Cooling components and oil heaters

A technology for heaters and components, which is applied to central heating components, heating methods, lighting and heating equipment, etc. It can solve the problems of temperature rise at the end of oil heater heaters, achieve simple welding methods, avoid excessive temperature rise, and be easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The cooling member and the oil heater of the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

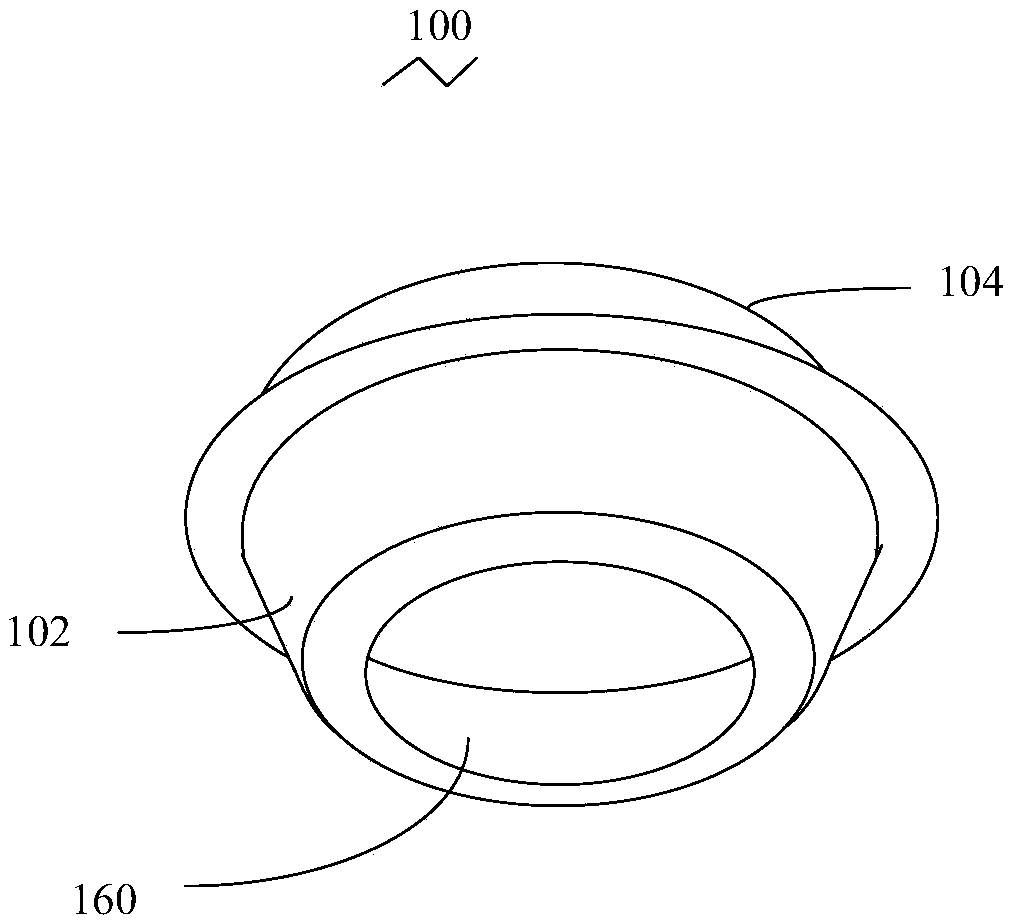

[0016] see figure 1 , the embodiment of the present invention provides a cooling member 100 for installation inside the oil heater 10, the cooling member 100 is a sealed shell structure, the cooling member 100 includes a front end and a rear end opposite to the front end, the cooling A cavity for accommodating heat transfer oil is defined inside the component 100 , and a first opening 160 is further opened at the front end of the cooling component 100 .

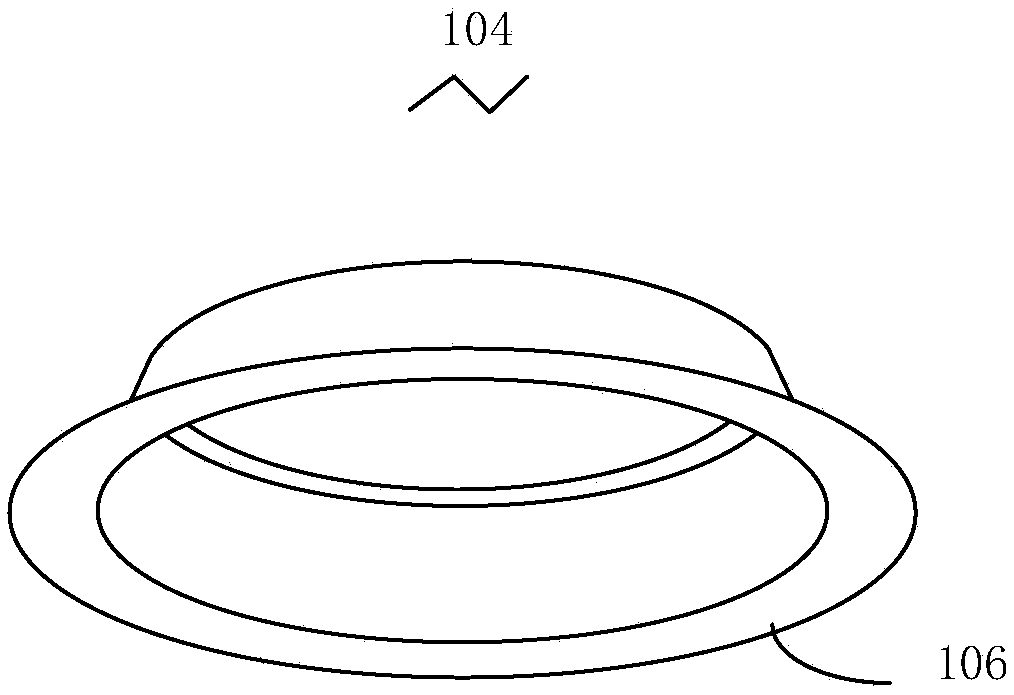

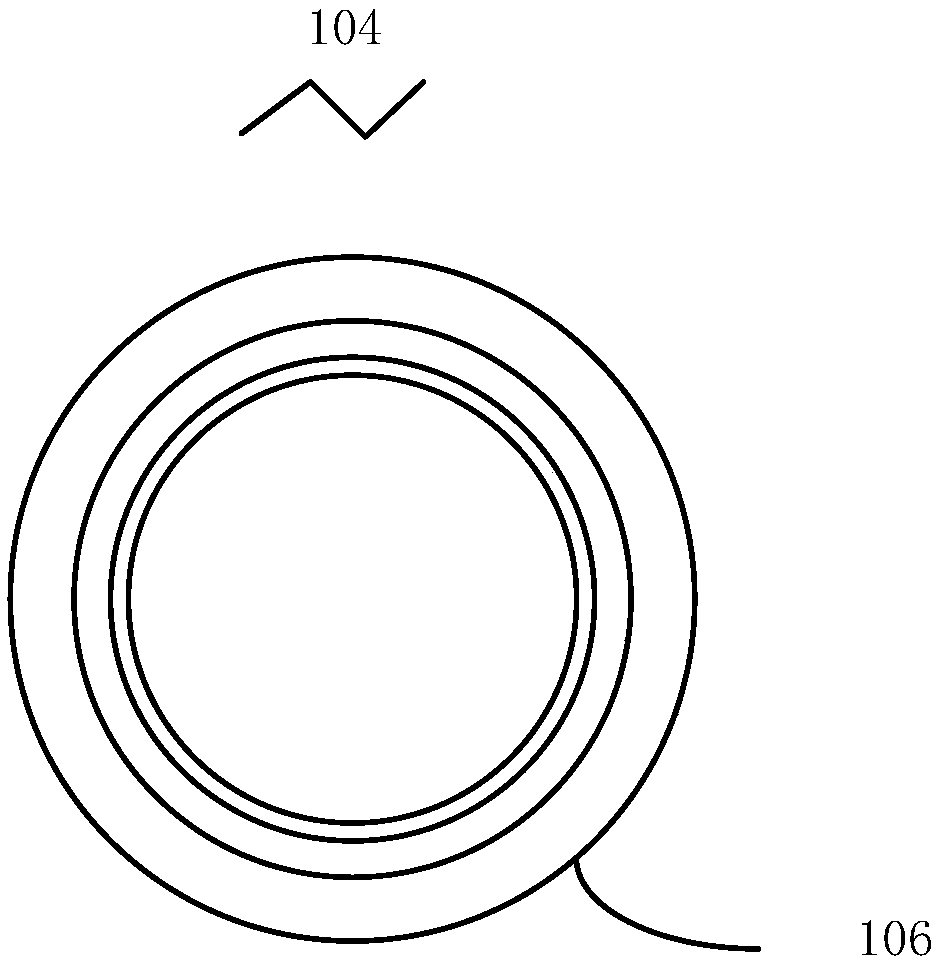

[0017] The material of the cooling component 100 can be metal or alloy. see Figure 2 to Figure 5 , in a preferred embodiment, the front end and the rear end of the cooling member 100 are the front piece 102 and the back piece 104 respectively, the front piece 102 and the back piece 104 are both bowl-shaped, and have the same bowl mouth, the front piece Bow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com