Laser welding forming internal cooling oil channel based steel piston and machining method thereof

A technology of cooling oil passage and laser welding, applied in laser welding equipment, piston, welding equipment and other directions, can solve the problems of affecting the axial size of the piston head, large dimensional tolerance of effective height, unreliable quality of welded joints, etc. The effect of simplifying the laser welding process, overcoming the difficulty of processing, and improving the cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

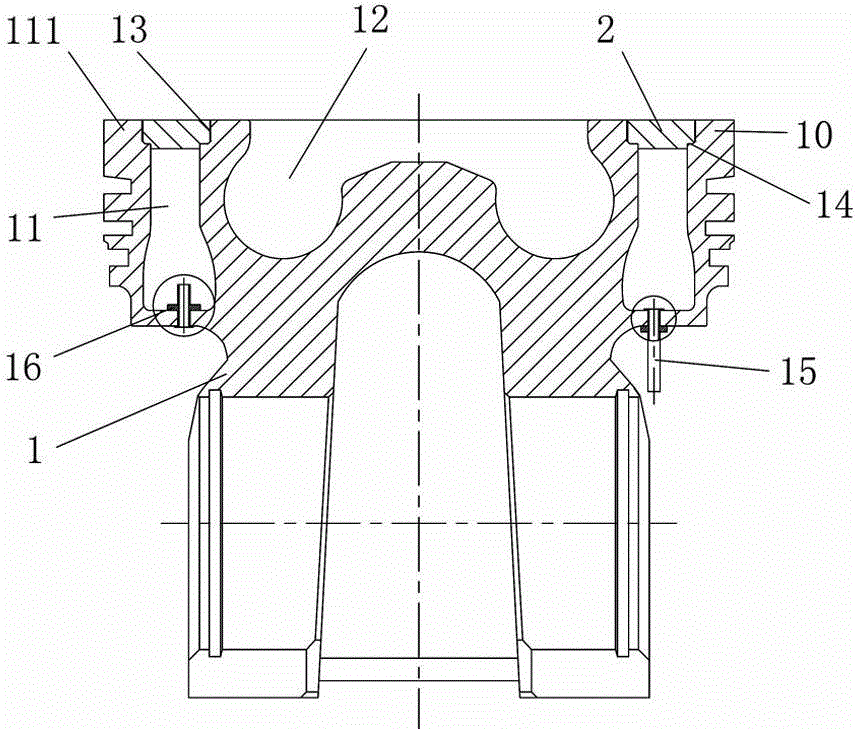

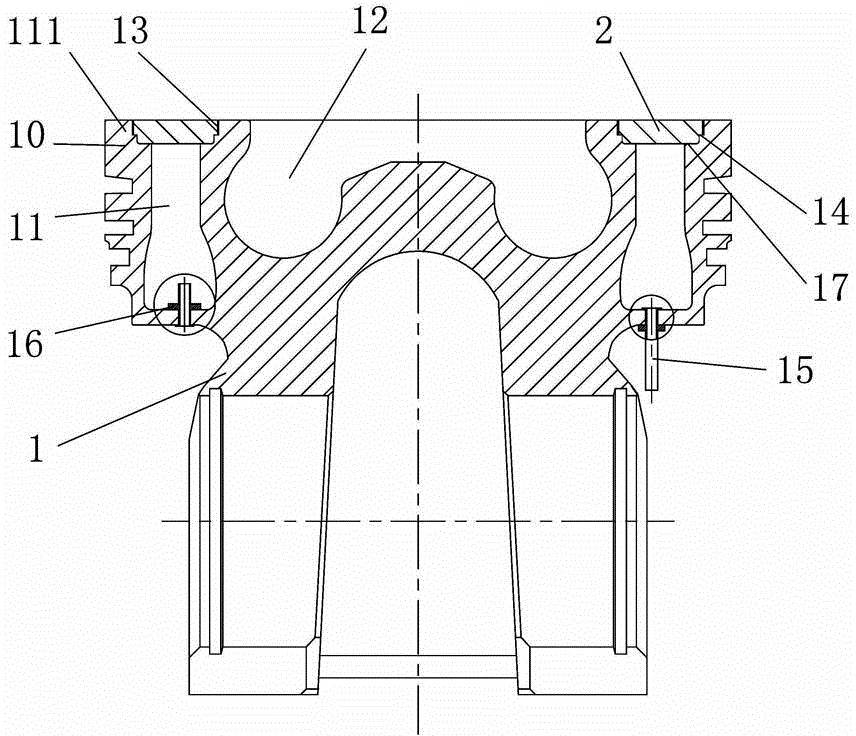

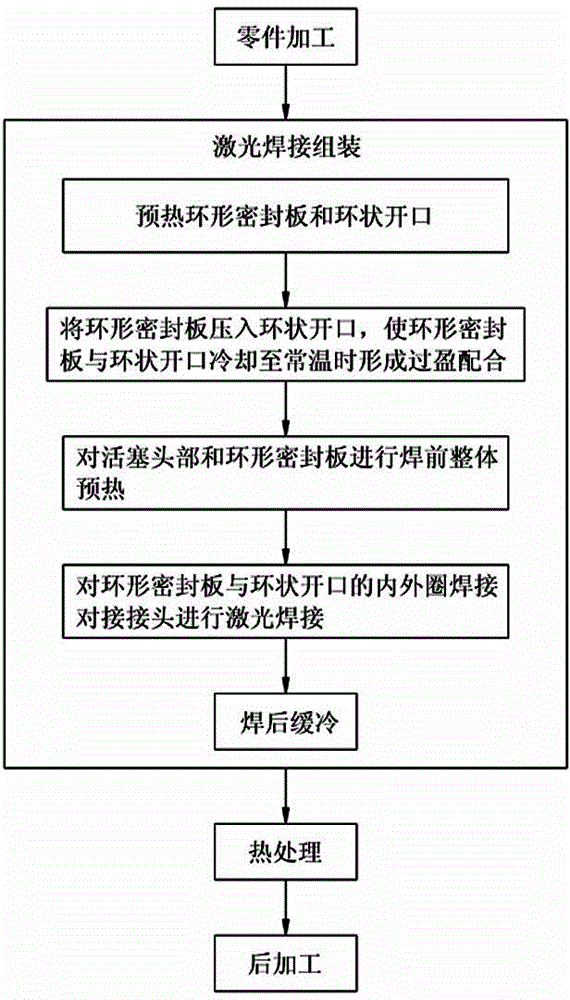

[0035] figure 1 It shows the first steel piston embodiment of the present invention based on the laser welding forming inner cooling oil passage, the steel piston includes a piston body 1 and an annular sealing plate 2, and the piston body 1 is provided with an inner cooling oil passage on the piston head 10 11 and the combustion chamber 12, the inner cooling oil passage 11 is set around the combustion chamber 12, the upper end of the inner cooling oil passage 11 is provided with an annular opening 13, the annular opening 13 is located at the top 111 of the piston head 10, and the annular sealing plate 2 is embedded in the annular The opening 13 is connected and fixed by laser welding, the upper end of the inner cooling oil passage 11 is sealed, and the inner cooling oil passage 11 can be independently processed before laser welding the annular sealing plate 2, the process is simple, the processing is convenient, and it is convenient to form a large volume of inner cooling oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com