Portable Thermocouple Spot Welder for Multi-Materials

A thermocouple, portable technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as inability to weld, weak welding, bad welding environment, etc., achieve simple panel, simple structure, improve welding bad environment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

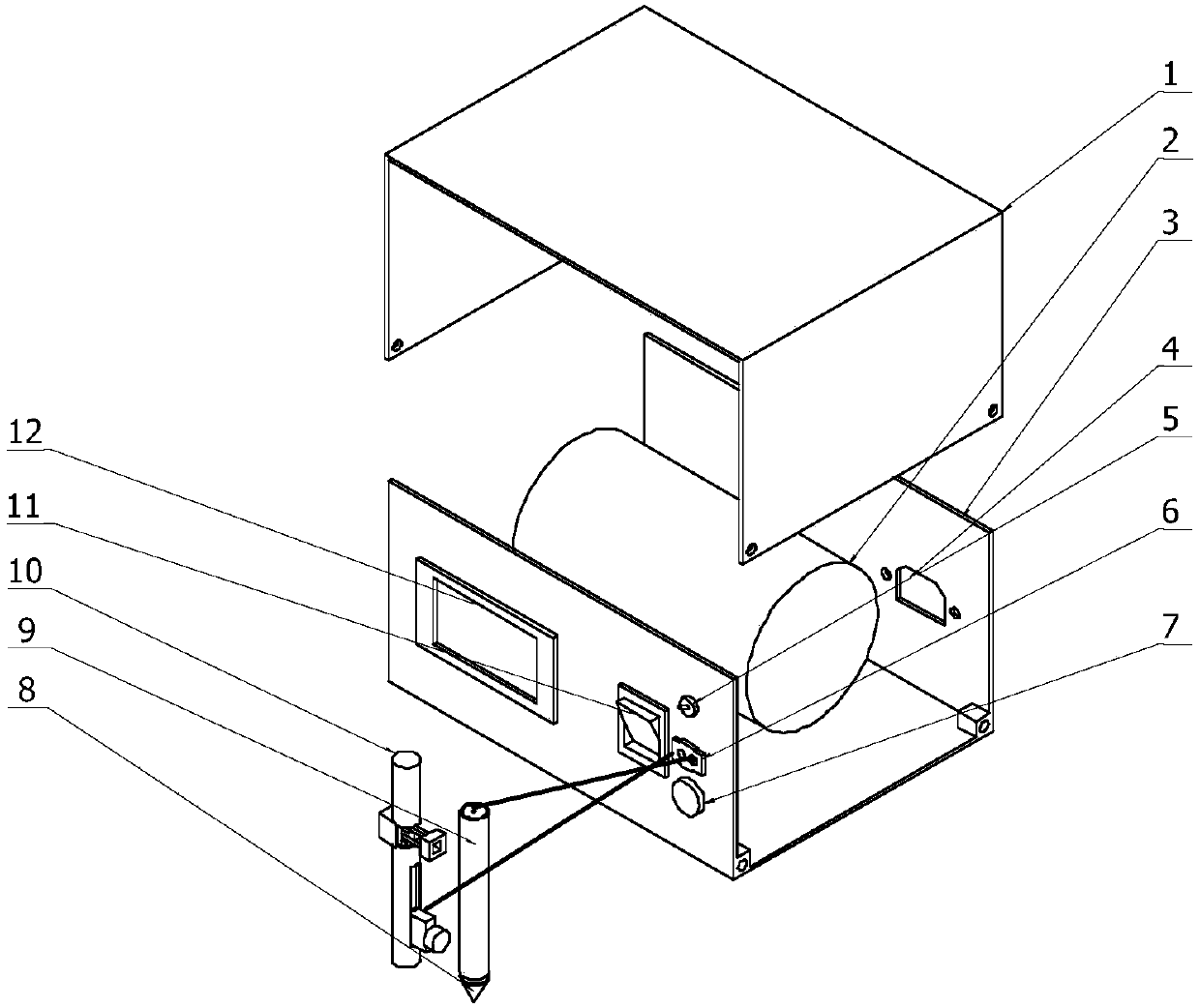

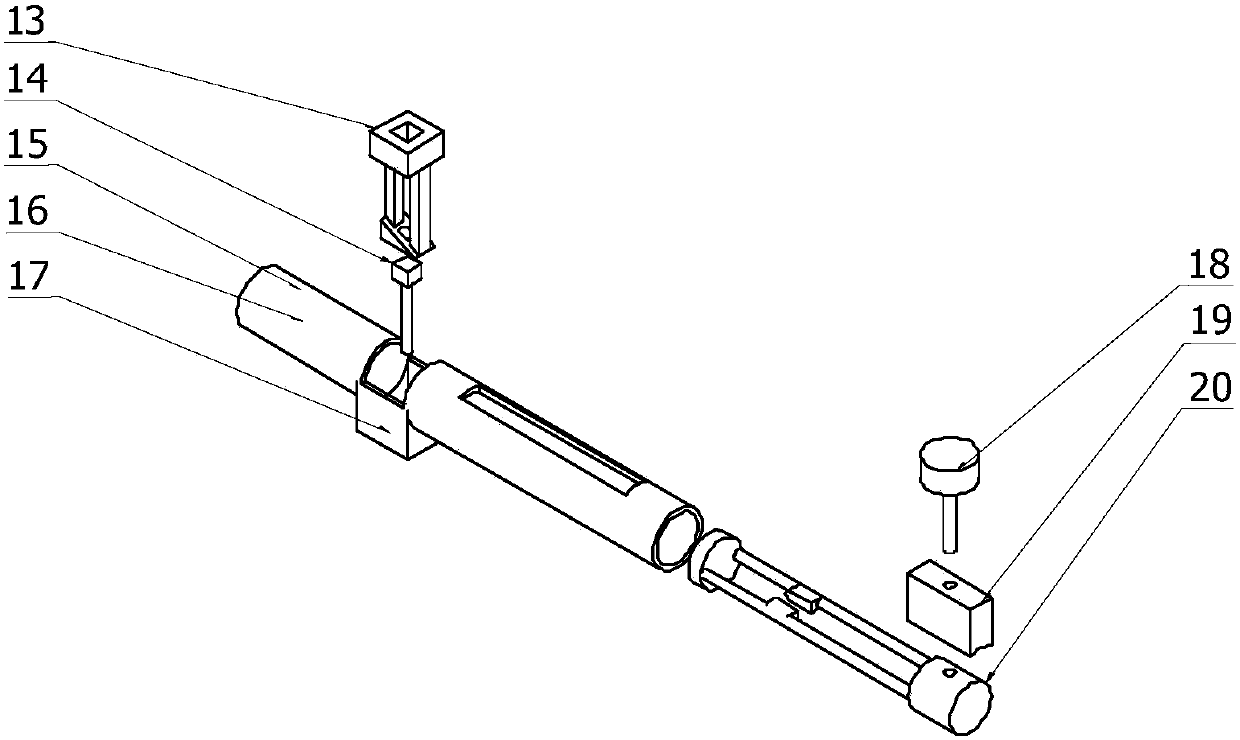

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

[0021] see figure 1 , the present invention includes a box, a welding electrode 10 clamping a thermal couple and a welding electrode contacting the surface of a welding material.

[0022] 1. Cabinet

[0023] Such as figure 1 As shown, the box body includes an upper end plate 1, an electrolytic capacitor 2, and a lower end plate 3. The upper end plate 1 and the lower end plate 3 are fixed with screws through the through holes of the upper end plate and the threaded holes of the lower end plate. The lower end plate 3 serves as a user interaction panel and includes a power supply hole 4. , power switch hole 5, welding electrode hole 6, fuse hole 7, charging and discharging switch hole 11 and digital voltmeter hole 12. The panel shows the recommended charging voltage value for welding different material surfaces. There is a single large Capacity electrolytic capacitor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com