Intensive-cooling steel piston of gas engine

A gas engine and steel piston technology, applied in the direction of engine components, machines/engines, pistons, etc., can solve the problem of large thermal load of the cylinder, achieve the effect of increasing the load limit, improving fatigue life, reducing thermal stress and thermal strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

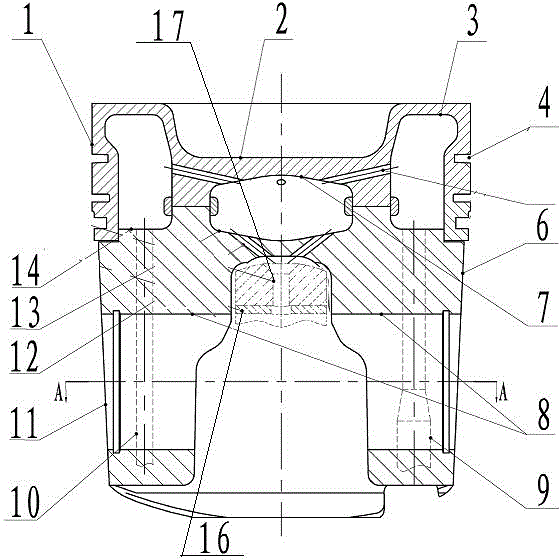

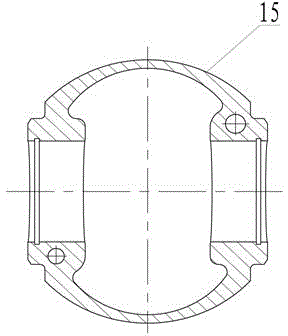

[0013] Such as figure 1 , figure 2 As shown, a gas engine strong cooling steel piston includes a piston head 1 and a piston skirt 6, both of which are friction welded into one, and the material is made of heat-resistant, high-strength 42CrMo forged steel. The piston head 1 includes a combustion chamber 2, a piston ring groove 4, an outer cooling groove I3, an inner cooling groove I7 and an oil guide hole 5; the combustion chamber 2 is shallow basin-shaped and arranged on the piston head 1 The middle part of the end face; the piston ring groove 4 has three lines, which are arranged on the outer surface of the piston head 1; the outer cooling groove I3 surrounds the combustion chamber 2, the piston ring groove 4 and the inner cooling groove of the piston head Groove I7 is set; the inner cooling groove I7 is located in the middle of the lower end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com