Slipping steering engine cover for loader

A skid-steering and loader technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of complicated installation and complicated operation, and achieve the requirements of reducing design, simplifying operation steps, and low welding and installation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the opening method of the novel skid steer loader hood of the present invention, it will be described below in conjunction with the accompanying drawings and embodiments.

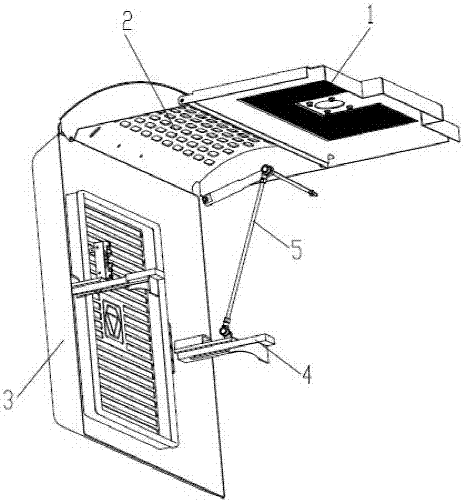

[0025] like figure 1 As shown, a skid steer cover for a loader includes a fixed cover 1 fixedly connected to a vehicle frame. The front edge of the rotating cover 2 is hinged with the rear edge of the fixed cover 1, and the rotating cover 2 can be turned up and down along the hinge shaft.

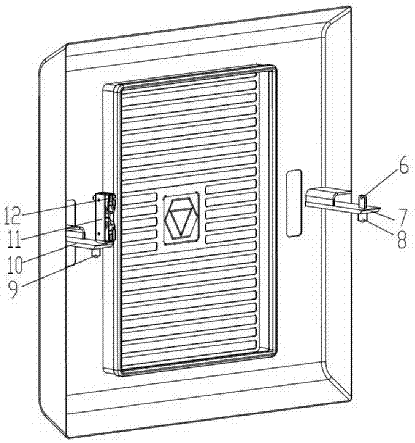

[0026] recombine figure 2 and image 3 As shown, the rear cover 3 is slidingly connected with the vehicle frame back and forth through the sliding device 4, the rear cover 3 can move forward and backward for a certain distance, and the rear cover 3 can rotate to one side; specifically:

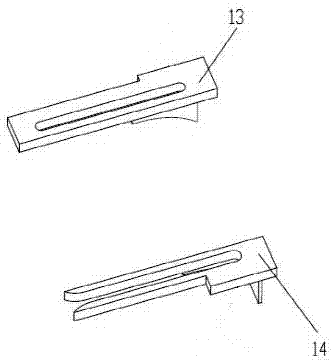

[0027] The sliding device 4 includes a left support 13 and a right support 14 separated from the two sides of the rear cover 3, and the left support 13 and the right support 14 are horizontally a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com