Large-span unequal-height steel structure net rack integral lifting temporary lifting point construction method

A technology of overall improvement and construction method, which is applied in the direction of building structure, construction, and building material processing, etc., which can solve the problems of large demand, large material consumption, and high construction cost, so as to achieve stress concentration and reduce material loss , Reduce the effect of installation hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

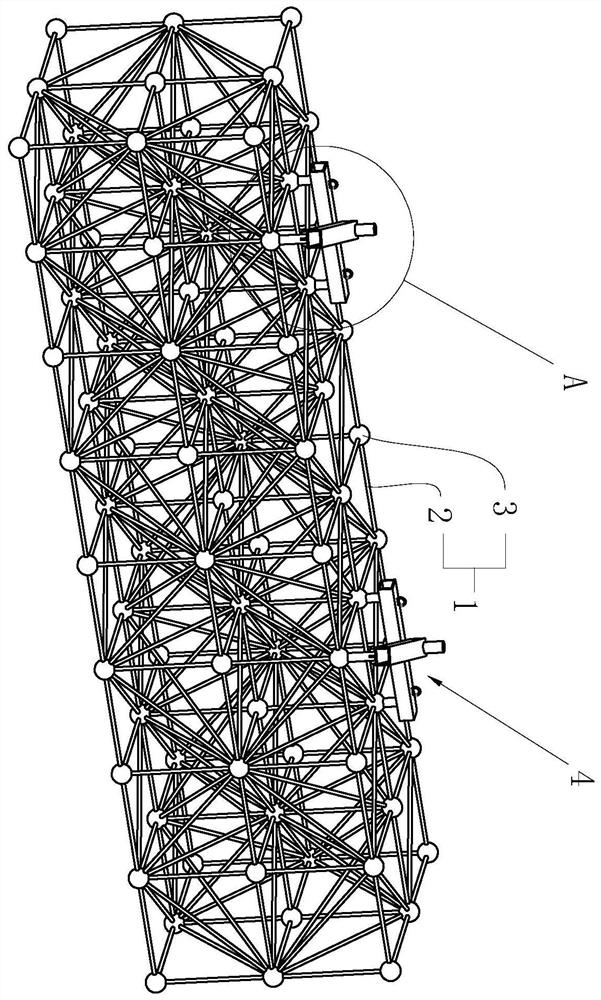

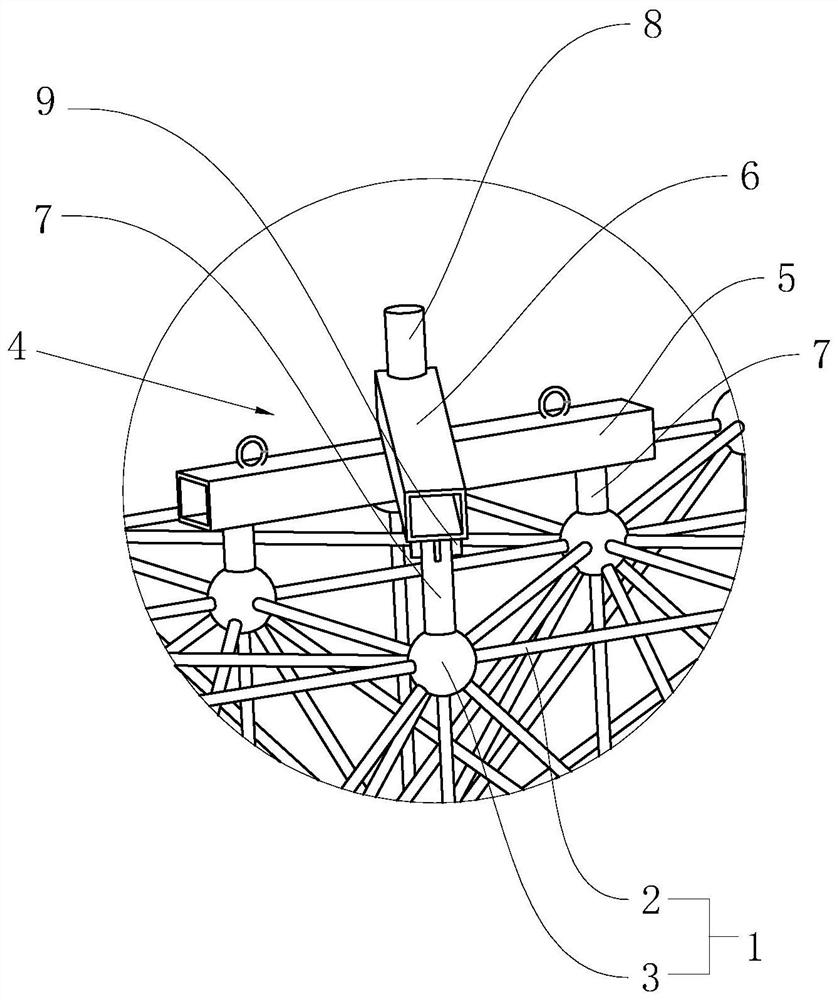

[0035] The following is attached Figure 1-2 The application is described in further detail.

[0036] This application is applied to a steel structure project consisting of the hangar hall and the hangar gate. The hangar hall has an upper chord elevation of 31m and a lower chord elevation of 26m. The hangar door is composed of two three-story bulb trusses, and the lower chord center elevation is 22m , the elevation of the middle chord is 26m, and the elevation of the top chord is 31m, both of which are located on the tire frame composed of a 50cm high steel pier and an adjusting ring. It needs to be lifted for the first time to hover at the same height as the top string of the hangar hall grid frame and the hangar gate grid frame, and then the overall synchronous lifting will be in place after the connection of the supplementary rod is completed. During the construction of this steel structure project, the first overall lifting cannot be done using the hydraulic lifter on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com