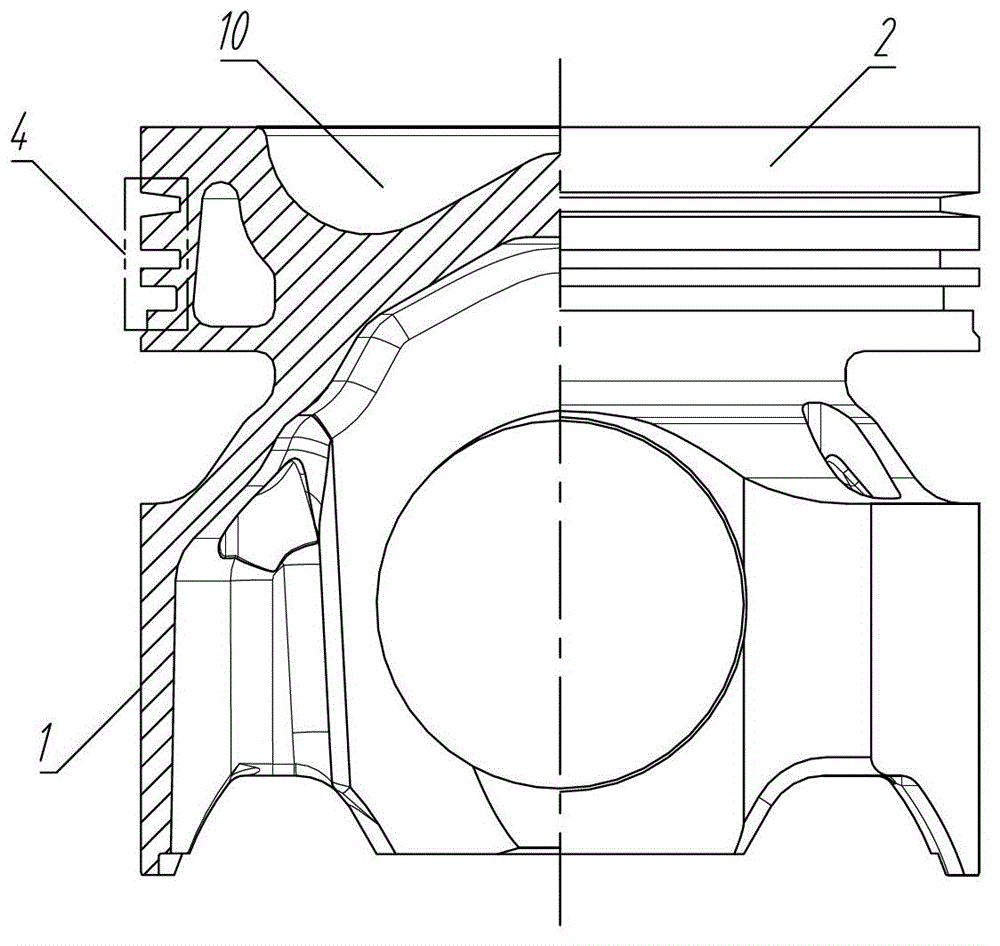

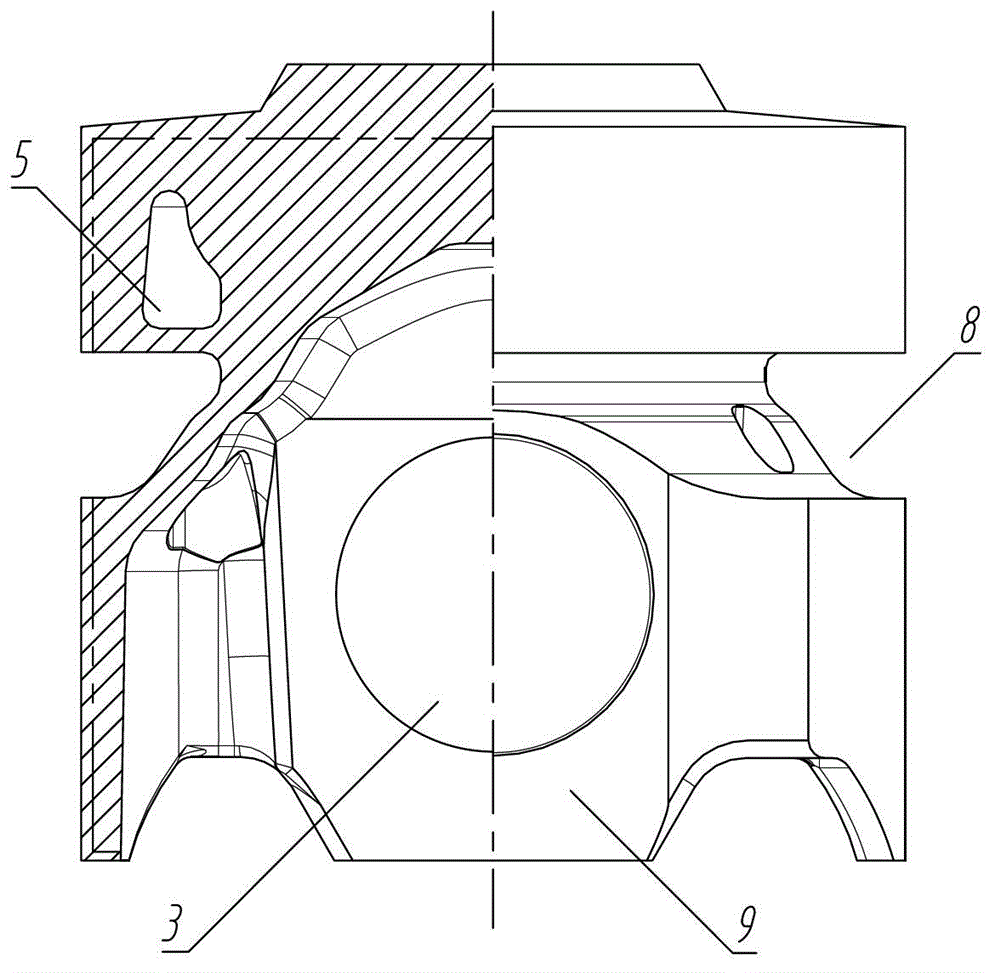

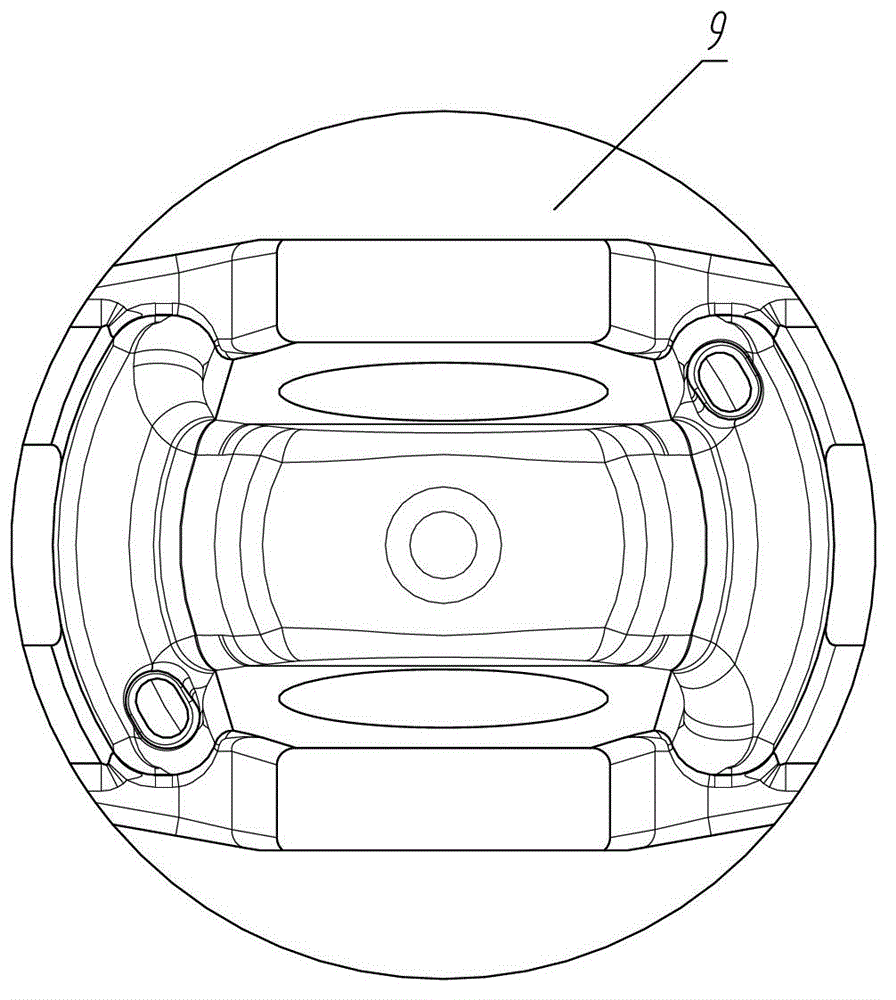

Integrated type cast steel piston and manufacturing method thereof

A manufacturing method and integrated technology, applied in the direction of pistons, manufacturing tools, furnace types, etc., can solve the problems of many manufacturing processes, expensive equipment, low production efficiency and pass rate, etc., to simplify the production process, reduce production costs, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present invention also provides a casting method of an integral cast steel piston, the method comprising the following steps:

[0036] the s 1 , Casting piston blanks, casting ring-shaped weight-reducing cavity, surface-window-type weight-reducing area, pin hole, closed cooling cavity, cooling oil outlet and cooling oil inlet;

[0037] the s 2 1. Carry out heat treatment to described piston blank, the process of its heat treatment comprises the following steps:

[0038] the s 21 , Annealing, heating temperature 860°C ± 10°C, heat preservation for 2 hours to 3 hours, cooling in the furnace to 200°C and then air cooling;

[0039] the s 22 , Quenching: Heating temperature 850°C±10°C, keep warm for 2 hours to 3 hours and then oil cool;

[0040] the s 23 , Tempering: heating temperature 580°C±20°C, heat preservation for 3 hours to 4 hours and then water cooling;

[0041] the s 24 , Stress relief aging: heating temperature 250 ℃ ± 10 ℃, heat preservation for 3 hou...

Embodiment 2

[0045] A method for casting an integral cast steel piston, the method comprising the following steps:

[0046] the s 1 , Casting piston blanks, casting ring-shaped weight-reducing cavity, surface-window-type weight-reducing area, pin hole, closed cooling cavity, cooling oil outlet and cooling oil inlet;

[0047] the s 2 1. Carry out heat treatment to described piston blank, the process of its heat treatment comprises the following steps:

[0048] the s 21 , Annealing, heating temperature 865 ° C, heat preservation for 2 hours and 30 minutes, cooling to 200 ° C in the furnace and then air cooling;

[0049] the s 22 , Quenching: heating temperature 855 ℃, heat preservation for 2 hours and 30 minutes and then oil cooling;

[0050] the s 23 , Tempering: heating temperature 590 ℃, heat preservation for 3 hours and 30 minutes and then water cooling;

[0051] the s 24 , Stress relief aging: heating temperature 255 ℃, heat preservation for 3 hours and 30 minutes and then air c...

Embodiment 3

[0055] A method for casting an integral cast steel piston, the steps comprising:

[0056] the s 1 , Casting piston blanks, casting window-type weight-reducing areas, pin holes, closed cooling chambers, cooling oil outlets and cooling oil inlets;

[0057] the s 2 1. Carry out heat treatment to described piston blank, the process of its heat treatment comprises the following steps:

[0058] the s 21 , Annealing, heating temperature 860°C ± 10°C, heat preservation for 2 hours to 3 hours, cooling in the furnace to 200°C and then air cooling;

[0059] the s 22 , Quenching: Heating temperature 850°C±10°C, keep warm for 2 hours to 3 hours and then oil cool;

[0060] the s 23 , Tempering: heating temperature 580°C±20°C, heat preservation for 3 hours to 4 hours and then water cooling;

[0061] the s 24 , Stress relief aging: heating temperature 250 ℃ ± 10 ℃, heat preservation for 3 hours to 4 hours and then air cooling.

[0062] the s 3 1. Machining a combustion chamber pit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com