Machining die, machining device and method for lined wear-resisting layer of iron three-way pipe fitting

A technology for processing molds and wear-resistant layers, which is applied in the direction of pipeline damage/abrasion prevention, pipeline protection, and branch pipelines. The processing workload, the processing process is simple, and the effect of reducing welding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0036] This embodiment provides a processing device for an iron tee liner wear-resistant layer, including an injection molding machine and the iron tee liner wear-resistant layer processing mold described in Embodiment 1, and the injection molding machine provided by the second part The mouth is matched with the injection molding machine, and the injection molding machine can be an existing injection molding machine, and its specific structure will not be described in detail.

Embodiment 3

[0038]This embodiment discloses a method for the processing device of the iron tee lining wear-resistant layer described in embodiment 2:

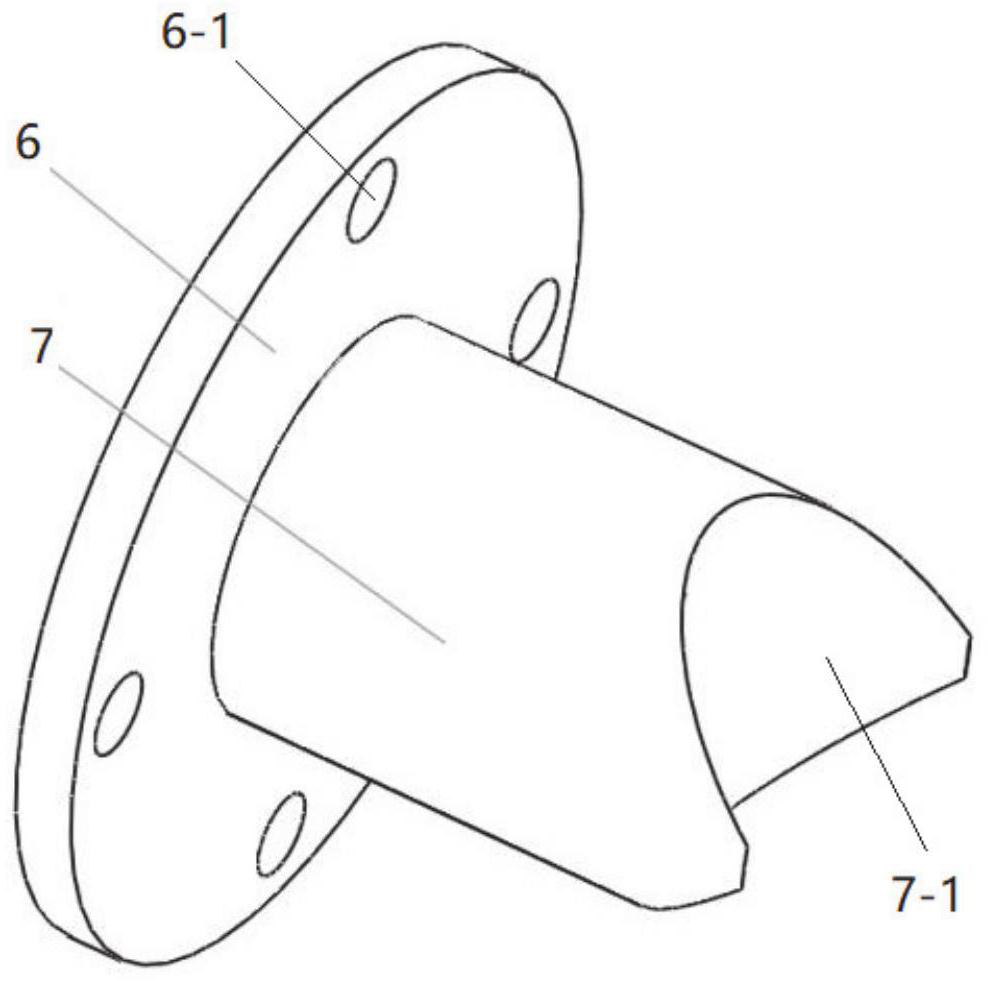

[0039] like Figure 4-5 As shown, the first blind flange of the first part and the connecting flange of the second part are fixed to the first flange 9 and the second flange 10 at both ends of the main pipe 8 of the iron tee through fixing bolts connection, the first mandrel end surface and the inner surface of the injection cap have a gap of 2mm, and the second blind flange of the third part is fixedly connected with the third flange 12 of the branch pipe 11 of the iron tee through fixing bolts, The end of the second mandrel closely fits the outer shaft surface of the first mandrel through the semicircular arc surface to complete the installation of the mold. The first mandrel, the second mandrel, the first blind flange, the second The blind flange, the connecting flange and the injection cap together with the inner surface of the iron t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com