Patents

Literature

57results about How to "Reduce thermal strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

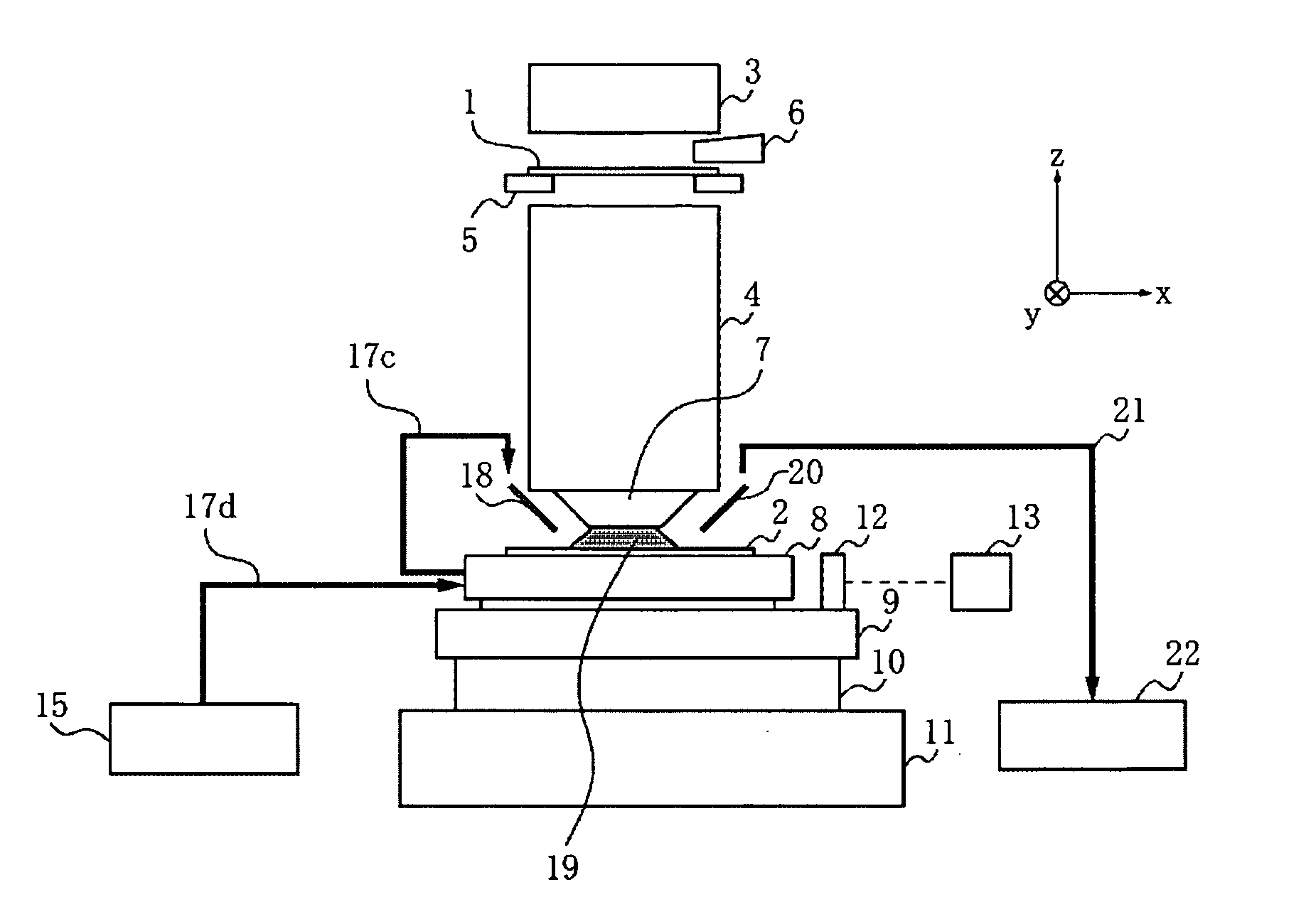

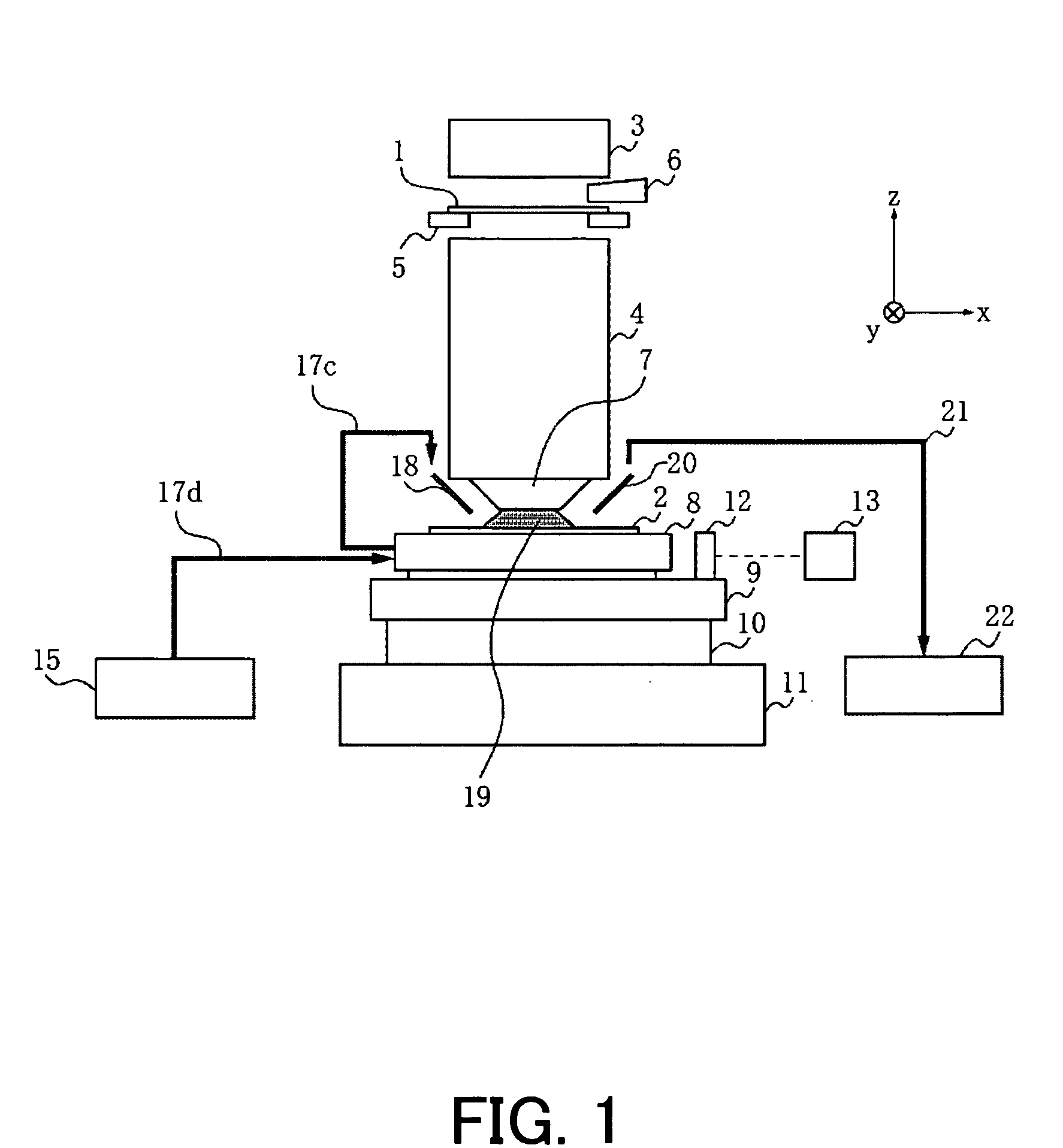

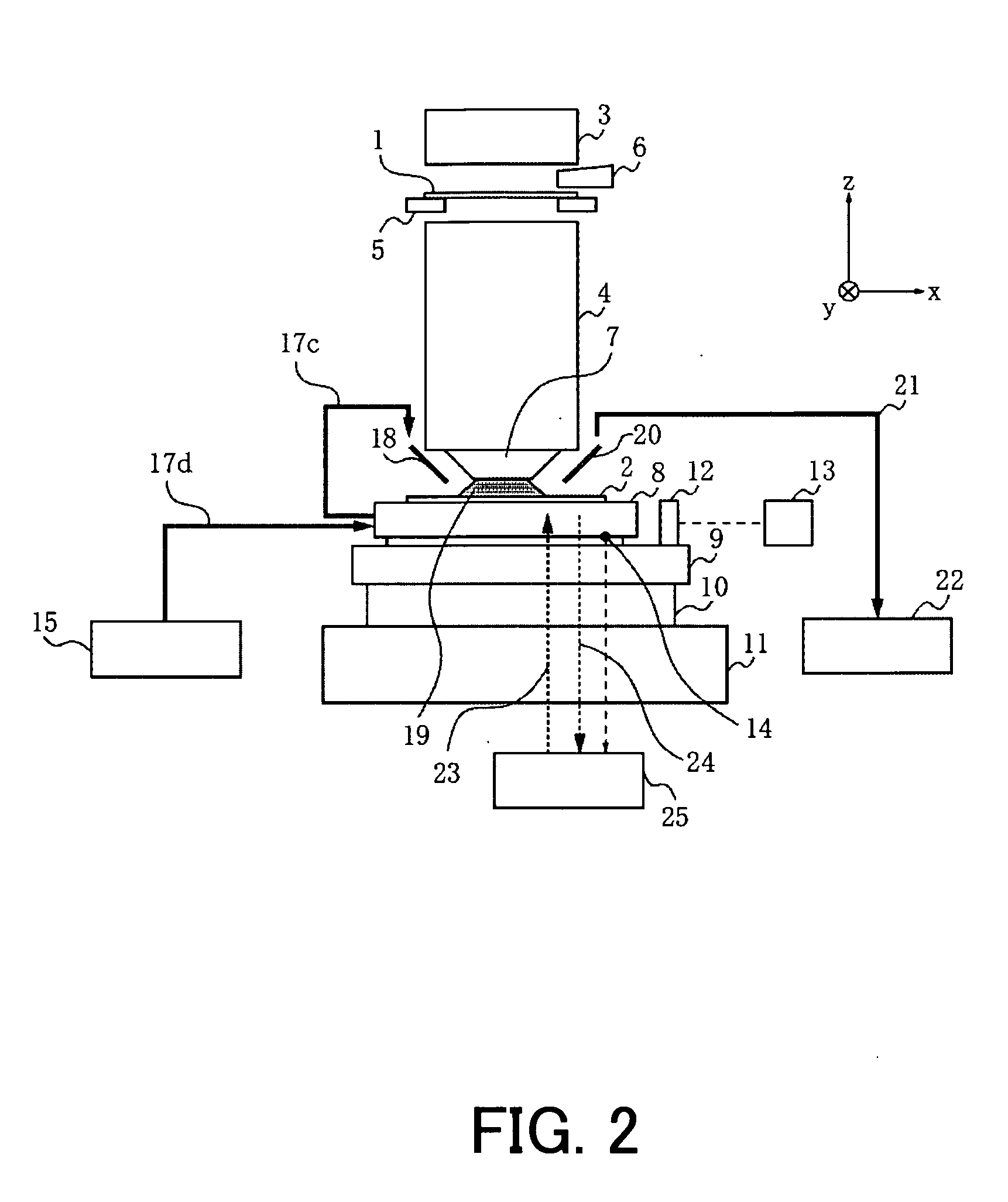

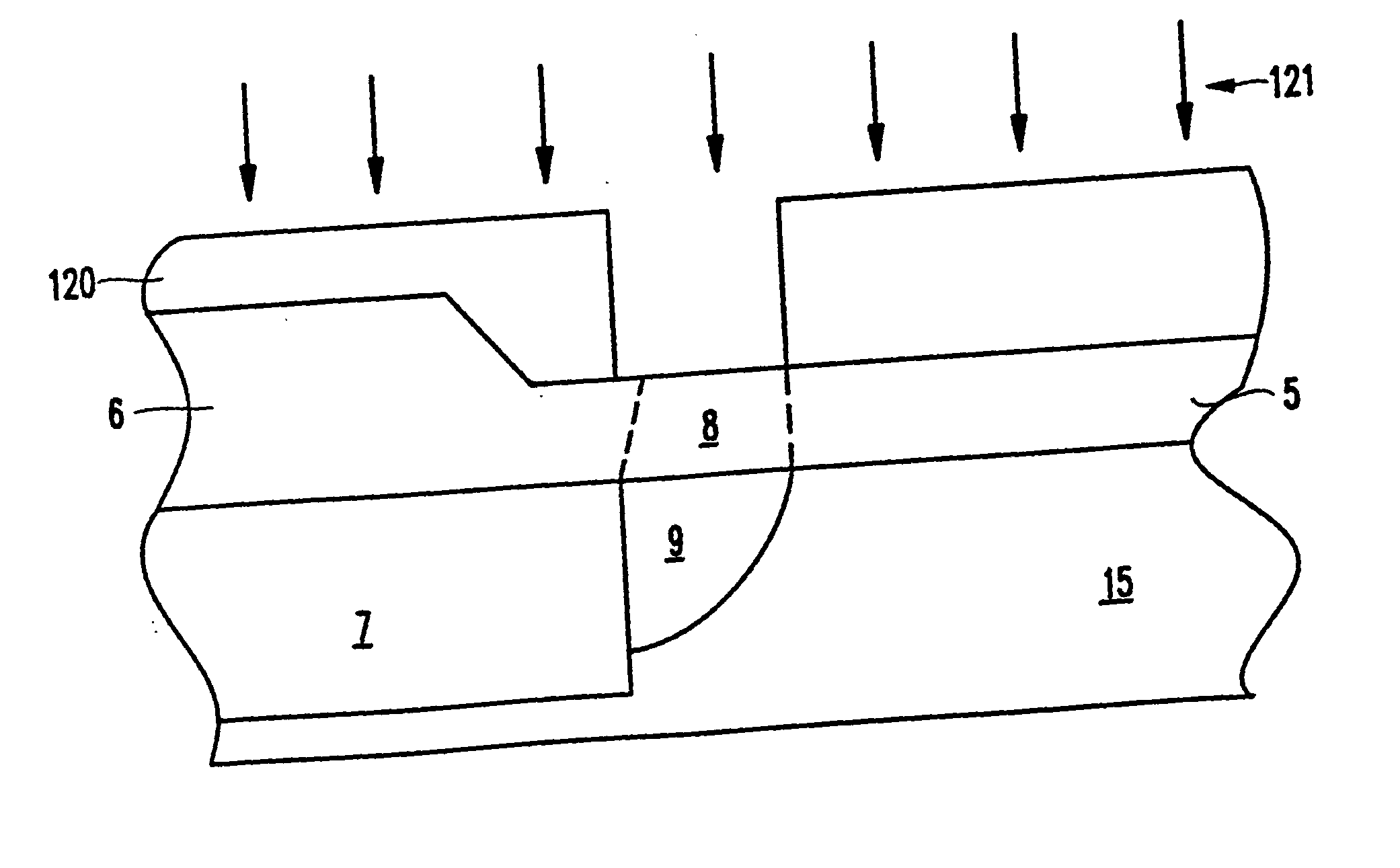

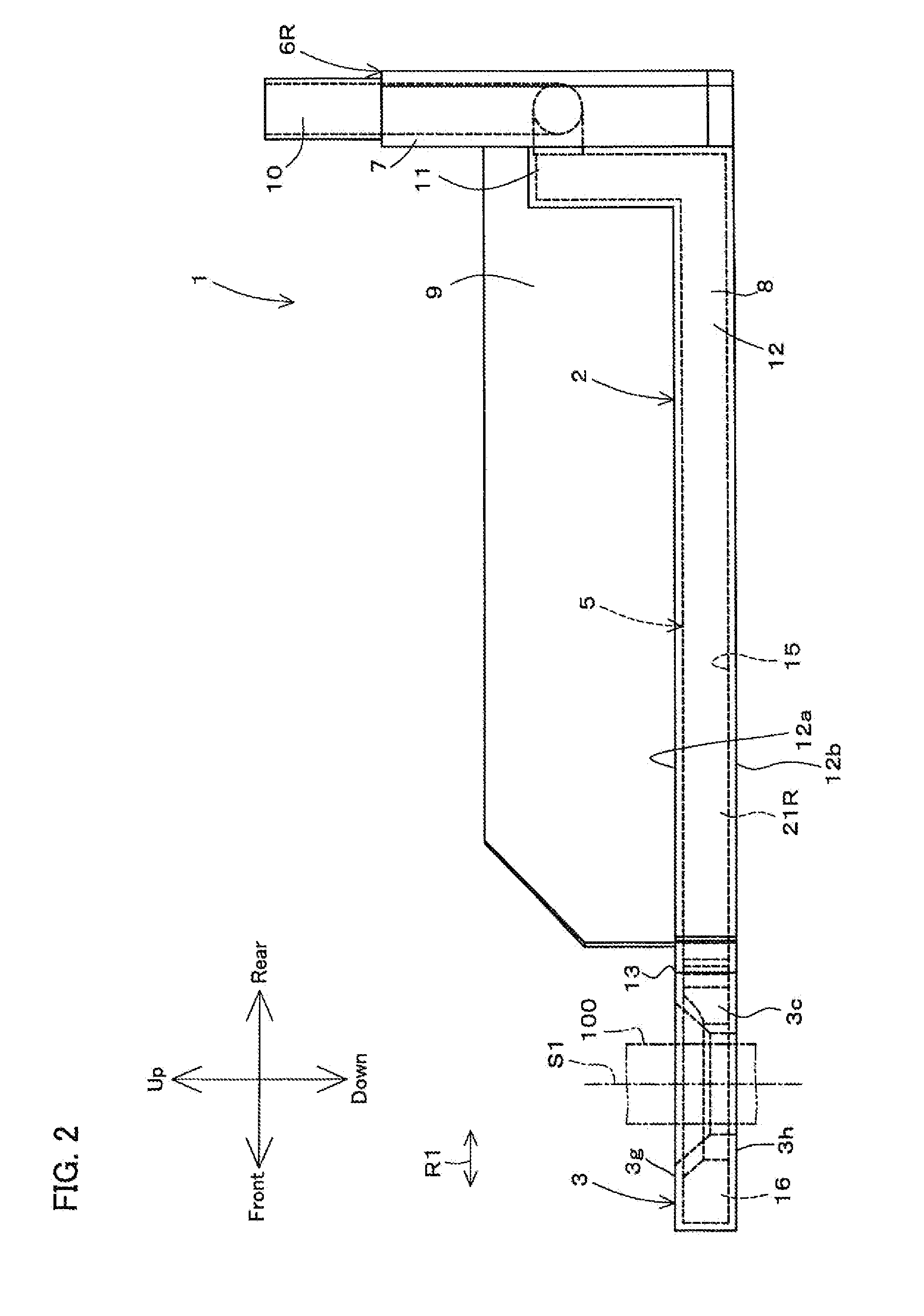

Exposure apparatus and device manufacturing method

InactiveUS20050146695A1Reduce thermal strainSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusBiomedical engineeringFluid supply

An exposure apparatus includes a projection optical system for projecting a pattern of a mask onto a substrate, a holder for holding the substrate and having a first channel for the fluid to flow, and a fluid supply unit for supplying the fluid from the first channel of the holder to at least part of a space between the projection optical system and the substrate, the exposure apparatus exposing the substrate via the projection optical system and the fluid.

Owner:CANON KK

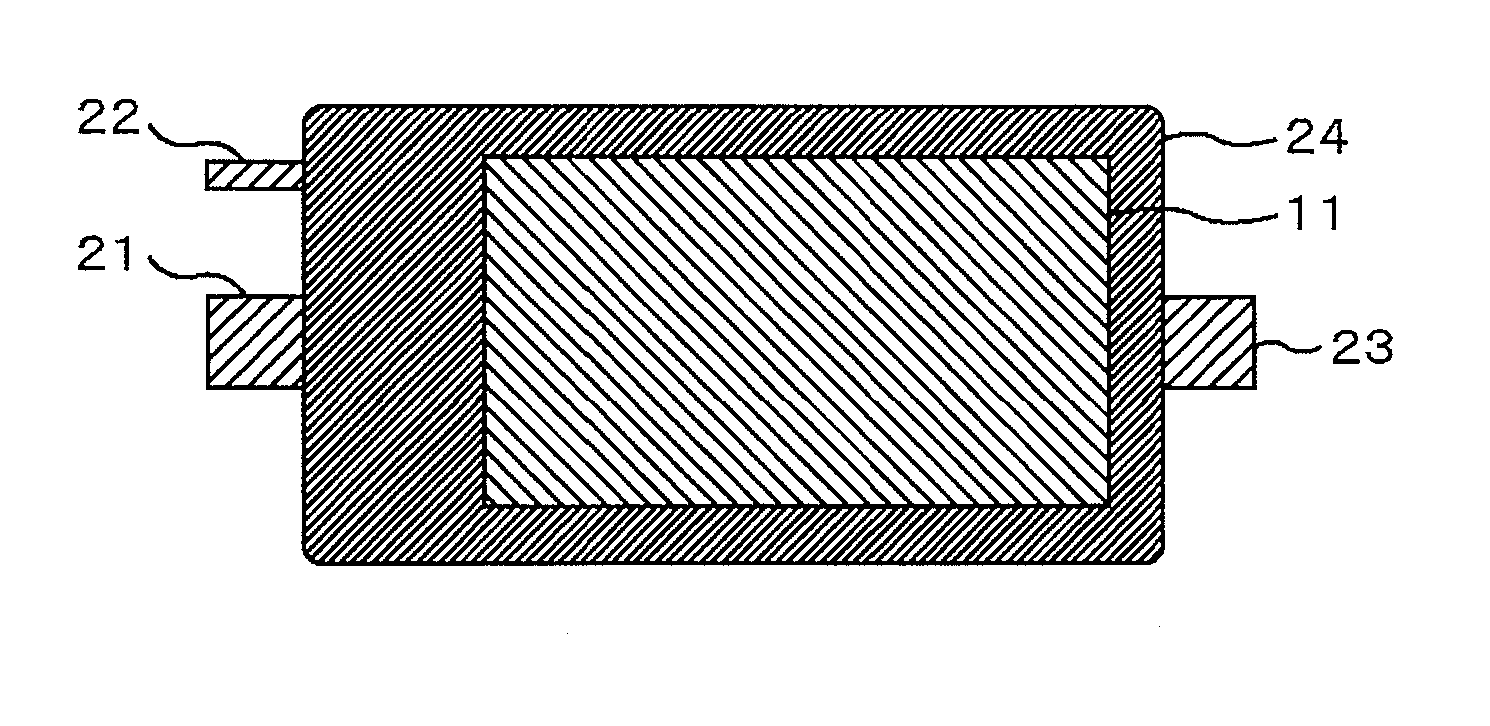

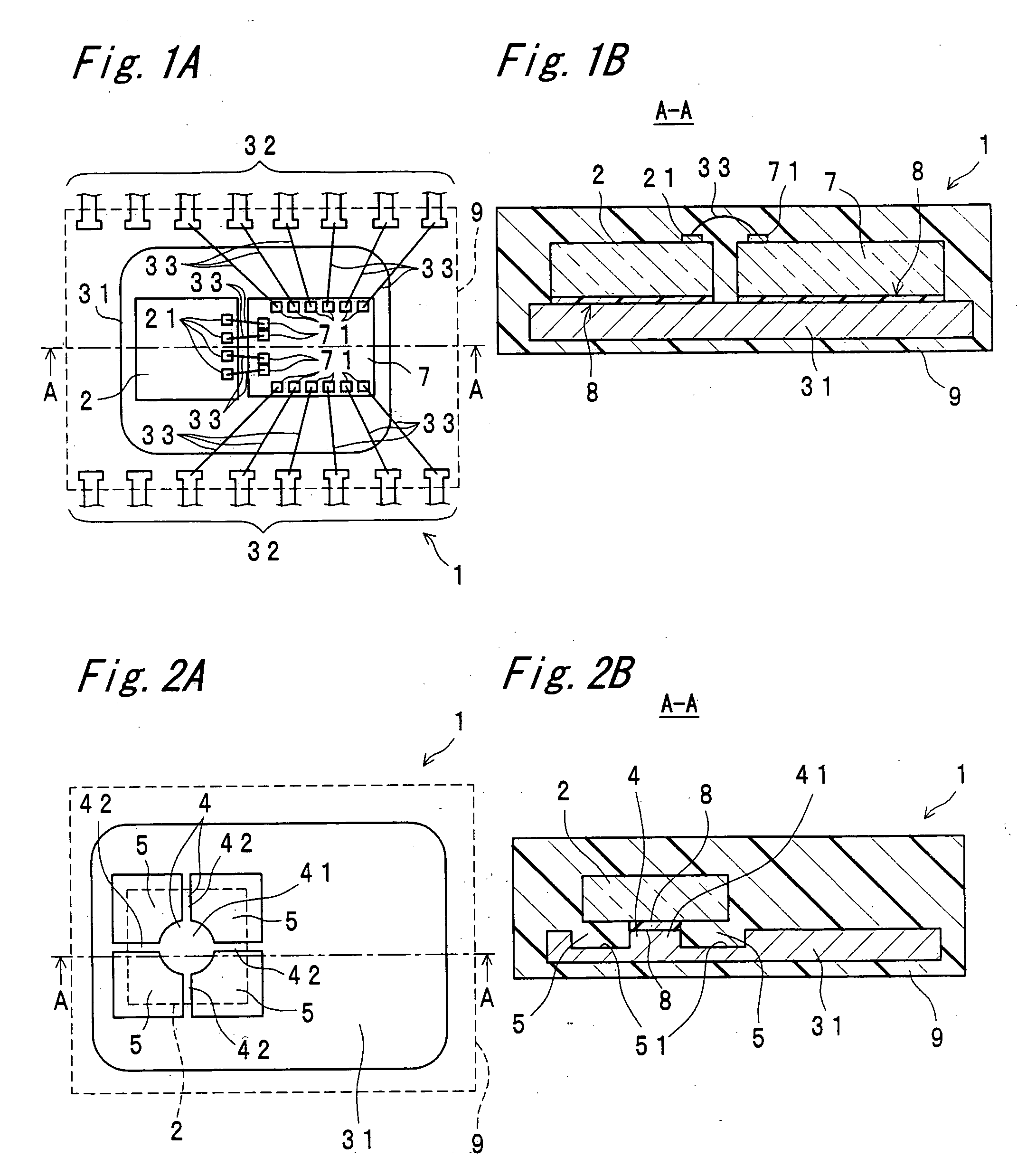

Semiconductor device provided with rewiring layer

InactiveUS6927489B1Relieve pressureIncrease bonding areaSemiconductor/solid-state device detailsSolid-state devicesDevice materialPrinted circuit board

In a small semiconductor device having external terminals on a semiconductor element and a semiconductor module mounted with the small semiconductor device, disconnection of the external terminals is prevented when a temperature change occurs under the conditions that the semiconductor device is mounted on a printed circuit board. To achieve this a projection is formed on a land which is an external terminal bonding area of the semiconductor device, and a protruded portion of the projection is bonded to the external terminal. An intervening portion of a protective film made of resin material is formed between the lands and semiconductor element.

Owner:INVENSAS CORP

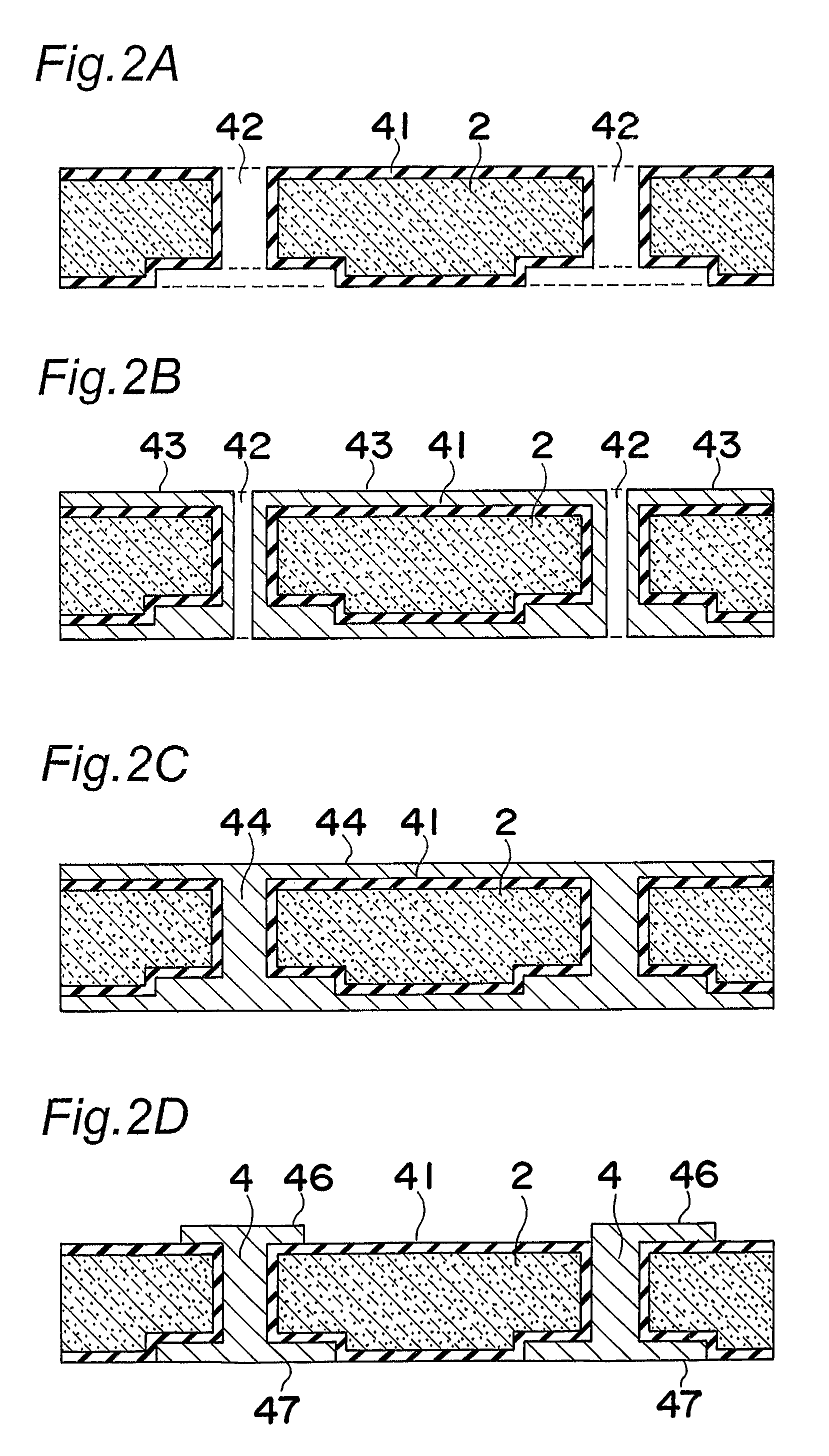

Power Semiconductor Module

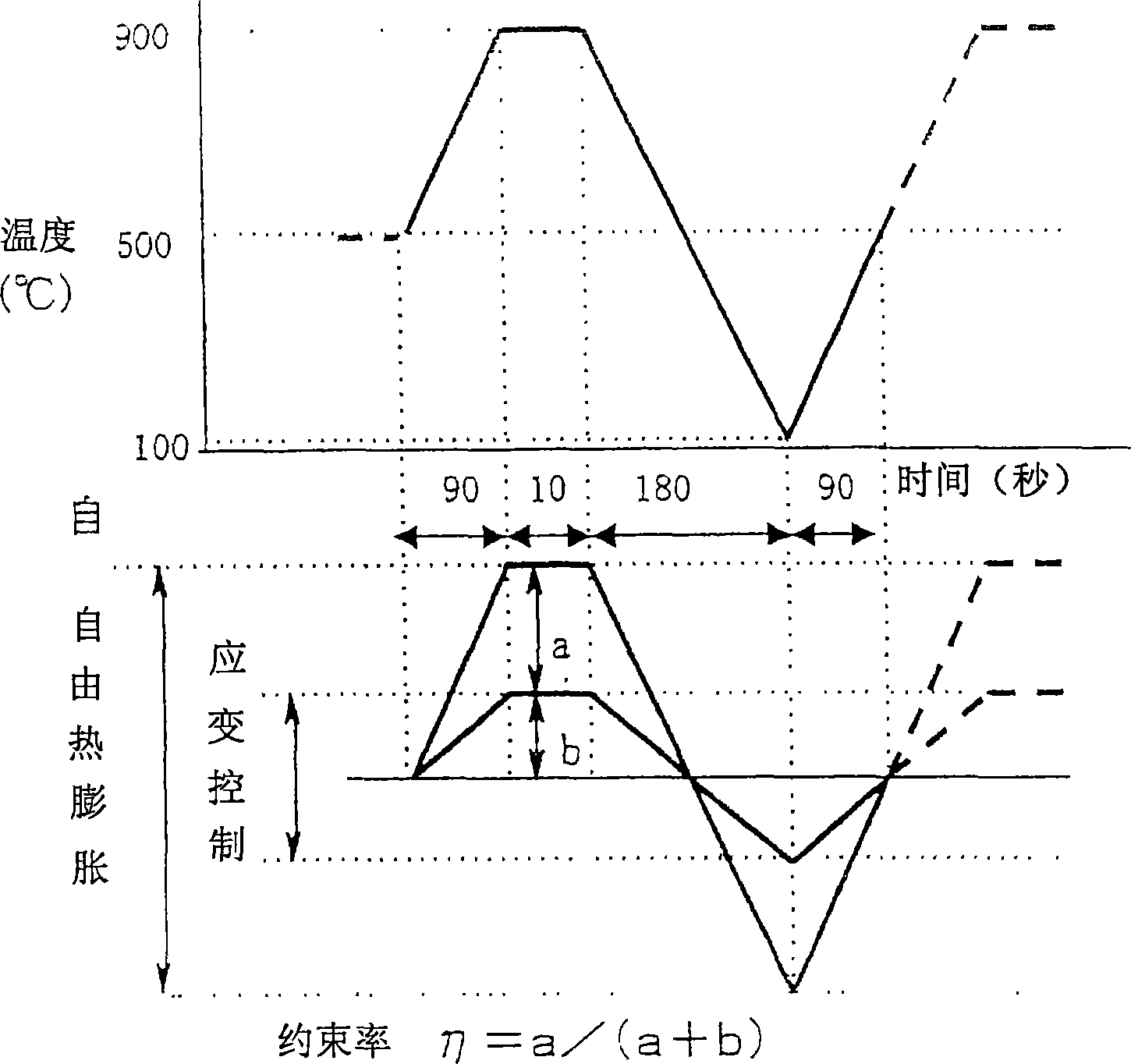

InactiveUS20070267739A1Possibility of damageAvoid fracturesSemiconductor/solid-state device detailsLaminating printed circuit boardsThermal expansionInorganic materials

A power semiconductor module and an inverter apparatus in which a device or a joining part is not mechanically damaged even when the temperature in use becomes a high temperature in the range of 175 to 250° C., resulting in excellent reliability at high temperature retaining test and thermal cycling test. Low thermal expansion ceramic substrates are disposed above and below the device. A material having a coefficient of thermal expansion of 10 ppm / K or less is disposed between the ceramic substrates. In addition, an inorganic material having a coefficient of thermal expansion in the range of 2 to 6 ppm / K or less is disposed around the device.

Owner:HITACHI LTD

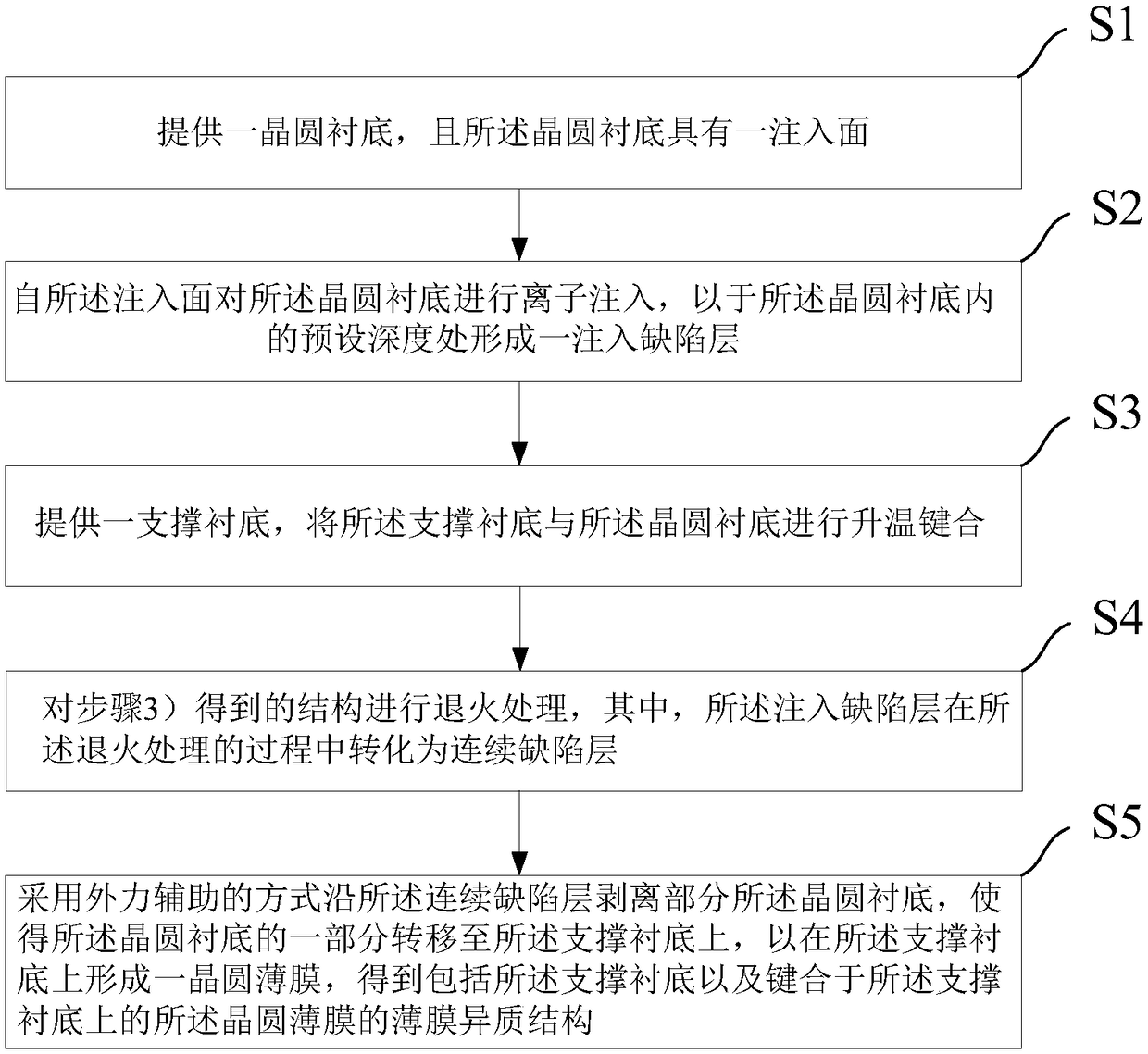

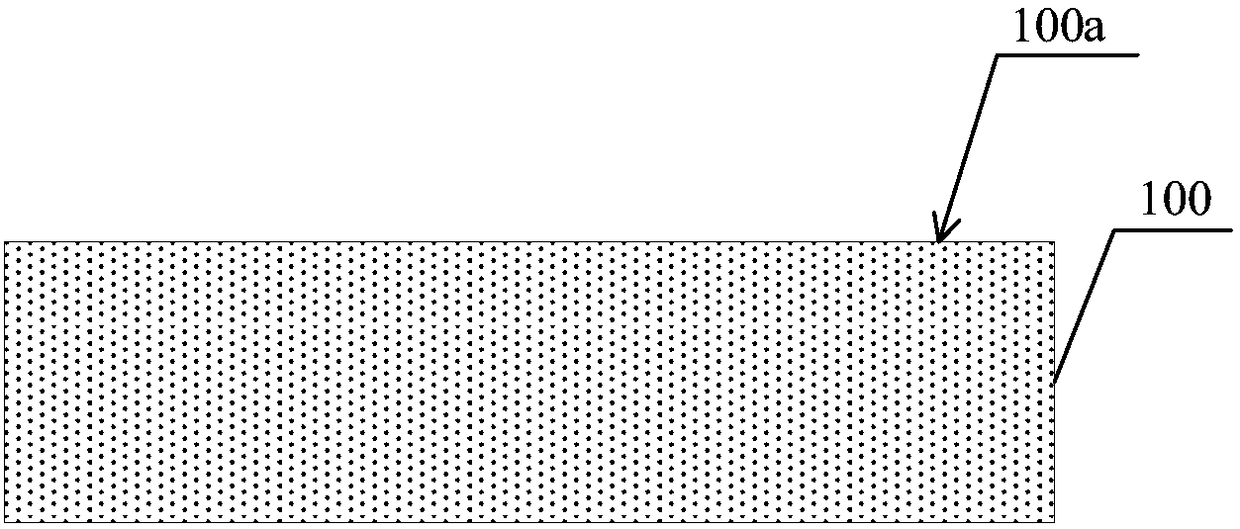

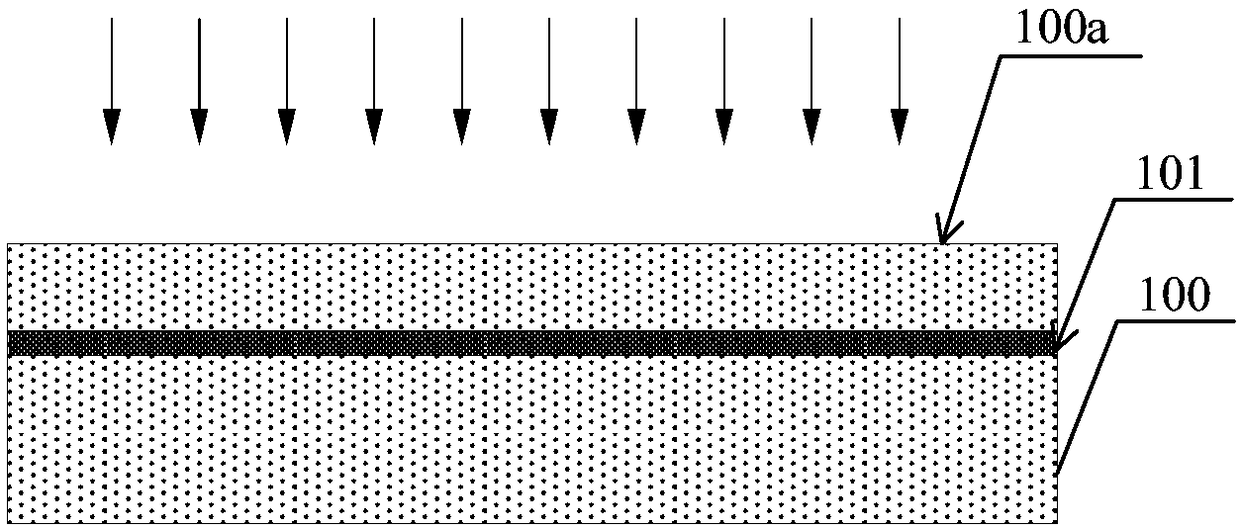

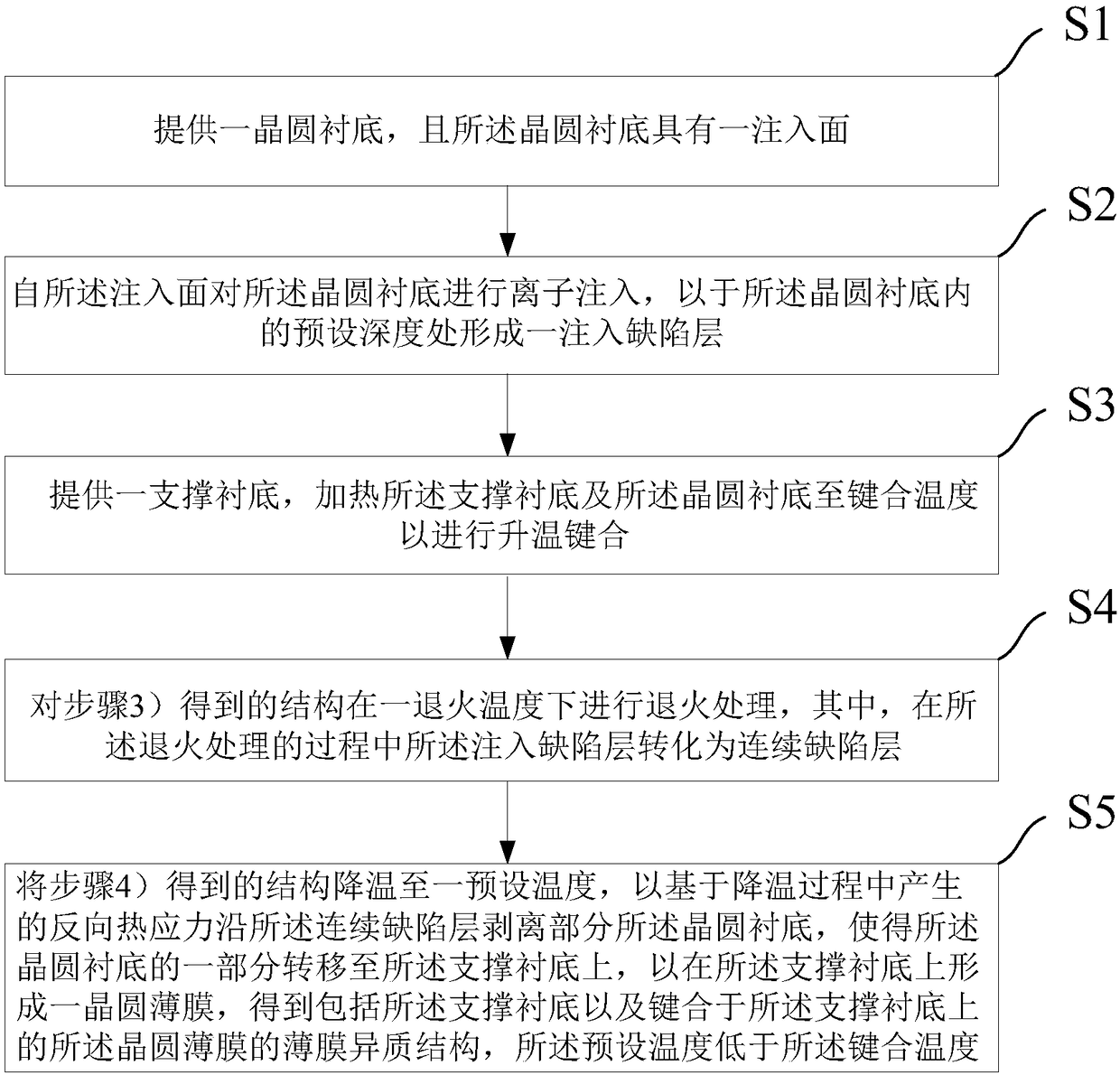

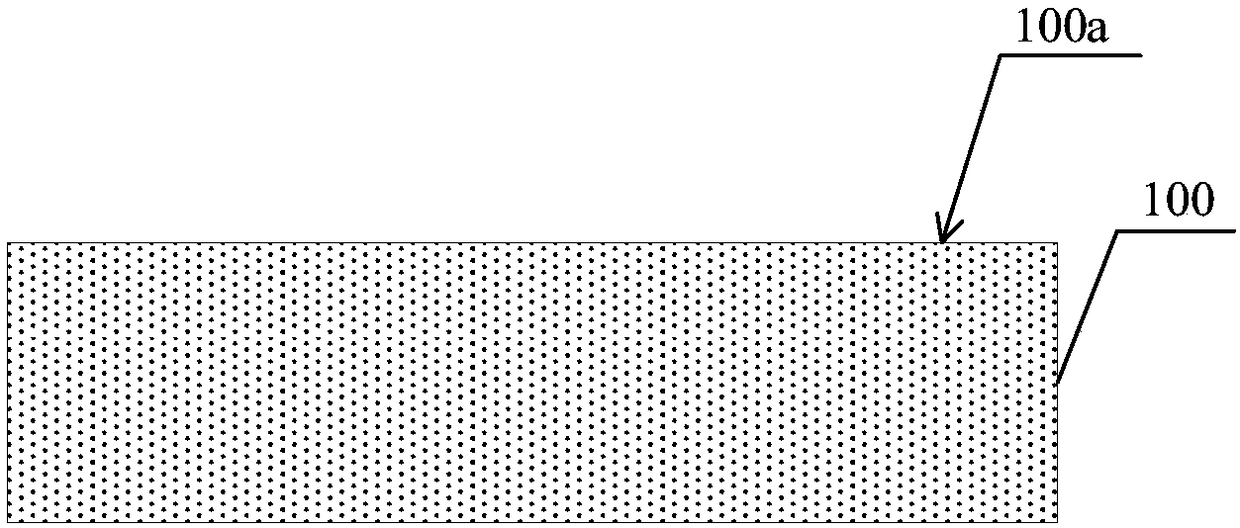

Method for preparing thin film heterostructure

InactiveCN108336219AReduce thermal strainAvoid chippingPiezoelectric/electrostrictive/magnetostrictive devicesOptoelectronicsIon implantation

The invention provides a method for preparing a thin film heterostructure. The method comprises the steps of providing a wafer substrate with an injection surface; conducting ion injection from the injection surface on the wafer substrate to form an injection defect layer at the predetermined depth of the wafer substrate; providing a support substrate, and performing temperature rising bonding onthe support substrate and the wafer substrate; annealing a obtained structure to form a continuous defect layer; stripping part of the wafer substrate through external force assisting, and forming wafer film on the wafer substrate to obtain a thin film heterostructure including the support substrate and the wafer film. The method can reduce the thermal strain of a bonding structure through the temperature rising bonding, so that the bonding structure remains stable and complete in the high-temperature process, and avoid the problem of film cracking caused by thermal mismatch in the stripping process, the bonding structure is separated from the continuous defect layer through the external force assisting method, so that no effect is caused on a bonding interface, and an external force assisting stripping method can reduce stripping temperature and stripping time, thereby reducing the cumulative effect of thermal stress in a piezoelectric crystal.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Thin film heterostructure preparation method

ActiveCN108493334ALow annealing temperatureShorten process timePiezoelectric/electrostrictive/magnetostrictive devicesOptoelectronicsHigh-temperature corrosion

The invention provides a thin film heterostructure preparation method. The method comprises steps: a wafer substrate with an injection surface is provided; ion implantation is carried out on the wafersubstrate from the injection surface, and an injection defect layer is formed at a preset depth in the wafer substrate; a support substrate is provided, and the support substrate and the wafer substrate are subjected to temperature rise bonding; the obtained structure is subjected to annealing treatment to form a continuous defect layer; the temperature of the obtained structure is reduced to a preset temperature, reverse thermal stress generated based on temperature reduction strips part of the wafer substrate along the continuous defect layer, and a thin film heterostructure comprising thesupport substrate and the wafer thin film is obtained, wherein the preset temperature is lower than the bonding temperature. In the temperature rise bonding mode, the thermal stress of the bonding structure can be reduced, the bonding structure can keep stable and complete in a high temperature process, the problem of wafer crack generated by thermal mismatch in the stripping process can be effectively solved, and through the reverse thermal stress assisting method, the bonding structure is separated at the continuous defect layer and a bonding interface is not influenced.

Owner:上海新硅聚合半导体有限公司

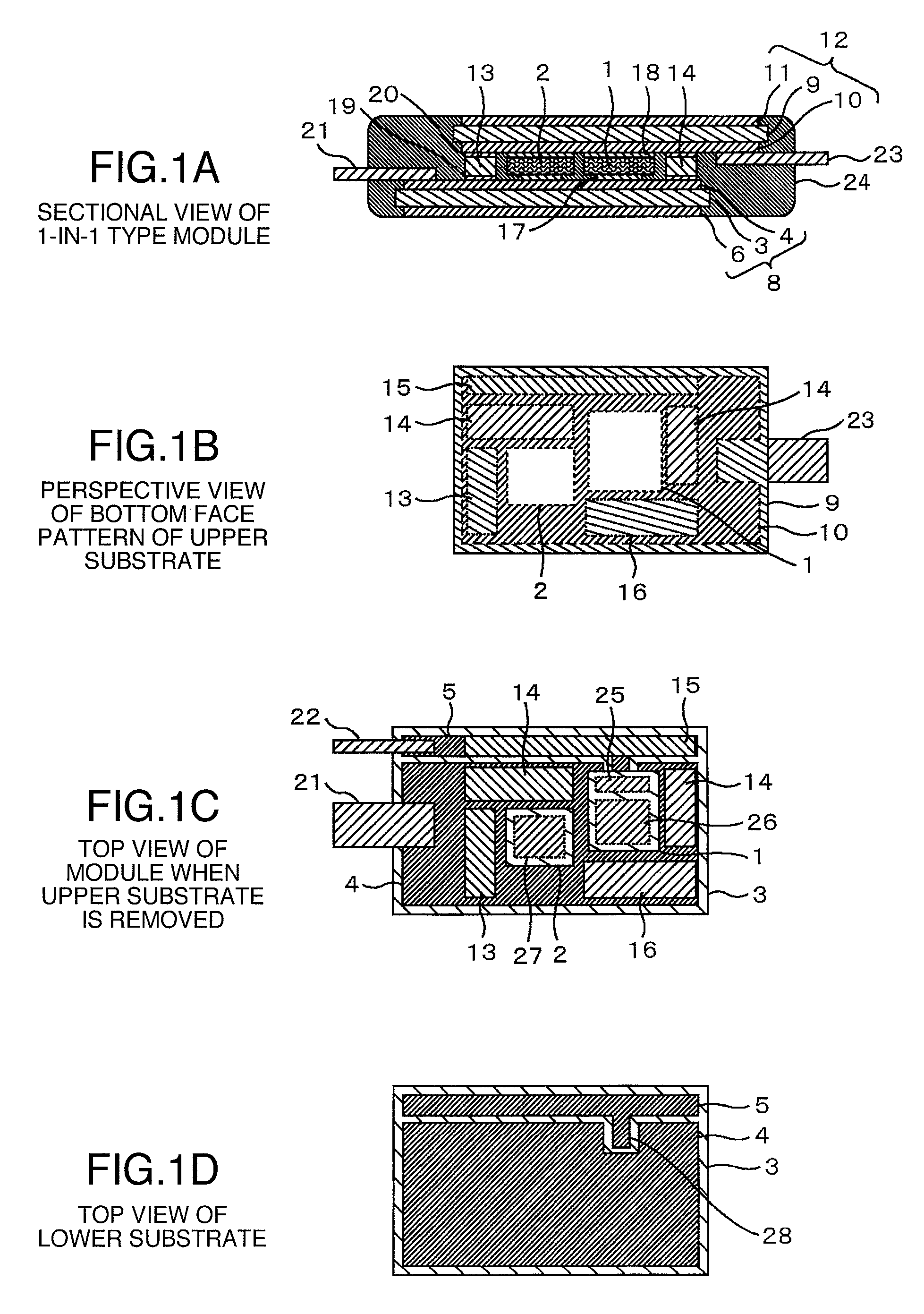

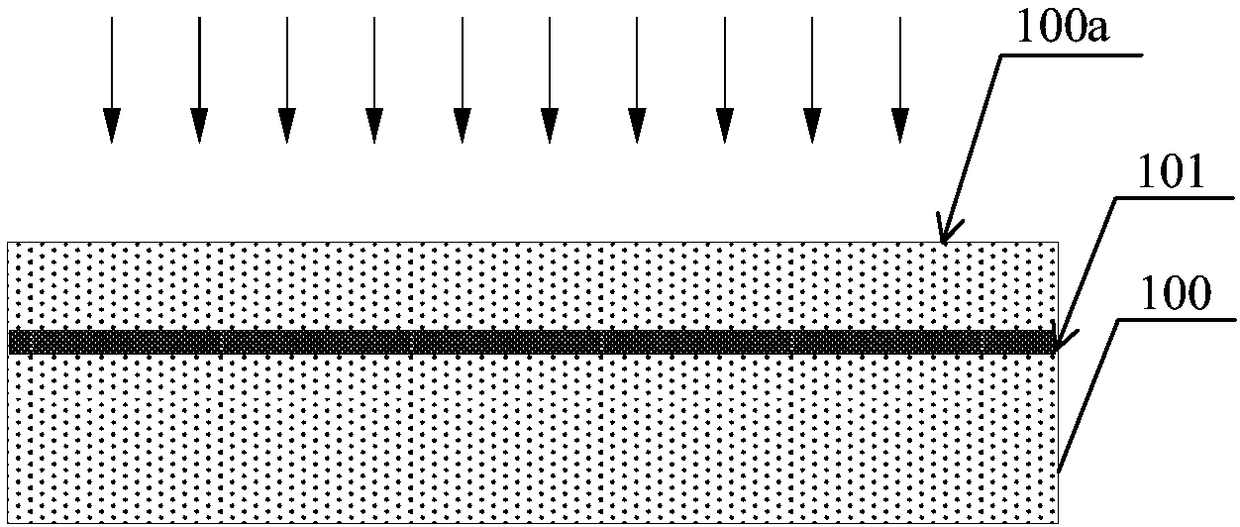

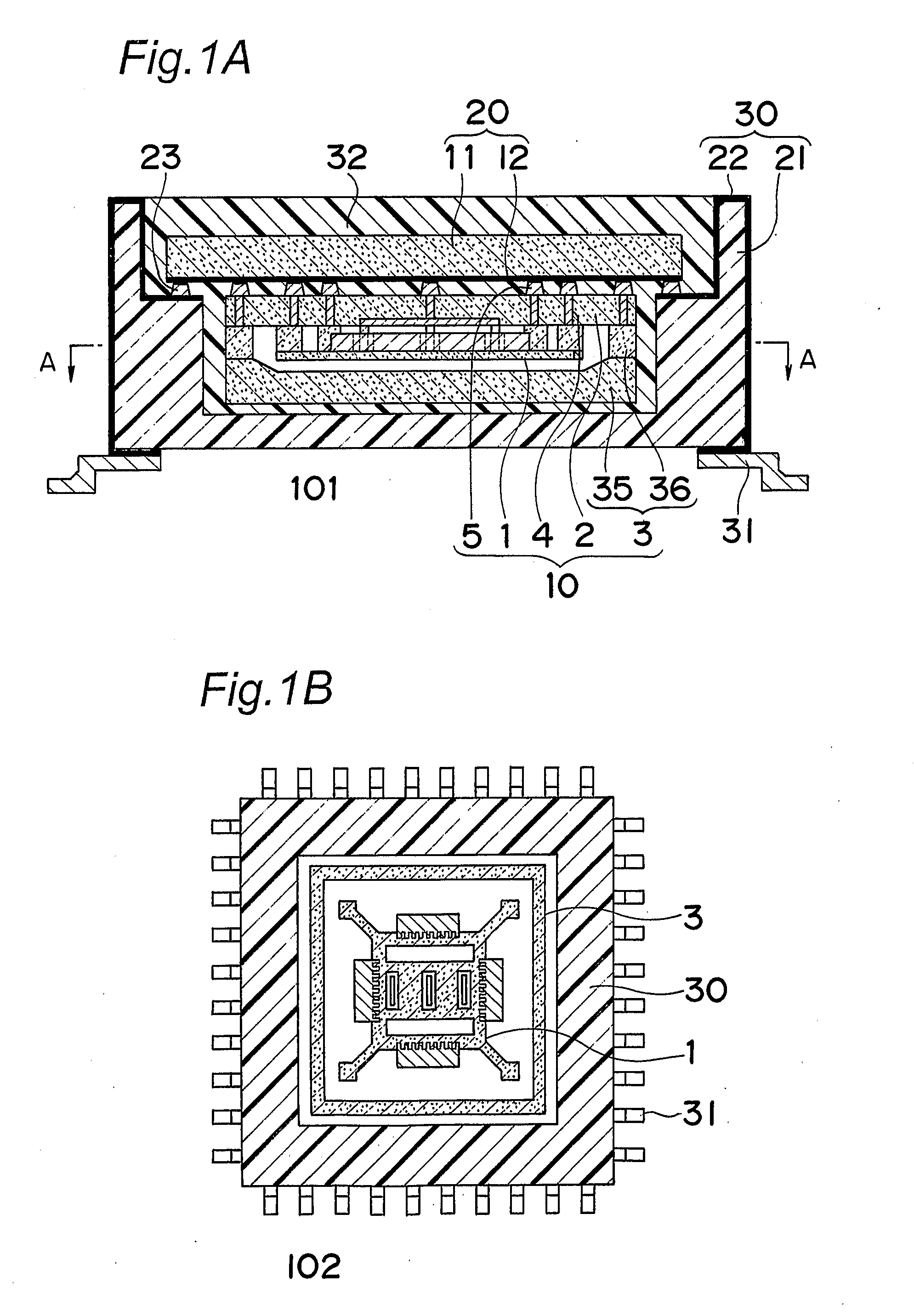

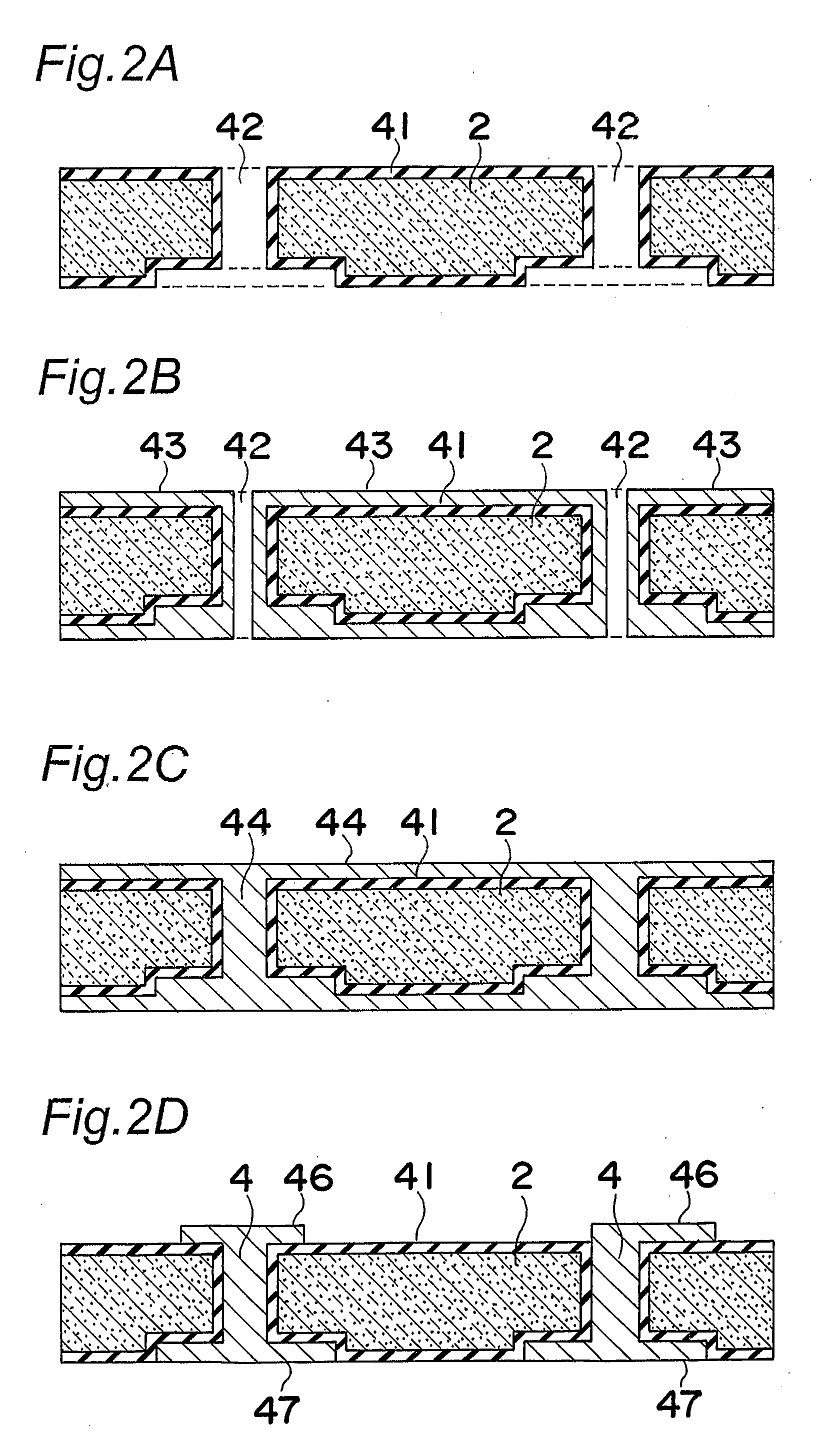

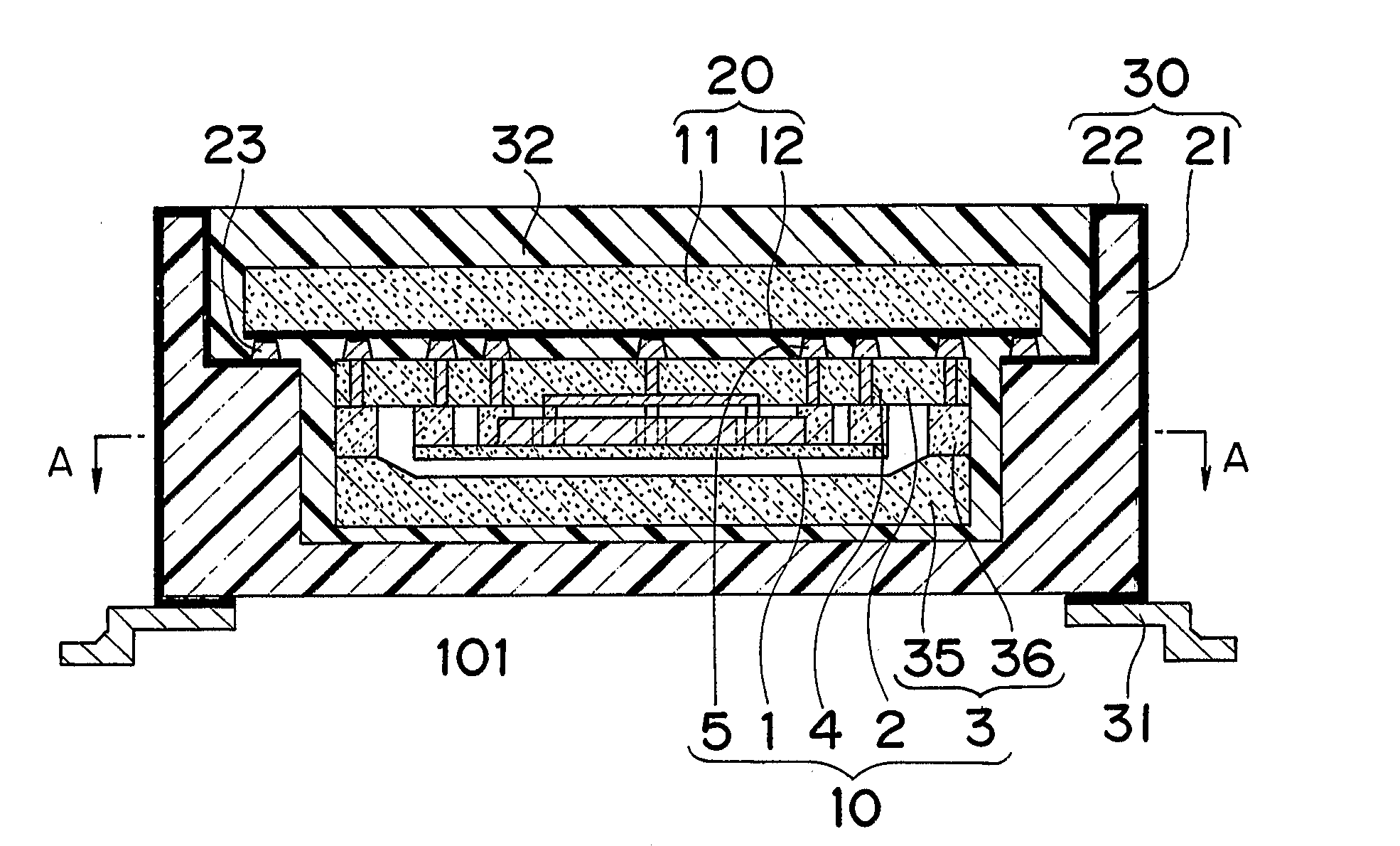

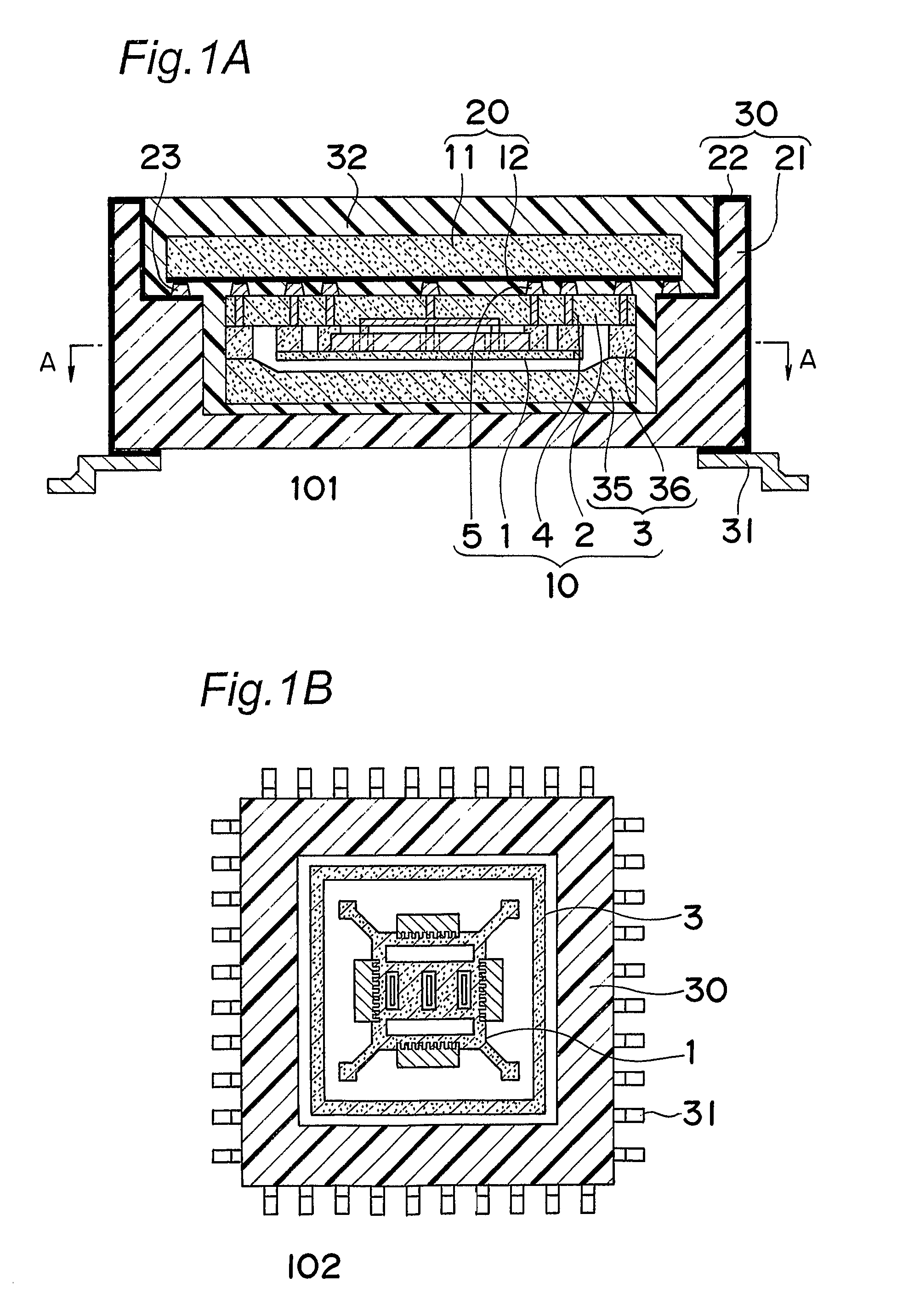

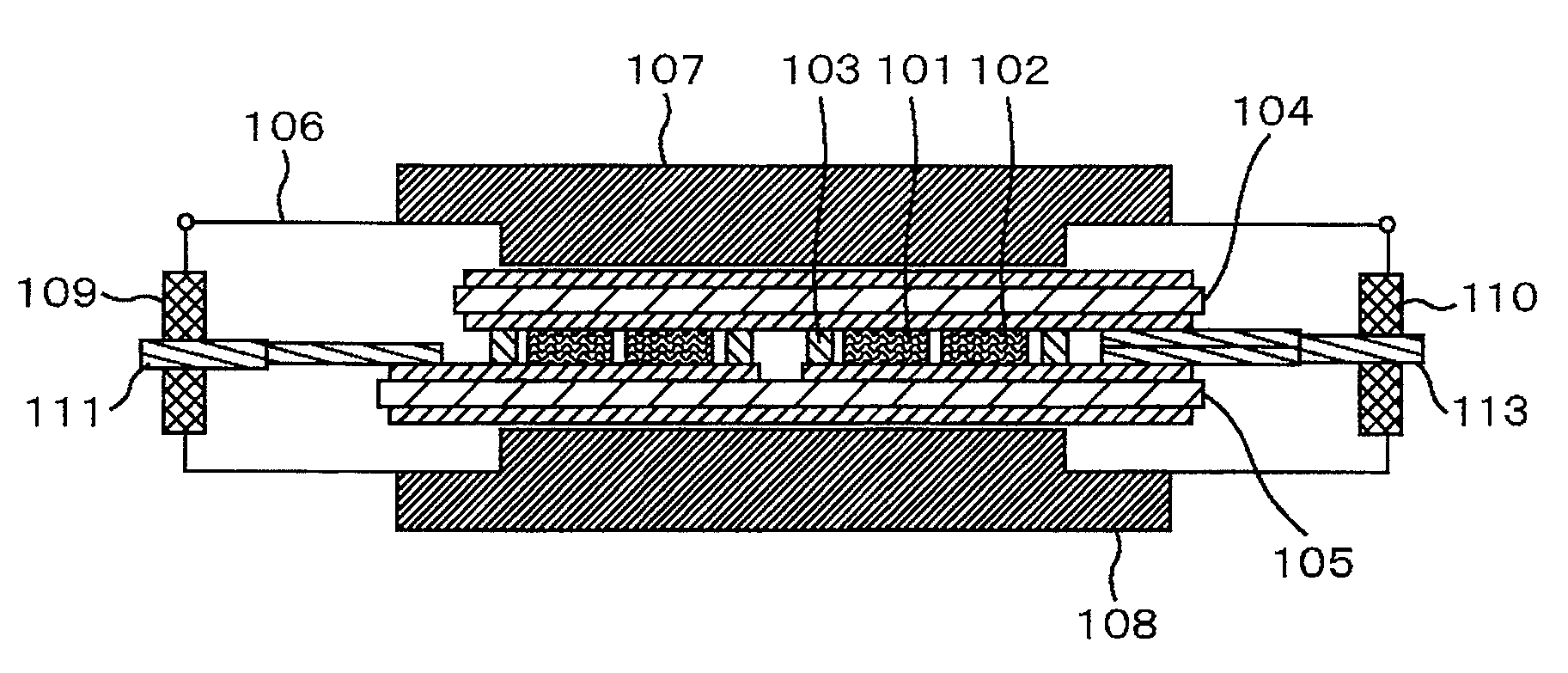

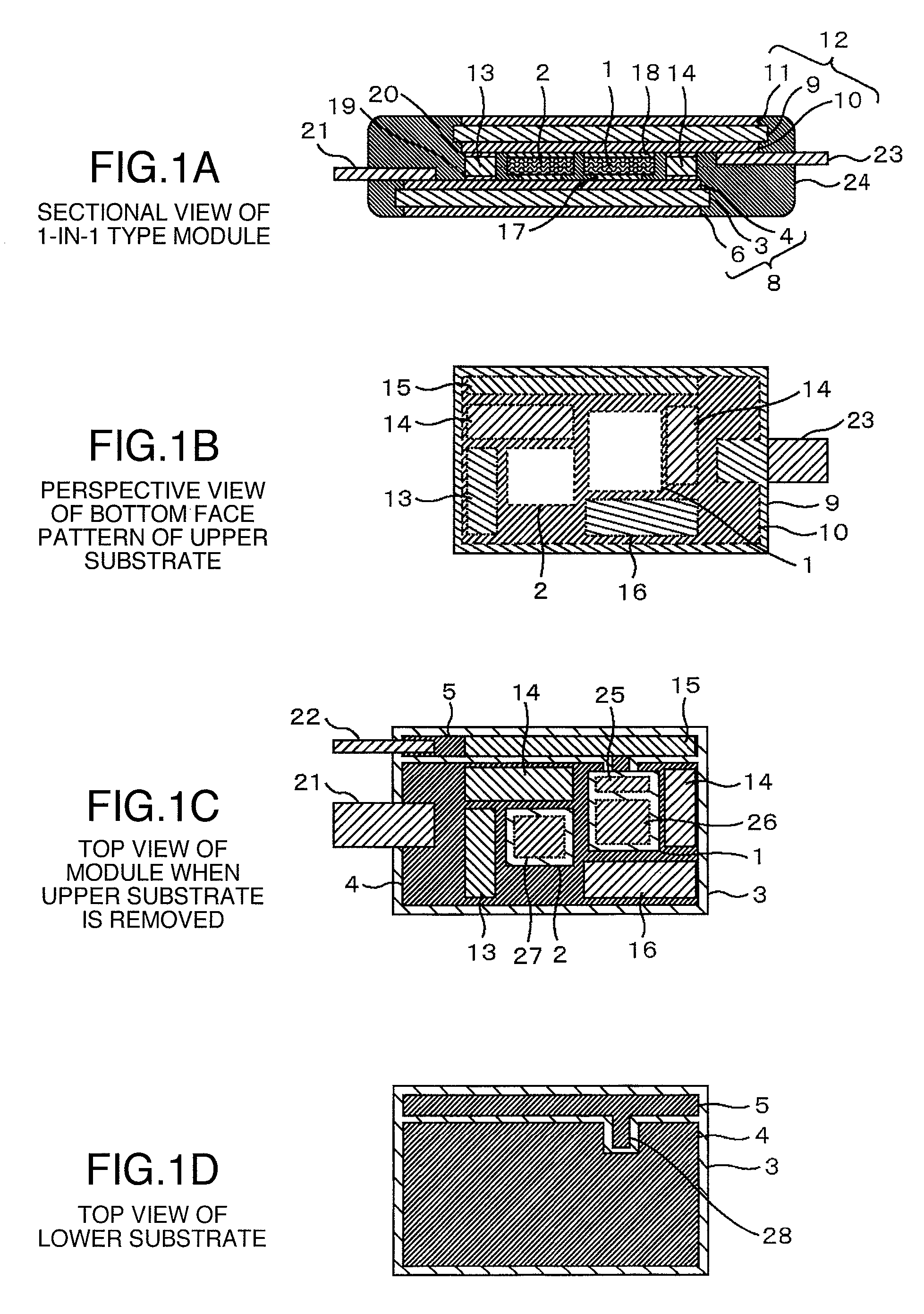

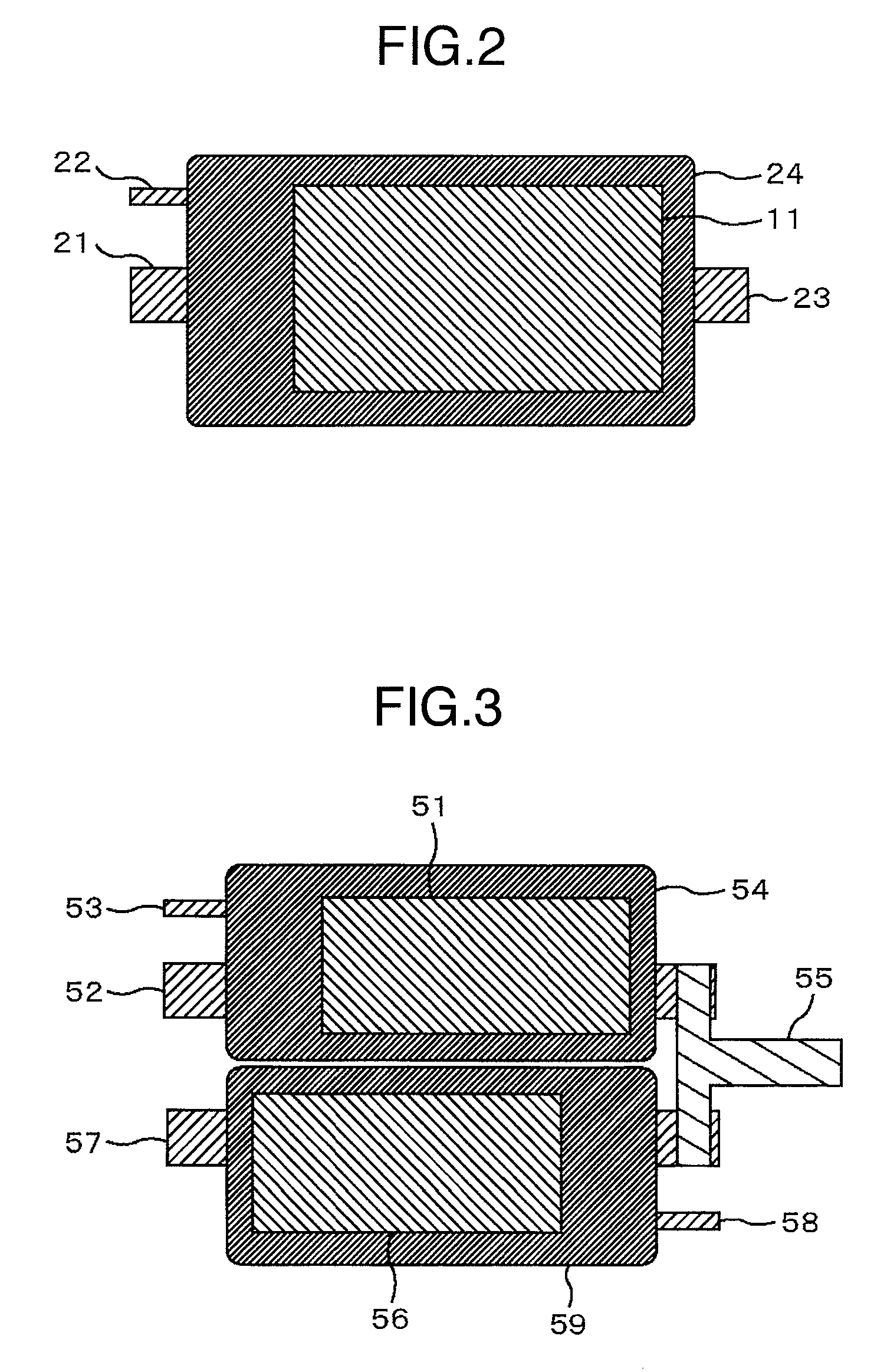

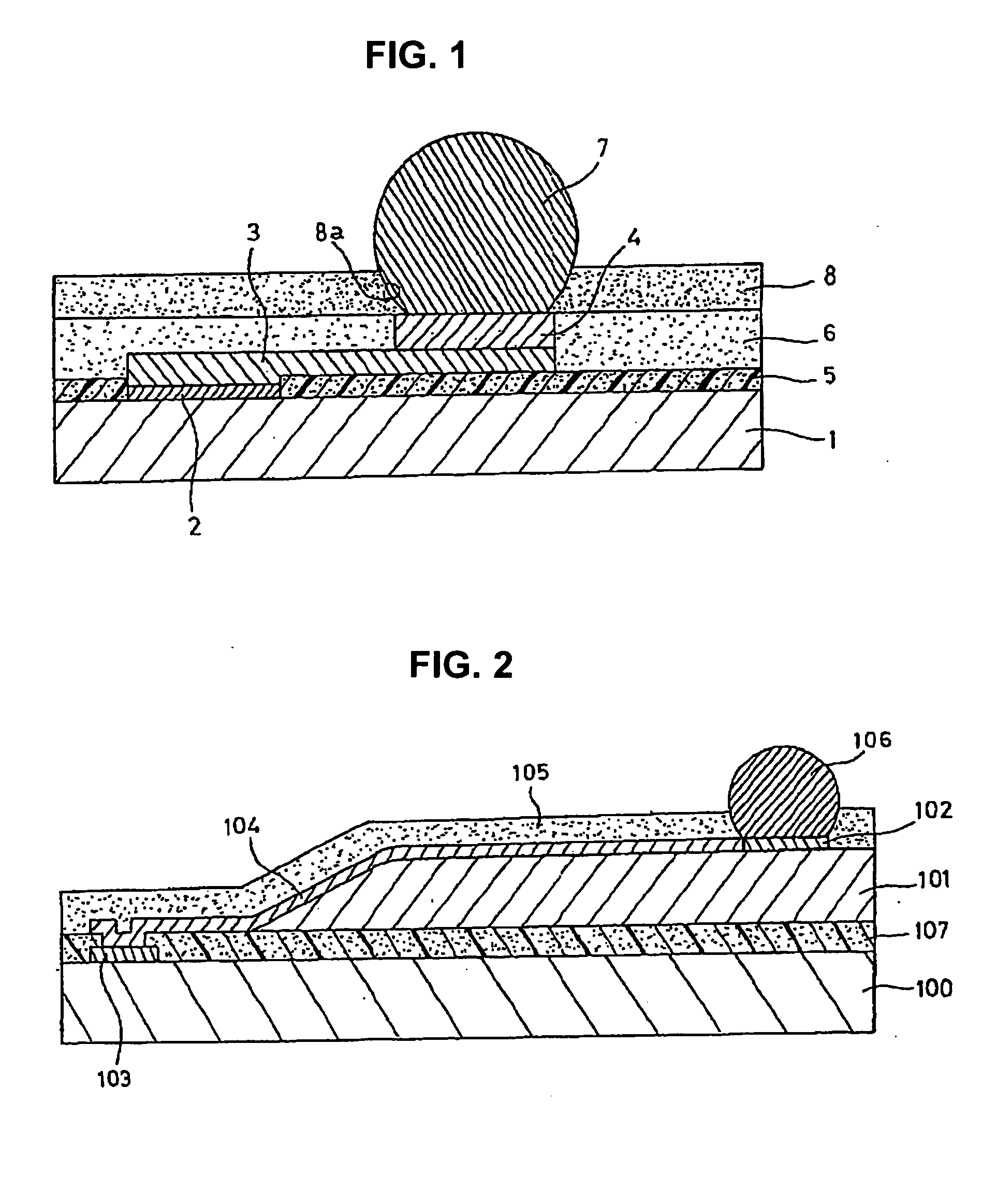

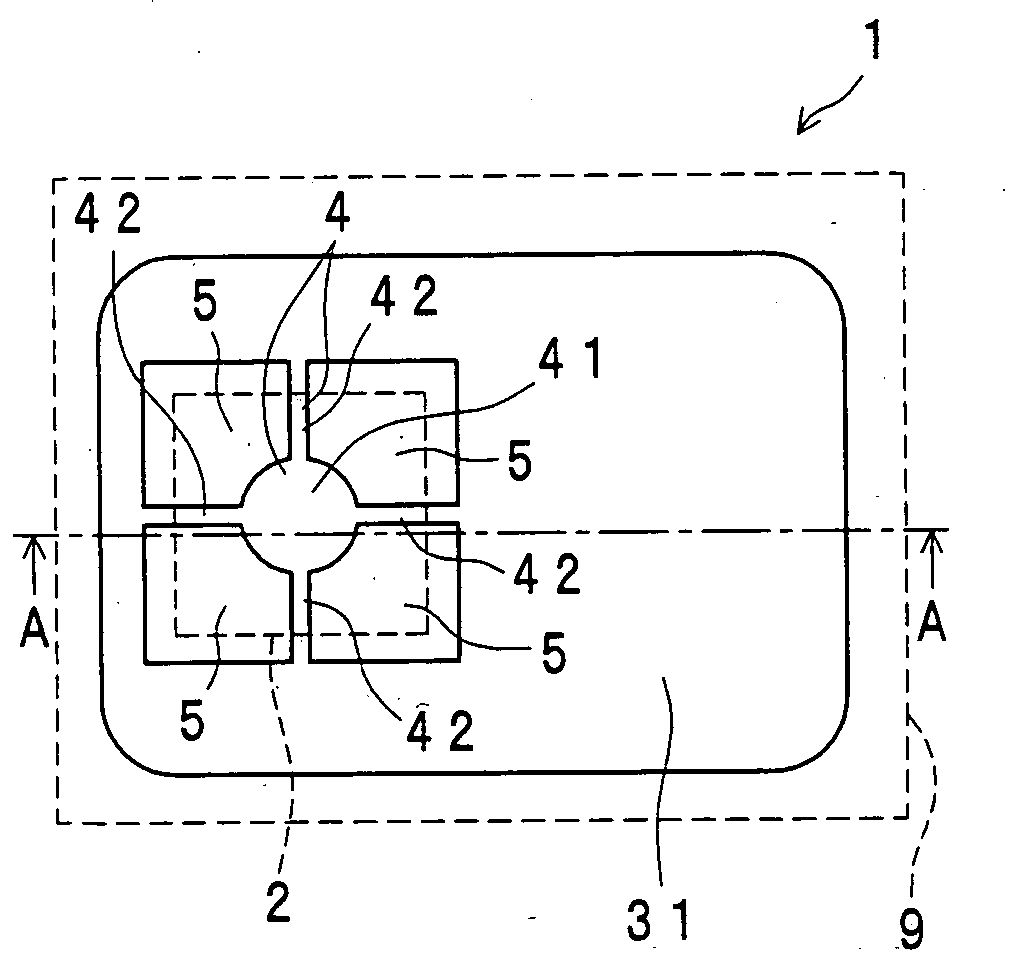

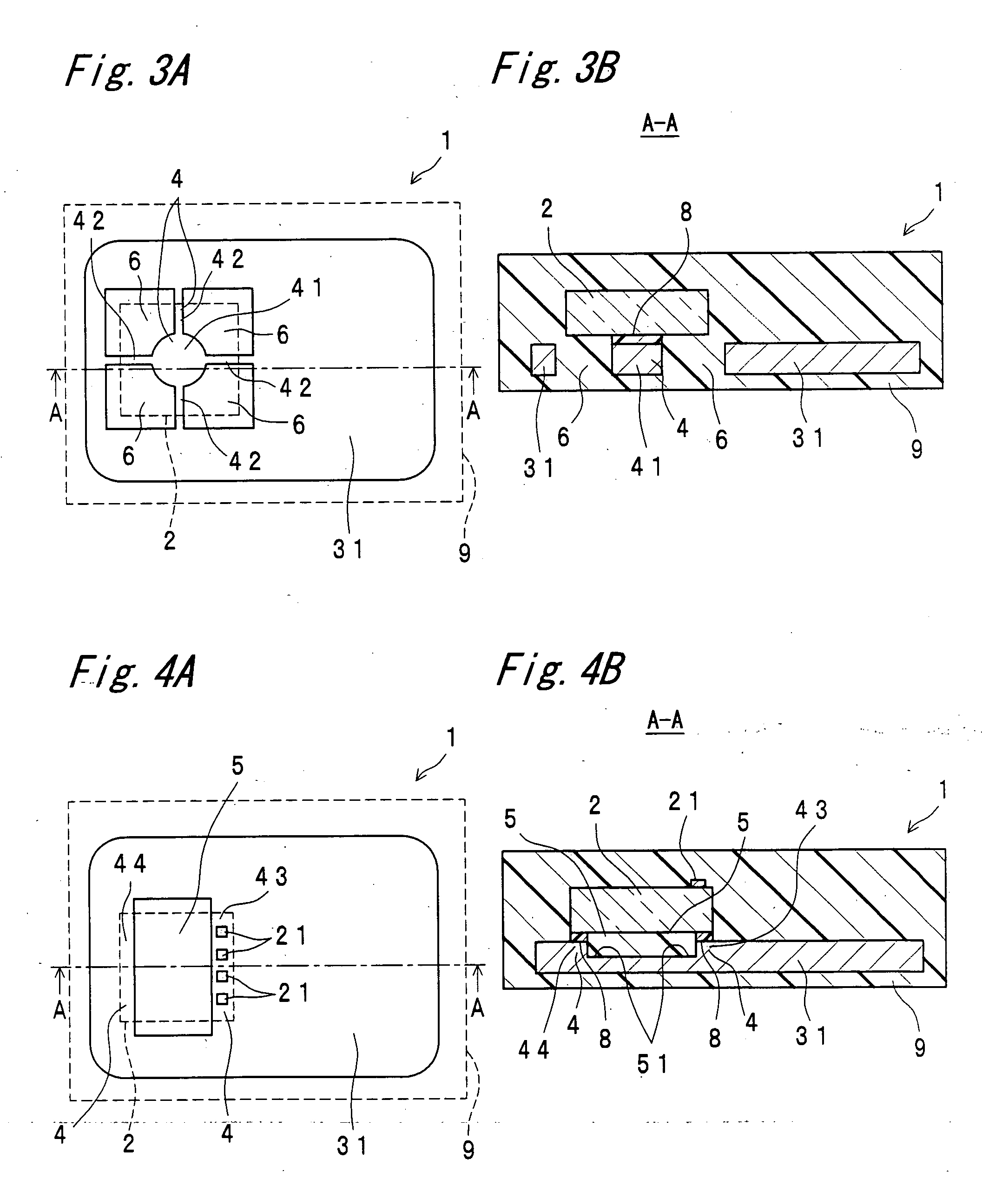

Sensor Device, Sensor System and Methods for Manufacturing Them

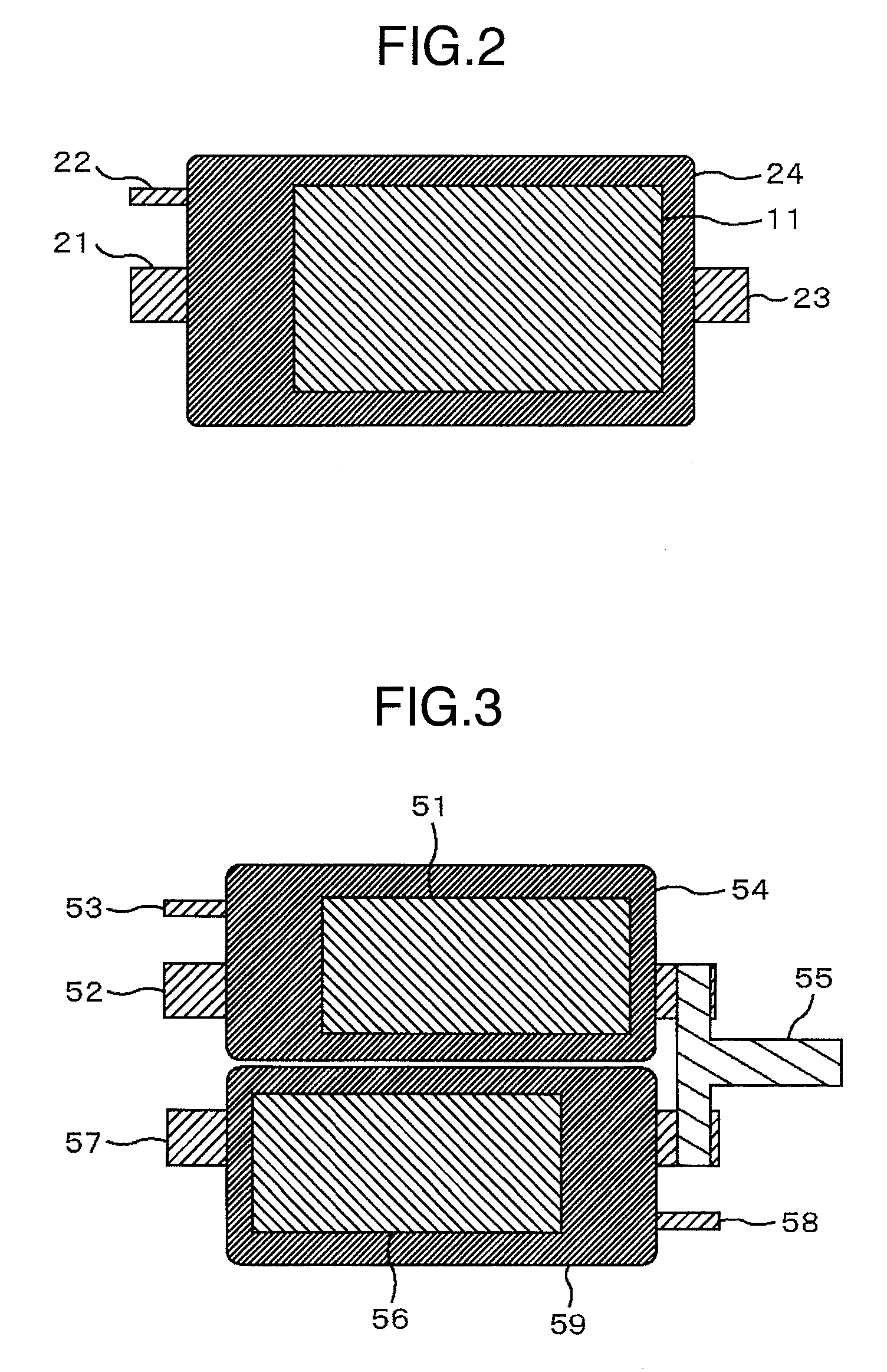

InactiveUS20080156095A1Inhibit temperature driftEasy to manufactureAcceleration measurement using interia forcesTransducer detailsSensor systemBiomedical engineering

A sensor system includes a sensor device (10) and an integrated circuit (20) for driving the device (10). The device (10) includes a sensor body (1) of a silicon-based material, an upper sealing member (2) of a silicon-based material and a lower sealing member (3) of a silicon-based material. The upper sealing member (2) and the lower sealing member (3) are joined together to cooperatively house the body (1) therewithin in an airtight manner. The device (10) and the circuit (20) are formed as a stacked body. The body (1) is electrically connected to a wiring pattern (12) of the circuit (20) through a conductive through-path (4) penetrating the upper sealing member (4) and a mounting electrode (5) provided on an outer surface of the upper sealing member (2). The device (10) is connected to an MID substrate (30) through the circuit (20).

Owner:MATSUSHITA ELECTRIC WORKS LTD

Sensor device, sensor system and methods for manufacturing them

InactiveUS7642611B2Reduce temperature driftFacilitate downsizingAcceleration measurement using interia forcesTransducer detailsSensor systemBiomedical engineering

A sensor system includes a sensor device (10) and an integrated circuit (20) for driving the device (10). The device (10) includes a sensor body (1) of a silicon-based material, an upper sealing member (2) of a silicon-based material, and a lower sealing member (3) of a silicon-based material. The upper sealing member (2) and the lower sealing member (3) are joined together to cooperatively house the body (1) therewithin in an airtight manner. The device (10) and the circuit (20) are formed as a stacked body. The body (1) is electrically connected to a wiring pattern (12) of the circuit (20) through a conductive through-path (4) penetrating the upper sealing member (4) and a mounting electrode (5) provided on an outer surface of the upper sealing member (2). The device (10) is connected to an MID substrate (30) through the circuit (20).

Owner:MATSUSHITA ELECTRIC WORKS LTD

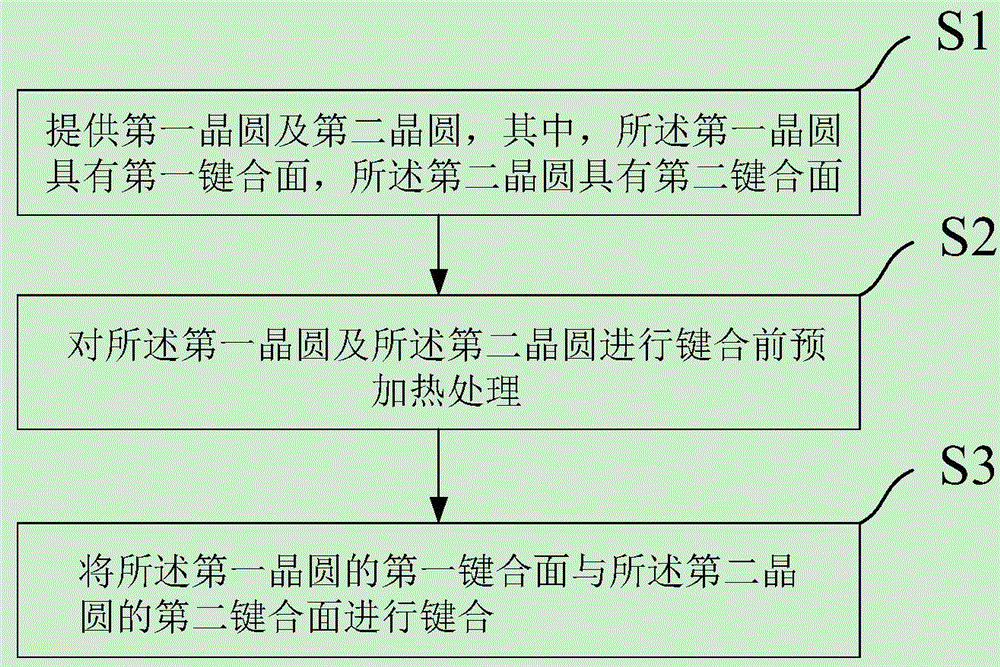

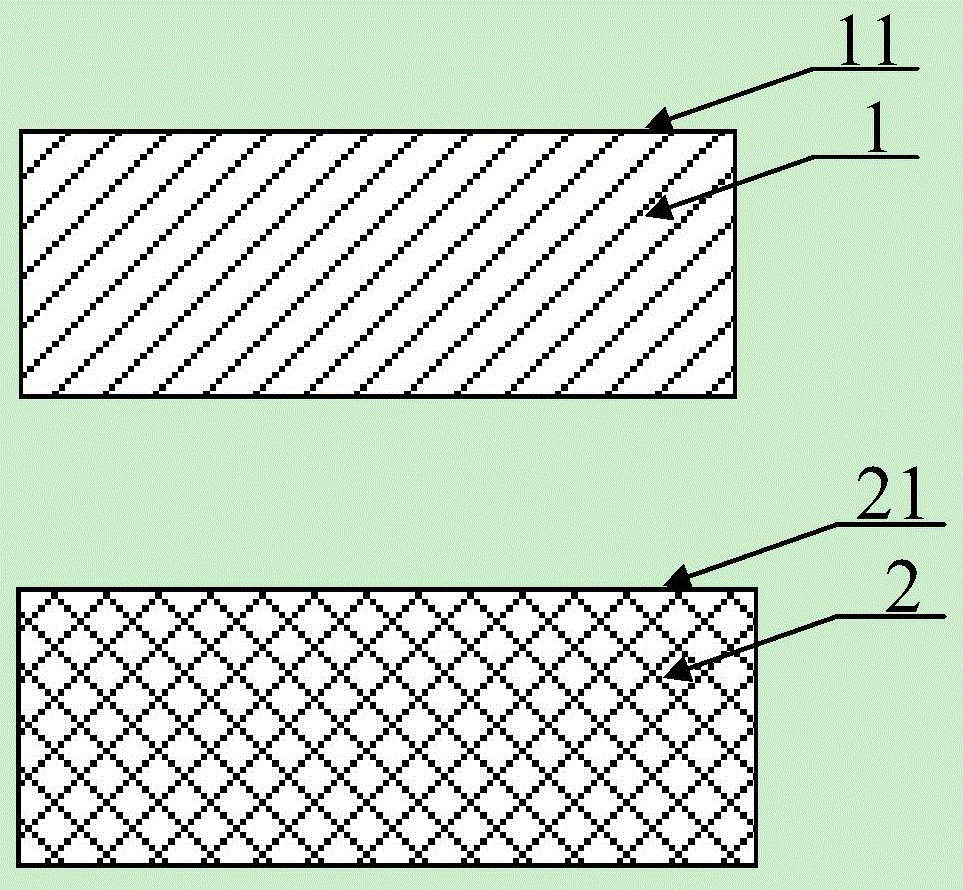

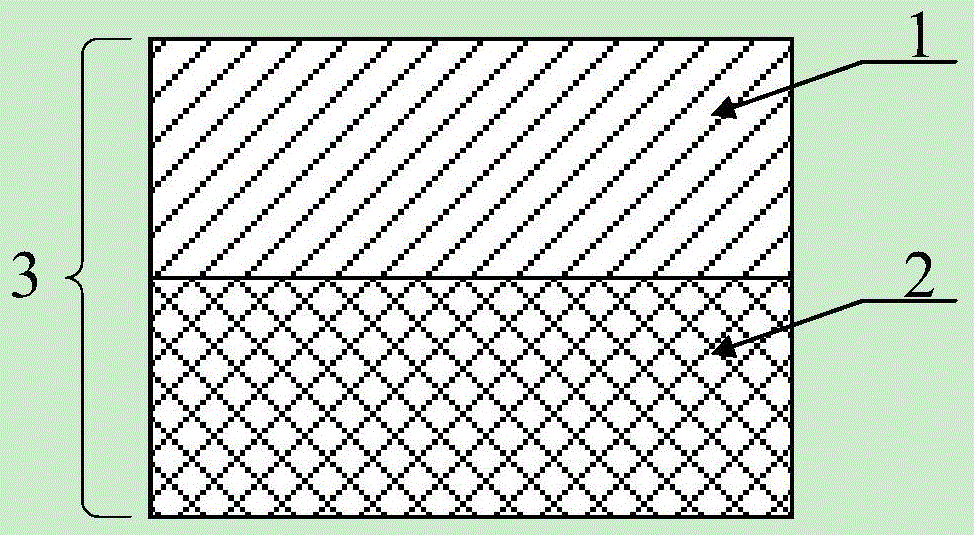

Wafer bonding method and preparation method for foreign substrate

ActiveCN106711027AReduce thermal strainImprove reliabilityPrecision positioning equipmentSoldering apparatusEngineeringWafer bonding

The invention provides a wafer bonding method and a preparation method for a foreign substrate. The wafer bonding method at least comprises the following steps: S1) supplying a first wafer and a second wafer, wherein the first wafer is equipped with a first bonding surface, and the second wafer is equipped with a second bonding surface; S2) preheating before bonding the first wafer and the second wafer; and S3) bonding the first bonding surface of the first wafer with the second bonding surface of the second wafer. According to the scheme, the preheating before the bonding for the wafers is capable of effectively reducing the thermal strain of the foreign bonding structure in a high-temperature post-annealing process, so that the use scope of the foreign bonding can be widened and the reliability of a foreign integrated material can be promoted. Meanwhile, the problems of de-bonding and broken bonding structure caused by thermal strain of the foreign bonding structure in the high-temperature post-annealing process can be solved.

Owner:SHANGHAI NOVEL SI INTEGRATION TECH CO LTD

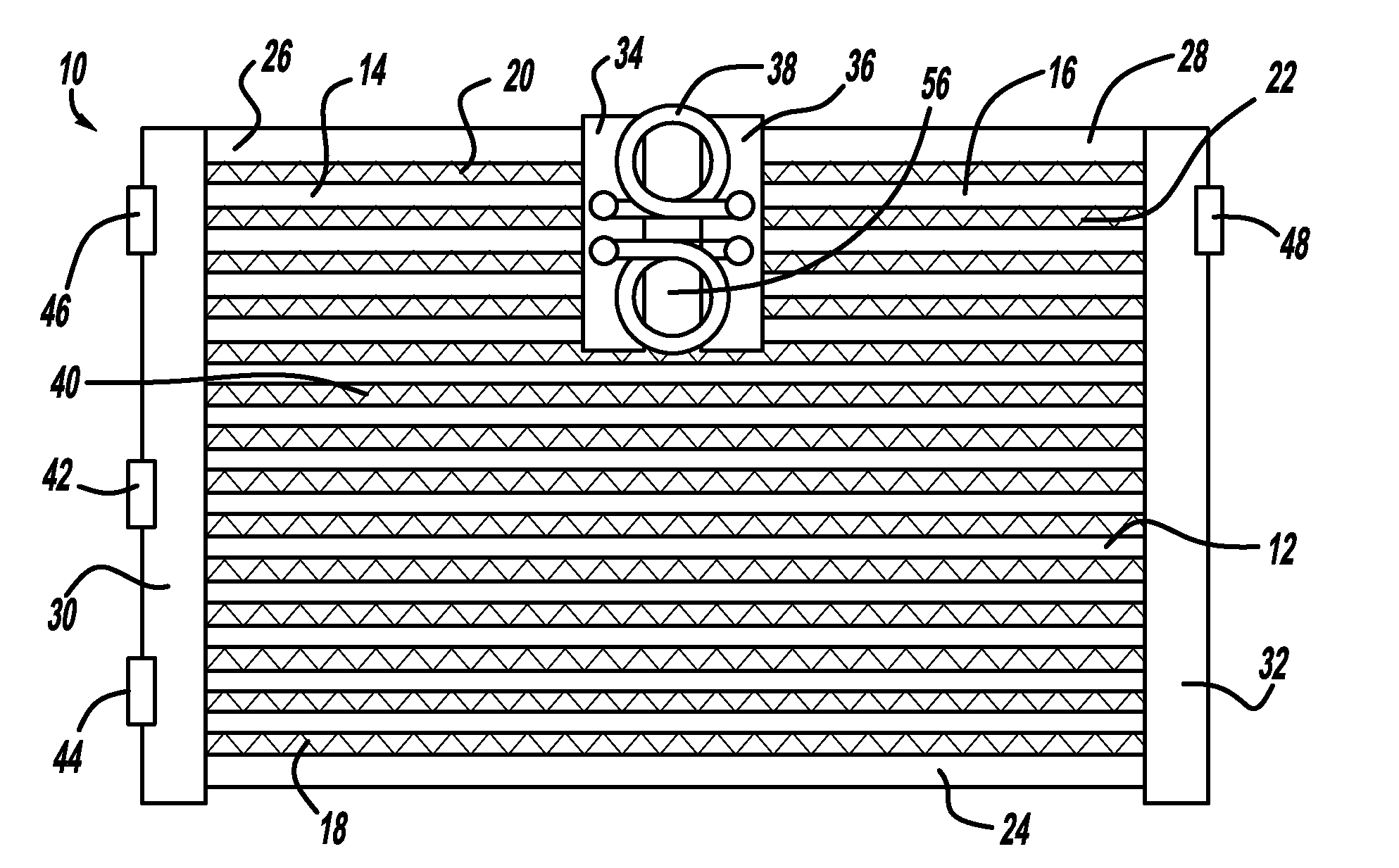

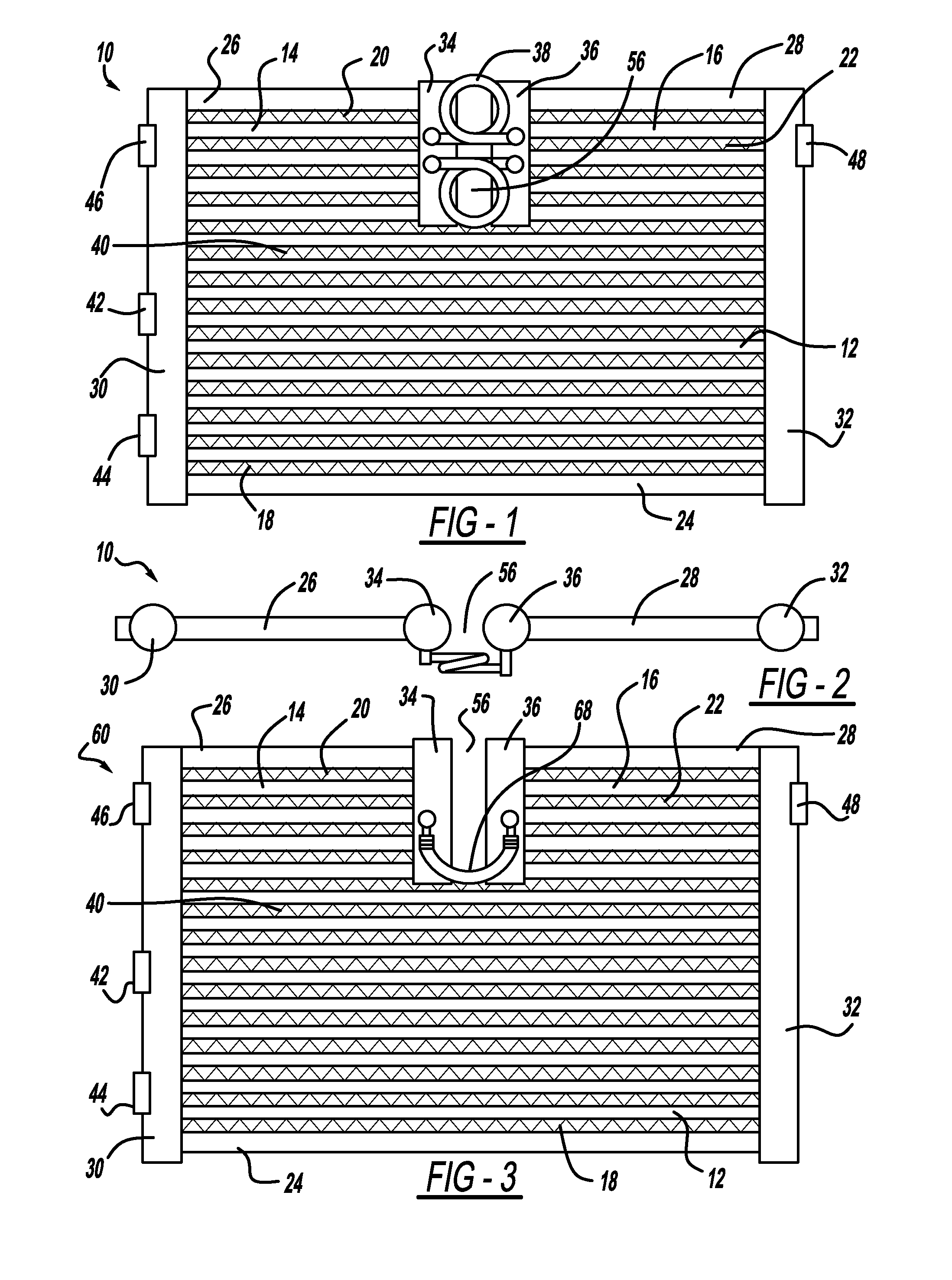

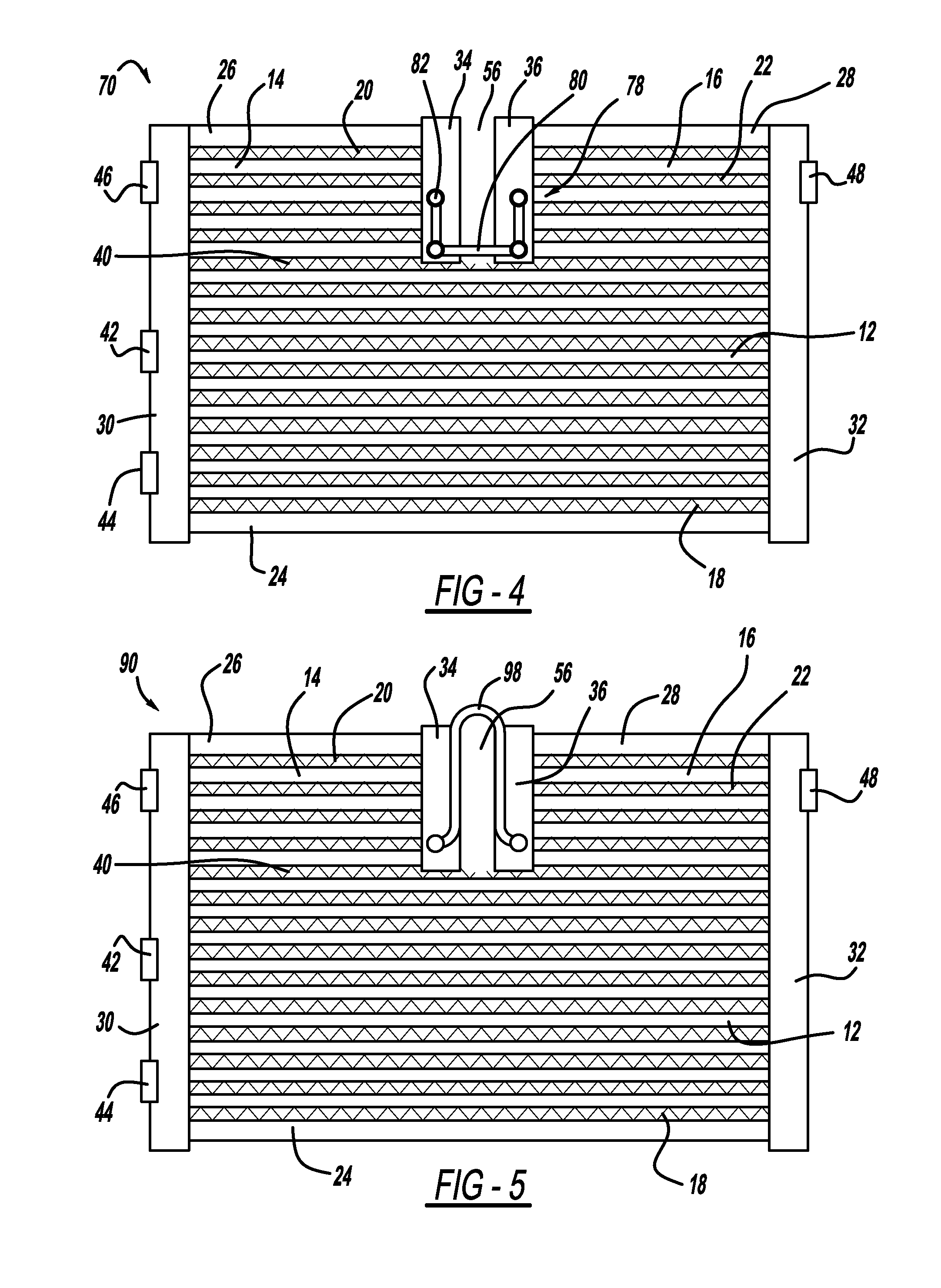

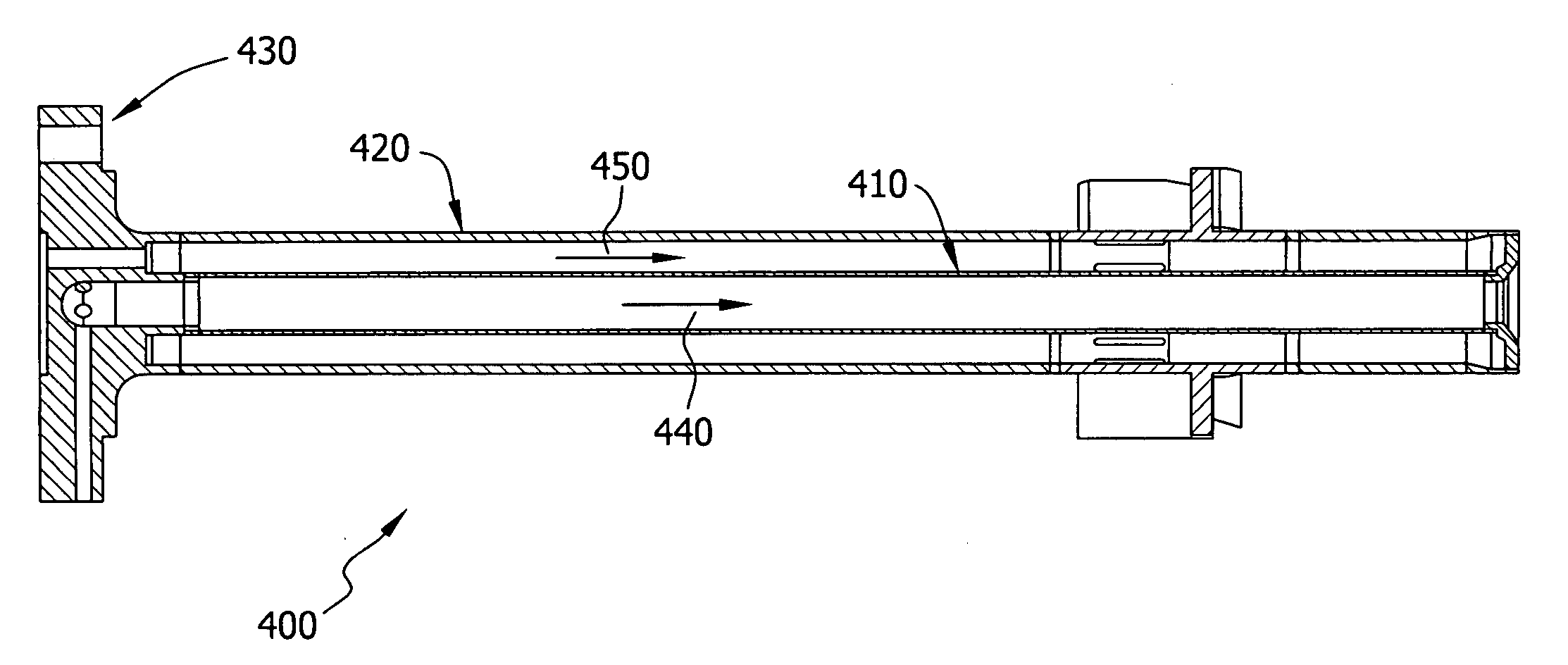

Low thermal strain multi-cooler

InactiveUS20110240275A1Reduce thermal strainSafety devices for heat exchange apparatusStationary conduit assembliesWaste managementHeat exchanger

A heat exchanger with multi-flow capabilities includes a pair of intermediate tanks located between a pair of header tanks. An open gap is provided between the two intermediate tanks. A first plurality of tubes extend between the header tanks. A second plurality of tubes extend between one of the header tanks and one of the intermediate tanks. A third plurality of tubes extend between the other header tank and the other intermediate tank. In a two flow system, the two intermediate tanks are in fluid communication through a flexible jumper tube. In a three flow system the two intermediate tanks are isolated from each other. The open gap between the intermediate tanks allows for the uneven heat expansion between the various fluid flows.

Owner:DENSO INTERNATIONAL AMERICA

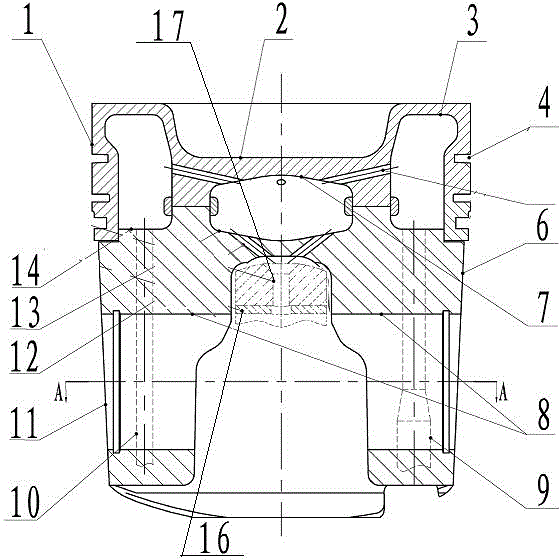

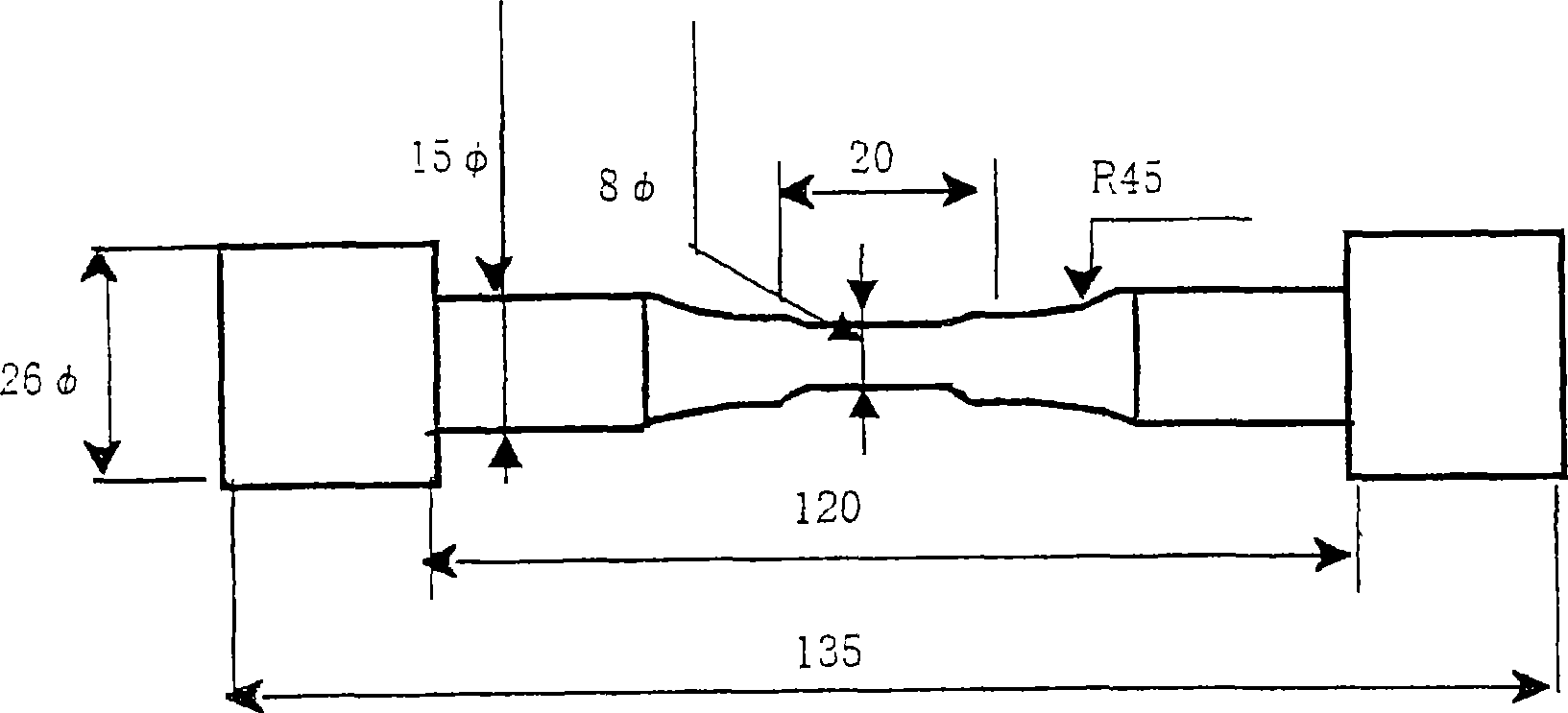

Intensive-cooling steel piston of gas engine

InactiveCN104153909AImprove reliabilityAdapt to job requirementsMachines/enginesPistonsCombustion chamberEngineering

The invention belongs to the technical field of engines and relates to an intensive-cooling steel piston of a gas engine. The piston is made from heat-resisting and high-strength 42CrMo forged steel, an inblock aluminum piston casting mode in the prior art is replaced, the bearing extremity of the piston is improved, and the working reliability of the gas engine is further improved. A combustion chamber is designed to be in a shape of a shallow basin, the specified gas compression ratio can be obtained, and the working requirement of the gas engine is met. An area defined by the piston head portion and the skirt portion is structurally utilized to design an outer cooling cavity and an inner cooling cavity, the outer cooling cavity cools an outer circle of the piston head portion and the side wall of the combustion chamber, and the inner cooling cavity cools the bottom of the combustion chamber. By the adoption of the design, the problem that a single piston cooling cavity difficultly meets the using requirement due to large heat load is solved, heat stress and heat strain produced by the piston bearing high heat load are remarkably reduced, and the fatigue life of the piston is prolonged.

Owner:HENAN DIESEL ENGINE IND

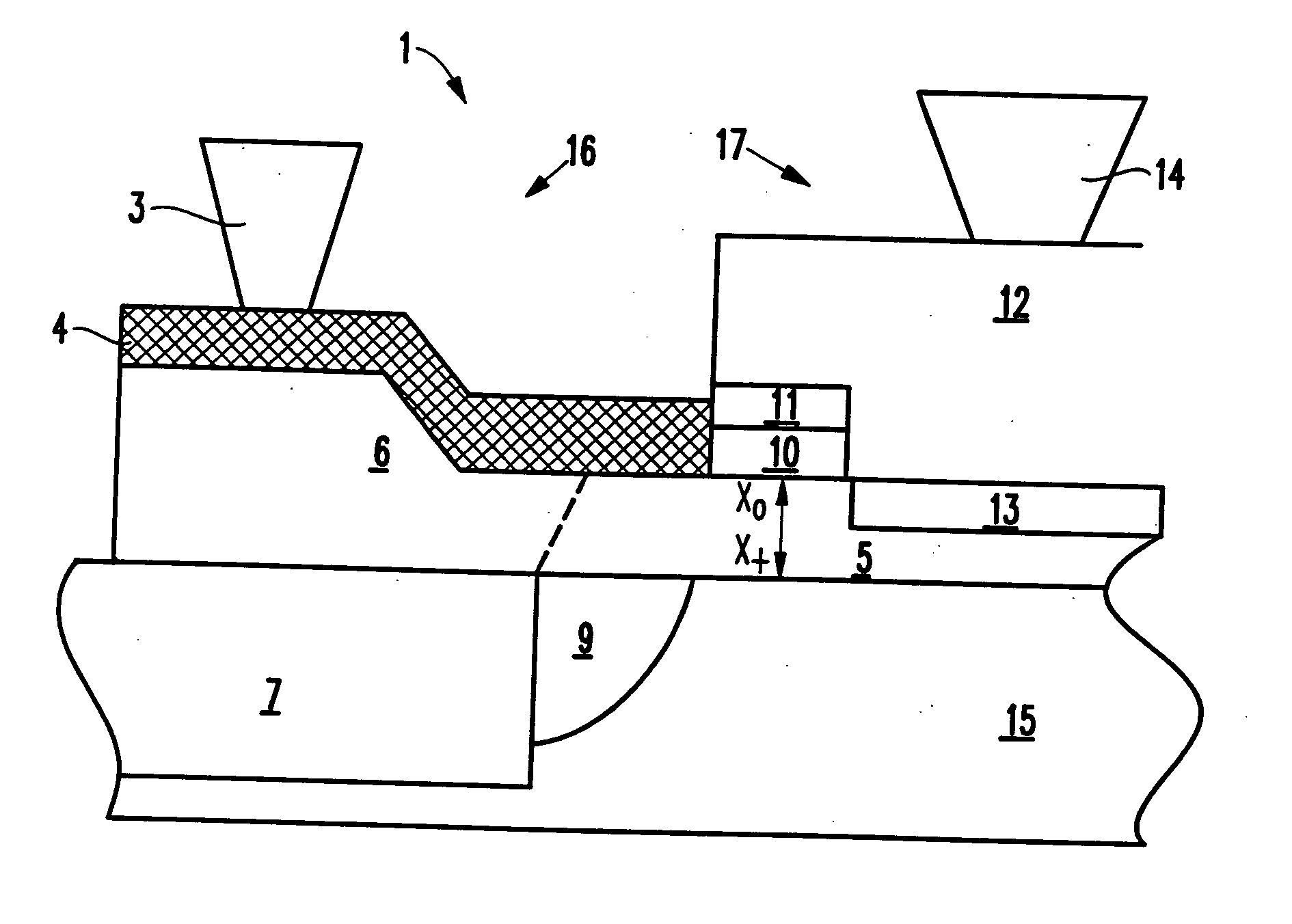

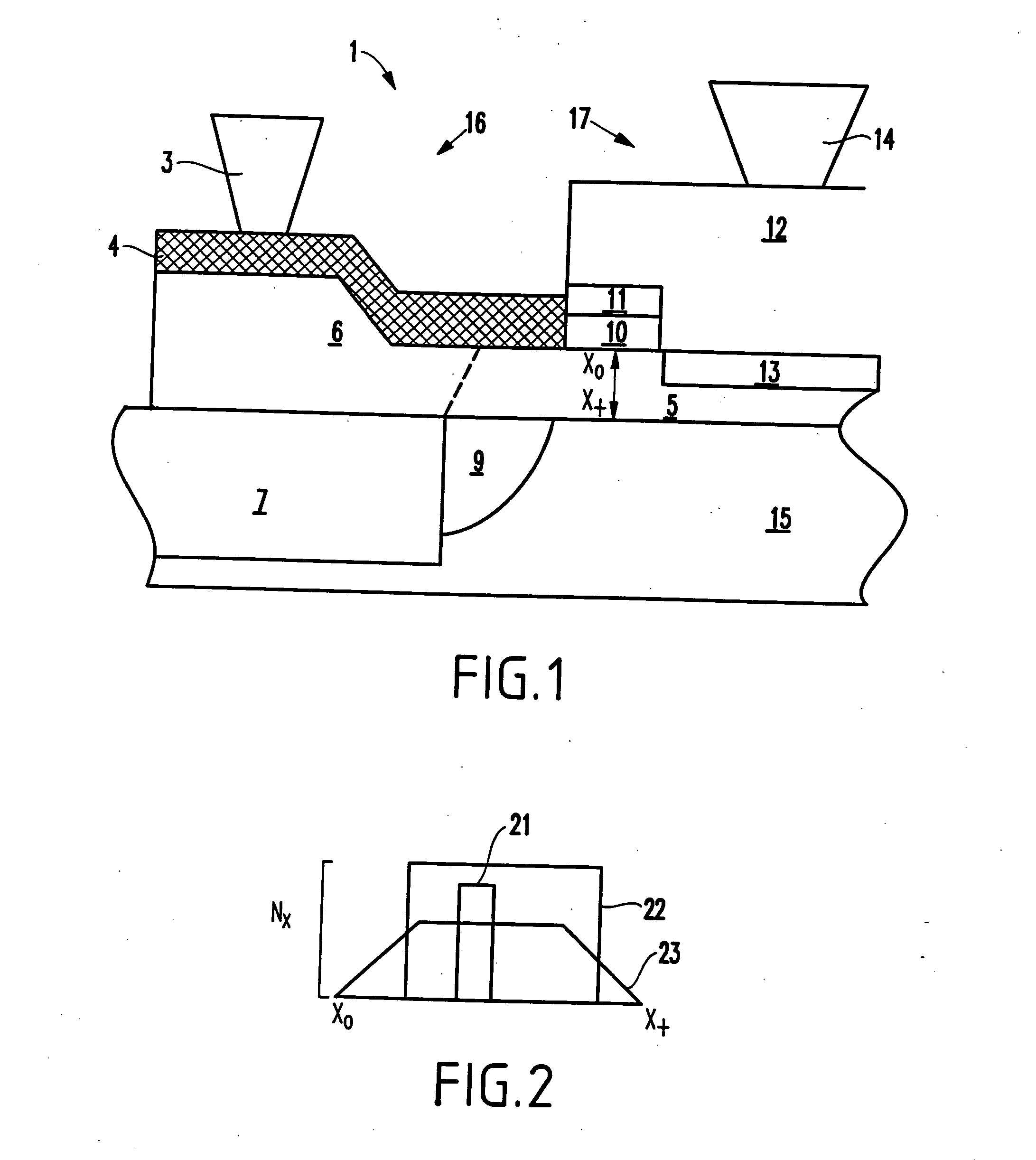

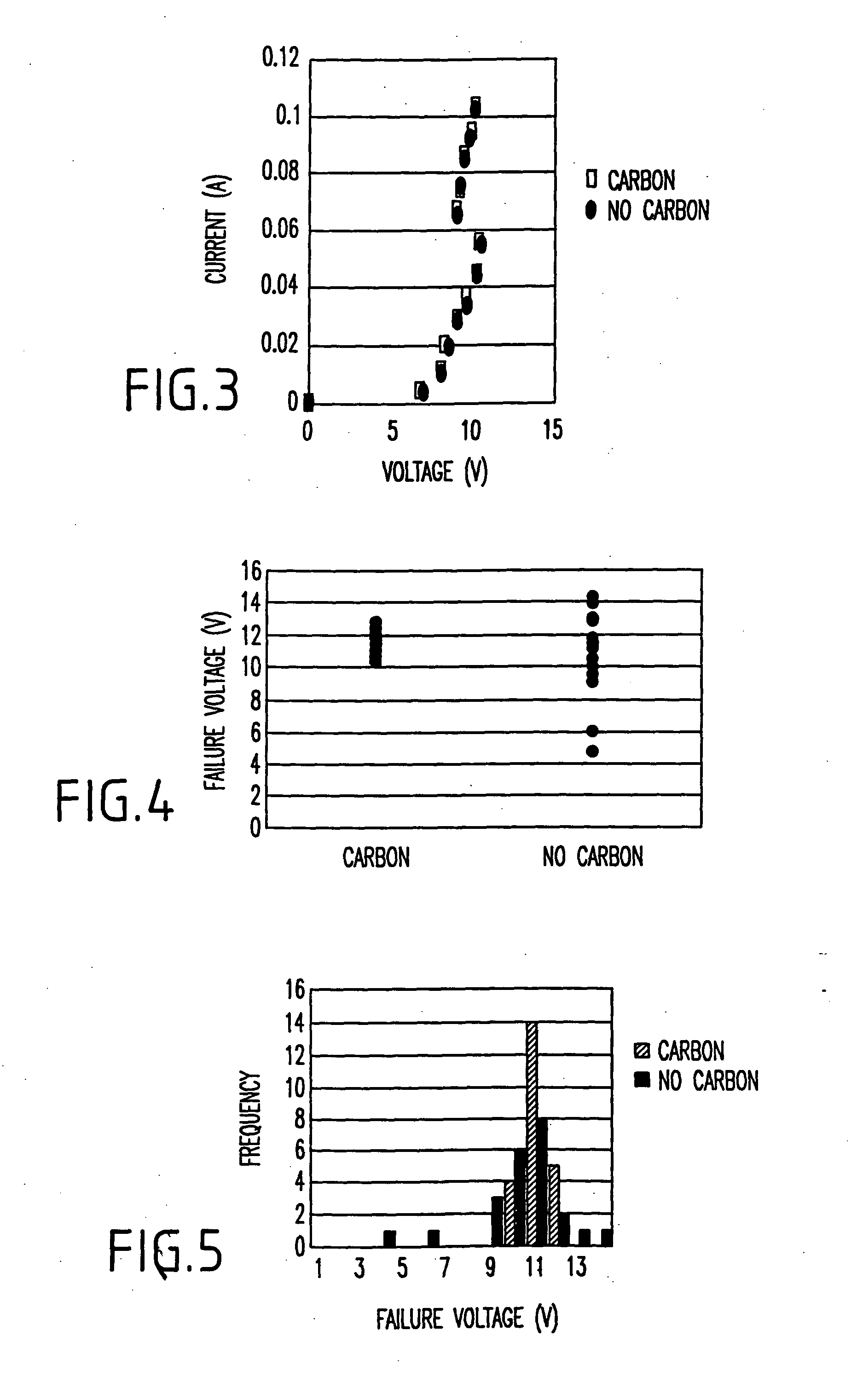

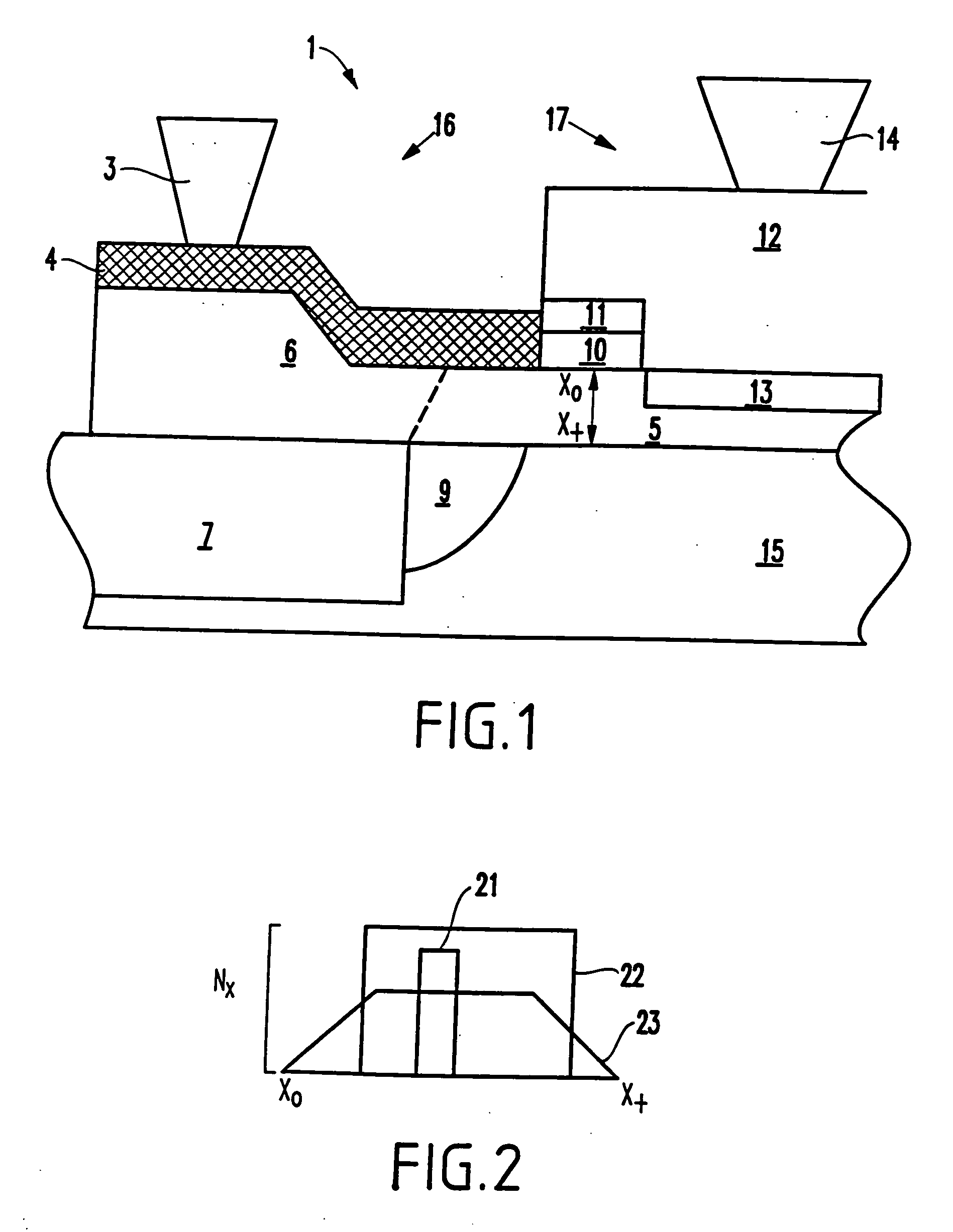

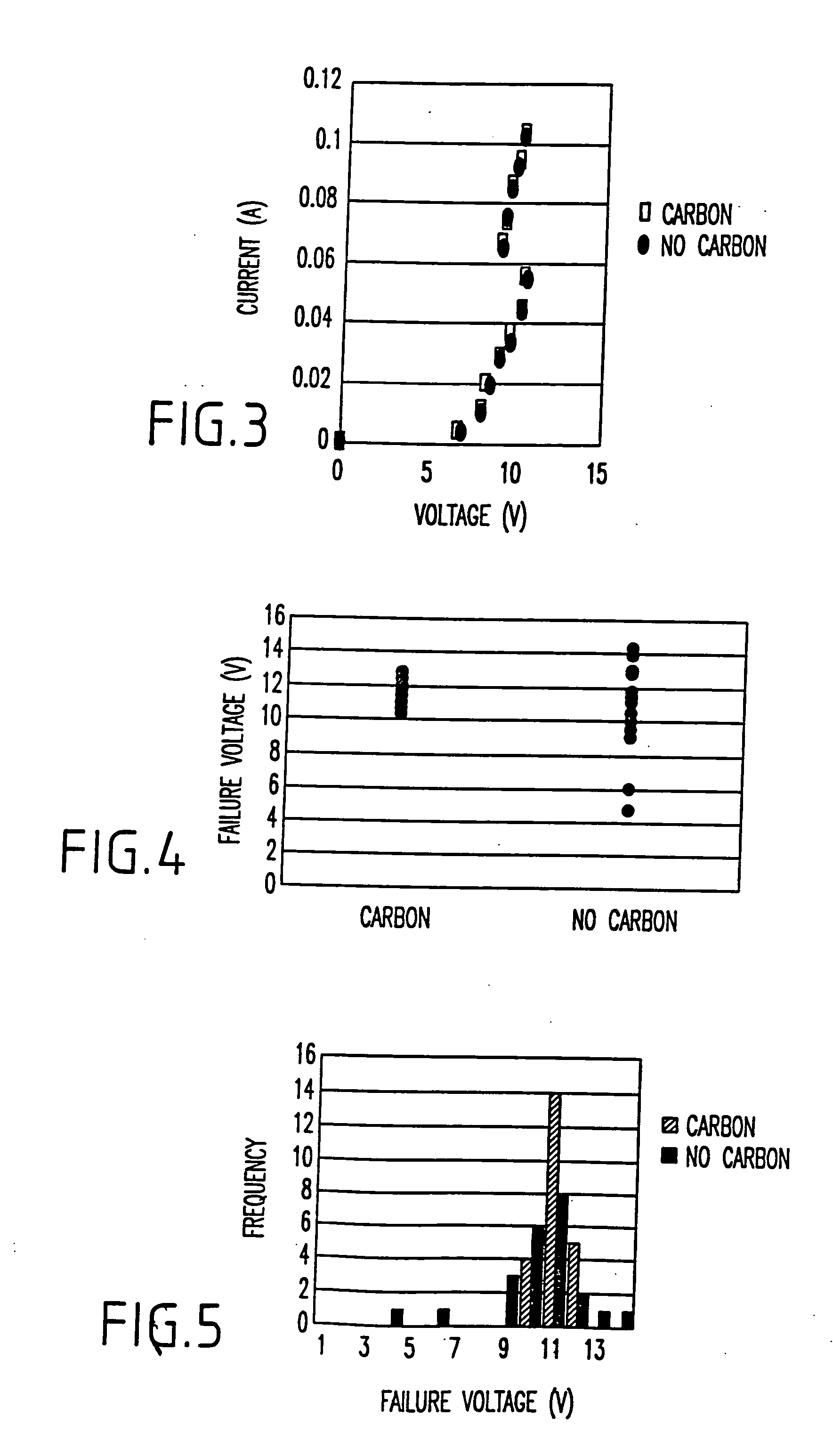

Silicon germanium heterojunction bipolar transistor with carbon incorporation

InactiveUS20050051798A1Initial strainHigh thermal strainSemiconductor/solid-state device manufacturingEmergency protective devicesDopantCritical thickness

A silicon germanium heterojunction bipolar transistor device and method comprises a semiconductor region, and a diffusion region in the semiconductor region, wherein the diffusion region is boron-doped, wherein the semiconductor region comprises a carbon dopant therein to minimize boron diffusion, and wherein a combination of an amount of the dopant, an amount of the boron, and a size of the semiconductor region are such that the diffusion region has a sheet resistance of less than approximately 4 Kohms / cm2. Also, the diffusion region is boron-doped at a concentration of 1×1020 / cm3 to 1×1021 / cm3. Additionally, the semiconductor region comprises 5-25% germanium and 0-3% carbon. By adding carbon to the semiconductor region, the device achieves an electrostatic discharge robustness, which further causes a tighter distribution of a power-to-failure of the device, and increases a critical thickness and reduces the thermal strain of the semiconductor region.

Owner:GLOBALFOUNDRIES INC

Silicon germanium heterojunction bipolar transistor with carbon incorporation

InactiveUS20050233534A1Reduce strainHigh thermal strainSemiconductor/solid-state device manufacturingEmergency protective devicesDopantCritical thickness

A silicon germanium heterojunction bipolar transistor device and method comprises a semiconductor region, and a diffusion region in the semiconductor region, wherein the diffusion region is boron-doped, wherein the semiconductor region comprises a carbon dopant therein to minimize boron diffusion, and wherein a combination of an amount of the dopant, an amount of the boron, and a size of the semiconductor region are such that the diffusion region has a sheet resistance of less than approximately 4 Kohms / cm2. Also, the diffusion region is boron-doped at a concentration of 1×1020 / cm3 to 1×1021 / cm3. Additionally, the semiconductor region comprises 5-25% germanium and 0-3% carbon. By adding carbon to the semiconductor region, the device achieves an electrostatic discharge robustness, which further causes a tighter distribution of a power-to-failure of the device, and increases a critical thickness and reduces the thermal strain of the semiconductor region.

Owner:GLOBALFOUNDRIES INC

Power semiconductor module

InactiveUS7608917B2Avoid warpingReduce thermal strainSemiconductor/solid-state device detailsLaminating printed circuit boardsThermal expansionInorganic materials

A power semiconductor module and an inverter apparatus in which a device or a joining part is not mechanically damaged even when the temperature in use becomes a high temperature in the range of 175 to 250° C., resulting in excellent reliability at high temperature retaining test and thermal cycling test. Low thermal expansion ceramic substrates are disposed above and below the device. A material having a coefficient of thermal expansion of 10 ppm / K or less is disposed between the ceramic substrates. In addition, an inorganic material having a coefficient of thermal expansion in the range of 2 to 6 ppm / K or less is disposed around the device.

Owner:HITACHI LTD

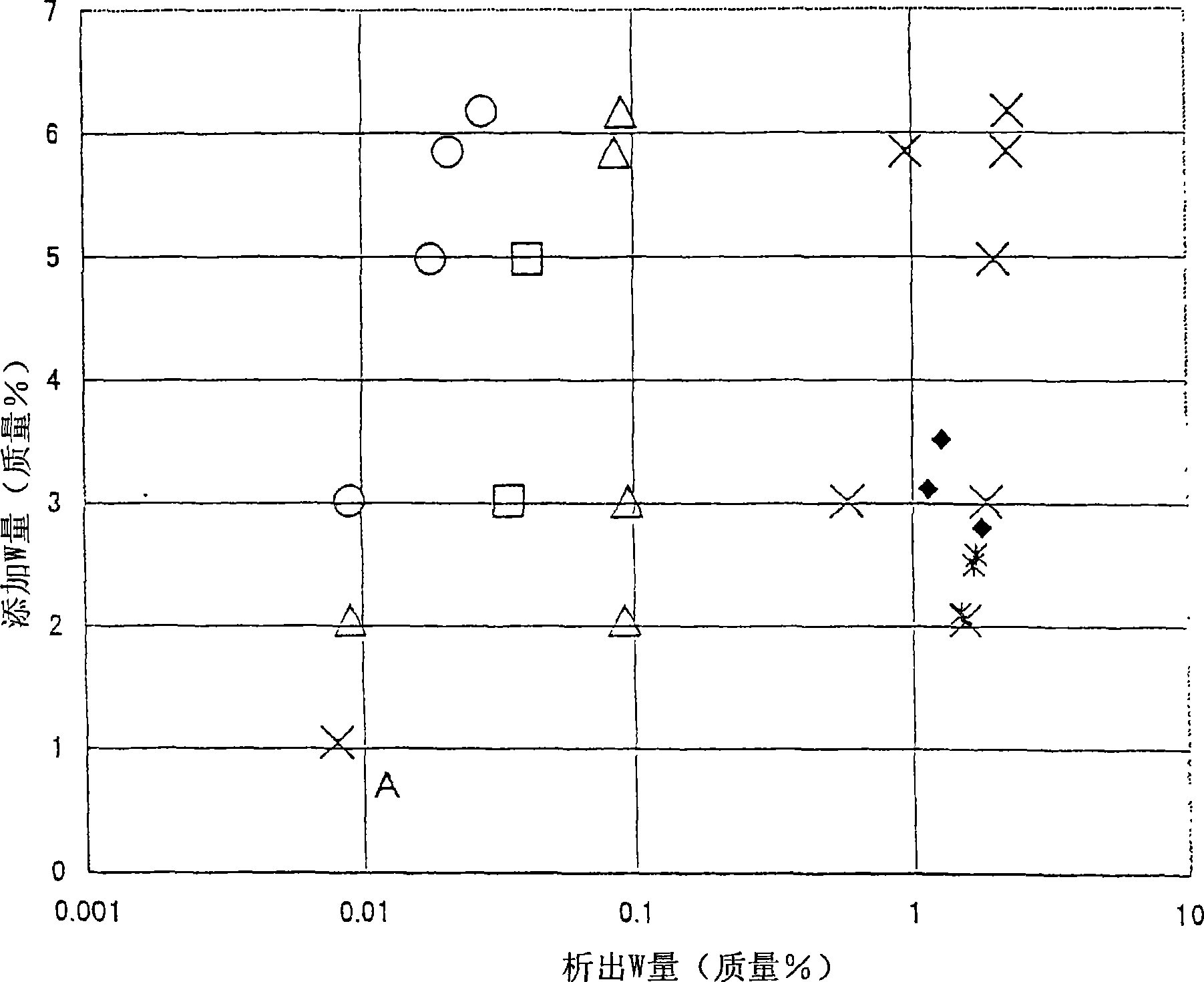

Ferritic cr-containing steel

InactiveCN1902333AExtend your lifeReduce thermal strainFurnace typesHeat exchange apparatusFerricThermal expansion

Disclosed is a ferritic Cr-containing steel whose thermal expansion coefficient is decreased for advantageously solving problems related to thermal expansion / contraction. Specifically disclosed is a ferritic Cr-containing steel consisting of, in mass%, C: 0.03% or less, Mn: 5.0% or less, Cr: 6-40%, N: 0.03% or less, Si: 5% or less, W:2.0-6.0% and the balance of Fe and unavoidable impurities, which is characterized in that the deposited W is not more than 0.1% and the average thermal expansion coefficient at 20-800 DEG C is less than 12.6 x 10<-6> / DEG C.

Owner:JFE STEEL CORP

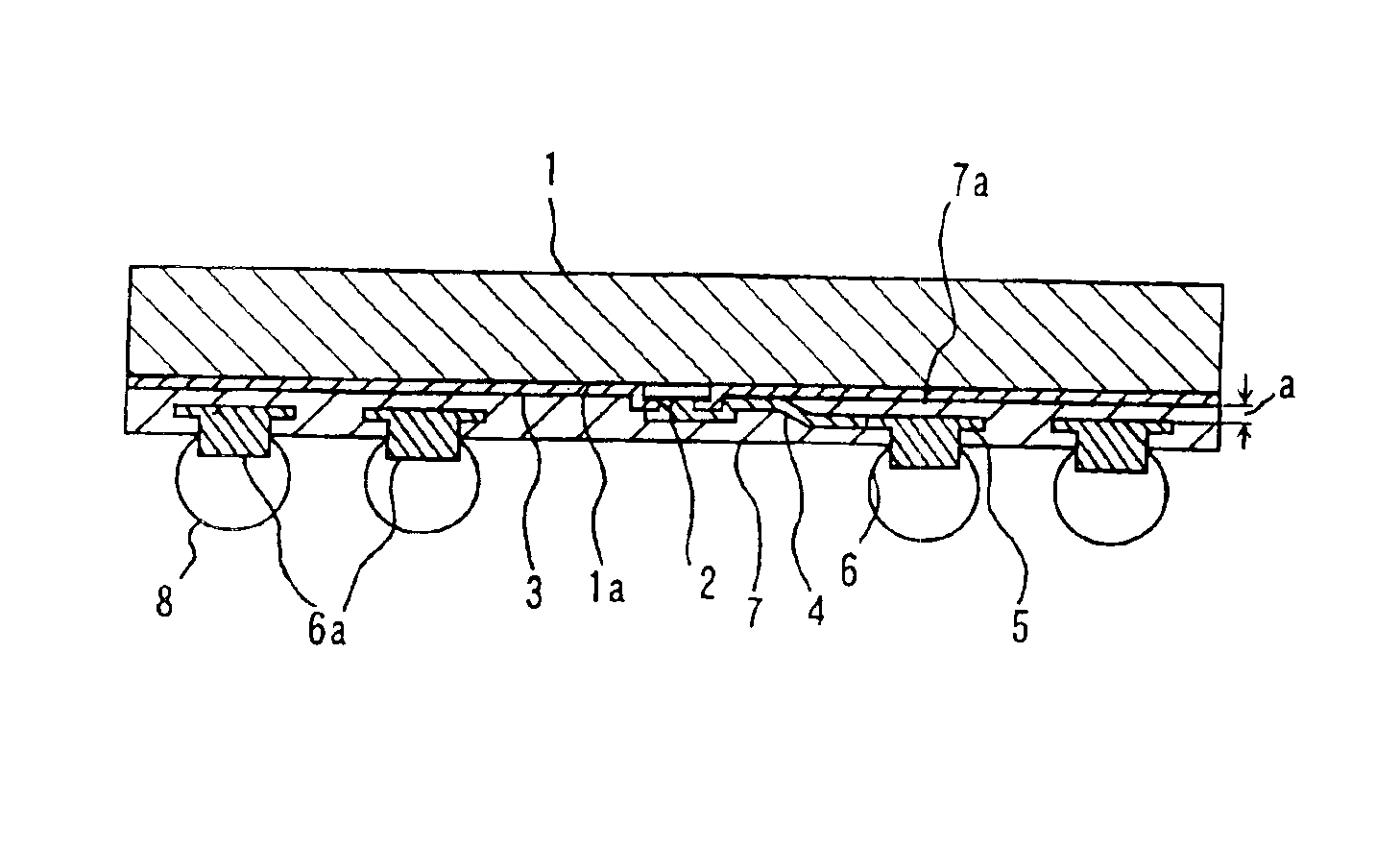

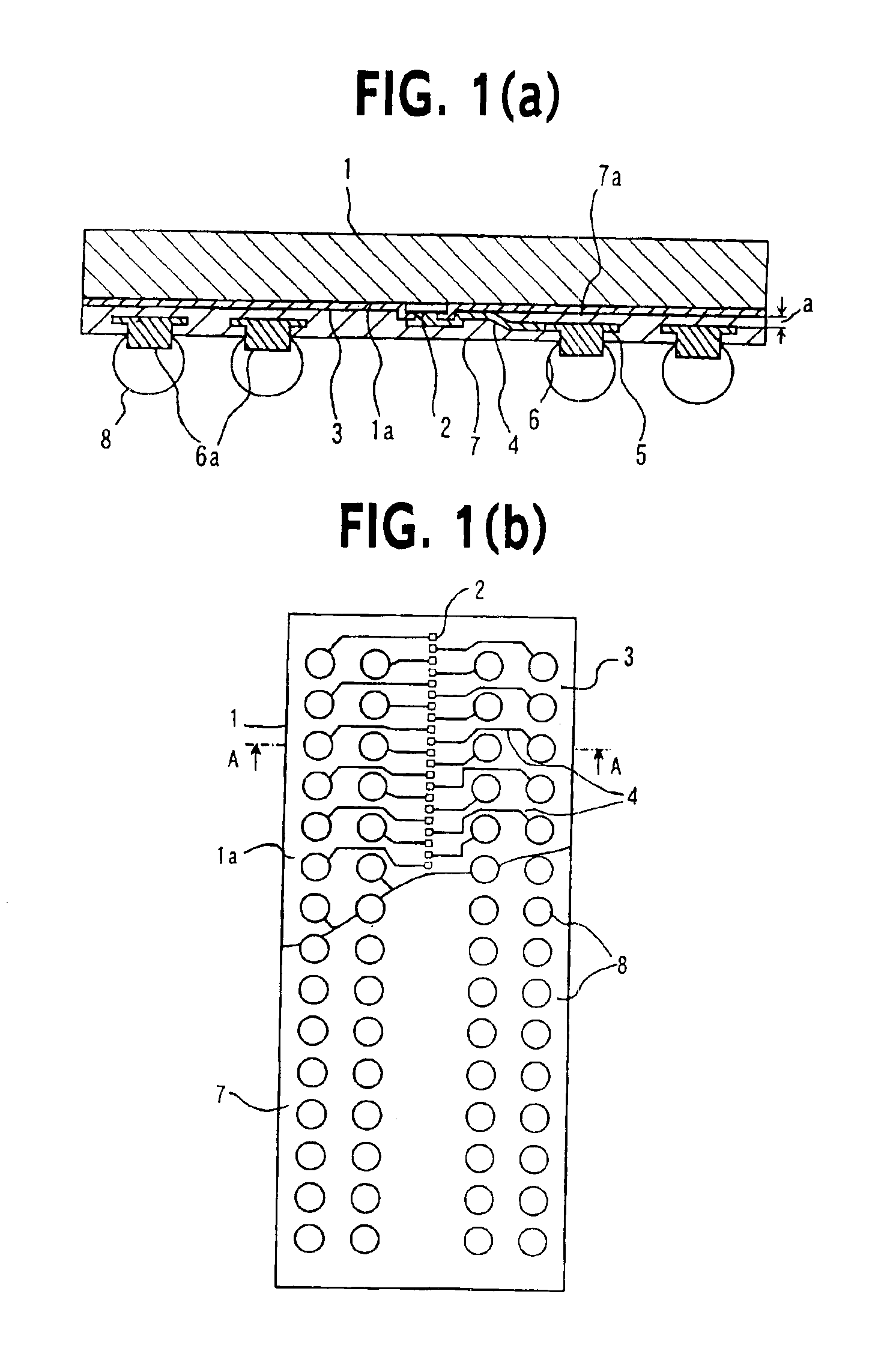

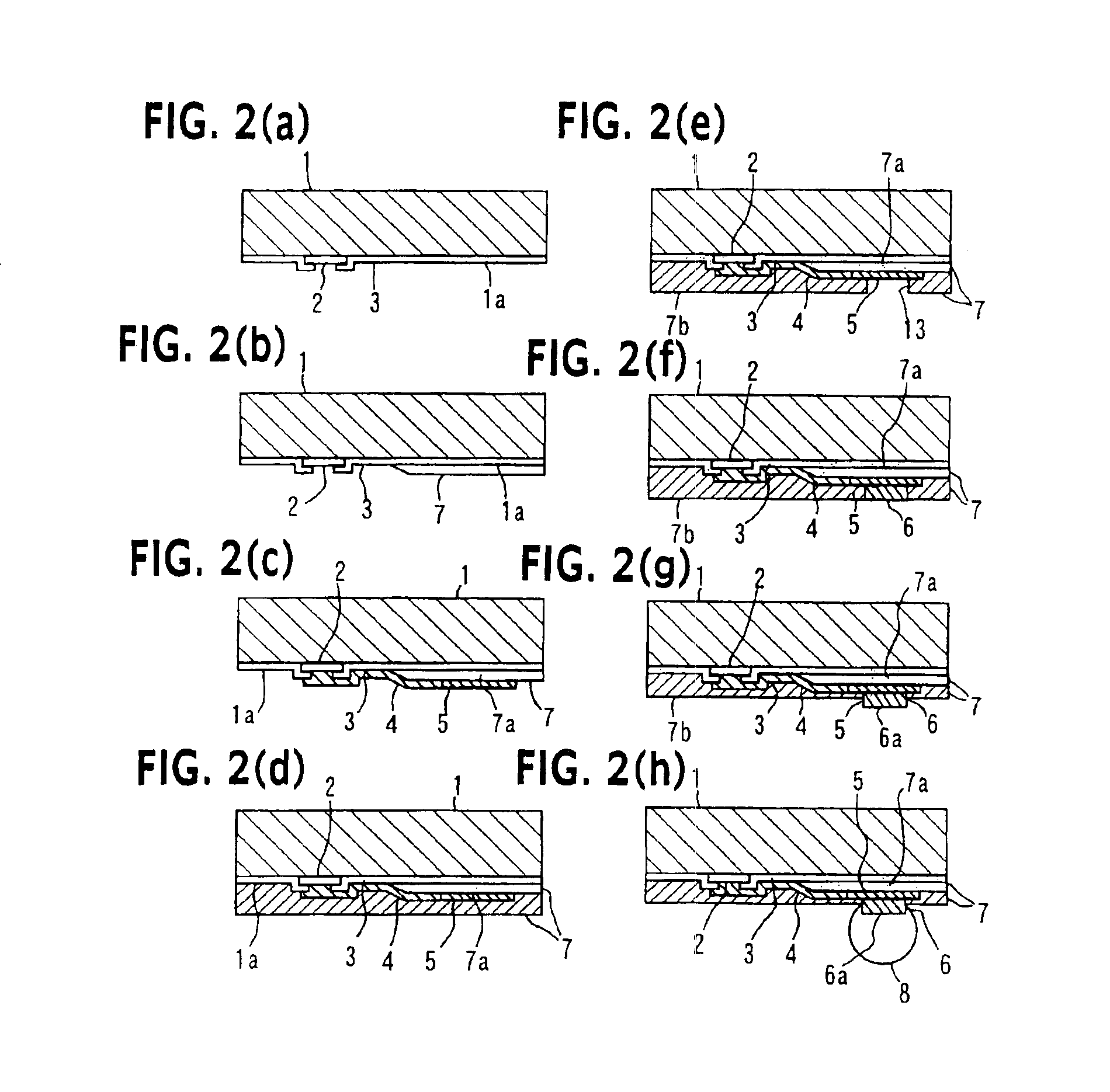

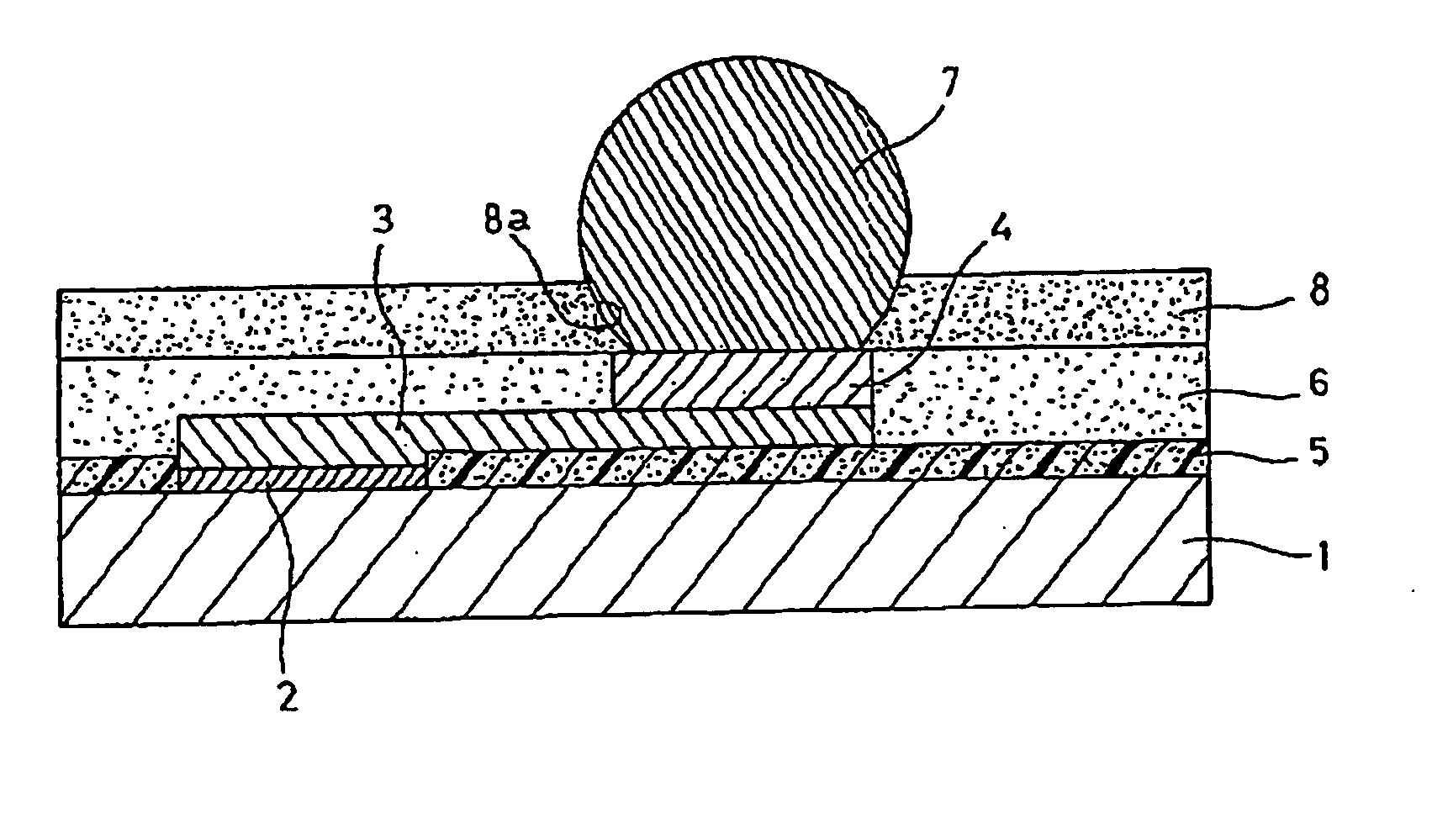

Method of manufacturing wafer level chip size package

InactiveUS20050064624A1Easy to operateReduce thermal strainSemiconductor/solid-state device detailsSolid-state devicesScreen printingChip size

To widely improve an entire manufacturing efficiency by efficiently forming a thermal stress relaxing post, an insulating layer and a solder bump, a rewiring circuit (3) is formed on a wafer (1) by plating, a thermal stress relaxing post (4) made of a conductive material such as a solder or the like is formed on the rewiring circuit (3), an insulating layer (6) made of a polyimide or the like is formed in the periphery of the rewiring circuit (3) and the thermal stress relaxing post (4) except a top surface of the thermal stress relaxing post (4), a solder bump (7) is formed on the thermal stress relaxing post (4), and the thermal stress relaxing post (4), the insulating layer (6) and the solder bump (7) are formed by screen printing.

Owner:MINAMI

Semiconductor micro device

InactiveUS20050253208A1Reduce areaIncreased thermal strainAcceleration measurement using interia forcesFixed microstructural devicesMicro structureLead frame

A semiconductor micro device is provided with a rectangular silicon micro structure chip; a lead frame having a die pad for securing the silicon structure chip comprising a contact portion with the chip; and a resin encapsulating material for encapsulating the silicon structure chip and part of the lead frame; wherein the die pad of the lead frame has a non-contact portion positioned lower than the contact portion not to be in contact with the silicon structure chip, the non-contact portion being formed at least in a position corresponding to a diagonal portion of the silicon structure chip. A clearance between the non-contact portion and the silicon structure chip is filled with the resin encapsulating material, whereby the die pad and the silicon structure chip are bonded to each other by the resin encapsulating material.

Owner:MITSUBISHI ELECTRIC CORP

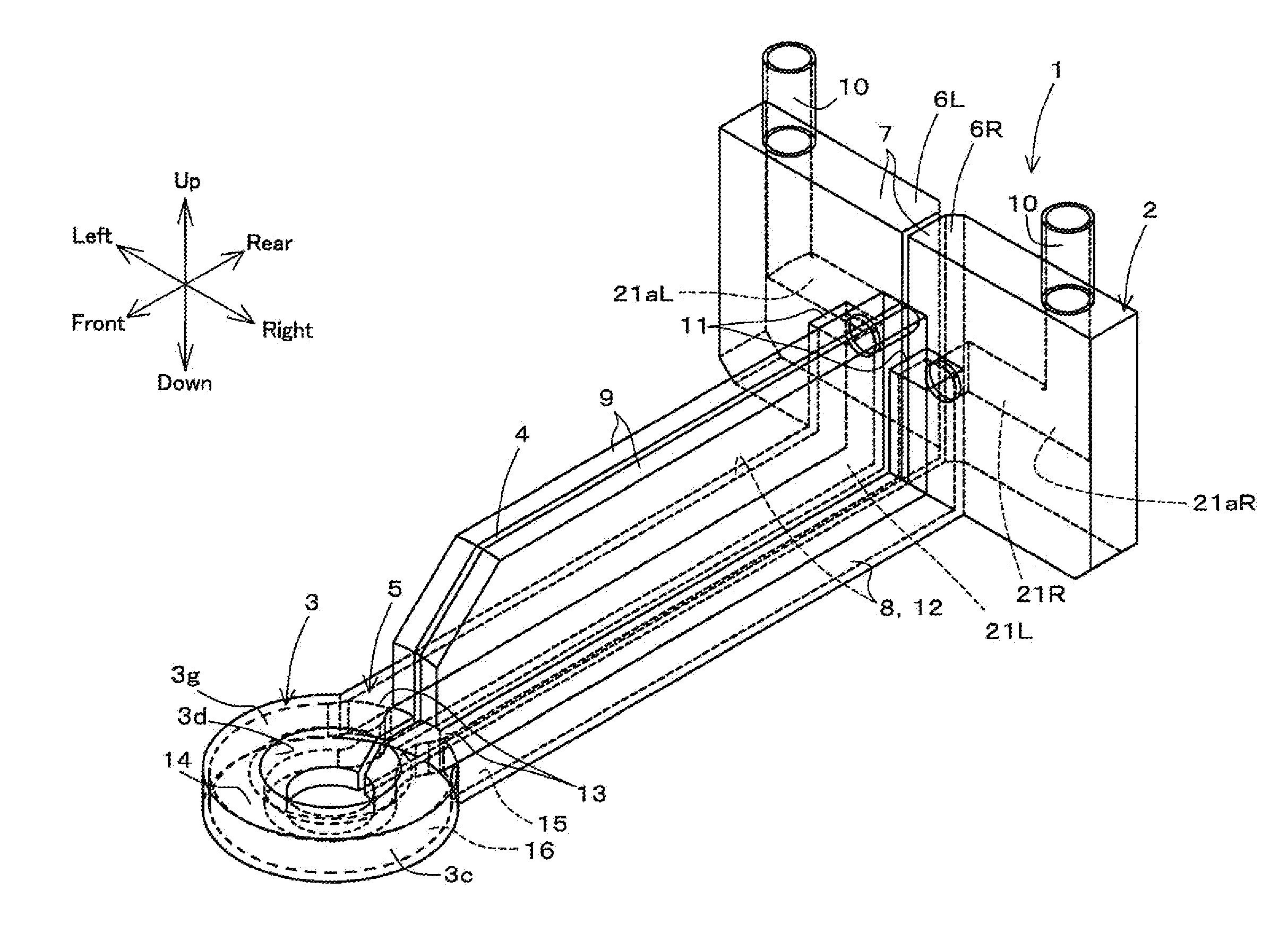

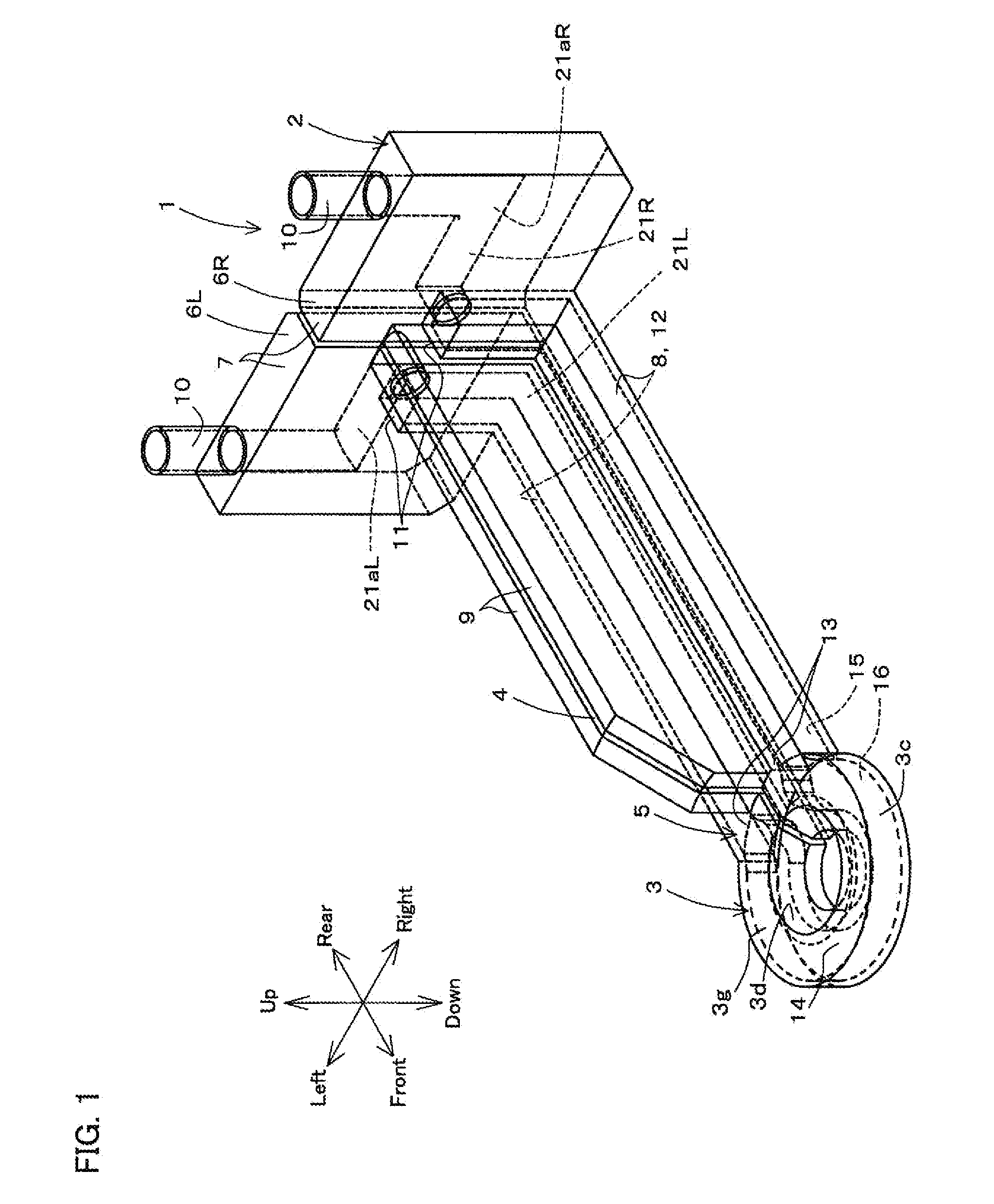

Induction heating coil and method for manufacturing induction heating coil

ActiveUS20150327335A1Improve efficiencyReduce imbalance in heat stressAdditive manufacturing apparatusCoil arrangementsCooling mediumElectrical and Electronics engineering

An induction heating coil includes a coil section configured to heat a treatment target by induction, a power supply section configured to supply power to the coil section, and a cooling medium passage that is arranged in the power supply section and the coil section, and is configured to supply a cooling medium to the coil section. The coil section, the power supply section, and the cooling medium passage are formed using a metal additive fabrication method.

Owner:KOYO THERMO SYST CO LTD

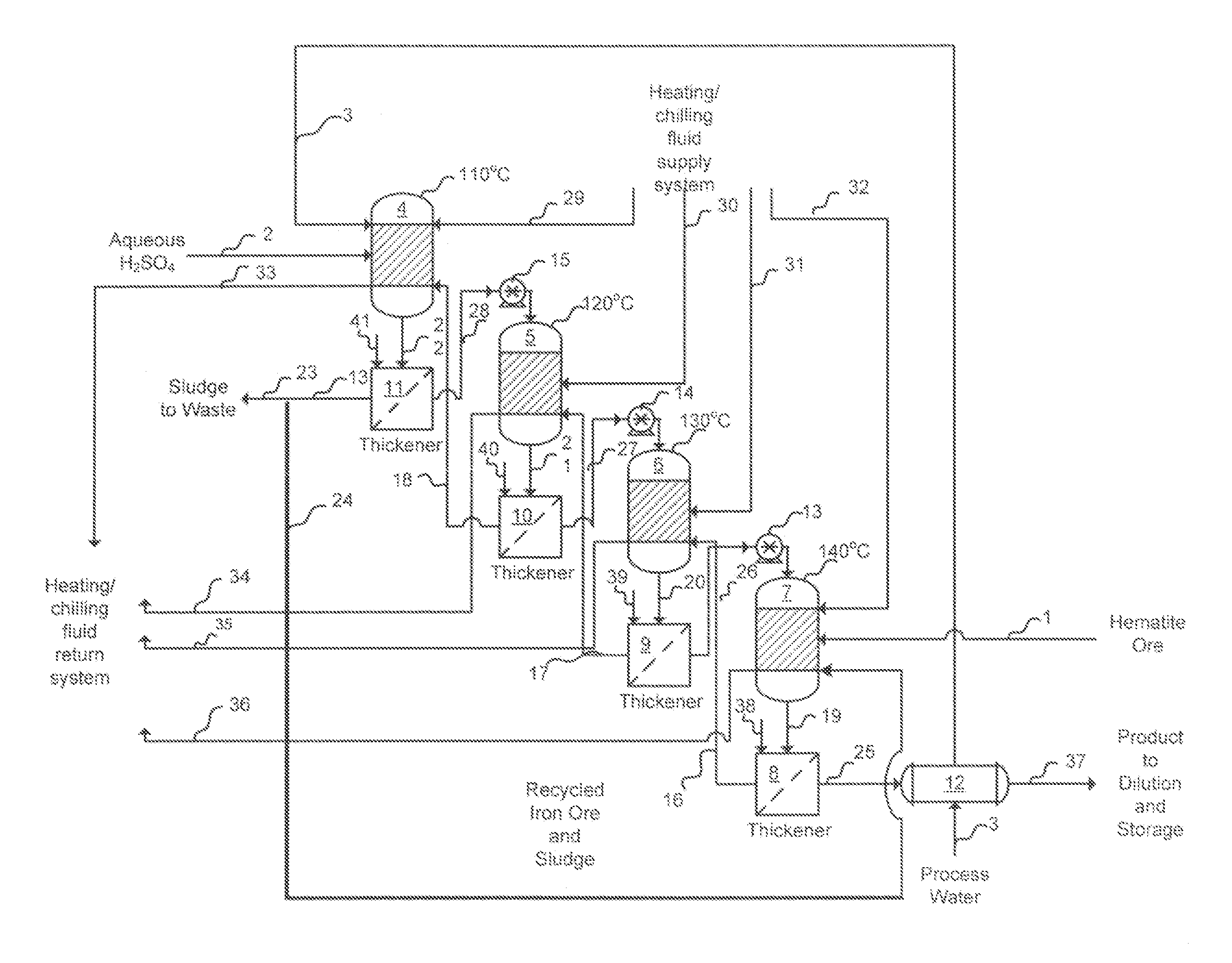

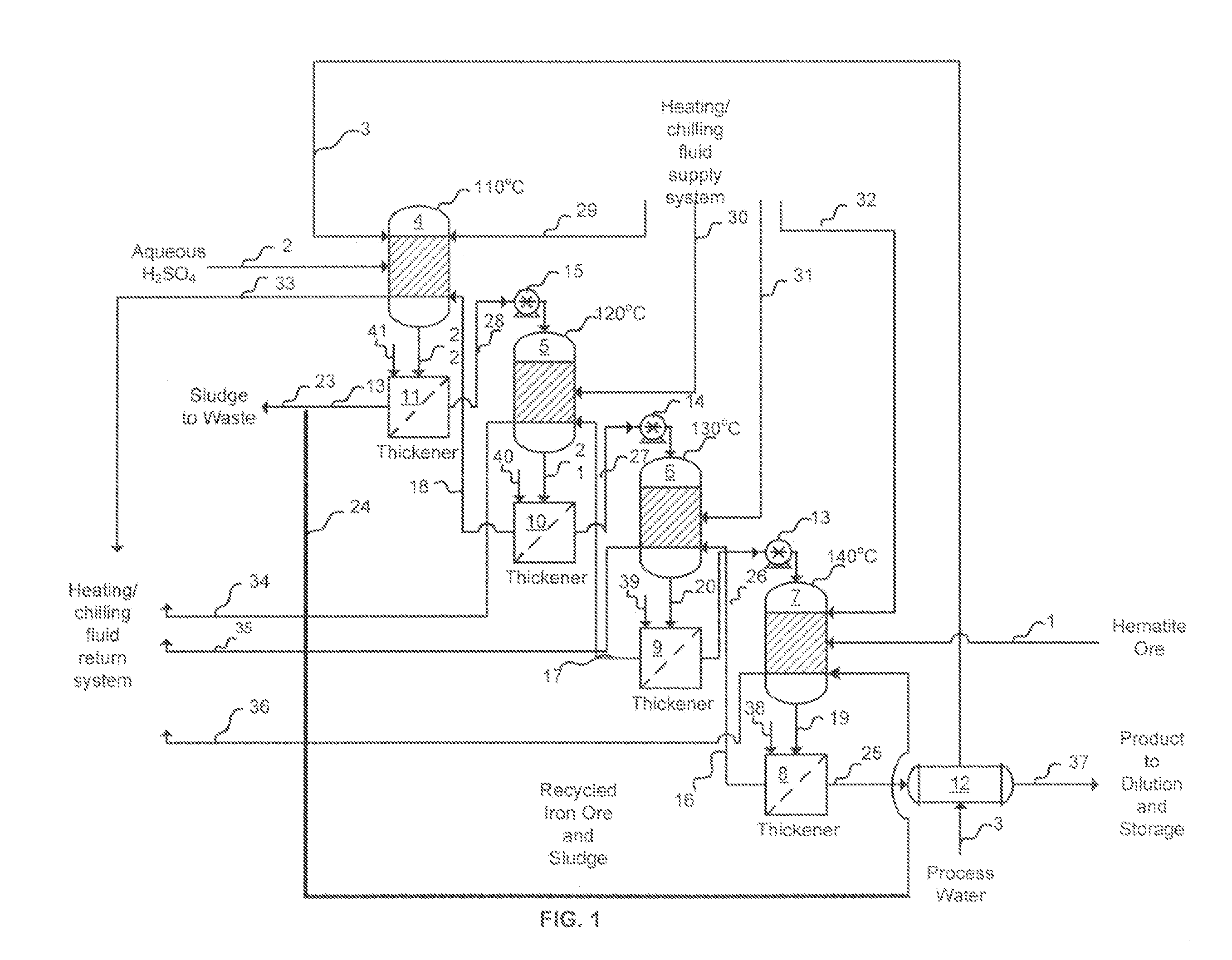

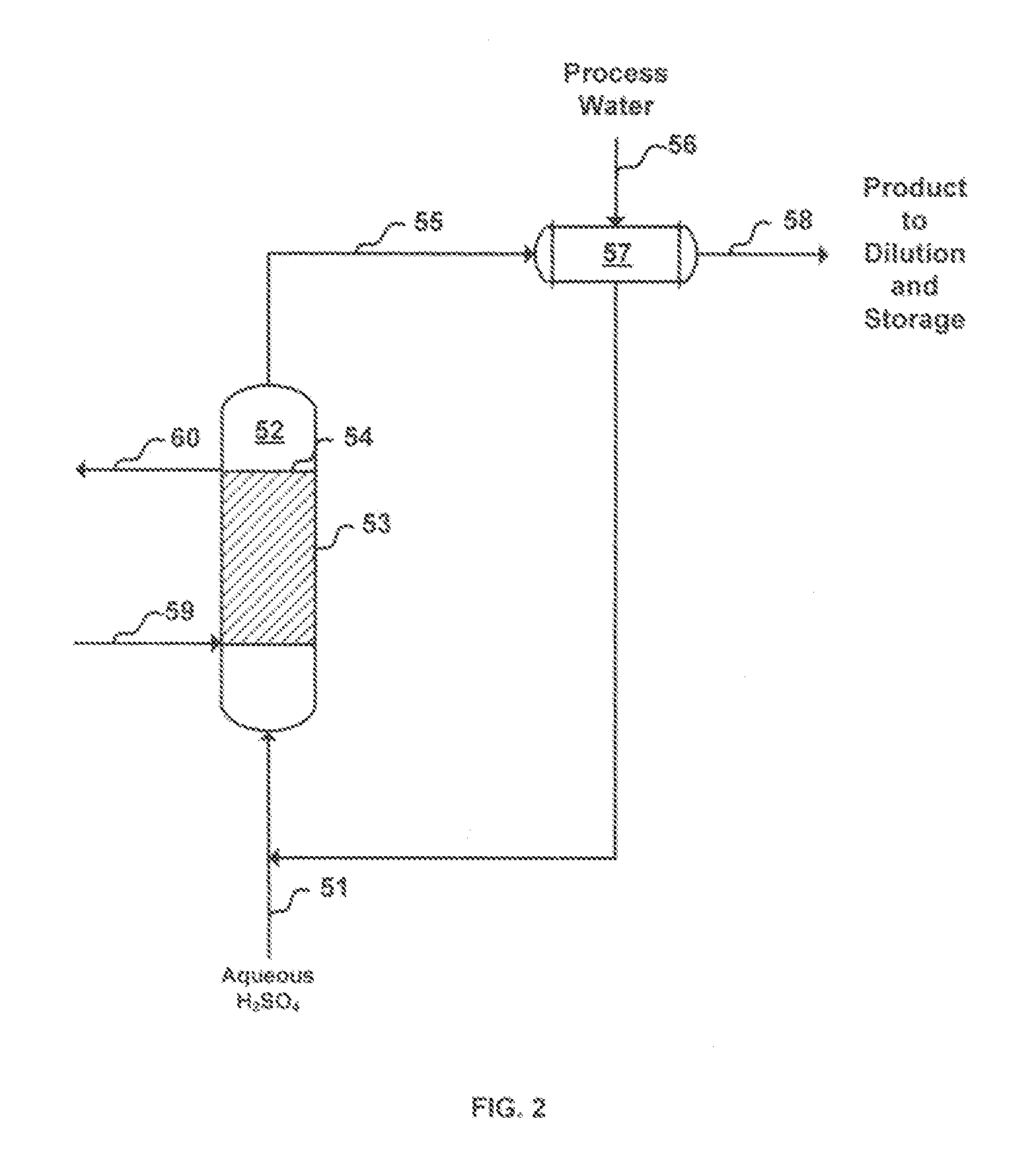

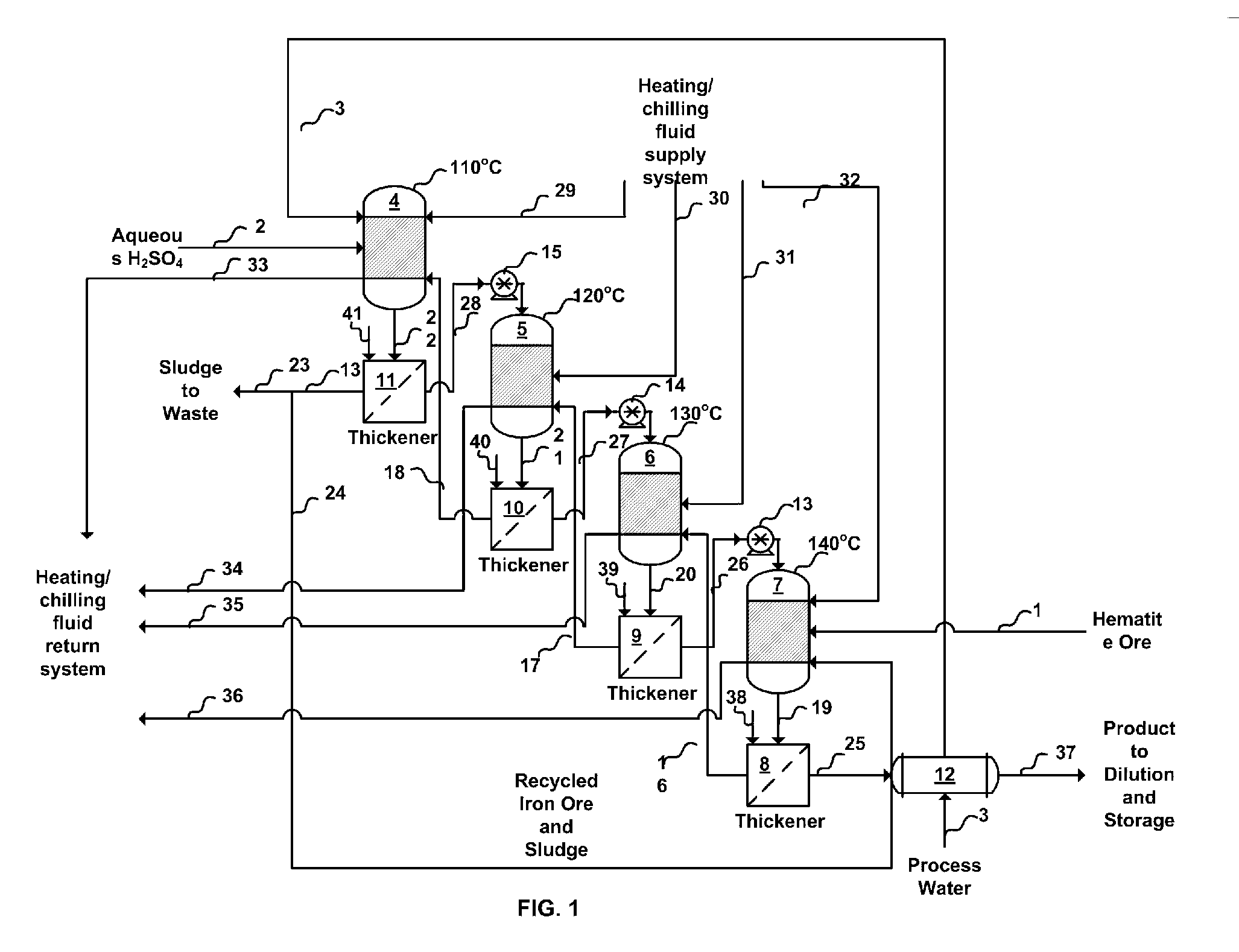

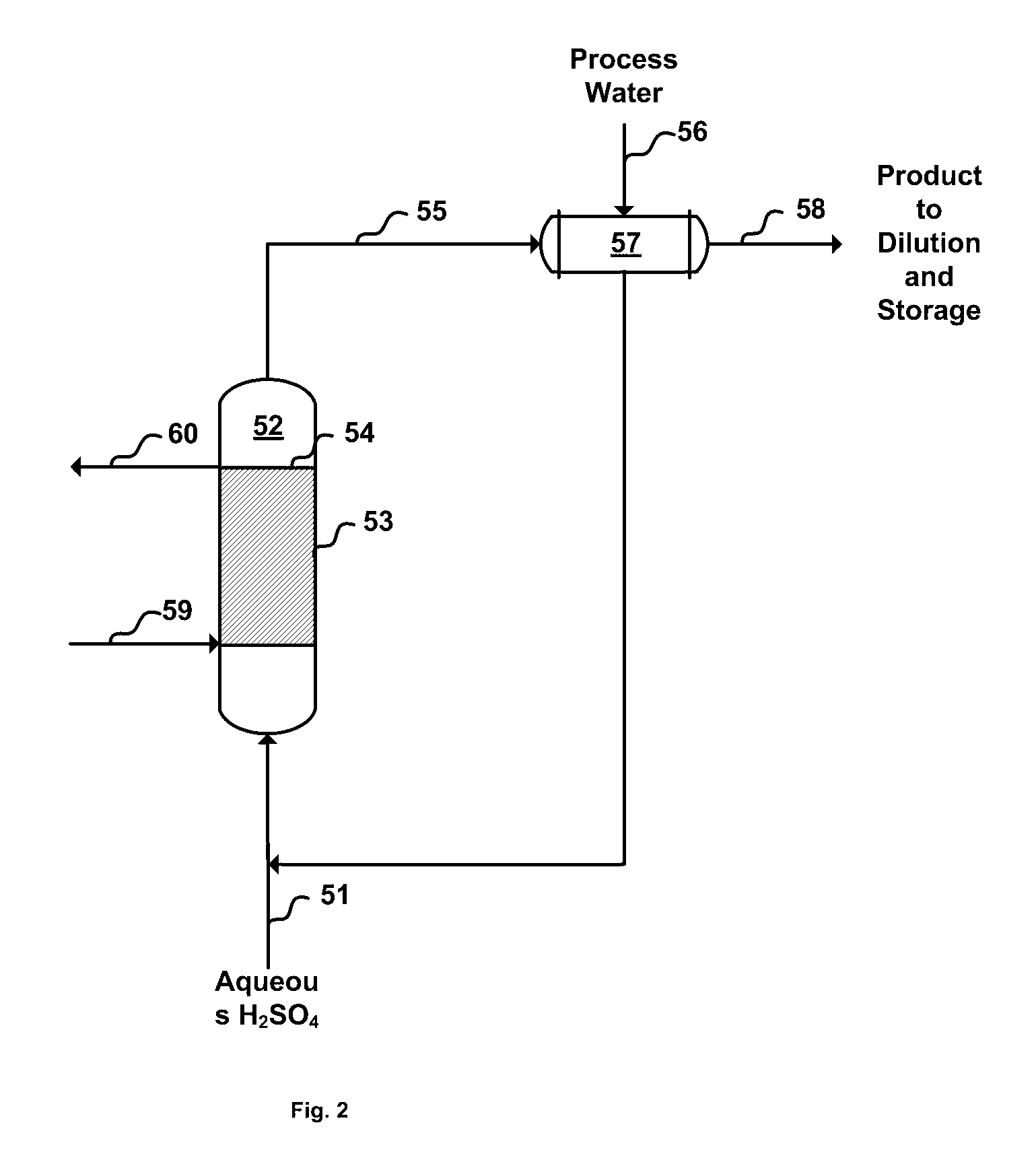

Method for ferric sulfate manufacturing

InactiveUS7387770B2Increase productionEasy to controlCobalt sulfatesIron sulfatesWaste streamIron(III) sulfate

A process is provided for the production of liquid ferric sulfate from finely-divided ferric oxide, sulfuric acid and water in a reaction system comprising at least one closed reaction vessel at temperatures ranging from about 120° C. to about 150° C. and pressures from about 25 psi to about 70 psi. Iron oxide streams are fed countercurrent to the ferric sulfate reaction product stream and to the sulfuric acid and water feeds. The continuity of the reaction is effected by re-circulating fractions while withdrawing a fraction of the liquid ferric sulfate having a trivalent iron concentration of at least 10% from the reaction vessel. Yield and efficiency are provided by controlling the rate of iron ore, sulfuric acid and specific gravity and by counter current cycling the waste stream from the reaction through the dilution water and use of a polymeric settling agent to remove unreacted iron content from the digester output.

Owner:GEN CHEM PERFORMANCE PRODS

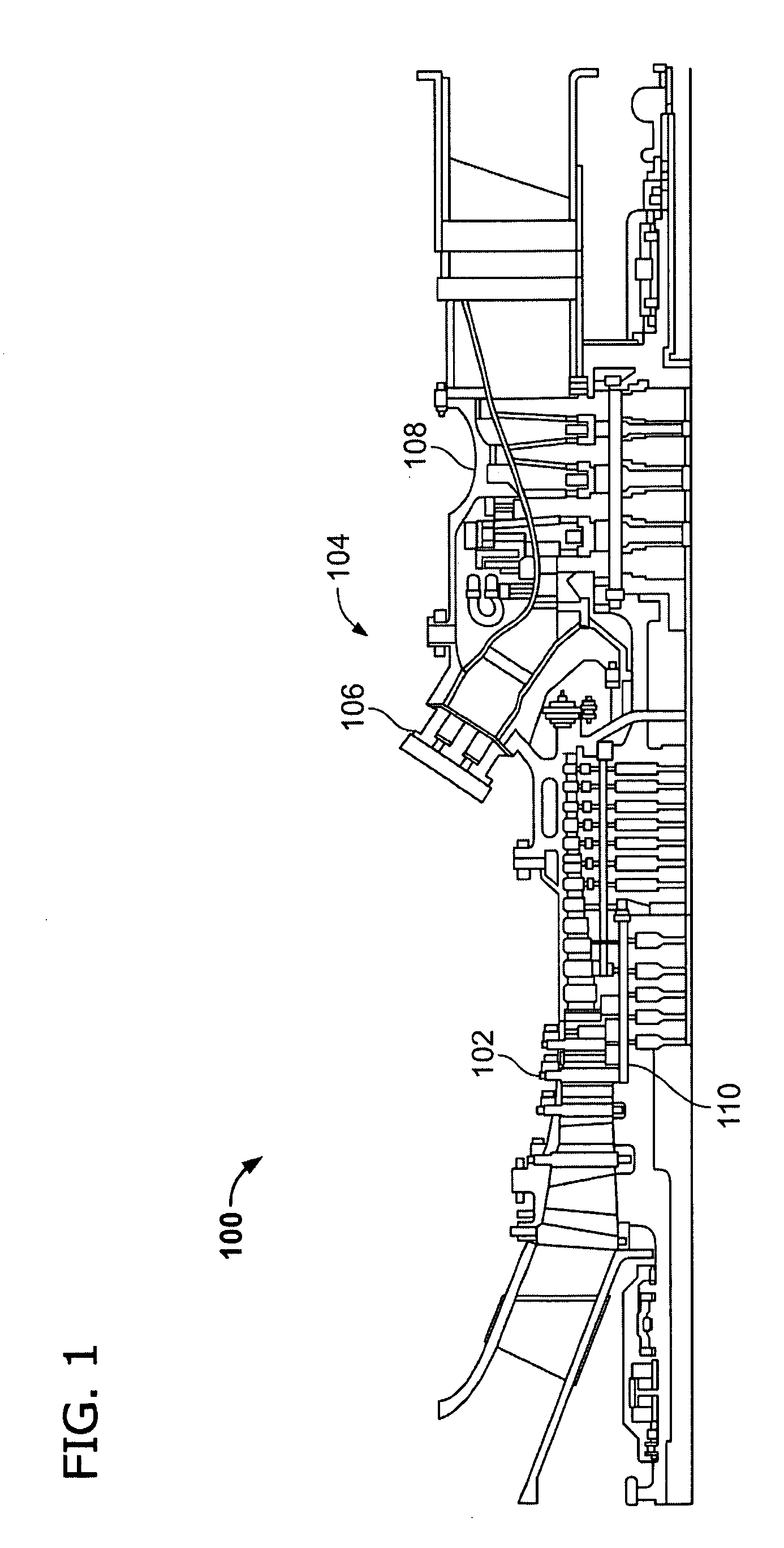

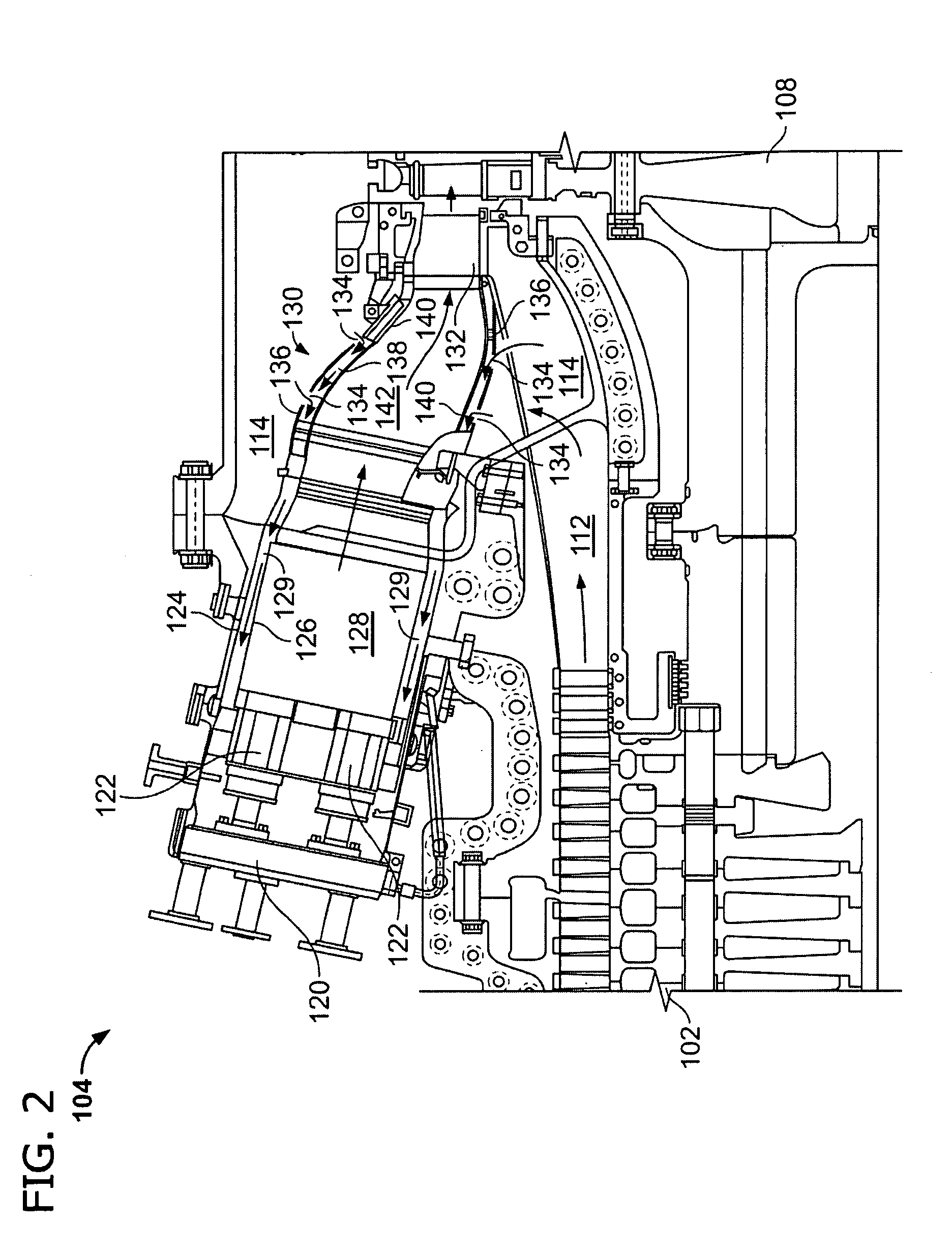

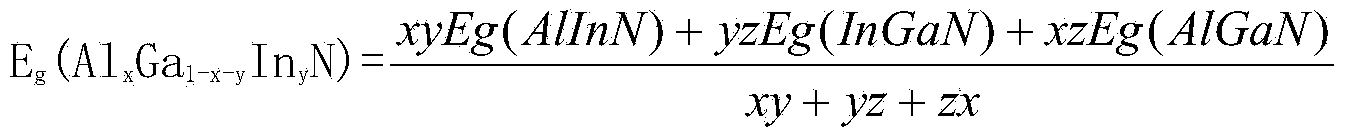

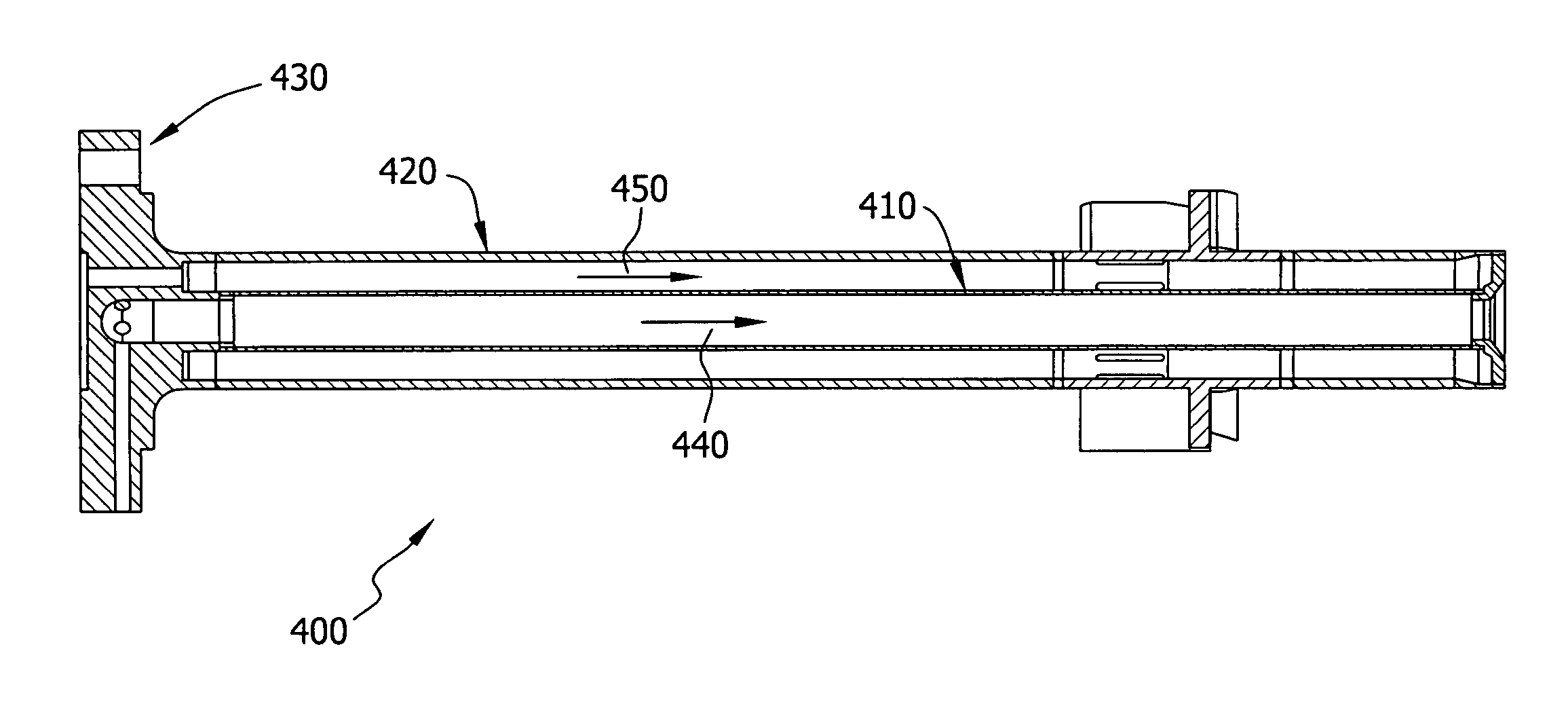

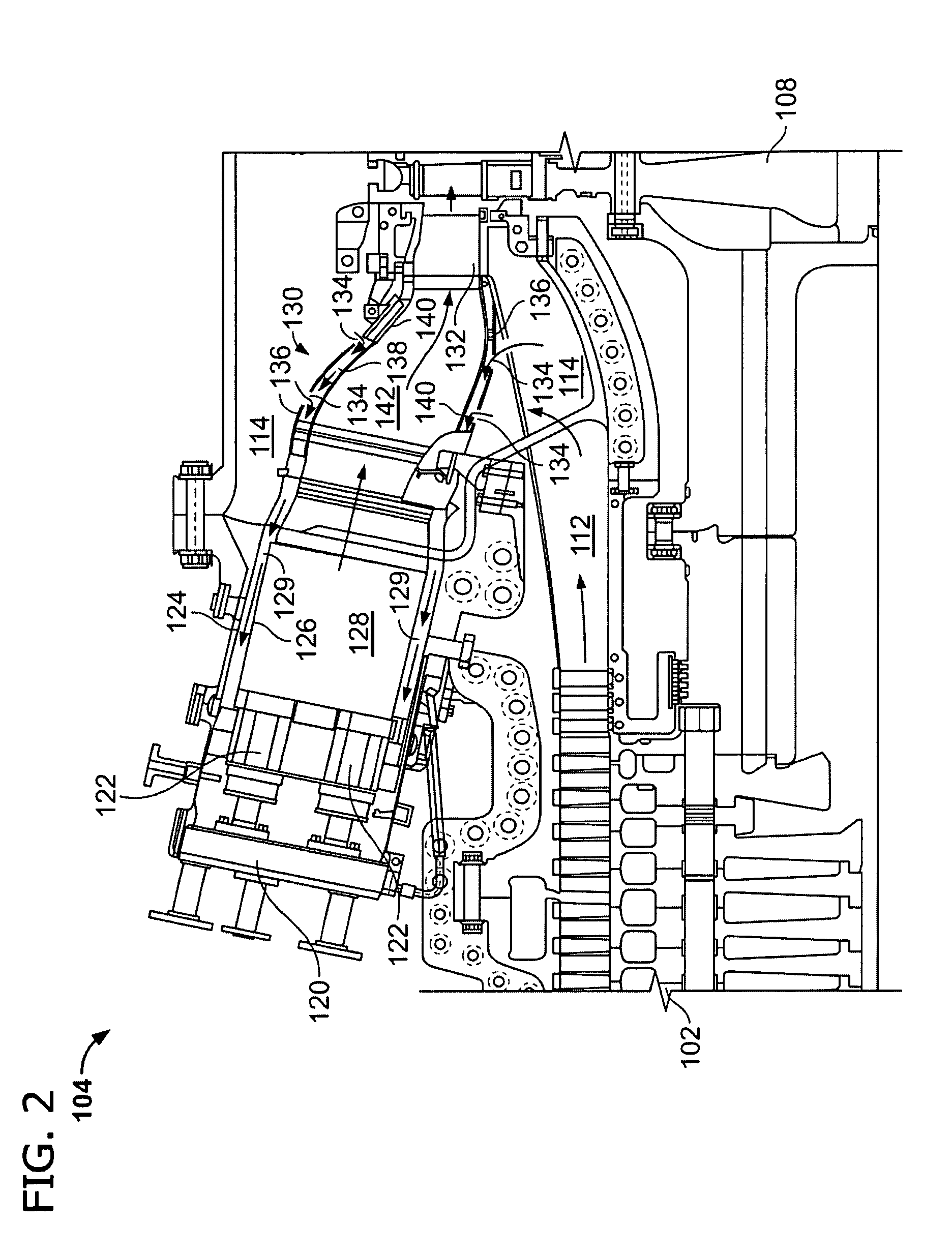

Fuel nozzle assembly for use with a gas turbine engine and method of assembling same

InactiveUS20100107639A1Easy to operateMaintaining structural robustnessContinuous combustion chamberTurbine/propulsion fuel supply systemsAerospace engineeringGas turbines

A fuel nozzle configured to channel fluid toward a combustion chamber within a gas turbine engine and a method for assembling the same are provided. The fuel nozzle includes a first hollow tube fabricated from a first material that has a first coefficient of thermal expansion and a second tube fabricated from a second material that has a second coefficient of thermal expansion that is different from the first coefficient of thermal expansion. The second tube is coupled within the first tube such that the first tube substantially circumscribes the second tube, and the second tube thermally expands approximately at a same rate as the first tube during fuel nozzle operation.

Owner:GENERAL ELECTRIC CO

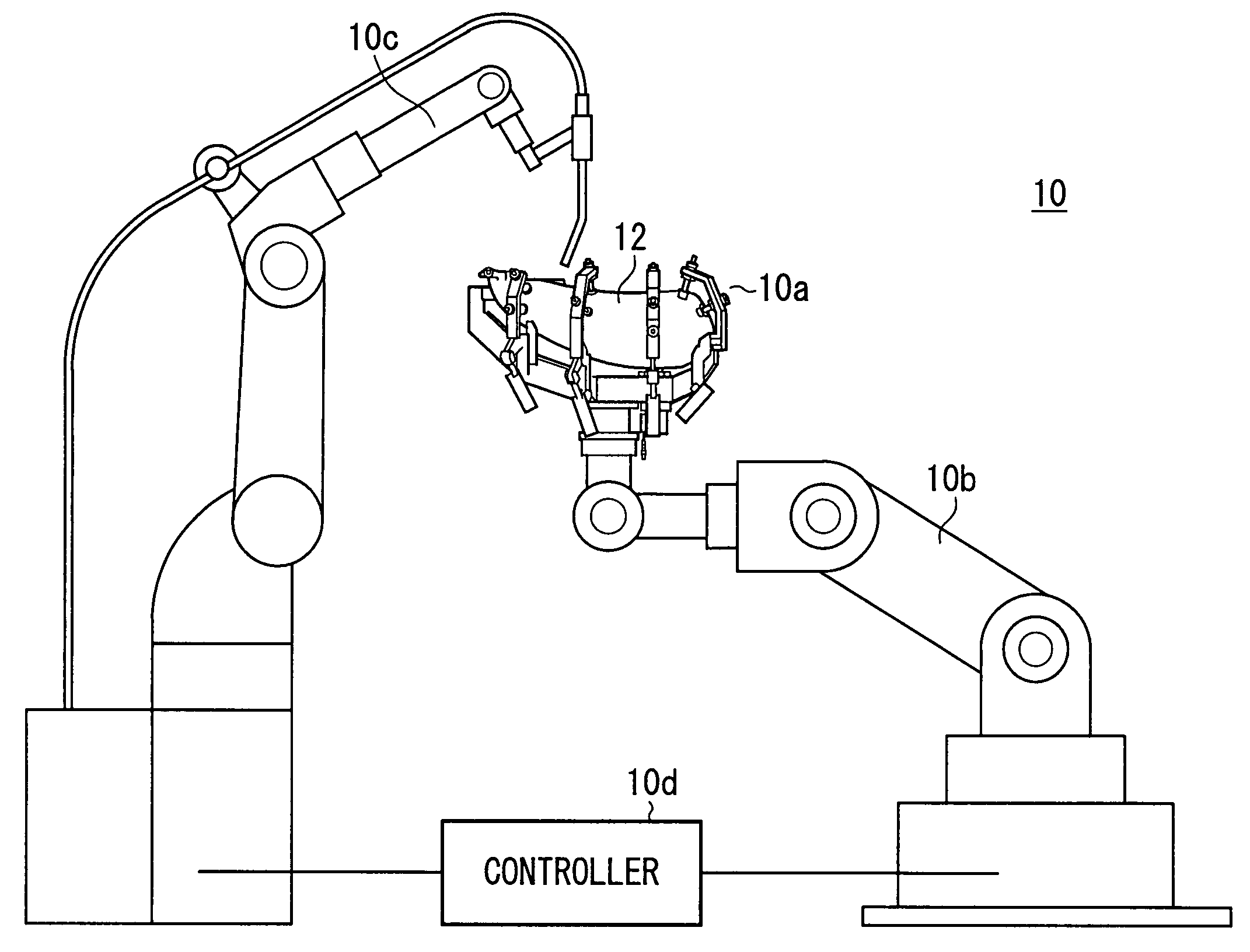

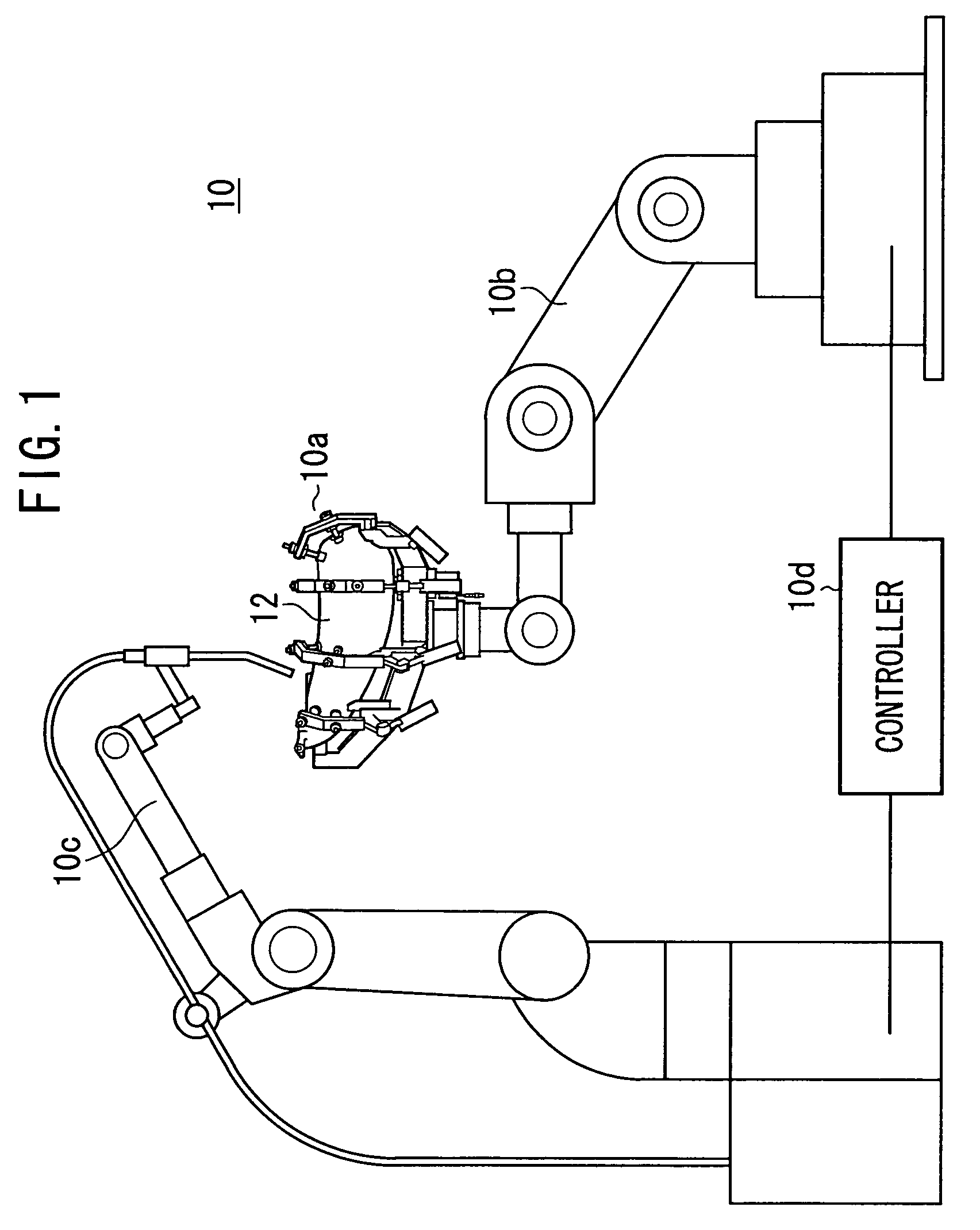

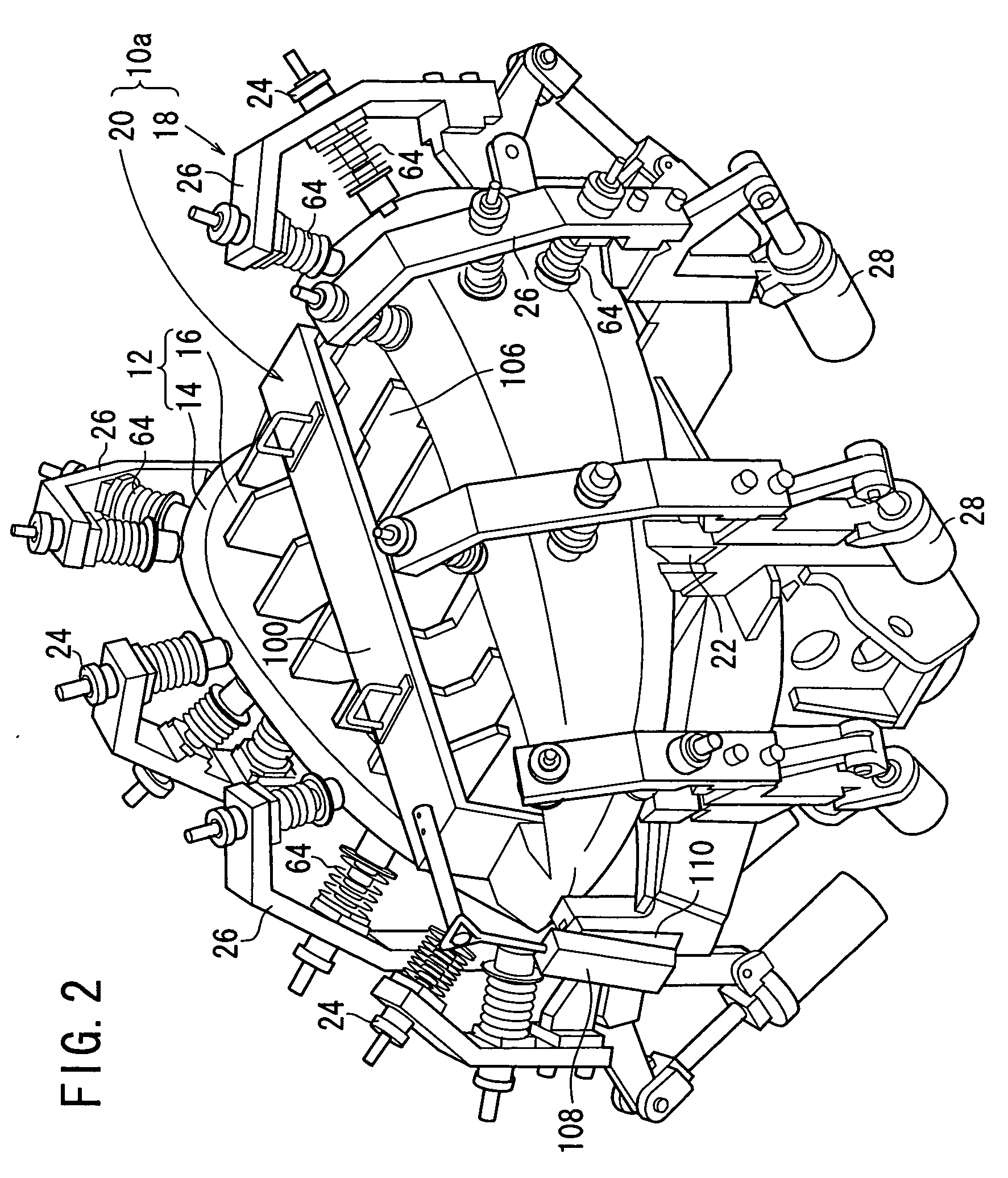

Welding method, welding system and welding jig

InactiveUS20060151572A1Reduce thermal strainPrevent crackingElectric heatingWelding/cutting auxillary devicesThermal deformationEngineering

A plurality of attachments having springs hold the outer plate of a fuel tank, and an inner jig positions the inner plate. The attachments are attached to clamp arms which are opened / closed by cylinders. When the overlap portion between the outer and inner plates is welded, the thermal deformation caused by welding is accommodated by the springs. The attachments are spaced from the fuel tank in the order in which the welding point is approached.

Owner:HONDA MOTOR CO LTD

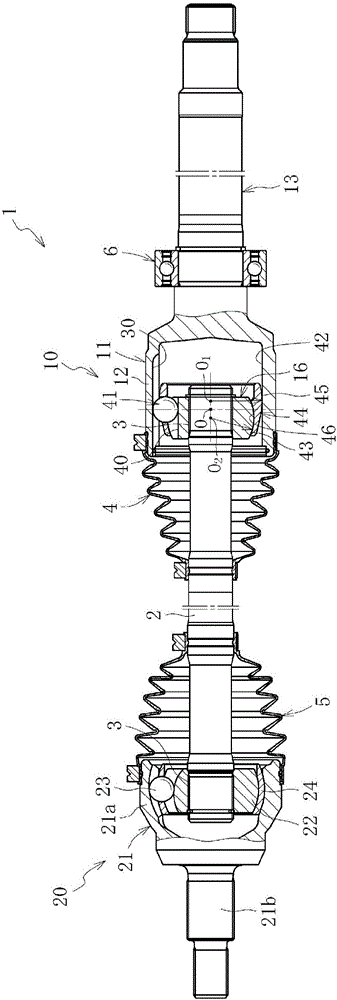

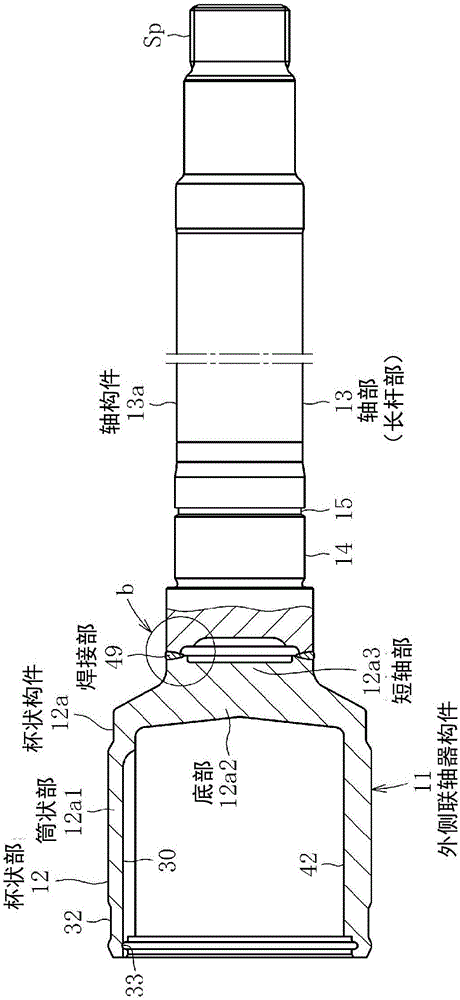

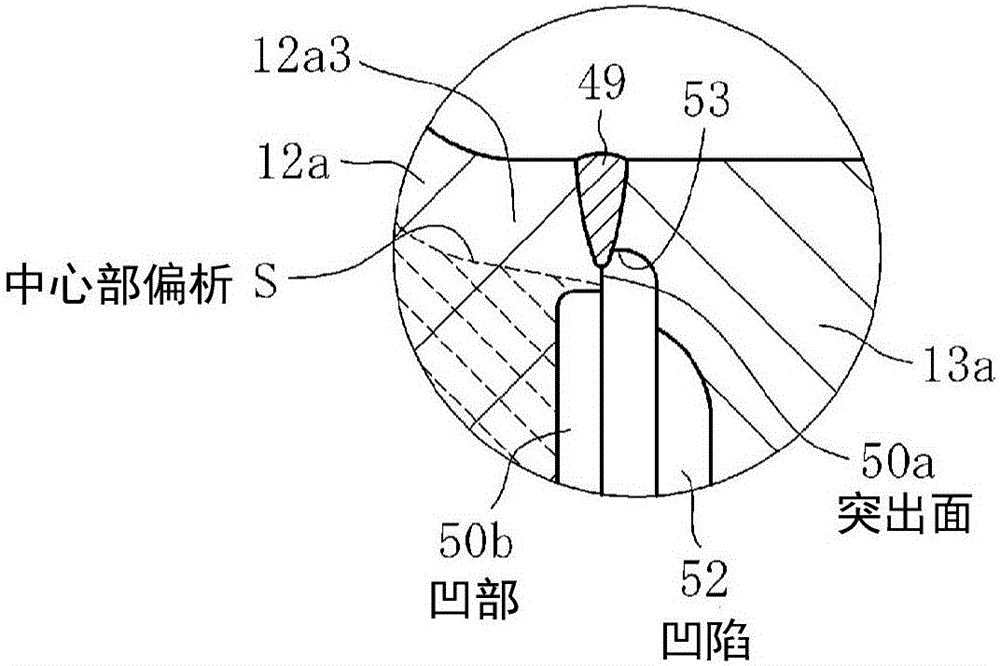

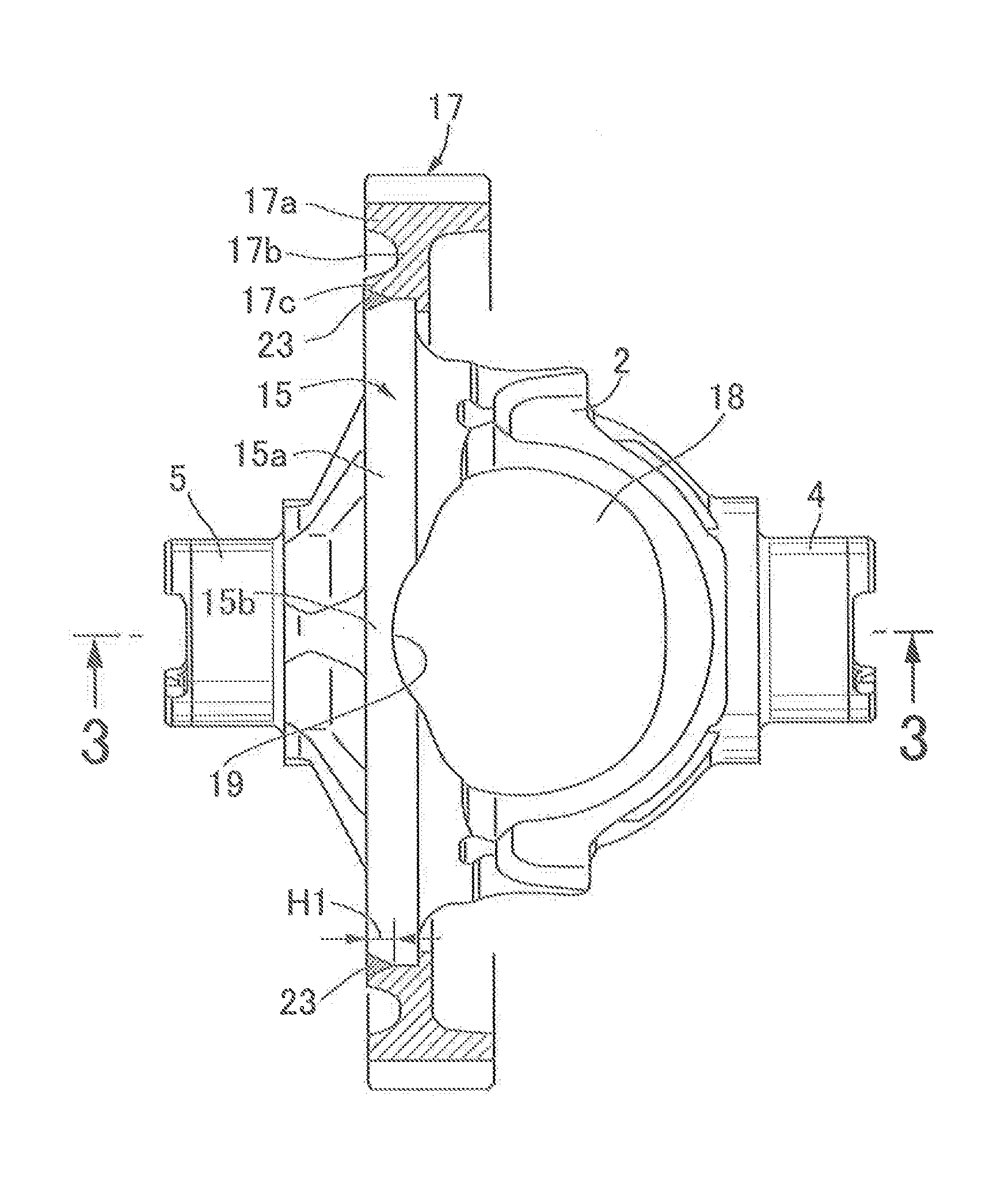

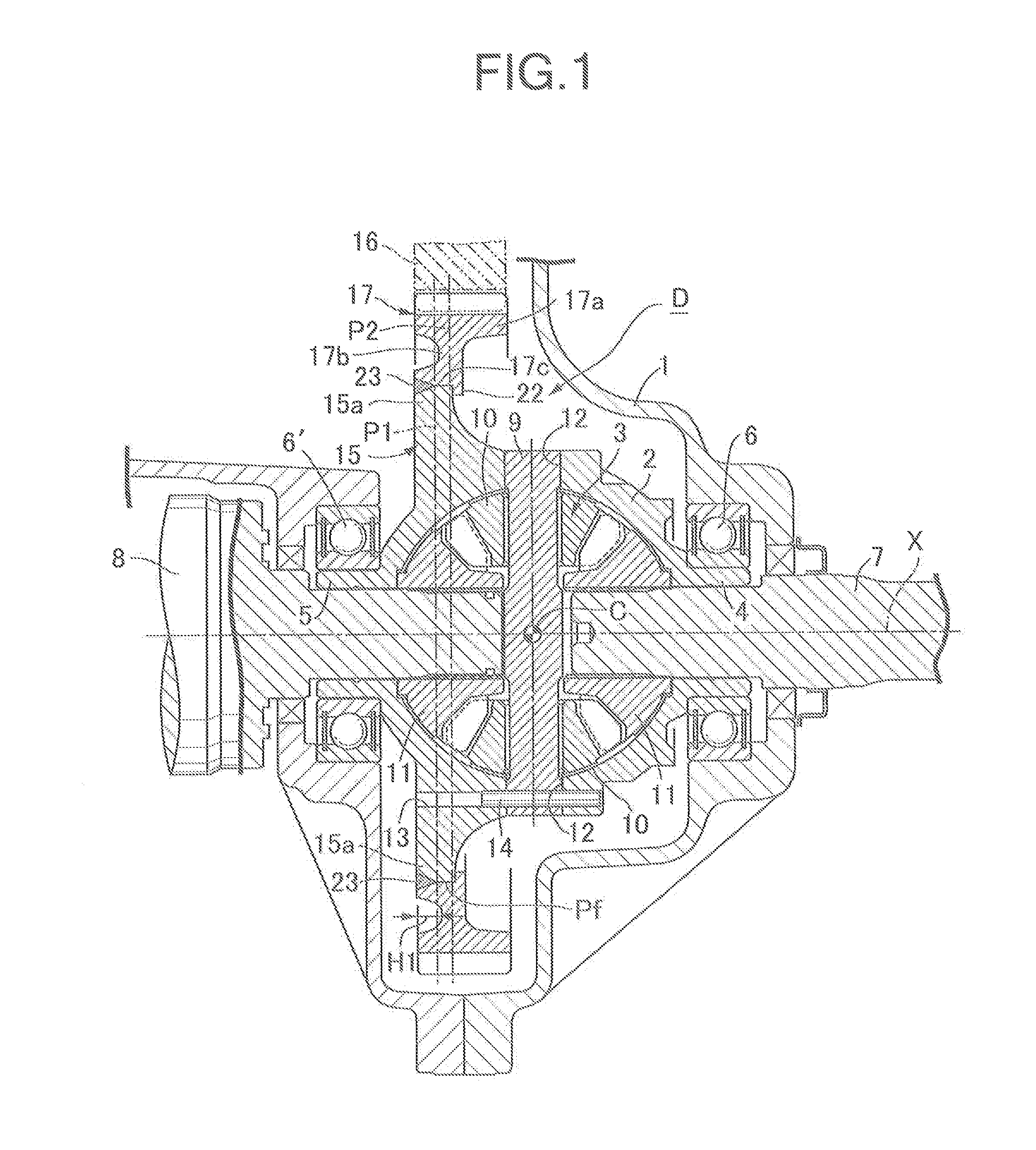

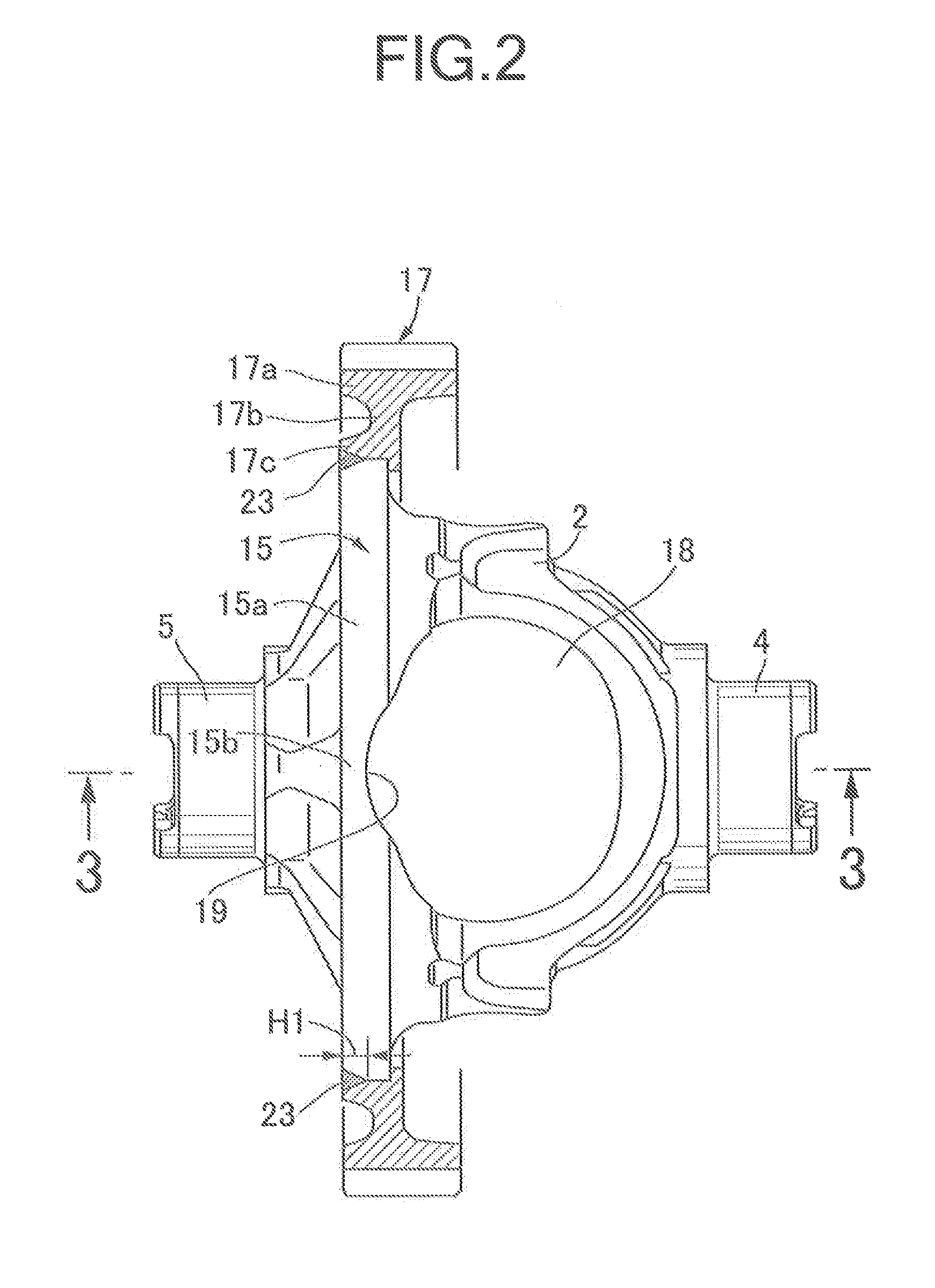

Constant velocity universal joint outer joint member and manufacturing method for same

ActiveCN106662160AImprove welding qualityGuaranteed StrengthYielding couplingCouplings for rigid shaftsHigh energyUniversal joint

In the present invention, a cup member (12a) is provided with a cylinder part (12a1), a bottom part (12a2), and a short shaft (12a3) that is a solid shaft and has a weld end face (50) on an end. A shaft member (13a) is a solid shaft and has a weld end face (51) on one end. An annular welded part (49) is formed by butting the weld end face of the cup member against the weld end face of the shaft member and focusing a high energy density beam from the outer diameter side to weld the weld end faces to each other. At this time, center segregation (S) is prevented from interfering with the welded part. The cup member is formed by a forging step comprising swaging in which a columnar billet is swaged continuously in multiple stages, pressing in which a cylindrical part and a short shaft part are formed, and squeezing in which the cylindrical part is squeezed, and during the swaging process, a region corresponding to the bottom side of the billet cup member is narrowed. Thus, the strength and quality of a constant velocity universal joint outer joint member in which a cup member and shaft member are joined by welding can be improved.

Owner:NTN CORP

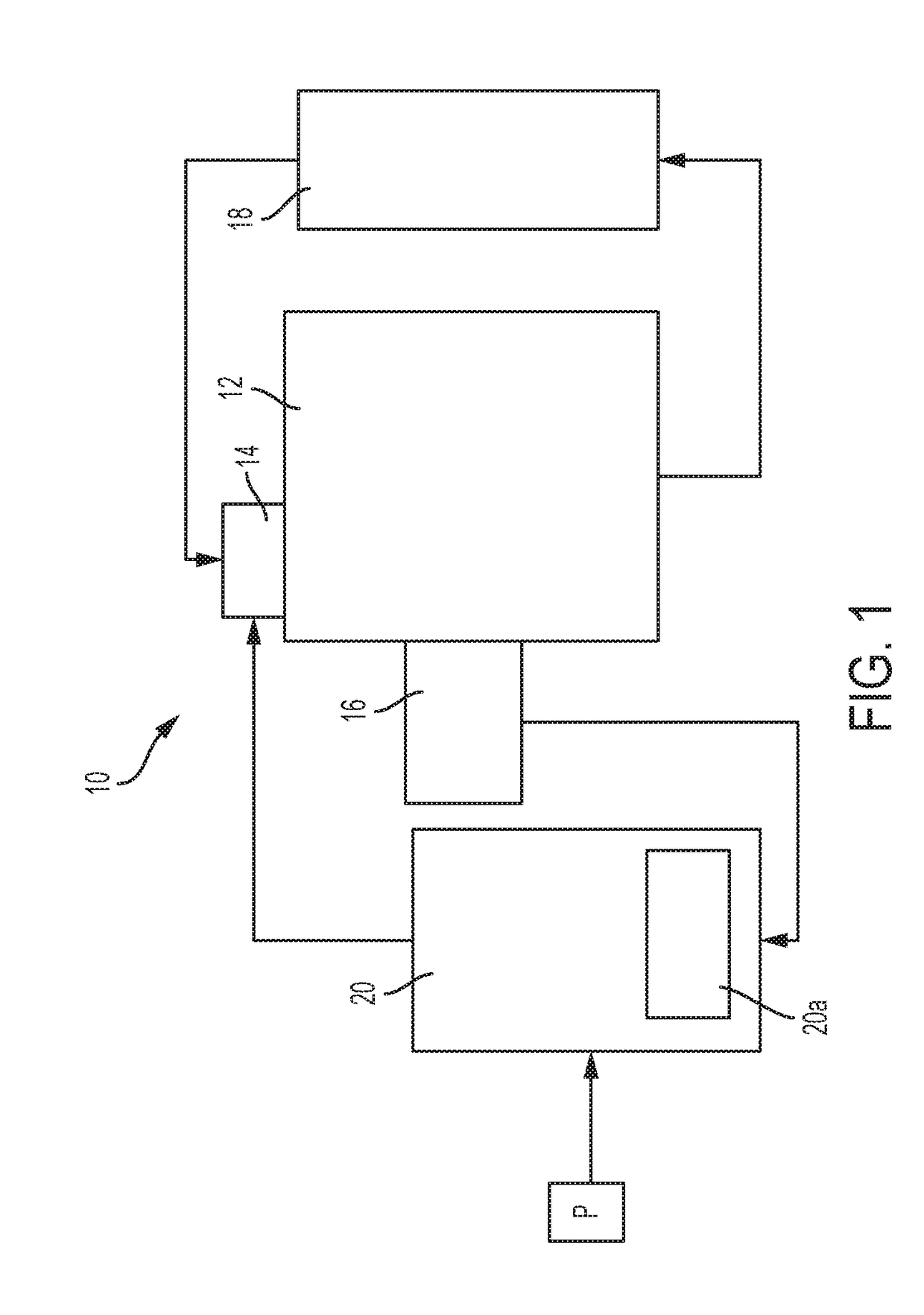

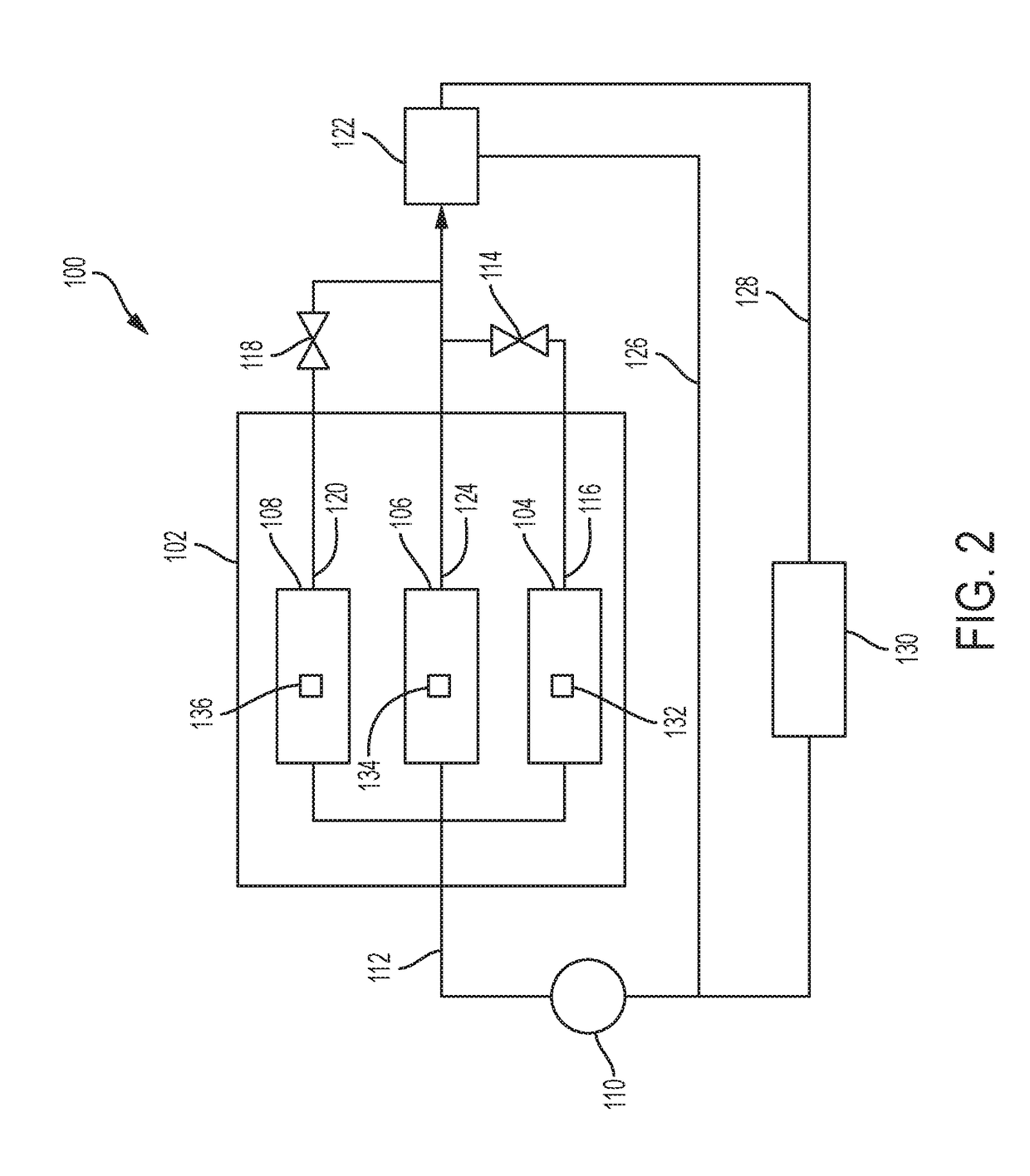

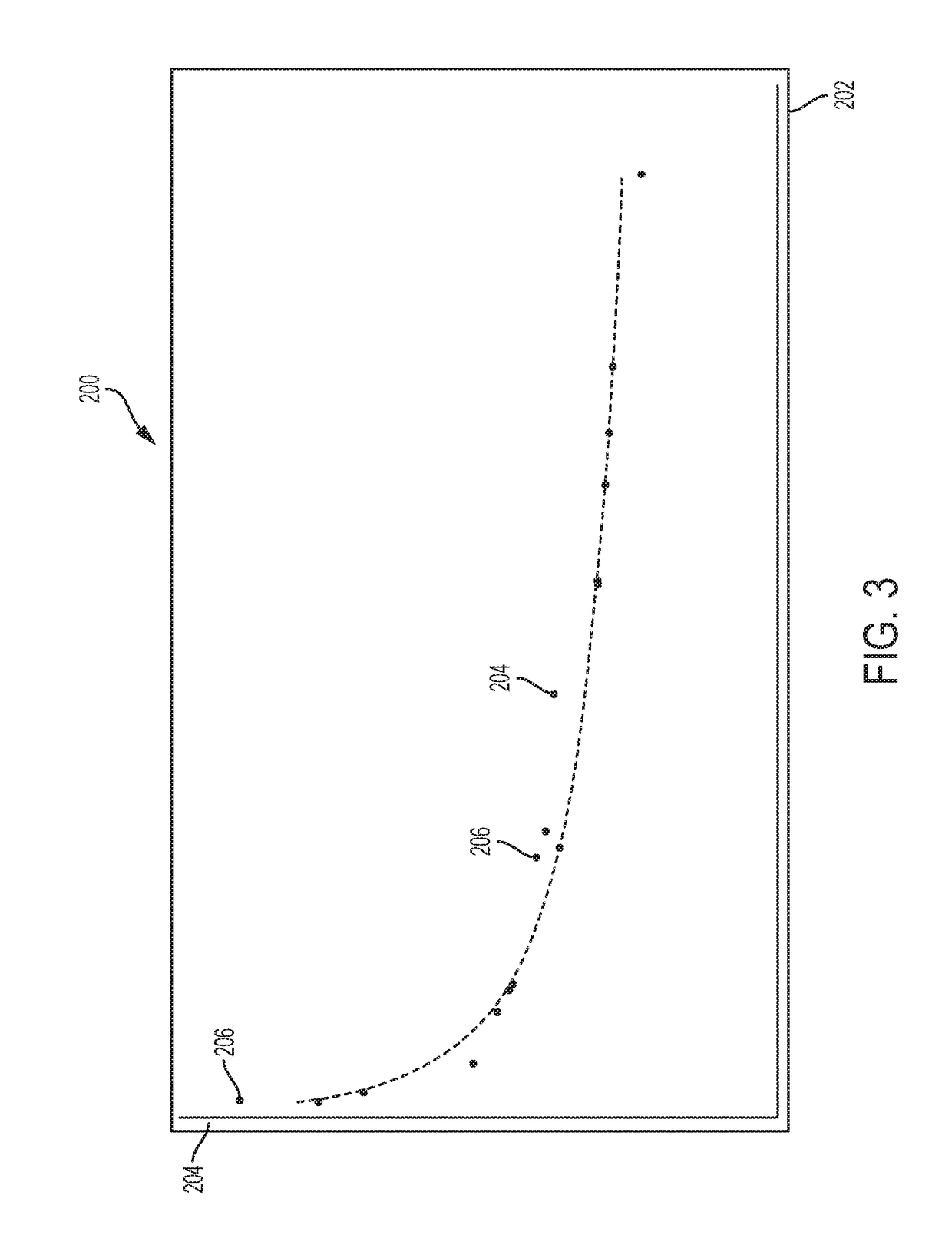

Method and system for coolant flow control for a prime mover in a vehicle propulsion system

InactiveUS20190085752A1Improve fuel economyImprove efficiencyLiquid coolingCoolant flow controlControl theoryStreamflow

A vehicle propulsion system includes a prime mover having a coolant inlet and coolant outlet, a coolant flow controller having a flow control inlet in communication with the prime mover coolant outlet, and a flow control outlet in communication with the prime mover coolant inlet, and a controller that determines a coefficient based upon a power of the prime mover, and that provides a coolant flow command signal to the coolant flow controller based upon the power of the prime mover.

Owner:GM GLOBAL TECH OPERATIONS LLC

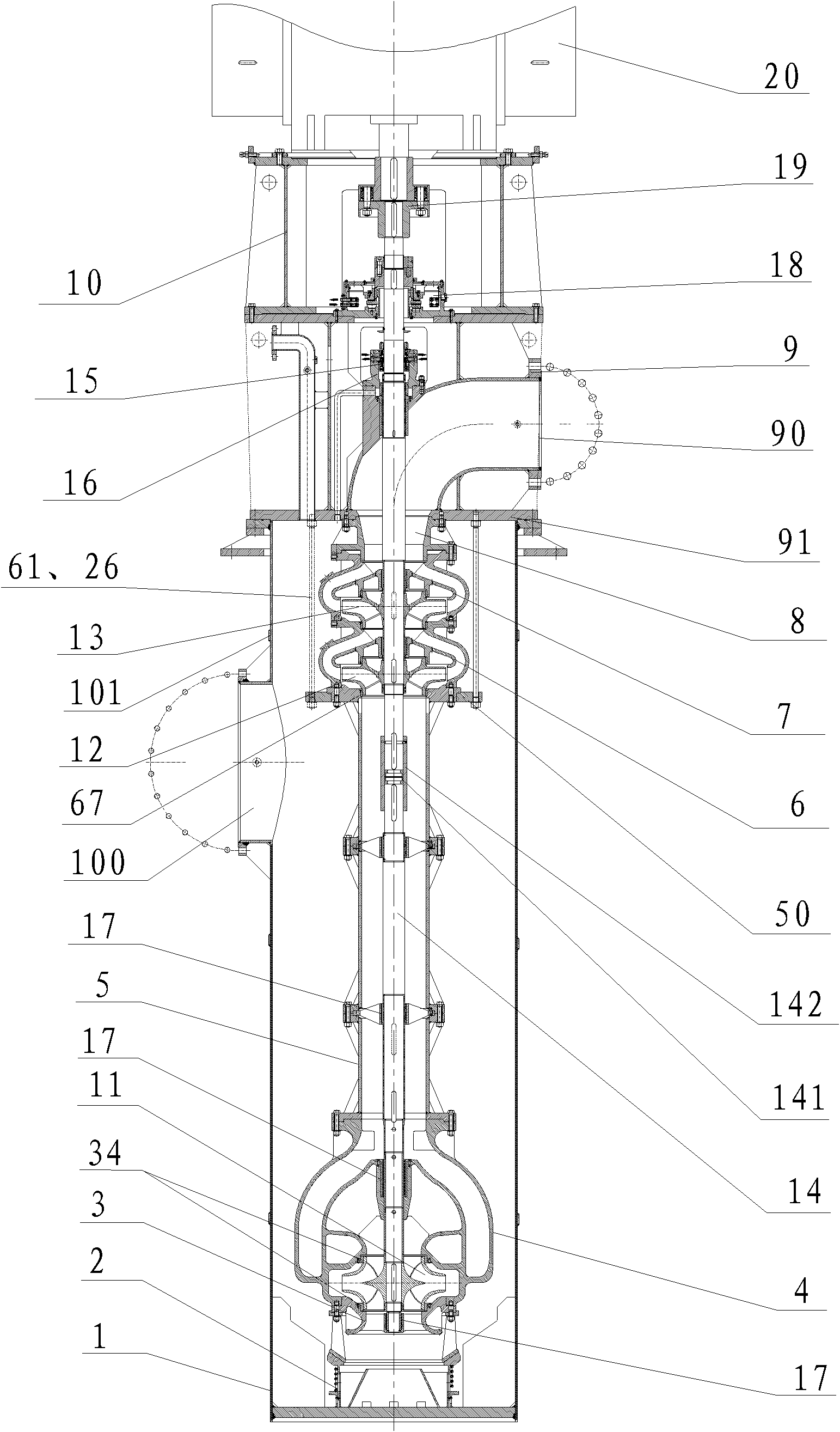

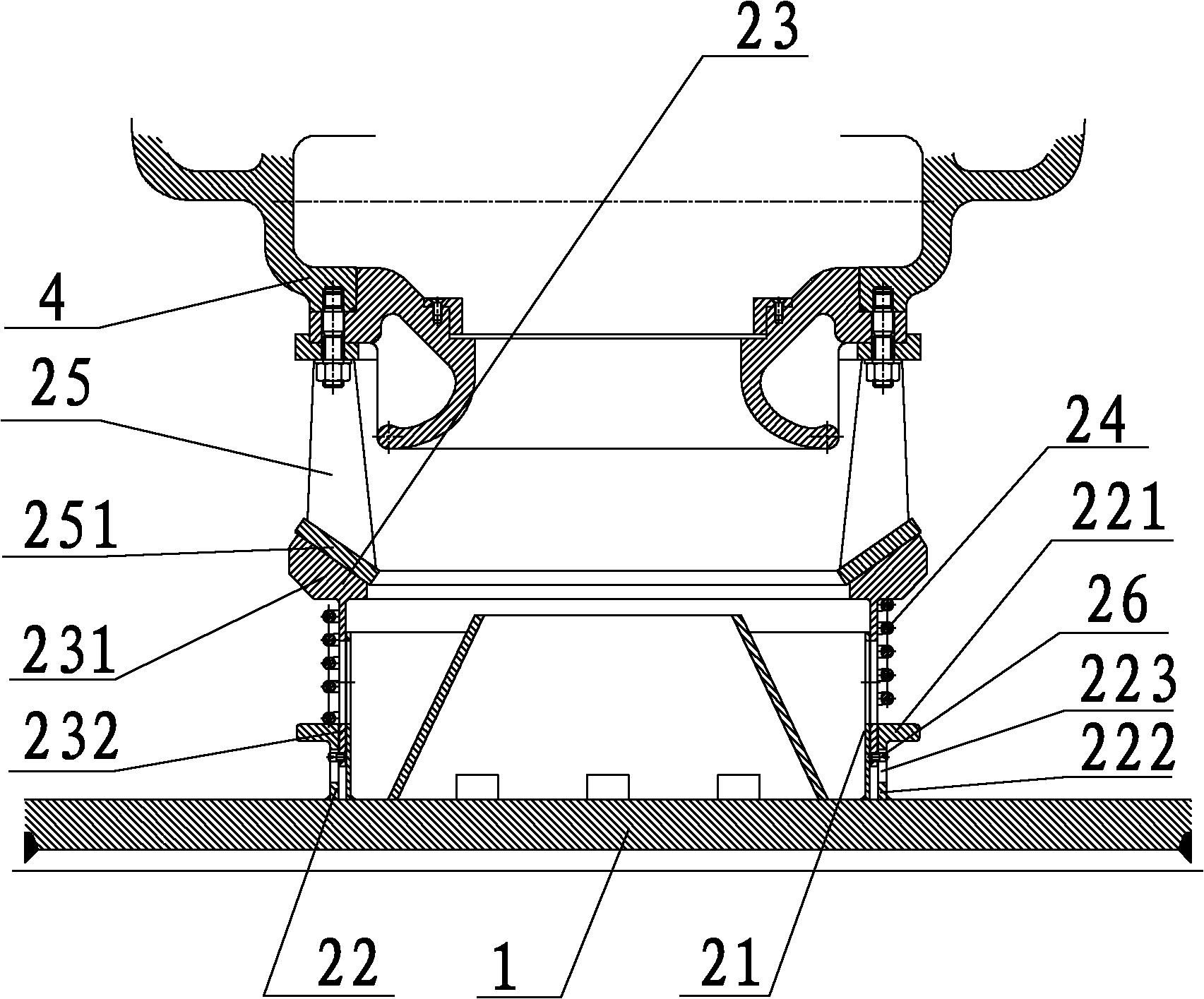

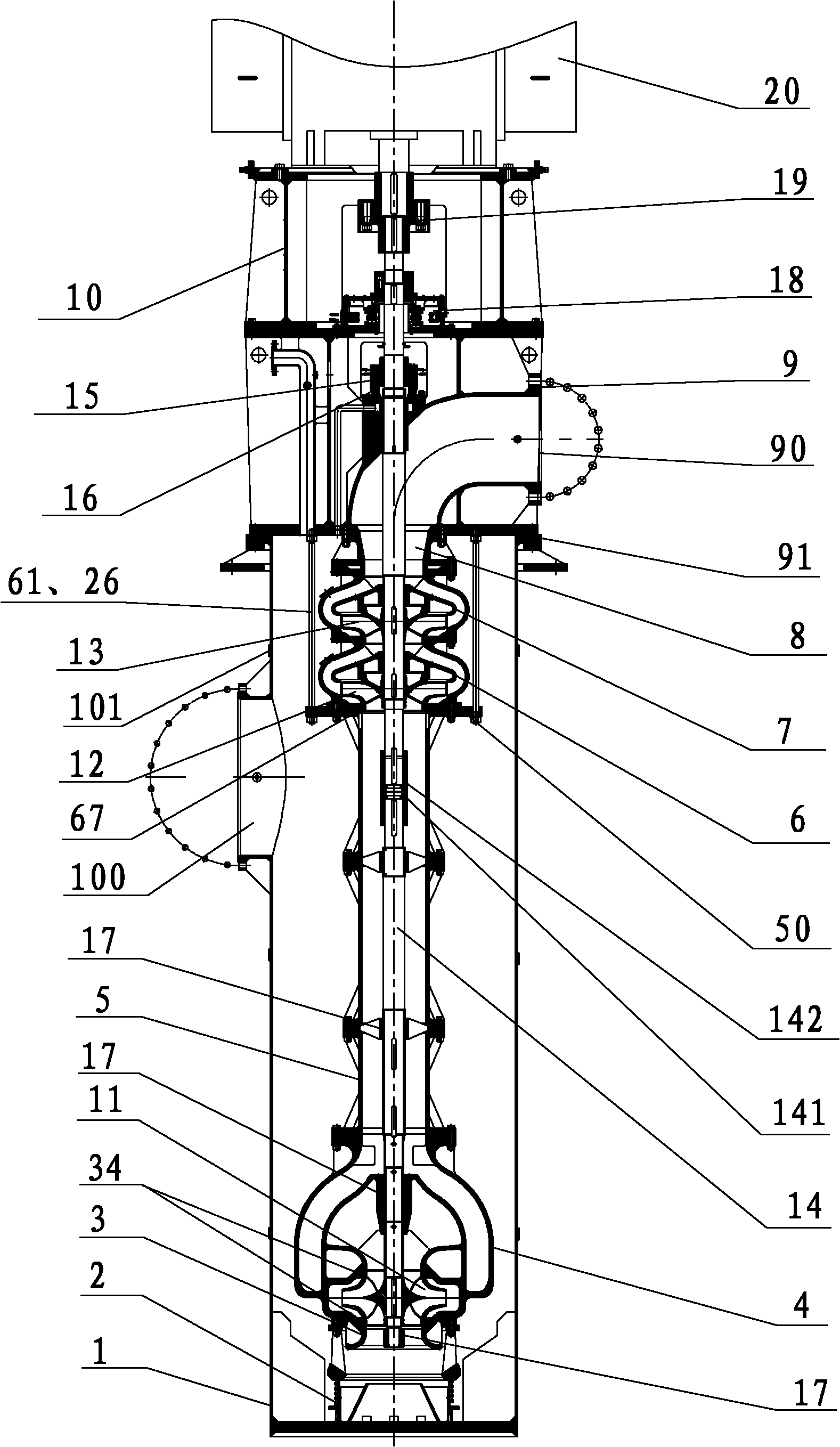

Condensate pump used in nuclear power station

ActiveCN102116319AGuaranteed service life requirement of 60 yearsReduce thermal strainPump componentsPumpsImpellerNuclear power

The invention discloses a condensate pump used in a nuclear power station. The condensate pump comprises an outer cylinder body, a pump body, a water outlet case body, a motor frame, a pump shaft, a first stage impeller, a second stage impeller, a last stage impeller, a mechanical seal, a bearing component and a motor, wherein the motor frame is fixed at the upper end of the water outlet case body; the mechanical seal is arranged in an inner cavity of the water outlet case body through a seal case body; the bearing component comprises a plurality of guide bearings and a vertical thrust bearing; the motor is fixed at the upper end of the motor frame and connected to the upper end of the pump shaft; the pump body comprises a double-suction spiral case body, a straight pipe, the second stage guide vane and the last stage guide vane which are arranged in an inner cavity of the outer cylinder body and coaxially connected with each other in sequence from bottom to up; the water outlet case body is fixed at the upper end of the outer cylinder body and connected with the last stage guide vane; a flange mounted on the peripheral surface of a top plate of the straight pipe is connected with a bottom plate of the water outlet case body through a plurality of penetrating rods and nuts which are evenly distributed in the radial direction, so as to grip the second stage guide vane and the last stage guide vane; and an auxiliary support device is further arranged between the pump body and the outer cylinder body.

Owner:SHANGHAI APOLLO MACHINERY

Method for Ferric Sulfate Manufacturing

InactiveUS20070048213A1Increase productionEasy to controlCobalt sulfatesIron sulfatesWaste streamIron(III) sulfate

A process is provided for the production of liquid ferric sulfate from finely-divided ferric oxide, sulfuric acid and water in a reaction system comprising at least one closed reaction vessel at temperatures ranging from about 120° C. to about 150° C. and pressures from about 25 psi to about 70 psi. Iron oxide streams are fed countercurrent to the ferric sulfate reaction product stream and to the sulfuric acid and water feeds. The continuity of the reaction is effected by re-circulating fractions while withdrawing a fraction of the liquid ferric sulfate having a trivalent iron concentration of at least 10% from the reaction vessel. Yield and efficiency are provided by controlling the rate of iron ore, sulfuric acid and specific gravity and by counter current cycling the waste stream from the reaction through the dilution water and use of a polymeric settling agent to remove unreacted iron content from the digester output.

Owner:GEN CHEM PERFORMANCE PRODS

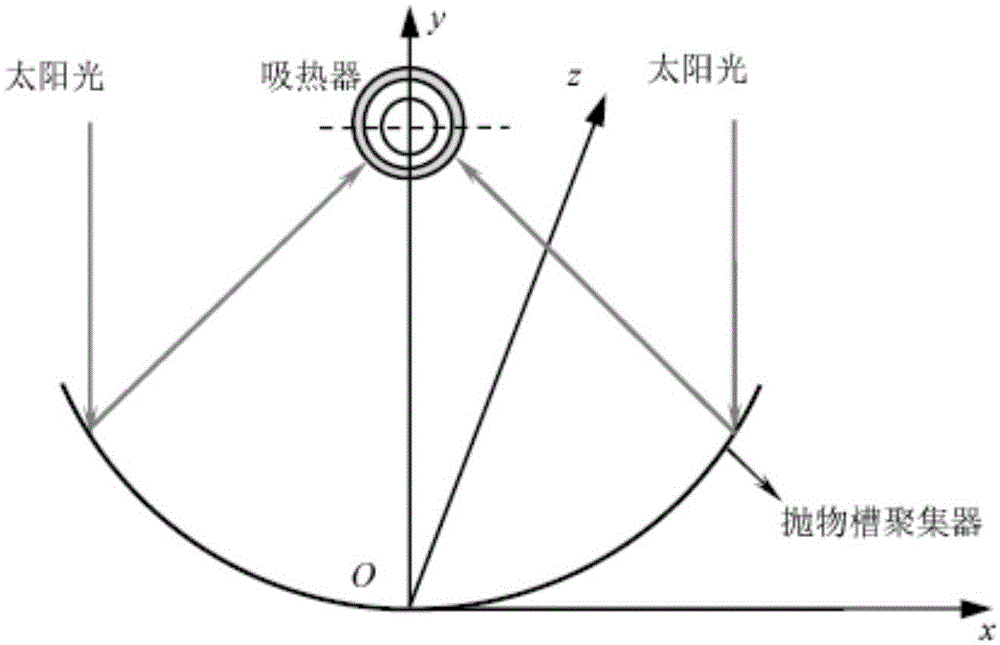

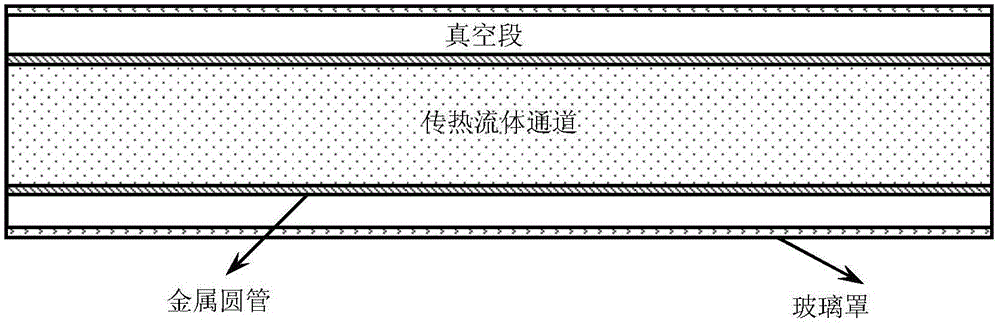

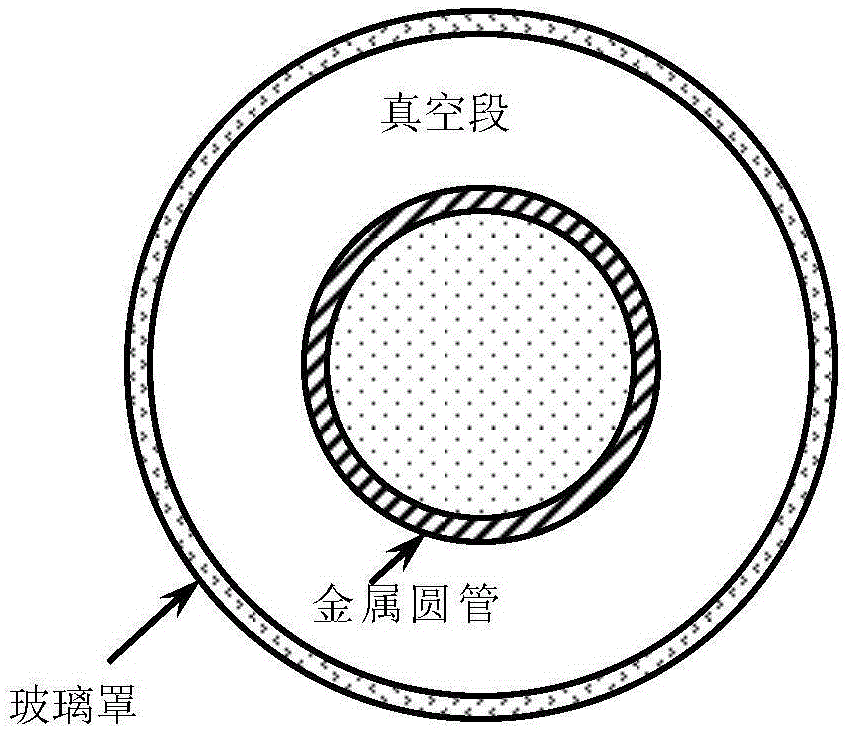

Corrugated tube type solar heat absorber with functions of strengthening heat transferring and reducing heat deformation

InactiveCN105066476ALow flow resistanceSmall pressure dropSolar heating energySolar heat devicesGlass coverEngineering

The invention relates to a corrugated tube type solar heat absorber with the functions of strengthening heat transferring and reducing heat deformation, and belongs to the technical field of solar utilization. The corrugated tube type solar heat absorber aims at solving the problem of heat deformation of a metal tube of a metal round tube solar heat absorber, and achieving the aim of strengthening heat transferring in the metal tube. The corrugated tube type solar heat absorber comprises a vacuum glass cover, and further comprises a corrugated tube; the corrugated tube is installed in the vacuum glass cover, a vacuum section is formed between the corrugated tube and the vacuum glass cover, and a heat transferring fluid channel is formed in the corrugated tube; and the corrugated tube is an outwards-protruding corrugated tube. According to the corrugated tube type solar heat absorber, a round tube in a traditional parabolic groove type solar spotlight system is replaced with the outwards-protruding corrugated tube, so that the aims of strengthening heat transferring, homogenizing temperature field distribution of the tubular heat absorber and reducing the heat deformation of the tubular heat absorber are achieved.

Owner:HARBIN INST OF TECH AT WEIHAI

Method of manufacturing differential device

ActiveUS20150184734A1Efficient weldingReduce and eliminate distortionMetal-working apparatusGear wheelsEngineeringDistortion

In a method of manufacturing a differential device, a hub of a ring gear is press-fitted to a flange from a first bearing boss side, then a press-fit portion between the flange and the ring gear is equally divided into a plurality of divided regions arranged along a peripheral direction, and simultaneously the divided regions are welded. Accordingly, the press-fit portion between the flange and the ring gear can be efficiently welded while welding distortion of the ring gear is eliminated or reduced even in a case where work windows of a differential case cut into a side surface of the flange on the first bearing boss side to form recessed portions.

Owner:MUSA PRECISION IND CO LTD

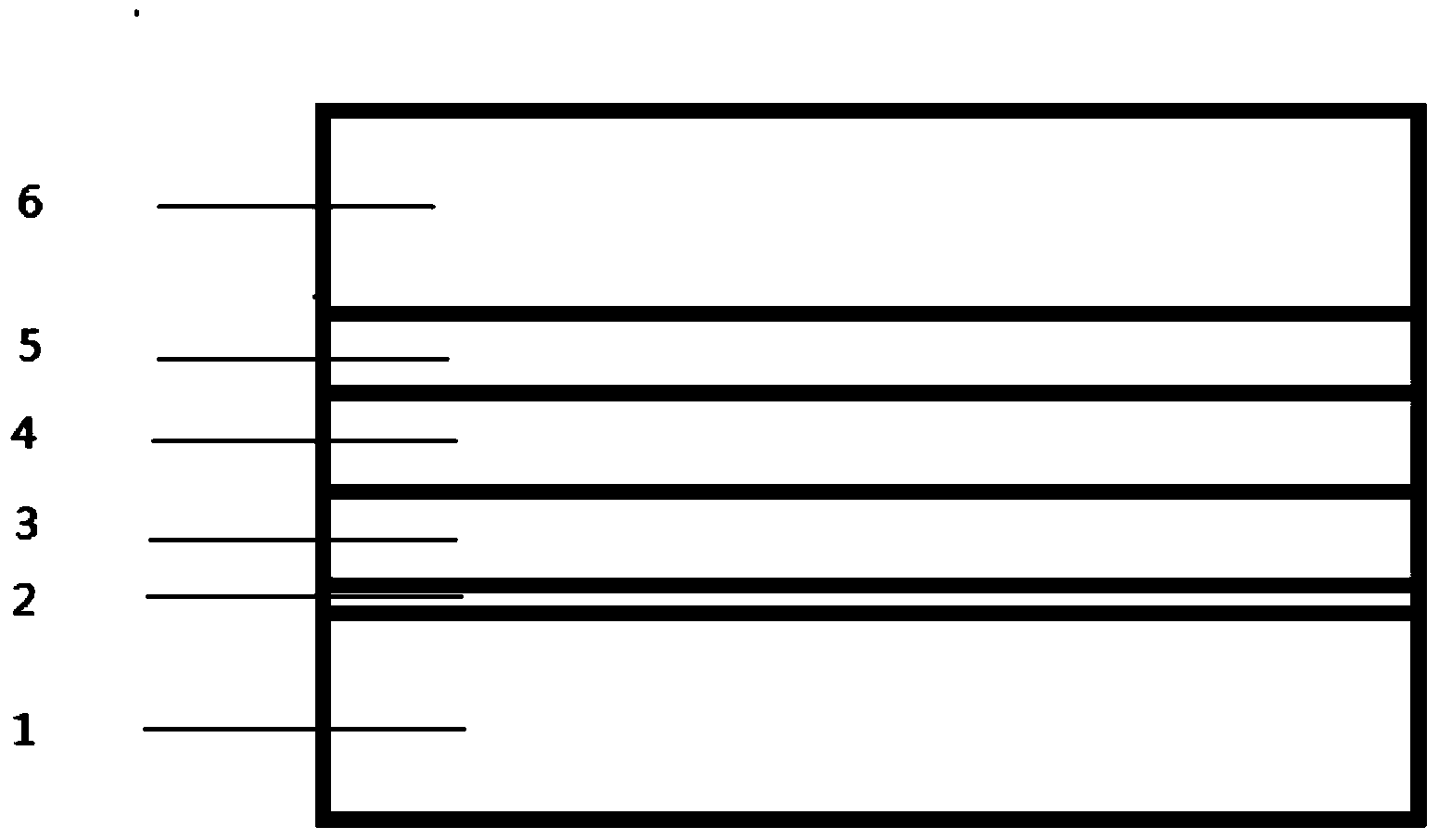

Lattice-matched LED epitaxial structure and preparation method thereof

InactiveCN104112799AImprove radiative recombination efficiencyReduce mismatchSemiconductor devicesQuantum wellNitride

The invention relates to a lattice-matched LED epitaxial structure and a preparation method thereof. The invention relates to a nitride light-emitting diode epitaxial structure whose nucleating layer, undoped layer, n type layer, luminous layer and p type layer all have polarization matching and a preparation method, and belongs to the technical field of photoelectronics. The epitaxy structure is provided with a substrate, a AlxGa(1-x)-yInyN nucleating layer, an undoped AlxGa(1-x)-yInyN layer, n type doped AlxGa(1-x)-yInyN layer, a multi-quantum well luminous layer formed by a InaGa(1-a)N well layer and a AlxGa(1-x)-yInyN barrier layer, and a p type doped AlxGa(1-x)-yInyN layer in sequence from bottom to top. Compared with a traditional structure, the epitaxial structure adopts quaternary AlxGa(1-x)-yInyN material matched with luminous layer well material from the nucleating layer to a luminous layer interval and P type doped layer, thereby eliminating a piezoelectric polarization effect between well and barrier layers in the luminous layer, and improving internal quantum luminous efficiency of the LED.

Owner:SHANXI FEIHONG MICRO NANO PHOTOELECTRONICS SCI & TECH

Fuel nozzle assembly for use with a gas turbine engine and method of assembling same

InactiveUS8752389B2Easy to operateMaintaining structural robustnessContinuous combustion chamberPipeline expansion-compensationCombustion chamberThermal expansion

A fuel nozzle configured to channel fluid toward a combustion chamber within a gas turbine engine and a method for assembling the same are provided. The fuel nozzle includes a first hollow tube fabricated from a first material that has a first coefficient of thermal expansion and a second tube fabricated from a second material that has a second coefficient of thermal expansion that is different from the first coefficient of thermal expansion. The second tube is coupled within the first tube such that the first tube substantially circumscribes the second tube, and the second tube thermally expands approximately at a same rate as the first tube during fuel nozzle operation.

Owner:GENERAL ELECTRIC CO

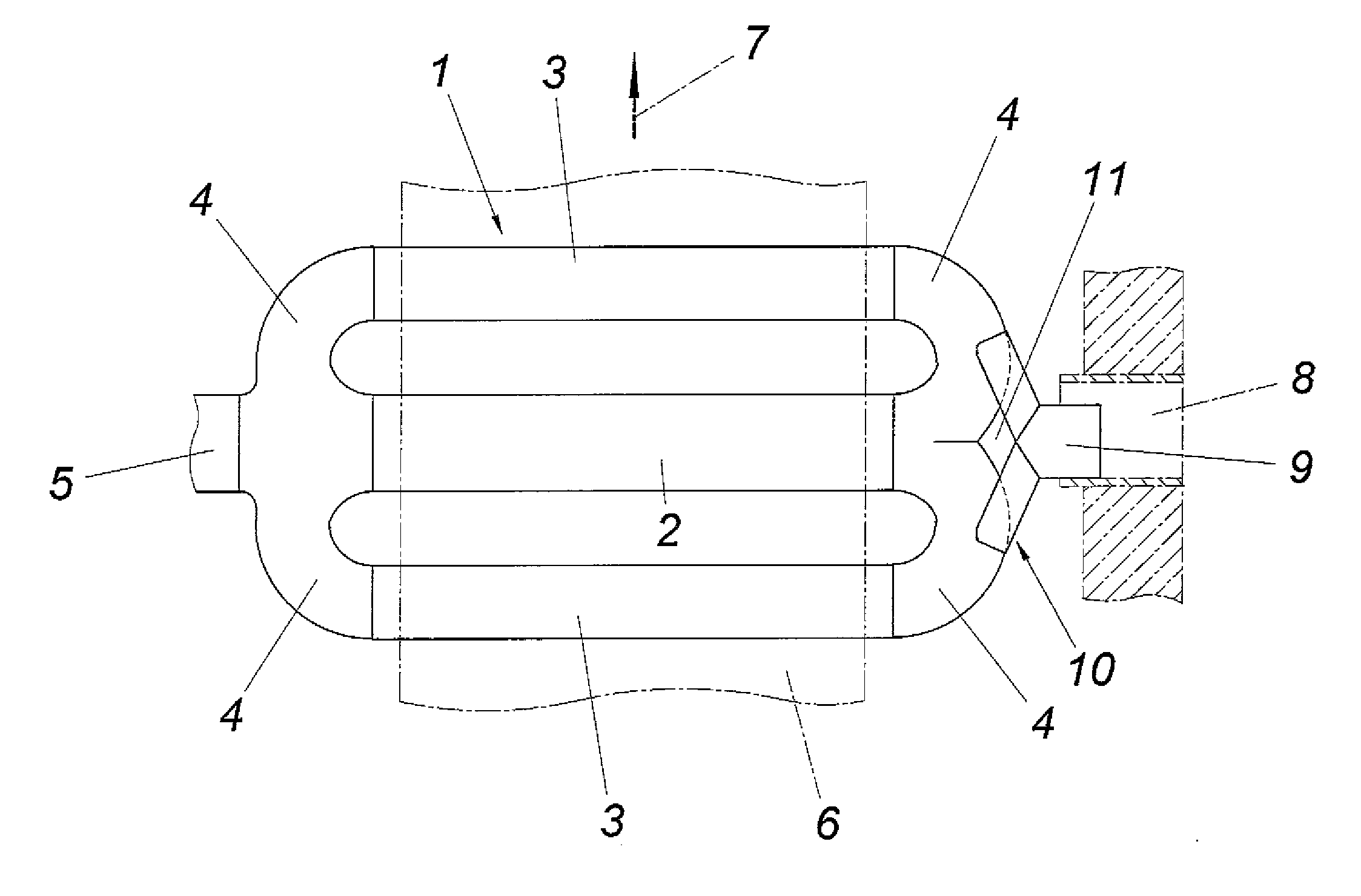

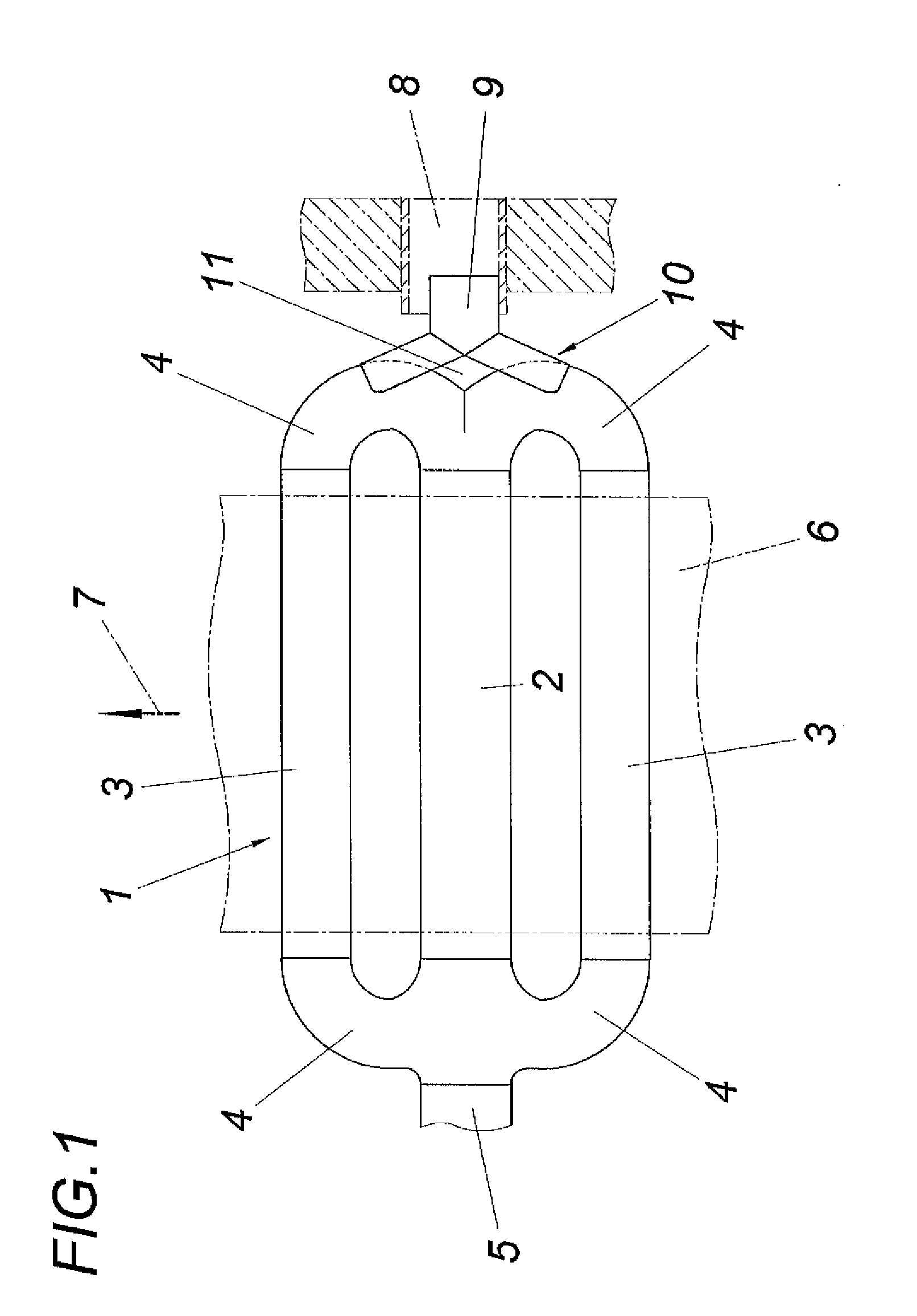

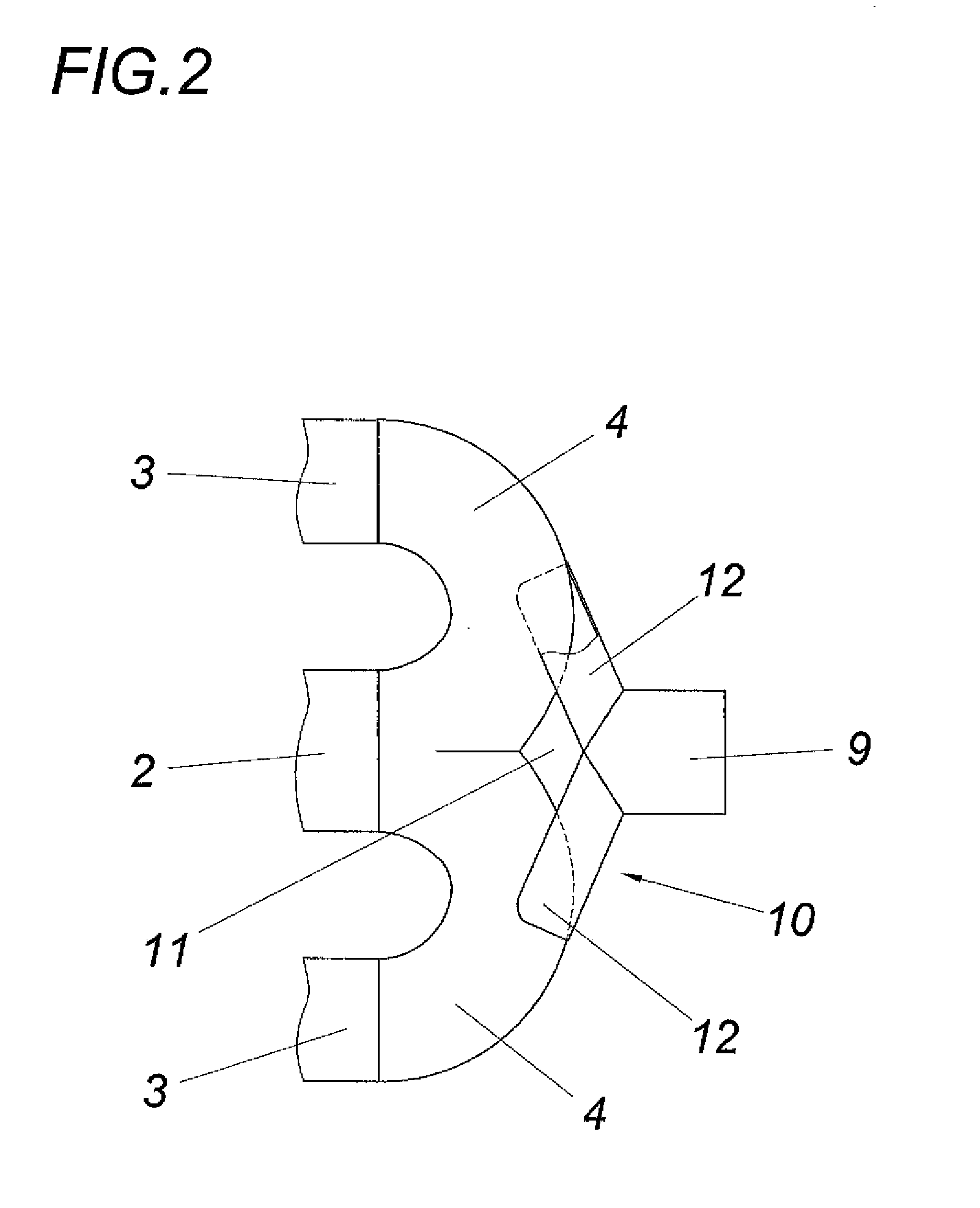

Device for heat-treating sheet metal strips

InactiveUS20120223466A1Sufficient length compensationKept substantially tension-freeFurnace componentsFurnace typesMetal stripsAcute angle

A device is described for heat-treating sheet metal strips (6) having at least one radiator pipe unit (1), which has three pipes located in a common axial plane parallel to the sheet-metal strip (6), namely one middle pipe (2) attachable to a burner and two outer pipes (3) connected at both ends to the middle pipe (2) via pipe elbows (4), and having a bearing pin (9), connected to the two pipe elbows (4) between the middle pipe (2) on one side and the two outer pipes (3) on the other side, on the side of the radiator pipe unit opposite to the burner. To be able to take the occurring thermal expansions in the area of the pipe elbows (4) into consideration, it is proposed that the bearing pin (9) be arranged on a bridge (10), which bridges a gusset (11) between the two pipe elbows (4), having two sections (12) which extend on both sides of the axis of the middle pipe (2) and are inclined at an acute angle to the axis of the middle pipe (2).

Owner:EBNER-INDUSTRIEOFENBAU GMBH

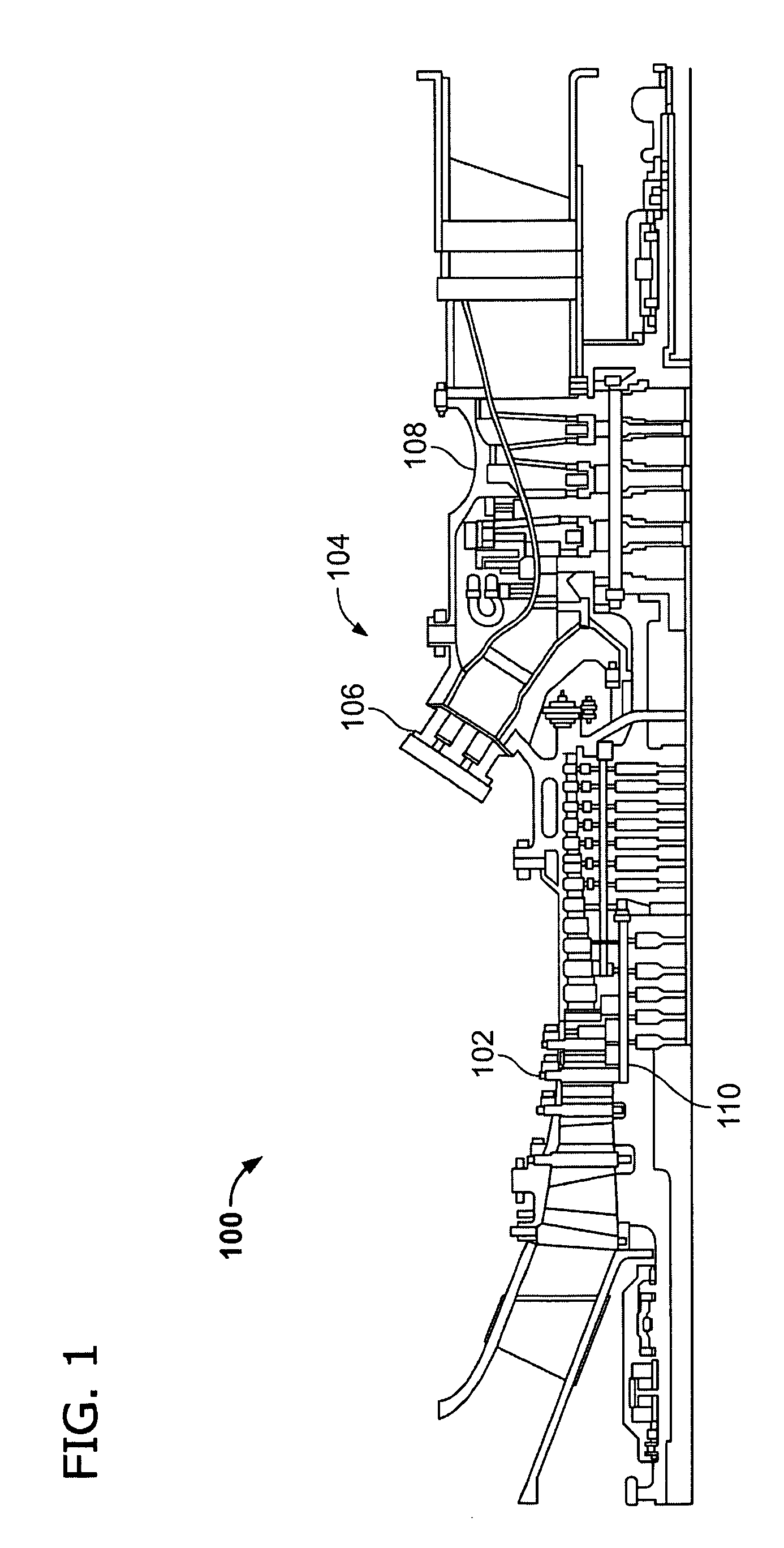

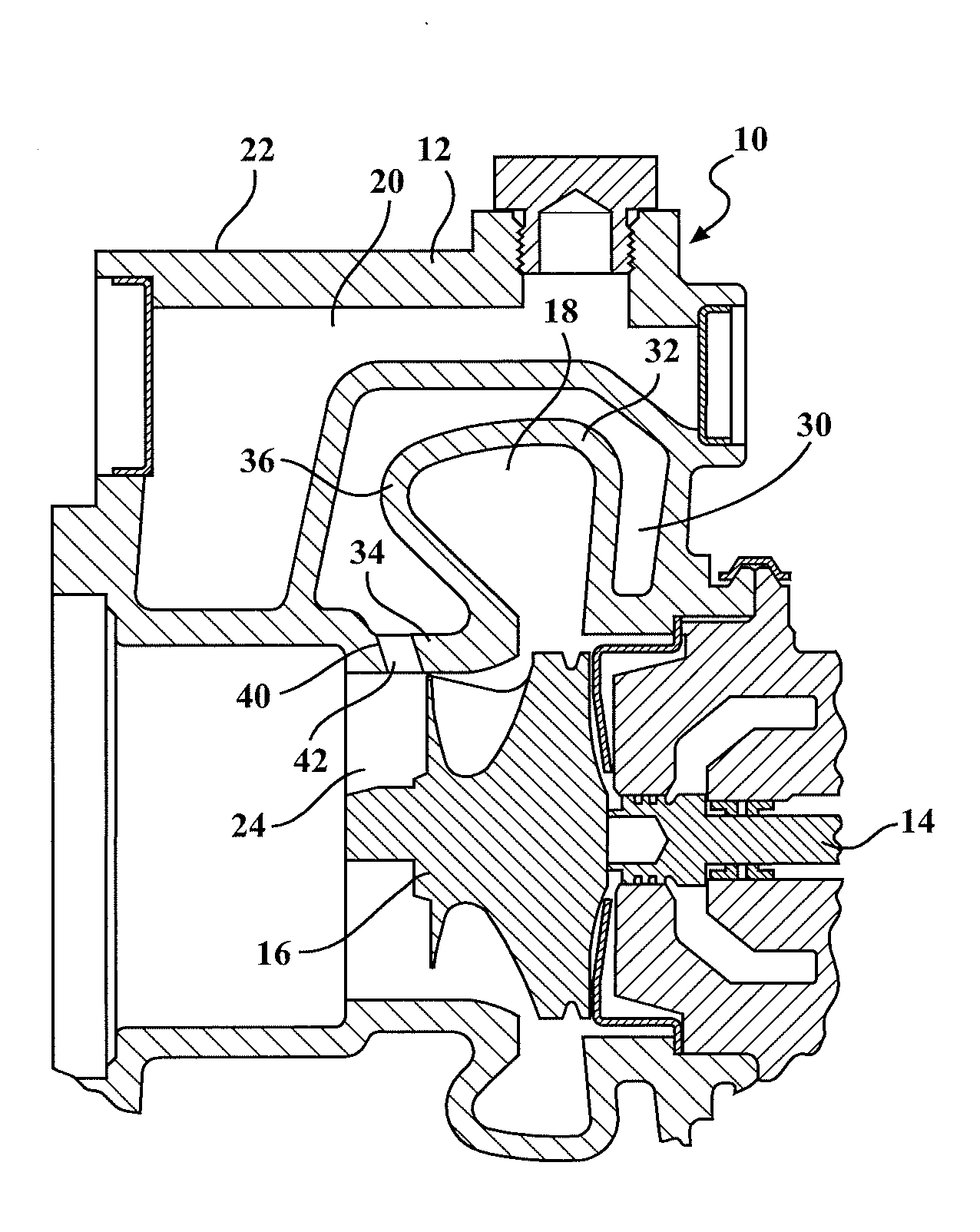

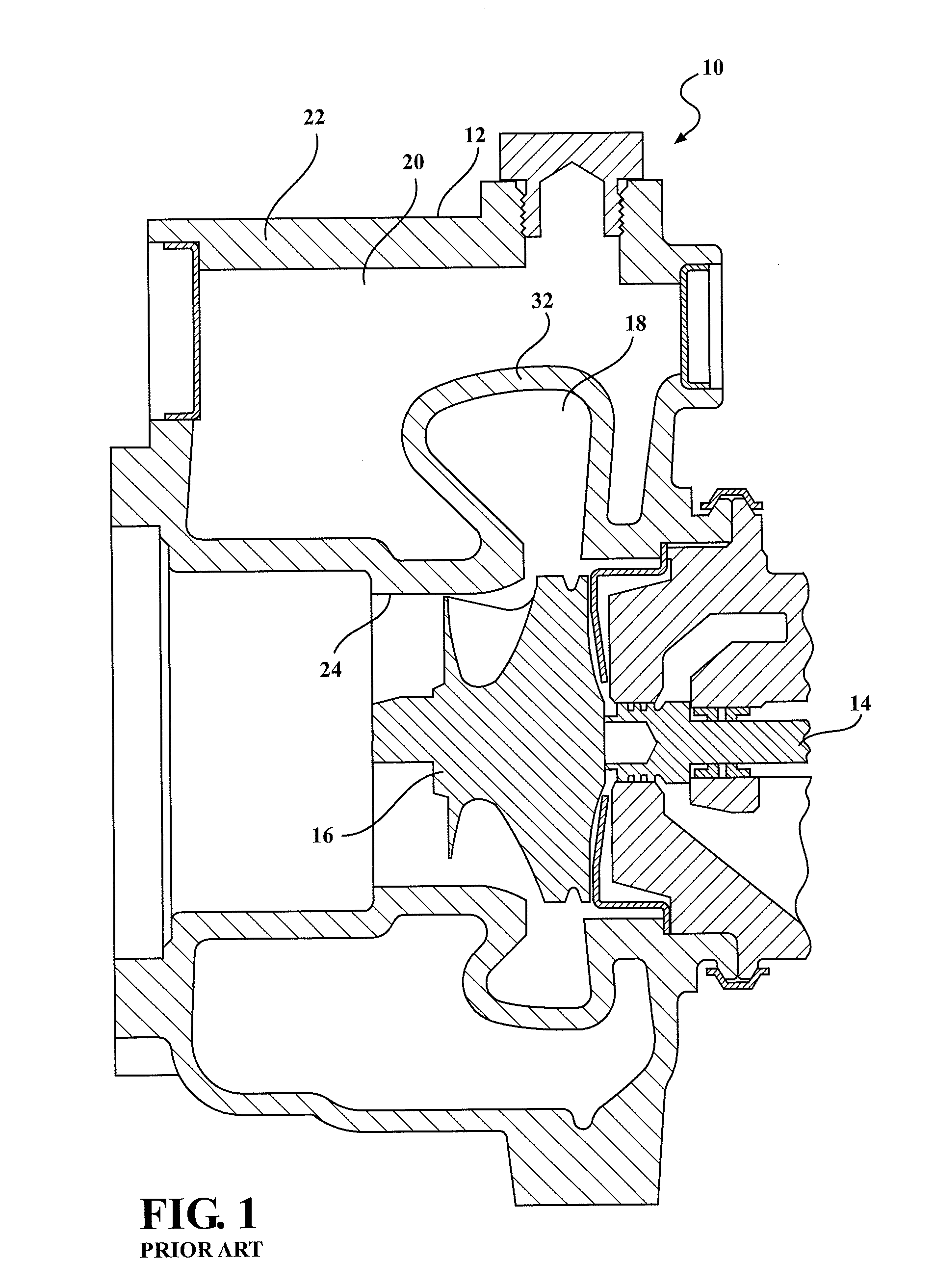

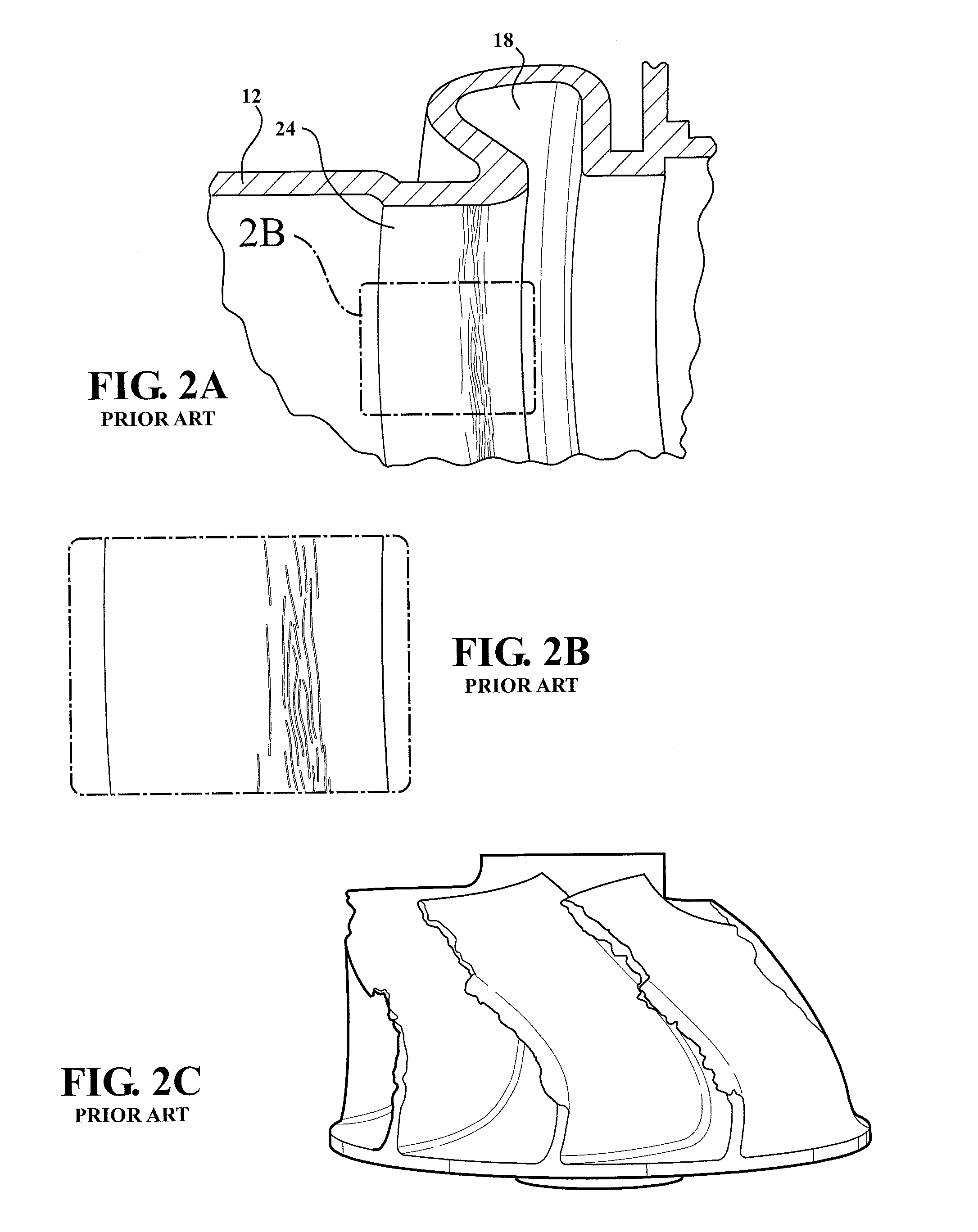

Liquid-cooled turbine housing with intermediate chamber

InactiveUS20160290159A1Improve efficiencyReduce thermal strainEngine fuctionsBlade accessoriesTurbine wheelExhaust gas

A turbocharger (10) with a liquid-cooled turbine housing (12) including an intermediate chamber (30) adjacent to the liquid chamber (20) of the turbine housing (12). The intermediate chamber (30) is between the liquid chamber (20) and a turbine housing exducer wall portion (34), partially near the turbine wheel blades. A preferred intermediate chamber (30) is a core that encloses the volute (18) and completely separates and insulates the hot volute (18) from the relatively cool liquid chamber (20). The intermediate chamber (30) may have a passage (40) as an exhaust gas inlet through the turbine housing exducer wall (24) or as an air inlet through the turbine housing (12) for flow into the intermediate chamber (30).

Owner:BORGWARNER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com