Ferritic cr-containing steel

A ferrite and steel technology, applied in the direction of furnace type, furnace, heat treatment equipment, etc., can solve the problems of reduced processability, high temperature fatigue, etc., and achieve the effect of improving life and reducing thermal strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

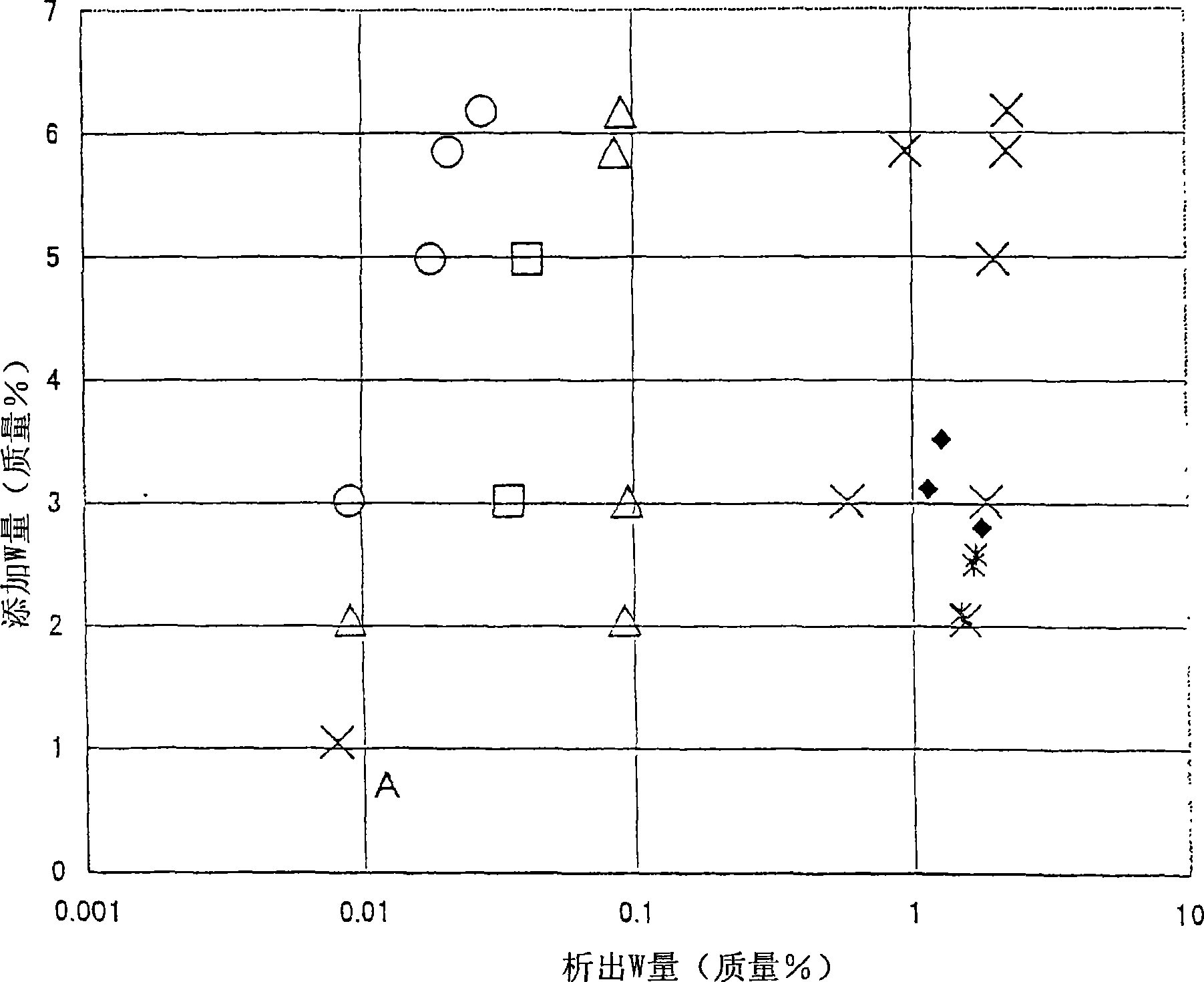

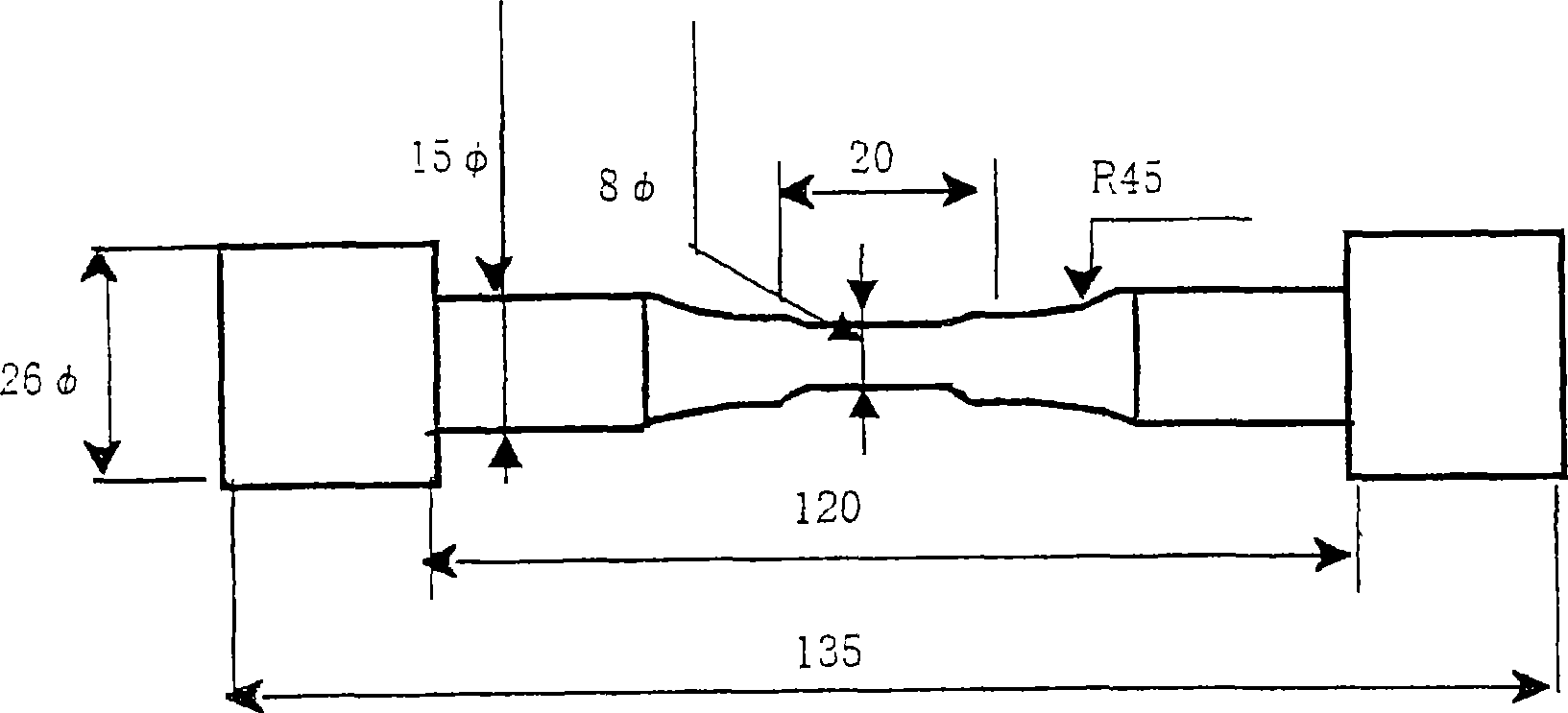

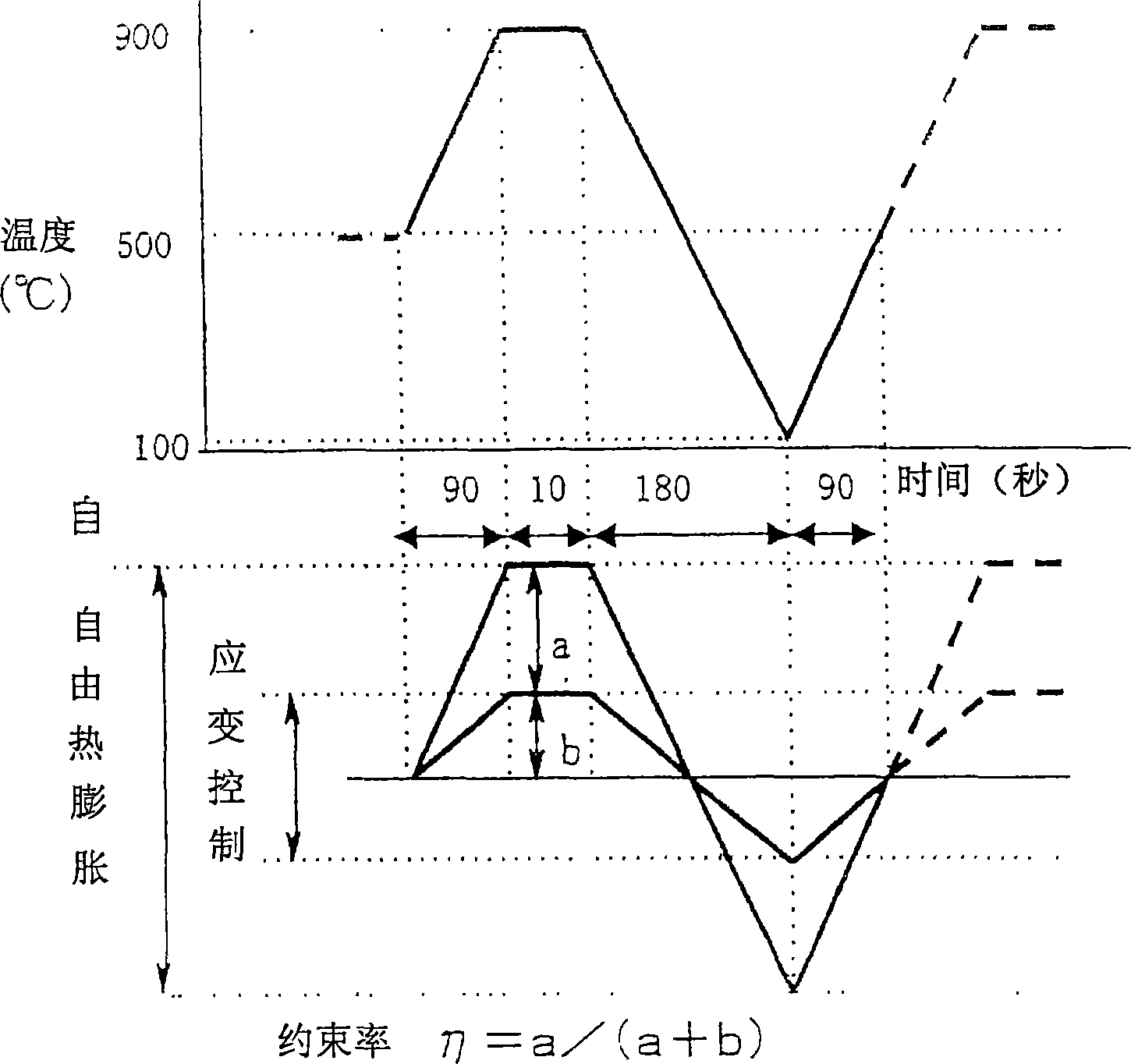

[0065] 50 kg of steel ingots (invention example, comparative steel, and conventional steel (Type429Nb, SUH409L)) having the composition shown in Table 1 were prepared, heated to 1100° C., and hot-rolled into 4 mm-thick hot-rolled sheets. Then, relative to these hot-rolled sheets, annealing of hot-rolled sheets (annealing temperature: 1090° C.)-pickling-cold rolling (cold rolling ratio: 62.5%)-final annealing (as shown in Table 1, annealing temperature Change from 900°C to 1220°C, hold at each temperature for 3 minutes, air-cool, adjust the amount of precipitated W)-acid pickling, and make a 1.5mm steel plate.

[0066] The coefficient of thermal expansion of the thus obtained cold-rolled and annealed sheets was investigated. The results are recorded in Table 1 together.

[0067] The average coefficient of thermal expansion at 20°C to 800°C was measured and evaluated as follows.

[0068] Using the vertical thermal dilatometer DL-7000 type produced by Vacuum Technology Co., Ltd...

Embodiment 2

[0081] Next, the relationship between the amount of precipitated W and the annealing temperature of the hot-rolled sheet was investigated. A 50kg steel ingot consisting of 0.005%C, 0.07%Si, 1.02%Mn, 15.2%Cr, 1.92%Mo, 3.02%W, 0.51%Nb, and 0.004%N was produced, and the steel ingot was heated to 1100°C Afterwards, it is made into a 4 mm thick hot-rolled plate by hot rolling. Next, for the hot-rolled sheet, annealing of the hot-rolled sheet (annealing temperature: change from 900°C to 1200°C, hold at each temperature for 3 minutes, then perform air cooling)-pickling-cold rolling (cold rolling) rate: 62.5%)-finish annealing (holding at the final annealing temperature of 1100° C. for 3 minutes, followed by air cooling)-acid pickling to produce a 1.5 mm annealed steel sheet.

[0082] The amount of precipitated W in the thus obtained cold-rolled annealed steel sheet was measured by the same method as in Example 1. In addition, on each steel sheet, samples for evaluating the amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com