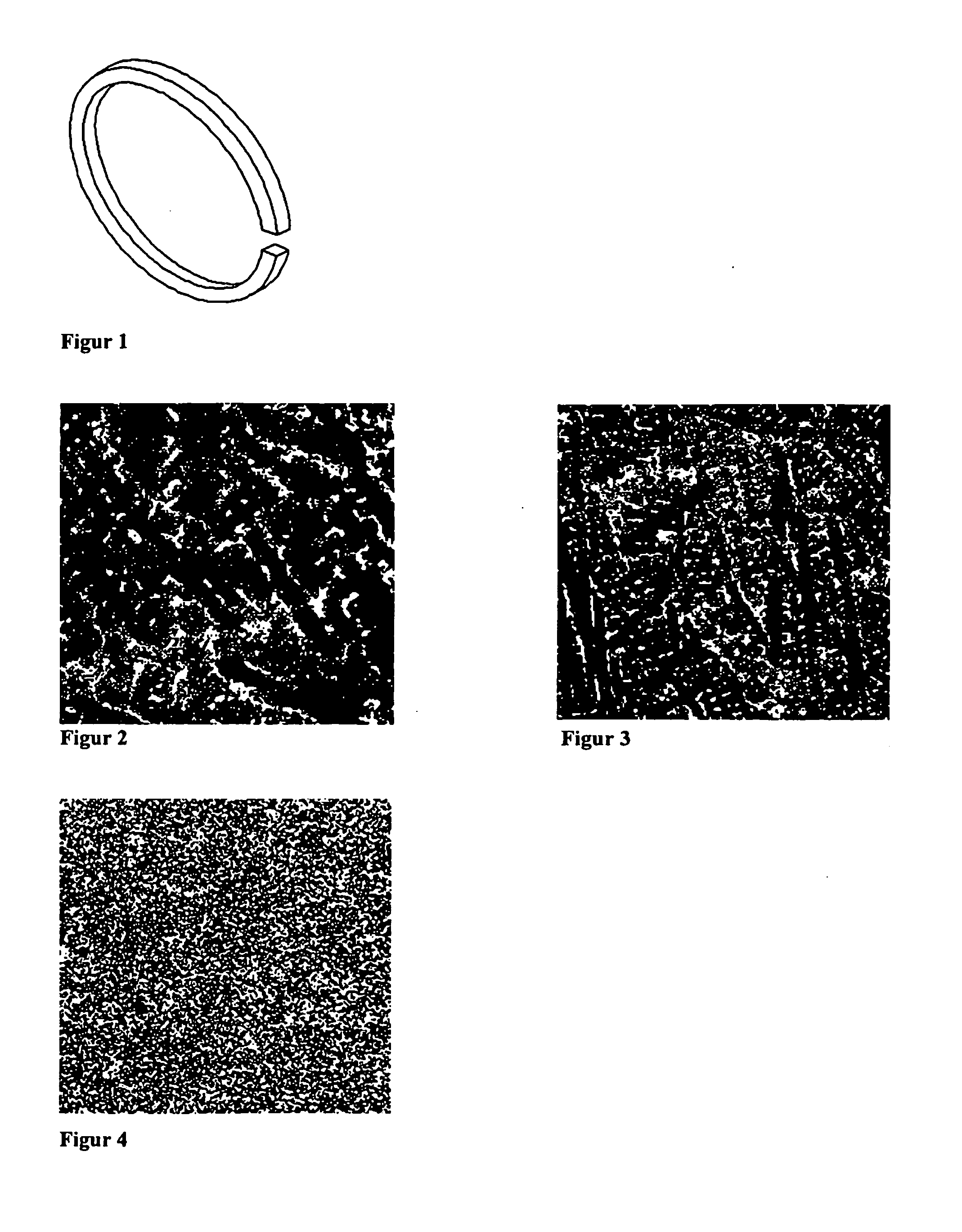

Nitratable steel piston rings and steel cylindrical sleeves, and casting method for the production thereof

InactiveUS20120090462A1Good nitridabilityEasy transitionPiston ringsBraking action transmissionCast ironSteel cylinder

A steel piston ring and a steel cylinder liner are described which comprise as the main body a steel composition which has good nitridability. The steel composition consists of the following elements: 0-0.5 weight % B, 0.5-1.2 weight % C, 4.0-20.0 weight % Cr, 0-2.0 weight % Cu, 45.30-91.25 weight % Fe, 0.1-3.0 weight % Mn, 0.1-3.0 weight % Mo, 0-0.05 weight % Nb, 2.0-12.0 weight % Ni, 0-0.1 weight % P, 0-0.05 weight % Pb, 0-0.05 weight % S, 2.0-10.0 weight % Si, 0-0.05 weight % Sn, 0.05-2.0 weight % V, 0-0.2 weight % Ti and 0-0.5 weight % W. The steel piston ring and the steel cylinder liner can be manufactured in a casting process using the machinery and technology employed for the manufacture of cast iron parts.

Owner:FEDERAL MOGUL BURSCHEID

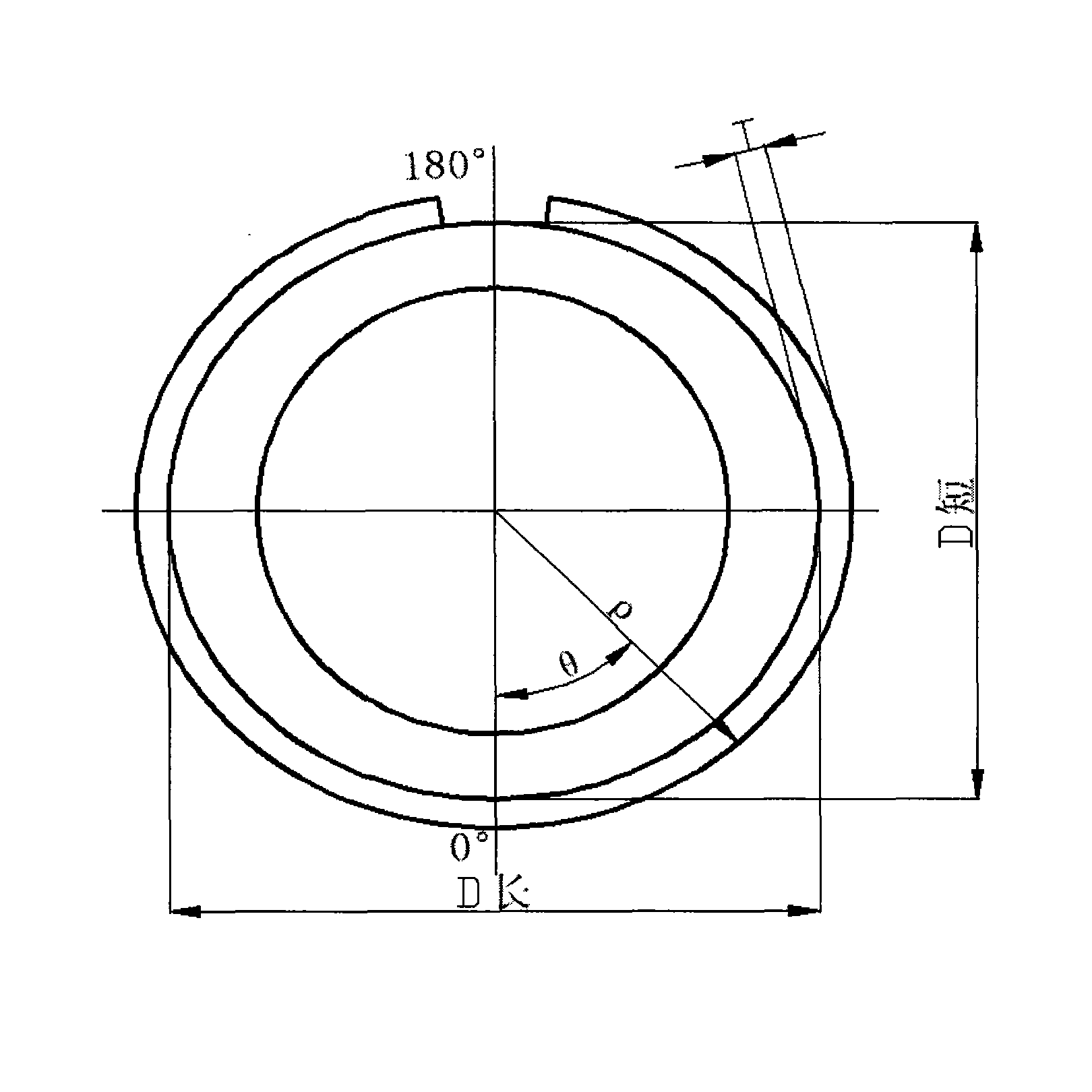

Processing method of steel piston gas ring

ActiveCN101649790ALow yieldSolve the cumbersome machining processPiston ringsMachines/enginesPliabilityProcess manufacturing

The invention discloses a processing method of a steel piston gas ring, which comprises the following steps: winding-destressing-grooving-shaping-top line trimming-flat surface grinding-excircle boning-chroming or nitriding-top line trimming-excircle boning-top line trimming-flat surface grinding; the size of a shaped blank rod is improved by calculating pressure distribution mold lines with different ovality requirements and fully considering the mold line change caused by nitriding shrinkage, thereby the problem of gas ring deformation after procedures, such as nitridation, and the like is greatly reduced, and the finished product ratio of the product is improved. Compared with the defects of long process routes, multi-workshop crossing processing and low comprehensive finished product ratio in the casting iron gas ring, the comprehensive finished product ratio of the steel gas ring processed by using the shaped blank rod can reach up to 95 percent. By utilizing the pliability characteristic of the steel and adopting a shaped steel winding and shaping process, the invention solves the fussy machining process of cast iron material, shortens the manufacturing period, also reduces the procedure waste simultaneously and saves the process manufacturing cost.

Owner:NANJING FAYN PISTON RING

Internal engine piston and its production method

ActiveUS7503304B2Good room-temperature elongationHigh high-temperature yield strengthValve arrangementsInternal combustion piston enginesMetallurgyInternal combustion engine

An integrally cast steel piston for internal engines, the cast steel having (a) a composition comprising 0.8% or less of C, 3% or less of Si, 3% or less of Mn,0.2% or less of S, 3% or less of Ni, 6% or less of Cr, 6% or less of Cu, and 0.01-3% of Nb, the balance being substantially Fe and inevitable impurities, or (b) a composition comprising 0.1-0.8% of C, 3% or less of Si, 3% or less of Mn, 0.2% or less of S, 10% or less of Ni, 30% or less of Cr, 6 % or less of Cu, and 0.05-8% of Nb, the balance being substantially Fe and inevitable impurities, by mass.

Owner:HITACHI METALS LTD +1

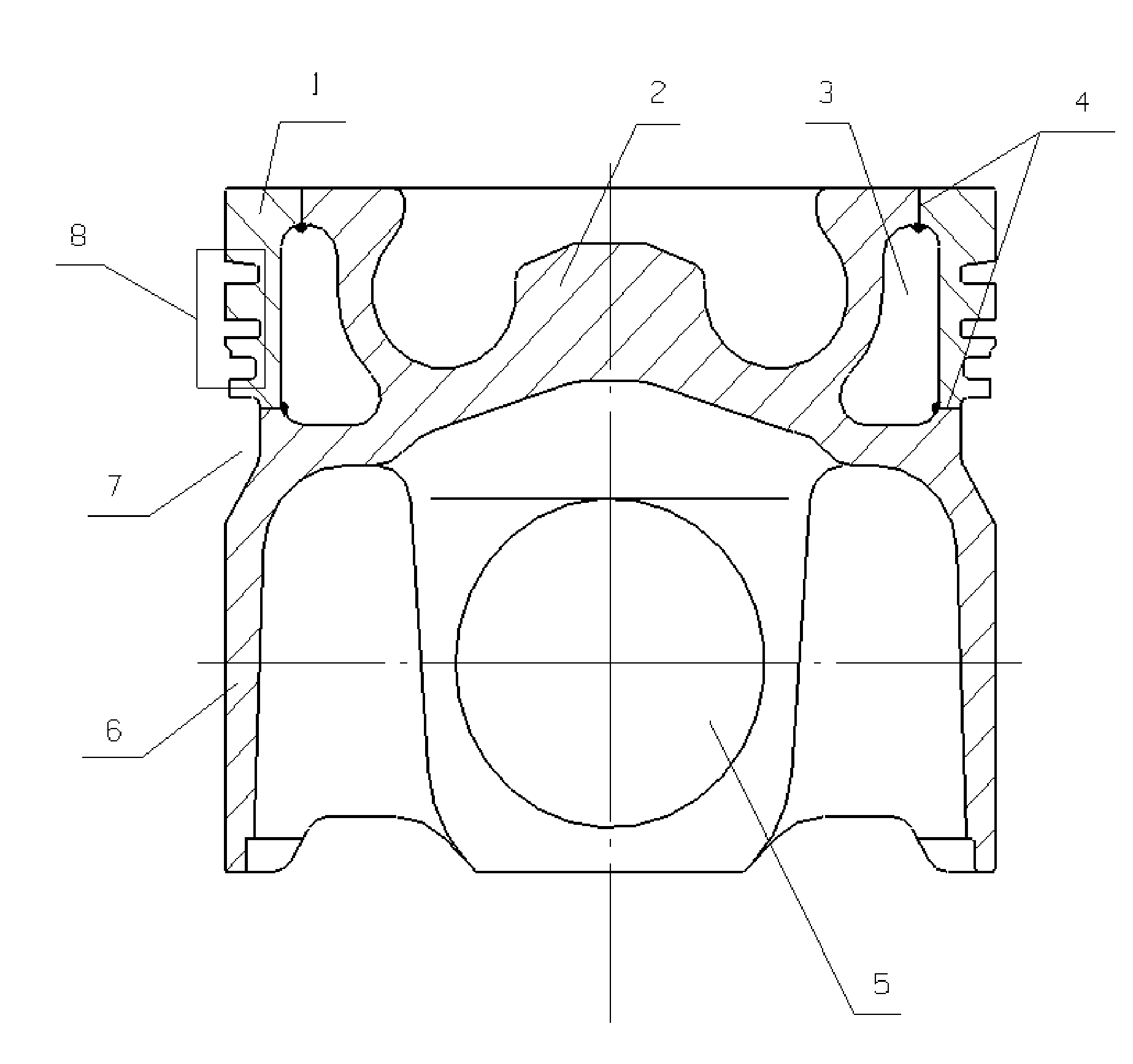

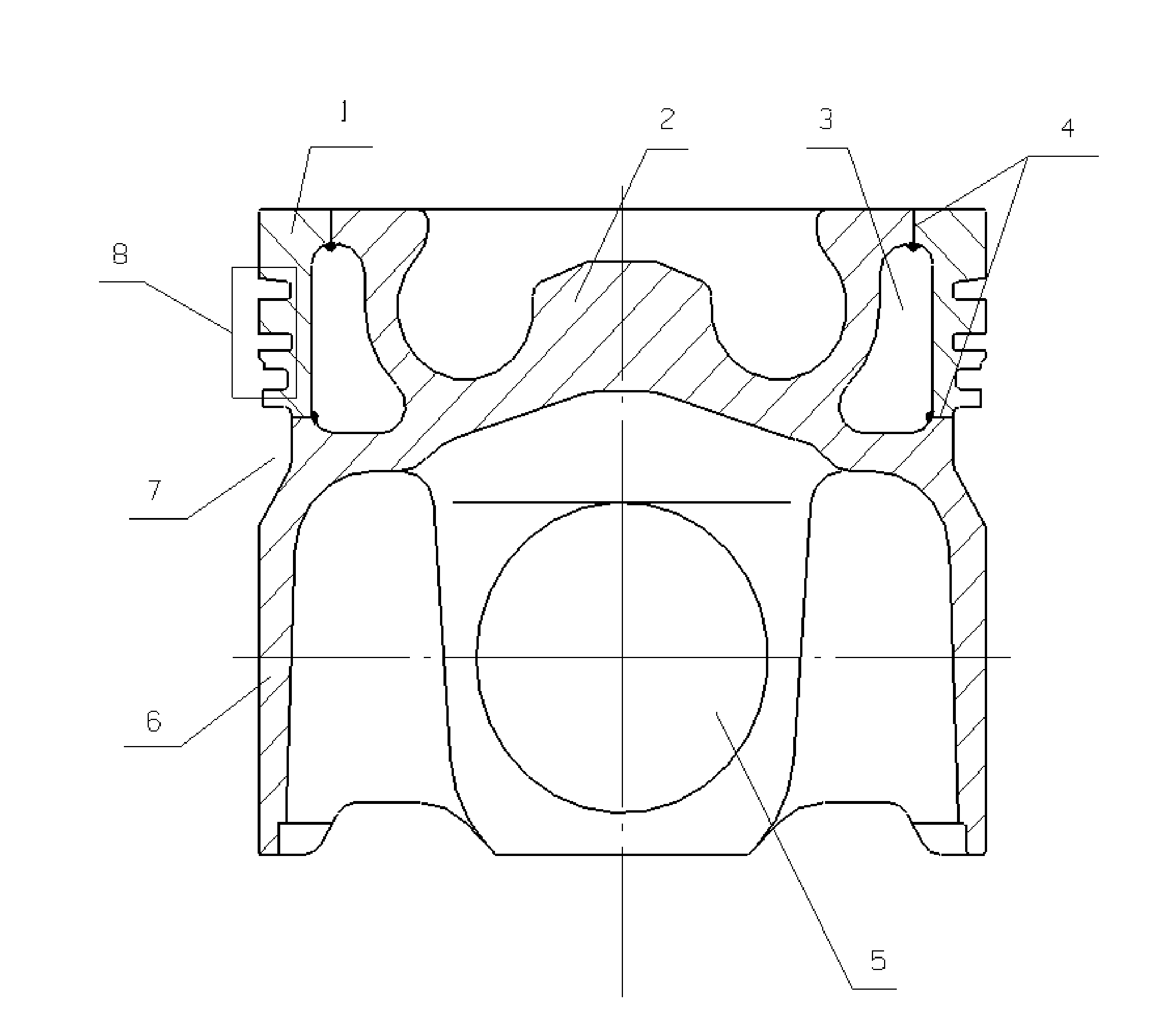

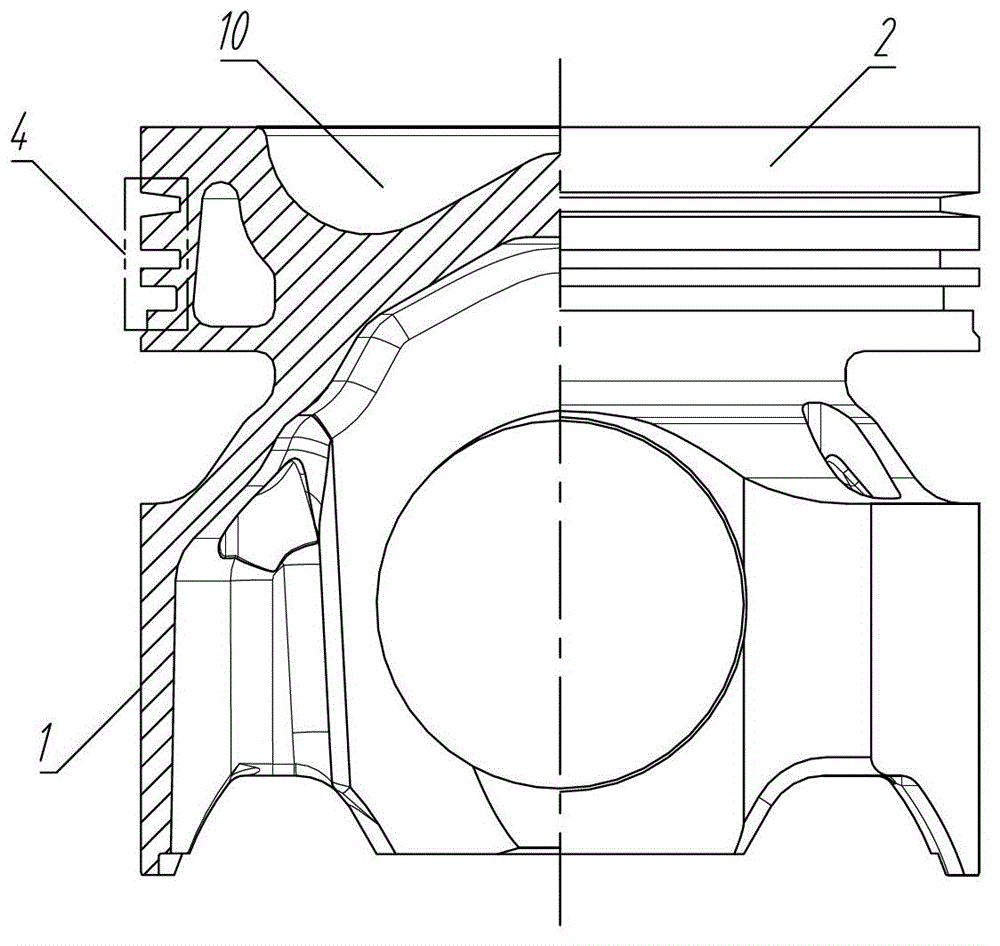

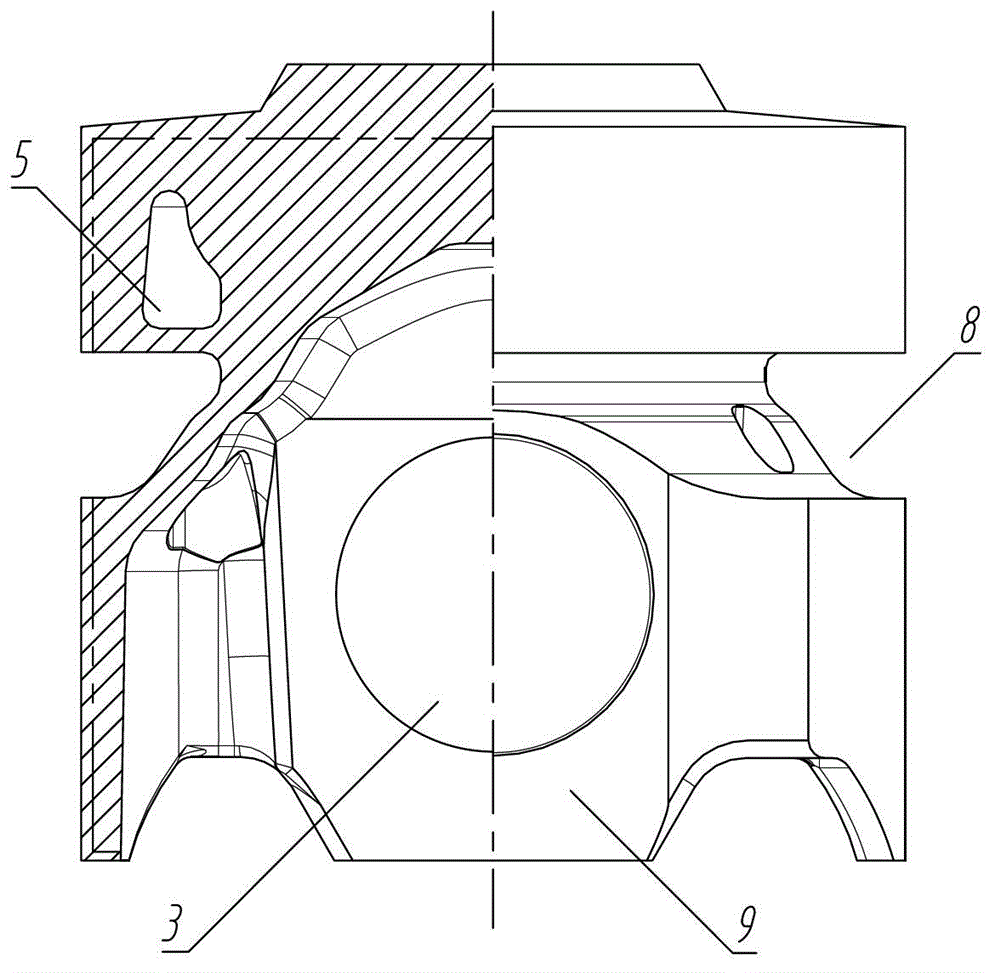

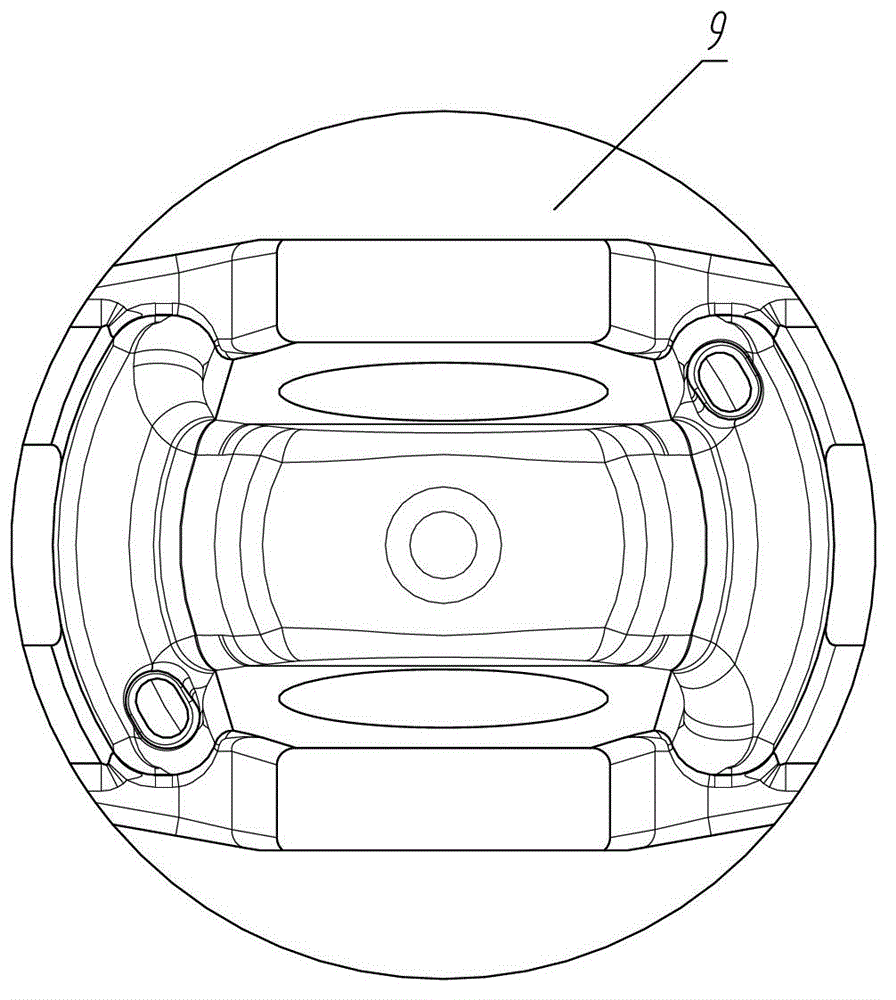

Intensive-cooling steel piston of gas engine

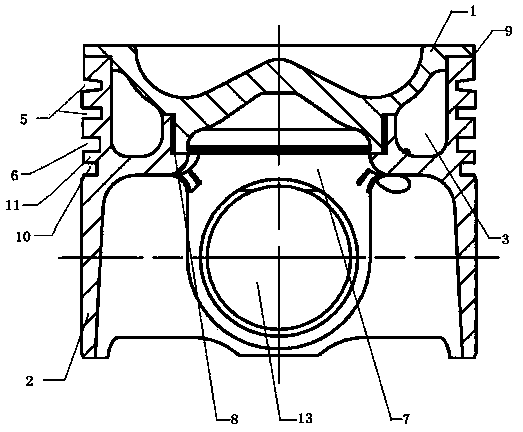

InactiveCN104153909AImprove reliabilityAdapt to job requirementsMachines/enginesPistonsCombustion chamberEngineering

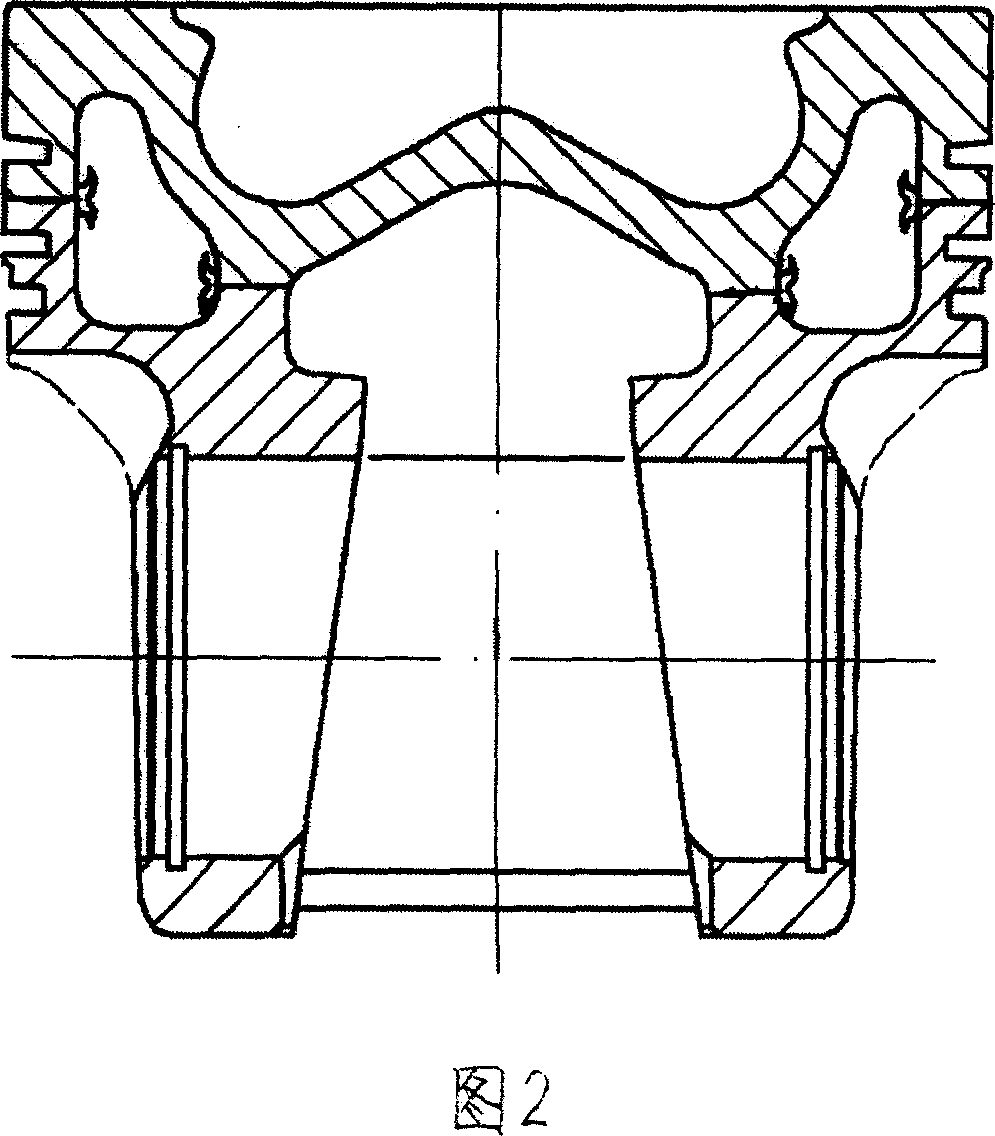

The invention belongs to the technical field of engines and relates to an intensive-cooling steel piston of a gas engine. The piston is made from heat-resisting and high-strength 42CrMo forged steel, an inblock aluminum piston casting mode in the prior art is replaced, the bearing extremity of the piston is improved, and the working reliability of the gas engine is further improved. A combustion chamber is designed to be in a shape of a shallow basin, the specified gas compression ratio can be obtained, and the working requirement of the gas engine is met. An area defined by the piston head portion and the skirt portion is structurally utilized to design an outer cooling cavity and an inner cooling cavity, the outer cooling cavity cools an outer circle of the piston head portion and the side wall of the combustion chamber, and the inner cooling cavity cools the bottom of the combustion chamber. By the adoption of the design, the problem that a single piston cooling cavity difficultly meets the using requirement due to large heat load is solved, heat stress and heat strain produced by the piston bearing high heat load are remarkably reduced, and the fatigue life of the piston is prolonged.

Owner:HENAN DIESEL ENGINE IND

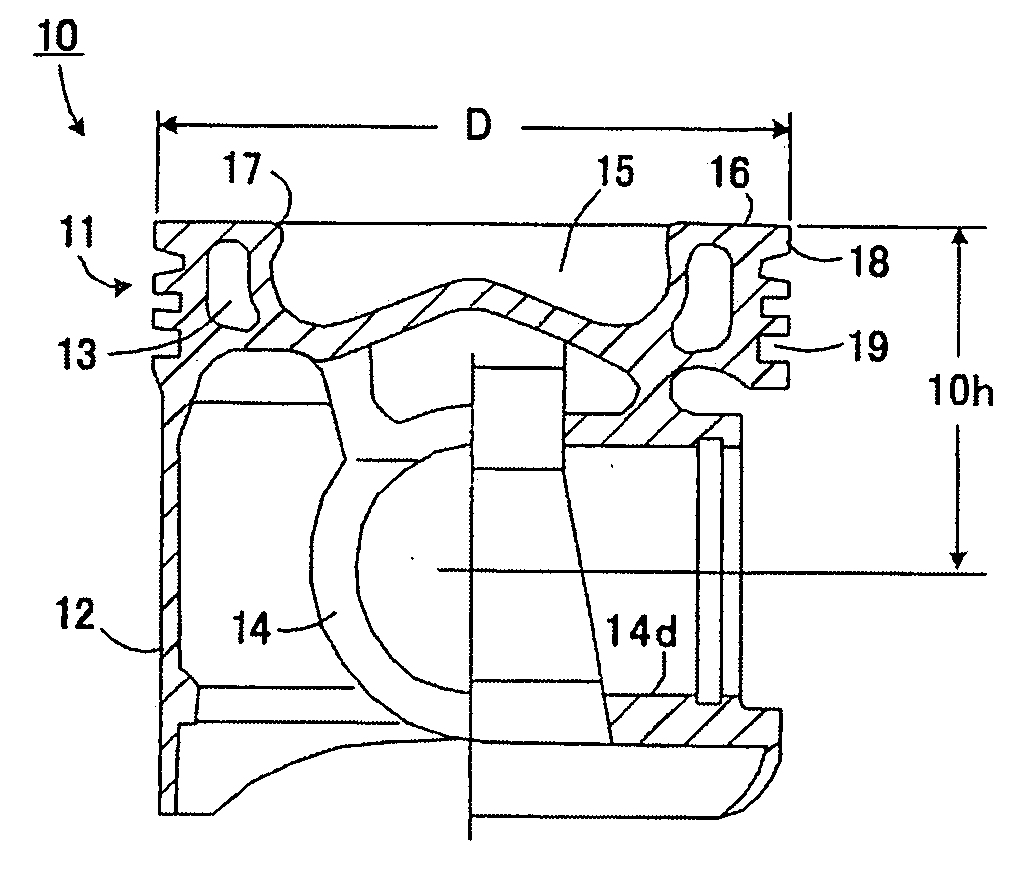

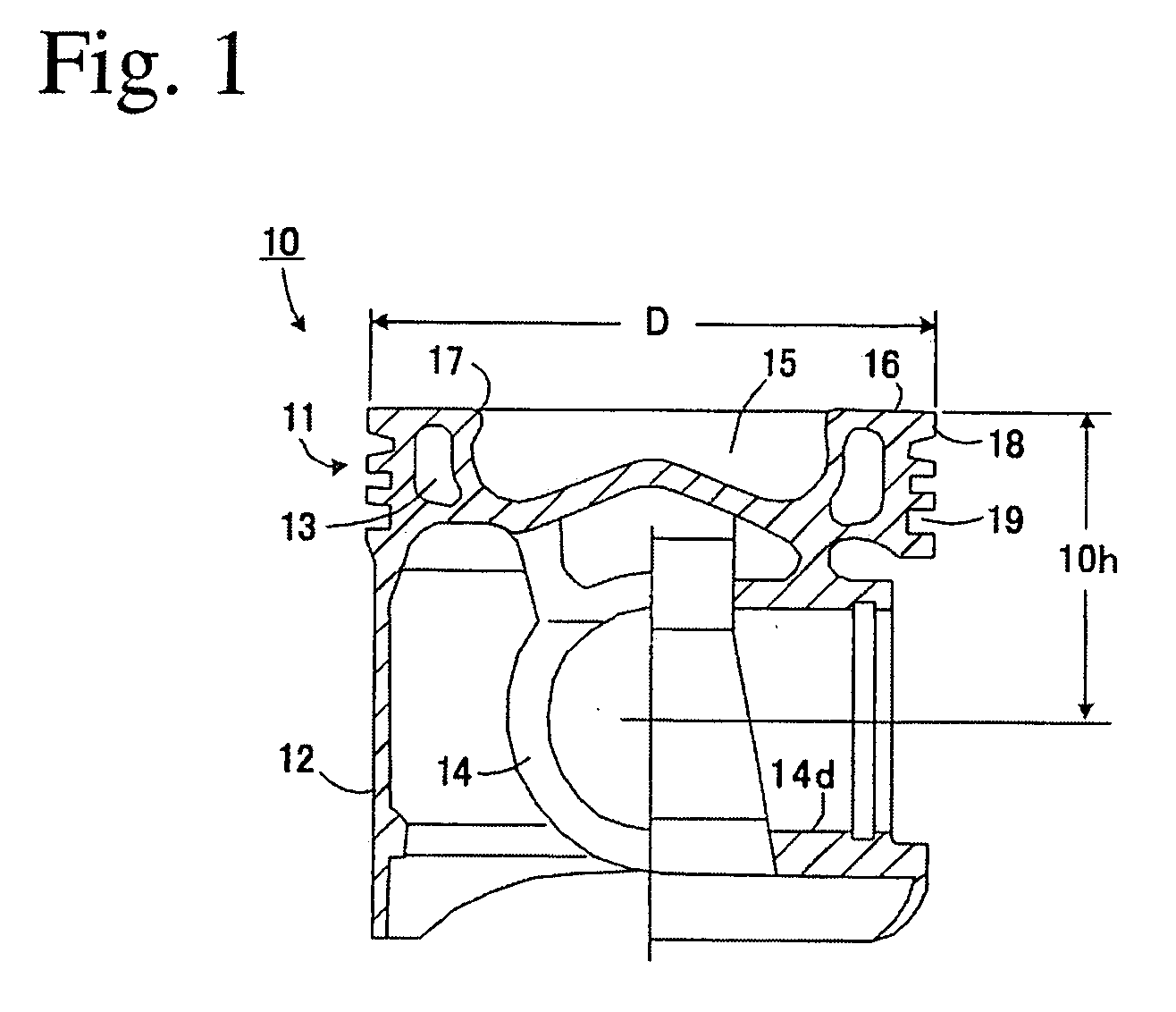

One-piece steel piston

A one-piece steel piston that is made from a piston blank that includes a portion that is configured and designed to be displaced to form a cooling gallery and ring belt. The piston blank can be formed by a casting or forging process. The portion that is designed and configured to be displaced is a flange that extends radially outward. The flange is bent downward or upward so that a peripheral edge of the flange contacts another portion of the piston. The peripheral edge of the flange and the other portion of the piston can be welded together or mechanically engaged.

Owner:KOLBENSCHMIDT AG

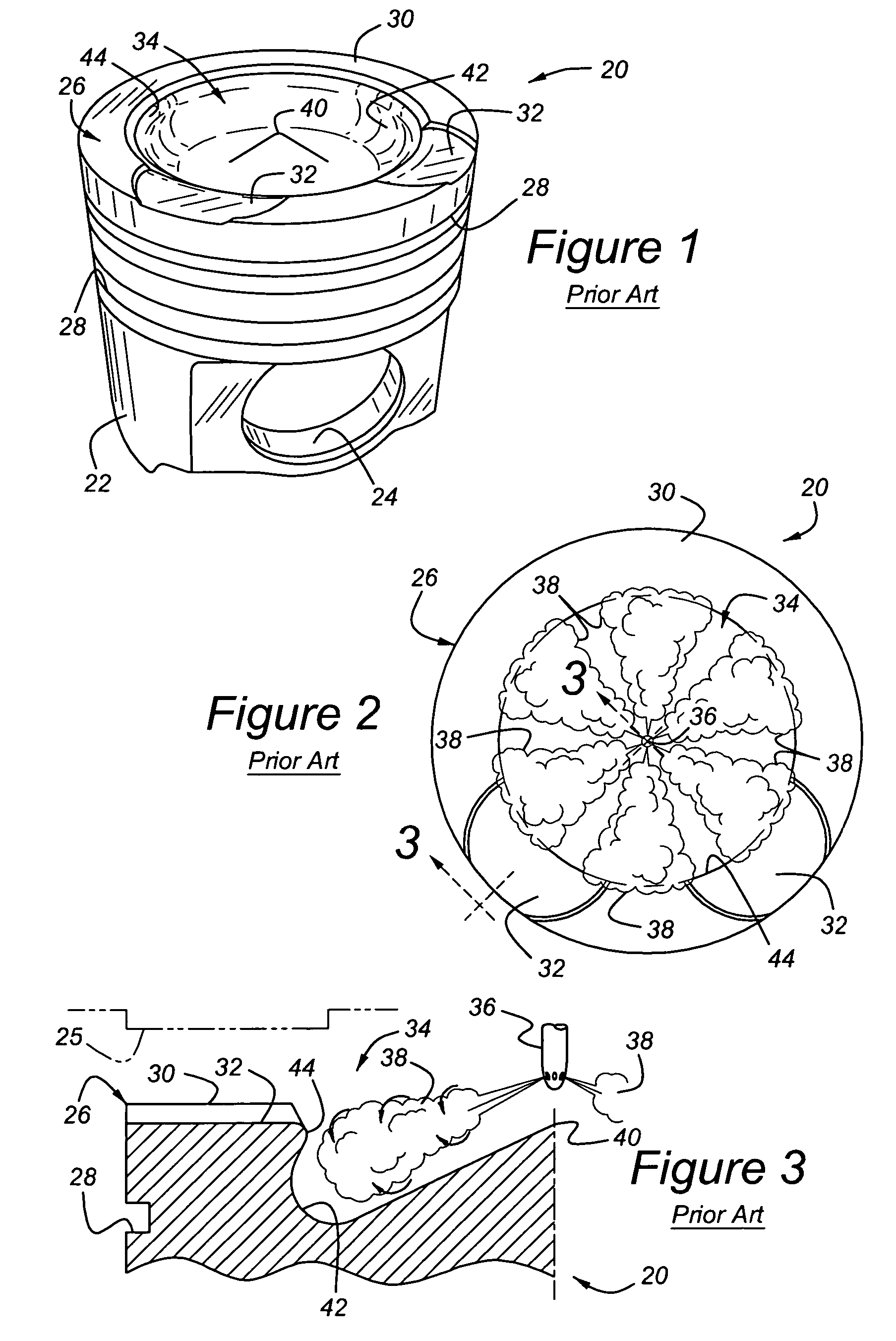

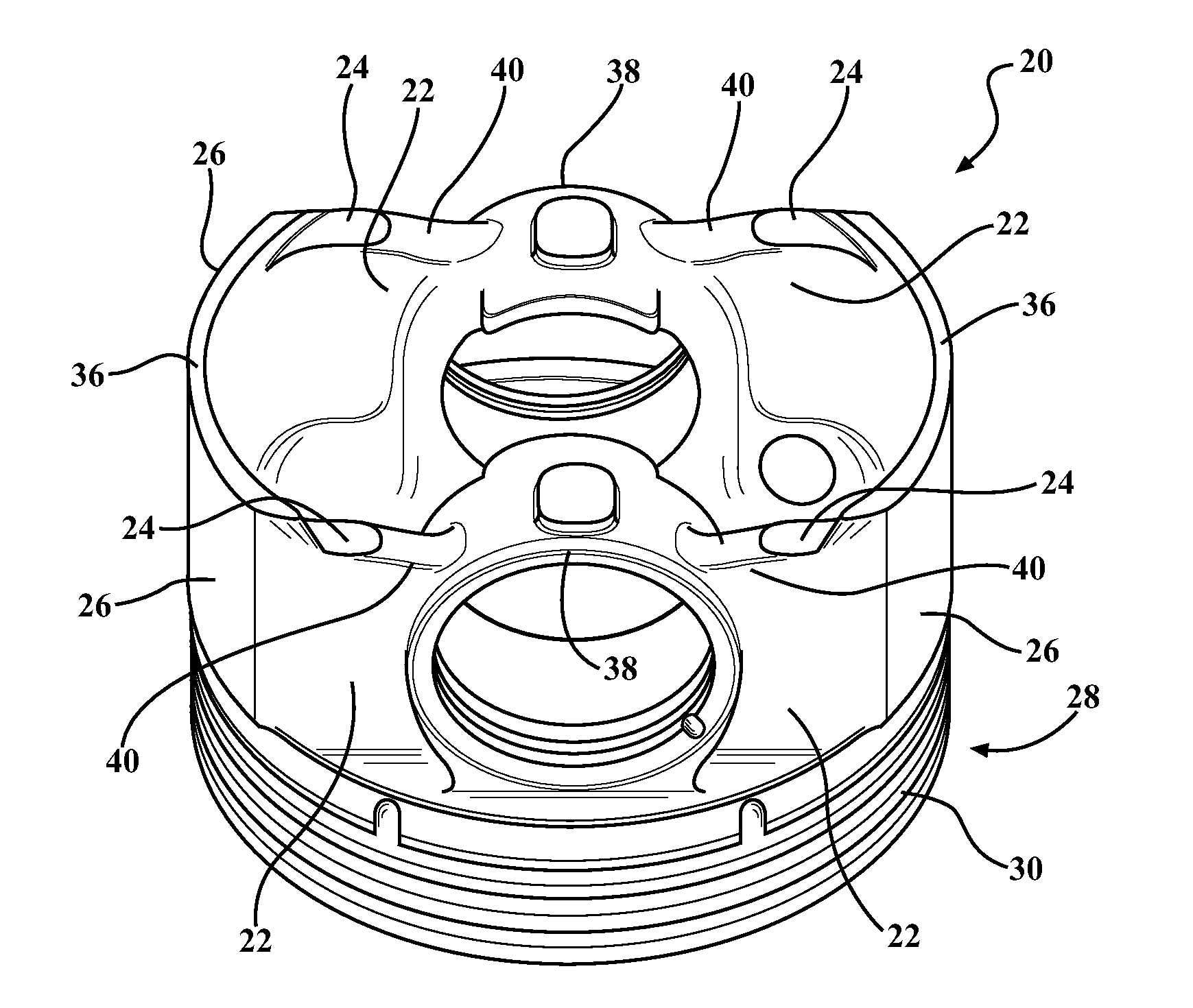

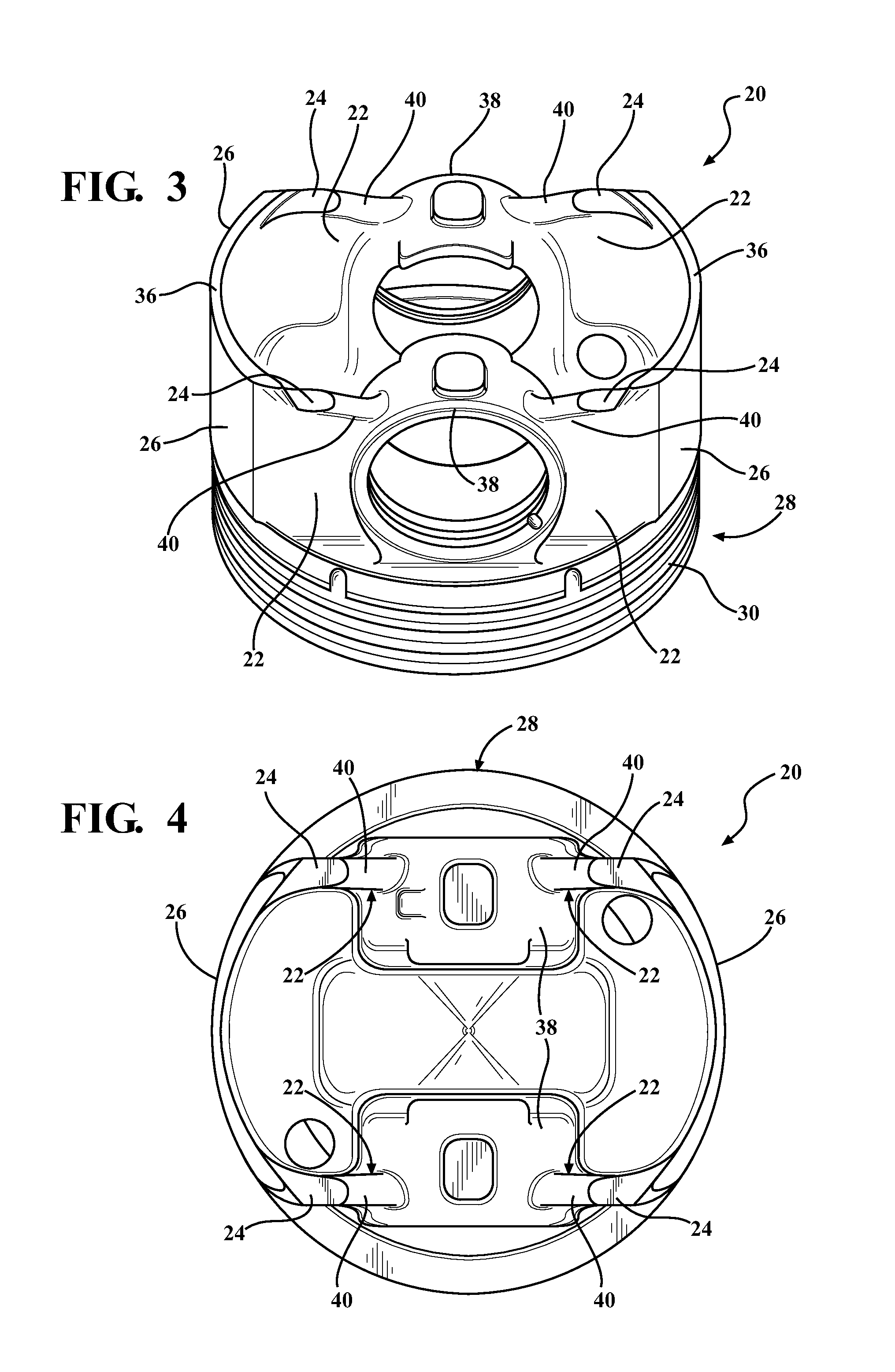

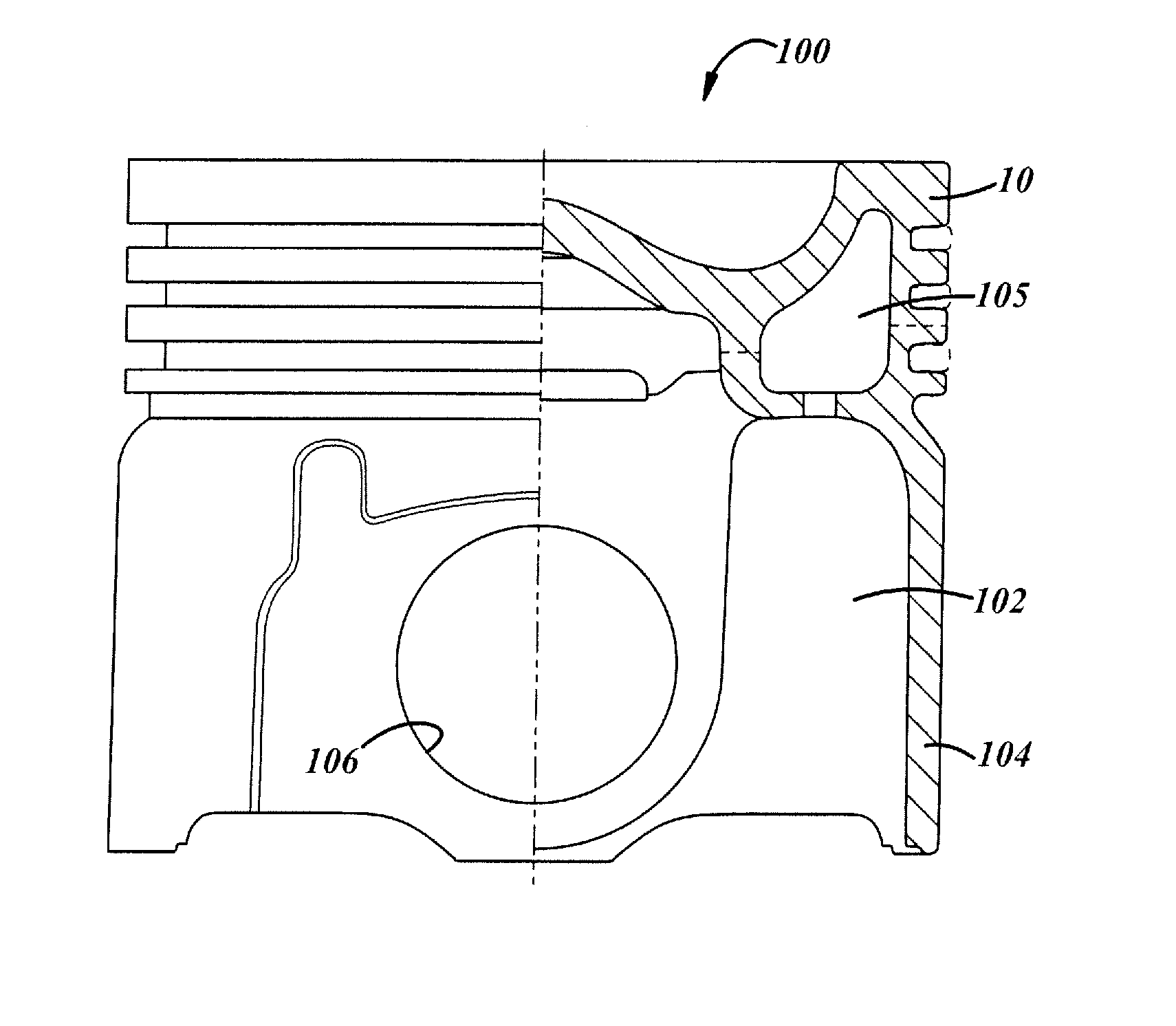

Monolithic, galleryless piston and method of construction thereof

ActiveUS20160115899A1Improve engine efficiencyImprove performanceMachines/enginesPistonsCombustionReciprocating motion

A galleryless steel piston for an internal combustion engine is provided. The piston has a monolithic piston body including an upper wall forming an upper combustion surface with first and second portions. The first portion extends annularly along an outer periphery of the upper wall and the second portion defines a combustion bowl. The piston further includes undercrown surface located directly opposite the combustion bowl with an exposed 2-dimensional surface area allowing for contact of cooling oil. The exposed 2-dimensional surface area ranges from 25 to 60 percent of a cross-sectional area defined by a maximum outer diameter of the piston body. To further enhance cooling, a portion of the undercrown surface is concave or convex, such that oil is channeled during reciprocation of the piston from one side to the opposite side of the piston.

Owner:TENNECO

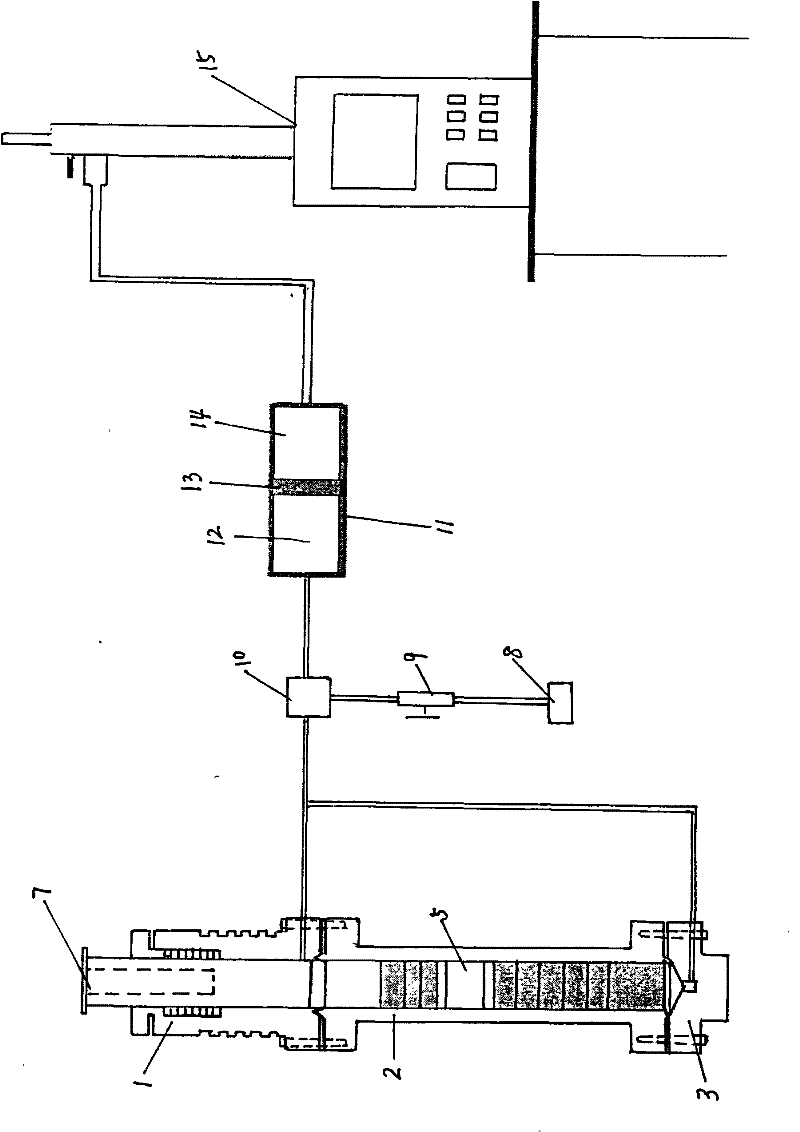

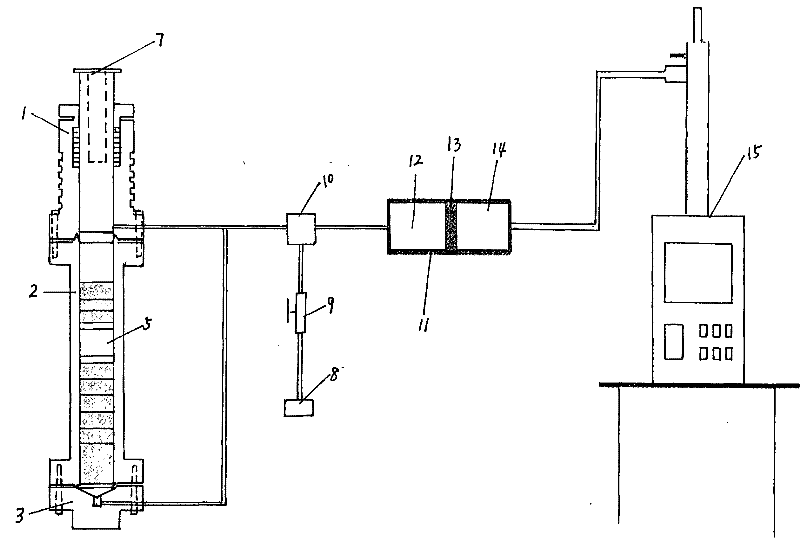

Solid-fluid coupling pressure controlled hydrocarbon generation and expulsion simulating experimental device

InactiveCN102160979AFluid properties are stableEasy to controlPressure vessels for chemical processDistilled waterEngineering

Owner:CHINA PETROLEUM & CHEM CORP +1

Steel piston with counter-bore design

ActiveUS20140076264A1Improve performanceReduce the total massMachines/enginesPistonsEngineeringInternal combustion engine

Owner:TENNECO

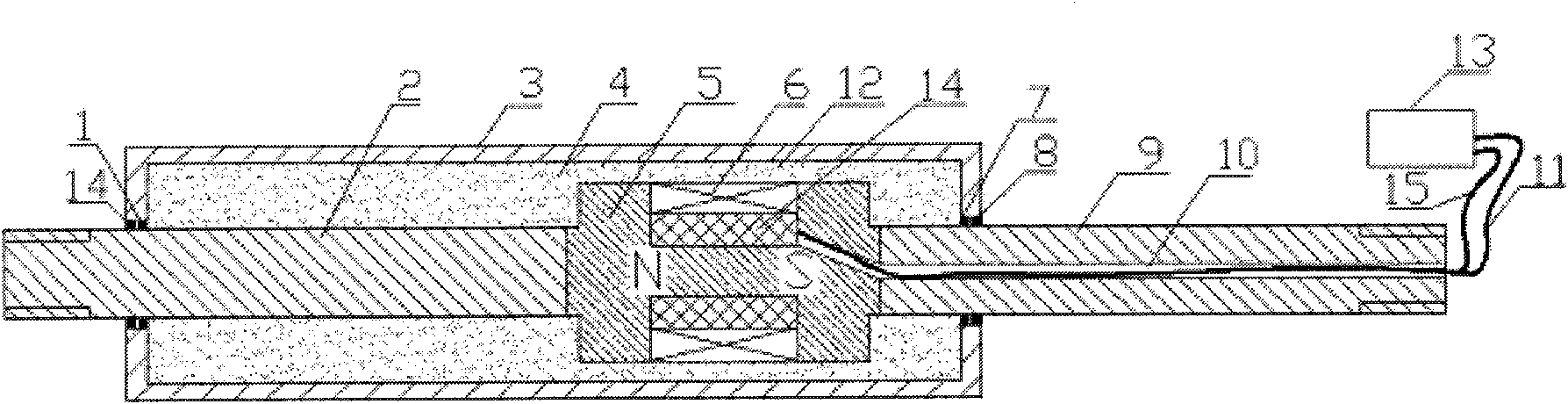

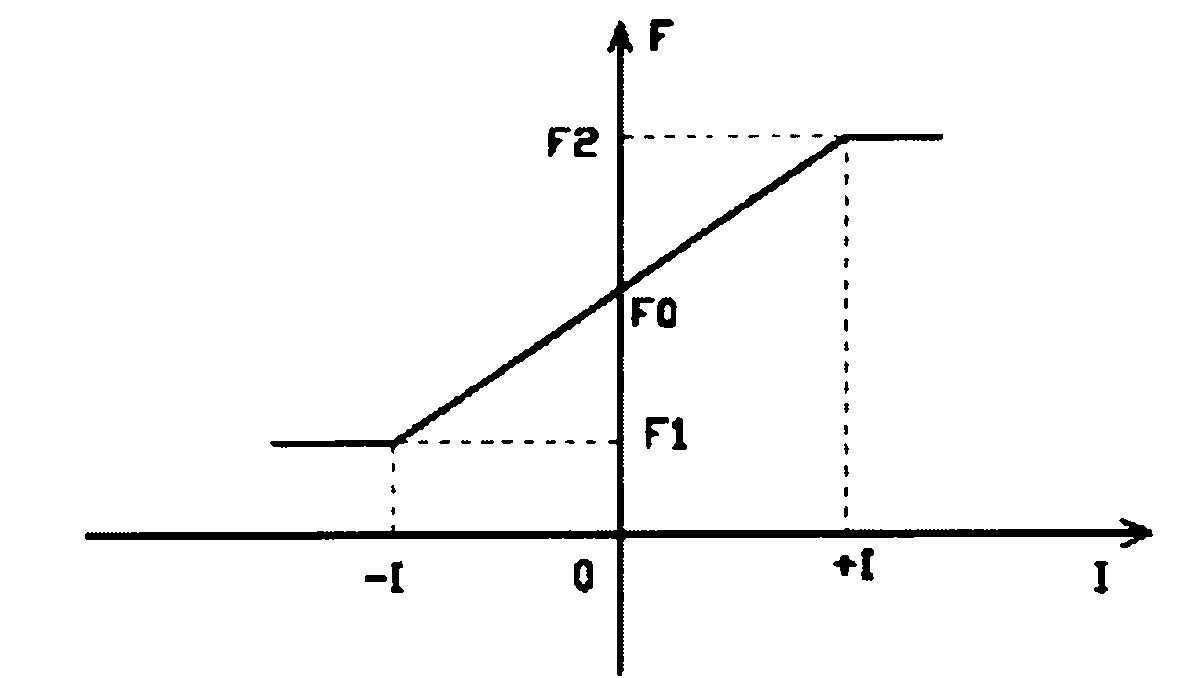

Magnetic steel piston type magneto-rheological damper with double ejection rods

InactiveCN102182785AHigh viscosityLow viscosityNon-rotating vibration suppressionPower flowNon magnetic

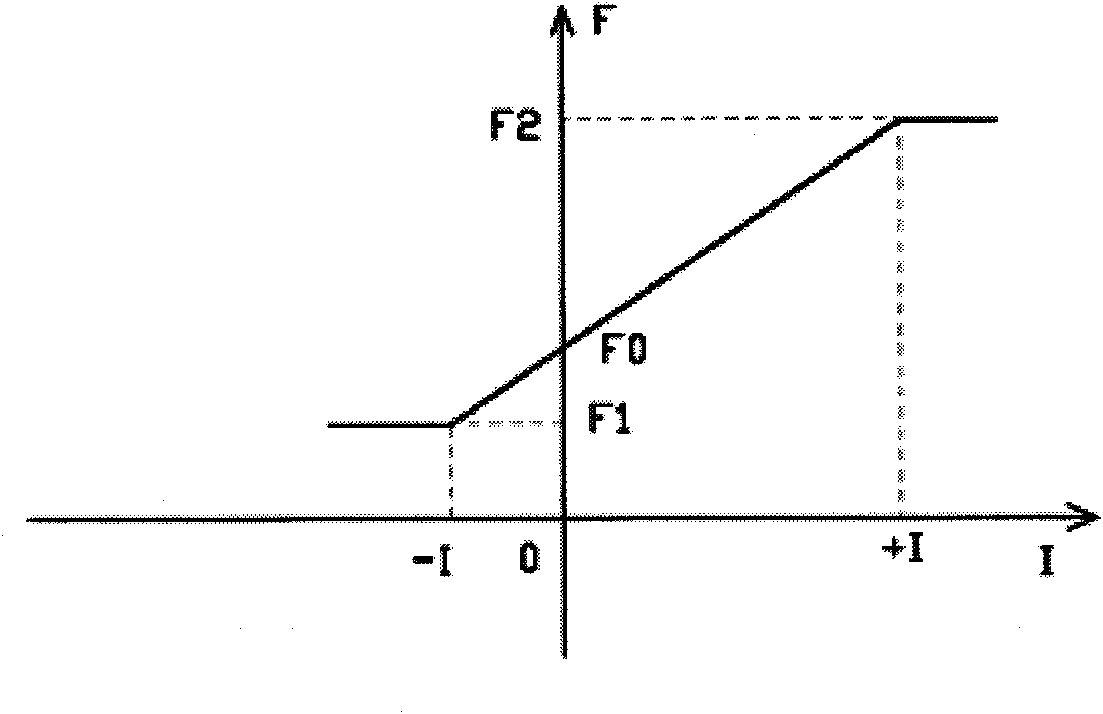

The invention discloses a magnetic steel piston type magneto-rheological damper with double ejection rods, comprising a working cylinder, a piston and two piston rods; the working cylinder is filled with magneto-rheological fluid; the piston is made of magnetic steel, two piston rods are both made of non-magnetic materials, a magnet exciting coil and a magnetizing-demagnetizing coil are wound in the middle of the piston, and the magnetic steel piston can be magnetized and demagnetized by controlling a power source, therefore, the magnetic steel piston has certain magnetic field intensity and the magnetic steel piston type magneto-rheological damper with double ejection rods has certain output damping force, and the output damping force of the magnetic steel piston type magneto-rheological damper with double ejection rods is regulated by changing the size and the direction of current input to the magnet exciting coil of the magnetic steel piston.

Owner:谭晓婧

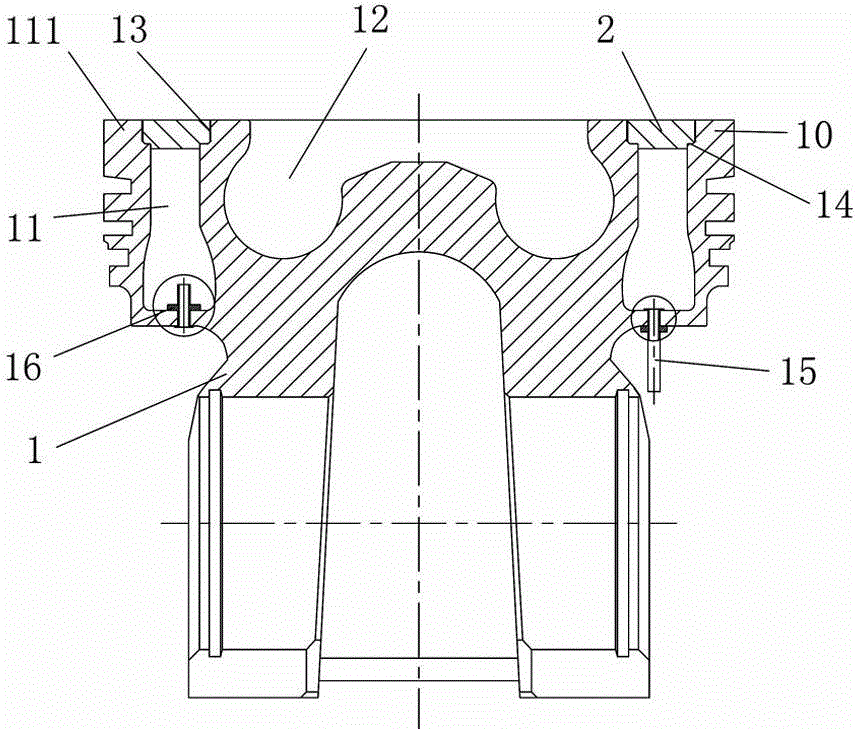

Threaded welding type integral forged steel piston

ActiveCN104005876AImprove stabilityReduced soldering requirementsMachines/enginesPistonsInterference fitEngineering

Owner:BINZHOU DONGHAILONG PISTON

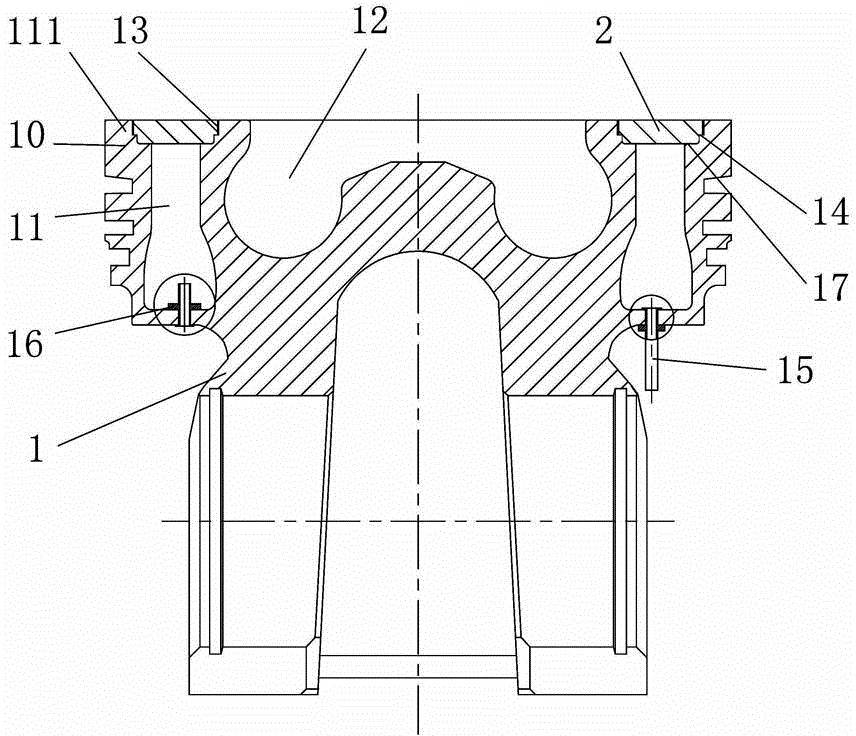

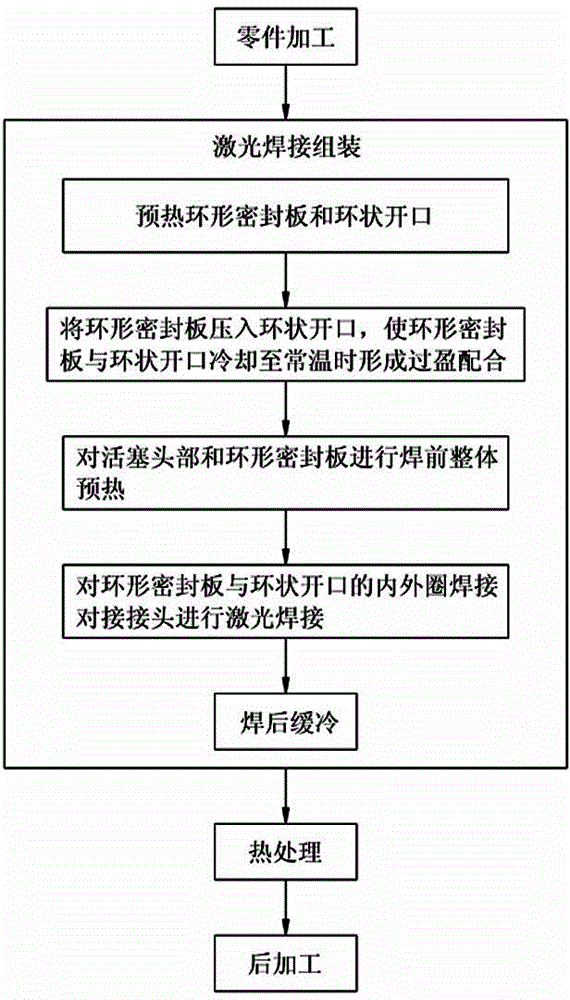

Laser welding forming internal cooling oil channel based steel piston and machining method thereof

InactiveCN105986922AImprove cooling effectImproved cooling performance for longer piston lifeMachines/enginesPistonsInterference fitCombustion chamber

The invention discloses a steel piston with an inner cooling oil channel formed by laser welding and a processing method thereof. The steel piston includes a piston body and an annular sealing plate. The piston body is provided with an inner cooling oil passage and a combustion chamber on the piston head. The upper end of the inner cooling oil passage is provided with an annular opening. The annular opening is located at the top of the piston head. The annular sealing plate It is embedded in the annular opening and fixed by laser welding, and the upper end of the inner cooling oil passage is sealed. The method includes the following steps: S1: parts processing; S2: laser welding assembly: including preheating the annular sealing plate and the annular opening; forming an interference fit when the annular sealing plate and the annular opening are cooled to normal temperature; The sealing plate is preheated as a whole before welding; laser welding is performed on the annular sealing plate and the inner and outer ring interfaces of the annular opening; slow cooling after welding; S3: heat treatment; S4: post-processing. It has the advantages of convenient processing, can effectively improve the cooling performance of the piston, prolong the service life, reduce the weight of the piston and improve the working performance.

Owner:强哲菲

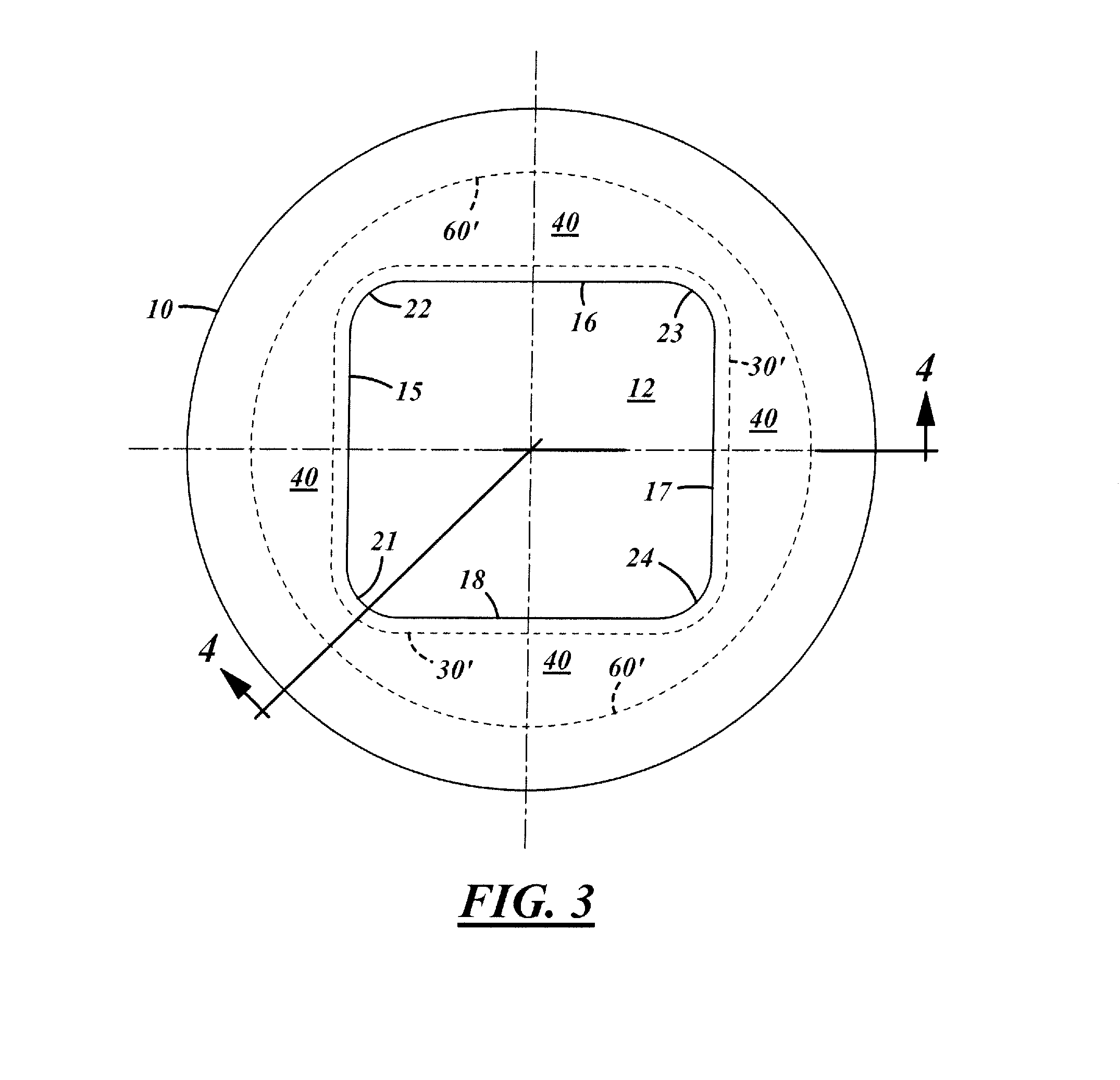

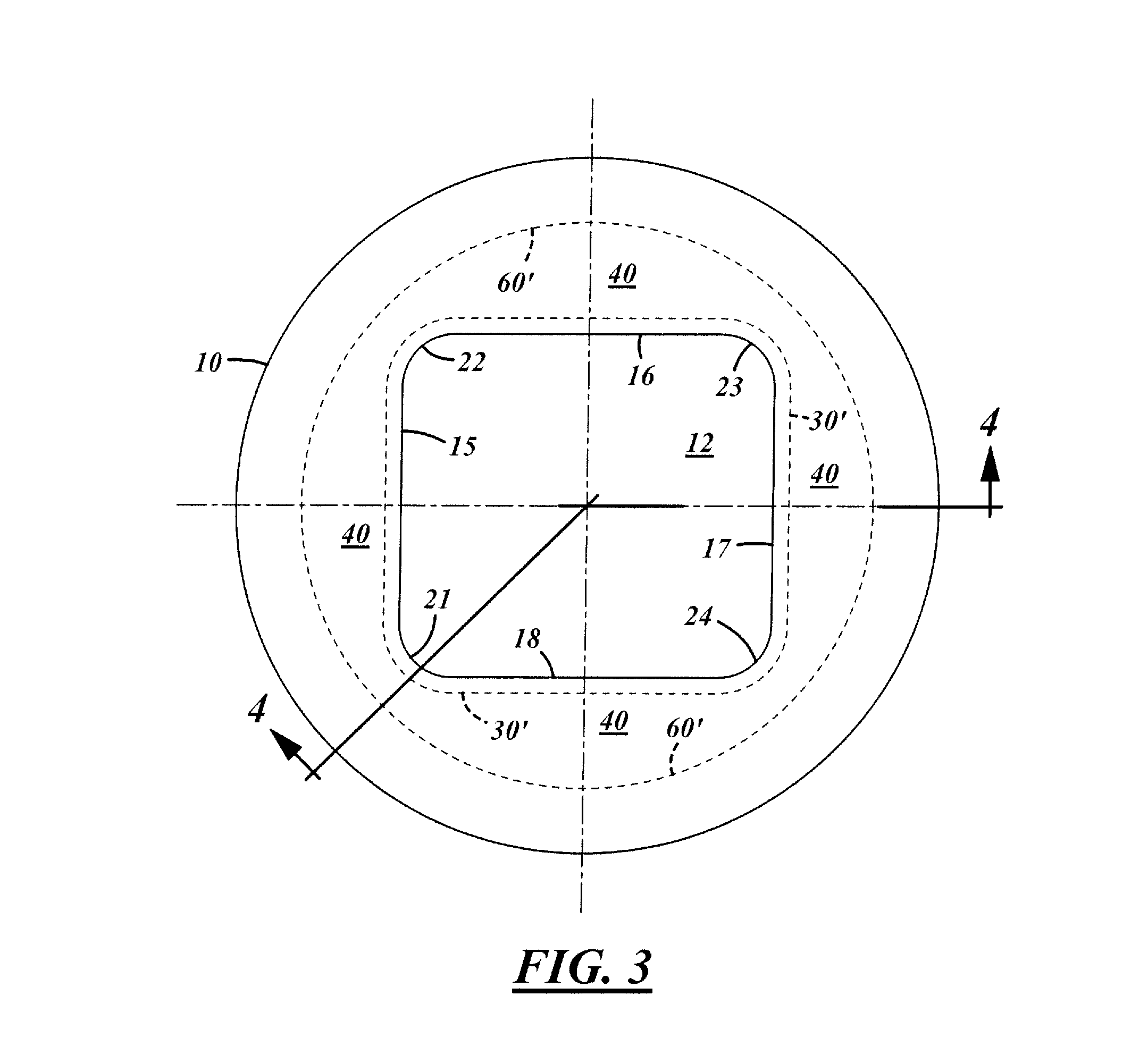

Complex-Shaped Piston Oil Galleries With Piston Crowns Made By Cast Metal or Powder Metal Processes

ActiveUS20140230774A1Uniform wall thicknessMinimizes and eliminates hot spotInternal combustion piston enginesPlungersCombustionMetallurgy

A steel piston with an oil gallery, and process for forming a steel piston oil gallery channel, which corresponds to the complex shape of the combustion bowl in the piston crown. The piston crown is made by a cast metal or powder metal forming process. The oil gallery channel is formed to the basic shape that corresponds to the shape of the walls of the combustion bowl. Machine-turning surfaces in the oil gallery channel can be machine-finished as desired. Surfaces in the oil gallery which cannot be machined with conventional turning operations, such as recesses and protrusions into the channel, are left in the original as-formed condition.

Owner:TENNECO

Piston ring and method for manufacturing same

InactiveCN105683631AAvoid deformationInhibitionPiston ringsVacuum evaporation coatingCarbon filmInter layer

In the present invention, in order to provide a piston ring covered with an amorphous hard carbon film that has low friction characteristics and outstanding abrasion resistance and film peeling resistance in order to achieve lower fuel consumption in an automobile, the outer peripheral surface of a steel piston ring base material is covered with a non-crystalline hard carbon film with a thickness of 0.4-20 [mu]m, with the following interposed therebetween: a base layer that comprises a CrN / Cr layered film or CrN / TiN layered film with a thickness of 10-60 [mu]m, in which CrN-type chromium nitride and chromium metal or TiN-type titanium nitride are layered alternately; and an intermediate layer that comprises chromium metal and / or titanium metal and has a thickness of 0.05-1.0 [mu]m.

Owner:RIKEN CO LTD

Integrated type cast steel piston and manufacturing method thereof

ActiveCN102979641ARequires minimizationReduce weightFurnace typesMachines/enginesCombustion chamberSteel casting

The invention discloses an integrated type cast steel piston, wherein a side window type weight losing area is arranged in a piston skirt part; the weight of the integrated type cast steel piston is decreased by more than 15% to 20%; in such a way, the weight of the integrated type cast steel piston is enabled to approach the weight of an aluminum alloy piston of the same type; and therefore, the requirement on the light weight of an engine is met. The invention also discloses a manufacturing method of the integrated type cast steel piston, wherein the method mainly comprises the following steps: casting a piston blank, and casting out the side window type weight losing area, a pin hole, a sealed cooling cavity, a cooling oil outlet and a cooling oil inlet; performing heat treatment on the piston blank; processing out a combustion chamber concave pit, a piston head, the piston skirt part and an annular groove area in the piston blank which undergoes the heat treatment; and performing overall phosphating on the piston. With the adoption of the method provided by the invention, the production technology of the integrated type cast steel piston is simplified, the production efficiency is improved, and the production cost is simultaneously lowered.

Owner:湖南江滨机器(集团)有限责任公司

One-piece steel piston

A one-piece steel piston that is made from a piston blank that includes a portion that configured and designed to be displaced to form a cooling gallery and ring belt. The piston blank can be formed by a casting or forging process. The portion that is designed and configured to be displaced is a flange that extends radially at the top of the piston blank. The flange is bent downward so that a peripheral edge of the flange contacts a top portion of the piston skirt. The peripheral edge of the flange and the top portion of the skirt can be welded together or provided with inter-engaging structures.

Owner:KS KOLBENSCHMIDT US

Complex-Shaped Forged Piston Oil Galleries

ActiveUS20140230646A1Uniform wall thicknessMinimizes and eliminates hot spotPlungersMachines/enginesCombustionPetroleum engineering

A steel piston with an oil gallery, and process for forming a steel piston oil gallery channel, which corresponds to the complex shape of the combustion bowl in the piston crown. The oil gallery channel is first forged to the basic shape that corresponds to the shape of the walls of the combustion bowl. Machine-turning surfaces in the oil gallery channel can be machine-finished as desired. Surfaces in the oil gallery which cannot be machined with conventional turning operations, such as recesses and protrusions into the channel, are left in the original forged condition.

Owner:TENNECO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com