Patents

Literature

32results about How to "Reduced soldering requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

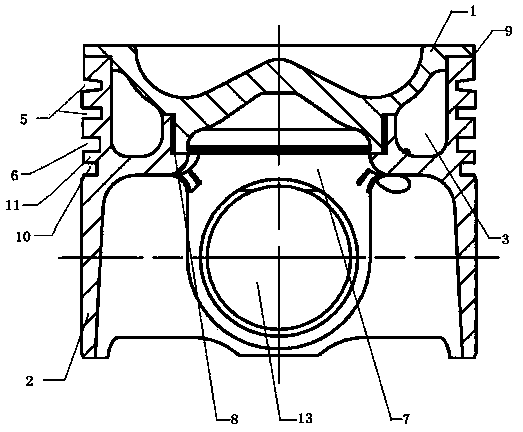

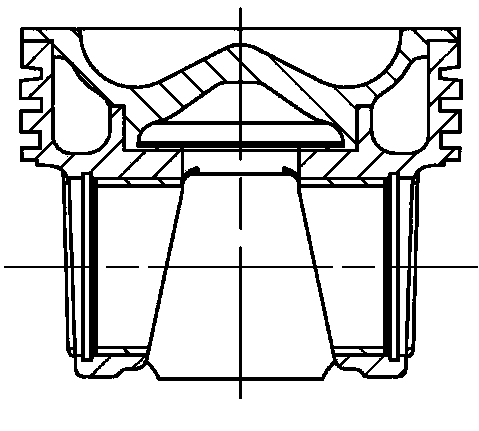

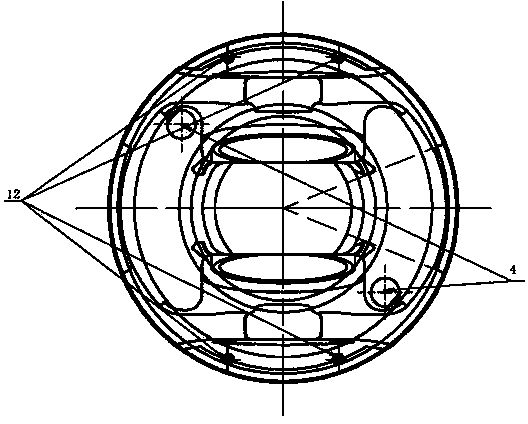

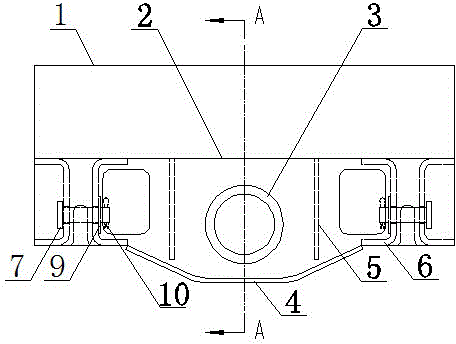

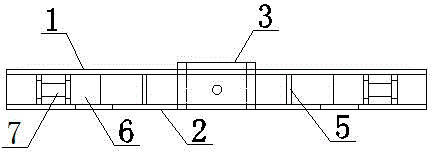

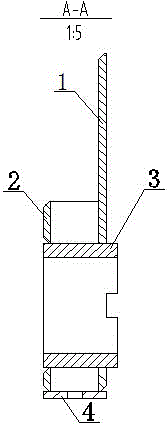

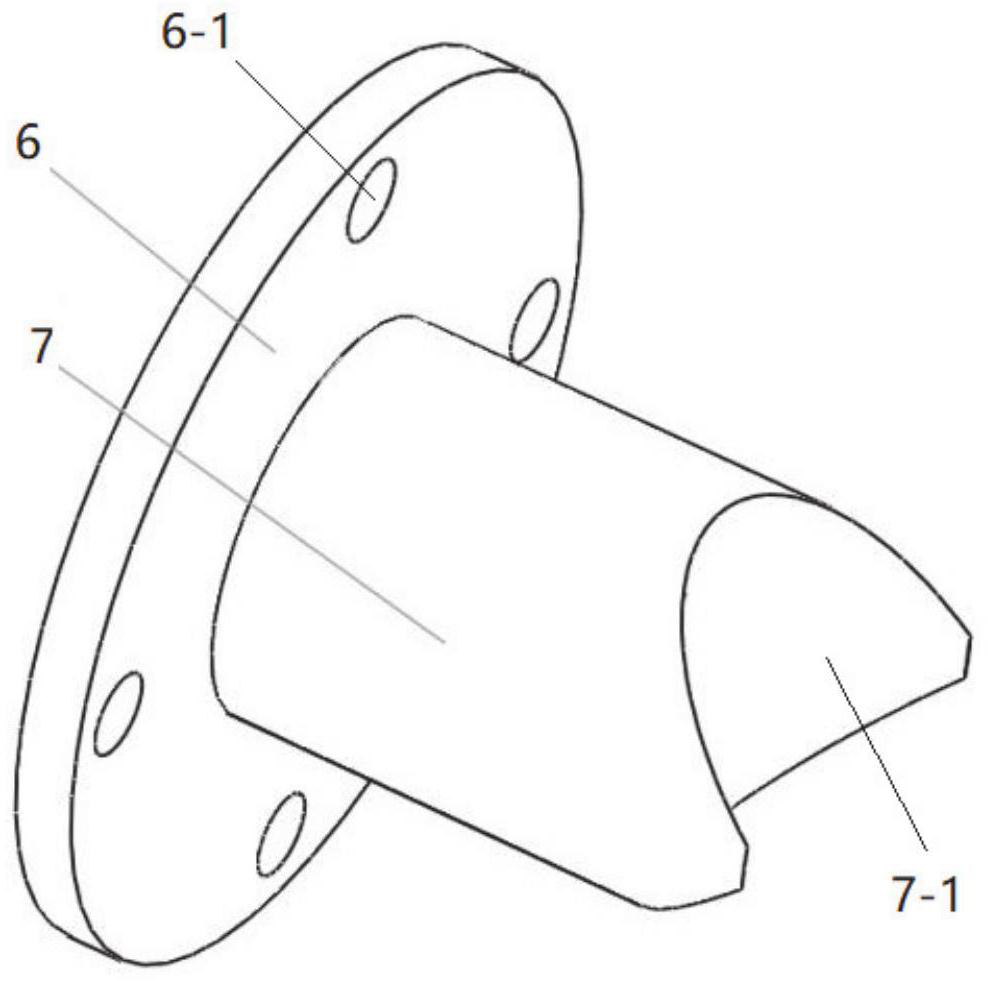

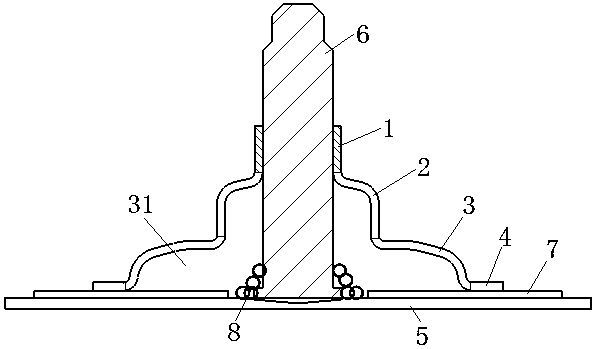

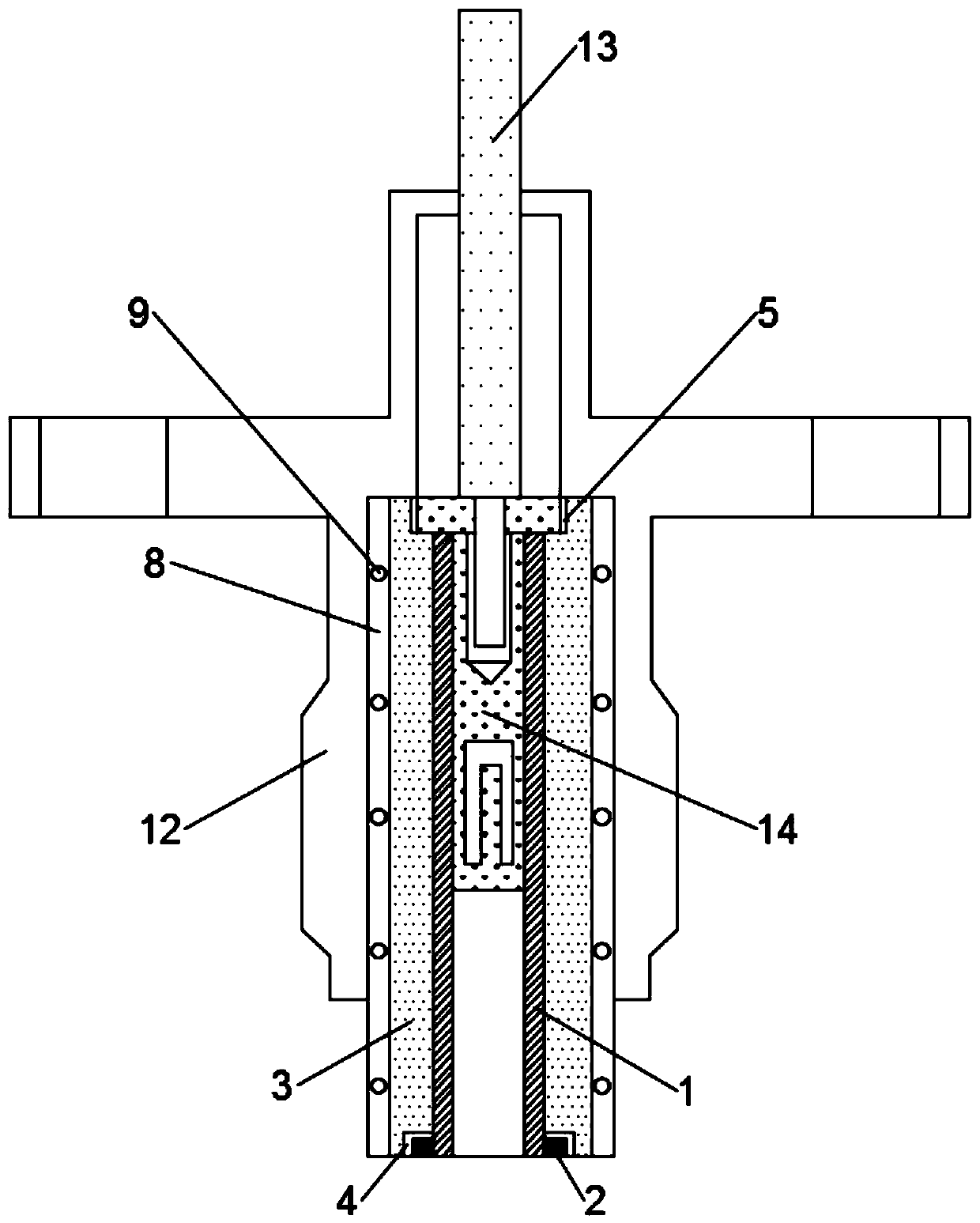

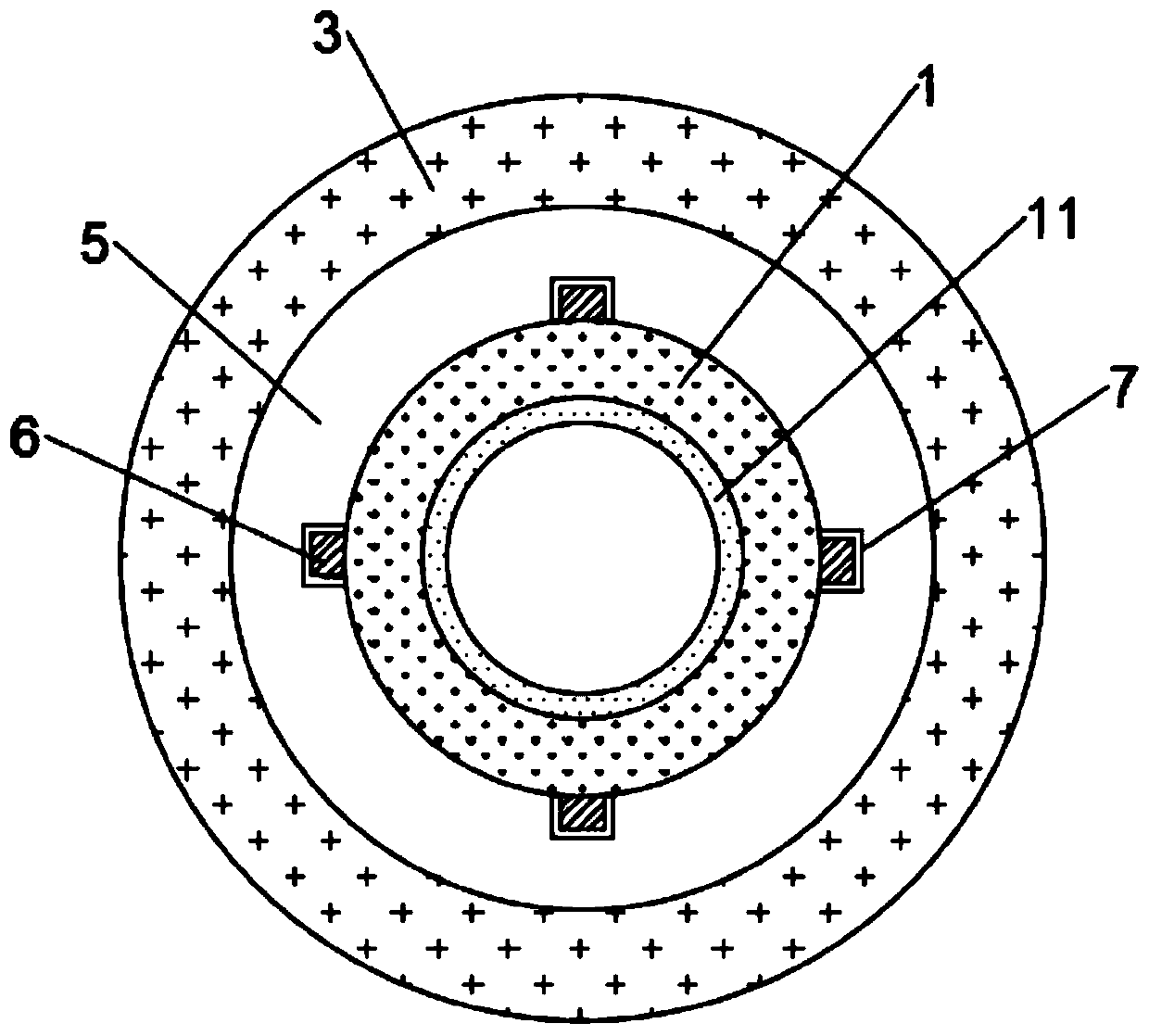

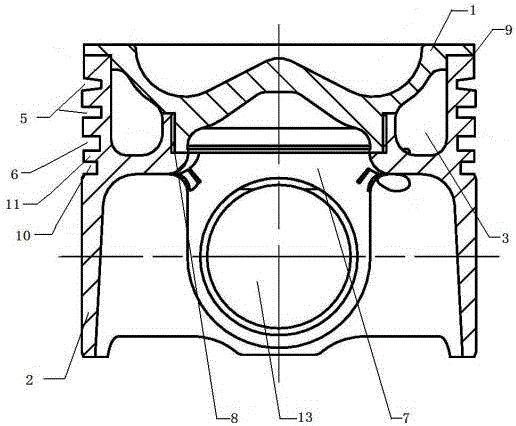

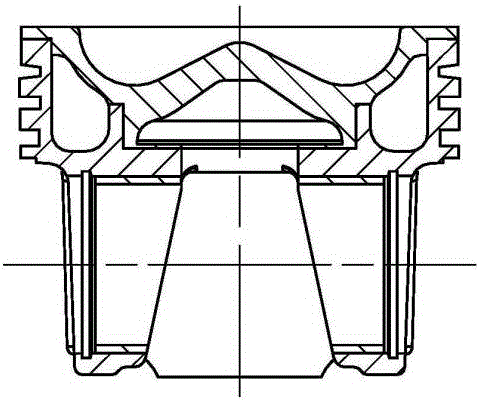

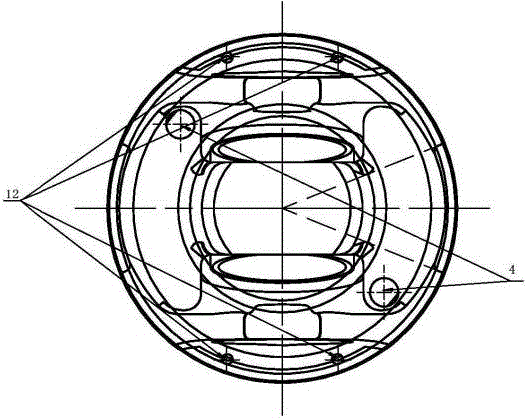

Threaded welding type integral forged steel piston

ActiveCN104005876AImprove stabilityReduced soldering requirementsMachines/enginesPistonsInterference fitEngineering

Owner:BINZHOU DONGHAILONG PISTON

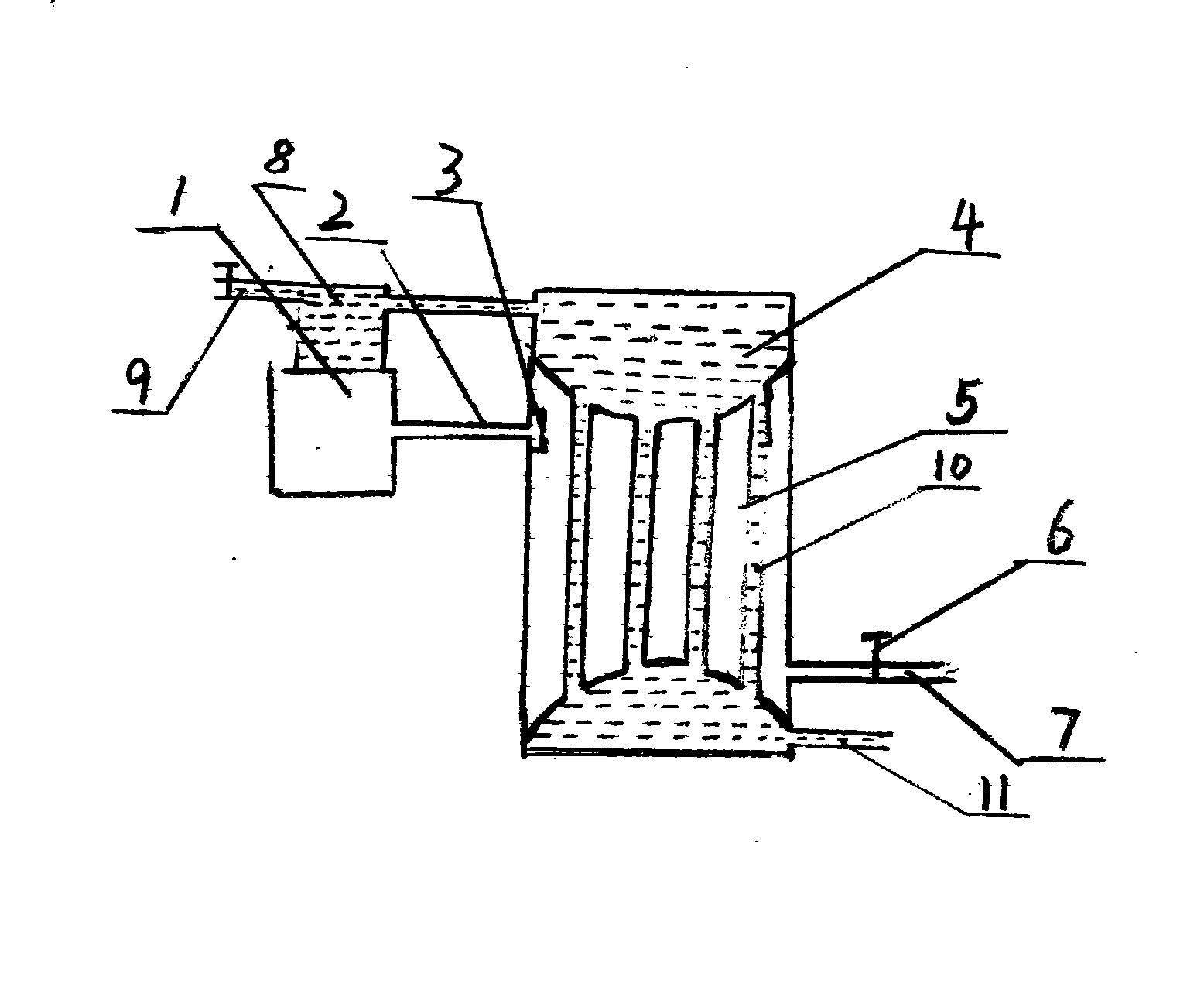

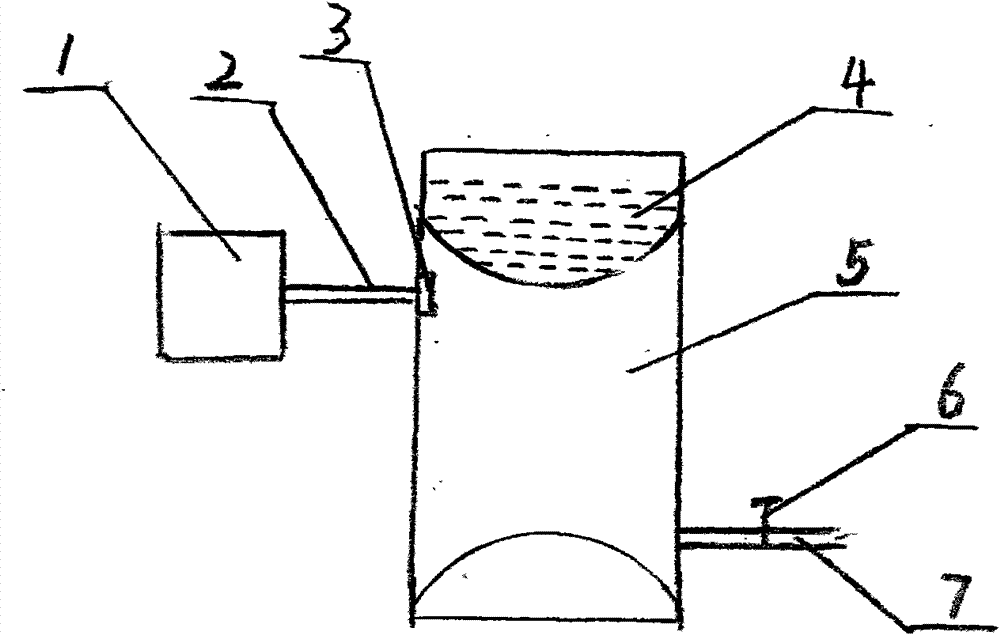

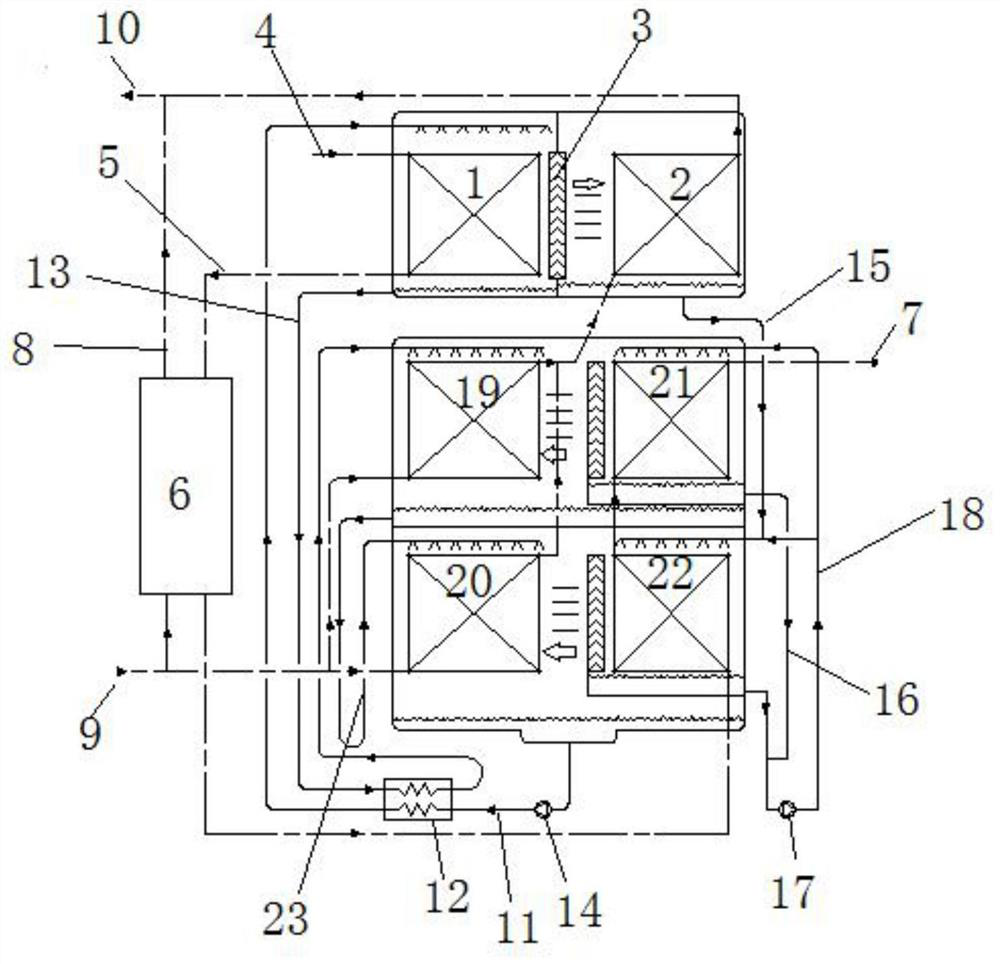

Improvement setting for water-cooled air conditioner

InactiveCN102878625AReduced soldering requirementsTo achieve the purpose of refrigerationLighting and heating apparatusAir conditioning systemsLow noiseAutomatic control

The invention discloses a water-cooled air conditioner. The water-cooled air conditioner comprises a high-pressure pump, a high-pressure tank, an air transmission pipe, a refrigeration water sump, a heat exchange pipe and the like, wherein the high-pressure pump adopts a low-noise high-pressure air pump in a cylinder type or other forms; the high-pressure tank adopts a double-ended arc-shaped inward concave type, so that the pressure resistance is high and the requirement on welding is low; water storage bins are formed on the protruded parts of the two ends of the high-pressure tank; an air automatic control switch is arranged on the high-pressure tank to control the start and the stop of the high-pressure pump automatically; an air inlet pipe is arranged on the upper part of the air automatic control switch; an air outlet pipe is arranged on the lower part of the air automatic control switch; high-pressure air is input into the high-pressure tank by the high-pressure pump; the principle that air generates heat under a high pressure is utilized, the heat generated by the high-pressure tank is adsorbed by the water in the water storage bins on the high-pressure tank; the high-pressure air is output by the air outlet pipe; the high-pressure air at the air outlet of the air outlet pipe expands suddenly, and the temperature of the air can drop suddenly, so that the aim of refrigerating is fulfilled; the water in the water storage bins is input from the lower end of each water storage bin and is conveyed to a cooling water tank on the high-pressure pump from the upper end of each water storage bin; and hot water is output through a valve. The improvement setting for the water-cooled air conditioner has great market potential.

Owner:赵文志

Water refrigeration air conditioner

InactiveCN102788391AReduced soldering requirementsTo achieve the purpose of refrigerationLighting and heating apparatusAir conditioning systemsLow noiseAutomatic control

A water refrigeration air conditioner comprises a high pressure pump, a high pressure tank, a gas delivery pipe and a refrigeration water chamber, wherein the high pressure pump is an air cylinder type low-noise high pressure gas pump or a low-noise high pressure gas pump in other types; the two ends of the high pressure tank are arc and indented, so that the compression resistance of the high pressure tank is high, and the welding requirement is low; the water chamber is arranged at the projecting part of the upper end of the high pressure tank; an automatic water level controller is arranged on the water chamber; an automatic gas pressure control switch for automatically controlling the on and off of the high pressure pump is arranged on the high pressure tank; a gas input pipe is arranged at the upper part of the high pressure tank; a gas output pipe is arranged at the lower part of the high pressure tank; the high pressure pump inputs high pressure gas into the high pressure tank; due to the principle of high pressure heating of the gas, the heat generated by the high pressure gas tank is absorbed by water in the water chamber on the high pressure tank; the high pressure gas is output by the output pipe; the high pressure gas expands suddenly at the gas outlet of the output pipe, and the gas temperature drops suddenly, so that the refrigeration purpose is realized. The water refrigeration air conditioner has a great market potential.

Owner:赵文志

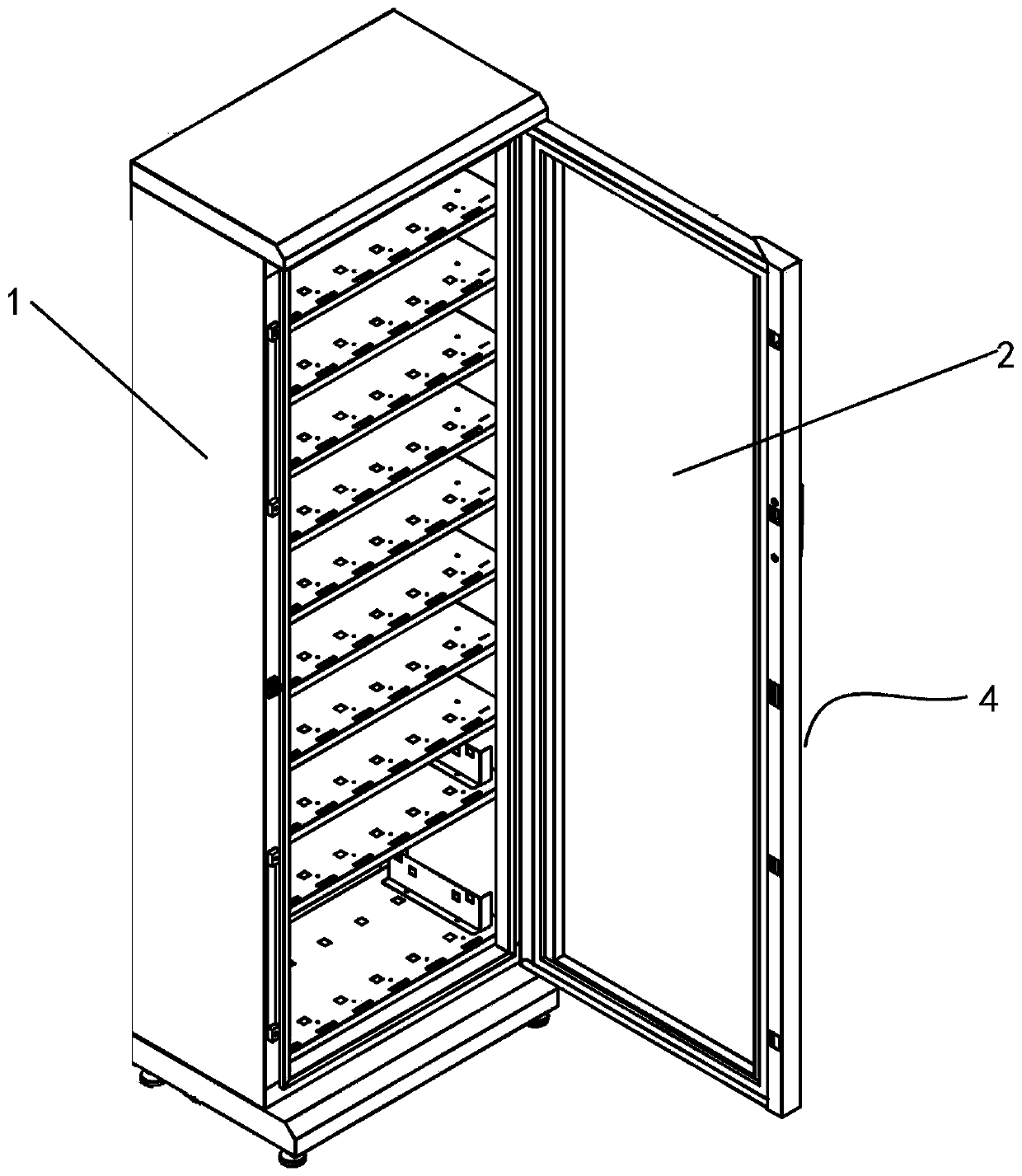

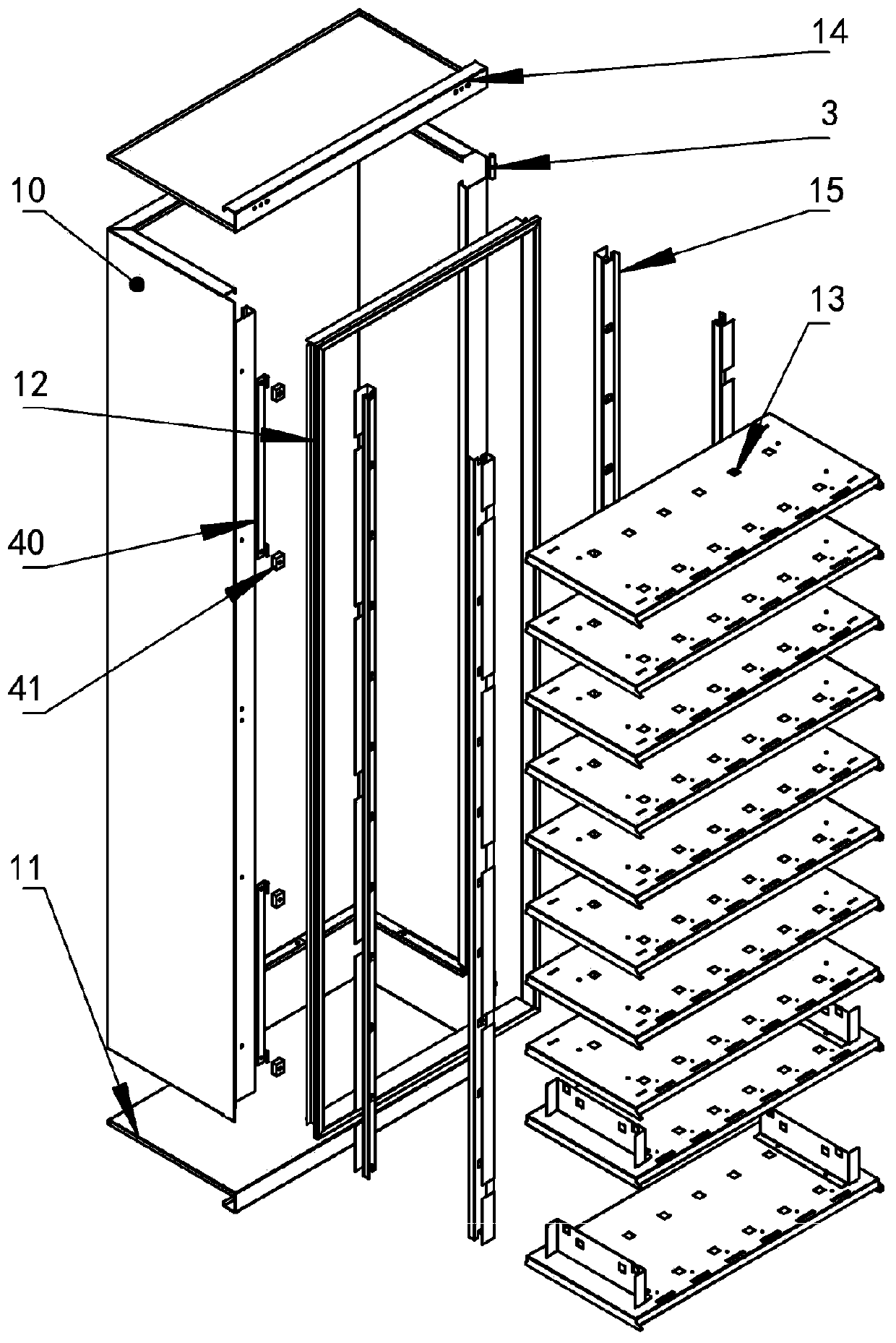

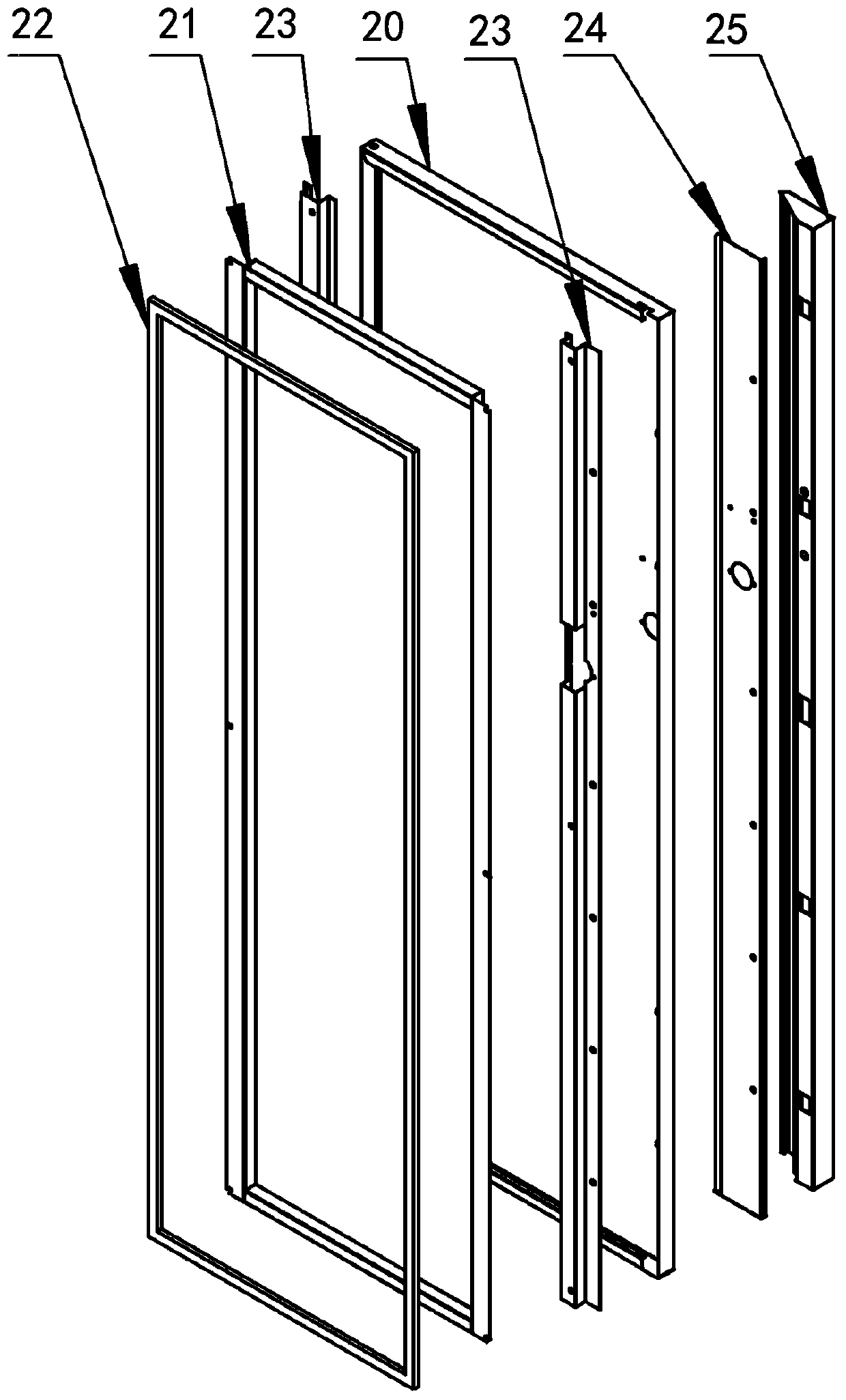

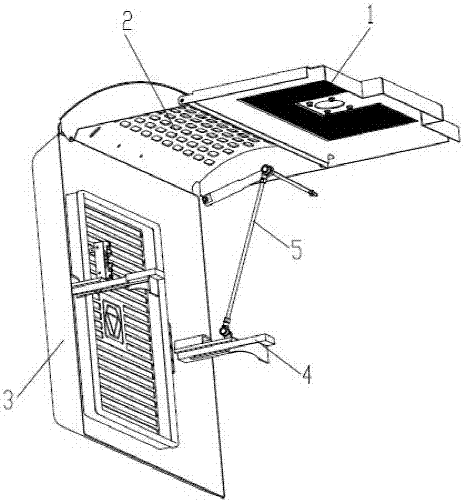

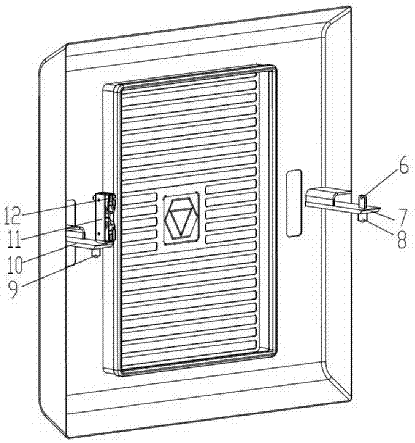

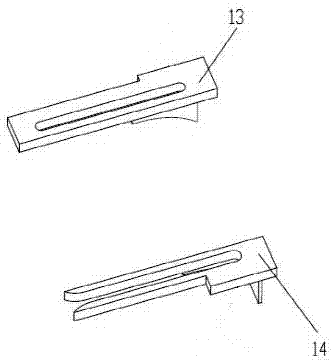

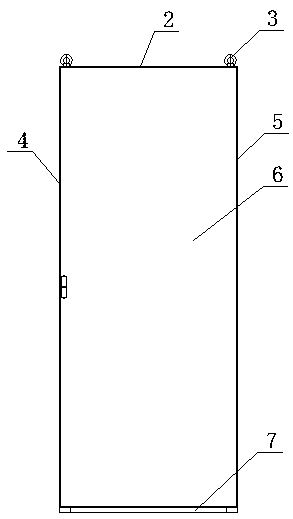

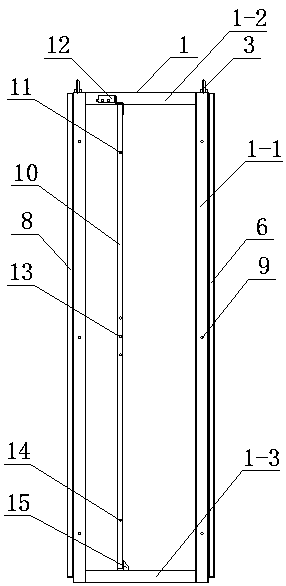

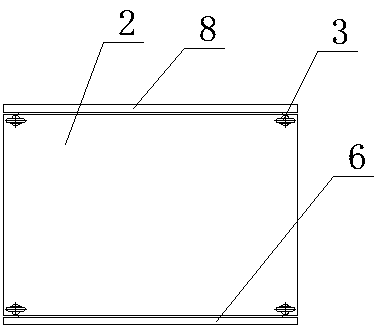

Shielding cabinet

PendingCN111543798AImprove rust resistanceAffect shieldingRadiation protectionScreening casingsManufactured materialStructural engineering

The invention discloses a shielding cabinet which comprises a cabinet body and a shielding door, the shielding door is rotatably connected with the cabinet body through a door shaft, three vertical faces of the cabinet body are cabinet body metal plates formed by bending a complete steel plate, the top of each cabinet body metal plate is fixedly connected with a top plate metal plate, and the bottom of each cabinet body metal plate is fixedly connected with a bottom plate metal plate. Welding a stainless steel shielding edge metal plate on an opening edge formed by the cabinet body metal plate, the top plate metal plate and the bottom plate metal plate; the shielding door comprises a shielding door outer door plate and a stainless steel inner door plate which are sequentially installed from outside to inside, and the stainless steel inner door plate is matched with the stainless steel shielding edge metal plate in shape. Shielding can be achieved through combination of the stainless steel inner door plate and the stainless steel shielding edge metal plate between the cabinet body and the shielding door, a stainless steel plate does not need to be adopted for manufacturing the cabinet body, and a large amount of raw material cost is saved; the shielding door is divided into the shielding door outer door plate and the stainless steel inner door plate, the shielding door outer door plate is independently processed and sprayed with anti-rust paint, and the welding difficulty and sealing requirements of the shielding door outer door plate are reduced.

Owner:GUANGZHOU GUUB TECH

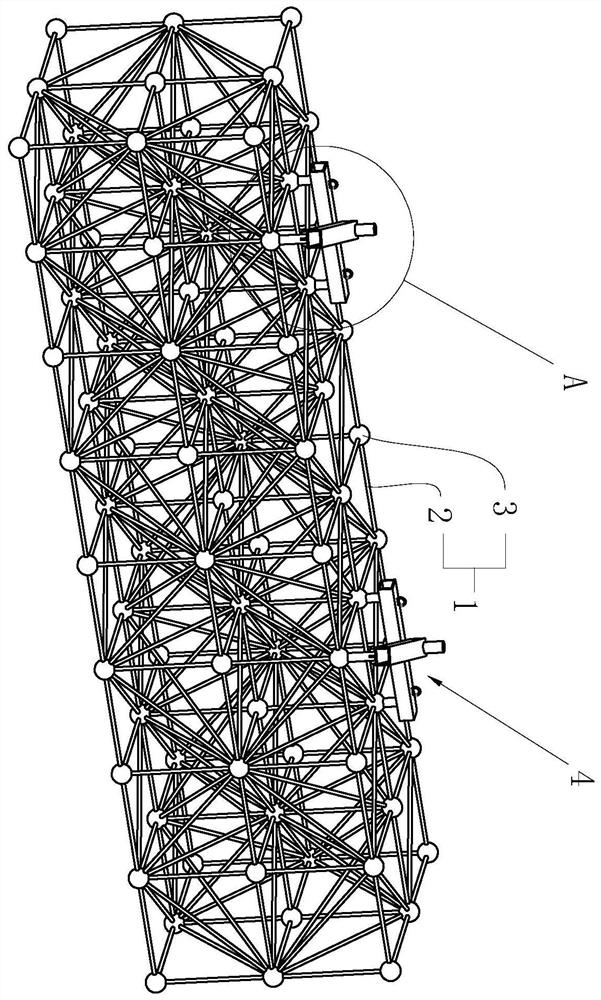

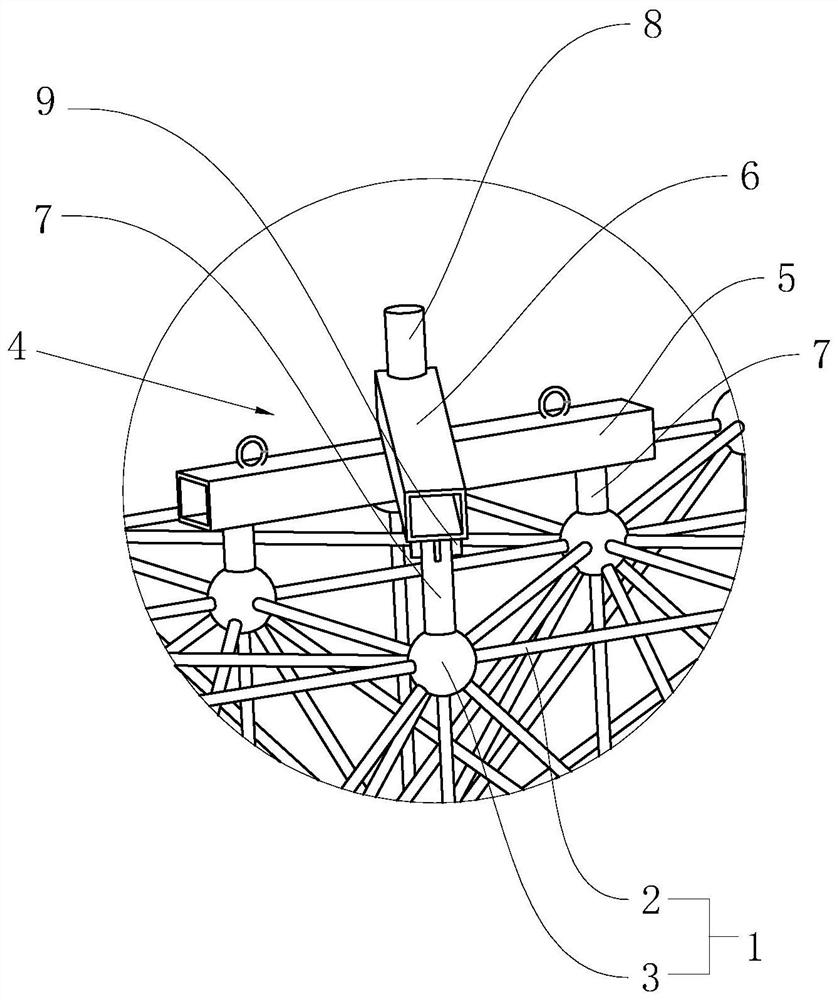

Large-span unequal-height steel structure net rack integral lifting temporary lifting point construction method

InactiveCN111779274AReduce usageReduce lossBuilding material handlingArchitectural engineeringUllage

The invention relates to a large-span unequal-height steel structure net rack integral lifting temporary lifting point construction method. The large-span unequal-height steel structure net rack integral lifting temporary lifting point construction method comprises the following steps of S1, construction preparation, and specifically, stress calculation is conducted on an assembled hangar gate truss firstly; S2, the structure of a temporary lifting point support and the form of a lifting point are determined; S3, the positions and the number of a lifting frame are determined according to the overall structure of a net rack of a hangar hall, and the positions and the number of the temporary lifting point support are determined; S4, the temporary lifting point support is arranged at the upper end of the hangar gate truss, an actual stress state is known by monitoring the stress of a component in a lifting process, and if the actual stress state exceeds the limit or is abnormal, a reasonis found, regulation and control are conducted. The large-span unequal-height steel structure net rack integral lifting temporary lifting point construction method has the effects that the assembled hangar gate truss is used as the support for the temporary lifting point support, the use amount of the temporary support is reduced, material loss is reduced, and the construction cost is reduced.

Owner:GUANGZHOU XIEAN CONSTR ENG

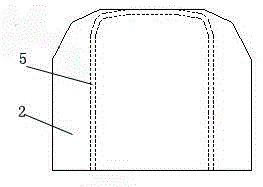

Slipping steering engine cover for loader

The invention discloses a slipping steering engine cover for a loader and belongs to the technical field of engineering machines. A fixed cover body, a rotating cover body and a rear cover body are included; the rear cover body is connected with a frame through a sliding device; a linkage device is connected between the rear cover body and the rotating cover body; the sliding device comprises a left support and a right support which are located on the two sides of the rear cover body separately; a left sliding plate and a right sliding plate are correspondingly fixed to the two sides of the rear cover body; the linkage device comprises a frame connection rod, a rear cover connection rod and a gas spring, and the top ends of the frame connection rod, the rear cover connection rod and the gas spring are hinged to one another; the other end of the frame connection rod is hinged to the frame; the other end of the rear cover connection rod is hinged to the rear cover body; and the other endof the gas spring is hinged to the rotating cover body. The slipping steering engine cover for the loader is firm and reliable in sealing, and the sealing effect is better; the model unifying rate isgreatly increased, and the rear cover variety is reduced; the design of independent self-locking devices in the engine cover is reduced while the operation steps are simplified; and the structure issimple, the welding and installing precision requirement is low, operation is portable, disassembling and assembling are easy, maintaining is convenient, and cost is low.

Owner:XCMG CONSTR MACHINERY

Electric cabinet with square tube frame

InactiveCN107706747AIncreased load-bearing capacityLow costSubstation/switching arrangement casingsEngineeringElectric power

Square tube frame electrical cabinet, involving the field of electrical equipment, including a square tube frame welded by square tubes, on which the left side panel, right side panel, rear door panel, top panel and bottom panel are connected, and on the square tube frame The front door panel is hinged, and the four corners of the top panel are respectively fixed and connected to the lifting rings; the square tube frame is welded by four square tube vertical bars, four square tube upper rails, and four square tube lower rails. The upper, middle and lower parts of the pipe vertical rods are all equipped with cabinet holes, the upper ends of the four square pipe vertical rods are connected by four square pipe upper cross bars, and the lower ends are connected by four square pipe lower cross bars; at the left and right sides of the square pipe frame The two sides are respectively connected to the mounting plate, the upper end of each mounting plate is connected with the corresponding upper cross bar of the square tube through the upper bracket, and the lower end of each mounting plate is connected with the corresponding lower cross bar of the square tube through the lower bracket. The upper part is provided with an upper installation hole, the middle part is provided with three middle installation holes, and the lower part is provided with a lower installation hole. The invention has low cost and reasonable structure.

Owner:扬州市庆源电气成套设备有限公司

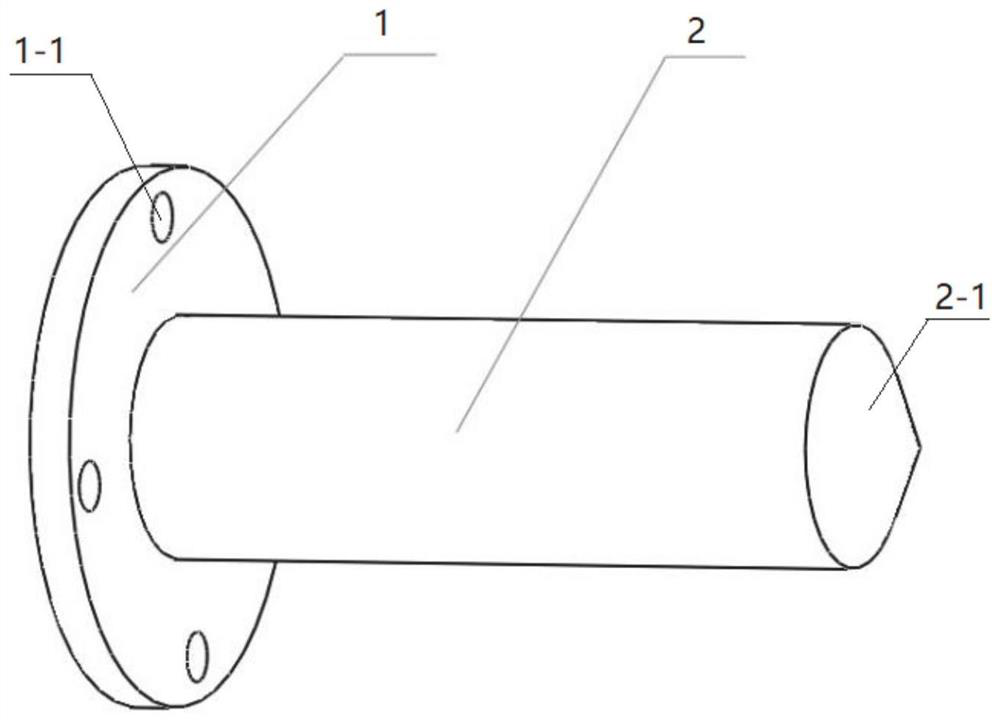

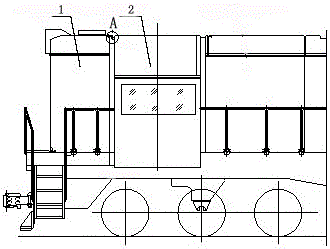

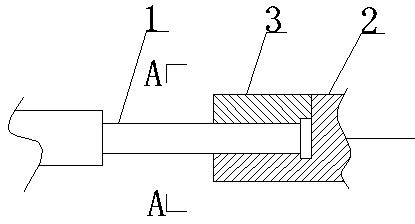

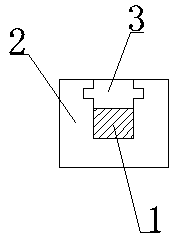

Novel locomotive lifting beam

The invention relates to the technical field of internal combustion engines, and particularly relates to a novel locomotive lifting beam. The novel locomotive lifting beam comprises an internal plate, an external plate, a crane cylinder, a base plate, rib plates and lifting seats, wherein two ends of the base plate are respectively connected to the bottom parts of the internal plate and the external plate; the lifting seats are clamped between the internal plate and the external plate so as to form a framework structure. The novel locomotive lifting beam is stable in structure, the structural rigidity is further enhanced by the rib plates, and an integrated lifting beam structure is formed, the intensity is improved, the welding requirement is lowered, and the lifting safety of a finished vehicle is guaranteed; moreover, the lifting seats are configured in the lifting beam, so that the problem of interference with a bogie during passing process in a curved mode is avoided, and the passing capacity is improved.

Owner:CRRC QISHUYAN CO LTD

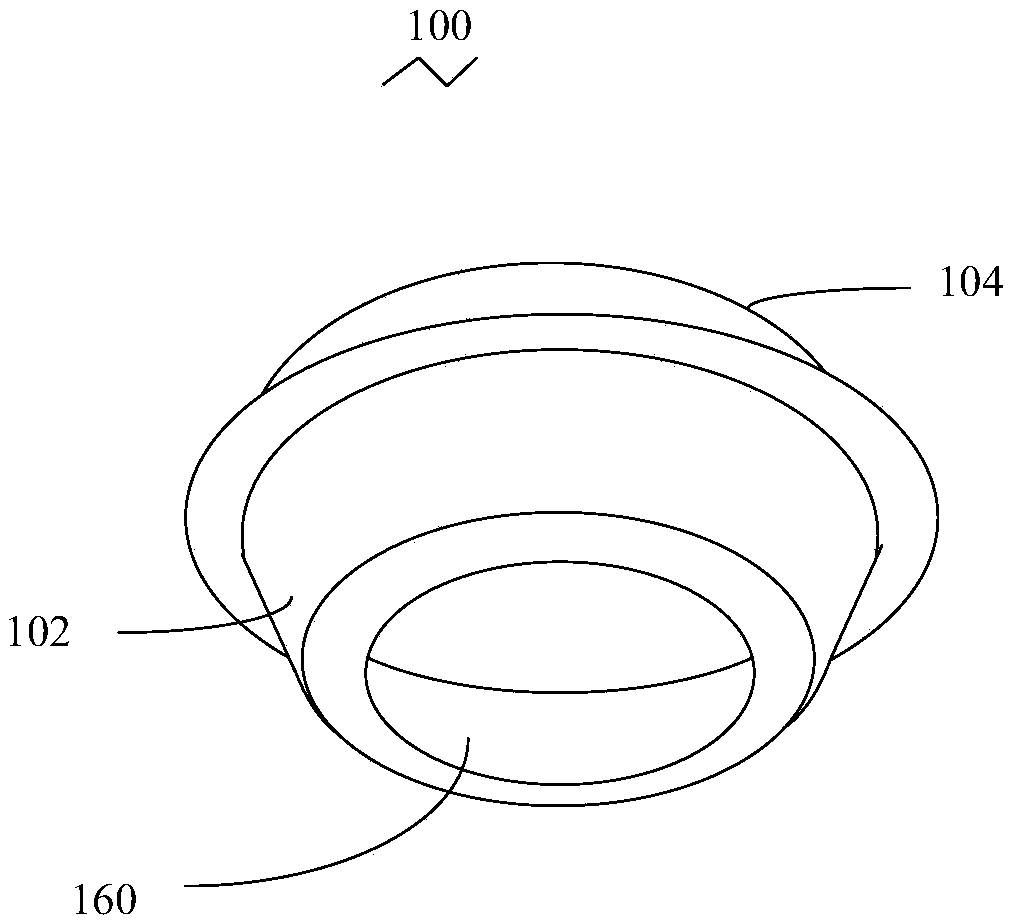

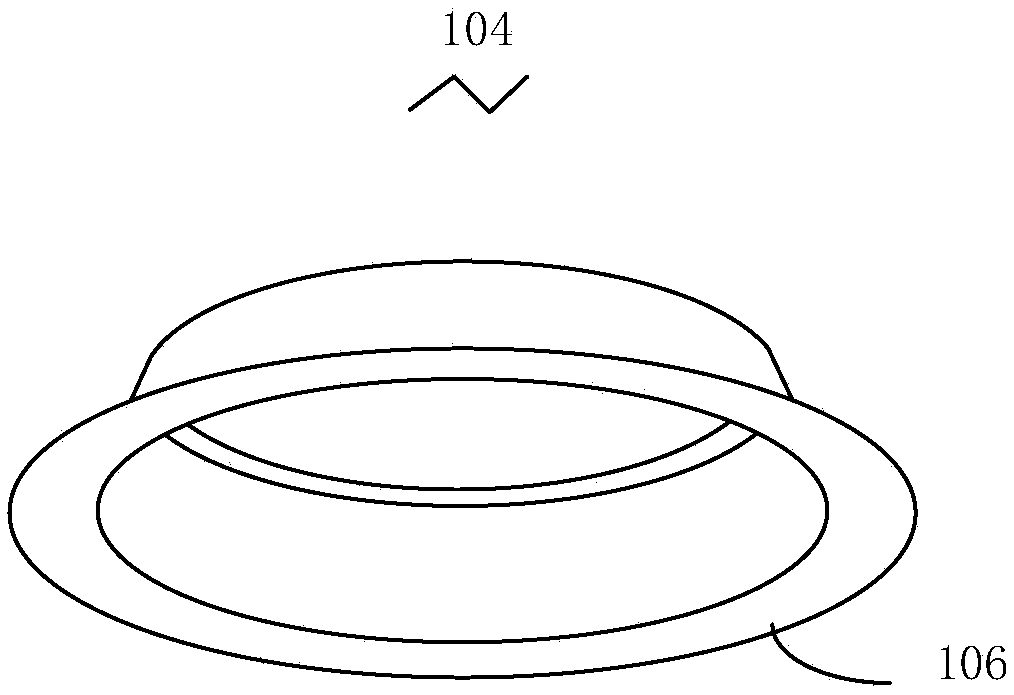

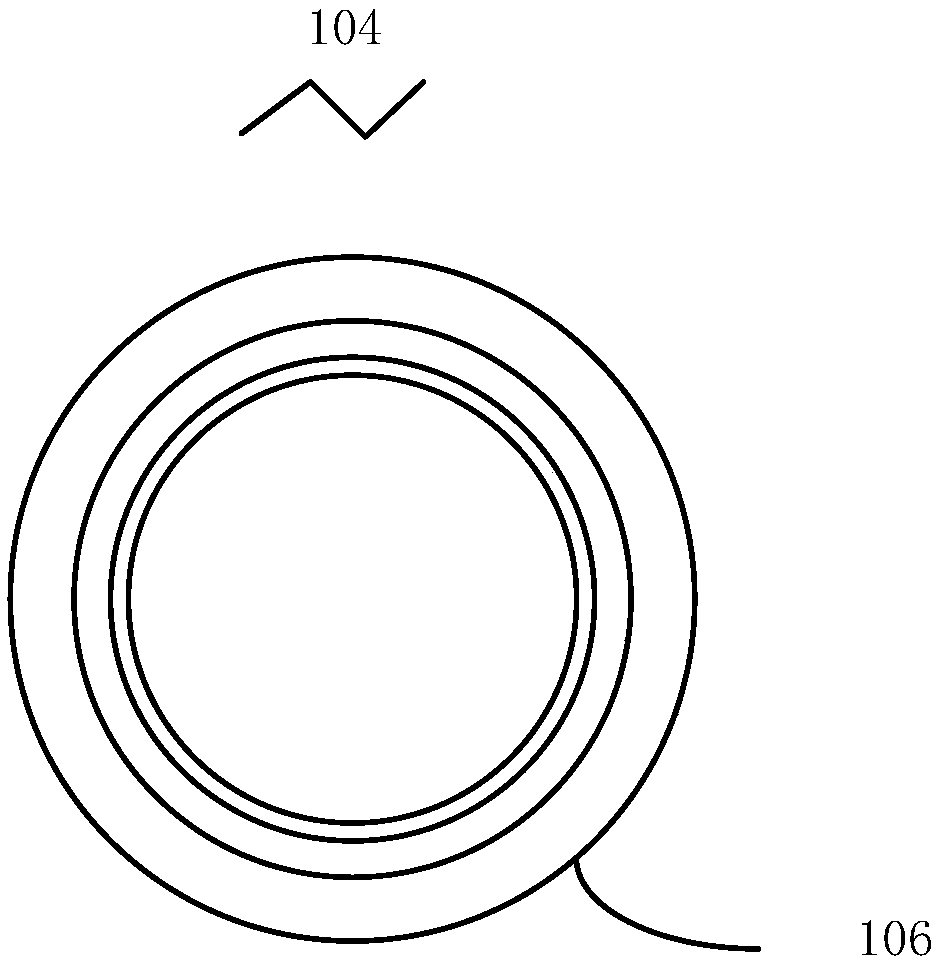

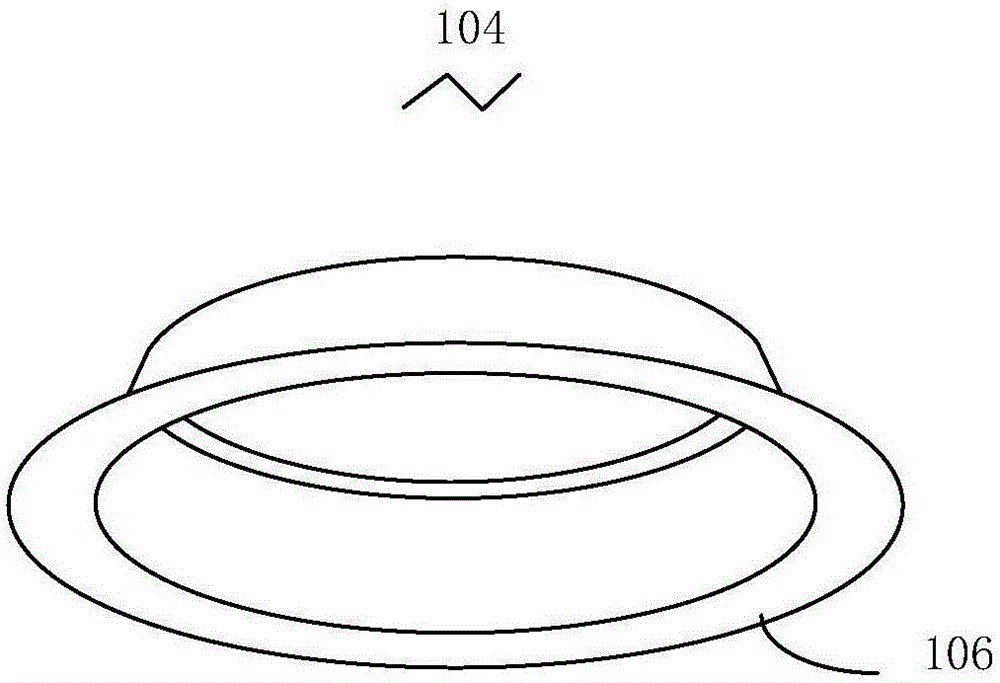

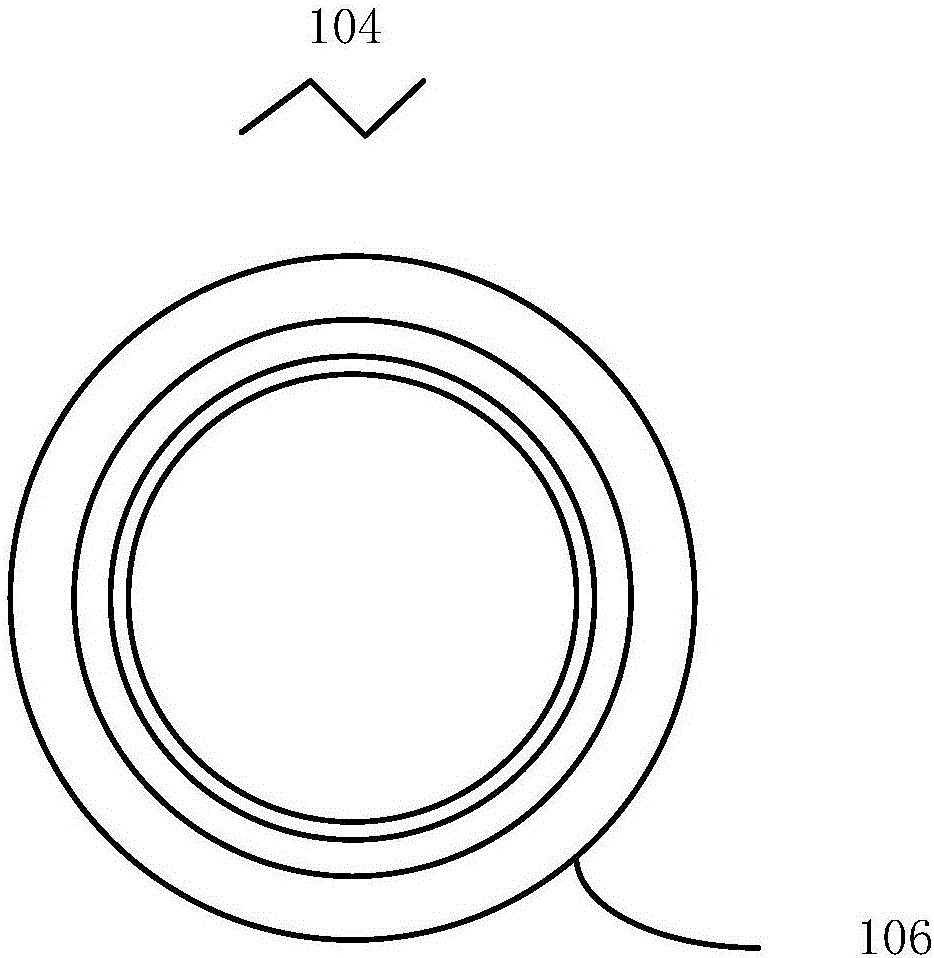

Cooling components and oil heaters

ActiveCN106287913BHigh welding requirementsReduced soldering requirementsHeating fuelLighting and heating apparatusHeat conductingEngineering

The invention relates to a cooling component, which is a sealed shell structure, including a front end and a rear end, and a cavity for accommodating heat transfer oil is defined inside the cooling component, and a first opening is further opened on the front end of the cooling component. hole. The present invention also relates to an oil heater, which includes a plurality of cooling units and cooling components, the cooling components are respectively arranged in the upper convex unit and the lower convex unit of the last cooling unit, and the front end of the cooling component faces the oil heater. The front end of the heater and the front end of the cooling member are respectively sealed and connected with the upper convex unit and the lower convex unit, so that the last heat dissipation unit of the oil heater is isolated from the heat transfer oil.

Owner:SHIJIAZHUANG GREE SMALL HOUSEHOLD ELECTRICAL APPLIANCES +1

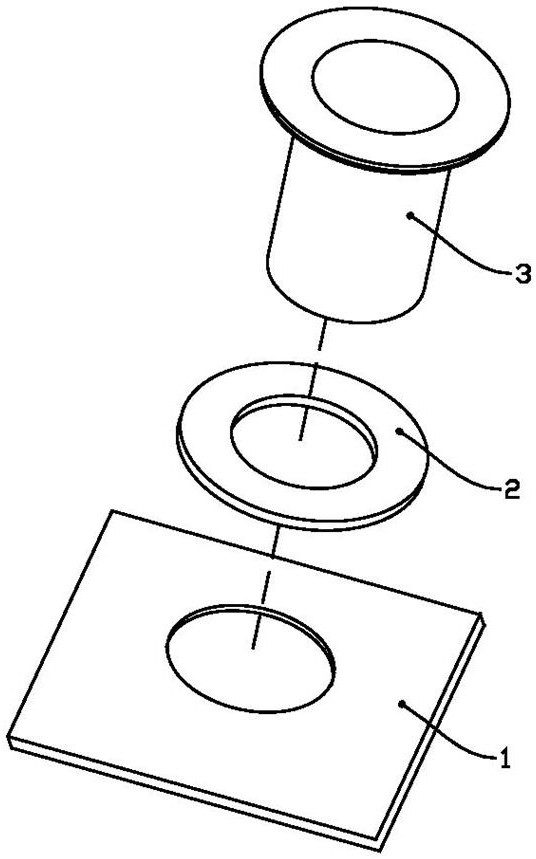

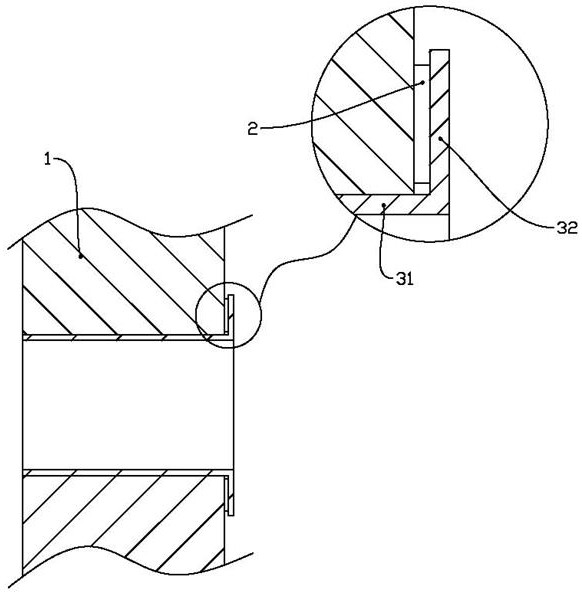

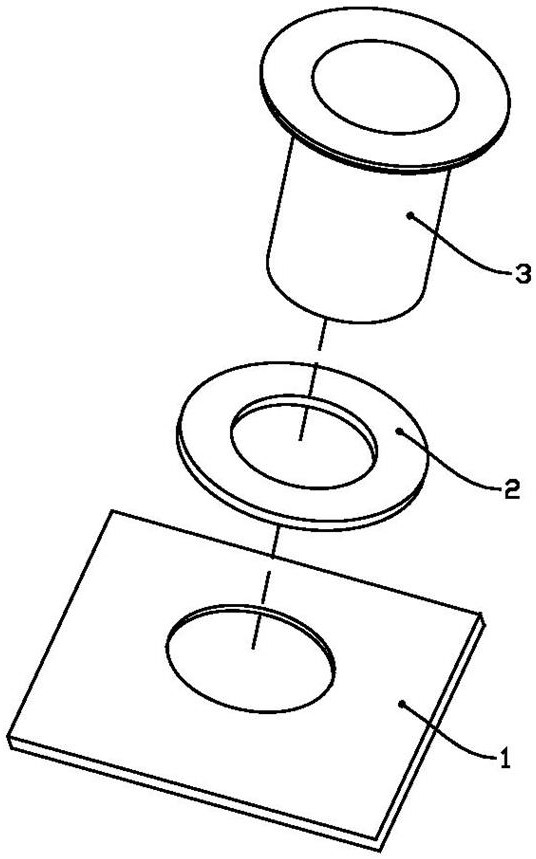

Tube plate welding method, tube body and tube plate connecting method and heat exchanger

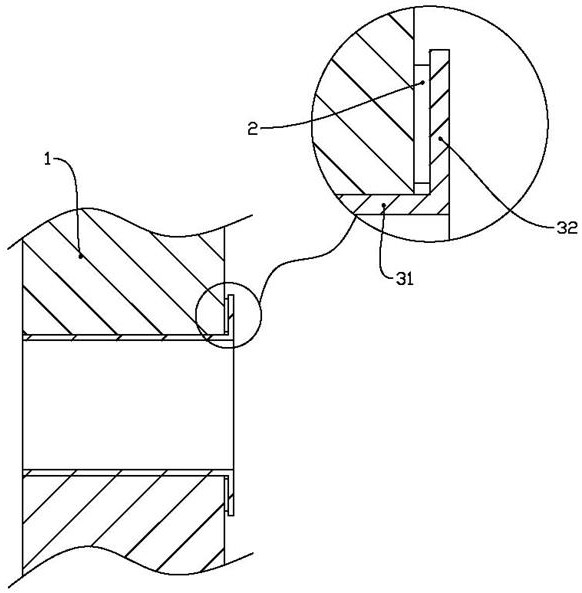

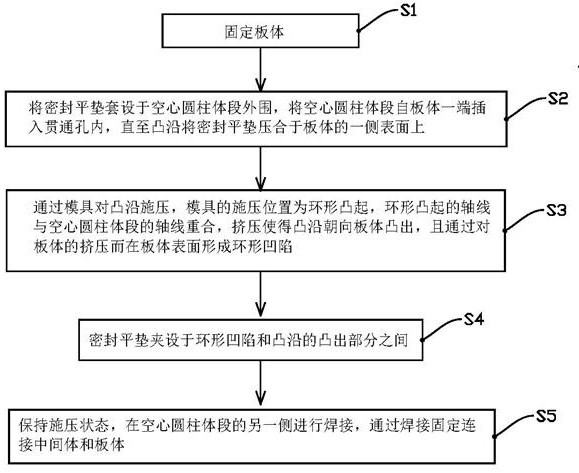

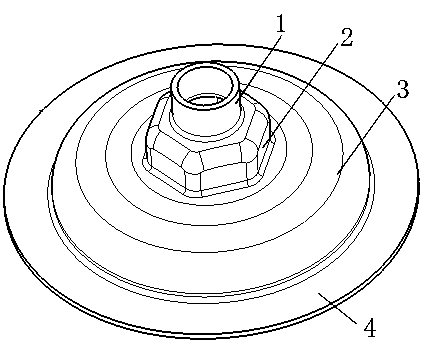

ActiveCN113996964AGuaranteed stabilityGuaranteed tightnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

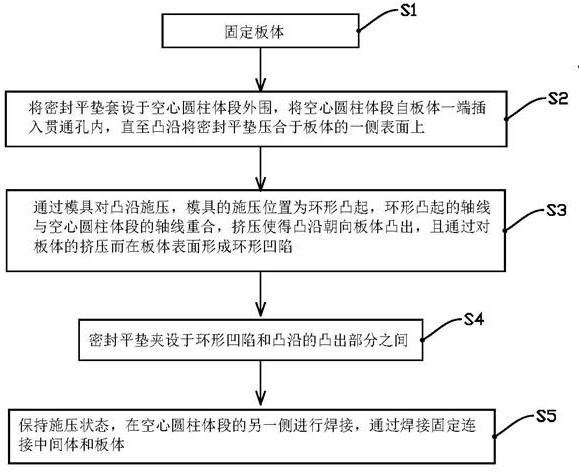

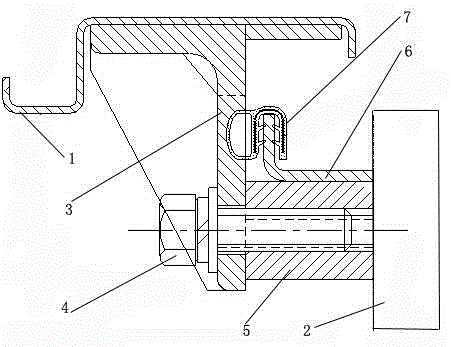

The invention relates to the technical field of metal structure machining, in particular to a tube plate welding method which comprises the following steps: fixing a plate body; arranging a sealing flat gasket on the periphery of a hollow cylinder section in a sleeving mode, the hollow cylinder section being inserted into the through hole from one end of the plate body; applying pressure to a convex edge through a die to protrude towards the plate body, and extruding the plate body to form an annular recess on the surface of the plate body; clamping the sealing flat gasket between the annular recess and the convex part of the convex edge; and keeping the pressing state, carrying out welding on the other side of the hollow cylinder section, and fixedly connecting the middle body and the plate body. According to the invention, the stability and the sealing performance of the relative position after the tube plate and the tube body are connected are guaranteed, the welding quality requirement can be properly lowered, the purpose of solving the sealing problem is achieved to a certain degree through the obtained tube plate by using the intermediate, so that the welding requirement is effectively lowered. The invention further discloses a tube body and tube plate connecting method and a heat exchanger.

Owner:常州新海飞金属制品有限公司

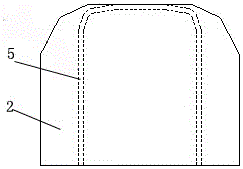

Novel module connecting structure of locomotive

ActiveCN104890688AReduce occupancyImprove space utilizationAxle-box lubricationLocomotivesInterior spaceEngineering

The invention discloses a novel module connecting structure of a locomotive. The novel module connecting structure comprises a first module and a second module; a module mounting beam is arranged on the right end surface of the first module; a mounting seat is arranged on the left end surface of the second module; the module mounting beam and the mounting seat are both n shaped and corresponding in size and position; the module mounting beam is vertically connected with the first module, and the right end of the module mounting beam is bent in 90 degrees to be closely mounted on the left end surface of the mounting seat as well as being fixedly connected through a plurality of bolts; an n-shaped connecting bottom plate is arranged on the outer side surface of the module mounting beam on the right end surface of the first module and is corresponding to the n-shaped outer side surface of the mounting seat; an n-shaped tape clamping groove is formed along the outer side surface of the mounting seat; another n-shaped tape clamping groove is correspondingly formed along the outer side surface of a connecting floor; the two tape clamping grooves are sealed and connected through a sealing tape. The novel module connecting structure has the beneficial effects that a small space in the locomotive is used; the dismounting and mounting are both performed at the outside of the locomotive; the requirements on the welding precision and assembling error are small; the sealing tape is easily overhauled and replaced.

Owner:CRRC ZIYANG CO LTD

Cooling component and oil heater warmer

ActiveCN106287913AHigh welding requirementsReduced soldering requirementsHeating fuelLighting and heating apparatusFront and back endsPetroleum engineering

The invention relates to a cooling component. The cooling component is of a sealed shell structure and comprises a front end and a rear end, a cavity used for containing heat conduction oil is defined in the cooling component, and a first open hole is further formed in the front end of the cooling component. The invention further relates to an oil heater warmer. The oil heater warmer comprises a plurality of cooling units and the cooling component, the cooling component is arranged in an upper convex hull unit and a lower convex hull unit of the last cooling unit, and the front end of the cooling component faces the front end of the oil heater warmer; the front end of the cooling component is in sealed connection with the corresponding upper convex hull unit and the corresponding lower convex hull unit. The last cooling unit of the oil heater warmer is isolated from the heat conduction oil.

Owner:SHIJIAZHUANG GREE SMALL HOUSEHOLD ELECTRICAL APPLIANCES +1

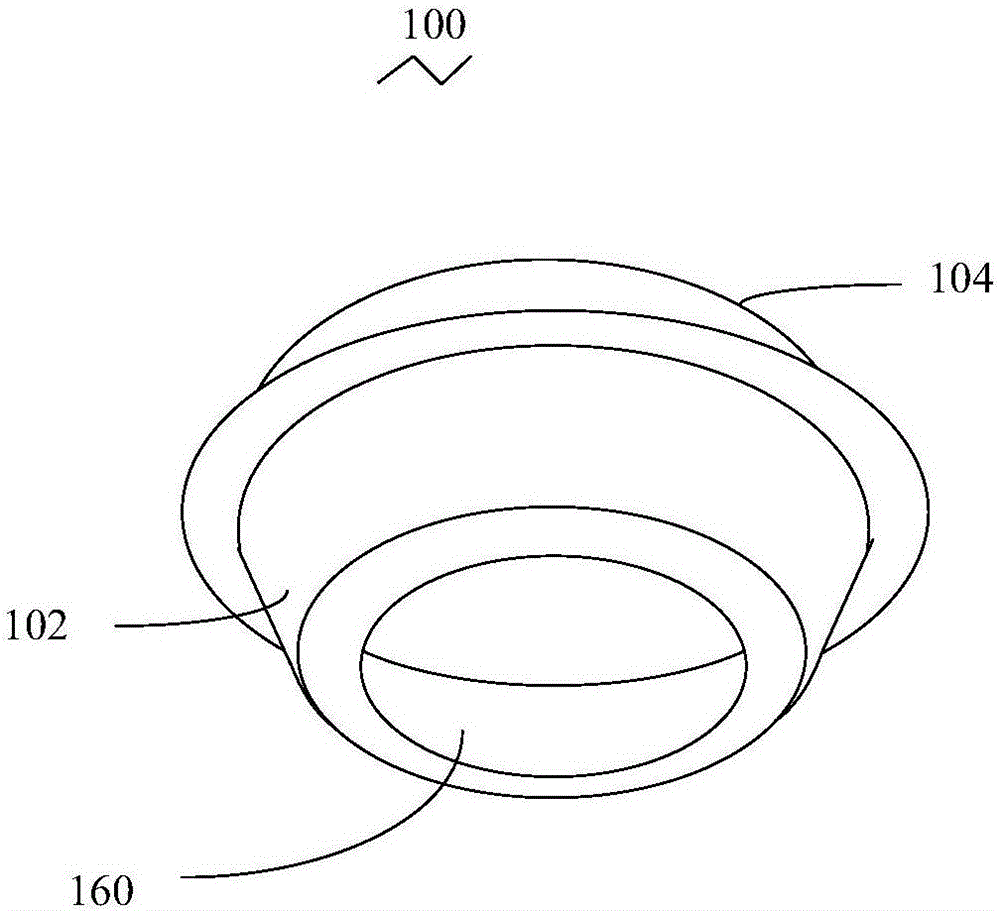

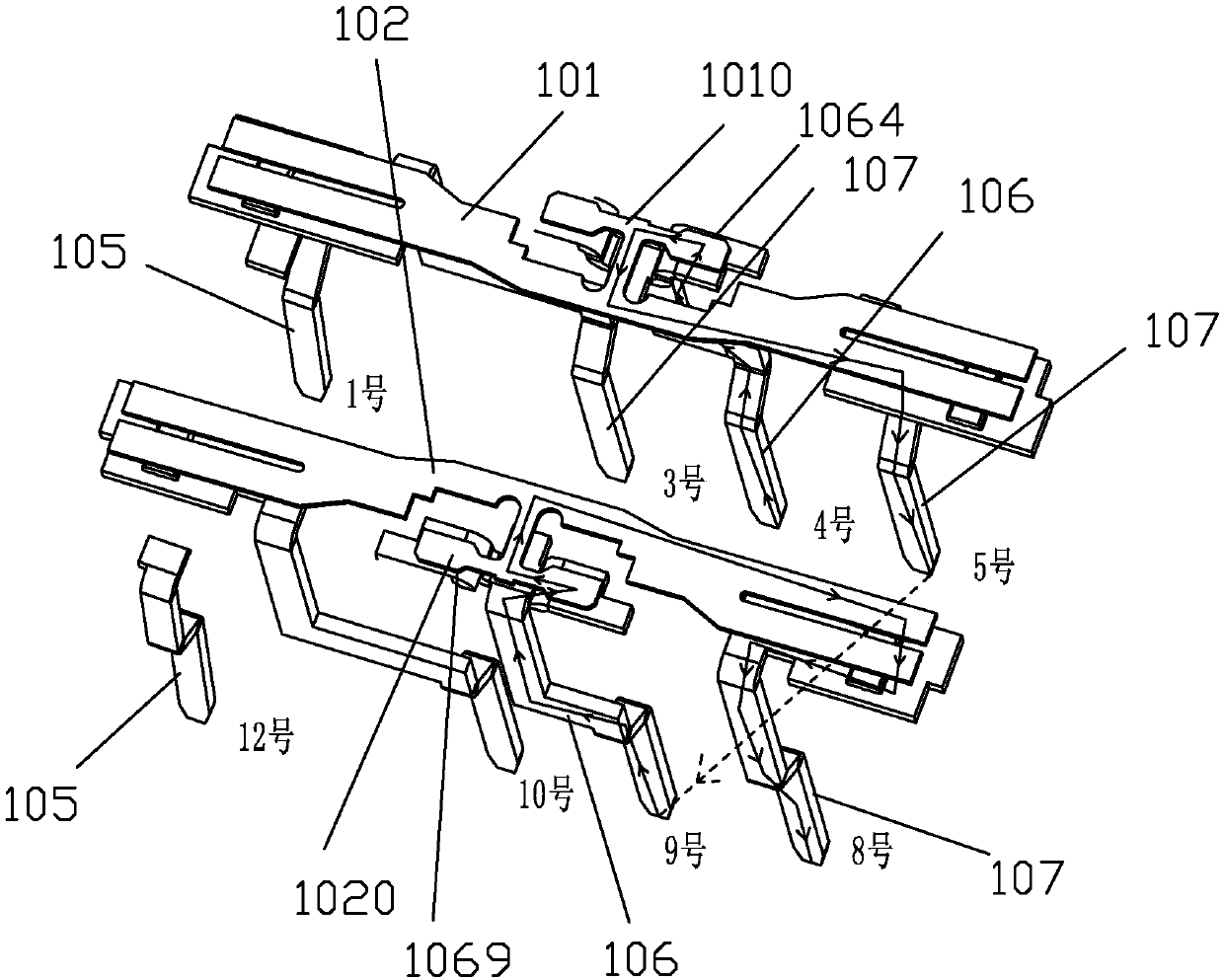

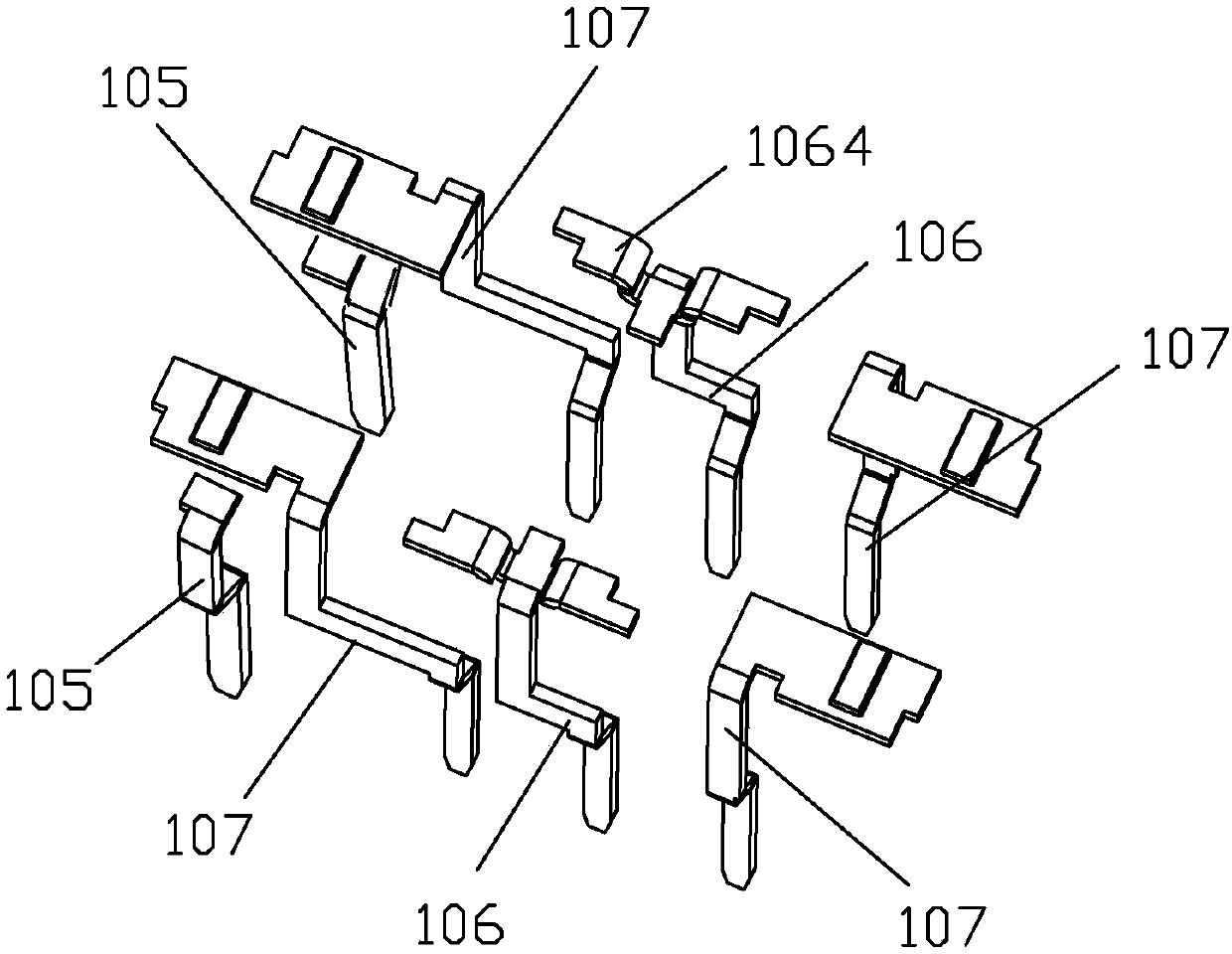

High-withstanding voltage subminiature electromagnetic relay

ActiveCN107833792ASimple designImprove reliabilityElectromagnetic relay detailsCircuit reliabilityPower flow

The present invention discloses a high-withstanding voltage subminiature electromagnetic relay. The subminiature electromagnetic relay comprises a moving reed part and a fixed reed part, the moving reed part comprises two moving reeds, and a connecting body which spans an acting magnetizer and can communicate two normally open contacts and / or two normally-closed contacts is also connected betweenthe two moving reeds. First positioning and welding parts used for positioning an overall acting assembly are also arranged at the outer sides of the two moving reeds, the second positioning parts matching the first positioning and welding parts are integrated in a pedestal part correspondingly, at the same time, a common terminal at the second positioning parts is canceled. The subminiature electromagnetic relay of the present invention can achieve the purpose of simplifying the relay leading-out terminal design and the user PCB design under the premise of not influencing the original performances of the relay, at the same time, and enables the paths through which the currents flow in the circuits to be shortened. Moreover, the paths through which the signals flow in the circuits do not pass the welding positions of the moving reeds and the leading-out terminals, so that the welding requirements are reduced, and the circuit reliability is improved.

Owner:XIAMEN HONGFA SIGNAL ELECTRONICS CO LTD

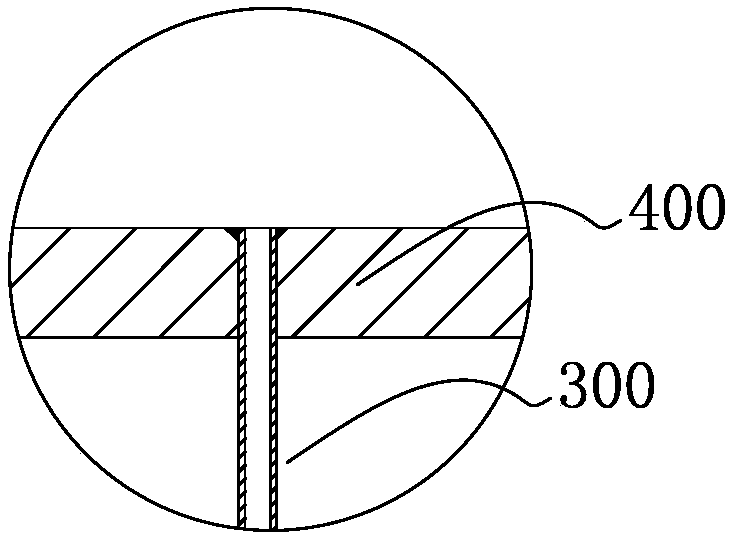

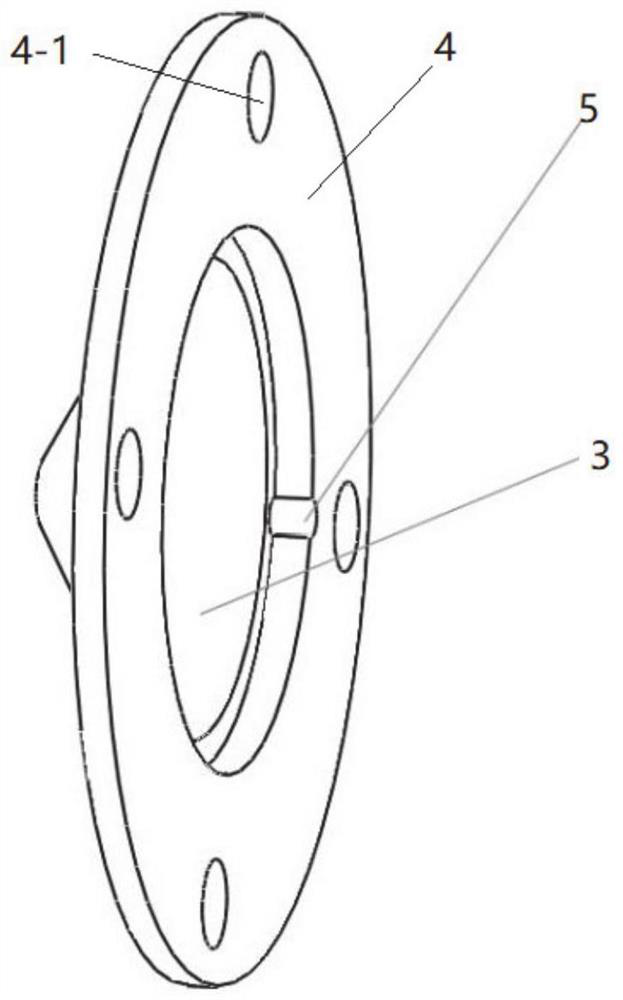

Evaporator and application thereof in heat pump unit

ActiveCN108507238AEasy to replaceNo leakageSafety devices for heat exchange apparatusEvaporators/condensersEngineeringFlange

The invention discloses an evaporator and an application thereof. The evaporator is used for solving the problem that a welding part of a heat exchange tube easily leaks. The evaporator comprises a shell pass and a tube pass, wherein a first working medium is introduced into the shell pass, a second medium is introduced into the tube pass, the two ends of the heat exchange tube in the evaporator and a tube plate are in tight fit, the end parts of the two ends of the heat exchange tube extend to the outer side of the tube plate, and the exposed length of the heat exchange tube is not smaller than the thickness of the tube plate; the evaporator comprises an adaptor, a conical sealing part and a locking nut, wherein the adapter comprises a flange part and a cylindrical part, the inner part ofthe cylindrical part is in a cone shape and is filled with a conical sealing part, the flange part and the tube plate are welded and fixed, and the locking nut is fastened on the cylindrical part andcompresses the conical sealing part. According to the evaporator, the adapter is connected with the tube plate in a welding mode, leakage cannot occur; and meanwhile, a first-stage over-tight fit seal and a second-stage seal sleeve seal are arranged between the heat exchange tube, the adapter and the tube plate simultaneously, so that no leakage liquid is generated between the tube pass and the shell pass.

Owner:云南穗特丰农业科技有限公司

Novel circulation manner large-temperature-difference heat exchange unit

PendingCN112268382AReduce the size of the unitReduce the amount of solutionBoilers/analysersEnergy efficient heating/coolingCold mediumEngineering

The invention discloses a novel circulation manner large-temperature-difference heat exchange unit. The novel circulation manner large-temperature-difference heat exchange unit comprises a generator,a condenser, an evaporator set, an absorber set and a water-water plate heat exchanger. The generator is sequentially connected with a primary network water inlet, the water-water plate heat exchanger, the evaporator set and a primary network water outlet. The water-water plate heat exchanger communicates with a secondary network water inlet and a secondary network water outlet through a secondarynetwork water pipeline, and the secondary network water inlet is sequentially connected with the absorber set, the condenser and the secondary network water outlet through a pipeline. The absorber set is connected with a first solution pipeline, the first solution pipeline communicates with the generator after passing through a solution heat exchanger, the generator communicates with a second solution pipeline, and the second solution pipeline is connected with the top of the absorber set after passing through the solution heat exchanger. The bottom of the condenser communicates with a refrigerant pipeline communicating with the evaporator set, and the bottom of the evaporator set is connected with a refrigerant pump and an evaporator set spraying device through the refrigerant pipeline.The novel circulation manner large-temperature-difference heat exchange unit is simple in structure, small in heat exchange area and high in heat exchange efficiency.

Owner:TONGFANG KAWASAKI ADVANCED ENERGY SAVING MACHINE

Machining die, machining device and method for lined wear-resisting layer of iron three-way pipe fitting

ActiveCN111750194AReduced soldering requirementsClose contactBranching pipesPipe protection against damage/wearPipe fittingStructural engineering

The invention relates to a machining die, machining device and method for a lined wear-resisting layer of an iron three-way pipe fitting. The machining die comprises a first component, a second component and a third component; the first component can be fixed to one end of a three-way pipe fitting main pipe in a sealed mode and is provided with a first mandrel capable of coaxially stretching intothe three-way pipe fitting main pipe, and the second component can be fixed at the other end of the three-way pipe fitting main pipe in a sealed mode and can keep a set distance from the end surface of the first mandrel; and the third component can be fixed to the end part of a three-way pipe fitting branch pipe in a sealed mode and is provided with a second mandrel capable of coaxially stretchinginto the three-way pipe fitting branch pipe, and the end part of the second mandrel can make close contact with the outer mandrel face of the first mandrel. The die is convenient to machine and simple in structure, and a machined wear-resisting layer is not prone to fall off.

Owner:SHANDONG DONGHONG PIPE IND

Evaporator and its application in heat pump unit

ActiveCN108507238BEasy to replaceNo leakageSafety devices for heat exchange apparatusEvaporators/condensersDielectricEngineering

The invention discloses an evaporator and an application thereof, which are used for solving the problem that the welded part of the heat exchange tube is easy to leak. It includes a shell side and a tube side, wherein the working medium I is passed into the shell side, and the medium II is passed into the tube side. Both ends of the heat pipe respectively extend to the outside of the tube sheet and the exposed length is not less than the thickness of the tube sheet, and also include an adapter, a tapered seal, and a lock nut, wherein the adapter includes a flange and a cylinder part, the inside of the cylindrical part is cone-shaped and filled with conical seals, the flange part and the tube sheet are welded and fixed, the lock nut is fastened to the cylindrical part and the conical seal Press tight. In the present invention, the connection between the adapter and the tube sheet is welded, so no leakage will occur. At the same time, there is a primary over-tight fit seal and a secondary sealing sleeve between the heat exchange tube, the adapter, and the tube sheet. It is sealed to ensure that there is no leakage between the tube side and the shell side.

Owner:云南穗特丰农业科技有限公司

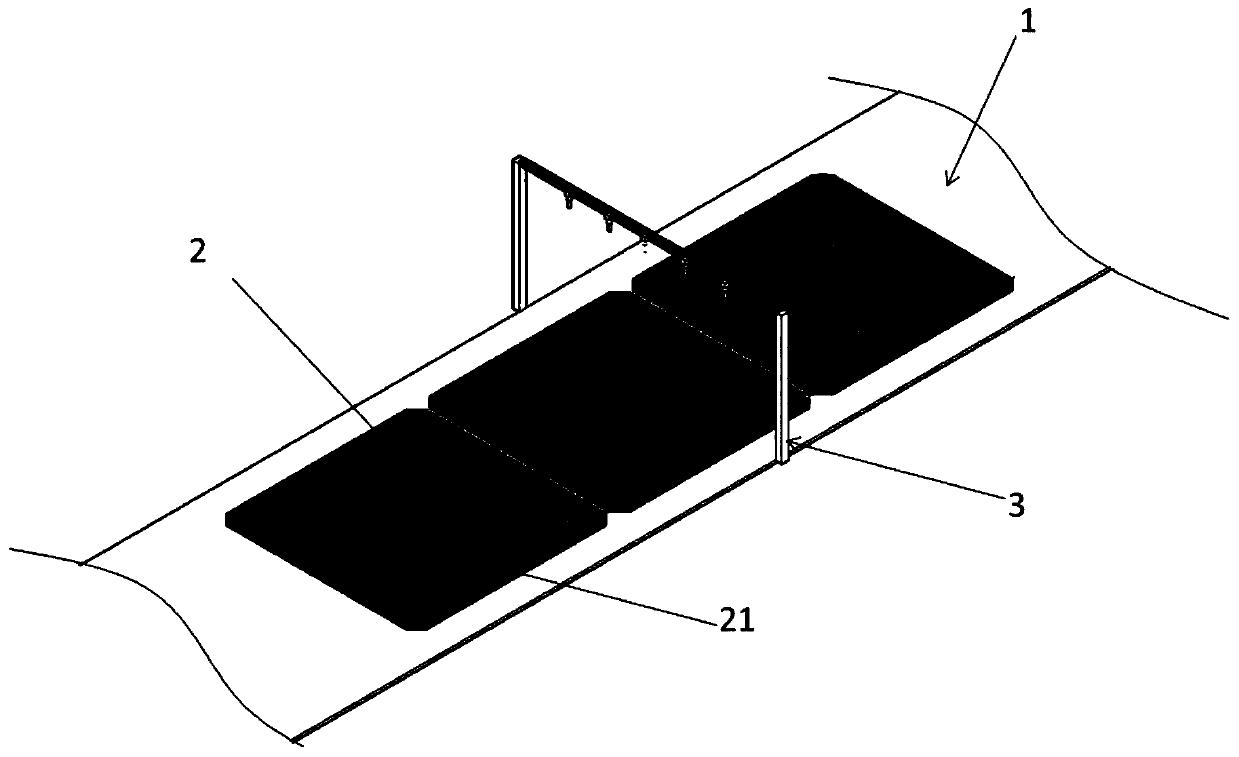

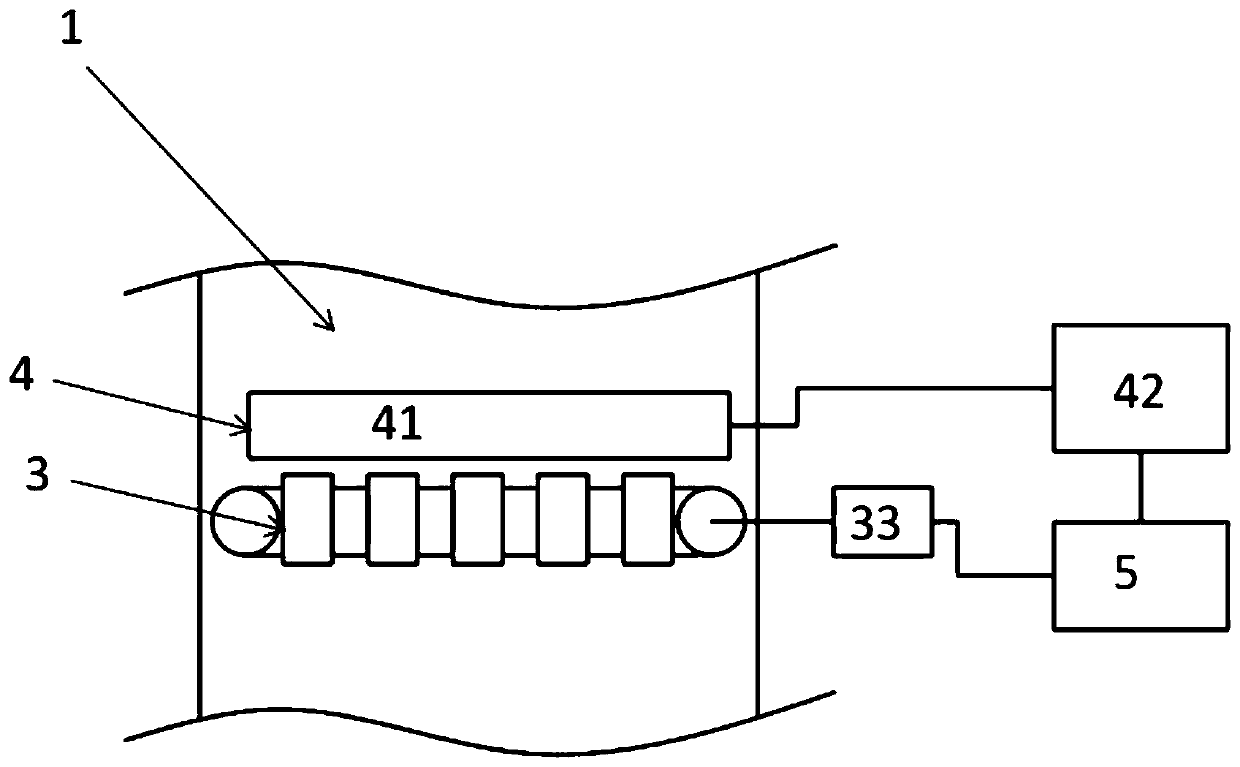

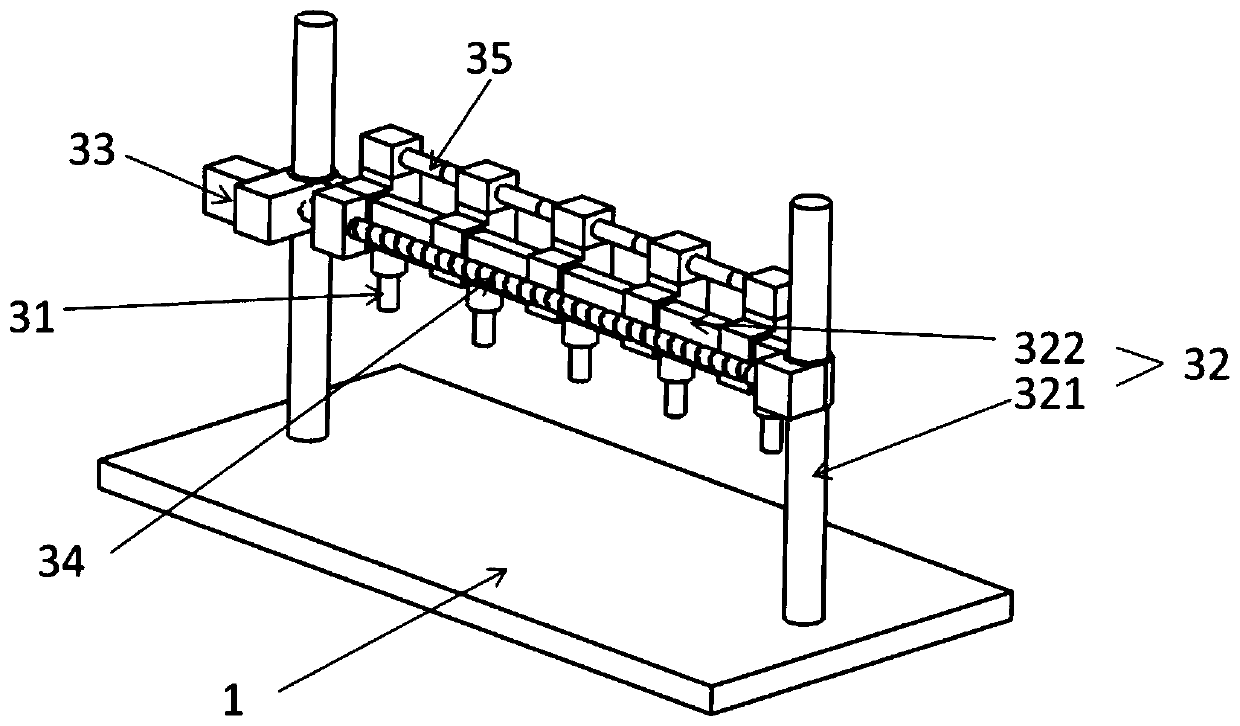

3D printing technology-based coloring device and coloring method of photovoltaic piece

PendingCN110600580AReduced soldering requirementsIncrease productivitySpraying apparatusPhotovoltaic energy generationImage sensorEngineering

A 3D printing technology-based coloring device of a photovoltaic piece comprises a transmission assembly line, wherein an identification assembly, a printing assembly and a controller are arranged onthe transmission assembly line, the printing assembly comprises a lifting rack and a sprayer, the lifting rack is arranged on the transmission assembly line, the sprayer is arranged on the lifting rack, the lifting rack comprises a lifting rod and a sliding rod, the lifting rod ascends and descends along a vertical direction, the sliding rod is arranged on the lifting rod, the sprayer is arrangedon the sliding rod in a sliding way, a CCD image sensor is used for shooting the photovoltaic piece on the transmission assembly line, a welding strip on the photovoltaic piece is identified by a processor, a position signal of the welding strip is transferred to the controller, the sprayer is controlled to slide on the sliding rod by the controller so as to spray a pigment onto the welding stripon the photovoltaic piece, a coloring layer is formed on a surface of the welding strip, so that the welding strip on the photovoltaic piece is maintained consistent with color of a battery piece, thewelding requirement of connecting the battery piece to form the photovoltaic piece is greatly reduced, and the production efficiency of the photovoltaic piece with color consistency is improved.

Owner:ZHEJIANG TRUMHE NEW MATERIAL CO LTD +1

A tube-sheet welding method, a tube body-tube-sheet connection method, and a heat exchanger

ActiveCN113996964BGuaranteed stabilityGuaranteed tightnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPipe

The present invention relates to the technical field of metal structure processing, in particular to a tube plate welding method, comprising the following steps: fixing the plate body; setting a flat sealing gasket on the periphery of the hollow cylinder section, and inserting the hollow cylinder section through one end of the plate body In the hole; press the convex edge through the mold to protrude toward the plate body, and form an annular depression on the surface of the plate body by pressing the plate body; the sealing flat gasket is sandwiched between the annular depression and the protruding part of the convex edge ; Keeping the state of pressure applied, welding is performed on the other side of the hollow cylinder section, and the intermediate body and the plate body are fixedly connected. The present invention provides a tube sheet processing method that ensures the stability and sealing of the relative position after the tube sheet and the tube body are connected, and can appropriately reduce the welding quality requirements. The obtained tube sheet is used in a certain To a certain extent, the purpose of solving the sealing problem is achieved, so the welding requirements are effectively reduced. In the present invention, protection is also claimed for a method for connecting a tube body and a tube sheet and a heat exchanger.

Owner:常州新海飞金属制品有限公司

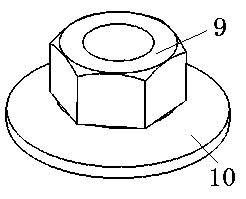

Engine thermal baffle installation nut and automobile

InactiveCN109973502AAvoid installation impactEasy to installThermal insulationNutsScrew threadAerospace engineering

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

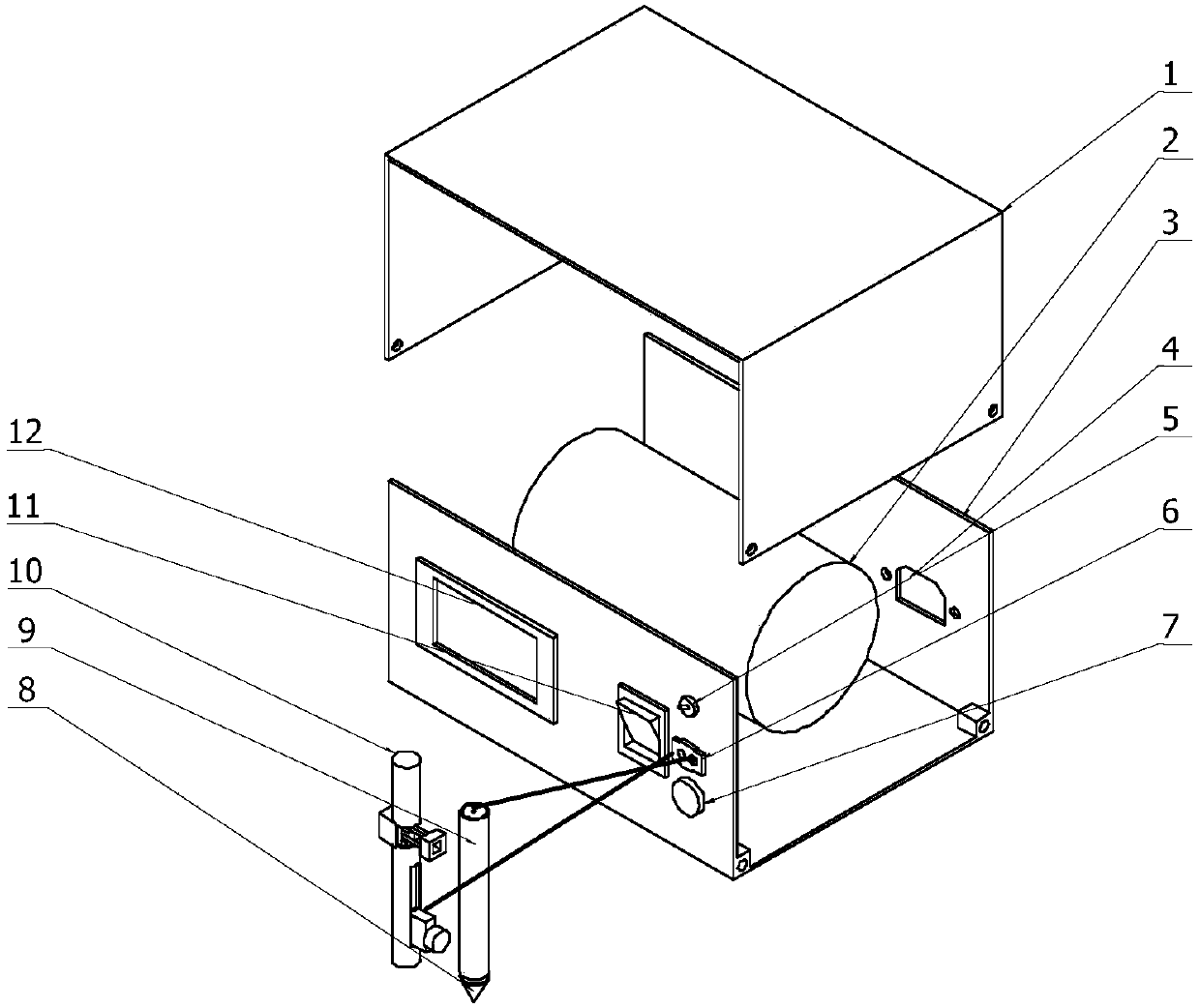

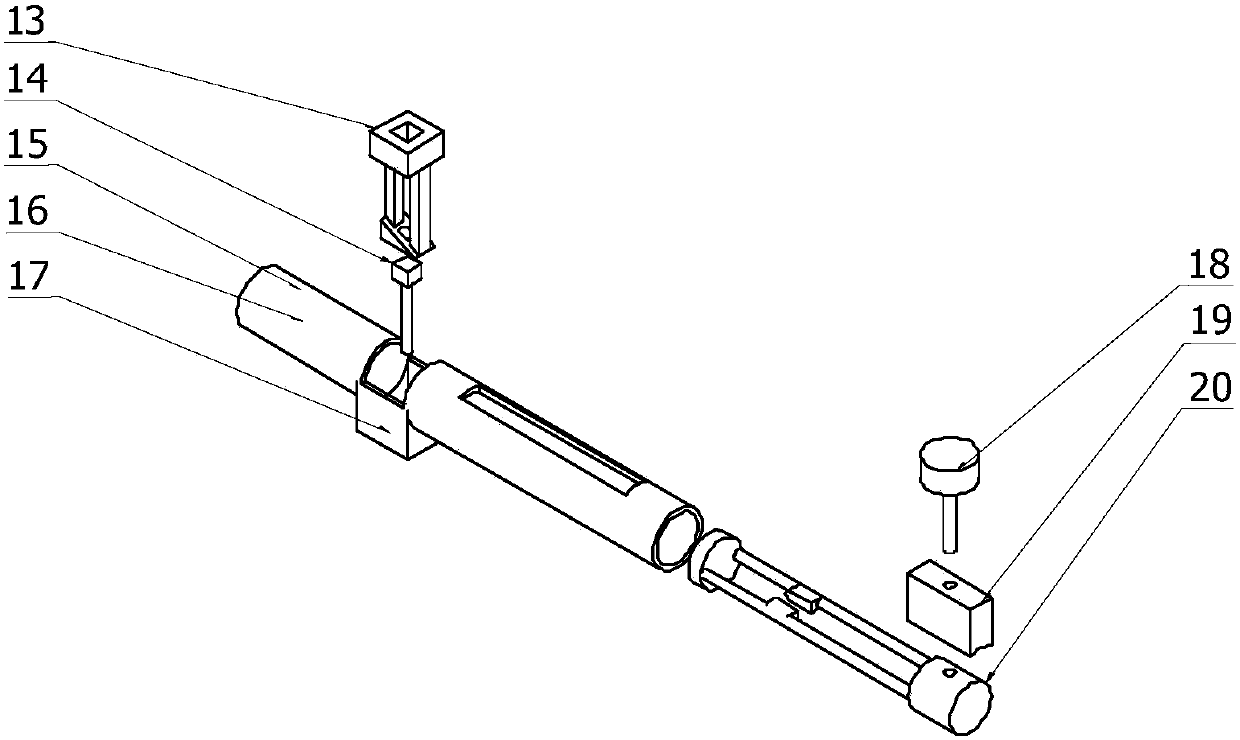

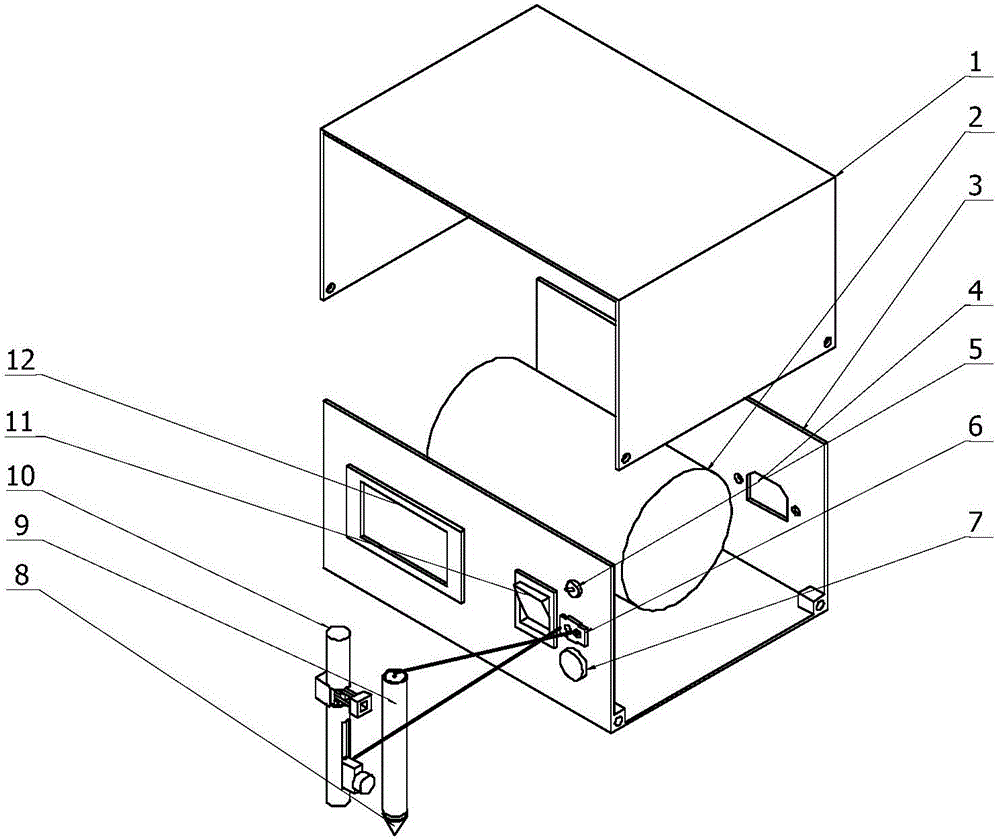

Portable Thermocouple Spot Welder for Multi-Materials

ActiveCN105855738BSolve the problem of weak or even impossible weldingReduce lossWelding/soldering/cutting articlesMetal working apparatusCapacitanceLow voltage

The invention discloses a portable thermocouple spot welding machine suitable for multiple materials and can inhibit generation of relatively large electric sparks under parameters of relatively high capacitance and relatively low voltage to form solder balls. A thermocouple is welded with various material surfaces with a high success rate through wire feeding, so that the problem that welding of the thermocouple on metal materials such as copper and aluminum by a conventional spot welding machine is not firm and even the thermocouple cannot be spot-welded is solved. Through adoption of a pen container type welding electrode and a function of automatically and quickly feeding wires, the phenomenon that the welding environment is severe is solved and the condition that the welding effect is poor as a result of an imprecise operation technology is avoided. The product designed by the invention is small in size, portable and easy to operate. Compared with conventional tin soldering and the thermocouple with a groove formed on the surface of a metal material, the temperature measuring precision is greatly improved, and a lot of energy loss as the temperature of an engineering material cannot be precisely measured or the temperature of the engineering material cannot be measured is reduced.

Owner:XI AN JIAOTONG UNIV

Portable thermocouple spot welding machine suitable for multiple materials

ActiveCN105855738ASolve the problem of weak or even impossible weldingReduce lossWelding/soldering/cutting articlesMetal working apparatusCapacitanceLow voltage

The invention discloses a portable thermocouple spot welding machine suitable for multiple materials and can inhibit generation of relatively large electric sparks under parameters of relatively high capacitance and relatively low voltage to form solder balls. A thermocouple is welded with various material surfaces with a high success rate through wire feeding, so that the problem that welding of the thermocouple on metal materials such as copper and aluminum by a conventional spot welding machine is not firm and even the thermocouple cannot be spot-welded is solved. Through adoption of a pen container type welding electrode and a function of automatically and quickly feeding wires, the phenomenon that the welding environment is severe is solved and the condition that the welding effect is poor as a result of an imprecise operation technology is avoided. The product designed by the invention is small in size, portable and easy to operate. Compared with conventional tin soldering and the thermocouple with a groove formed on the surface of a metal material, the temperature measuring precision is greatly improved, and a lot of energy loss as the temperature of an engineering material cannot be precisely measured or the temperature of the engineering material cannot be measured is reduced.

Owner:XI AN JIAOTONG UNIV

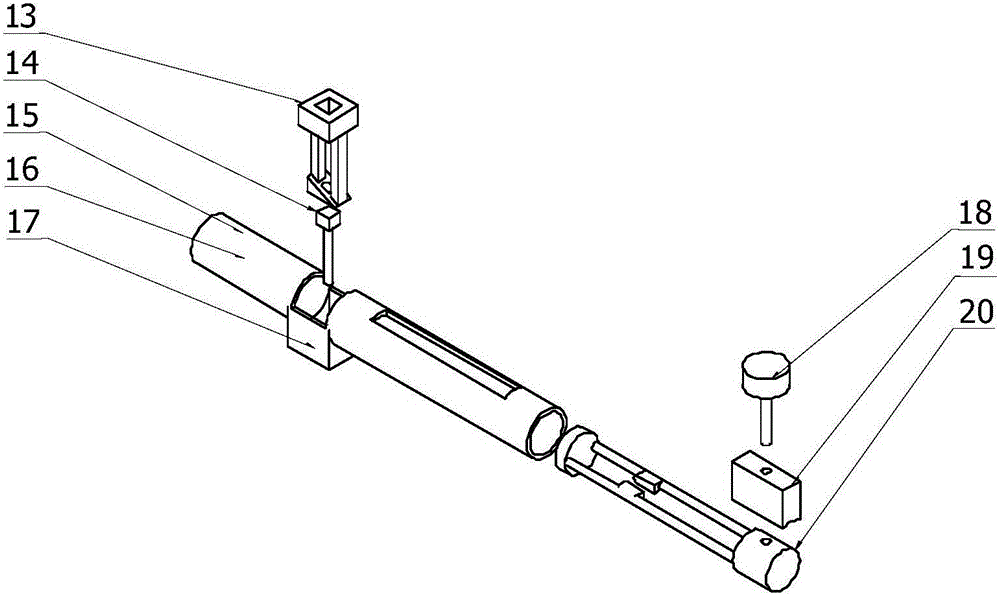

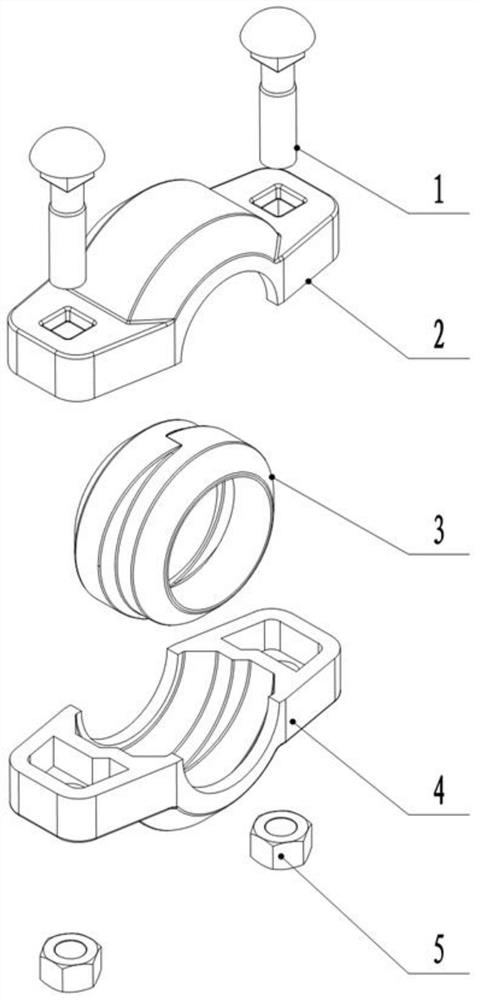

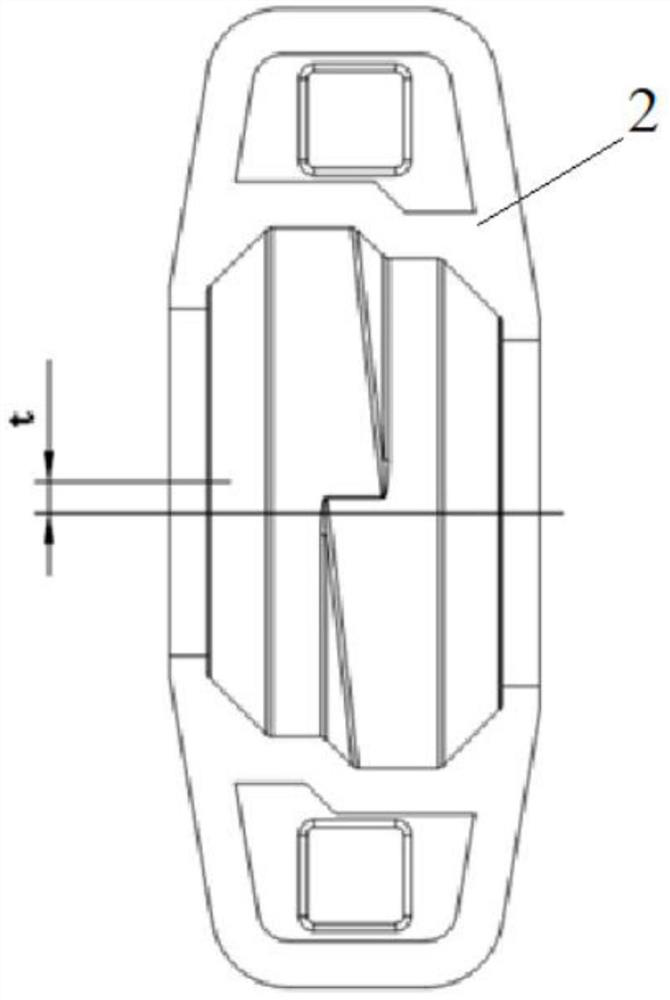

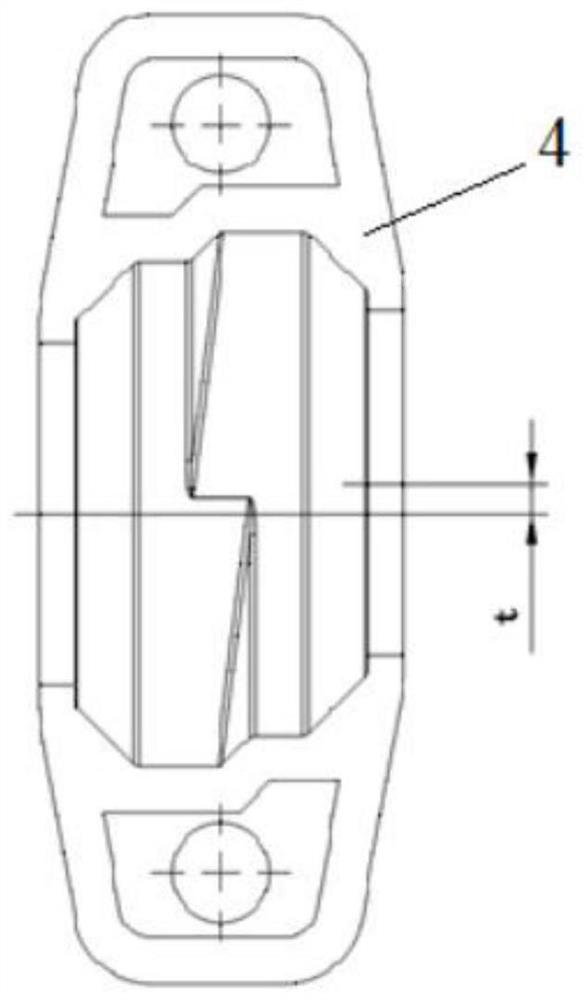

Eccentric clamp

The invention provides an eccentric clamp. The eccentric clamp is composed of a square hole hoop semi-ring, an eccentric sealing ring, a round hole hoop semi-ring, a round-head square-neck bolt and a nut, and the square hole hoop semi-ring, the round hole hoop semi-ring and the eccentric sealing ring are each provided with an upper circular ring locking face and a lower circular ring locking face which are not coaxial and a sealing face, the axial distance between each circular ring locking face and the sealing face is t, the square hole hoop semi-ring and the round hole hoop semi-ring are installed at the upper end and the lower end of the eccentric sealing ring and connected through the round-head square-neck bolt, and the nut is in threaded connection with the outer portion of the bottom end of the round-head square-neck bolt. The eccentric clamp provided by the invention solves the problem of position deviation of two connected joints of a pipeline or a pipe fitting, or solves the problem that the pipeline and the pipe fitting displace when the pressure and the temperature change to cause the position deviation of the axis of the joint, so that the connecting part bears extra load and leaks.

Owner:山东沣纳环保科技有限公司

Horizontal type large motor stator iron core pressing machine

PendingCN106787504AEasy loading and unloadingEasy to operateManufacturing stator/rotor bodiesControl engineeringElectrical control

The invention relates to the technical field of motor stator pressing equipment, in particular to a horizontal type large motor stator iron core pressing machine. The horizontal type large motor stator iron core pressing machine comprises a fixed box body and an operating box body installed at the upper end of the fixed box body, wherein the operating box body is internally provided with an operating groove, and an opening is formed in the front of the operating groove; the operating groove is internally provided with a left bolt clamping mechanism used for fixing a workpiece, and a right bolt clamping mechanism used for fixing an electrical control hydraulic machine; a control box which is internally provided with a direct current (DC) motor is fixedly connected with the upper end, positioned at the left side of the operating box body, of the fixed box body. According to the horizontal type large motor stator iron core pressing machine, the operating groove which is internally provided with the bolt clamping mechanisms is formed in the operating box body, the DC motor arranged in the control box is used for driving a horizontally arranged transmission rod to control the positions of the bolt clamping mechanisms, and the bolt clamping mechanisms can be conveniently assembled and disassembled by inserting a telescopic rod into a telescopic hole; the horizontal type large motor stator iron core pressing machine is very simple to operate, low in requirements for a buckle piece and welding, and high in accuracy.

Owner:CHANGZHOU SHENLI MOTOR

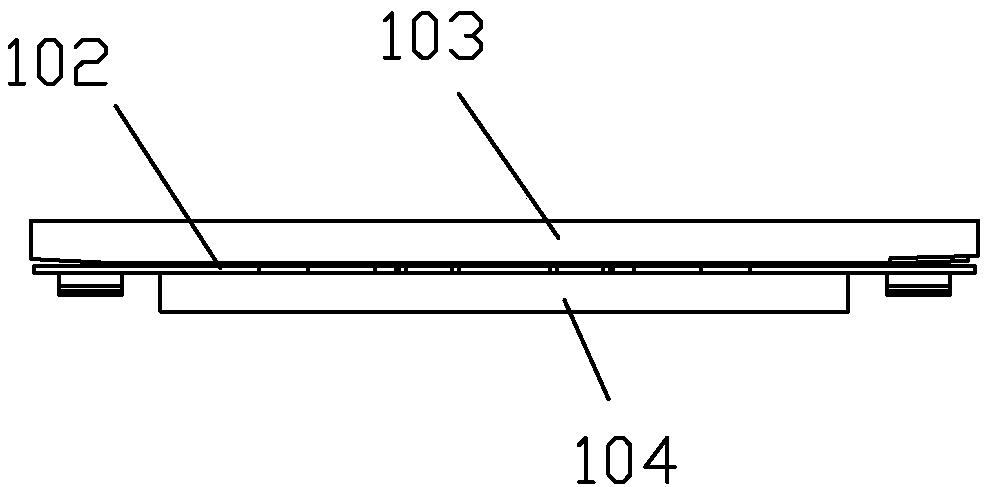

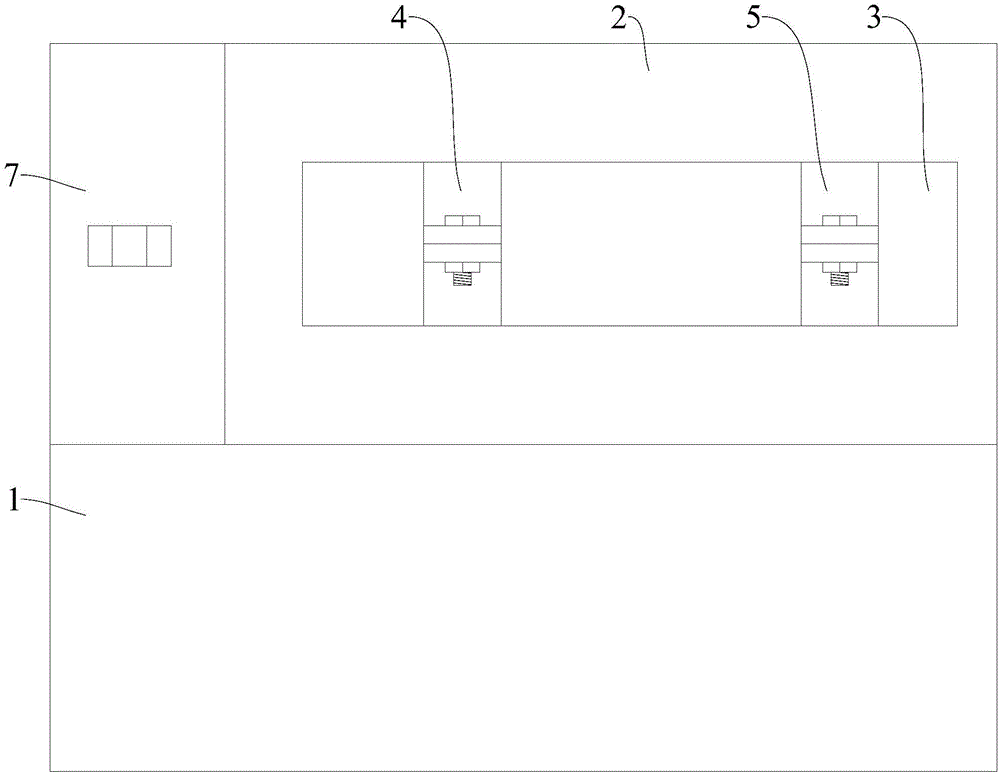

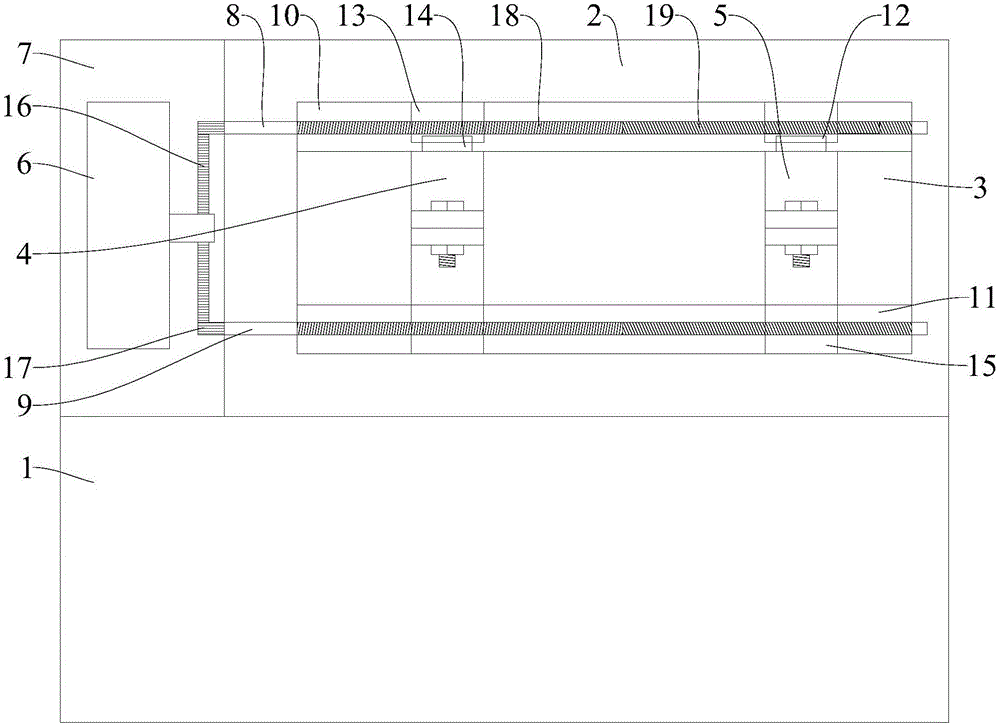

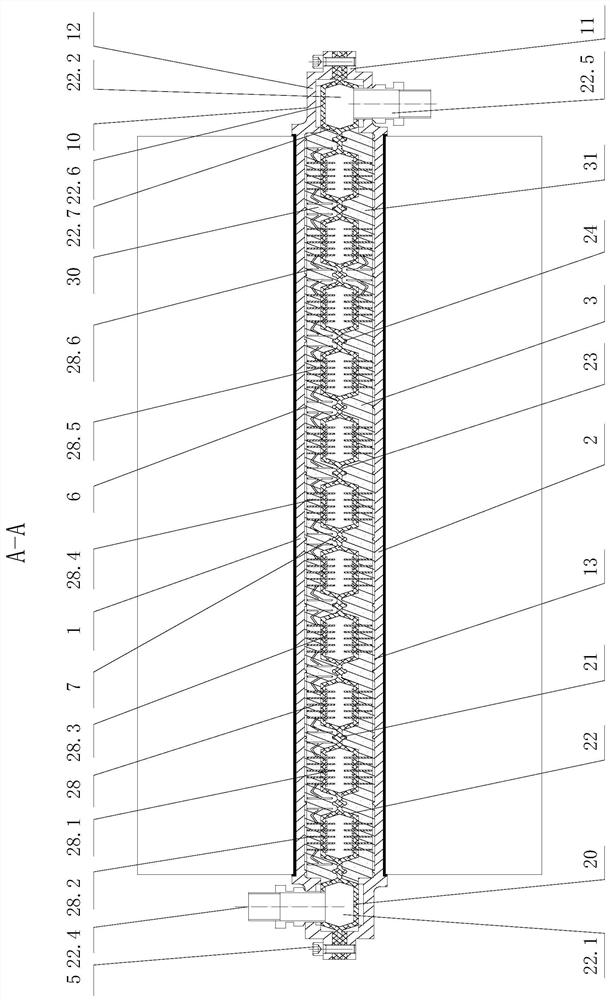

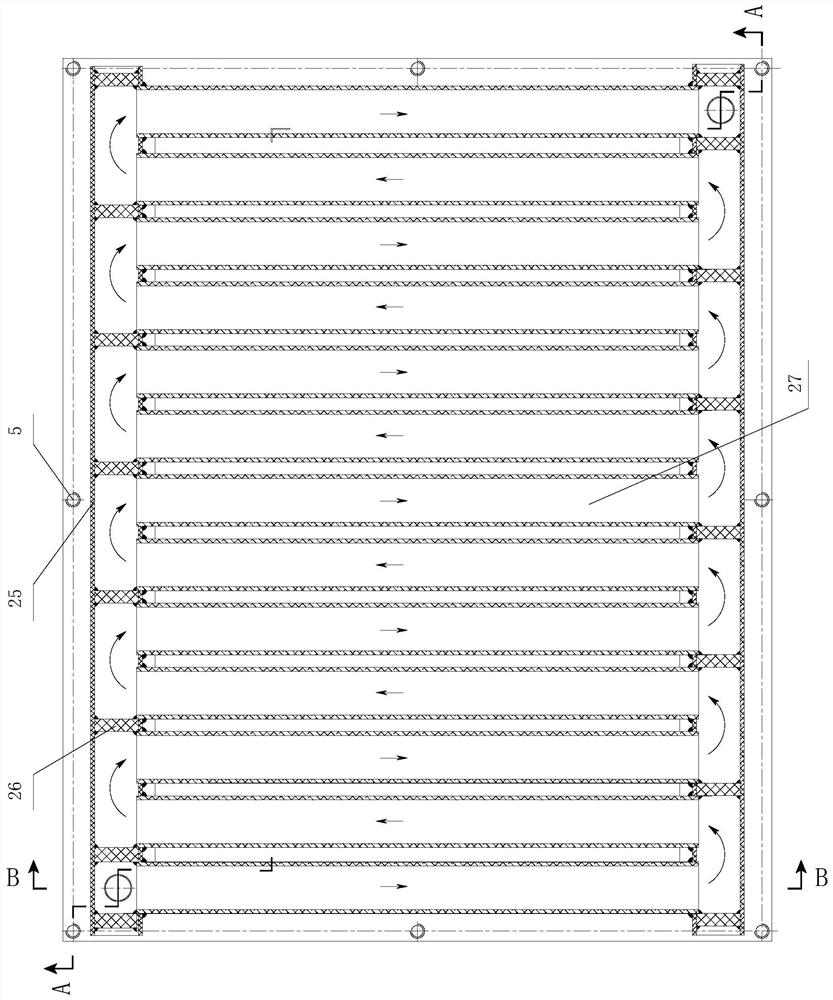

A constant temperature liquid cold plate for electronic components

ActiveCN110690531BGood constant temperature effectReduce weightSecondary cellsPower batteryThermodynamics

A high-heat-flux electronic component constant-temperature liquid cooling plate comprises an upper cooling plate, a liquid cooling mechanism and a lower cooling plate which are stacked in sequence, after stacking, a concave cavity of the upper cooling plate and a concave cavity of the lower cooling plate are oppositely combined to form a constant-temperature cavity surrounding the two sides of theliquid cooling mechanism, and a solid-liquid phase change heat storage mechanism is arranged in the constant-temperature cavity; the liquid cooling mechanism comprises a liquid cooling plate body anda connecting pipe body, the liquid cooling plate body comprises multiple paths of parallel pipe body parts, the head ends and the tail ends of the pipe body parts penetrate the connecting pipe body and are integrally welded, and the connecting pipe body is provided with multiple plugs at intervals, so that the multiple paths of parallel pipe body parts communicate end to end to form an S-shaped cooling path; and the solid-liquid phase change heat storage mechanism comprises a solid-liquid phase change heat storage material which is in gapless direct contact with the inner wall of the concavecavity in a solid state or a liquid state. The high-heat-flux electronic component constant-temperature liquid cooling plate can keep the long-term temperature of a power battery below the melting point of a solid-liquid phase change material, the temperature rise rate is low, and the temperature difference of all parts is small.

Owner:付香花

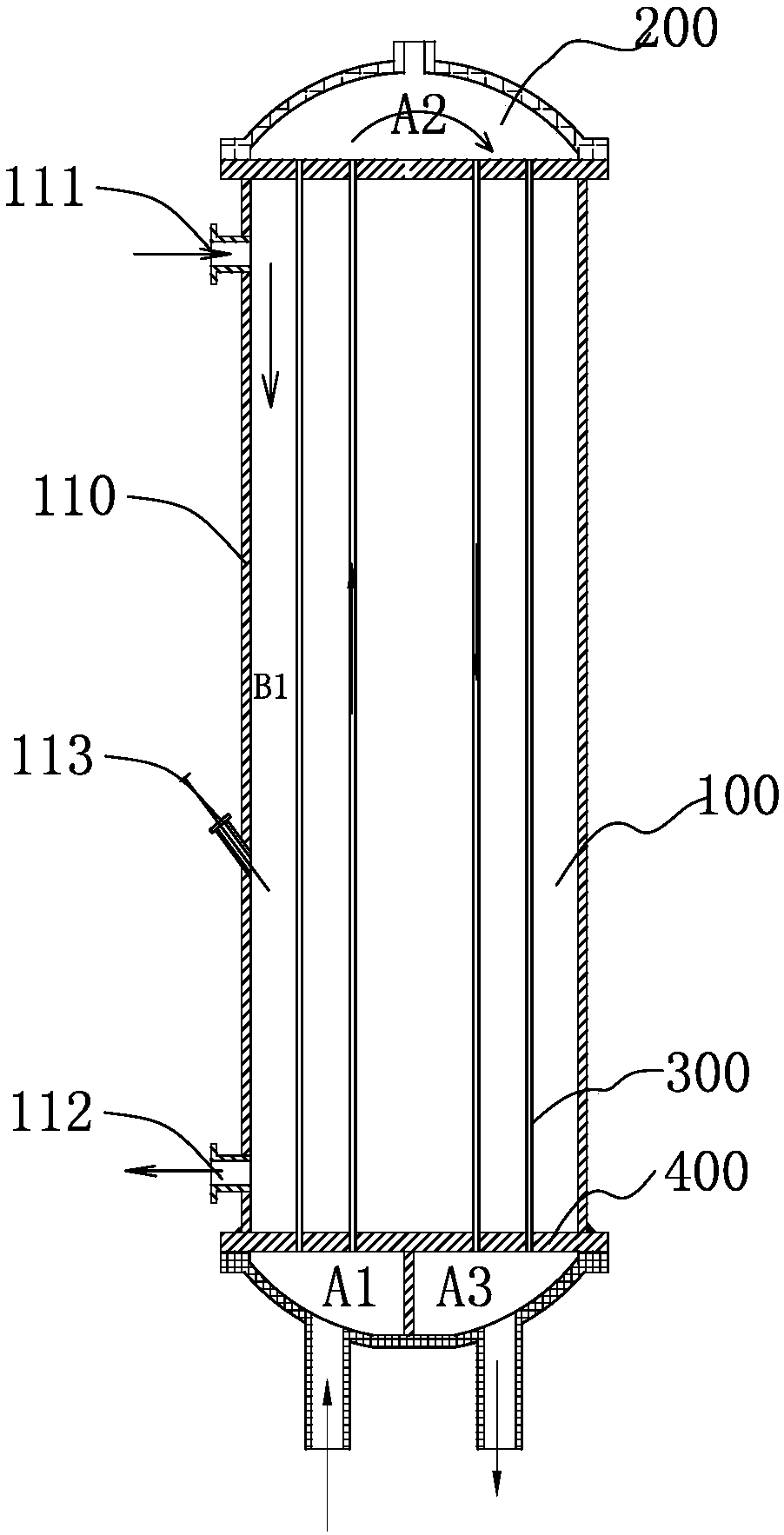

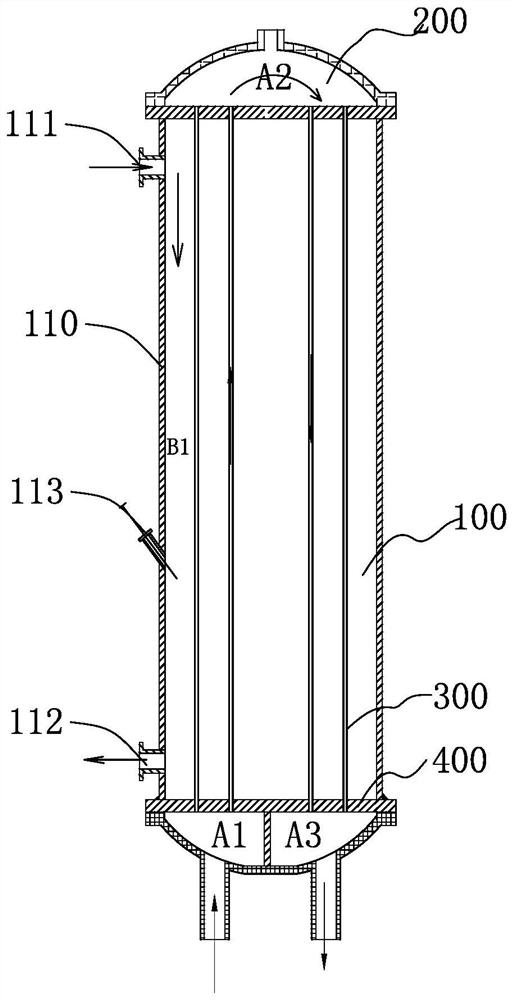

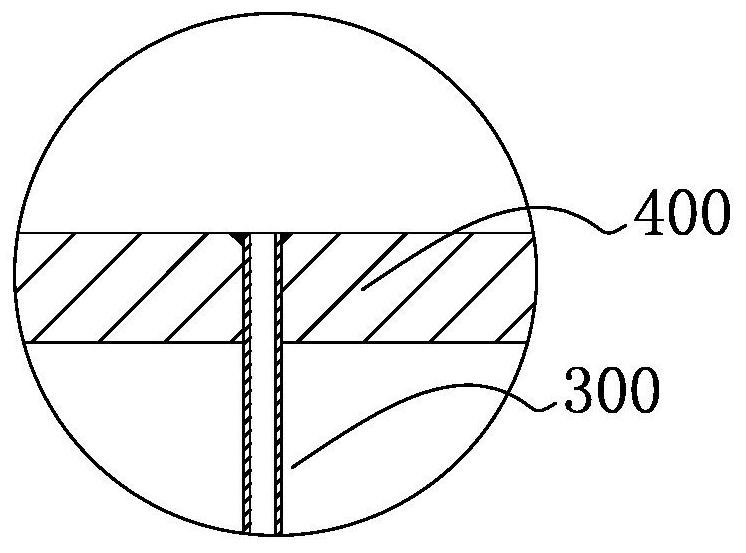

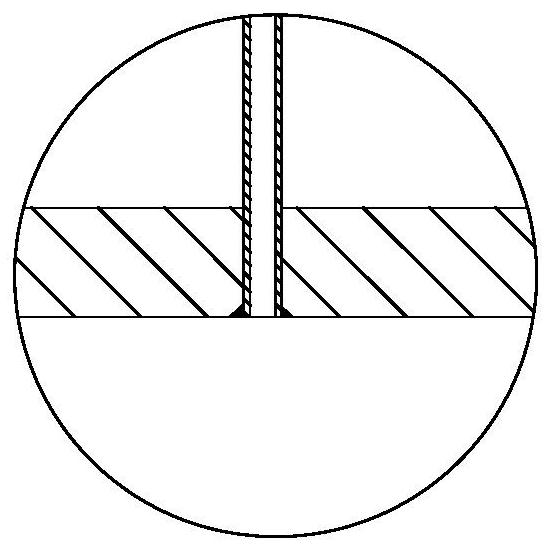

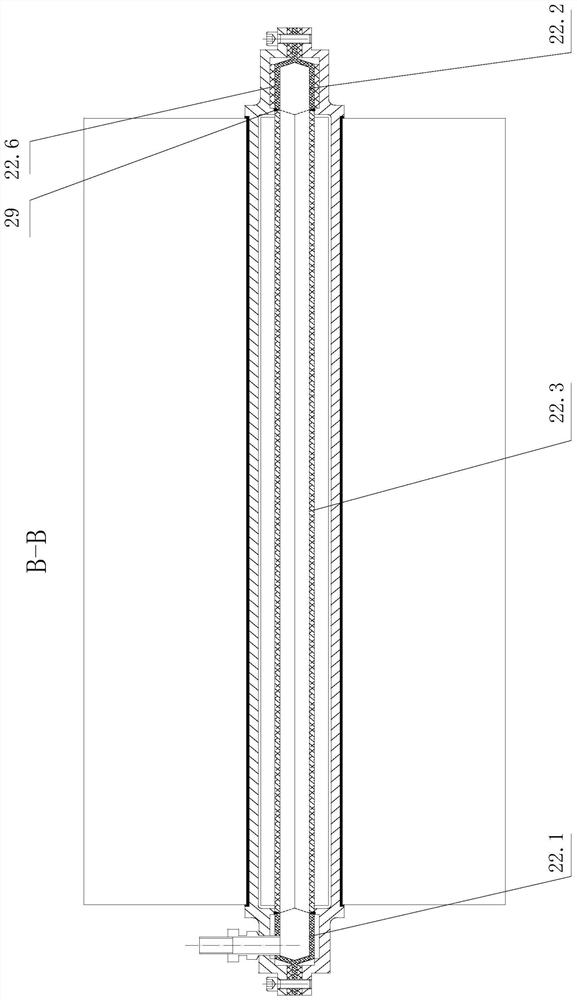

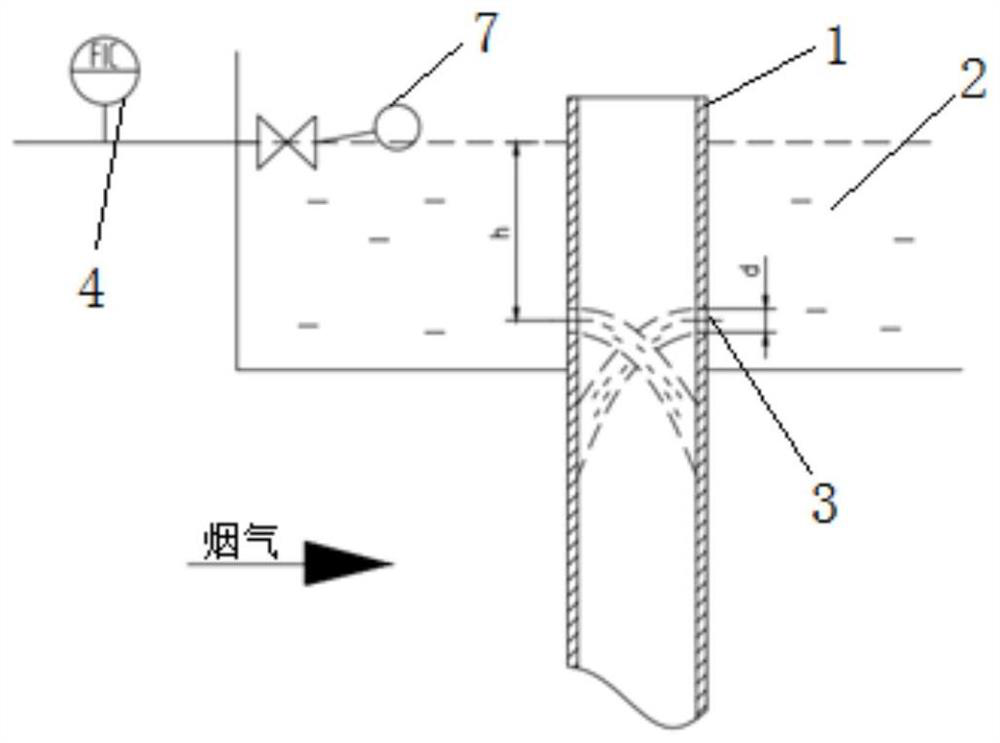

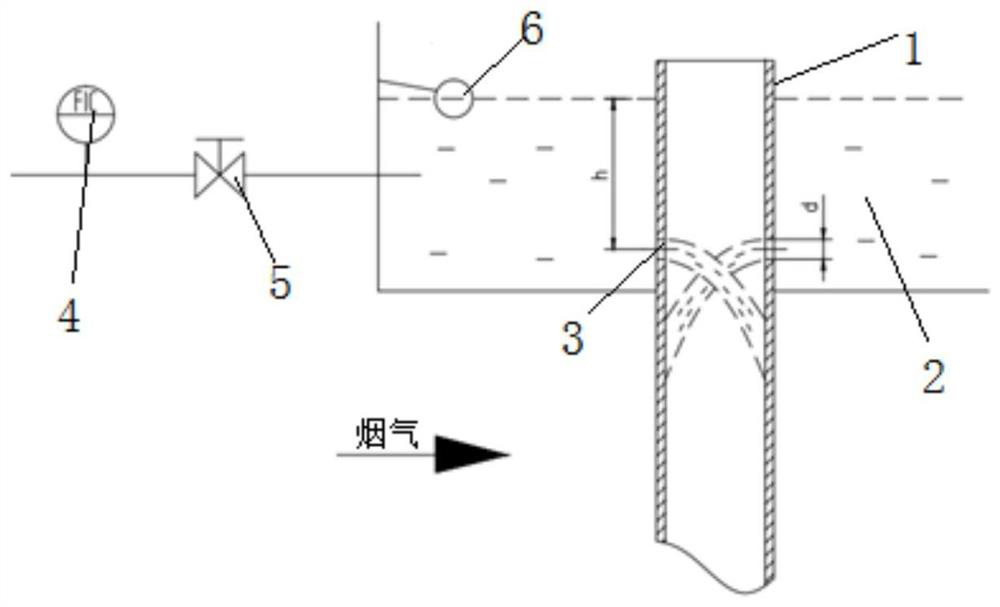

Liquid-holding flowing water cooling device and method

PendingCN112880462AWill not affect operationReduced soldering requirementsHeat transfer modificationTubular elementsThermodynamicsFlue gas

The invention belongs to the field of flue gas cooling, and relates to a liquid-holding flowing water cooling device and method. The liquid-holding flowing water cooling device comprises more than one heat exchange tube and a liquid-holding area arranged on the periphery of the upper part of the heat exchange tube, and more than one through hole communicating with the liquid-holding area is formed in the heat exchange tube. According to the device, cooling water naturally flows along the inner wall of the heat exchange tube from top to bottom through the through holes in the heat exchange tube to take away heat outside a flue gas passing tube; the weight of water in the whole operation system is effectively reduced, so that the weight of the whole equipment is smaller; and the whole system is in a normal pressure state, even if the wall of the heat exchange tube is slightly damaged, the operation of the whole equipment is not influenced, the welding and sealing requirements are reduced, and the equipment manufactured according to the principle can obtain longer service life.

Owner:LIAONING ZHONGWANG MACHINERY EQUIP MFG

A locomotive module connection structure

ActiveCN104890688BReduce occupancyImprove space utilizationAxle-box lubricationLocomotivesMechanical engineeringEngineering

The invention discloses a novel module connecting structure of a locomotive. The novel module connecting structure comprises a first module and a second module; a module mounting beam is arranged on the right end surface of the first module; a mounting seat is arranged on the left end surface of the second module; the module mounting beam and the mounting seat are both n shaped and corresponding in size and position; the module mounting beam is vertically connected with the first module, and the right end of the module mounting beam is bent in 90 degrees to be closely mounted on the left end surface of the mounting seat as well as being fixedly connected through a plurality of bolts; an n-shaped connecting bottom plate is arranged on the outer side surface of the module mounting beam on the right end surface of the first module and is corresponding to the n-shaped outer side surface of the mounting seat; an n-shaped tape clamping groove is formed along the outer side surface of the mounting seat; another n-shaped tape clamping groove is correspondingly formed along the outer side surface of a connecting floor; the two tape clamping grooves are sealed and connected through a sealing tape. The novel module connecting structure has the beneficial effects that a small space in the locomotive is used; the dismounting and mounting are both performed at the outside of the locomotive; the requirements on the welding precision and assembling error are small; the sealing tape is easily overhauled and replaced.

Owner:CRRC ZIYANG CO LTD

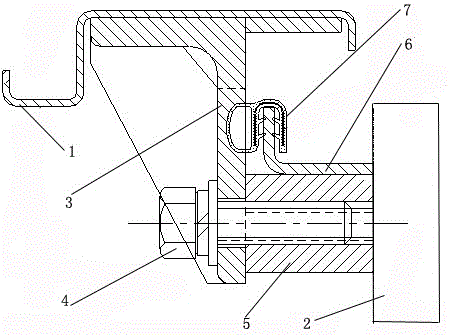

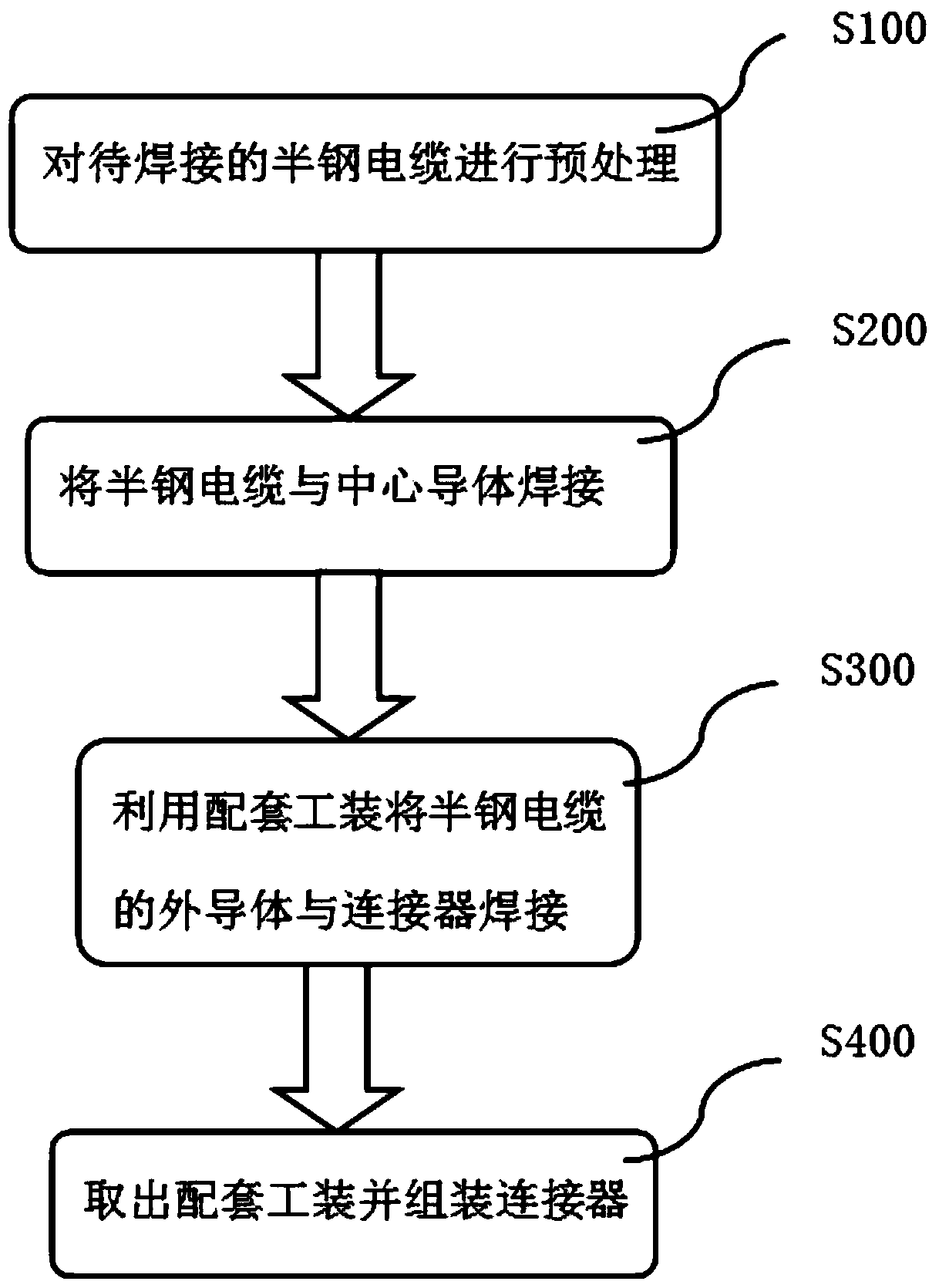

A semi-rigid cable welding void rate control method and supporting tooling

ActiveCN109066252BAvoid damageAvoid affecting performanceLine/current collector detailsSoldering apparatusElectrical conductorStructural engineering

The invention discloses a semi-rigid cable welding void rate control method, comprising the following steps: S100, pre-treating the semi-rigid cable to be welded; S100, pre-treating the semi-rigid cable to be welded; S100, pre-treating the semi-rigid cable to be welded. S200, welding the semi-rigid cable and the central conductor; S300, welding the outer conductor of the semi-rigid cable and the connector by using the matching tooling; S400, take out the matching tooling and assemble the connector, the process can avoid high welding temperature, if the welding time is too long, At that same time, the process has very low requirements on solder and does not require precise soldering operation, which is conducive to ensuring the qualified rate of the product. In addition, the process can reduce the requirements on the product structure, avoid fixing the product modules, and is conducive to the research and development of new products.

Owner:BEIJING GR TECH CO LTD

Hydraulic cylinder piston rod welding structure

InactiveCN107747572AImprove stabilityPrecise positioningFluid-pressure actuatorsHydraulic cylinderEngineering

The invention discloses a hydraulic cylinder piston rod welding structure, which belongs to the technical field of hydraulic cylinders. It includes a rod body, a rod end and a clamp block; the extension rod of the rod body slides into the bottom of the chute from the upper side of the rod end, and the positioning block of the rod body slides into the bottom of the positioning groove from the upper side of the rod end; the clamp The block slides into the bottom of the chute from the left end of the bar end, and the block is pressed on the upper side of the extension bar and the positioning block, and meanwhile, the protruding bar on the block slides into the draw-in groove of the bar end. In the welding structure of the present invention, the extension rod and the positioning block in the rod body only have a tendency to move upward; the block is pressed on the extension rod and the positioning block, and the block itself only has a tendency to move to the left. The block has a good positioning effect; since the block itself is only subjected to an upward force and no force to the left, the requirements for the welding of the block are very low, and the requirements for the welding structure of the fixed whole are very low.

Owner:XUZHOU YONGJIA HYDRAULIC EQUIP

A thread welded integral forged steel piston

ActiveCN104005876BImprove stabilityReduced soldering requirementsMachines/enginesPistonsInterference fitSteel piston

Owner:BINZHOU DONGHAILONG PISTON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com